Patents

Literature

57results about How to "High quality finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated Metal Product, Method to Produce It and Use of the Method

InactiveUS20090181262A1High quality finishResistant to damageDecorative surface effectsPretreated surfacesLacquerMetallic substrate

Owner:SANDVIK INTELLECTUAL PROPERTY AB

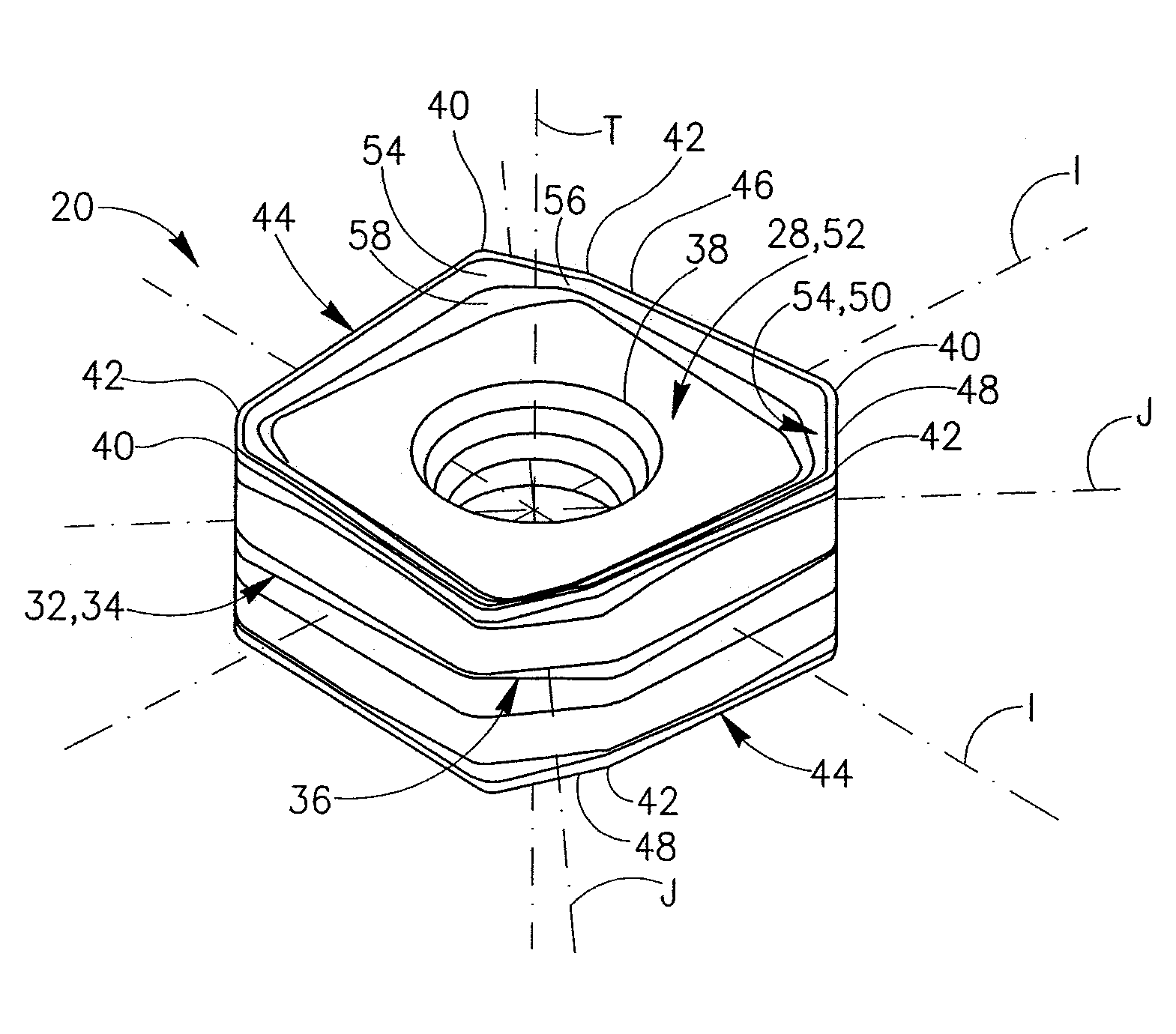

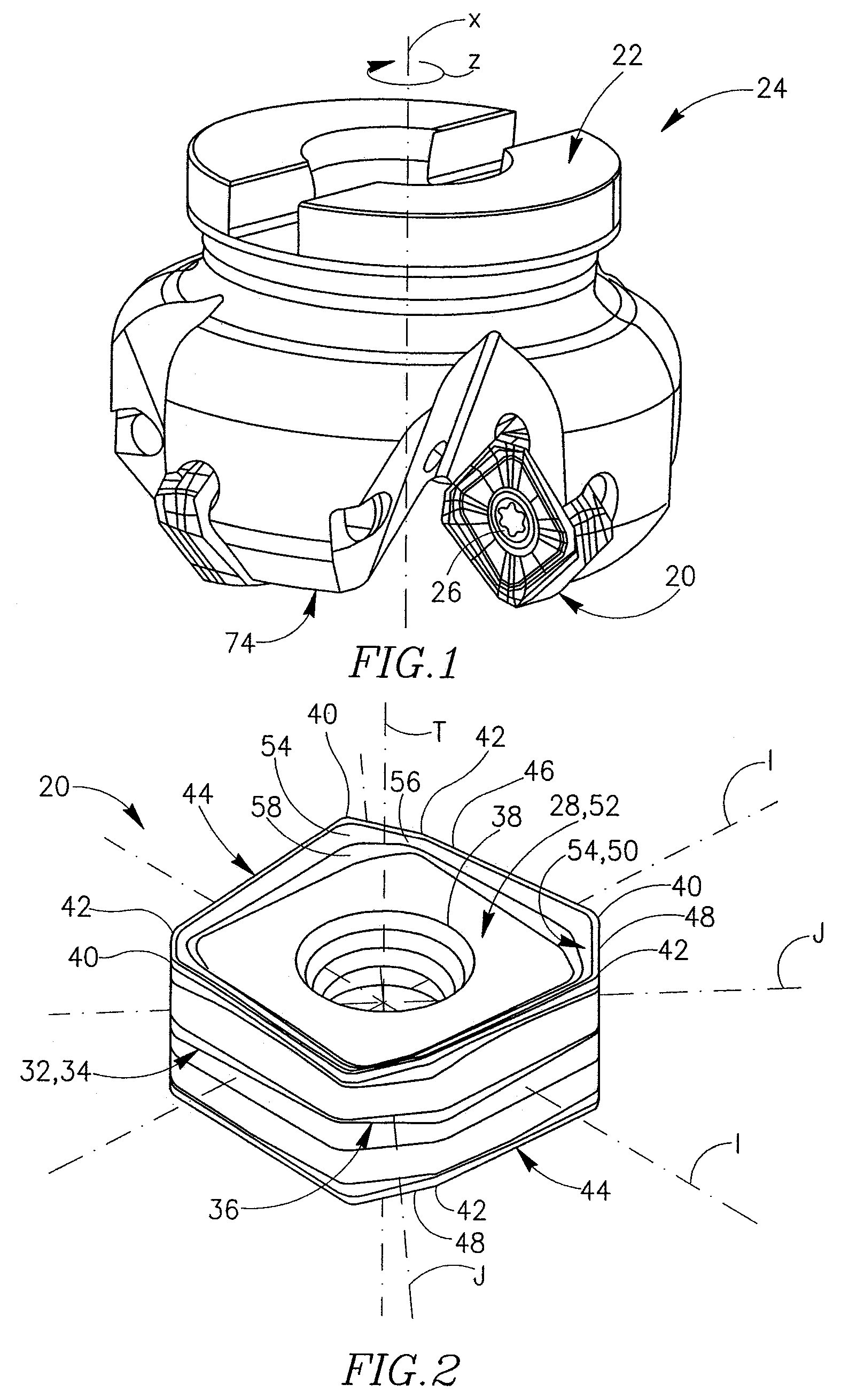

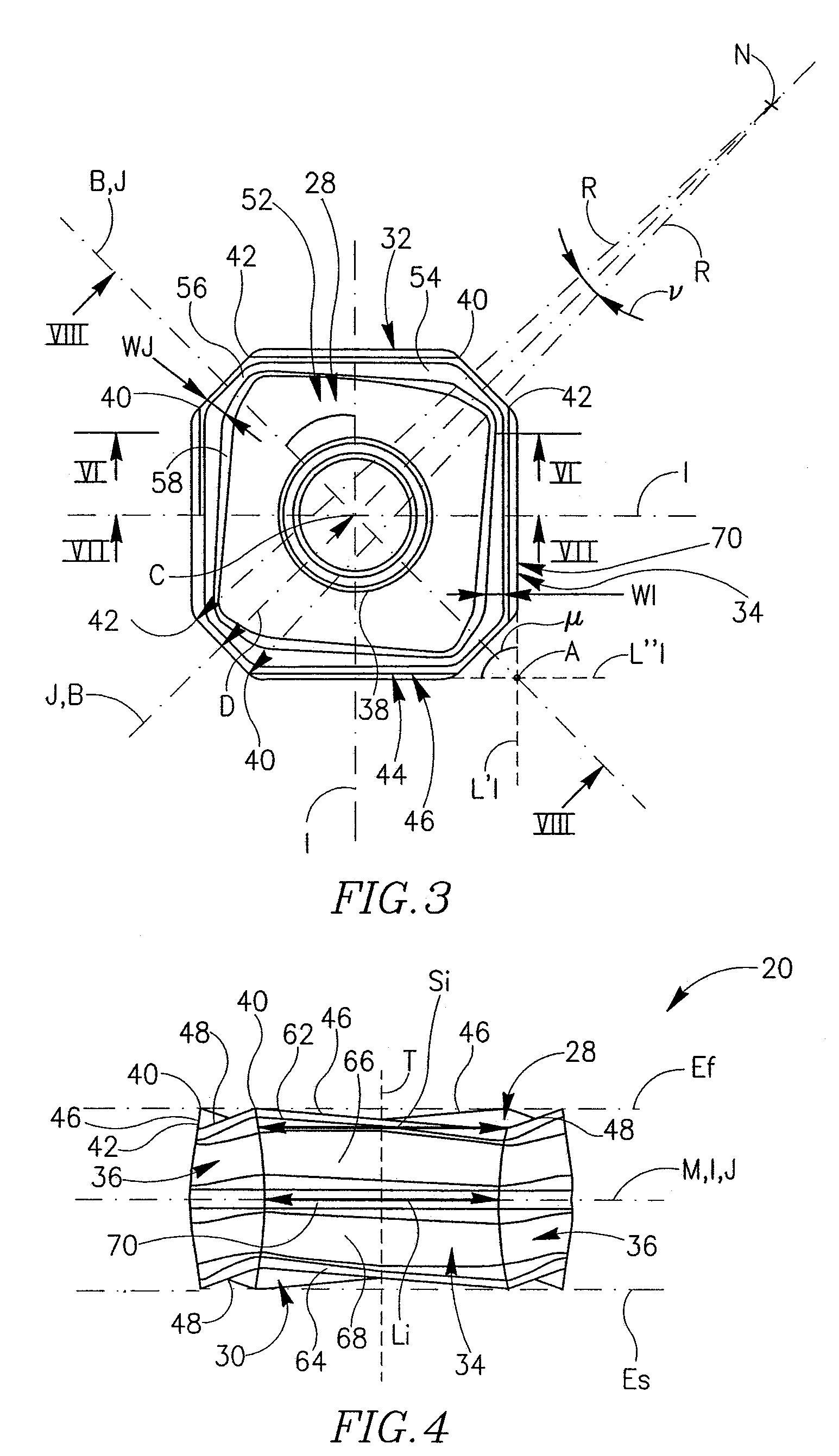

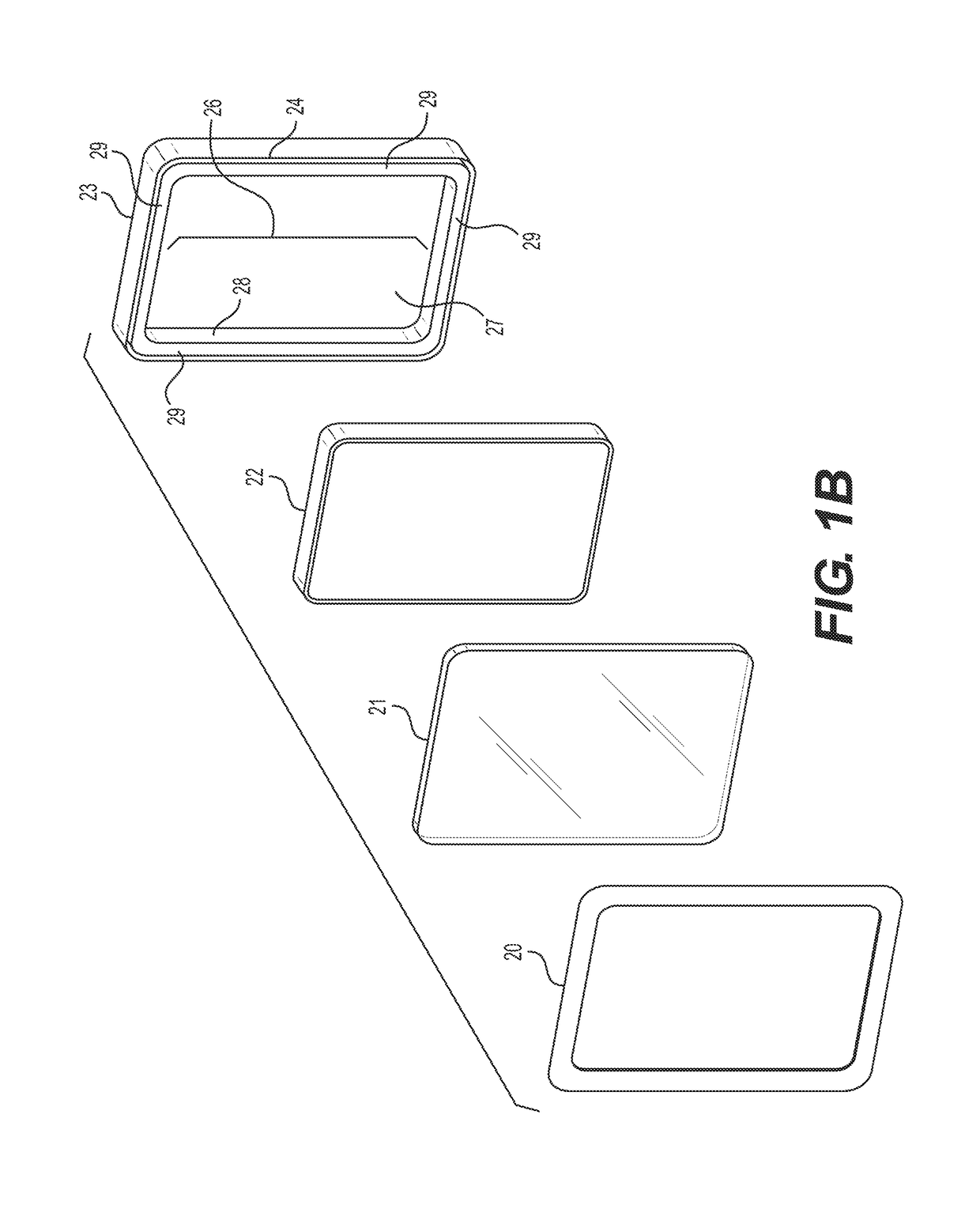

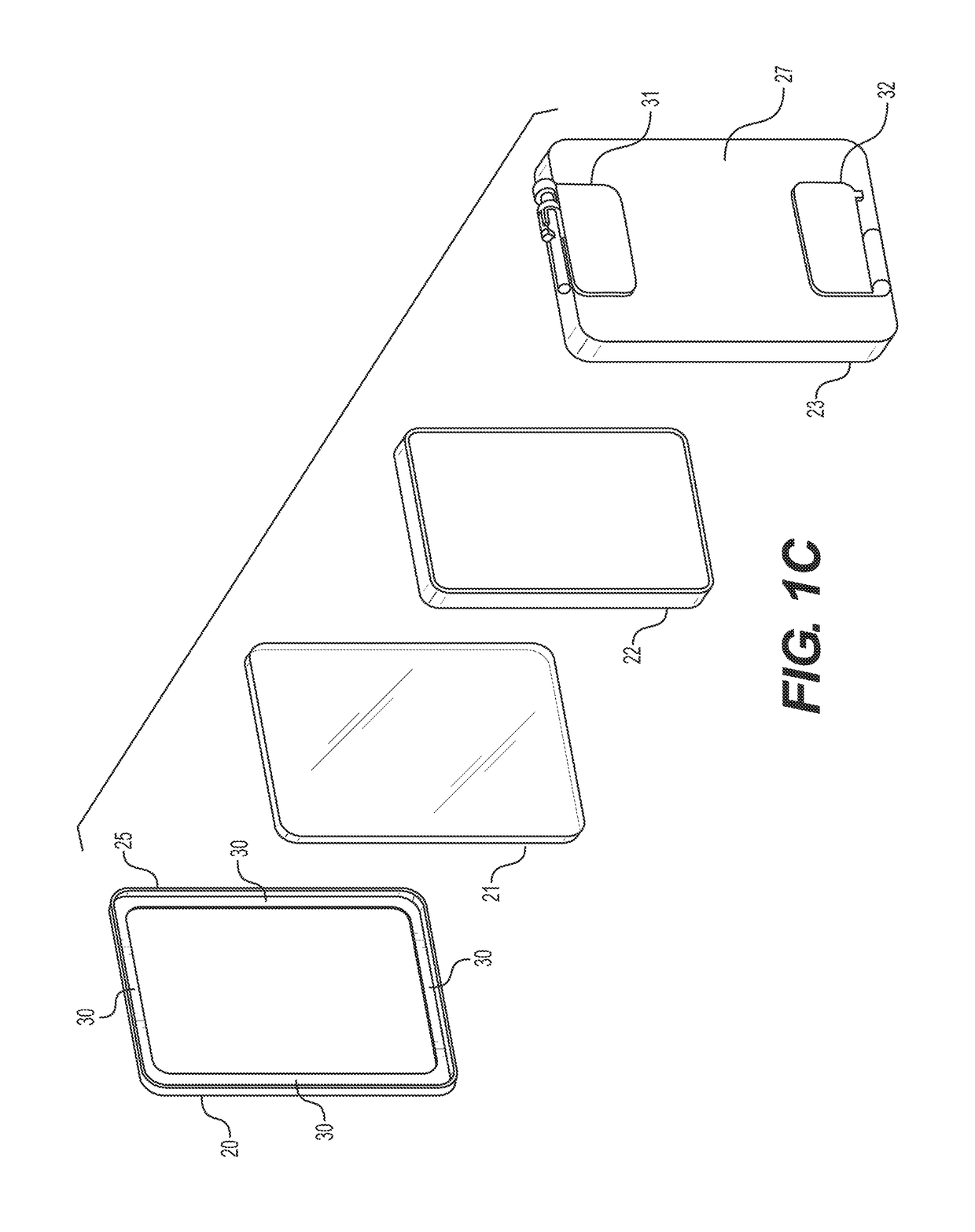

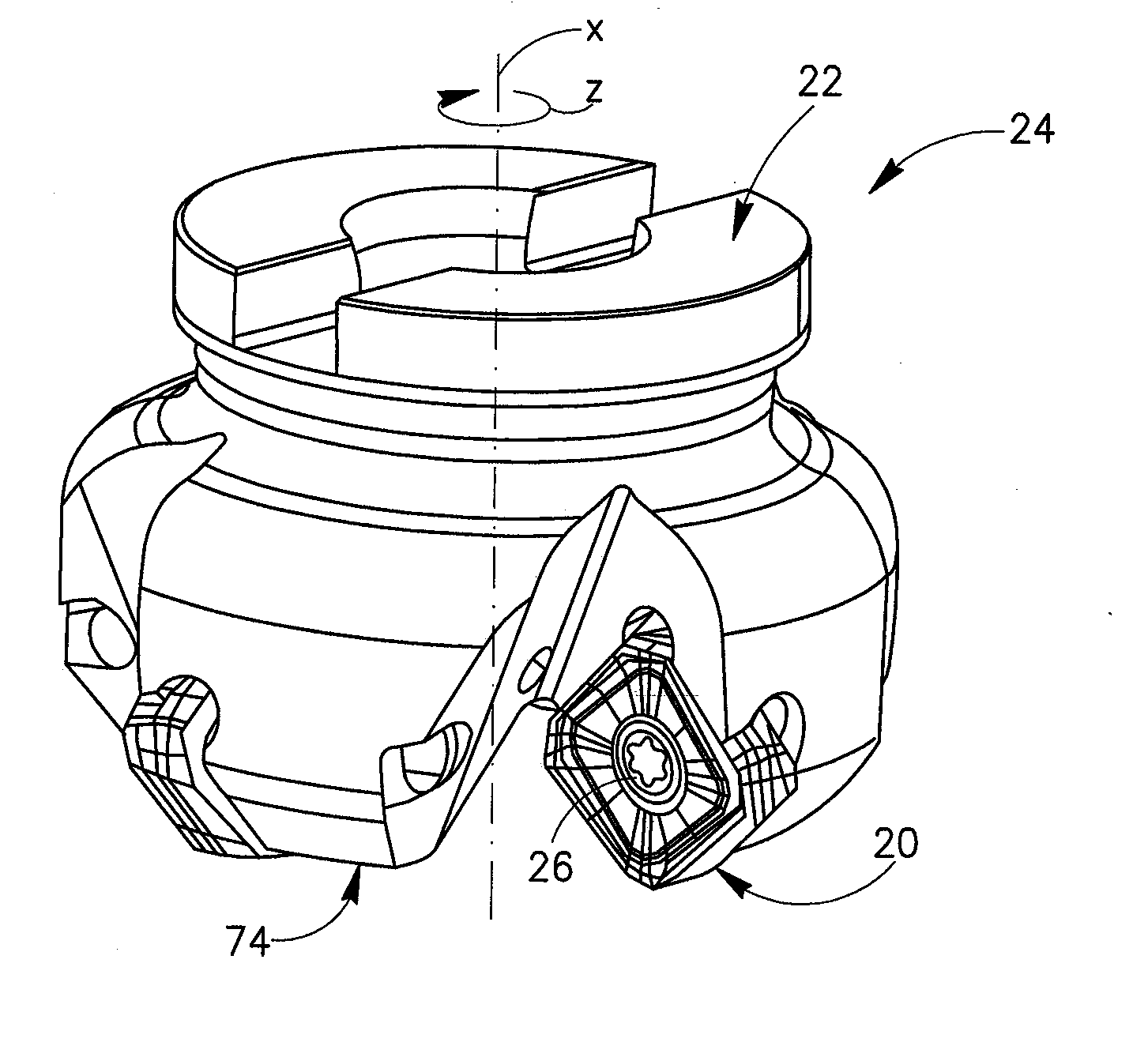

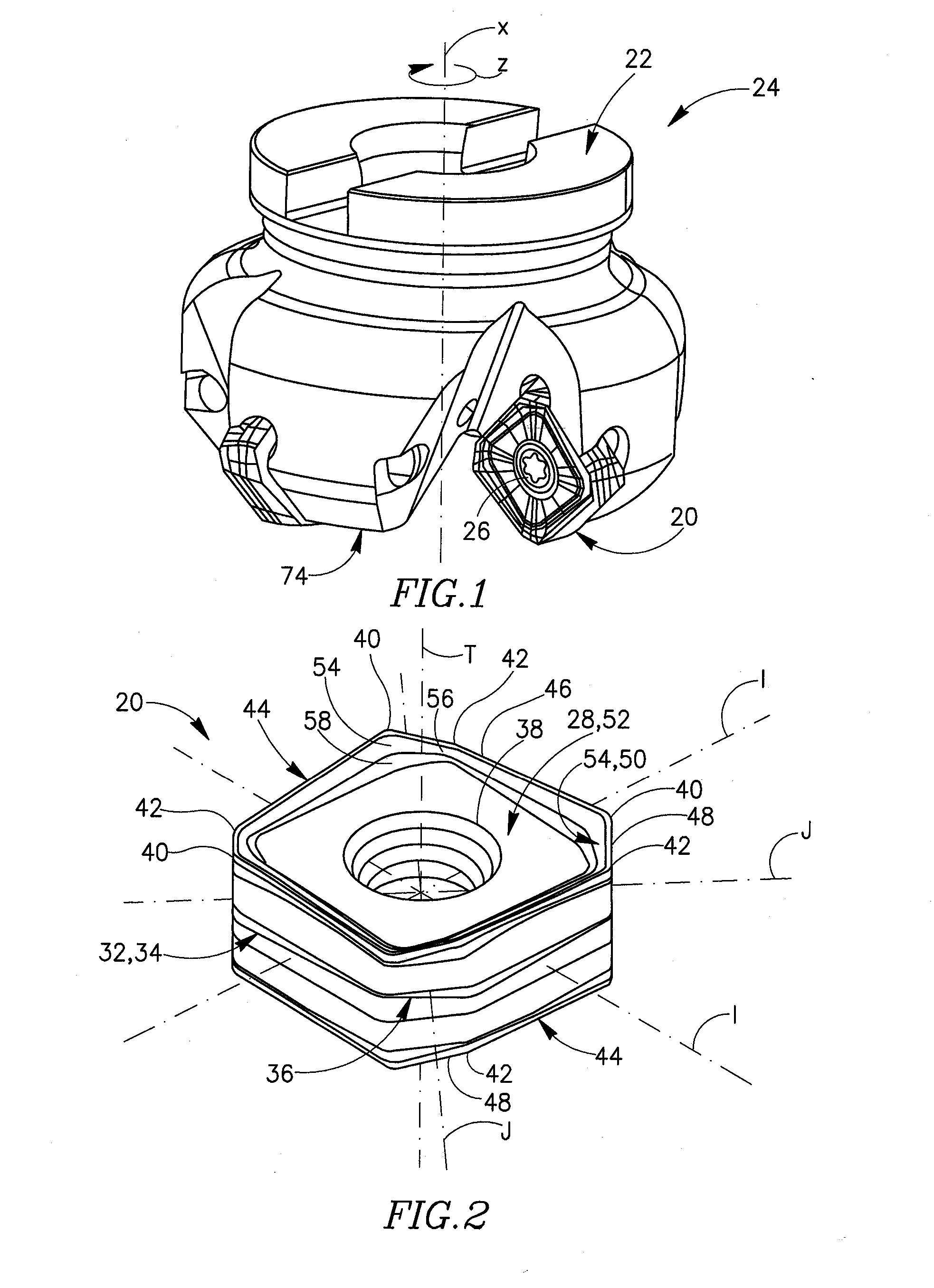

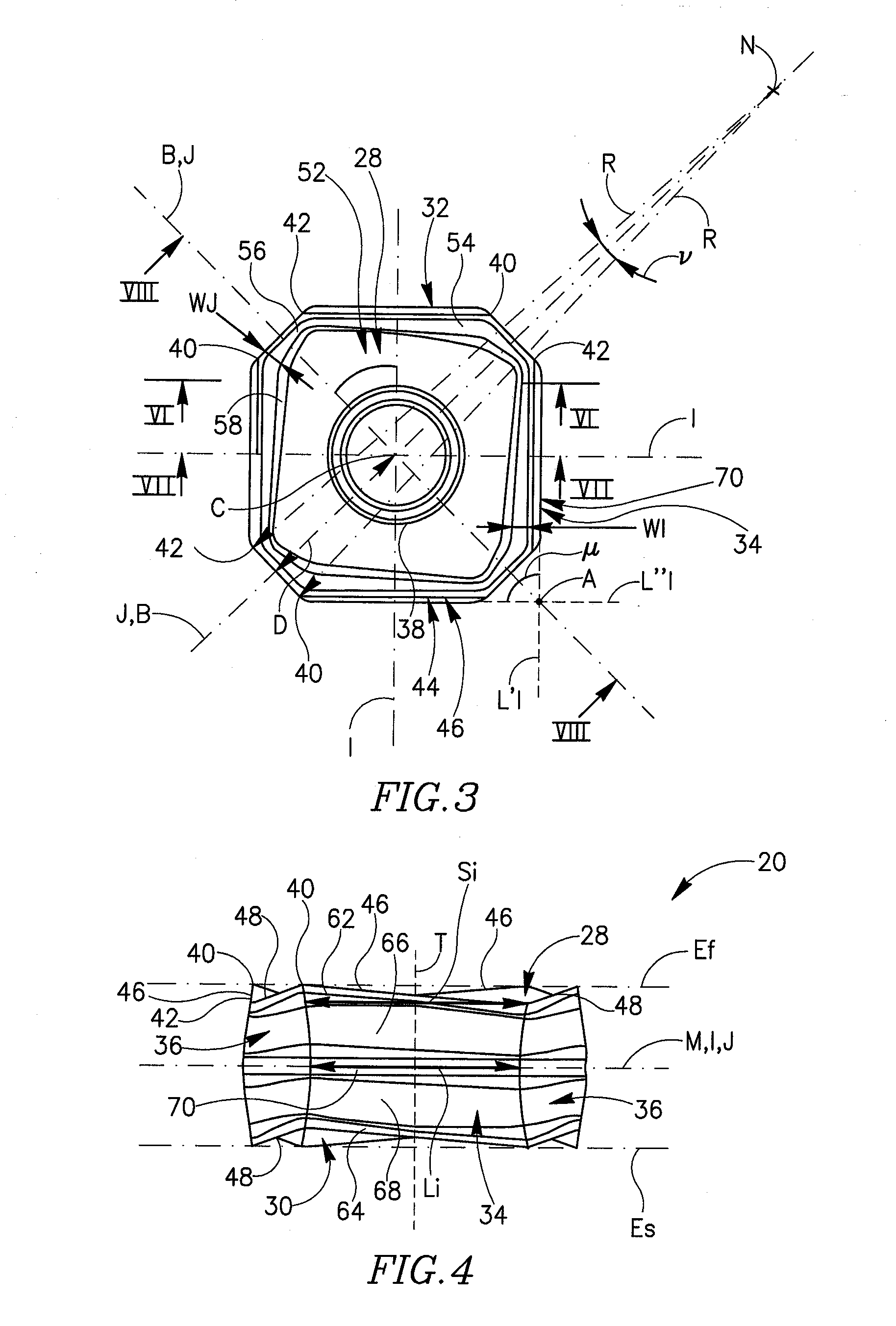

Cutting insert having cylindrically shaped side surface portions

ActiveUS7232279B2Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsEngineeringMechanical engineering

