Magnesium hot rolling method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

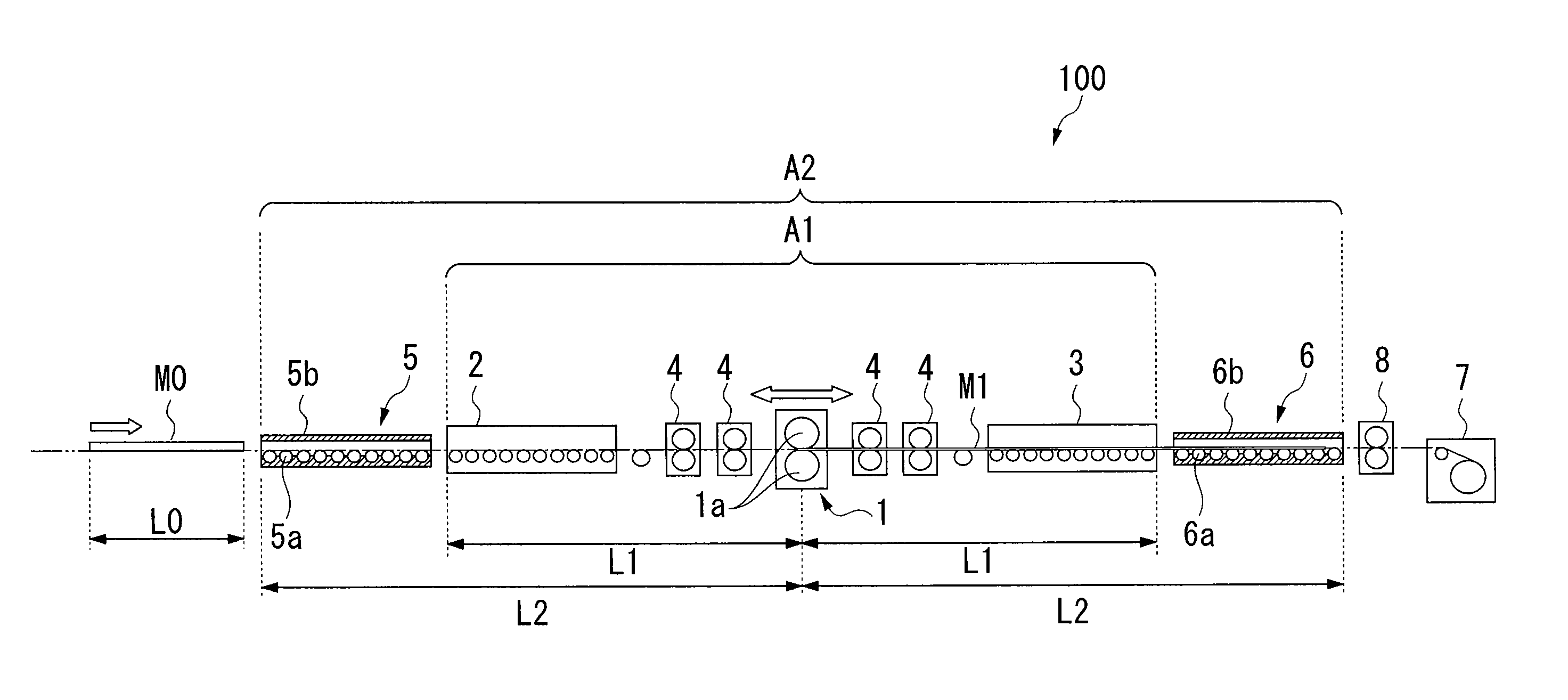

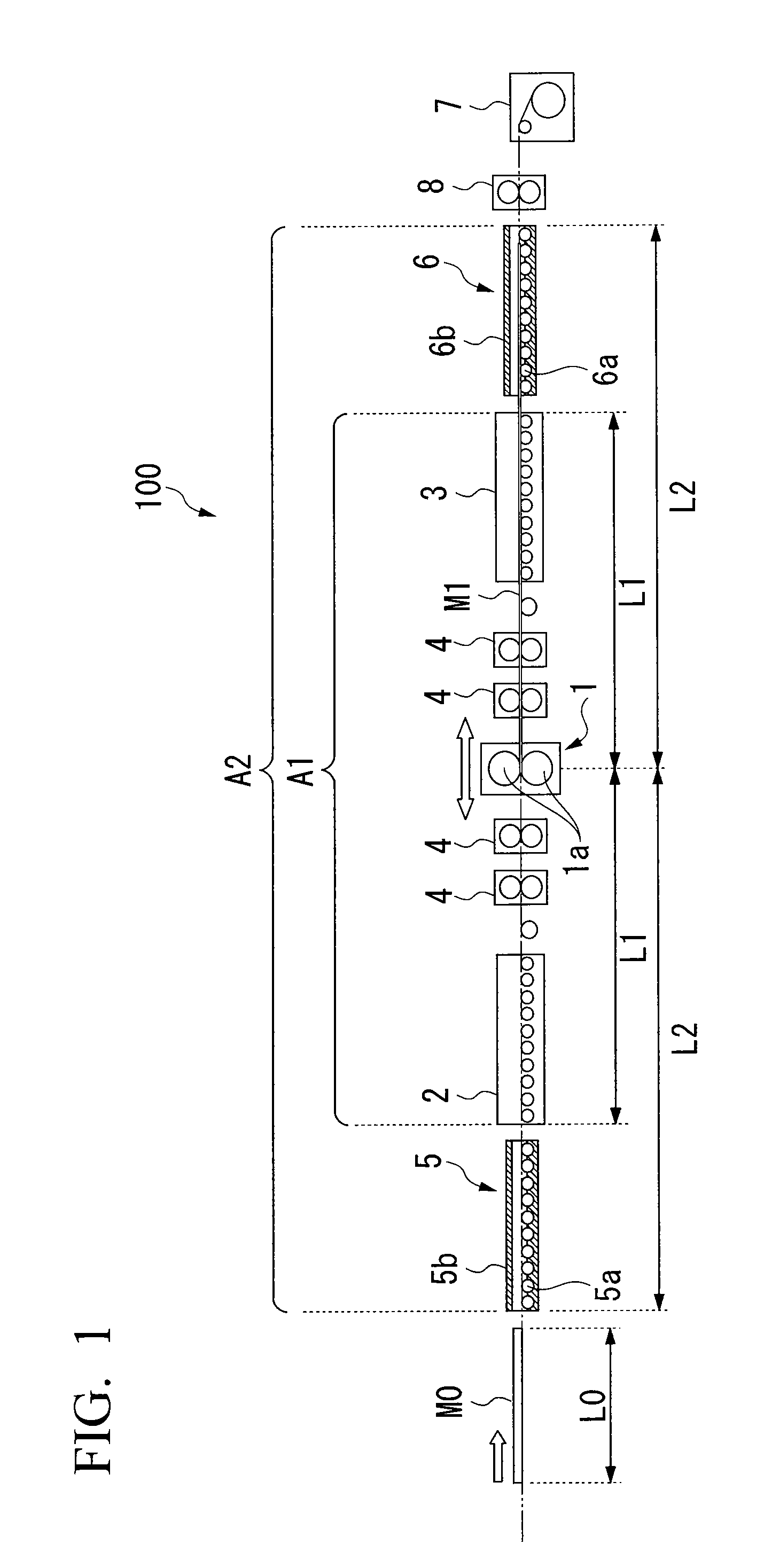

[0032]An embodiment of the present invention will now be described with reference made to the drawings.

[0033]FIG. 1 is a schematic front view showing the schematic structure of a hot rolling apparatus 100 (i.e., a magnesium alloy hot rolling apparatus) in the present embodiment.

[0034]As is shown in FIG. 1, the hot rolling apparatus 100 according to the present embodiment is provided with a rolling mill 1, a first heating furnace 2, a second heating furnace 3, pinch rollers 4, a first table roller 5, a second table roller 6, a winder 7, and pinch rollers 8.

[0035]The rolling mill 1 has a pair of working rollers 1a that are in parallel with each other and also face each other, and with a drive source (not shown) which drives the working rollers 1a to rotate.

[0036]The working rollers 1a are heating rollers whose surface temperature is raised to a suitable temperature and which, while feeding a magnesium cut plate material M0 (i.e., a magnesium plate) which is passing between the working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com