Patents

Literature

289 results about "Microwave curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave curing bypasses the time dependent outside heat source transferal needed in conventional curing methods and begins the process directly in the acrylic, immediately, at the molecular level. Curing by this method can be accomplished in 3 minutes using an inexpensive conventional microwave oven, Naturecryl MC, and a fiber reinforced flask.

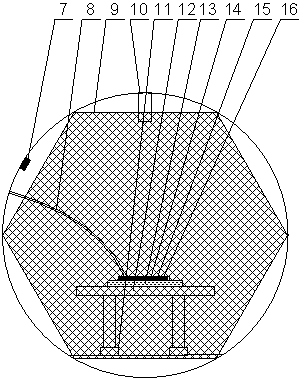

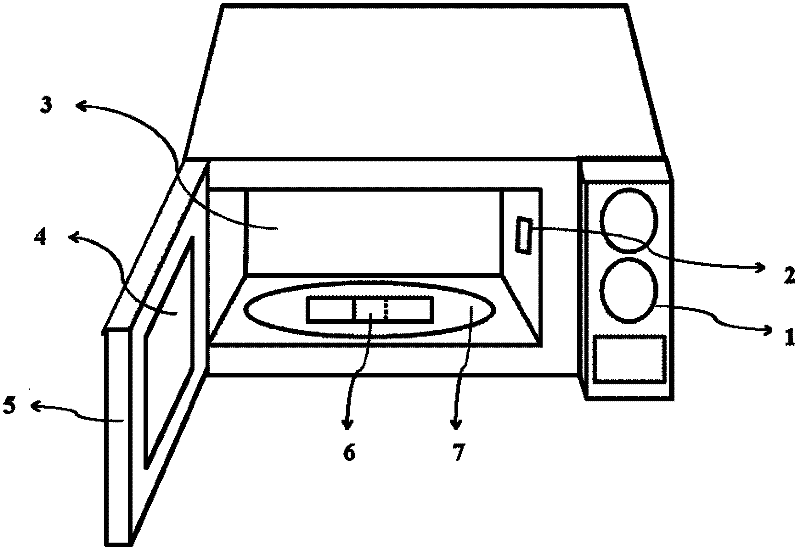

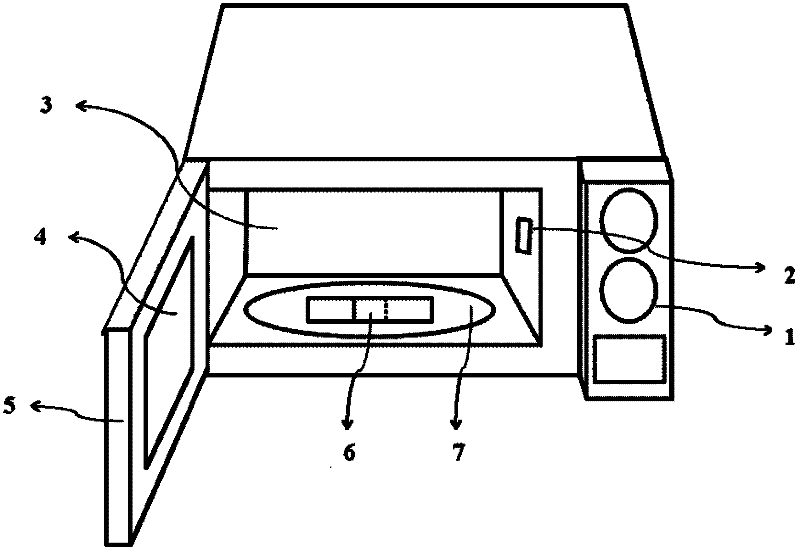

Method and device for curing fiber-reinforced resin-based composite material component by utilizing microwaves

ActiveCN103587130ASolve for uniformitySolve power problemsResin-Based CompositeFiber-reinforced composite

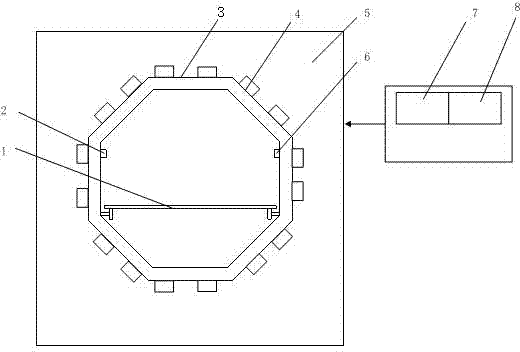

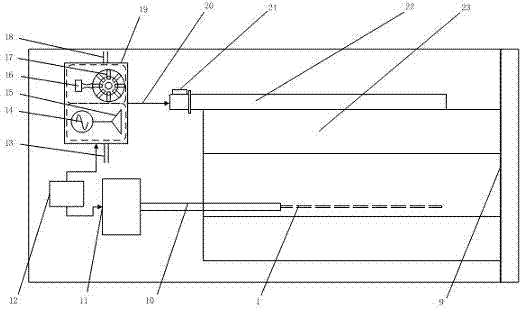

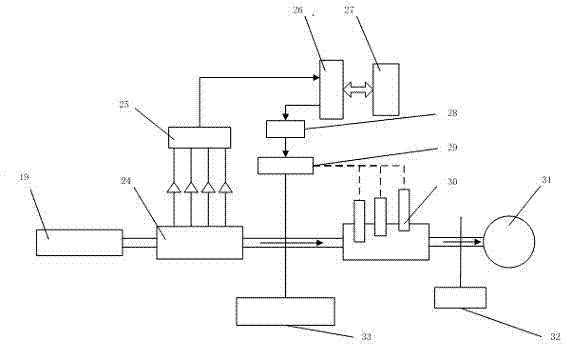

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

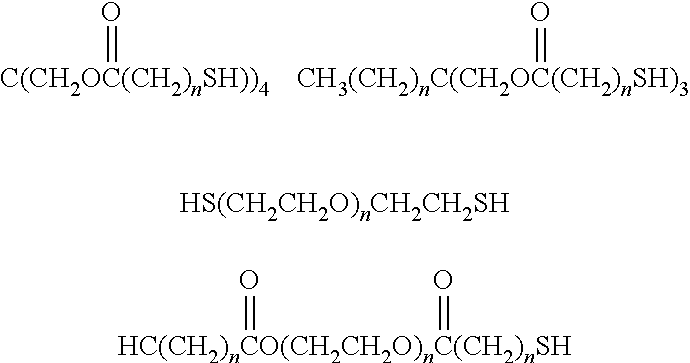

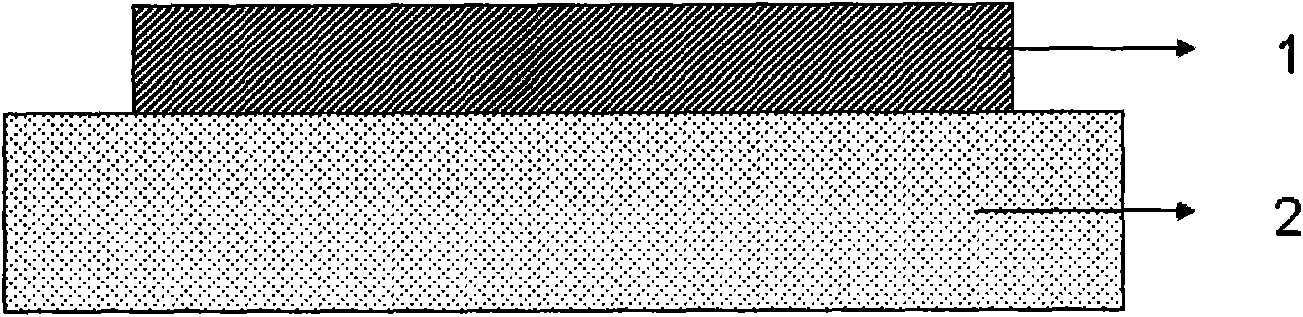

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

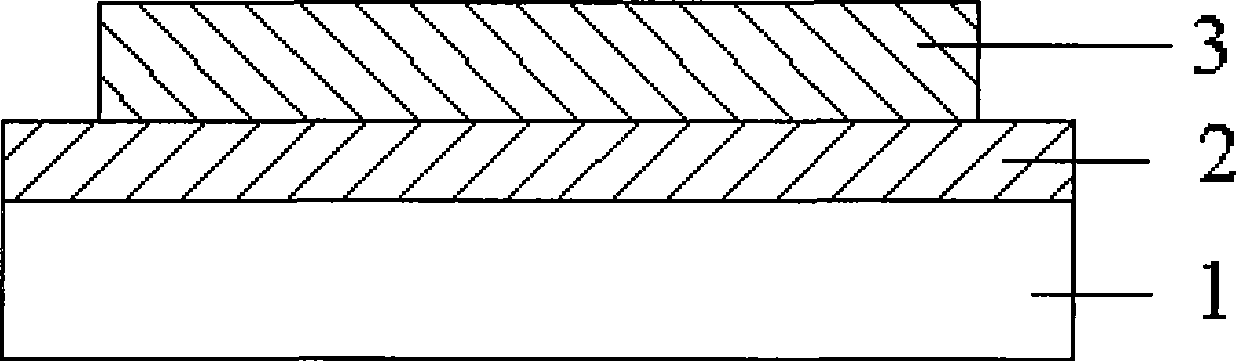

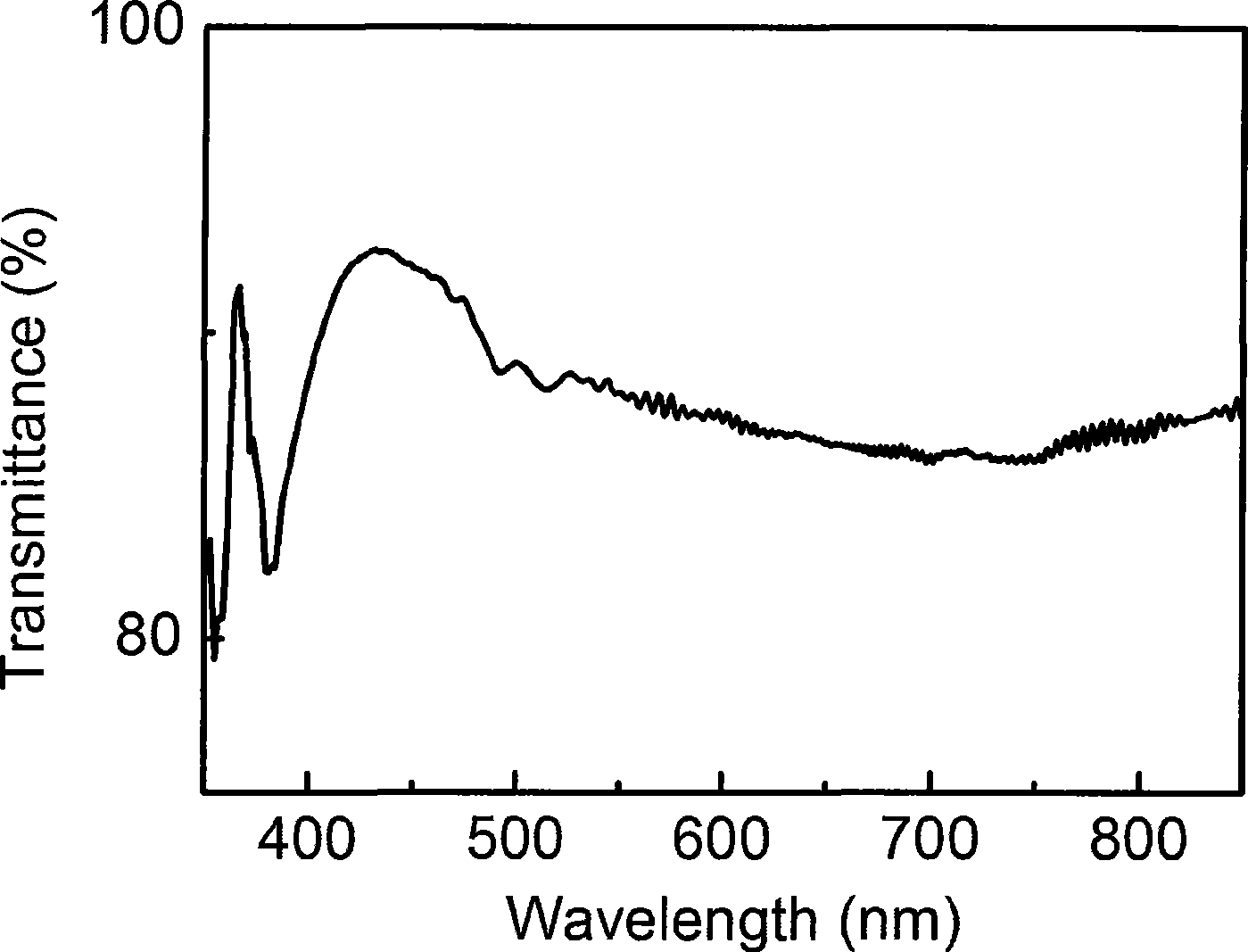

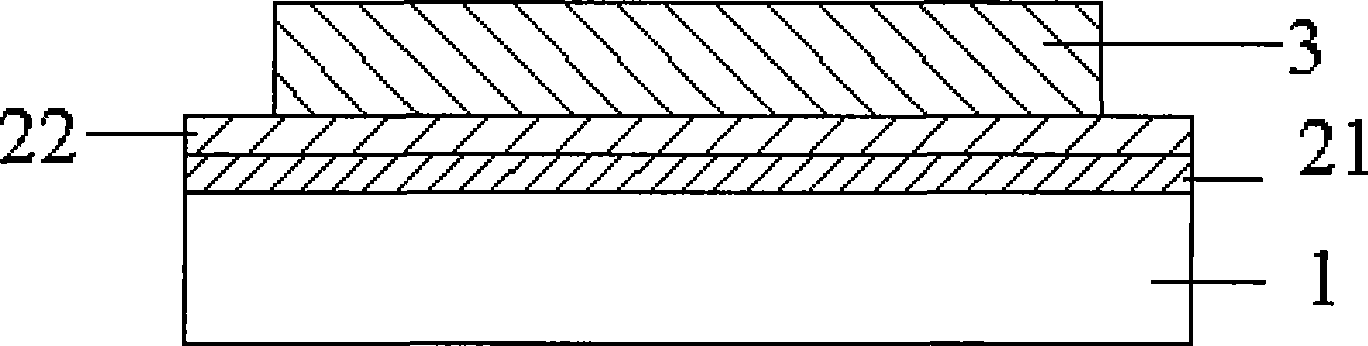

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Microwave curing process for ceramic material gel casting

The invention relates to a microwave curing process for ceramic material gel casting, which comprises the following steps: firstly, dissolving organic monomer and crosslinker in sequence in the solvent, adding a dispersant and obtaining pre-prepared liquid; adjusting the pH value of the pre-prepared liquid to be 7-11, adding ceramic powder to the pre-prepared liquid, stirring the mixture stronglyand mechanically for 1h and obtaining even slurry; adding an initiating agent and a catalytic agent to the slurry and mixing evenly; soon afterward, removing the gas in the slurry by vacuum; casting the slurry into a module; placing the module packed with the slurry in a microwave oven for a curing process, and obtaining a gel casting ceramic body; and drying the ceramic body, and then sintering at the temperature of 1200 DEG C-2200 DEG C for 1-6h, and finally obtaining a ceramic product. Compared with the conventional gel casting curing method, the microwave curing process has the advantagesthat the process has fast heating speed and uniform temperature field, reduces the activation energy of reaction, accelerates the reaction rate, causes the polymerization reaction to be finished rapidly and achieves the purpose of high speed and high quality moulding of materials.

