Inner diameter finishing machine tool of small-size connecting bend

A technology for connecting elbows and inner diameters, which is applied in the field of trumpet connecting elbow inner diameter trimming machine tools, which can solve the problems of inability to ensure the uniform inner diameter of "U"-shaped elbows, the influence of trumpet pitch, and the easy breakage of steel cables, achieving structural Simple, improved machining accuracy, uniform inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

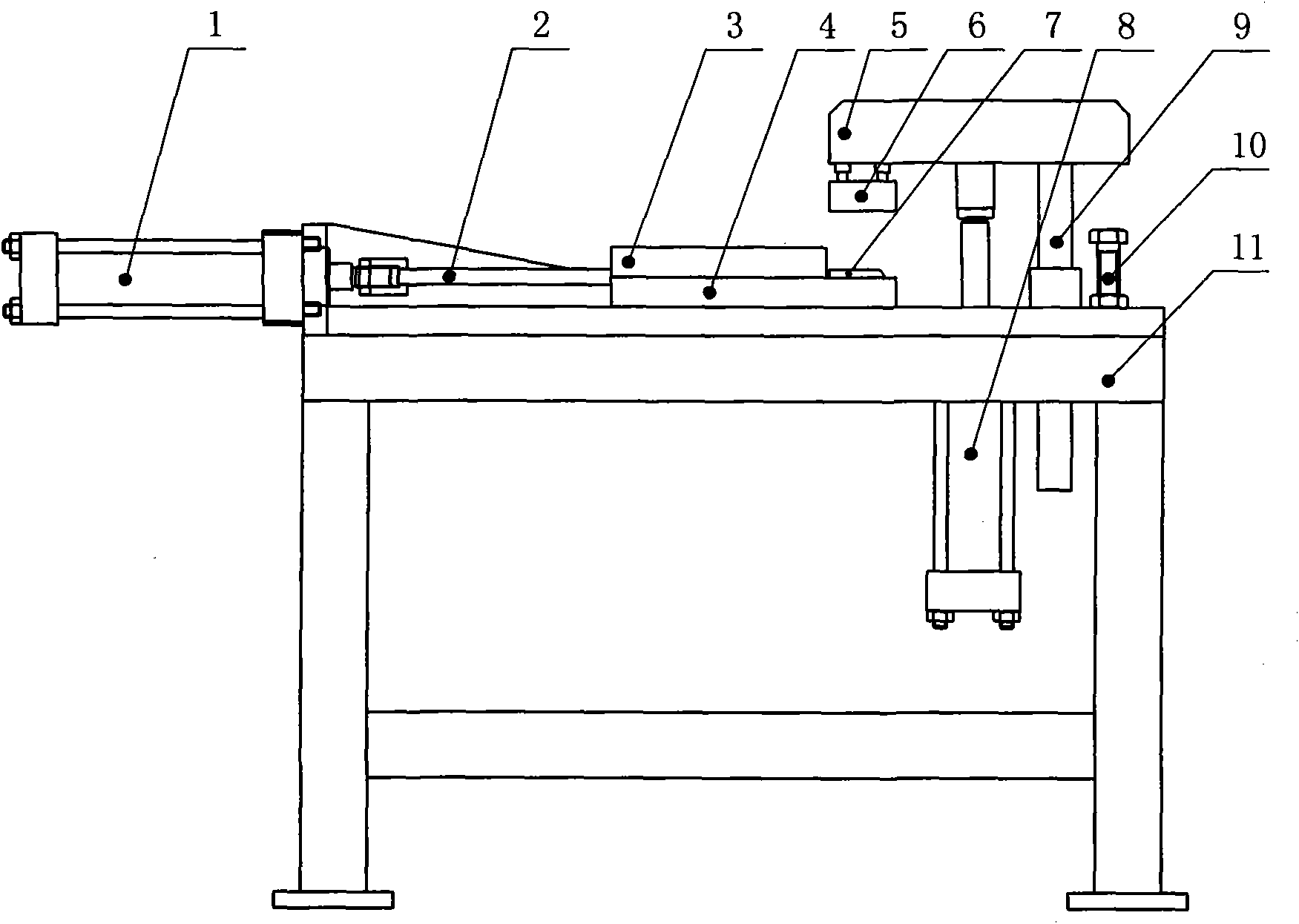

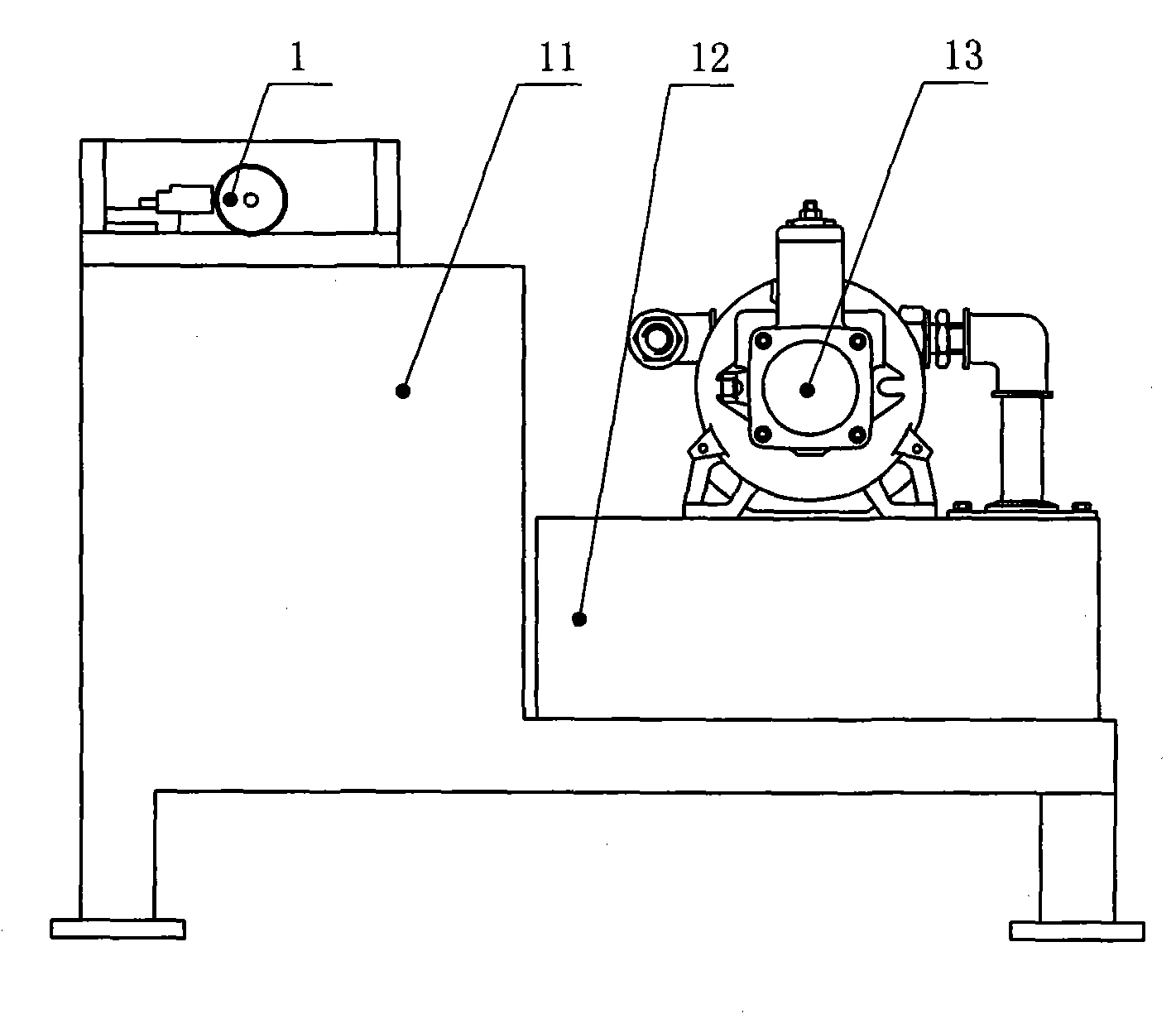

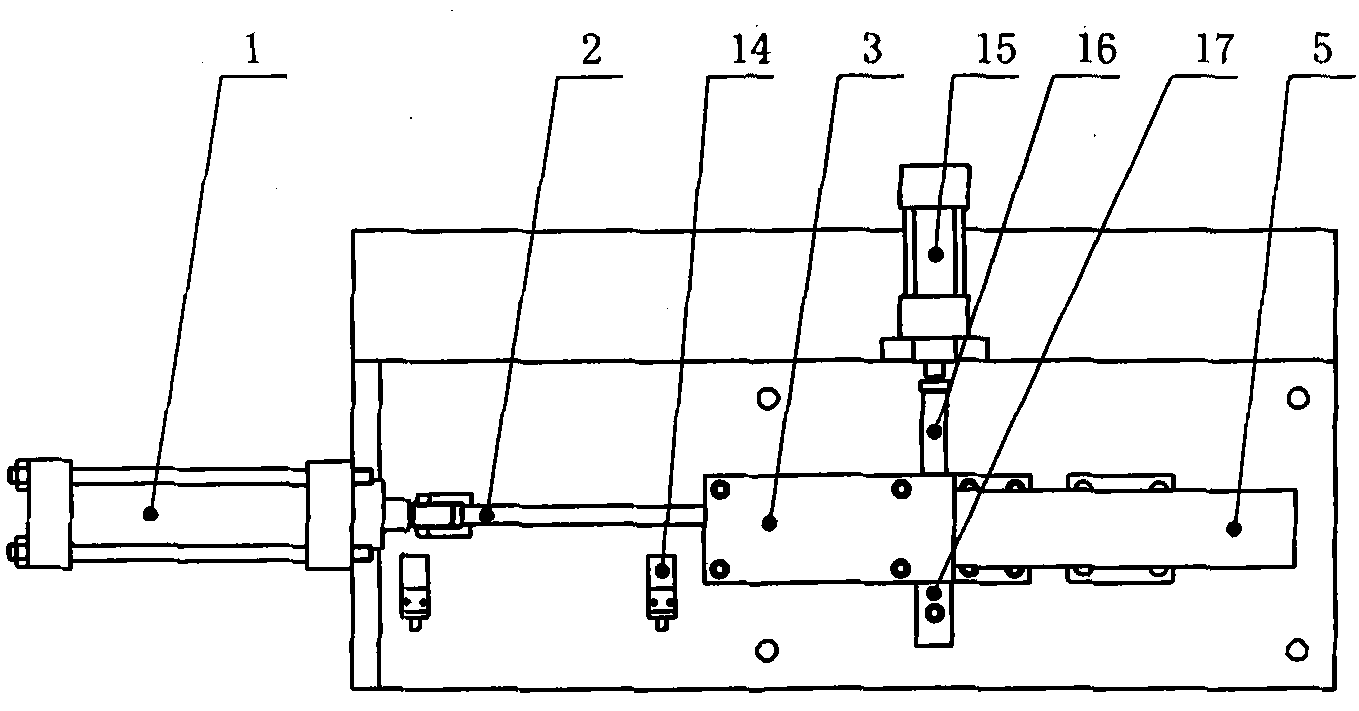

[0021] A small connection elbow inner diameter trimming machine tool, such as Figure 1~6 As shown, the innovation of the present invention is: comprise workbench 11, electric control box (omit this part), propulsion cylinder 1, workpiece fixture and high-pressure air injection device, electric control box is installed on the right side of workbench, and propulsion cylinder is installed on the working On the left end of the upper surface of the stage, the workpiece fixture is installed on the right side of the propulsion cylinder, and the high-pressure air injection device is installed on the outside of the workpiece fixture.

[0022] (1) The workpiece fixture includes a lower mold 4, an upper mold 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com