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

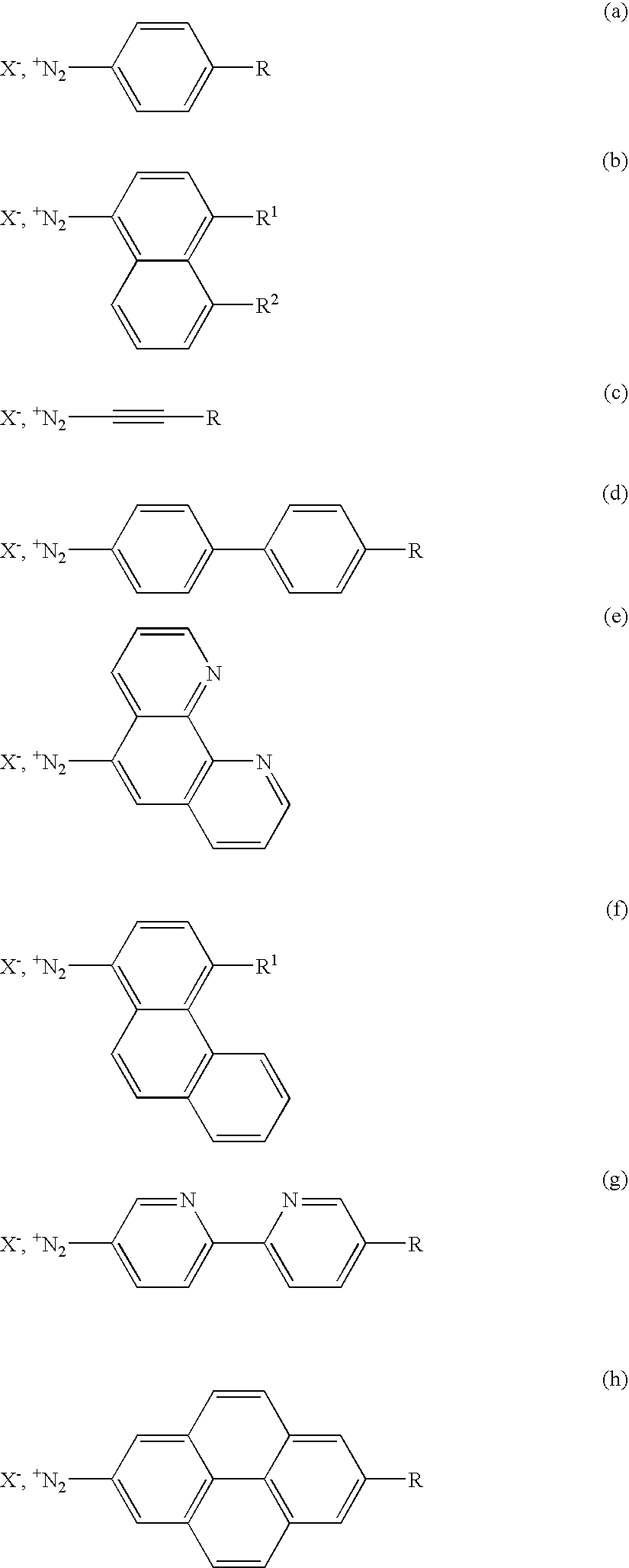

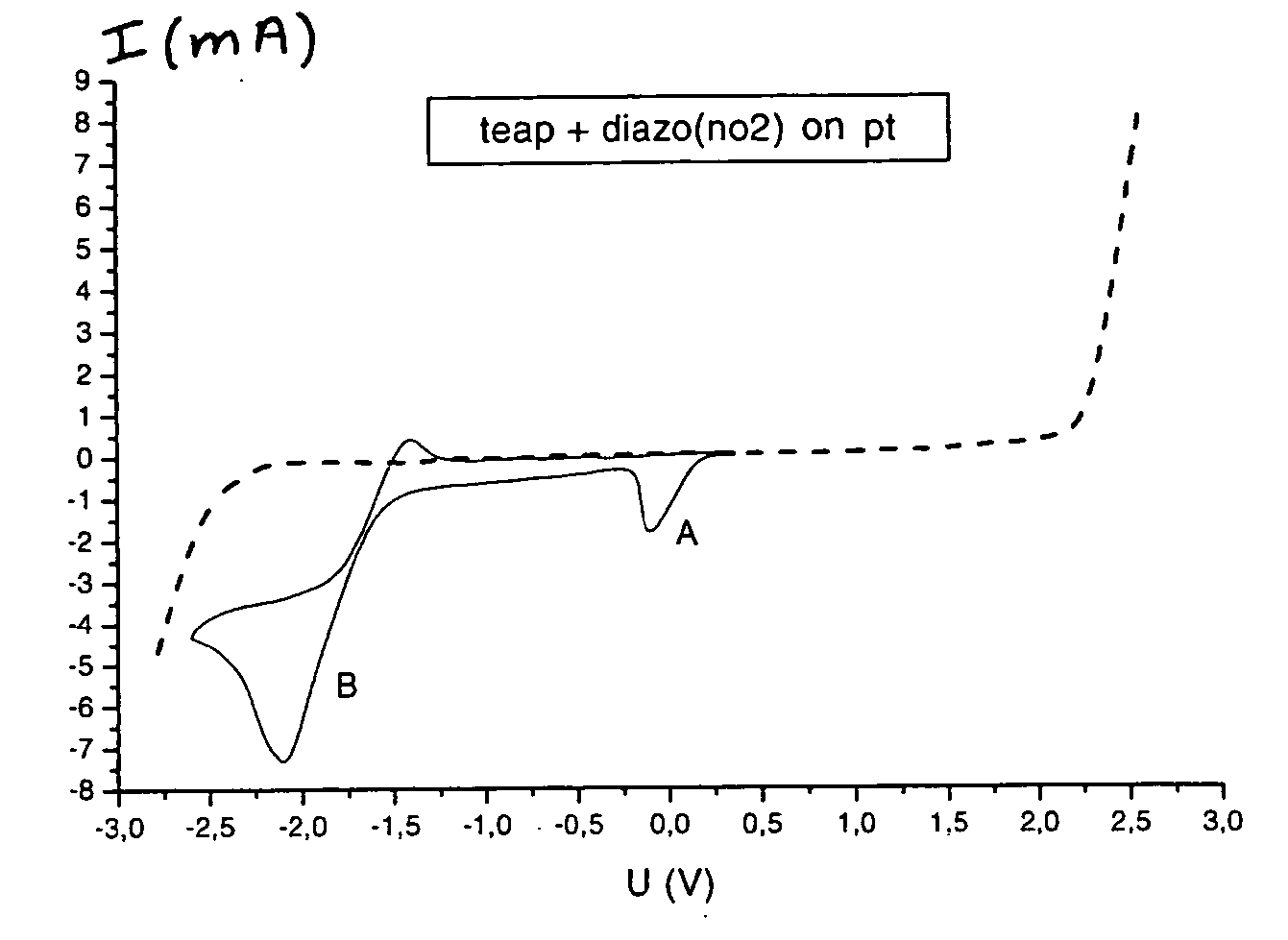

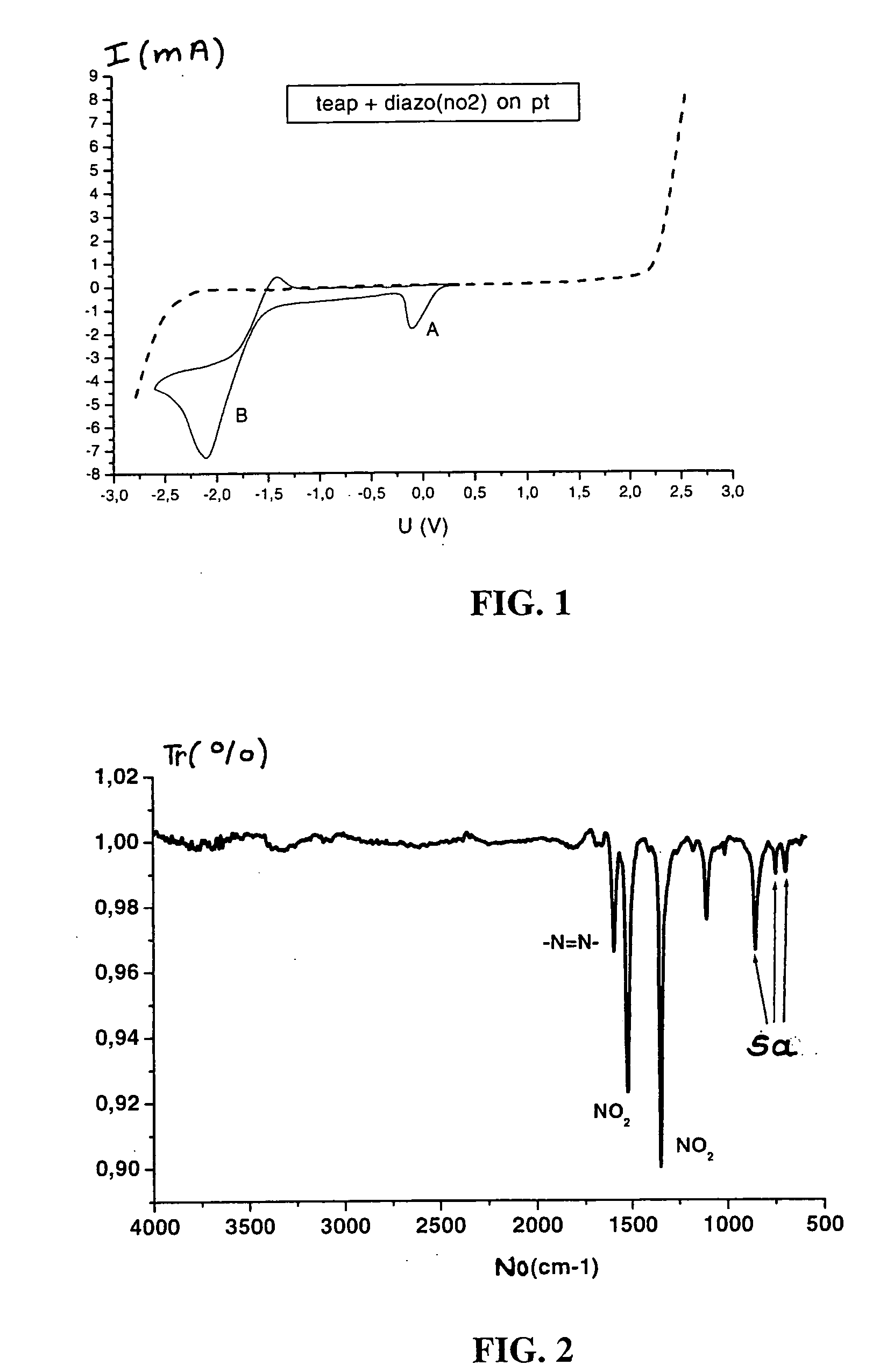

Method for grafting and growing a conductive organic film on a surface

ActiveUS20040248428A1High quality finishSurface reaction electrolytic coatingSemiconductor/solid-state device manufacturingOrganic filmElectricity

The present invention relates to a process for grafting and growing a conductive organic film on(to) an electrically conductive or semiconductive surface in which the grafting and growing of the film are performed simultaneously by electro-reduction of a diazonium salt that is a precursor of the said film on(to) the said surface cathodically polarized at a potential greater than or equal, in absolute value, to the electro-reduction potential of the diazonium salt relative to a reference electrode. The invention finds an application especially in the protection of surfaces, the manufacture of localized conductive coatings, of chemical sensors in the fields of chemistry and molecular biology, the manufacture of biomedical equipment, etc.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Casket having an integral image

InactiveUS20070144659A1Quality improvementHigh quality finishCoffinsAdhesivesComputer graphics (images)

Owner:DE LA FUENTE JOSE A

Ink composition and printed article

ActiveUS20120040156A1Sufficient abrasion resistanceProvides adequateLayered productsDuplicating/marking methodsWaxSilver particles

An ink composition which can be used to form an image having excellent metallic luster and excellent abrasion resistance is provided, and a printed article in which the image having excellent metallic luster and excellent abrasion resistance is formed is provided. Such an ink composition is ejected by an ink jet technique and contains silver particles, wax particles, and water. The wax particles are contained in an amount that is in the range from 0.02 to 1.5 weight %. Assuming that the average diameter of the silver particles is D1 [nm] and that the average diameter of the wax particles is D2 [nm], the relationship of 0.98≦D2 / D1≦5.40 is satisfied.

Owner:SEIKO EPSON CORP

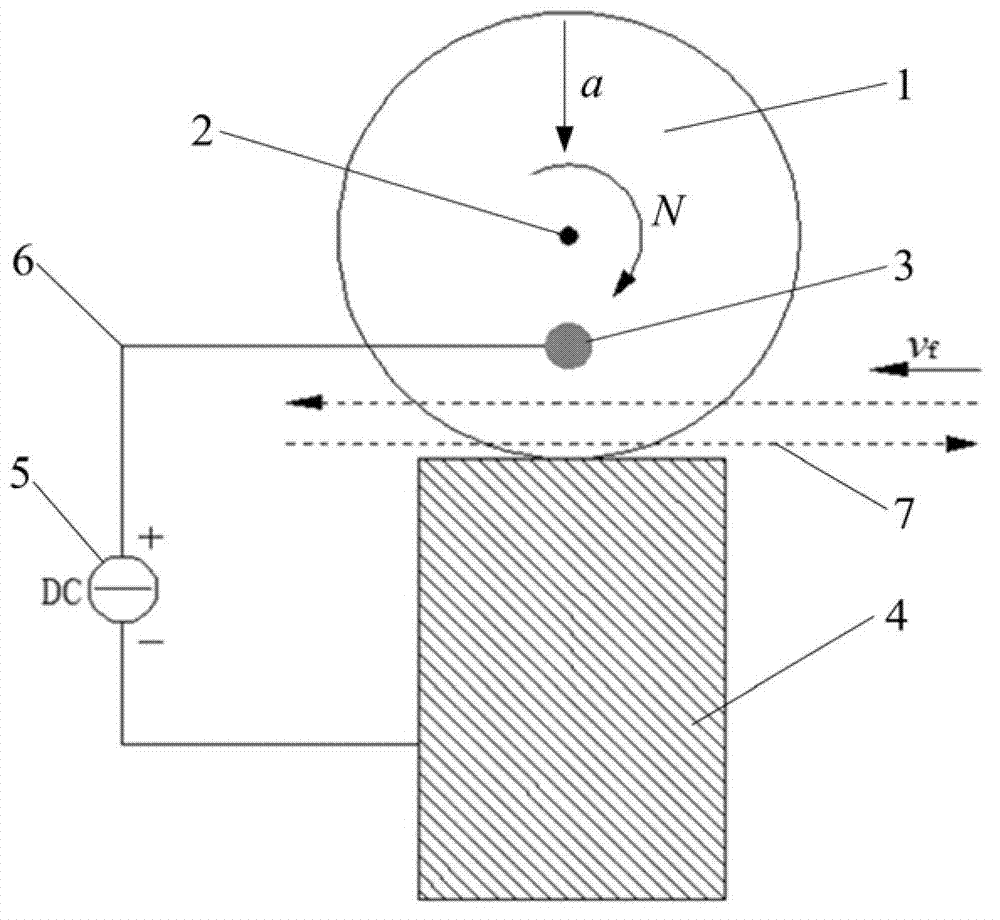

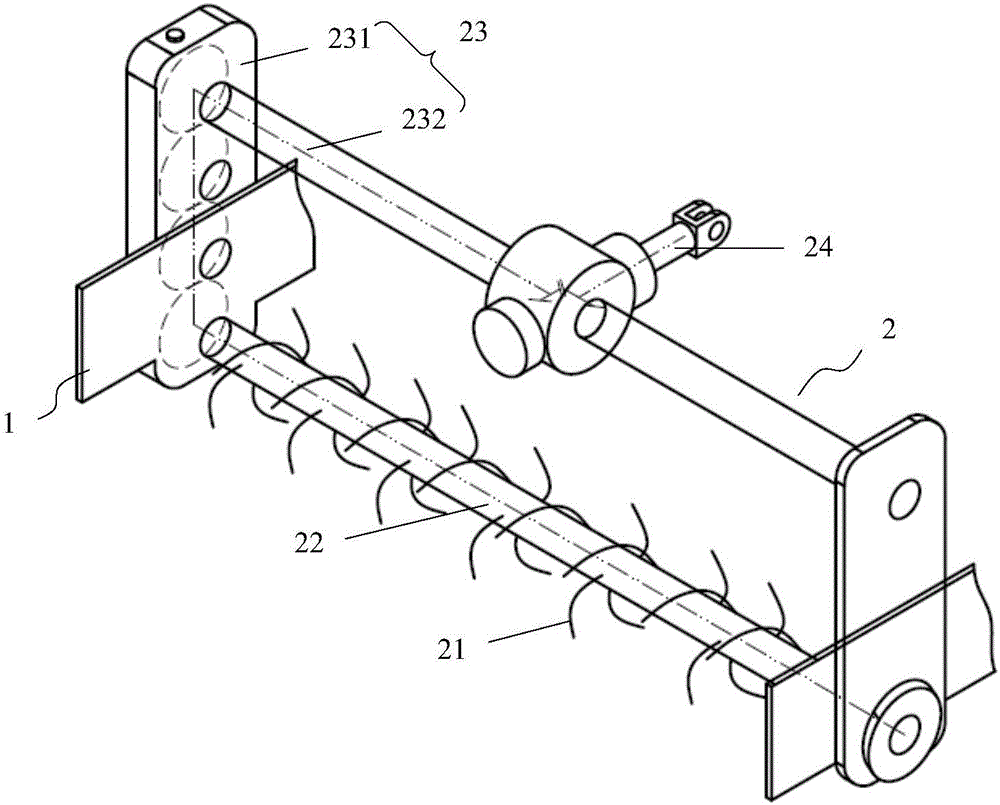

In-gas discharge dressing and truing method for large-particle diamond grinding wheel

ActiveCN103395002AWon't burnAvoid arcingAbrasive surface conditioning devicesWear particleCopper electrode

The invention discloses an in-gas discharge dressing and truing method for a large-particle diamond grinding wheel. The method includes: fixing the diamond grinding wheel on a grinding wheel shaft, and fixing a conducting electrode on the horizontal plane; connecting the diamond grinding wheel, the electrode, a graphite brush, a power source and a wire to form a discharge circuit; connecting a positive pole of the power source to the grinding wheel, and connecting a negative pole of the power source to the electrode. When rotating, the diamond grinding wheel linearly reciprocates on the surface of the electrode; metal bond is removed by pulse sparks generated between the electrode and the metal bond of the grinding wheel, so that diamond abrasive particles are edged from the surface of the grinding wheel; spark discharge occurs between the metal bond and whirling conducting chips generated when the edged diamond abrasive particles cut the copper electrode, generated instant high temperature is transmitted to cutting edges of the diamond abrasive particles in contact cutting through the chips, the tips of the cutting edges are pneumatically dressed, and accordingly micro edging, dressing and truing of the grinding wheel are achieved, more effective abrasive particles are generated and efficient grinding of smooth mirrors is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Catalytic system for cellulose acylation process for producing said catalytic system, and for its practical application

InactiveUS6407224B1Reduce the degree of polymerizationExtended durationSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidCellulose

A catalytic system for cellulose acylation includes an adduct of sulfuric acid with N,N-dimethylacetamide, free sulfuric acid or free N,N-dimethylacetamide with the following mole ratio of the components: adduct:1.0; free sulfuric acid, max:0.49; or free N,N-dimethylacetamide, max:0.4. A process for producing such a catalytic system is based upon reacting sulfuric acid with N,N-dimethylacetamide in an anhydrous medium at a temperature of 0° C.-25° C. with the following mole weight ratio of the components: sulfuric acid:1.0; N,N-dimethylacetamide, max:1.4. A process for cellulose acylation in the presence of this catalytic system incorporates cellulose treatment with acetic acid followed by treatment of the resultant activated cellulose with a lower fatty acid anhydride at a temperature of 10° C.-90° C. in the presence of this catalytic system taken in an amount of 1.5-30.0 wt. % of the cellulose weight in terms of sulfuric acid, a weight ratio of the liquid phase and cellulose being 3-7:1, respectively.