Owner:OCEAN UNIV OF CHINA

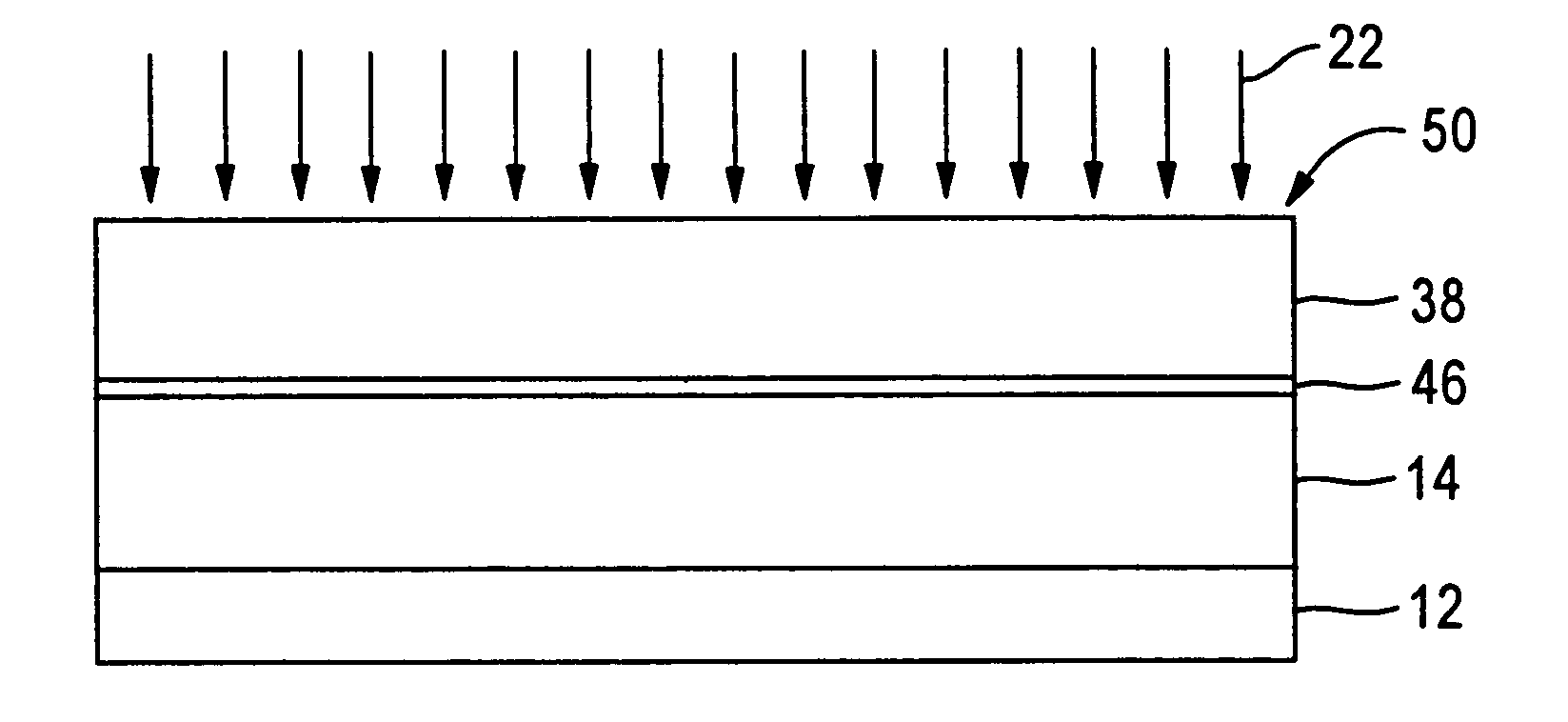

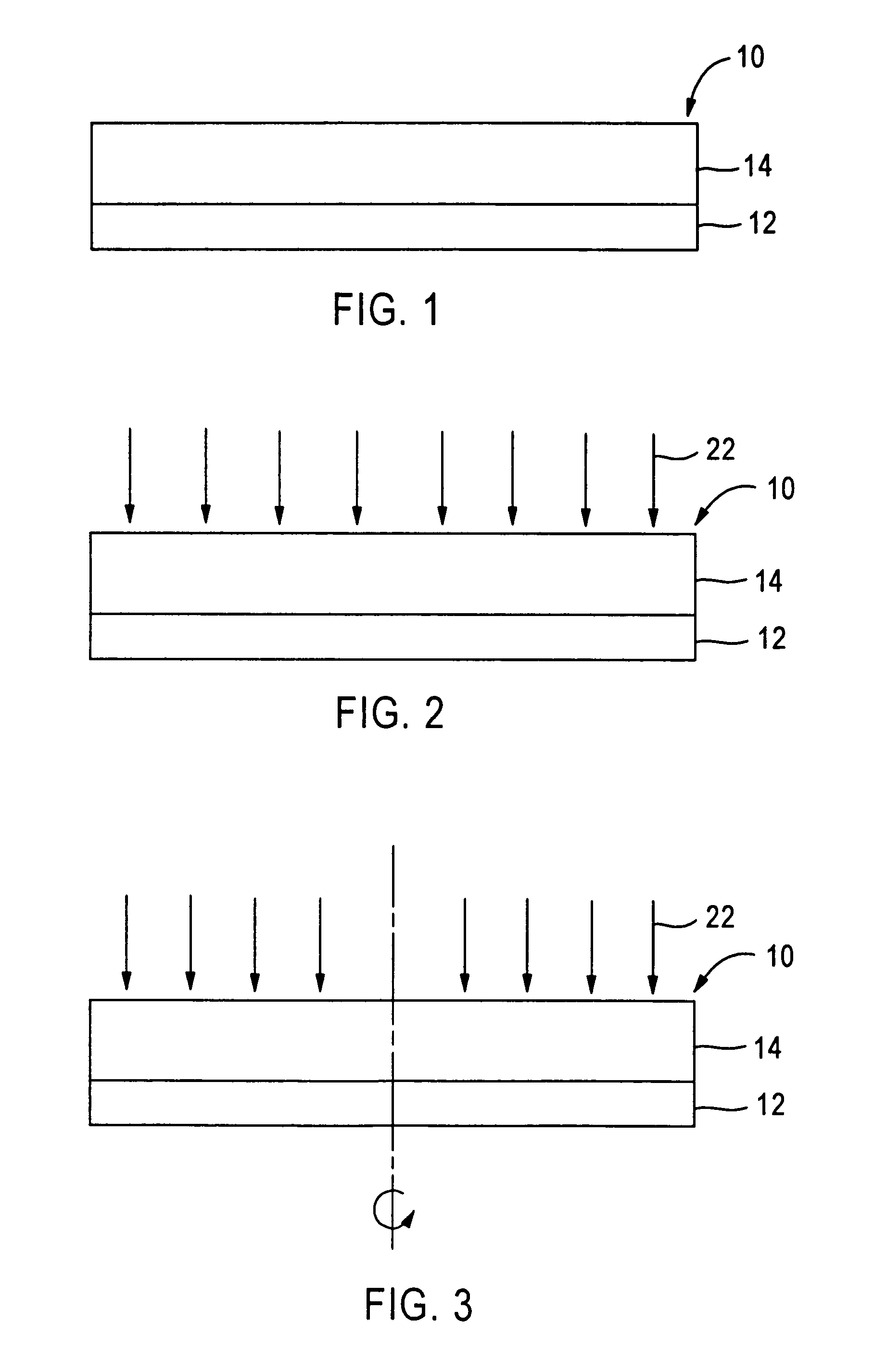

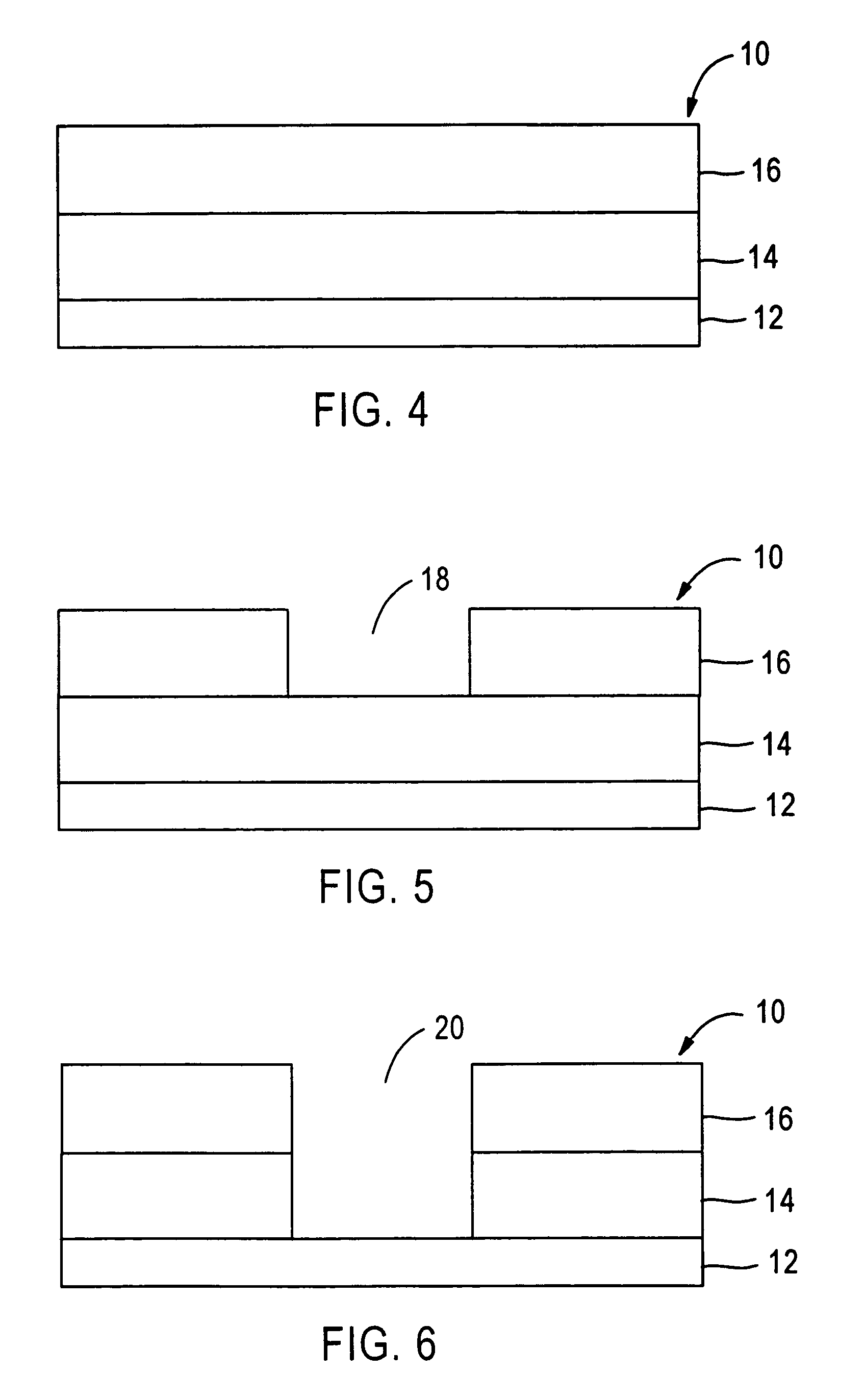

Method of forming semiconductor devices by microwave curing of low-k dielectric films

InactiveUS7557035B1Inhibition formationReduce thermal stressSemiconductor/solid-state device manufacturingUltimate tensile strengthMechanical property

The invention provides a method of exposing low-k dielectric films to microwave radiation to cure the dielectric films. Microwave curing reduces the cure-time necessary to achieve the desired mechanical properties in the low-k films, thus decreasing the thermal exposure time for the NiSi transistor contacts. A lower thermal budget for interconnect fabrication is necessary to prevent damage to the NiSi transistor contacts and minimize thermal stressing of previously formed interconnect layers. Microwave-cured dielectric films also have higher mechanical strength and strong adhesion to overlying layers deposited during subsequent semiconductor device manufacturing steps.

Owner:GLOBALFOUNDRIES US INC

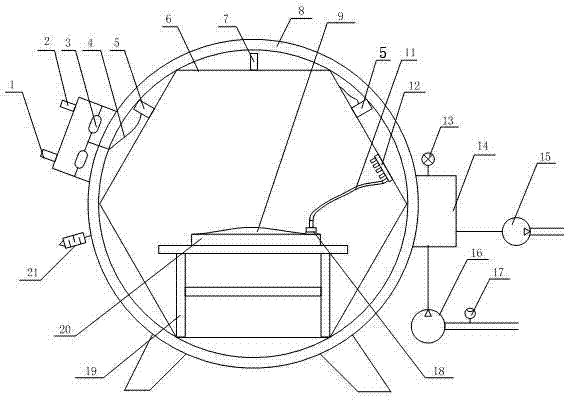

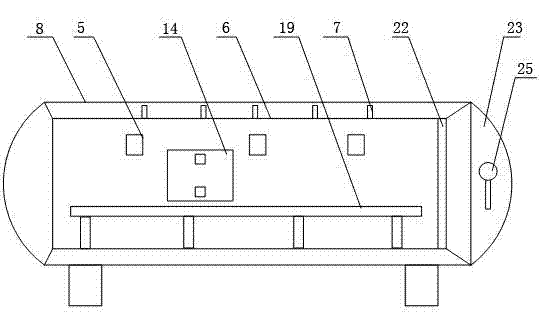

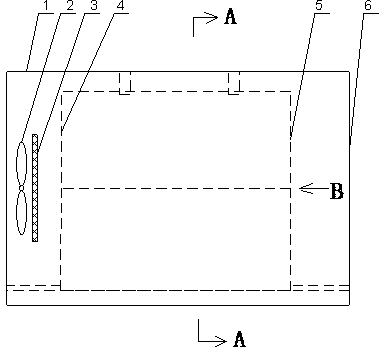

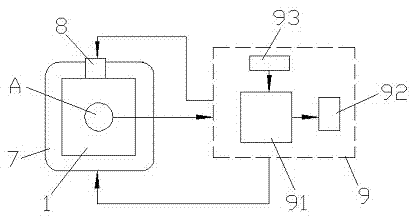

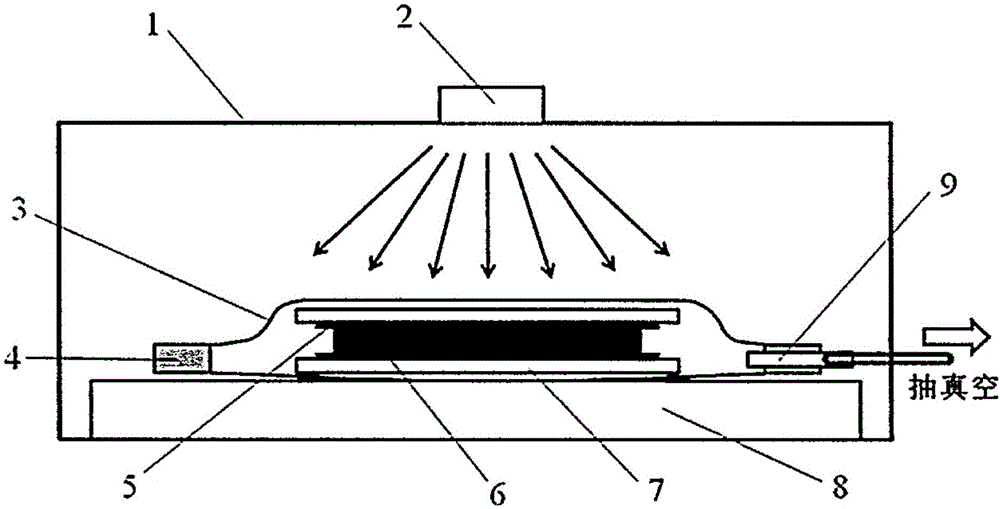

Processing apparatus and processing method for microwave cured fiber reinforced resin matrix composite

