Patents

Literature

66results about How to "High graphic precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

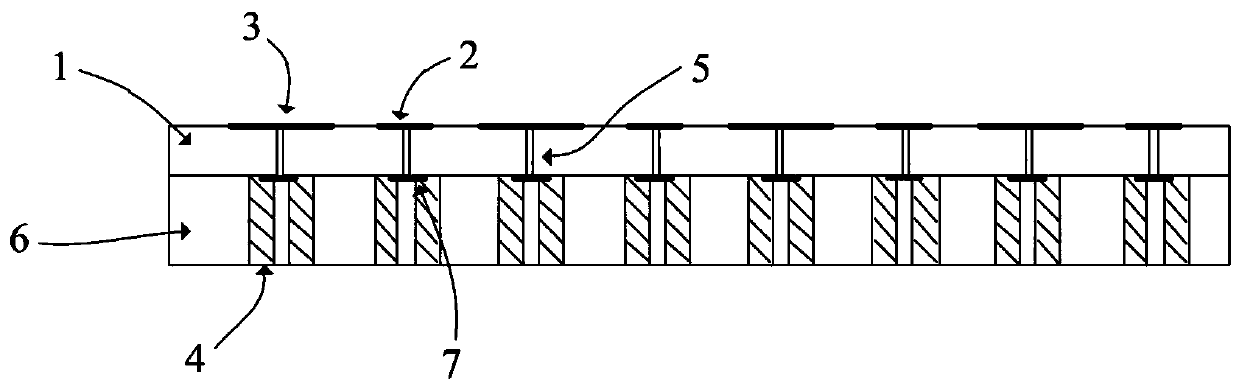

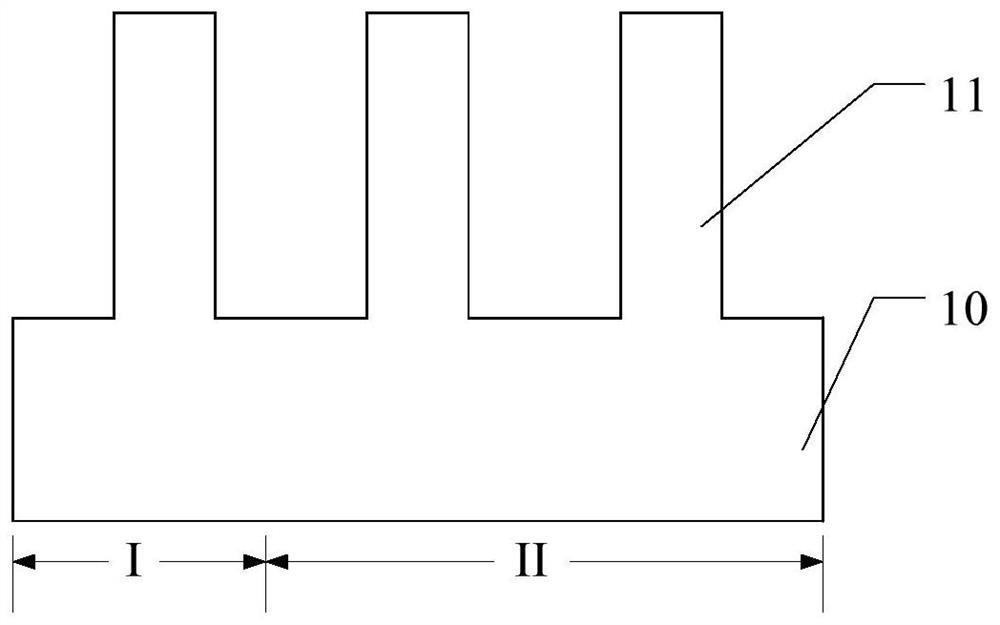

Microwave film resistor, microwave film resistor network module and manufacturing method thereof

InactiveCN101533693AReduce microwave lossReduce areaOther resistor networksResistors adapted for applying terminalsFilm resistanceHigh resistance

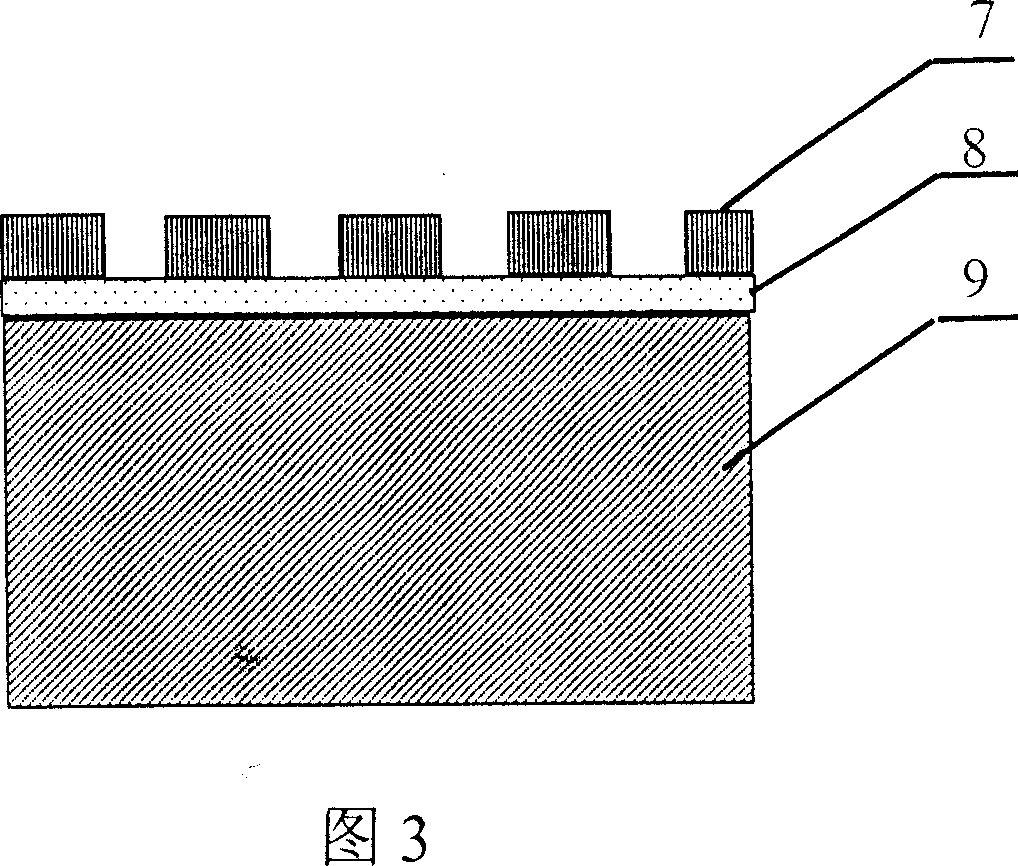

The invention discloses a microwave film resistor and a manufacturing method thereof, and belongs to the field of circuit elements. The microwave film resistor comprises a ceramic substrate, a film resistance layer which is adhered to the upper surface of the ceramic substrate and an electrode layer which is adhered to the film resistance layer. The film resistor has the advantages of high precision, high using frequency and high resistance stability. In addition, the invention also discloses a microwave film resistor network module and a manufacturing method thereof, wherein the microwave film resistor network module is formed by integrating three or more microwave film resistors on one module.

Owner:广州翔宇微电子有限公司

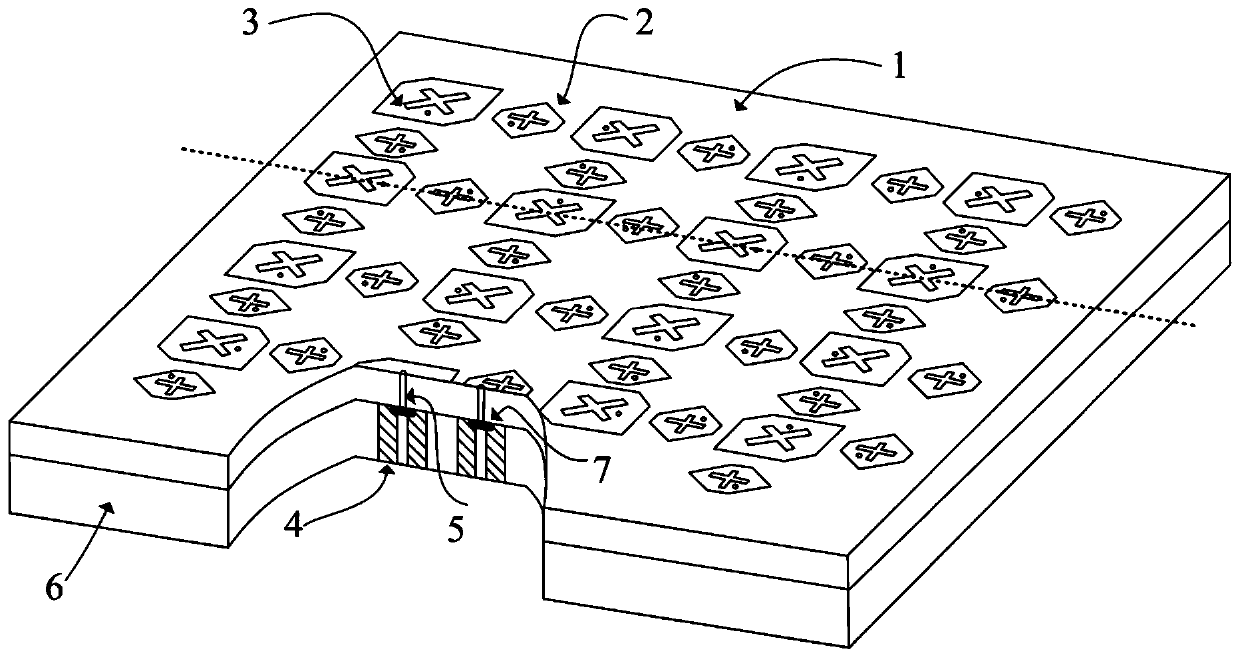

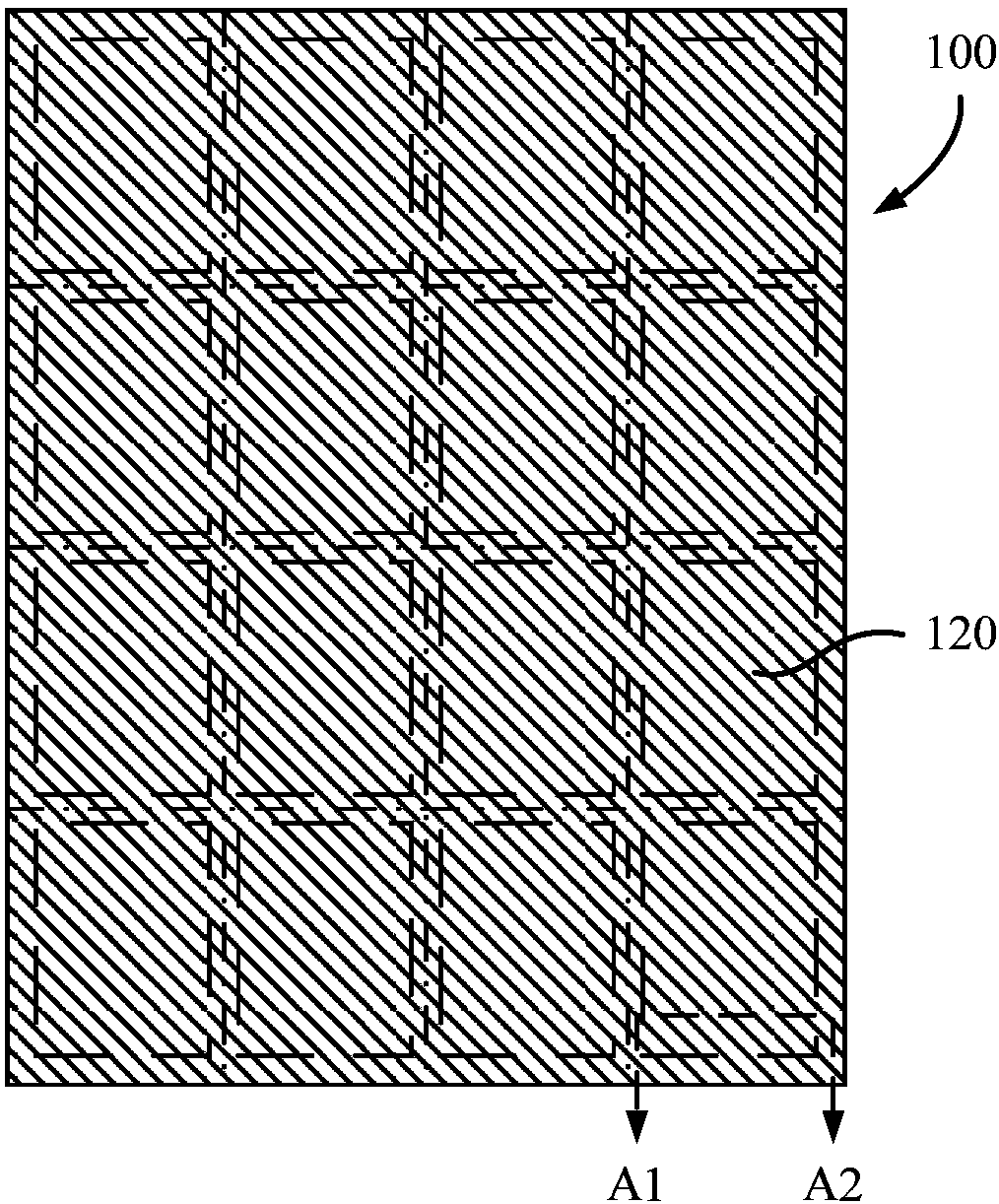

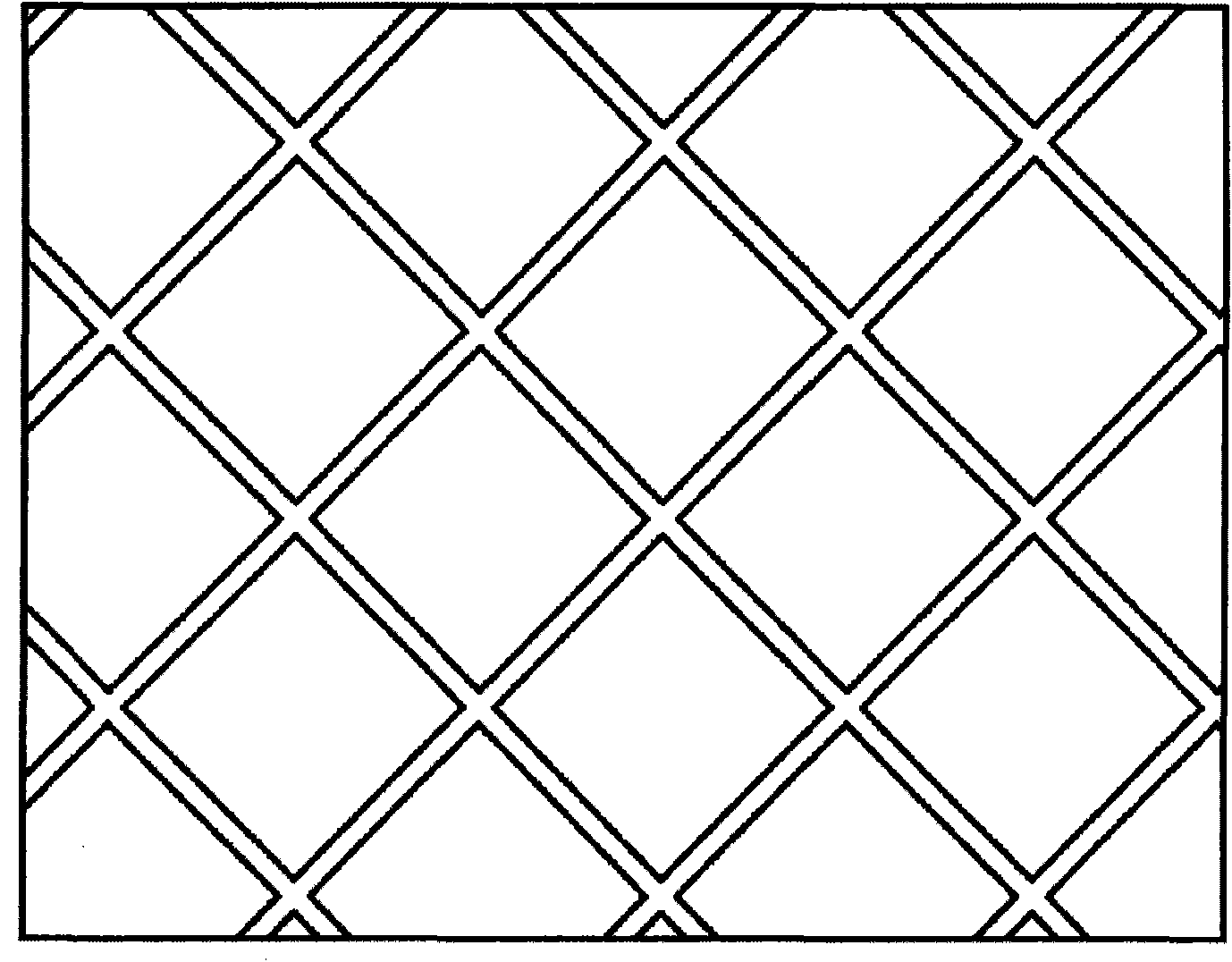

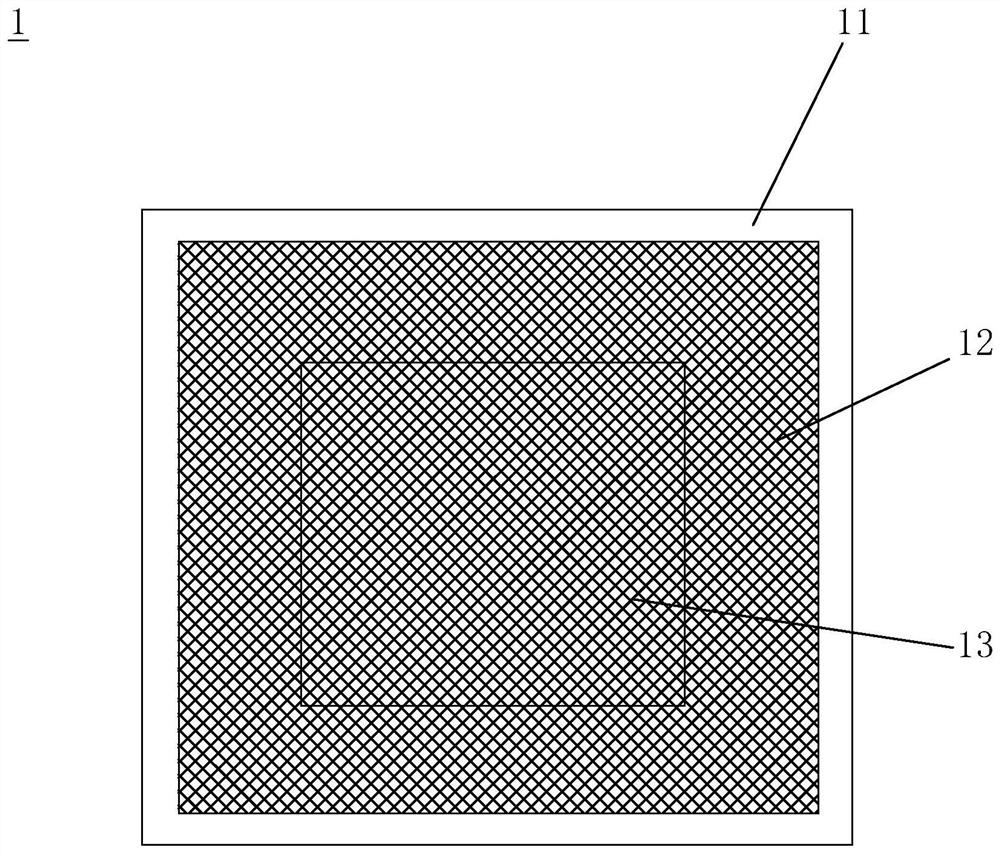

K/Ka dual-band common-aperture antenna array

InactiveCN109904599AEasy to design and applyCompact structureAntenna arraysRadiating elements structural formsDielectric substrateAntenna array

The invention discloses a K / Ka dual-band common-aperture antenna array, aiming to provide an antenna array surface capable of reducing the antenna profile, covering K and Ka bands and sharing a dual-band aperture. The invention is implemented by the following technical schemes: K-band patches are distributed on a dielectric substrate in the form of a uniform rectangular array, Ka-band patches areinterspersed in the center of the interval of adjacent K-band patches in an interpolation manner, the K-band patches are in orthogonal connection with a bonding pad located on the bottom surface of the dielectric substrate through a feeder pillar that penetrates through the dielectric substrate, the bonding pad is connected with a coaxial feeder, and the coaxial feeder penetrates through a metal base plate to connect with the bonding pad and feeds in a touch-type connection manner, wherein the K-band patches are combined with the metal base plate through the feeder pillar to form a K-band antenna array surface, the feeder pillar is connected with the coaxial feeder through the bonding pad to form a K-band channel; and the Ka-band patches are combined with the metal base plate through the feeder pillar to form a Ka-band antenna array surface, and the feeder pillar and the bonding pad conduct the coaxial feeder to form a Ka-band channel.