Owner:NAUCHNO PROIZVODSTVENNAYA FA EFIRY TSELLJULOSY

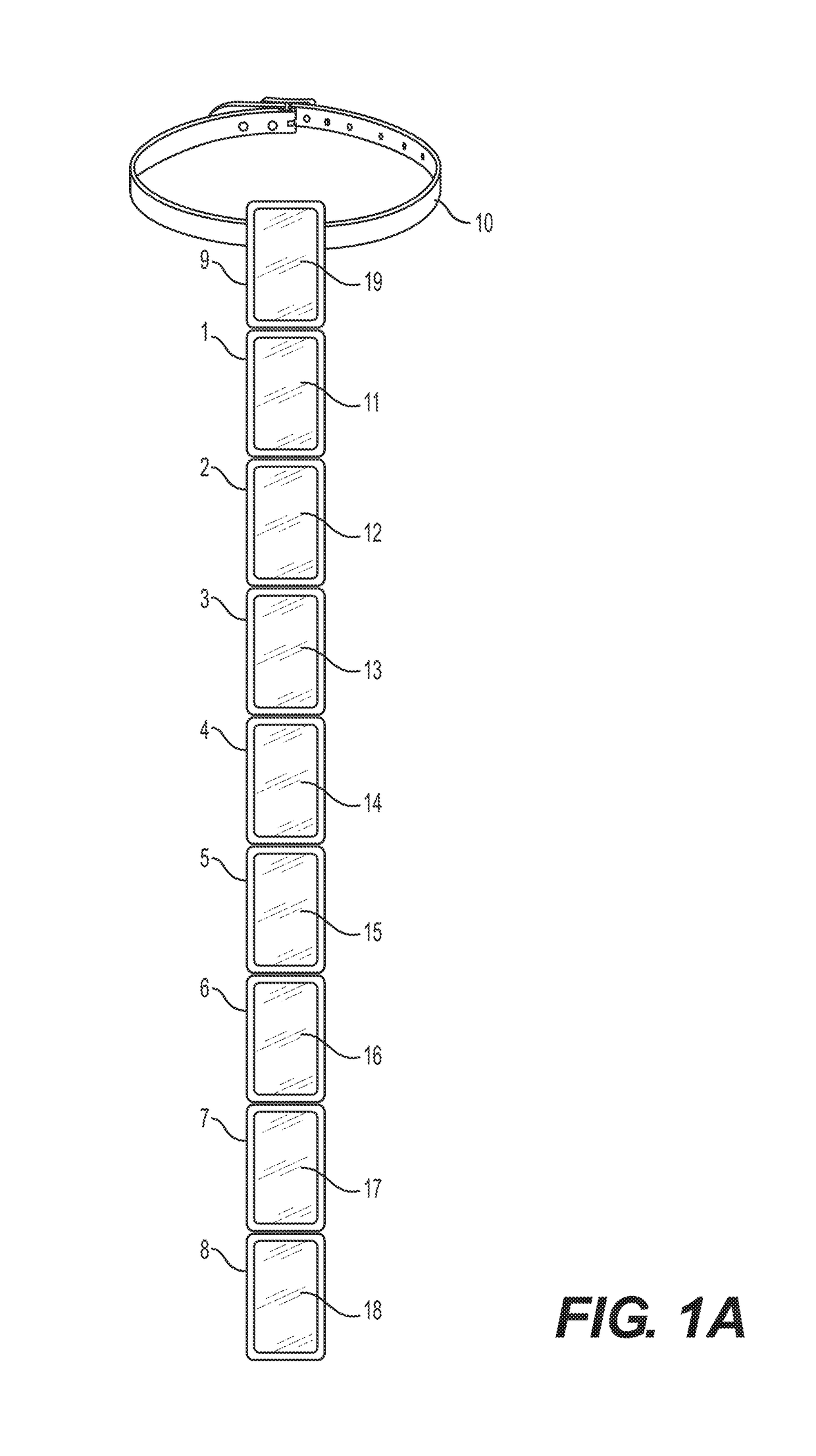

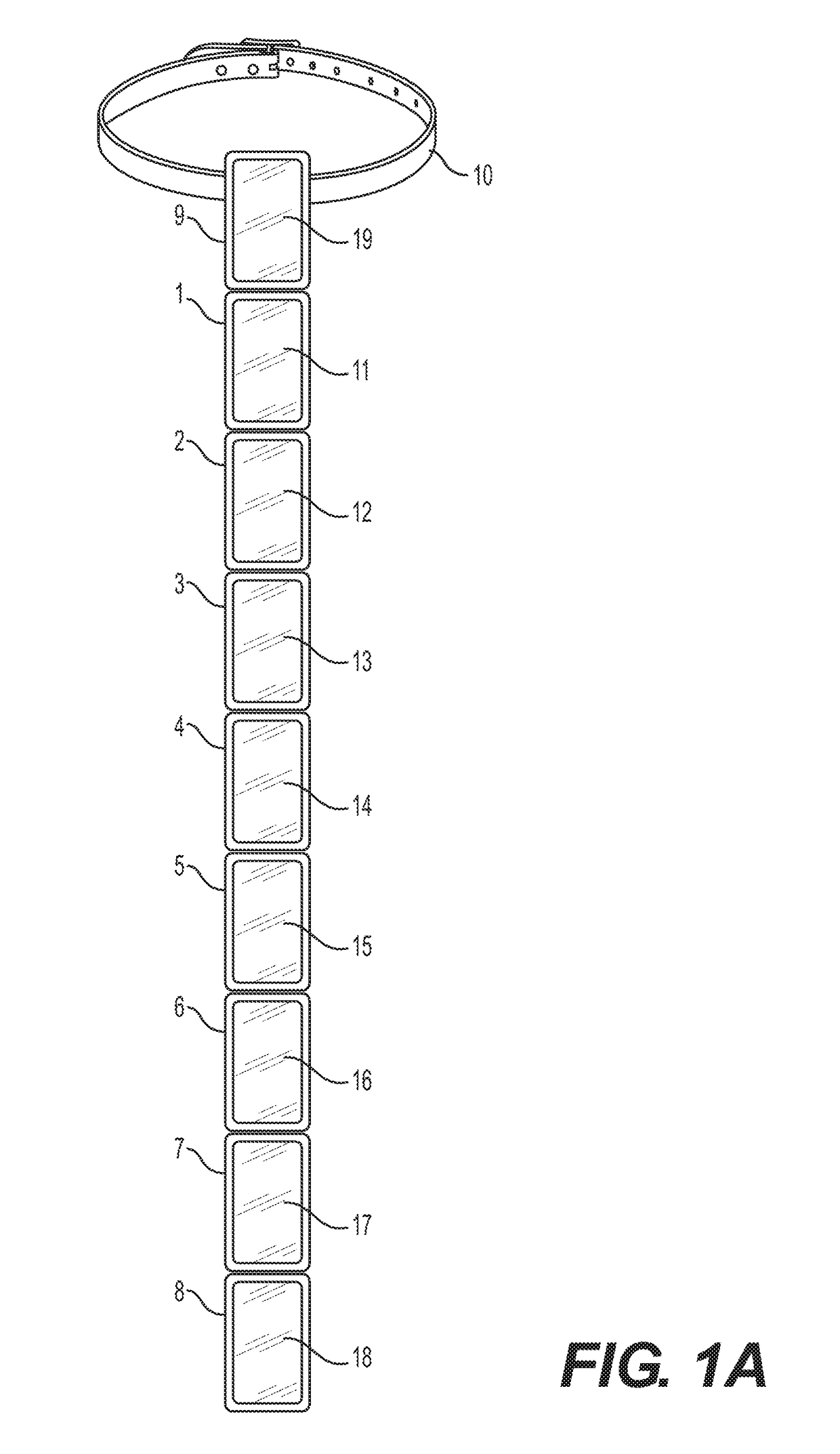

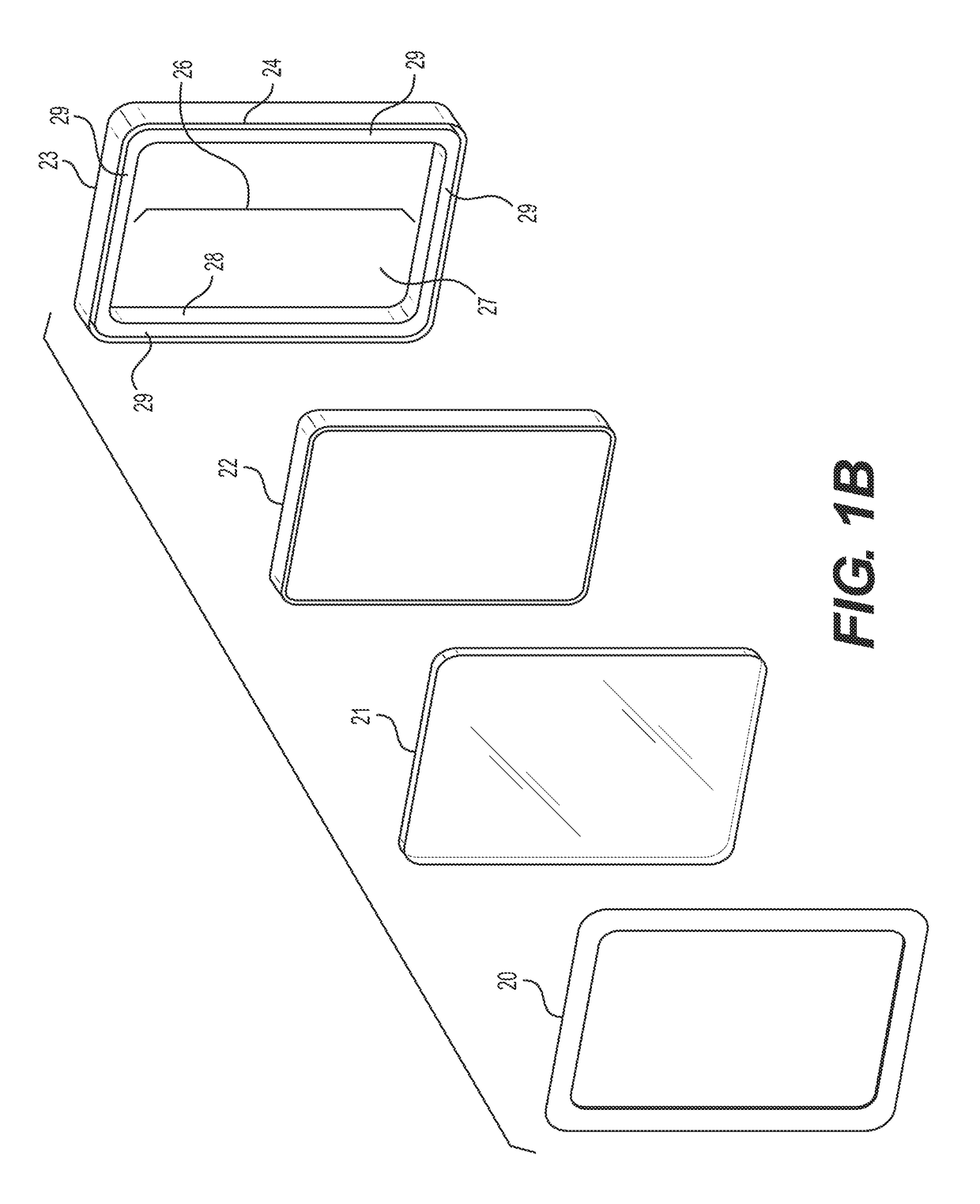

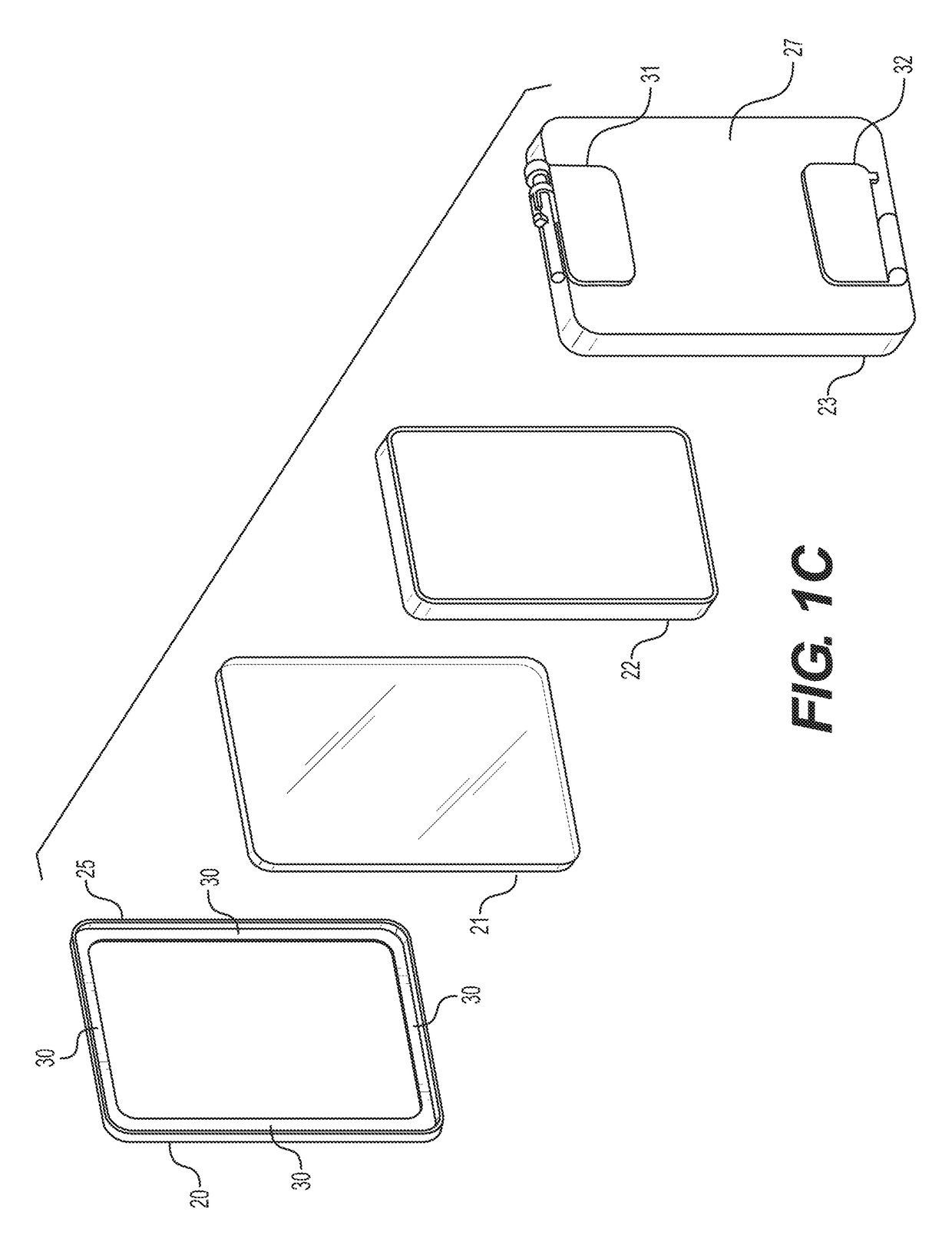

Neckwear for displaying coins, medals or bars

ActiveUS10136689B1Quality improvementExquisitely detailedSnap fastenersConvertible garmentComputer moduleEngineering

A neckwear includes a neckband and a neckband module and may further include one or more fastener members and one or more display segments for coins, medals or bars. The neckband is connected to said neckband module, and said one or more fastener members pivotably connects said neckband module and said one or more display segments. Also provided for a neckwear are a hermetically sealed neckband module or display segment, a display segment configured to be intra-changeable, display inserts for a neckband module or display segments, torso segments, and a neckband module with a member of a fastener to accommodate interchangeable display segments.

Owner:PATUGA LLC

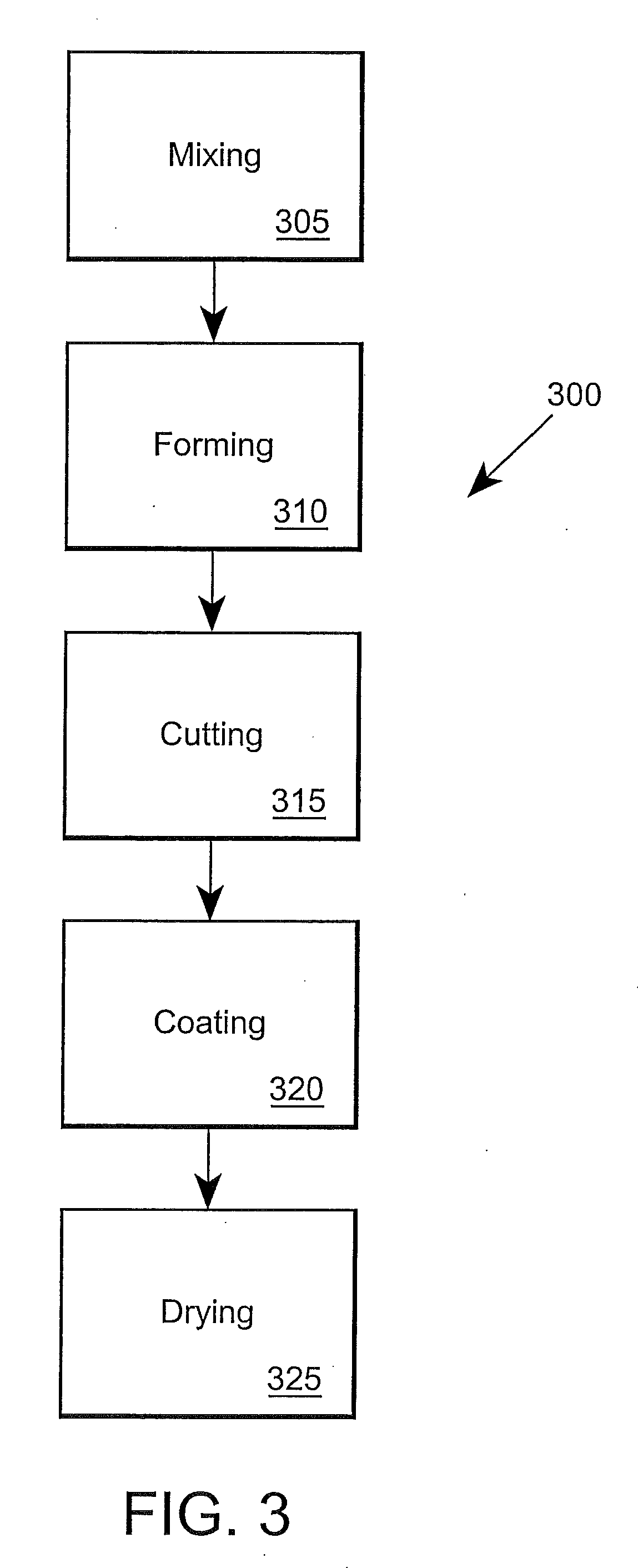

Coated gypsum board products and method of manufacture

InactiveUS20100047461A1High quality finishEfficient preparationCovering/liningsPretreated surfacesPolymer scienceJoint compound

A method of producing a coated gypsum board includes depositing a gypsum slurry to form a wet gypsum board having a gypsum core; applying a coating to the wet gypsum board; and drying the wet gypsum board, wherein the step of applying the coating occurs prior to the step of drying and the coating penetrates through at least a portion of the facing sheet and into at least a portion of the gypsum core. A board produced by the method is made with a coating that matches a joint compound.

