Wet method pattern technology of chrome-nickel alloy thin film

A nickel-chromium alloy and patterning technology, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve problems affecting device quality, photoresist carbonization, and high temperature resistance, and achieve high pattern accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

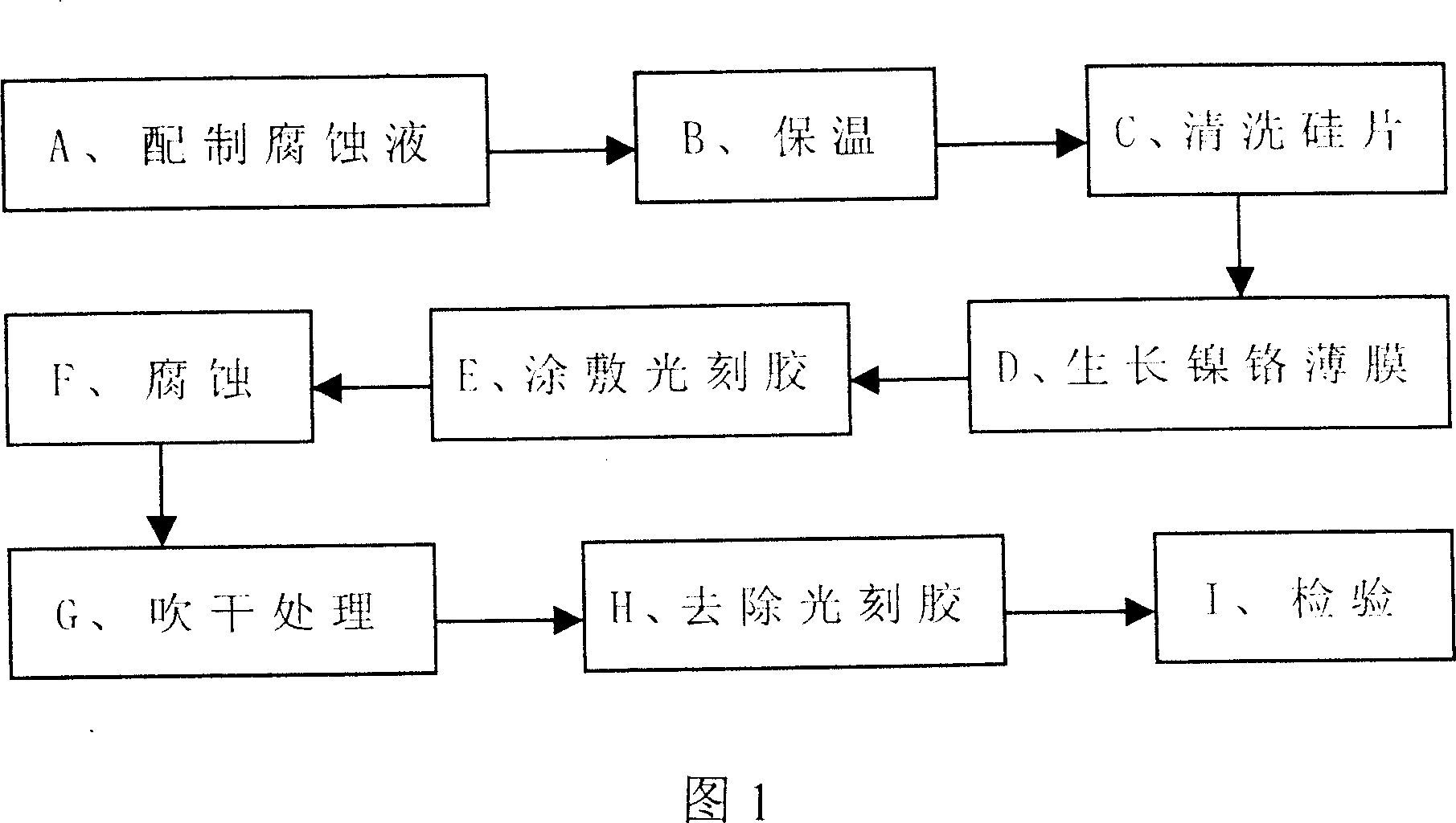

Method used

Image

Examples

Embodiment 2

[0016] Potassium permanganate 2%, cerium sulfate 50%, hydrochloric acid 11%, ammonium chloride 8%, distilled water.

Embodiment 3

[0018] Potassium permanganate 6%, cerium sulfate 40%, hydrochloric acid 7%, ammonium chloride 10%, distilled water.

