Patents

Literature

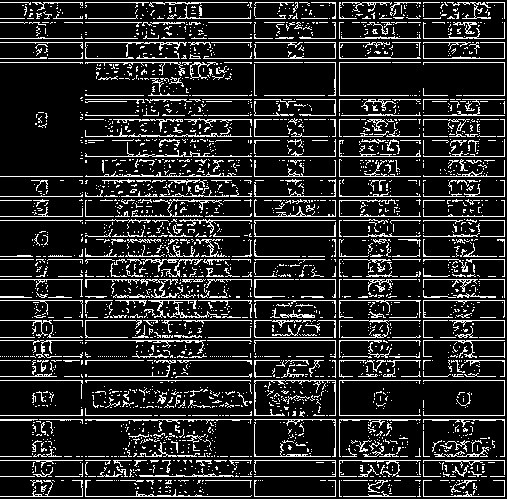

81results about How to "Uniform outer diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

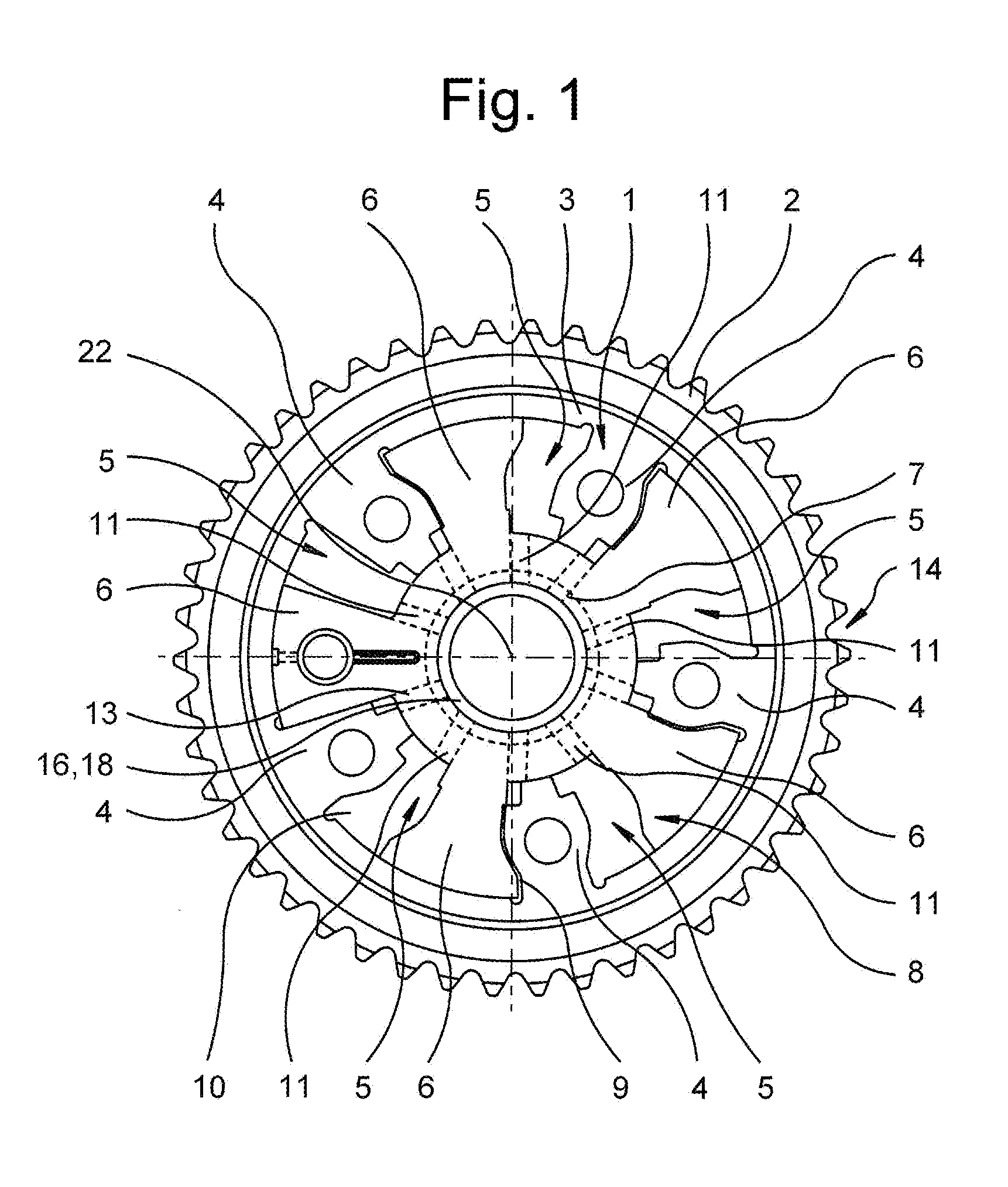

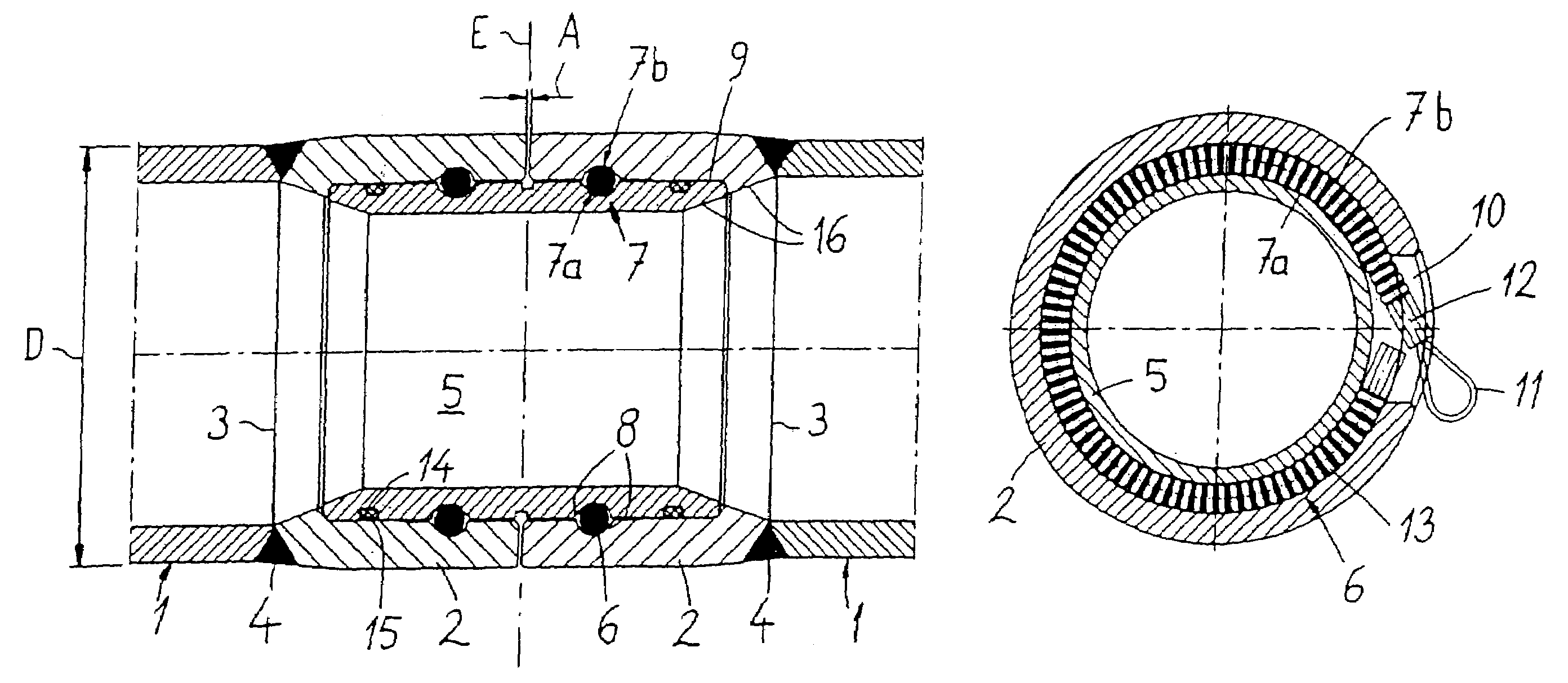

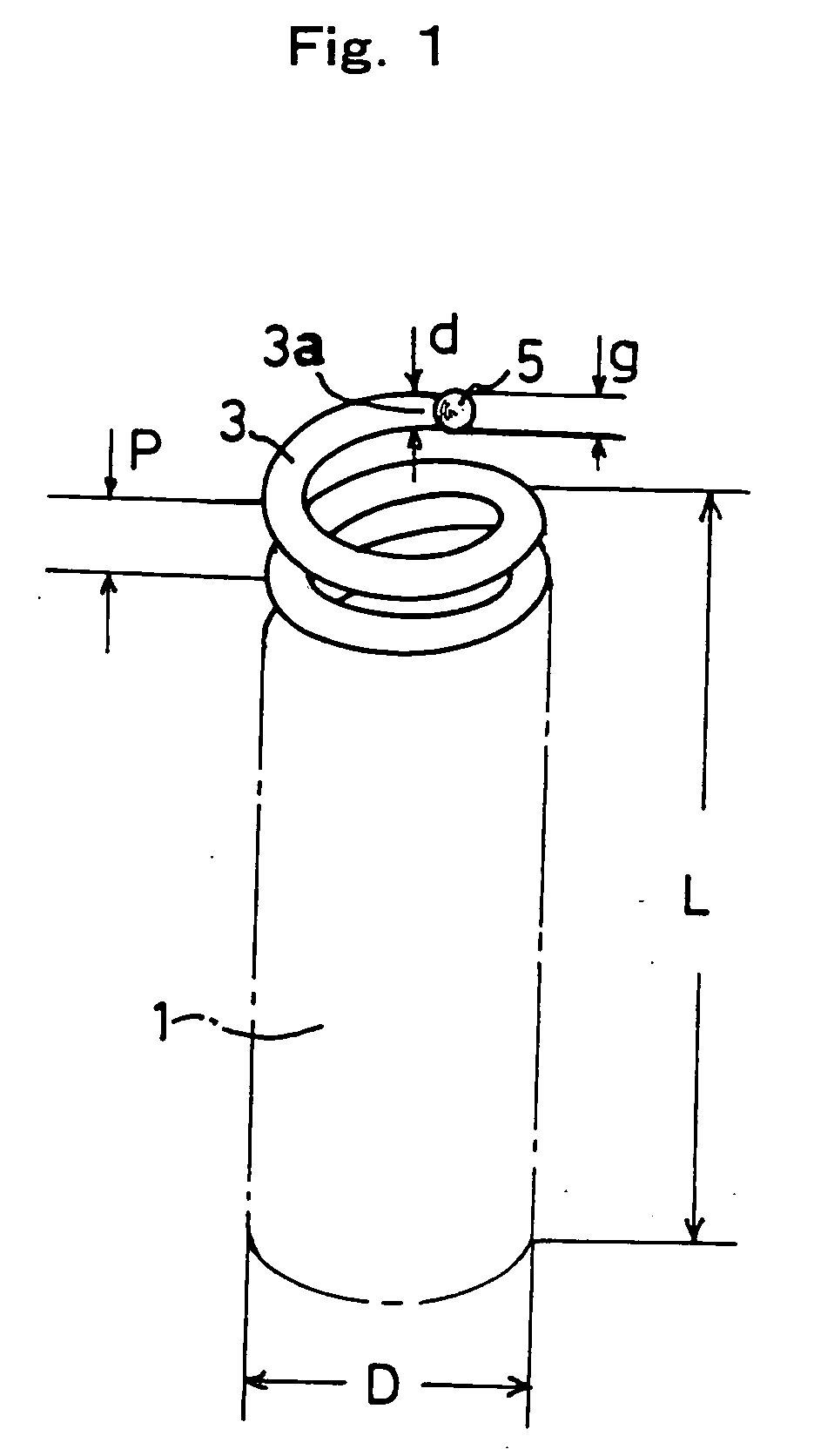

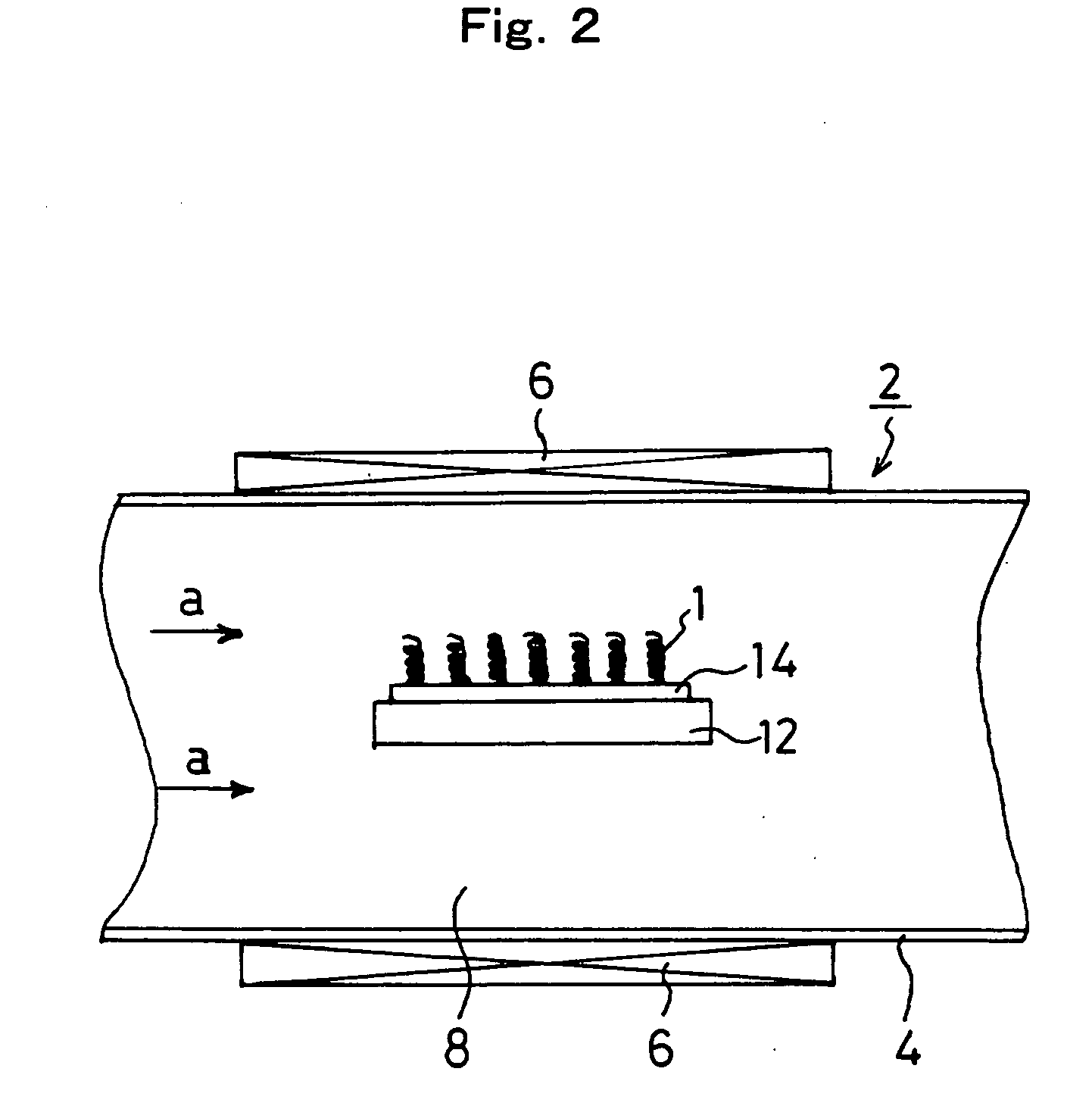

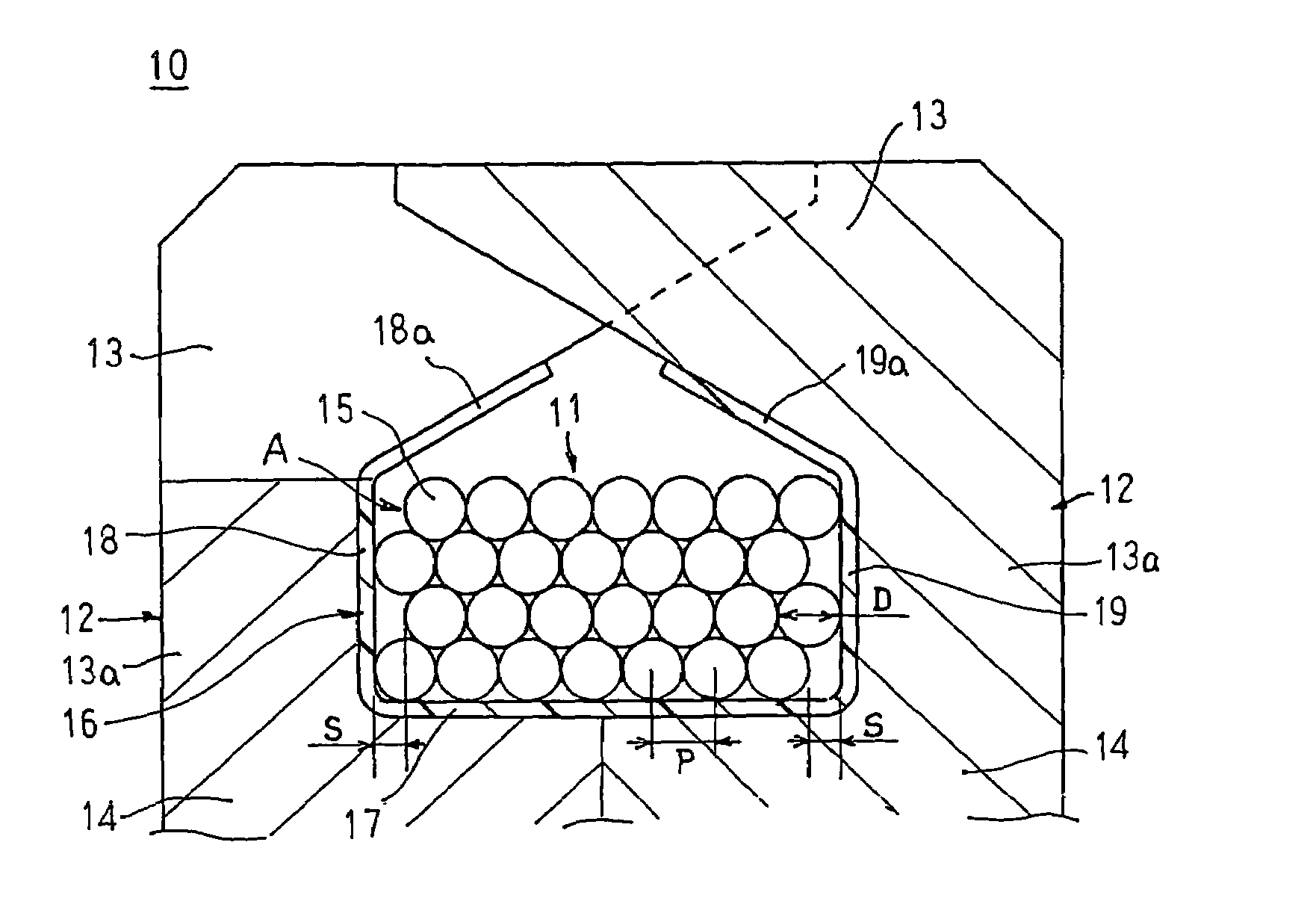

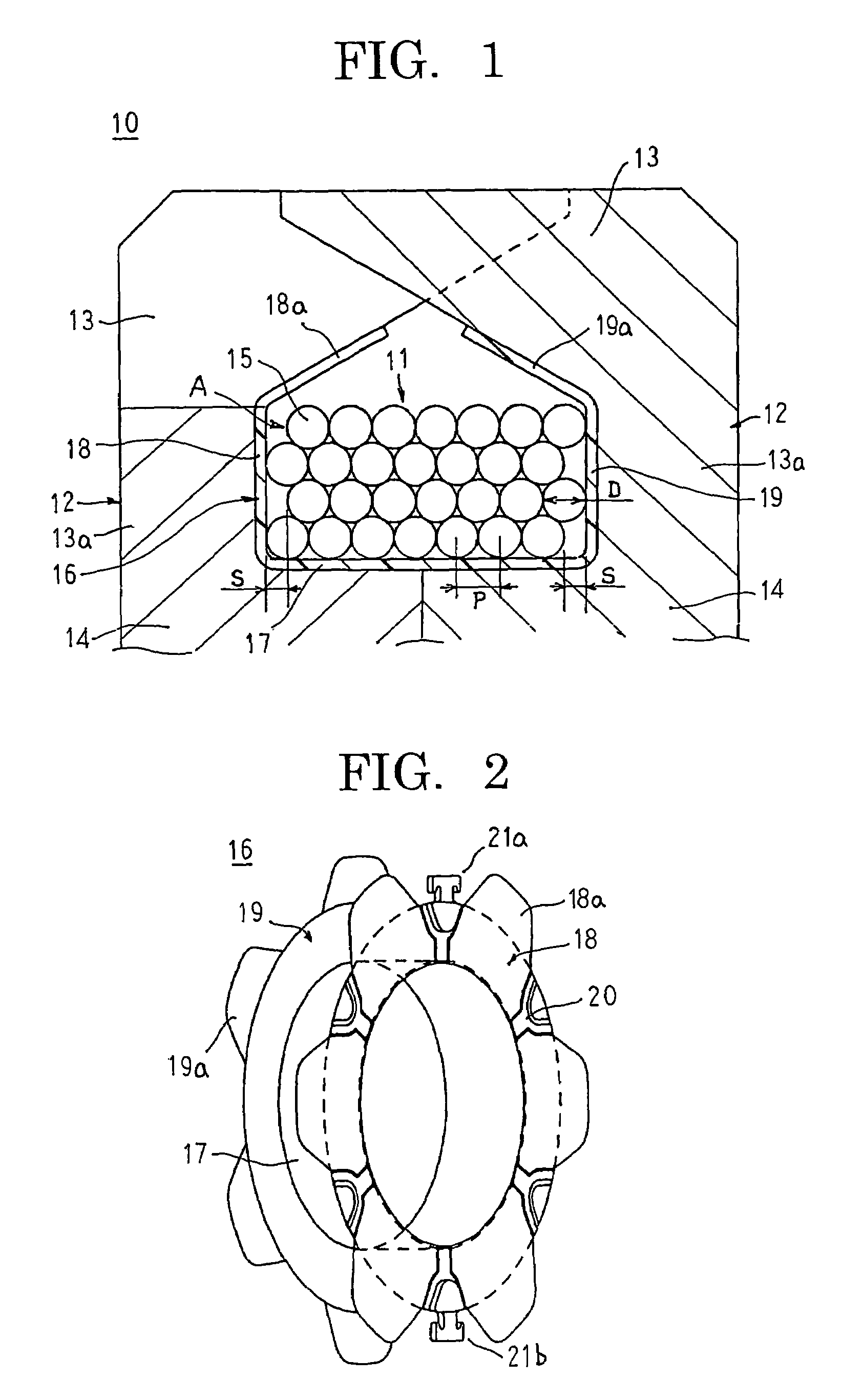

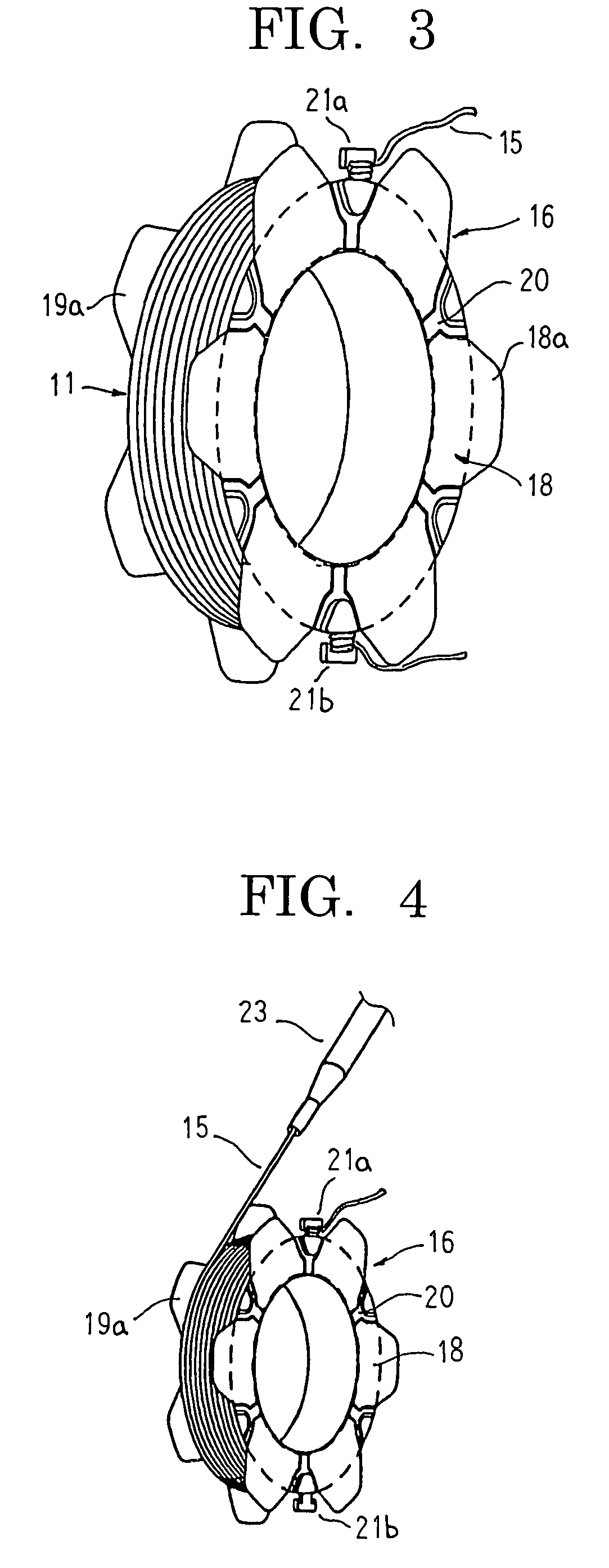

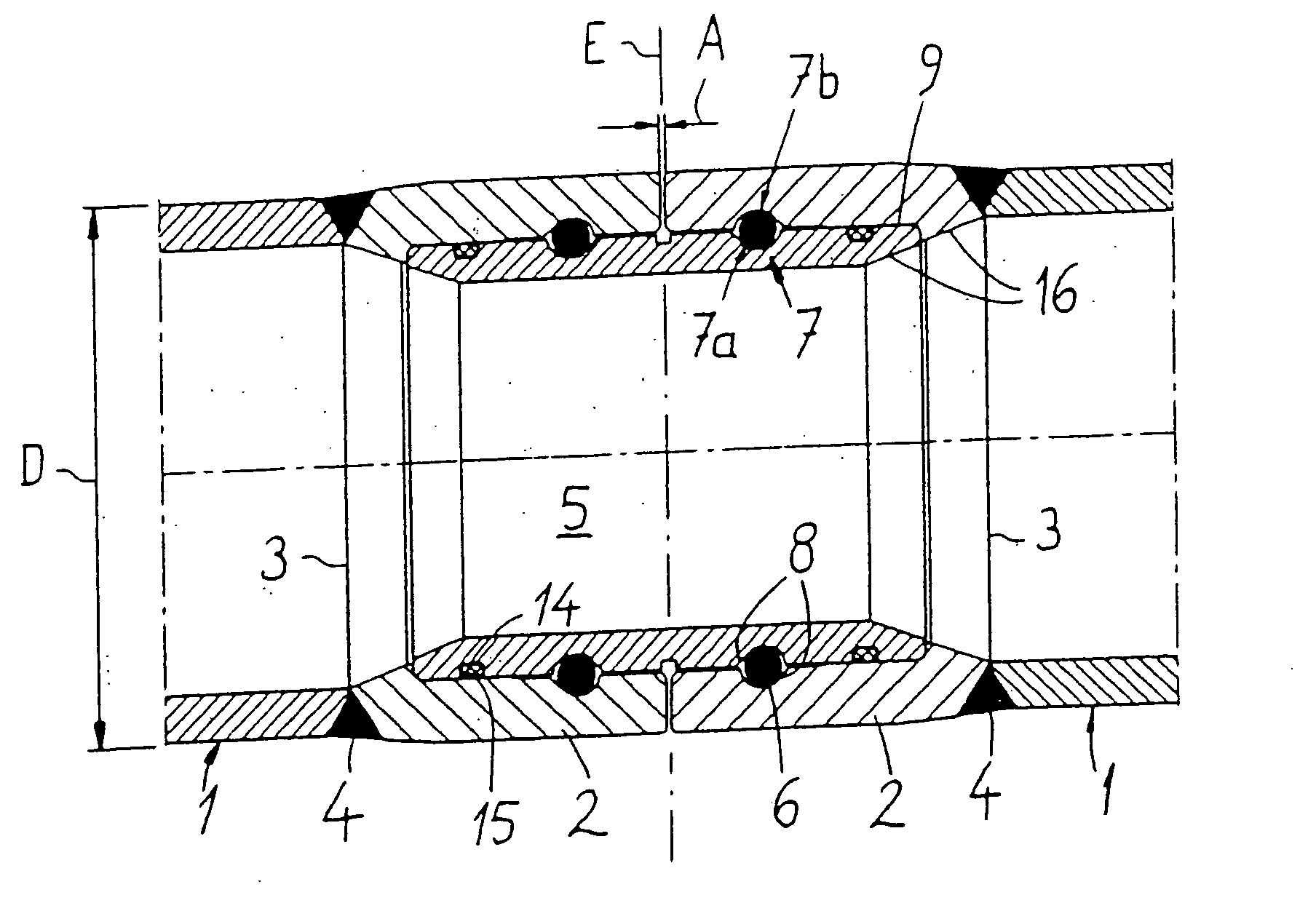

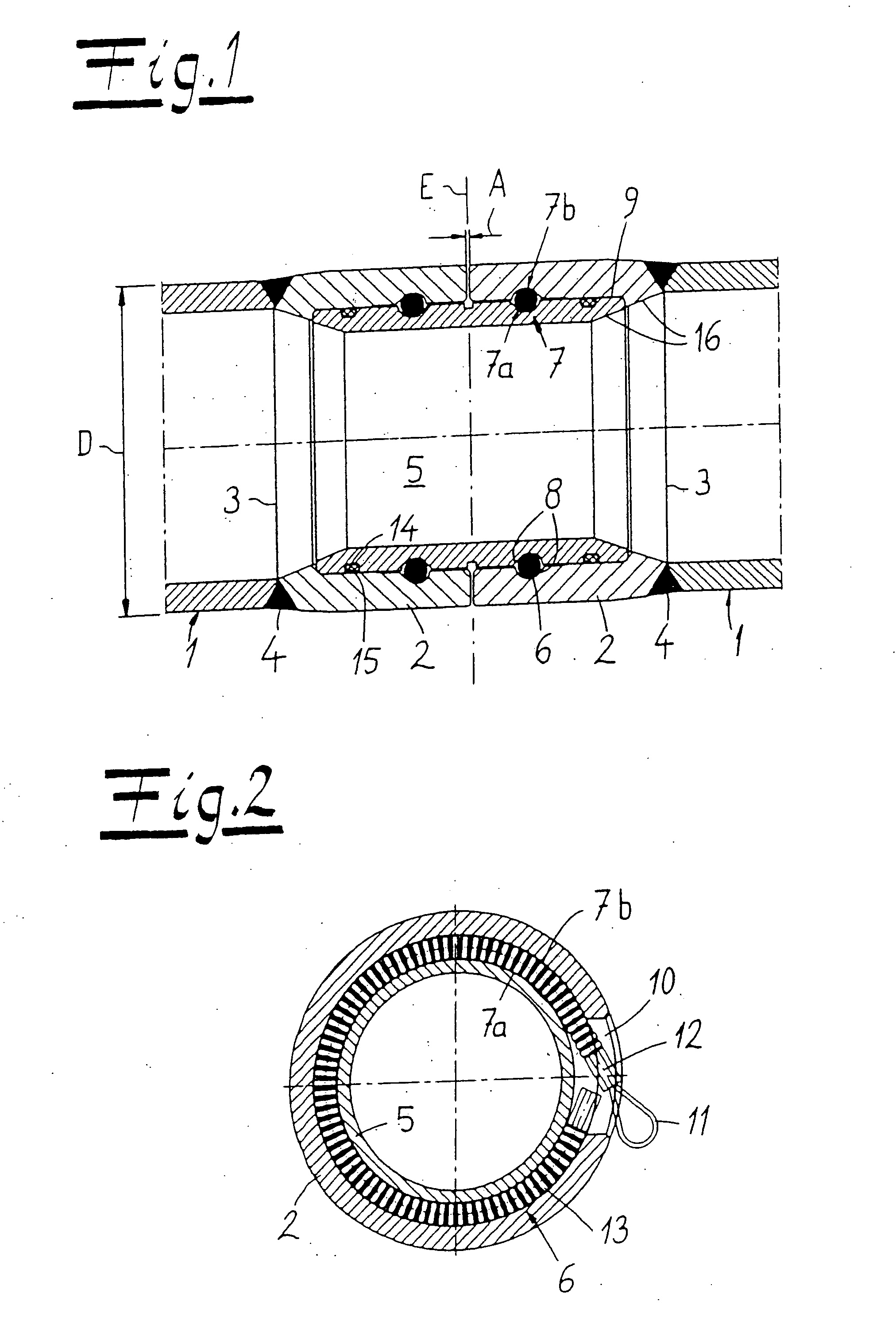

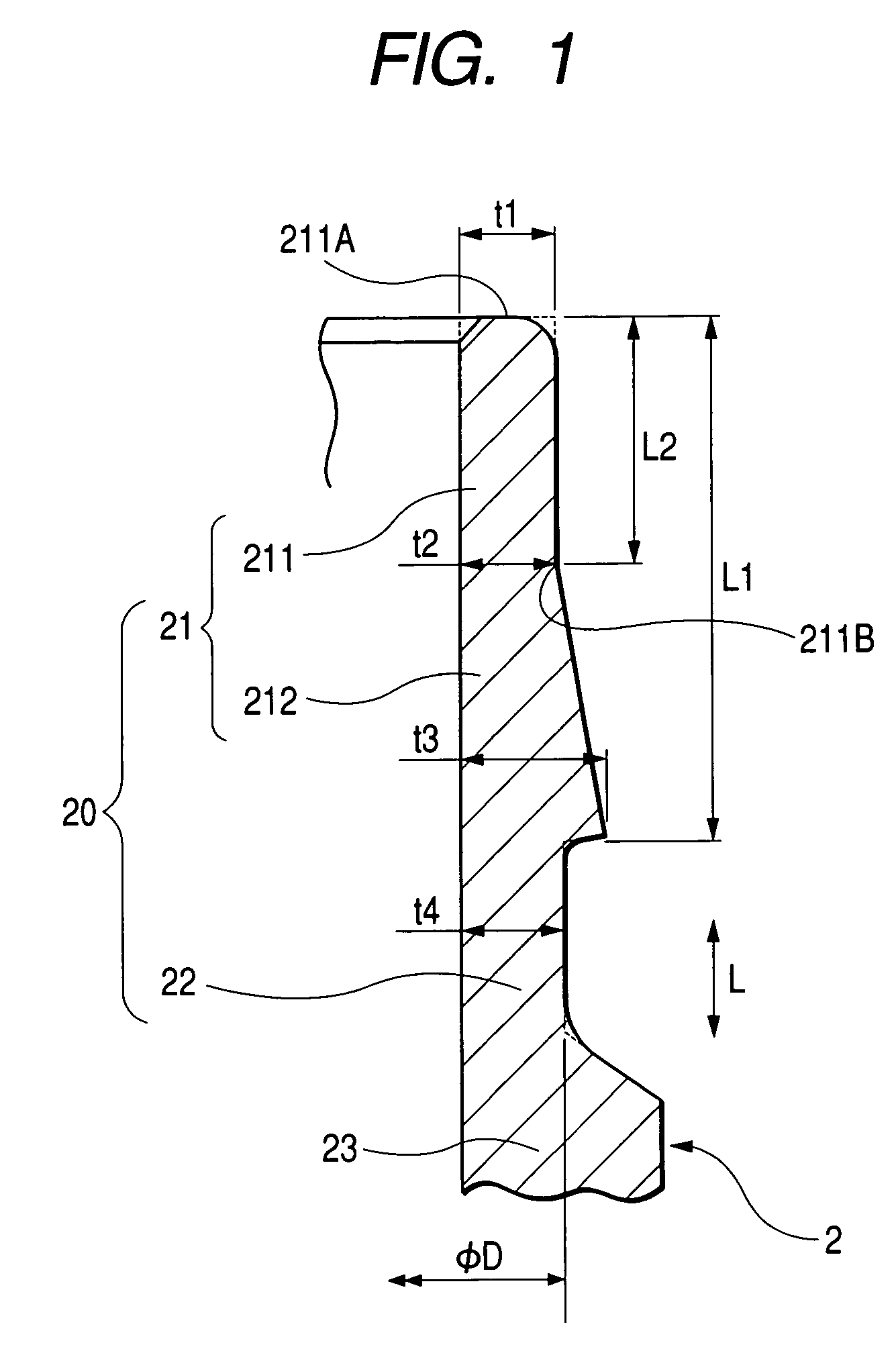

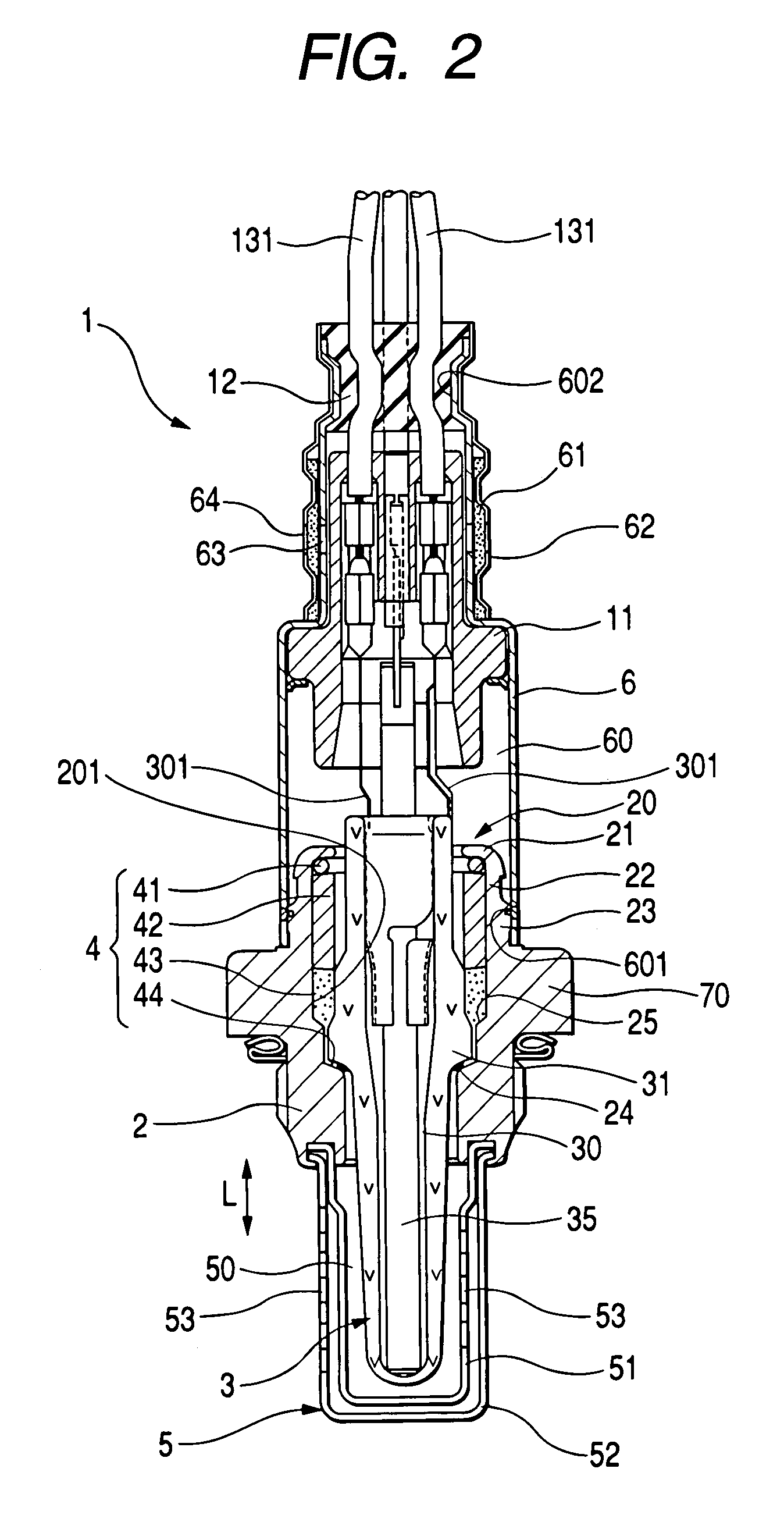

Rotor for dynamo-electric machine

InactiveUS20050218744A1Suppress occurrenceInhibitionSynchronous generatorsMagnetic circuit rotating partsElectric generatorEngineering

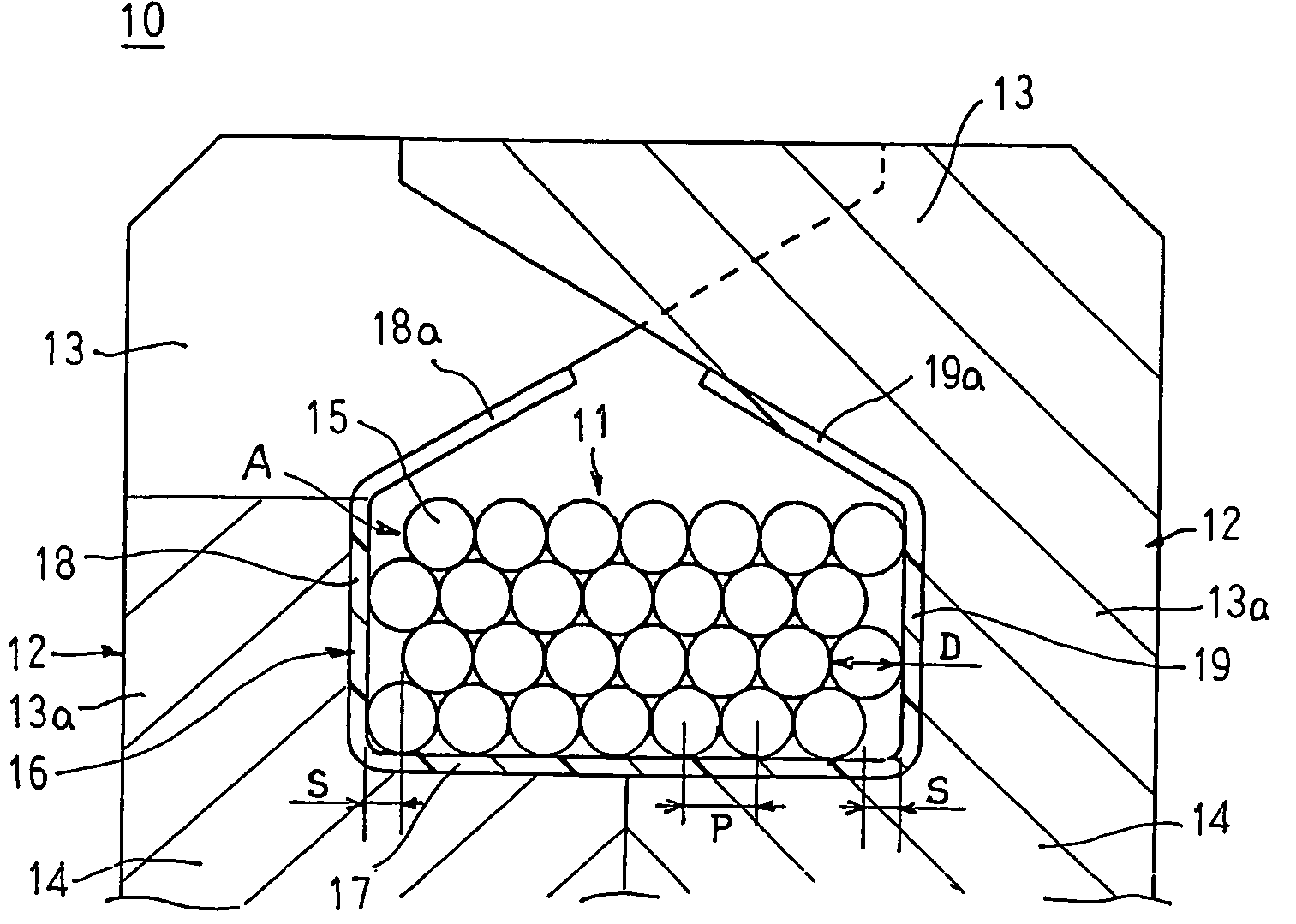

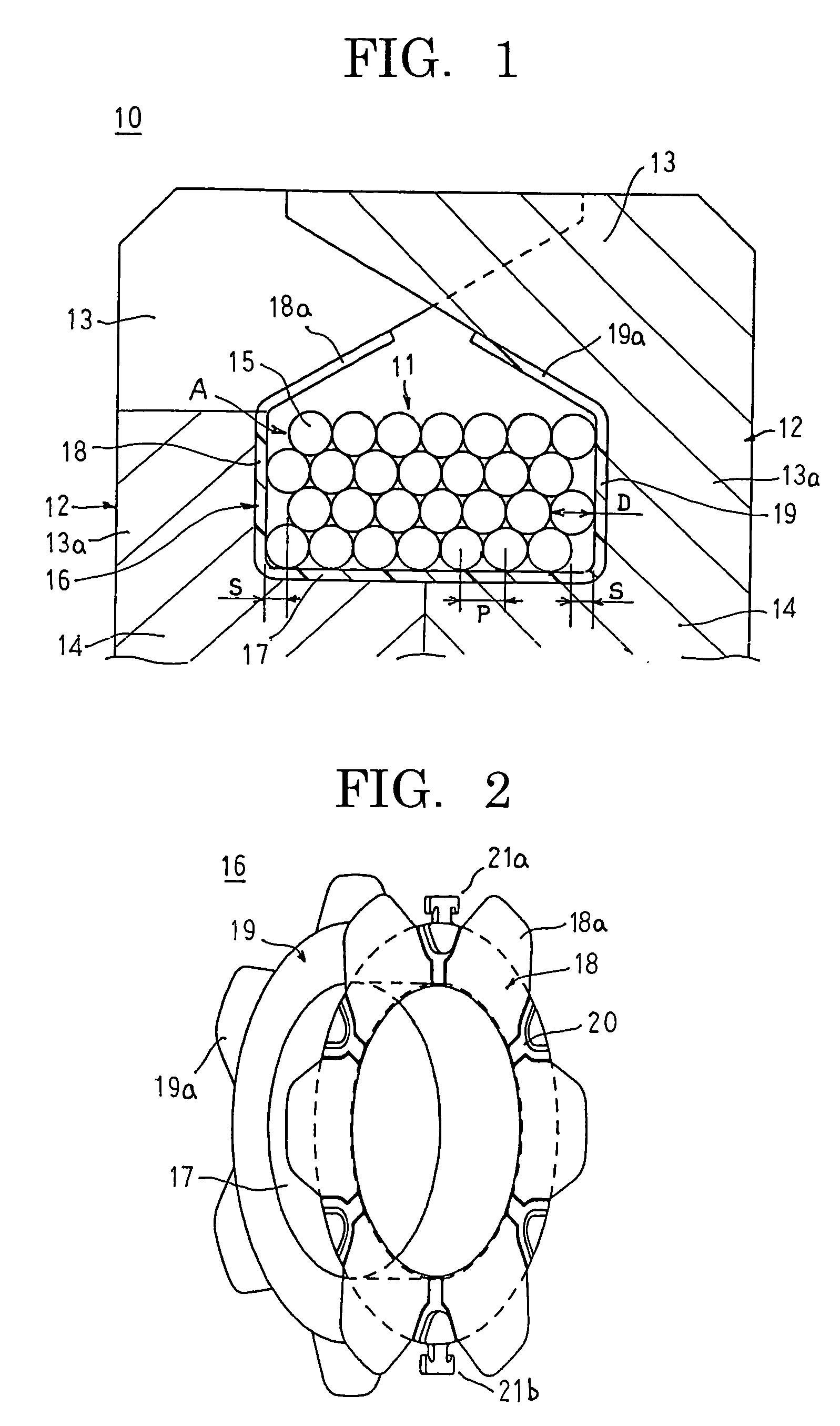

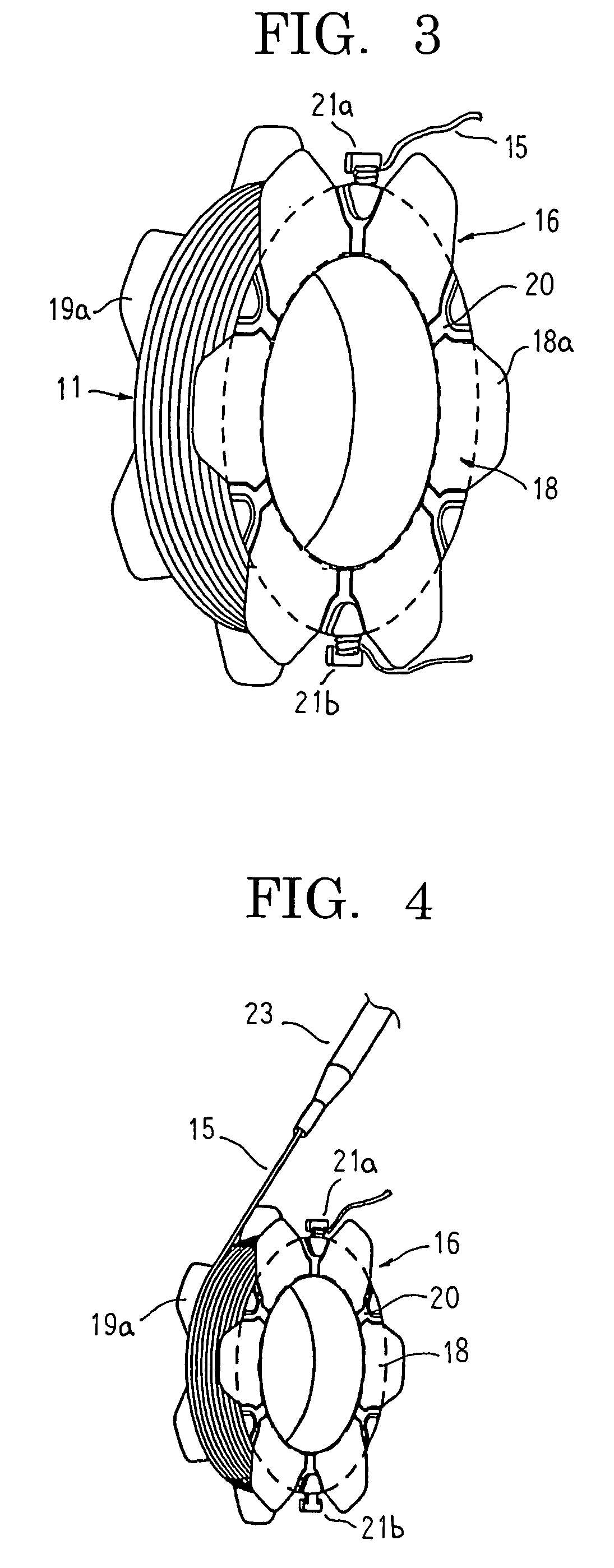

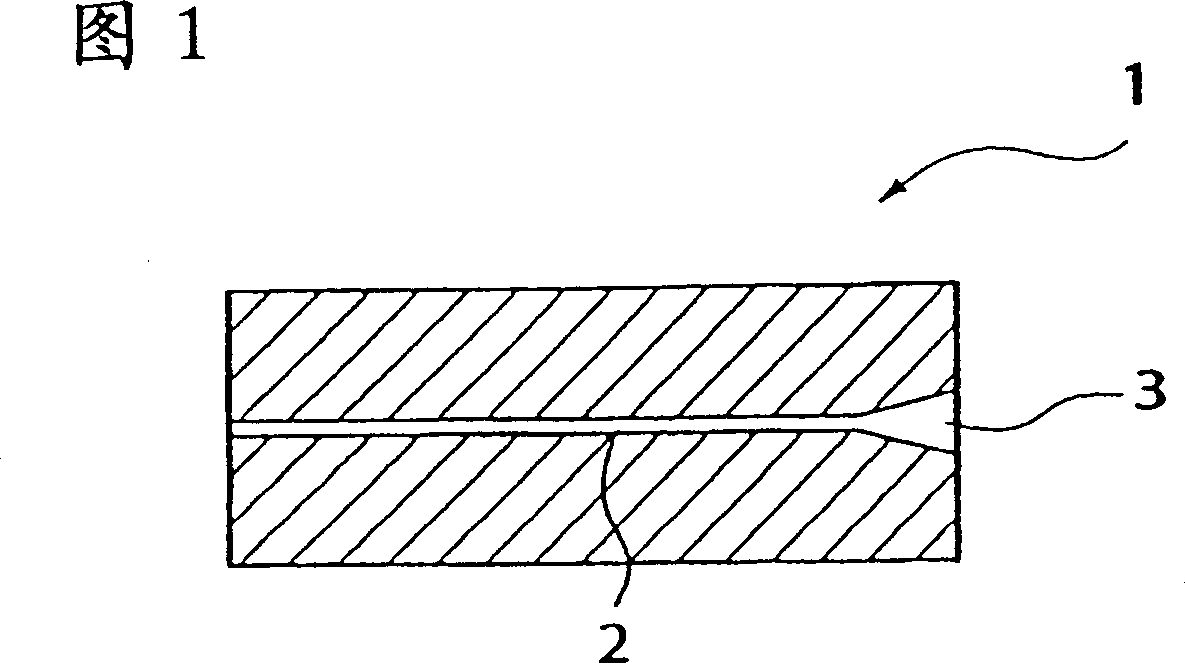

The present invention provides a rotor for a rotary electric machine that suppresses the occurrence of winding disturbances in the process of winding a coil wire and has a coil field having a uniform outside diameter that is less likely to collapse. A coil field of a rotor coil is constructed by winding a coil wire having a circular cross section onto an outer circumference of a drum portion of a bobbin in multiple layers so as to make columns in each of the layers equal in number in an axial direction. Odd numbered layers of the coil field are constructed such that the coil wire is wound for approximately one turn around the drum portion in contact with an inner peripheral wall surface of a first flange portion of the bobbin, then wound into a plurality of columns in an axial direction such that the columns of the coil wire contact each other, and the coil wire in a final column forms a gap S relative to an inner peripheral wall surface of a second flange portion of the bobbin, and even numbered layers of the coil field are constructed such that the coil wire is wound for approximately one turn around the drum portion in contact with an inner peripheral wall surface of the second flange portion, then wound into a plurality of columns in an axial direction such that the columns of the coil wire contact each other, and the coil wire in a final column forms a gap S relative to an inner peripheral wall surface of the first flange portion. The gap S satisfies an expression D / 4≦S≦D / 2 relative to a diameter D of the coil wire. Thus, because the occurrence of winding disturbances in the process of winding the coil wire is suppressed, the coil wire can be wound into an aligned state, enabling a coil field that is less likely to collapse to be achieved, and the outside diameter of the coil field is made uniform, also preventing damage to an electrically-insulating coating resulting from contact with claw-shaped magnetic poles.

