Hydraulic system for self-propelled tomato harvester

A hydraulic system and harvester technology, applied in the field of hydraulic systems, can solve the problems that growers are difficult to buy by themselves, harvesters cannot fully adapt to tomato varieties in Xinjiang, planting mode usage conditions, hindering the promotion of tomato mechanized harvesting, etc., to achieve reliable performance, The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

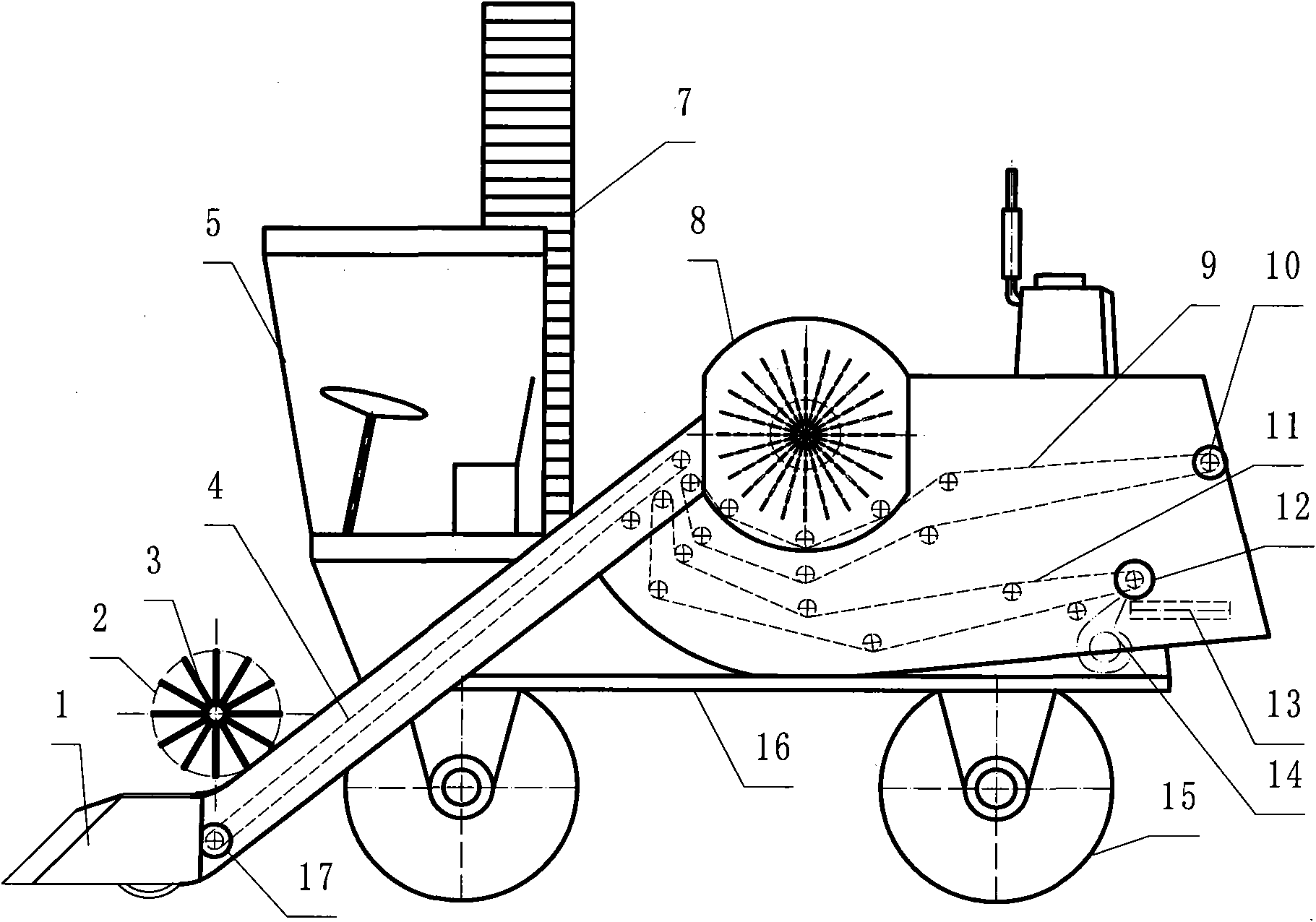

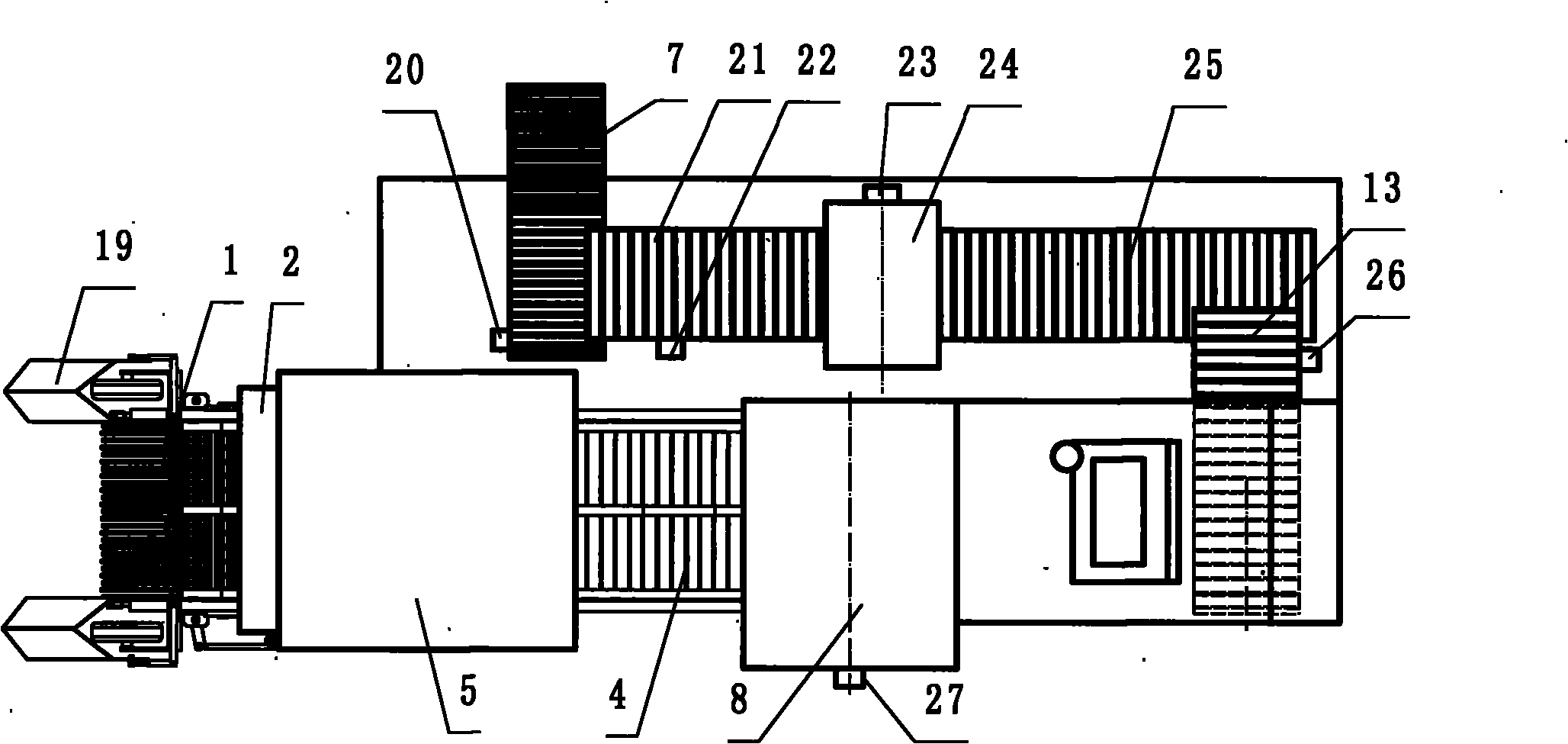

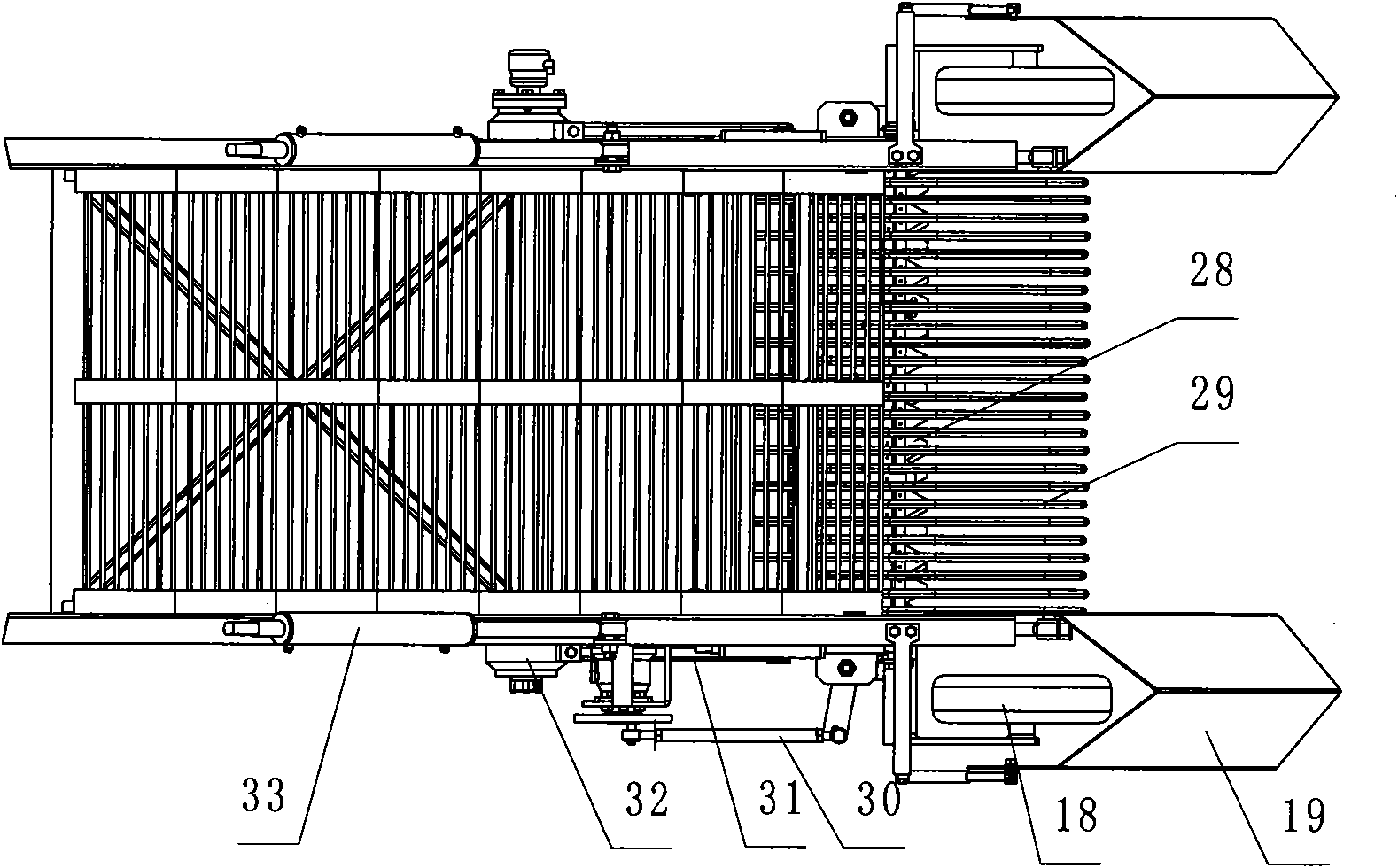

[0058] Refer to attached figure 1 - attached Figure 7 , the structure of the matching processing tomato combine harvester of the present embodiment comprises frame 16, wheel, is provided with cutter 1 at the front portion of frame 16, and frame 16 is provided with transmission mechanism, rattan fruit separation device 8, described The transmission mechanism