Columnar activated carbon based on coal pitch binders and preparation method of columnar activated carbon

A technology of coal tar pitch and binder, which is applied in the preparation field of shaped granular activated carbon, which can solve the problems of kneading, no cohesiveness, coal tar pitch powder and carbonaceous materials can not be mixed at high temperature, etc., and achieve the improvement of carbonization yield , water capacity increase, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

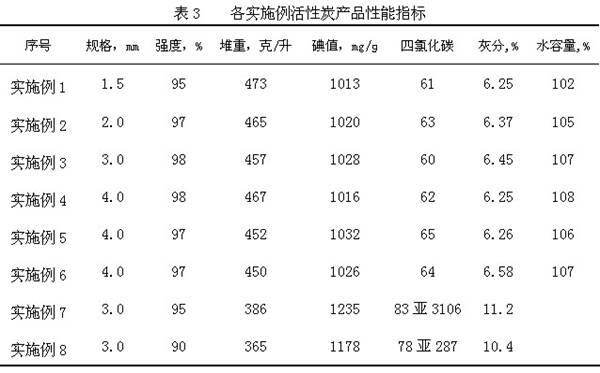

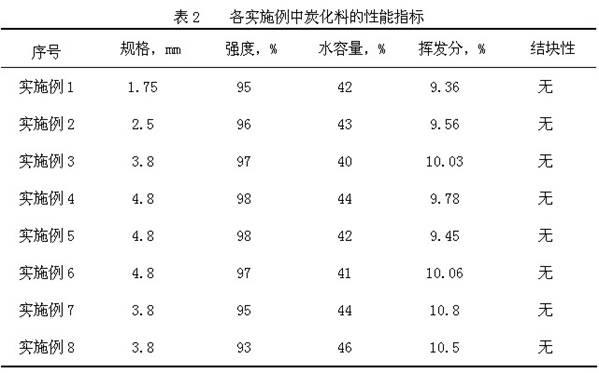

Examples

Embodiment 1

[0061] Take 1.5Kg of polyvinylpyrrolidone, 3Kg of hydroxypropyl methylcellulose, and 1Kg of calcium lignosulfonate and dissolve them in 100Kg of water, stir evenly to make a temporary binder.

[0062] Use AVCM-700 jet mill to grind Taixi anthracite clean coal with moisture <5%, ash <3%, volatile content 10.47%; coal softening point 110℃, moisture <5%, ash <0.3%, coking value 56% of the coal tar pitch is milled separately, and more than 95% of the finished flour is required to pass through a 200-mesh sieve.

[0063] Take 236Kg of the above-mentioned Taixi smokeless cleaned coal powder and 64Kg of coal tar pitch powder, add a total of 300Kg into the kneading pot, mix at room temperature for 12 minutes, add 84Kg of the above-mentioned temporary binder, and knead at 60°C for 20 minutes to make the bonding The agent fully infiltrates and penetrates the mixed powder.

[0064] Choose a 500t hydraulic press, press and stretch at a molding temperature of 25-50°C and a molding pressure...

Embodiment 2

[0067] Take 2Kg of polyvinyl alcohol, 3Kg of carboxymethyl hydroxyethyl cellulose, and 1.5Kg of sodium lignosulfonate dissolved in 100Kg of water, stir evenly to make a temporary binder.

[0068] Taixi anthracite washed clean coal and coal tar pitch are pulverized separately, and more than 95% of the finished powder is required to pass through a 200-mesh sieve.

[0069] Take 237Kg of the above-mentioned Taixi smokeless cleaned coal powder and 63Kg of coal tar pitch powder, add a total of 300Kg to the kneading pot, mix at room temperature for 10 minutes, add 81Kg of the above-mentioned temporary binder, and knead for 15 minutes at 55°C to make the bond The agent fully infiltrates and penetrates the mixed powder.

[0070] Choose a 500t hydraulic press, press and stretch at a molding temperature of 25-50°C and a molding pressure of 16-25Mps to form strip-shaped carbon bars with a diameter of 2.5mm.

[0071] The formed carbon strip has a smooth surface, no cracks, no adhesion, an...

Embodiment 3

[0073] Take 2Kg of carboxymethyl cellulose, 4.5Kg of sodium humate and 1.5Kg of calcium lignosulfonate into 100Kg of water, stir evenly to make a temporary binder.

[0074] Taixi anthracite washed clean coal and coal tar pitch are pulverized separately, and more than 95% of the finished powder is required to pass through a 200-mesh sieve.

[0075] Take 238Kg of the above-mentioned Taixi smokeless cleaned coal powder and 62Kg of coal tar pitch powder, add a total of 300Kg to the kneading pot, mix at room temperature for 10 minutes, add 80Kg of the above-mentioned temporary binder, and knead at 60°C for 15 minutes to make the bonding The agent fully infiltrates and penetrates the mixed powder.

[0076] Choose a 500t hydraulic press, press and stretch at a molding temperature of 25-50°C and a molding pressure of 16-24Mps to form strip-shaped carbon bars with a diameter of 3.8mm.

[0077] The formed carbon strip has a smooth surface, no cracks, no adhesion, and has a certain init...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com