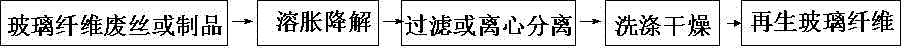

Method for regenerating glass fibers from waste glass fibers or products at normal temperature under normal pressure

A glass fiber and product technology, applied in the direction of solid waste removal, etc., can solve the problems of high technical threshold and large investment cost, and achieve the effect of obvious economic benefits, low equipment cost, and promoting the development of circular economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

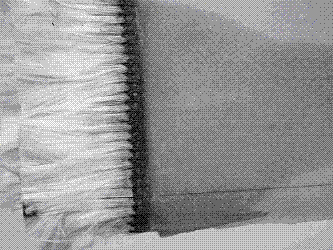

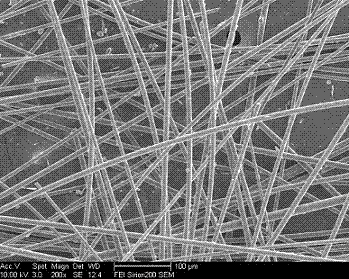

[0022] Example 1 Fiberglass recycling.

[0023] Put the waste glass fiber waste into a glass tank of the corresponding size, add a mixture of concentrated sulfuric acid, alkylphenol polyoxyethylene ether and tetrahydrofuran (8:1:1), immerse the glass fiber, and soak it at room temperature for 2 hours , filter and separate to remove the glass fiber, wash it with water for several times until it is clean, dry it naturally or heat it to obtain the regenerated glass fiber, store it for later use; soak the waste liquid to distill off tetrahydrofuran, add sodium hydroxide to neutralize it, and use it as a binder Or the use of additives for coatings.

Embodiment 2

[0024] Example 2 Fiberglass recycling.

[0025]Put the waste glass fiber mat into a glass tank of corresponding size, add a mixture of concentrated sulfuric acid, petroleum ether and polyethylene glycol 400 (7:2:1) to immerse the glass fiber, soak it at room temperature for 1 hour, and filter it out Glass fiber, washed with clean water for many times until clean, dried naturally or heated to obtain regenerated glass fiber, stored for later use; soaked in waste liquid and distilled to remove petroleum ether, added calcium hydroxide to neutralize, used as a binder or Additives for coatings are used.

Embodiment 3

[0026] Example 3 Fiberglass recycling.

[0027] Put the glass fiber cloth into a glass tank of the corresponding size, add the mixture of concentrated sulfuric acid, fatty alcohol polyoxyethylene ether and dioxane (4:5:1), immerse the glass fiber cloth, and soak at room temperature for 2 hours Finally, filter out the glass fiber, wash it with clean water several times until it is clean, dry it naturally or heat it to get the regenerated glass fiber, store it for later use; soak the waste liquid and distill to remove dioxane, then add calcium oxide to neutralize it as a viscose Additives for mixtures or coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com