ActiveCN102729490AMeasure temperature in real timeEnsure controllabilityResin matrixResin-Based Composite

The invention relates to a processing apparatus and a processing method for a composite and especially to a processing apparatus and a processing method for a microwave cured fiber reinforced resin matrix composite. According to the invention, a polygonal multi-mode cavity is arranged in a tank; a microwave source water cooling interface and a microwave source electrical interface are connected with a magnetron; the magnetron is arranged at an outer side of the tank and connected with a rectangular waveguide tube through a magnetron antenna; the rectangular waveguide tube is arranged at an outer side of the polygonal multi-mode cavity; a vacuum pipe joint is arranged at an inside wall of the polygonal multi-mode cavity; a worktable is disposed in the polygonal multi-mode cavity; a die is disposed on the worktable; the composite is disposed in the die and a vacuum valve is arranged at the upper end of the die; and the vacuum valve is connected with the vacuum pipe joint through a vacuum pipe.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

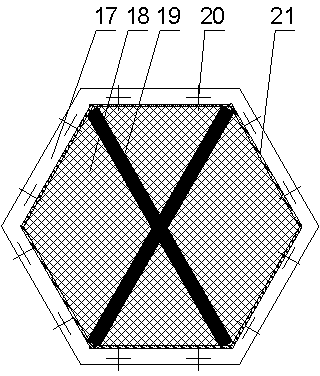

Uniform temperature distribution method and curing device for microwave-pressure curing composite material

ActiveCN104139532AImprove temperature uniformityGood mechanical properties after moldingDistribution methodElectromagnetic shielding

The invention discloses a uniform temperature distribution method and a complete set of curing device for a microwave-pressure curing composite material. The method is characterized in that a polygon cavity is used in a pressure container tank, so that the microwave can be reflected for multiple times in the cavity and the uniformity of the microwave entering the composite material is improved; meanwhile, waveguide windows are formed in the front and the back of the cavity, so that a gas medium can flow into the cavity and carry out convection heat transfer with the composite; the temperature uniformity of the material can be further improved; and the pressure is applied by the air in the pressure container when the composite material is heated and cured. The device mainly comprises a polygon cavity and an electromagnetic shielding window. Through the uniform temperature distribution method and the curing device for the microwave-pressure curing composite, the temperature uniformity of a composite part can be improved, and the buckling deformation of the composite material cured by the microwave can be reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

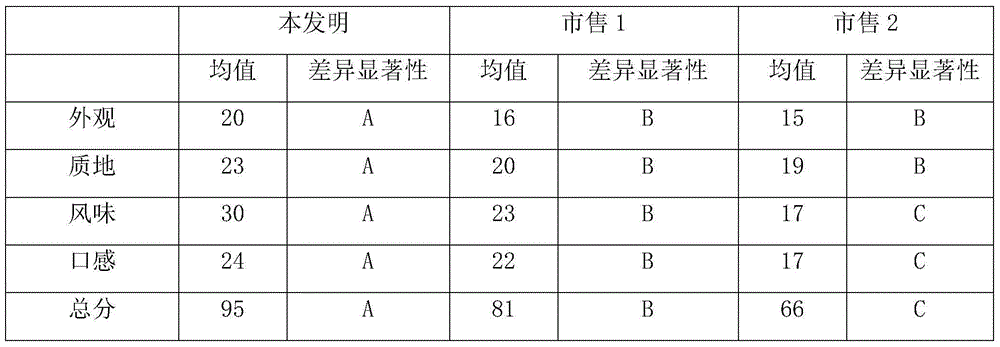

Preparation method of purple sweet potato fermented product

InactiveCN103004988AFacilitated releaseEffective useMilk preparationFood preparationAnimal proteinMixed materials

The invention discloses a preparation method of a purple sweet potato fermented product. The preparation method comprises the following steps of: preparing whole purple sweet potato powder through microwave curing by using purple sweet potatoes and fresh milk or milk as main materials, and preparing fermented milk by using mixed bacteria of beneficial lactobacillus lactobacillus bulgaricus and streptococcus thermophilus according to a volume ratio of 1 to 1 as a mixed leavening agent; fermenting the microwave cured whole purple sweet potato powder and the fermented milk in a mixed manner; and sterilizing and filling, so as to obtain a finished product. The preparation method is simple to mix; the release of nutrient elements, such as anthocyanin of the purple sweet potato and selenium, can be effectively promoted by using the microwave cured whole purple sweet potato powder as a main material for fermenting the purple sweet potato; the effects of animal protein nutrition and plant dietary fiber can be effectively combined through fermentation; the purple sweet potato fermented product has the advantages of comprehensive nutrition, high additional value and good taste, and is beneficial to reception and digestion of a human body; and the purple sweet potatoes can be comprehensively used, and the waste emission and the environment pollution can be avoided.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI

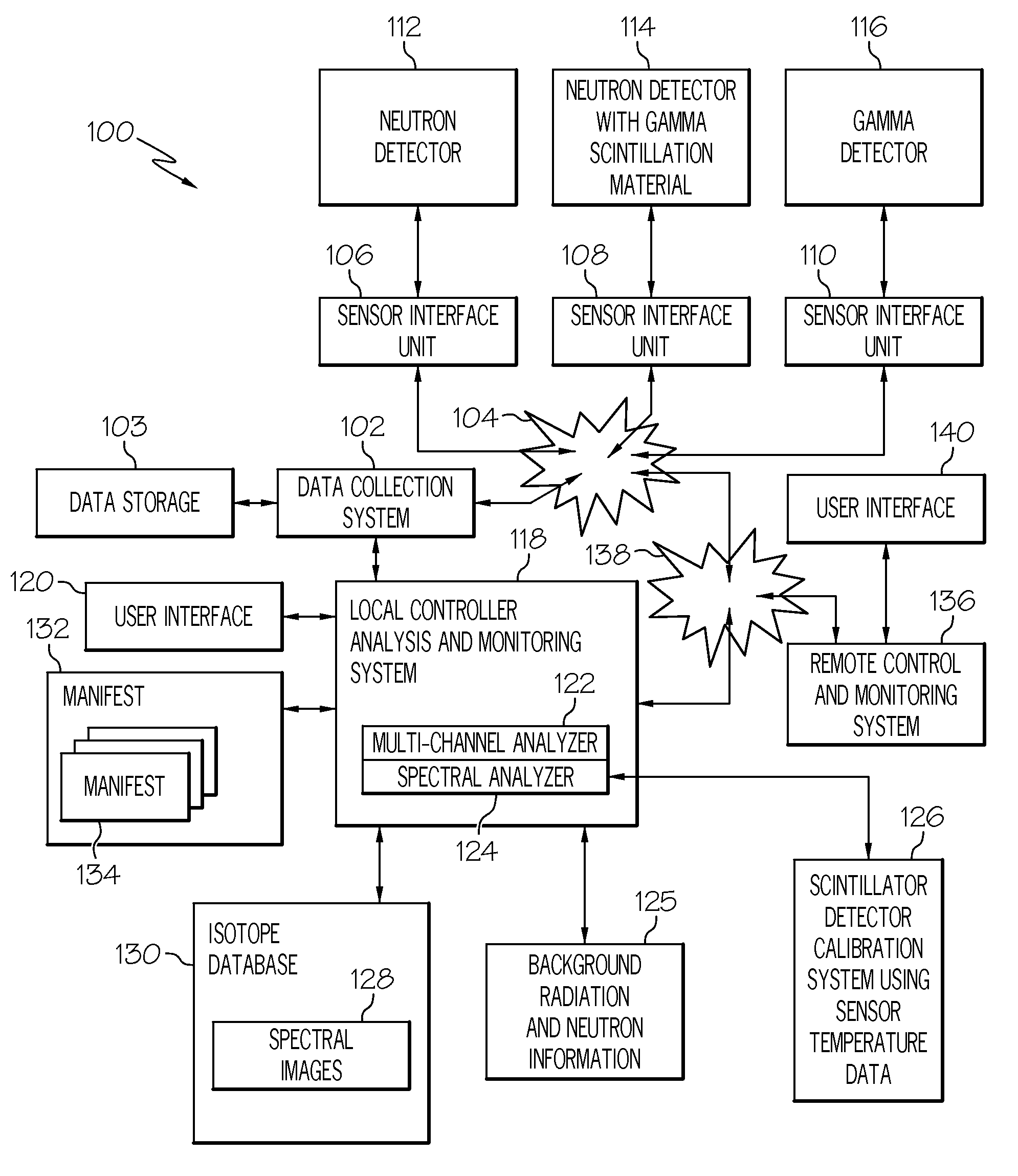

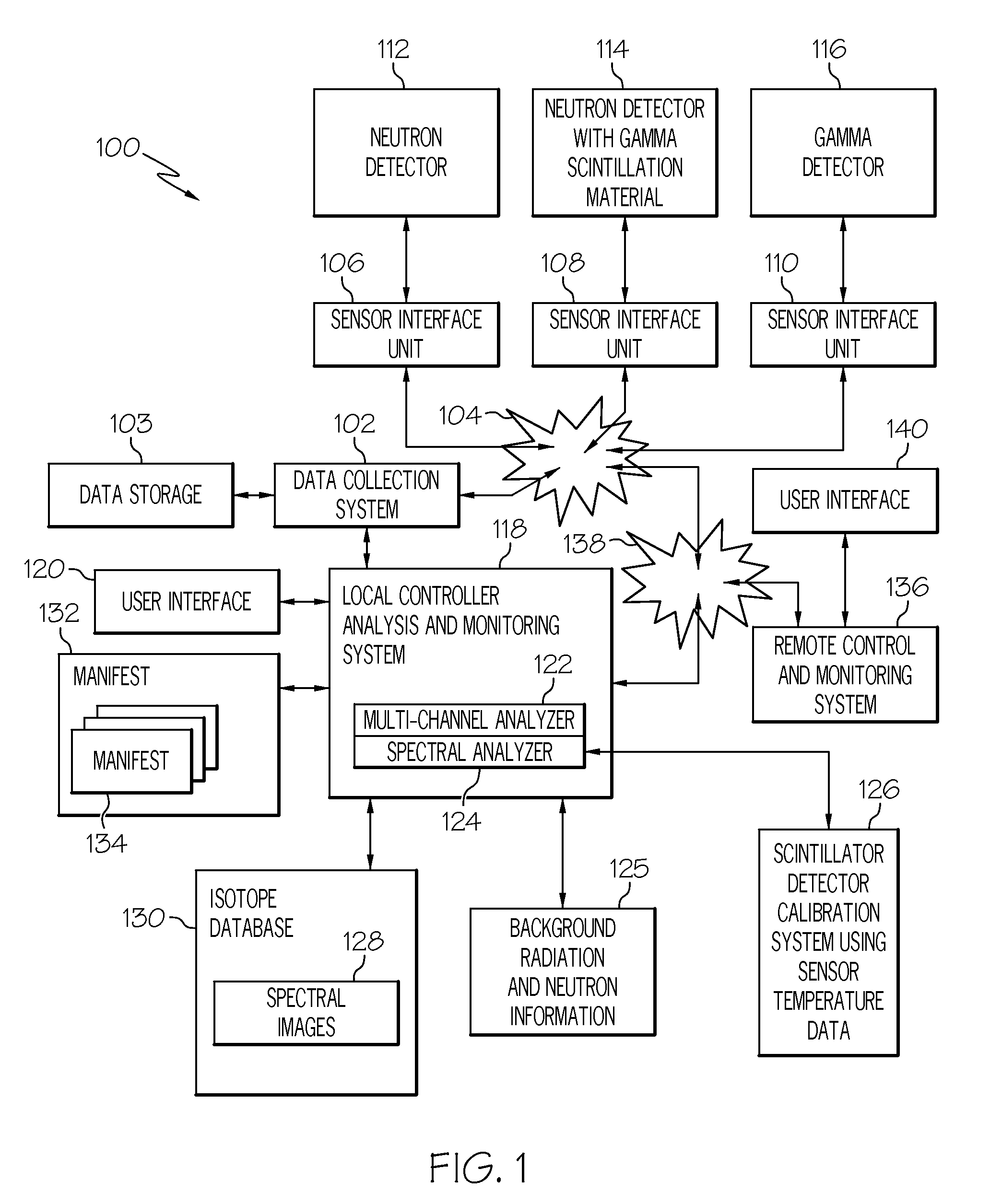

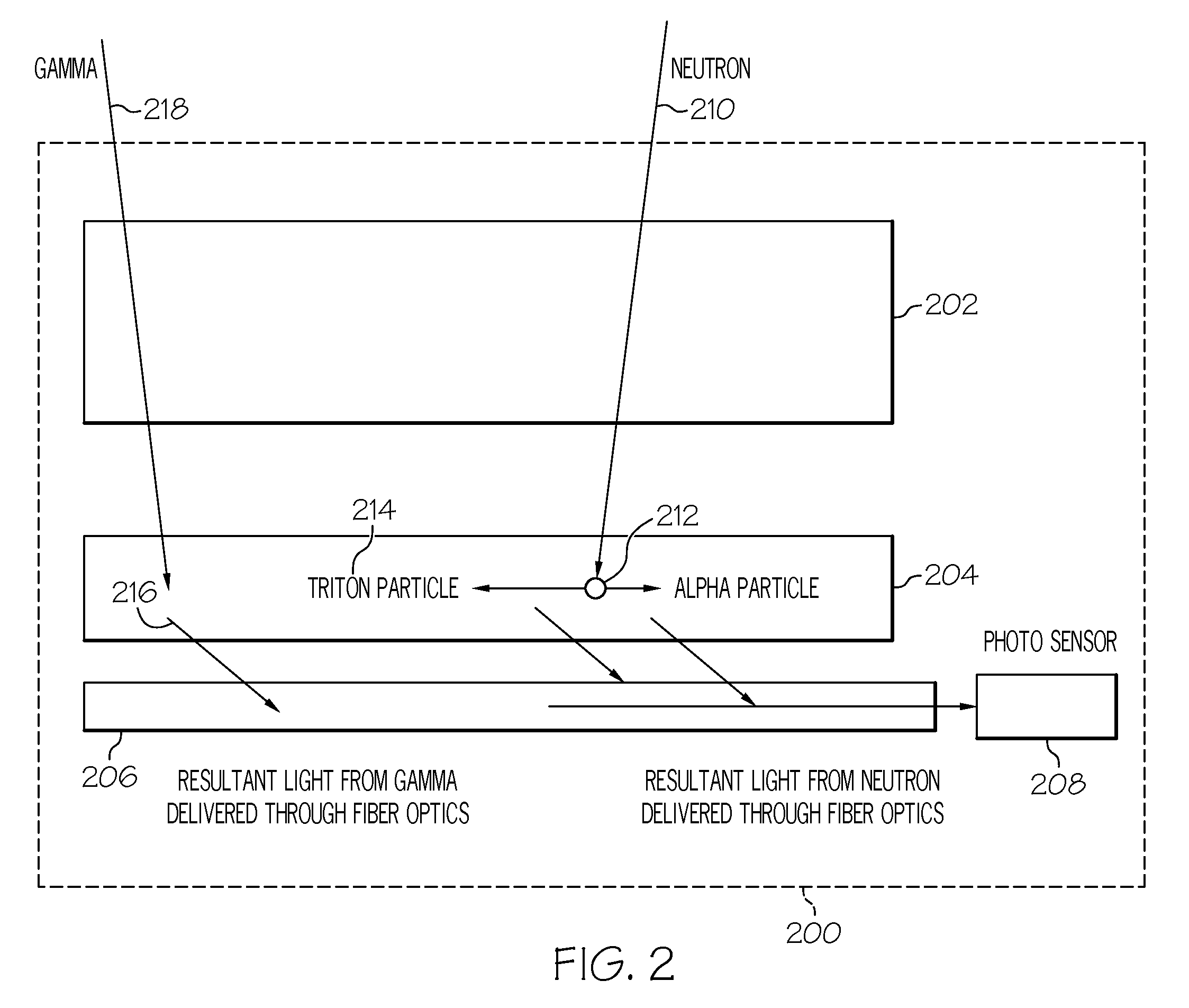

Fabrication of a high performance neutron detector with near zero gama cross talk

InactiveUS20100294415A1Located very closeImprove performanceLamination ancillary operationsMeasurement with scintillation detectorsFiberLight guide

A fabrication method is provided for making a high efficiency neutron detector using a scintillator medium coupled with fiber optic light guides. The light guides provide light pulses to photo sensor and thereby to high speed analog to digital conversion and digital electronics that perform digital pulse shape discrimination for near zero gamma cross talk. Optionally, microwave curing techniques are used for fabricating a high performance neutron detector with high reliability and homogenous distribution of the particles encapsulated in a polymer to produce a high performance neutron detector.

Owner:EMR RESOURCES +2

Method for preparing sand-base water-permeable brick

ActiveCN102555044AThe temperature inside and outside the brick is the sameHigh strengthCeramic shaping apparatusBrickCompressive strength

The invention provides a method for preparing a sand-base water-permeable brick. The method comprises the following steps: preparing a prefabricated part of the sand-base water-permeable brick and performing microwave solidification on the prefabricated part of the sand-base water-permeable brick, wherein the condition of the microwave solidification comprises solidifying temperature at 80-150 DEG C and solidifying time being 3-20 minutes. According to the method, the solidifying time is greatly shortened and the pressure resistance and water permeability of the sand-base water-permeable brick are obviously increased.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

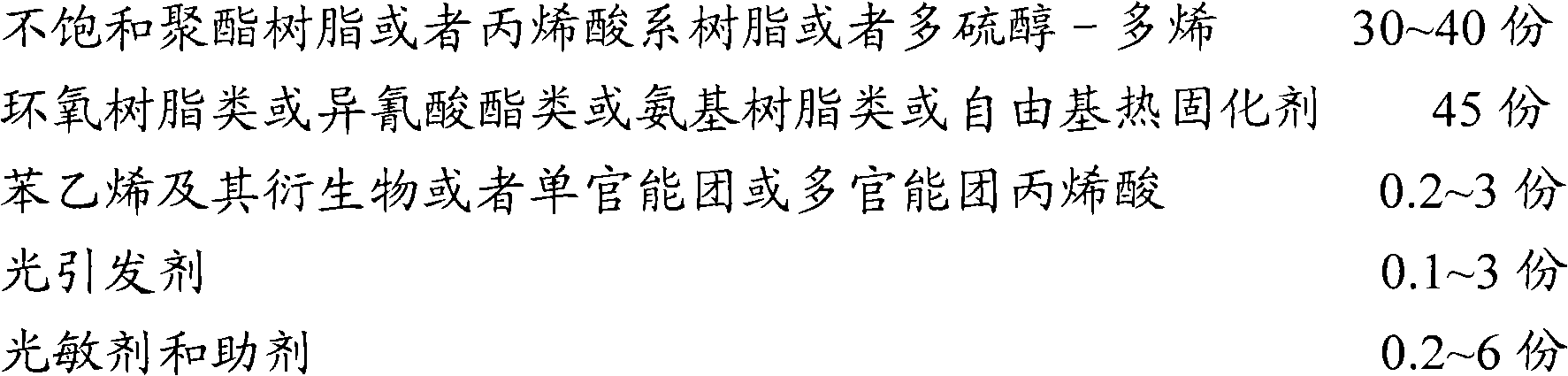

Cyanate esters electric packaging material and microwave curing preparation method thereof

The invention relates to an ethylene rhodanate electronic packing material and a microwave solidification preparation method thereof, which is technically characterized by comprising the following components: ethylene rhodanate resin, bismaleimides prepolymer, nano-silicon dioxide and micron-silicon dioxide and is prepared as follows: the bismaleimides prepolymer which is firstly heated and added with the ethylene rhodanate resin and also with the mixture of the nano- and the micron-silicon dioxide, then the obtained mixture is poured into a preheated polyfluortetraethylene mould; and the mould is vacuumized and then put into a microwave oven for carrying out variable-power intermittent solidification so as to acquire the ethylene rhodanate electronic packing material. The content of reactive diluent allyl ether in the bismaleimides prepolymer of the invention is beneficial to the dispersion of inorganic filler and can play the role of toughening under high temperature. Due to the adoption of the microwave solidification and variable-power intermittent solidification methods for preparing the material, the preparation process is simple, and the obtained material has excellent mechanical and dielectric properties and can be used as the integrated circuit boards or packing materials in the electronic field.

Owner:南通优尼科化工有限公司 +1

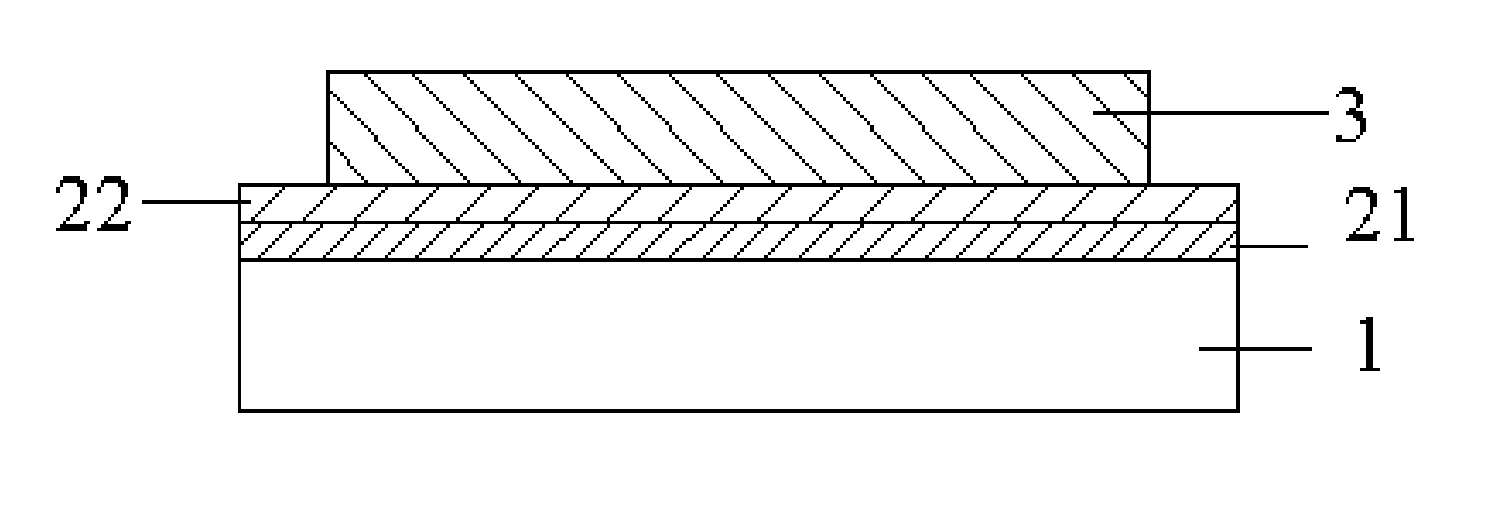

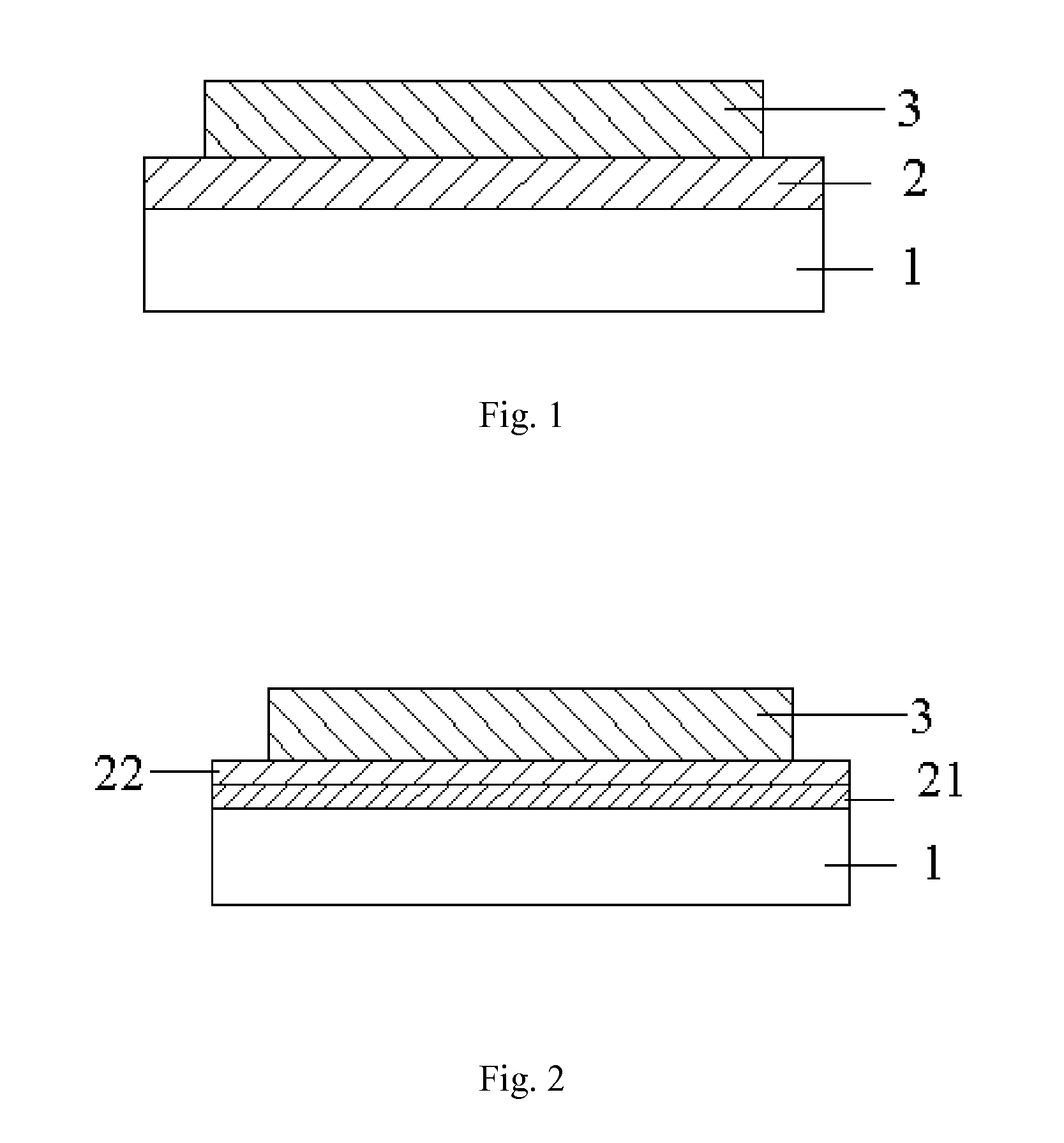

Active matrix organic electroluminescent device and method of manufacture thereof

InactiveUS20110221331A1Improve adhesionImprove abilitiesDischarge tube luminescnet screensLamp detailsAdhesiveActive matrix

An active matrix organic electroluminescent device includes a thin-film transistor, an organic electroluminescent device, and a spacer layer deposited between the thin-film transistor and the organic electroluminescent device, wherein the spacer layer is made of adhesive for a dual curing system selected from the group consisting of ultraviolet curing-thermal curing, ultraviolet curing-microwave curing, ultraviolet curing-anaerobic curing, and ultraviolet curing-electron beam curing system. The present invention solves the poor adhesiveness between the thin-film transistor and the organic electroluminescent device, and improves the moisture and oxygen proof ability. The preparation method is simple, effective, and able to lower the cost and difficulty, and greatly improve the yield rate of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Substrate for flexible photoelectronic device and preparation method thereof

InactiveCN102208542AImprove flatnessImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingDoped grapheneAdhesive

The invention discloses a substrate for a flexible photoelectronic device. The substrate comprises a flexible substrate and a conducting layer, wherein the flexible substrate and the conducting layer are formed by one of the following two ways: (1) the flexible substrate is an adhesive needing dual-curing; the conducting layer is a silver nanowire film; and the gap of the silver nanowire film is filled with graphene; and (2) the flexible substrate is a graphene doped adhesive needing dual-curing; the conducting layer is a silver nanowire film; the gap of the silver nanowire film is filled with the graphene doped adhesive needing dual-curing; and the adhesive needing dual-curing comprises an ultraviolet curing-thermocuring system, an ultraviolet curing-microwave curing system, an ultraviolet curing-anaerobic curing system and an ultraviolet curing-electron beam curing system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Edible grain, bean and potato coarse cereal rice composition and preparing method thereof

InactiveCN104855830AHigh economic valueImprove immunityNatural extract food ingredientsFood ingredient functionsHydrolysateEdible Grain

The invention discloses an edible grain, bean and potato coarse cereal rice composition and a preparing method thereof and belongs to the technical field of grain deep processing. According to the edible grain, bean and potato coarse cereal rice composition, broken rice is used as a main raw material, after ultrasonic cleaning, microwave curing, drying and sterilizing of the broken rice, the broken rice, grain powder with a special flavor, enzymatic hydrolysate and other functional raw materials are pelletized, and then grain arrangement and processing through a microwave drying device are carried out, so that the edible grain, bean and potato coarse cereal rice composition is obtained. The edible grain, bean and potato coarse cereal rice composition has a tissue structure, granularity, hardness and viscosity which are similar to those of rice, can be boiled and cooked with rice, has the taste and chewiness, which are similar to those of cooked rice, is unique in flavor, soft in fragrance, high in appetite attractiveness, easy to digest and comprehensive in nutrition, and can improve the immunity and disease resistance of the human bodies and improve the gastrointestinal function. The guarantee period is three times of that of commercial rice. More importantly, a shortcut is developed for the efficient value-added comprehensive utilization of the broken rice, the road for the deep processing of the broken rice is broadened, and the economical value of the broken rice is increased. Better social benefits and economic benefits are realized and a sustainable development road for the deep processing of agricultural byproducts and the effective solving of Three-Rural problems is explored.

