Patents

Literature

2284results about How to "Avoid getting lost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

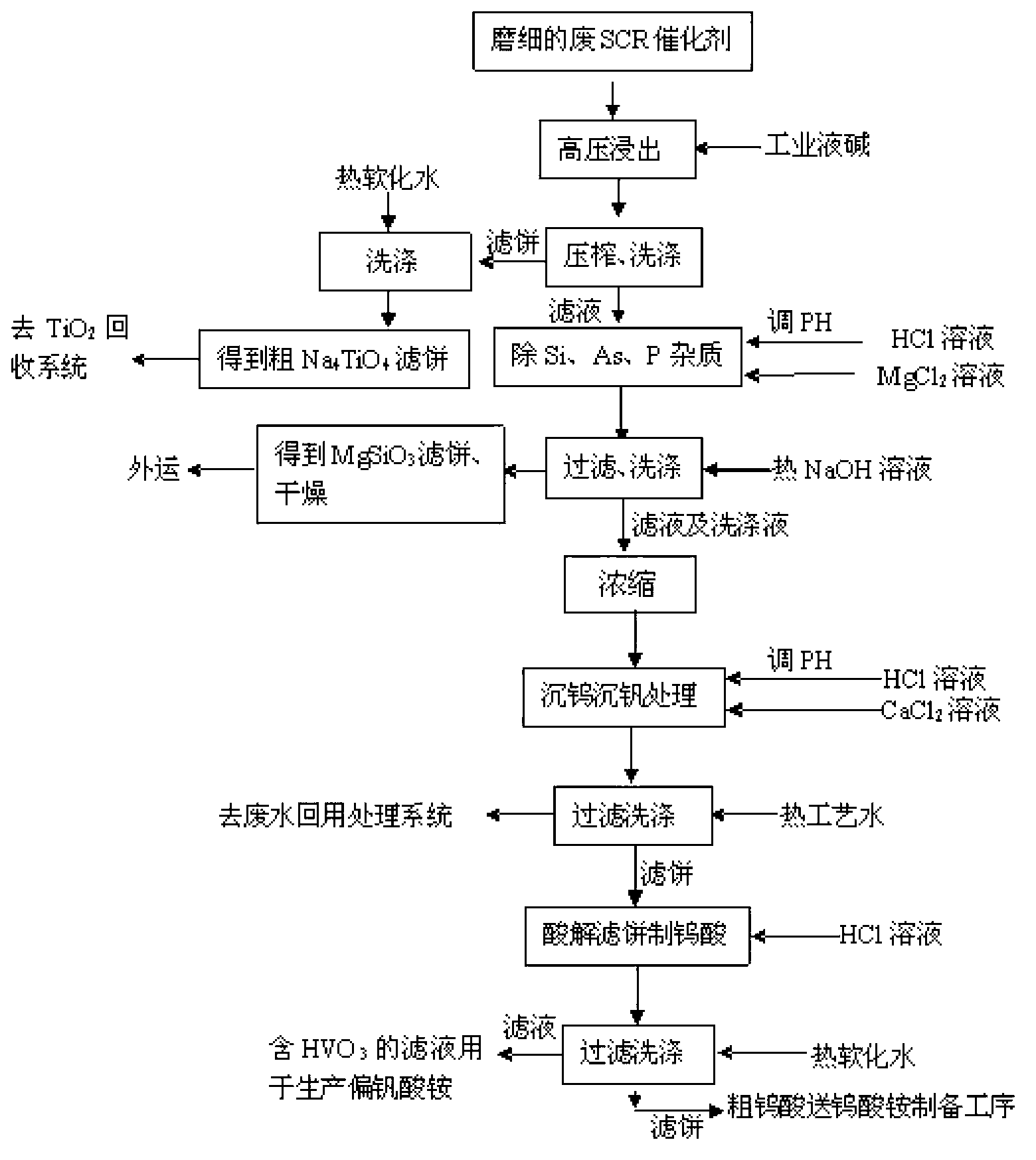

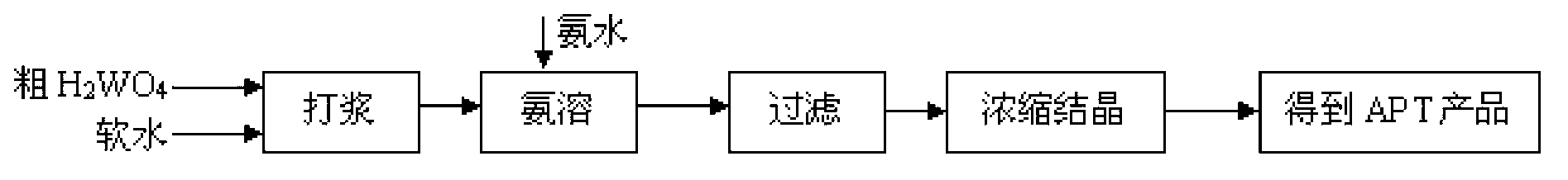