Owner:10TH RES INST OF CETC

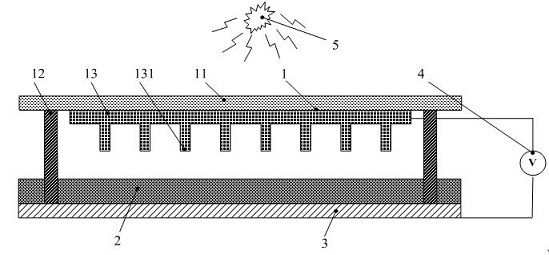

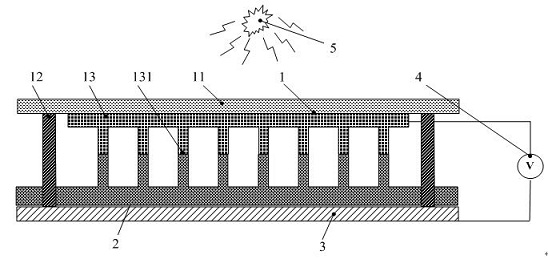

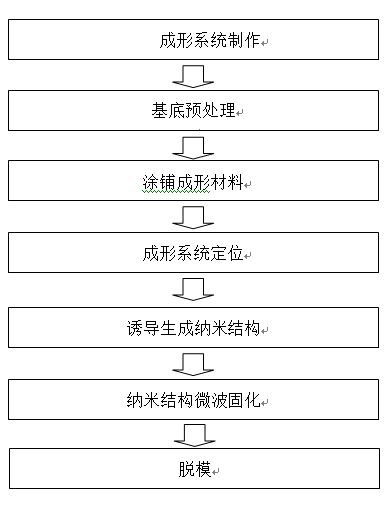

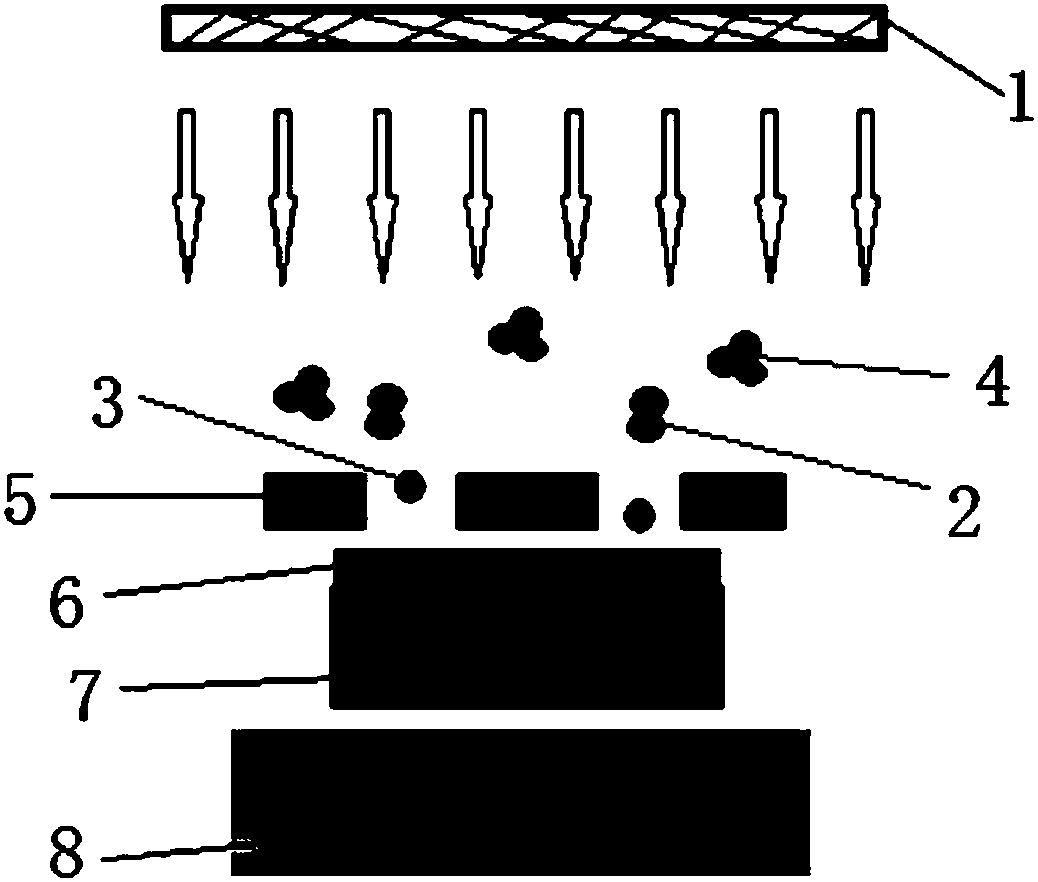

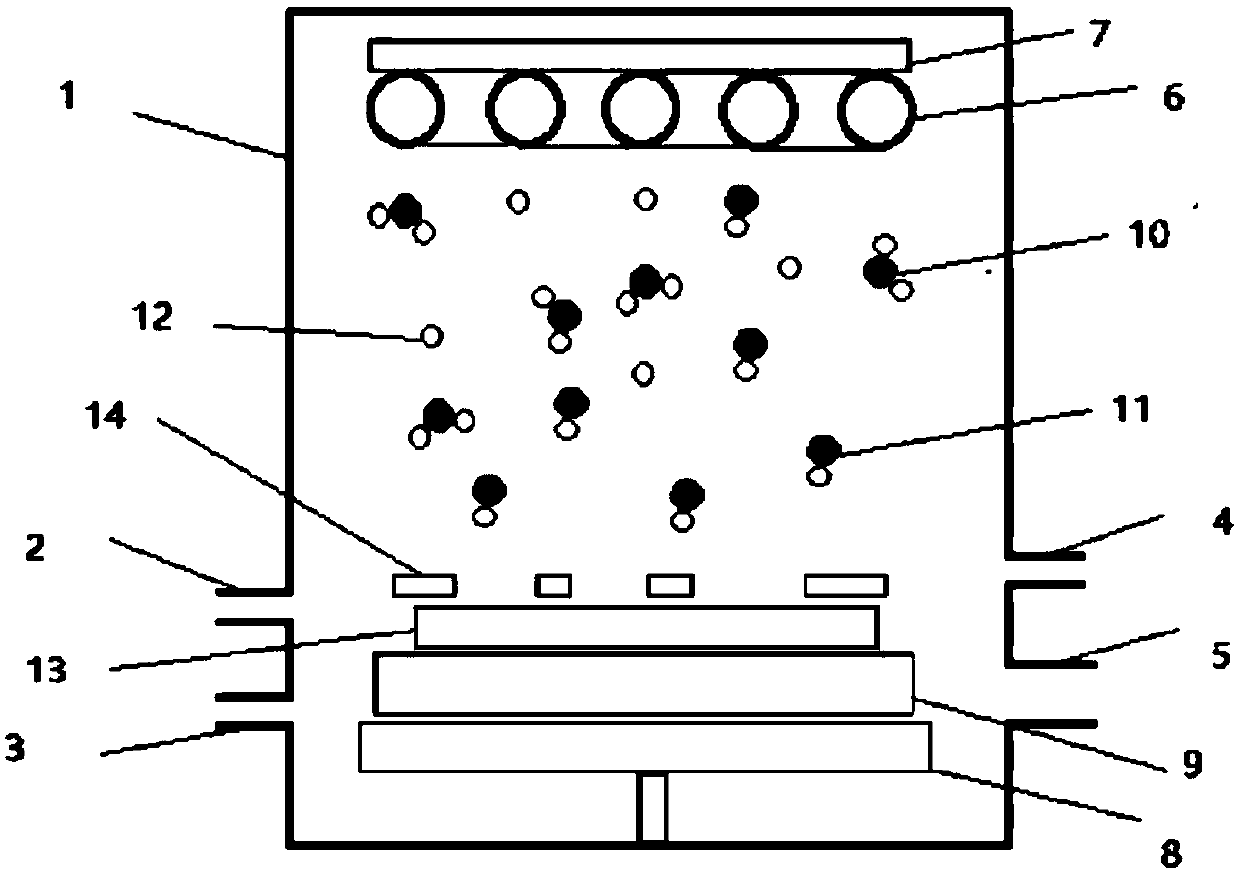

Apparatus and method for graphically producing nano structures by way of electrode induction and microwave curing

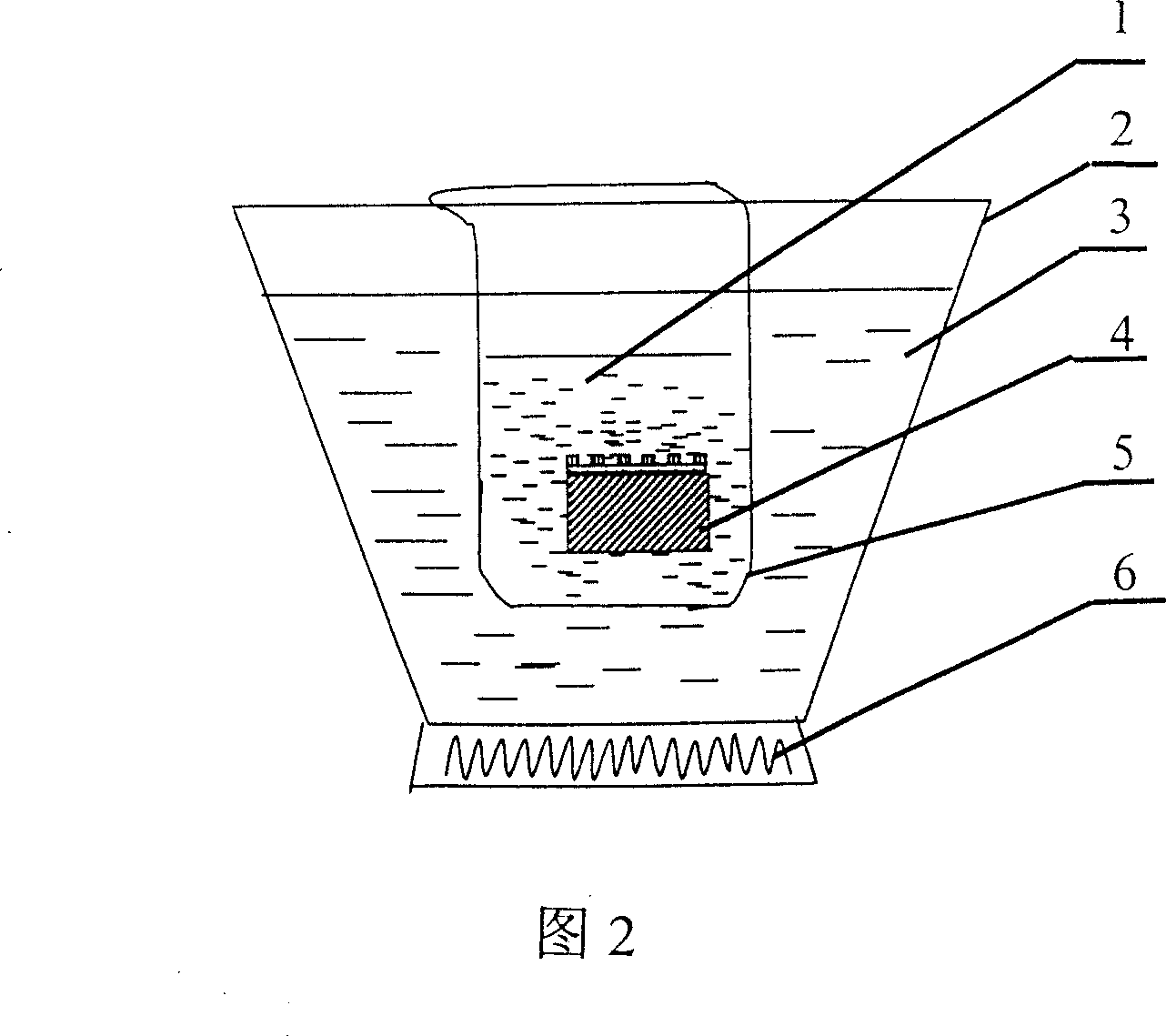

The invention relates to an apparatus and a method for graphically producing nano structures by way of electrode induction and microwave curing. The apparatus comprises a molding system, a molding material, a substrate, a nano structure induction system and a microwave curing system. The method for producing nano structures based on the apparatus includes the following steps: (1) the fabrication of the molding system; (2) the preprocessing of the substrate; (3) the coating of the molding material; (4) the positioning of the molding system; (5) the inductive production of a nano structure; (6)the microwave curing of the nano structure; and (7) demolding. The invention is characterized by simple structure, low cost, high productivity, long electrode service life, high pattern precision andthe like, and can efficiently produce nano structures less than 100 nanometers at low cost.

Owner:SHANDONG UNIV

Magnetic ink and preparation method for ink-jet printing flexible electromagnetic wave absorption film

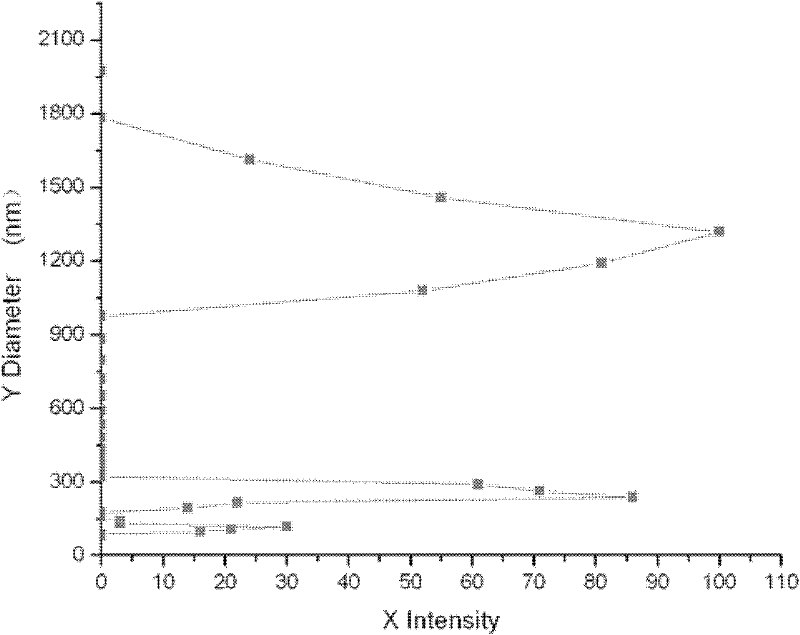

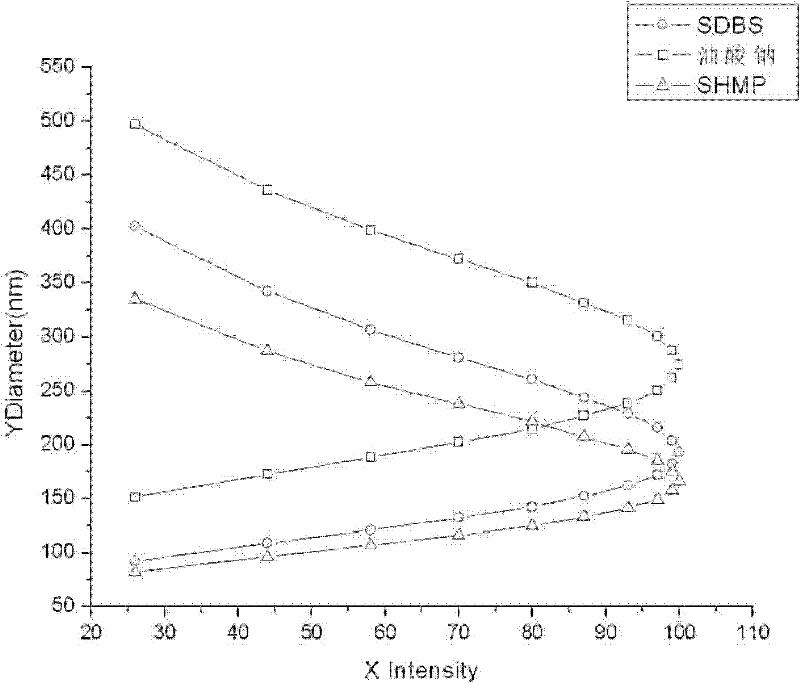

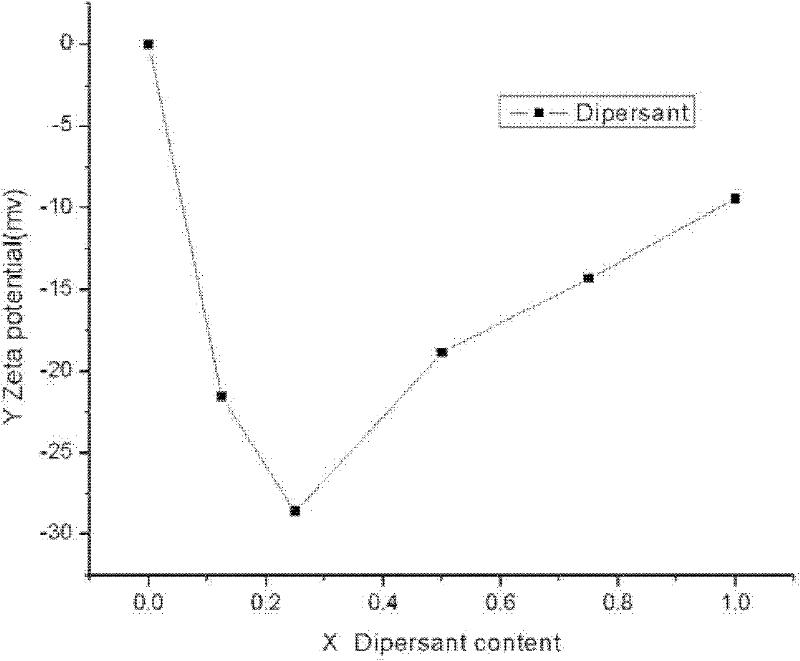

The invention discloses magnetic ink, and relates to an electronic material technology. The magnetic ink comprises a solvent and a solute, wherein the solvent consists of ethanol, isopropanol and deionized water in a volume ratio of A: B: C, wherein A is more than or equal to 1 and less than or equal to 4, B is more than or equal to 1 and less than or equal to 3, and C is more than or equal to 6 and less than or equal to 12; the solute comprises nano magnetic granules, dispersant, connecting agent, surfactant, wetting agent and defoaming agent; the mass ratio of the nano magnetic granules to the dispersant is x: y, wherein x is more than or equal to 4 and less than or equal to 25, and y is more than or equal to 1 and less than or equal to 3; the ratio of the solvent: the connecting agent: the surfactant: the wetting agent: the defoaming agent is a: b: c: d: e, wherein a is more than or equal to 86.95 and less than or equal to 99.199, b is more than or equal to 0.3 and less than or equal to 5, c is more than or equal to 0.5 and less than or equal to 5, d is more than or equal to 0 and less than or equal to 3, and e is more than or equal to 0.001 and less than or equal to 0.05; and the ratio of the mass of the nano magnetic granules to the volume of the solvent is 0.002 to 0.02 gram per milliliter. The method realizes low-cost production of the large-area electromagnetic wave absorption film and preparation of flexible wave absorption films with high output graph precision, clear graph boundary, uniform distribution and various complex components and images.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Plate burning process of precise screen

ActiveCN102736406AGood tangentHigh graphic precisionPhotomechanical apparatusExposure latitudePeak value

The present invention provides a plate burning process of a precise screen. The process employs a way of secondary exposure way to complete the film graphic transfer to the screen, and specifically comprises steps of: A) film production: first compensating the film, then adding composing and positioning to ensure a composing position deviation no more than 100 mum in a secondary plate burning of the screen; B) plate burning: carrying out composing and plate burning according to composing position required by printing, wherein the first plate burning energy set value is a minimum value of the exposure latitude, and the secondary plate burning energy value is set at a peak value of the optimum exposure. The method of the invention employs a parallel light plate burning machine to achieve clear text and effectively control edge jag and side virtual exposure; meanwhile, as the screen is treated with exposure for two times, the exposure energy is sufficient, and the pressrun of the screen film is improved.

