Method for manufacturing enameled rectangular copper wire for wind driven generator by die method and device thereof

A technology for wind turbines and flat copper wires, applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of uneven distribution of paint film, reduced viscosity of paint liquid, affecting paint quality, etc., and achieve quality smoothness. High, chemical resistance, high surface finish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is illustrated by specific examples below, but only for illustration rather than limitation of the present invention.

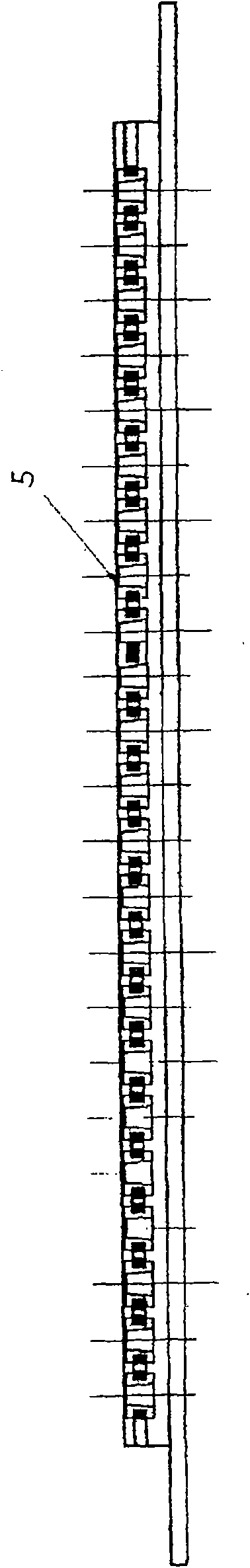

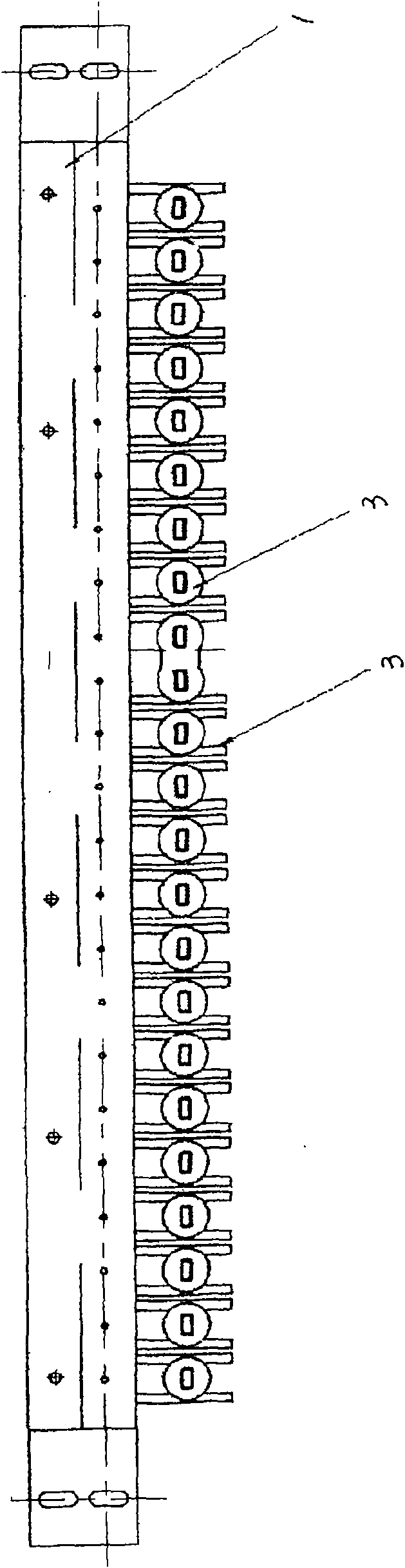

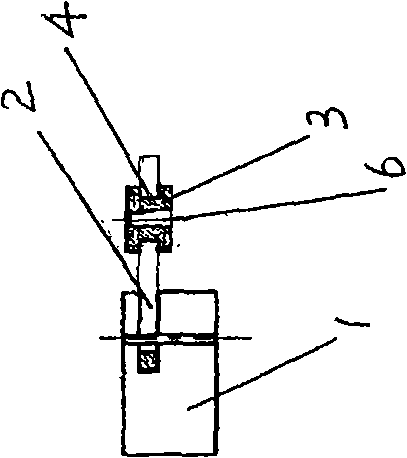

[0034] As shown in the figure, 1 mold support, 2 mold holder, 3 painting mold, 4 annular groove, 5 fillet, 6 sizing hole.

[0035] The invention provides a device for manufacturing enamelled copper flat wires for wind power generators by mold method, which is composed of a mold frame 2, a mold frame 1, a painting mold 3, and a sizing hole 6, and one end of the mold frame 2 is fixed on the mold frame 1 Above, the other end of the mold frame 2 is a concave frame body with buckles at the end, the painting mold 3 is a cylinder, and a hollow prism-shaped sizing hole 6 is provided in the middle, and an annular ring is provided radially outside the painting mold. Groove 4, the snap-fit of the lug at the other end of the mold frame 2 is fixed in the annular groove 4 of the painting mould.

[0036] Each corner of the sizing hole is roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com