Owner:MITSUBISHI ELECTRIC CORP

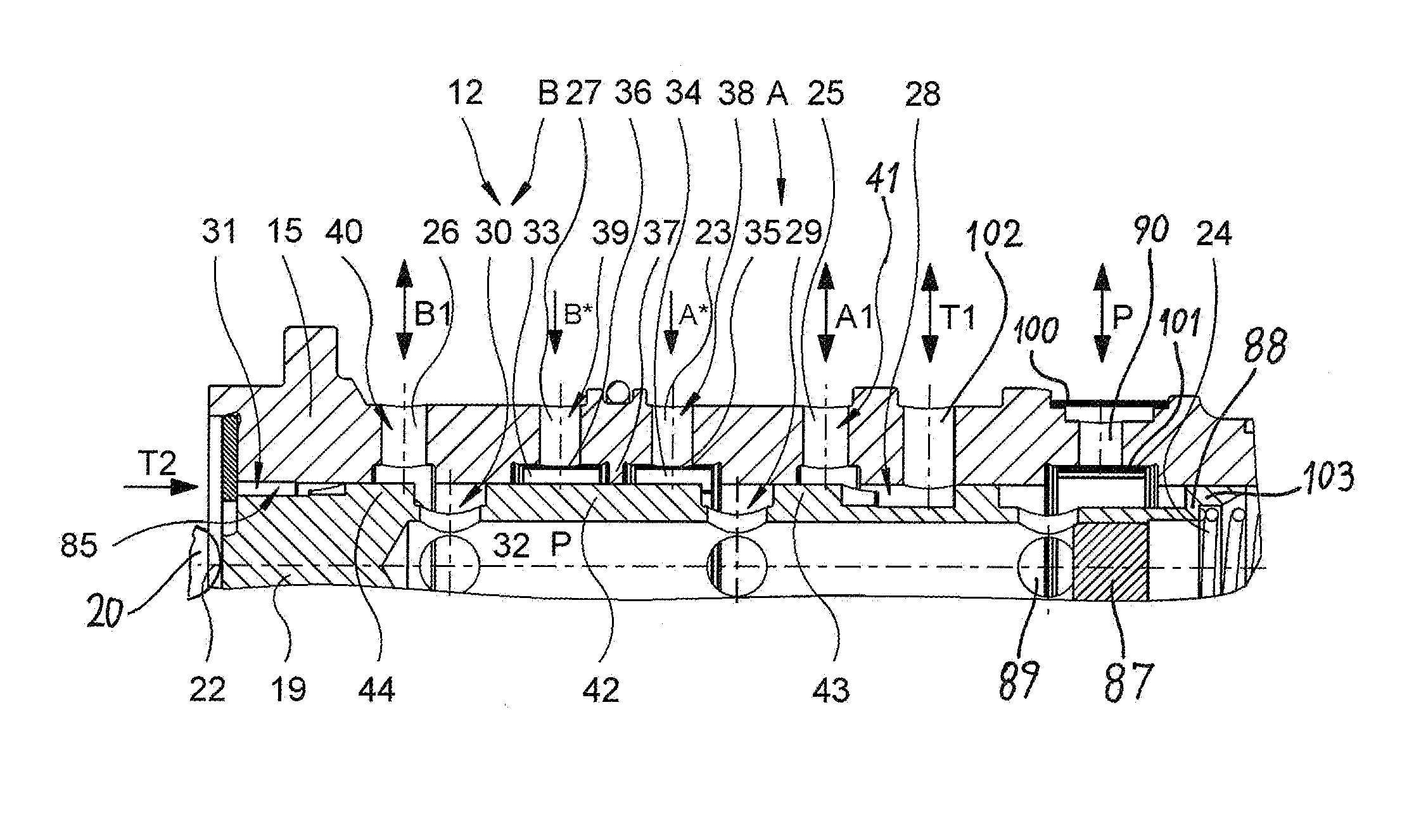

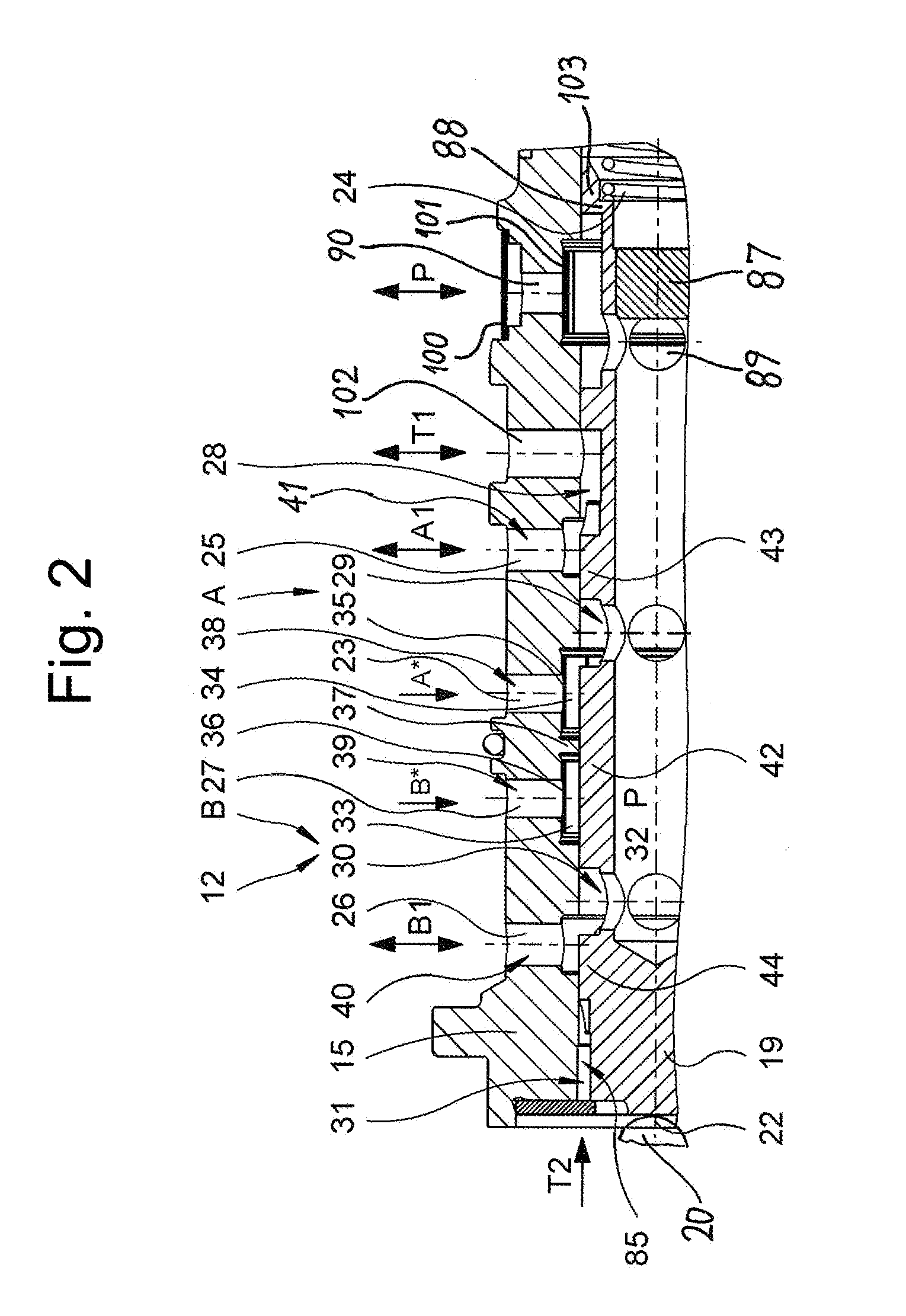

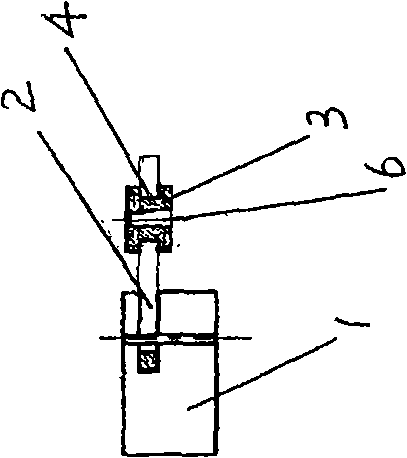

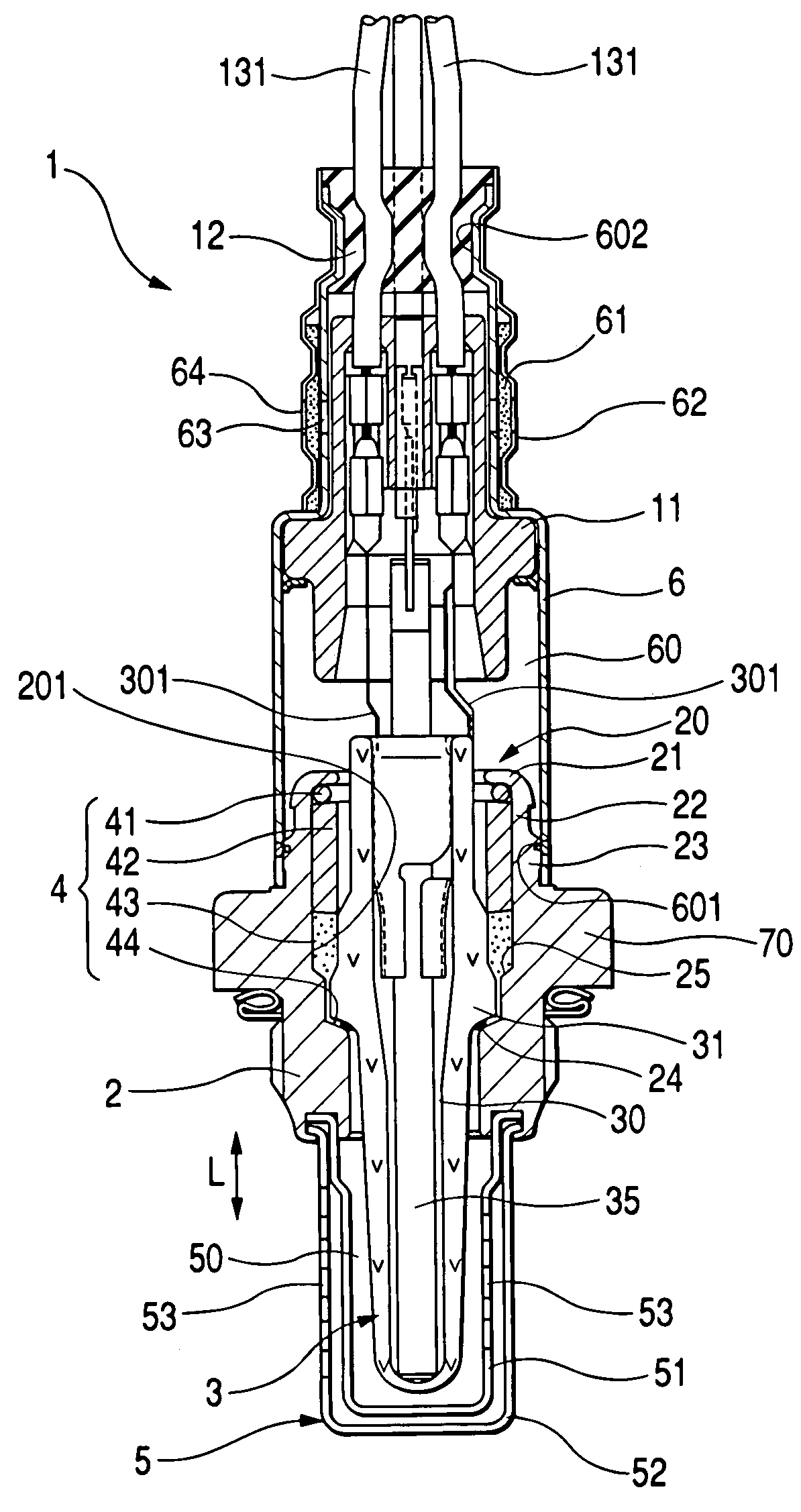

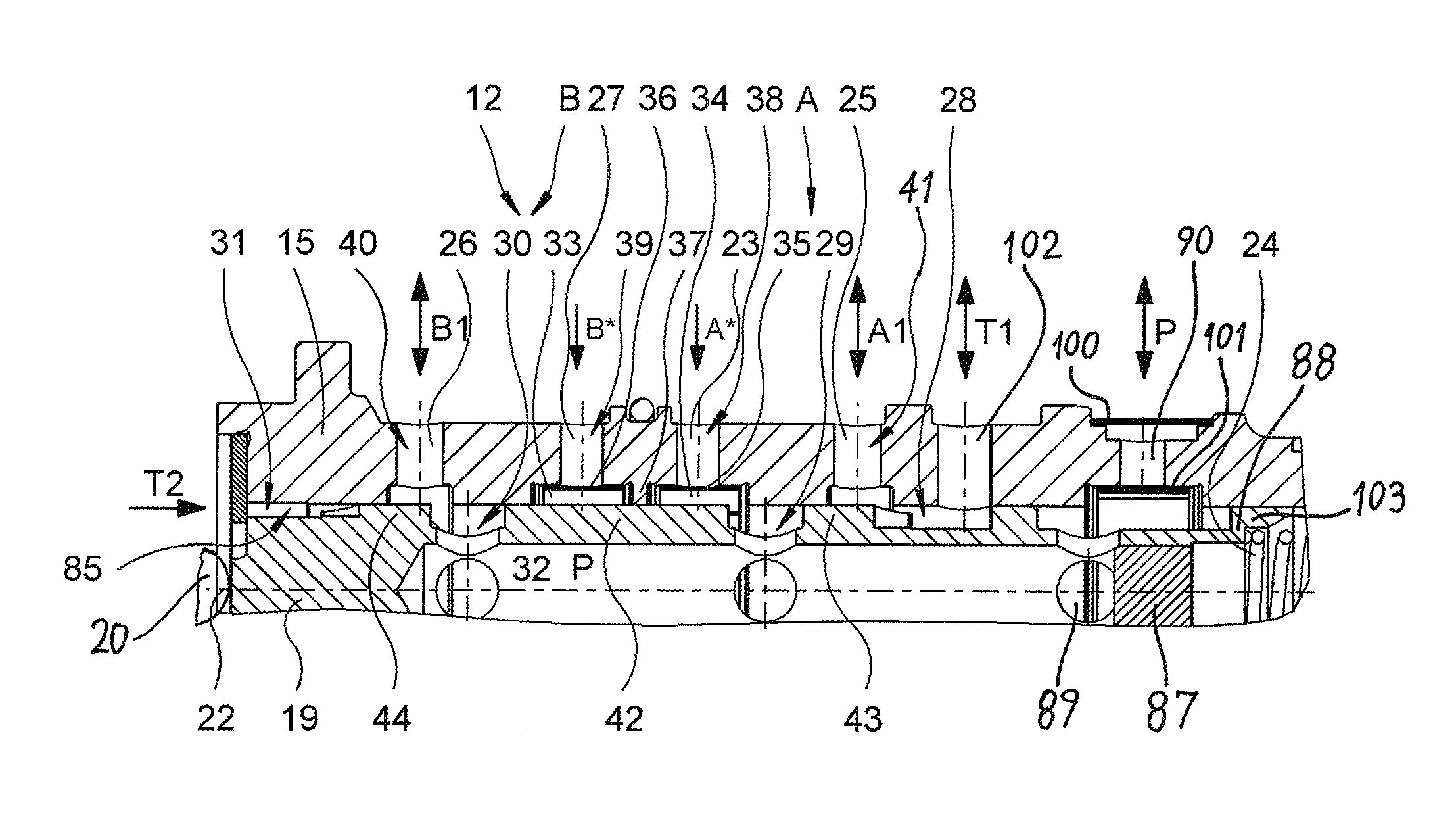

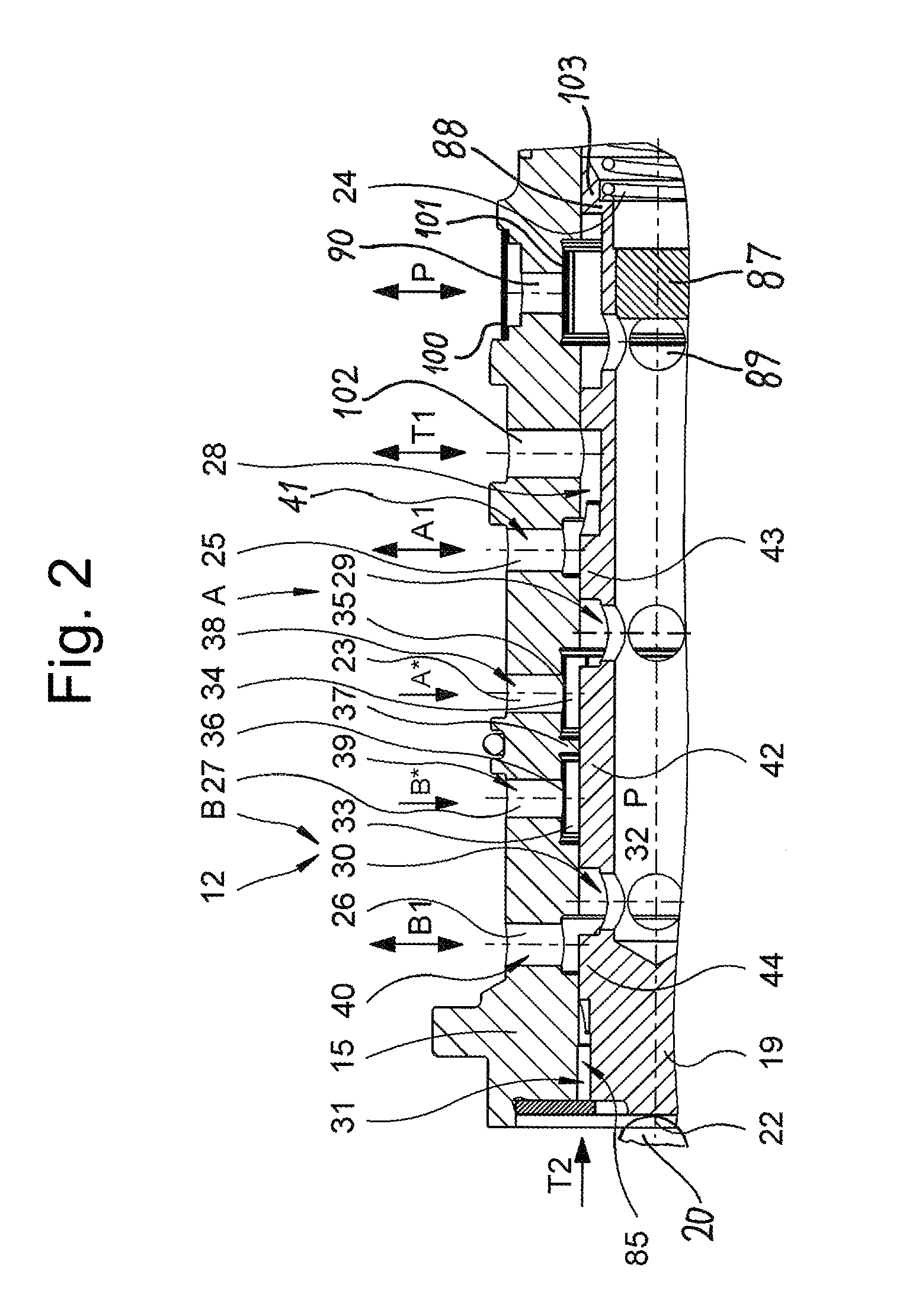

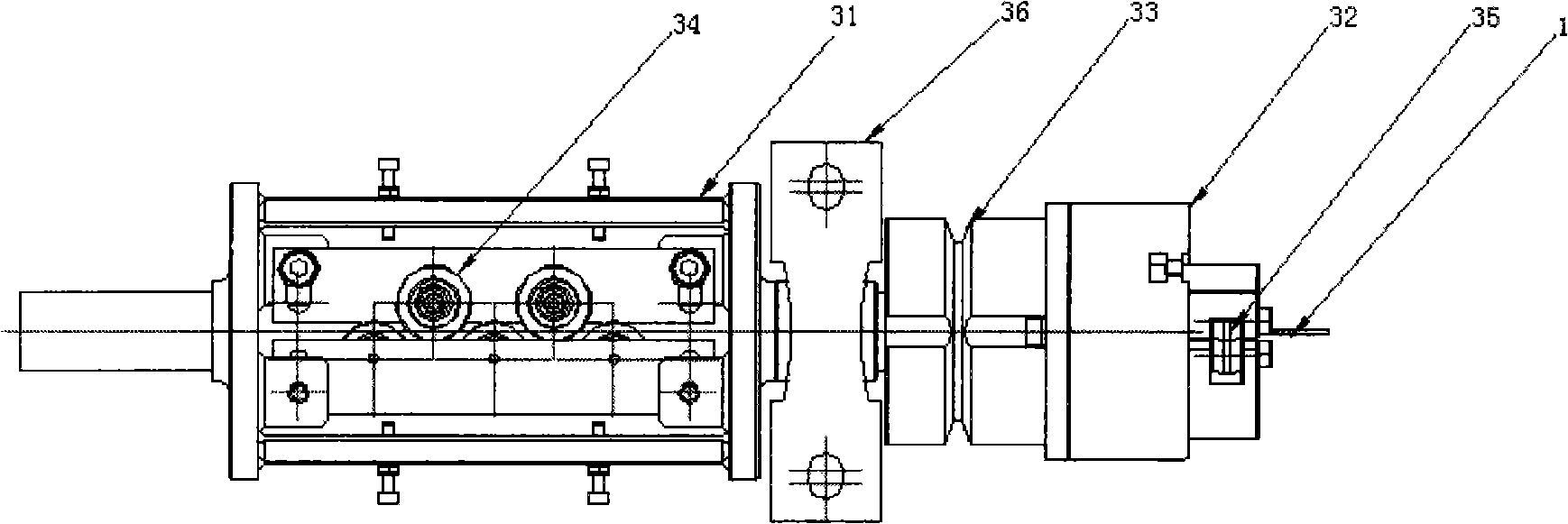

Hydraulic valve for an oscillating motor adjuster

ActiveUS20120152195A1Configuration become largeAccurately designMultiple way valvesMachines/enginesPistonEngineering

The invention relates to a hydraulic valve for an oscillating motor adjuster that utilizes camshaft alternating torques by means of non-return valves for more rapid adjustment. The non-return valve that is not used for the respective rotation is additionally closed by means of the piston of the hydraulic valve.

Owner:HILITE GERMANY

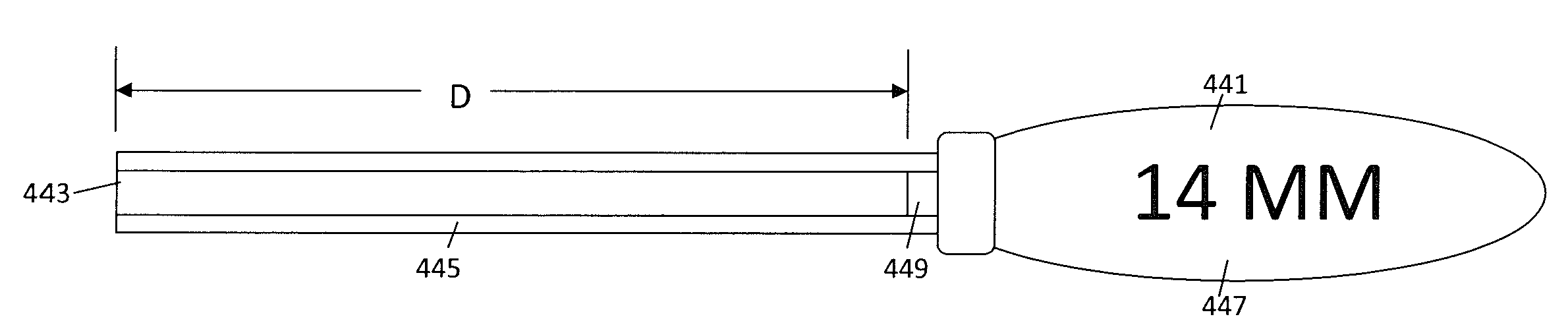

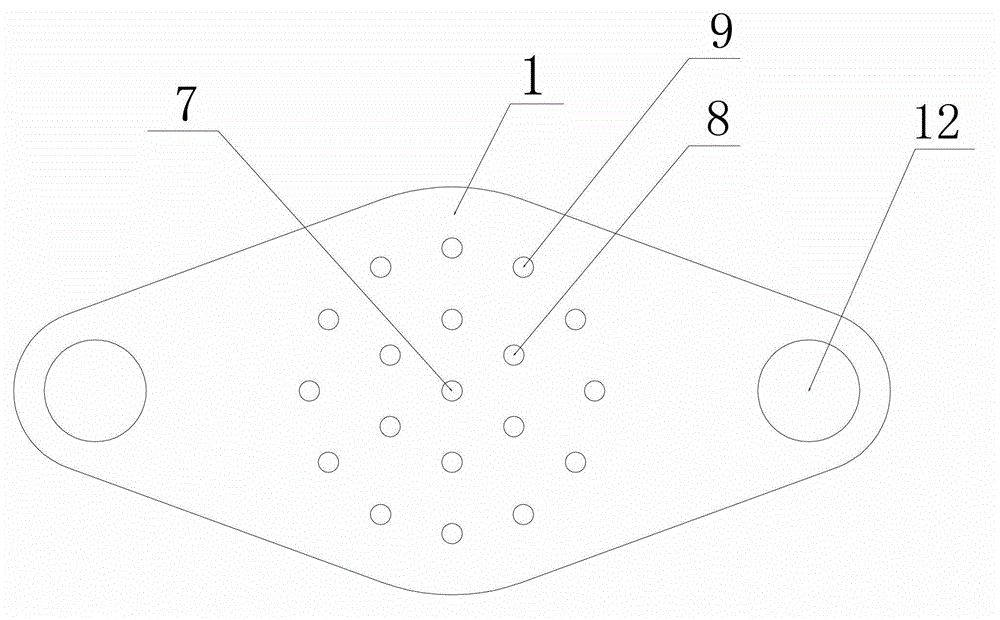

Casper pin apparatus and method of use

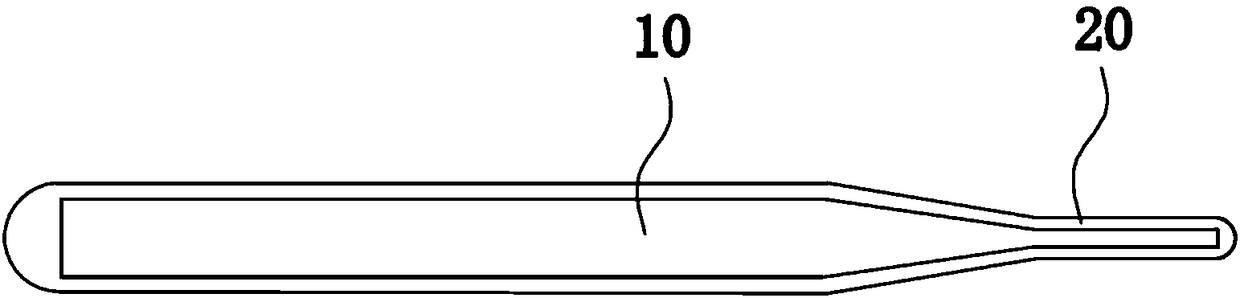

InactiveUS20100274298A1Sure easyUniform outer diameterSuture equipmentsInternal osteosythesisInsertion depthIntervertebral disk

Casper pins have a single uniform length and are inserted to different depths into vertebrae using different depth insertion tools. The Casper pins have a sharp threaded tip and a drive head at the opposite end. The Casper pins are used with insertion tools that are each marked with a different insertion depth. The insertion tools each have a tubular front section and a driver within the tubular section and a handle for rotating the insertion tool. Once the proper insertion depth is determined, the Casper pin is placed into the corresponding insertion tool. Using the insertion tool, the tip of the Casper pin bores into the vertebra and when the designated insertion depth is reached, the driver of the insertion tool is separated from the driver head of the Casper pin. Thus, the Casper pin cannot be inserted beyond the designated insertion depth of the insertion tool. The process is repeated for the adjacent vertebrae so that two Casper pins extend from the patient. A distractor is used to separate the vertebrae so the surgeon can operate on the disc. Once the disc operation is completed, the distractor is removed and a plate is placed over the Casper pins and moved against the vertebrae. The Casper pins are replaced with screws to hold the plate in place against the vertebrae. With the plate in secured in place, the incision cut into the patient can be closed so the spine is allowed to heal.