Owner:LAFARGE PALTRES SA

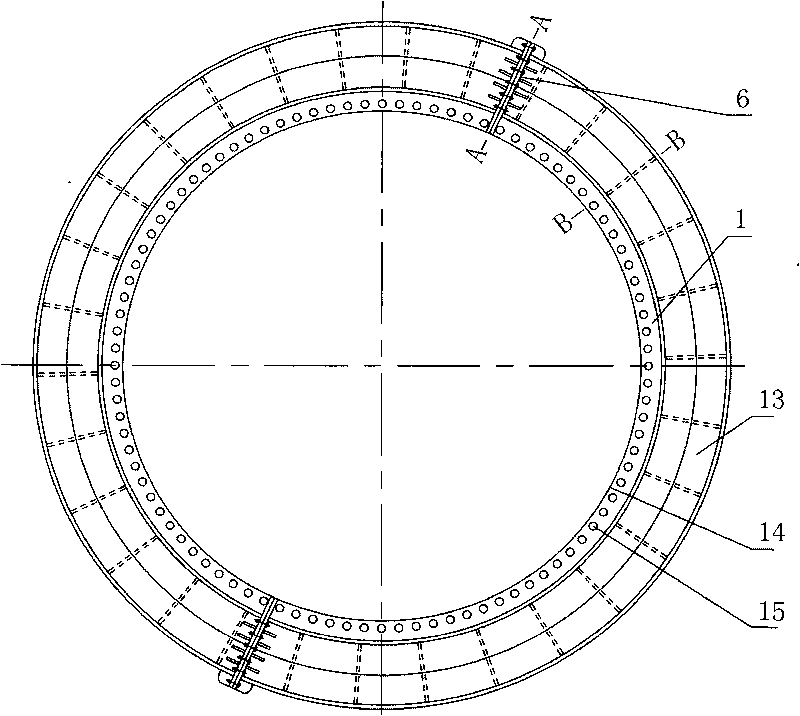

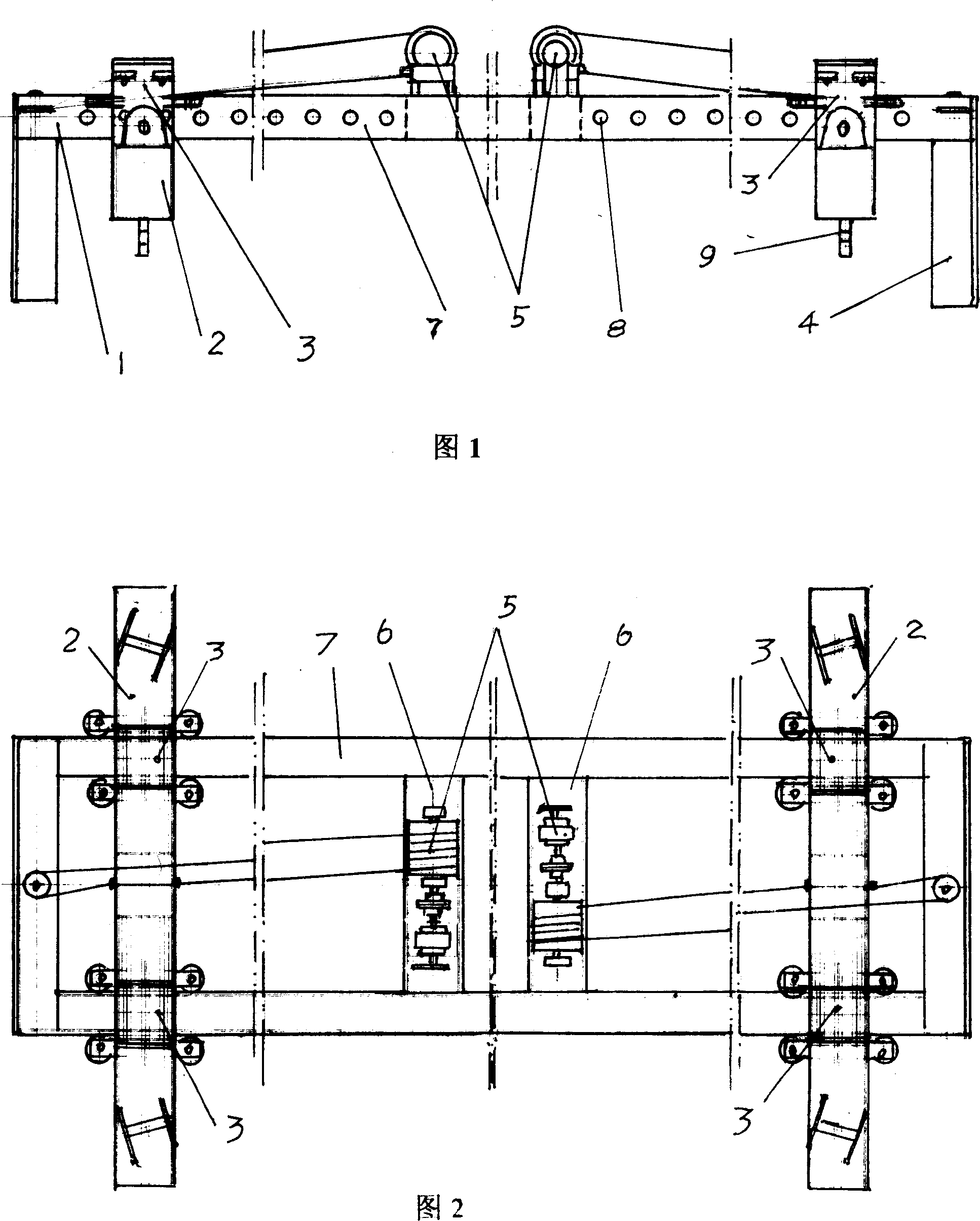

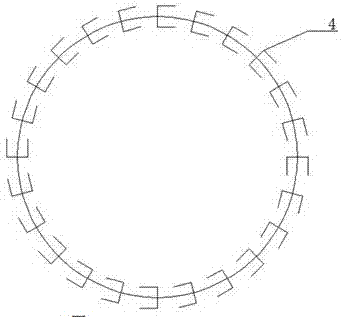

Technique for processing circular ring box type beam of lifting tool

Owner:ZHEJIANG DADI STEEL STRUCTURE

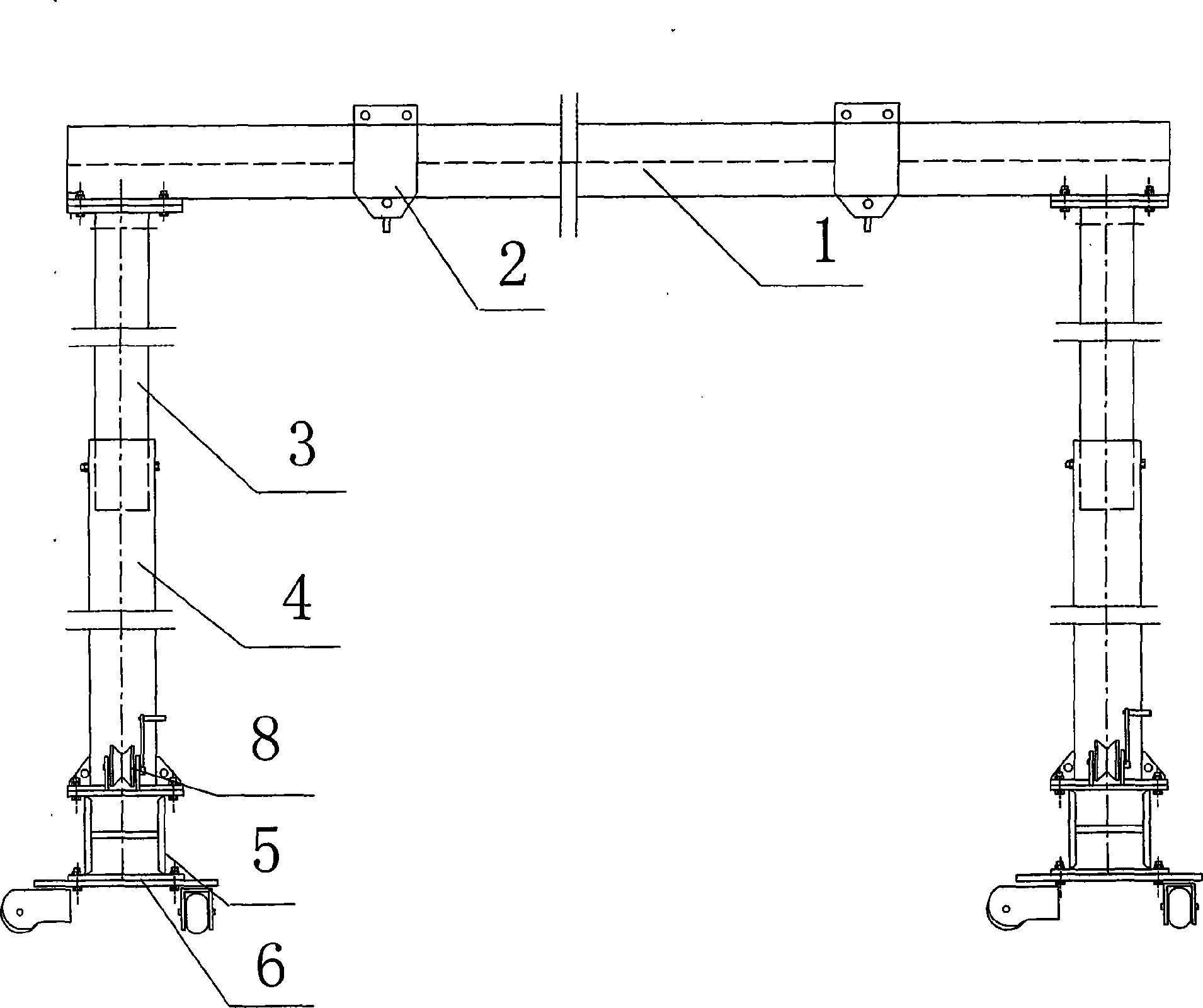

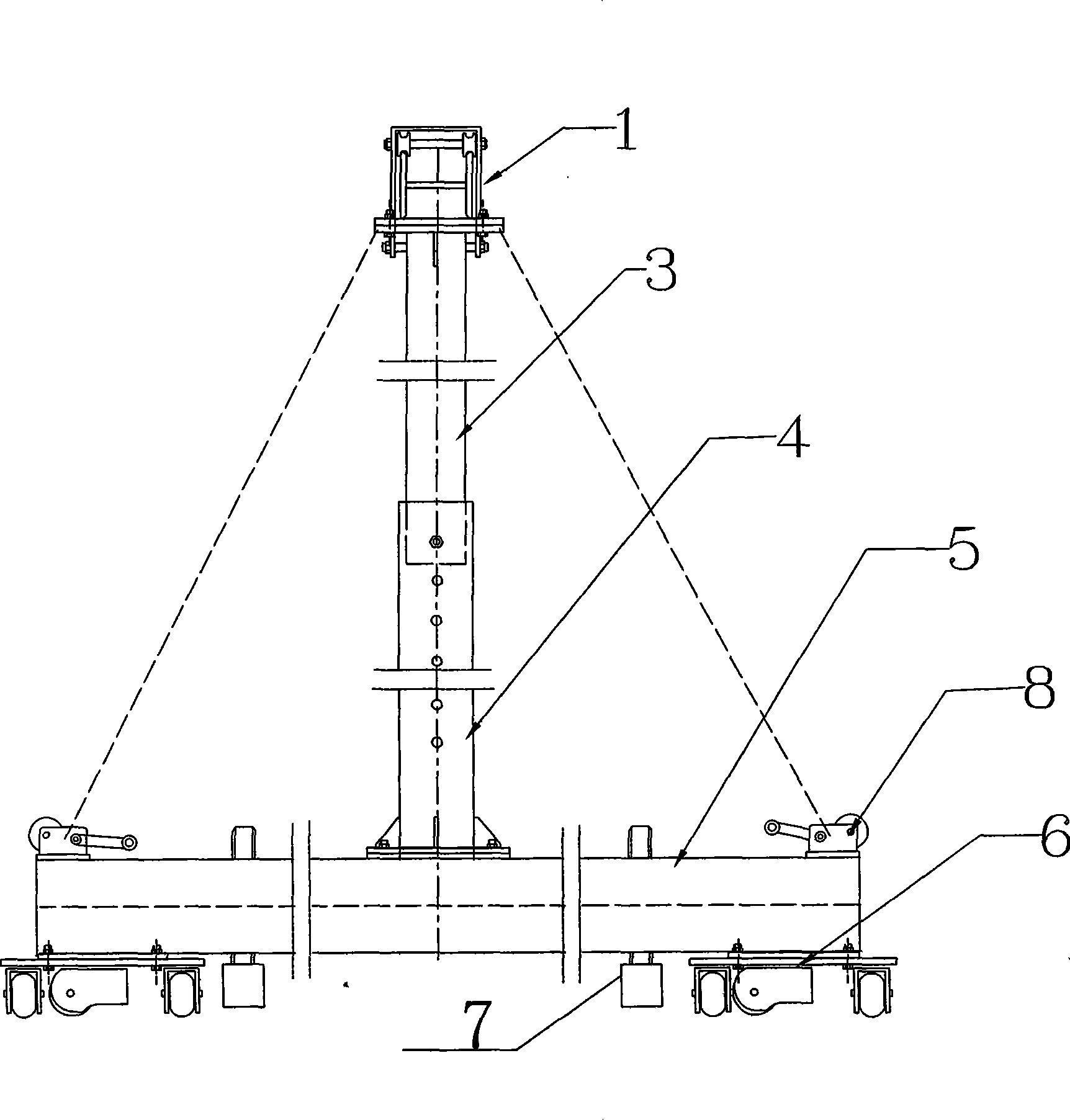

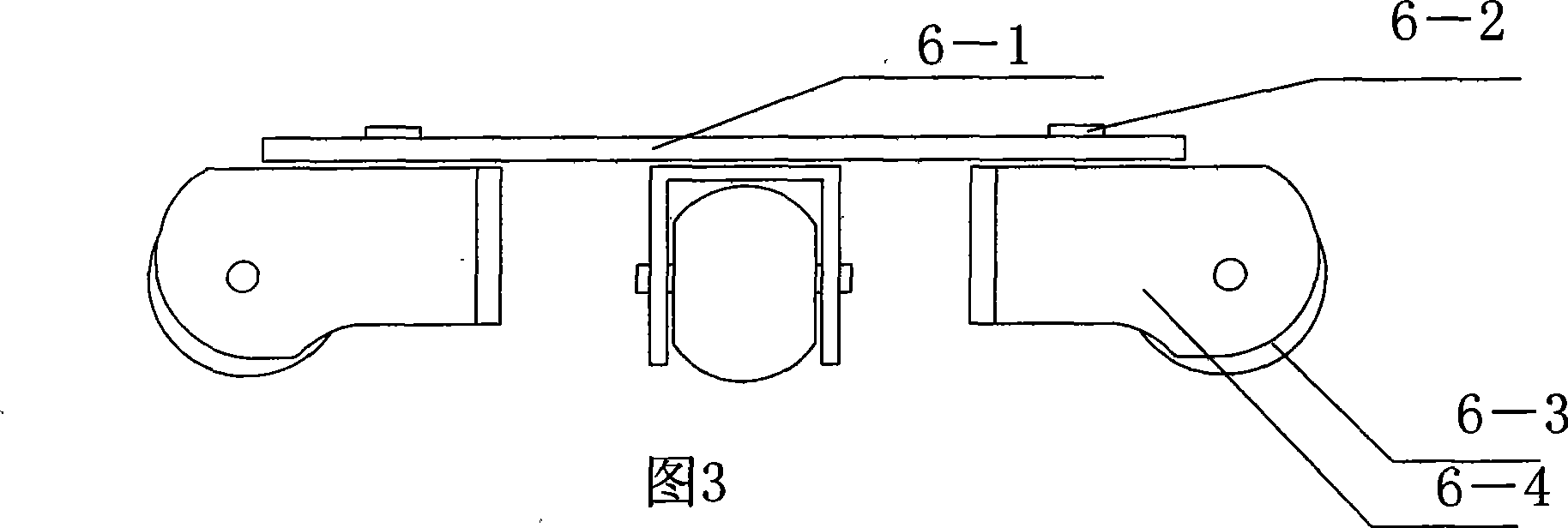

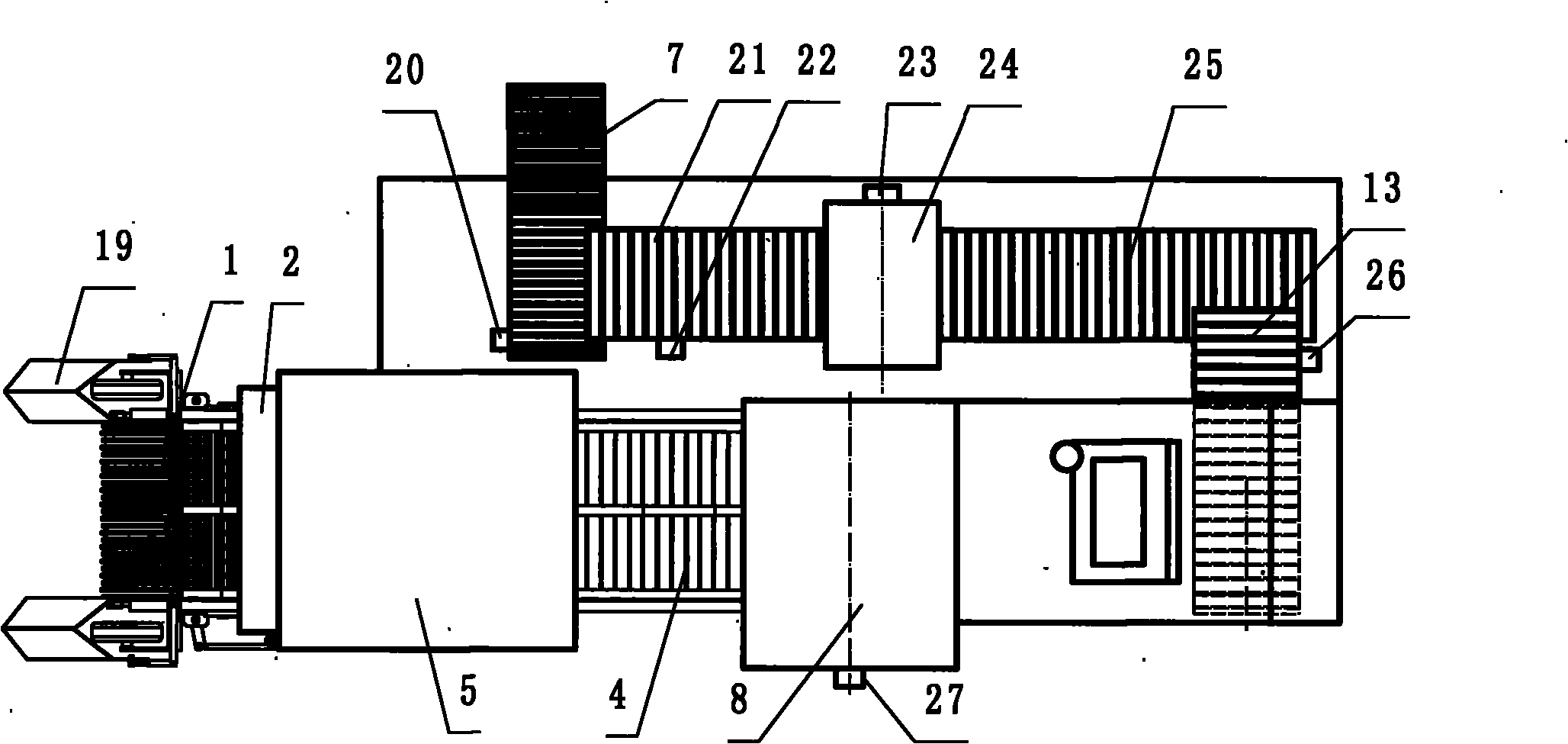

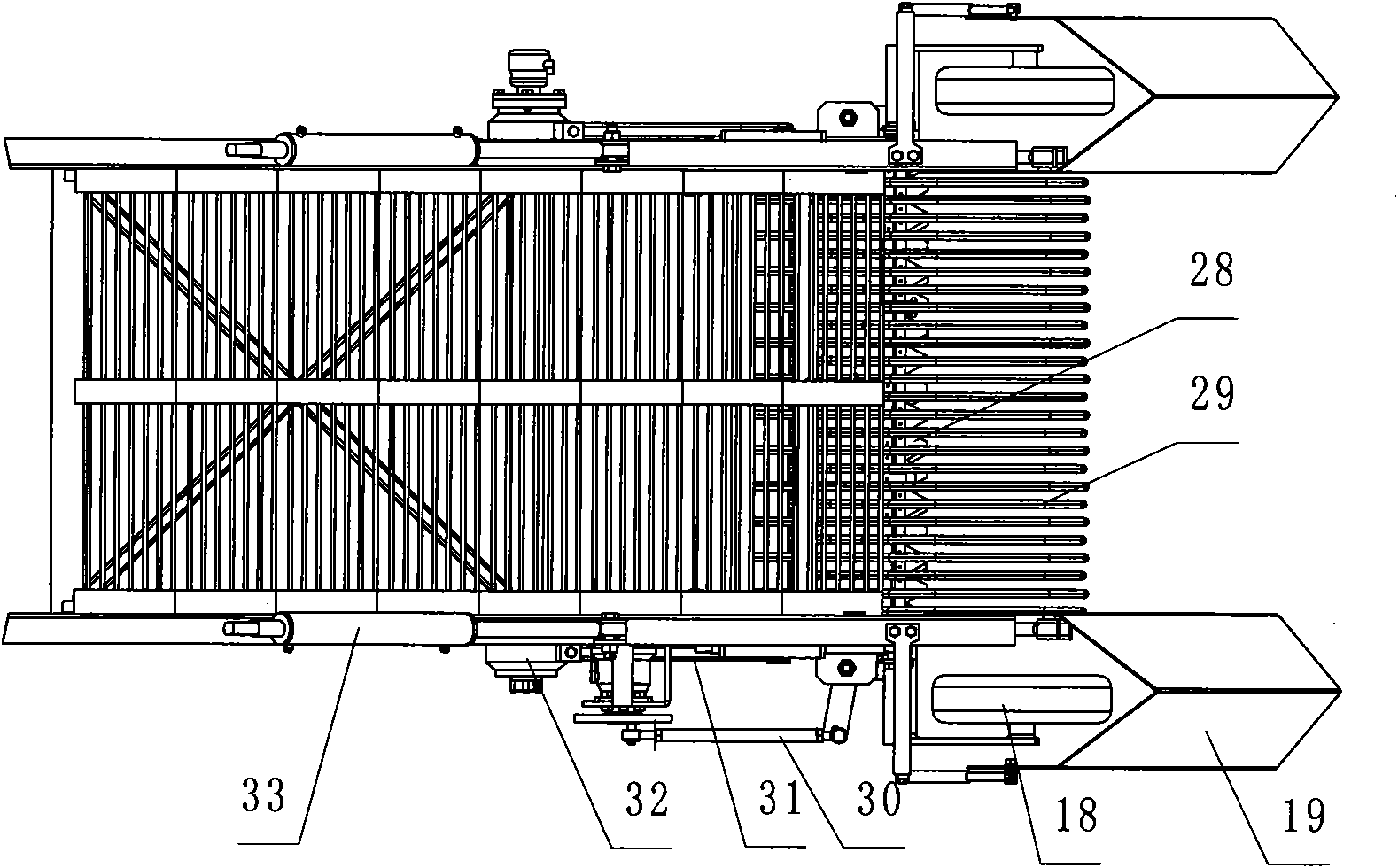

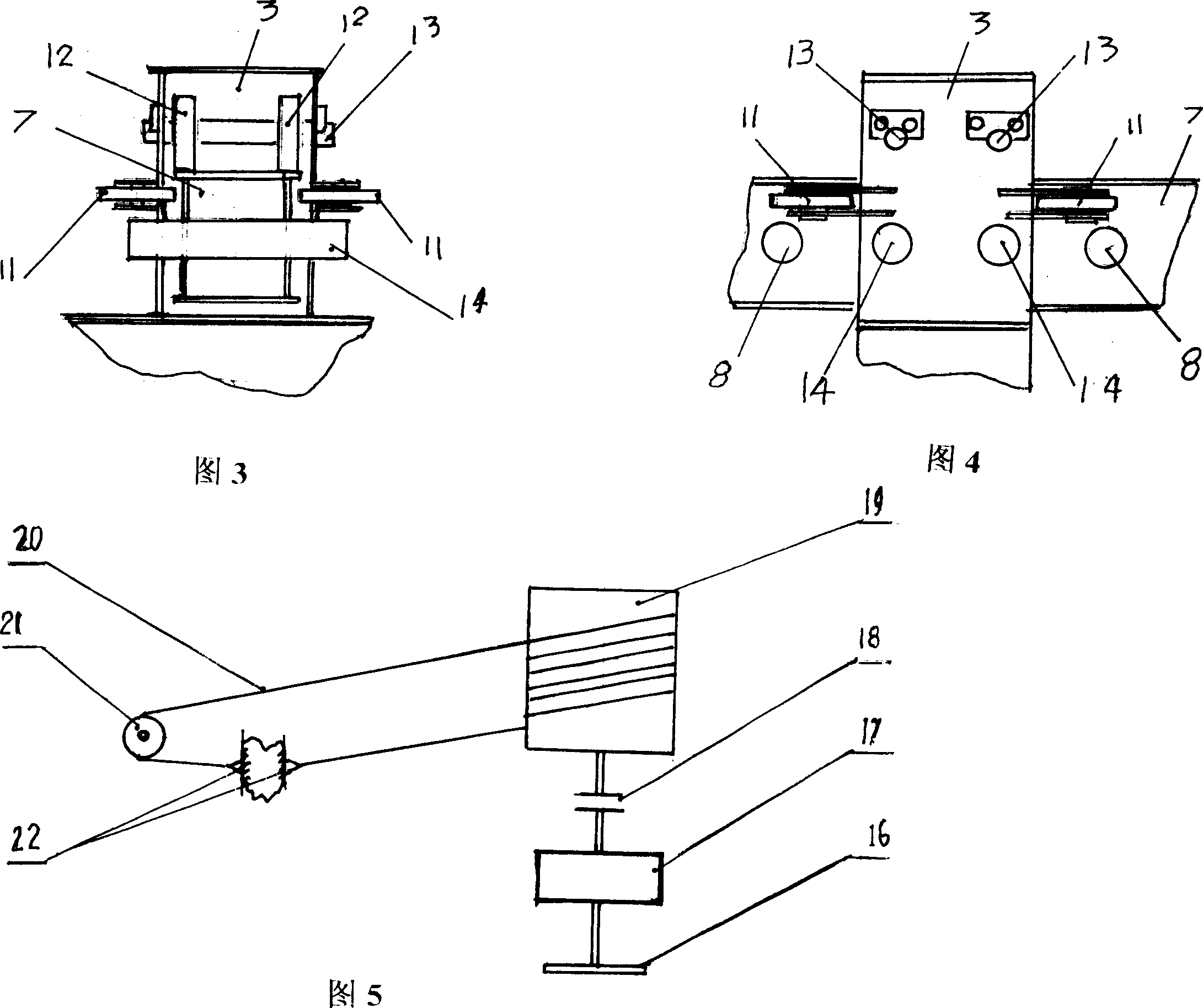

Mobile assembling gantry crane

InactiveCN101417774AHigh quality finishComplete efficientlyBase supporting structuresBraking devices for hoisting equipmentsGantry craneSetting time

The invention discloses a movable assemble type gantry crane, which is characterized in that the gantry crane comprises two base beams (5), and two ends under every base beam (5) are respectively connected with universal combined wheels (6), and the middle part of every base beam (5) is respectively fixed with a lower pillar (4) by a bolt, and an upper pillar (3) is connected in the lower pillar(4), and the two ends of every base beam (5) are respectively provided with hand cranking wire tightening devices (8), and a wire rope of the hand cranking wire tightening device (8) is fixed on the top end of the upper pillar (3), and the upper pillar (3) is connected with an upper beam (1), and a slide spreader (2) is hung on upper beam (1). The invention is simple in structure, safe and reliable and fast in assembly, and is suitable in hanging of different environment equipment indoor, can finish repairing with good quality and high efficiency within the set time, thus reducing the cost and enhancing the working efficiency.

Owner:YANTAI POWER SUPPLY

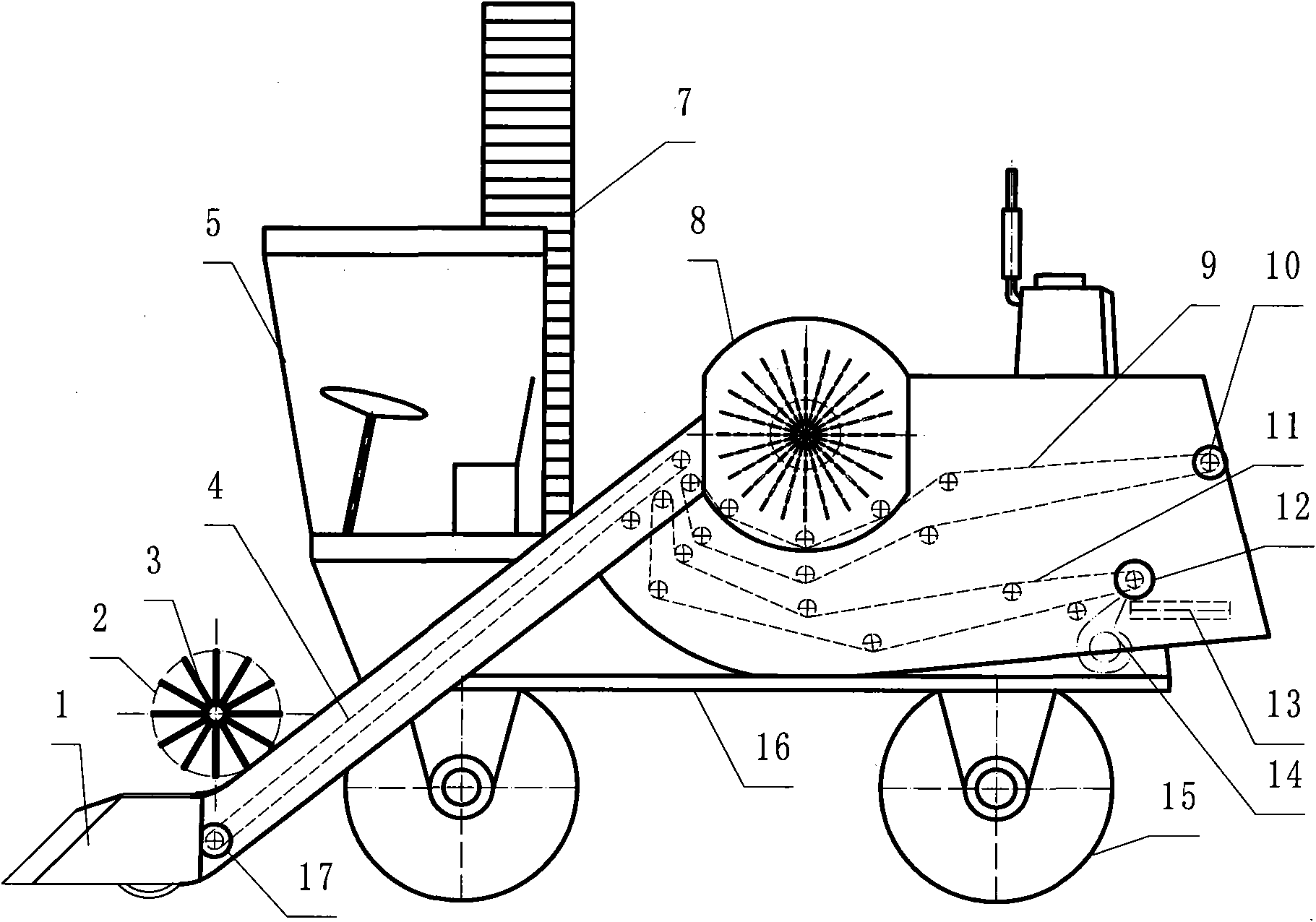

Hydraulic system for self-propelled tomato harvester

The invention relates to a hydraulic system for an agricultural machine, in particular to a hydraulic system for a self-propelled tomato harvester. The hydraulic system comprises five independent hydraulic loops; the five hydraulic loops share an oil tank; and an air cooler and a return oil filter are arranged on a master return oil passage. The hydraulic system for the self-propelled tomato harvester has stable transmission and reliable performance, and is easy to implement multiple complex mechanical operations such as lifting, transmission, steering and the like; and when the hydraulic system is used with the corresponding tomato harvester, the tomato harvester has a power system with excellent performance and further can finish tomato harvesting operation with high quality and high efficiency.

Owner:SHIHEZI UNIVERSITY +1

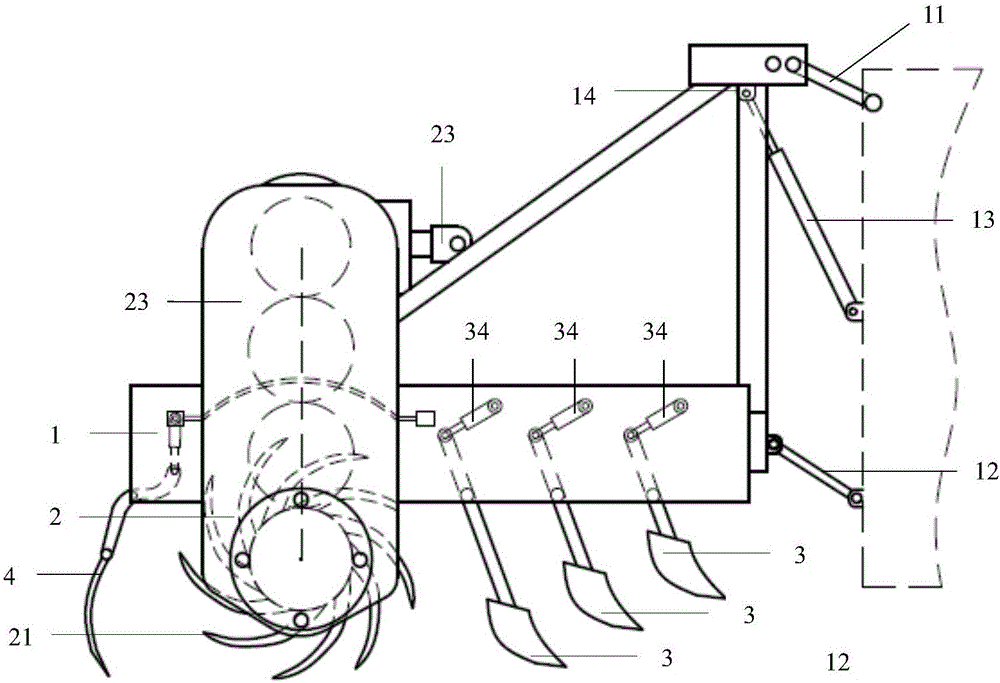

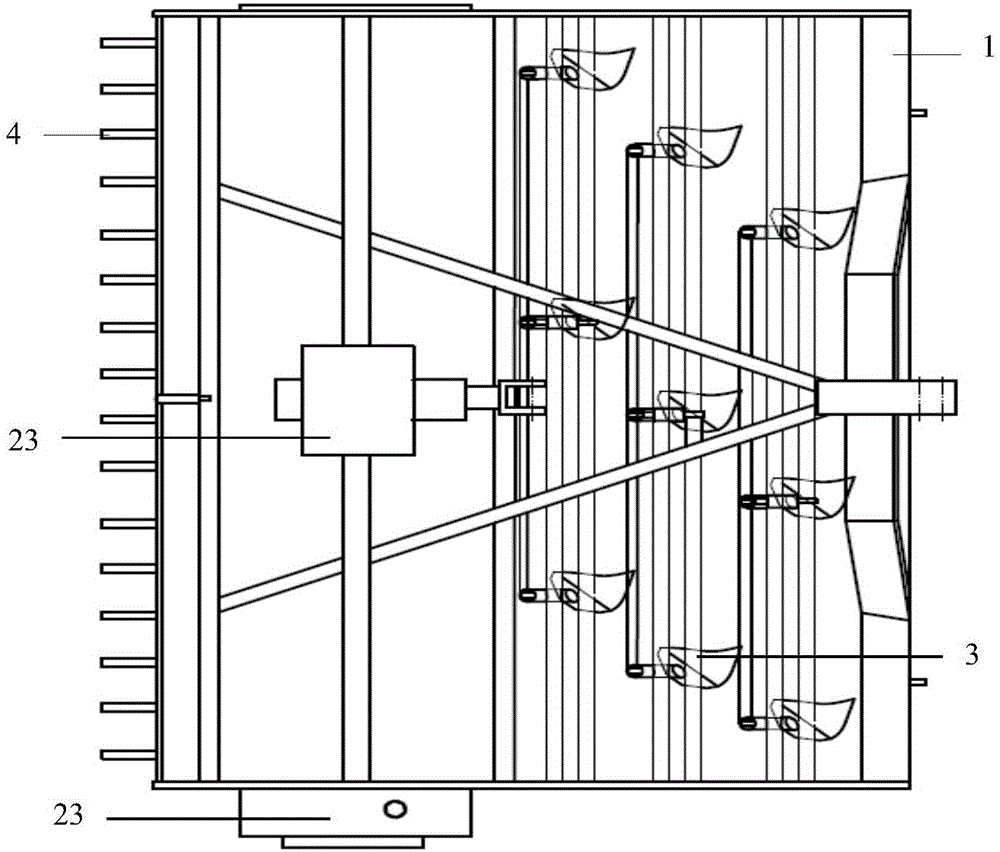

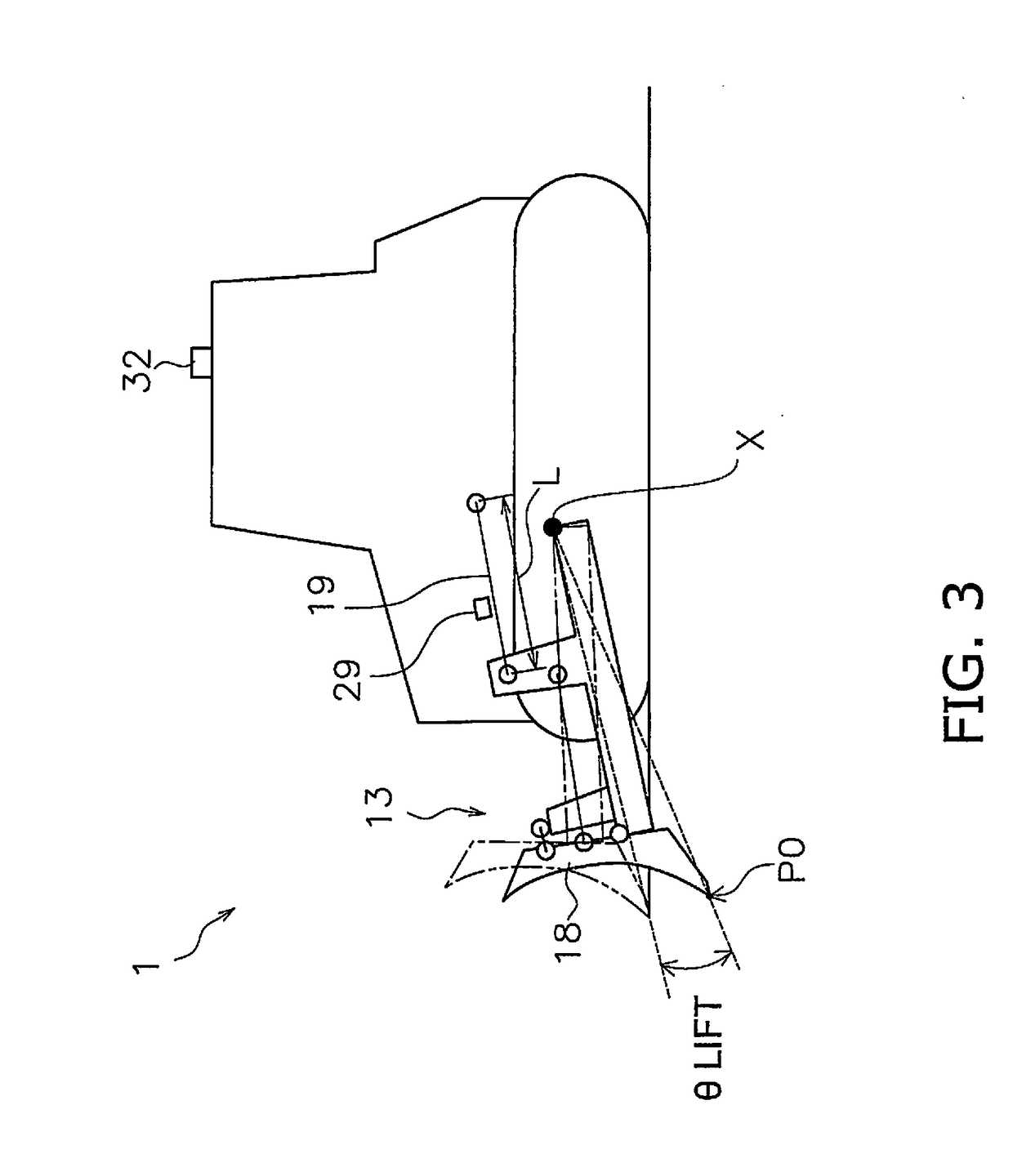

Efficient deep ploughing machine tool with controllable ploughing depth

InactiveCN106612656AEasy to installStable and adjustableSpadesAgricultural machinesHydraulic cylinderAgricultural engineering

The invention relates to the field of farming machines, in particular to an efficient deep ploughing machine tool with controllable ploughing depth. The efficient deep ploughing machine tool comprises a rack and a rotary tillage mechanism installed on the rack. Plough share sets with adjustable wedge-in angles are arranged on the portion, in front of the rotary tillage mechanism, of the rack in rows. The rack is connected to the tail of a tractor through an upper connecting rod and a lower connecting rod, a quadrilateral structure capable of moving in the vertical direction is formed by connecting parts of the rack and the tractor, and a jacking hydraulic cylinder is arranged in the middle of the quadrilateral structure. One end of the jacking hydraulic cylinder is connected to the position, close to an upper connecting rod connecting point, of the rack, and a cushioning device is arranged at the connecting end. The other end of the jacking hydraulic cylinder is connected to the tail of the tractor, and a stable triangular structure is formed by the jacking hydraulic cylinder and the upper connecting rod. By the adoption of the scheme, the efficient deep ploughing machine tool with controllable ploughing depth is simple in structure and convenient and rapid to operate, can effectively control the ploughing depth, and efficiently completes ploughing work at high quality.

Owner:HUNAN CHUNYAN MACHINERY MFG

Epoxy colored sand floor construction method

The invention discloses an epoxy colored sand floor construction method which comprises the following steps of: (1) performing basement layer treatment; (2) performing site maintenance; (3) coating a bottom coating layer; (4) performing intermediate coating construction; (5) performing colored sand construction; (6) performing sealing; and (7) performing surface coating. The epoxy colored sand floor construction method has the advantages of scientific construction rule and high construction speed; the demand for compensating the shortage of the construction period can be met; by reasonable arrangement of working procedures, the waste of materials is avoided, and the cost of the materials is saved; the working procedure connection time is shortened, so that the labor cost is saved, and the working period of general similar engineering is reduced by 0.4 day at every square meter; and the worker cost is greatly saved, and the construction cost is reduced. By the method for the construction, the construction capacity is enhanced, the experience is supplied to engineering construction enterprises with the same type, and the great reference significance and a high instructing function are supplied to the engineering with the same type; according to the method, a construction task can be finished with high quality and high efficiency; and the high application and popularization value is achieved.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

