Preparation method of Sb2S3 nanowire

A nanowire and solution technology, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve the problems of high cost, complicated preparation method operation, long reaction cycle, etc., and achieve low cost, simple preparation method, and short reaction cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 10mmol of Sb 2 Cl 3 , Pour it into 2ml of ethylene glycol, stir with a stirrer until Sb 2 Cl 3 Dissolve completely; then, pour 10ml of deionized water into it while stirring to form a white emulsion A;

[0020] (2) Weigh 15mmol of Na 2 S·9H 2 O is dissolved in 10ml of deionized water to form solution B;

[0021] (3) Drop solution B into solution A at a rate of 2 drops / sec to form an orange-red precursor;

[0022] (4) Add CO(NH 2 ) 2 , Make up 30ml solution C;

[0023] (5) Place solution C in a 50ml reaction kettle, place the reaction kettle in a thermostat to heat, and when the temperature rises to 240°C, keep it for 12 hours. After the reaction, rinse the product with deionized water until the pH is 7. Then dry in a vacuum oven at 80℃ for 4h to obtain Sb 2 S 3 Nanowires.

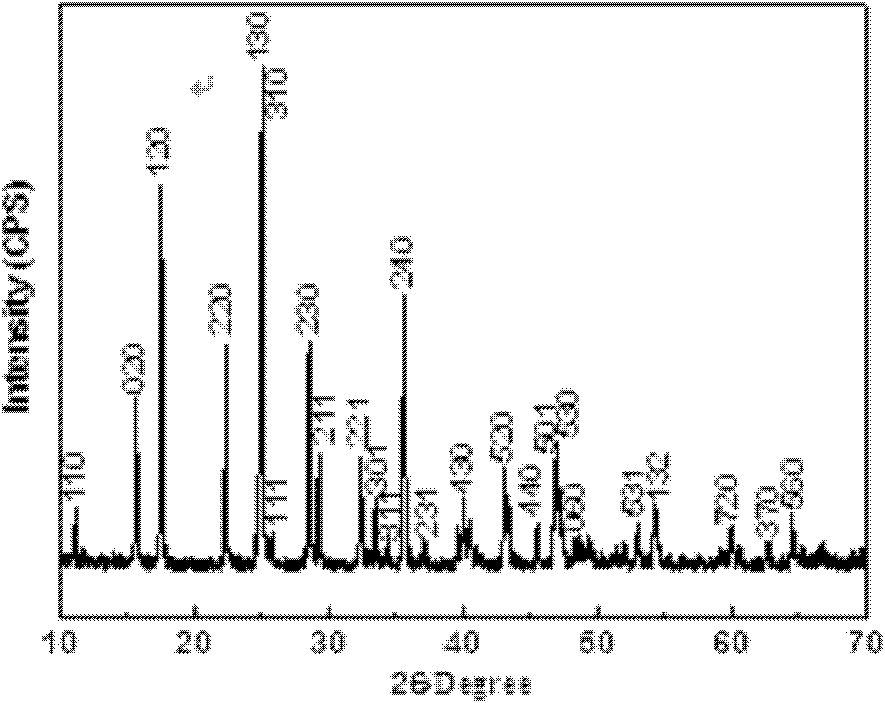

[0024] The obtained product was analyzed by Rigaku D / max2550VB+ / PC X-ray diffractometer, and figure 1 It can be seen that all the diffraction peaks correspond to the standard card (JCPDS-42-1393, a=...

Embodiment 2

[0027] (1) Weigh 10mmol of Sb 2 Cl 3 , Pour it into 2ml of ethylene glycol, stir with a stirrer until Sb 2 Cl 3 Dissolve completely; then, pour 10ml of deionized water into it while stirring to form a white emulsion A;

[0028] (2) Weigh 15mmol of Na 2 S·9H 2 O is dissolved in 10ml of deionized water to form solution B;

[0029] (3) Drop solution B into solution A at a rate of 2 drops / sec to form an orange-red precursor (;

[0030] (4) Add CO(NH 2 ) 2 , Make up 30ml solution C;

[0031] (5) Place solution C in a 50ml reaction kettle, heat the reaction kettle in a thermostat, and keep it warm for 8 hours when the temperature rises to 240°C. After the reaction is over, rinse the product with deionized water until the pH is 7. Then dry in a vacuum oven at 80℃ for 4h to obtain Sb 2 S 3 Nanowires.