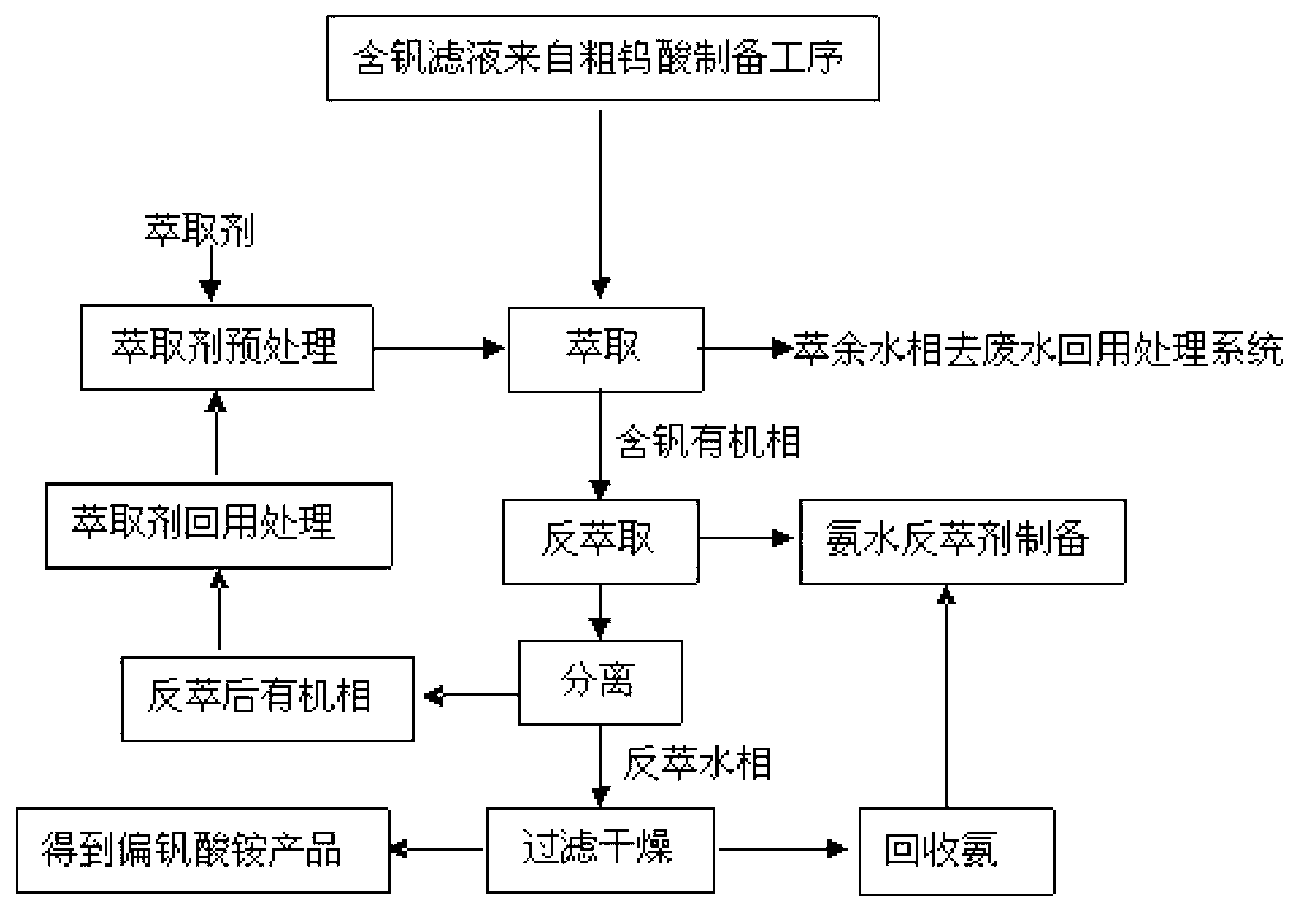

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

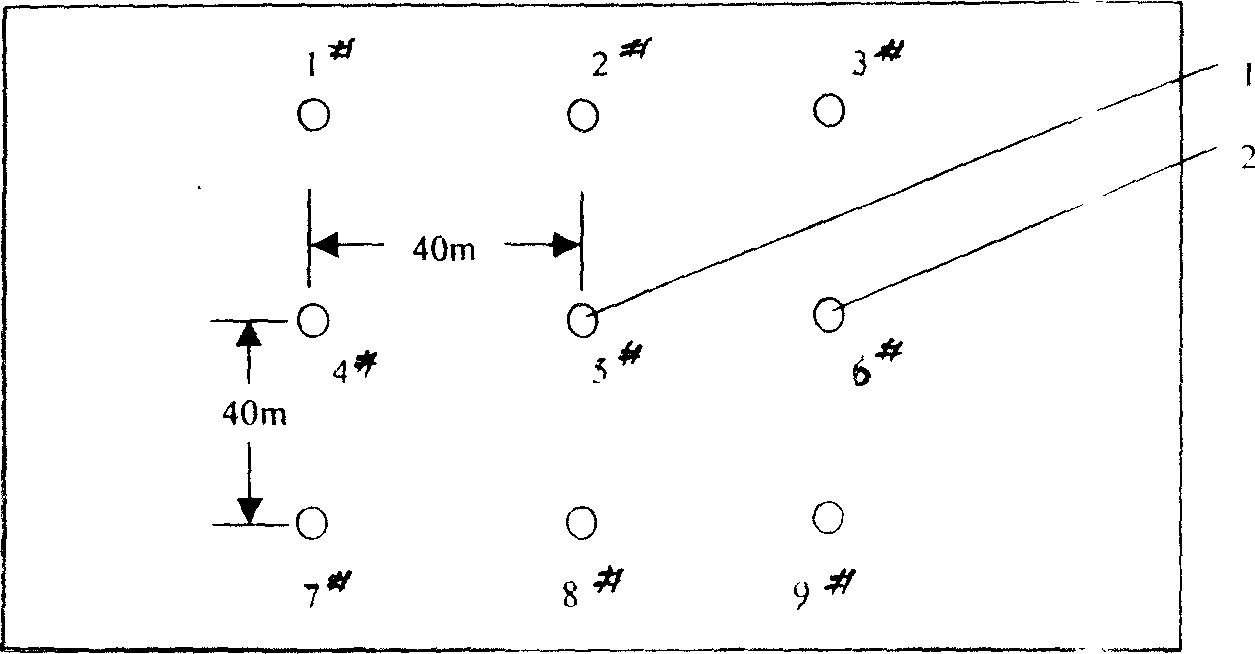