Owner:昆山良品丝印器材有限公司

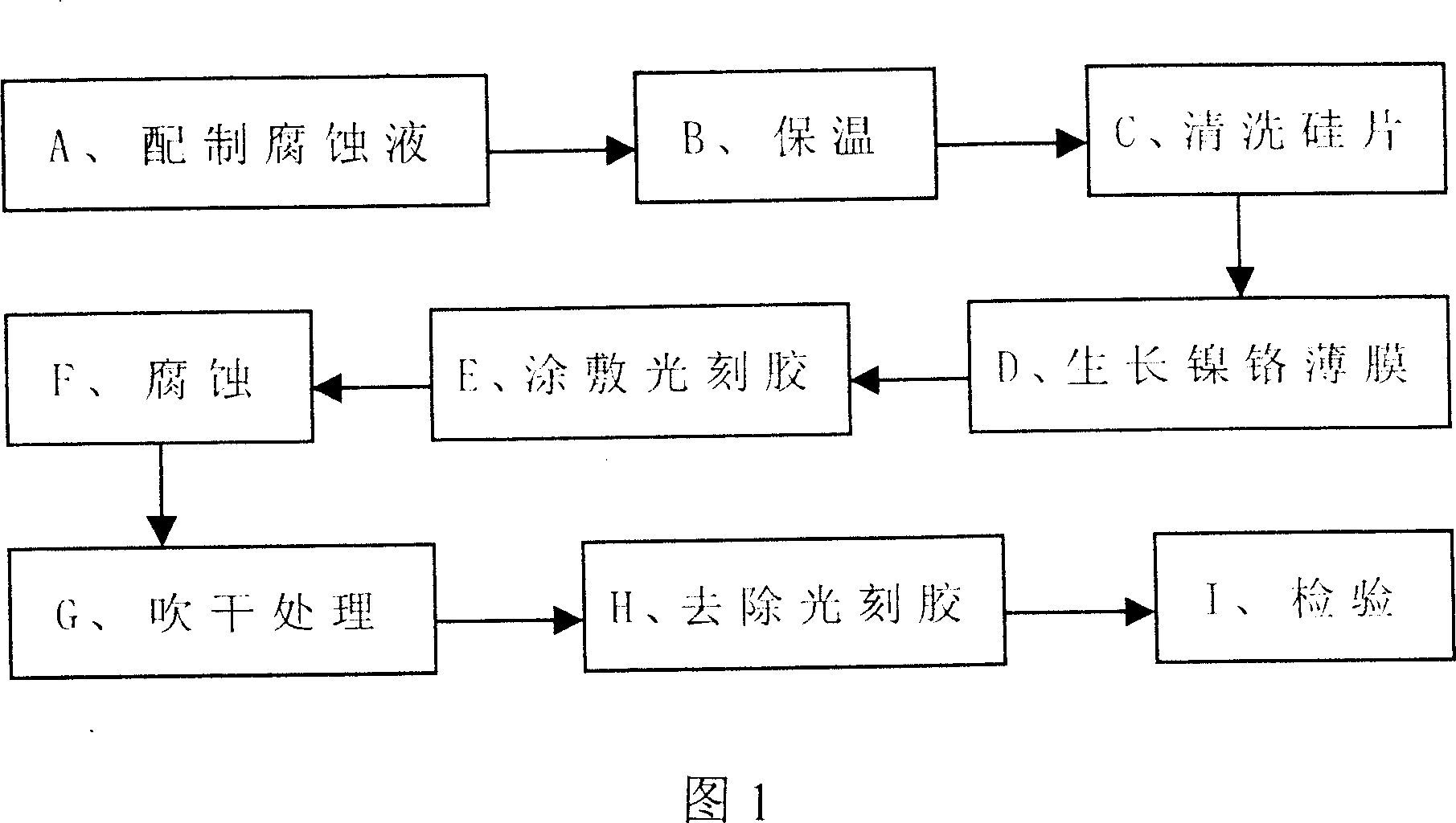

Wet method pattern technology of chrome-nickel alloy thin film

InactiveCN1920097AHigh graphic precisionConductive material chemical/electrolytical removalSulfateDistilled water

The invention discloses the nickel-chromium thin film liquid graphic-arts technique. The technology comprises 2-10% kalii permangana, 30-505 cerous sulfate, 5-11% chlorhydric acid, 5-10% ammoniation ammonia and distilled water. The technology has the advantages of low cost, clear line and high accuracy.

Owner:KUNMING INST OF PHYSICS

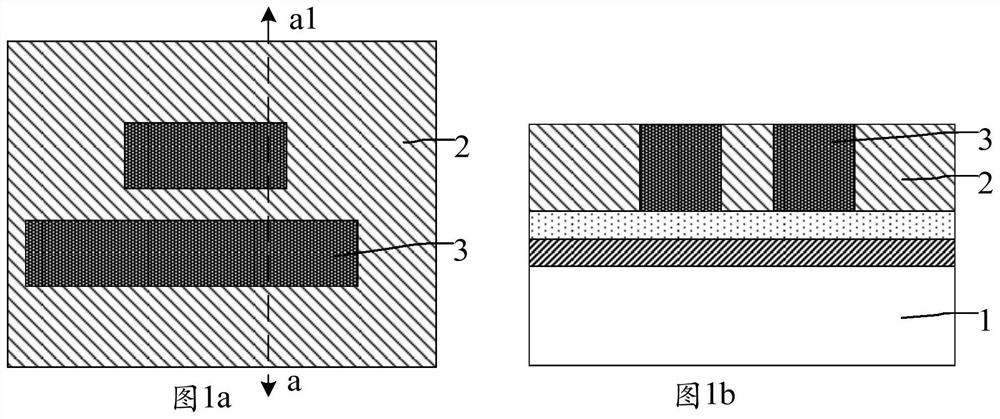

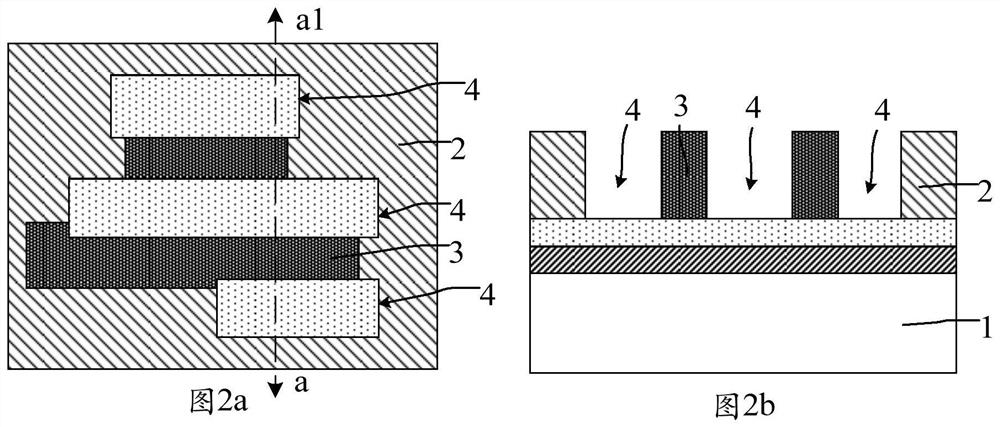

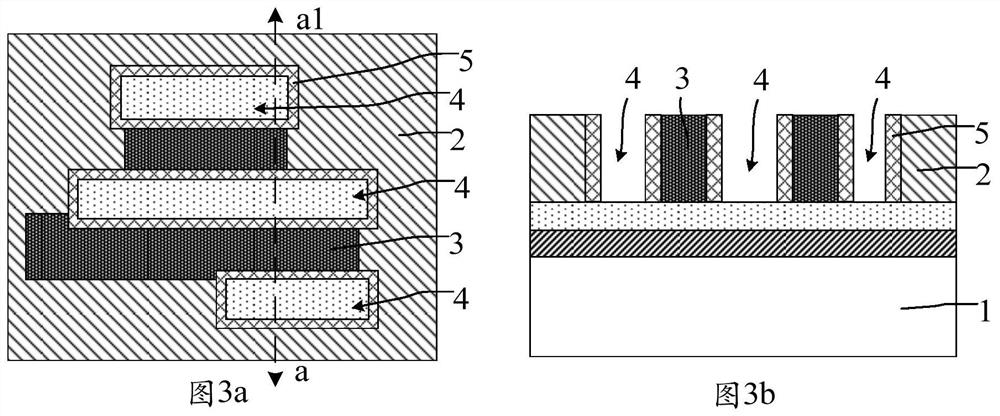

Three-dimensional ceramic substrate comprising cavity structure and fabrication method of three-dimensional ceramic substrate

ActiveCN106981458AHigh strengthImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesLow temperature curingElectrical devices

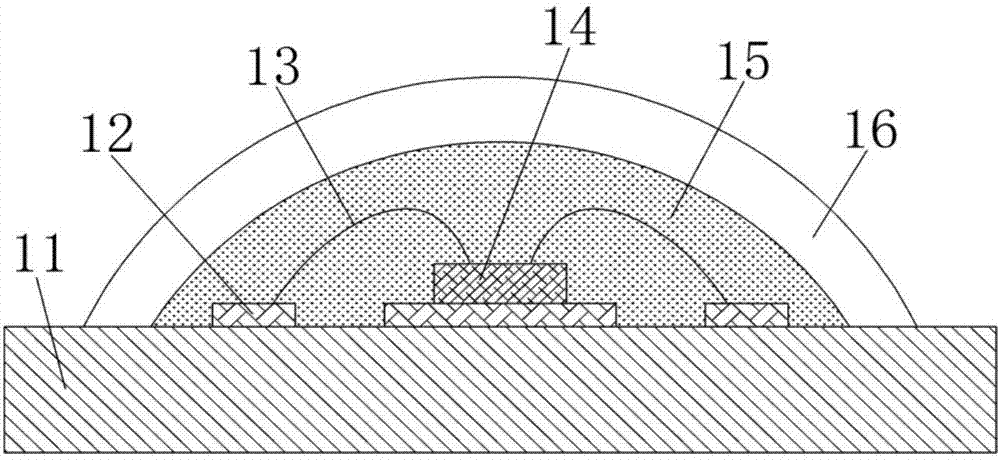

The invention discloses a three-dimensional ceramic substrate comprising a cavity structure. The three-dimensional ceramic substrate comprises a planar ceramic substrate and the cavity structure attached onto the planar ceramic substrate. The invention also discloses a fabrication method of the three-dimensional ceramic substrate. The fabrication method comprises the steps of firstly, fabricating the planar ceramic substrate with a surface comprising a metal circuit, designing and fabricating a die according to the cavity structure and the size requirement, and fabricating low-temperature cured ceramic paste; secondly, combining the die after the planar ceramic substrate and a plastic die are aligned, and uniformly filling the ceramic paste in a die cavity by modes such as mechanical vibration, pressure injection or vacuum pumping; and finally, allowing to stand for 15-60 minutes under a room temperature or a low temperature (lower than 100 DEG C), and removing the die after the paste is cured. The three-dimensional ceramic substrate has good thermal resistance, corrosion resistance and sealing performance; and the fabrication method of the three-dimensional ceramic substrate has the advantages of low material cost, simple process and high pattern accuracy, particularly, the ceramic paste can be cured under the room temperature or the temperature lower than 100 DEG C, and the hermetical package demands of white-light LED, ultraviolet-light LED and other electrical devices are satisfied.

Owner:武汉利之达科技股份有限公司

Zinc oxide film imaging method

InactiveCN104087897AImprove conductivityGood light transmissionVacuum evaporation coatingSputtering coatingOrganic solventPhotoresist

The invention discloses a zinc oxide film imaging method comprising the following steps of firstly, cleaning a substrate, photoetching and developing to obtain an imaged photoresist; secondly, placing the substrate into a vacuum chamber to deposit a ZnO film with the thickness of 100-200nm; finally, ultrasonically stripping the substrate in an organic solvent to obtain an imaged zinc oxide film. The zinc oxide film imaging method is simple in process; the imaged zinc oxide film is high in image precision, favorable in dielectric property and good in application prospect and has favorable conductivity and light transparency.

Owner:TIANJIN UNIV

Cover plate, forming method thereof, cover plate mother board and electronic equipment

InactiveCN109239815AReduce usageImprove performanceSemiconductor/solid-state device manufacturingOptical elementsGlass coverTransmittance

The invention discloses a cover plate, a forming method thereof, a cover plate mother board and electronic equipment. The forming method of the cover plate comprises the following steps: providing a mother board base, wherein the mother board base comprises a base layer and a sacrificial layer positioned on the base layer; carrying out schematization on the sacrificial layer to form a graphic sacrificial layer; and by using the graphic sacrificial layer as a mask, etching the base layer to form a substrate and a texture bulging the substrate. The substrate and the texture are formed by etchingthe base layer, compared with a glass cover plate comprising a UV glue material graphic layer, the application of the UV glue material graphic layer is omitted, the problems caused by the UV glue material graphic layer and a forming technology thereof can be avoided effectively, the performance, reliability and manufacturing yield of the formed cover plate are improved, the structure of the coverplate is simplified, the light transmittance of the cover plate is improved, and the performance and aesthetic degree of the formed electronic equipment are improved.

Owner:SHANGHAI OXI TECH

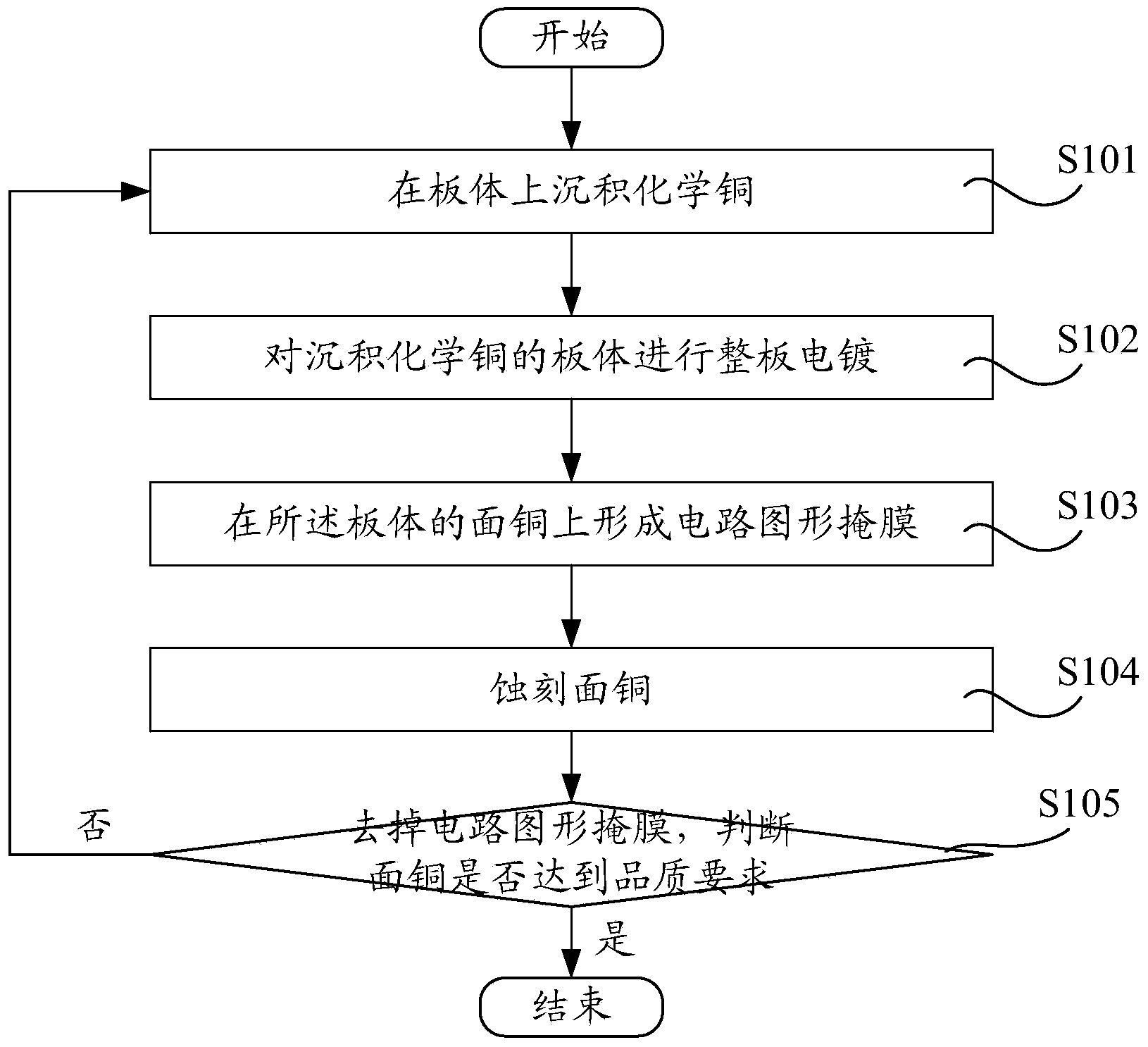

Method for making thick copper printed circuit board

InactiveCN103889157AAvoid detailed questionsHigh graphic precisionConductive material chemical/electrolytical removalCopper platingEtching

The invention discloses a method for making a thick copper printed circuit board. The method comprises the following steps of (A) depositing chemical copper on a board body, (B) carrying out whole board plating on the board body where the chemical copper is deposited, (C) forming a circuit pattern mask on the surface copper of the board body, (D) etching the surface copper, and repeating the steps of (A), (B), (C) and (D) until the surface copper reaches the requirement of quality. According to the above method for making the thick copper printed circuit board, a circuit pattern is thickened gradually through the processes of repeated copper deposition, copper plating and etching, and problems of 'film clipping' and too thin conductive wire brought by the direct etching on the thick copper board can be effectively avoided.