Owner:敖汉旗北方粮仓农产品批发市场有限公司

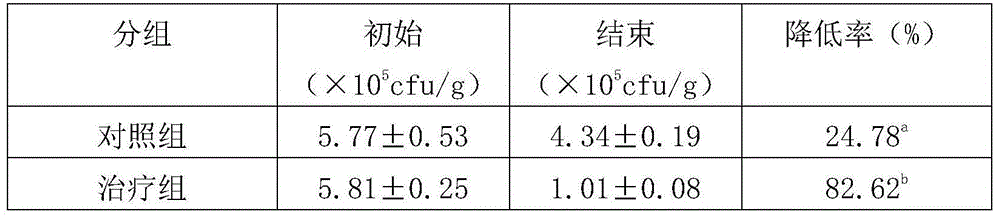

Protein antimicrobial catheter and manufacturing method thereof

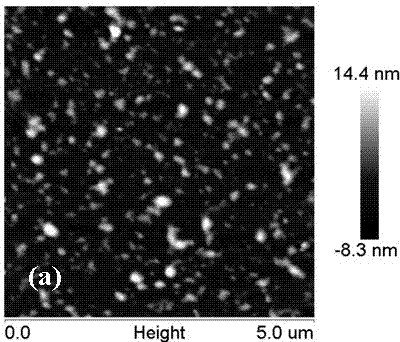

ActiveCN103768700AGood antibacterial effectImprove antibacterial propertiesCatheterCoatingsAdditive ingredientUltraviolet

The invention discloses a protein antimicrobial catheter. A non-diffusivity nanoscale smooth coating is arranged on the surface of the material of the catheter body, the main ingredient of the coating is natural protein harmless to the human body, the thickness of the coating is 10 nm to 500 nm, and the RMS roughness of the coating is not larger than 100 nm. The invention further discloses a manufacturing method of the protein antimicrobial catheter. The method includes the main steps that the material of the catheter body is pre-processed, protein glue solution is prepared, the surface of the material of the catheter body is coated with the protein glue solution one time or multiple times, and finally the protein glue solution adhering to the surface of the material of the catheter body is cured with the method of natural curing or microwave curing or hot curing or ultraviolet curing or cross-linking curing or the like. The catheter manufactured with the method is excellent in bacteria resistance and antibacterial effects, economical burdens and body pains caused when a catheter is frequently replaced for a patient can be reduced, the catheter is good in stability and low in virulence in body, some discomfort symptoms will not be caused to the patient, and the catheter is safe in clinical use.

Owner:SUZHOU RYAN NANOMEDICINE

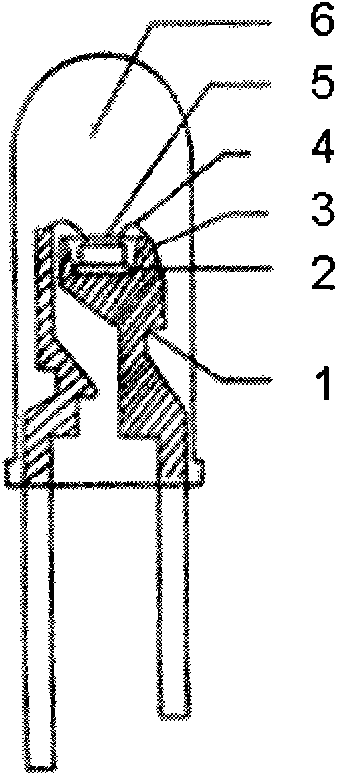

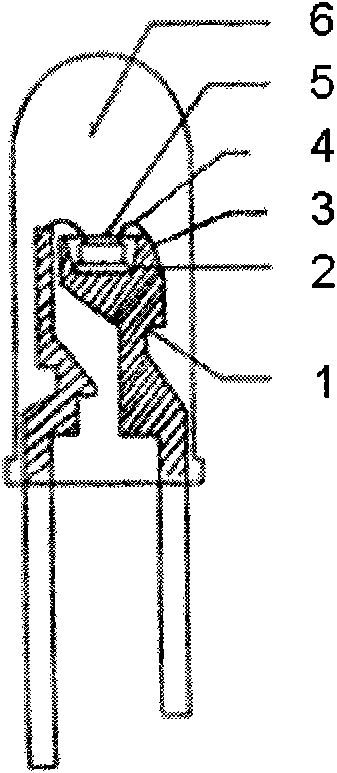

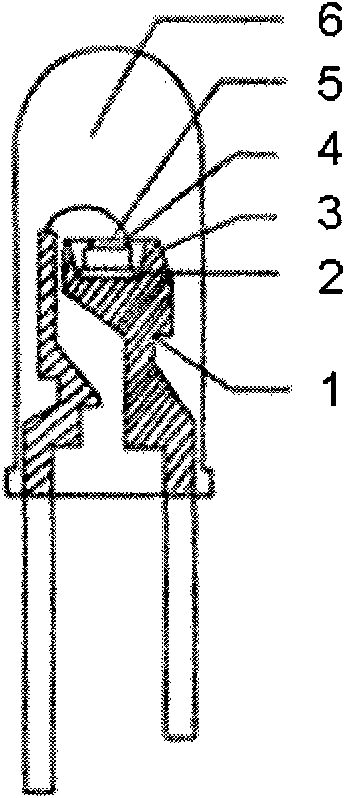

Light-emitting diode and preparation method thereof

The invention discloses a light-emitting diode (LED). The LED at least comprises a bracket, an LED chip and a light-emitting layer arranged on the LED chip and is characterized in that: the light-emitting layer is a mixed system of one or more kinds of fluorescent powder capable of sending out light with various colors and an adhesive requiring double curing; and the adhesive is an adhesive of a double curing system consisting of ultraviolet curing-thermocuring, ultraviolet curing-microwave curing, ultraviolet curing-anaerobic curing or ultraviolet curing-electron beam curing. The light-emitting layer solves the problems of colloid solidification and fluorescent powder sedimentation in the process of coating the fluorescent powder, so the LED has the advantages of improving the uniformity of the fluorescent powder on the chip, enhancing the adhesive property between the light-emitting layer and the chip and shortening the curing time of the light-emitting layer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Microwave solidification type bonding agent and microwave solidification method thereof

InactiveCN102352190AFast curingUniform curingNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentEpoxyCarbon composites

The invention discloses a microwave solidification type bonding agent and a microwave solidification method thereof. The bonding agent is prepared by adopting aluminum dihydrogen phosphate solution and phenolic resin as base materials, adopting compounds of two kinds of materials or several kinds of materials from magnesium oxide, zinc oxide, ferric oxide and zirconium oxide as solidification agents, adopting aluminum oxide as fillings and adopting boron carbide micro particles and ultra-fine silicon dioxide powder as modified fillings. All ingredients are mixed according to a certain proportion and are stirred at a high speed for obtaining the bonding agents. After the bonding agent is adopted for bonding devices, the convenient and fast solidification can be carried out under the microwave radiation effect. The bonding agent has excellent heat resistance performance, can be used for bonding ceramics, graphite, plastics, glass, epoxy resin, carbon / carbon composite materials and the like and has the characteristics that the temperature gradient of a solidified glue layer is small, the solidification is uniform, and the solidification time is short.

Owner:BEIHANG UNIV

Method of solidifying composite material with wave-absorbing material mould through microwave heating

ActiveCN104760302AShorten the timeSolve the problem that microwave curing cannot be usedFiberGlass fiber

A method of solidifying a composite material with a wave-absorbing material mould through microwave heating is disclosed. In the method, the wave-absorbing material mould is placed in a microwave field and the temperature of the wave-absorbing material mould is rapidly increased by means of a characteristic of quick and uniform heating of microwave, wherein generated heat is transferred to the composite material in the wave-absorbing material mould in a heat conduction manner, so that the temperature of the composite material is rapidly increased and the composite material is solidified. The method fully utilize the characteristic of quick and uniform heating of the microwave, which can significantly reduce required time of a conventional solidifying process of the composite material and increase production efficiency. Meanwhile, because that the microwave field does not act on a structural layer of the composite material, a problem of sparking in the microwave field of high-electric-conductivity fibers, such as carbon fibers and the like, can be avoided, so that the method not only is suitable for solidifying a low-electric-conductivity composite material such as glass fibers and the like, but also is suitable for solidifying a high-electric-conductivity composite material such as carbon fibers and the like, thereby solving a problem that the carbon fiber cannot be solidified through the microwave since the carbon fiber sparks in the microwave field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

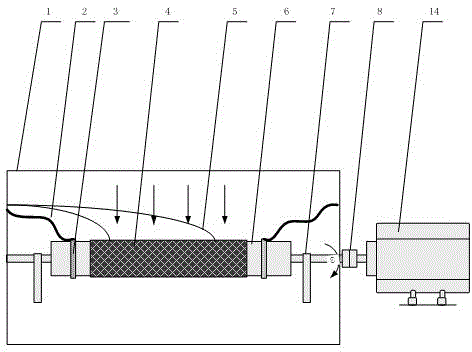

Microwave curing method and microwave curing device of composite shaft part

The invention relates to a microwave curing method and a microwave curing device of a composite shaft part. The method is characterized by comprising the following steps: firstly, laying uncured composite materials on the surface of a smooth mandrel coated with a release agent, so as to form a to-be-cured shaft part, then arranging the to-be-cured shaft part in a vacuum bag in a sleeving manner, sealing both ends of the vacuum bag by high temperature resistant adhesive tapes, then vacuumizing the vacuum bag, so as to compact the to-be-cured shaft part, then putting the compacted to-be-cured shaft part and the mandrel into a microwave curing oven, setting heating parameters of the microwave curing oven according to a composite material heating process, and heating and curing the composite shaft part; after the final heat preservation time is finished, directly moving the shaft part out of the curing oven and cooling in the outdoor environment. The microwave curing method has the advantages of short heating and curing time, low energy consumption, good temperature uniformity and easiness in control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fast food rocessing method for fresh chilled vegetables by microwave curing

InactiveCN102845691AGuaranteed FreshnessKeep the tasteFood preparationMicrowave ovenMicrowave curing

The invention discloses a fast food rocessing method for fresh chilled vegetables by microwave curing. The method comprises the following steps of: a, cleaning raw materials, b, cooking sauce, c, treating by boiled water, d, pouring sauce, e, cooling, f, subpackaging, g, refrigerating and transporting, and h, curing by microwave: cooking for 18s to 22s by the microwave at the cooking temperature of 92 DEG C to 98 DEG C by using a microwave oven. The fast food rocessing method for fresh chilled vegetables by microwave curing, provided by the invention, has the advantages that the microwave cooking speed is high, the cooking efficiency is high, the vegetable is unlikely to turn yellow, the color of the fast food is bright, the pleasant taste of the vegetable is maintained, the taste is authentic, and only a small part of nutrition is lost.