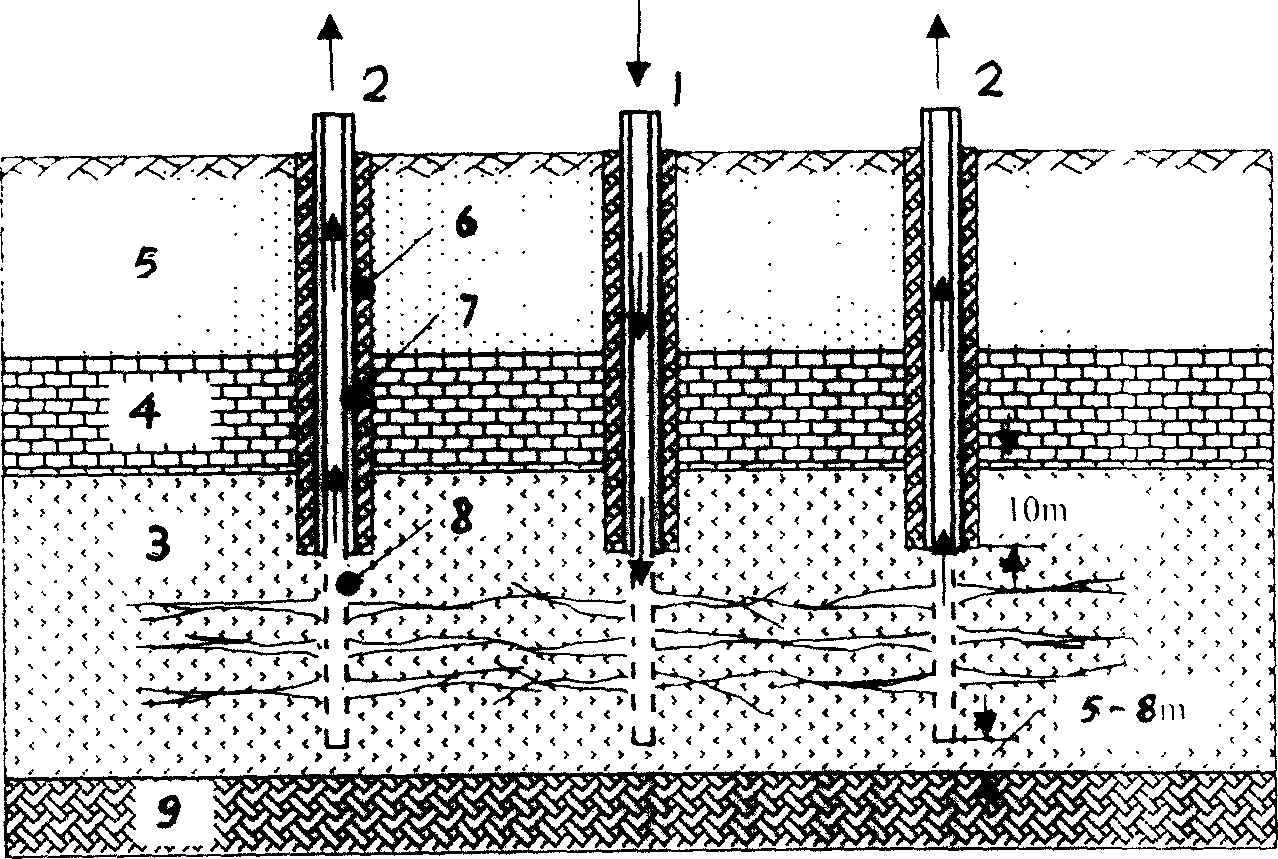

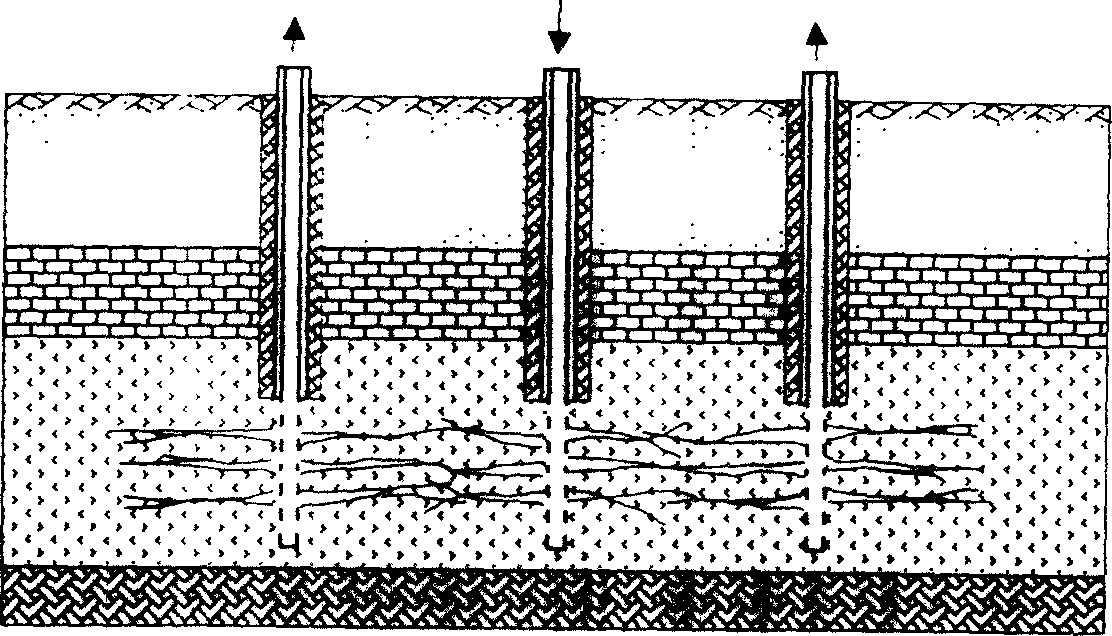