Owner:JIUJIANG HUAXIANG TECH +2

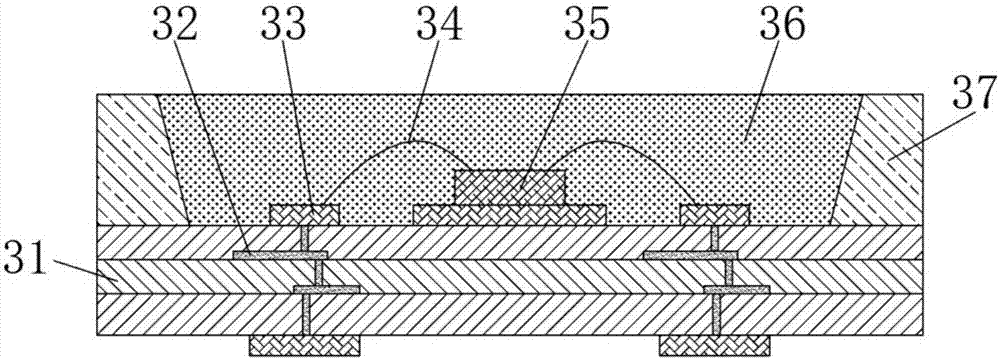

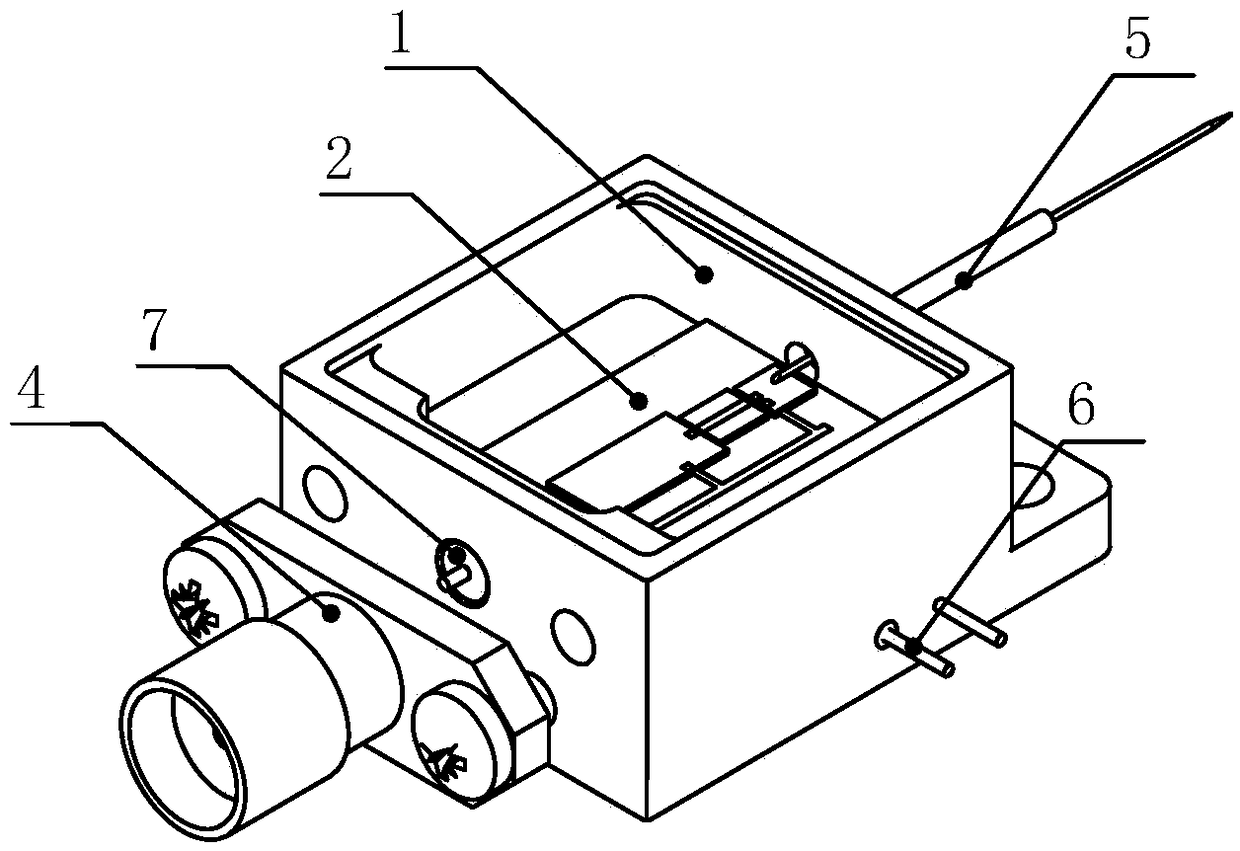

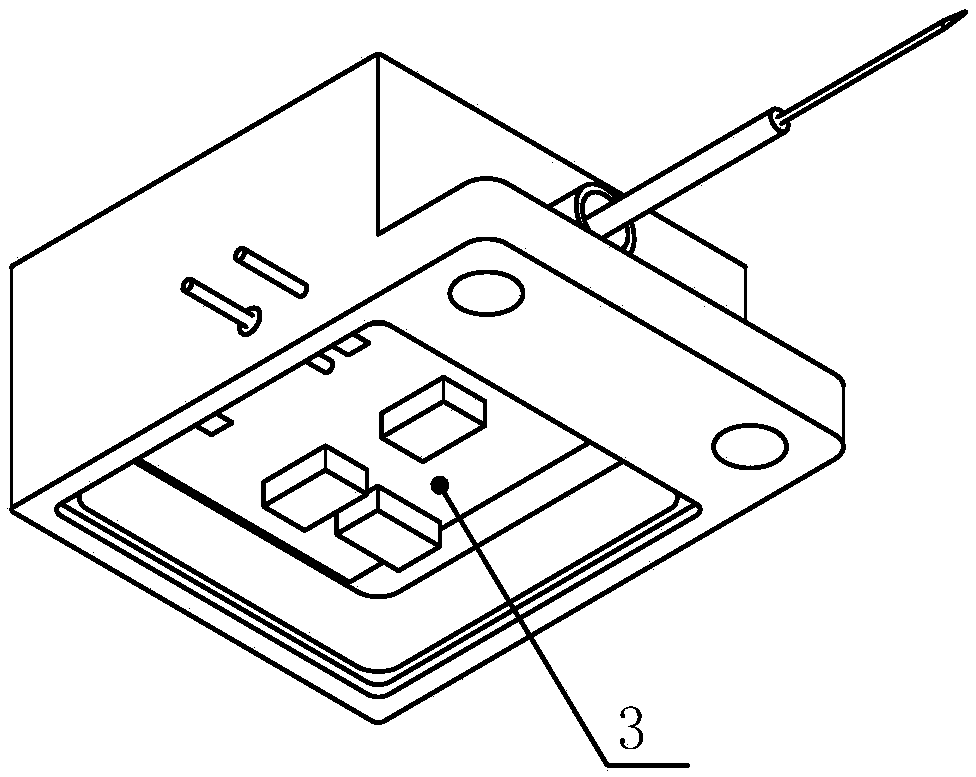

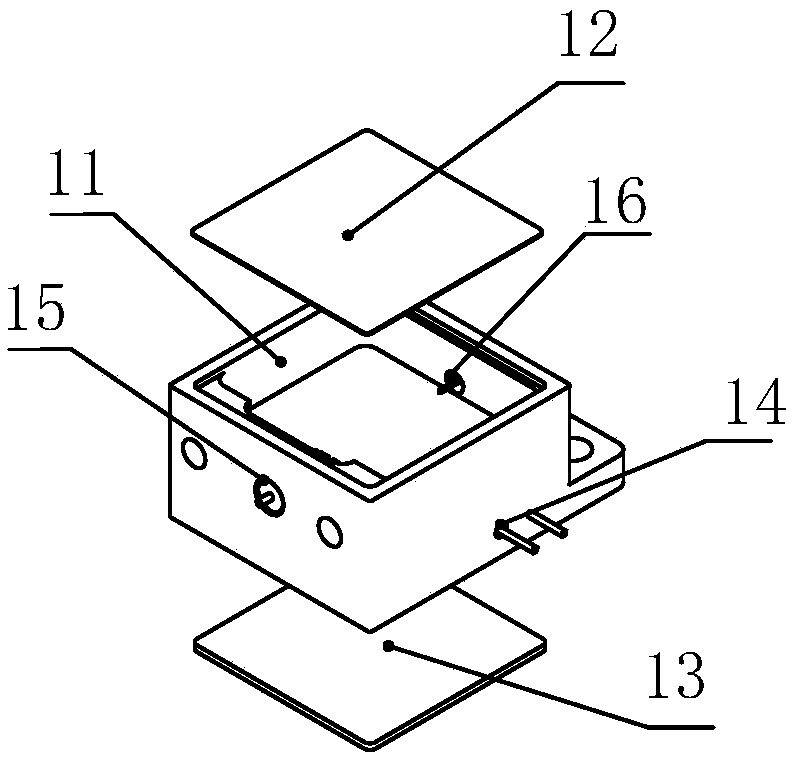

An integrated photoelectric receiving module containing a low noise amplifier and a production process thereof

InactiveCN108873190AImprove processing efficiencyHigh thermal conductivityCoupling light guidesEngineeringOpto electronic

The invention provides an integrated photoelectric receiving module containing a low noise amplifier and a production process thereof. The module adopts the design of a hybrid integration structure ofa high-speed photodiode die and a low noise amplifier chip; compared with a split structure, the structure has the advantages that the size is reduced, the radio frequency performance is improved andthe reliability is improved. The hybrid integration process is a common-substrate micro-assembly process and the high-speed photodiode die, the low noise amplifier chip and micro-strip lines are aligned, bonded and baked at a time through an epoxy silver glue process, and the process is simple, the process time is reduced and the process efficiency is high; a hybrid integration circuit substrateis made of AlN substrate material with good surface finish and high thermal conductivity; the hybrid integration circuit substrate adopts a thin film circuit process and a gold wire wedge welding process is utilized for welding, so that the influence of parasitic inductance is effectively reduced and the requirement of high-speed module packaging is better satisfied; the whole packaging structureis simple and practical in design, is high in process production feasibility and is suitable for batch production.

Owner:重庆霓扬科技有限责任公司

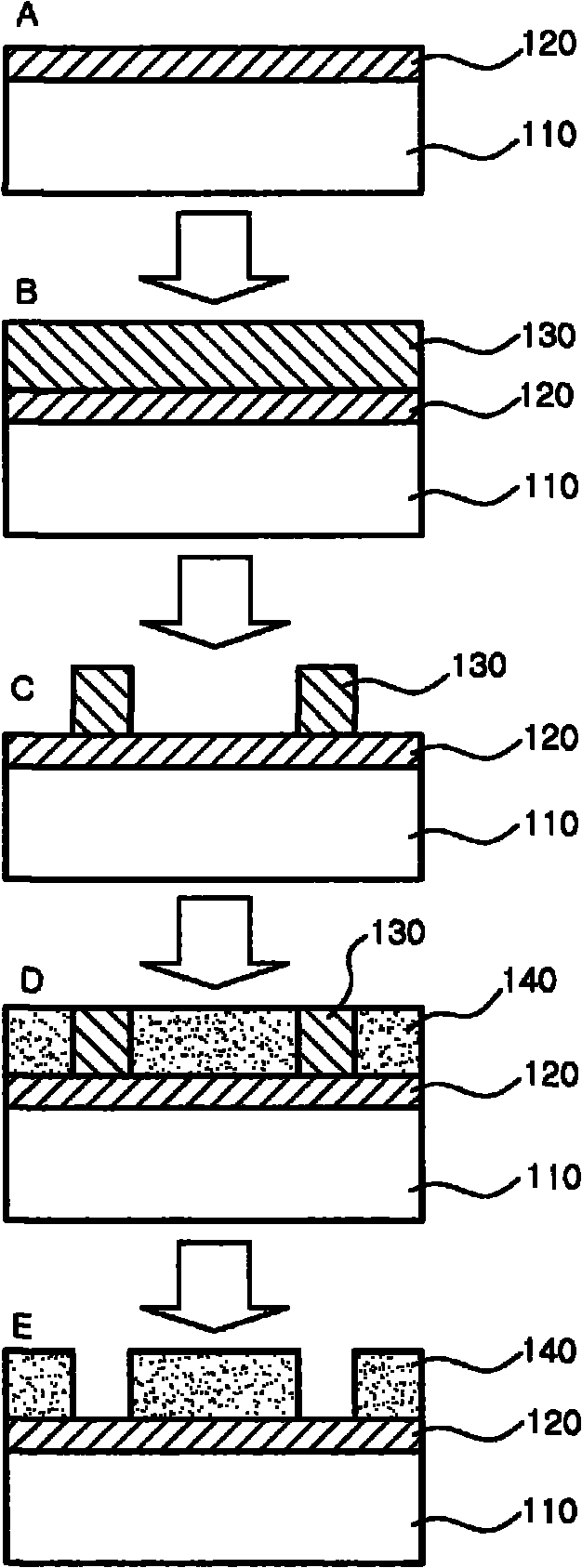

Method of manufacturing gravure plates for offset printing

InactiveCN101918222AHigh graphic precisionImprove thickness uniformityPlate printingPhotosensitive material processingPhotoresistPhotolithography

There is provided a method of manufacturing a gravure plate for offset printing. The method includes: coating a glass substrate with a copper metal; forming a photoresist film on the coated copper metal; forming a desired photoresist pattern by exposing the photoresist film to light and then developing the photoresist film to remove photoresist from some of the photoresist film; plating the photoresist-removed region with nickel; and removing the remaining photoresist and grinding a nickel-plated surface. The method for manufacturing a gravure plate for offset printing may be useful to provide a gravure plate that has high pattern precision since the photoresist pattern is formed by the photolithography process, excellent thickness uniformity due to the use of the glass substrate, and excellent durability since the outermost surface of the gravure plate is made of nickel.

Owner:LG CHEM LTD

Method for preparing anode glass fluorescent powder coating

InactiveCN101447381AHigh-resolutionHigh graphic precisionLuminescent coatings applicationActive agentFluorescence

The invention relates to a method for preparing field emission display anode panel fluorescent powder coating, which comprises the following steps: selecting photosensitive fluorescent powder; adding hydroxyl dimethyl siloxane as a foam killer; taking Texanol alcohol as a solvent; adding acrylic resin and an activator which takes a pyrolysis type initiator as the primary ingredient; applying to anode baseplate glass in a printing manner; subjecting the baseplate glass on which photosensitive paint is printed to drying and baking to enable the coating layer to solidify as a film; exposing with ultraviolet light, and developing; after developing, carrying out solidification treatment; and after cleaning, blow-drying with nitrogen. When being applied to the screen printing coating technology, the invention can produce an anode fluorescent powder coating with clear images; the accuracy of the produced images is high; the manufacture process is simple; and the paint has a low cost. The invention combines the screen printing technology and the developing technology, and achieves the effects of saving time and improving the display resolution when being applied to the technology for manufacturing a field emission display.

Owner:IRICO

Method utilizing ultraviolet oxidation in implementing and regulating graphene film patterning

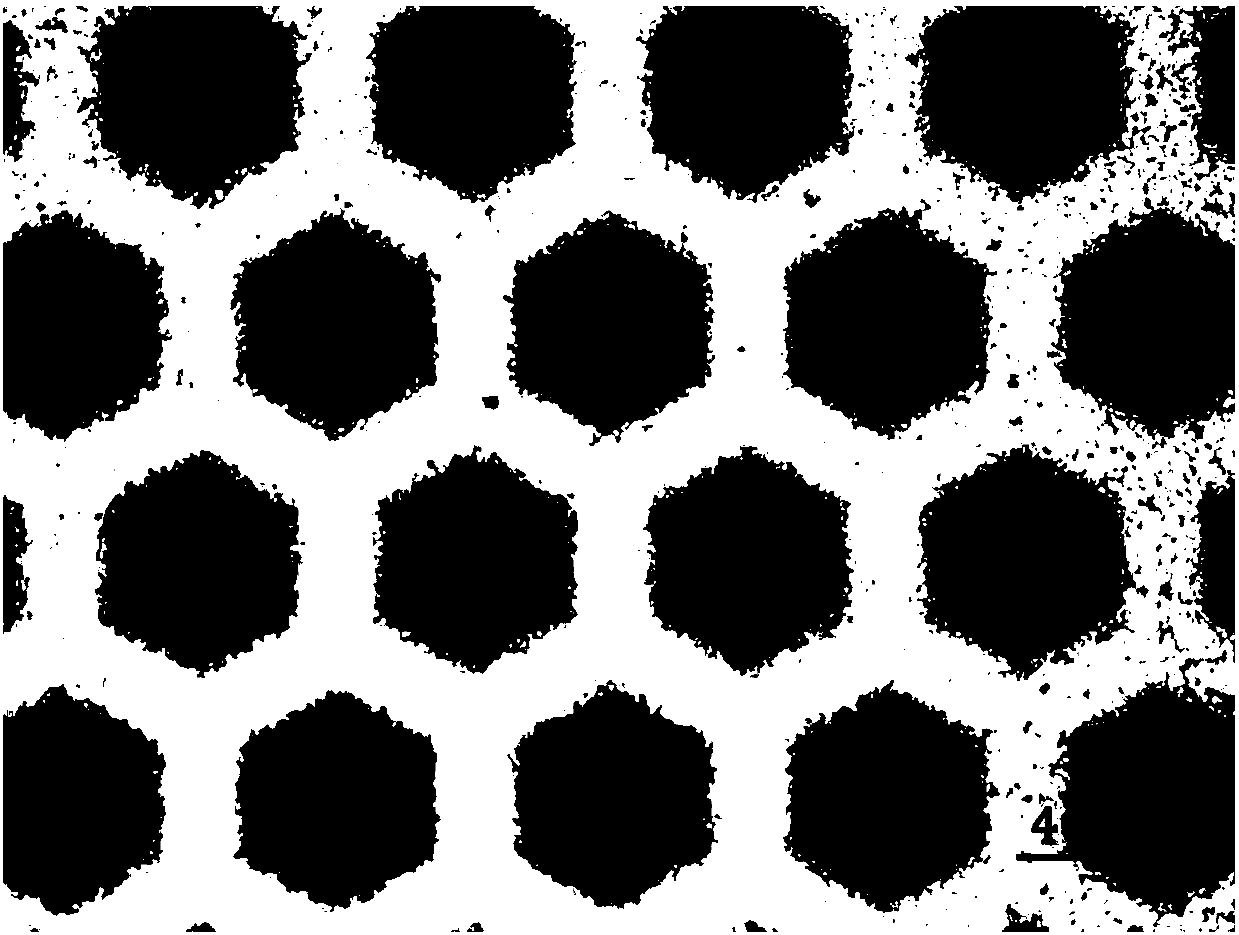

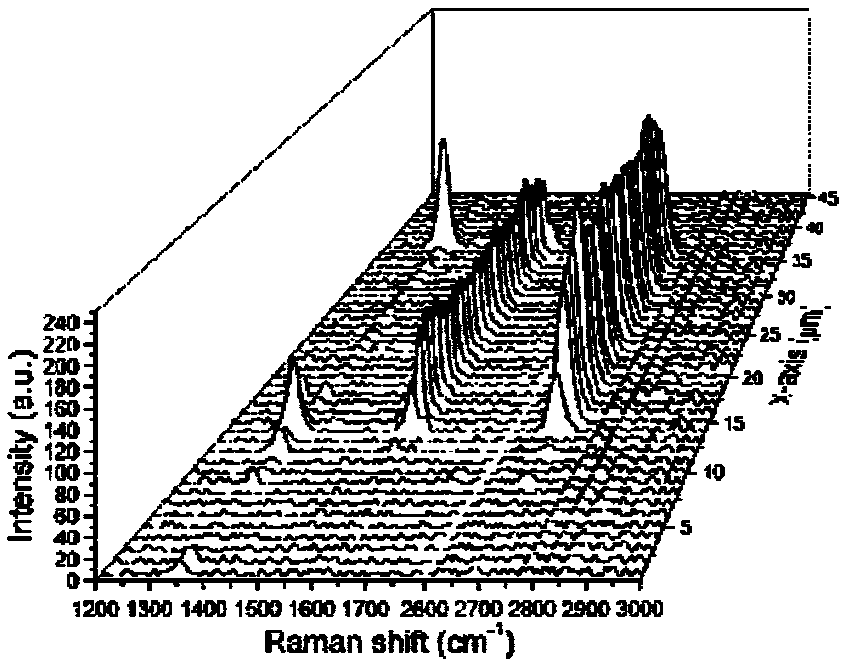

ActiveCN107611020AQuality improvementHigh graphic precisionSemiconductor/solid-state device manufacturingNanotechnologyCvd grapheneMicrometer

Provided in the invention is a method for utilizing ultraviolet oxidation in implementing and regulating graphene film patterning, comprising: a step 1: utilizing a xenon lamp excimer ultraviolet oxidation method and a hard mask in implementing graphene film microstructure graphic patterning; a step 2: by applying a nonuniform magnetic field in the perpendicular direction to the surface of a graphene film, controlling oxygen excitons to move in the direction of the magnetic field towards the graphene film, thus enhancing the directionality of etching the graphene film in the perpendicular direction, and increasing the quality of graphene film microstructure patterning; and a step 3: by adjusting the strength and direction of the magnetic field (such as in the horizontal direction), controlling the directionality of the movement of the oxygen excitons, and regulating the shape being etched on the graphene film graphic structure, thus achieving the goal of regulating graphene film patterning. The method of the invention implements and regulates a micrometer graphic structure array, is suitable for large-area graphene film patterning, free of photoresist contamination, and inexpensive, and provides a patterned graphene film of high quality.

Owner:SHANGHAI JIAO TONG UNIV

Method and device for realizing patterning of graphene film by magnetic field assisted ultraviolet oxidation

InactiveCN110862083AEnhanced oxidation etch effectQuality improvementCarbon compoundsMagnetic field gradientUltraviolet lights

The invention provides a method for realizing patterning of a graphene film by magnetic field assisted ultraviolet oxidation. The method comprises the following steps of step 1, placing a magnetic field generator on a sample holder (8) of ultraviolet oxidation vacuum equipment, adjusting a magnetic field of the ultraviolet oxidation vacuum equipment to a preset magnetic field, wherein the preset magnetic field is a magnetic field in a reaction chamber, and the gradient direction of the magnetic field in the reaction chamber is perpendicular to the sample holder (8); step 2, placing a sample (13) with mask plates (14) placed on the surface on the sample holder (8), and adjusting the distance between the sample holder (8) and light sources (6) to preset distance; and step 3, discharging airin the reaction chamber (1). According to the method, by utilizing the magnetic field assisted ultraviolet light oxidation method, taking water molecules as oxidation sources, and applying a non-uniform magnetic field in the vertical direction to the surface of the sample, paramagnetic OH (X<2>II) free radicals generated by ultraviolet light are controlled do directional movement, and have an enhanced oxidation etching effect.

