Etching solution for use in wet etching of bismuth-based thin films

A wet etching and etching solution technology, applied in the field of materials, can solve problems such as difficulty in etching bismuth-based thin film materials, inability to guarantee pattern accuracy, etc., and achieve the effect of effective control of pattern precision, clear pattern and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

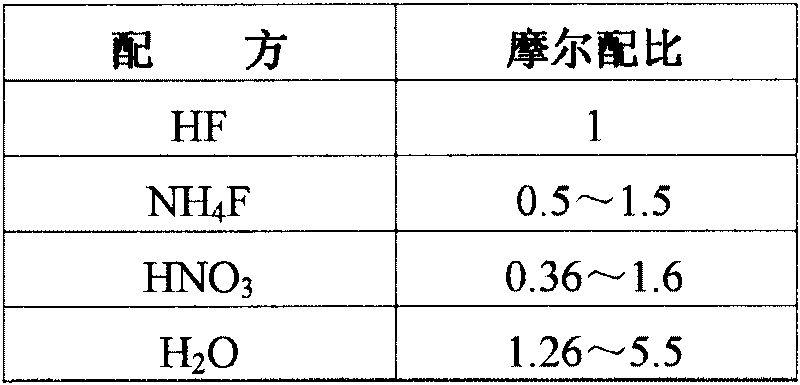

[0034] The chemicals used in this method include but are not limited to the following raw materials: concentrated hydrofluoric acid (analytical pure, ≥40%), concentrated nitric acid (analytical pure, 65~68%), ammonium fluoride crystals (analytical pure, ≥98%), Deionized water.

[0035] 1) First weigh an appropriate amount of HF (analytical pure) solution with a plastic measuring cylinder and pour it into a plastic beaker, then weigh the required amount of deionized water in the formula and pour it into the beaker together. Stir the solution well with a plastic stick.

[0036] 2) Weigh NH with an electronic balance 4 F (analytical pure), the weighed NH4F is added in the HF aqueous solution, and it is fully dissolved.

[0037] 3) Weigh the required amount of nitric acid (concentration: 65-68%) with a glass calciner and add the prepared HF, NH 4 F aqueous solution.

[0038] 4) Putting the prepared substrate into the etching solution for etching.

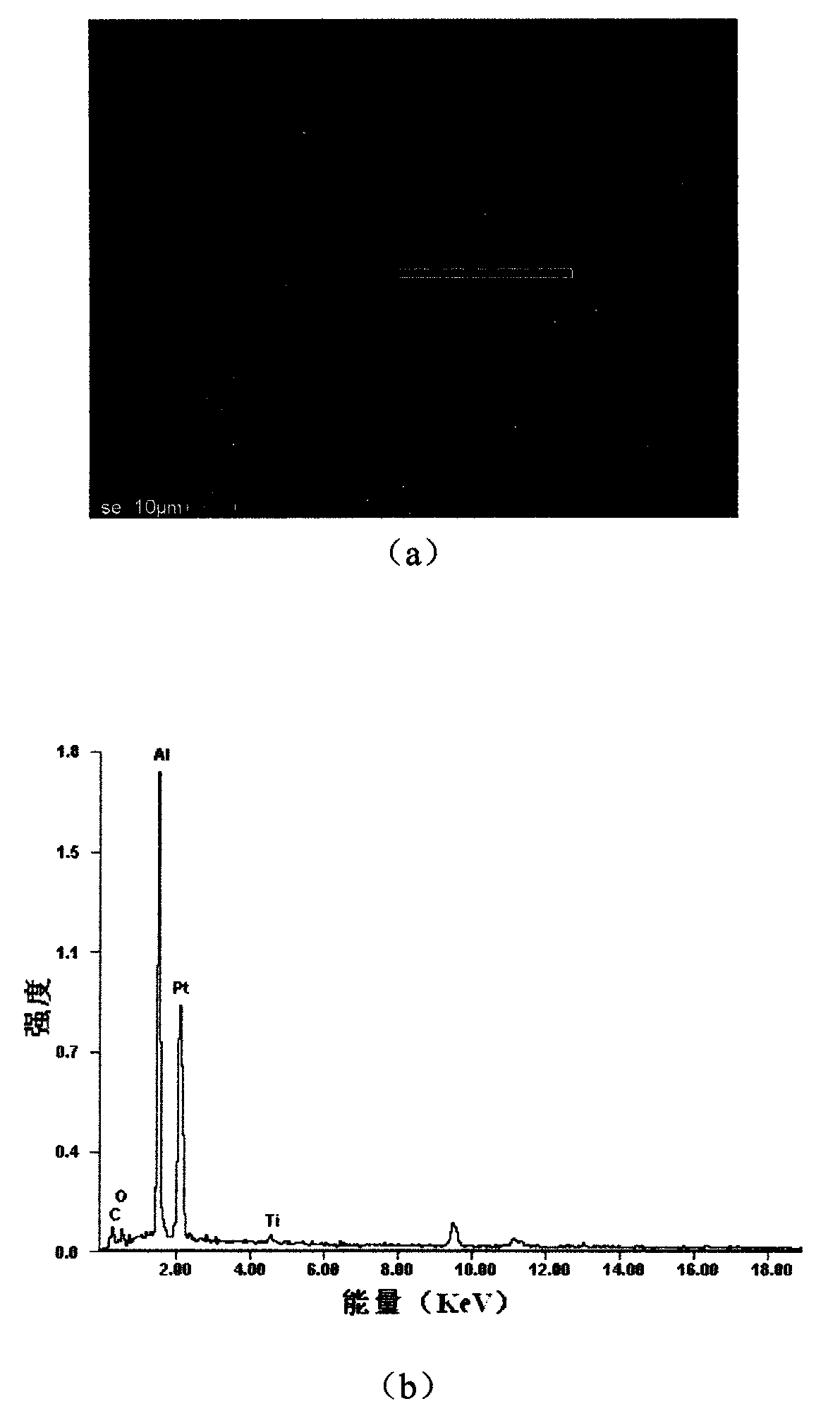

[0039] The specific experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com