Owner:SCHIFF DAVID C M

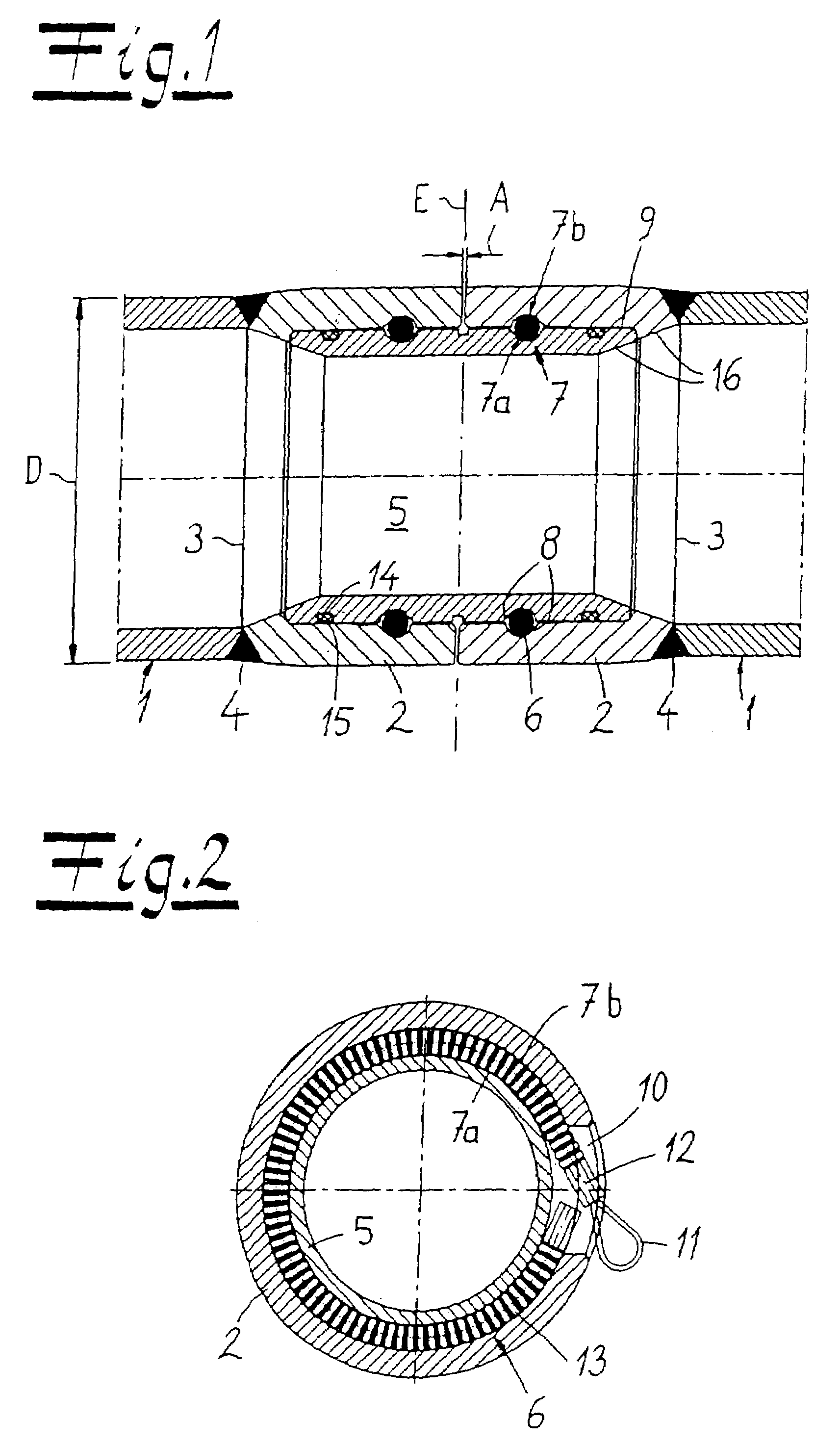

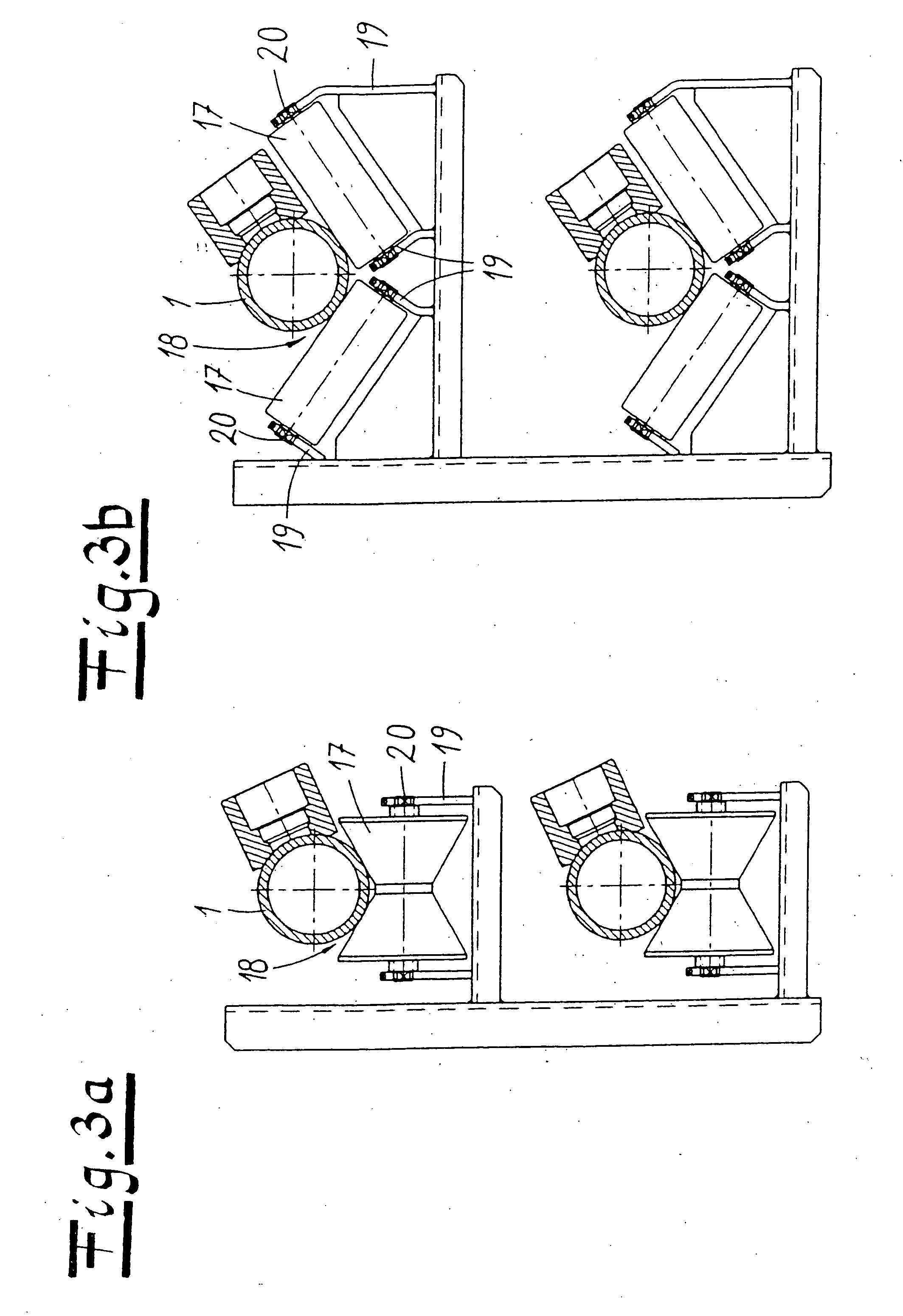

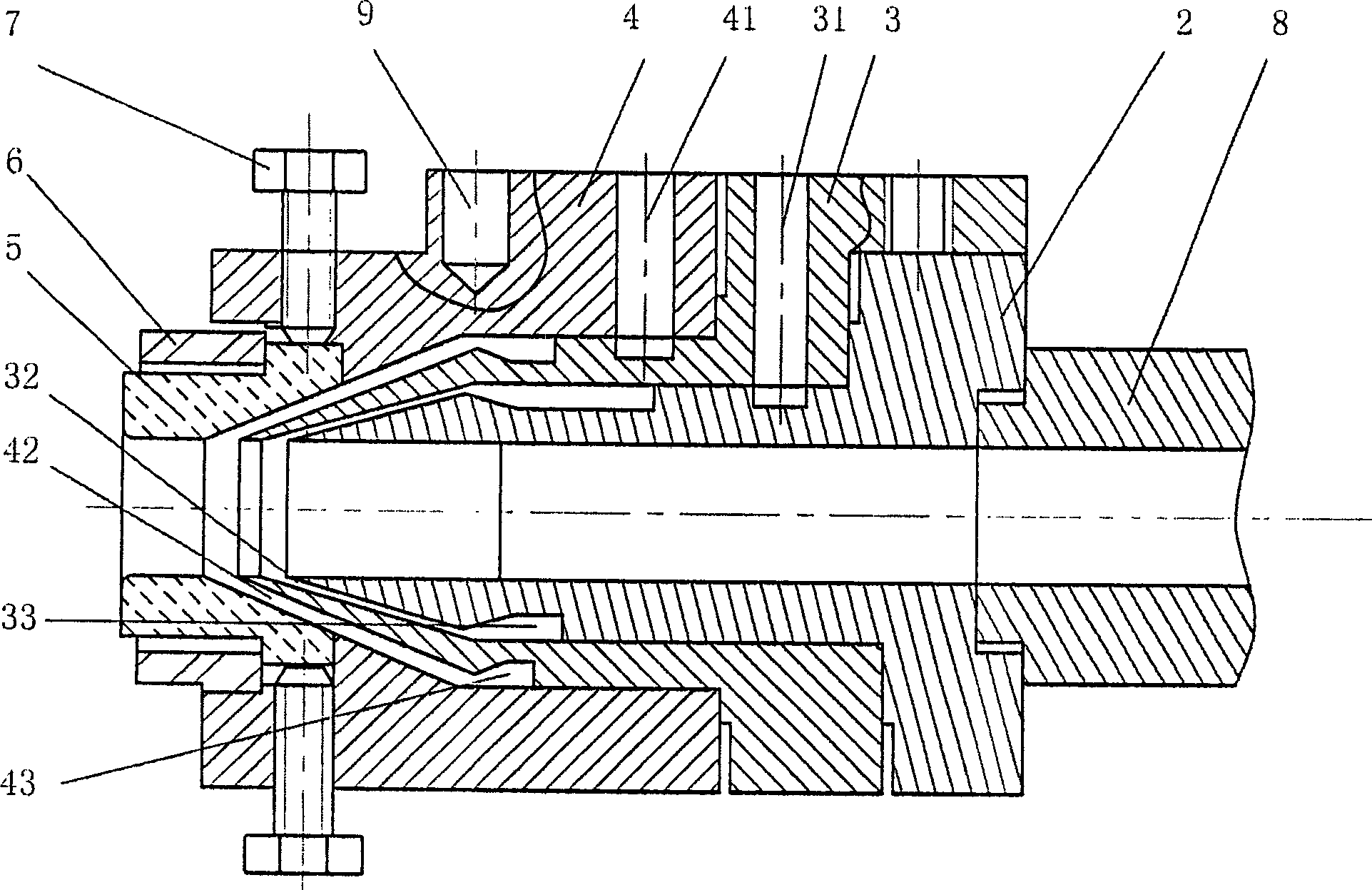

Coupling, particularly pipe coupling for high-pressure pipes or hoses

InactiveUS7481464B2Damage-free and simple transportUniform outer diameterSleeve/socket jointsPipe supportsCouplingEngineering

A coupling, particularly a pipe coupling for high-pressure pipes or high-pressure hoses, is equipped with coupling pieces provided at the ends to be connected, in each instance, and with a cuff that couples the coupling pieces, using at least two shear elements. The coupling pieces engage over the cuff that lies on the inside, as an extension of the ends, with almost the same diameter.

Owner:KARL HAMACHER

Method for manufacturing enameled rectangular copper wire for wind driven generator by die method and device thereof

ActiveCN101630544AHigh surface finishUniform outer diameterInsulating conductors/cablesViscosityPolyamide-imide

The invention provides a method for manufacturing an enameled rectangular copper wire for a wind driven generator by a die method and a device thereof. The method comprises the following steps: setting the fillet radius of a metering hole which takes a hollow prismoid shape and is arranged at the middle part of a die holder into 0.7-0.9mm, annealing the pressed rectangular copper wire after cleaning and antioxidation, continuously painting a polyurethane primer and a 200-grade polyamideimide finish paint by the dies, baking and cooling to the room temperature to obtain the finished product. In the invention, the dies are adopted to paint the composite-layer enamelled wire with high viscosity. The invention has the advantages of high surface finish of products, unified outer diameters, good high temperature resistance, good chemical resistance, higher tensile strength, higher flexibility, higher adhesiveness, higher softening breakdown resistance and the like, thus being suitable for the application requirements of the wind driven generator on high quality of surface finish, no paint blotches and great length of the enameled wire.

Owner:TIANJIN JINGWEI HUIKAI OPTOELECTRONICS CO LTD

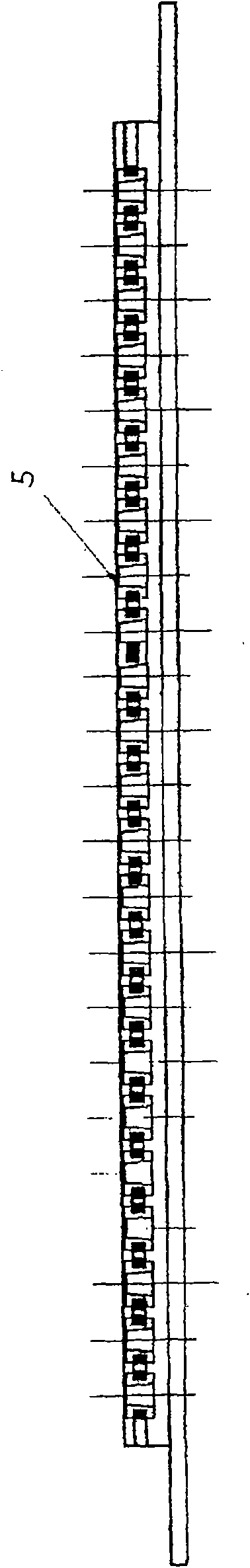

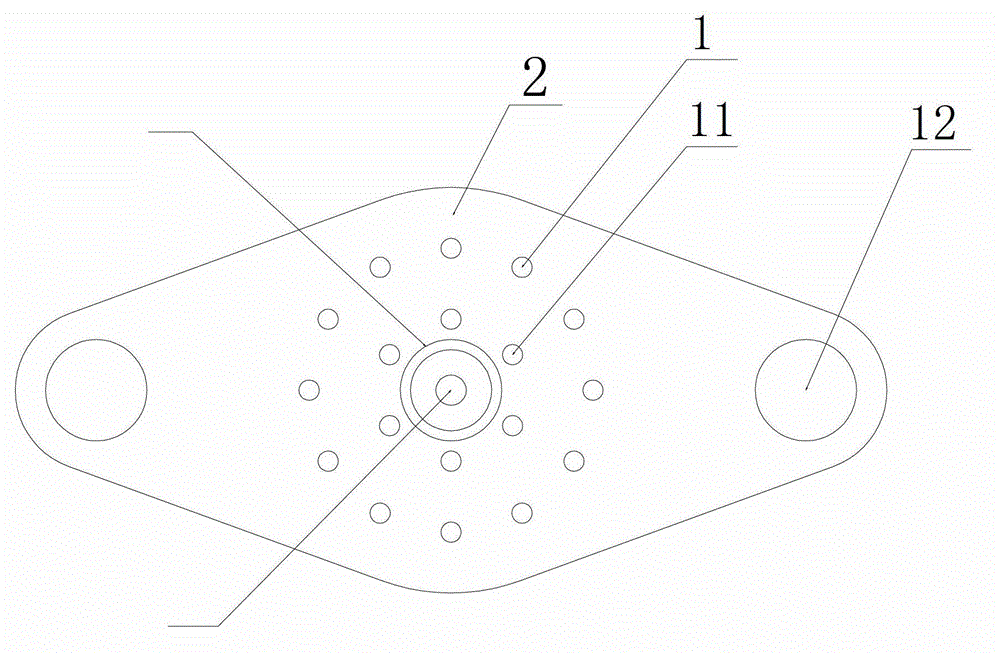

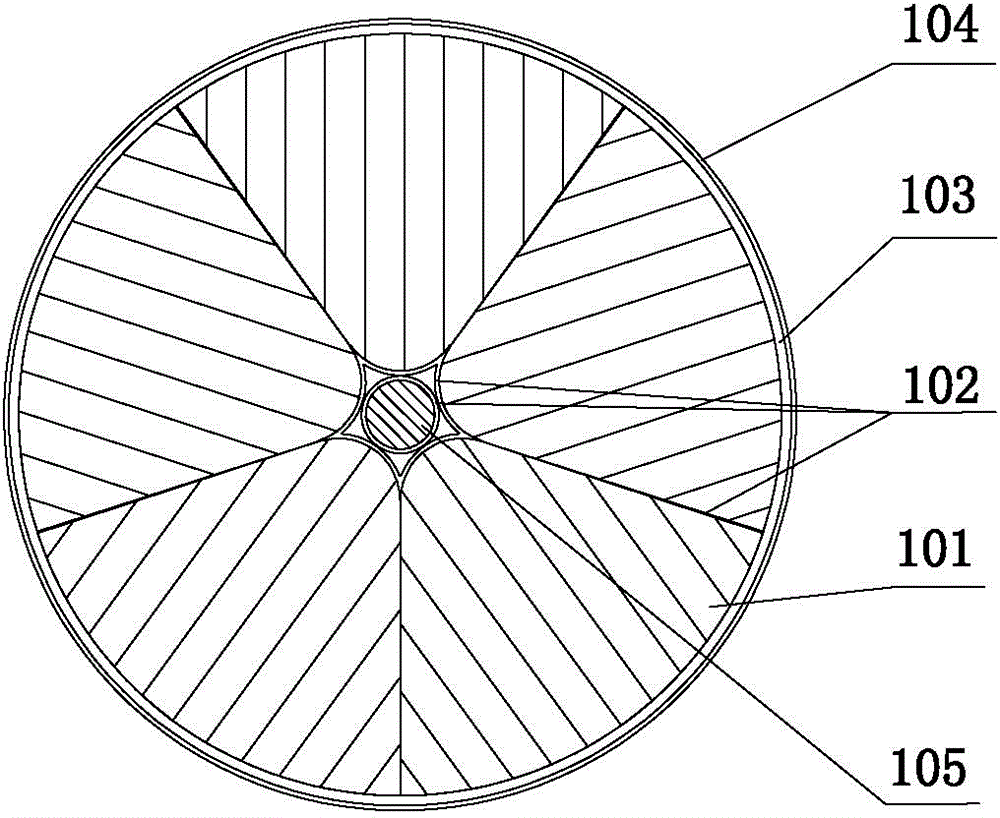

Stranding lead in device of stranding machine

InactiveCN102945713AIncrease profitIncrease productivityCable/conductor manufactureElectrical conductorEngineering

The invention provides a stranding lead in device of a stranding machine. A first wire split die plate, a second wire split die plate and a second wire combining die sleeve are sequentially arranged along the wire feeding direction, a first wire combining die sleeve is arranged at the center of the second wire split die plate, a first wire combining hole and a second wire combining hole are mounted on the first wire combining die sleeve and the second wire combining die sleeve respectively, wire penetrating holes are arranged on the first wire split die plate and the second wire split die plate respectively, and the number of the wire penetrating holes is equal to that of conductors to be required to be stranded. By means of the stranding lead in device of the stranding machine, a stranded body with numerous single strands and two or more than two stranded layers can be stranded once, the production efficiency and applicability of the stranding machine are improved, and the stranding quality of the stranded body can meet technological requirements.

Owner:江苏和和电缆科技有限公司

Low smoke zero halogen flame retardant sheath layer for optical cable

ActiveCN102977451ASolve the technical problem of outer diameter fluctuationReduced filling capacityFibre mechanical structuresAluminium hydroxideCarvacryl acetate

The invention discloses a low smoke zero halogen flame retardant sheath layer for an optical cable, wherein the optical cable comprises an optical cable core and a low smoke zero halogen flame retardant sheath layer covering the outer surface of the optical cable, and the low smoke zero halogen flame retardant sheath layer is composed of the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high-pressure metallocene polyethylene, 10-20 parts of special modified polyethylene, 70-110 parts of aluminium hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 parts of antioxidant and 2-5 parts of black master batch. The low smoke zero halogen flame retardant sheath layer for the optical cable enables the outer diameter of the optical cable to be even, thereby guaranteeing the shrinkage integrity of the optical cable core; as a result, signals can not be greatly attenuated in the transmission process in the cable; and simultaneously, the tensile strength of the cable is greater than or equal to 13 MPa, while the elongation at break is greater than or equal to 250% and the oxygen index is greater than or equal to 34%; and the cable has excellent mechanical properties.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