Owner:深圳市慈浩餐饮科技有限公司

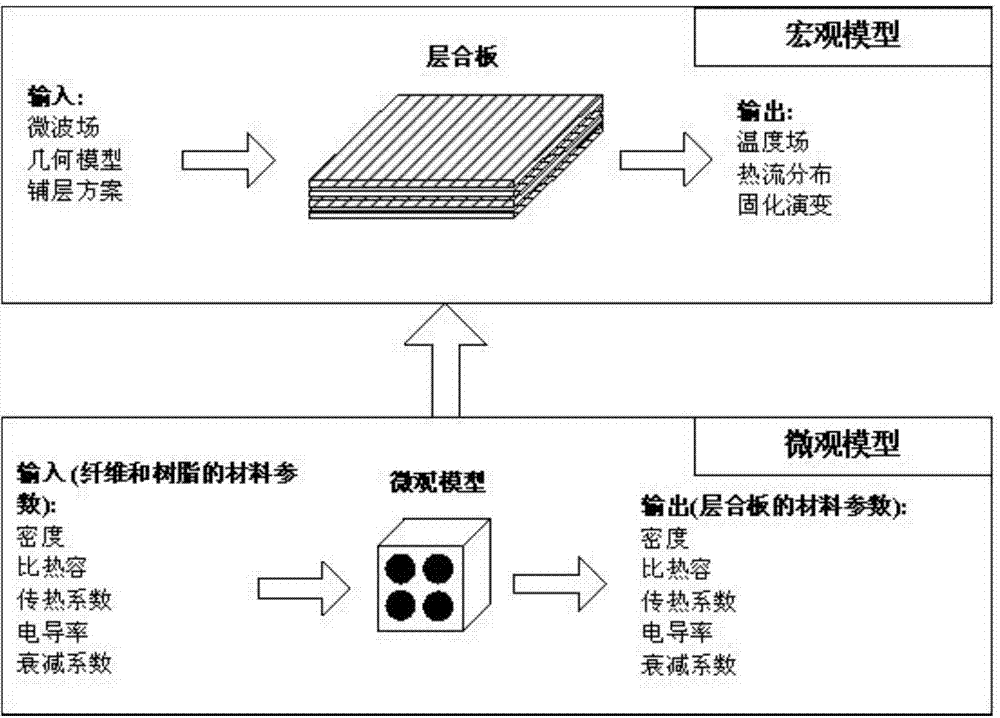

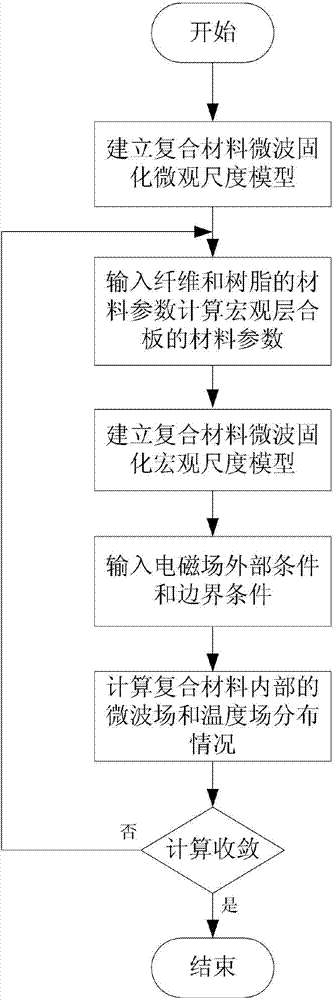

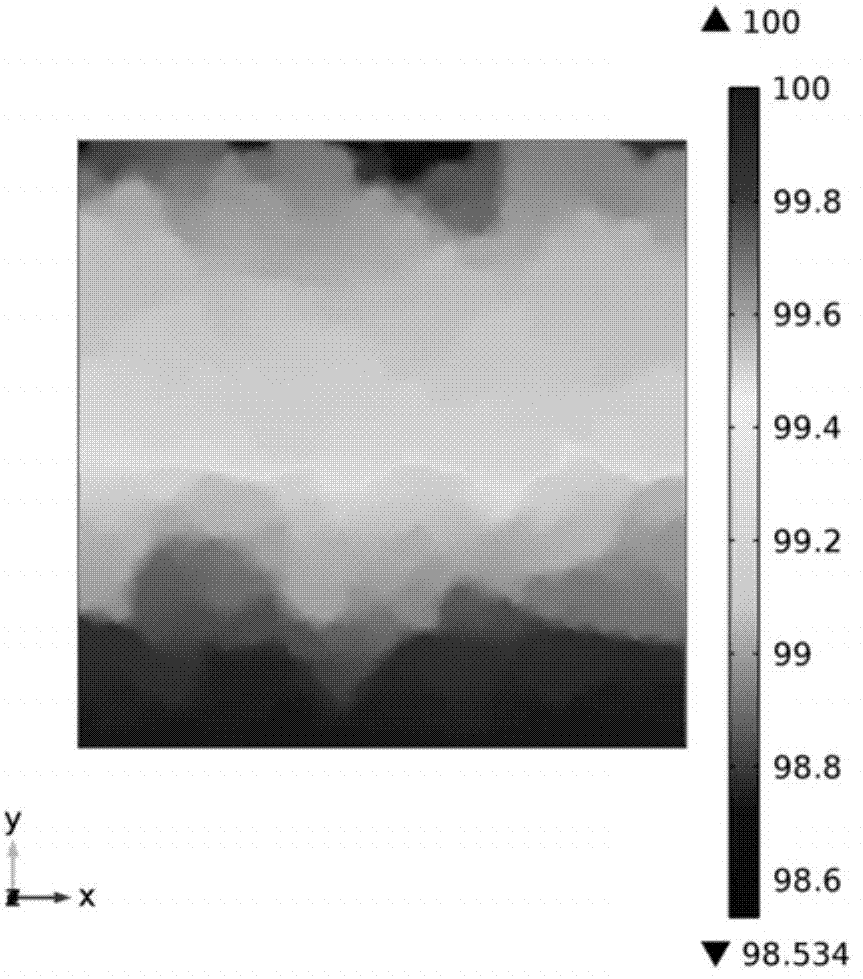

Prediction method for composite microwave curing temperature field

ActiveCN104732022AImprove forecast accuracyWith analysisSpecial data processing applicationsScale modelUltrasound attenuation

The invention relates to a prediction method for a composite microwave curing temperature field and provides a prediction method for a microwave field and a temperature field in the microwave heating curing process of a resin matrix composite. The prediction method comprises the steps that a micro-scale model and a macro-scale model of a reinforcement body and a resin matrix are established, attenuation of microwaves in a material is mainly included in the micro-scale model, and reaction heat release of the microwave curing composite and heat convection and heat radiation of the composite and a mould and the peripheral room temperature environment are mainly included in the macro-scale model. The coupled solution is conducted on the micro-scale model and the macro-scale model so as to accurately predict and analyze the microwave and temperature distribution of the microwave curing composite.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

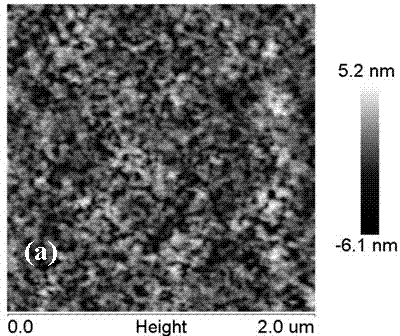

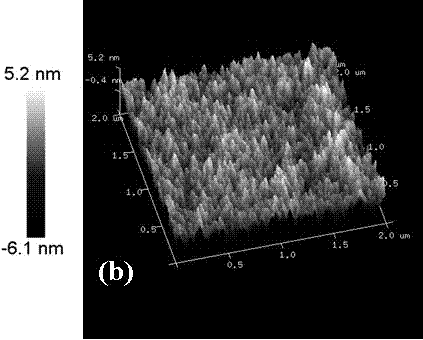

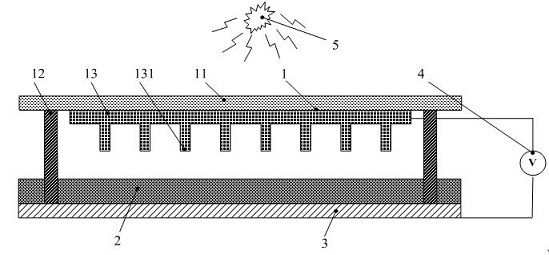

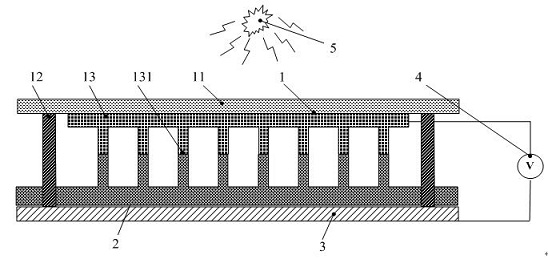

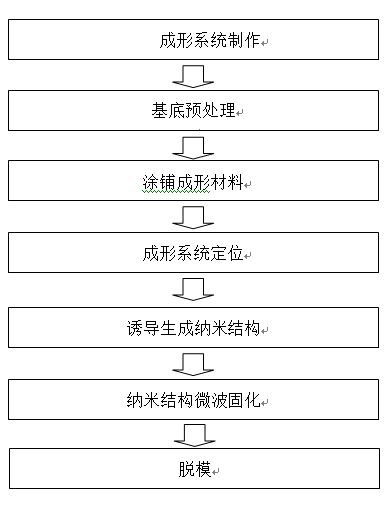

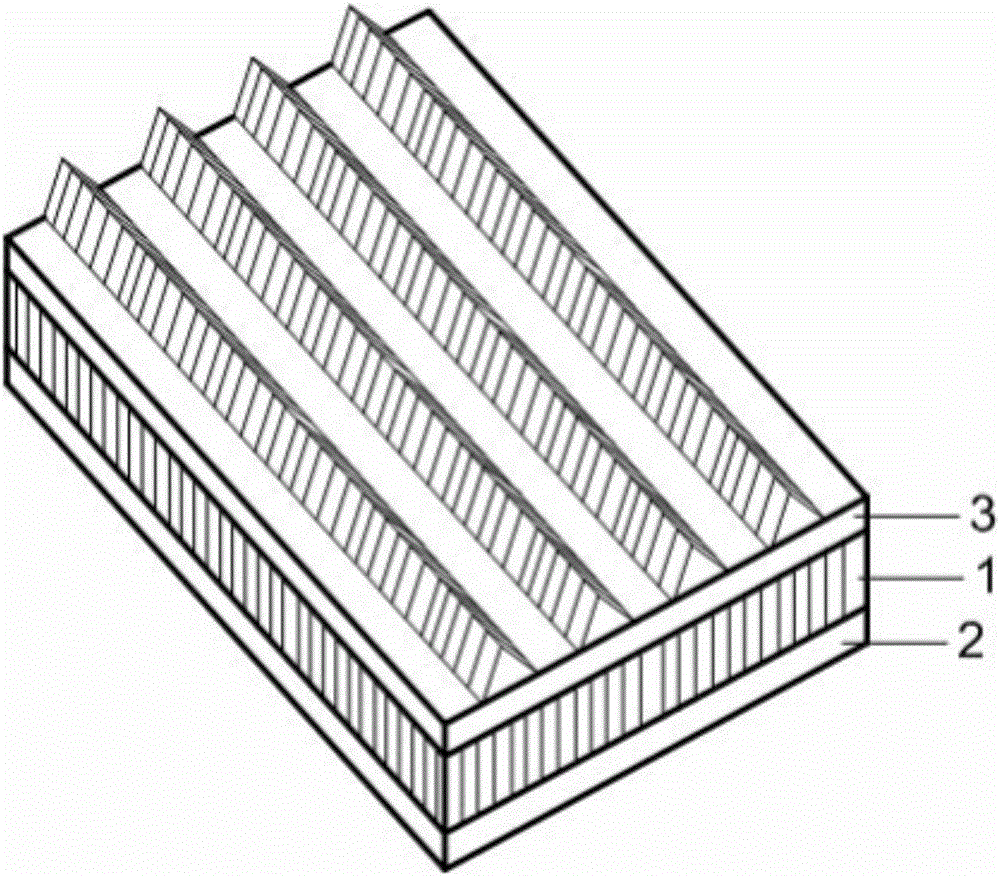

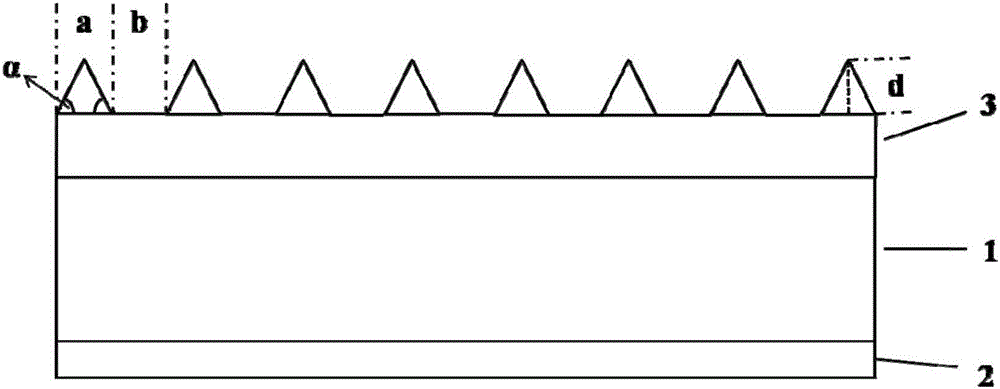

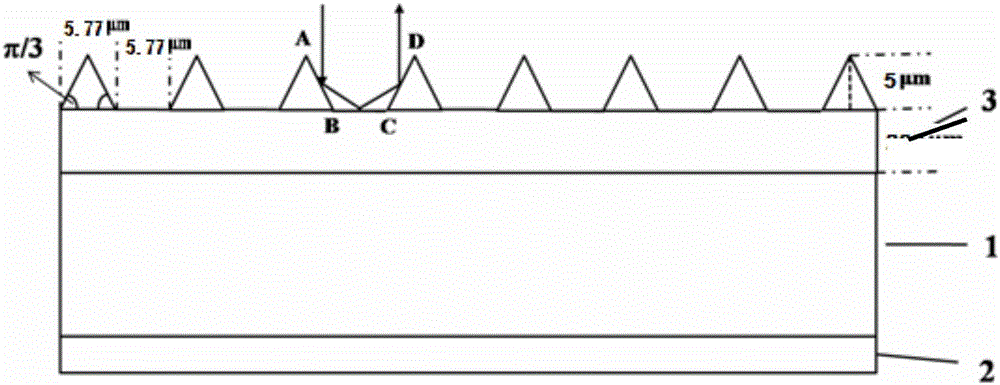

Apparatus and method for graphically producing nano structures by way of electrode induction and microwave curing

The invention relates to an apparatus and a method for graphically producing nano structures by way of electrode induction and microwave curing. The apparatus comprises a molding system, a molding material, a substrate, a nano structure induction system and a microwave curing system. The method for producing nano structures based on the apparatus includes the following steps: (1) the fabrication of the molding system; (2) the preprocessing of the substrate; (3) the coating of the molding material; (4) the positioning of the molding system; (5) the inductive production of a nano structure; (6)the microwave curing of the nano structure; and (7) demolding. The invention is characterized by simple structure, low cost, high productivity, long electrode service life, high pattern precision andthe like, and can efficiently produce nano structures less than 100 nanometers at low cost.

