Heat preservation lining oil pipe

An oil pipe and lining technology, which is applied in the field of thermal insulation lined oil pipes, can solve the problems of no insulation effect of lined oil pipes, increased viscosity and wax deposition, etc., and achieves significant economic benefits, convenient management and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

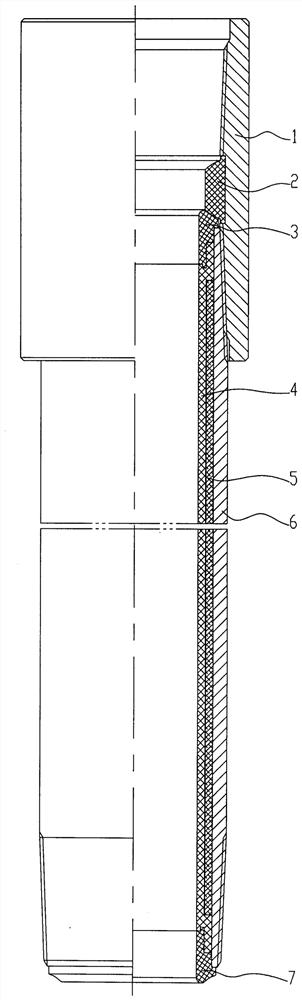

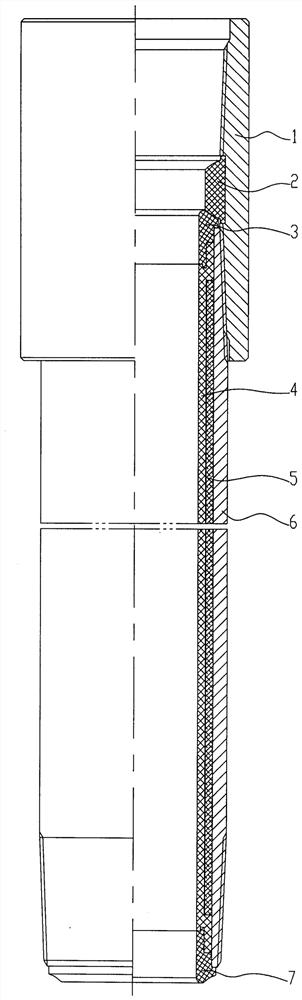

[0011] Attached below figure 1 Examples of the present invention will be described.

[0012] Depend on figure 1 It can be seen that the embodiment of the present invention includes a collar 1, an anti-corrosion ring 2, an upper sealing ring 3, an internal supplementary pipe 4, an insulation layer 5, an oil pipe 6, and a lower sealing ring 7. Both ends of the oil pipe 6 have external threads of the oil pipe, and the oil pipe 6 There is an internal supplementary pipe 4 inside, the lower internal thread of the coupling 1 is connected with the upper external thread of the oil pipe 6, and the joint is kept sealed, the upper part of the coupling 1 has an internal thread of the oil pipe, and an insulation layer is set between the internal supplementary pipe 4 and the oil pipe 6 5. The upper sealing ring 3 is installed on the upper part of the inner replenishing pipe 4 and the upper part of the oil pipe 6. The upper sealing ring 3 fixes the upper part of the inner replenishing pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com