Patents

Literature

33results about How to "Uniform inner diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

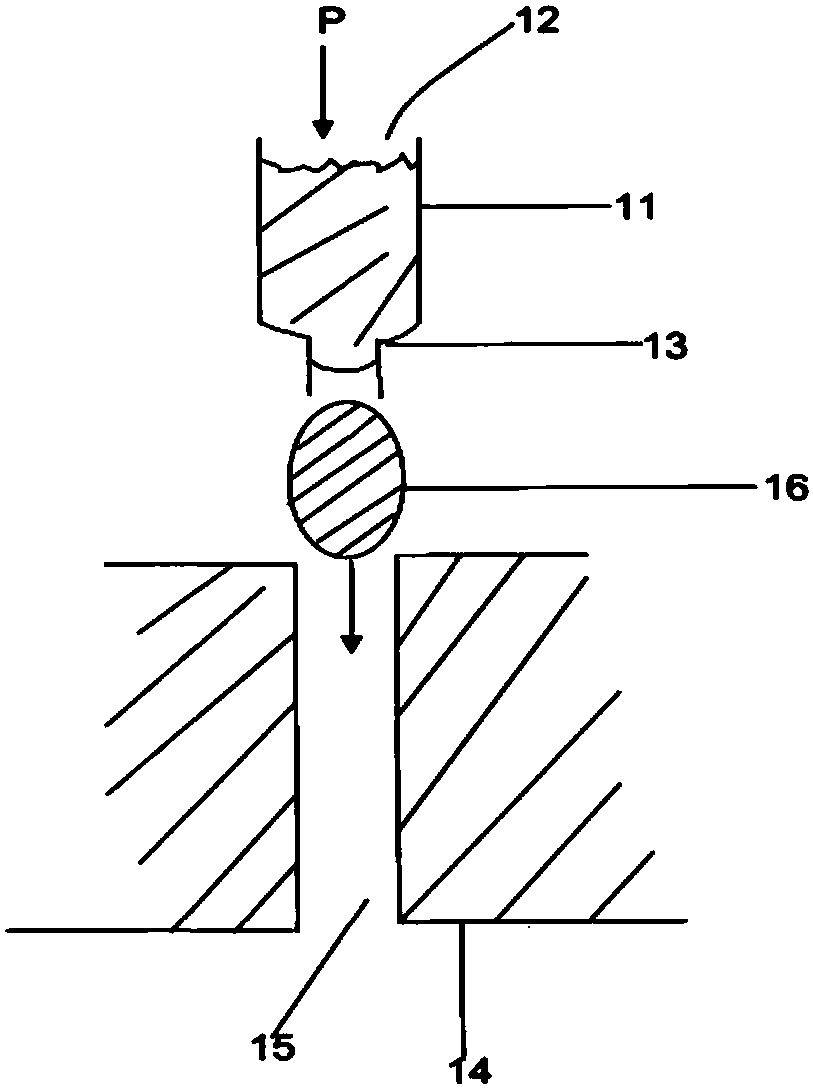

Method of manufacturing hollow body

ActiveUS20120068388A1Uniform inner diameterUniform thicknessTubular articlesHollow articlesMaterials scienceSurface smoothness

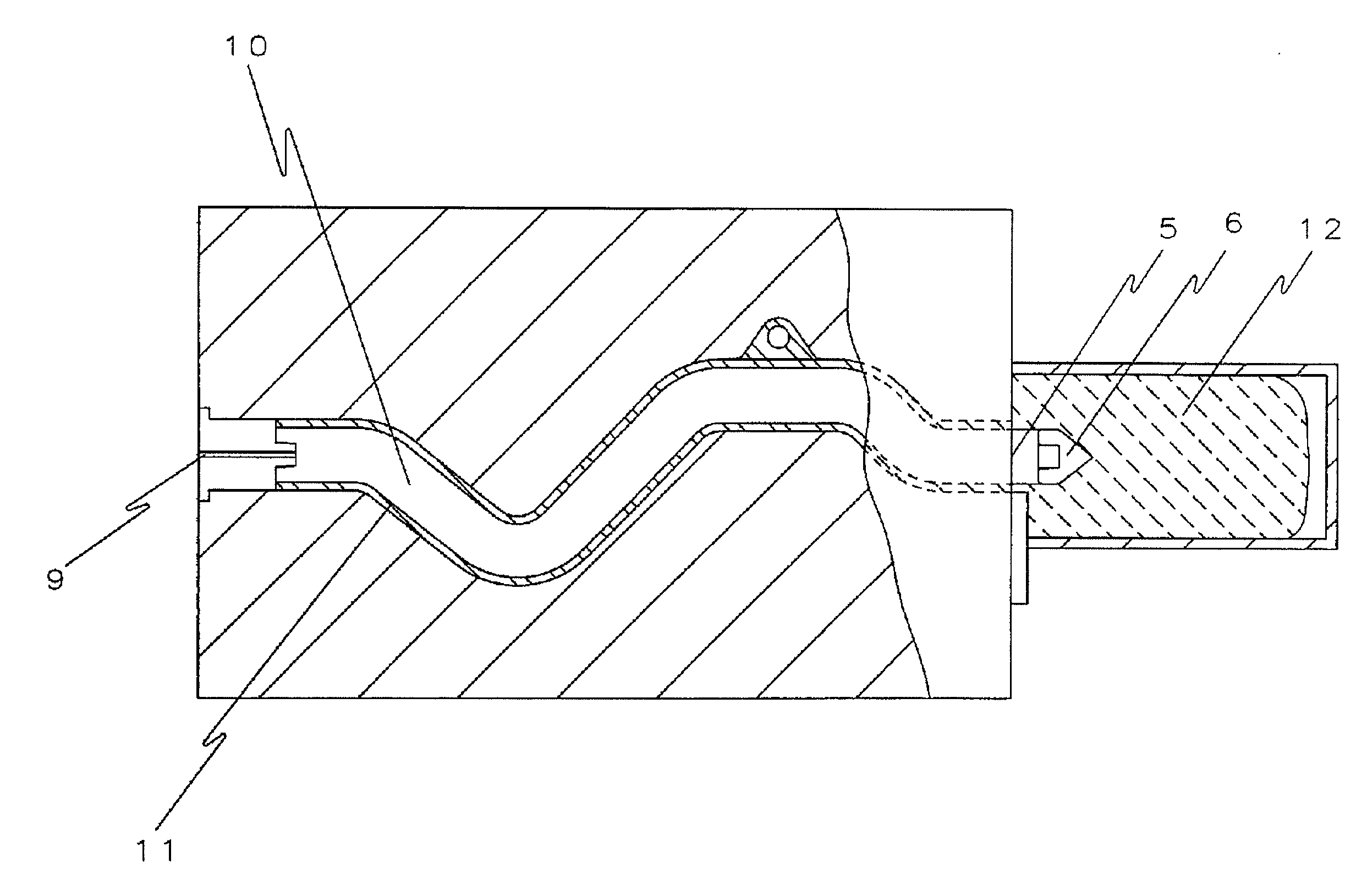

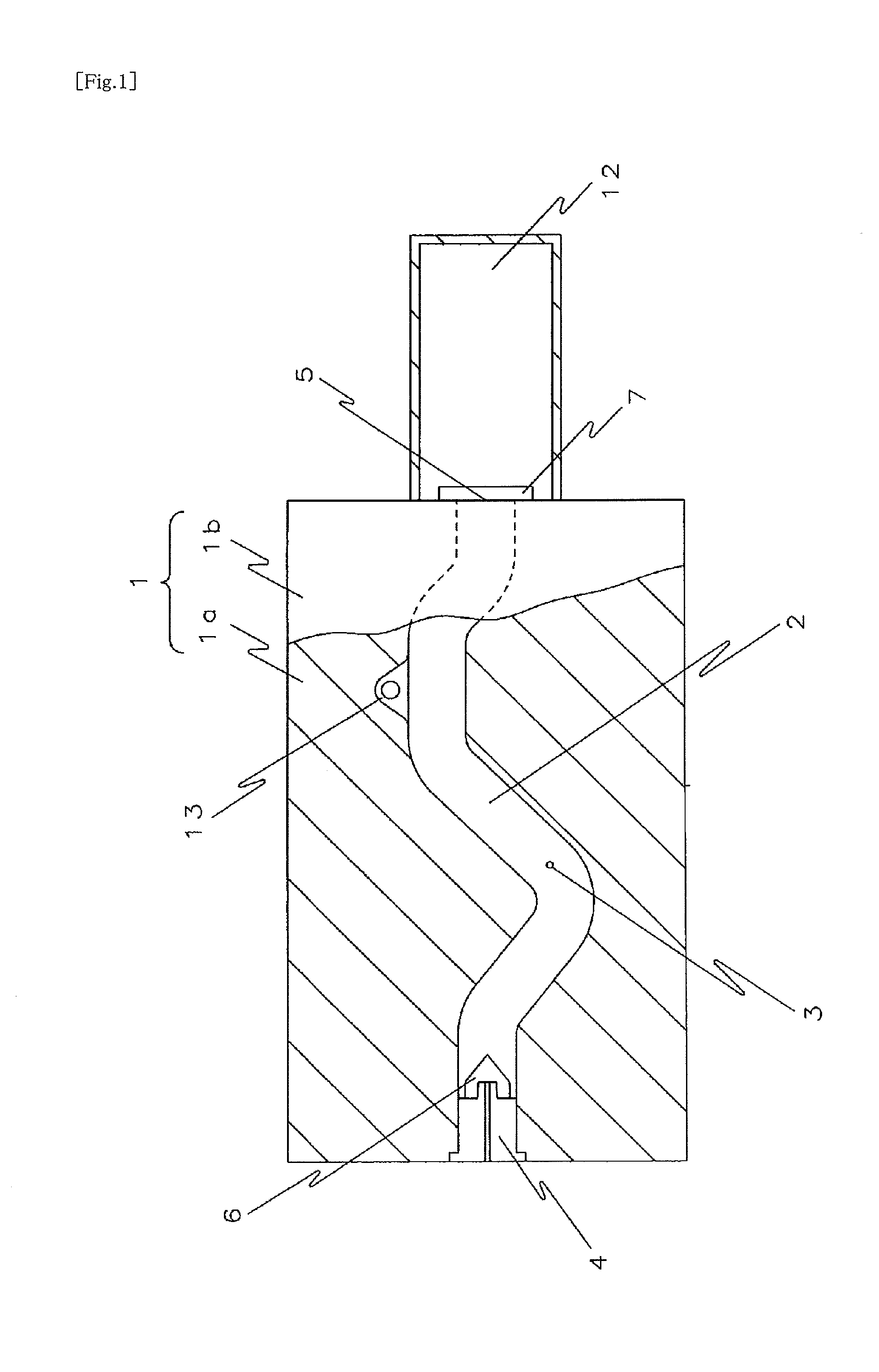

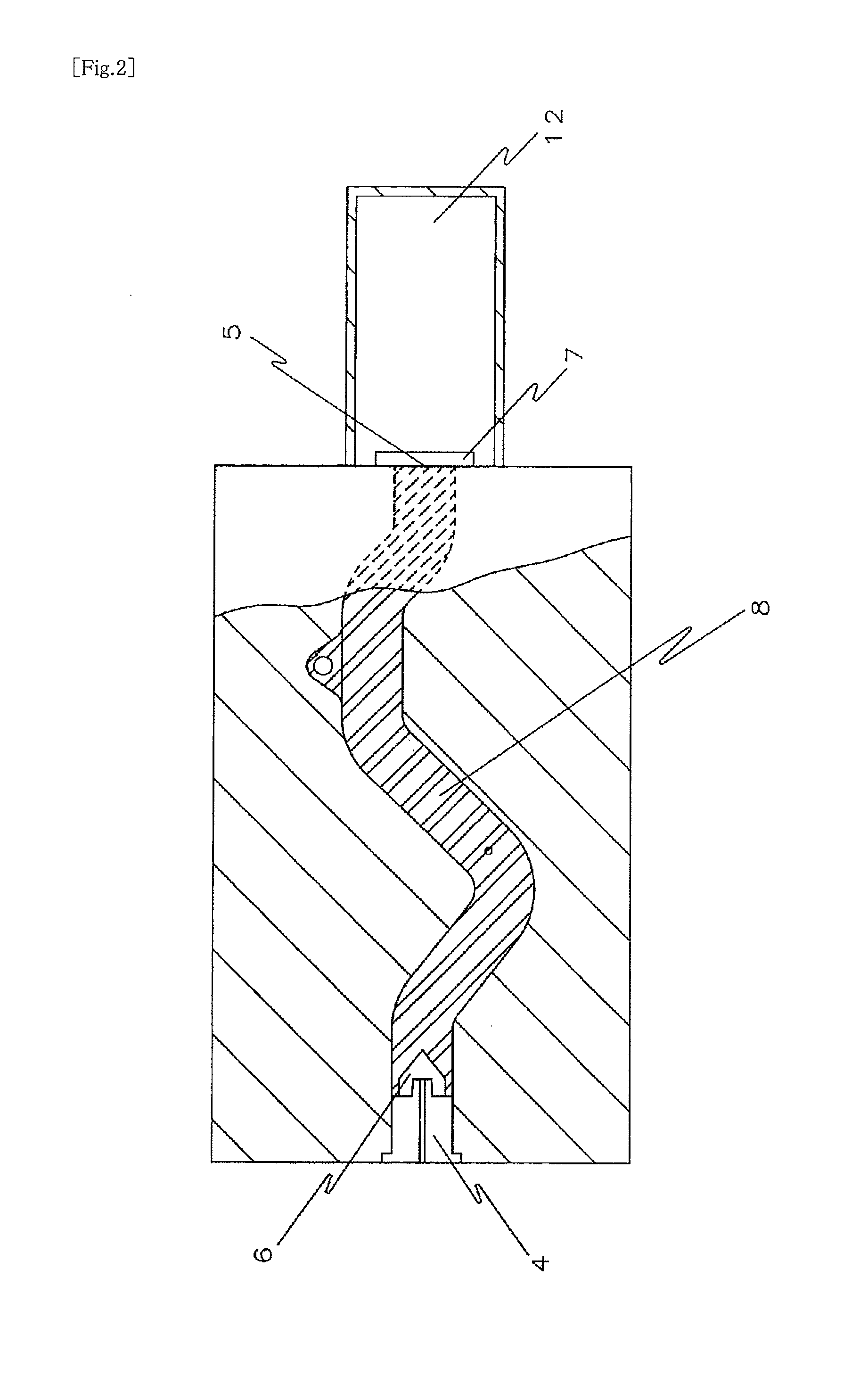

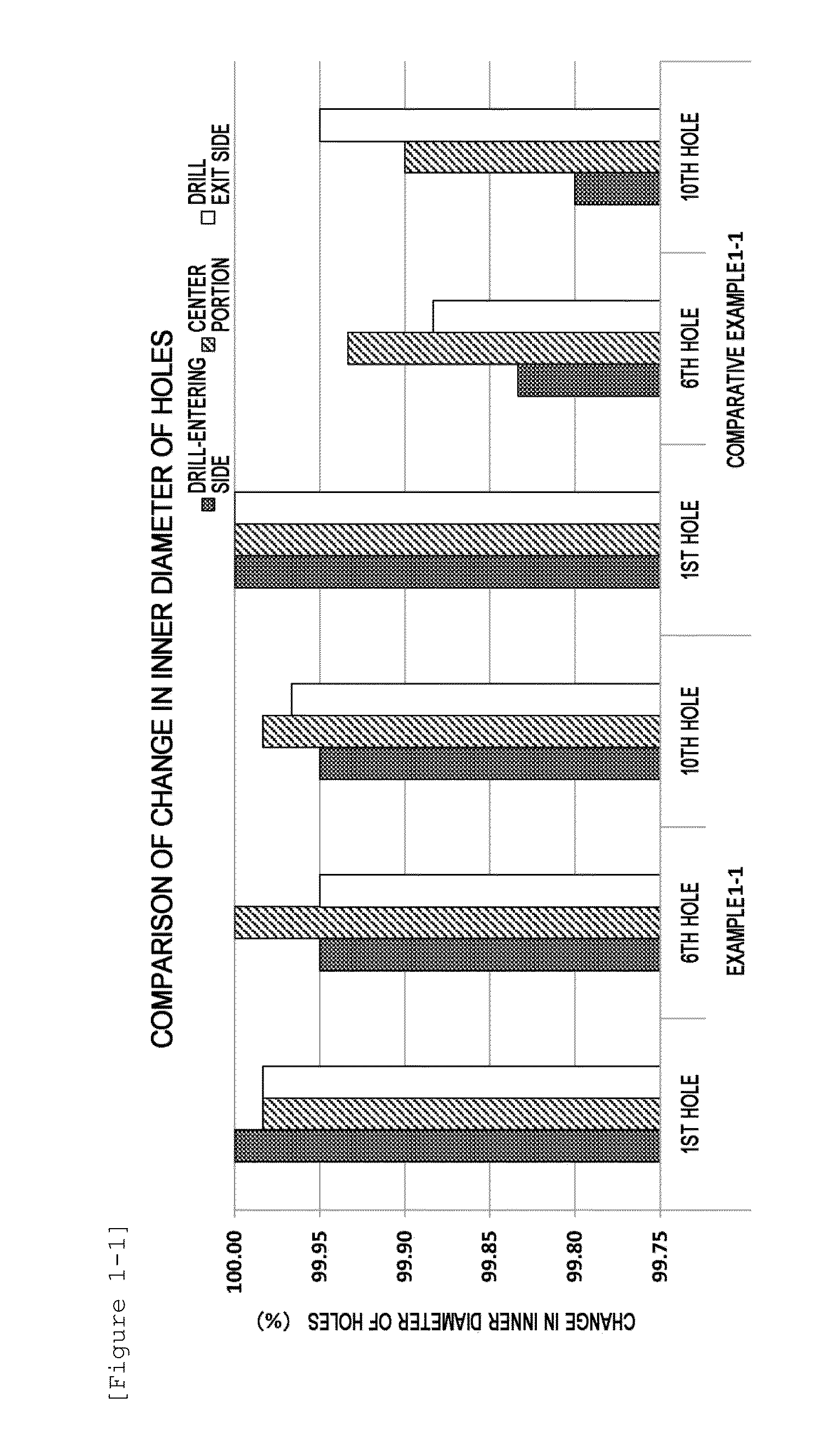

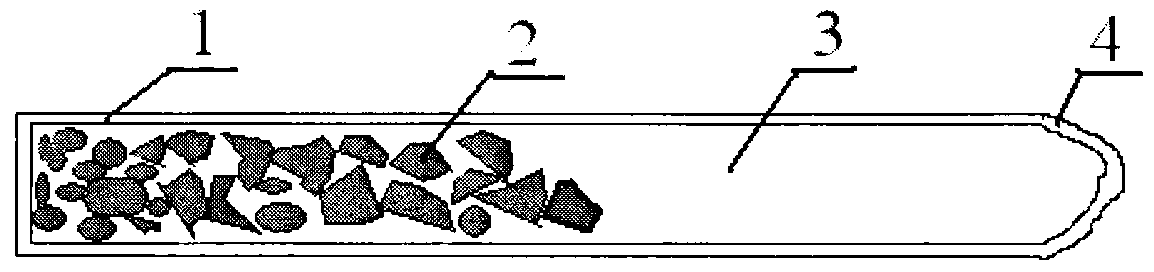

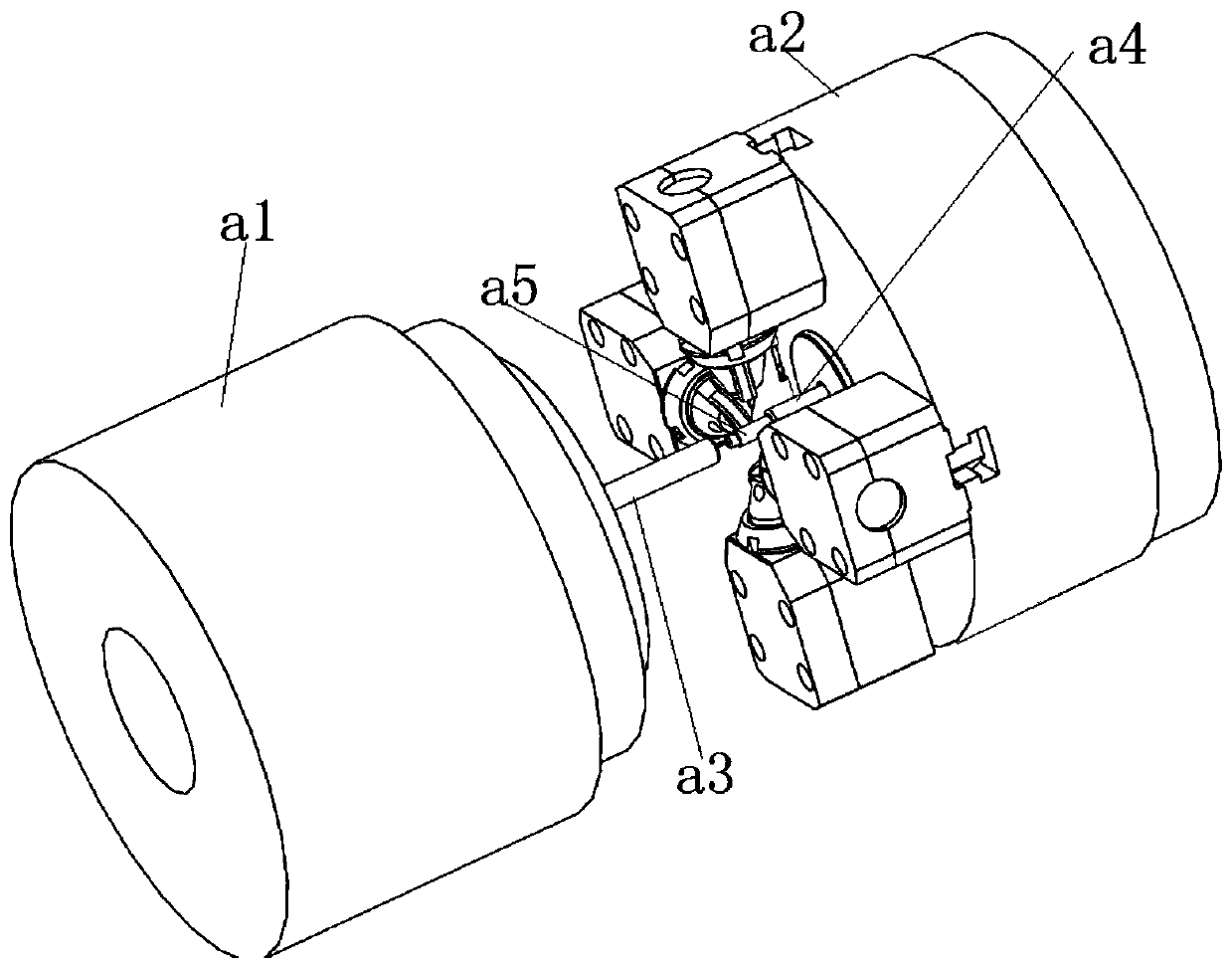

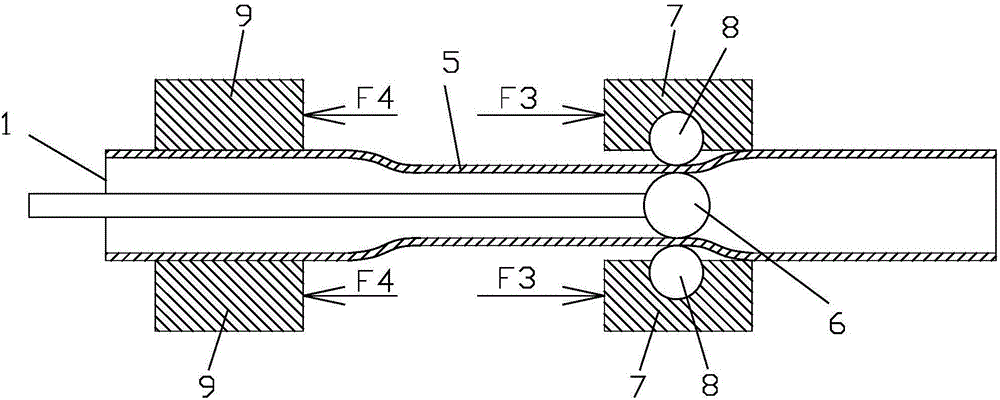

A hollow body formed of a thermoplastic resin and having uniform inner diameter and thickness and an excellent inner surface smoothness, and, in particular, a pipe-shaped hollow body having a bent portion is manufactured by injection molding.A method of manufacturing a hollow body includes injecting a molten resin 8 into a mold cavity 2 of a mold 1, the mold cavity 2 having on its one end a pressure port 4 provided with a floating core 6 and on its other end an outlet 5, pressure-injecting a pressurized fluid through the pressure port 4 after the injection of the molten resin 8, and moving the floating core 6 toward the outlet 5, and, at the same time, extruding the molten resin 8 from the outlet 5. In the method, the floating core 6 is constituted of a columnar portion and a top portion, which is continuously connected to one surface of the columnar portion and has a shape that a cross-sectional area perpendicular to a central axis of the columnar portion gradually decreases from one surface side of the columnar portion. When a diameter of the columnar portion is represented by A, the height of the columnar portion is 0.1 A to 1 A, and the height of the top portion is 0.3 A to 1.6 A.

Owner:RP TOPLA

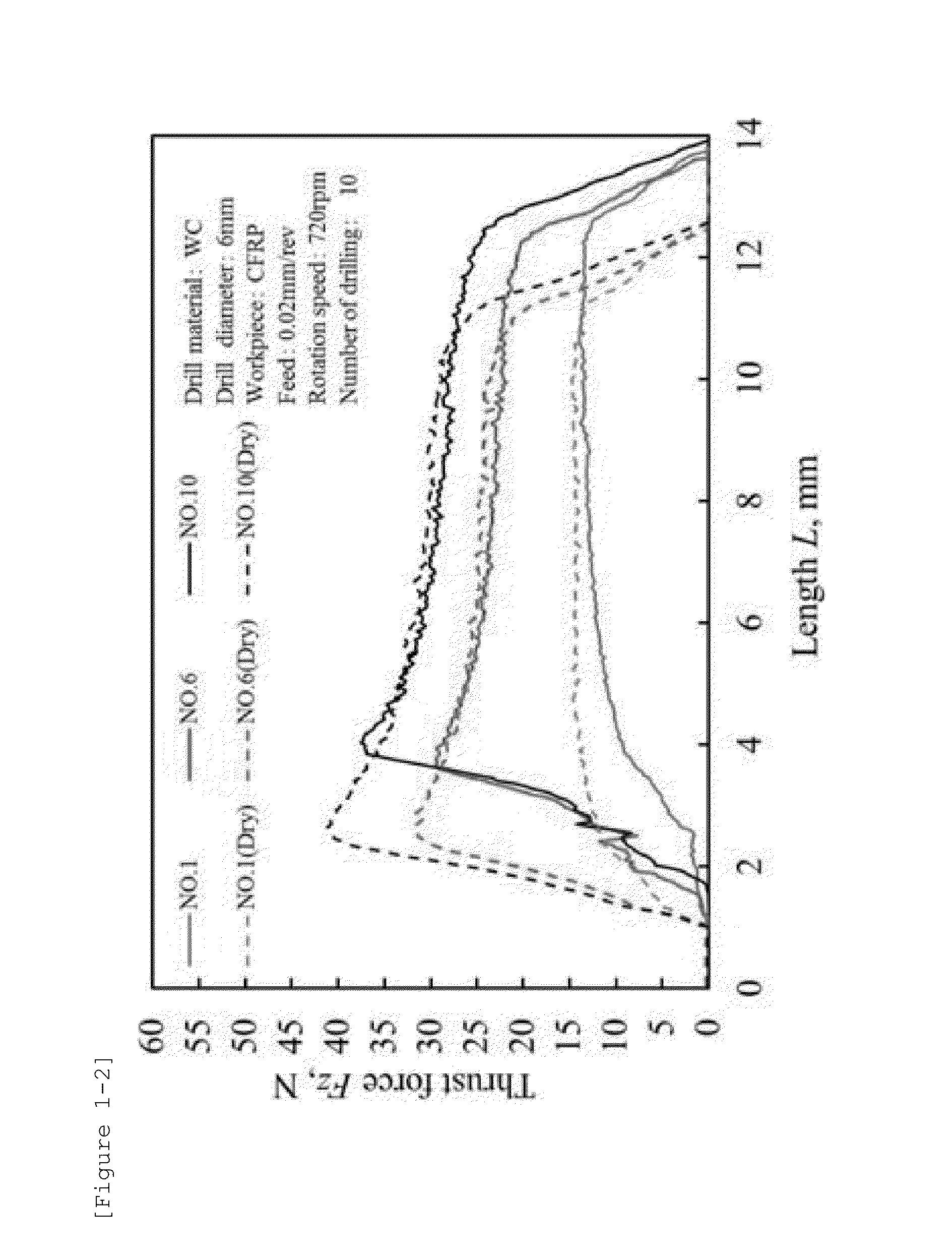

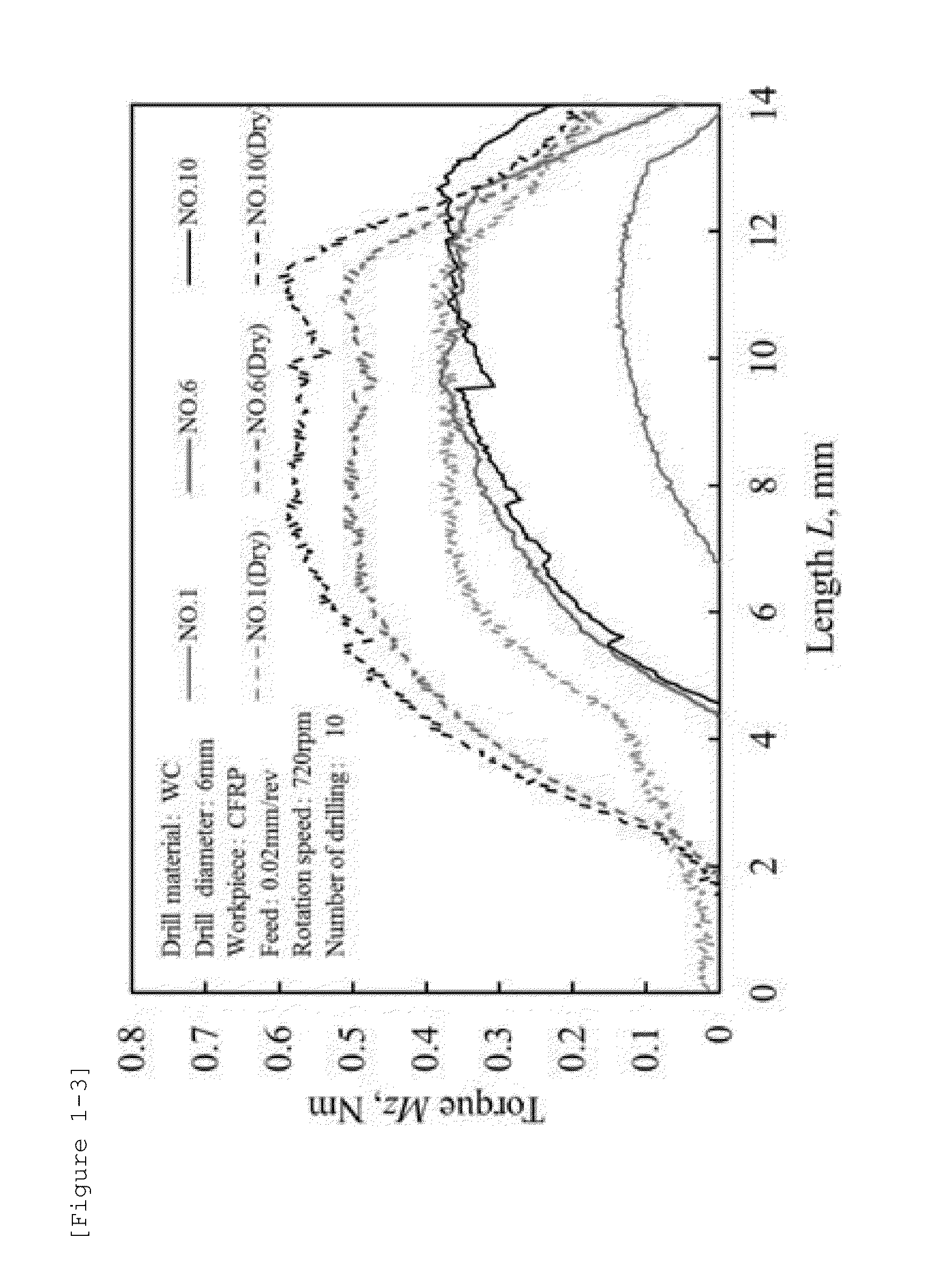

Entry sheet for cutting fiber reinforced composite material or metal, and cutting method for cutting fiber reinforced material or metal

InactiveUS20160045961A1Inhibit wearIncrease production capacityAircraft componentsSynthetic resin layered productsFiber-reinforced compositeMaterials science

An entry sheet of the present invention is used in cutting a fiber reinforced composite material and / or a metal. Moreover, in a cutting method of the present invention, cutting of a fiber reinforced composite material and / or a metal is performed using the entry sheet.