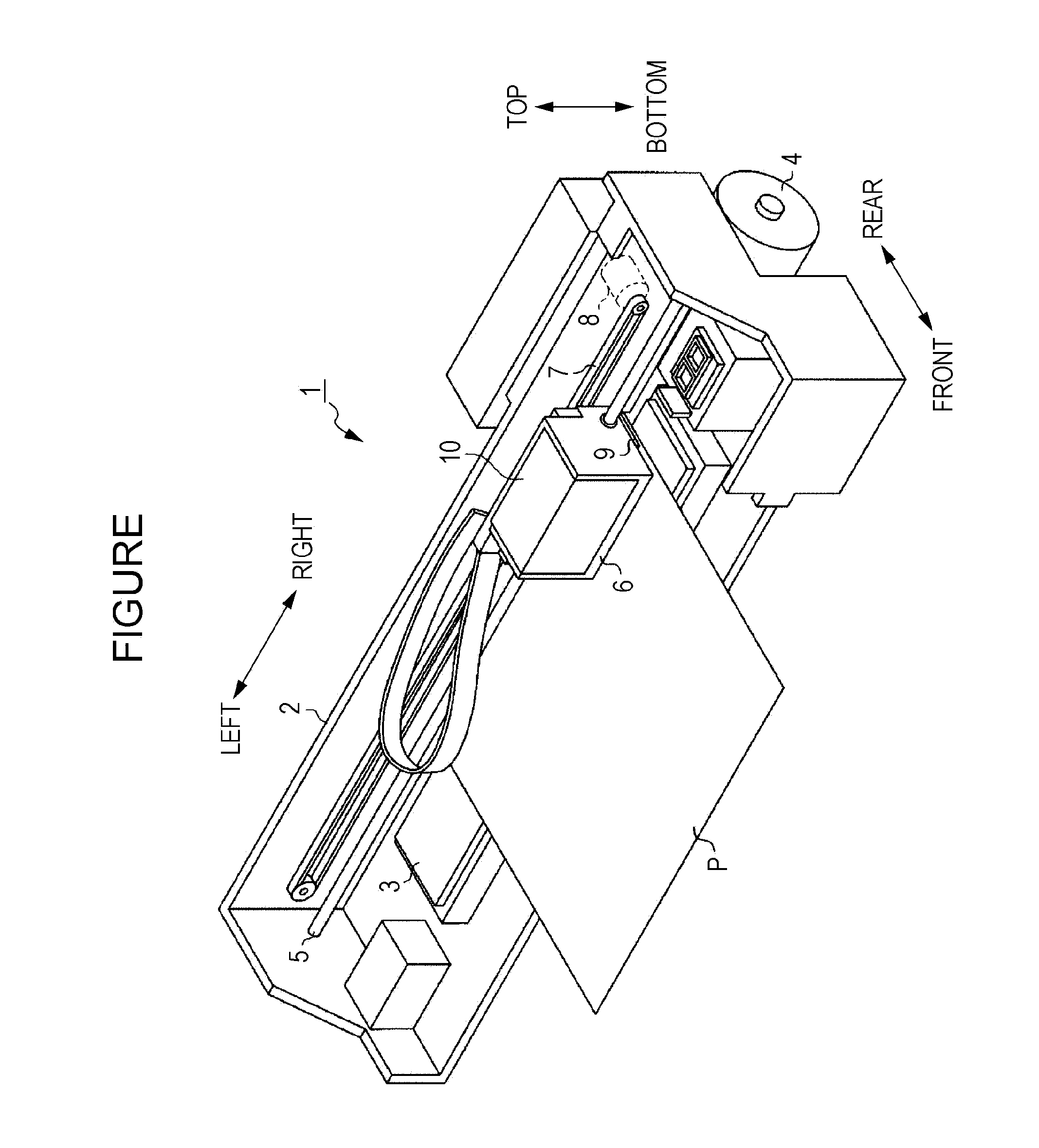

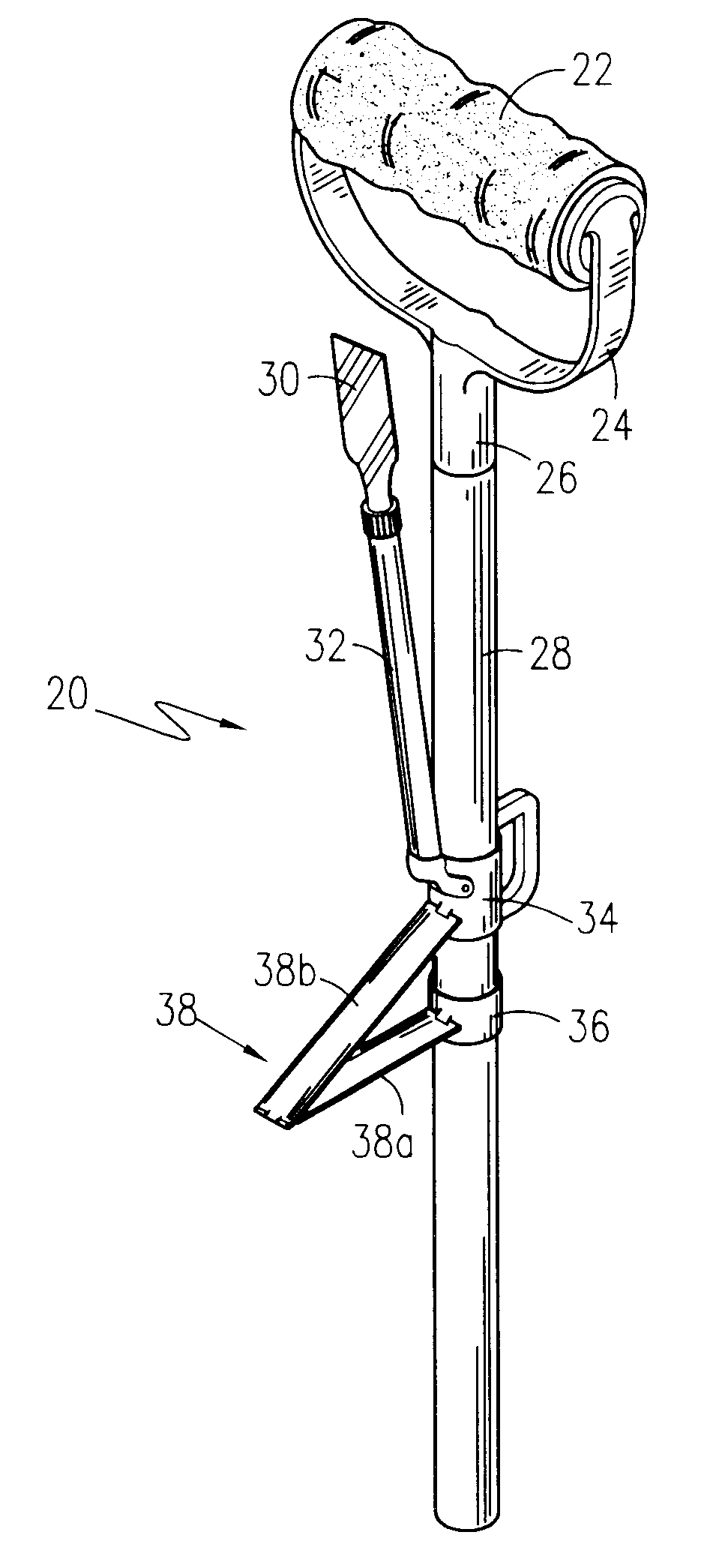

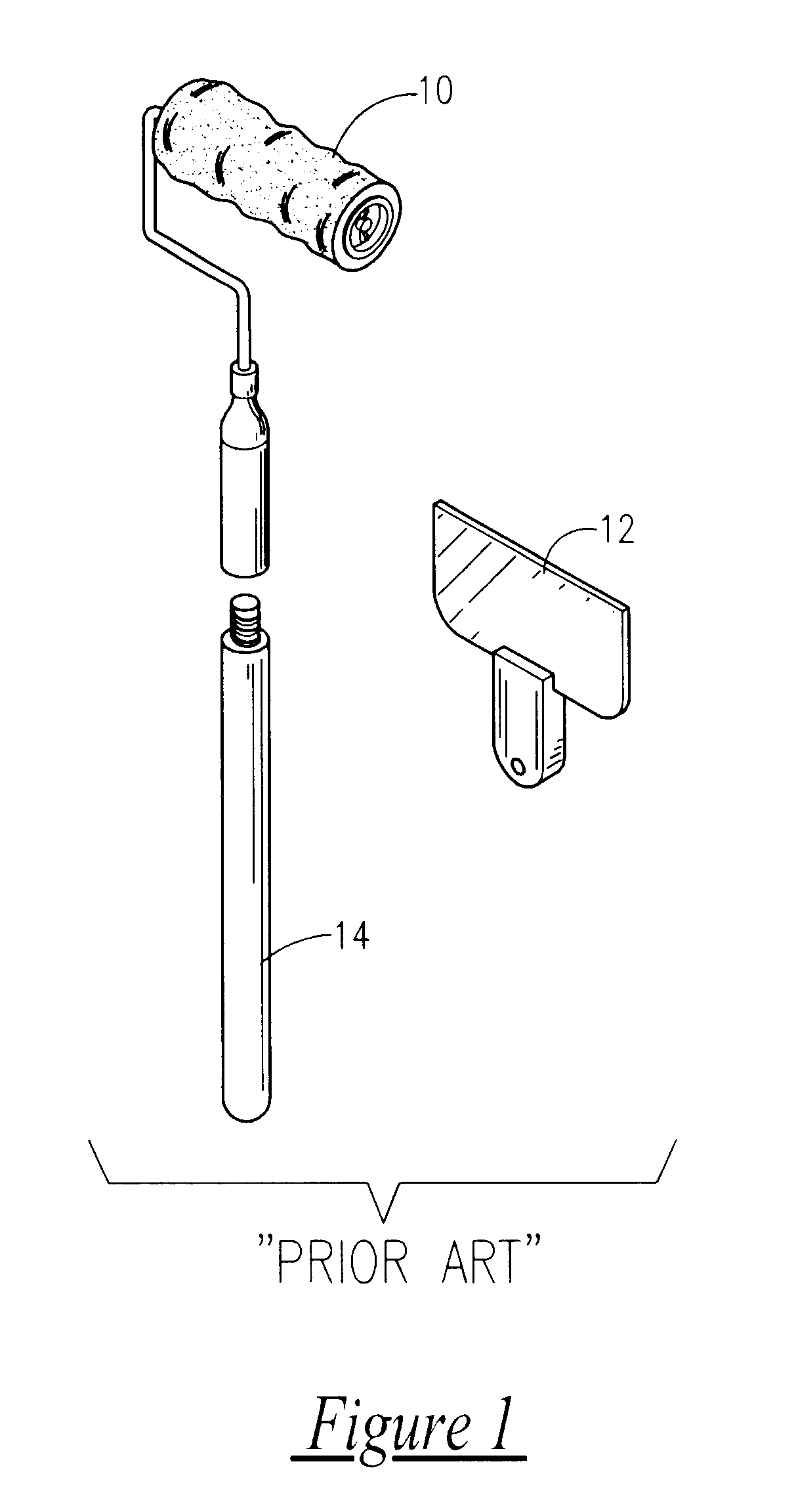

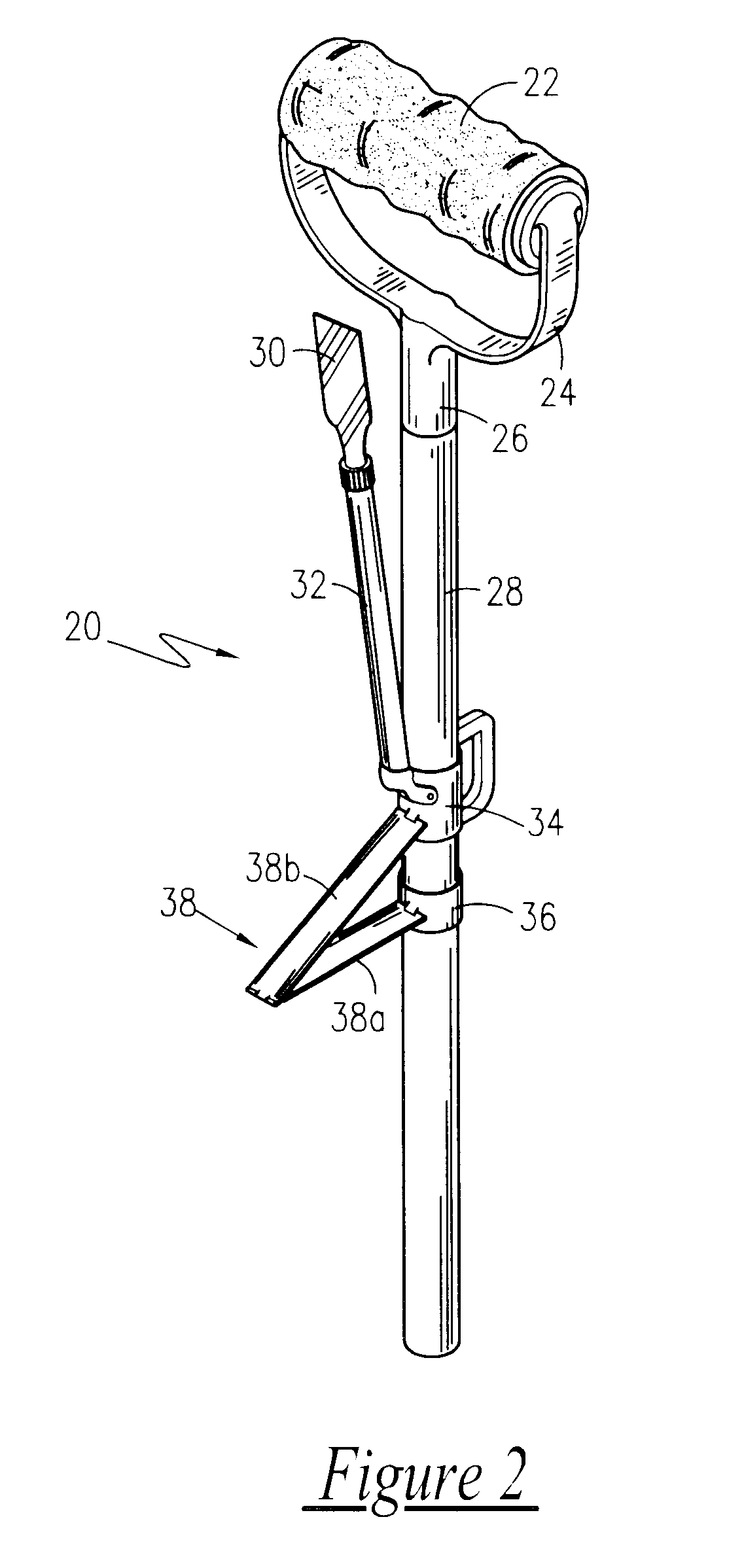

Extendable interior ceiling finishing tool

InactiveUS6688367B1Shorten application timeHigh quality finishLiquid surface applicatorsKitchenware cleanersKnife bladesBiomedical engineering

An apparatus is provide that aids in the finishing of ceilings. The tool provides for the rolling on of cement or other similar finishes and then an integral knife blade smoothes over the finished surface. Such an invention prevents the user from using multiple tools, and from using stilts to reach the ceiling surface.

Owner:RUPOSKY GEORGE A +1

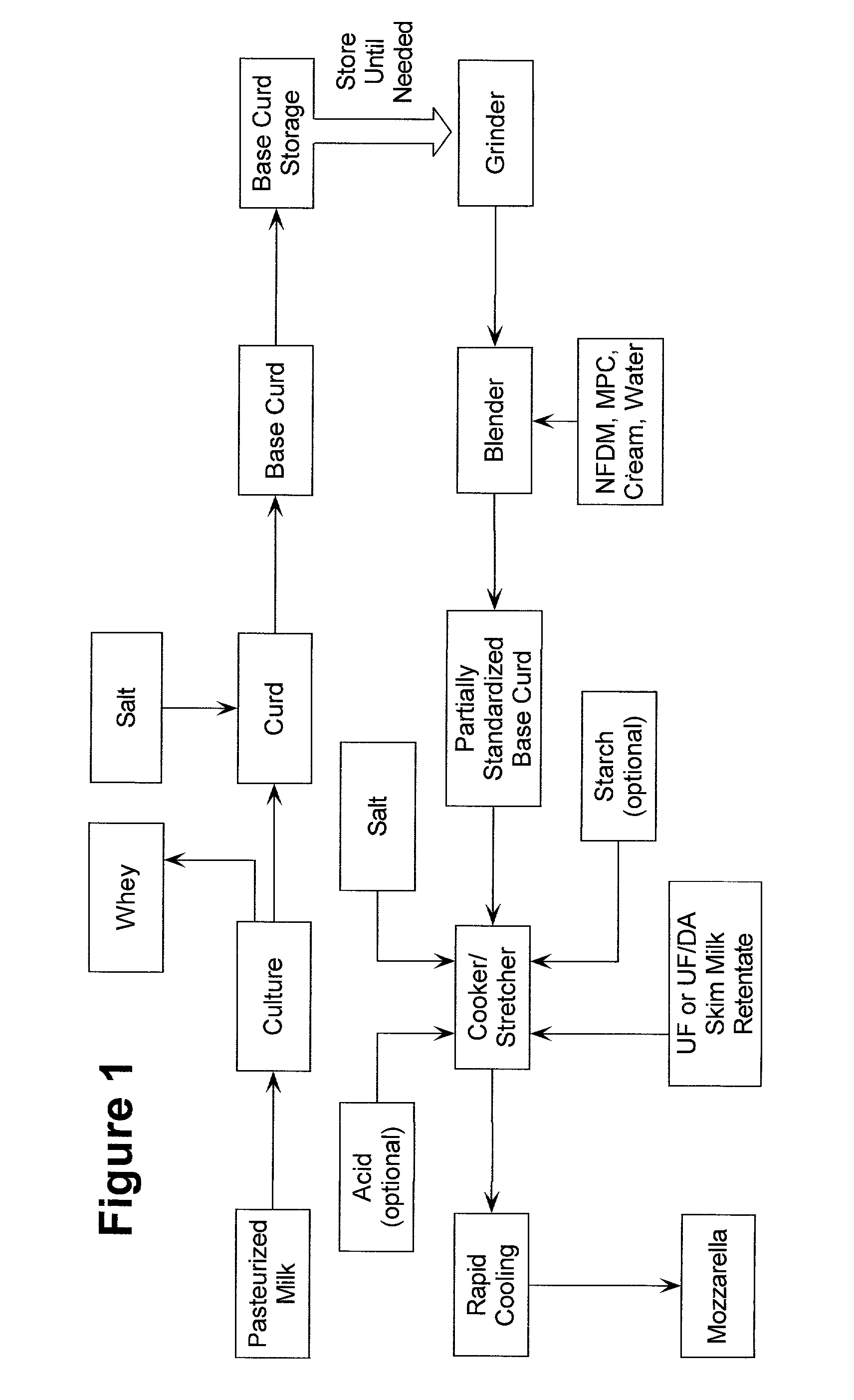

Process for mozzarella cheese

InactiveUS20020127301A1Economical to useProduced economicallyMilk preparationCheese manufactureMozzarella cheeseEngineering

The present invention is directed to an improved process of producing natural mozzarella cheese. The process starts with a liquid dairy substrate that is cultured and coagulated. The resulting curd is cut and salted. The resulting curd (i.e., base curd) may be frozen or refrigerated and stored until needed. Once needed, the stored base curd is ground and treated in a blender where it is partially standardized to form a "partially standardized base curd." The partially standardized base curd is then cooked in a cooker or cooker / stretcher (preferably in a lay-down cooker) where standardization is completed by the addition of a cultured or uncultured skim milk retentate. No emulsifying salts are used in the cooker / stretcher. The cheese mass is then rapidly cooled to produce the mozzarella cheese. The conventional brine cooling step normally used in mozzarella cheese production is not used in the present invention. In an especially preferred embodiment, starch is also added to the standardized, cooked, stretched mozzarella prior to the cooling step. Such starch is typically added at a level of up to about 10 percent of the finished product and, more preferably, at a level of about 0.1 to about 2 percent. The added starch serves to bind the moisture in the product and results in a firmer cheese which is easier to shred.

Owner:KRAFT FOODS GRP BRANDS LLC

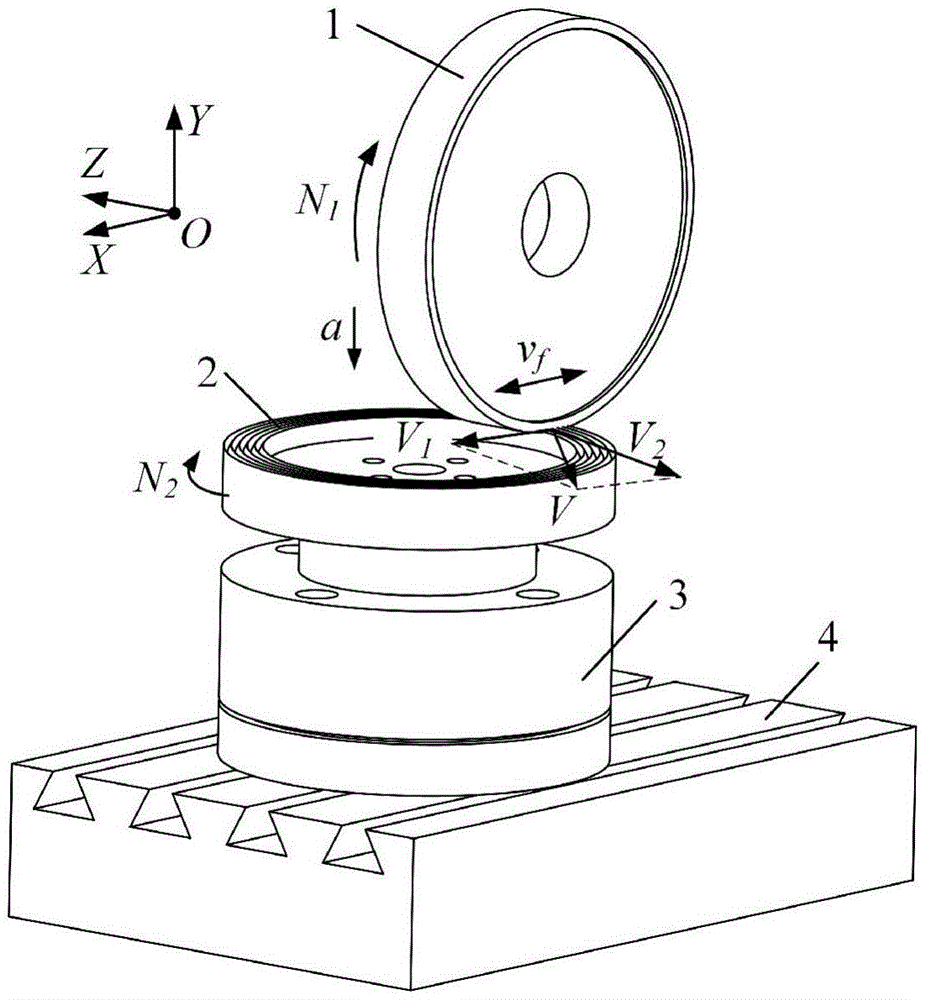

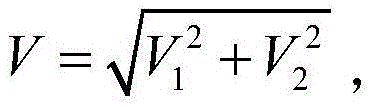

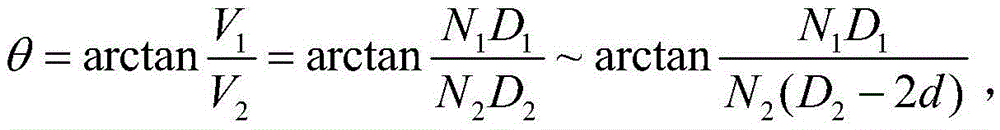

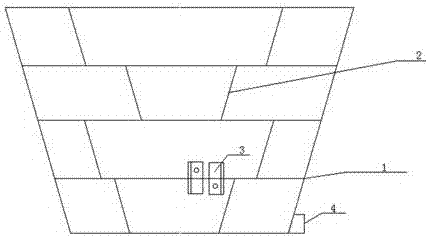

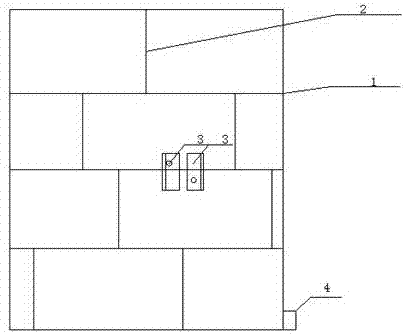

Leveling and aligning device and method for point of micro abrasive particle protruding edge of rough diamond abrasion wheel

ActiveCN105458930AImprove the efficiency of trimming and trimmingImprove stabilityAbrasive surface conditioning devicesNumerical controlMachine tool

The invention discloses a leveling and aligning device for the point of a micro abrasive particle protruding edge of a rough diamond abrasion wheel. The leveling and aligning device comprises a grinding disc with the particle size of 600-3,000 meshes and an air shaft. The grinding disc is arranged on the air shaft. The air shaft is fixed to a horizontal workbench of a numerical control machine tool. The grinding disc is a cast iron containing superfine diamond grinding disc. Round microstructure arrays concentric with the rotating axis of the grinding disc are evenly arranged on the grinding surface of the grinding disc. The invention further provides a leveling and aligning method for the point of the micro abrasive particle protruding edge of the rough diamond abrasion wheel. The rotating speed of the grinding disc and the diamond abrasion wheel is controlled to control the relative speed direction of abrasive particles during grinding, so that the grinding force direction of the abrasive particles during grinding changes within the range of 90 degrees of two orthorhombic abrasion wheel rotating speed directions, the diamond abrasion wheel point is leveled and aligned in the direction where diamond abrasive particles are prone to be damaged during crystallization, and it is guaranteed that the grinding area covers the whole work surface of the diamond abrasion wheel.

Owner:SOUTH CHINA UNIV OF TECH

Cutting Insert Having Cylindrically Shaped Side Surface Portions

ActiveUS20070224006A1Reduced cutting performanceWithout of to qualityMilling cuttersCutting insertsMechanical engineeringSurface distance

A double-sided reversible and indexable cutting insert has identical opposing first and second end faces and a peripheral side surface extending therebetween. A clamping through-bore extends between, and opens out to, the first and second end faces. The cutting insert has a median plane between the first and second end faces, and a through-bore axis extending perpendicularly through the median plane. The cutting insert also has a Y-fold rotational symmetry about the through-bore axis. The peripheral side surface has Y major side surfaces and Y minor side surfaces, each minor side surface interconnecting two adjacent major side surfaces. Each minor side surface is a section of a single cylindrical surface having a given radius, the given radius being greater than a minor side surface distance of each minor side surface from the through-bore axis.

Owner:ISCAR LTD

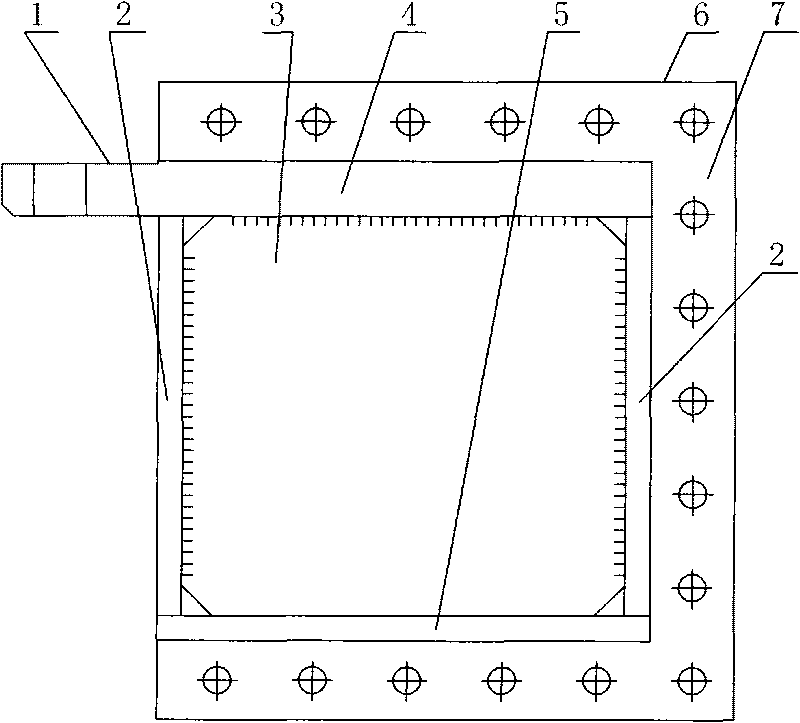

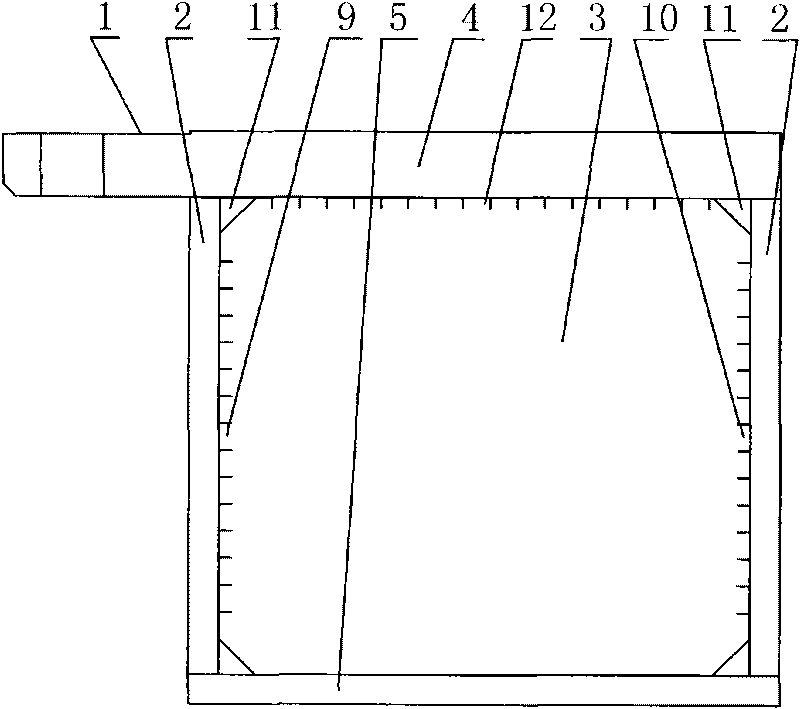

80-ton adjustable large-piece hoister

The 80-ton adjustable large sling includes one rectangular support frame comprising transverse beams and longitudinal beams, two long hangers mounted onto the longitudinal beams, suspending sets in the ends of hangers, pinch wheels and guide wheels in the joints between long hanger and longitudinal beam, one towing shifter on the joining beam for towing long hangers, support legs below the ends of the longitudinal beams, and one hanging plate with holes for hoisting steel cables to pass through. The sling has high adaptability, convenient operation, capacity of raising hoisting efficiency and high large goods hoisting safety and reliability.