[0019] The above three examples represent the prepared corrosive solutions, all of which can meet the requirements of the present invention, and can produce qualified nickel-chromium alloy thin film patterned products, and other examples within the range of proportions will not be listed one by one.

[0020] In process B, examples of the temperature of the corrosive liquid in the beaker are kept at 40°C, 45°C, 50°C, 60°C, 70°C, 80°C, and 90°C, all of which can meet the needs of the present invention and can produce qualified nickel-chromium Alloy thin film patterned products.

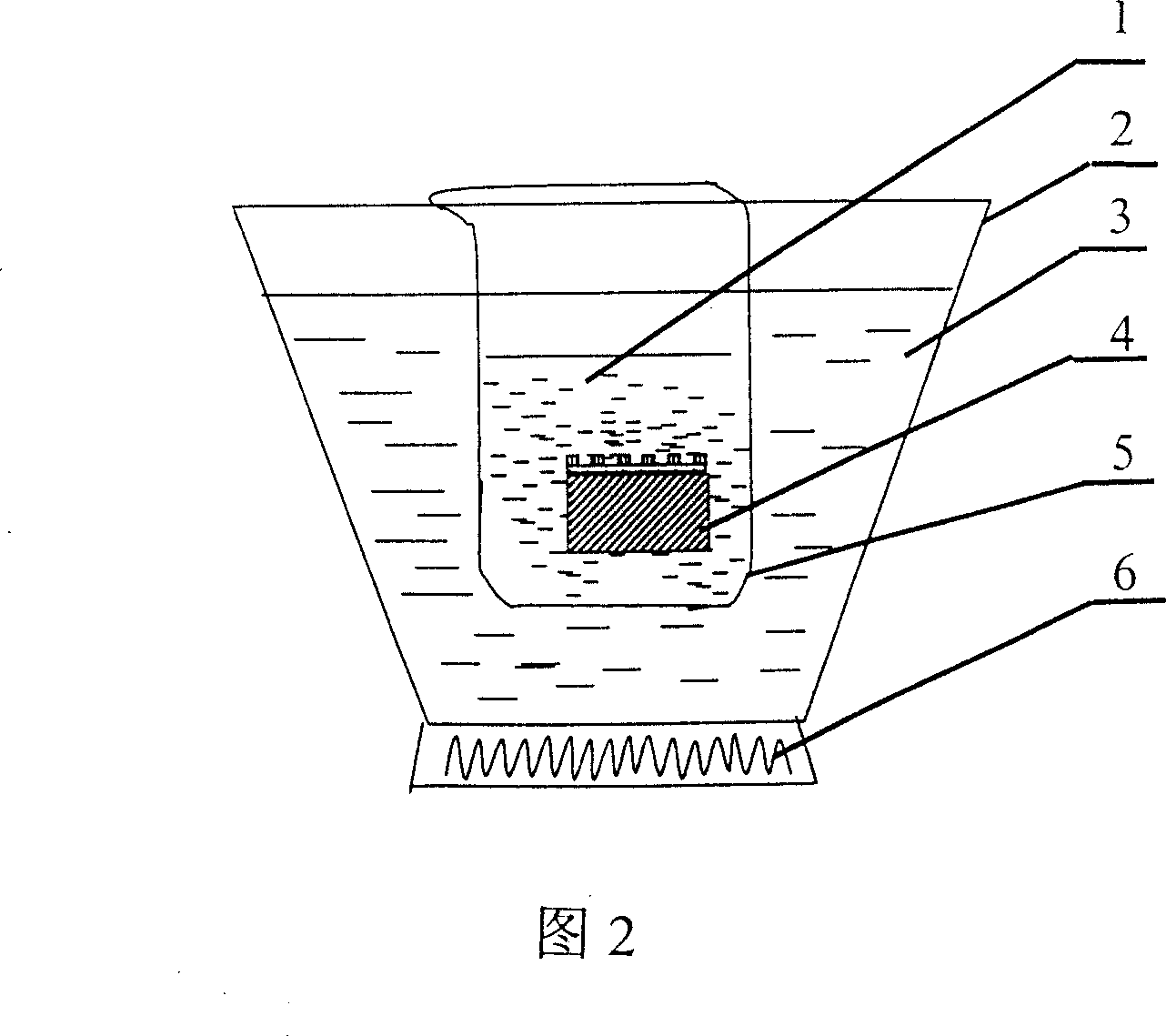

[0021] With reference to Fig. 2, the nickel-chromium alloy film corrosion system of the present invention is made up of: corrosion solution 1, water bath 2, warm water 3, the silicon wafer 4 that has nickel-chromium alloy film long, beaker 5, electric furnace 6.

[0022] Potassium perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com