Owner:MITSUBISHI GAS CHEM CO INC

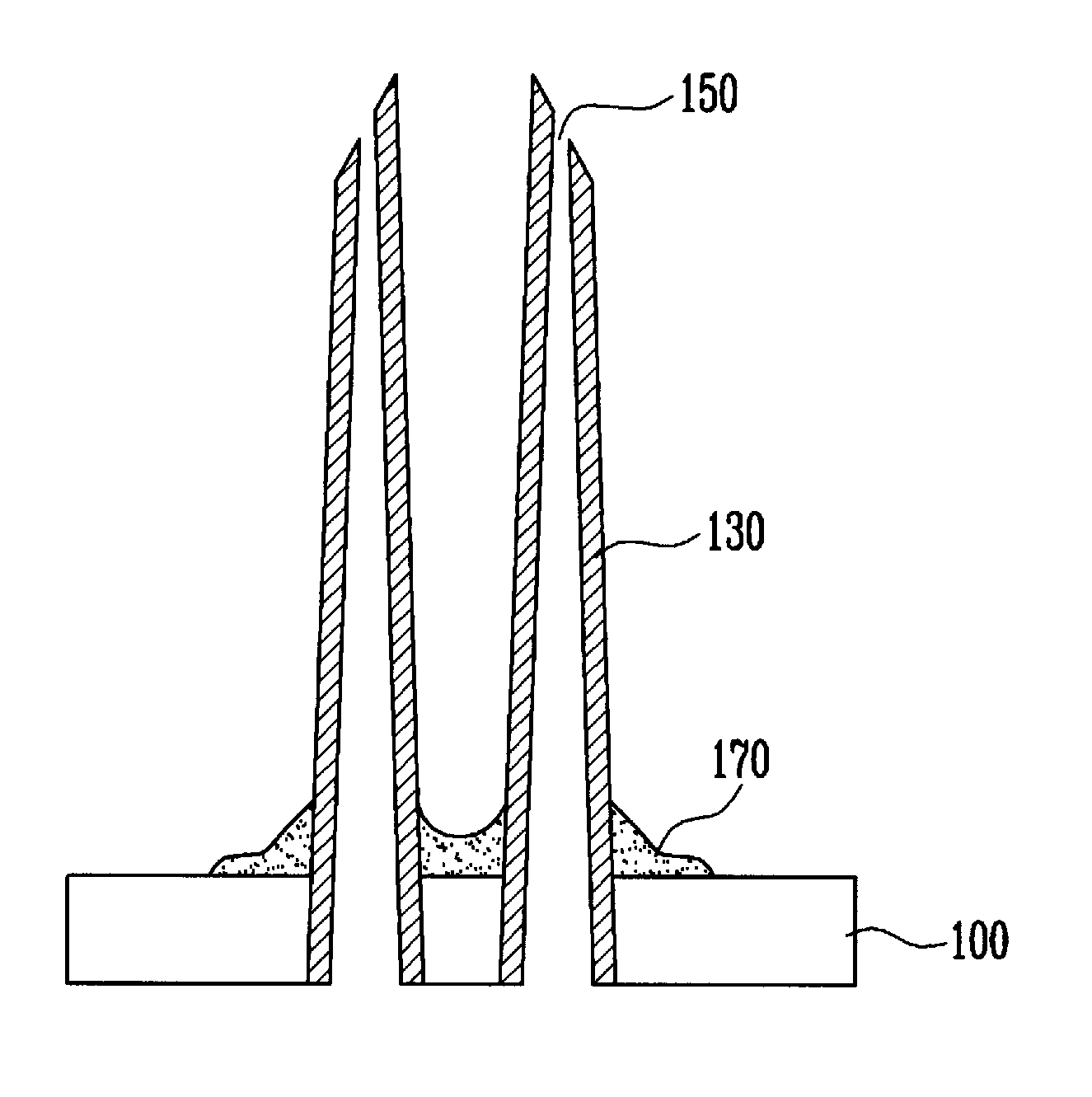

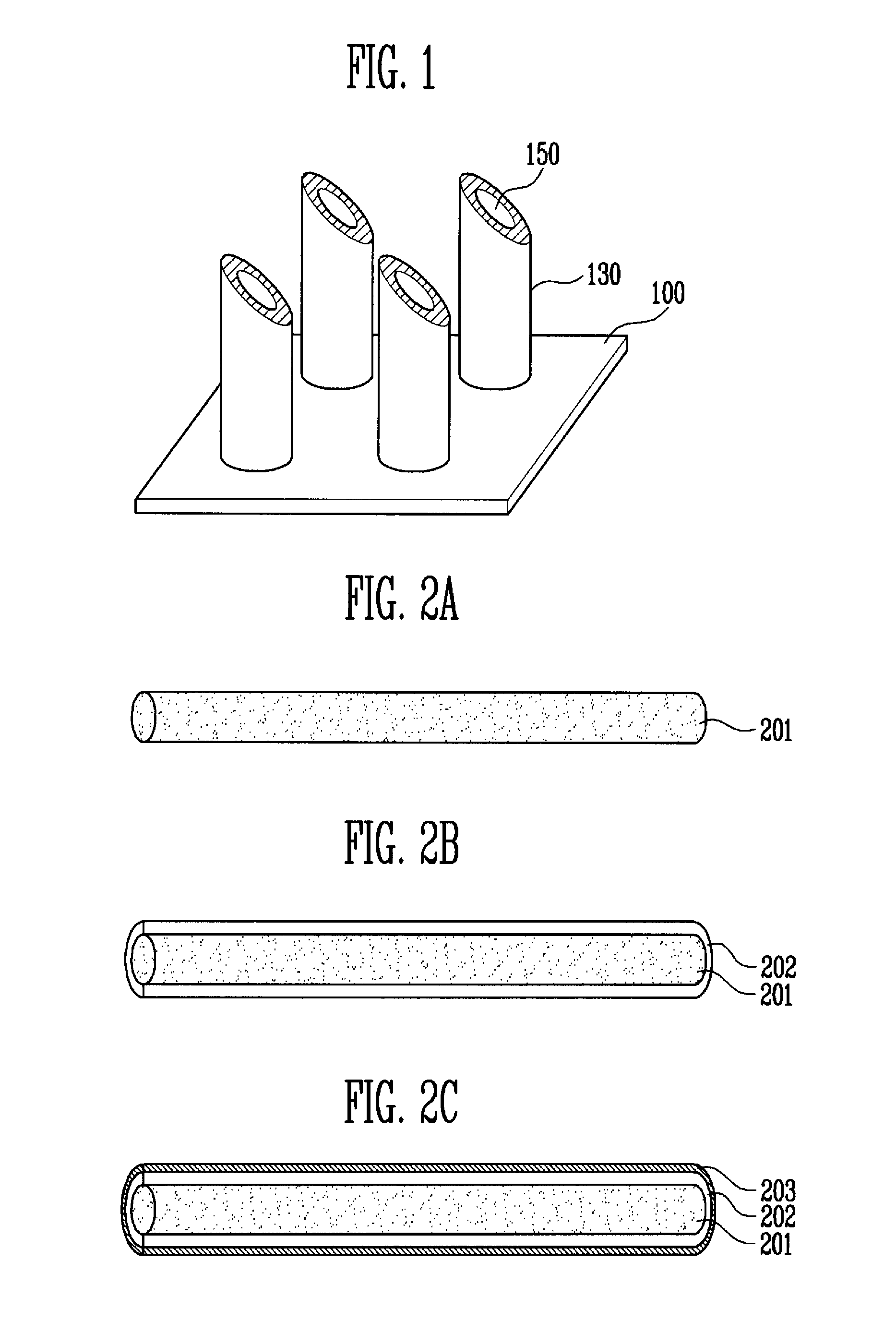

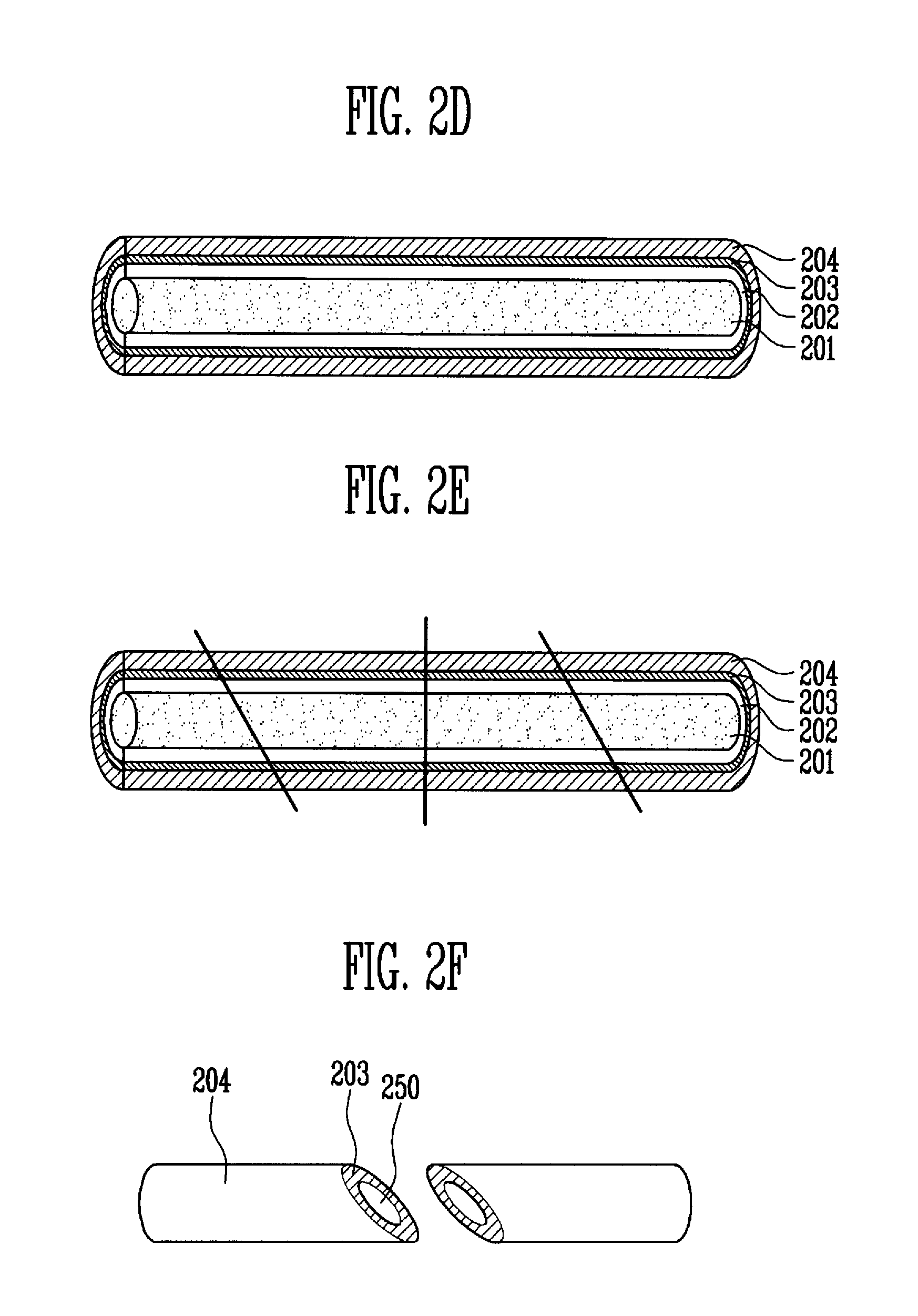

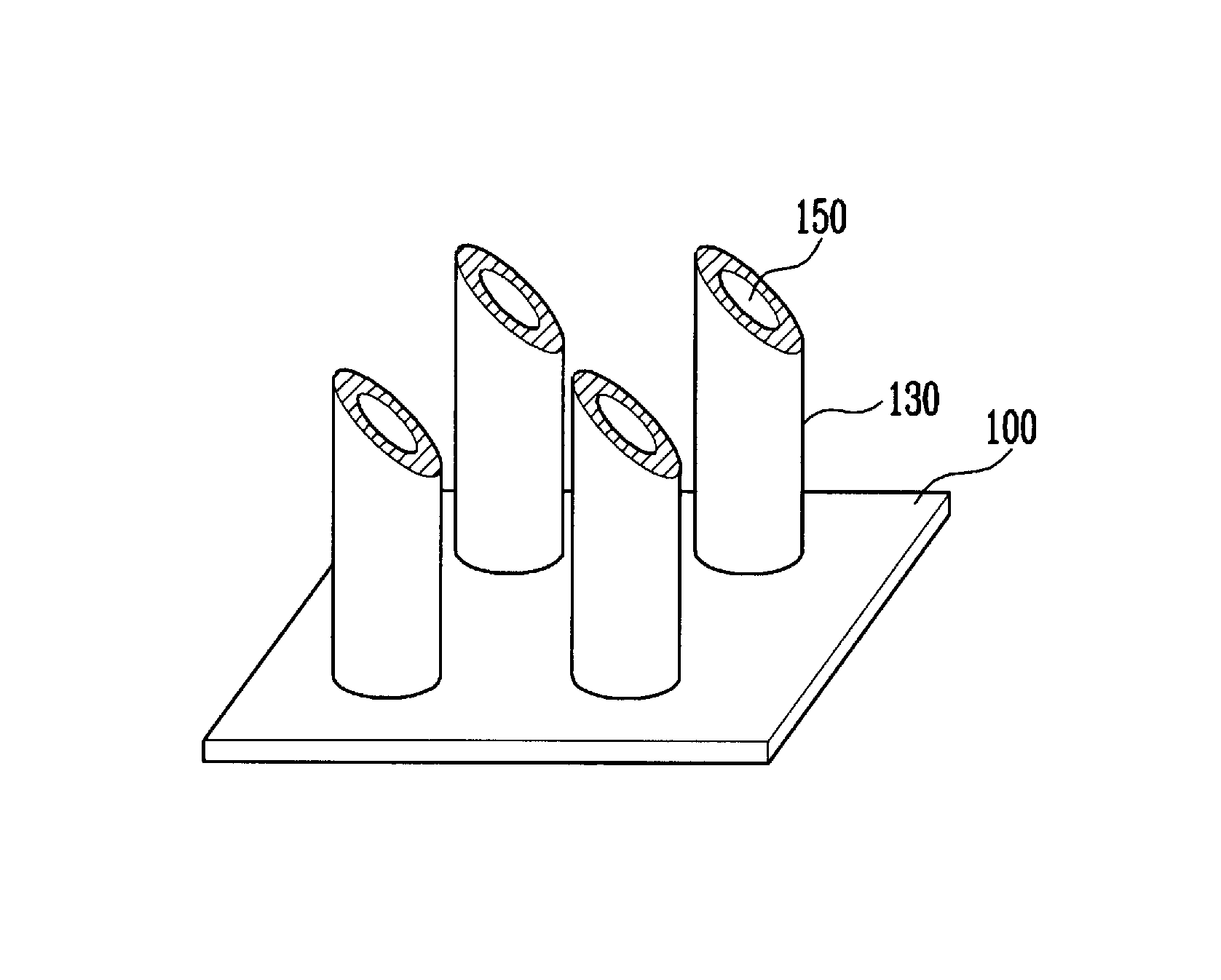

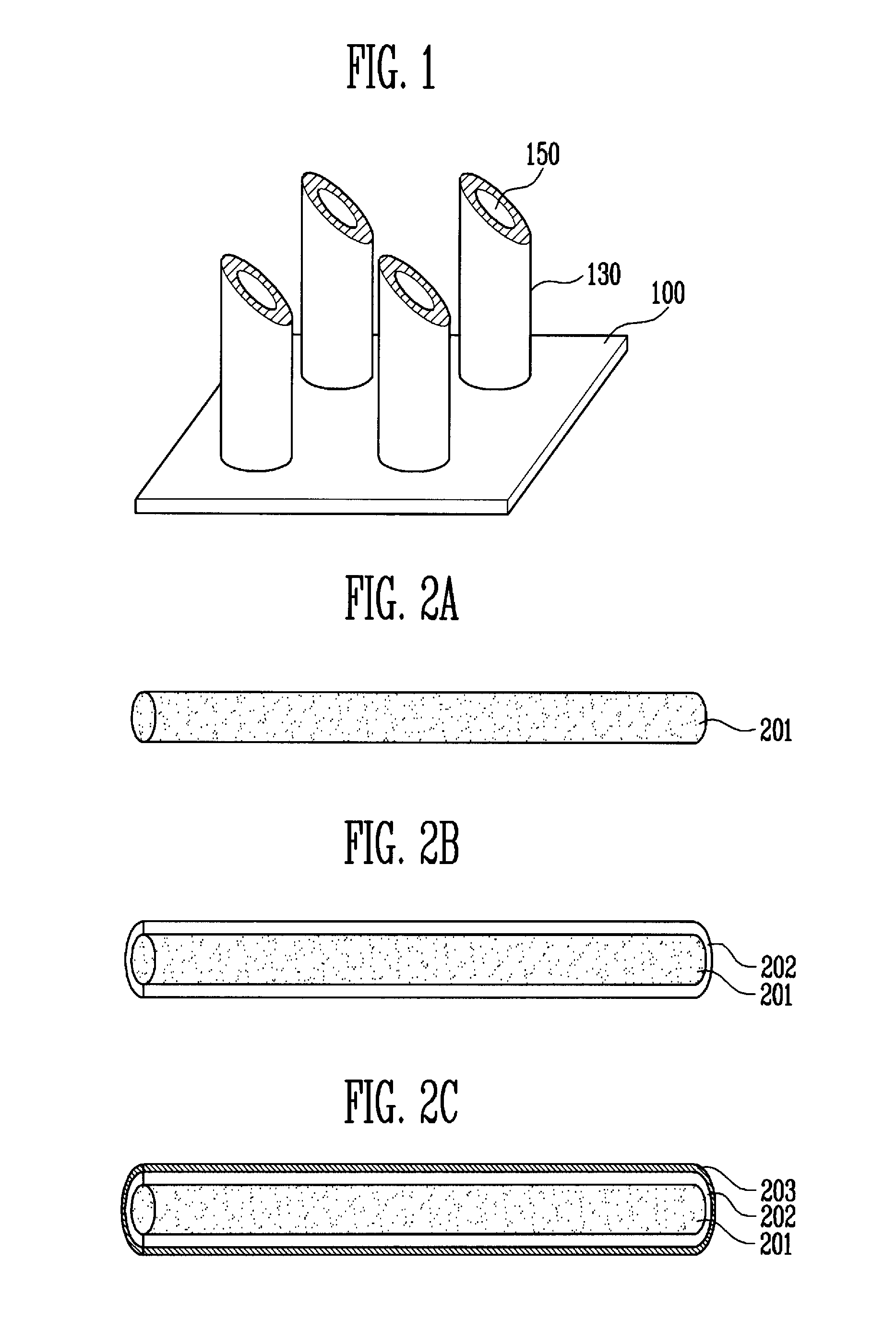

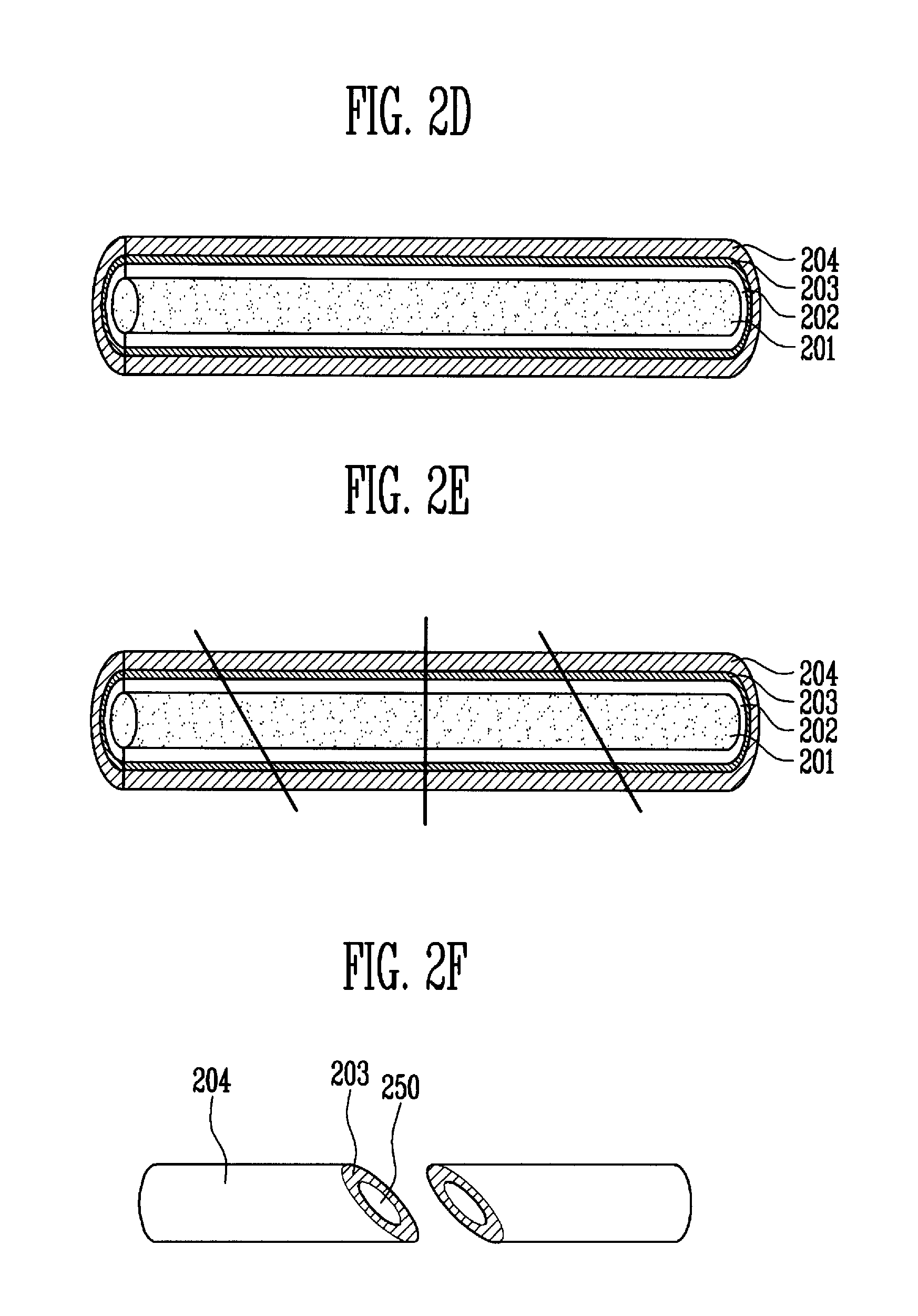

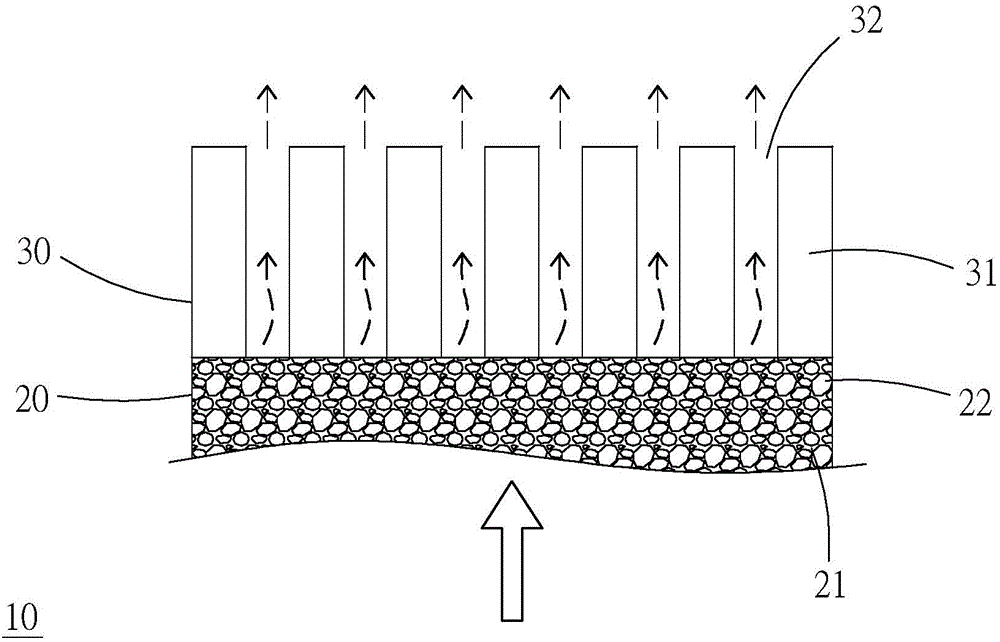

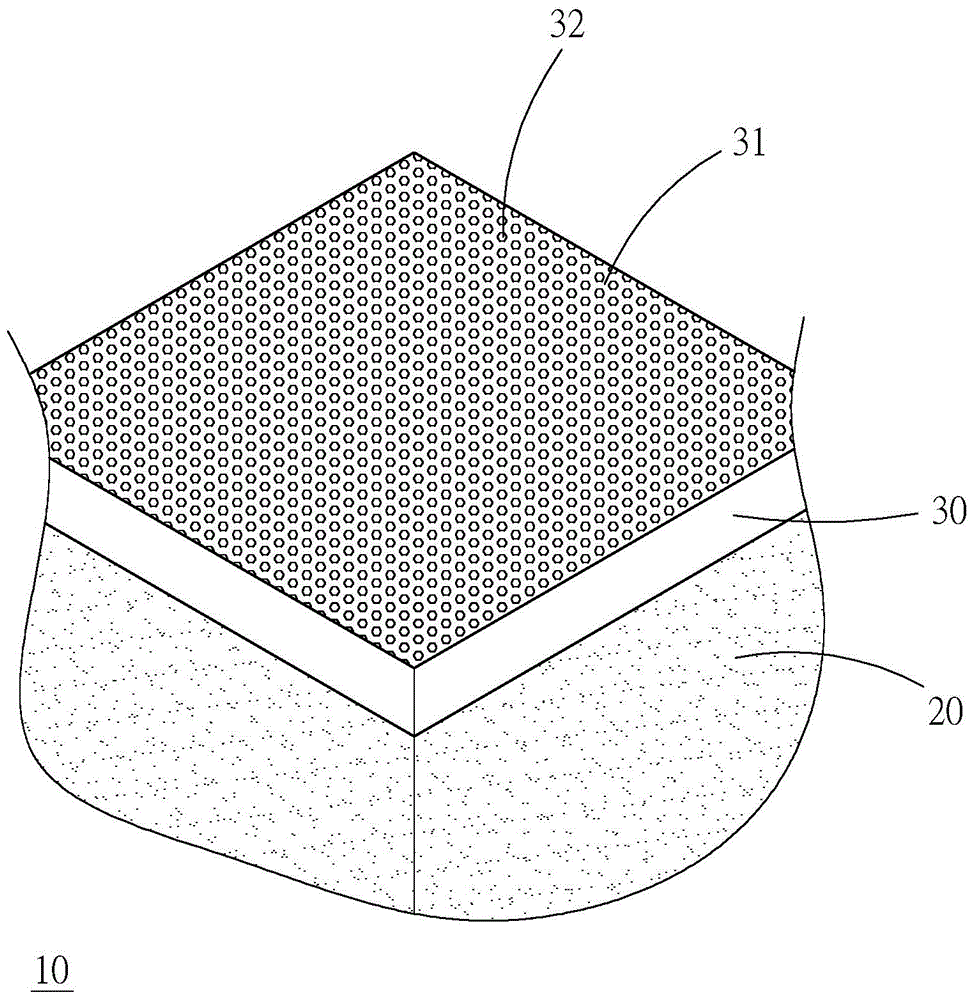

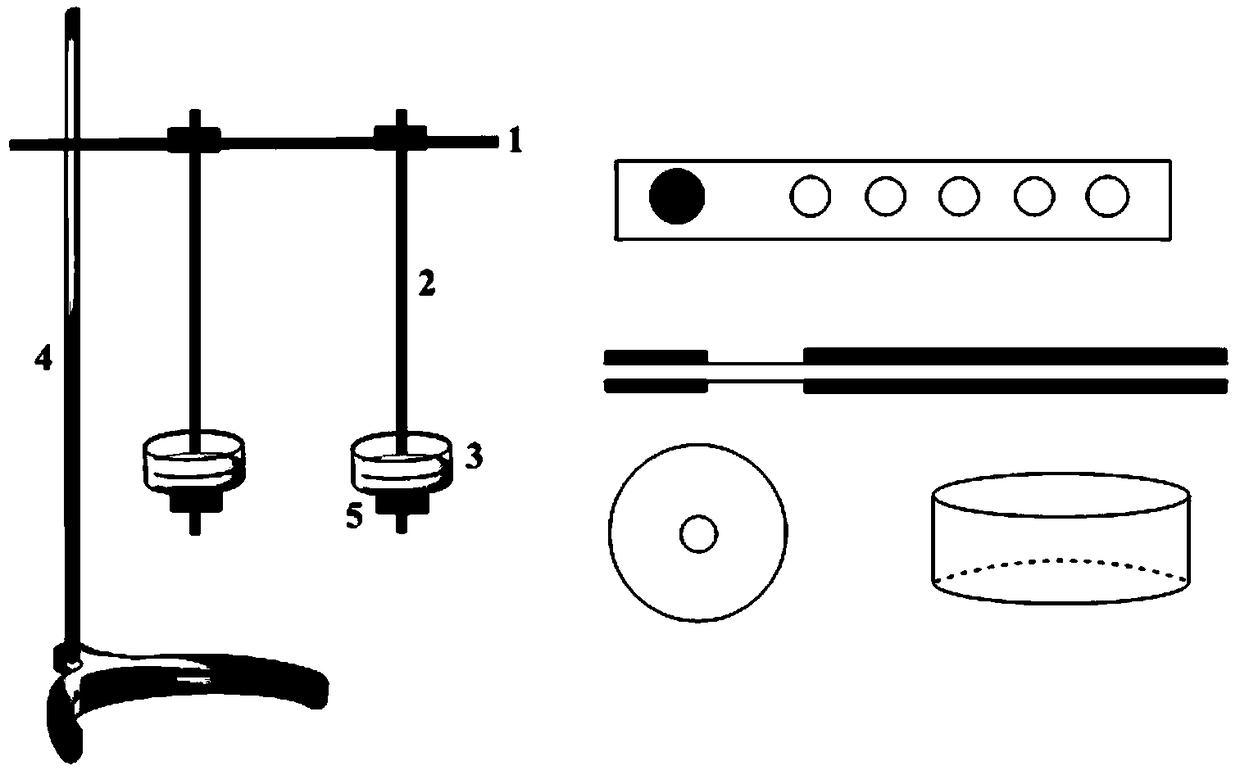

Method of manufacturing hollow microneedle structures

InactiveUS20110005669A1Uniform inner diameterSimple processGlovesPretreated surfacesHardnessMinimizing pain

Provided is a method of manufacturing a hollow microneedle structure. The method includes coating a hollow core having a predetermined section and being long in a lengthwise direction with a coating solution, and solidifying the coating solution to form a coating layer, depositing a metal seed layer on the coating layer, plating the seed metal layer with a metal to form a plated layer, cutting the hollow core having the plated layer at an inclination angle with respect to the lengthwise direction to form a surface inclination, and removing the hollow core and the coating layer to form a hollow. Thus, the hollow microneedle structure can be manufactured to have such diameter, length, hardness, and inclination angle as to minimize pain. By use of the hollow core, the microneedle structure can have vertical microneedles with a uniform inner diameter.