Owner:天津港第二港埠有限公司

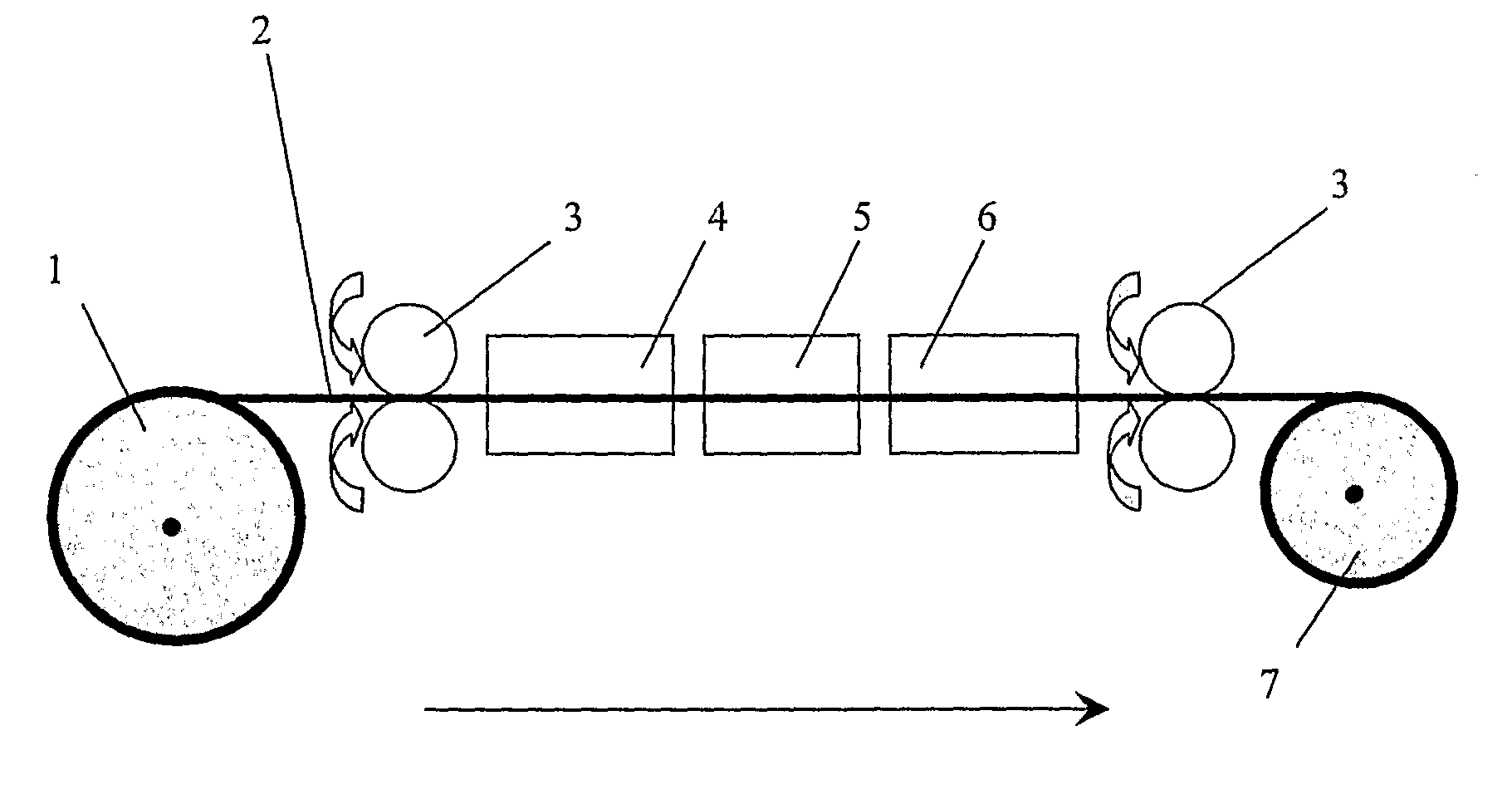

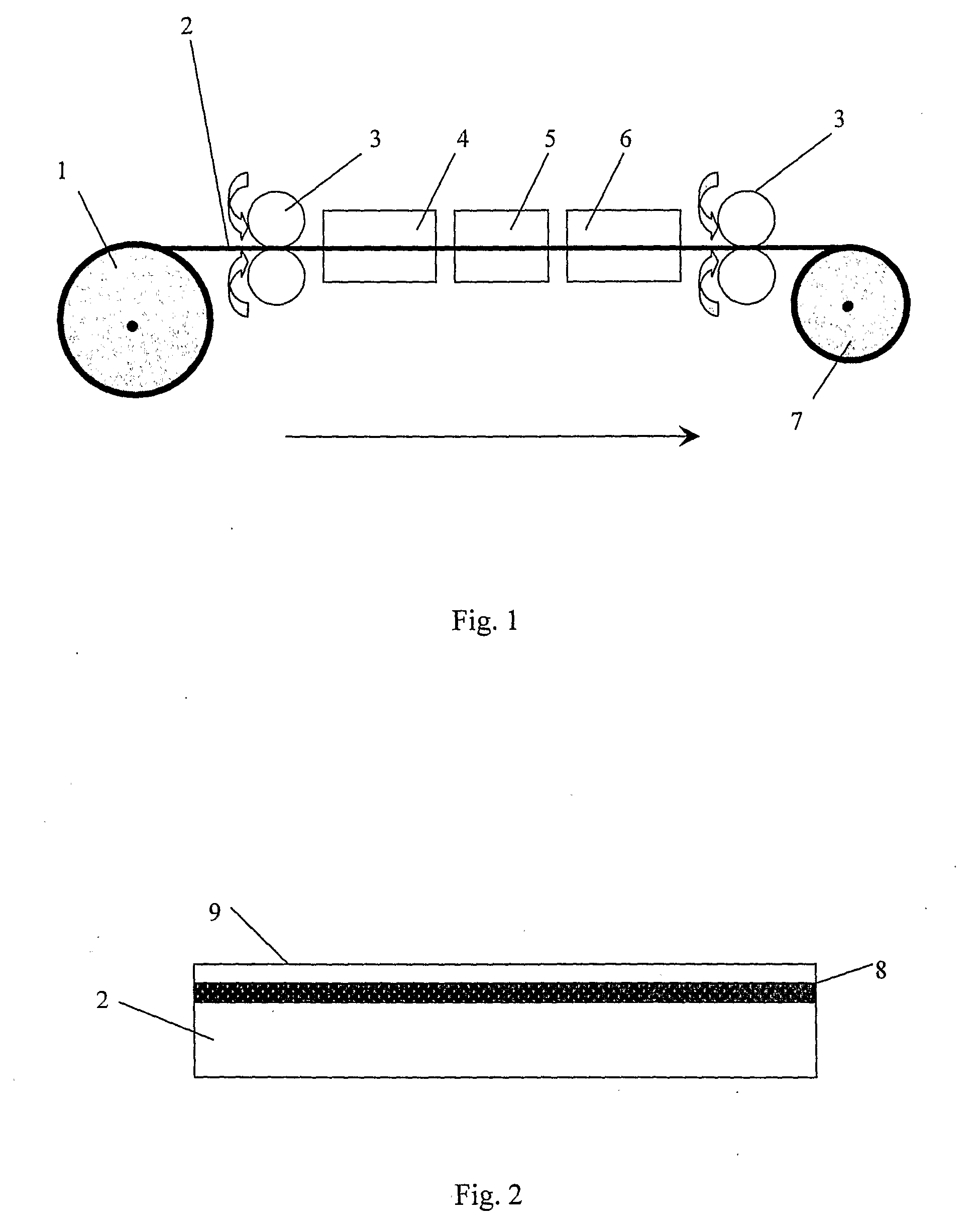

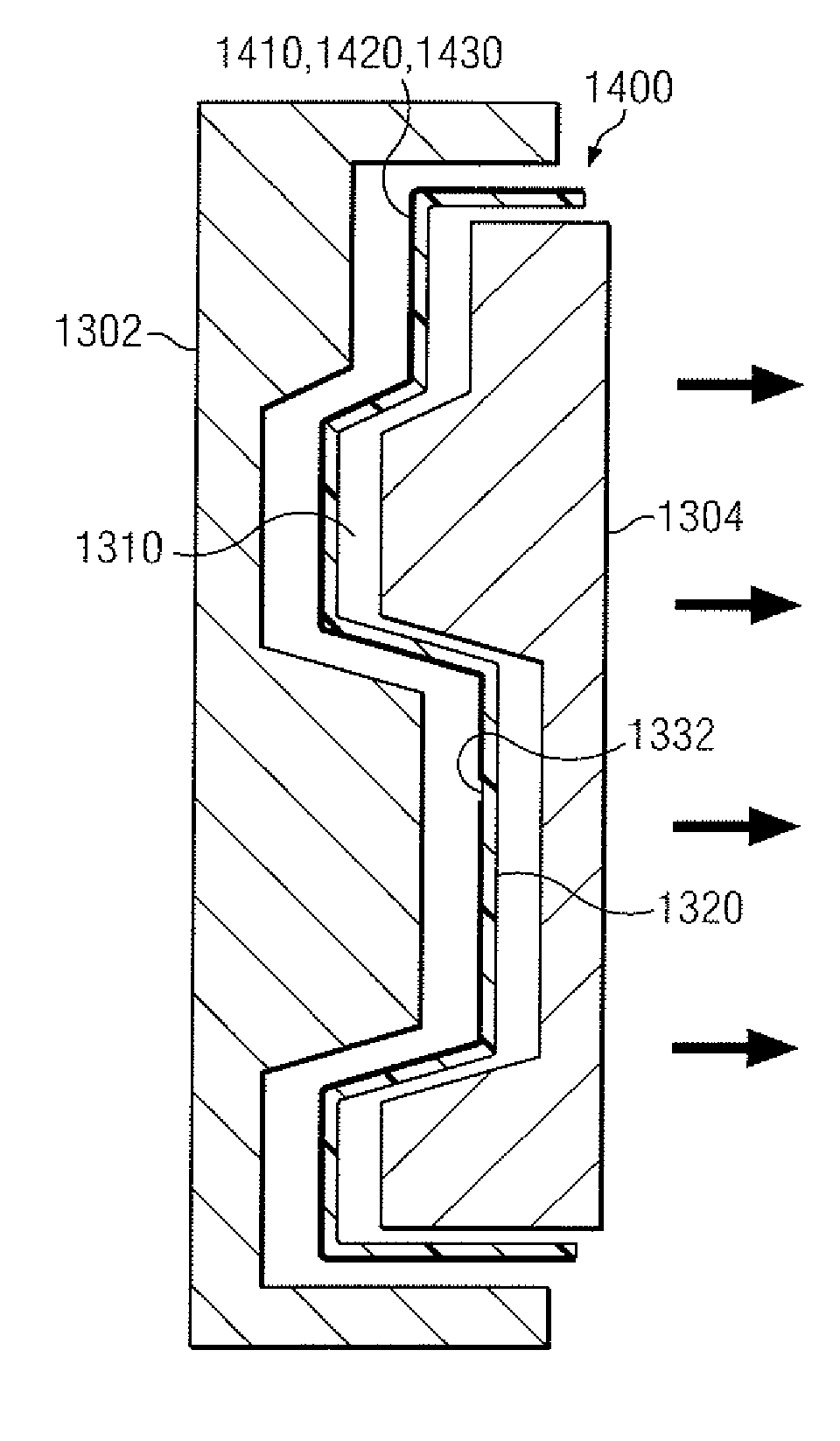

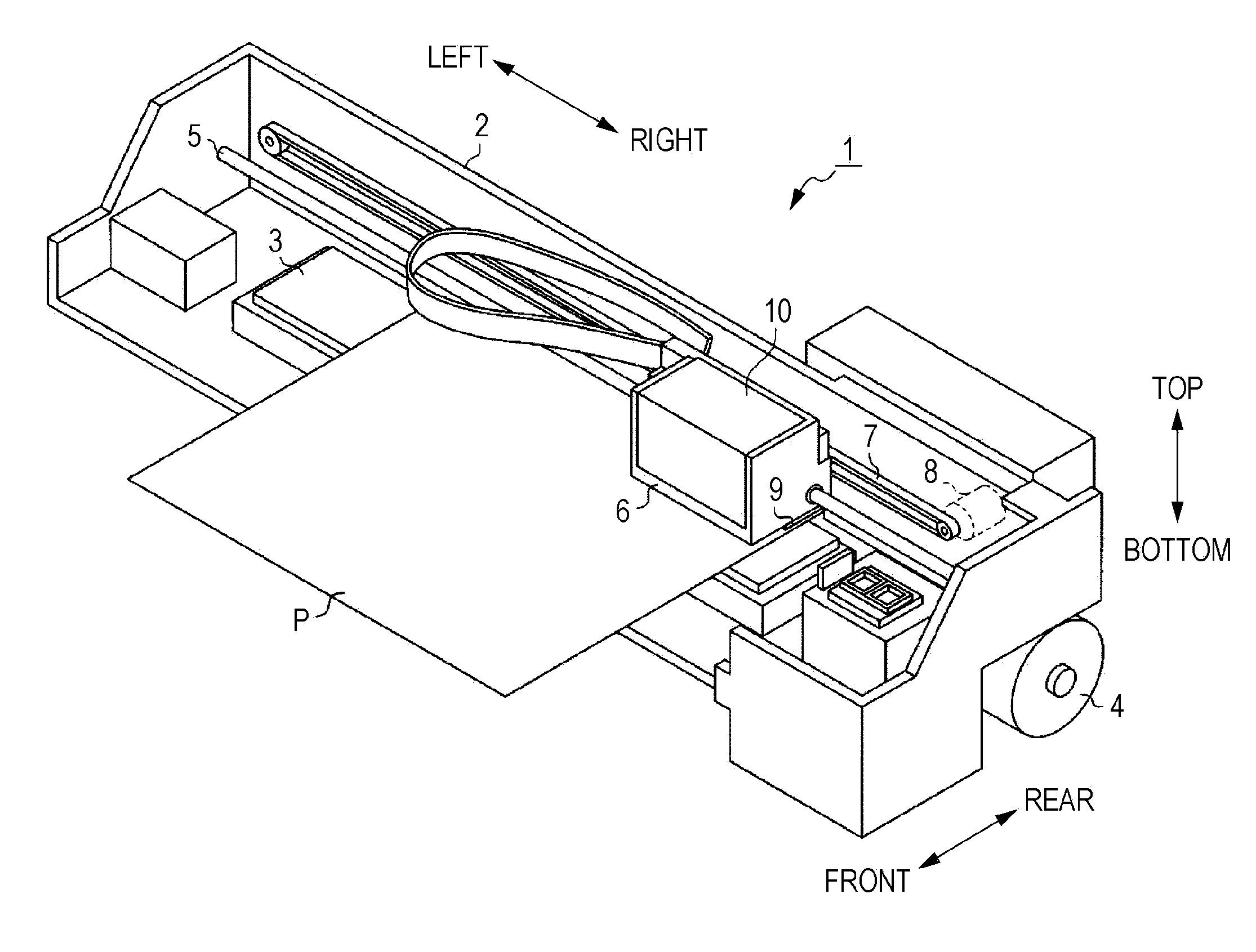

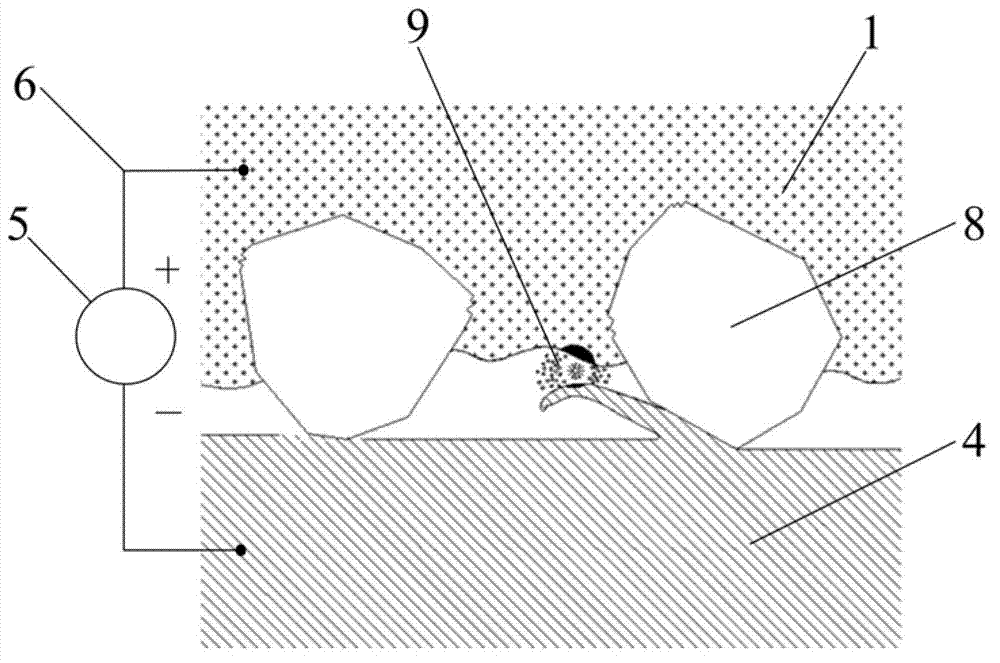

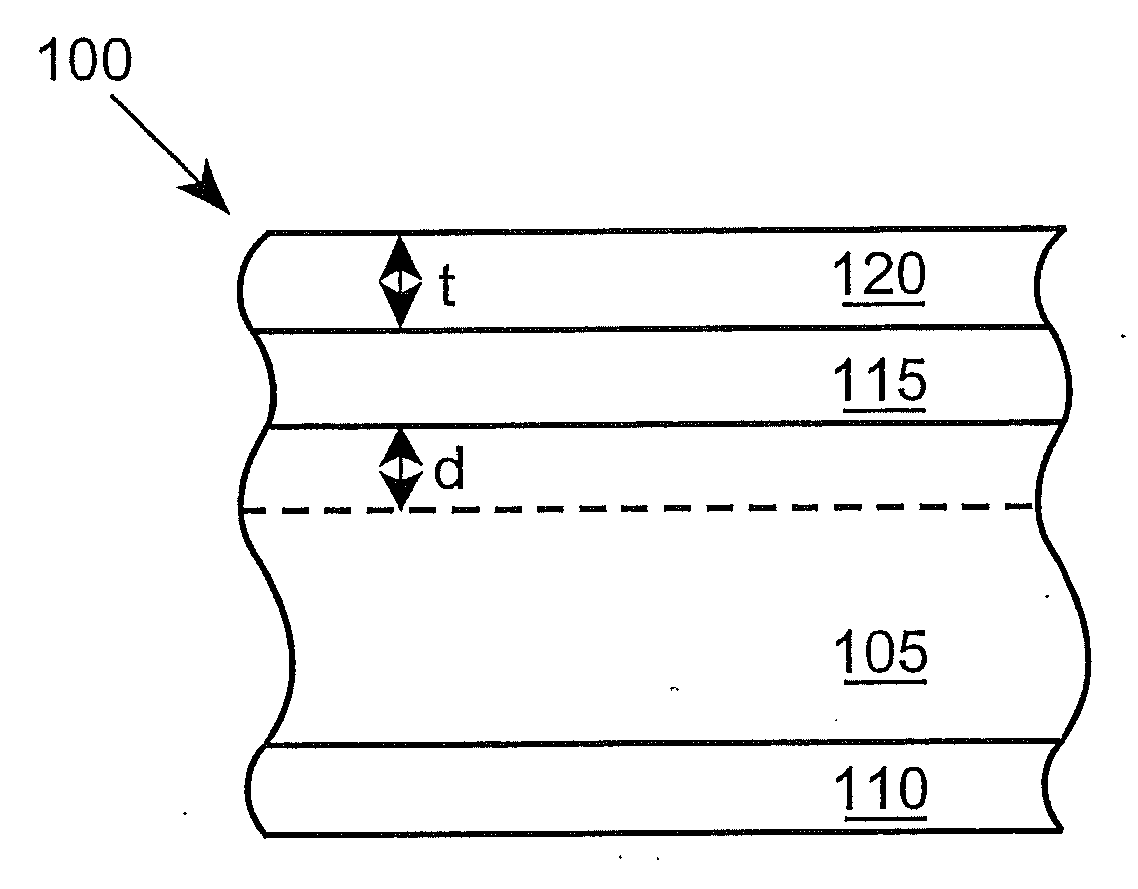

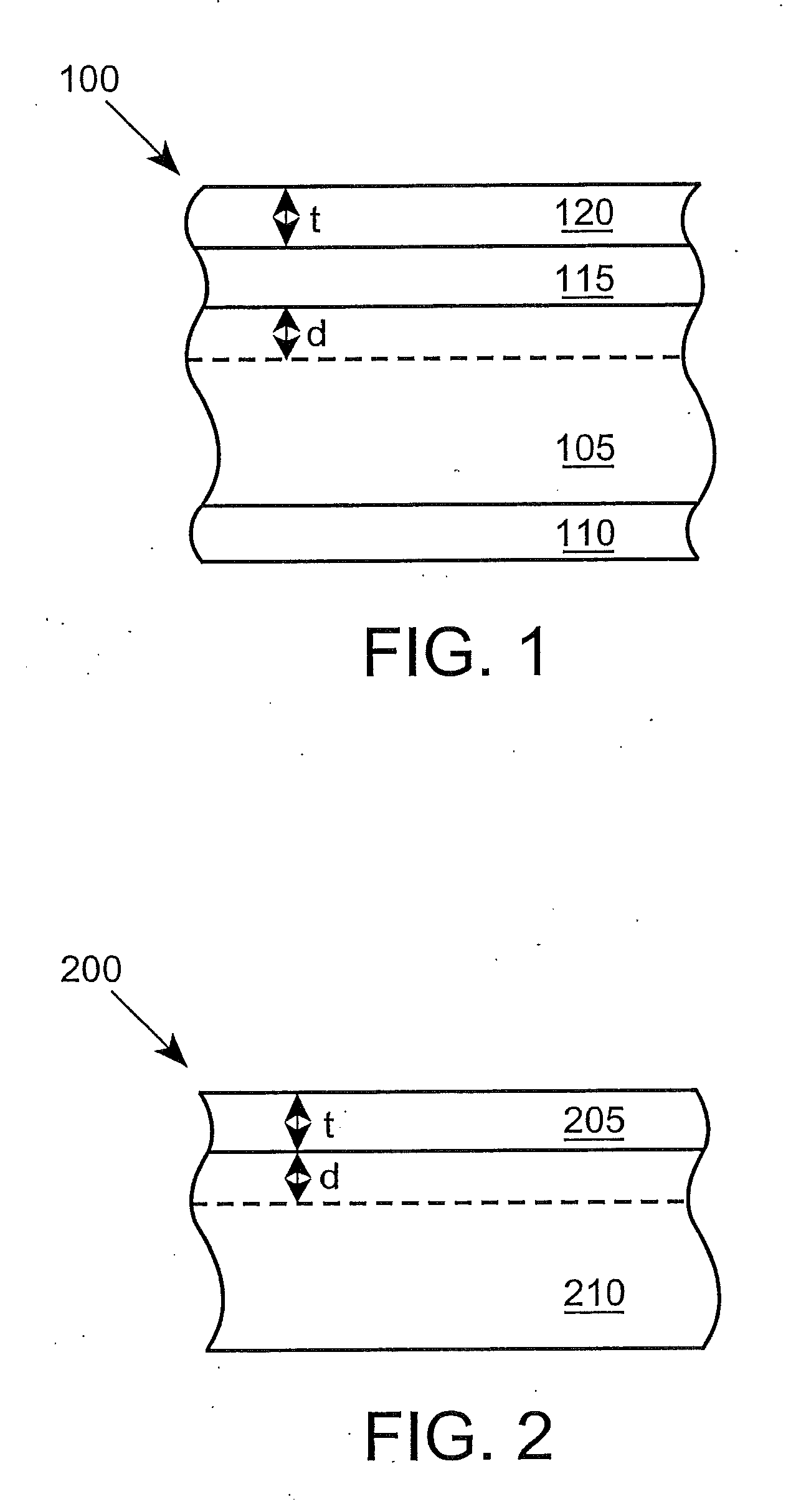

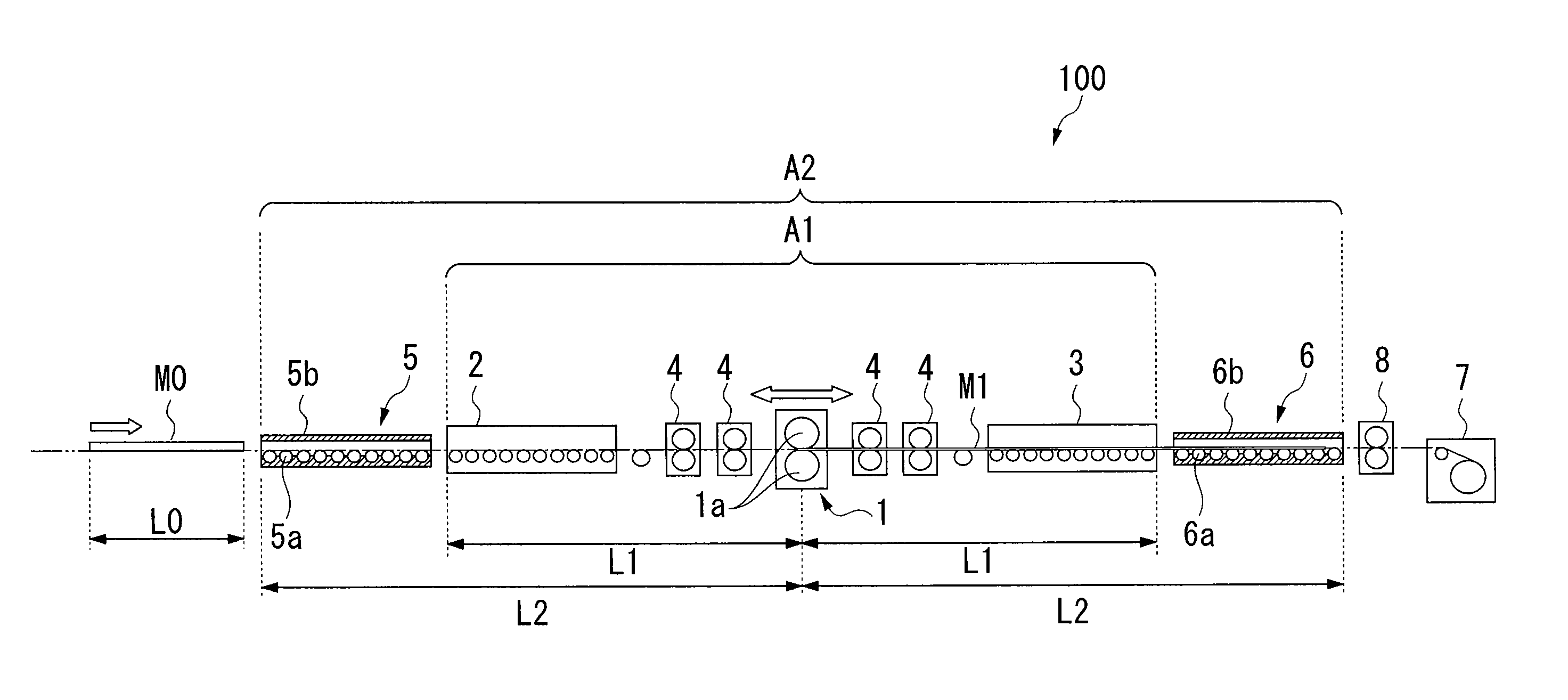

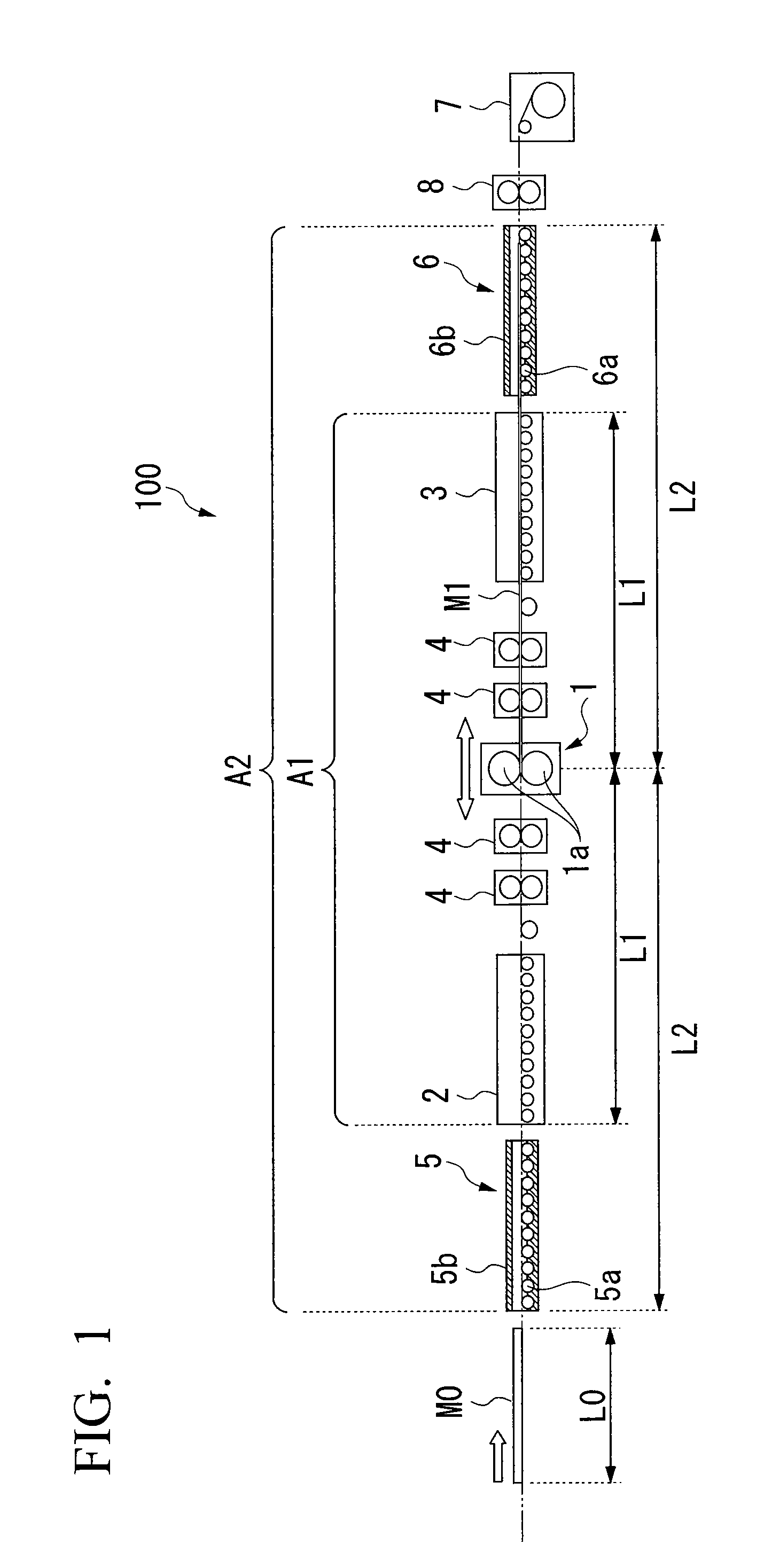

Magnesium hot rolling method and apparatus

InactiveUS20110100083A1Temperature dropSuperior qualityTemperature control deviceRollsHeating furnaceHot rolled

A magnesium alloy hot rolling method includes: a first rolling step in which a magnesium plate (M0, M1) is rolled reciprocatingly between an upstream heating furnace (2) which is located on an upstream side of a rolling mill (1) and which heats the magnesium plate (M0, M1), and a upstream heating furnace (3) which is located on a downstream side of the rolling mill (1) and which heats the magnesium plate (M0, M1); and a second rolling step in which the temperature of respective end portions of the magnesium plate (M0, M1) on both the upstream and downstream sides is maintained while the magnesium plate (M0, M1) is being rolled reciprocatingly between an upstream temperature maintaining apparatus (5) which transports the heated magnesium plate (M0, M1) while maintaining the temperature thereof, and a downstream temperature maintaining apparatus (6) which transports the heated magnesium plate (M0, M1) while maintaining the temperature thereof. According to the magnesium hot rolling apparatus of the present invention and to the magnesium hot rolling method of the present invention which uses this apparatus, it is possible to prevent any deterioration in the quality of a product which is due to temperature variations during the hot rolling of magnesium alloy.