Owner:SHANDONG UNIV

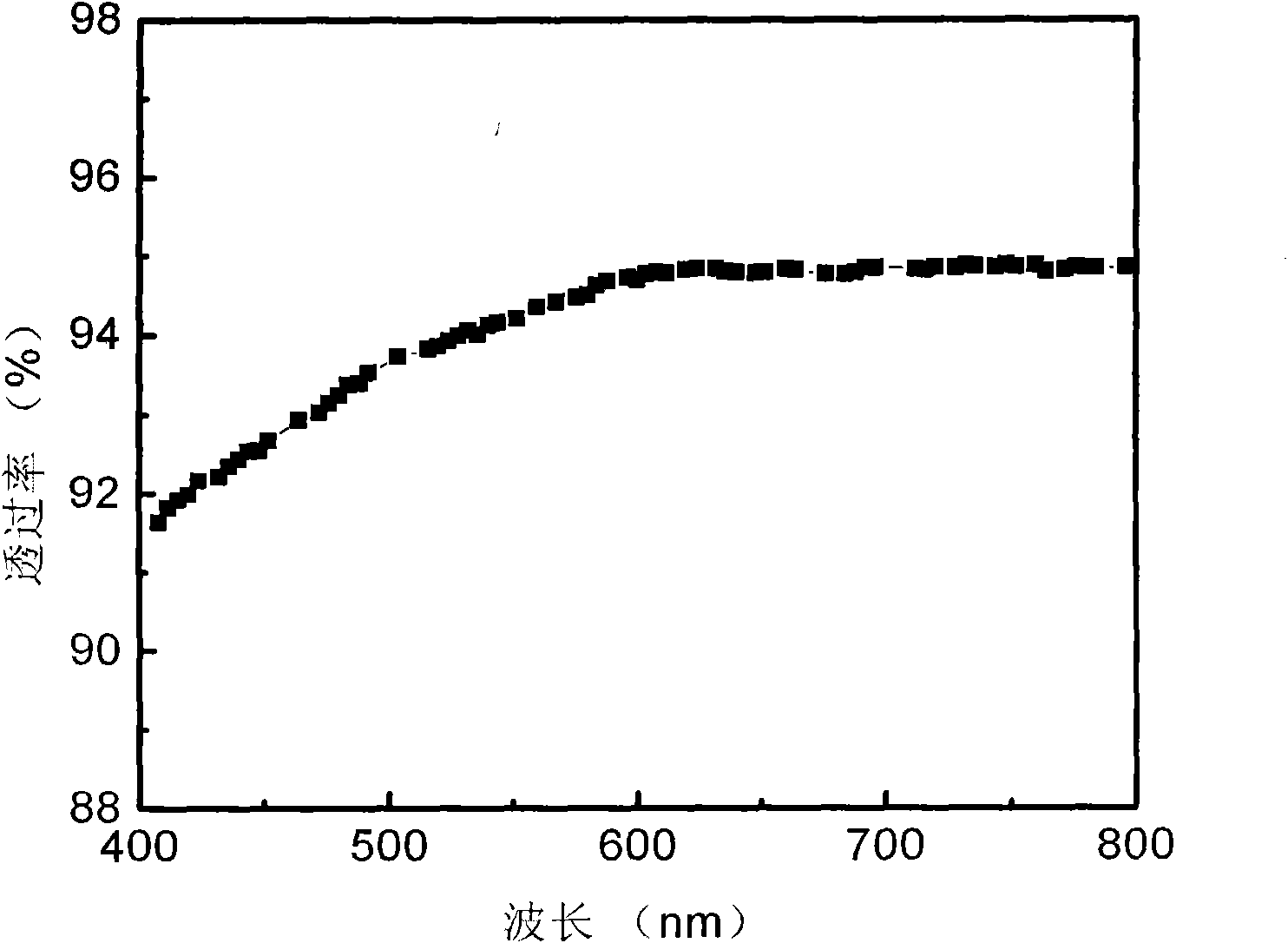

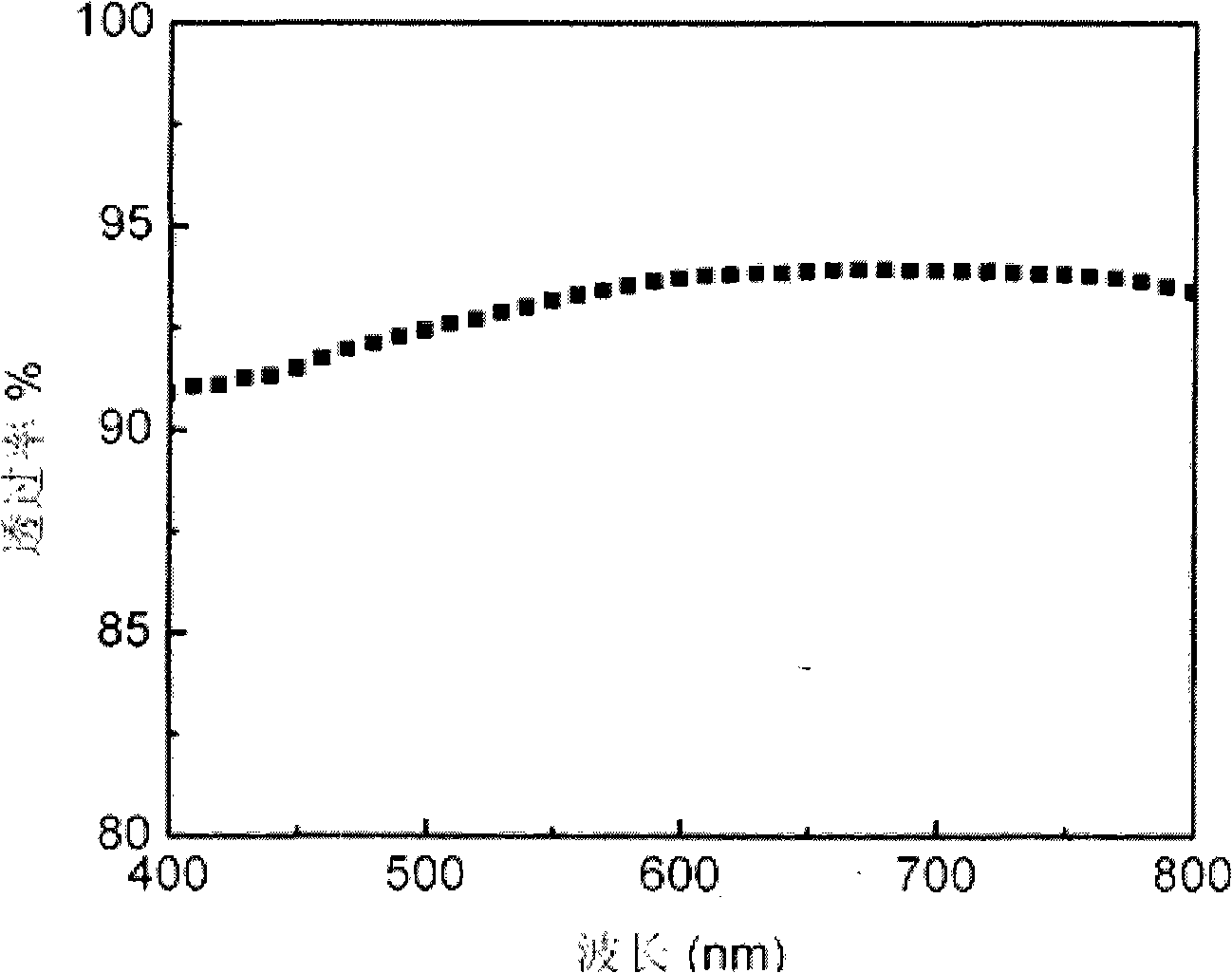

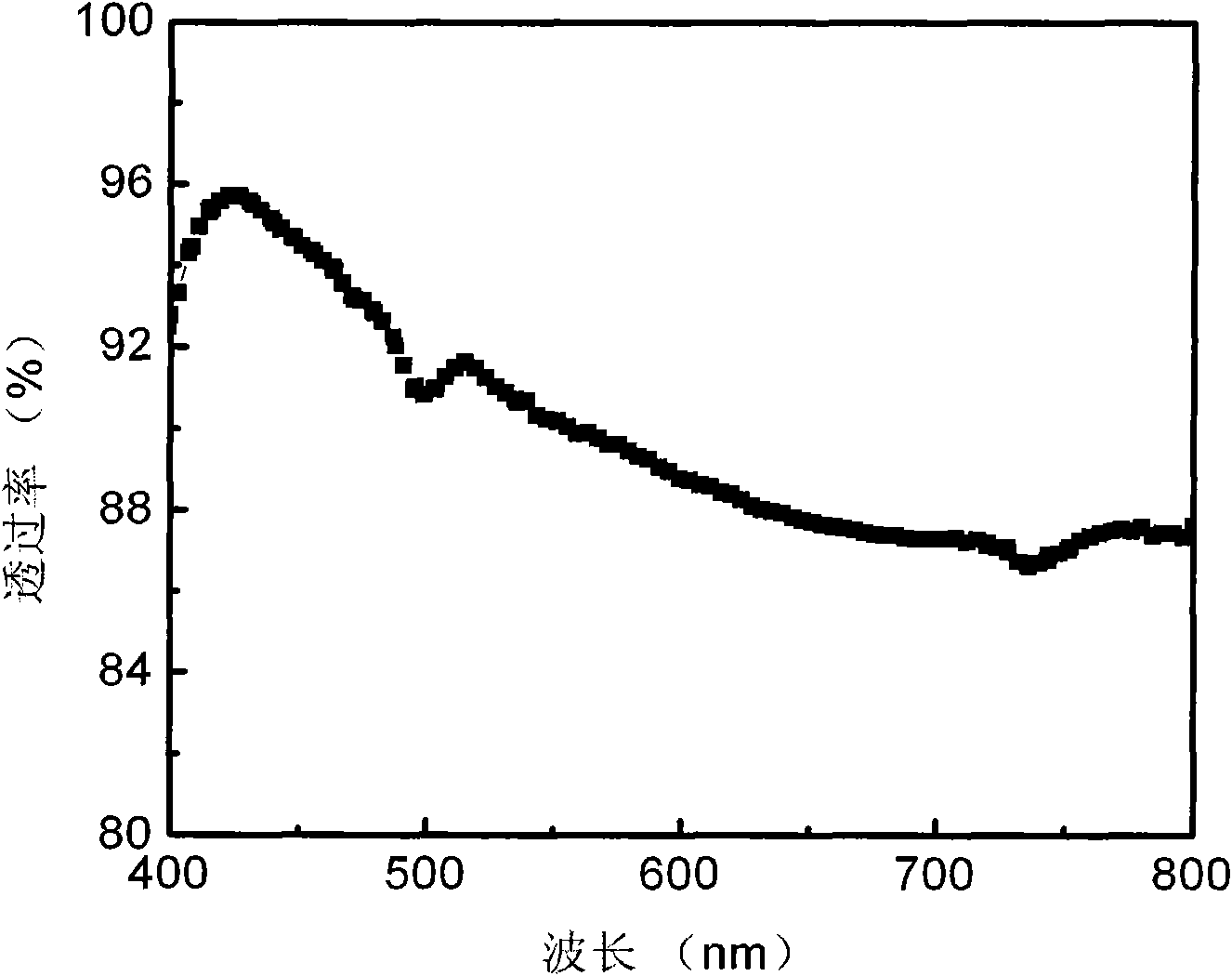

Patterned power-gain type solar back plate material

InactiveCN106024946AImprove reflectivityImprove power generation efficiencyPhotovoltaic energy generationSemiconductor devicesWater vaporHigh reflectivity

The invention discloses a patterned power-gaining solar backboard material. The backboard material is composed of a pattern layer, an intermediate layer and a weather-resistant layer. The weather-resistant layer is made by extrusion, casting or wet coating at 60-260 ° C. The pattern layer is melt-extruded and cast to the middle layer at 60-300 ° C. After that, it is mechanically printed and then thermally cured. , radiation curing, microwave curing in one or more ways to shape the system. The reflectivity of the backsheet material prepared by the present invention exceeds 90% in the visible light and short-wave near-infrared regions. The high reflectivity has a great gain for the power generation of solar modules, and it also has good water vapor barrier properties, insulation properties and Long-term weather resistance. The pattern of the invention is easy to prepare, the reflectivity is significantly improved, the comprehensive performance of the product is stable, and the compatibility with the internal material of the solar module is good, which is beneficial to the simplification of the module preparation process.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Composite pleurotus eryngii nutrition powder and chewable tablets and preparation method thereof

InactiveCN103431369AHigh in dietary fiberIt has the function of regulating blood lipidFood preparationDietary fiberSecondary hyperlipidemia

The invention discloses composite pleurotus eryngii nutrition powder and chewable tablets. The composite pleurotus eryngii nutrition powder and chewable tablets are prepared from the following raw materials in parts by weight: 40-70 parts of pleurotus eryngii, 10-30 parts of celery, 10-30 parts of onion, 5-10 parts of konjak and 5-30 parts of auxiliary materials. The composite pleurotus eryngii nutrition powder and chewable tablets are prepared from the pleurotus eryngii, the celery, the onion and the konjak together. A manufacturing method of the composite pleurotus eryngii nutrition powder and chewable tablets is simple and reasonable, microwave curing and other technologies are used in the preparation process, the raw materials are cured, a sterilization effect is achieved, the components with nutritional and active effects are kept, and the prepared nutrition powder and chewable tablets contain rich edible mushroom polysaccharide, onion active substances, dietary fiber and the like, are low in heat and high in nutrition and have a certain effect of preventing hyperlipidemia, hypertension and the like.

Owner:连云港海昇生物科技有限公司

Preparation method of freeze-dried ginkgo powder

InactiveCN103610141BEfficient removalReduce weightFood shapingFood preparationFreeze-dryingAdditive ingredient

The invention discloses a preparation method of freeze-dried ginkgo powder, belonging to the technical field of agricultural product and food processing. The preparation method comprises the following steps: soaking broken ginkgoes in clear water, taking out, and draining; performing microwave curing on the drained ginkgoes; removing shells and seeds from the cured gingkoes, grinding, extruding to form slices, and degreasing; pre-freezing the degreased gingkoes, and after pre-freezing, performing heating and freeze-drying; grinding the freeze-dried ginkgoes into powder, namely the freeze-dried ginkgo powder. The freeze-dried ginkgo powder is low in harmful ingredient content, light in weight, easy to carry and transport, relatively concentrated and relatively rich in nutrition.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Substrate for flexible luminous device and preparation method thereof

InactiveCN102208554AHigh visible light transmittanceHigh luminous intensitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveCarbon nanotube

The invention discloses a substrate for a flexible luminous device. The substrate comprises a flexible substrate and a conductive layer, and the flexible substrate and the conductive layer are formed in one of the following two modes: (1) the flexible substrate is adhesive to be doubly cured, the conductive layer is a thin layer carbon nano tube, and inorganic luminous nano particles are filled into gaps of the thin layer carbon nano tube; and (2) the flexible substrate is inorganic luminous nano particle-doped adhesive to be doubly cured, the conductive layer is a thin layer carbon nano tube, and the inorganic luminous nano particle-doped adhesive to be doubly cured is filled into gaps of the thin layer carbon nano tube, wherein the adhesive to be doubly cured comprises an ultraviolet curing and thermal curing system, an ultraviolet curing and microwave curing system, an ultraviolet curing and anaerobic curing system and an ultraviolet curing and electron beam curing system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Substrate for flexible photoelectronic device and preparation method thereof

InactiveCN102208538AImprove flatnessImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveUltraviolet

The invention discloses a substrate for a flexible photoelectronic device. The substrate comprises a flexible substrate and a conducting layer, wherein the flexible substrate and the conducting layer are formed by one of the following two ways: (1) the flexible substrate is an adhesive needing dual-curing; the conducting layer is a silver nanowire film; and the gap of the silver nanowire film is filled with a carbon nanotube; and (2) the flexible substrate is a carbon nanotube doped adhesive needing dual-curing; the conducting layer is a silver nanowire film; the gap of the silver nanowire film is filled with the carbon nanotube doped adhesive needing dual-curing; and the adhesive needing dual-curing comprises an ultraviolet curing-thermocuring system, an ultraviolet curing-microwave curing system, an ultraviolet curing-anaerobic curing system and an ultraviolet curing-electron beam curing system.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for processing anti-retrogradation instant cooked rice using indica rice

The present invention discloses a method for processing anti-retrogradation instant cooked rice using indica rice. The indica rice is used as a raw material, and the method comprises the steps of screening and impurity removing, soaking and microwave pretreating, superheated steam pre-gelatinizing and shaping, vacuum quantitative packaging, back pressure microwave curing and instant cooked rice obtaining. The method aims at problems that the instant cooked indica rice is serious in retrogradation, poor in mouthfeel, more in broken grains, not easy for digestion, etc., uses a compound retrogradation inhibiting agent to soak the indica rice, combines the microwave pretreating and back-pressure microwave curing ripening, and effectively inhibits the retrogradation. The superheated steam fluidized state treatment is used, so that surface starch of the indica rice grains is pre-gelatinized and then an air-cooling achieves a shaping. The vacuum packaging and back pressure microwave curing are combined to prevent the rice grains from being over-expanded. The product is good in flavor, excellent in mouthfeel, advanced and reasonable in processing technology, good in quality and broad in prospects.