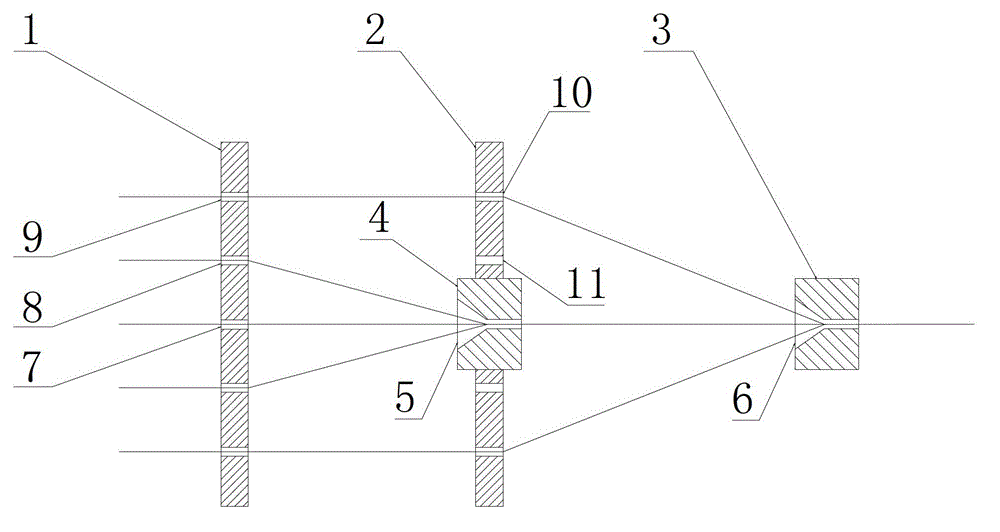

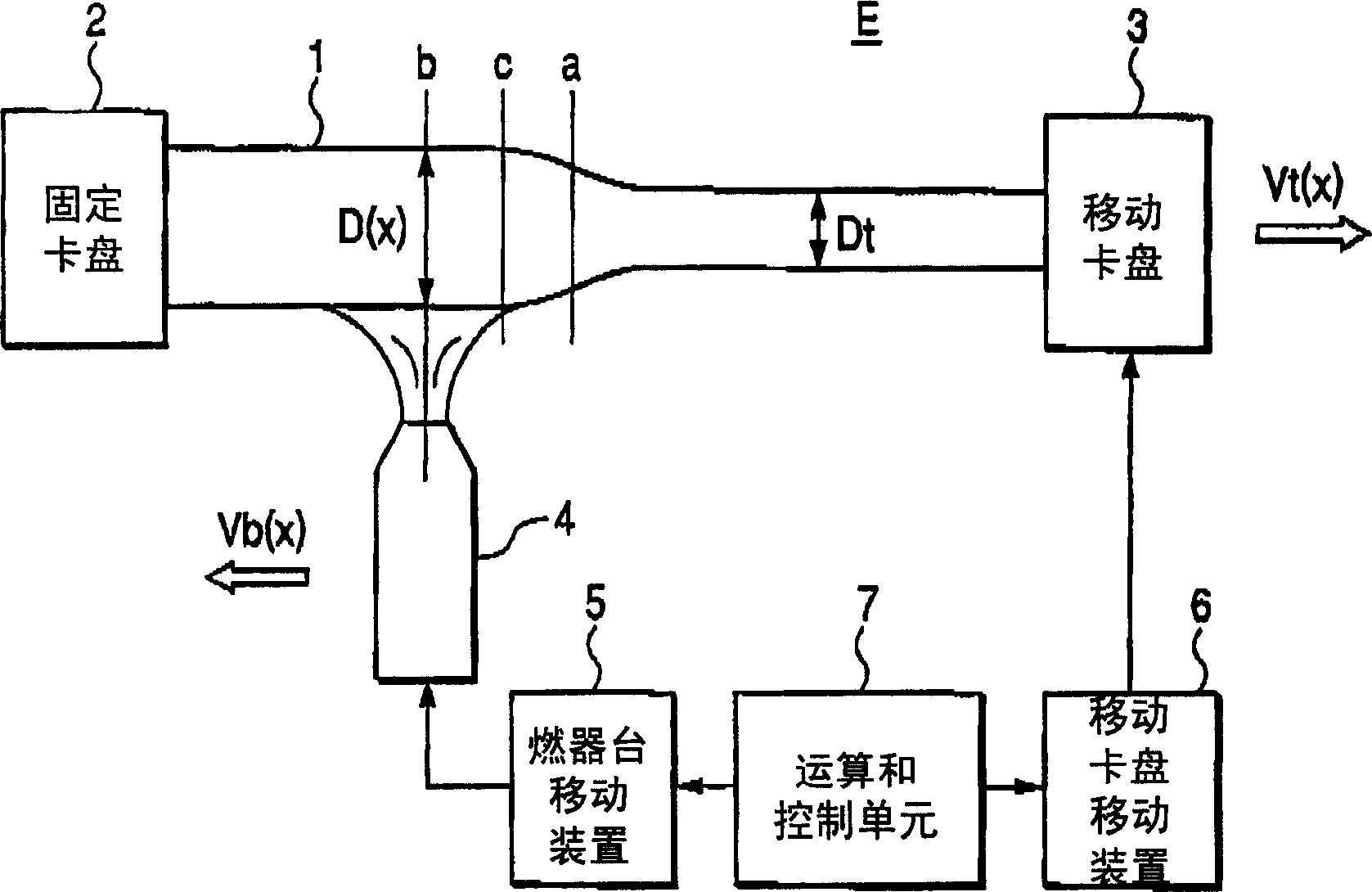

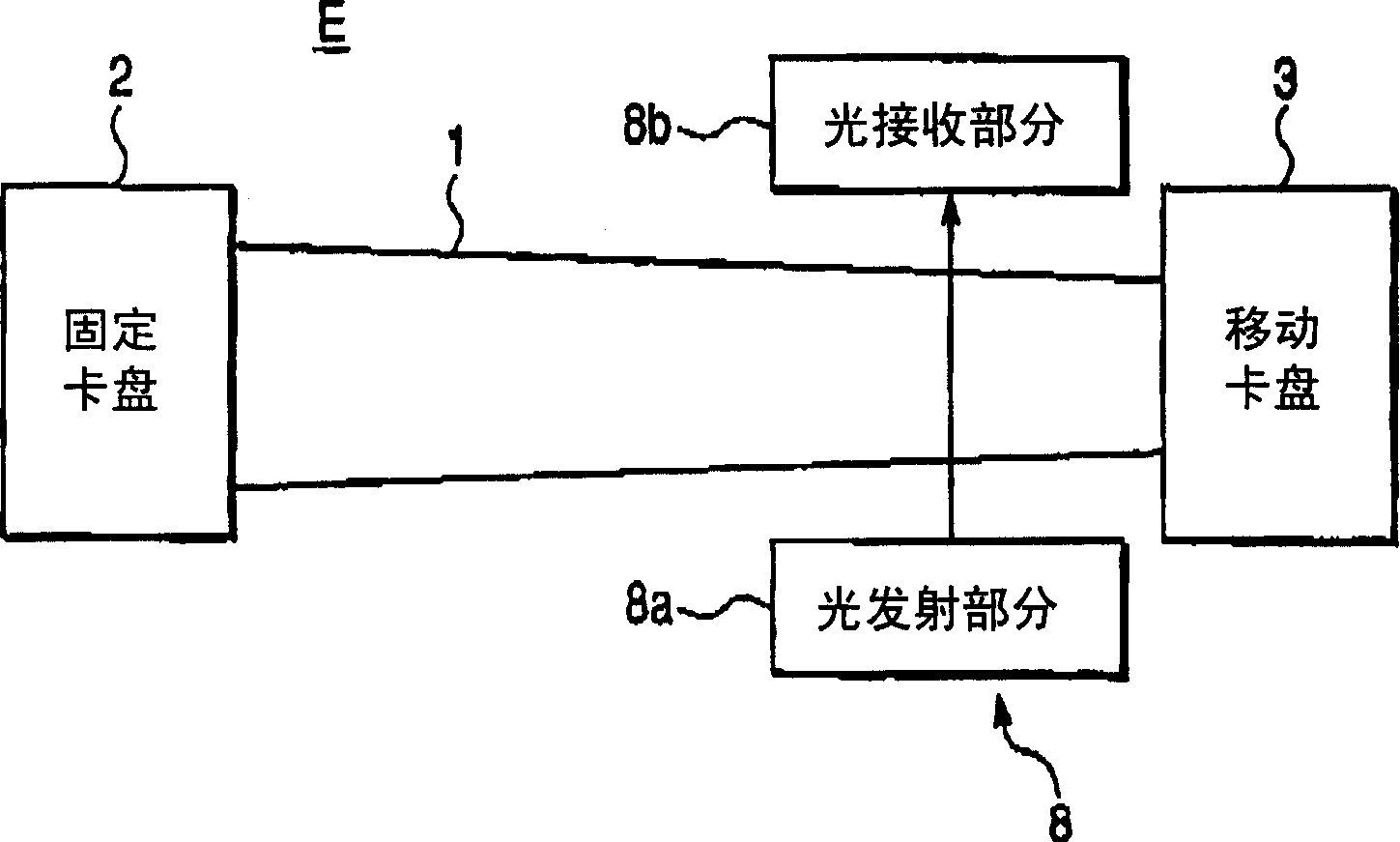

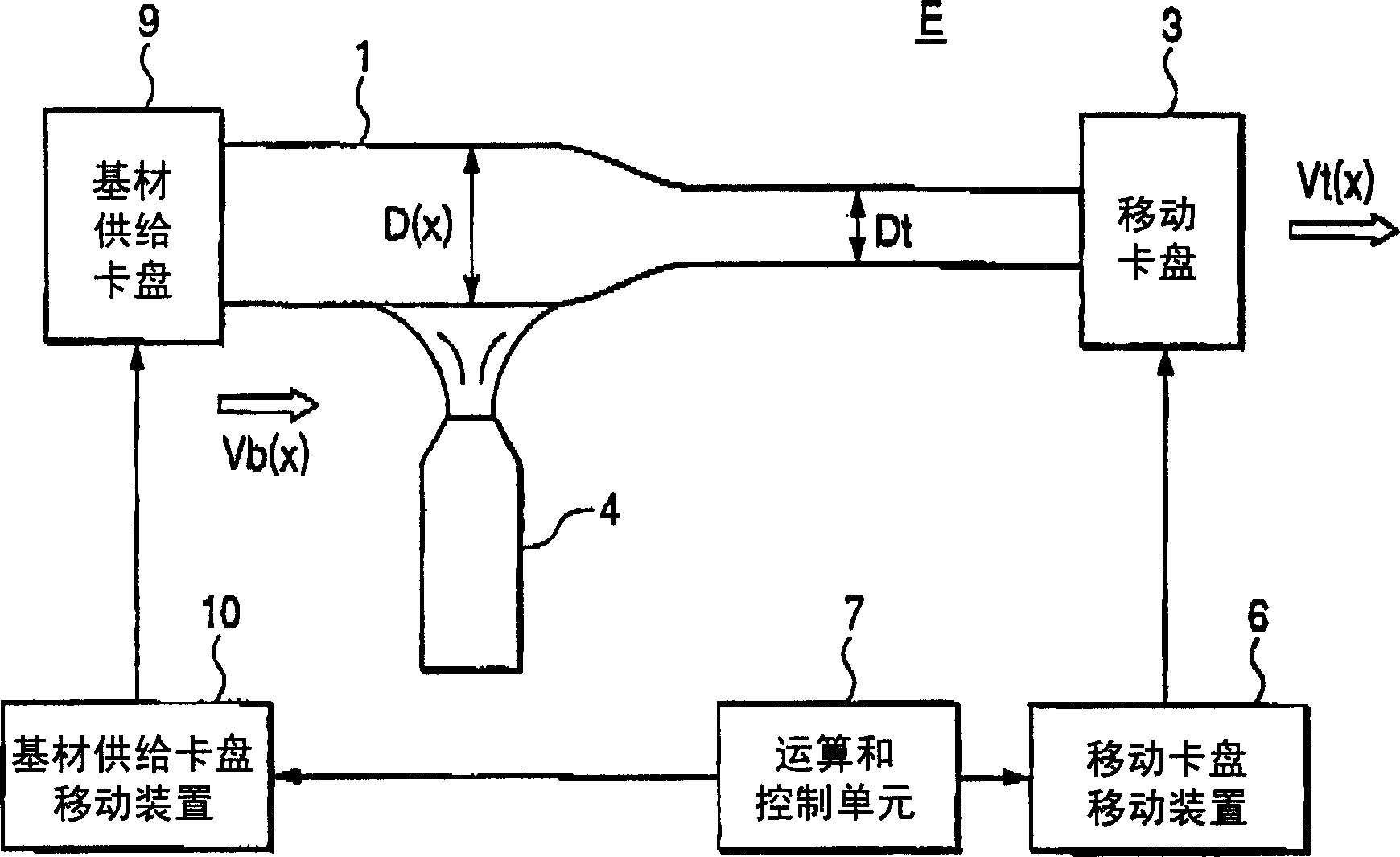

Method of stretching optical fiber base material and stretching device

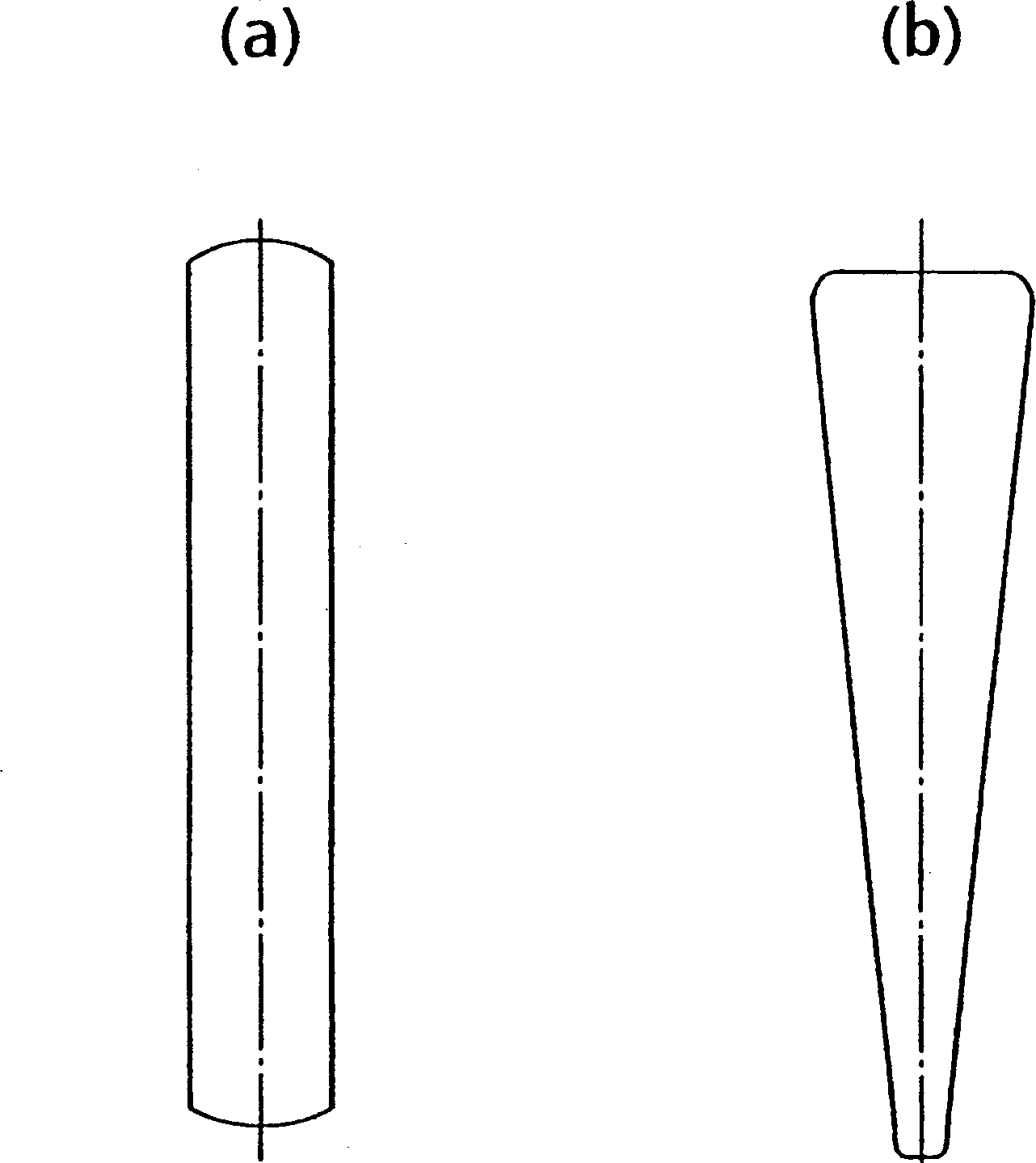

InactiveCN1890189AStretch PreciselyIncrease movement speedGlass making apparatusOptical light guidesEngineeringOptical fiber

A method of stretching an optical fiber base material comprising the step of gripping the opposite ends in a length-wise direction of an optical fiber base material with a pair of grip tools and moving one or both of the pair of grip tools in a first direction parallel to the above length-wise direction to thereby pull the optical fiber base material while moving a heating device relatively to the optical fiber base material in a second direction opposite to the first direction; and a device therefore; wherein the above optical fiber base material is stretched while the above relative moving speed Vb(x) is changed according to the expression (1): Vb.[Dmax / D(x)]<2> <= Vb(x) <= Vb.[Dmax / D(x)]<3> (1), in the expression, Vb denotes a reference speed, Dmax the maximum outer diameter of the optical fiber base material, D(x) the outer diameter of the optical fiber base material at a heated position x, and Vb(x) the moving speed of a heating device relative to the optical fiber base material when the optical fiber base material is at a heated position x.

Owner:SHIN ETSU CHEM CO LTD

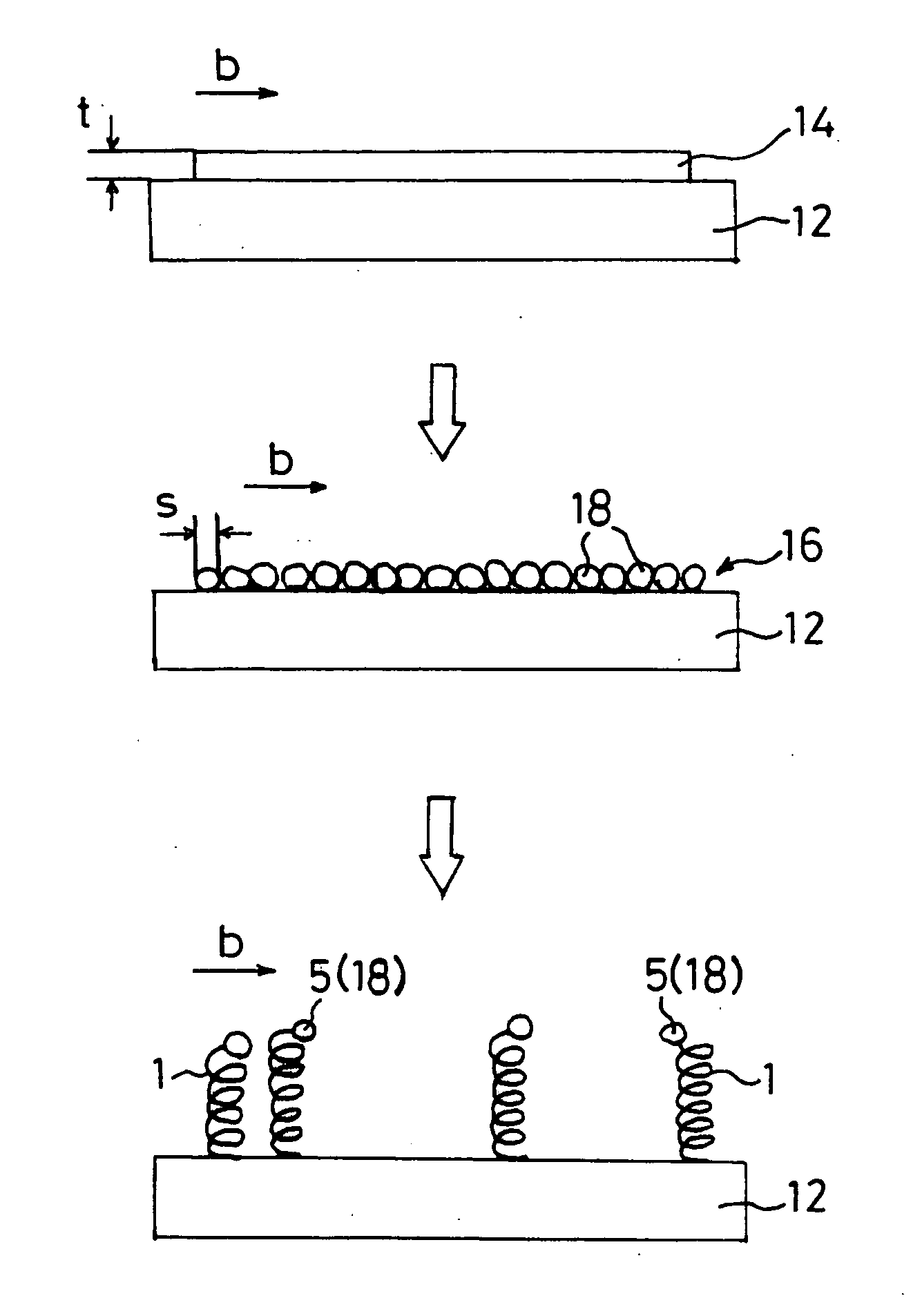

Catalyst for synthesizing carbon nanocoils, synthesizing method of the same, synthesizing method of carbon nanocoils, and carbon nanocoils

InactiveUS20070098622A1Uniform outer diameterQuality improvementMaterial nanotechnologyMolecular sieve catalystsCarbon nucleusMetal catalyst

A method for synthesizing carbon nanocoils with high efficiency, by determining the structure of carbon nuclei that have been attached to the ends of carbon nanocoils and thus specifying a true catalyst for synthesizing carbon nanocoils is implemented. The catalyst for synthesizing carbon nanocoils according to the present invention is a carbide catalyst that contains at least elements (a transition metal element, In, C) or (a transition metal element, Sn, C), and in particular, it is preferable for the transition metal element to be Fe, Co or Ni. In addition to this carbide catalyst, a metal catalyst of (Fe, Al, Sn) and (Fe, Cr, Sn) are effective. From among these, catalysts such as Fe3InC0.5, Fe3InC0.5Snw and Fe3SnC are particularly preferable. The wire diameter and the coil diameter can be controlled by using a catalyst where any of these catalysts is carried by a porous carrier.

Owner:JAPAN SCI & TECH CORP +3

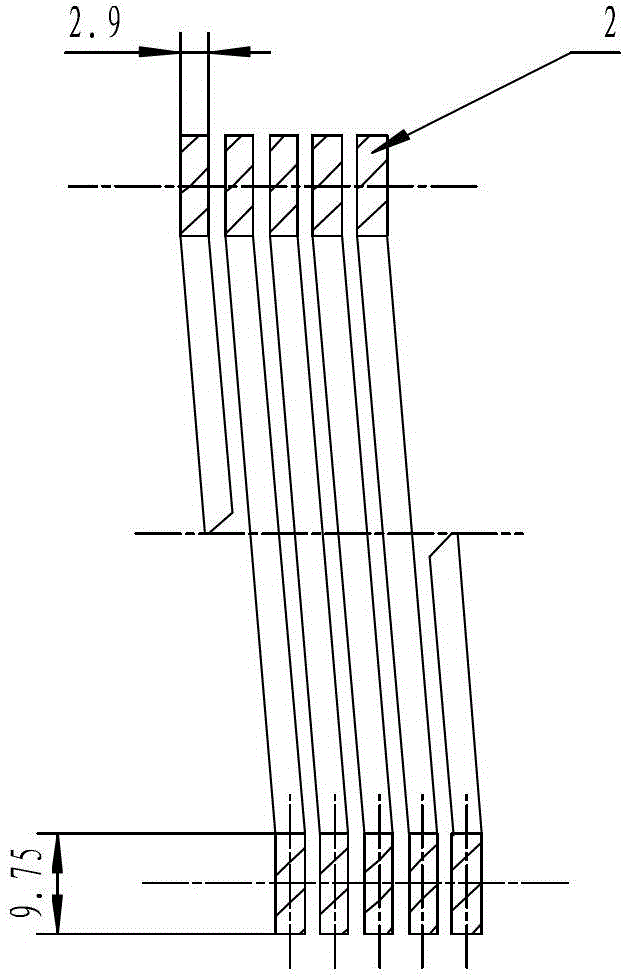

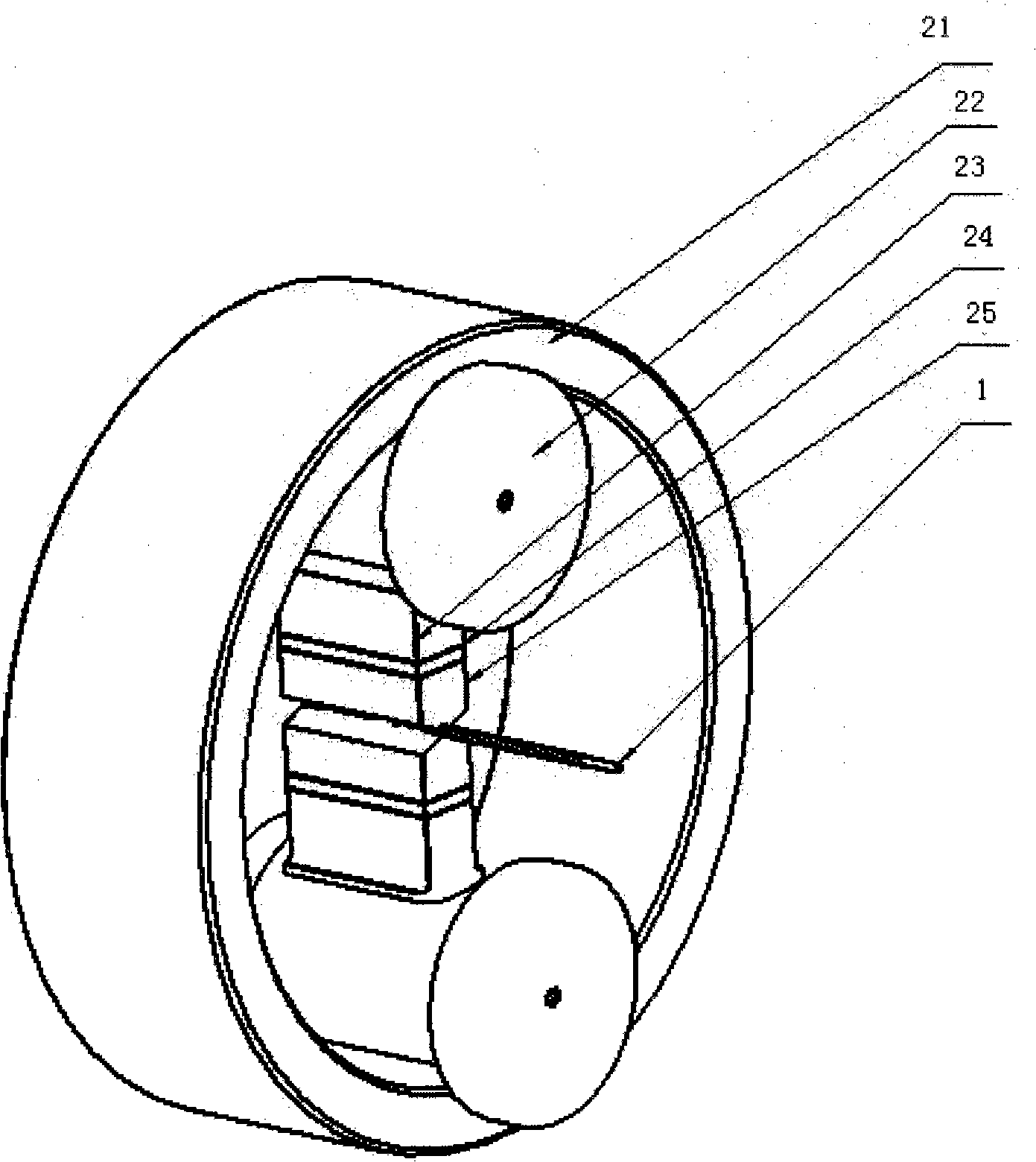

Rotor for dynamo-electric machine

InactiveUS7053515B2InhibitionUniform outer diameterSynchronous generatorsMagnetic circuit rotating partsBobbinElectric machine

The present invention provides a rotor for a rotary electric machine that suppresses the occurrence of winding disturbances in the process of winding a coil wire and has a coil field having a uniform outside diameter that is less likely to collapse.A coil field of a rotor coil is constructed by winding a coil wire having a circular cross section onto an outer circumference of a drum portion of a bobbin in multiple layers so as to make columns in each of the layers equal in number in an axial direction. Odd numbered layers of the coil field are constructed such that the coil wire is wound for approximately one turn around the drum portion in contact with an inner peripheral wall surface of a first flange portion of the bobbin, then wound into a plurality of columns in an axial direction such that the columns of the coil wire contact each other, and the coil wire in a final column forms a gap S relative to an inner peripheral wall surface of a second flange portion of the bobbin, and even numbered layers of the coil field are constructed such that the coil wire is wound for approximately one turn around the drum portion in contact with an inner peripheral wall surface of the second flange portion, then wound into a plurality of columns in an axial direction such that the columns of the coil wire contact each other, and the coil wire in a final column forms a gap S relative to an inner peripheral wall surface of the first flange portion. The gap S satisfies an expression D / 4≦S≦D / 2 relative to a diameter D of the coil wire.Thus, because the occurrence of winding disturbances in the process of winding the coil wire is suppressed, the coil wire can be wound into an aligned state, enabling a coil field that is less likely to collapse to be achieved, and the outside diameter of the coil field is made uniform, also preventing damage to an electrically-insulating coating resulting from contact with claw-shaped magnetic poles.

Owner:MITSUBISHI ELECTRIC CORP

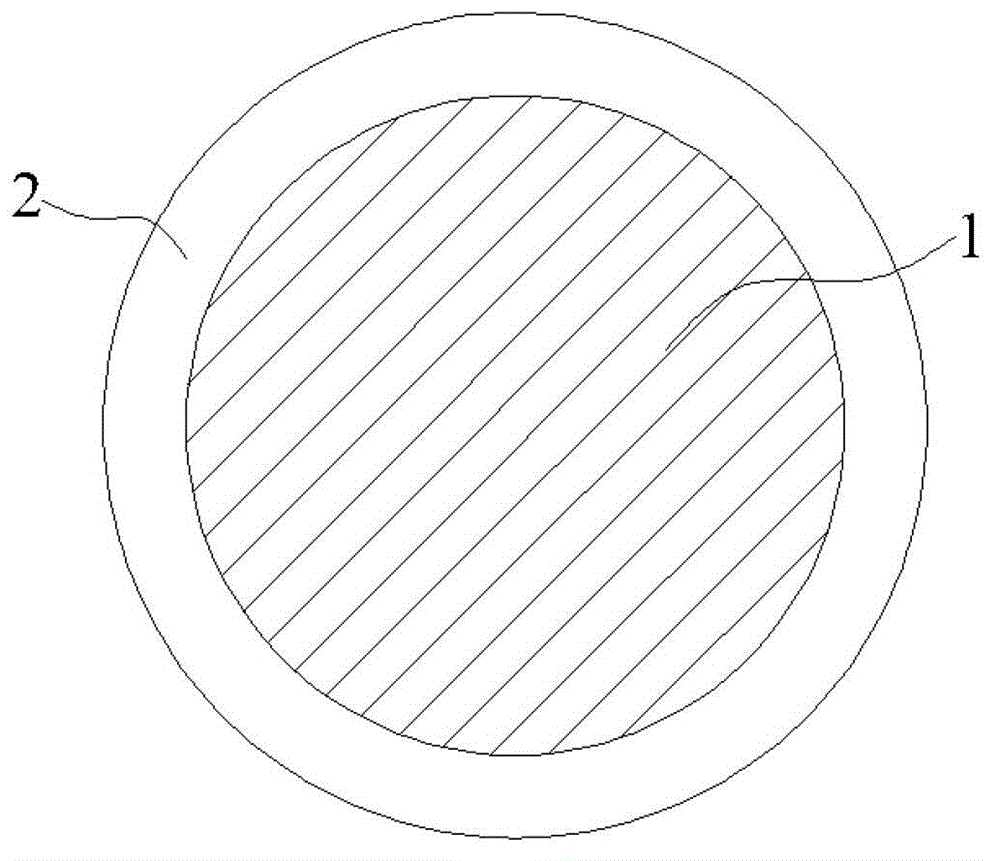

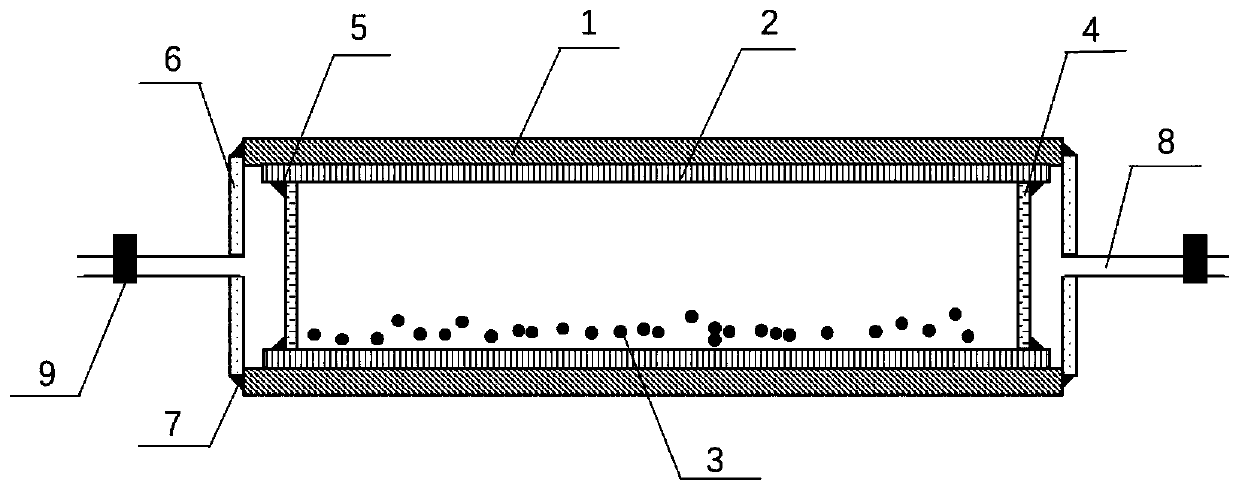

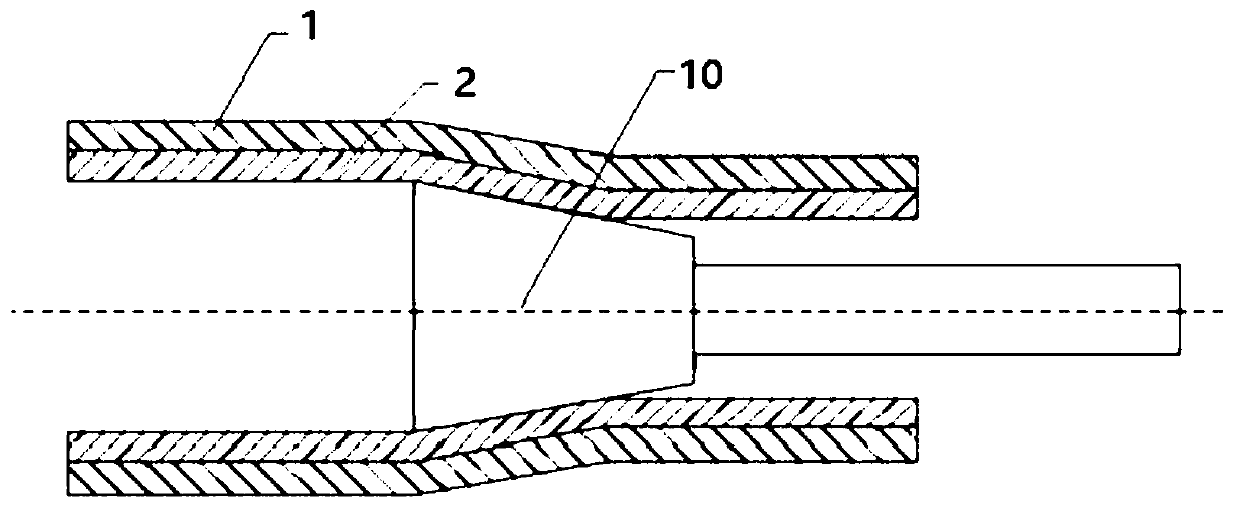

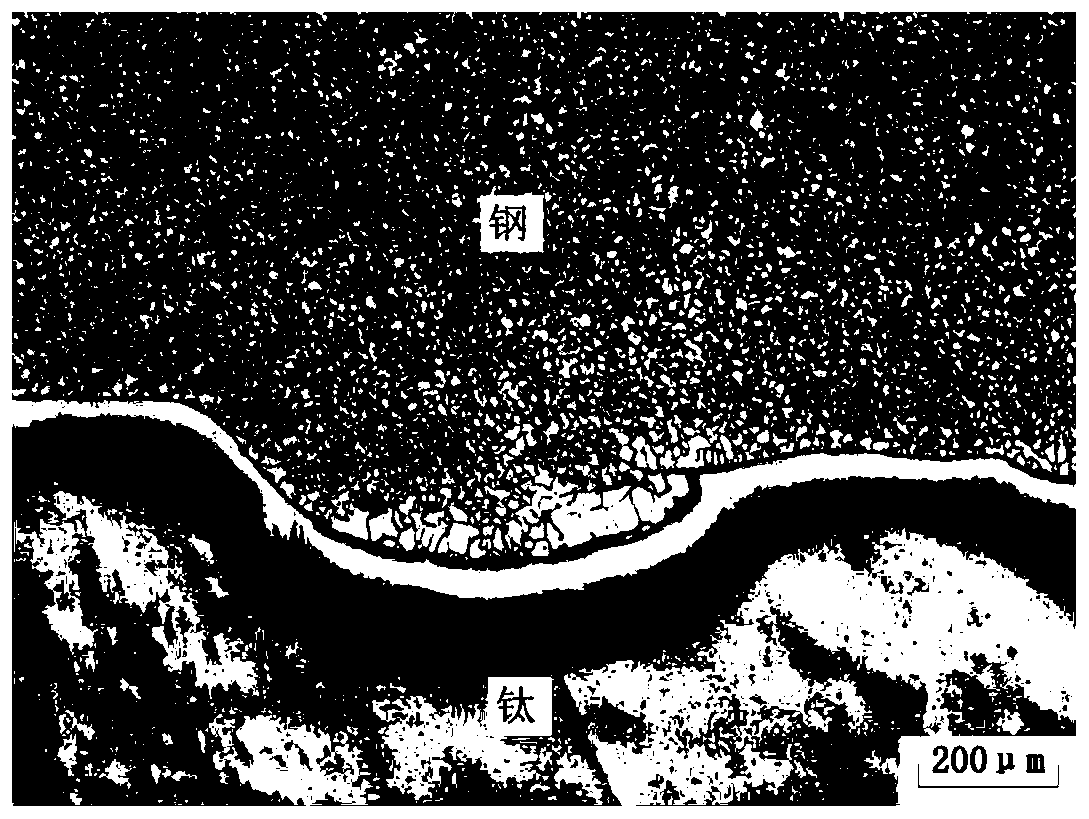

Preparation method of corrugated interface steel-titanium composite tube

The invention relates to a preparation method of a corrugated interface steel-titanium composite tube, belongs to the technical field of bimetal composite tubes, and solves the technical problem thatin an existing diffusion composite method, an interface is low in cleanliness and straight, which leads to the strength of a composite interface is low and the forming performance is poor. The preparation method of the corrugated interface steel and titanium composite tube comprises the following steps of S1, machining the inner surface of a steel tube and the outer surface of a titanium tube to form convex annular or double-sided annular spiral corrugated grooves; S2, cleaning impurities and oxides on the surfaces of the steel tube and the titanium tube; S3, making the titanium tube and the steel tube form mechanical interference fit; S4, placing solid powder into the titanium tube, and sealing the two ends of the titanium tube; S5, vacuumizing the interface of the steel tube and the titanium tube, until the vacuum degree of the interface between the titanium tube and the steel tube reaches 10<-2>Pa or below; S6, placing the steel-titanium composite tube blank into an annealing furnace to carry out diffusion annealing treatment; and S7, cutting off the head and tail part of the steel-titanium composite tube to obtaine a finished composite tube. The steel-titanium composite tube prepared by the preparation method disclosed by the invention realizes steel and titanium interface metallurgical bonding, the binding rate is 100%, and the shearing strength is greater than 250 MPa.

