Apparatus and method for graphically producing nano structures by way of electrode induction and microwave curing

A nanostructure, microwave curing technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of many defects, low nanoimprint mold life, difficult to align, etc., to achieve high productivity, simple structure, graphics high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

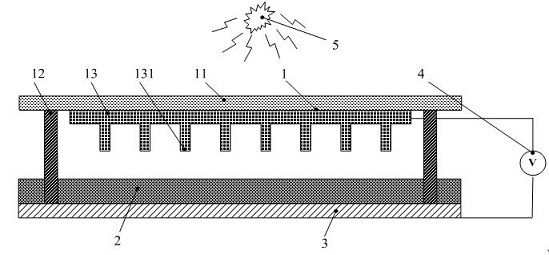

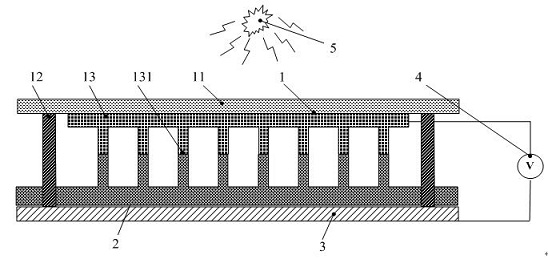

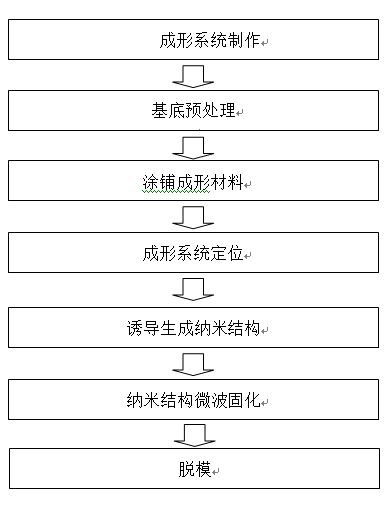

[0047] The schematic diagram of the nanostructure device produced by patterned electrode induction and microwave solidification disclosed by the present invention is as follows Figure 1a , Figure 1b shown. It consists of five parts: forming system 1, forming material 2, substrate 3, DC electric field 4, and microwave curing system 5. The forming system 1 is composed of a back plate 11 , a support 12 and a patterned electrode 13 . The back plate 11 plays the role of support and connection. The support 12 and the patterned electrode 13 are assembled into a complete forming system through the back plate 11. The function of the support 12 is to maintain a uniform gap between the patterned electrode 13 and the substrate 3 , the height difference between the support 12 and the nanostructure-inducing protrusion 131 (characteristic pattern to be transferred) formed by the protruding part of the patterned electrode determines the height of the fabricated nanostructure. Therefore, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com