Mobile assembling gantry crane

A gantry crane and assembled technology, which is applied in the direction of hoisting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems that affect the progress of the project, the safety cannot be guaranteed, and the power failure time is long, so as to achieve the reliability of enhanced power supply performance, improve safe and stable operation, and reduce power outage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

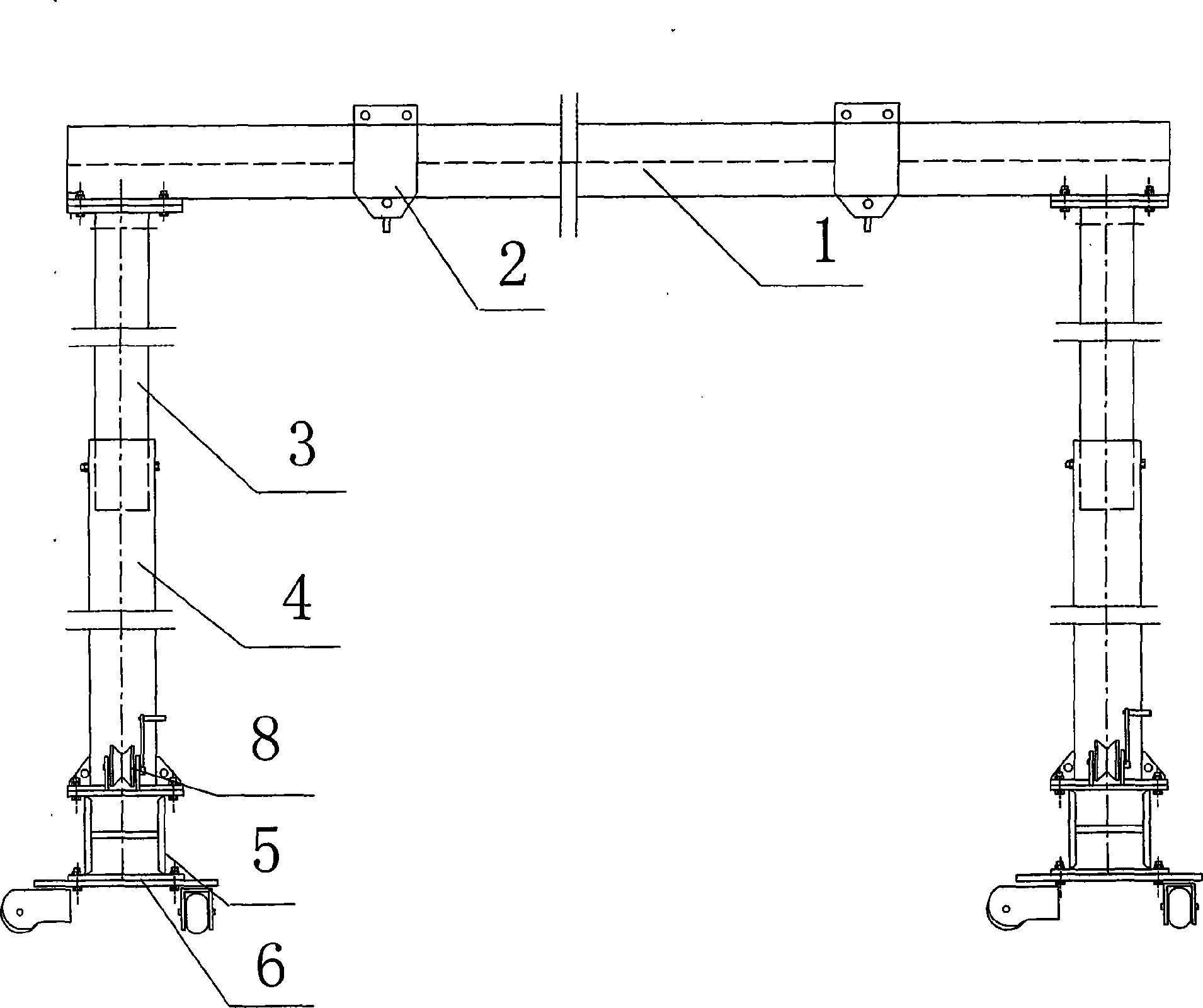

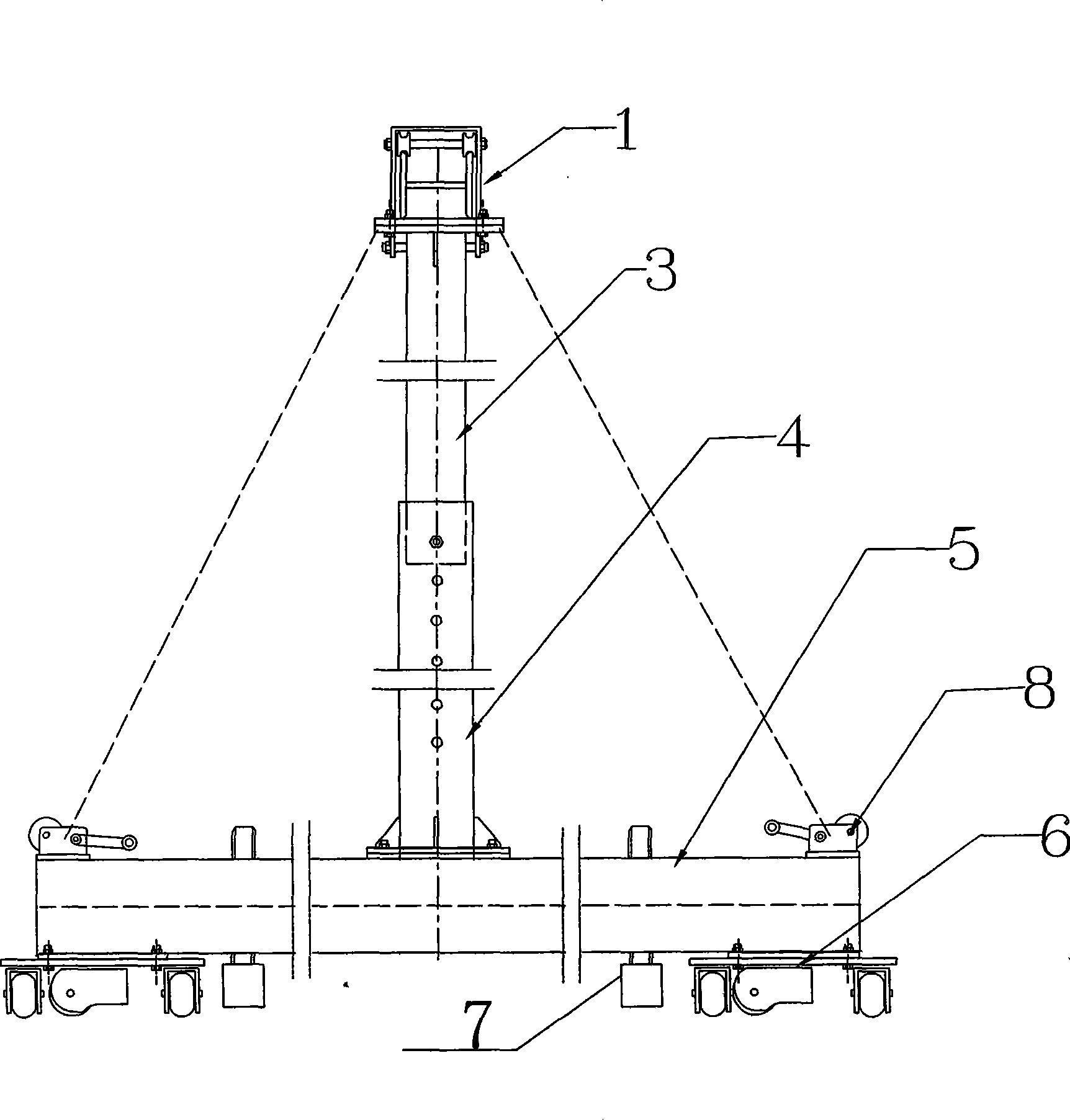

[0024] The specific embodiment: below in conjunction with accompanying drawing, the best embodiment of the present invention is described in detail:

Embodiment

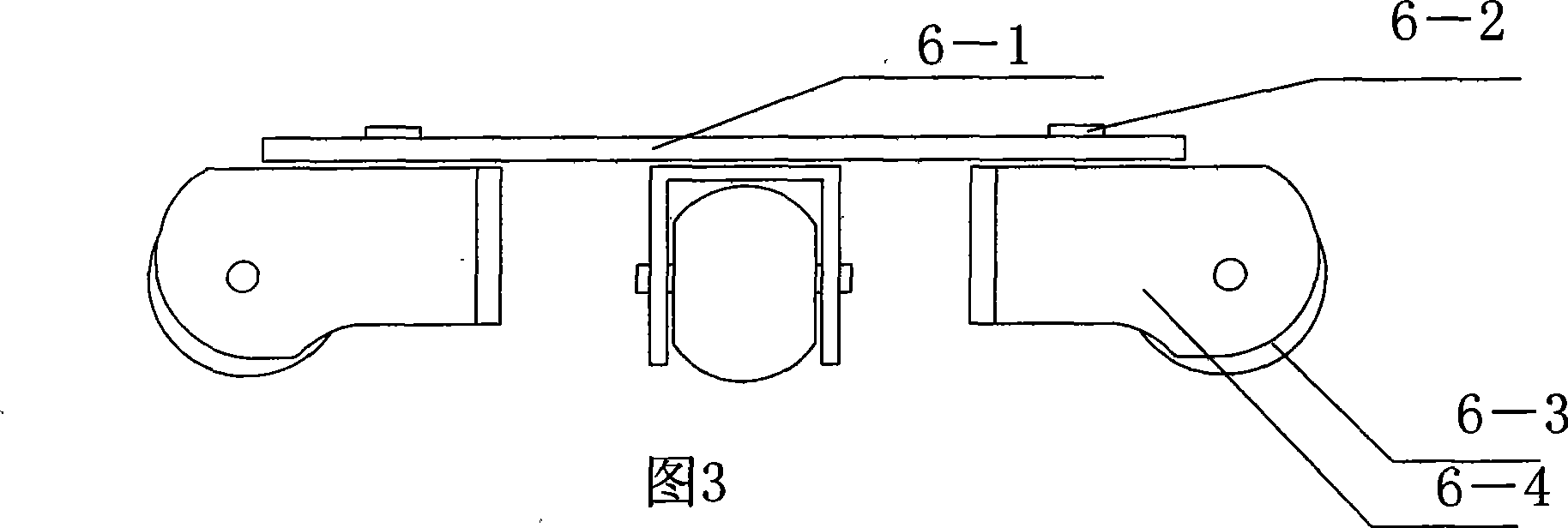

[0025] Embodiment: mobile assembled gantry crane (see figure 1 , figure 2 ), it has two base crossbeams 5, and two base crossbeams 5 are fixed four universal combination wheels 6 with bolts, each universal combination wheels 6 (referring to Fig. 3, Figure 4 ) has a tray 6-1, the tray 6-1 is processed with 20mm steel plate, the tray 6-1 is triangular, the three corners of the tray 6-1 are connected with three universal wheels through the bearing assembly 6-2, the universal The direction wheel is composed of a fixed frame 6-4 and a transport wheel 6-3 connected in the fixed frame 6-4; the distance between the shafts of the three bearing assemblies 6-2 is 320mm, and the diameter of the transport wheel 6-3 is 90mm , the width is 70mm. The pallet 6-1 is provided with four fixing holes 6-5, and the universal combination wheel 6 is fixed under the base beam 5 by bolts through the four fixing holes 6-5. The middle part of each base crossbeam 5 is all fixed with lower pillar 4 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com