Owner:CENT IRON & STEEL RES INST +1

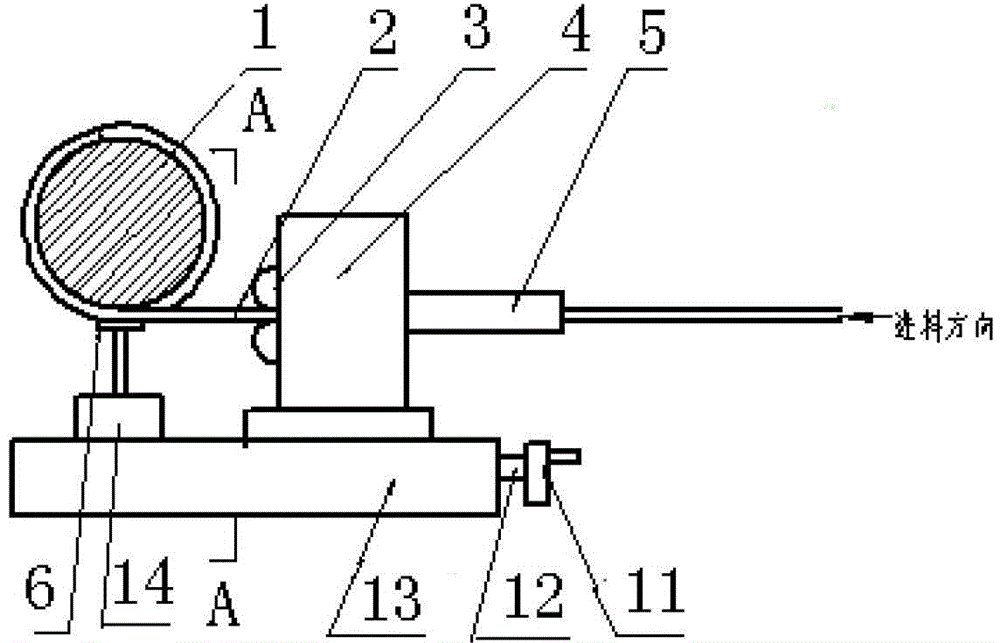

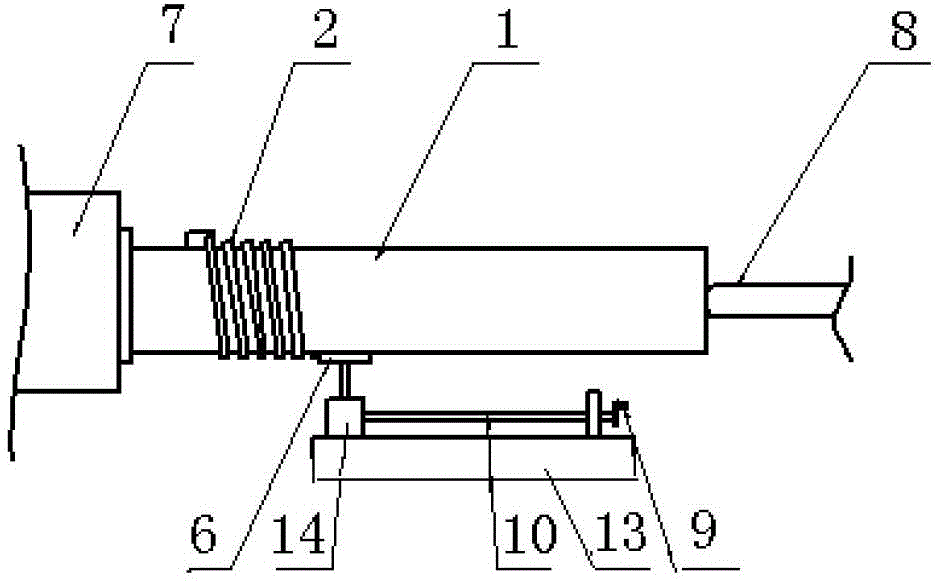

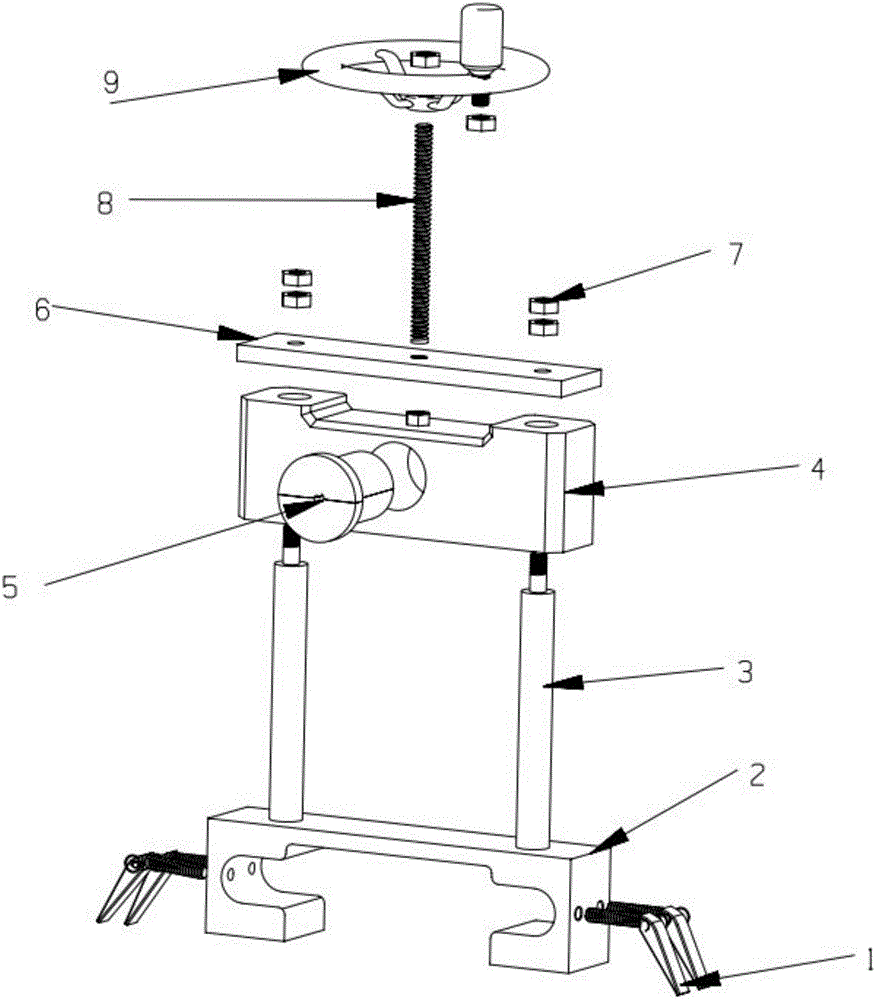

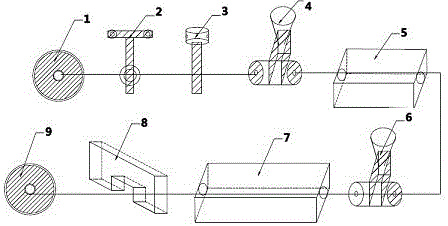

Fixture and method for winding rectangular-section wire torsional springs

The invention relates to a fixture for winding rectangular-section wire torsional springs. The fixture comprises a bed plate and a guide support arranged above the bed plate. The guide support is connected with the bed plate in a matched manner by a first screw rod, a support moving handle is connected with one end of the first screw rod in a matched manner, and the support can move from left to right on the bed plate by turning the support moving handle. A correction clamp plate is arranged on the right side of the guide support, a groove type guide wheel is arranged on the left side of the guide support, and a wire with a rectangular section sequentially penetrates through the correction clamp plate and the groove type guide wheel to be wound on a torsion mandrel. The invention further provides a method for winding the rectangular-section wire tensional springs. By the aid of the method, appearance quality of the torsional springs can be guaranteed, sizes of outer diameters of the torsional springs are consistent, and pitches are uniform. By the aid of the fixture and the method, accuracy of guiding can be guaranteed, deflection of feeding is effectively prevented, distance between a feeding outlet and the torsion mandrel can be adjusted, consistency and reliability of winding torsional spring forming are guaranteed, deflection and lodging of the torsional springs can be further avoided during winding.

Owner:CHONGQING WANGJIANG IND

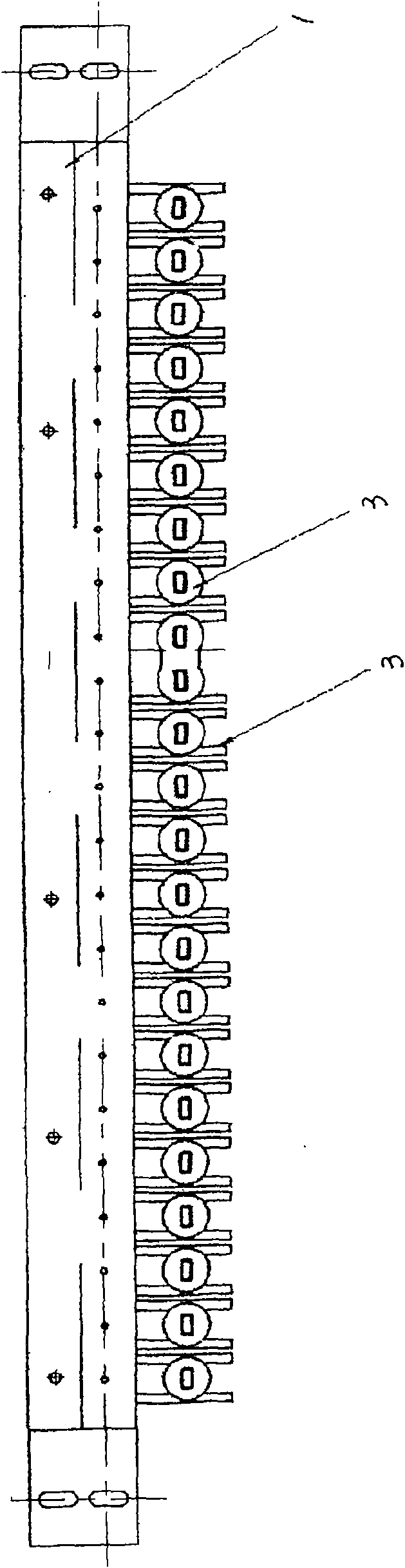

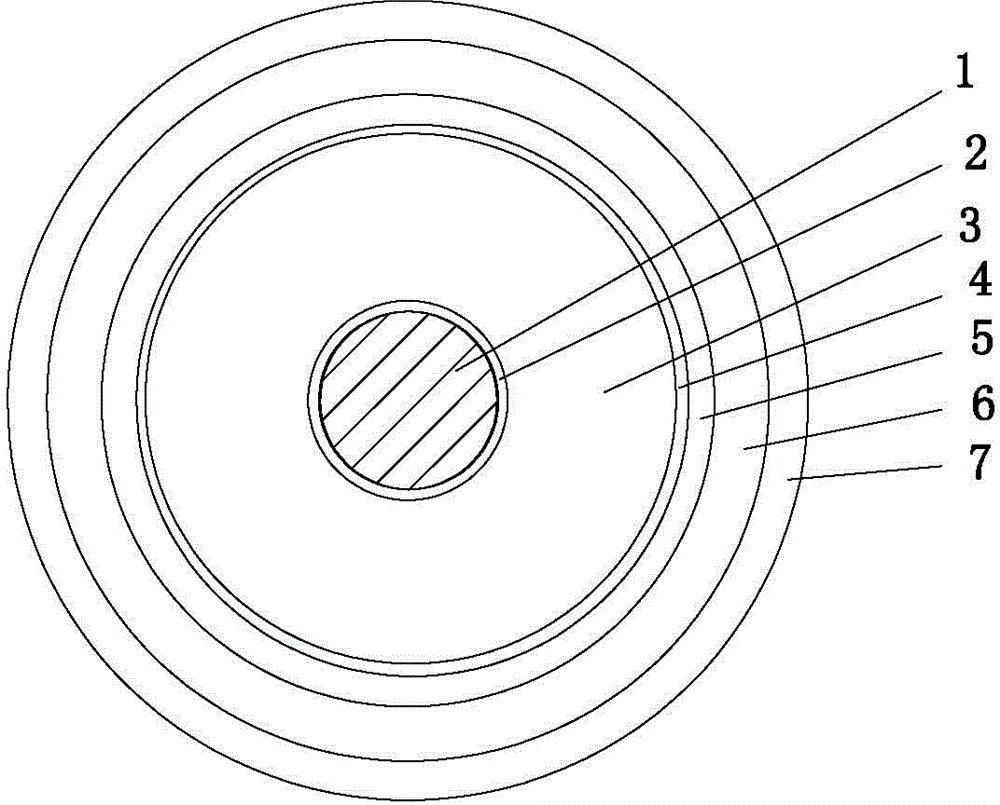

Large-section milliken-conductor comprehensive water-retaining crosslinking electric cable

InactiveCN102881377AUniform outer diameterAvoid pollutionPower cables with screens/conductive layersElectrical resistance and conductanceInsulation layer

The invention discloses a large-section milliken-conductor comprehensive water-retaining crosslinking electric cable which is characterized in that a conductor unit (1) is arranged at the center of the electric cable, a conductor shielding layer (2), an insulation layer (3), an insulation shielding layer (4), a semi-conductive water-retaining buffer belt layer (5), a corrugated aluminum sheath (6) and an outer sheath (7) are sequentially coated on the conductor unit (1) from inside to outside. The large-section milliken-conductor comprehensive water-retaining crosslinking electric cable is high in conductivity, comprehensive in radial water-retaining / waterproofness and weather fastness and has the advantages of resistance to low temperature, low-temperature flexibility, good electric performance, high tensile resistance and long service life and the like.

Owner:SINOSTAR CABLE CO LTD

Coupling, particularly pipe coupling for high-pressure pipes or hoses

InactiveUS20070284879A1Simple wayDamage-free and simple transportSleeve/socket jointsPipe supportsCouplingEngineering

A coupling, particularly a pipe coupling for high-pressure pipes or high-pressure hoses, is equipped with coupling pieces provided at the ends to be connected, in each instance, and with a cuff that couples the coupling pieces, using at least two shear elements. The coupling pieces engage over the cuff that lies on the inside, as an extension of the ends, with almost the same diameter.

Owner:KARL HAMACHER

Seamless titanium welded pipe and manufacturing method thereof

ActiveCN102500619AUniform wall thicknessUniform outer diameterFurnace typesMetal rolling arrangementsWeld seamTitanium

The invention discloses a seamless titanium welded pipe with a small caliber and a thin wall, which is characterized by being composed of a mother pipe (2) through at least one path of cold rolling, hole shrinkage and wall reduction, and heat treatment, wherein the mother pipe (2) is a straight welded titanium pipe; original welding lines (1) on the surface of the prepared seamless titanium welded pipe (3) are invisible, the wall thickness and the outer diameter of the seamless titanium welded pipe are uniform; the original welding lines (1) are arranged in a length direction and a circumferential direction; the organization and the performance of the original welding lines are the same as those of the mother pipe (2). A manufacturing method comprises the following steps of selecting and treating the mother pipe, and carrying out the cold rolling, the hole shrinkage and the wall reduction, and the heat treatment on the mother pipe. The seamless titanium welded pipe manufactured by the invention has the advantages that: the wall thickness and the outer diameter of the seamless titanium welded pipe are very uniform, the size precision is better than that of a seamless pipe and a common welded pipe, a process route for preparing a thin-wall tubular material by directly utilizing a thicker raw material coiled stock is realized, and the production cost is greatly reduced.

Owner:HUNAN XIANGTOU GOLDSKY NEW MATERIALS CO LTD

Anti-blocking low smoke zero halogen flame-retardant cable material for optical cable

ActiveCN103849063AFast demouldingGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesMelt flow indexCarvacryl acetate

The invention discloses an anti-blocking low smoke zero halogen flame-retardant cable material for an optical cable. The anti-blocking low smoke zero halogen flame-retardant cable material comprises the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high pressure metallocene polyethylene, 10-20 parts of modified polyethylene, 70-110 parts of aluminum hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 part of antioxidant, and 2-5 parts of black master batch, wherein the content of VA in the ethylene-vinyl acetate copolymer is 20-28%, the melt index of 2.16Kg of high pressure metallocene polyethylene at 190DEG C is less than or equal to 3g / 10min, the density is less than 0.92g / cm<3>. By adopting the anti-blocking low smoke zero halogen flame-retardant cable material, the outer diameter of the optical cable is uniform, so that the shrinkage integrity of the core of the optical cable is guaranteed, the signal transmitted in the optical cable is not attenuated sharply; and in addition, the tensile strength of the cable is greater than or equal to 13MPa, the elongation at break is greater than or equal to 250%, the oxygen index is greater than or equal to 34%, and the cable has excellent mechanical property.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

Structure of gas sensor ensuring high degree of gas-tight seal

ActiveUS7222408B2High degreeSimple structureMaterial analysis by electric/magnetic meansManufacture of electrical instrumentsHermetic sealAbutment

An improved structure of a gas sensor is provided which is designed for achieving desired crimping of an end portion of a sensor housing to establish a higher degree of gas-tight seal between the housing and a sensor element. The sensor element is fitted within the sensor housing. The end portion of the sensor housing is crimped or bent to urge the sensor element into constant abutment with an inner wall of the housing through a sealing member. The housing has an unique shape and dimensions selected to ensure the higher degree of gas-tight seal regardless of the degree of wear of a crimper and / or dimensional error of the housing.

Owner:DENSO CORP

Hydraulic valve for an oscillating motor adjuster

The invention relates to a hydraulic valve for an oscillating motor adjuster that utilizes camshaft alternating torques by means of non-return valves for more rapid adjustment. The non-return valve that is not used for the respective rotation is additionally closed by means of the piston of the hydraulic valve.

Owner:HILITE GERMANY

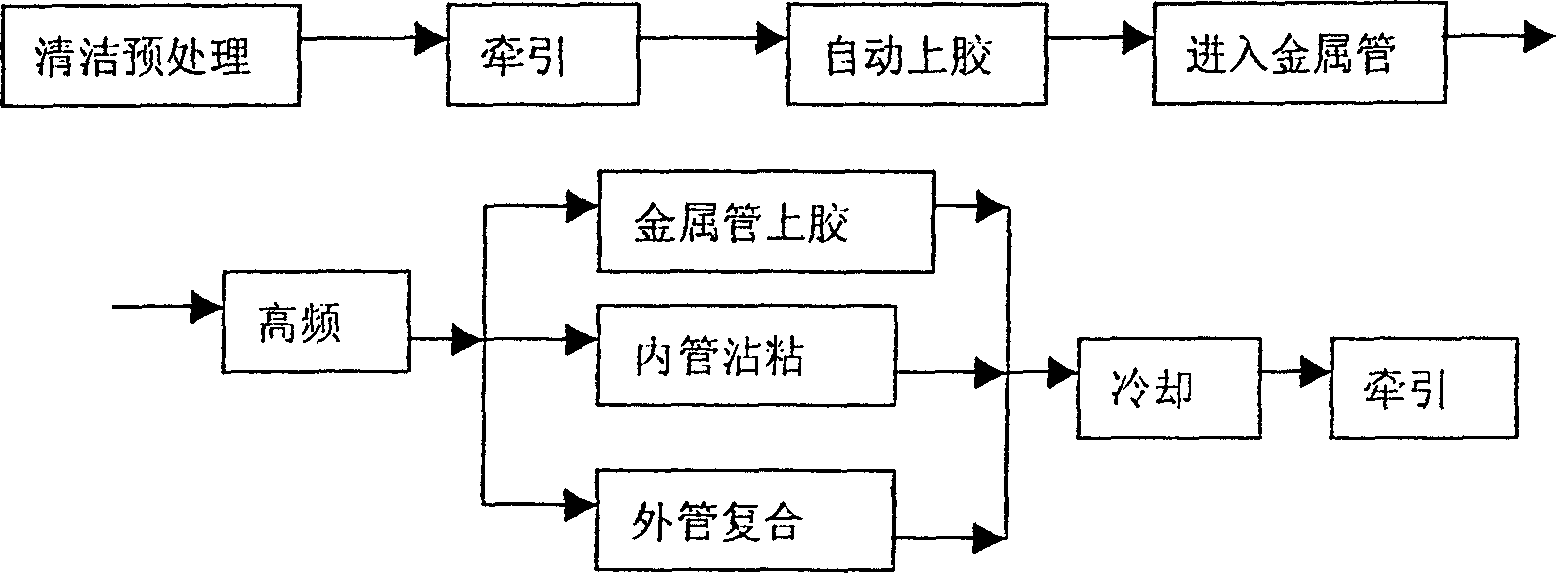

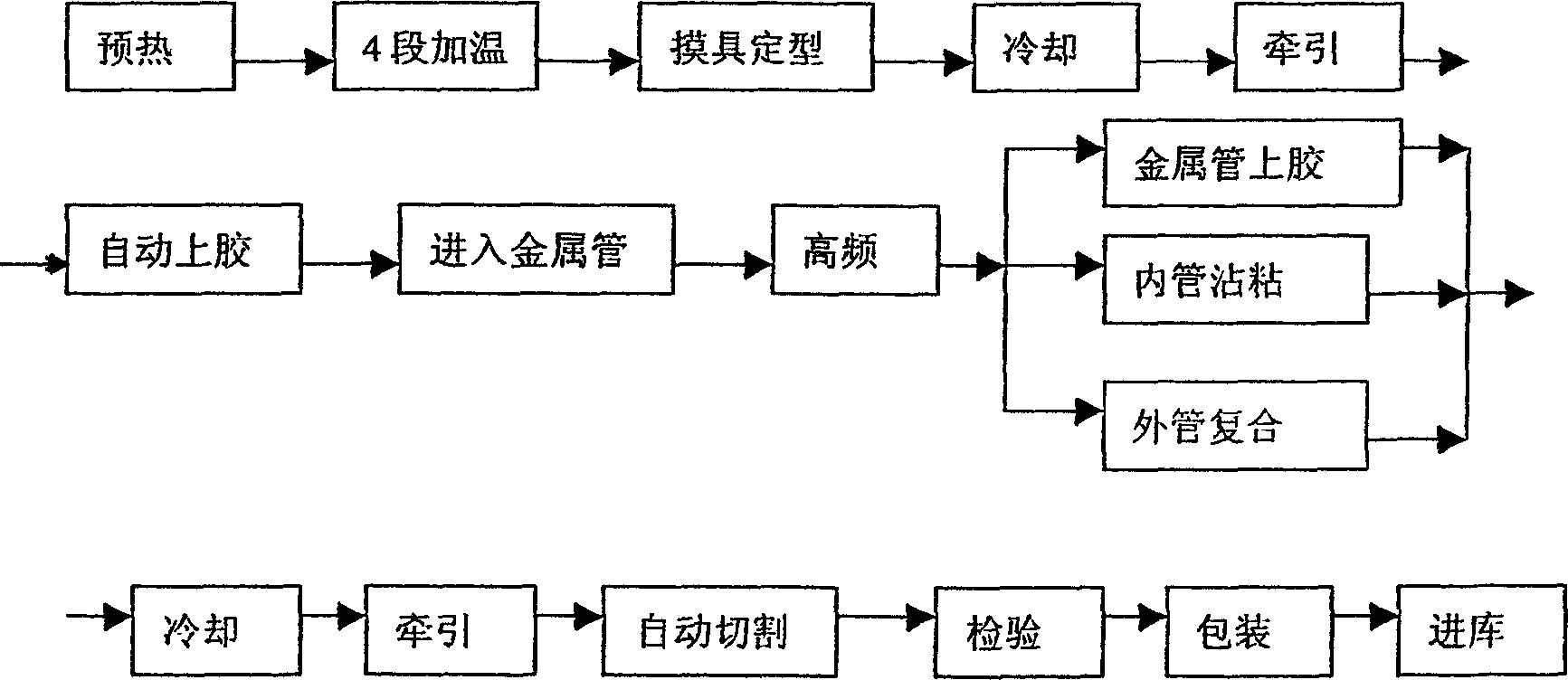

Producing teahnology for high-polymer composite pipe and its special die

The production process of the composite polymer pipe includes the following steps: coating one layer of thermosol to the inner surface of inner plastic pipe and inserting matched seamless metal pipe; reducing and drawing the combination of the inner plastic pipe and outer metal pipe; heating the reduced and drawn pipe; coating the outer surface of the outer metal pipe with adhesive; compounding one layer of outer plastic pipe; and cooling to form during drawing. The special production mold includes outer mold and inside core mold, the core mold consists of inner core mold and outer core mold, and there are inner molding nozzles and outer molding nozzles set between the inner core mold and the outer mold and between the outer core mold and the outer mold separately.