Owner:ELECTRONICS & TELECOMM RES INST

Method of manufacturing hollow microneedle structures

InactiveUS8402629B2Uniform inner diameterSimple processGlovesPretreated surfacesHardnessMinimizing pain

Provided is a method of manufacturing a hollow microneedle structure. The method includes coating a hollow core having a predetermined section and being long in a lengthwise direction with a coating solution, and solidifying the coating solution to form a coating layer, depositing a metal seed layer on the coating layer, plating the seed metal layer with a metal to form a plated layer, cutting the hollow core having the plated layer at an inclination angle with respect to the lengthwise direction for form a surface inclination, and removing the hollow core and the coating layer to form a hollow microneedle structure. Thus, the hollow microneedle structure can be manufactured to have such diameter, length, hardness, and inclination angle as to minimize pain. By use of the hollow core, the microneedle structure can have vertical microneedles with a uniform inner diameter.

Owner:ELECTRONICS & TELECOMM RES INST

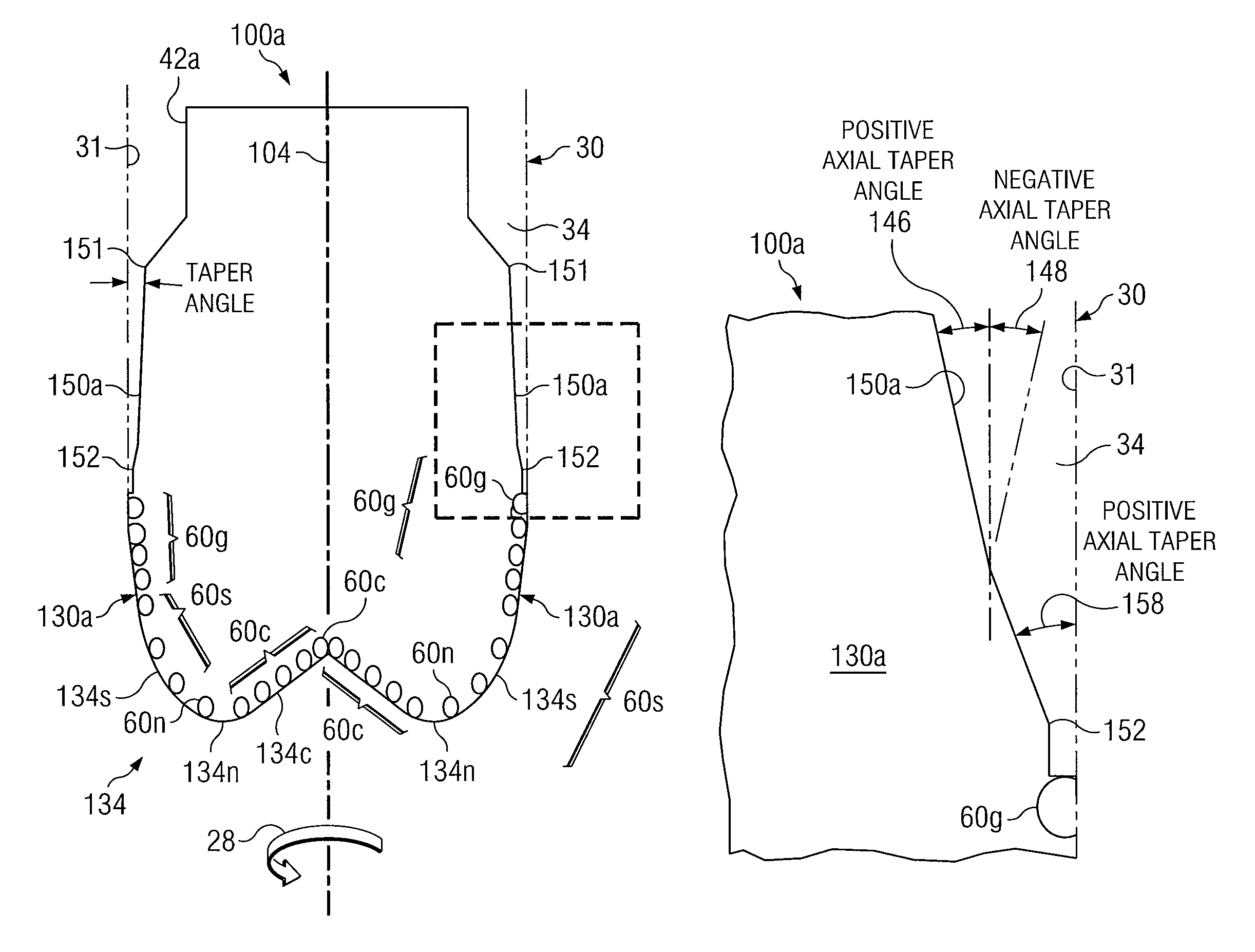

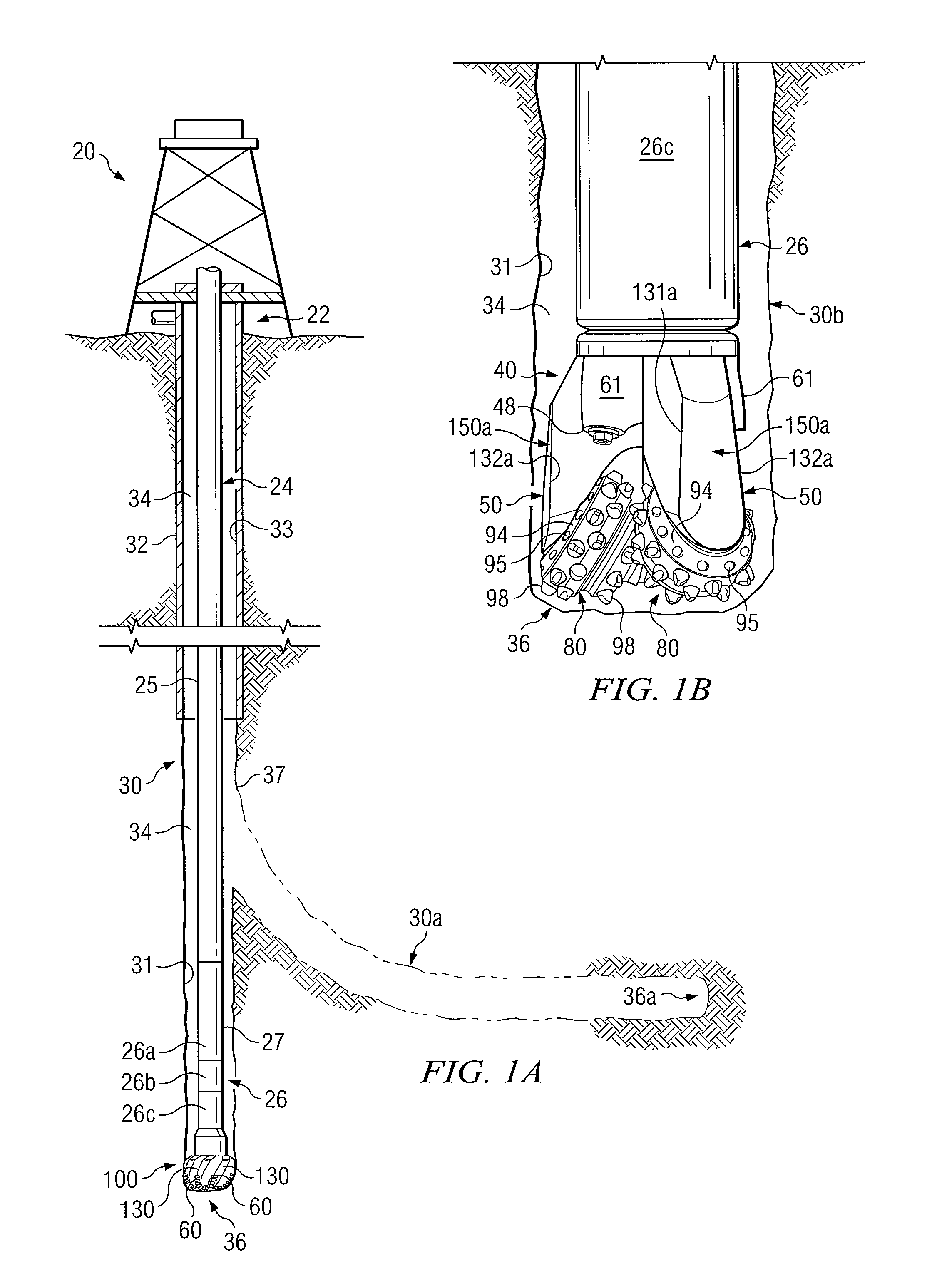

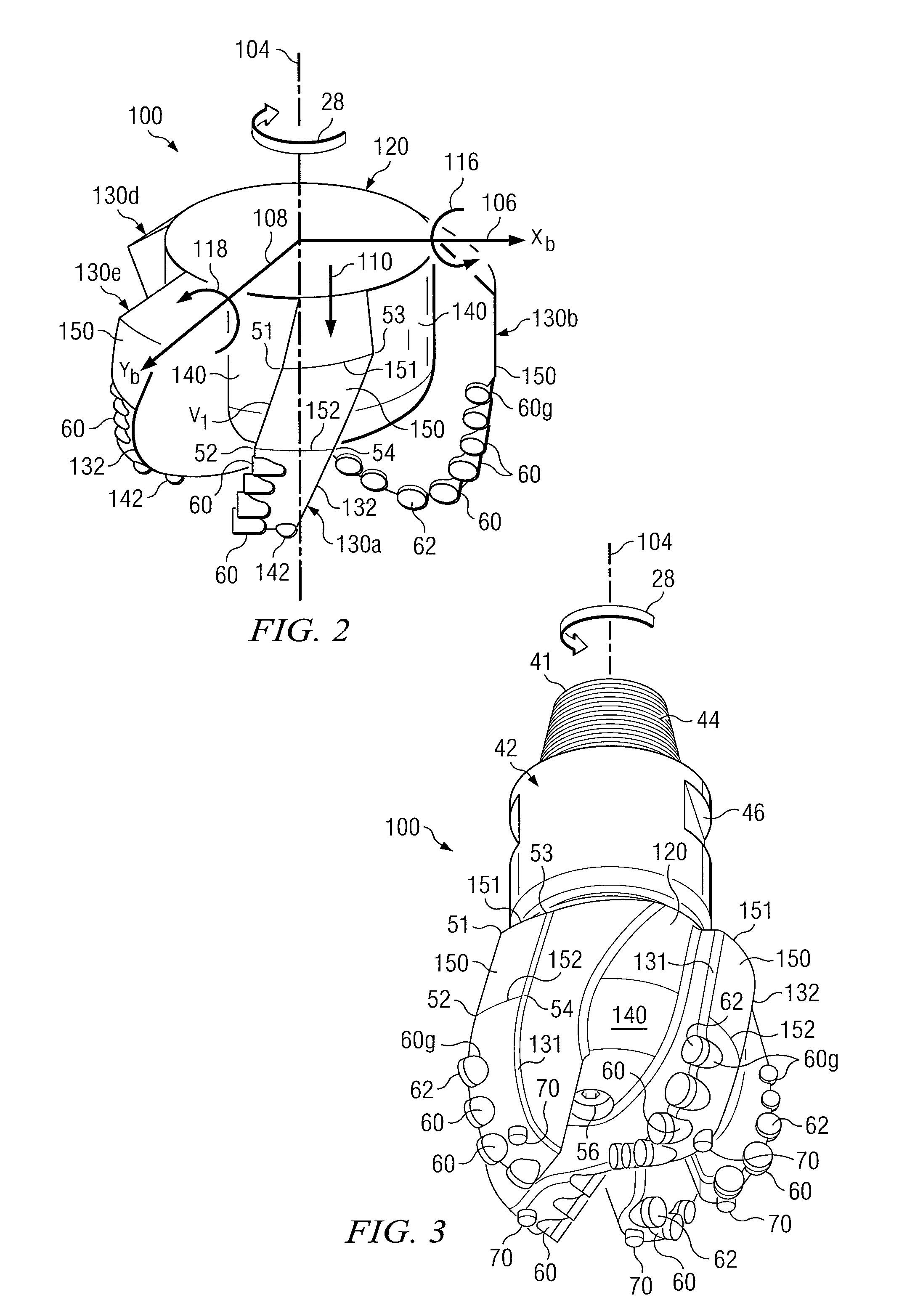

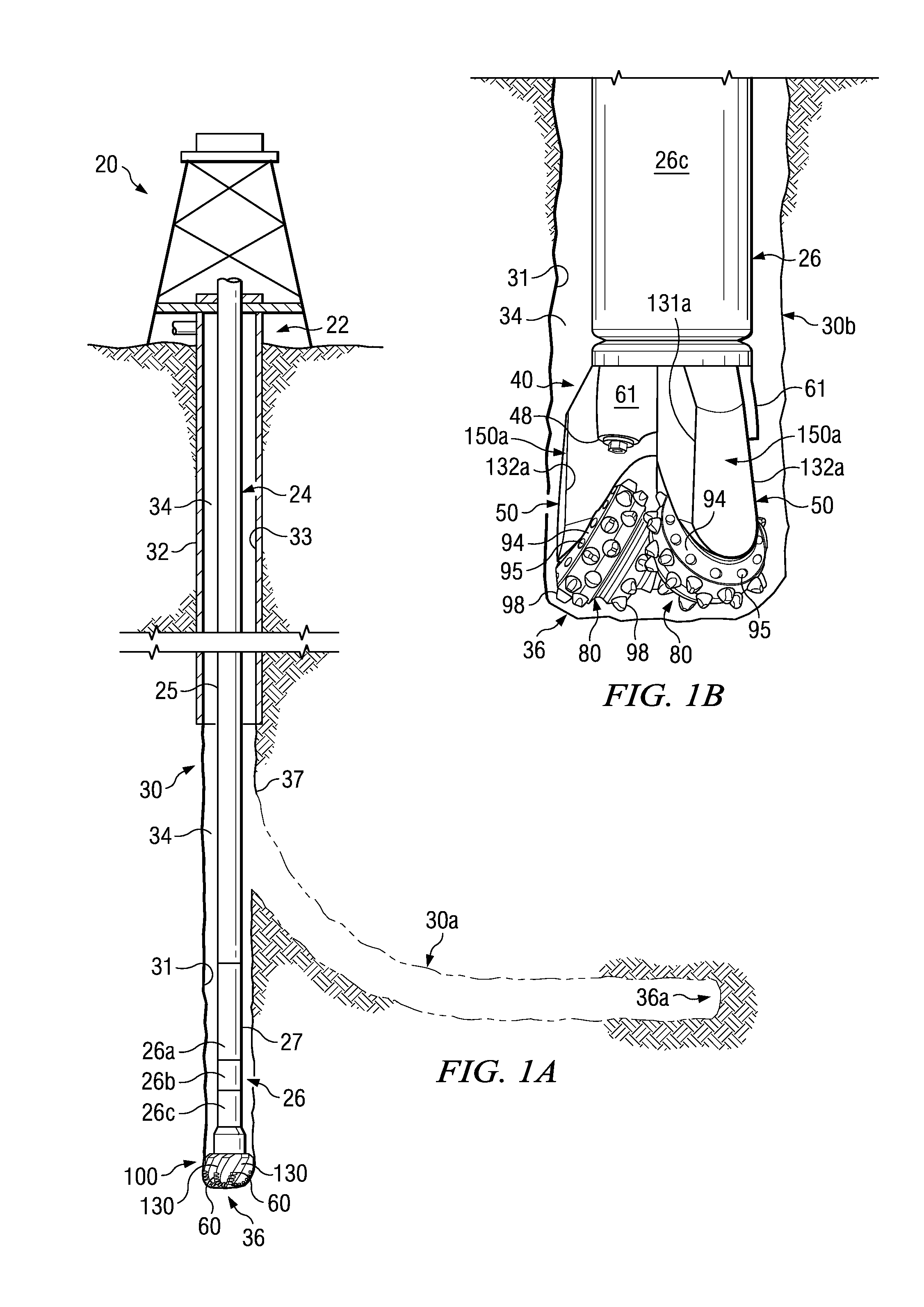

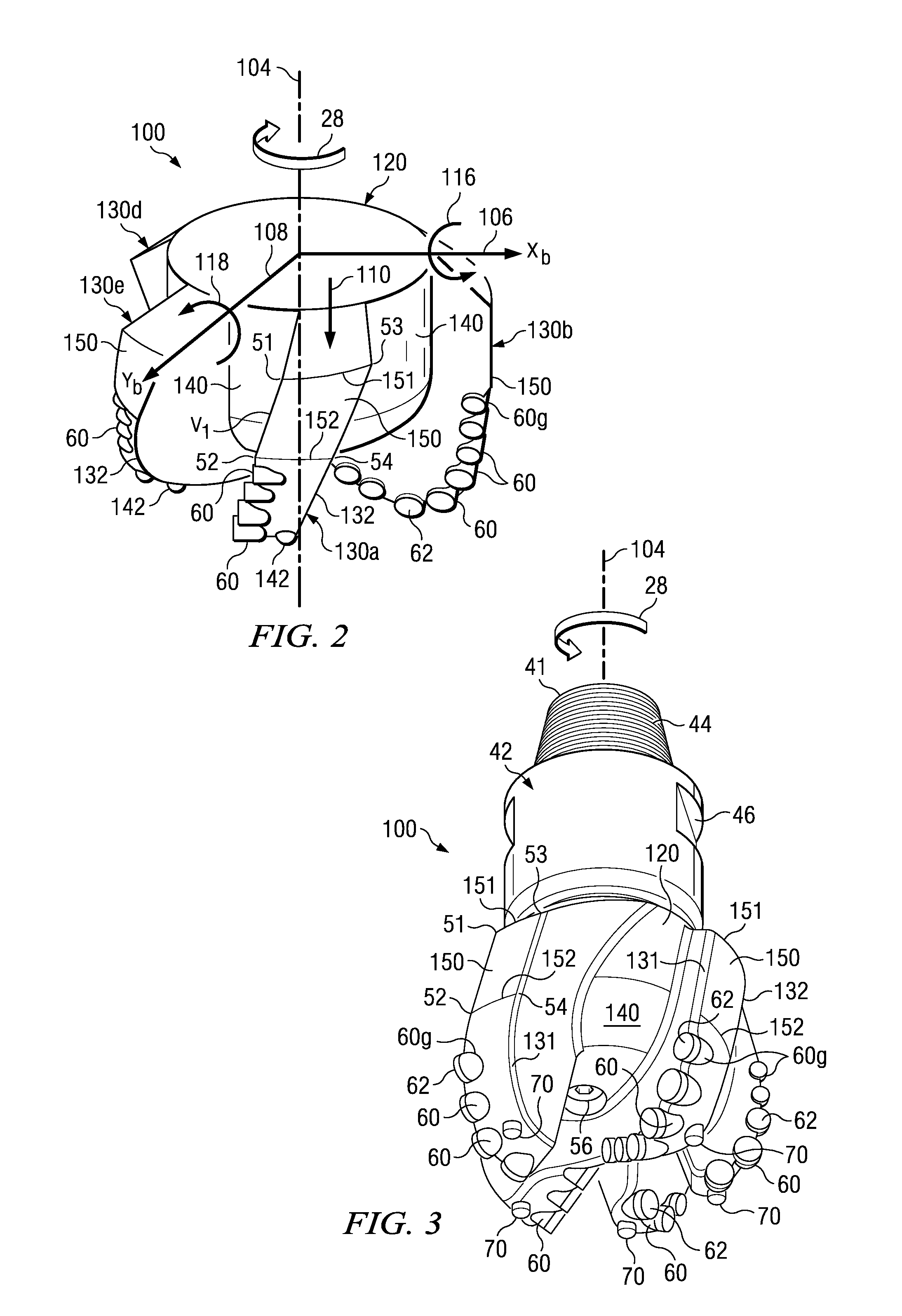

Rotary drill bits with gage pads having improved steerability and reduced wear

Owner:HALLIBURTON ENERGY SERVICES INC

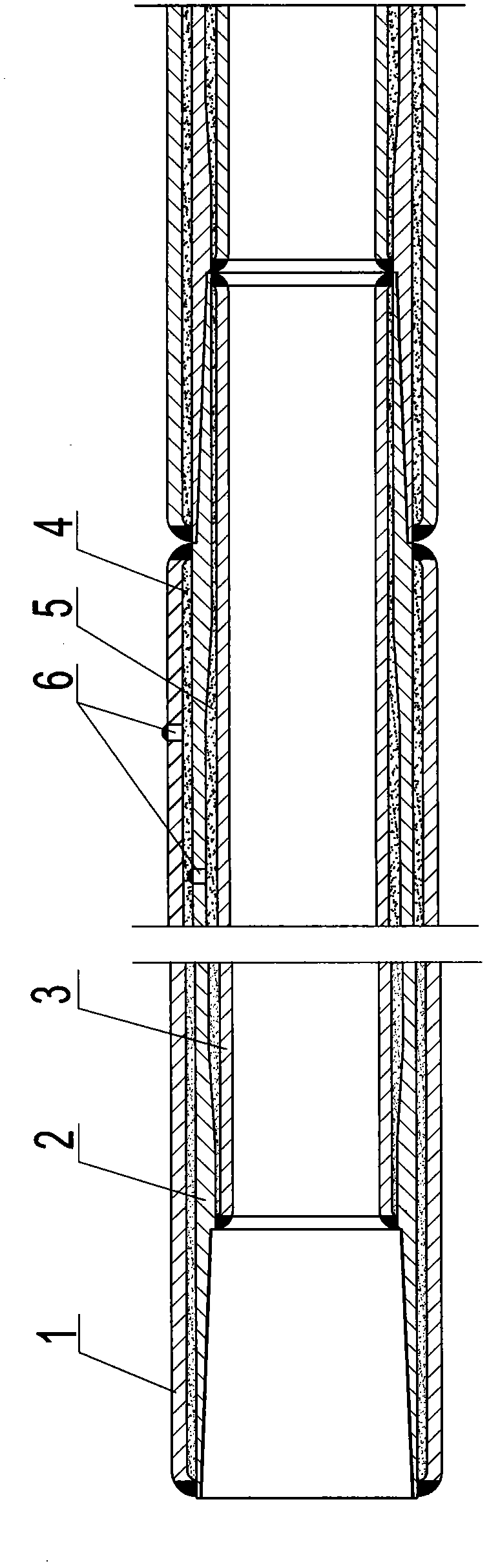

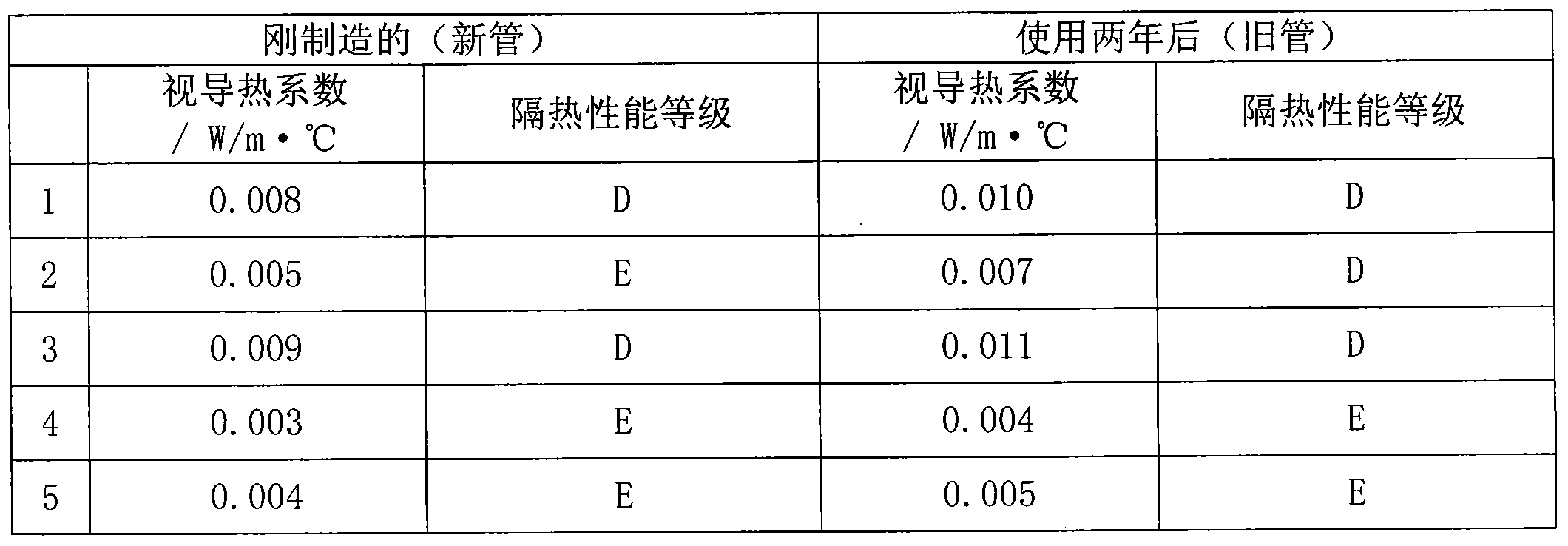

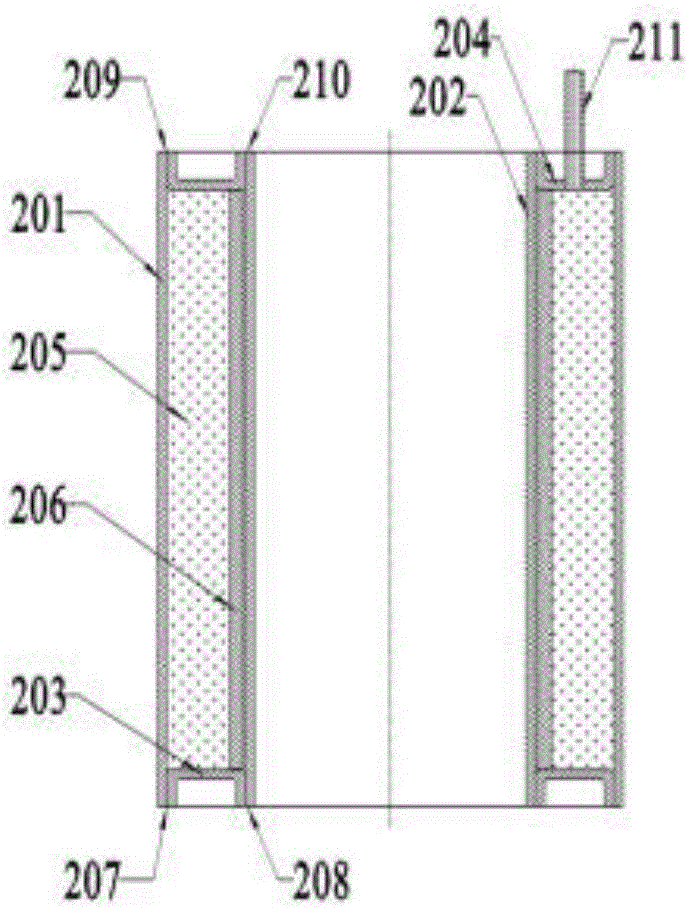

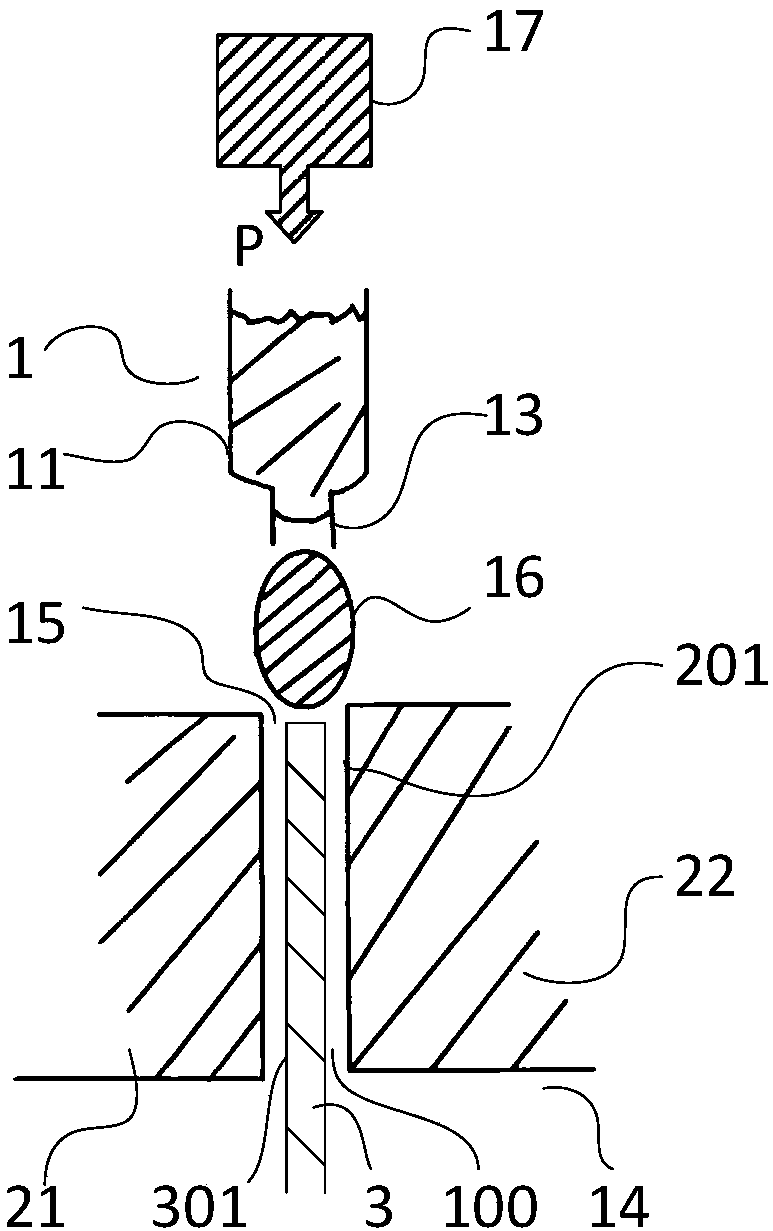

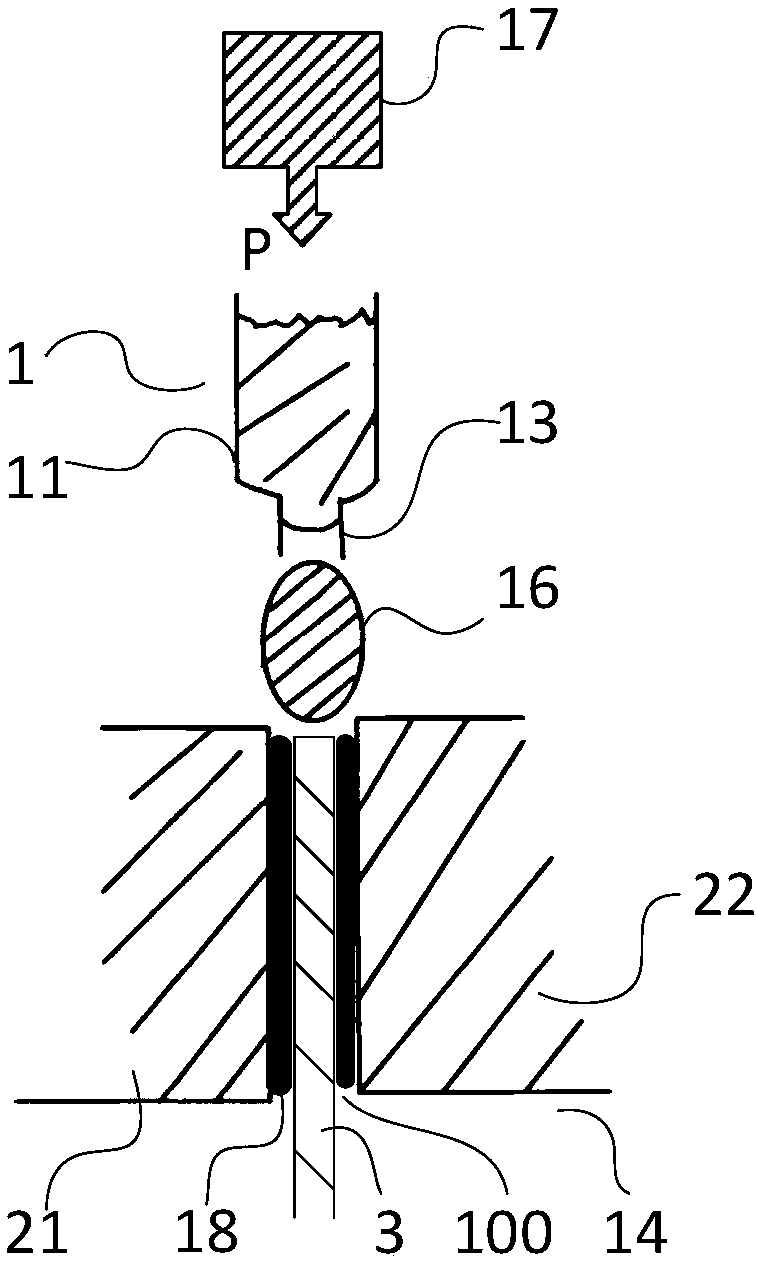

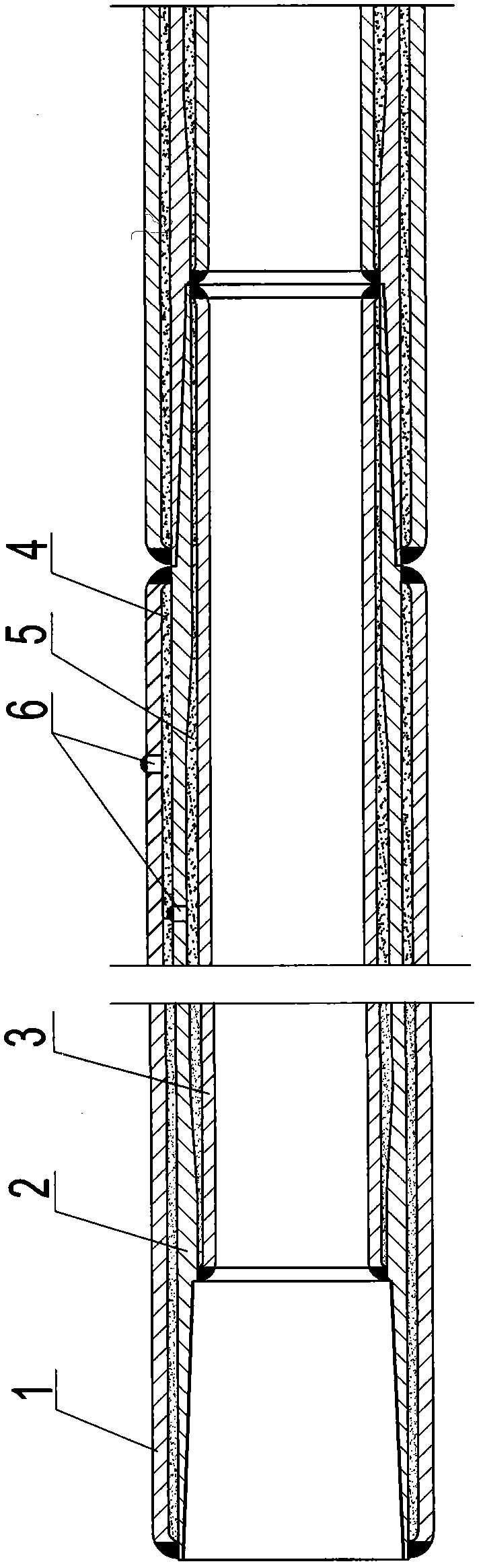

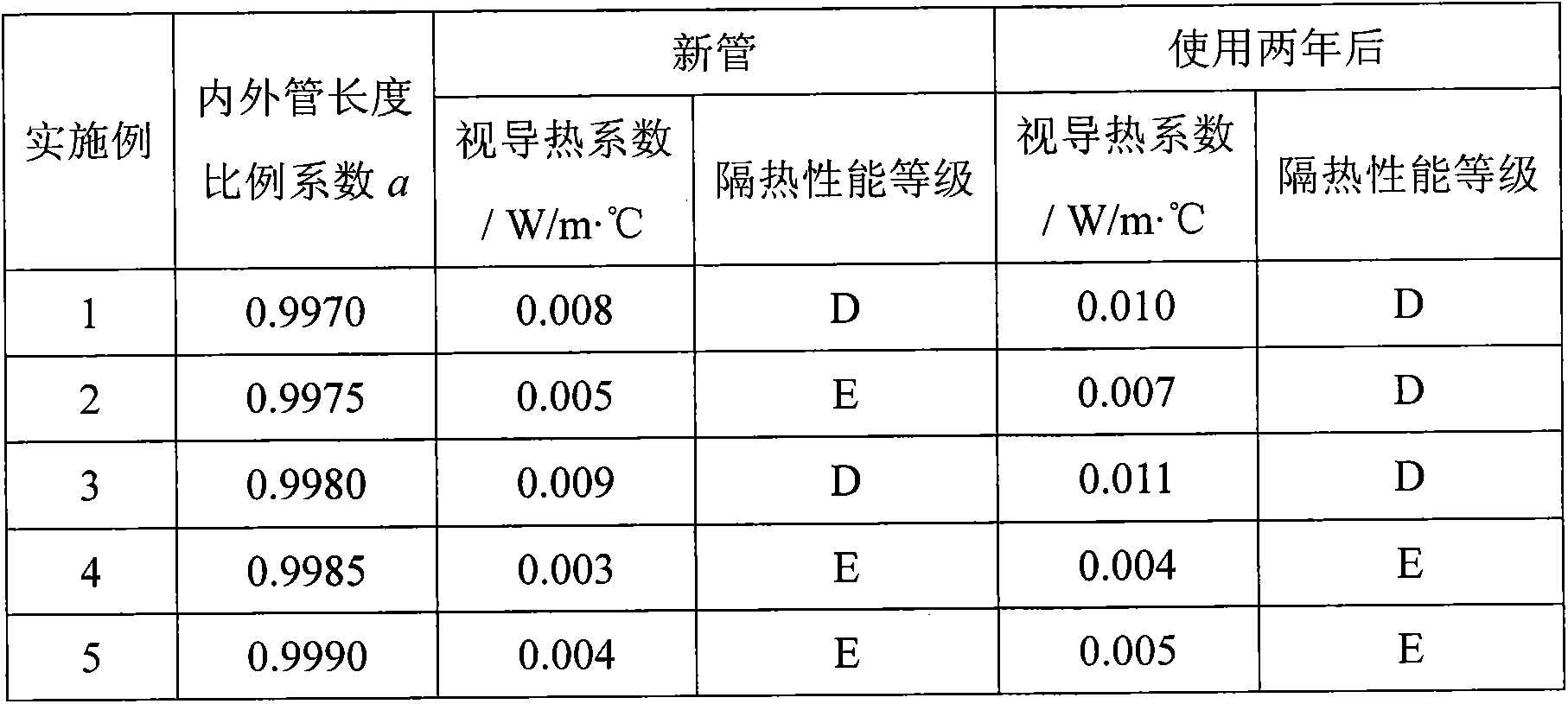

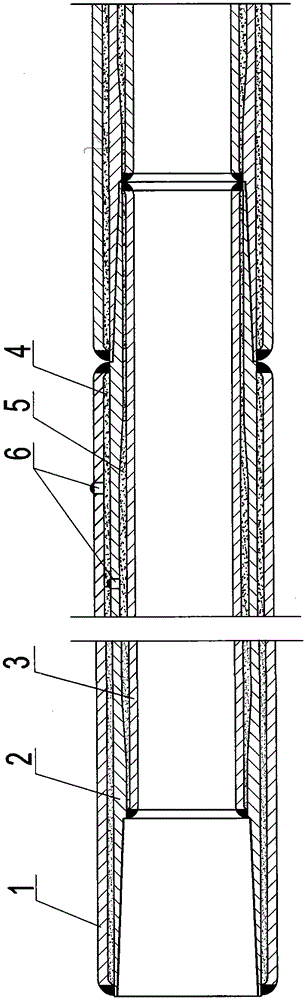

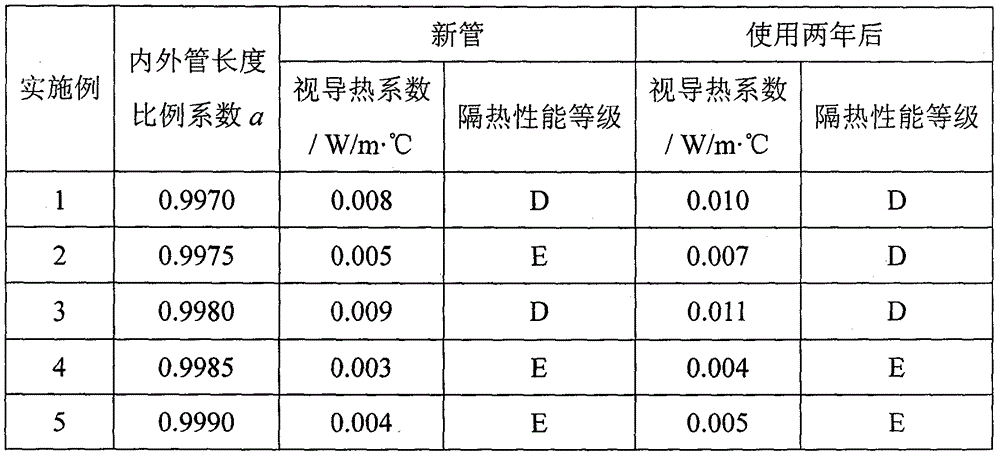

Heat-insulating oil sleeve and manufacturing method thereof

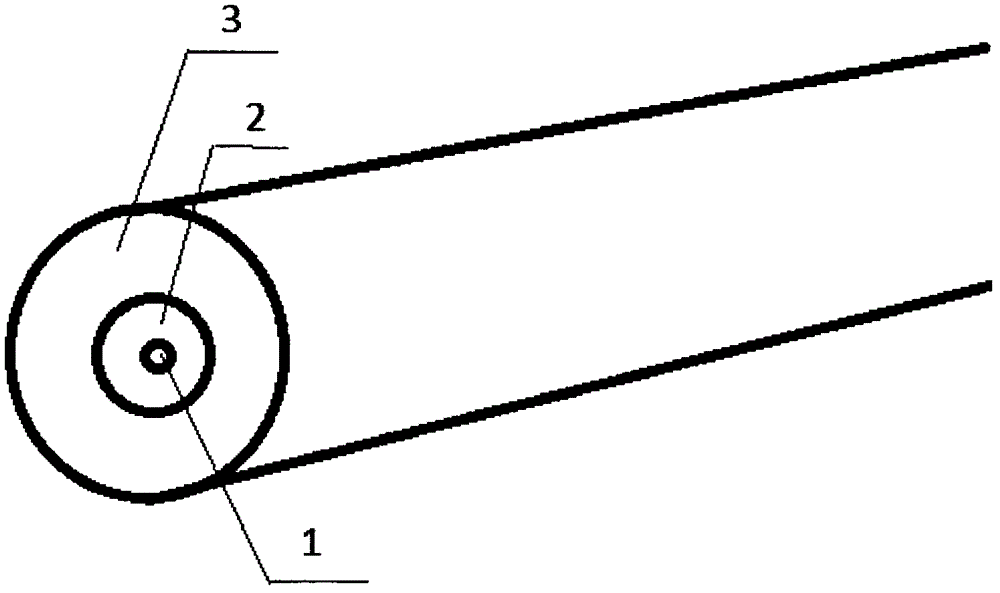