Owner:SHANGHAI JIAO TONG UNIV

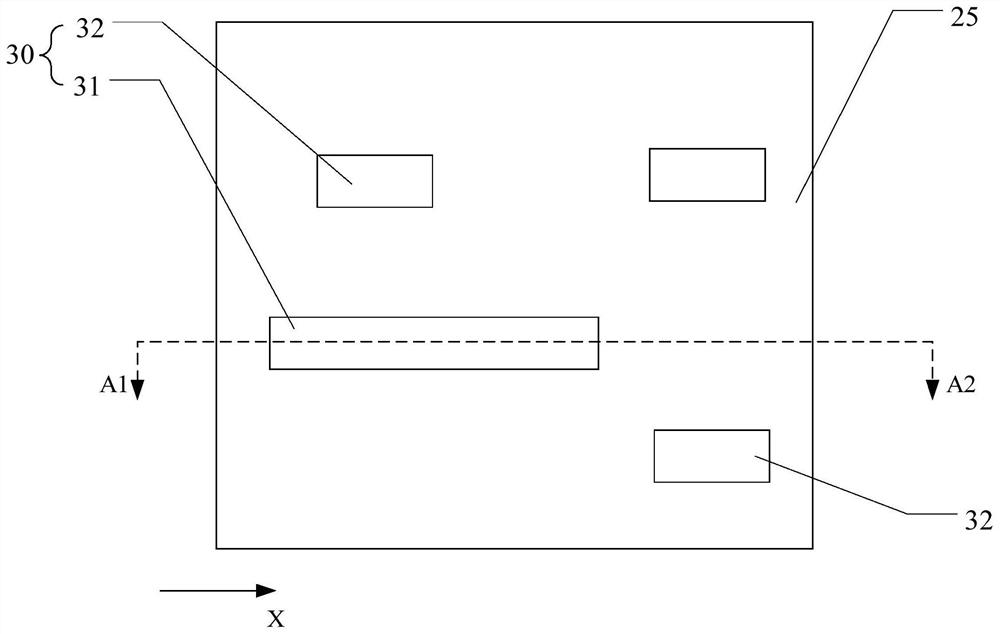

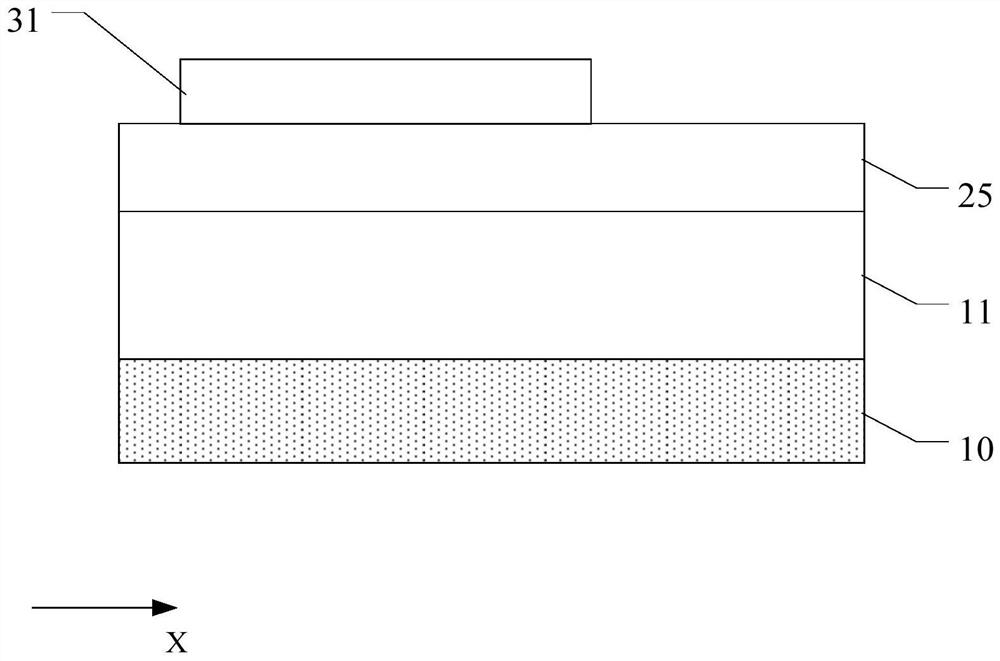

Memory and forming method thereof

PendingCN111640750AHigh graphic precisionEtching process omittedTransistorSemiconductor/solid-state device manufacturingGraphicsBit line

The invention provides a memory and a forming method thereof. A bit line and an insulating line are used for defining a first grid array, after the bit lines and the insulating lines are formed, the isolation layer is used for further defining the second lattice array corresponding to the first lattice array, so that the first lattice array and the second lattice array can be combined to define the node contact window, and then the node contact structure can be filled in the node contact window in a self-aligned mode. Therefore, according to the memory and the forming method thereof, when a node contact structure is prepared, a graphical process does not need to be executed on a conductive material used for forming the node contact structure, thus, the etching process in the patterning process of the conductive material with high hardness can be omitted, the pattern precision of the formed node contact structure can be improved, polymers can be prevented from being generated, and the polymers are prevented from being attached to the node contact structure.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

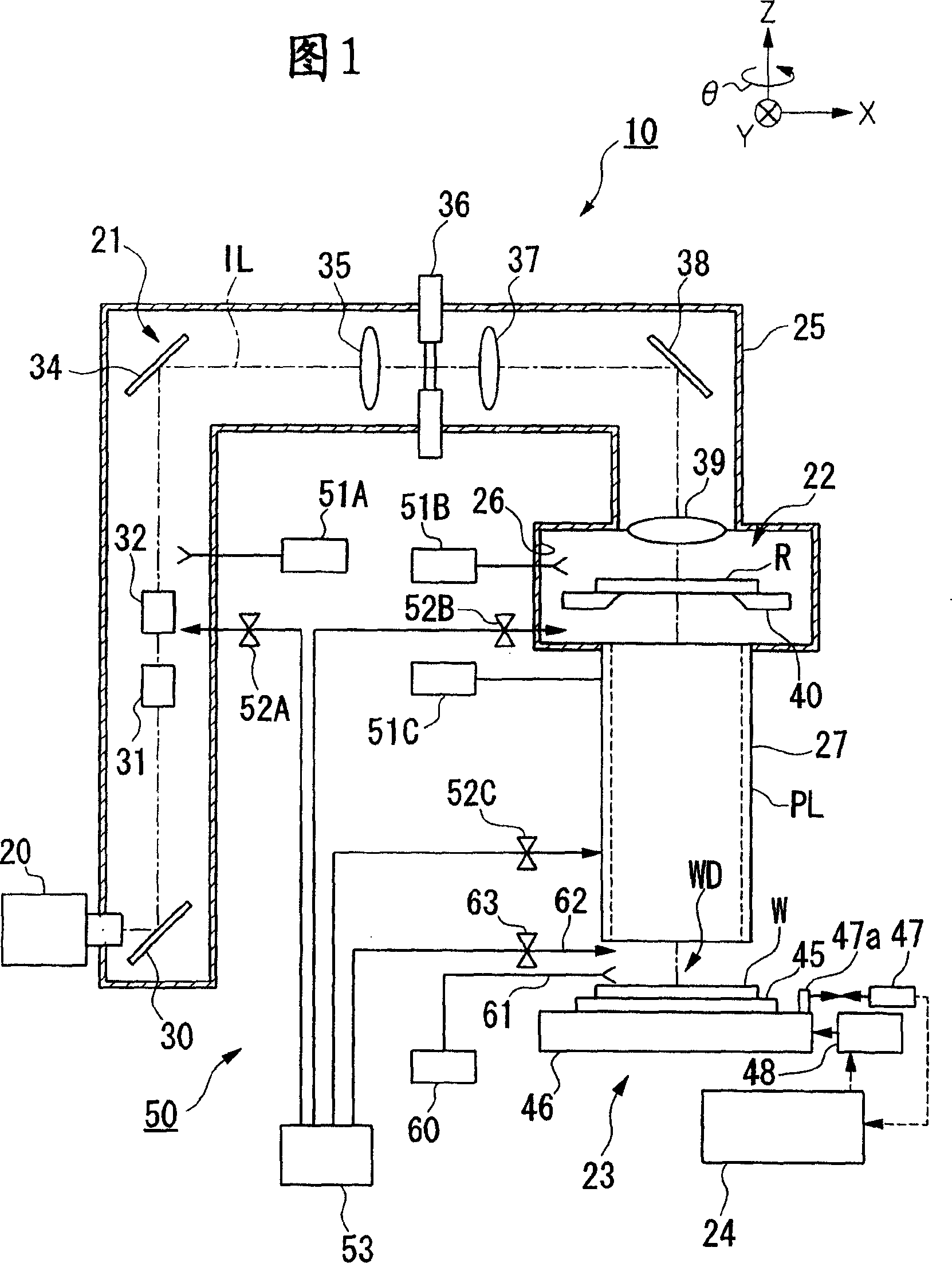

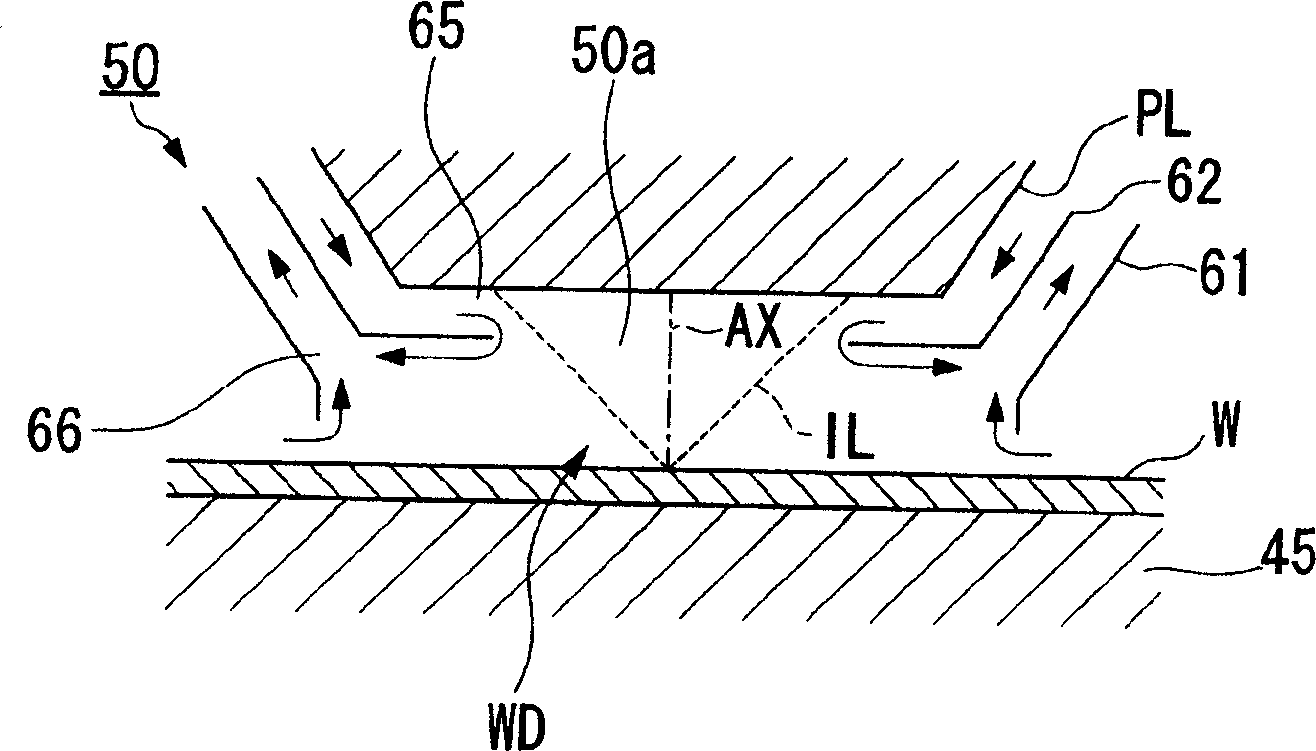

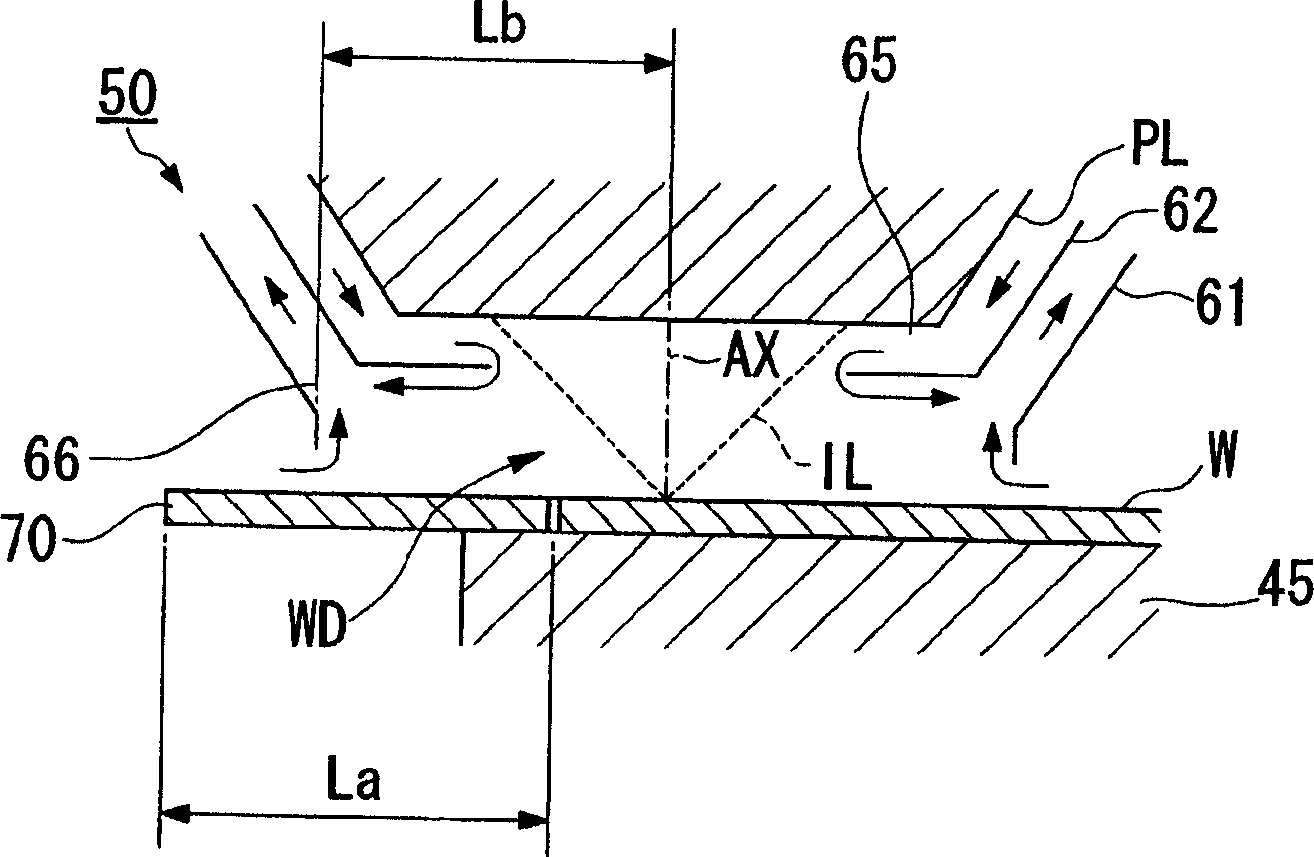

Exposure method, exposure apparatus, and method for manufacturing device

InactiveCN1650401AHigh control precisionHigh graphic precisionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamEngineering

A substrate (W) serves as a part of a partition wall and an injection end side of a shot optical system (PL) is filled with a penetrating gas penetrating an energy beam (IL). When the substrate (W) is moved or exchanged, in order to maintain the gas state at the injection end side of the shot optical system (PL), an object (70) is arranged at the injection end side of the shot optical system (PL) instead of the substrate (W). Thus, it is possible to properly exclude light absorbing substance from the injection end side of the shot optical system and maintain the gas state even when the substrate is moved or exchanged.

Owner:NIKON CORP

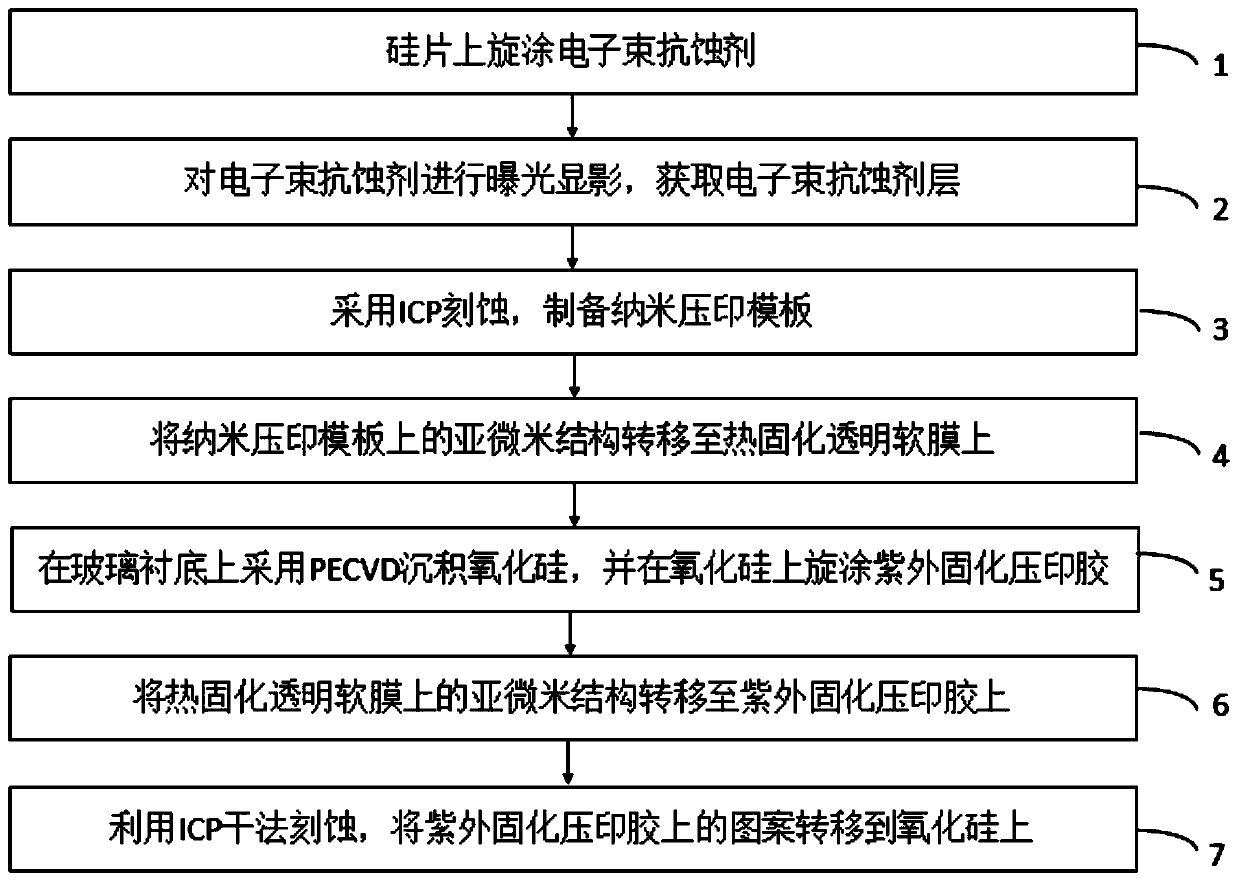

Method for preparing grating with submicron structure

InactiveCN111308597AHigh graphic precisionFlat surfacePhotomechanical apparatusDiffraction gratingsPhysicsChemistry

The invention discloses a method for preparing a grating with a submicron structure, which belongs to the technical field of microstructures in semiconductors, and particularly comprises the followingsteps of: spin-coating an electron beam resist on a silicon wafer, and performing electron beam exposure to obtain an electron beam resist layer; performing dry etching by taking the electron beam resist layer as a mask to prepare a nanoimprint template; transferring the submicron structure on the nanoimprint template to a thermocuring transparent soft film; spin-coating an ultraviolet curing imprinting adhesive on the substrate for preparing the grating; transferring the submicron structure on the thermocuring transparent soft film to an ultraviolet curing imprinting adhesive through a nanoimprinting method; and transferring the submicron pattern on the ultraviolet curing impressing adhesive to a substrate for preparing the grating by using a dry etching method. The nanoimprint templateprepared through electron beam exposure and dry etching is high in pattern precision and smooth in surface. The sub-micron structure grating prepared through soft film transfer printing, nanoimprint lithography and dry etching is good in uniformity, high in yield, accurate in size and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Semiconductor structure and forming method thereof