Owner:IHI METALTECH CO LTD +1

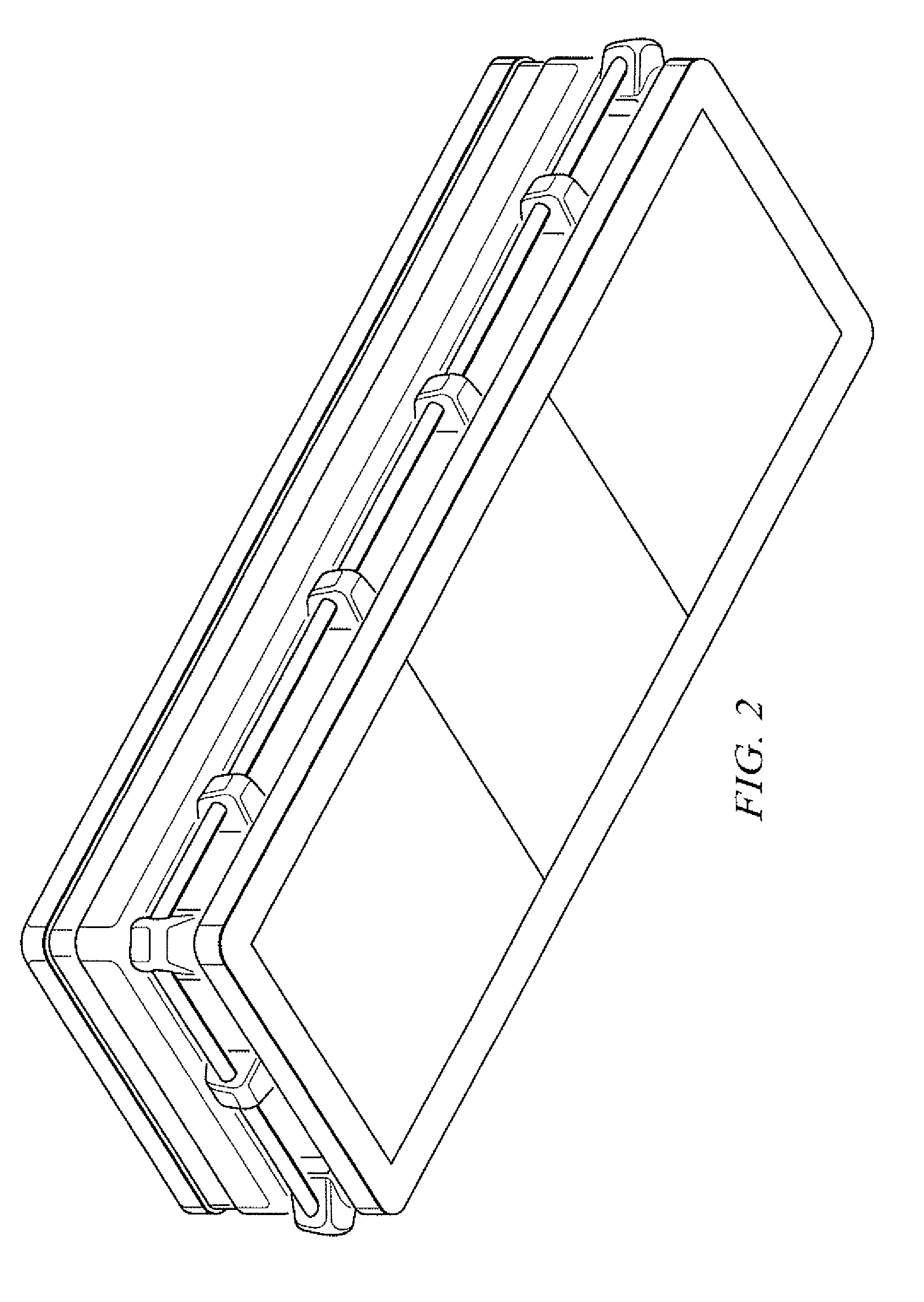

Neckwear for displaying coins, medals or bars

ActiveUS20190000166A1Quality improvementExquisitely detailedSnap fastenersConvertible garmentEngineeringFastener

A neckwear includes a neckband and a neckband module and may further include one or more fastener members and one or more display segments for coins, medals or bars. The neckband is connected to said neckband module, and said one or more fastener members pivotably connects said neckband module and said one or more display segments. Also provided for a neckwear are a hermetically sealed neckband module or display segment, a display segment configured to be intra-changeable, display inserts for a neckband module or display segments, torso segments, and a neckband module with a member of a fastener to accommodate interchangeable display segments.

Owner:PATUGA LLC

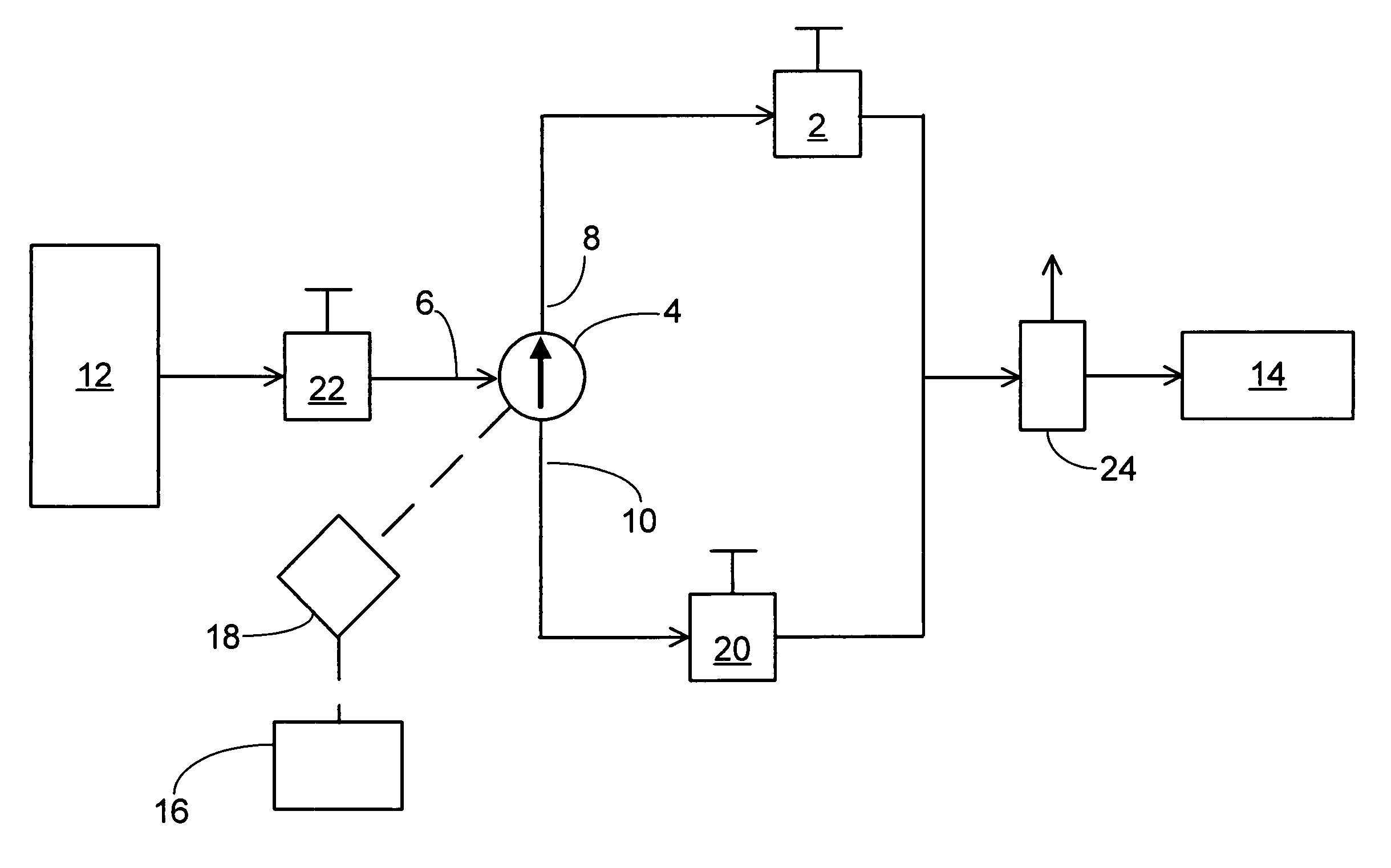

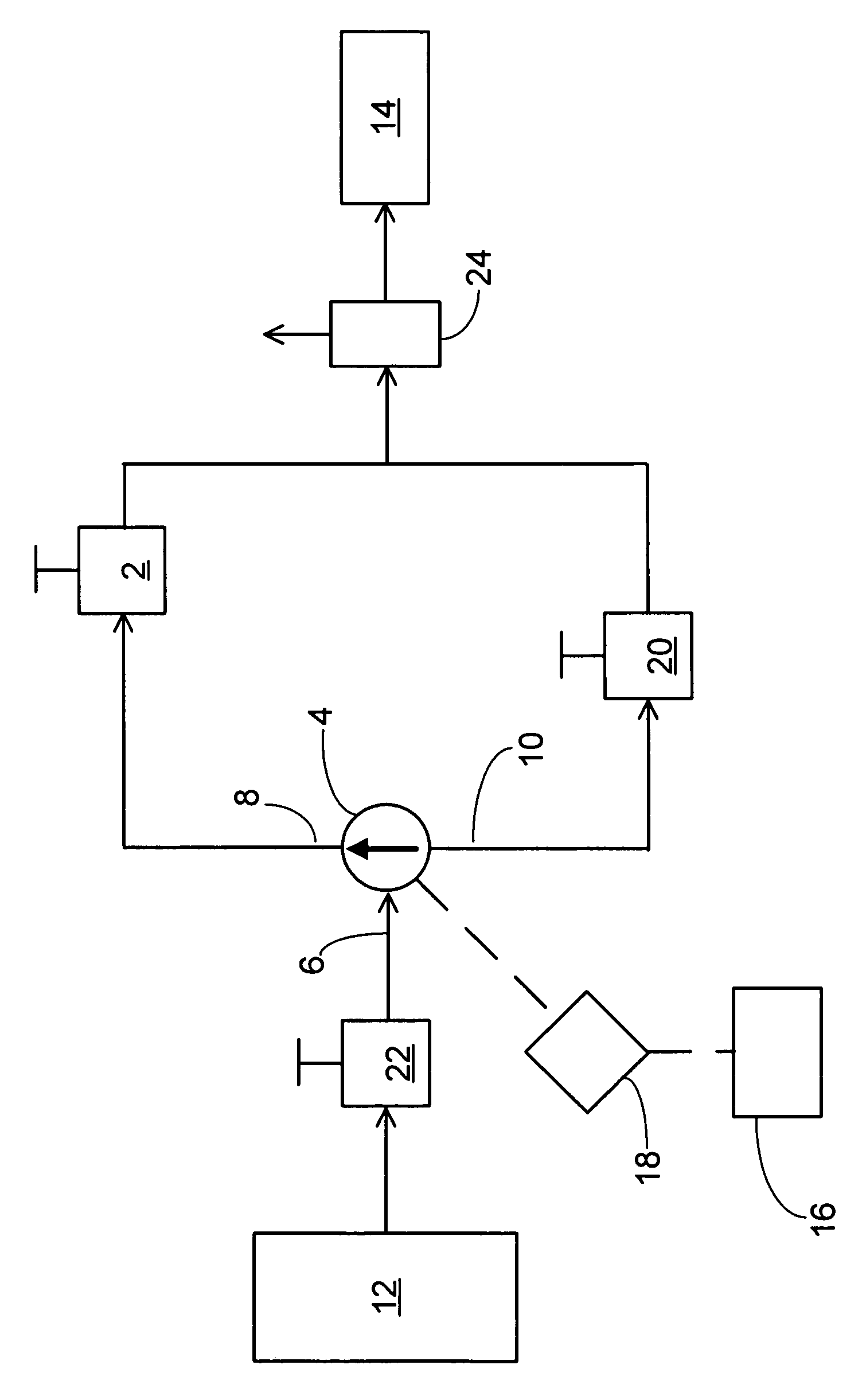

Blow air control system

InactiveUS20060197263A1Quality improvementHigh quality finishHollow articlesBlow moldingControl system

Owner:GRAHAM PACKAGING CO LP

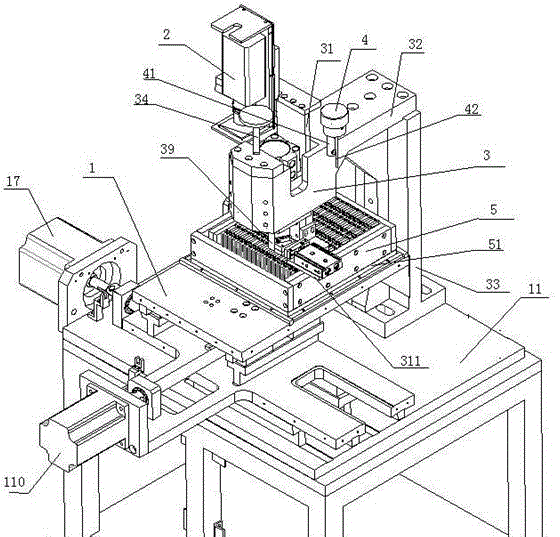

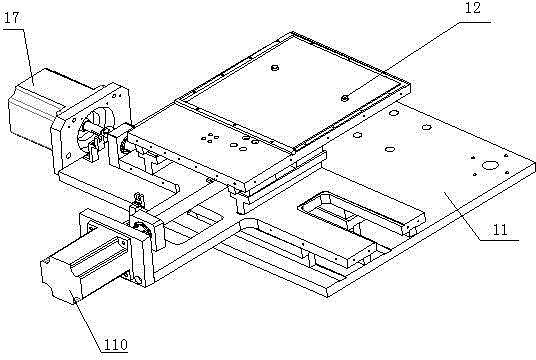

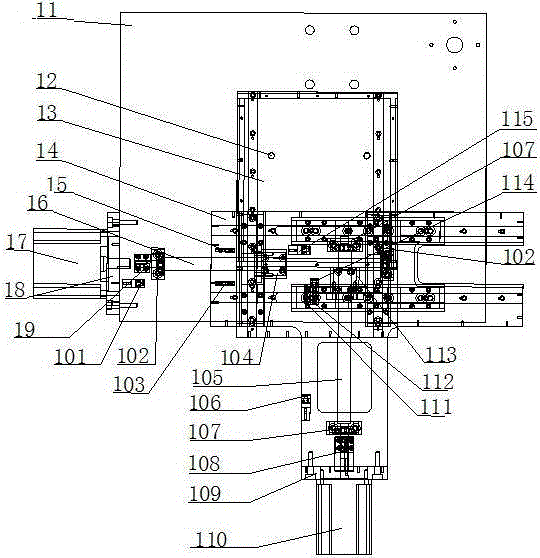

Aluminum shell lithium battery sealing equipment

InactiveCN104577034AAchieve efficiencyAchieve qualityNon-aqueous electrolyte cellsCell component detailsPunchingElectrical battery

The invention discloses aluminum shell lithium battery sealing equipment which consists of an X / Y-axis coordinate platform system, an image taking system, a steel ball sealing system, a steel ball discharge system and a battery assembling system, wherein the X / Y-axis coordinate platform system is fixed with the battery assembling system through positioning pins; the height of a cylinder base inside a steel ball sealing head is adjusted through an adjusting screw rod of the steel ball sealing system, so that a punching needle fixing base can be in the working height of an aluminum shell lithium battery to be sealed; a camera inside the camera system is operated to capture different aluminum shell lithium battery filling holes inside a battery system and calculate coordinates inside the X / Y-axis coordinate platform system, and is used for respectively driving an X plate and a Y plate to move through an X axial motor and a Y axial motor so as to convey (X, Y) coordinates of the aluminum shell lithium battery filling holes below the steel ball sealing system for sealing. The aluminum shell lithium battery sealing equipment has the characteristics that the structure is compact, the arrangement is reasonable, the operation is simple, the machining process is safe, the process control is precise and accurate, the automatic degree is high, the machining production of aluminum shell lithium battery sealing can be continuously, efficiently and excellently completed, and the like.

Owner:JIAN UTILITY TECH CO LTD

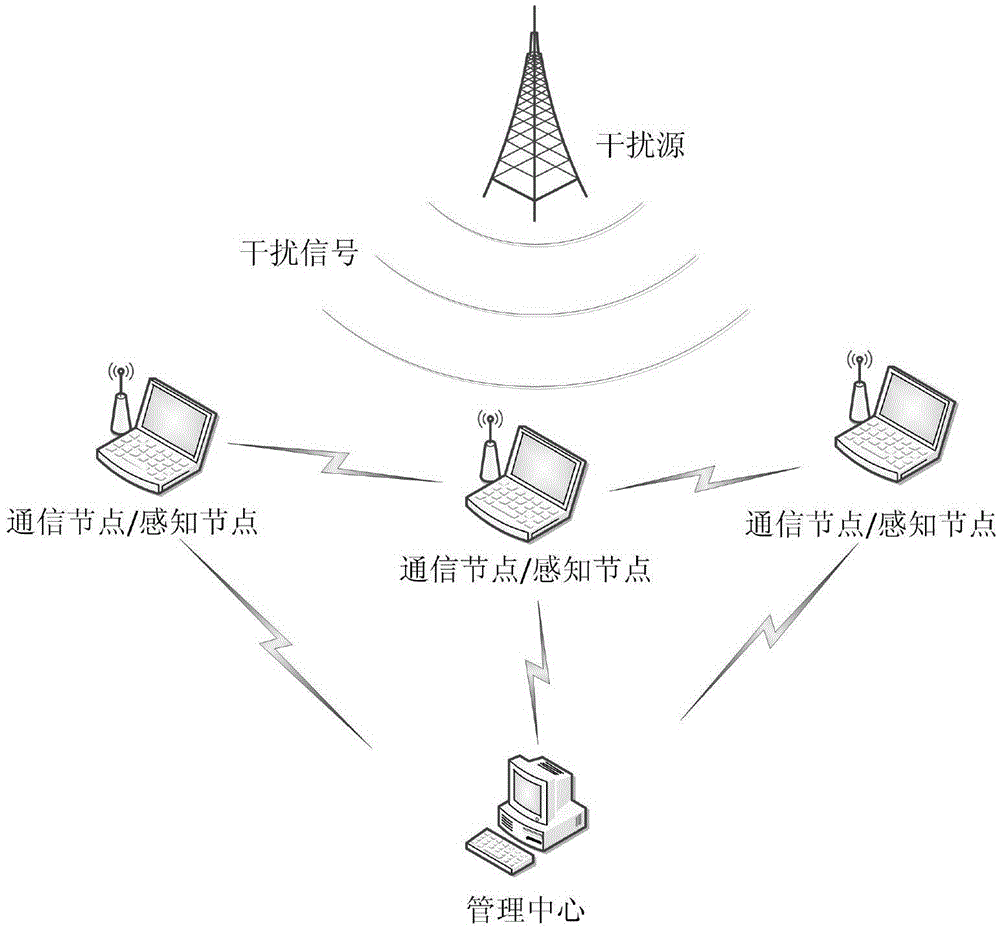

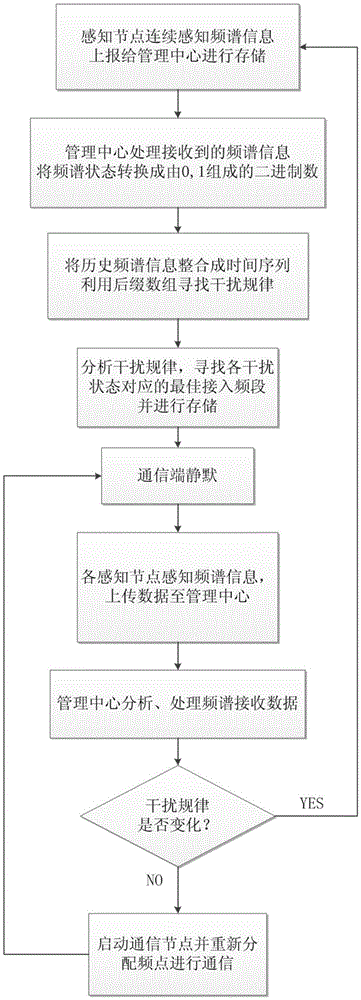

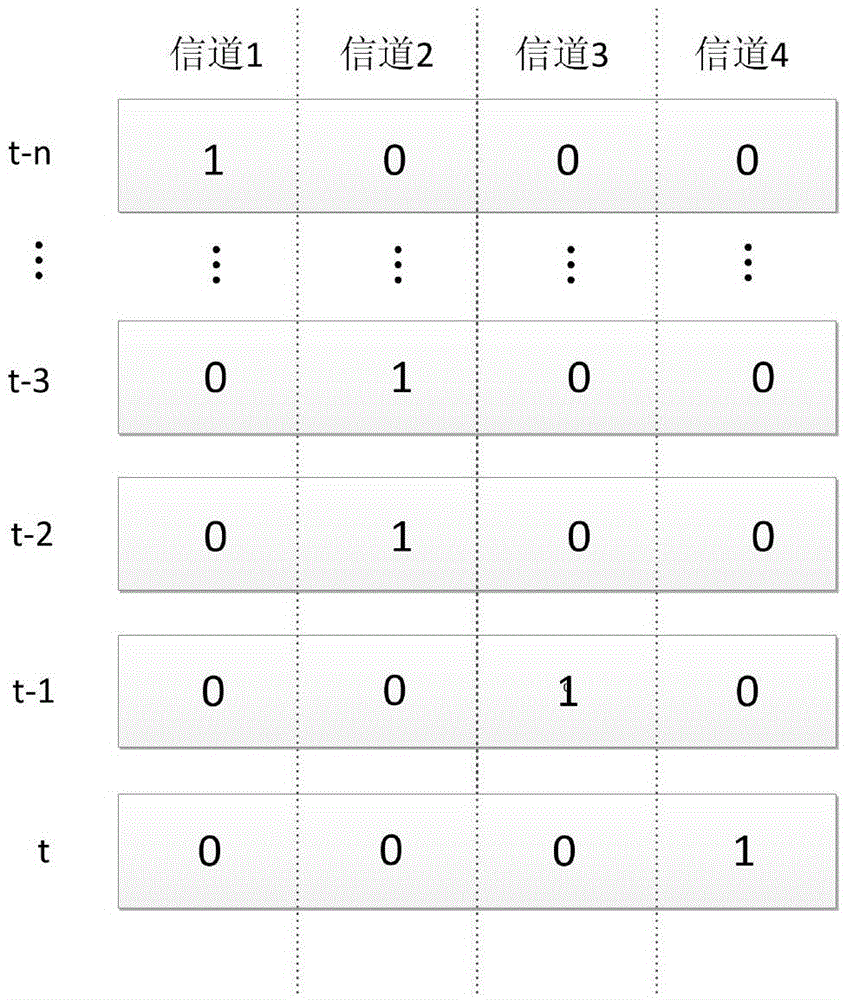

Cognitive radio interference prediction method and system

ActiveCN105491573AHigh quality finishReduce complexityTransmissionNetwork planningFrequency spectrumAccess frequency

The invention relates to a cognitive radio interference prediction method and system. The method comprises: analyzing historical frequency spectrum information and looking for interference patterns; analyzing the interference patterns and finding the optimal access frequency band; and realizing dynamic access of the communication frequency band according to the obtained optimal access frequency band. The system comprises a sensor node, a communication node and a management center. The nodes work in conjunction with each other according to the above cognitive radio interference prediction method. The invention guarantees that proactive frequency spectrum shifting be realized when cognitive users are communicated, thereby preventing confliction with interference.