Owner:马林远

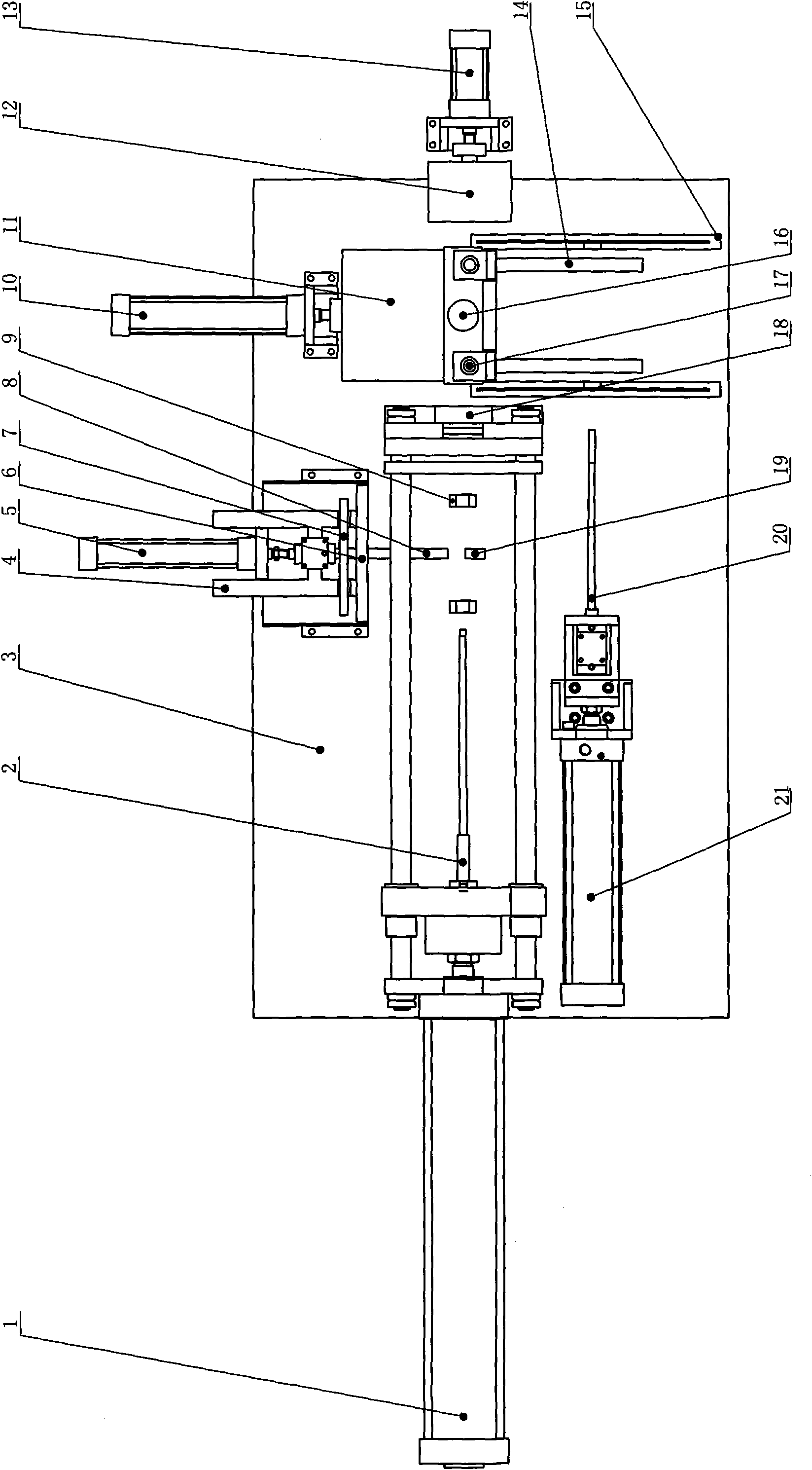

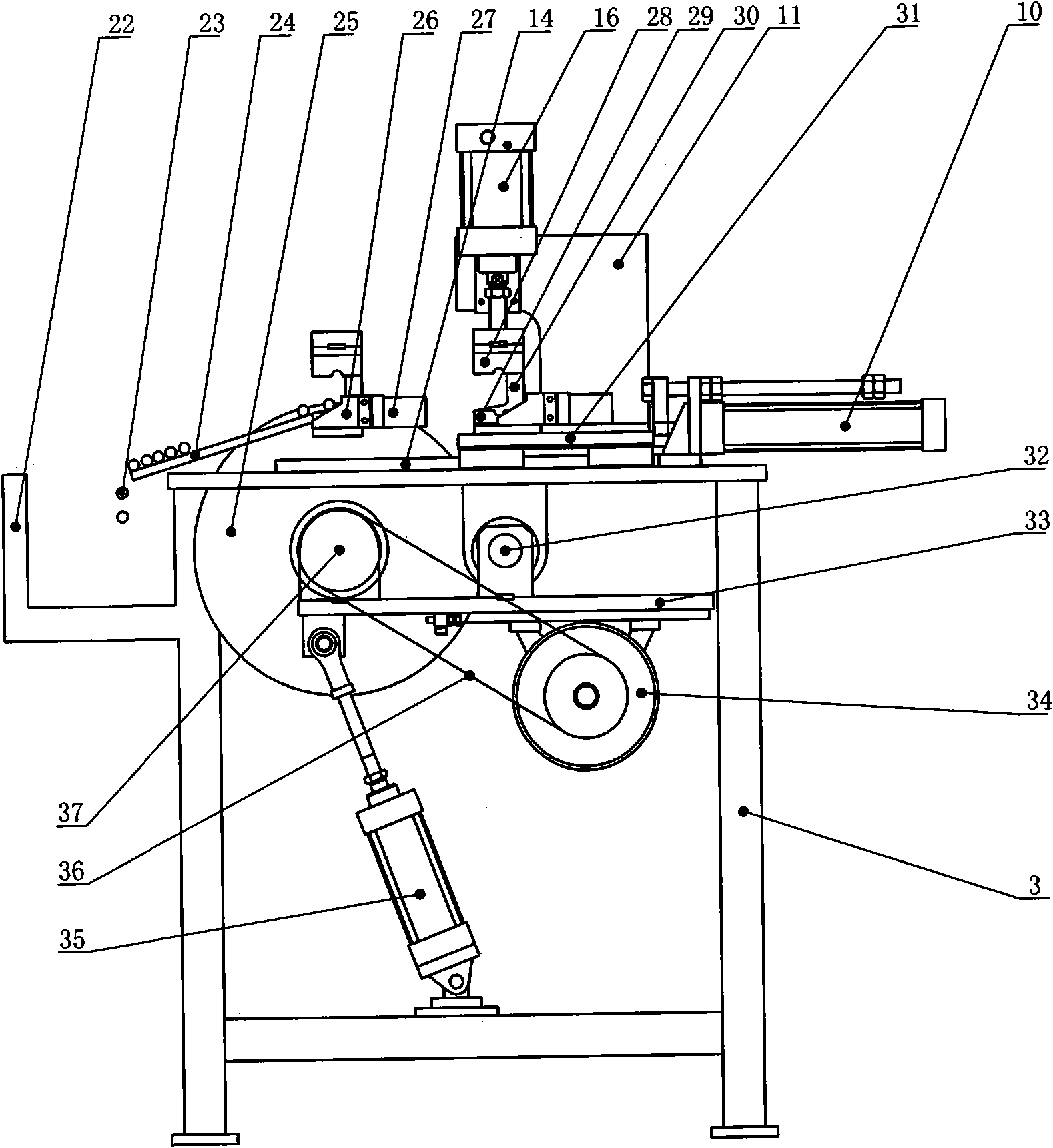

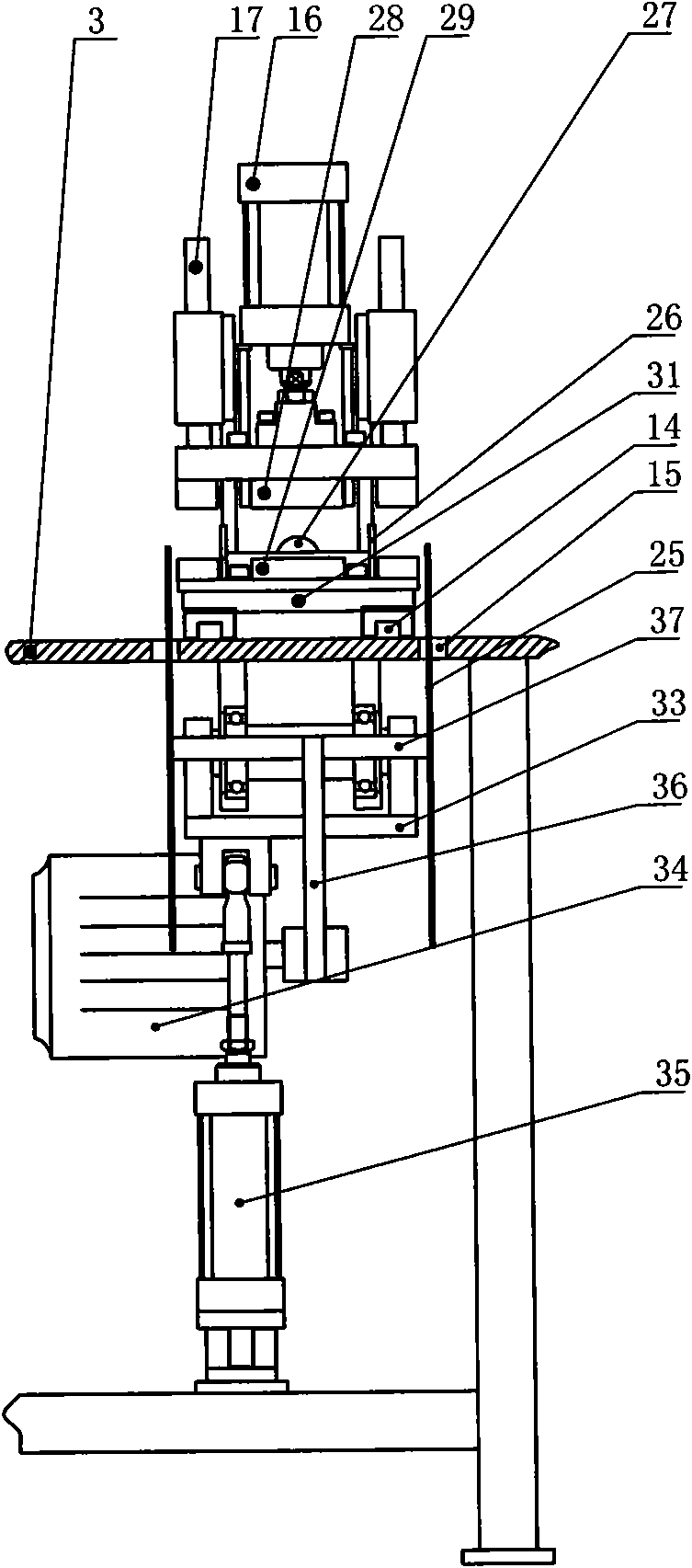

Trumpet nozzle pipe molding machine tool

InactiveCN102059506AUniform outer diameterUniform inner diameterWind musical instrumentsMolding machineEngineering

The invention relates to a trumpet nozzle pipe molding machine tool, which comprises a workbench, an electric control box, a propelling cylinder, a material feeding mechanism, an outer diameter trimming mechanism, a nozzle pipe clamping mechanism, a cutting mechanism and a positioning cylinder, wherein the electric control box is arranged at any side edge of the workbench; the propelling cylinder is arranged at the left end of the workbench; the outer diameter trimming mechanism and the nozzle pipe clamping mechanism are arranged in turn on the right side of the propelling cylinder; and the material feeding mechanism is arranged on the outer side of the outer diameter trimming mechanism. The machine tool has a simple structure, combines the cylinder with electric control equipment, realizes trimming of the inner diameter and the outer diameter of the nozzle pipe and length processing, automatically finishes feeding, inner diameter trimming, outer diameter trimming and length trimming, has high control level, makes the inner diameter and the outer diameter of a processed nozzle pipe more uniform, has more accurate length, lowers the working intensity of operating personnel, improves working efficiency and ensures sounding of an assembled trumpet.

Owner:TIANJIN JINBAO MUSICAL INSTR

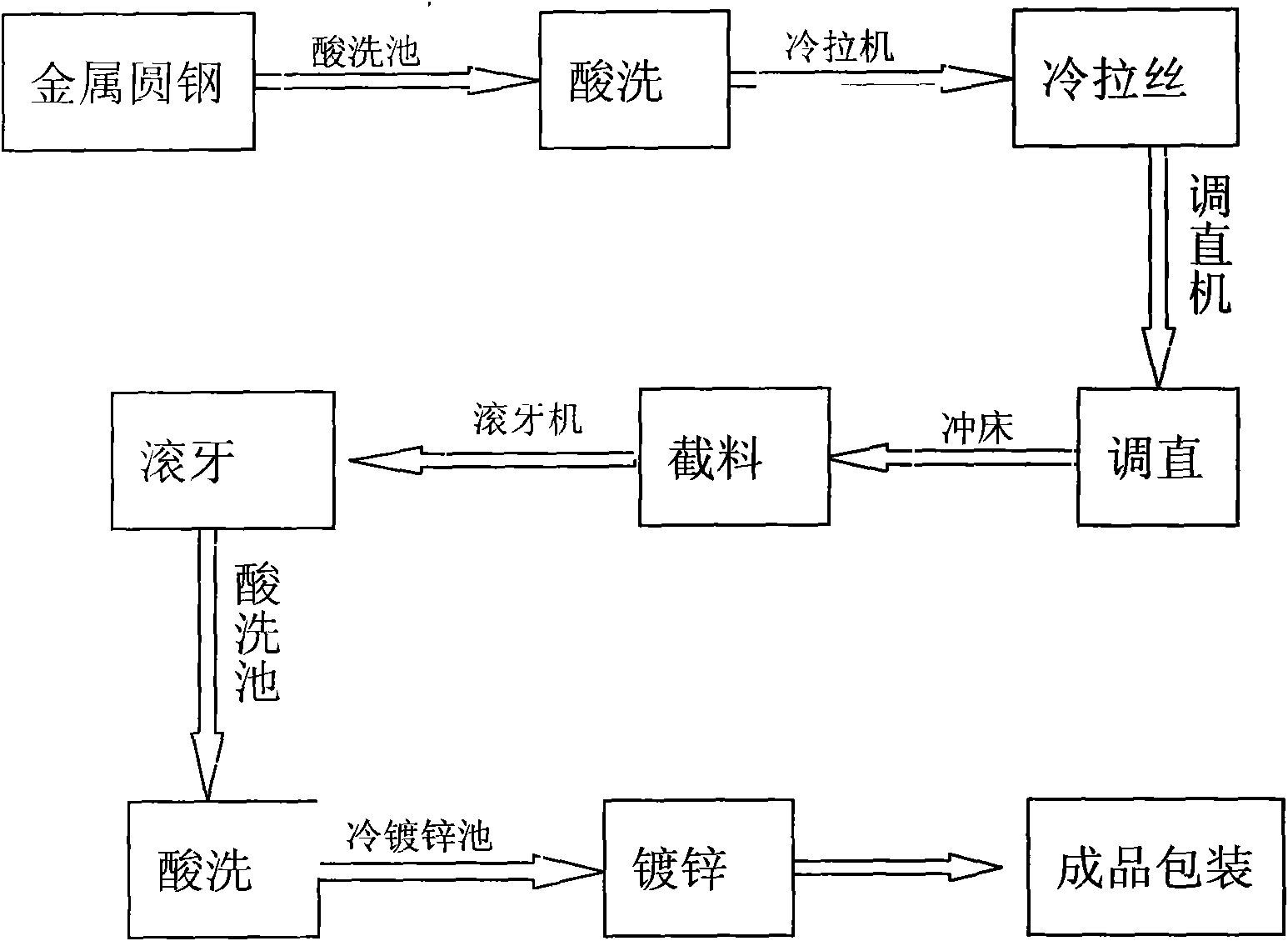

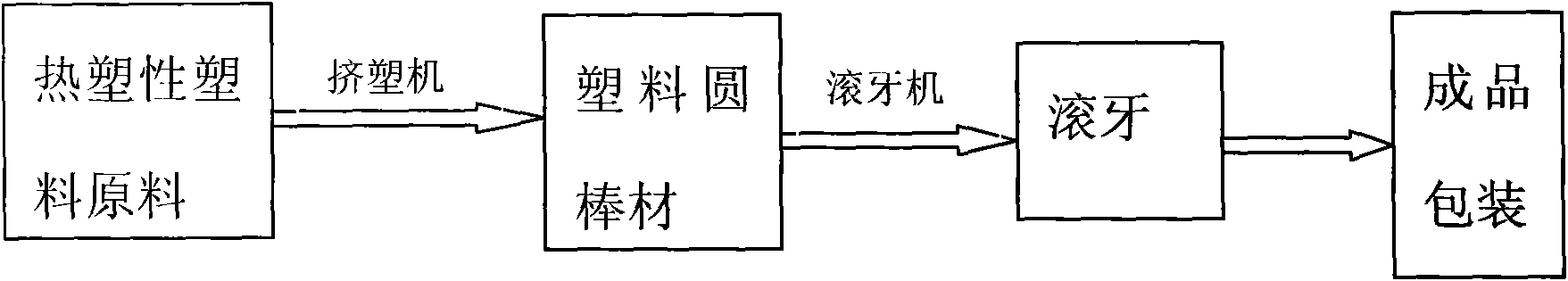

Plastic steel screw

InactiveCN101628478AHas metal strengthWide range of usesScrew-threads articlesThermoplasticProduction line

The invention relates to a plastic steel screw made of a thermoplastic plastic material. A manufacturing method comprises the following steps that: a thermoplastic resin material is added into an extrusion molding production line to produce a round bar material; and the round bar material is rolled by a roller and can be packaged to form a finished product. The plastic steel screw has the functions of antirust, acid and alkali anticorrosion and good flexibility and the like which a metal screw does not have. Simultaneously, the plastic steel screw overcomes the defects of difficult processing and complicated and excessive processes of the prior metal screw. The plastic steel screw can be molded once only through the extrusion molding process, has few production process flows, simple production equipment, zero pollution and even thickness of external diameter, can adopt the plastic materials with different properties according to different application requirements, has wide application of a finished product and can meet different requirements of different fields.

Owner:刘国兴

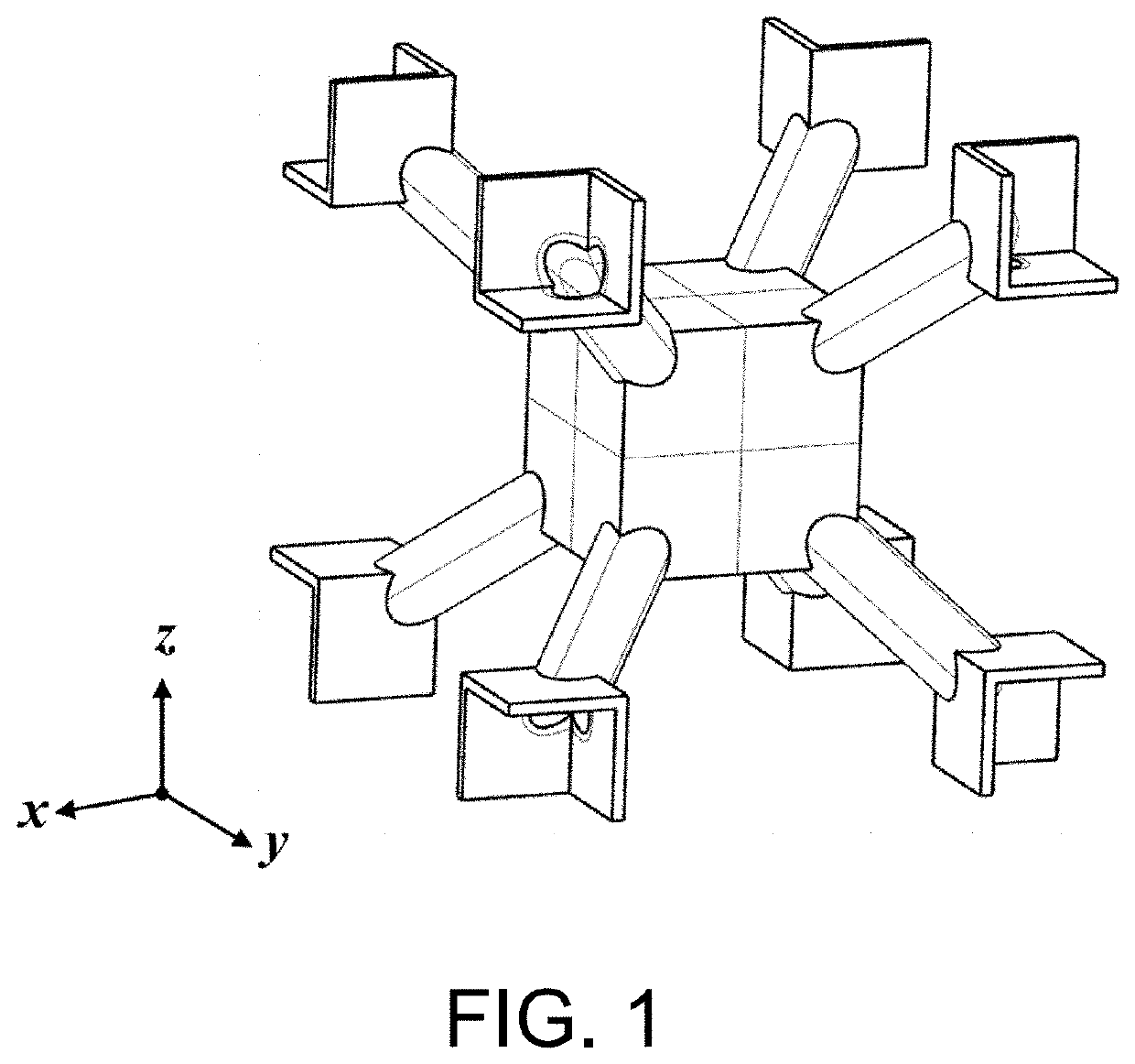

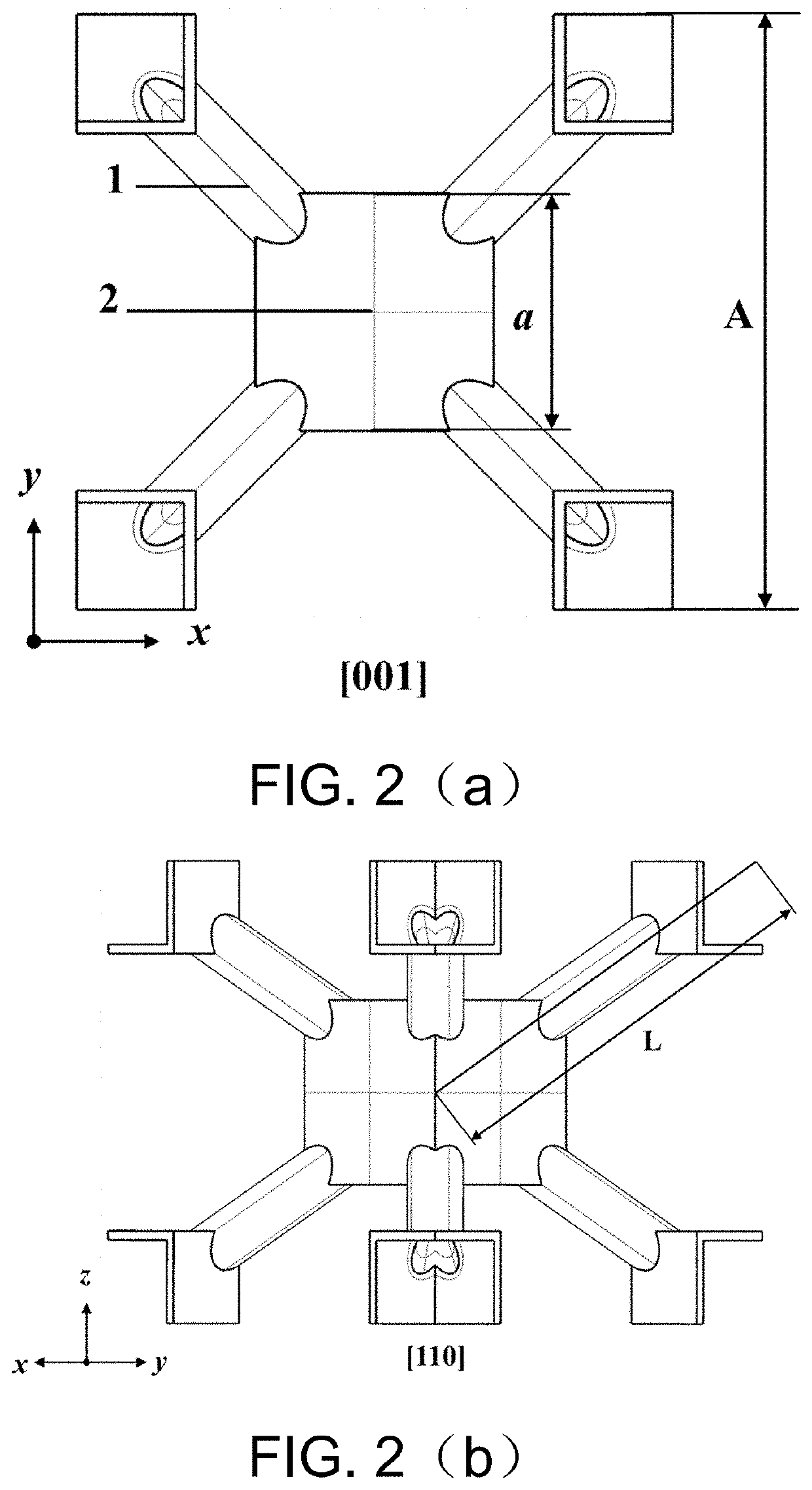

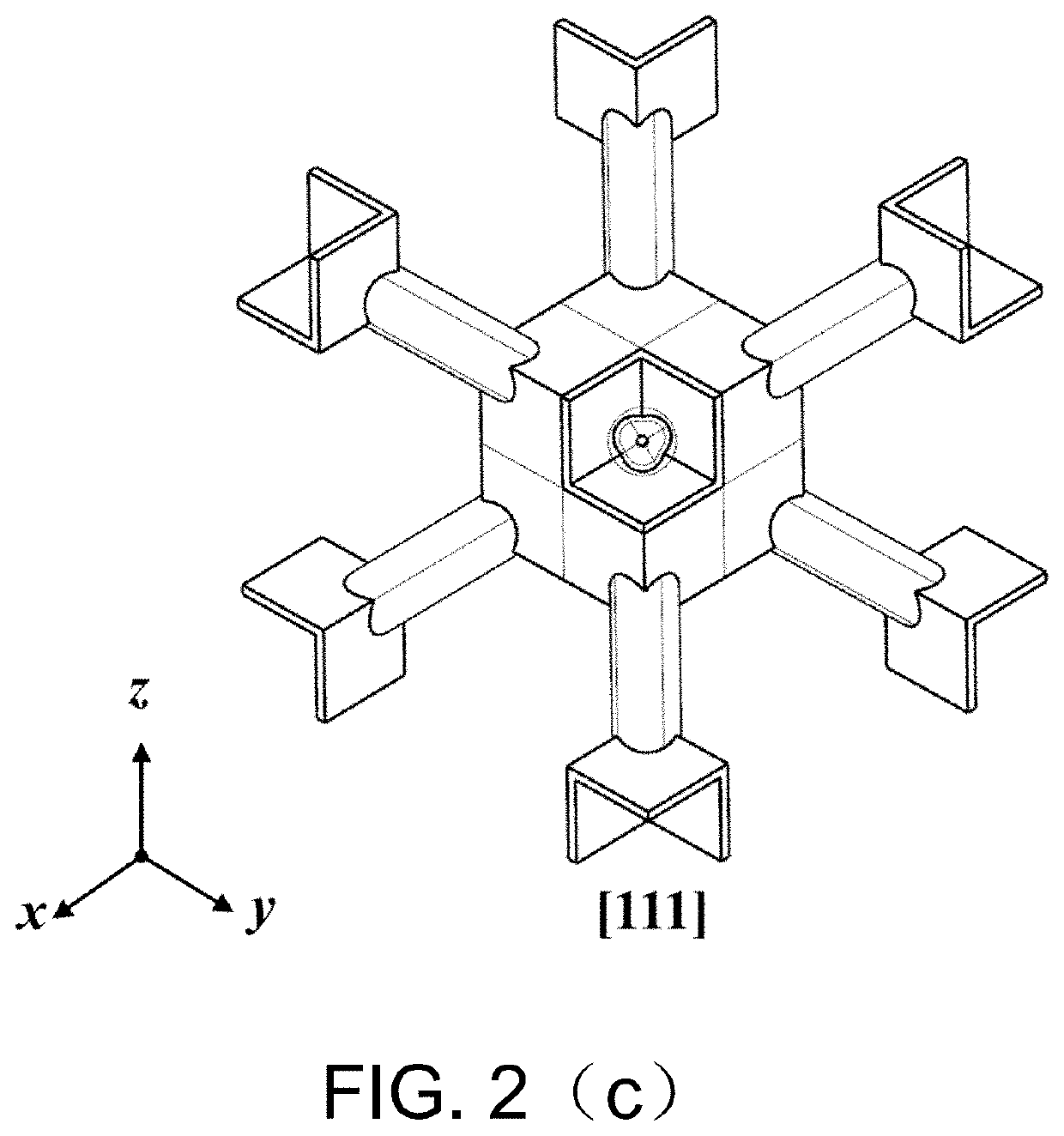

Multi-scale three-dimensional pentamode metamaterial and additive manufacturing method thereof

ActiveUS20220118518A1Different functionsIncrease freedomAdditive manufacturing apparatusIncreasing energy efficiencyCrystallographyEngineering

The disclosure belongs to a technical field related to metamaterials and discloses a multi-scale three-dimensional pentamode metamaterial and an additive manufacturing method thereof. The multi-scale three-dimensional pentamode metamaterial has a body centered cubic (BCC) structure and includes a plurality of rods and a plurality of node structures. Two ends of each of the rods are connected to the node structures. Each of the rods has a cylindrical shape and is provided with a biconical through hole. From one end of the rod towards the other end of the rod, a diameter of the biconical through hole gradually decreases and then gradually increases. A chamber is formed inside each of the node structures, the biconical through hole communicates with the chamber, and the chamber is filled with a lattice structure.

Owner:HUAZHONG UNIV OF SCI & TECH

Formula of insulating material low in loss and high in phase stability, and method for preparing insulating conductor core thereof

InactiveCN104893193AReduce lossUniform outer diameterInsulated cablesInsulated conductorsPolytetrafluoroethyleneSieve

The invention discloses the formula of an insulating material low in loss and high in phase stability, and a method for preparing an insulating conductor core thereof. According to the formula, the material comprises the following raw materials in percentage: 66-67% of dispersion polymerized polytetrafluoroethylene resin, 15-16% of aromatic solvent, 1.0-1.5% of white polytetrafluoroethylene color paste, and 16.5-17.0% of silicon dioxide powders. The method for preparing the insulating conductor core comprises the steps of mixing the above raw materials, sieving the obtained mixture through a sieve to obtain particles, putting obtained particles in a plastic and sealed wild-mouth bottle, shaking up the particles, placing the particles in an aging room for 48-72 hours at the environment temperature of 25-40 DEG C, pouring the particles in precast rod molding equipment to form hollow and cylindrical embryonal rods of 1.2-1.3 mm in length, 15.8-16.2 mm in internal diameter and 76.0-76.2 mm in external diameter, inserting the embryonal rods in a polytetrafluoroethylene extruding production line, driving an internal conductor to pass through a host and an internal mold of 1.50-1.55 mm, installing an outer film of 4.2-4.3 mm, starting the host and a traction part, tightly coating the cylindrical embryonal rods onto the surface of the conductor, adjusting the traction and extrusion speed, controlling the external diameter of the conductor to be 4.40-4.45 mm before the sintering process, and completing the preparation of the conductor core through a sintering region.

