Special pulverizing and softening device for primary shaping of fungi blank

A softening device and grinding wheel technology, applied in application, horticulture, grain processing, etc., can solve the problems of unreasonable utilization, lack of confidence in effective utilization, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

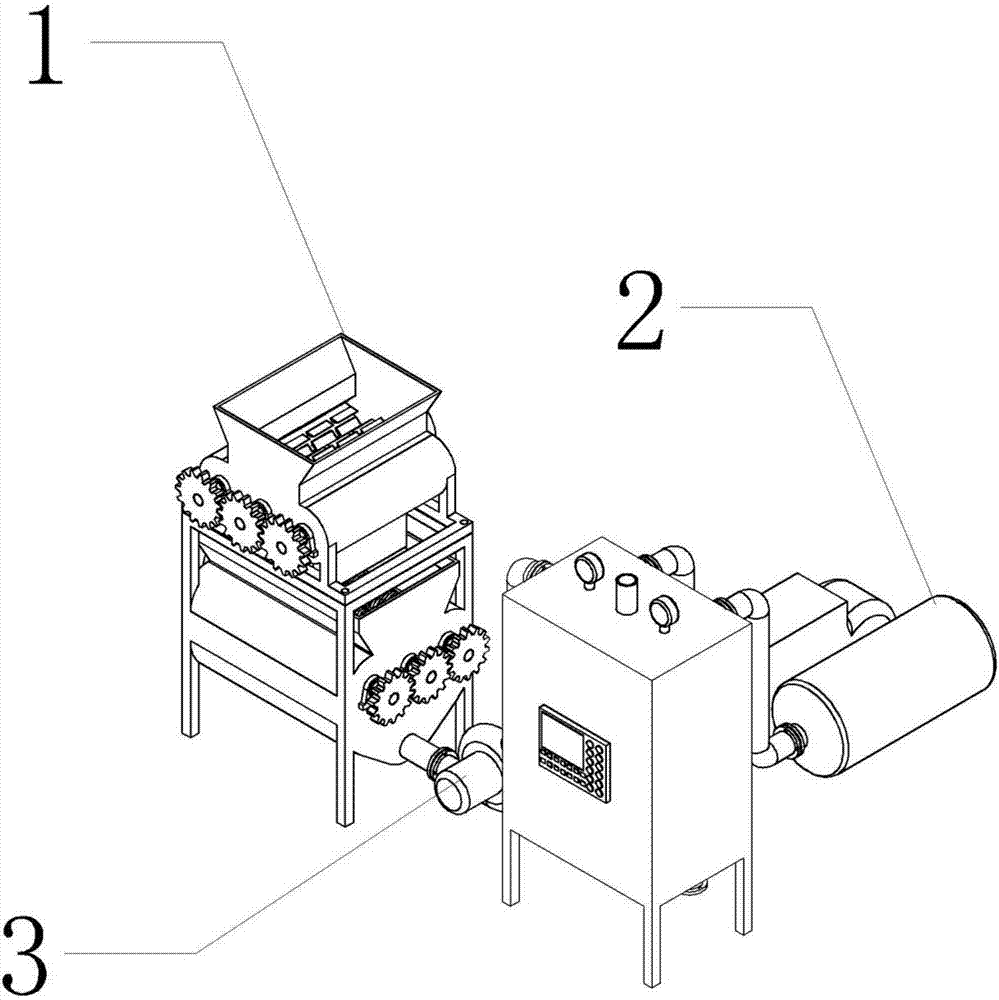

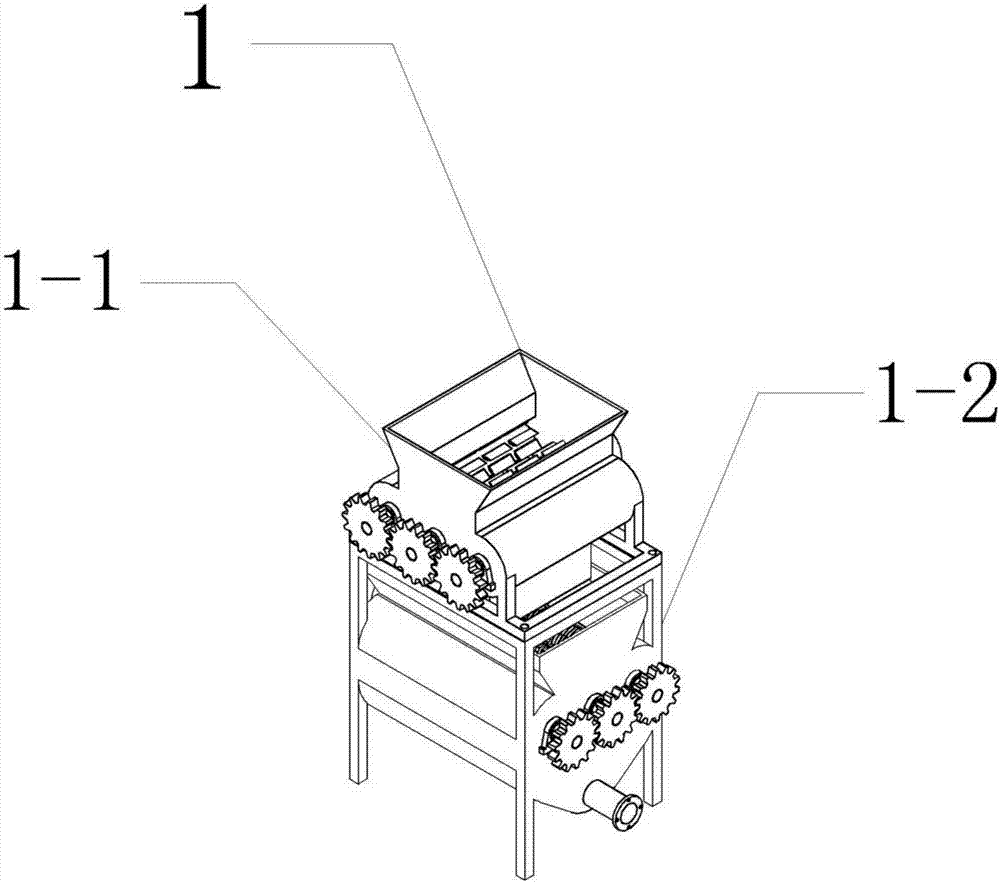

[0036] It can be seen from the content of the invention and the accompanying drawings that a dedicated pulverizing and softening device for a one-time molding fungus base is composed of a pulverizer 1, a softening device 2, and an induced draft fan 3; the softening device 2 is installed on the right side of the pulverizer 1 through the induced draft fan 3 .

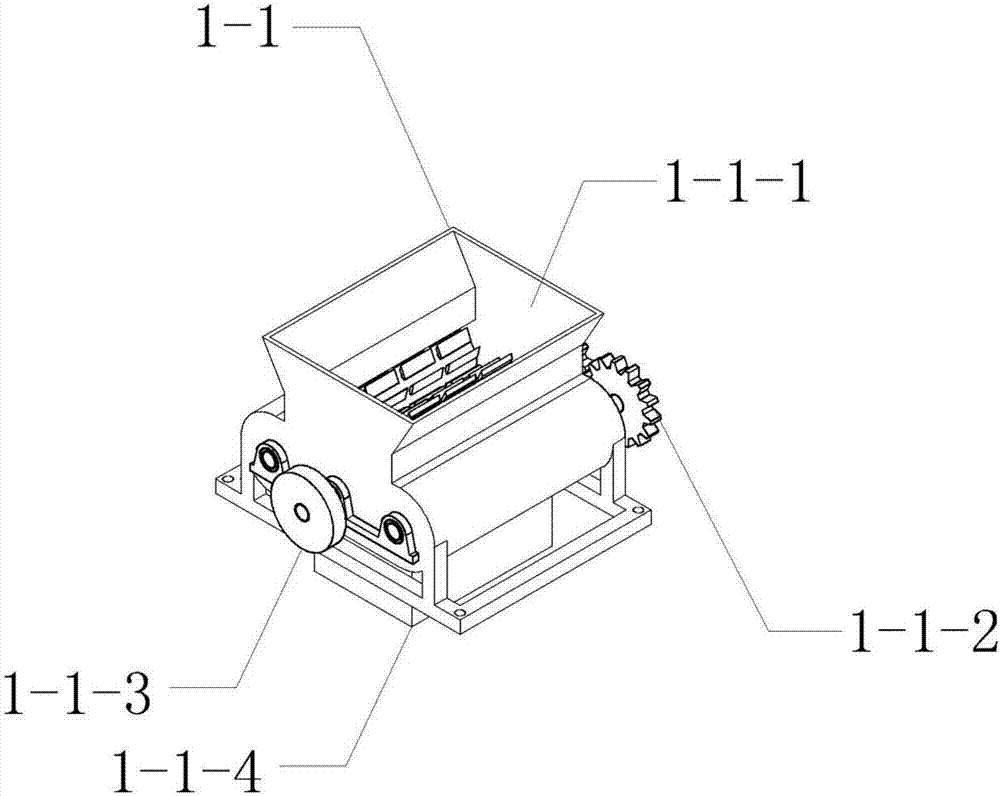

[0037] The present invention is provided with pulverizer 1 in order to realize one-time chopping of crop stalk; It is made up of primary pulverization part 1-1 and secondary pulverization part 1-2; Primary pulverization part 1-1 is installed in secondary pulverization part 1-2 top; primary crushing part 1-1 consists of feed hopper 1-1-1, primary crushing part driven crushing wheel 1-1-2, primary crushing part active crushing wheel 1-1-3 and primary crushing part machine The frame is composed of 1-1-4, the feed hopper 1-1-1 is installed on the top of the frame 1-1-4 of the primary crushing part, the driven crushing wheel 1...

Embodiment 2

[0044] In the pulverizer 1 mentioned above, the crop straws are put into the pulverizer 1 for one-time chopping, passed through a 5mm hole sieve and stored in the pulverized material temporary storage chamber 1-2-2-4.

[0045] The above-mentioned softening device 2 introduces the crushed crushed material stored in the crushed material temporary storage chamber 1-2-2-4 into the softening device 2 through the induced draft fan 3, and then closes the softening device 2, and passes through the pressurizing device 2- 6 Pressurization, heating by hot air blower 2-7, adding quicklime water to external pipe 2-8, heating the pulverized material in softening device 2 to 100 degrees, adding 5 kg of pressure per square centimeter, and adding an appropriate amount of 1%-1.5% quicklime water , Monitor the temperature through the thermometer 2-1, monitor the pressure with the pressure gauge 2-3, and intelligently control the softening reaction by the intelligent controller 2-4 for 10-15 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com