Owner:SHANGHAI INTERNET OF THINGS

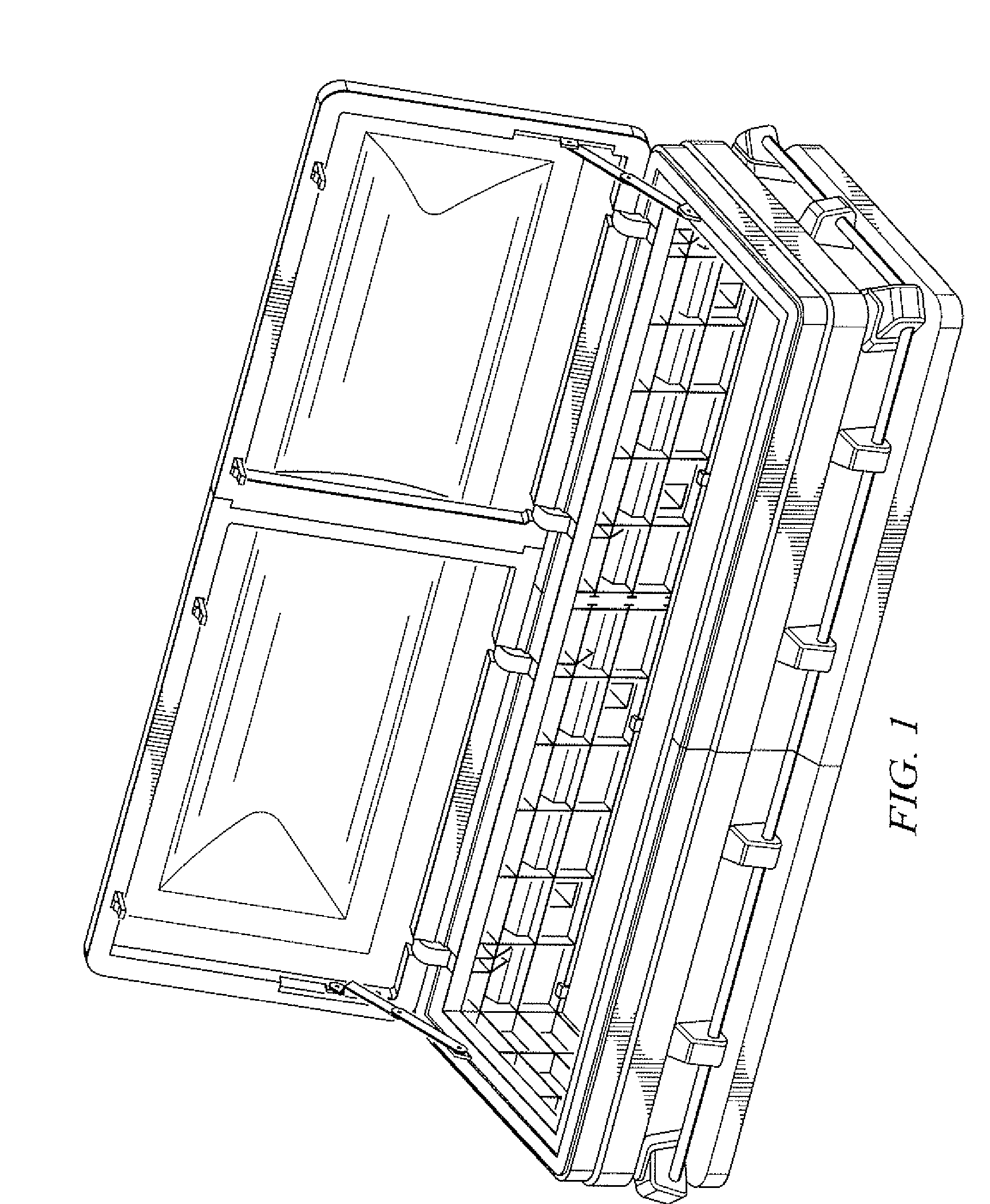

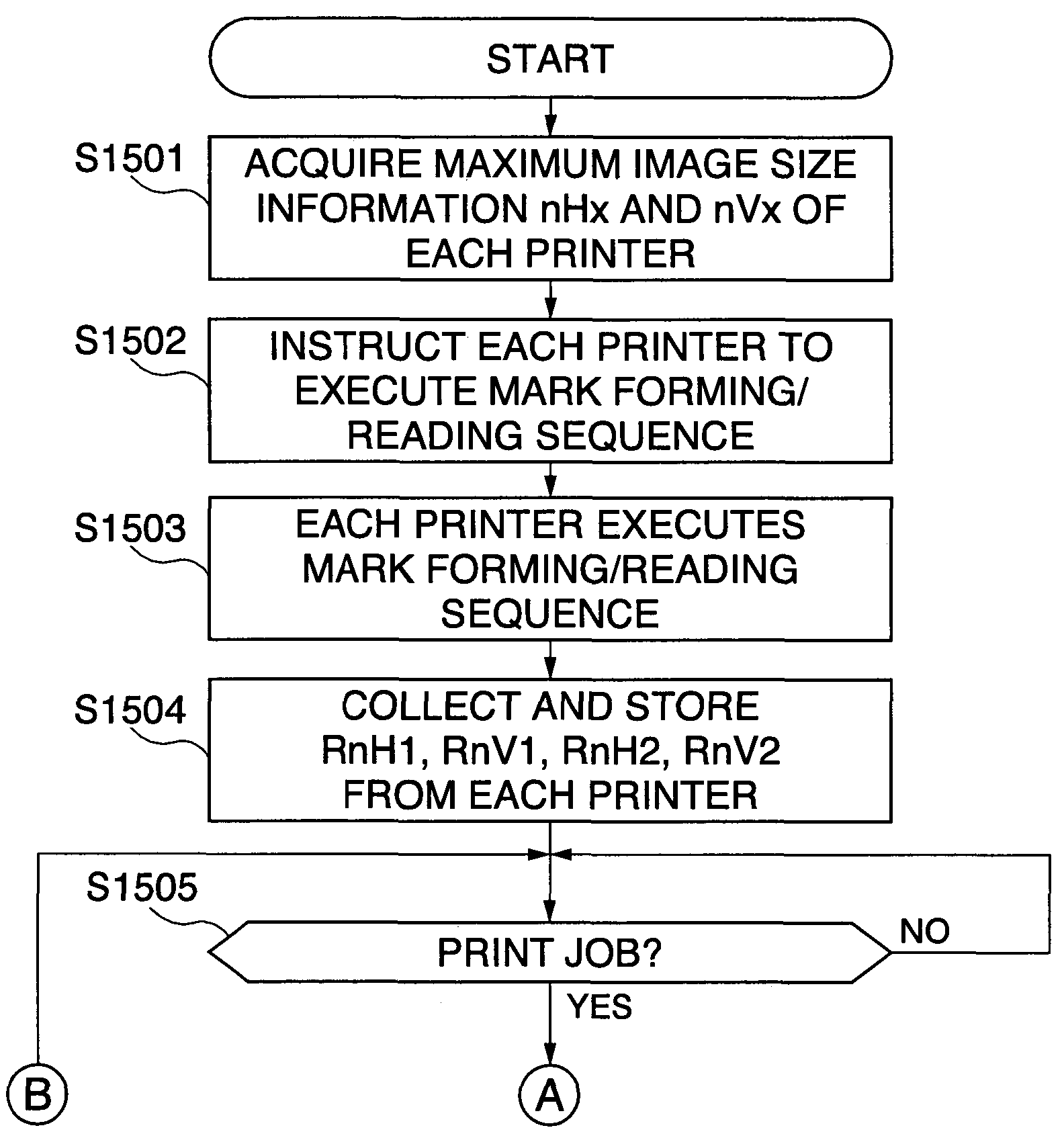

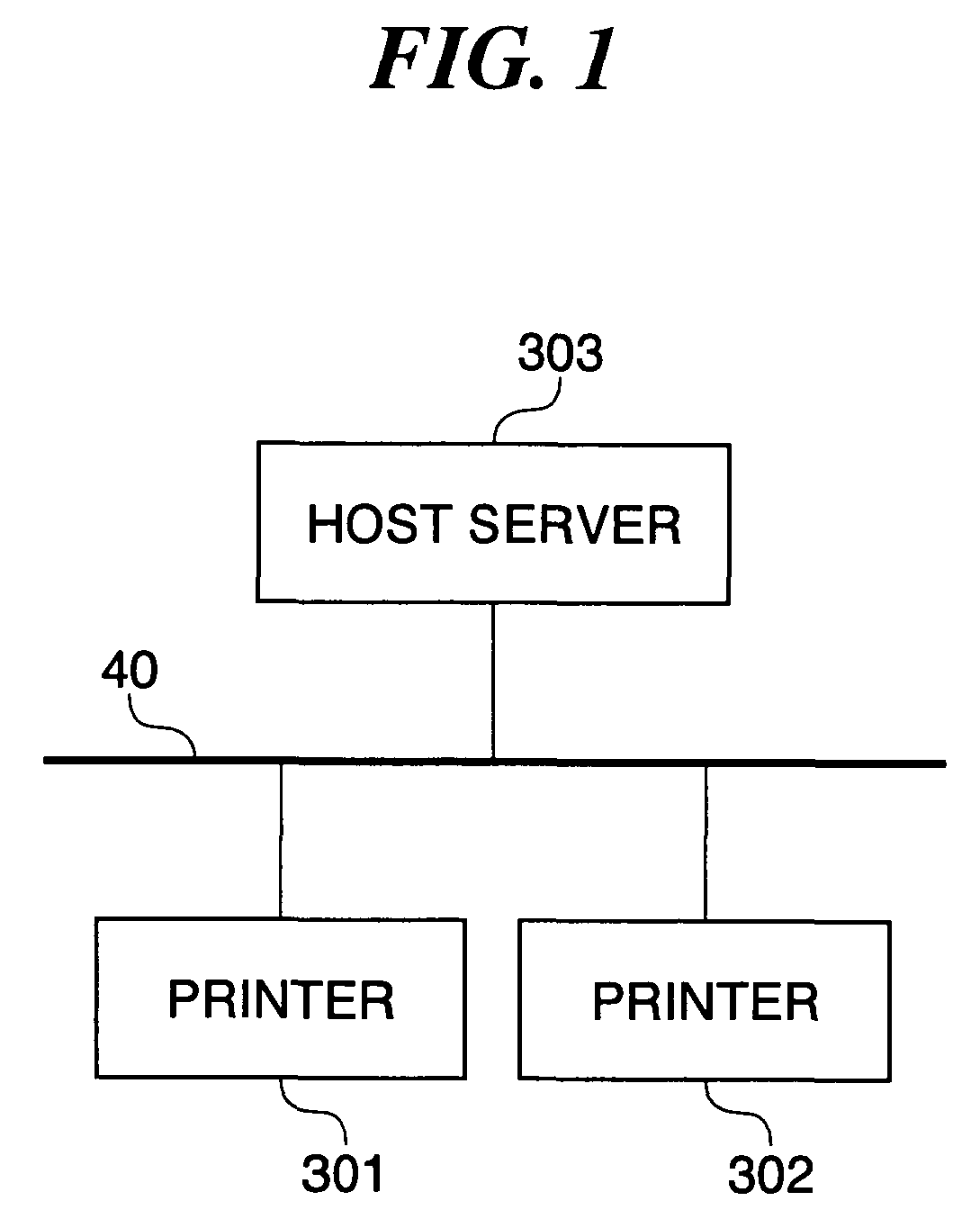

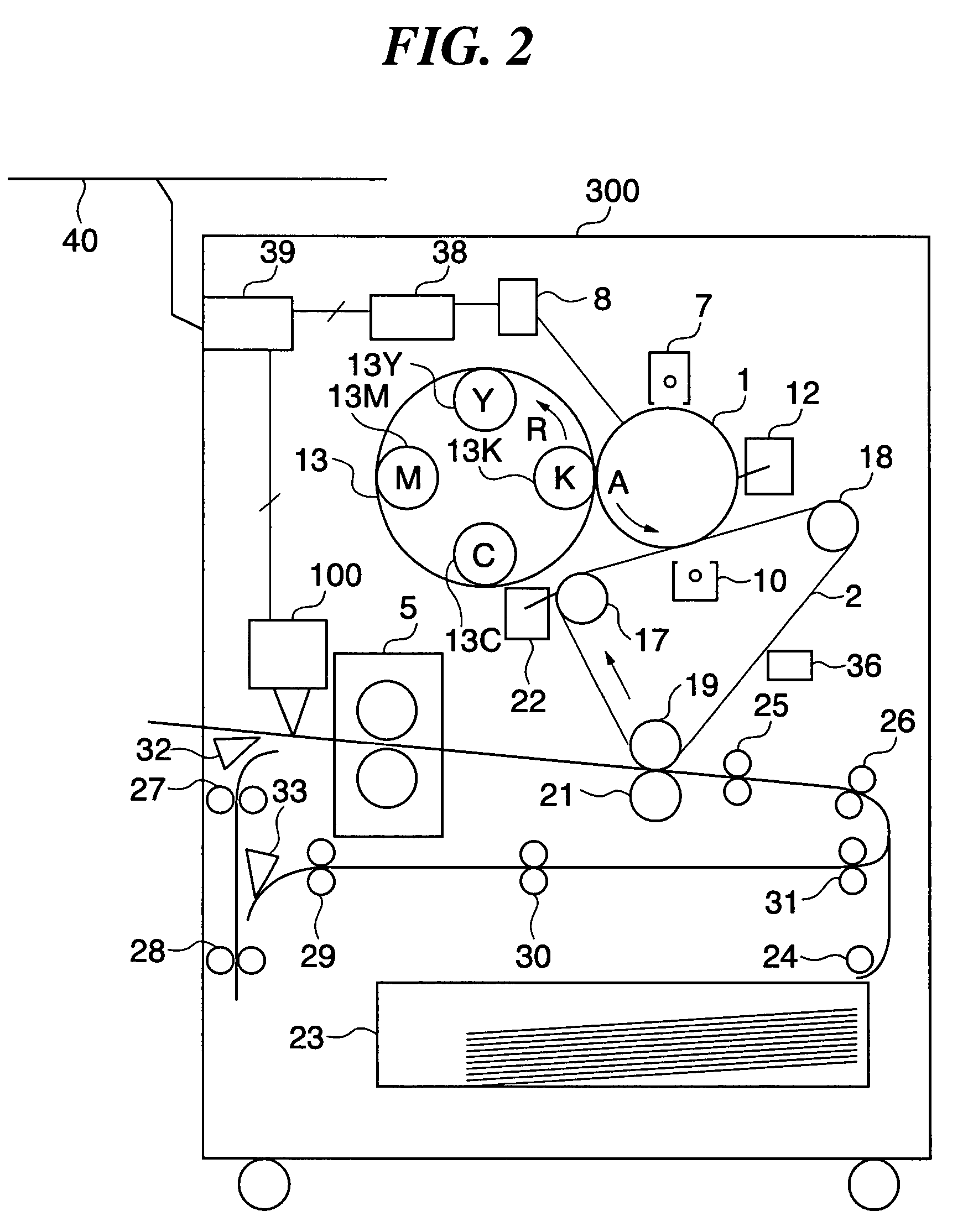

Image forming system, image distribution apparatus, and image forming method

InactiveUS7301677B2Uniform sizeHigh quality finishDigitally marking record carriersVisual presentation using printersData shippingSufficient time

There is provided an image forming system that is capable of making uniform in size printed images, which should originally be the same in size, between transfer sheets on which the images have been printed by a plurality of printers having different functions and capabilities when enough time has elapsed after fixing. In each of the printers, an image controller or the like forms predetermined marks on a transfer material, and a fixing device thermally fixes of the predetermined marks formed on the transfer material, and a mark detecting device or the like detects the predetermined marks. A host server connected to the printers via a network adjusts the sizes of images to be formed by the respective printers according to the predetermined marks detected by the respective printers, and then transfers the image data to the printers. Each of the printers performs image formation based on the transferred image data.

Owner:CANON KK

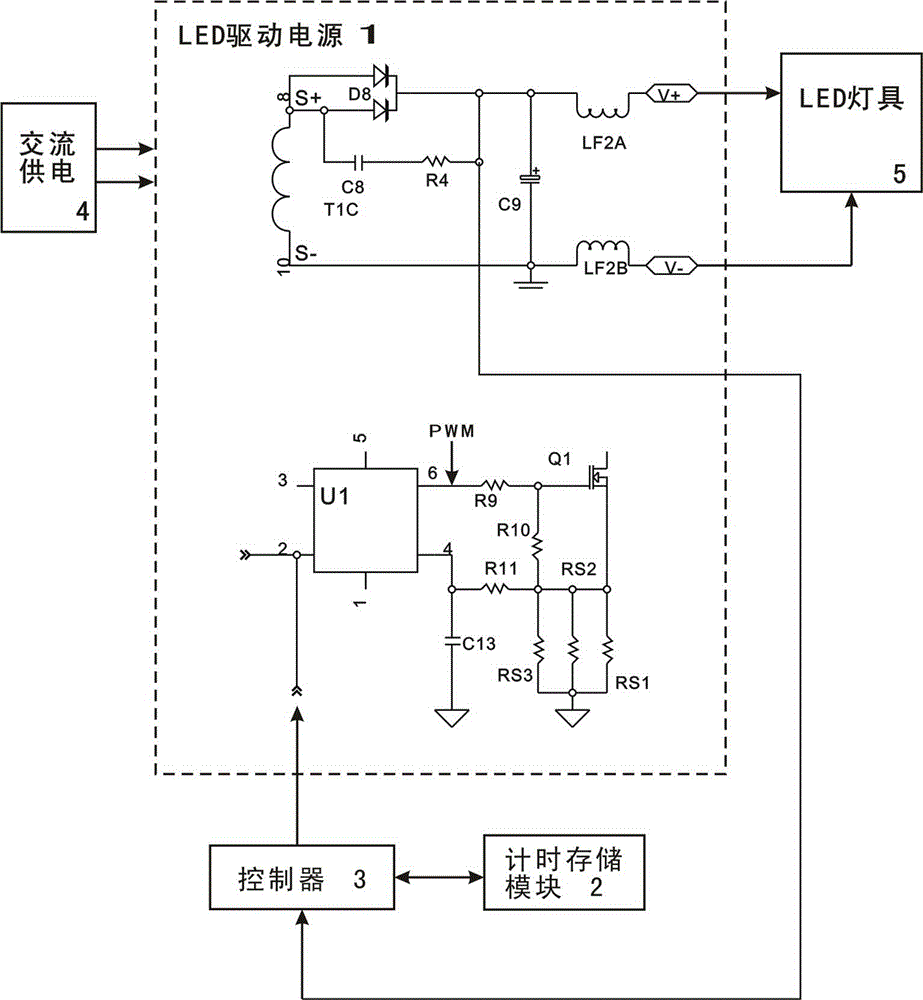

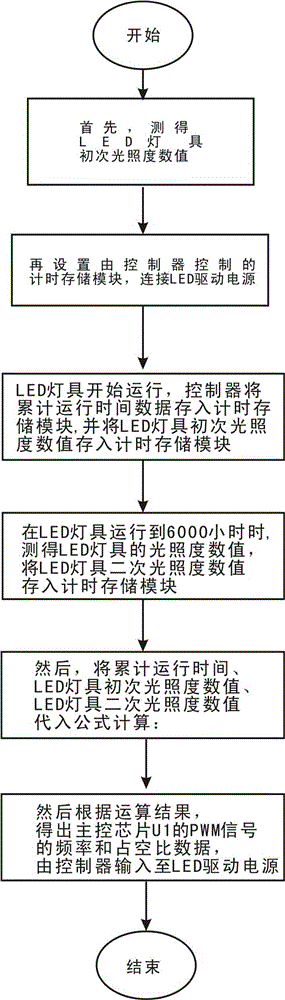

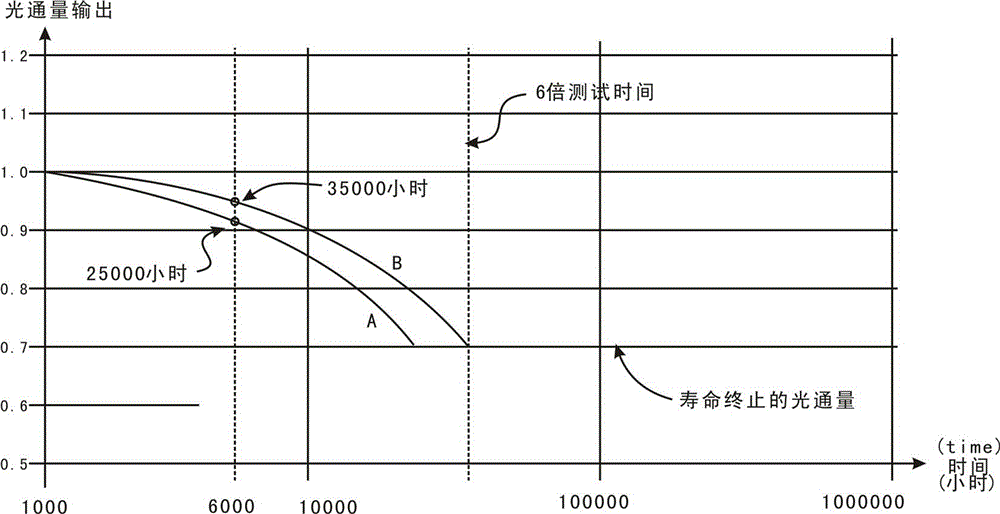

Method for stabilizing luminous attenuation in lighting life period of LED lamp

InactiveCN104619096AThe output luminous flux is constantLow costElectric light circuit arrangementEnergy saving control techniquesUltrasound attenuationIlluminance

The invention discloses a method for stabilizing luminous attenuation in a lighting life period of an LED lamp. The method comprises the steps of measuring a preliminary illuminance value of the LED lamp; then arranging a timing storage module which is controlled by a controller and is connected with an LED driving power supply; storing accumulated operation time data into the timing storage module; storing the preliminary illuminance value of the LED lamp into the timing storage module; at preset time, storing a measured secondary illuminance value into the timing storage module; then substituting all pieces of data into a formula to obtain frequency and duty ratio data of a PWM signal of a main control chip, and inputting the data into the LED driving power supply by the controller. According to the method, the controller and the timing storage module which are low in cost are additionally arranged in the LED driving power supply, so that the cost increase is extremely low; however, the output luminous flux of the lamp is constant in the life period of the LED lamp. Therefore, a standard lighting environment is provided for a user, and the user can finish work in a high quality manner.

Owner:DONGGUAN SHILONG FUHUA ELECTRONICS

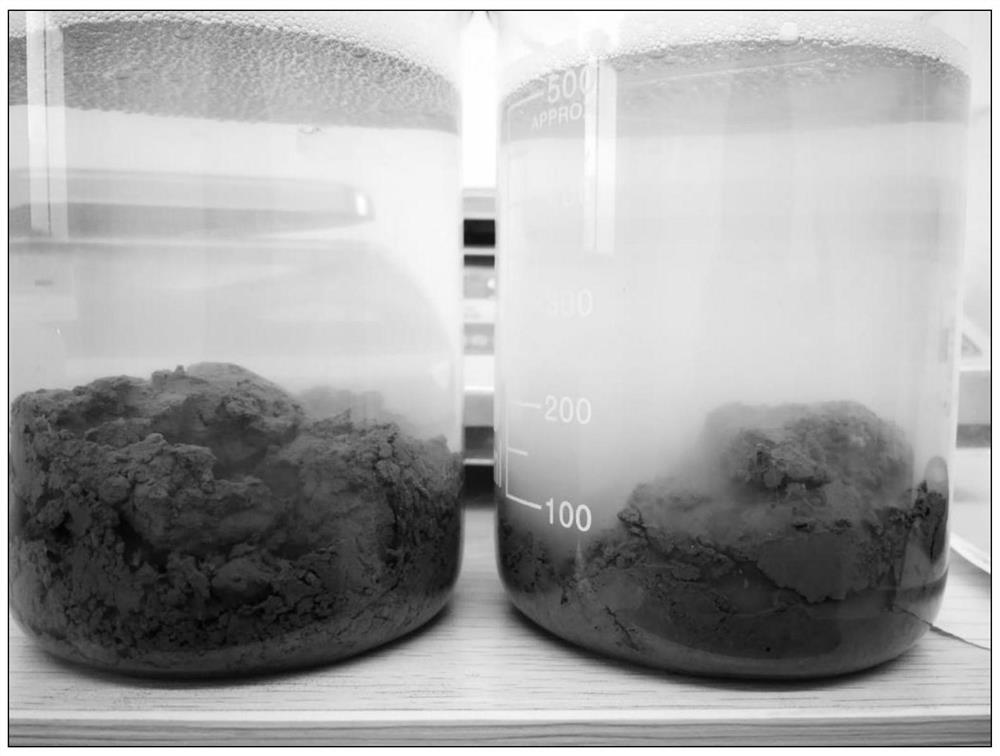

High-molecular water-soluble polymer residue soil dispersing agent

ActiveCN112029563ADissolve electrostatic adsorption binding forceReduce viscosityTunnelsLubricant compositionPolyethylene glycolPyrrolidinones

The invention discloses a high-molecular water-soluble polymer residue soil dispersing agent, which is composed of the following components in percentage by mass: 18%-24% of sodium polyacrylate, 4% ofpolyethylene glycol, 3% of fatty acid polyethylene glycol ester, 5-6% of fatty alcohol polyoxyethylene ether, 5-6% of N-methylpyrrolidone and 57-65% of water. The anionic dispersing agent composed ofsodium polyacrylate and an auxiliary agent thereof is designed according to the chemical principle of mud cake formation of residual soil, the electrostatic adsorption binding force of soil aggregation is decomposed, the viscosity of soil is reduced, the dispersion effect is achieved, the problem of 'mud cake formation' in a cutterhead of a shield tunneling machine is effectively prevented and solved, the use process is simple, the dispersing effect is good, the construction pressure of the shield tunneling machine is greatly relieved, and the construction efficiency and safety are improved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

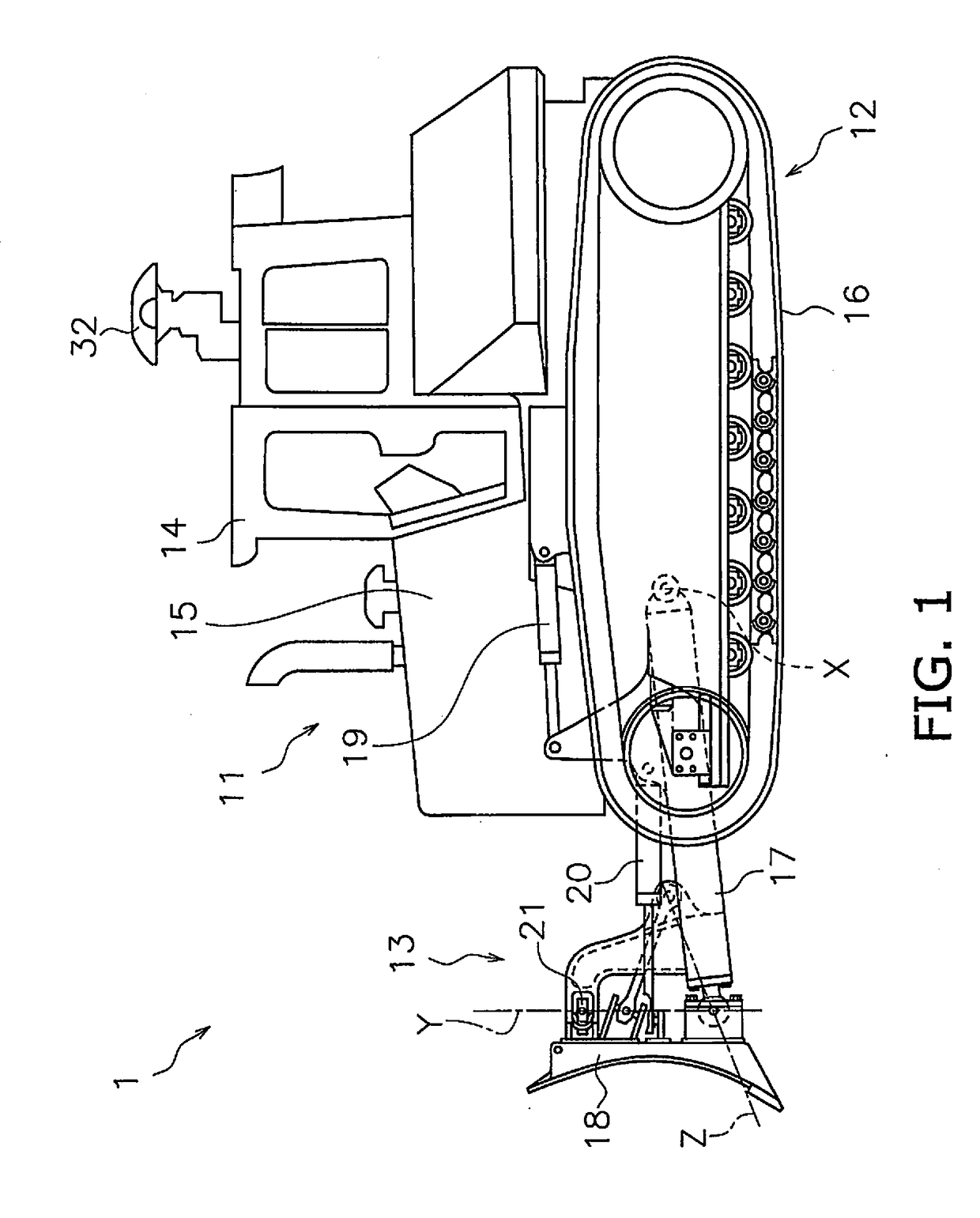

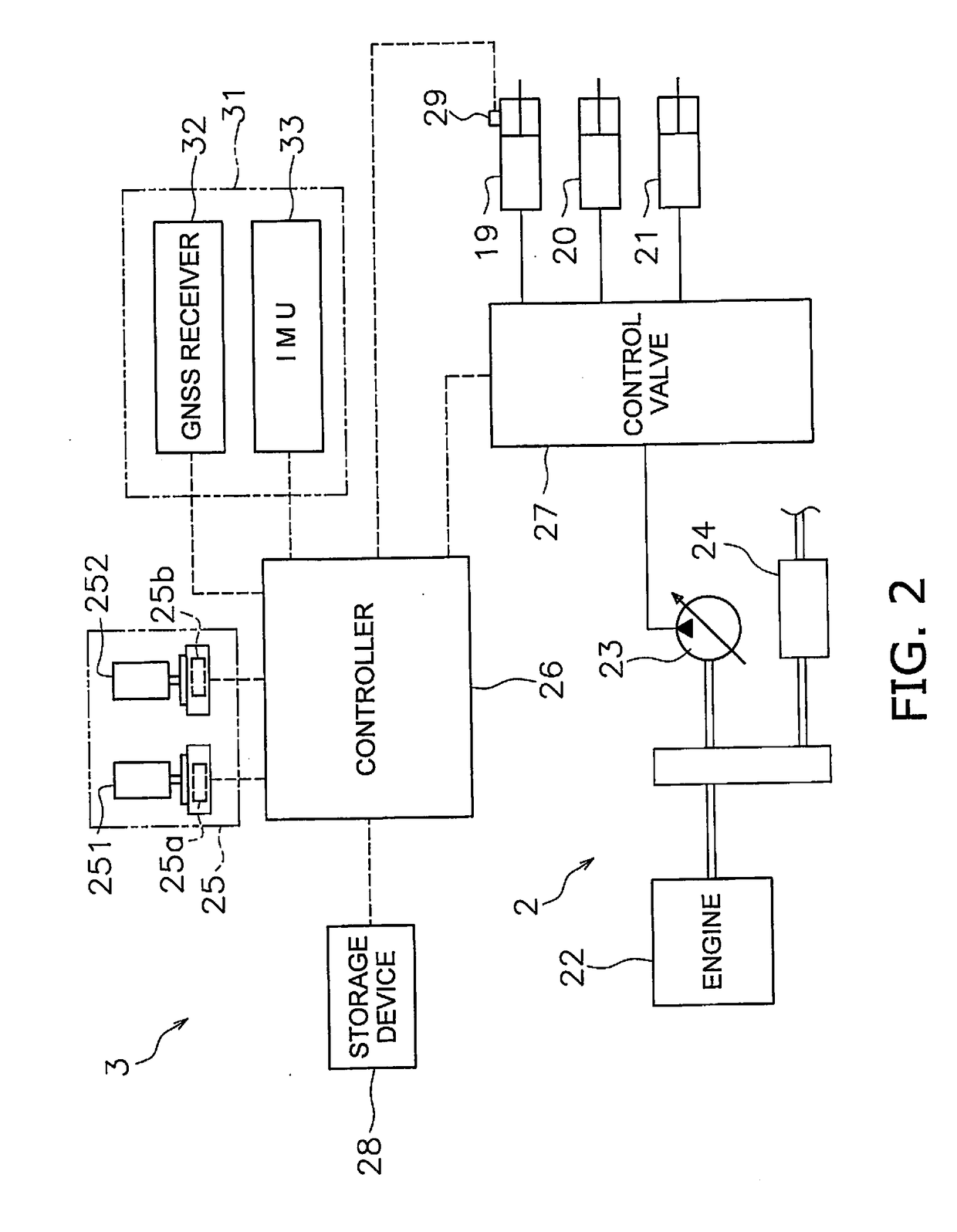

System for controlling work vehicle, method for controlling work vehicle, and work vehicle

ActiveUS20190071846A1Process stabilityAvoid swingingMechanical machines/dredgersPosition/course control in two dimensionsManufacturing engineeringEngineering

A controller calculates a virtual design surface including a first design surface extending from an excavation start position in a traveling direction of a work vehicle and a second design surface further extending from the first design surface in the traveling direction. The controller generates a command signal that causes the work implement to move along the virtual design surface. The controller changes a position of the first design surface so that the first design surface extends along the current landscape or is located below the current landscape when the first design surface is located above the current landscape.

Owner:KOMATSU LTD

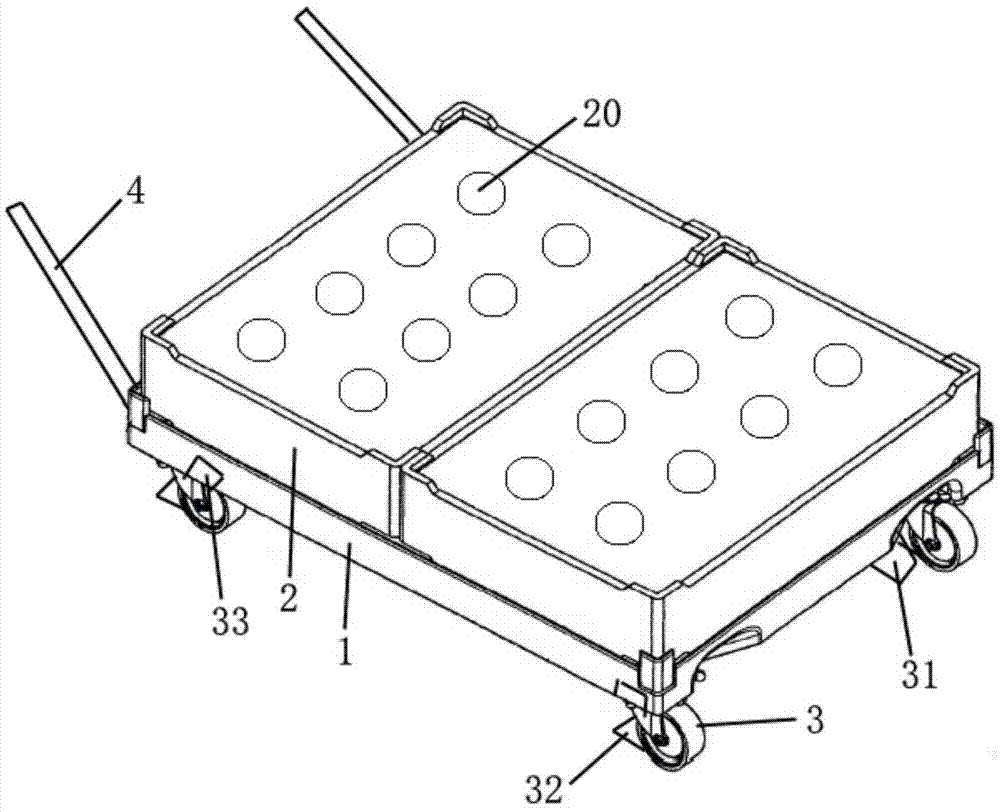

Universal wheel transport cart mechanism

InactiveCN104742946AHigh quality finishComplete efficientlyHand carts with multiple axesWork taskEngineering

The invention discloses a universal wheel transport cart mechanism which comprises a mechanism body. A containing device is arranged on the upper end face of the mechanism body, a plurality of containing holes are formed in the containing device, and universal wheels are arranged at the four corners of the bottom of the mechanism body. The universal wheels are provided with accelerating devices, and the universal wheels are further provided with foot clamping devices. The universal wheel transport cart mechanism is reasonable in structural design, the structure is firm and simple, safety and reliability are achieved, the universal wheel transport cart mechanism is suitable for different environments for use, transported goods can be moved flexibly, the operating precision is improved, the cost is lowered, safe and risk-free transportation of transported containers of different sizes or dimensions is achieved, work tasks can be efficiently completed in shortest time in a high quality mode, the working efficiency is improved, and the application prospect is good.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

Manufacturing and mounting methods of energy-saving Maerz lime kiln housing

ActiveCN107954614AAvoids the problem of requiring extensive lengthening of welding handlebar wiresHigh quality finishLime kilnArchitectural engineering

A mounting method of an energy-saving Maerz lime kiln housing is characterized by comprising: (1) prefabricating 48 paired positioners, wherein each paired positioner is a non-equilateral steel angle100 mm in length, and a bolt hole 20 mm in diameter is drilled in a position 33 mm away from an end of the long side of the steel angle; (2) welding short sides of the prefabricated paired positionersto a prefabricating platform, and mounting bolts 20 mm in diameter into the bolt holes; (3) pre-assembling a cone; (4) pre-assembling a straight barrel. The mounting method of the invention has the advantages that the construction cost is low and construction quality is easy to control; the mounting method has good construction safety and reliability. Compared with other kiln construction techniques, the method of the invention has the advantages that small space is used, construction machinery selection is flexible, and the size of a kiln body is easy to precisely control.

Owner:CHINA CHEM ENG SECOND CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com