includes a vine and fruit transmission mechanism 4, a fruit transmission mechanism 11 and a vine transmission mechanism 9, the cutter 1 is connected with the vine and fruit separation device 8 through the vine and fruit transmission mechanism 4, and the fruit transmission mechanism 11 and the vines transmission mechanism 9 are placed Below the vine and fruit separation device 8, and the fruit transmission mechanism 11 is placed below the vine transmission mechanism 9, and the fruit transmission mechanism 11 is connected with the external transmission belt 13. A color sorting device 24 is provided on the external transmis...

Embodiment 2

[0072] Compared with Embodiment 1, this embodiment differs in that the oil tank 53 is equipped with a liquid level gauge, a temperature measuring probe, an oil drain valve and an air filter.

Embodiment 3

[0074] Compared with Embodiment 1, the difference of this embodiment is that in the second hydraulic circuit, a unidirectional variable motor is used to replace the motor 27 of the vine and fruit separating device. The mechanical structure of the tomato harvester can be simplified like this, the rattan fruit separating device described in the structure of the tomato harvester of original design comprises two parts, the swinging mechanism 43 and the spring tooth drum 42, and the swinging mechanism 43 controls the vines from the power source. The rotary motion of the fruit separation device motor 27 is converted into a variable speed rotary motion, and the spring tooth cylinder 42 is driven to complete the separation of tomato seedlings. The swing mechanism 43 can be omitted, and a unidirectional variable motor is directly used to drive the spring tooth cylinder 42. The periodic rotation of the spring tooth cylinder 42 can also be realized by periodically adjusting the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com