ActiveCN103850653AImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsEngineeringScrew thread

The invention relates to a heat-insulating oil sleeve. The heat-insulating oil sleeve is characterized by comprising an outer pipe, an intermediate pipe and an inner pipe which are sleeved in a clearance fit way; internal threads are machined at one end of the intermediate pipe; external threads are machined at the other end of the intermediate pipe; one end, provided with the internal threads, of the intermediate pipe is welded with the outer pipe at a pipe end, and is welded with the inner pipe at the length position of the preserved internal threads; one end, provided with the external threads, of the intermediate pipe is welded with the outer pipe at the length position of the preserved external threads, and is welded with the inner pipe at the pipe end; an annular cavity formed by the outer pipe and the intermediate pipe is filled with a heat-insulating material and is vacuumized to form a first heat-insulating layer; an annular cavity formed between the intermediate pipe and the inner pipe is vacuumized and is injected with inert gas to form a second heat-insulating layer. A manufacturing method for the heat-insulating oil sleeve comprises the following steps in sequence: performing pretreatment on the three pipes, sleeving and welding the inner pipe and the intermediate pipe, treating the annular cavity between the inner pipe and the intermediate pipe, sleeving and welding the outer pipe and the intermediate pipe, treating the annular cavity between the outer pipe and the intermediate pipe, testing an apparent heat conductivity coefficient and machining threads at the two ends of the intermediate pipe. The heat-insulating oil sleeve has a structure with three layers of steel tubes and double layers of heat-insulating layers, high heat insulation performance, long heat insulation life and high performance.