PendingCN112713087AIncreased etch resistanceReduce the probability of misetchingSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps of providing a substrate, and forming a to-be-etched layer on the substrate, forming a core layer and a plurality of sacrificial layers located in the core layer on the to-be-etched layer, and enabling the sacrificial layers to be arranged at intervals, removing part of the core layer between the adjacent sacrificial layers to form a first groove penetrating through the core layer, and exposing the sacrificial layers from the side wall of the first groove, carrying out first ion doping treatment on the core layer of the side wall of the first groove, wherein the first ion doping treatment is suitable for increasing the etching resistance of the core layer of the side wall of the first groove, forming a side wall on the side wall of the first groove, after first ion doping processing and side wall forming are carried out, removing the sacrificial layer, forming a second groove penetrating through the core layer, and isolating the second groove and the first groove by a side wall, and etching the to-be-etched layers at the bottoms of the first groove and the second groove by taking the core layer and the side walls as masks. According to the embodiment of the invention, the probability that the core layer on the side wall of the first groove is mistakenly etched in the step of removing the sacrificial layer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

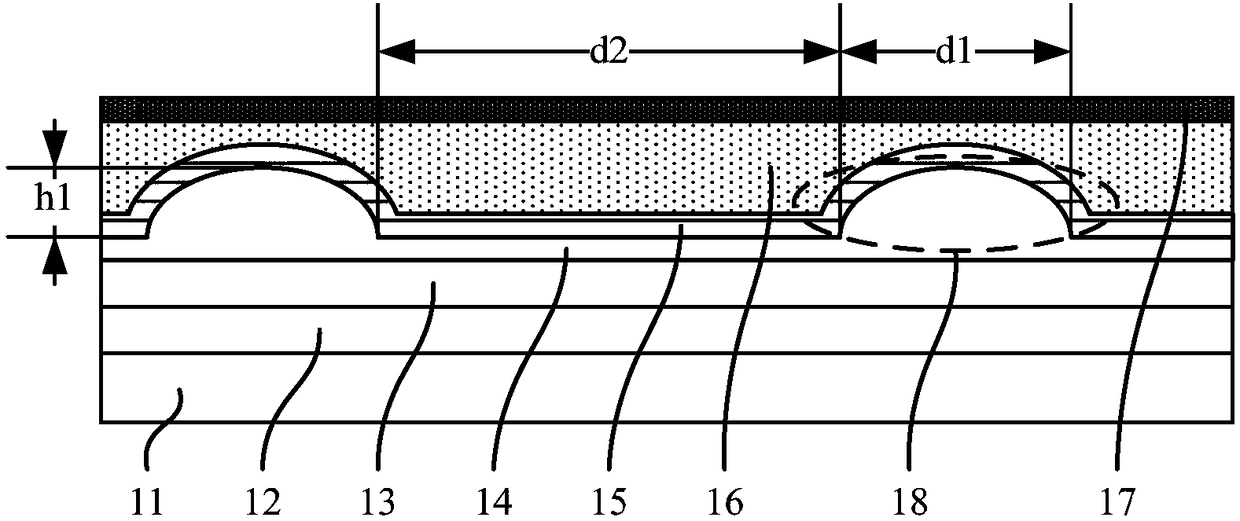

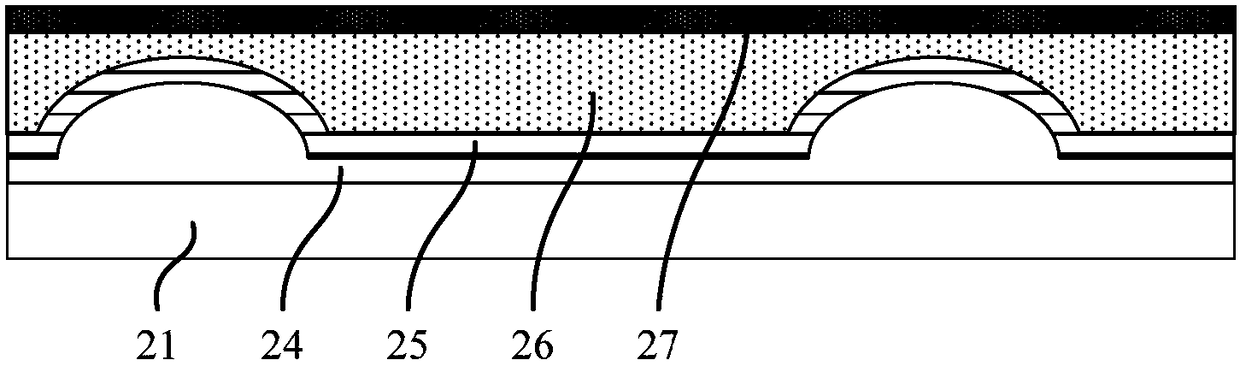

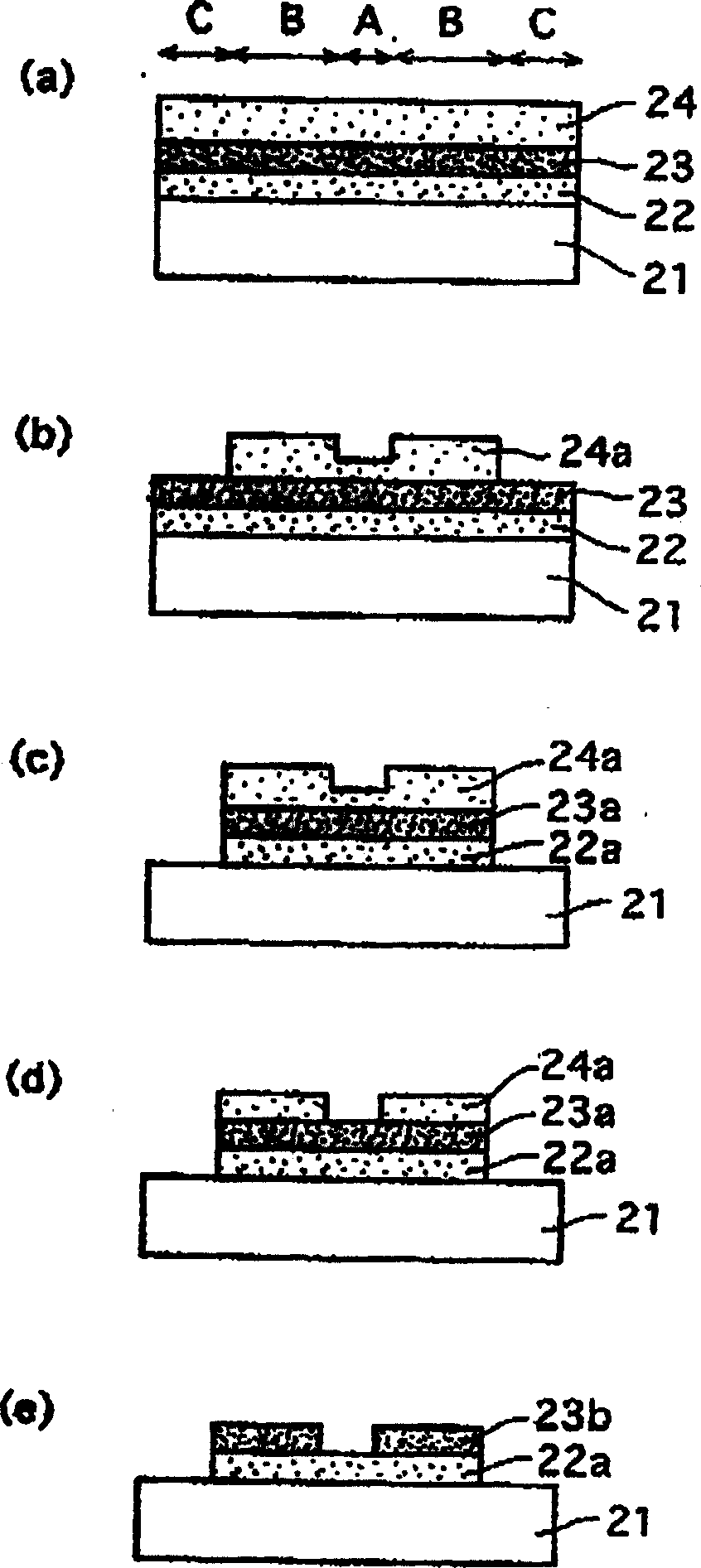

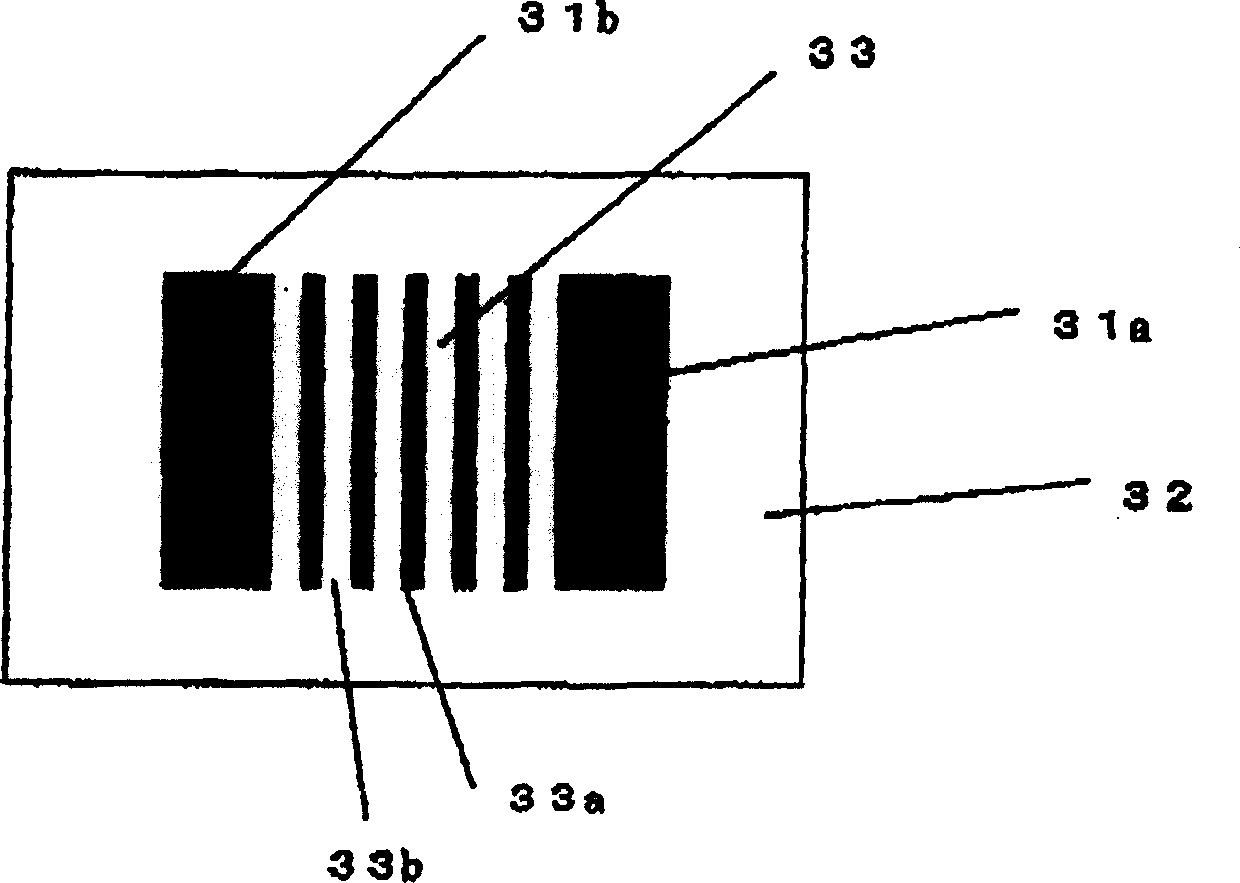

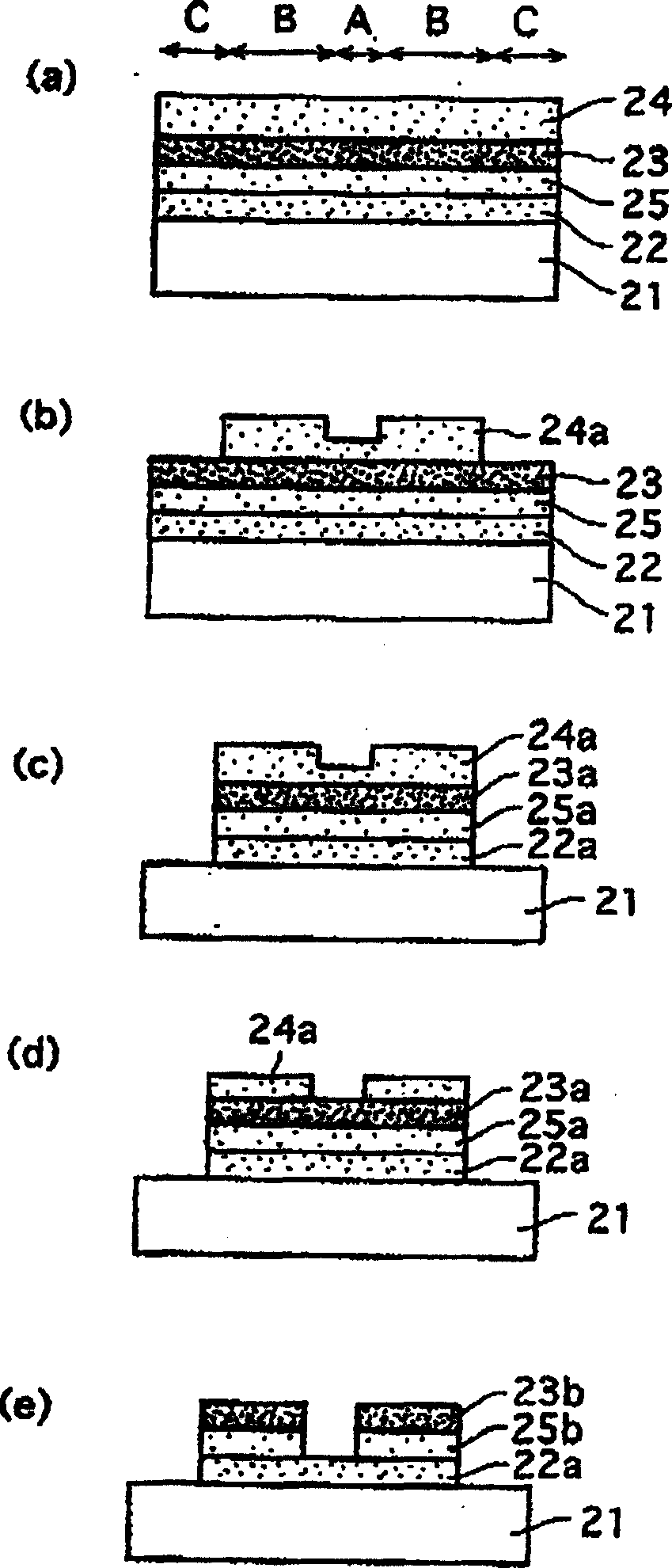

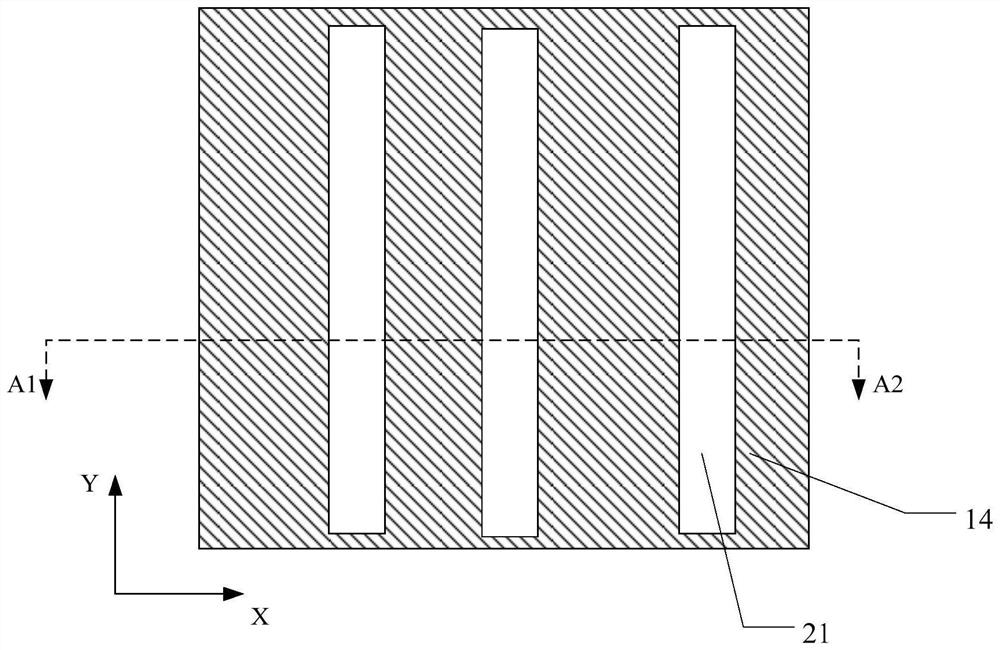

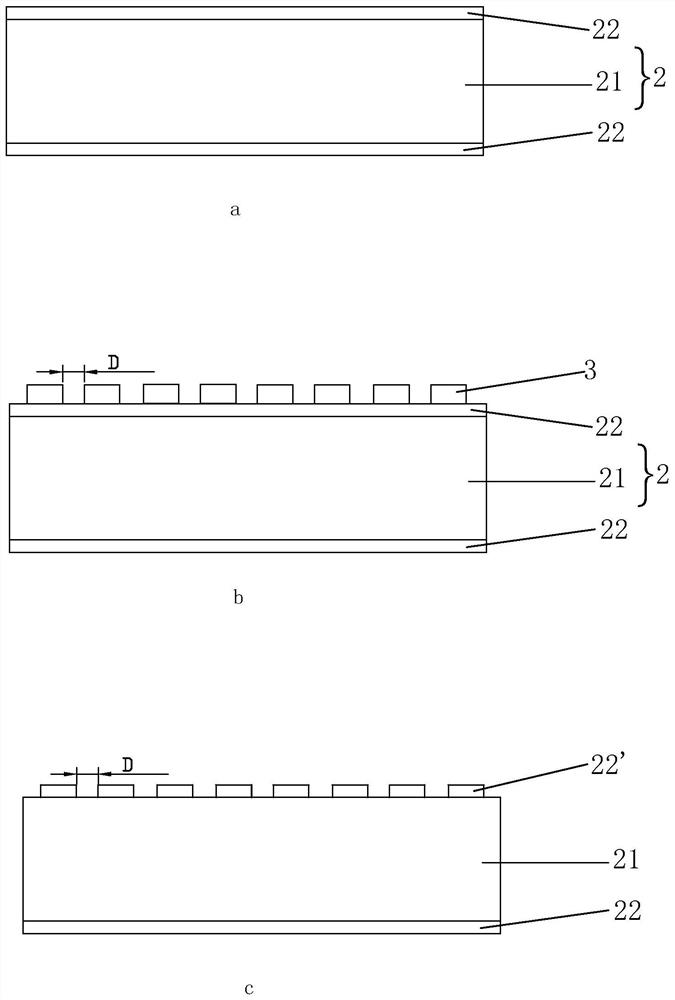

Method for producing grey mask

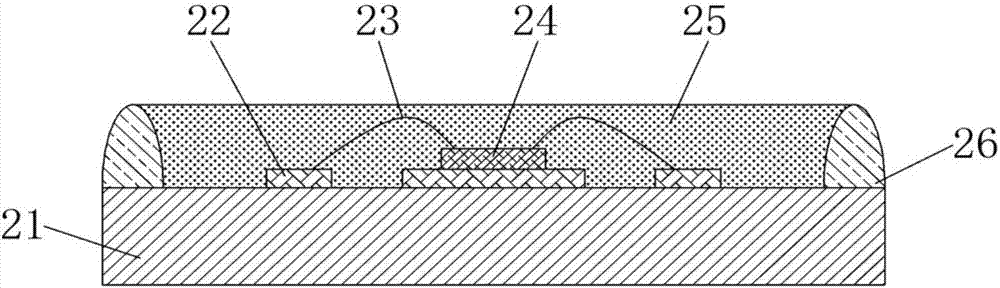

InactiveCN1577084APrevent quality deteriorationGuaranteed qualitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistImaging processing

PURPOSE: A manufacturing method of a gray tone mask is provided to improve preciseness with a simplified imaging process, and thus to ensure the quality of the resulted product, while reducing imaging processing time, through only single number of imaging process, thereby being suitably used in TFT-LCD. CONSTITUTION: The manufacturing method of a gray tone mask comprised of a light shield part, projection part, a transmission part and a semi-transmission part comprises: preparing a mask blank where at least a semi-transmission film(22) and a light shield part(23) are formed in this order on a transparent substrate(21); forming a resist film(24) on the mask blank; light exposing the resist film in order to expose patterns that are below the resolution limit of a light exposure device to the part forming the semi-transmission part of the resist film; developing the resist film and forming resist patterns(24a) in a way that the residual film values become different between the part forming the light shield part and the part forming the semi-transmission part; etching the light shield film(23a) and semi-transmission film with the resist patterns as a mask to form the transmission part; removing only resist patterns present on the semi-transmission part; and etching a part of the light shield film and the semi-transmission film with the residual resist patterns as a mask to form the semi-transmission part(22a).