Owner:福建御厨食品有限公司

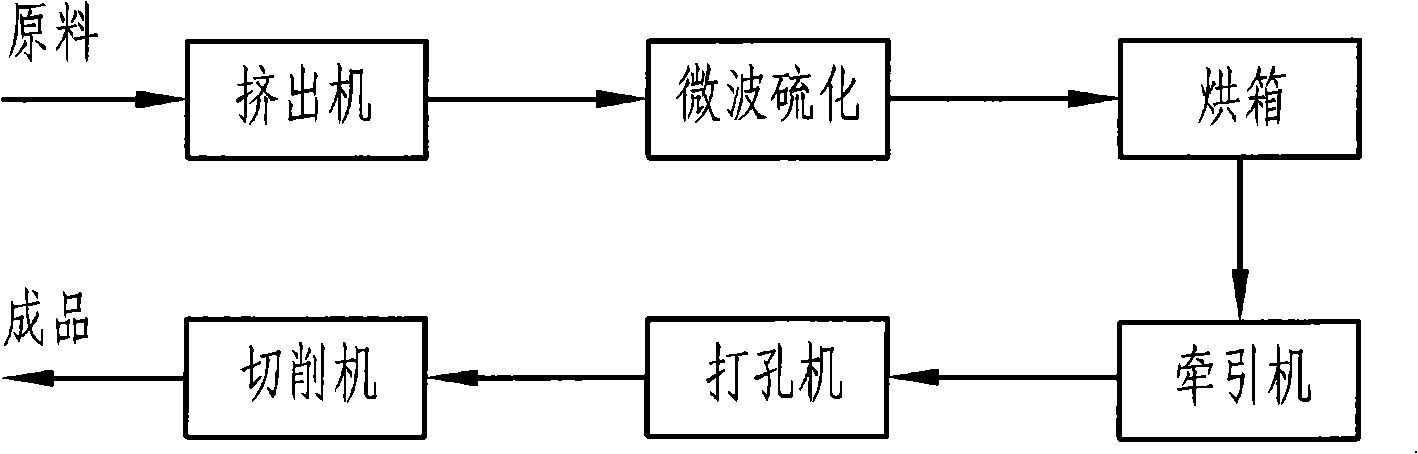

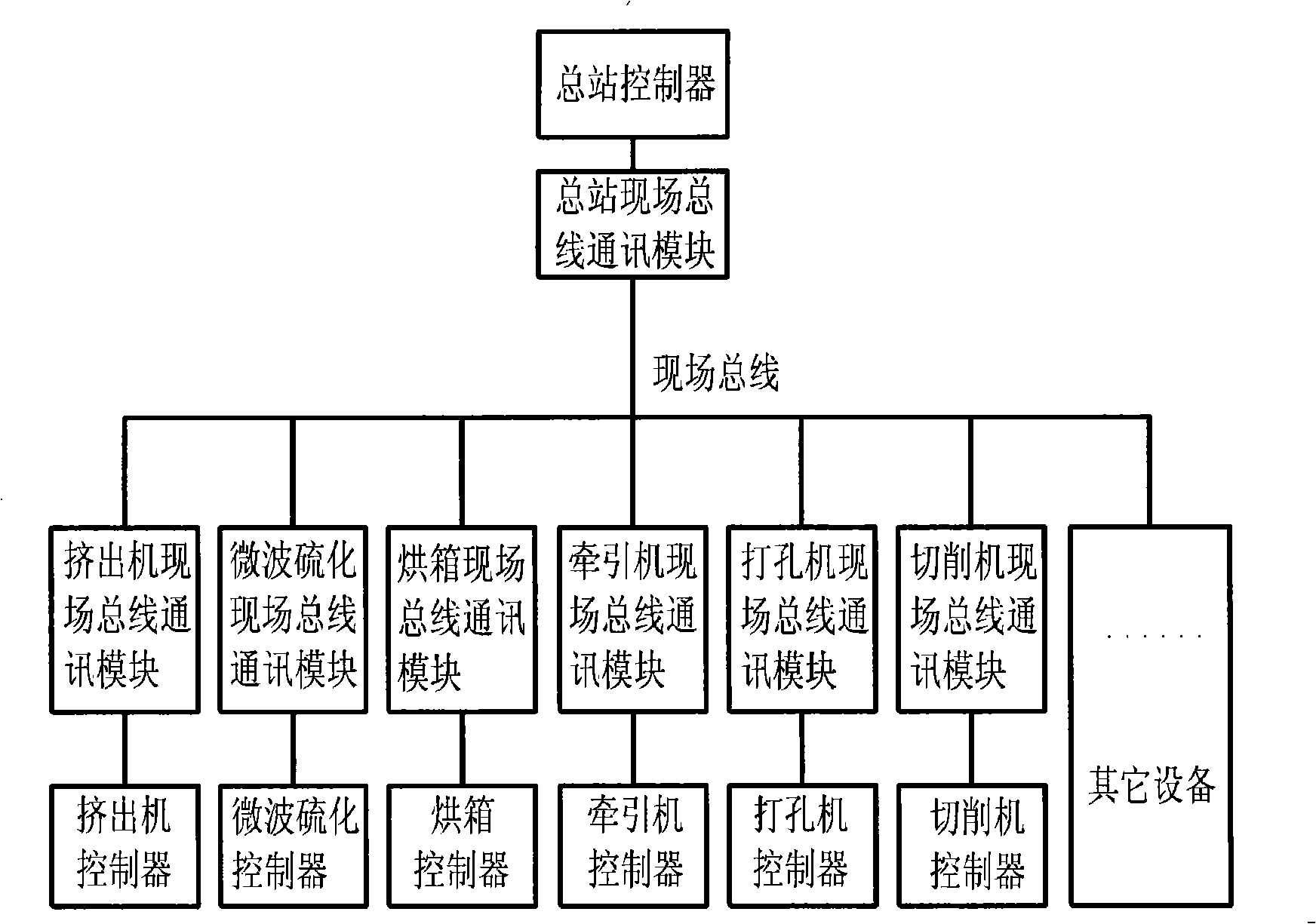

On-site bus control apparatus and method of rubber seal strip extrusion production line

InactiveCN101329577ACentralized monitoring of process parametersGuaranteed continuityProgramme total factory controlProduction linePunching

The invention relates to a fieldbus control device and a control method in the extrusion production field of rubber sealing strip which belongs to the technical field of industry control; the device comprises a master station controller, a fieldbus communication module of a master station, a fieldbus, an extruder controller, a fieldbus communication module of an extruder, a controller of a microwave curing machine, a fieldbus communication module of the microwave curing machine, an oven controller, a fieldbus communication module of the oven, a tractor controller, a fieldbus communication module of the tractor, a punching machine controller, a fieldbus communication module of the punching machine, a cutter controller and a fieldbus communication module of the cutter; the master station controller carries out real-time monitoring, setting and synchronous adjustment to the technique parameters of all the equipment; the control method takes the master station controller as a core and carries out real-time monitoring and synchronous adjustment to the technique parameters of all the equipment such as the extruder, the microwave curing machine, the oven, the tractor, the punching machine, the cutter and other equipment. The fieldbus control device and the control method of the invention improve the production efficiency of the extrusion line of the rubber sealing strip.

Owner:SHANGHAI JIAO TONG UNIV

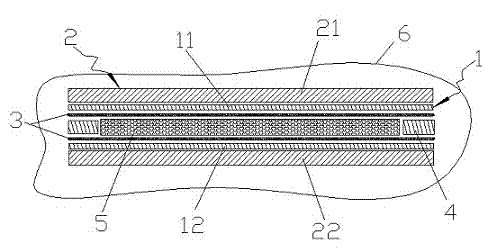

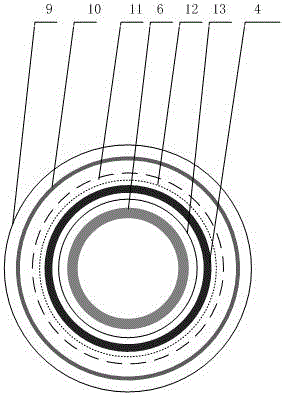

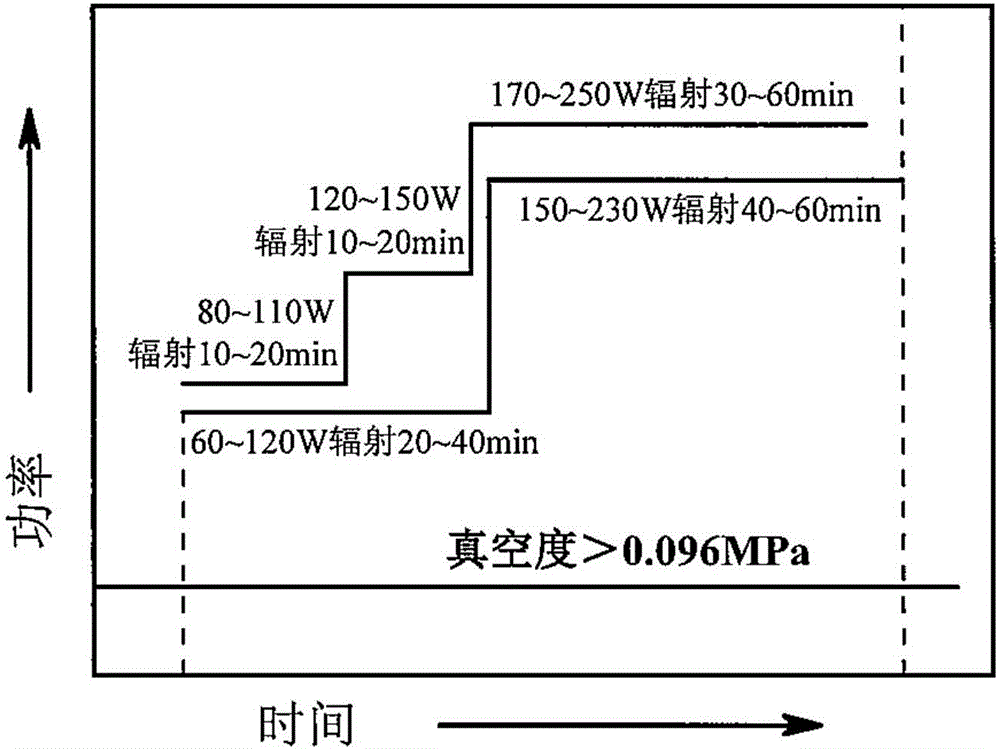

Microwave curing formation method for carbon fiber/epoxy resin composite materials and laminated plate made of composite materials

The invention provides a microwave curing formation method for a laminated plate made of carbon fiber / epoxy resin composite materials. The microwave curing formation method for the laminated plate made of the carbon fiber / epoxy resin composite materials comprises the steps that a laid carbon fiber / epoxy resin prepreg laminated plate is placed in a vacuum bag, the upper / lower surface of the laminated plate is isolated from the inner wall of the vacuum bag through a plate mold, and the interior of the vacuum bag is vacuumized, so that the laminated plate is compacted by means of external atmospheric pressure; and then under the condition that the vacuum degree in the vacuum bag is maintained, microwave curing formation is conducted under at least one stepwise-increasing power, wherein the microwave frequency range is 2.25-2.65 GHz, the microwave power range is 40-400 W, and the total microwave radiation time is 50-100 min. In this way, the obtained microwave curing-formed carbon fiber / epoxy resin laminated plate has the characteristics of being smooth in surface and good in forming quality; and meanwhile, compared with a traditional thermocuring method, the cycle of the curing process is obviously shortened while uniform and complete curing is guaranteed, and approximate or higher glass-transition temperature and compression strength are achieved.

Owner:COMAC +1

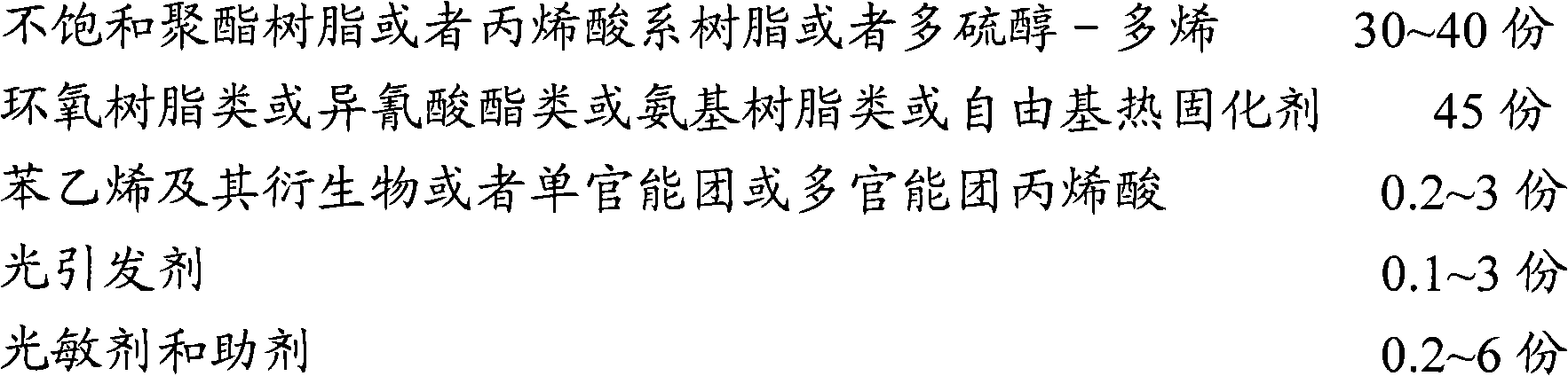

Tint seal strip without nitrosamine release and preparation method thereof

The invention discloses a tint seal strip without nitrosamine release. The seal strip comprises the following components in parts by weight: 100 parts of ethylene-propylene-diene rubber serving as a basic formula, 10-30 parts of nano kaolin, 10-30 parts of ground calcium carbonate, 5-20 parts of white carbon black, 5-30 parts of titanium powder, 30-50 parts of paroline, 2-8 parts of Vaseline, 0.5-5 parts of antiager, 0.5-5 parts of peroxide vulcanization, 0.5-3 parts of dihydric alcohol and 5-10 parts of crylic acid. The invention also discloses a preparation method of the tint seal strip without nitrosamine release. The preparation method comprises the steps such as mixing, thin through treatment, microwave curing and the like. The tint seal strip can be used for eliminating the release of the nitrosamine, thus the tint seal strip has the characteristic of environmental friendliness.

Owner:ZHEJIANG DALI AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com