Owner:淄博孚瑞特热能科技有限公司

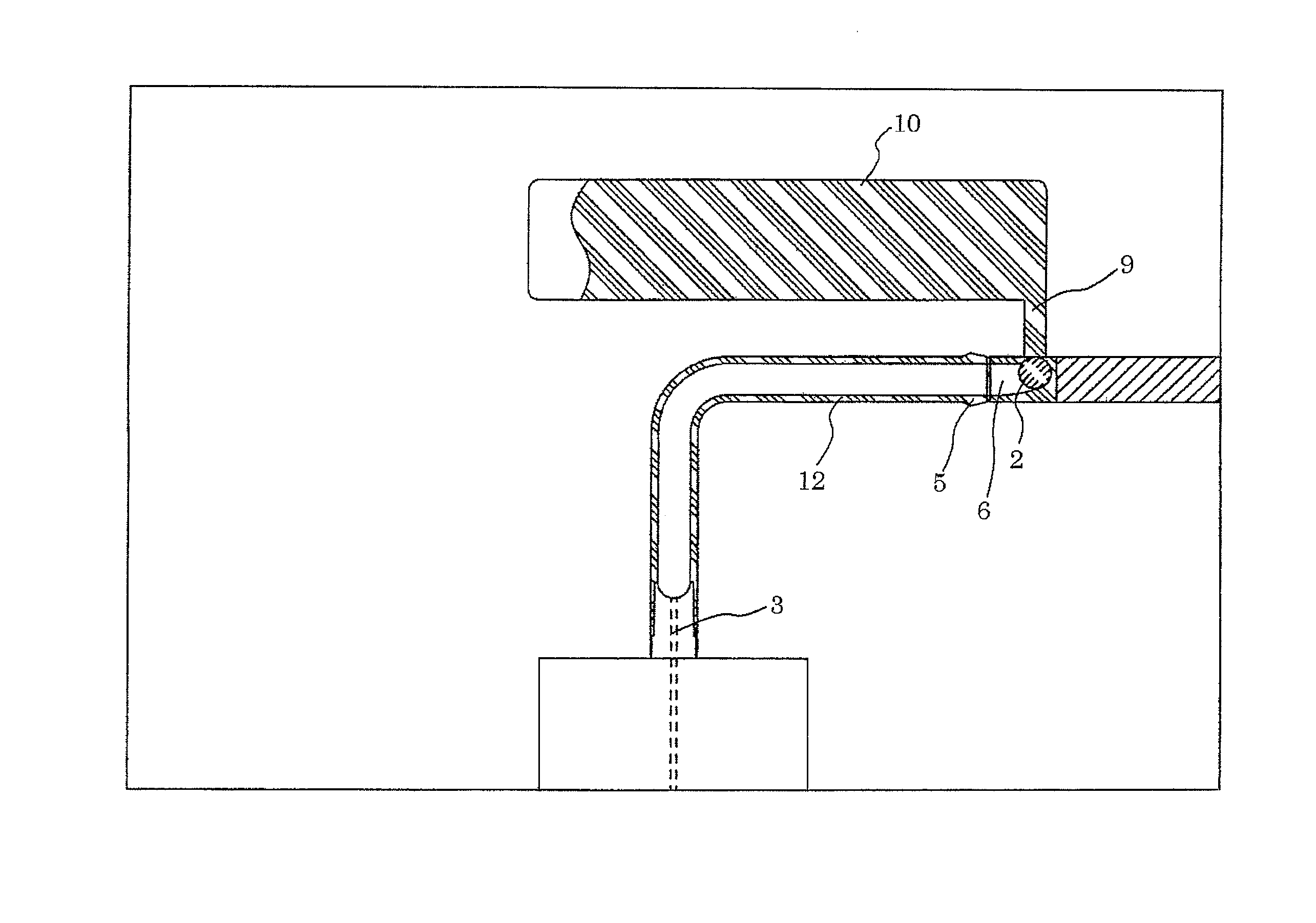

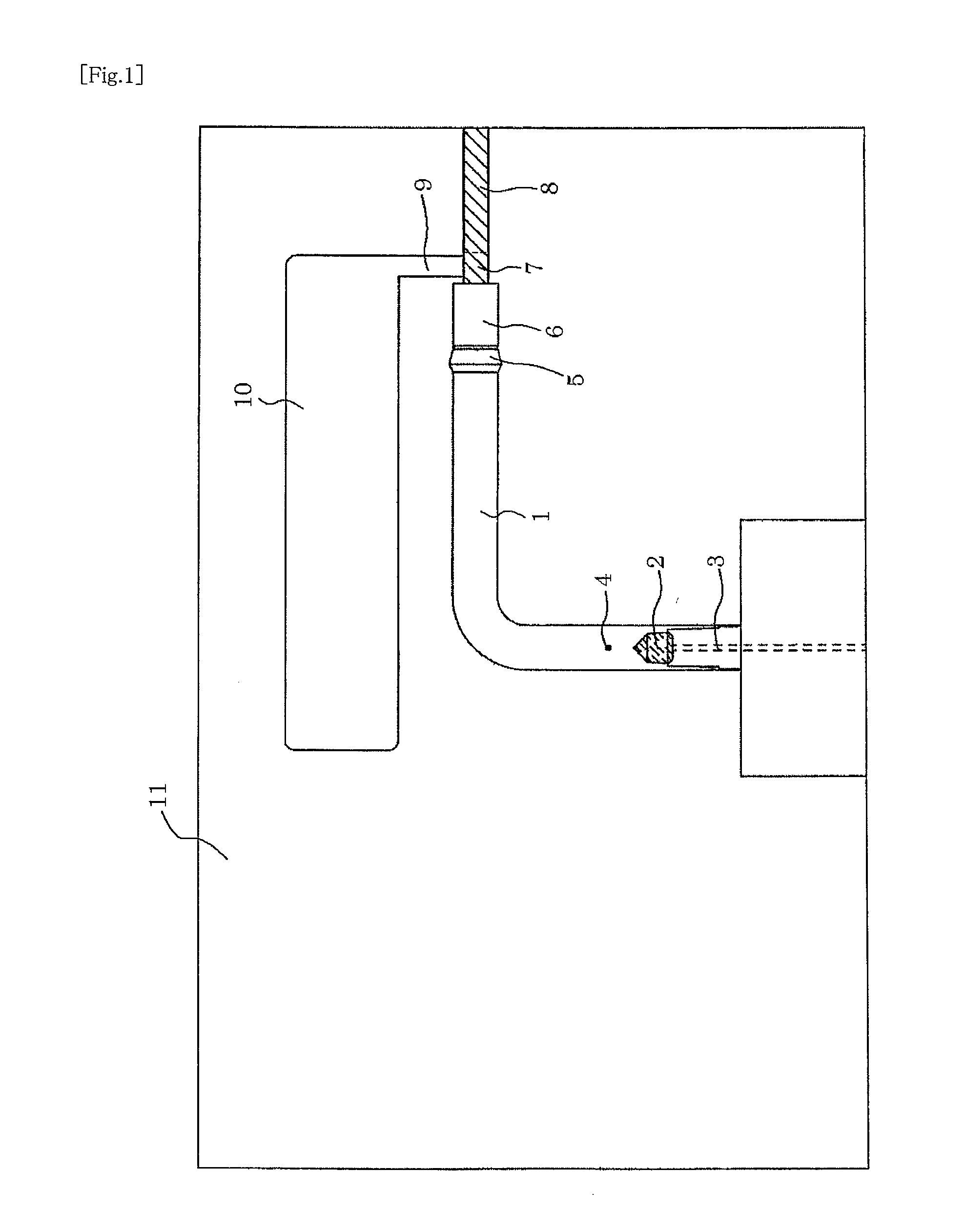

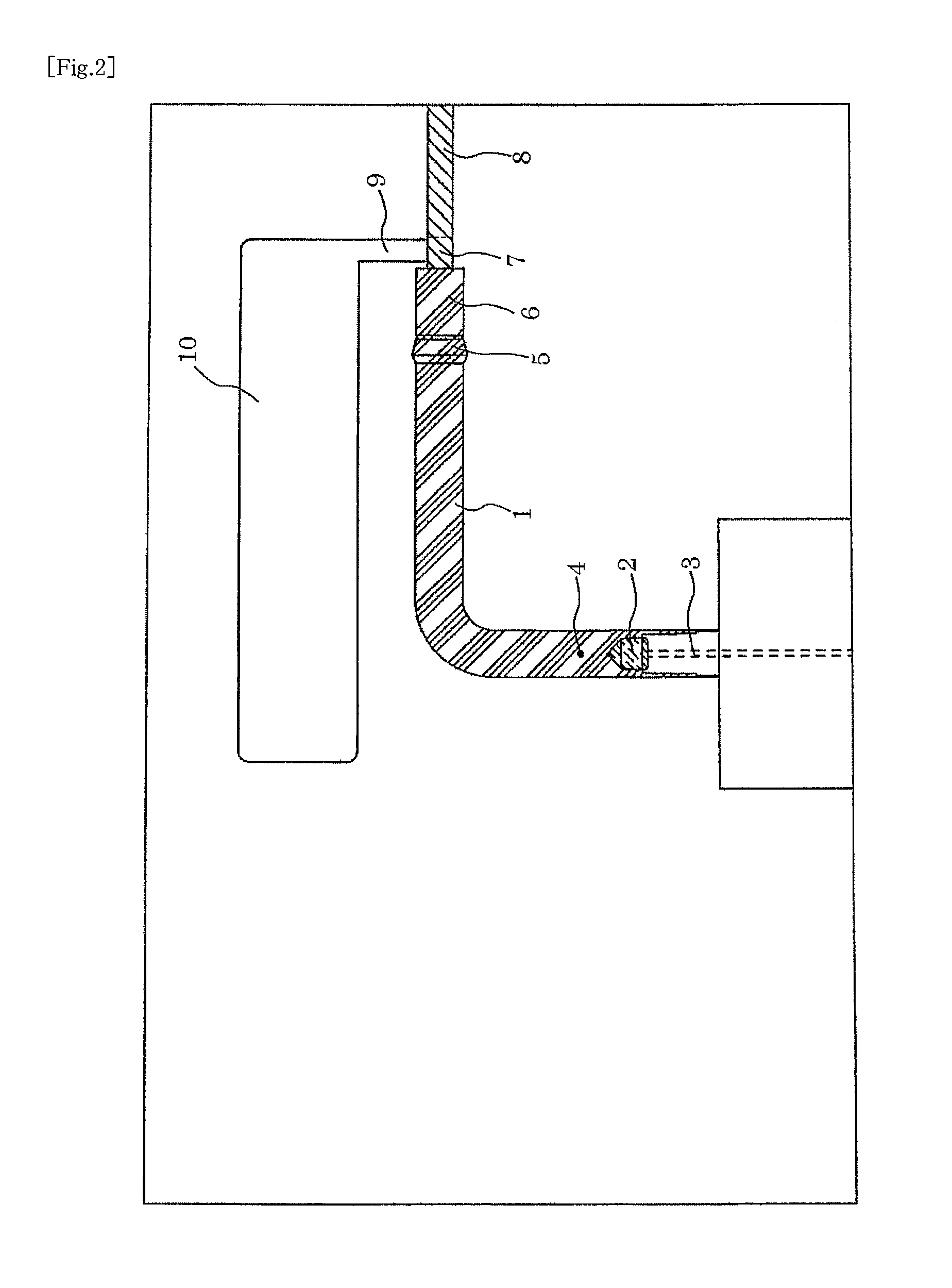

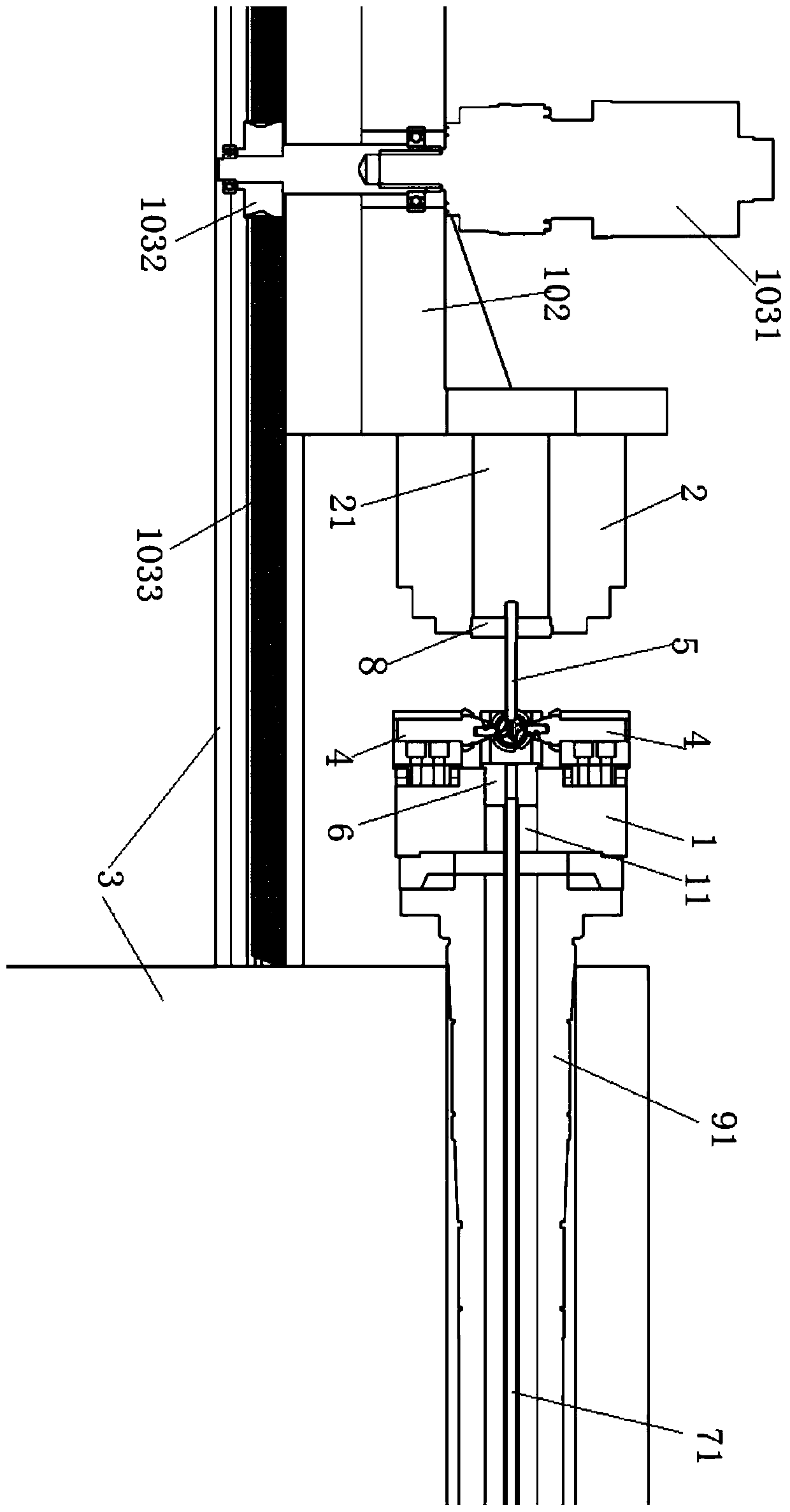

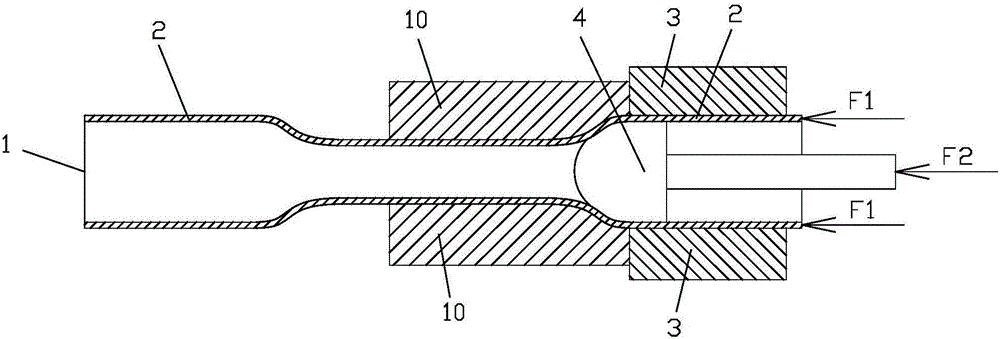

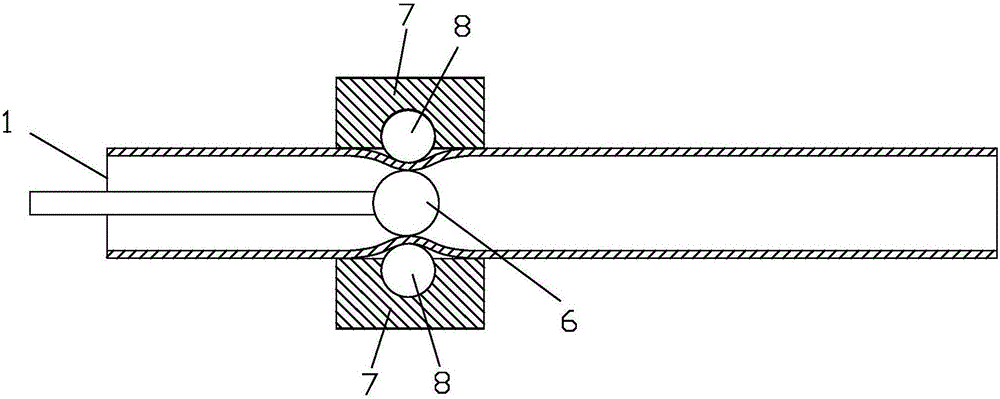

Hollow body molding device

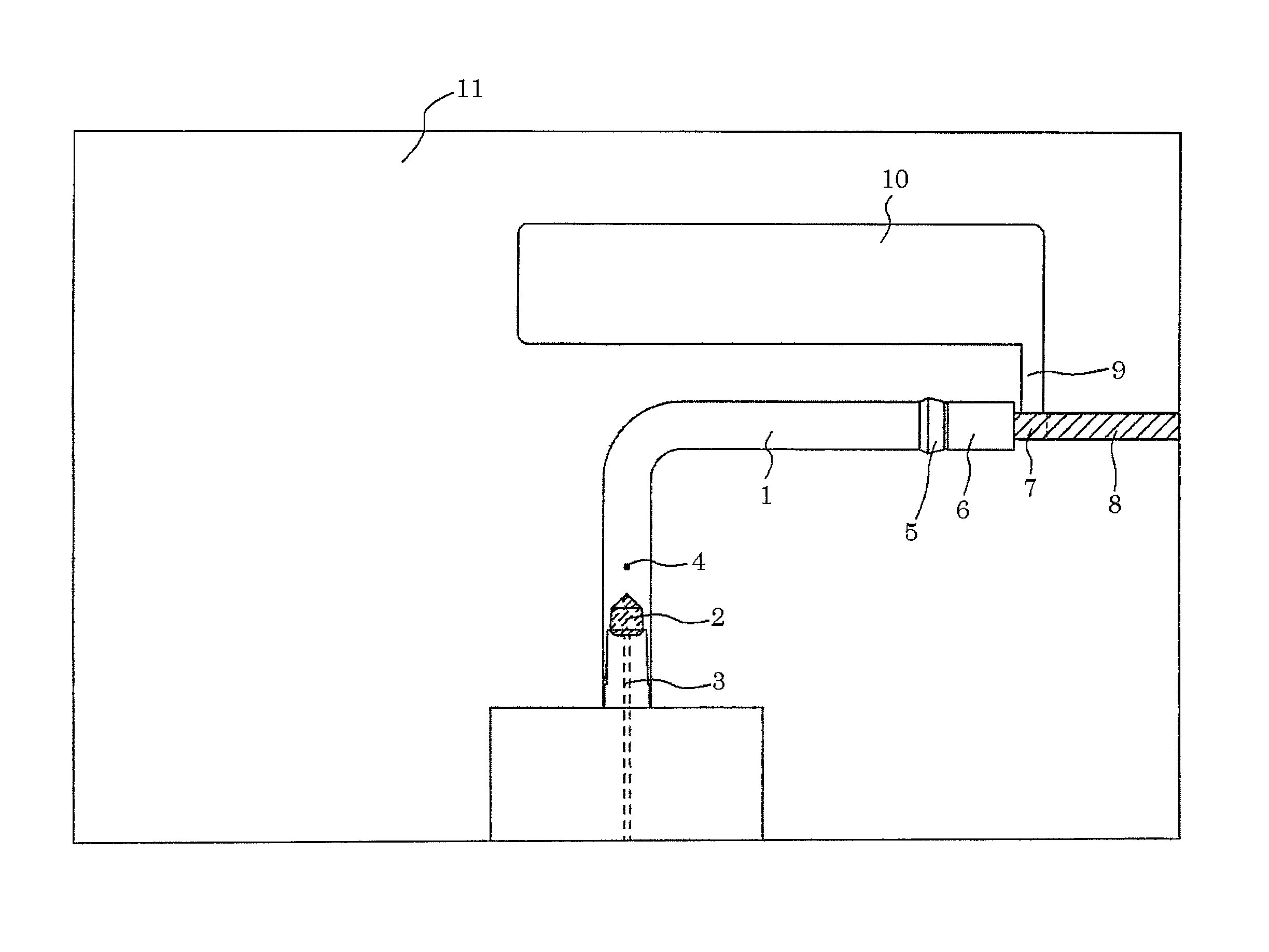

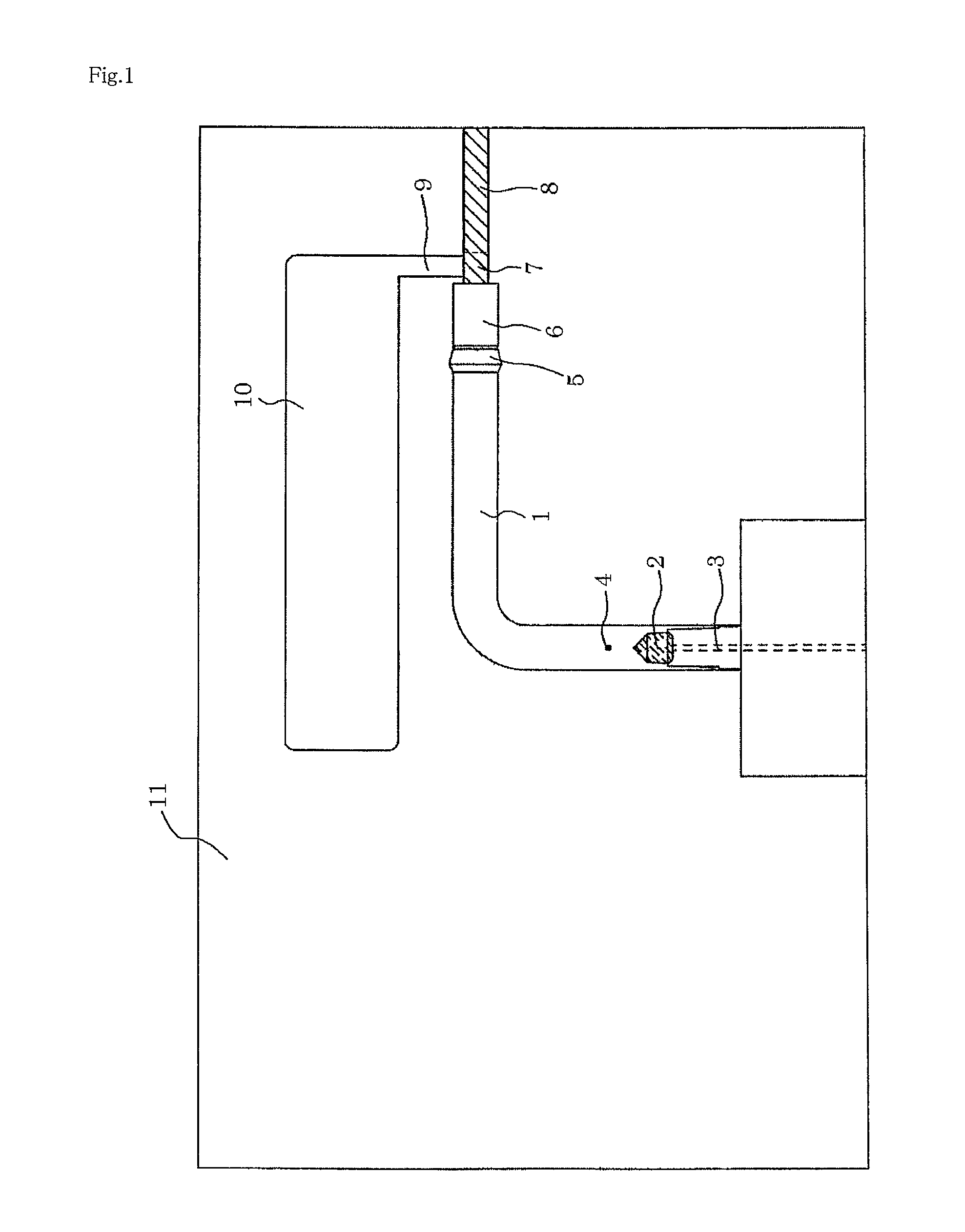

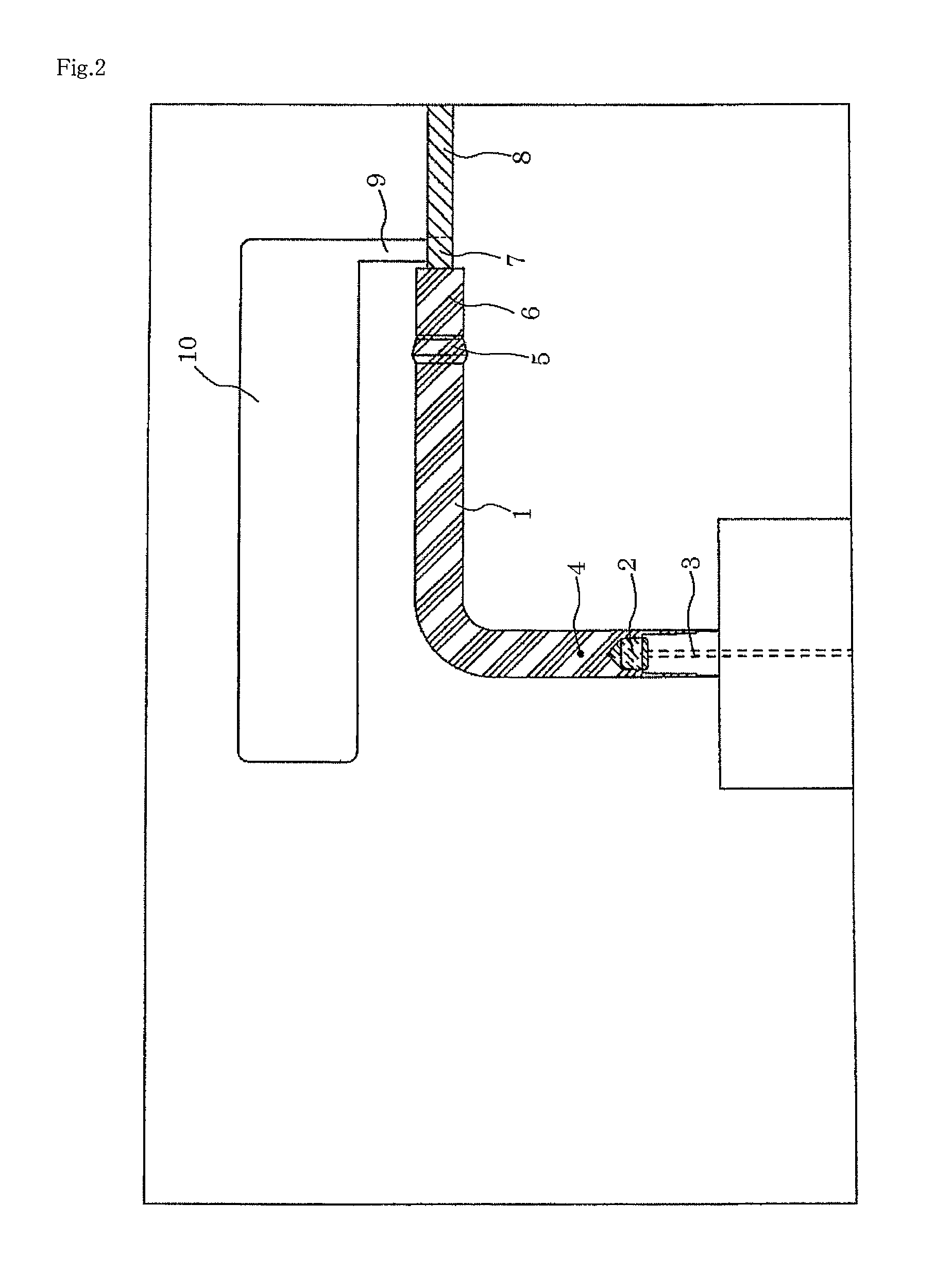

ActiveUS20130236591A1Good lookingGood dimensional stabilityFood shapingMaximum diameterMaterials science

The present invention provides a hollow body molding device which allows easy confirmation of passage of a floating core through a molded body and facilitates quality control at the site.In a hollow body molding device in which a molten resin is injected into a main cavity 1, a pressurized fluid is pressure-injected through a pressure port 3 after the injection of the molten resin, a floating core 2 is moved to the outlet side, the molten resin is extruded from the outlet simultaneously with the movement of the floating core 2, and a hollow molded body 12 is molded, the hollow body molding device is provided with a floating core storage portion 6 which is connected to the main cavity 1 and stores the floating core 2 moved by the pressurized fluid, an auxiliary cavity 10 which stores a molten resin discharged from the main cavity 1 and the floating core storage portion 6, communication passages 7 and 9 which communicate the floating core storage portion 6 and the auxiliary cavity 10 with each other; and an opening and closing means 8 that opens and closes the communication passages 7 and 9 by sliding movement. In the hollow body molding device, each inlet cross-sectional area B of the communication passages 7 and 9 is B<πA2 / 4 (A is the maximum diameter of the floating core 2).

Owner:RP TOPLA

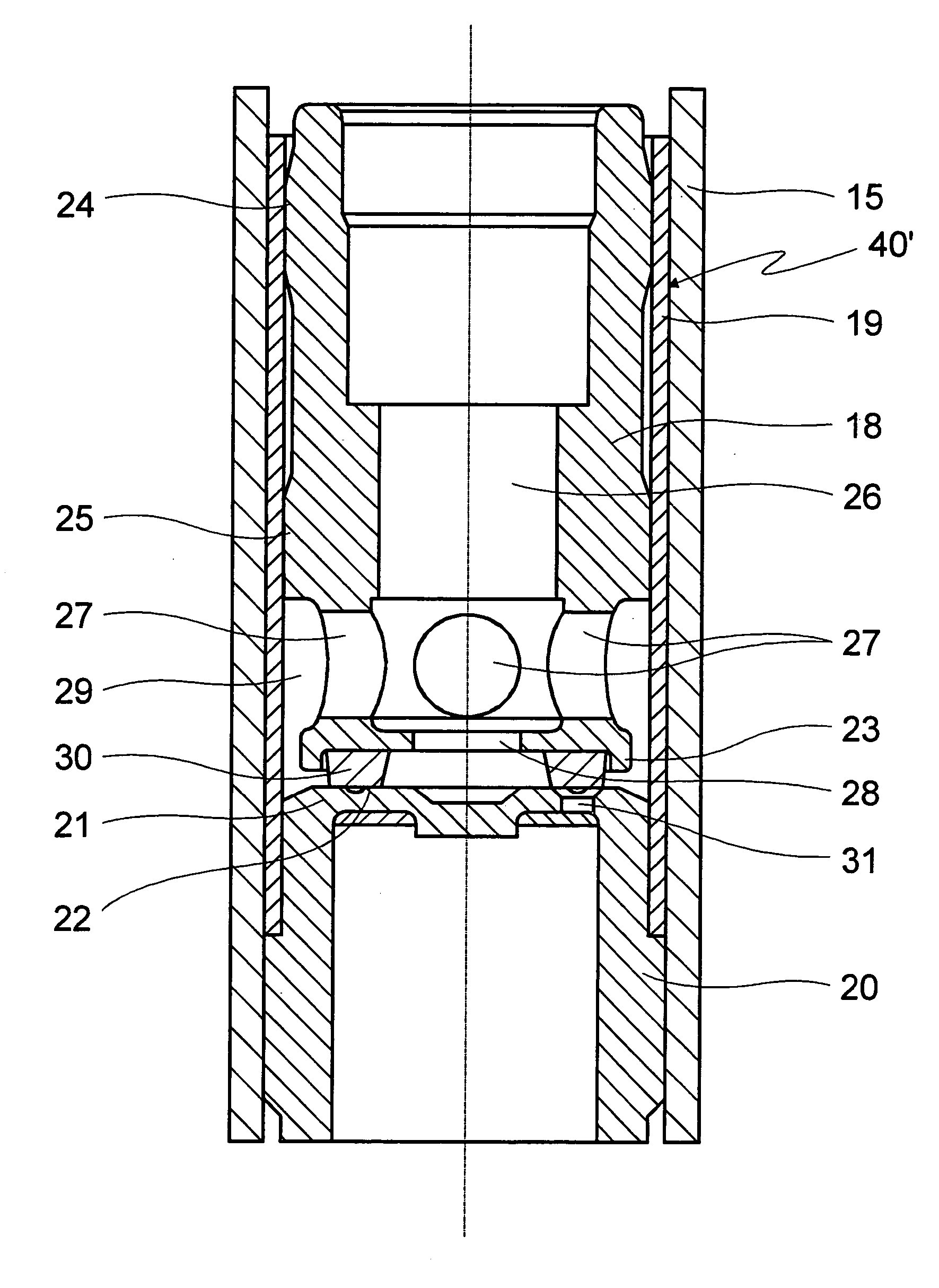

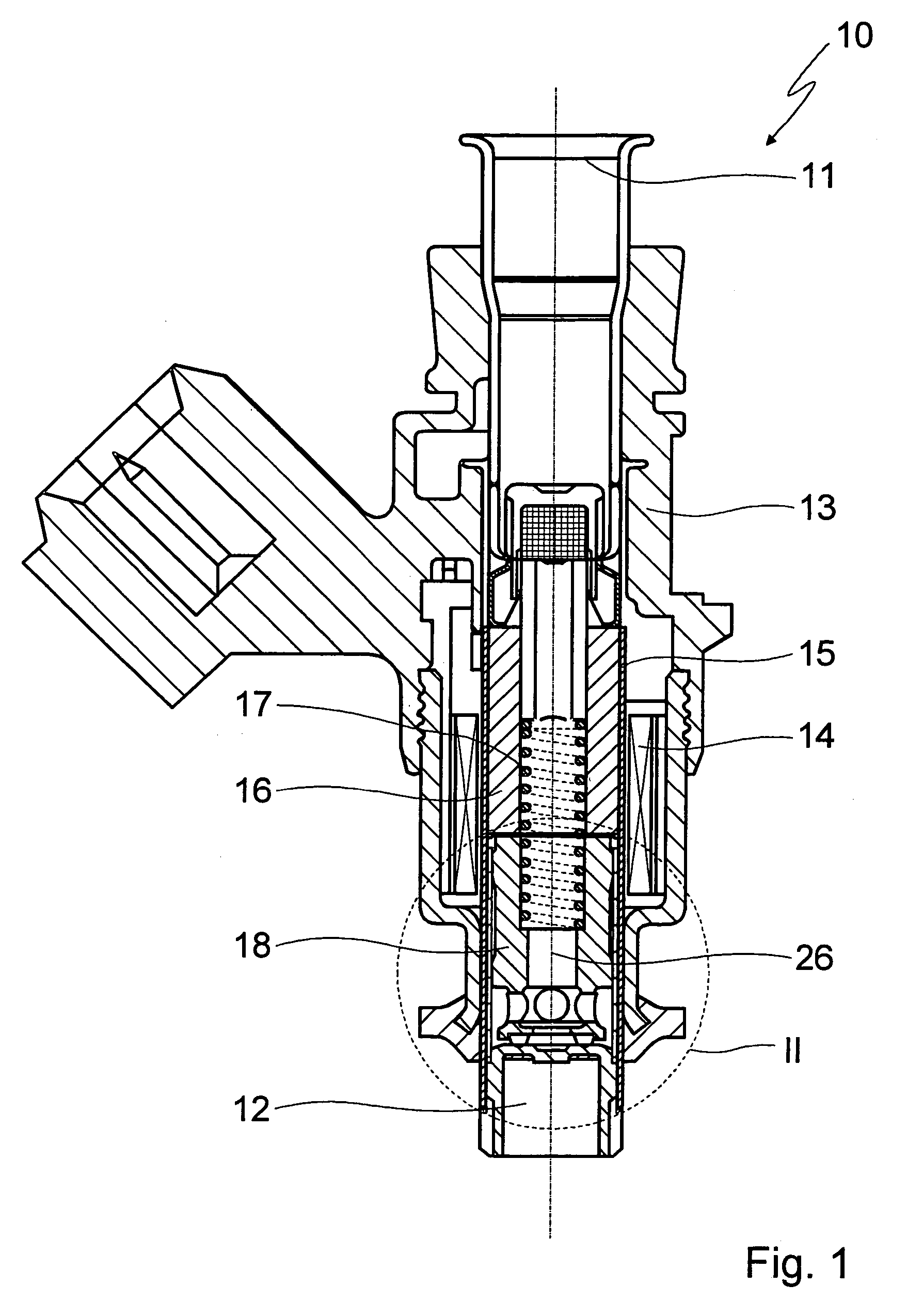

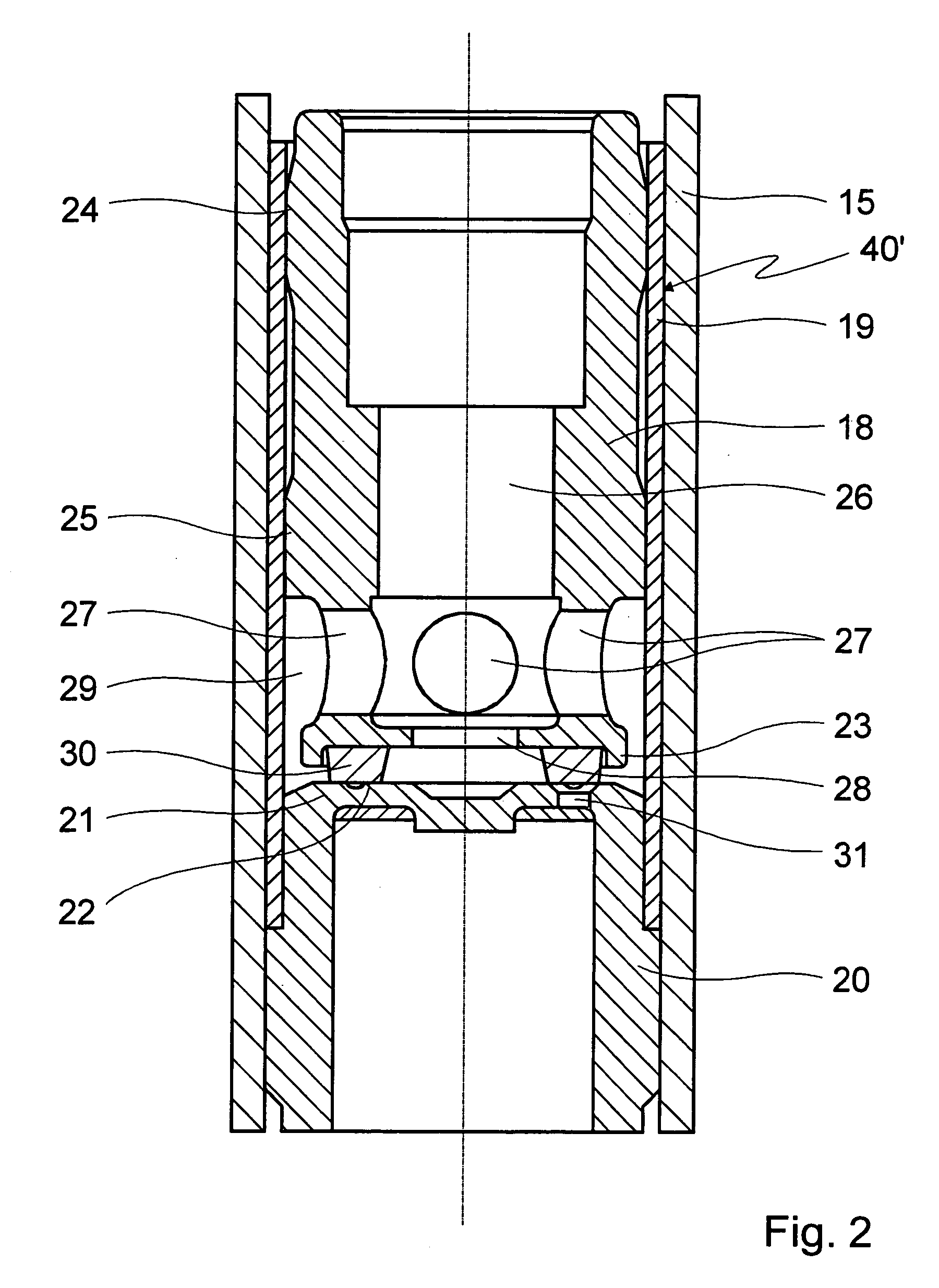

Valve for controlling a fluid

InactiveUS7229064B2Uniform inner diameterSlight tilting tendencyOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringElectromagnetic actuator

A valve for controlling a fluid, in particular for controlling a gas. The valve includes a valve housing having a housing sleeve and an electromagnetic actuator for an armature which is guided in an axially displaceable manner and which cooperates with a valve seat situated on a seating plate so that a fluid flow through outflow orifices in the seating plate is controllable. The armature is guided along an armature sleeve which is situated in the housing sleeve.