Owner:HOYA CORP

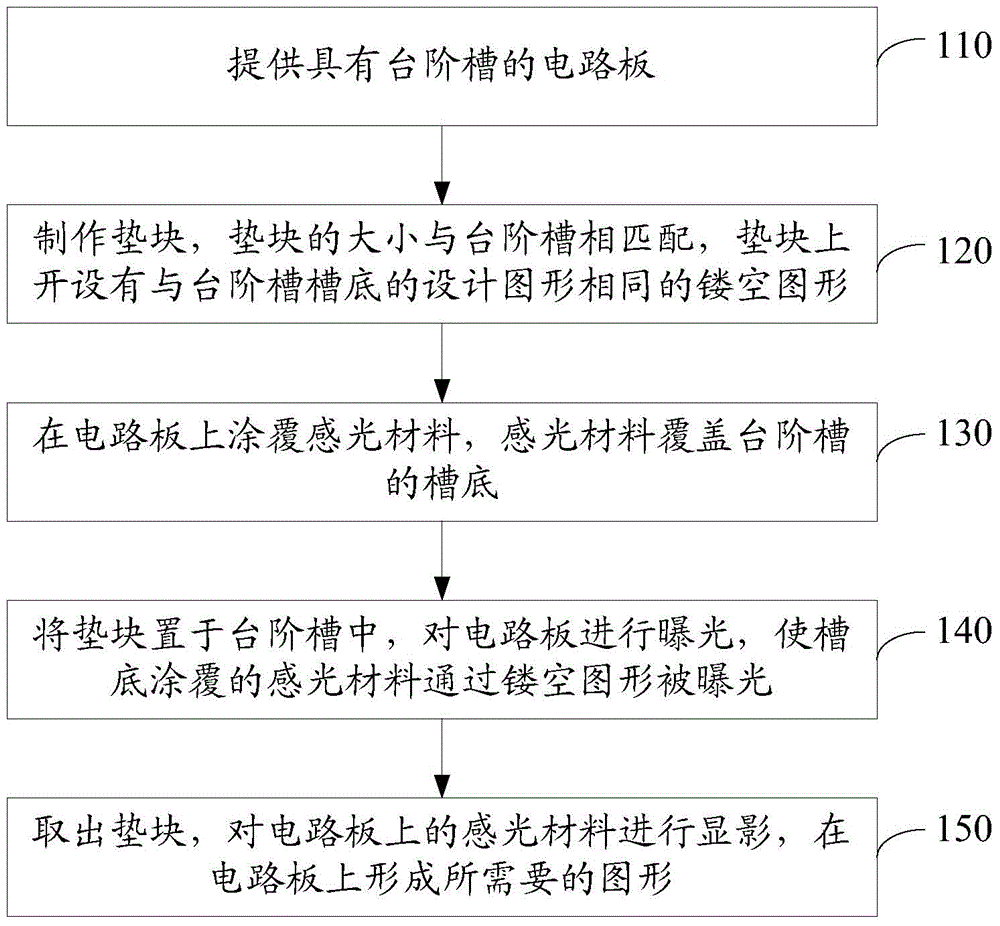

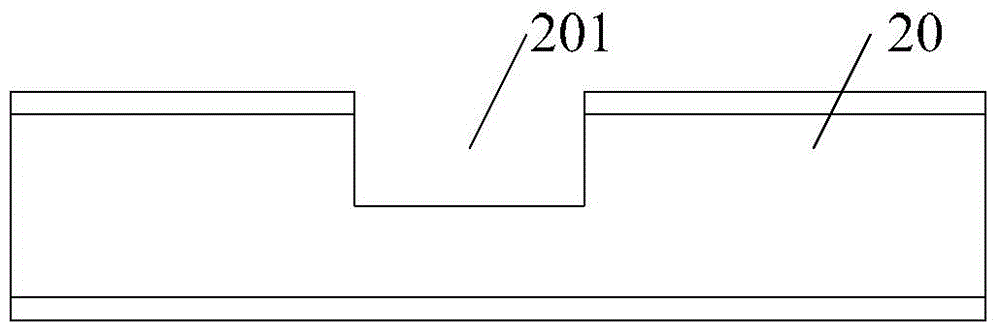

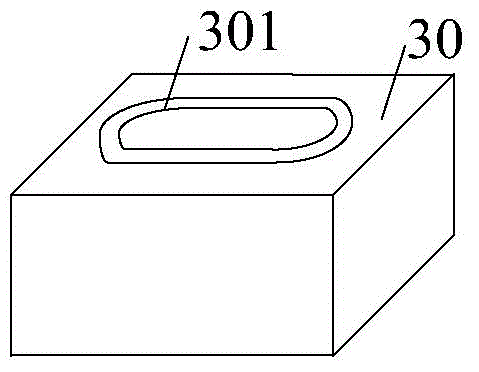

Exposure development method for circuit board

The invention discloses an exposure development method for a circuit board and solves problems of deficient exposure, poor graph precision and poor graph uniformity existing during groove bottom graph exposure in the prior art. The method comprises steps that, a circuit board having a step groove is provided; a pad is made, the size of the pad is in matching with the step groove, and the pad is provided with a hollowed-out graph identical to a design graph of the bottom of the step groove; the circuit board is coated with a photosensitive material, and the photosensitive material covers the bottom of the step groove; the pad is arranged in the step groove, exposure of the circuit board is carried out, and exposure of the photosensitive material coated at the bottom of the step groove is realized through the hollowed-out graph; the pad is taken out, development of the photosensitive material on the circuit board is carried out, and the required graph is formed on the circuit board.

Owner:SHENNAN CIRCUITS

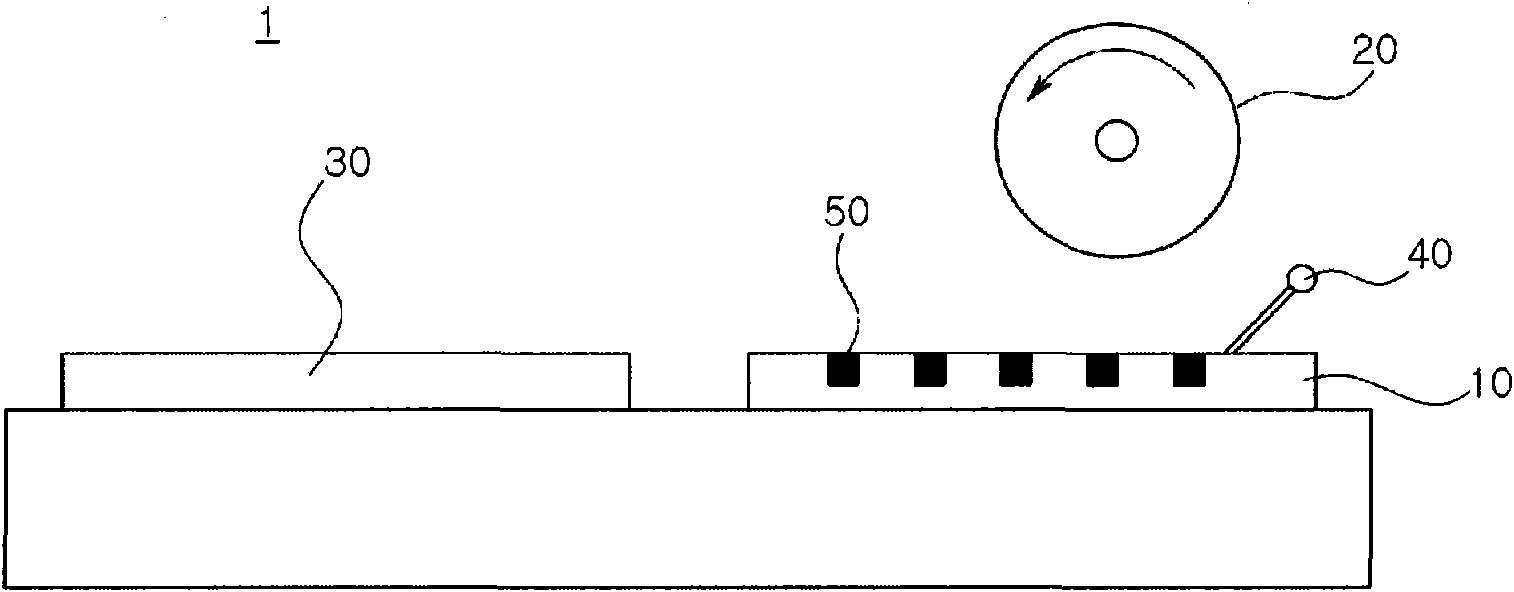

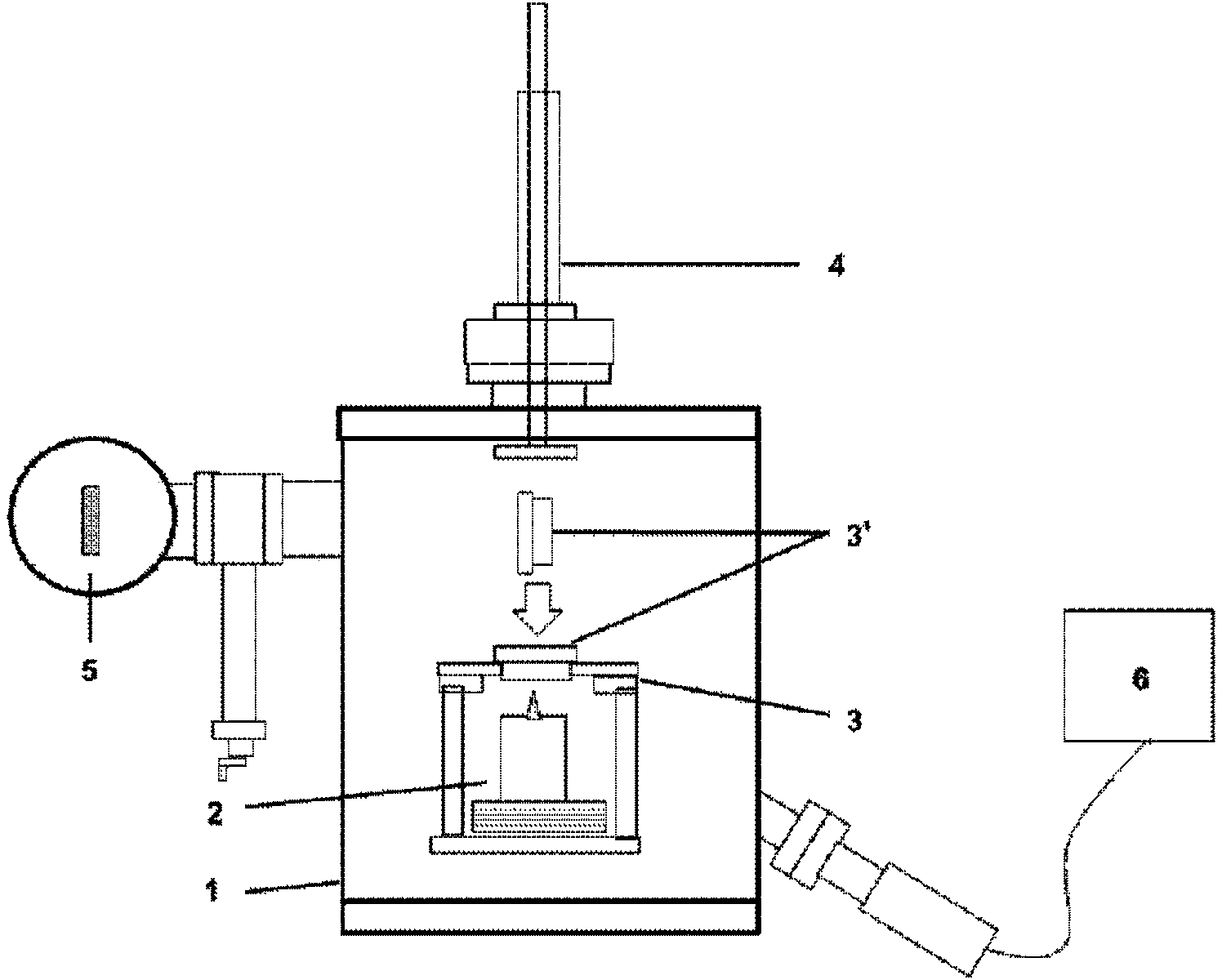

Positioning nanoimprint lithography system for preparation of patterned substrate by utilizing AFM (Atomic Force Microscope) probe

ActiveCN103592818AAccurate measurementHigh graphic precisionPhotomechanical apparatusNanometreMicroscope

The invention provides a positioning nanoimprint lithography system for preparation of a patterned substrate by utilizing an AFM (Atomic Force Microscope) probe. The positioning nanoimprint lithography system comprises an ultrahigh vacuum chamber compatible with other vacuum growth equipment, an AFM fixed at the bottom of the ultrahigh vacuum chamber, a substrate holder fixing device fixed on the AFM, a substrate holder positioned in a hole formed in the middle of the substrate holder fixing device, a mechanical arm fixed on the ultrahigh vacuum chamber and used for transmitting of the substrate holder, a probe replacement cavity fixed in the side wall of the ultrahigh vacuum chamber and used for replacement of the probe of the AFM, and a monitoring system used for control to the preparation of the imprinted patterned substrate by the AFM. The positioning nanoimprint lithography system has the characteristics of high patterned substrate precision (more than 50 nm), small extension damage, capability of facilitating preparation of high-integration-level arrays of photoelectronic devices and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Semiconductor structure and forming method of semiconductor structure

PendingCN113497142AHigh graphic precisionReduce capillary forceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureMaterials science

The invention discloses a semiconductor structure and a forming method of the semiconductor structure, and the method comprises the steps: providing a substrate which is provided with a fin structure; and forming a hydrophobic film on the surface of the substrate and the surface of the fin structure. Therefore, the defects of the semiconductor structure are reduced, and the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

TFT circuit substrate production process

InactiveCN113056093AEffective distributionHigh graphic precisionPrinted circuit manufactureCircuit susbtrate materialsSputteringPulse electroplating

The invention relates to the technical field of circuit substrate production, and discloses a TFT circuit substrate production process. The process comprises the following steps: selecting a base material which is made of glass or ceramic; carrying out surface treatment on the base material, and sputtering a transition metal thin layer on the surface of the base material through a vacuum sputtering method; pasting a high-resolution exposure dry film on the surface of the transition metal thin layer, and exposing a shadow line pattern on the base material through an exposure machine; electroplating a circuit pattern on the base material through pulse electroplating, removing the exposure dry film, removing the transition metal thin layer formed by vacuum sputtering, and performing gold immersion or other protection treatment on the circuit surface on the base material; and cutting the base material into a required size by a laser to obtain a finished product. The base material made of glass or ceramic materials with good dimensional stability is selected, meanwhile, the circuit pattern is manufactured through a vacuum sputtering method, pattern precision is high, glass or ceramic is used as the base material, heat generated by long-term work of a product can be effectively dissipated, and the service life of the product is prolonged.