Owner:江苏通光电子线缆股份有限公司

Stainless steel/aluminium tape longitudinal tubing corrector

PendingCN106526771AUniform outer diameterImprove product qualityFibre mechanical structuresEngineeringMechanical engineering

The invention provides a stainless steel / aluminium tape longitudinal tubing corrector. The corrector is characterized in that a slide block is arranged at the bottom end; rotatably adjustable lock nuts are arranged at the opposite sides of the slide block respectively; two feed rods are fixed at the upper end of the slide block; threads are arranged on the tops of the feed rods; a mold rack is connected on the threads of the feed rods; a mold hole is formed in the central position of the mold rack; a mold is inserted in the mold hole and is shaped like a stepped shaft; a pressing plate is arranged at the upper end of the mold rack; lock nuts are matched with the threads of the feed rods to fix the pressing plate on the mold rack; a threaded hole is formed in the center of the pressing plate so that an elevating screw passes through the pressing plate and the top of the mold rack in sequence to come into contact with the mold; a rotation handle is installed at the top of the elevating screw. Meanwhile, the invention provides a using method of the corrector. The corrector can effectively correct deformation during longitudinal cable core tubing of stainless steel / an aluminium tape, so that the stainless steel / aluminium tape is tubed more correctly and then the outer diameter of a sheath is rounder, thus avoiding the quality problem caused by deformation of the stainless steel / aluminium tape.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

Method of manufacturing large-diameter seamless steel tube

The invention relates to a manufacture method for a seamless steel pipe of a large caliber. In the method, a straight-seam welding steel pipe with an outer diameter of Phi 508mm to Phi610mm is selected as a main pipe, is processed into a main pipe without defects, becomes a crude tube with outer diameter of Phi 620mm to Phi1400mm through at least one thermal diameter expanding, becomes a crude steel pipe an outer diameter of Phi 630mm to Phi1422mm through cold diameter expanding and straightening and finally the finished product of the seamless steel pipe of a large caliber is obtained by carrying out the fine processing like pipe end processing, water pressure test, pipe end flaw detection, pipe body flaw detection, length detecting, weighting as well as spraying, printing and oil coating on the crude steel pipe. The method not only can produce the seamless steel pipe of a large caliber without welding lines, replace UOE and JCOE, but also has a lower cost and a high production efficiency; the product of the invention can be directly used for conveying oil and gas.

Owner:潘克云

Production assembly line and production technology of optical unit sheath

The invention discloses a production assembly line and production technology of an optical unit sheath. The production assembly line comprises a paying-off device, a tension controller, a hot melt adhesive coating device, a first extruding machine, a preliminary cooling water tank, a second extruding machine, a complete cooing water tank, an online external diameter monitor and a take-up device which are arranged successively; a stainless steel pipe is coiled on the paying-off device; and the tension controller controls a tension force, the hot melt adhesive coating device coats a surface with an adhesive, the first extruding machine carries out first plastic extrusion of the sheath, the preliminary cooling water tank carries out preliminary cooling, the second extruding machine carries out secondary plastic extrusion of the sheath, the complete cooing water tank carries out complete cooling, the online external diameter monitor detects an external diameter value, and the take-up device carries out rolling. According to the invention, the thickness and external diameters of prepared optical units are uniform, the radial water-blocking performance is high, the stainless steel pipe is combined with the sheath tightly, and the vertical water blocking performance is high.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

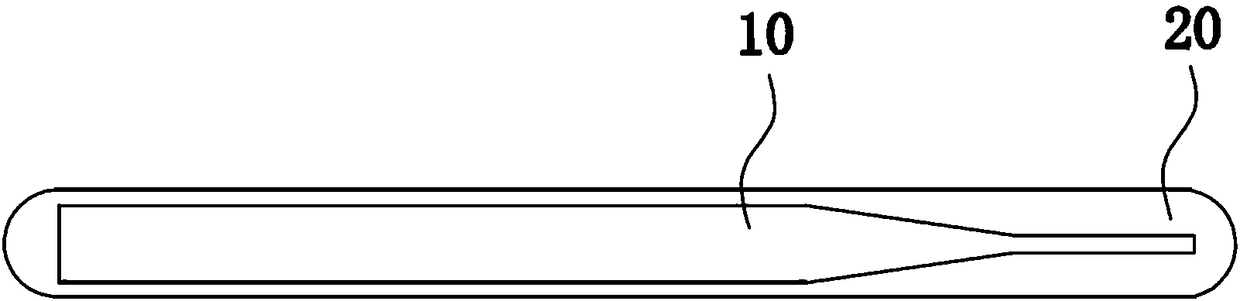

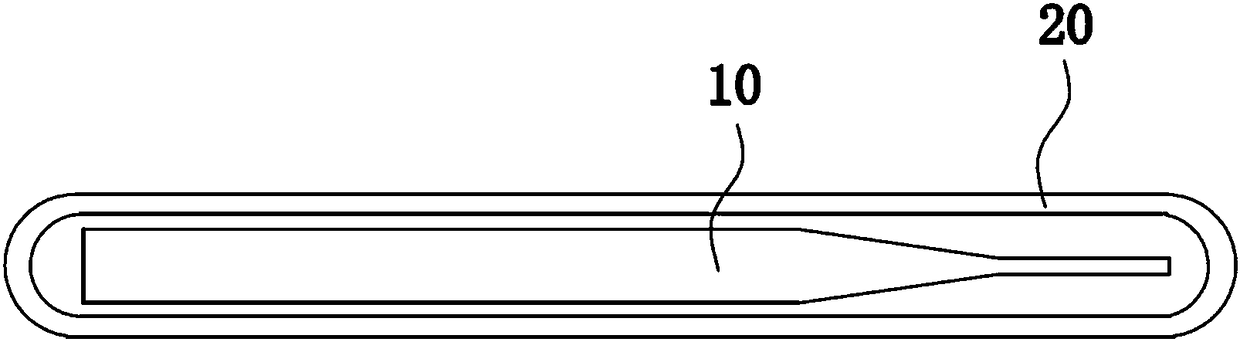

Super-slip guide wire outer wrapped layer solid solution molding device and wrapping method thereof

The invention discloses a super-slip guide wire outer wrapped layer solid solution molding device including a wrapping mold, a wrapping material supply device, a variable speed traction device and a cooling device; a molding channel for a core wire to pass through and a melt runner intersected with the molding channel are formed on the wrapping mold; the wrapping material supply device is used forproviding a wrapping material melt for the wrapping mold; the variable speed traction device is used for pulling a core wire out from the molding channel at different speeds according to the diametersizes of the core wire in different regions, wherein the core wire passes through the molding channel and is coaxial with a second molding channel of the molding channel; the cooling device is used for cooling the core wire removed out of the wrapping mold. The core wire is wrapped tightly by a solid solution way, so slipping is not easy, a head end of the core wire is prevented from puncturing the outer wrapping layer, and the risk of scrapping a chamber channel by a guide wire is reduced; at the same time, with adopting of the variable speed traction way, different-diameter regions of the core wire have more fit wrapping time and wrapping material melt amount, and uniform, smooth and reliable outer diameter of the guide wire after wrapping can be guaranteed.

Owner:SUZHOU HIGHWIRE MEDICAL DEVICES CO LTD

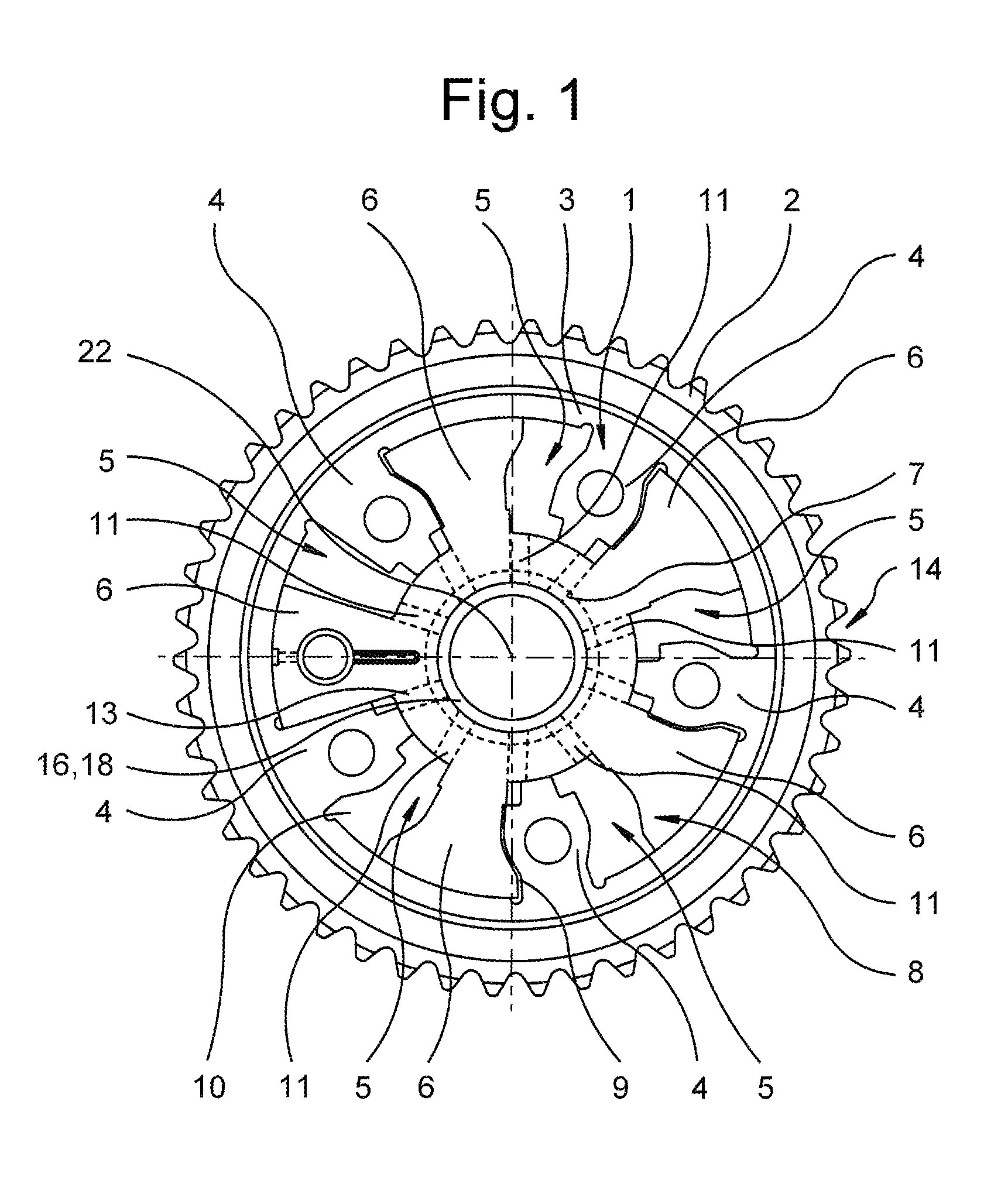

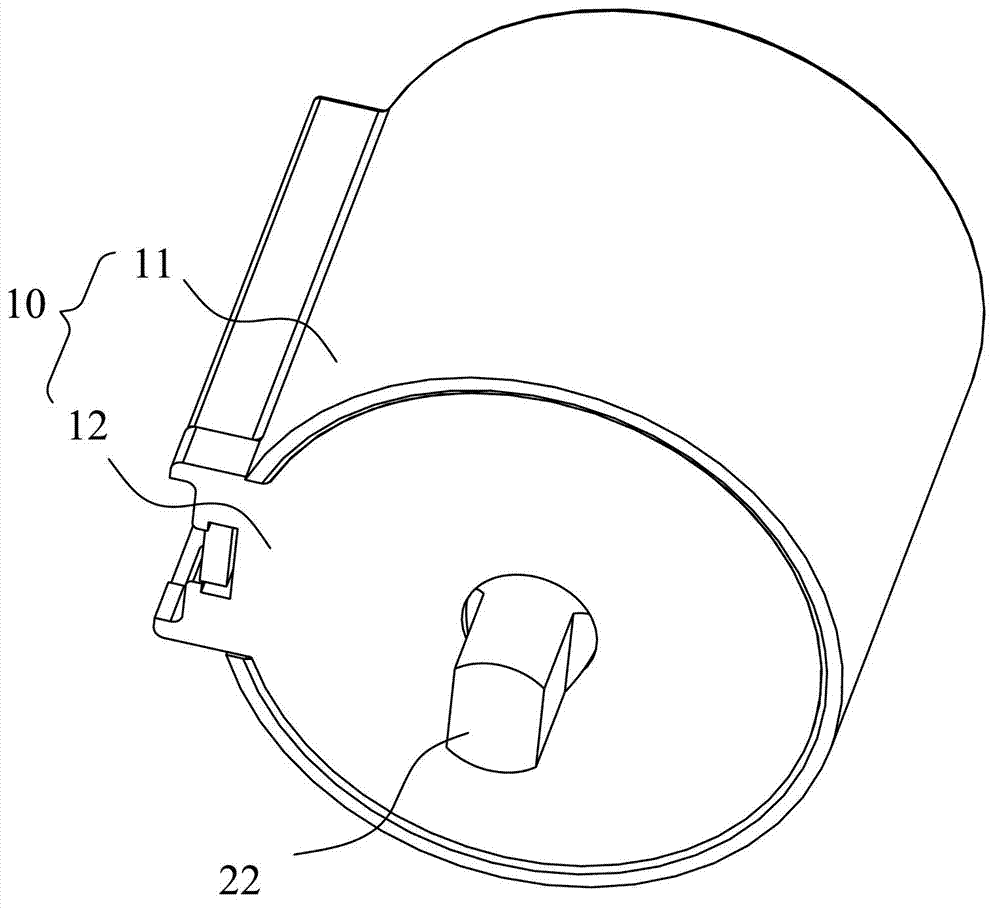

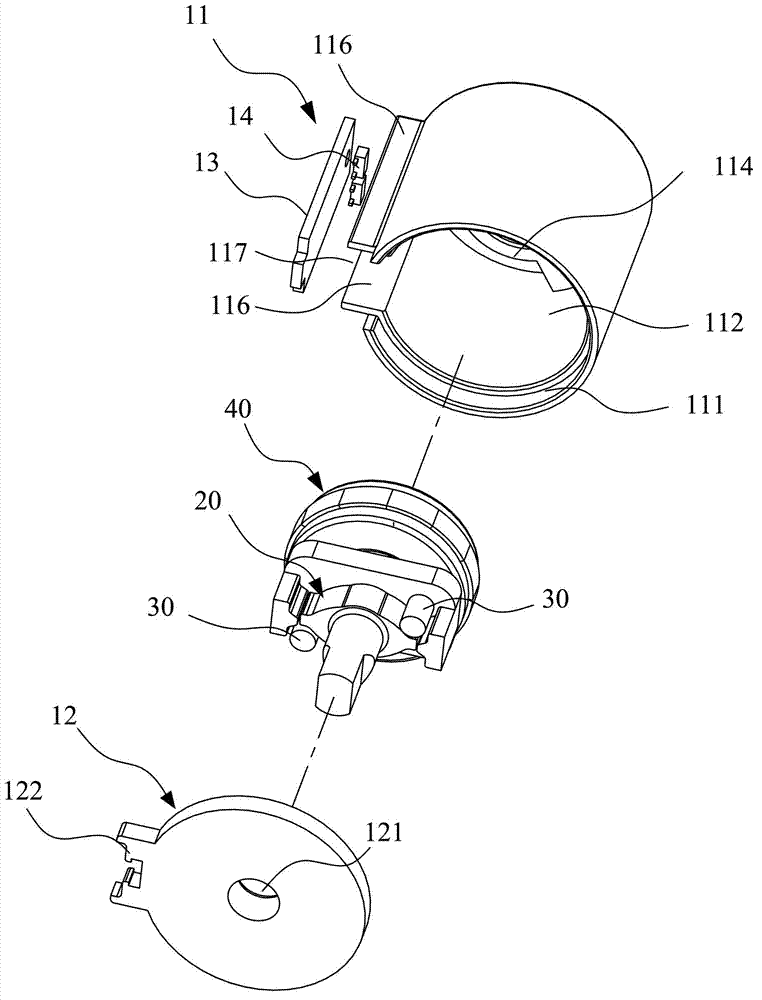

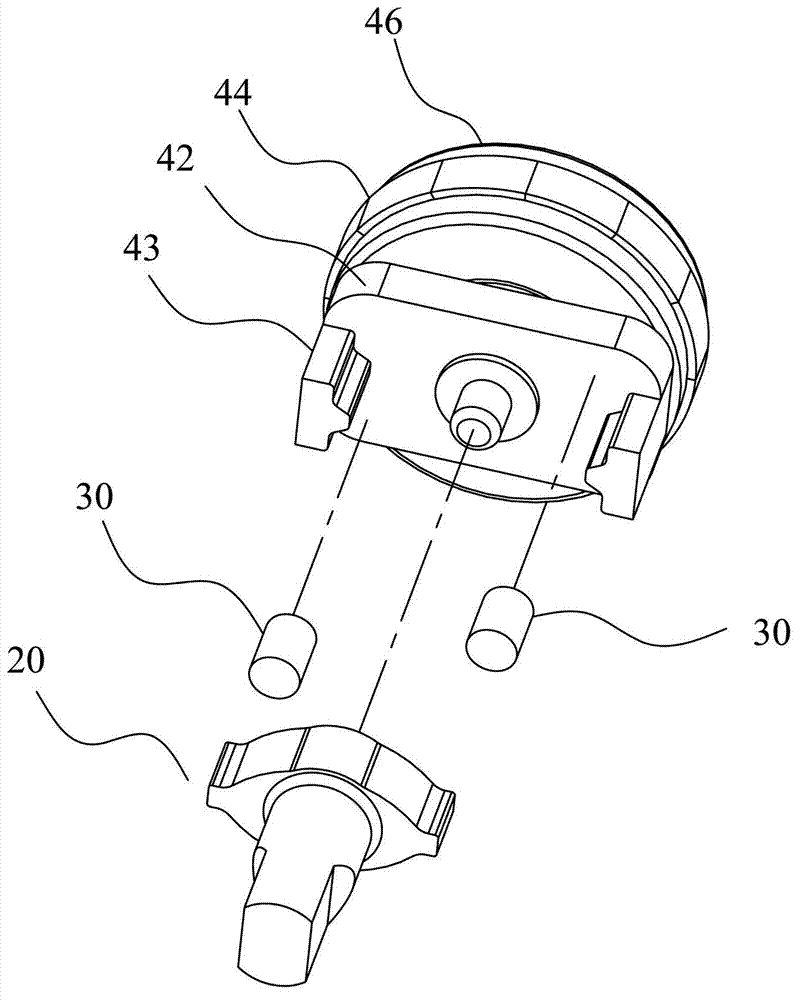

Built-in clutch and combined motor with same

ActiveCN103206468ARealize clutchGuaranteed running stabilityMagnetically actuated clutchesMechanical energy handlingEngineeringCam

The invention discloses a built-in clutch and a combined motor with the same. The clutch comprises a fixed shell and a clutch component in the shell. The shell comprises a shell body and a cover. The clutch component comprises a magnetic drive member, a non-magnetic driven member and a magnetic slider. The drive member and the driven member are connected concentrically. The drive member is a cam structure with first clamping parts on the outer side. The first clamping parts can drive the slider to rotate and guarantee that the slider does not move radially. The driven member is provided with at least one drive block relative to the outer side of the cam. The inner side of the drive block is provided with second clamping parts. The shell adjacent to the drive member is provided with a magnetic inner annular face. The end face of the slider always attaches to the inner annular face of the shell. The side of the slider always attaches to on the inner side wall between the first clamping parts. When the clutch is closed, the slider is located between the first clamping parts and the second clamping parts, and the drive member can drive the driven member to rotate simultaneously.

Owner:湖州荣辉进出口有限公司

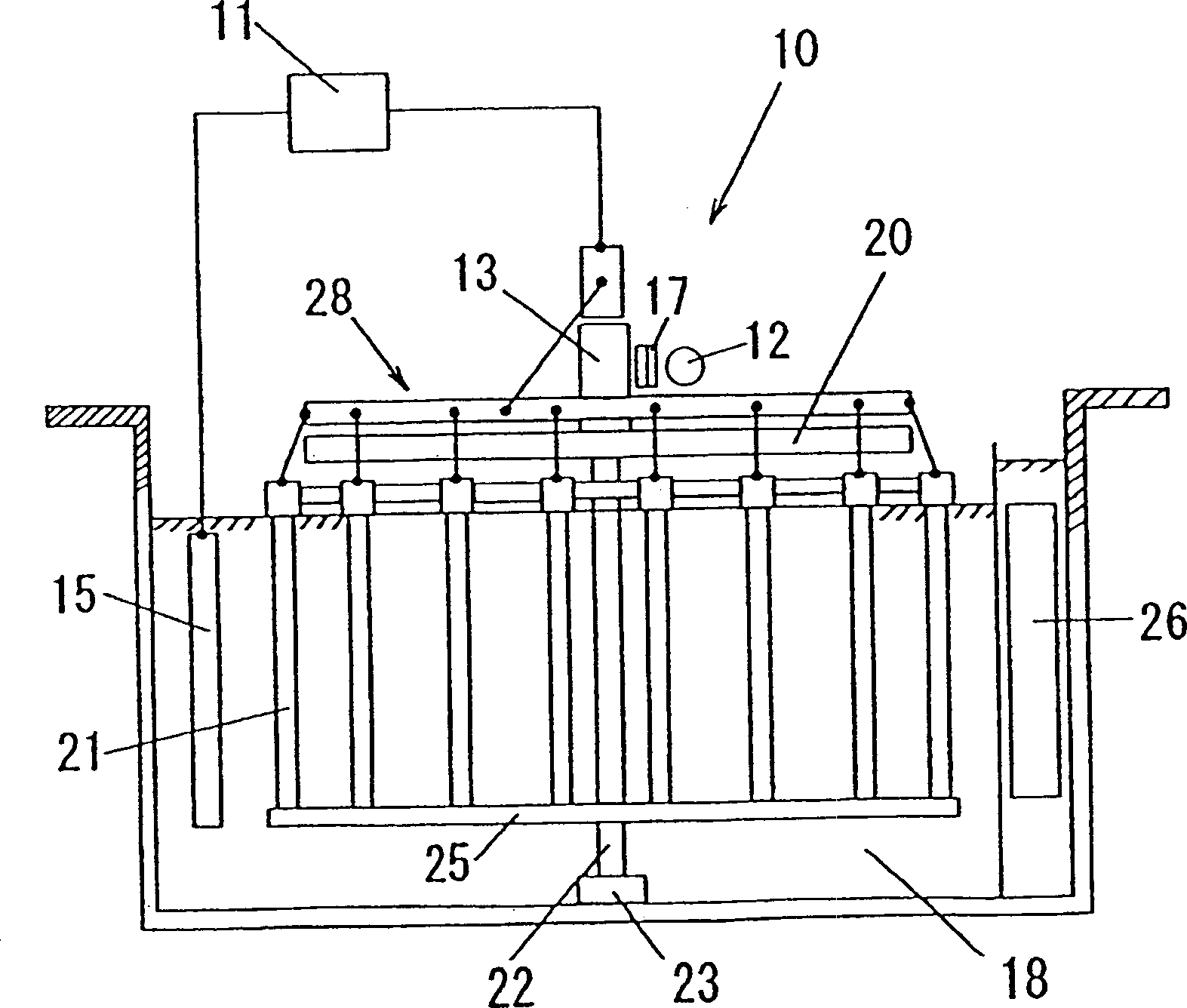

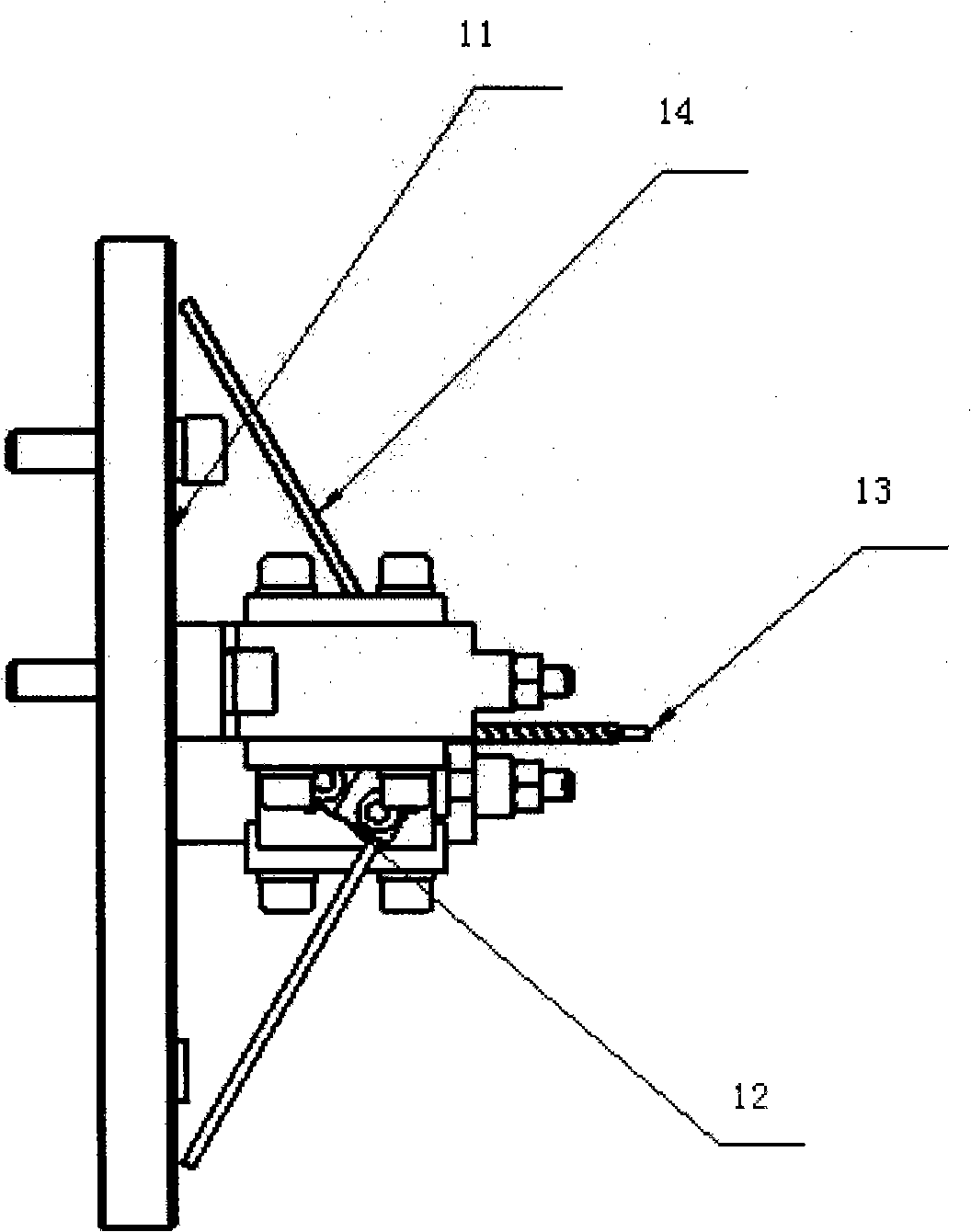

Method of producing metal ferrules and device therefor

InactiveCN1415025AUniform outer diameterImprove roundnessElectroforming processesElectric dischargeThin layer

A method of producing metal ferrules and a device therefor, wherein metal ferrules are produced with high productivity and high dimensional accuracy by arranging a plurality of long-sized core wires. A metal ferrule producing method and device, characterized in that a jig for receiving a metal to be electrocast is placed in an electrocasting tank, a holding unit in which a plurality of core wire holders for holding core wires are held in circumferential array is installed in the electrocasting tank, and the core wire holders and the holding unit are rotatable on their respective axes. It is preferable that the resistivity of the core wires be 5 x 10<-6> OMEGA cm or less. A core wire plated with a thin layer of metal having a resistivity of 5 x 10<-6> OMEGA cm or less may be used. Further, it is advisable to provide a conductive electric discharge body on the front end of the core wire. The resistivity of the conductor is preferably 10 x 10<-6> OMEGA cm or less, and the surface area of the conductive electric discharge body is preferably 10 - 100 times the outer surface area of the core wire. Further, the jig for receiving the metal to be electrocast is preferably such that a metal plate of given width extending longitudinally of the jig substantially throughout the length of the jig is formed to face in the direction of the core wire in such a manner as to project perpendicularly from the lateral surface of the jig. Further, the core wire holder is preferably provided with an elastic mechanism, such as a spring or rubber for tightening the core wire, or with a wide prop projecting outwardly of the holder.

Owner:SMK CO LTD

Method for making wire cable packaged with flat yarn in appearance

The invention discloses a method for producing a steel rope with a flat wire covered on the surface, which comprises the following: 1) a step of covering of the flat wire, in which the flat wire is wound on the surface of the steel rope; 2) a step of radial rotation cold forging, in which the flat wire is firmly fastened onto the surface of the steel rope, and the strength of the flat wire is improved; and 3) a step of rolling shaft grinding, in which the flat wire is calendered and ground. The steel rope with the flat wire covered on the surface produced by the method has a uniform outer diameter, uniform gaps, excellent flexibility and elasticity, ensures that a flat wire covering layer and the steel rope are firmly fastened together and can not slide with each other, and fully satisfies demands for mechanical control, automobile shift control, tow target steel ropes of airplanes and so on.

Owner:易卫东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com