Owner:ROBERT BOSCH GMBH

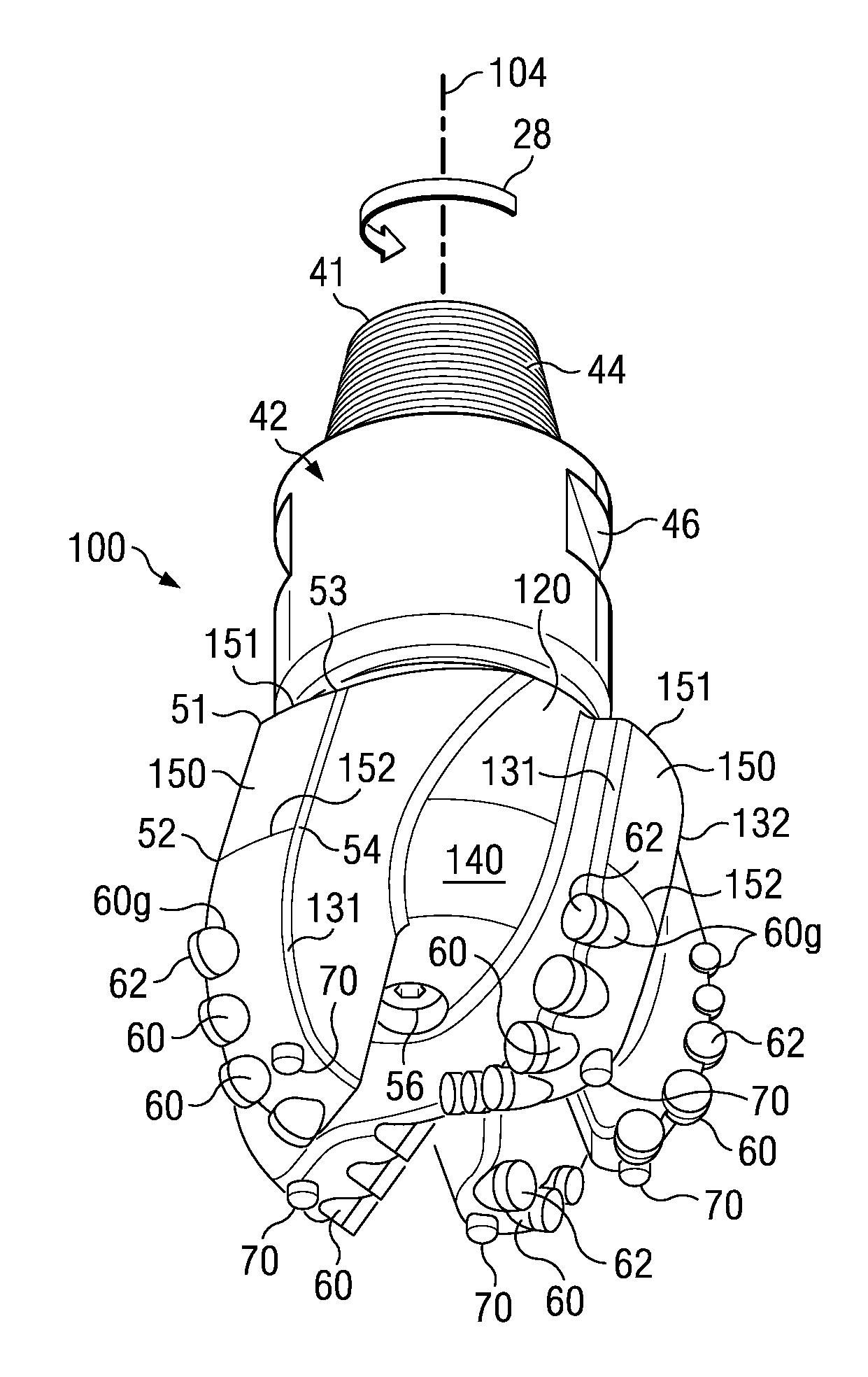

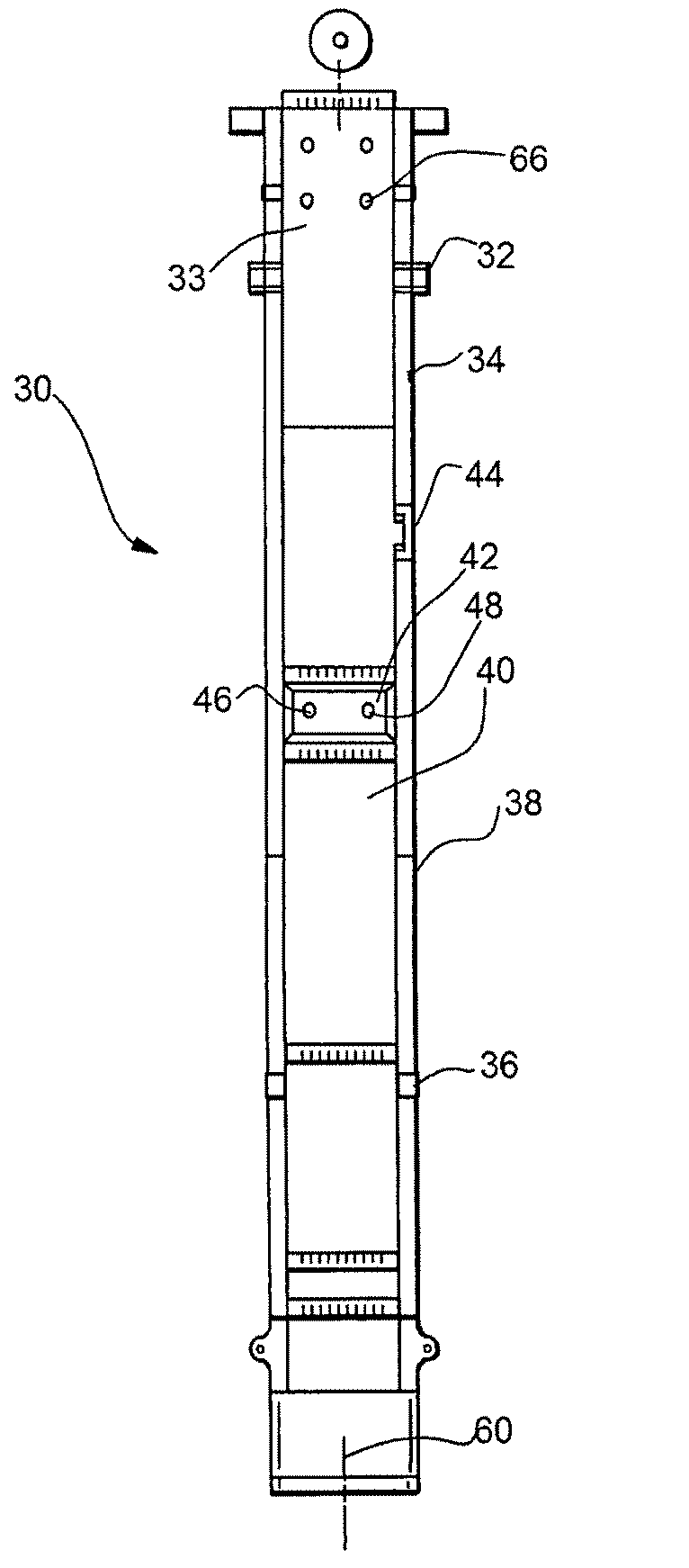

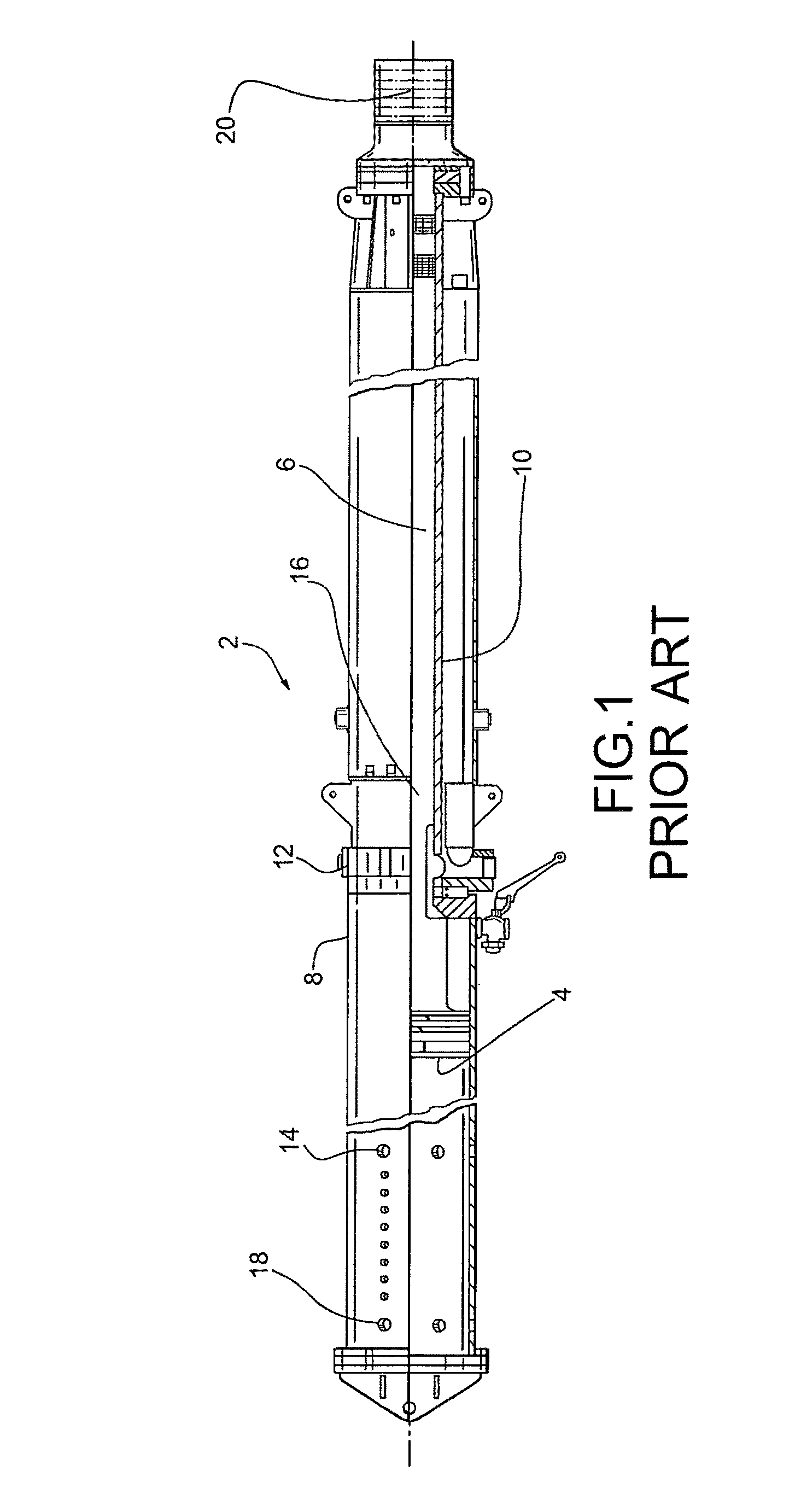

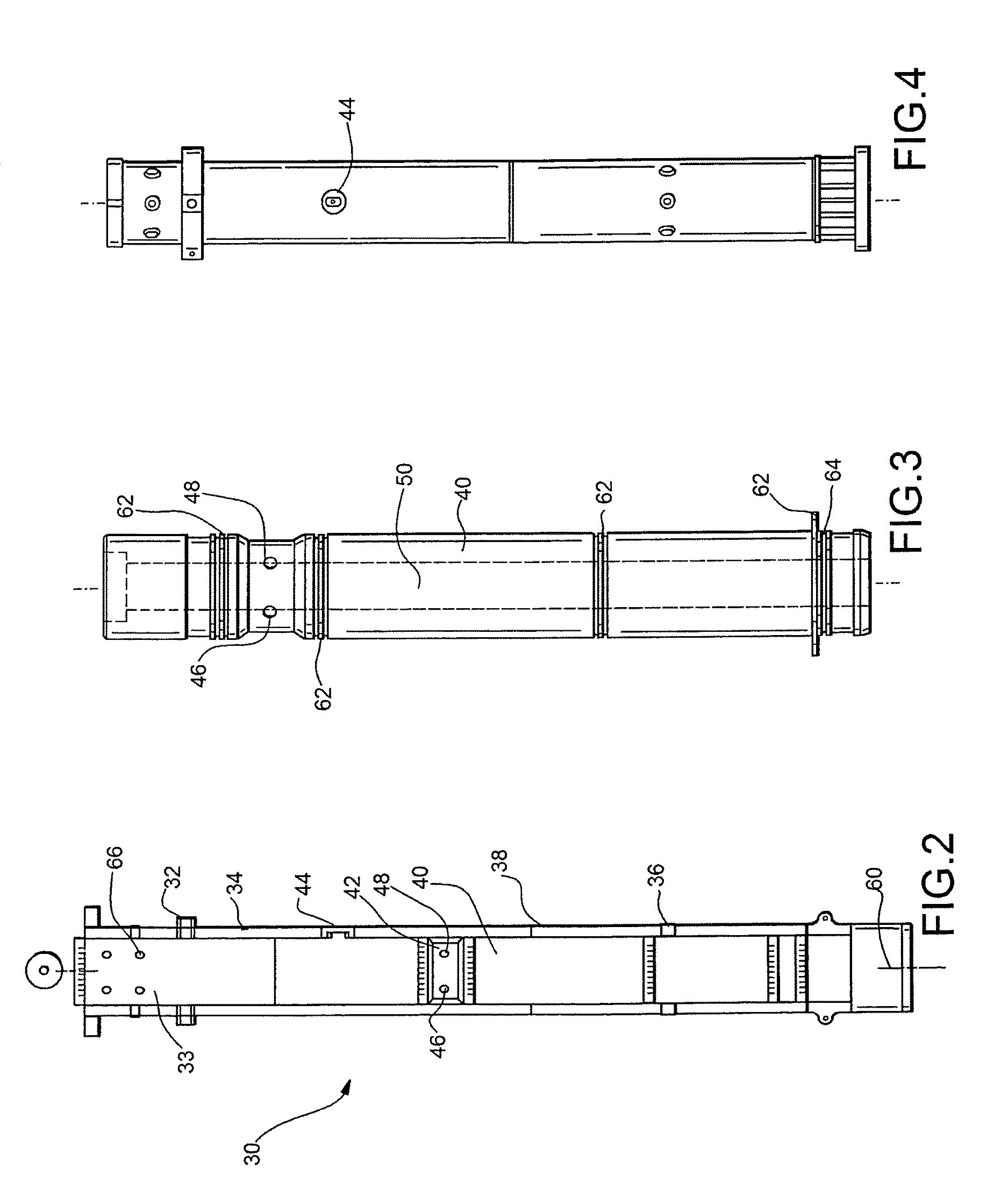

Rotary drill bit with gage pads having improved steerability and reduced wear

A rotary drill bit having blades with gage pads disposed on exterior portions thereof to improve steerability of the rotary drill bit during formation of a directional wellbore without sacrifice of lateral stability. One or more of the gage pads may include radially tapered exterior portions and / or cut out portions to assist with reducing wear of the associated gage pad. For some applications, a rotary drill bit may be formed having blades with gage pads having a relatively uniform exterior surface. Hard facing material and / or buttons may be disposed on exterior portions of the gage pad to form a radially tapered portion to improve steerability, reduce wear of the gage pad and / or improve ability of the rotary drill to form a wellbore having a generally uniform inside diameter, particularly during directional drilling of the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

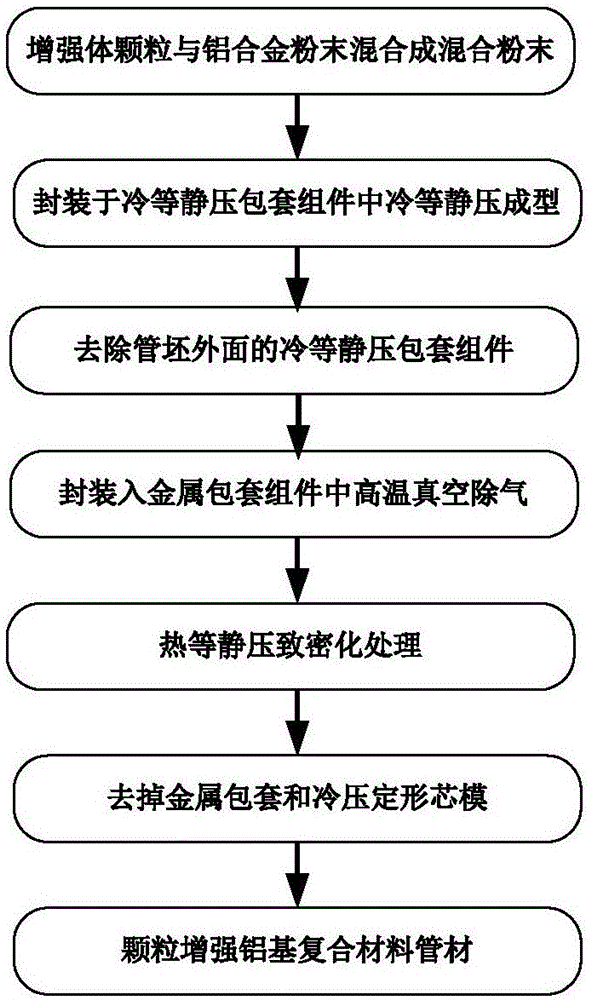

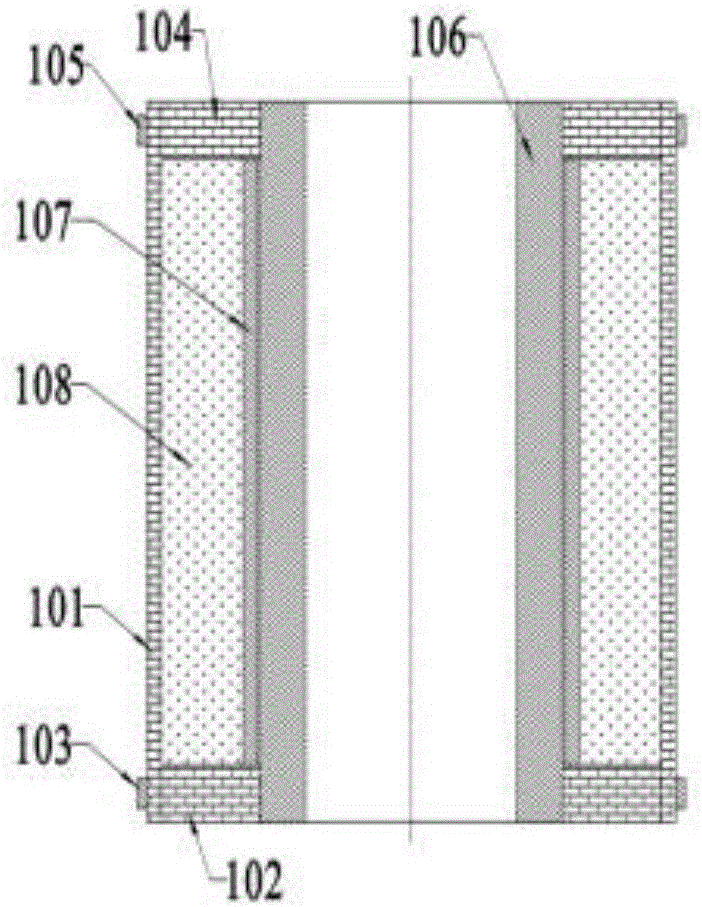

Preparing method for particle reinforcement aluminum matrix composite large-size thick-wall pipe material

The invention discloses a preparing method for a particle reinforcement aluminum matrix composite large-size thick-wall pipe material and belongs to the technical field of preparing of metal matrix composite pipe materials. According to the preparing method, reinforcement particles and aluminum alloy powder are evenly mixed according to a certain proportion; obtained mixed powder is packaged in a cold isostatic pressing sheathing assembly to be subjected to cold isostatic pressing forming, and a pipe blank is formed; the cold pressing pipe blank is subjected to vacuum gas removing, then hot isostatic pressing densifying is conducted, and a completely-dense pipe material is prepared; and finally the composite pipe material is obtained through machining. The prepared large-size thick-wall pipe material has the beneficial effects of being light, high in strength, high in modulus and the like, in addition, the quality is stable, the cost is low, and the large-size thick-wall pipe material can be widely applied to high-strength and light large-size pipes in the fields of aerospace, automobiles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

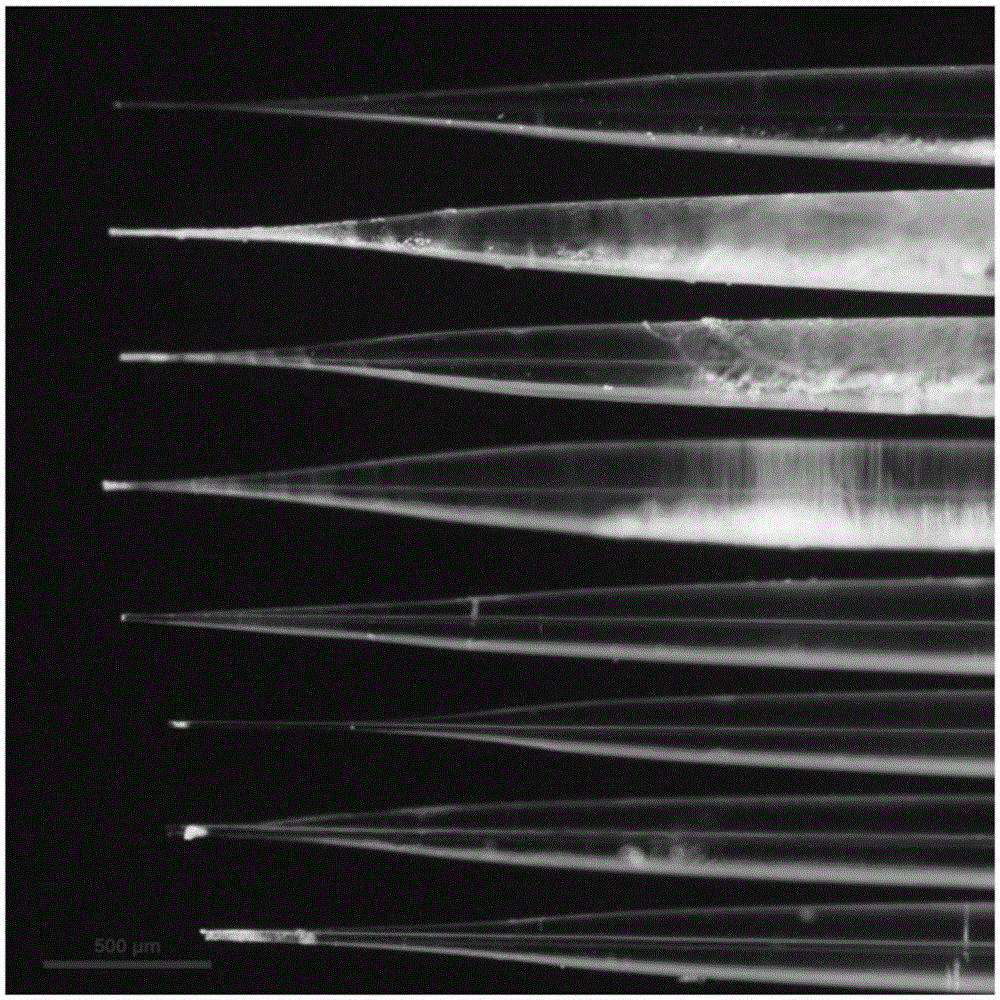

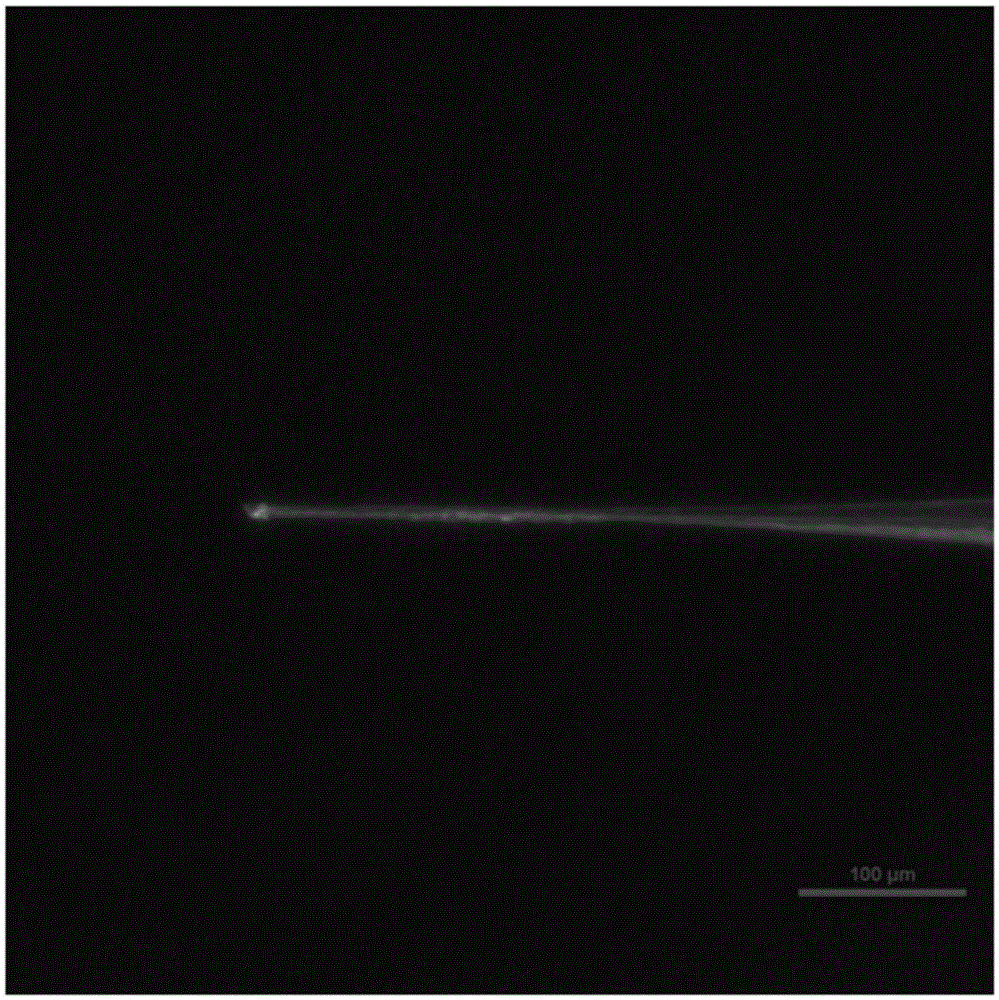

Method for preparing quartz needle by etching capillary tube by hydrofluoric acid

ActiveCN106486336ASimple and fast operationReduce usageSamples introduction/extractionMaterial analysis by electric/magnetic meansHydrofluoric acidCapillary Tubing