Embodiment 3

[0033] (1) Weigh 10mmol of Sb 2 Cl 3 , Pour it into 2ml of ethylene glycol, stir with a stirrer until Sb 2 Cl 3 Dissolve completely; then, pour 10ml of deionized water into it while stirring to form a white emulsion A;

[0034] (2) Weigh 15mmol of Na 2 S·9H 2 O was dissolved in 10ml of deionized water to form solution B; (3) Solution B was dropped into solution A at a rate of 2 drops / sec to form an orange-red precursor;

[0035] (4) Add CO(NH 2 ) 2 , Make up 30ml solution C;

[0036] (5) Place solution C in a 50ml reaction kettle, place the reaction kettle in a thermostat for heating, and when the temperature rises to 240°C, keep it for 12 hours. After the reaction is over, rinse the product with deionized water until the pH is 7. Then dry it in a vacuum oven at 80℃ for 4h to obtain Sb 2 S 3 Nanowires.

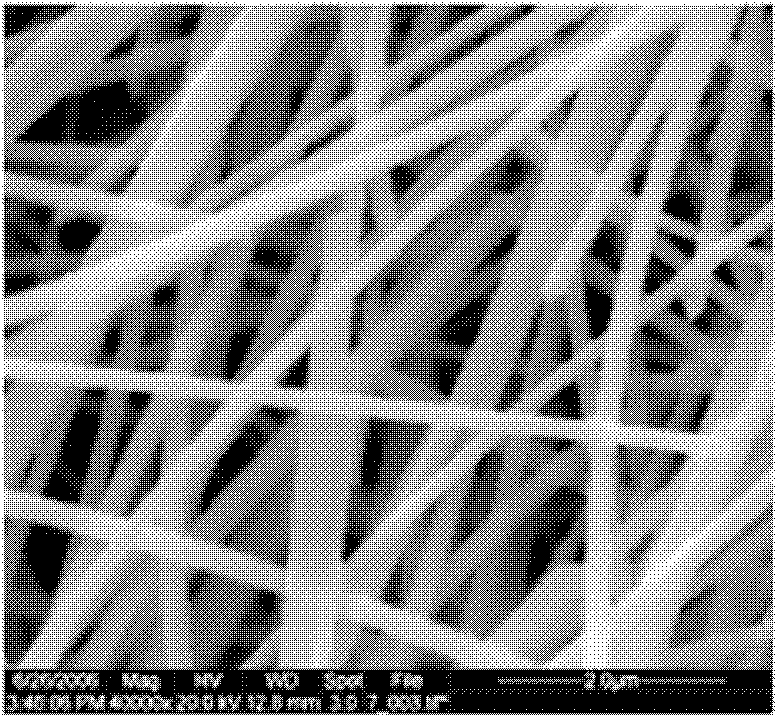

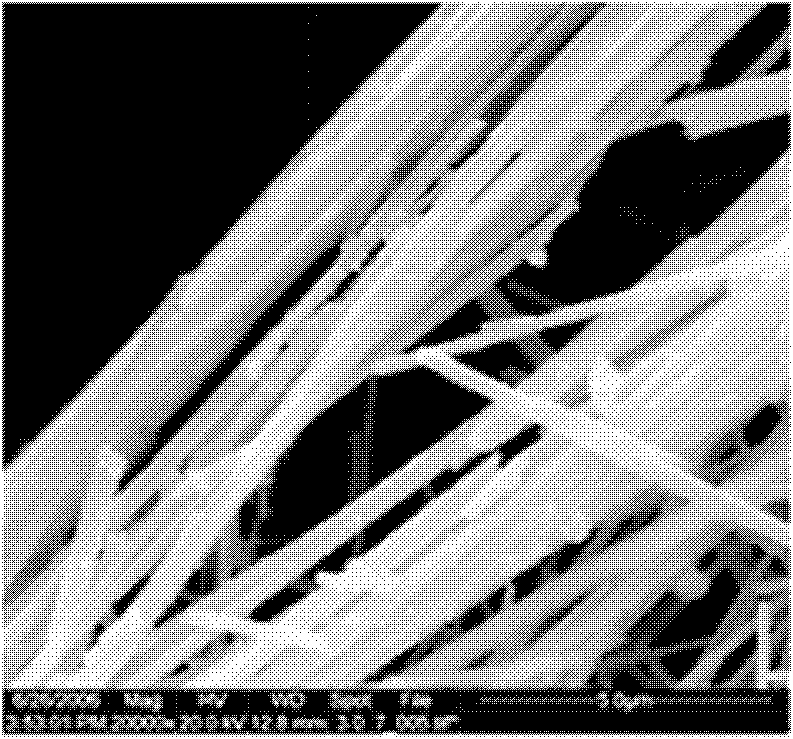

[0037] See Figure 3 to Figure 6 As shown, the Sb obtained by this method 2 S 3 The diameter of the nanowire is about 200nm, the length is 20μm, and it grows along the [001] crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com