Owner:深圳市昱安旭瓷电子科技有限公司

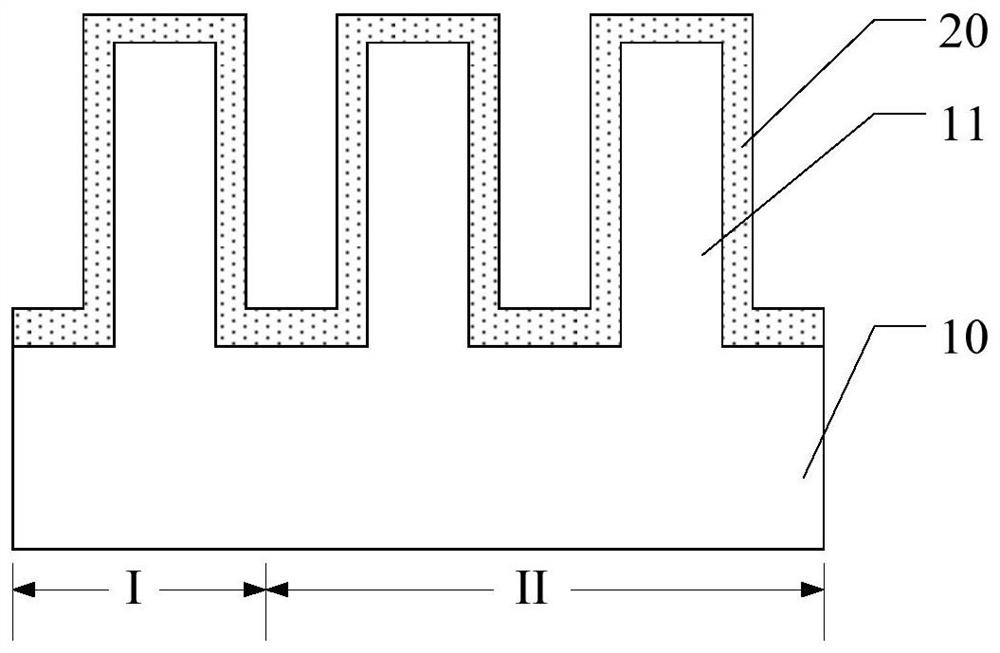

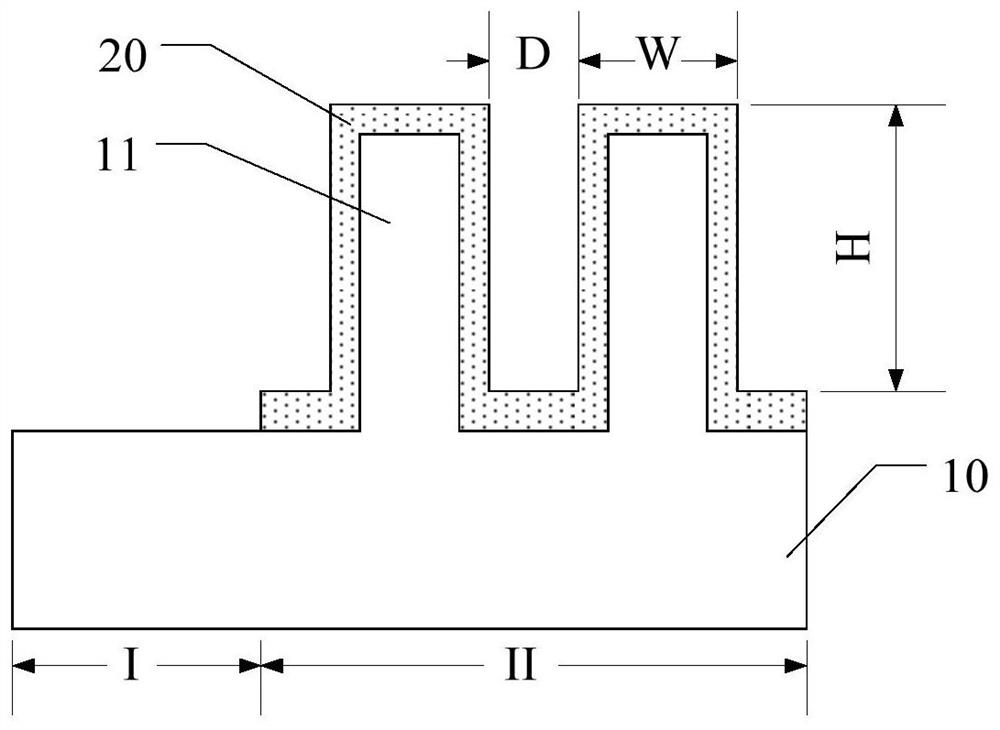

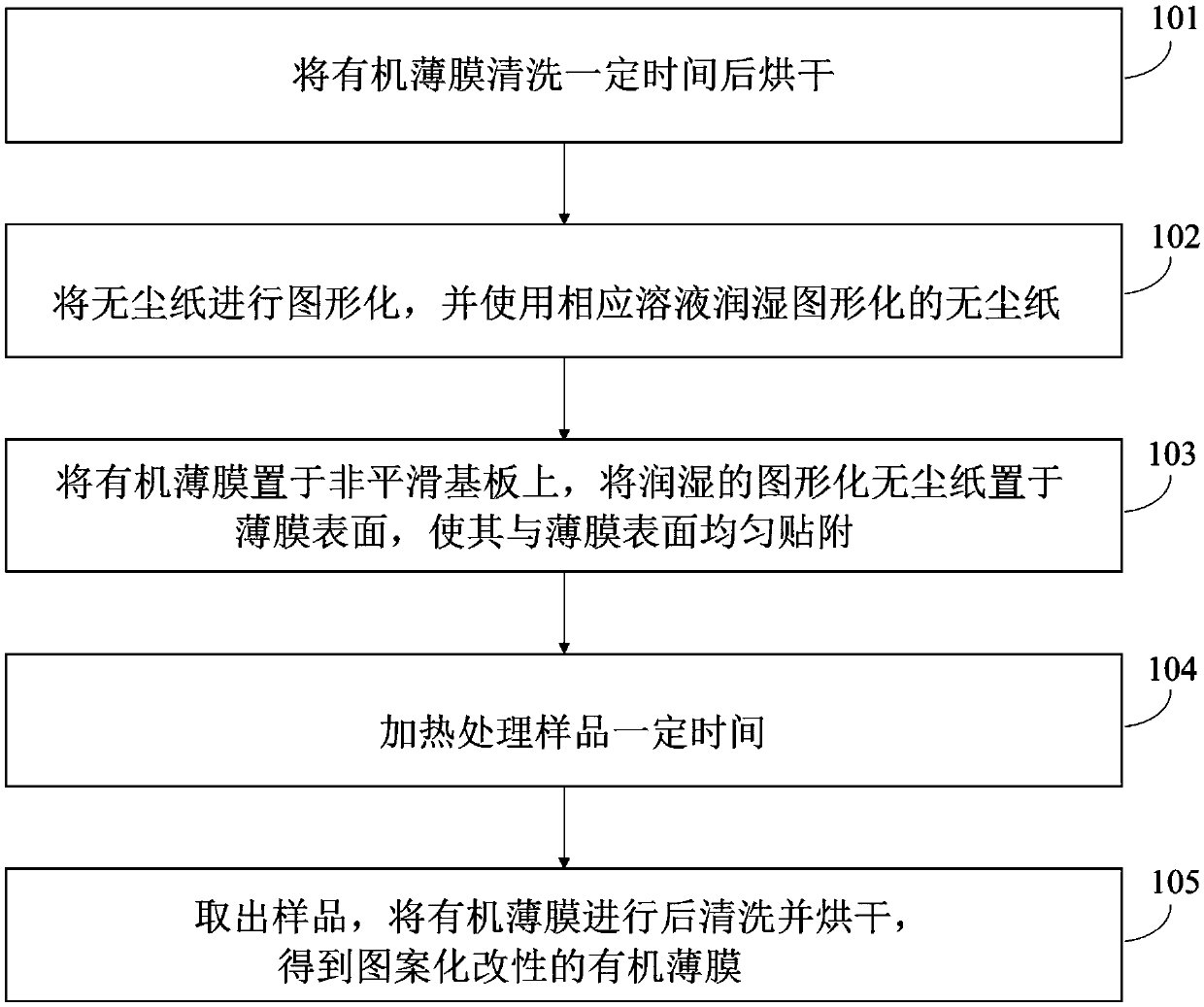

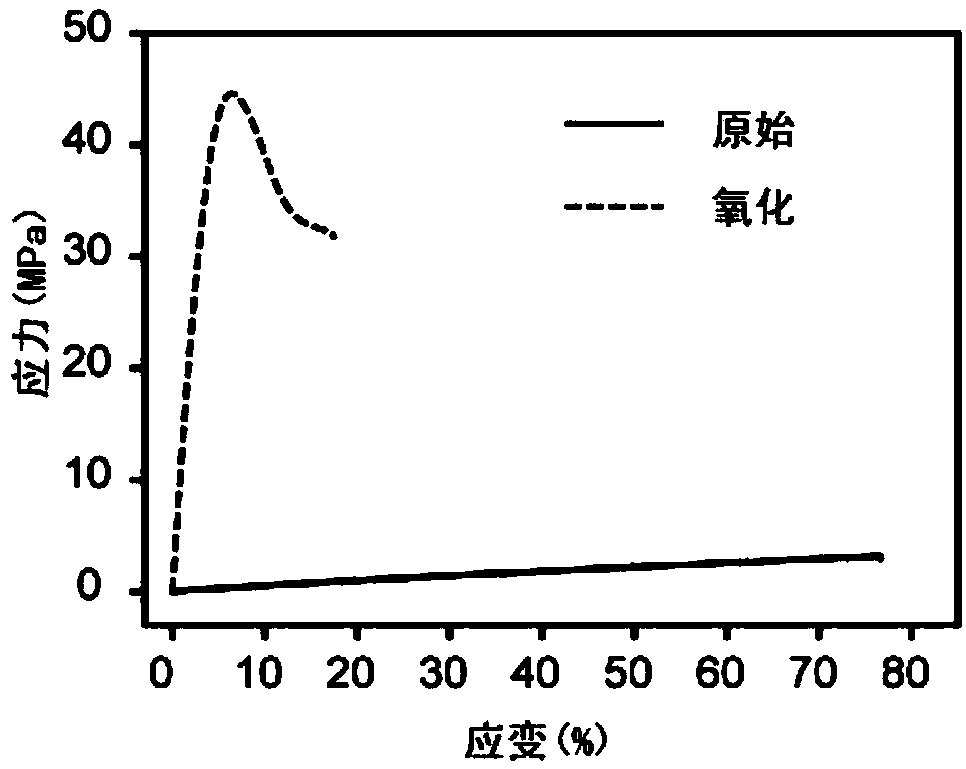

Patterned flexible organic film and manufacturing method thereof, stacked body and patterning method

ActiveCN108682627AHigh precisionImprove flatnessSemiconductor/solid-state device manufacturingFiberOrganic film

The invention relates to a patterned flexible organic film and a manufacturing method thereof, a stacked body and a patterning method. A patterned flexible organic film is obtained through making a functional film be contacted with a flexible organic film to be patterned and carrying out patterning. The functional film contains a solution capable of reacting with the flexible organic film to be patterned. And the functional film is a fiber-containing film acquired through a dry paper making method.

Owner:浙江荷清柔性电子技术有限公司

Metal heat-conducting substrate and manufacturing method thereof

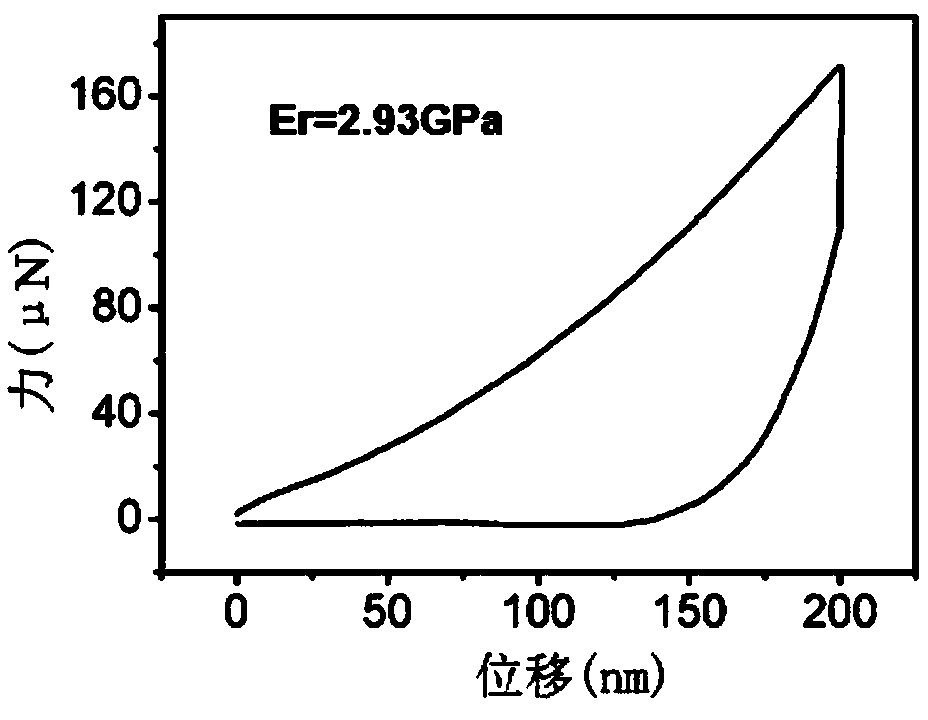

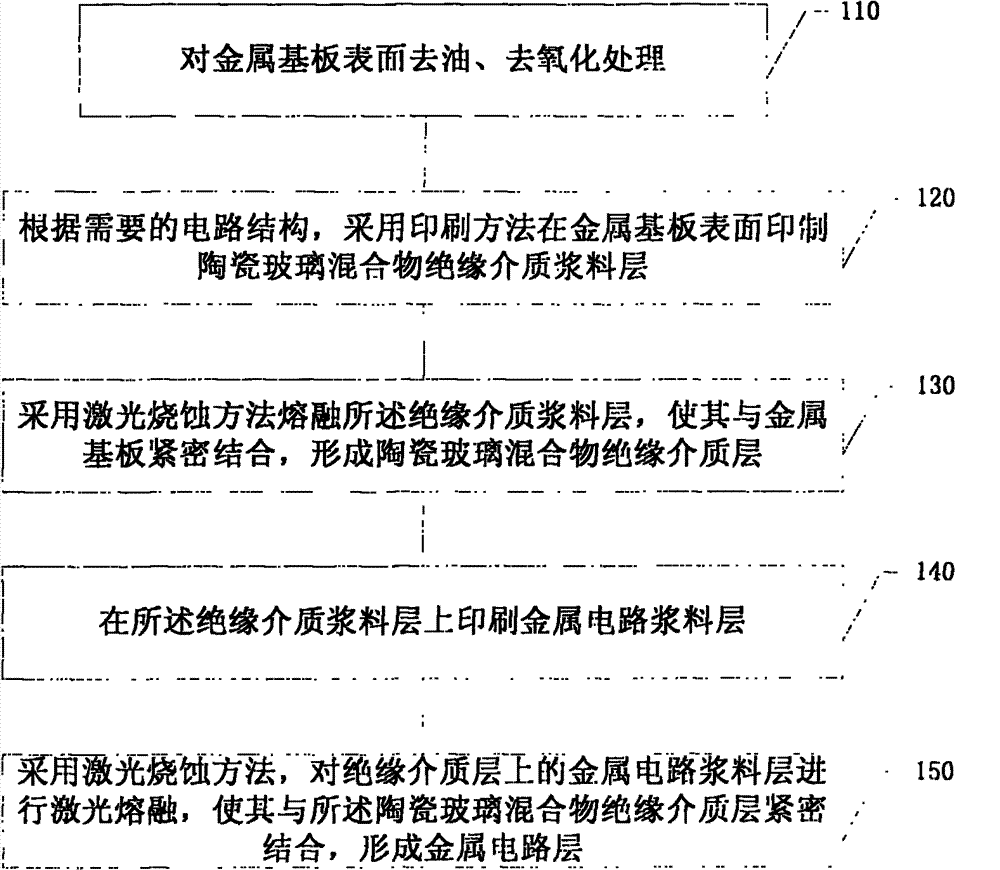

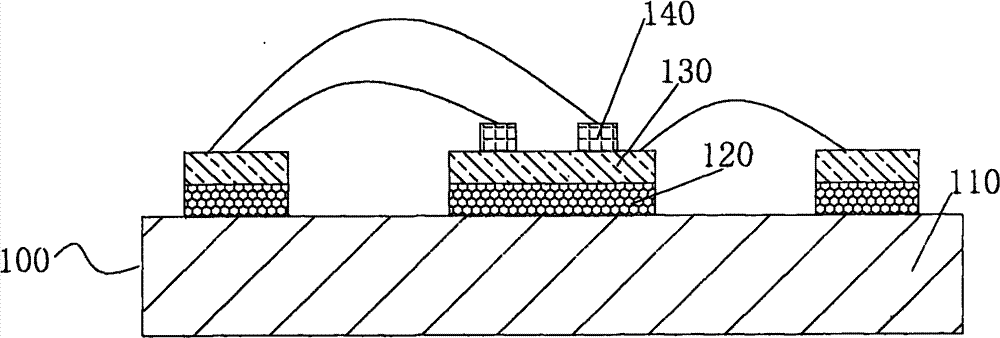

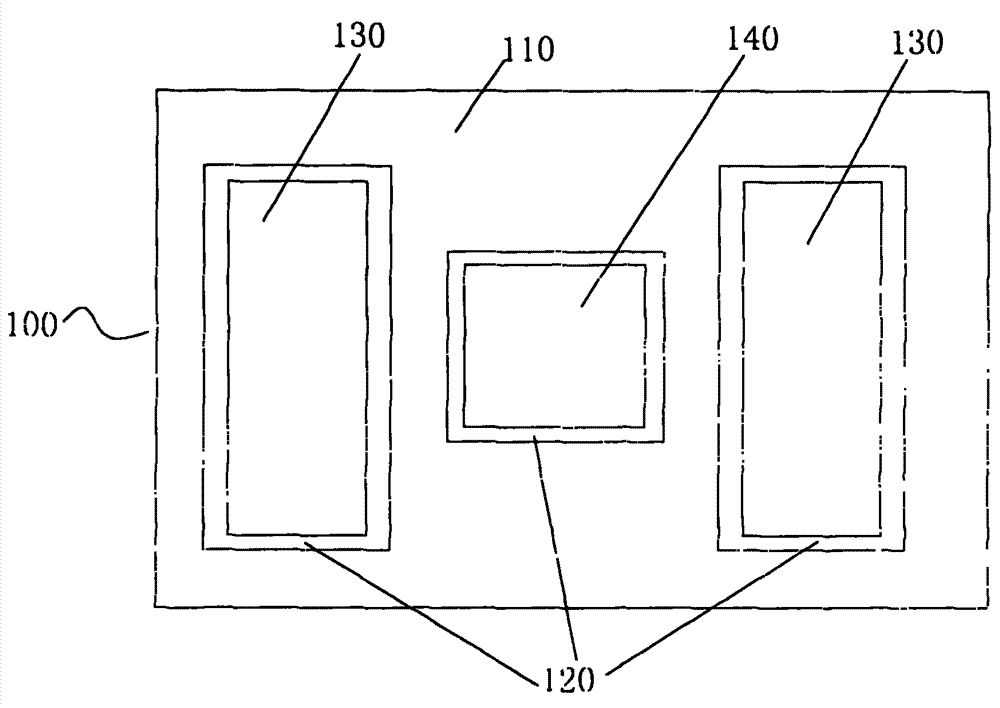

InactiveCN101894762BSimple designSimple processSemiconductor/solid-state device detailsSolid-state devicesHeat conductingMiniaturization

The invention relates to the technical field of electronic packaging and discloses a metal heat-conducting substrate and a manufacturing method thereof. An insulating medium slurry layer is printed on a metal substrate and molten by a laser ablation method to form an insulating medium layer, and a metal circuit slurry layer is printed on the insulating medium layer and molten by the laser ablation method to form a metal circuit layer, so that a well-insulated radiating passage is provided. The laser melting method has the advantages of achieving extremely high pattern accuracy, contributing to product miniaturization and precision, simplifying the technology of a manufacturing process, preventing pollution, saving materials, lowering cost and achieving good radiating effect.

Owner:SHENZHEN UNIV

Mask layout correction method and mask layout

ActiveCN113517180AHigh precisionGood lookingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComputer hardwareComputer graphics (images)

The invention discloses a mask layout correction method and a mask layout. The method comprises the steps that a first mask layout which comprises a plurality of first patterns extending along a first direction is formed; second mask layout information is obtained, the second mask layout information comprises a second mask layout, the second mask layout comprises a plurality of second patterns extending in the second direction, and after the first mask layout and the second mask layout are overlapped, the second patterns stretch across one or more first patterns, the second direction is perpendicular to the first direction; and the plurality of first patterns are compensated and corrected according to the layout information of the second mask. Therefore, the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

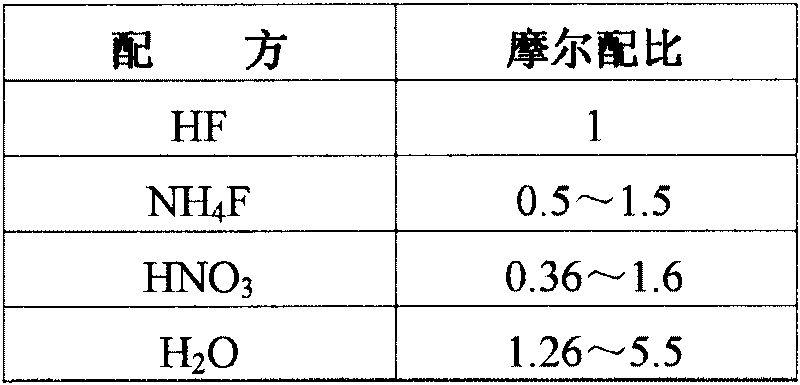

Etching solution for use in wet etching of bismuth-based thin films

Aiming at the technical problem that aqueous solution of HF, serving as etching solution, cannot etch a bismuth-based thin film material, nor ensure the accuracy of patterns, the invention provides etching solution for use in the wet etching of bismuth-based thin films, belongs to the technical field of materials and relates to micro machining technology, in particular to etching solution for use in a photoetching process. The etching solution is mixed solution comprising HF serving as an etching agent, NH4F serving as a complexing agent and H2O serving as a diluting agent in a molar ratio of 1: (0.5-1.5): (1.26-5.5). To enhance the etching effect of the etching solution on the bismuth-based thin film material and increase etching speed, HNO3 serving as an assistant can be added into the etching solution, wherein the ratio of the HF to the NH4F to the HNO3 to the H2O is 1: (0.5-1.5): (0.36-1.6): (1.26-5.5). The wet etching of the bismuth-based thin film material by the etching solution has the advantages of clean etched surface, clear patterns, high precision and no residual precipitate. After the HNO3 assistant is added, the speed of the wet etching of the bismuth-based thin films is increased, and the etching process and the pattern precision can be controlled effectively.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Silicon carbide friction pair used for non-contact mechanical seal and manufacturing method thereof

InactiveCN103671928AReduce intensityThe effect of uniform dischargeEngine sealsLaser processingCarbide

The invention relates to a silicone carbide friction pair used for a non-contact mechanical seal and a manufacturing method of the silicon carbide friction pair. Concave points or geometry-shaped grooves are evenly distributed in the friction end face of the silicon carbide friction pair used for the mechanical seal, and the depth of the groove can be evenly changed gradually. The concave points or the geometry-shaped grooves evenly distributed in the friction end face of the silicon carbide friction pair are manufactured through laser processing.

Owner:辽宁天泽产业集团机械制造有限公司

A touch screen manufacturing method for improving etching traces

ActiveCN108958526BAvoid light transmittanceLow costCoatingsInput/output processes for data processingPolyesterEngineering

The invention discloses a touch screen manufacturing method for improving etching traces. It is to make a composite screen composed of a polyester mesh located on the periphery and a steel wire mesh located in the middle, and then use acid-resistant ink TPER‑5200 to cooperate with the composite screen to print through the screen. The process forms a shielding layer with a gap of 0.07-0.15 mm, and then etches to form an electrode pattern with a corresponding gap. Etching traces of this width are difficult to be detected by the naked eye, thus realizing the shadow removal effect without the shadow removal coating, avoiding the problems of light transmittance and chromatic aberration caused by the shadow removal coating, and compared with the shadow removal substrate , the material cost is reduced by 60-70%; compared with the yellow light process, the production cycle is shorter, the manufacturing cost is low, and the same manufacturing precision as the yellow light process can be achieved, economical and practical, suitable for popularization and application.

Owner:福建宸为电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com