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

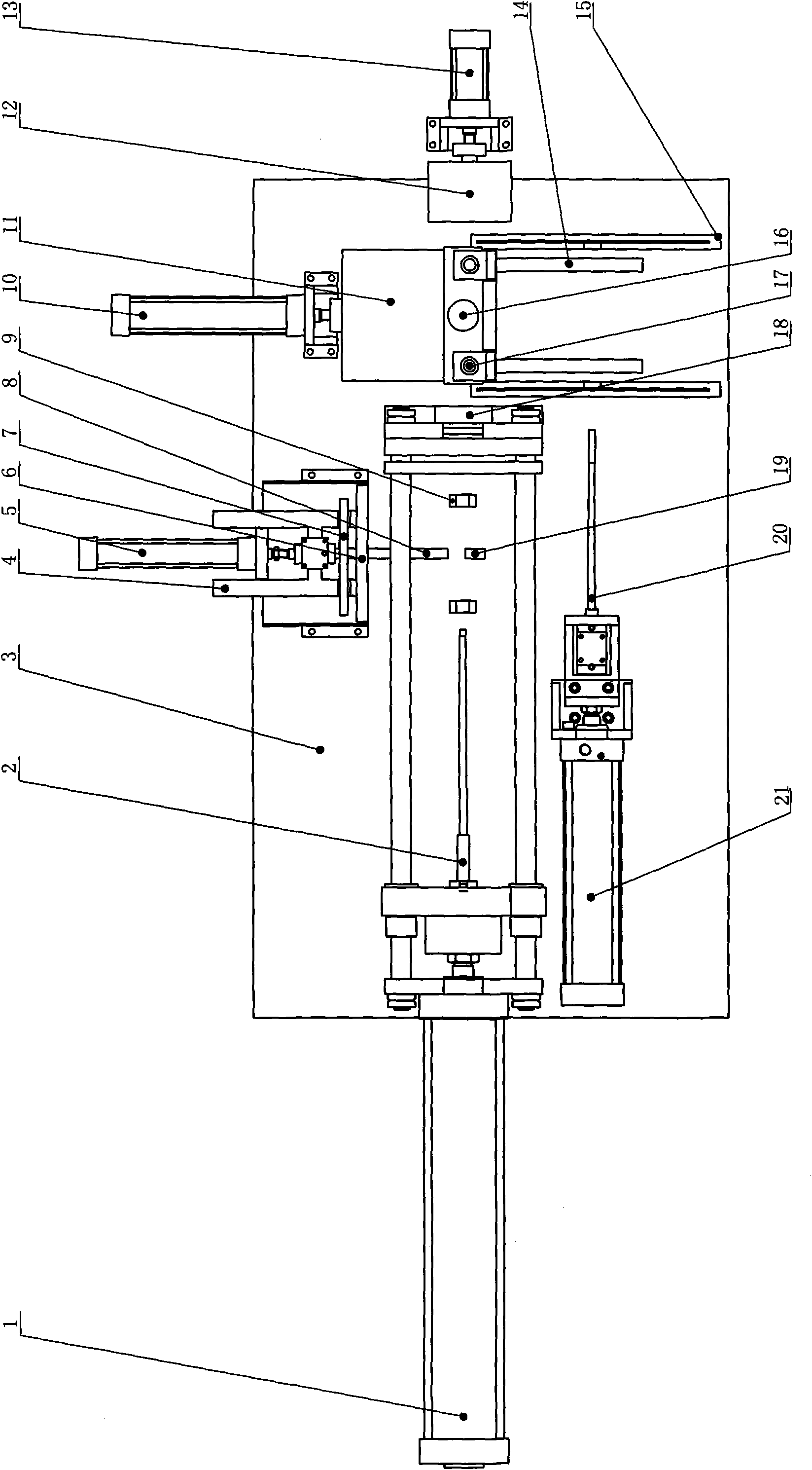

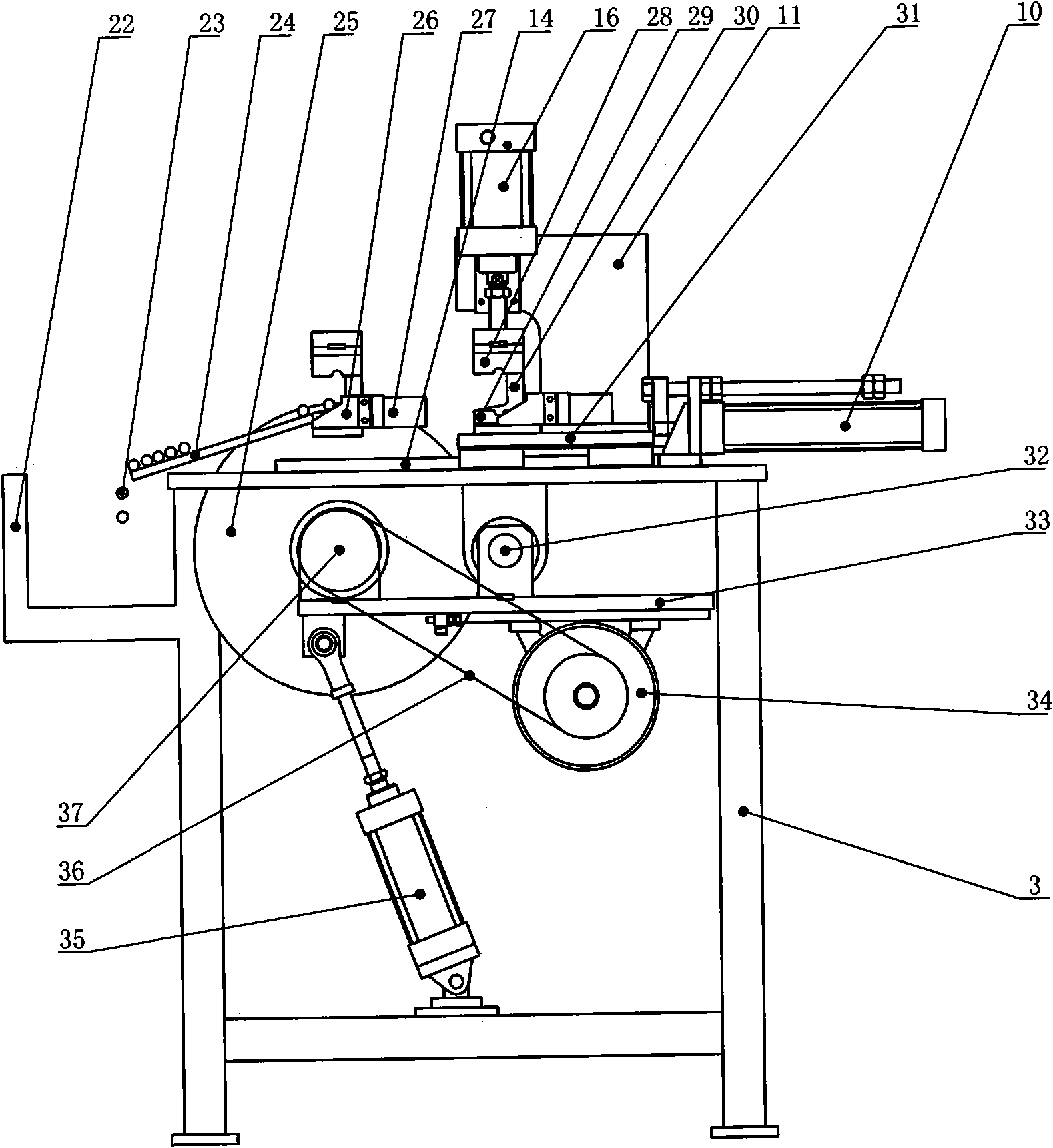

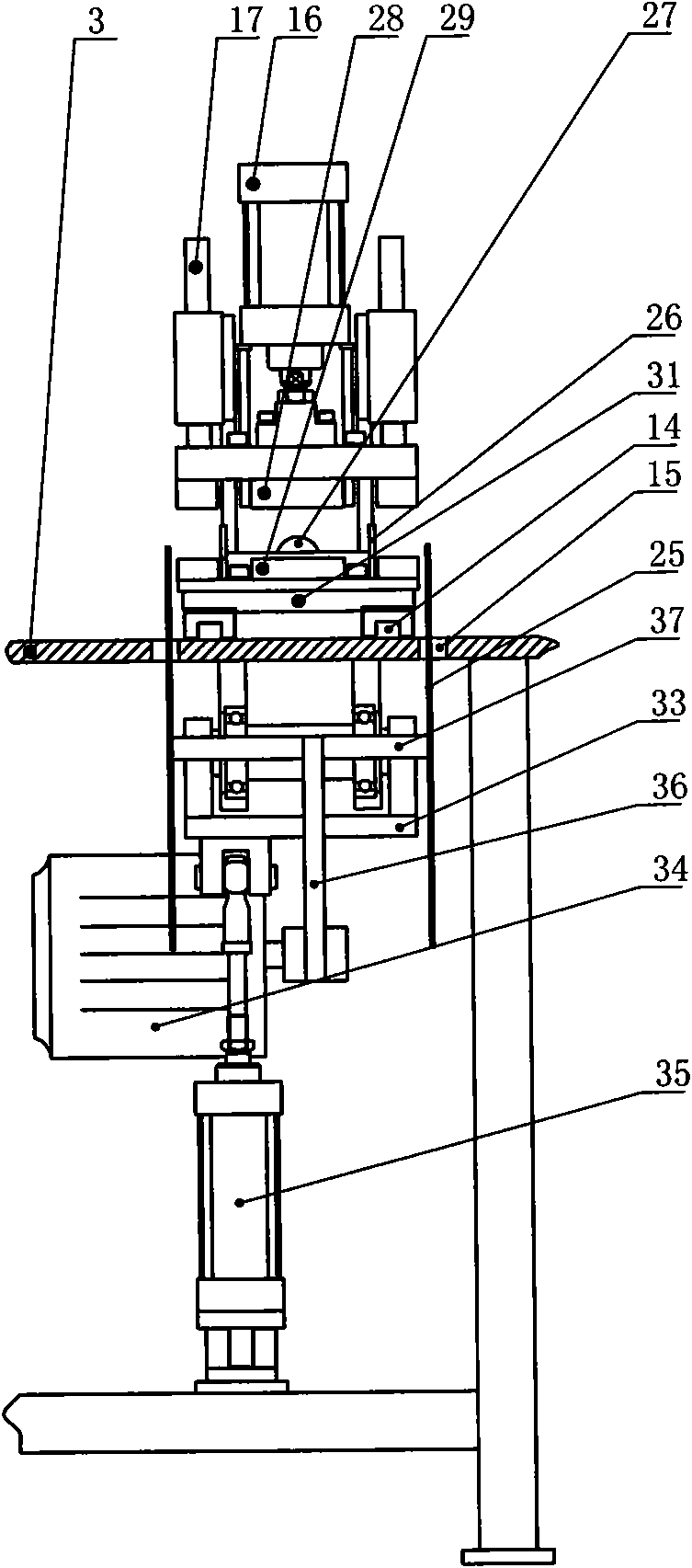

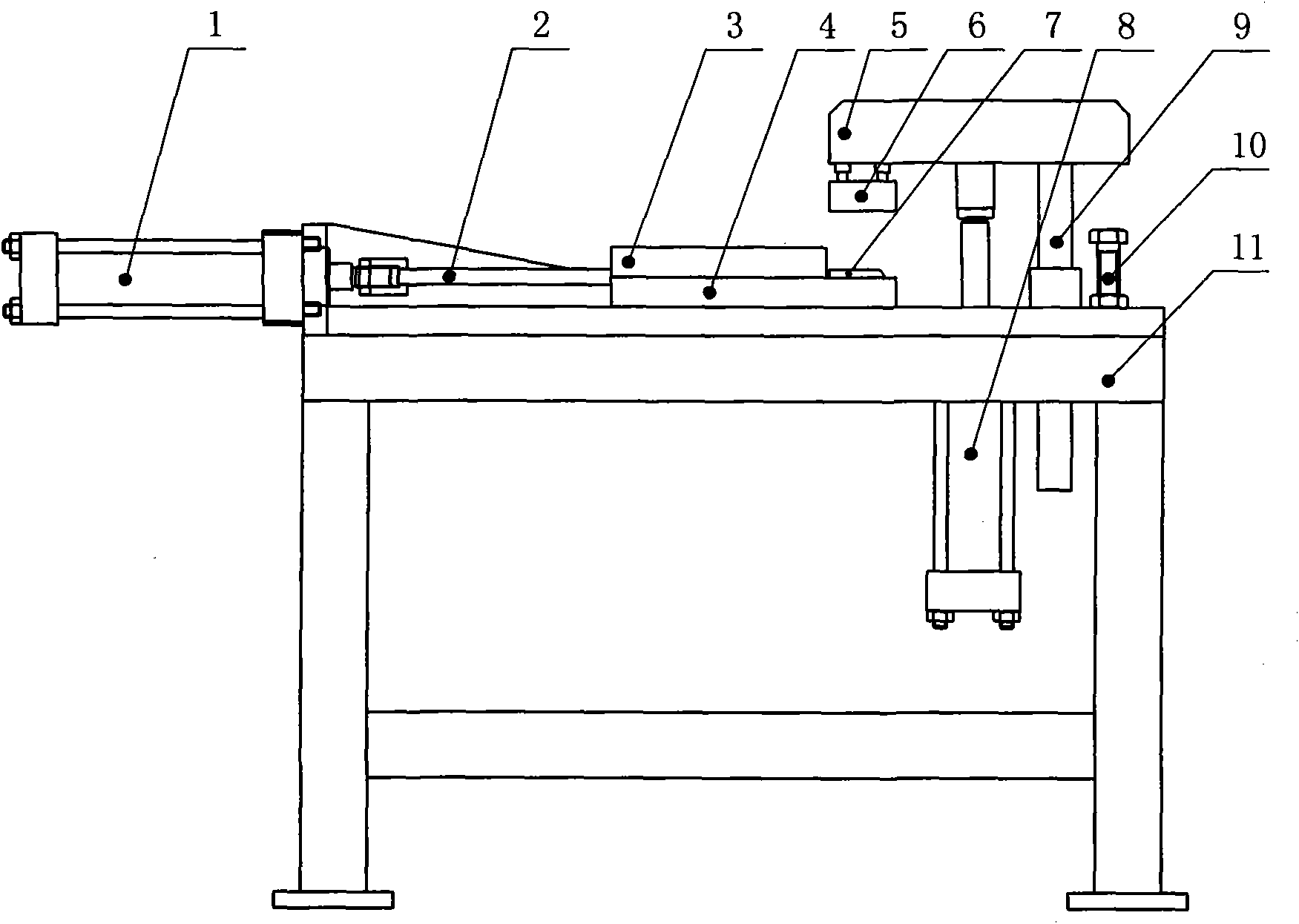

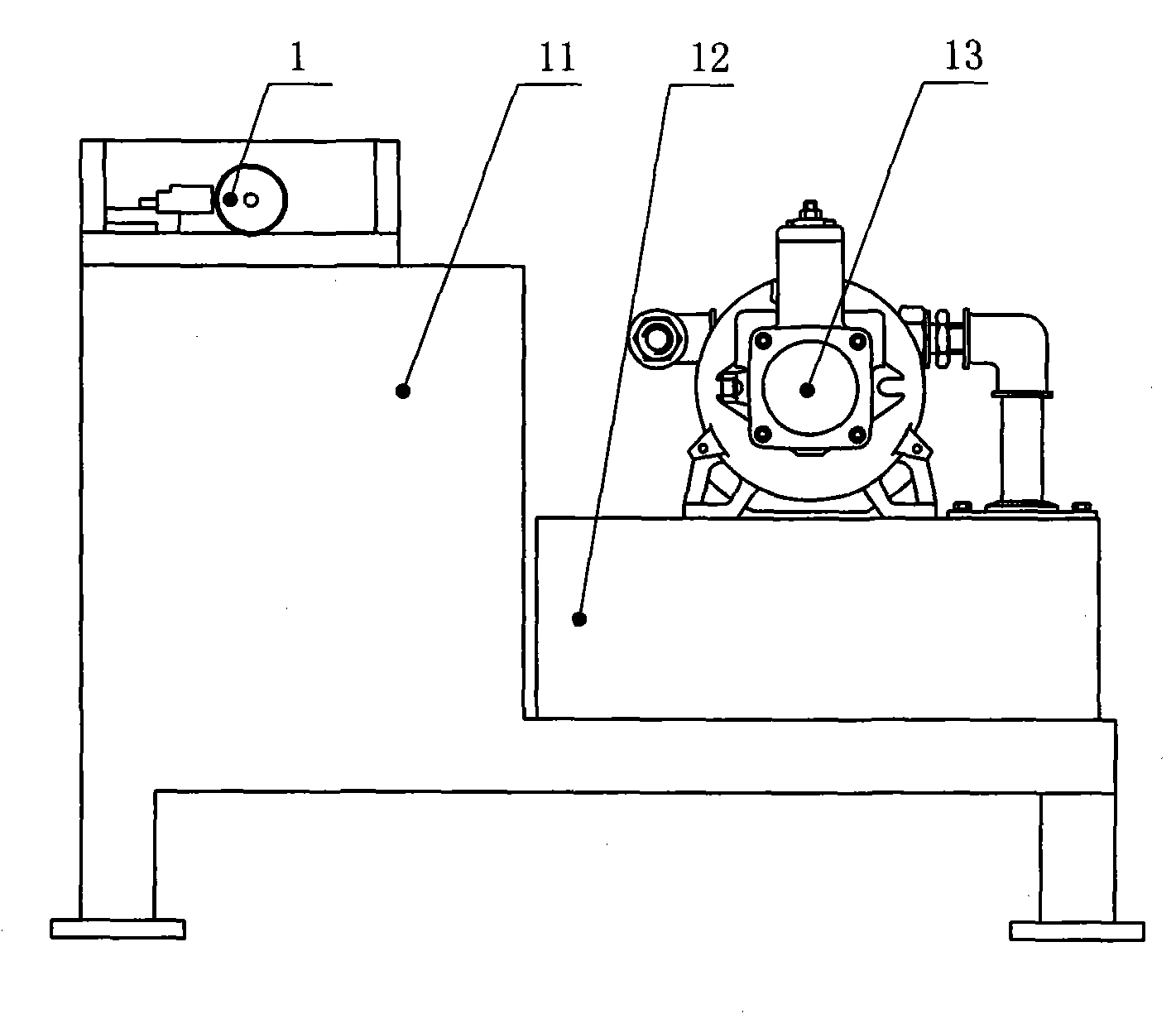

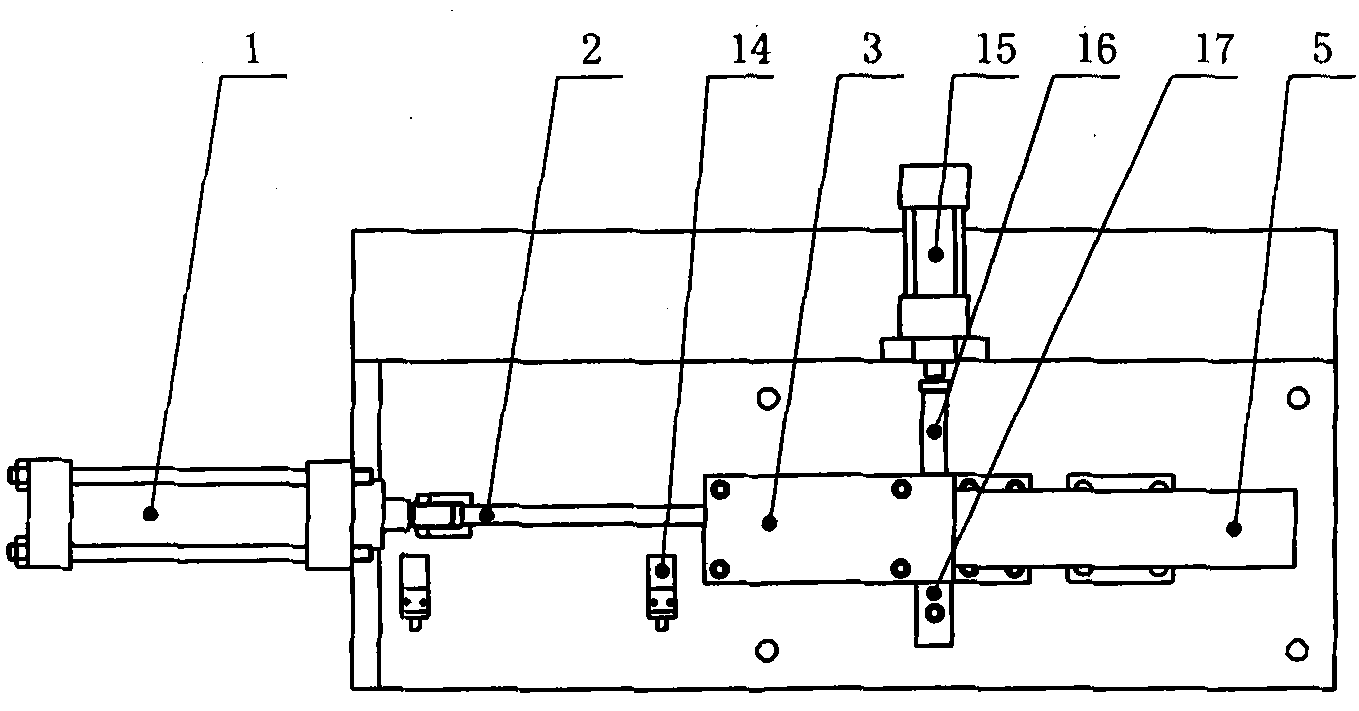

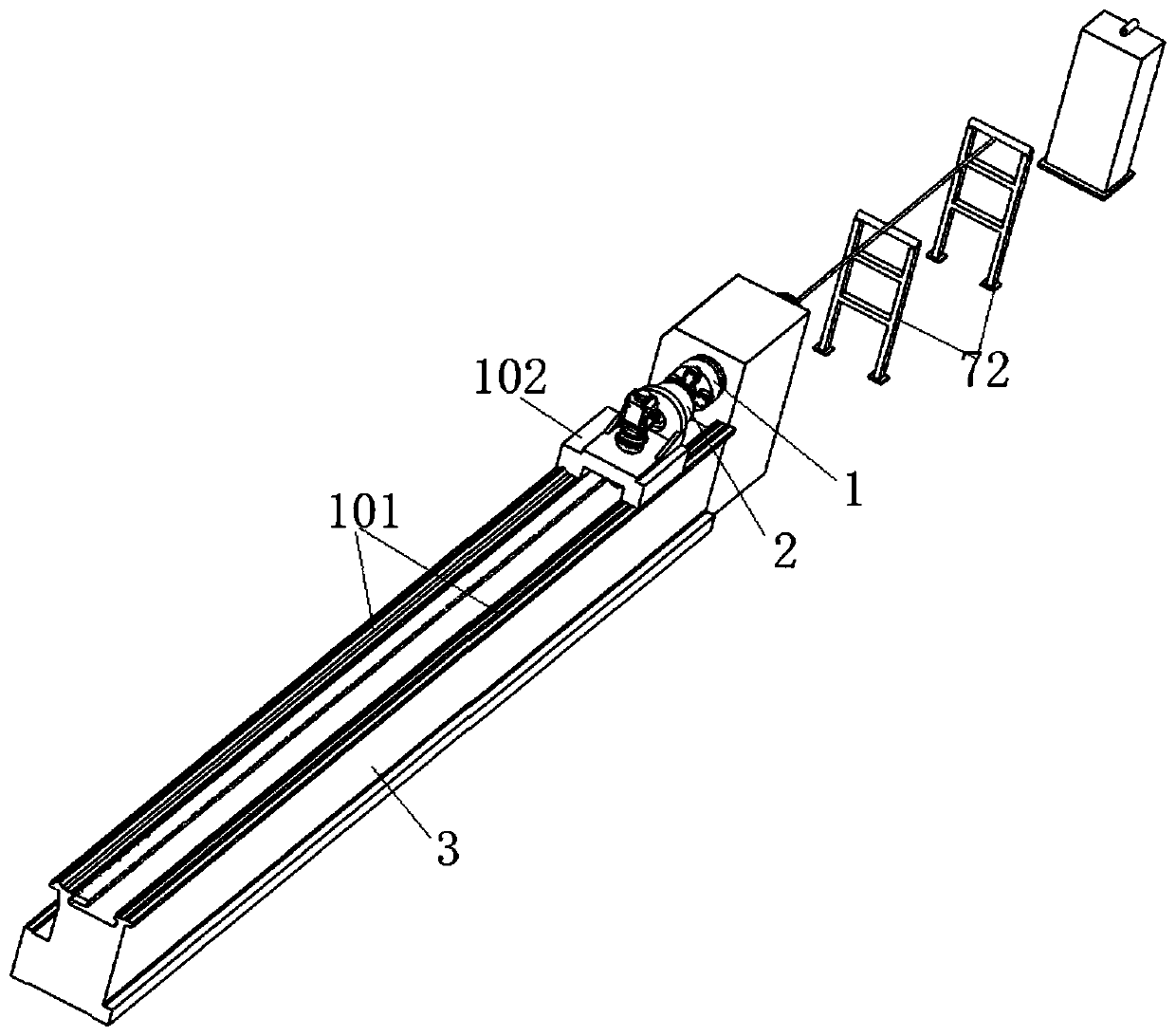

Trumpet nozzle pipe molding machine tool

InactiveCN102059506AUniform outer diameterUniform inner diameterWind musical instrumentsMolding machineEngineering

The invention relates to a trumpet nozzle pipe molding machine tool, which comprises a workbench, an electric control box, a propelling cylinder, a material feeding mechanism, an outer diameter trimming mechanism, a nozzle pipe clamping mechanism, a cutting mechanism and a positioning cylinder, wherein the electric control box is arranged at any side edge of the workbench; the propelling cylinder is arranged at the left end of the workbench; the outer diameter trimming mechanism and the nozzle pipe clamping mechanism are arranged in turn on the right side of the propelling cylinder; and the material feeding mechanism is arranged on the outer side of the outer diameter trimming mechanism. The machine tool has a simple structure, combines the cylinder with electric control equipment, realizes trimming of the inner diameter and the outer diameter of the nozzle pipe and length processing, automatically finishes feeding, inner diameter trimming, outer diameter trimming and length trimming, has high control level, makes the inner diameter and the outer diameter of a processed nozzle pipe more uniform, has more accurate length, lowers the working intensity of operating personnel, improves working efficiency and ensures sounding of an assembled trumpet.

Owner:TIANJIN JINBAO MUSICAL INSTR

Method for producing roller body of high precision compound guiding cloth guide roller

InactiveCN101323081ASuperiorExtended service lifeTextile treatment machine partsTextile printerMetallurgy

The invention discloses to a manufacturing method for a high-precision composite cloth guide roller body which relates to the technological field of textile, plastic, paper making and leather making, and the like, and more particularly relates to the technological field of textile printing and dyeing equipment. The invention comprises the following steps: a stainless steel external roller body and a cold rolled sheet roller body are rolled and welded respectively to form a stainless steel external roll blank and a cold rolled sheet roll blank; the cold rolled sheet roll blank is sheathed in the stainless steel external roll blank to make a double layer roll blank, and the spin-drawn forming is carried out at last. The method is the manufacturing method for the composite cloth guide roller body with good quality, reliable performance, low energy storage and high precision.

Owner:葛心民

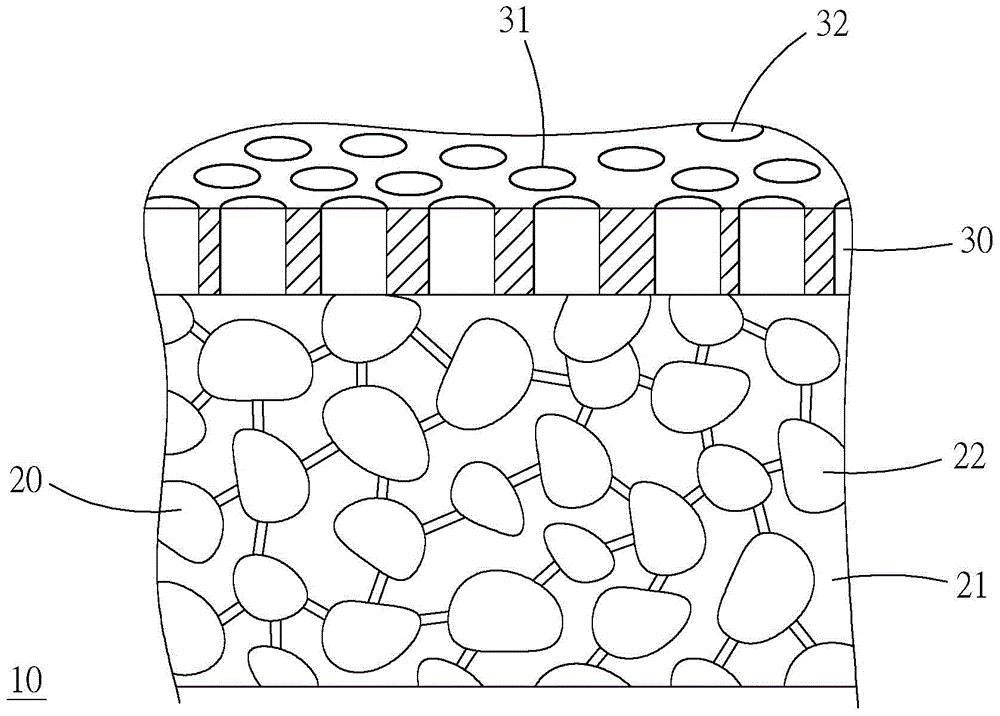

Improved structure of air bearing

The invention provides an improved structure of an air bearing, and the improved structure is a porous air bearing which comprises a porous body and a throttling layer part; the porous body is provided with a base part and an air chamber arranged on the base part, and is formed by enabling a plurality of gaps inside the base part to communicate with one another; the throttling layer part is arranged on one side end surface of the porous body, and is composed of an aluminum layer and a plurality of through holes with predetermined length; the through holes separately penetrate through the aluminum layer in the same direction relative to each other, and communicate with the air chamber. In order to increase, degree of freedom of regulation, on hole diameter parameters, of a porous material, double-layer limitation of the porous material, the through hole aluminum layer and the like is matched with through holes which are distributed in equal rectangular array and nano-scale hole diameters, so that hole uniformity, permeability consistency and isotropy are guaranteed; and meanwhile, bearing force, gas film stability and static rigidity are increased.

Owner:HIWIN MIKROSYST

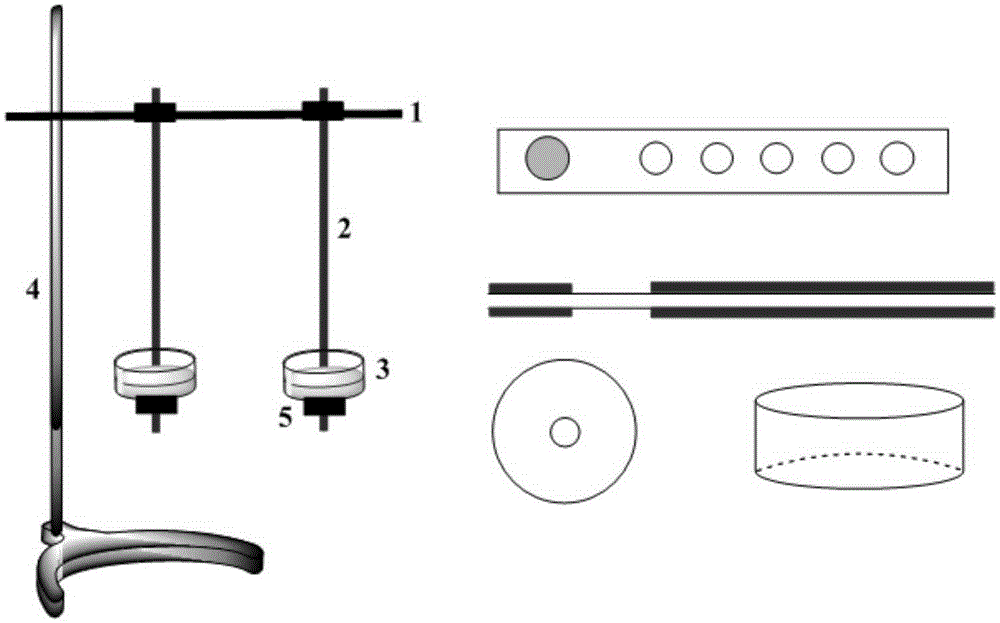

Method for preparing hollow fiber catheter for repairing nerves and bundling structure of hollow fiber catheter

The invention provides a method for preparing a hollow fiber catheter for repairing nerves and the bundling structure of the hollow fiber catheter. The method includes: preparing a tube with the innerdiameter not smaller than 0.3mm in a mixed material which contains at least one biodegradable polymer with the elongation at break being 300-1000%; inserting rigid fibers into the tube, and then applying traction force to two ends of the tube at normal temperature and normal pressure until the tube tightly wrap the rigid fibers; removing the rigid fibers to obtain the hollow fiber catheter; usingammonia plasma to perform surface treatment on the hollow fiber catheter; using biodegradable hydrogel to adhere at least two surface-treated hollow fiber catheters into a bundle to obtain the bundling structure for repairing nerves. The method has the advantages that hollow fibers of different specifications can be fast and accurately prepared, solvent use can be avoided, and the prepared bundling structure has a microscopic orientation structure.

Owner:南京邦鼎生物科技有限公司

Preparation method and device for alloy tubular product with controllable diameter and wall thickness

The invention provides a preparation method and device for an alloy tubular product with controllable diameter and wall thickness. The preparation device comprises a liquid alloy melt generating unit,a mould and a tubular product forming component. The mould is provided with a mould cavity. The tubular product forming component is installed in the mould cavity so that a cavity for preparing the alloy tubular product is formed between the outer surface of the tubular product forming component and the inner surface of the mould. The liquid alloy melt generating unit can provide a liquid alloy melt to the cavity so as to prepare the alloy tubular product. The liquid alloy melt can be adhered to the inner surface of the mould and / or the outer surface of the tubular product forming component.The method comprises the following steps: providing the liquid alloy melt for the cavity so as to prepare the alloy tubular product, and separating the alloy tubular product from the mould. The preparation method and device can be used for preparing the alloy tubular product with the controllable and uniform diameter and wall thickness, especially a non-crystal alloy tubular product.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Prestressed thermal insulation oil casing and production method thereof

ActiveCN103850654AImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsThermal insulationEngineering

The invention relates to a prestressed thermal insulation oil casing. The prestressed thermal insulation oil casing is characterized by comprising an outer tube, a middle tube and an inner tube which are sleeved at intervals, wherein an internal thread is processed on one end of the middle tube, an external thread is processed on the other end of the middle tube, one end, which is provided with the internal thread, of the middle tube is welded with the outer tube at a tube end, and is welded with the inner tube at a reserved internal thread length position, one end, which is provided with the external thread, of the middle tube is welded with the outer tube at a reserved external thread length position, and is welded with the inner tube at a tube end; an annulus, which is formed by the outer tube and the middle tube, is filled with a thermal insulation material, and is vacuumized so as to form a first thermal insulation layer, after an annulus, which is formed by the middle tube and the inner tube, is vacuumized, inert gas is filled so as to form a second thermal insulation layer; the prestressed thermal insulation oil casing comprises the following production steps of pretreating three tubes, sleeving and welding the inner tube and the middle tube, treating the annulus of the inner tube and the middle tube, sleeving and welding the outer tube and the middle tube, treating the annulus of the outer tube and the middle tube, testing a visible heat conductivity coefficient and processing screw threads on two ends of the middle tube in sequence. The prestressed thermal insulation oil casing is provided with three layers of steel pipes and two layers of thermal insulation structures, so that the prestressed thermal insulation oil casing has good thermal insulation performance and excellent working performance.

Owner:淄博孚瑞特热能科技有限公司

Manufacturing method of low-melting-point glass optical fiber perform coating sleeve pipe

InactiveCN102976606AAvoid mixingAvoid Bubble StreaksGlass making apparatusManufacturing technologyQuartz

The invention relates to a manufacturing method of a low-melting-point glass optical fiber perform coating sleeve pipe. The method belongs to the technical field of glass optical fiber manufacturing. The method is characterized in that the preparation of the coating sleeve pipe comprises the steps that: (1) low-melting-point glass is molten, cooled, and crushed; and the glass is preserved for later use; (2) the low-melting-point glass is weighed and placed in a quartz tube; (3) the loaded quartz tube is vacuumed and sealed; (4) the sealed quartz tube is heated in a rocking furnace, such that the glass in the tube is molten into liquid; (5) an electric furnace rocking switch is tuned on, such that the glass liquid is well mixed; (6) the electric furnace is opened, the quartz tube is rapidly fetched and horizontally placed in a rotation device; the quartz tube is fixed, and high-speed rotation is carried out; (7) the quartz tube is fetched, and is rapidly annealed in an annealing furnace; and (8) the quartz tube is cracked, such that the coating sleeve pipe obtained. The method has the advantages that the manufactured coating sleeve pipe has smooth and non-polluted inner surface, controllable inner and outer diameters, and no bubble and line inside.

Owner:苏州佳因特光电科技有限公司

Hollow body molding device

ActiveUS8827690B2Good lookingGood dimensional stabilityLaminationLamination apparatusMaterials scienceMagnetic core

A hollow body molding device having molten resin injected into a main cavity, fluid is pressure-injected through a pressure port after the injection of molten resin, a floating core moves to the outlet side, the molten resin is extruded from the outlet simultaneously with the movement of the floating core, and a hollow molded body is molded, the hollow body molding device having a floating core storage portion connected to the main cavity and stores the floating core moved by the pressurized fluid, an auxiliary cavity stores molten resin discharged from the main cavity and the floating core storage portion, communication passages and which communicate the floating core storage portion and the auxiliary cavity with each other; and an opening and closing means that opens and closes the communication passages by sliding movement. In the hollow body molding device, each inlet cross-sectional area B of the communication passages is specified.

Owner:RP TOPLA

A kind of single-mode chalcogenide glass optical fiber and its manufacturing method

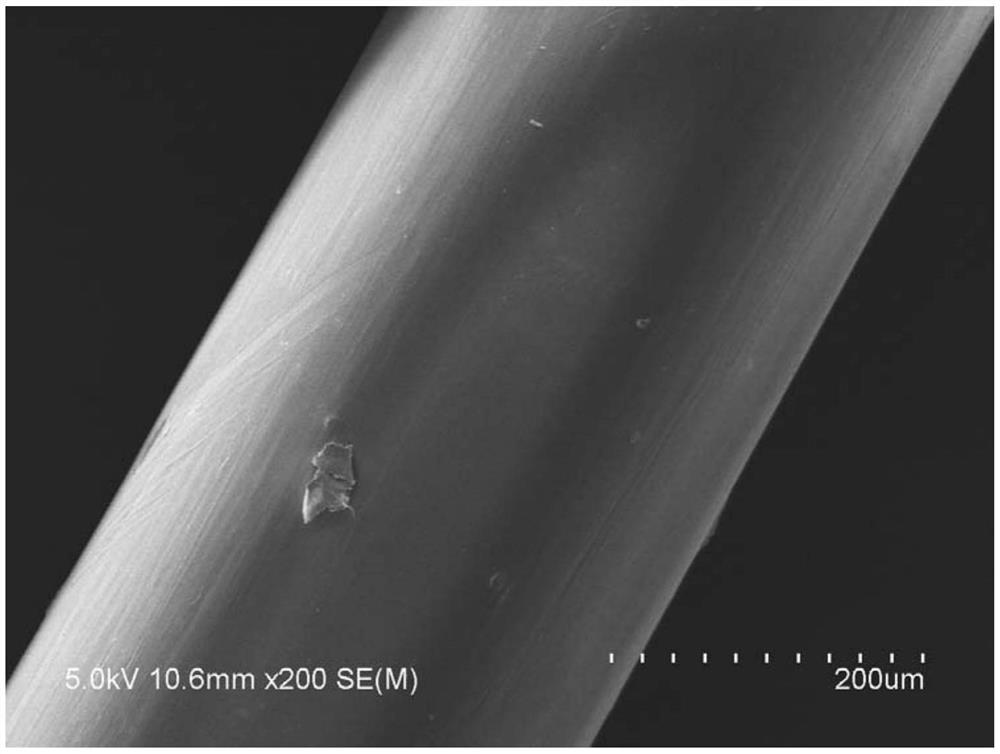

InactiveCN102976607BUniform inner diameterImprove optical qualityGlass making apparatusOptical fibre with multilayer core/claddingLayer interfaceSulfur

The invention relates to the technical field of a glass optical fiber material and a preparation method thereof, and especially relates to a single-mode chalcogenide infrared glass optical fiber and preparation method thereof. The optical fiber has the characteristics that: an As-S-Se infrared glass system is adopted as a coating layer, and an As-Se infrared glass system is adopted as a core layer. During a process for preparing an optical fiber preform rod, a coating sleeve pipe is prepared with a vacuum sealed rotary method; core-layer glass is prepared through vacuum sealed annealing; the core-rod glass rod is inserted into the coating sleeve pipe, and a core rod with a coating is prepared by using a wire-drawing machine; the core rod is inserted into the coating sleeve pipe again, and the single-mode optical fiber is prepared with a repeated drawing method. Through the regulation upon the composition of the coating glass, multi-coating chalcogenide glass optical fiber can be conveniently prepared. With the method, the prepared optical fiber has the advantages of controllable core-coating ratio; no defect such as impurity, bubble, or line on core-coating layer interface; high core-coating layer concentricity; and low optical loss.

Owner:苏州佳因特光电科技有限公司

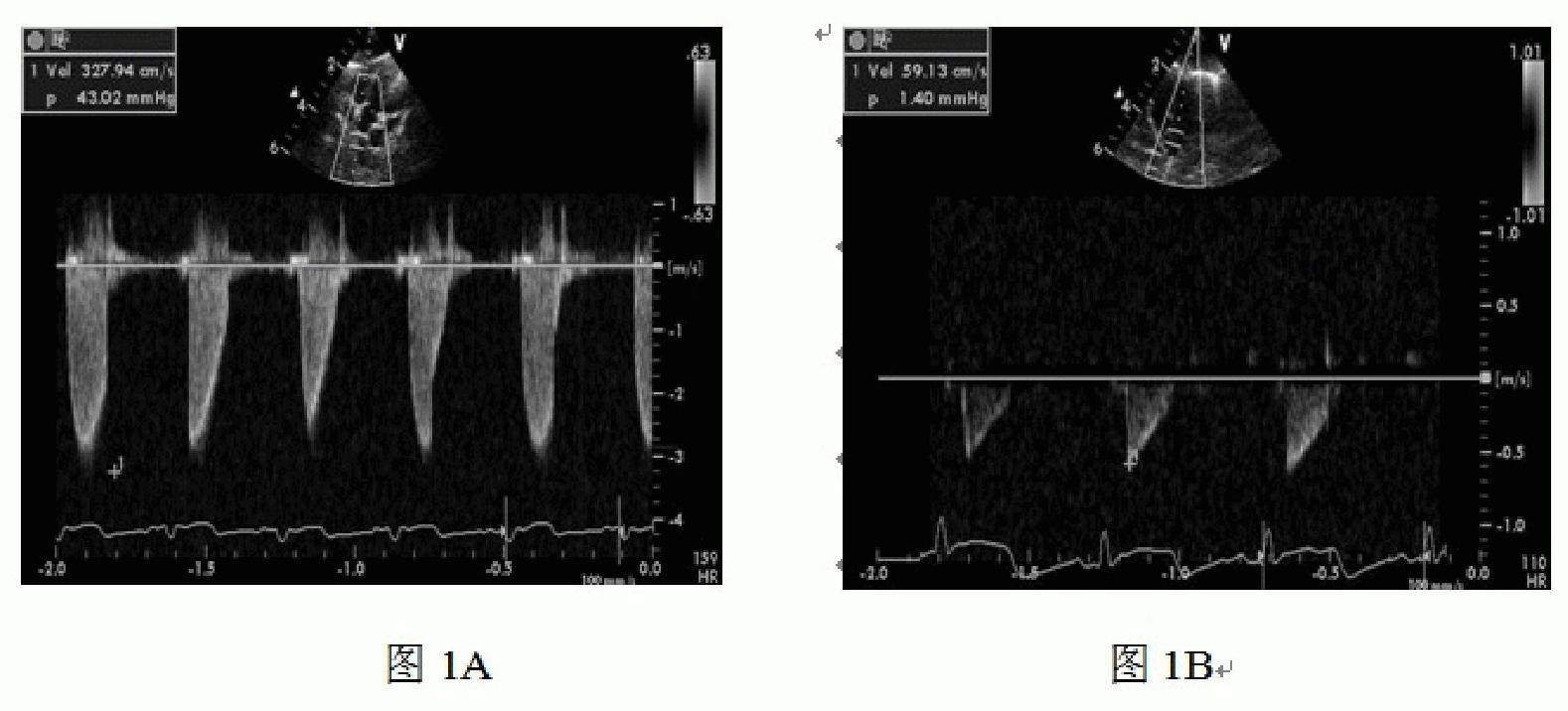

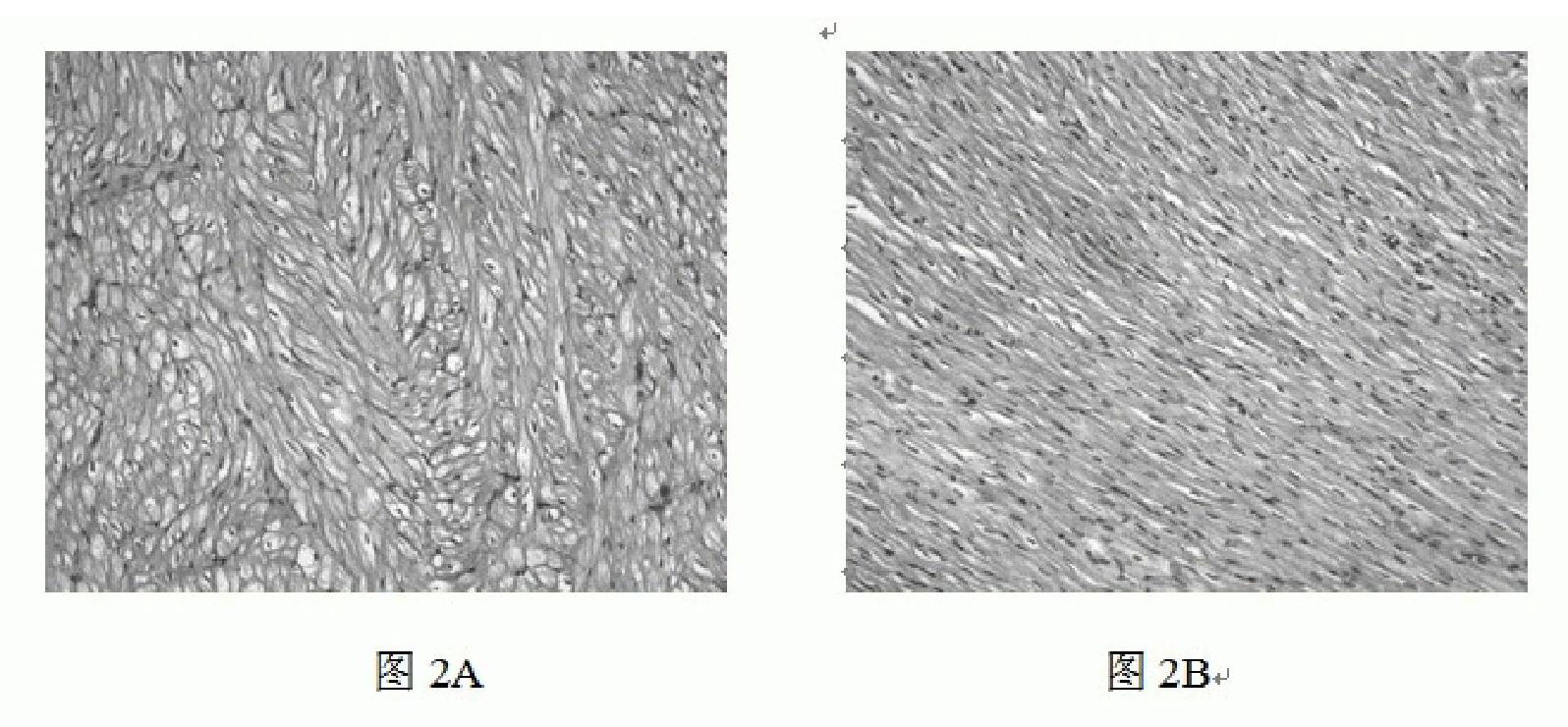

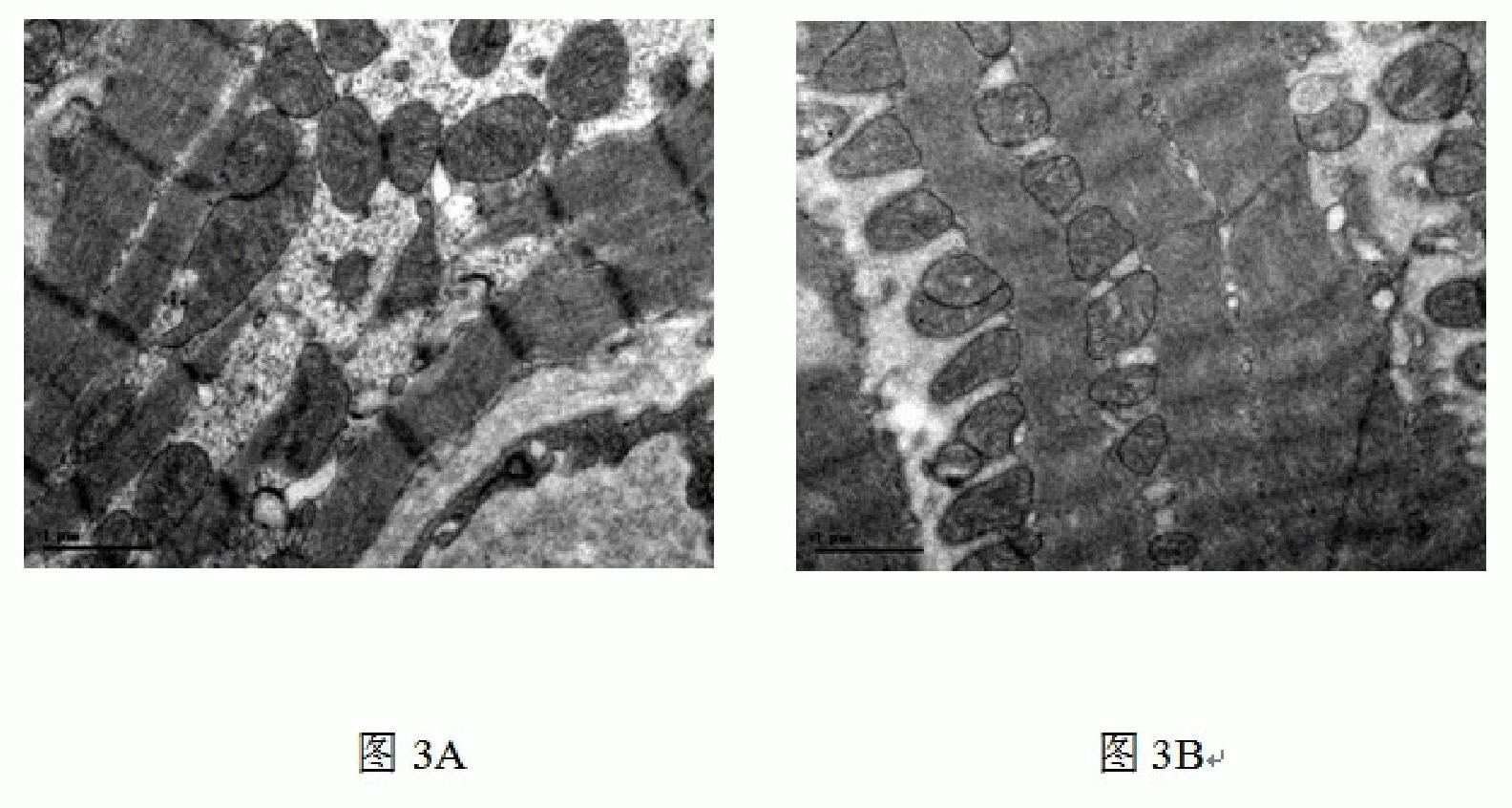

Method for preparing animal model with cardiac hypertrophy by unartificial ventilation

InactiveCN101828540AHigh blood pressure does not occurHigh simulationMedical devicesAnimal husbandryDiseaseArtificial ventilation

The invention relates to a method for preparing an animal model with cardiac hypertrophy by unartificial ventilation, comprising the following steps of: (1) narcotizing a healthy rabbit without using a breathing machine and keeping the natural breathing state of the rabbit; (2) ligaturing the root of an ascending aorta by using a Prolenen thread with the model of 3 / 0 so that the diameter of the ascending aorta is reduced by 45-55 percent; and (3) obtaining a model animal with obvious cardiac hypertrophy and coarctated ascending aorta after 4-8 weeks. The animal model is prepared without the breathing machine, thereby avoiding tracheal injury and complicating diseases of mechanical ventilation, reducing experimental facilities, lowering the cost, and playing a very important role in researching the mechanism of cardiac hypertrophy and treating.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

Die structure for producing agricultural tractor wheel seat rings

InactiveCN106180518AEasy to processEasy clampingForging/hammering/pressing machinesAgricultural engineeringMachining time

The invention discloses a die structure for producing agricultural tractor wheel seat rings. The die structure comprises a core roller and a main die, wherein a forging piece is arranged between the core roller and the main die, the middle of the core roller is a cylinder section of a cylinder structure, and the main die is provided with a first vertical section, a first slope section, a second slope section and a second vertical section in sequence from top to bottom. With the die structure for producing agricultural tractor wheel seat rings, the machined agricultural tractor wheel seat rings are uniform in dimensions of product inner diameters, and very high in accuracy of inner diameters, forging allowance is only 2 millimeters to 3 millimeters, and materials are saved by 15% to 20%; because the inner diameters are uniform in dimension, calibration and clamping of machining are easy, the inner diameter allowance is small, finishing turning can be directly carried out, the working procedure of semi-finishing turning is omitted, the time for machining on batched products can be greatly shortened, and the efficiency is improved.

Owner:LIUZHOU LIUPIN TECH

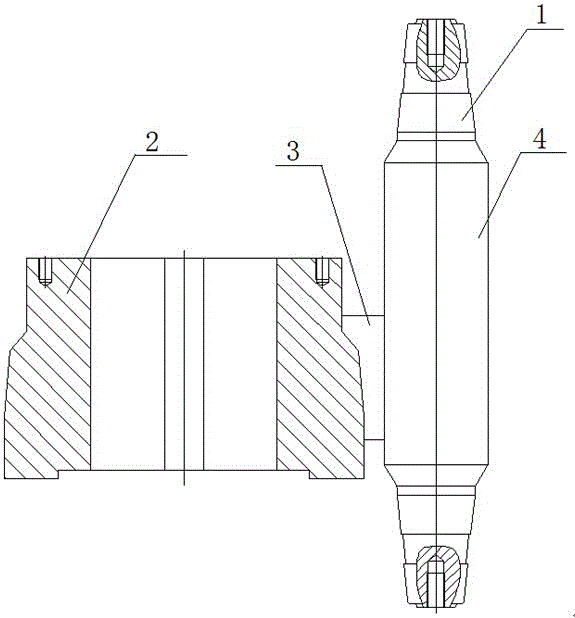

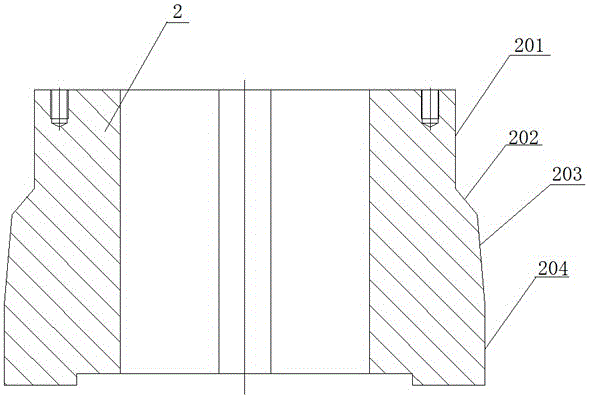

Inner diameter finishing machine tool of small-size connecting bend

InactiveCN102059290AUniform inner diameterUniform outer diameterMetal-working feeding devicesPositioning devicesElectric controlHigh pressure

The invention relates to a inner diameter finishing machine tool of a small-size connecting bend, comprising a workbench, an electric control cabinet, a propelling oil cylinder, a workpiece clamp and a high-pressure air injecting device, wherein the electric control cabinet is installed on the side surface of the workbench, the propelling oil cylinder is installed on one end of the upper surface of the workbench, the workpiece clamp is installed on the right side of the propelling oil cylinder, and the high-pressure air injecting device is installed on the outer side of the workpiece clamp. The inner diameter finishing machine tool has the advantages of simple structure, low cost, automatic accomplishment of a finishing process, high speed, good effect and high working efficiency; and the an air cylinder, the oil cylinder and other kinds of equipment are combined with the electric control cabinet so that the inner diameter finishing machine tool finishes the inner diameter of the small-size connecting bend by utilizing high-pressure air for blowing rolling balls.

Owner:TIANJIN JINBAO MUSICAL INSTR

A method for preparing quartz needles by etching capillaries with hydrofluoric acid

ActiveCN106486336BSimple and fast operationReduce usageSamples introduction/extractionMaterial analysis by electric/magnetic meansHydrofluoric acidPolymer coatings

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing hollow fiber catheter and bundled structure thereof for nerve repair

ActiveCN110124102BBig spaceGood for inducing regenerationTissue regenerationProsthesisHollow fibreFiber

The present invention provides a method for preparing a hollow fiber catheter for nerve repair and a bundled structure thereof, which includes: preparing a mixed material containing at least one biodegradable polymer with an elongation at break of 30-1000% into an inner diameter of ≥0.3 mm tube; insert the rigid fiber into the tube and apply traction on both ends of the tube at normal temperature and pressure until the tube tightly covers the rigid fiber; remove the rigid fiber to obtain a hollow fiber catheter; use ammonia plasma to treat the hollow fiber The catheter is surface-treated; and then at least two surface-treated hollow fiber catheters are bonded into a bundle using biodegradable hydrogel to obtain a bundled structure for nerve repair. The method of the present invention can quickly and accurately prepare hollow fibers of different specifications, avoid the use of solvents, and produce bundled structures with a more microscopic orientation structure.

Owner:南京邦鼎生物科技有限公司

Threaded pipe pulling device

PendingCN110653287AAvoid the phenomenon that the inner diameter is instantly reducedWill not affect healthMetal-working feeding devicesPositioning devicesThreaded pipeEngineering

The invention discloses a threaded pipe pulling device. The threaded pipe pulling device comprises a first chuck, a second chuck, a plurality of groups of pulley components and a fixing part. The circumferential outer walls of pulleys of the pulley components surround to define a chamber body communicating with a first through hole; and the front end, far away from the second chuck, of the fixingpart forms a start position rolling region with the pulleys when extending into the chamber body with the second chuck. The threaded pipe pulling device is not provided with a lining core and a core head which are used for supporting the inner wall of a pipe, so defects such as friction marks or scratches are not formed on the inner wall of the pipe in a pipe pulling process; when the pulleys areused for rolling screw threads at a start position, as the front end of the fixing part extends into the chamber body in order to support the inner wall of the position of start rolling screw threadsof the pipe, the inner diameter of the pipe is prevented from being immediately reduced when the pulley form screw thread position rolling at the start position of the pipe; and thus the inner diameter of a pulled threaded pipe is uniform at different positions.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Method for producing roller body of high precision compound guiding cloth guide roller

InactiveCN101323081BSuperiorExtended service lifeTextile treatment machine partsTextile printerMetallurgy

The invention discloses to a manufacturing method for a high-precision composite cloth guide roller body which relates to the technological field of textile, plastic, paper making and leather making,and the like, and more particularly relates to the technological field of textile printing and dyeing equipment. The invention comprises the following steps: a stainless steel external roller body anda cold rolled sheet roller body are rolled and welded respectively to form a stainless steel external roll blank and a cold rolled sheet roll blank; the cold rolled sheet roll blank is sheathed in the stainless steel external roll blank to make a double layer roll blank, and the spin-drawn forming is carried out at last. The method is the manufacturing method for the composite cloth guide rollerbody with good quality, reliable performance, low energy storage and high precision.

Owner:葛心民

Manufacturing method of prestressed heat insulating oil casing

ActiveCN103850654BImprove insulation performanceSlow down the phenomenon of "hydrogen permeation"Drilling rodsDrilling casingsThermal insulationEngineering

The invention relates to a prestressed thermal insulation oil casing. The prestressed thermal insulation oil casing is characterized by comprising an outer tube, a middle tube and an inner tube which are sleeved at intervals, wherein an internal thread is processed on one end of the middle tube, an external thread is processed on the other end of the middle tube, one end, which is provided with the internal thread, of the middle tube is welded with the outer tube at a tube end, and is welded with the inner tube at a reserved internal thread length position, one end, which is provided with the external thread, of the middle tube is welded with the outer tube at a reserved external thread length position, and is welded with the inner tube at a tube end; an annulus, which is formed by the outer tube and the middle tube, is filled with a thermal insulation material, and is vacuumized so as to form a first thermal insulation layer, after an annulus, which is formed by the middle tube and the inner tube, is vacuumized, inert gas is filled so as to form a second thermal insulation layer; the prestressed thermal insulation oil casing comprises the following production steps of pretreating three tubes, sleeving and welding the inner tube and the middle tube, treating the annulus of the inner tube and the middle tube, sleeving and welding the outer tube and the middle tube, treating the annulus of the outer tube and the middle tube, testing a visible heat conductivity coefficient and processing screw threads on two ends of the middle tube in sequence. The prestressed thermal insulation oil casing is provided with three layers of steel pipes and two layers of thermal insulation structures, so that the prestressed thermal insulation oil casing has good thermal insulation performance and excellent working performance.

Owner:淄博孚瑞特热能科技有限公司

The Manufacturing Process of Copper Pipe with Equal Wall Thickness and Reduced Diameter

The invention discloses a manufacturing process for an equal wall thickness variable-diameter copper pipe. The manufacturing process includes the steps that a section of copper pipe required by the design length is selected; the copper pipe is fixed, the diameters of the two ends of the copper pipe are expanded, two diameter-expanding sections are machined, protecting bodies are clamped at the ends of the copper pipe in the diameter expanding process, core rods are pushed into the copper pipe from outside to inside in the axial direction from the two ends of the copper pipe, the ends of the copper pipe are heated in the pushing-in process of the core rods, and the ends of the copper pipe are pushed in the axial direction from outside to inside; knurling treatment is conducted on the diameter-expanding sections, so that corrugated spiral grooves are formed in the surfaces of the diameter-expanding sections; the outer ends of the diameter-expanding sections are subjected to diameter changing and shrinking treatment to be in the designed pipe diameter size, straight-pipe-shaped pipe opening sections are formed, and threads are machined on the pipe opening sections. The equal wall thickness variable-diameter copper pipe manufactured through the method is integrally formed, the utilization rate of materials is high, the cost is low, the pipe is pushed while diameter expansion is conducted, the wall thicknesses of all the portions of the pipe are made moderate and consistent, bending and mounting are easy, the compression strengths of all the portions of the pipe are consistent, the overall pressure-resistant property of the pipe is balanced and high, and leakage is not likely to happen; the inner diameter of the pipe can be kept even, the flow velocity and the flow of refrigerating fluid in the pipe are made even, and therefore an air conditioning unit can work stably for a long time.

Owner:左铁军 +1

Pile hammer

InactiveUS9562337B1Simplify operator 's jobReduce weightReciprocating drilling machinesPortable percussive toolsEngineeringMechanical engineering

An improved pile hammer provides a cylinder, such as one with a uniform interior diameter wall and uses a piston ram to cycle up and down therein to contact an anvil on a downstroke. The anvil preferably provides a cavity to both lessen the weight and improve upward force on the ram for the upstroke. An air inlet is preferably located above an air outlet which was not possible with prior art designs. An air reservoir can be located above and external to the wall in the cylinder.

Owner:TREMMIER JONATHAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com