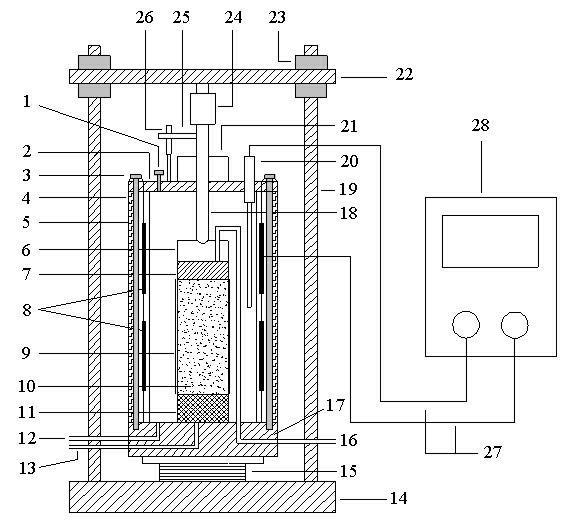

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

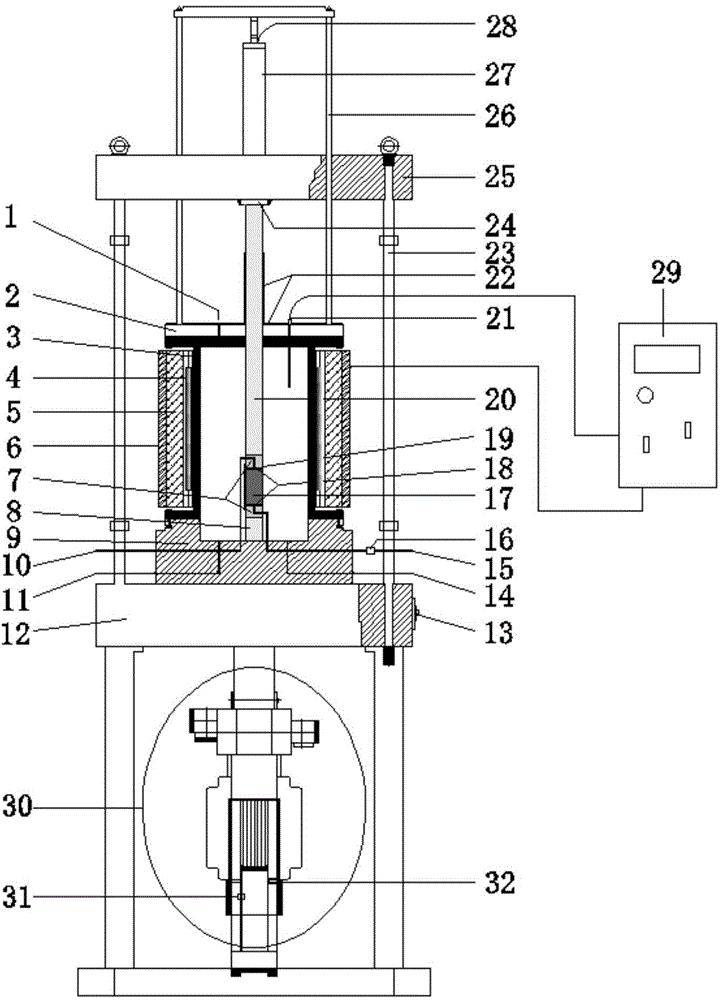

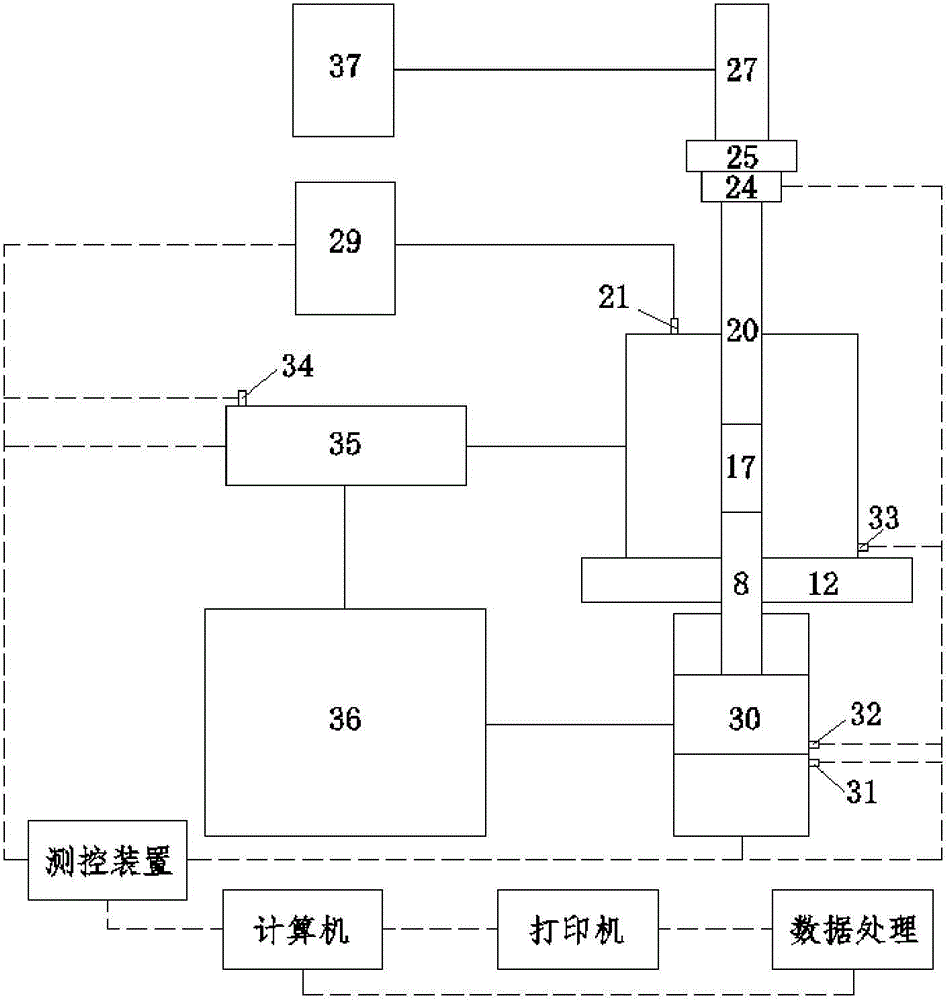

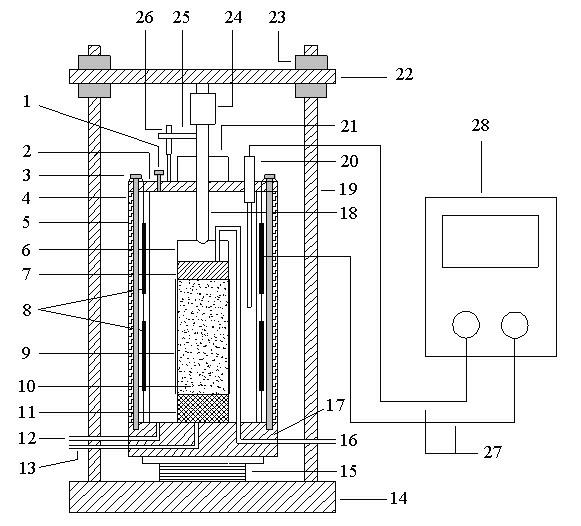

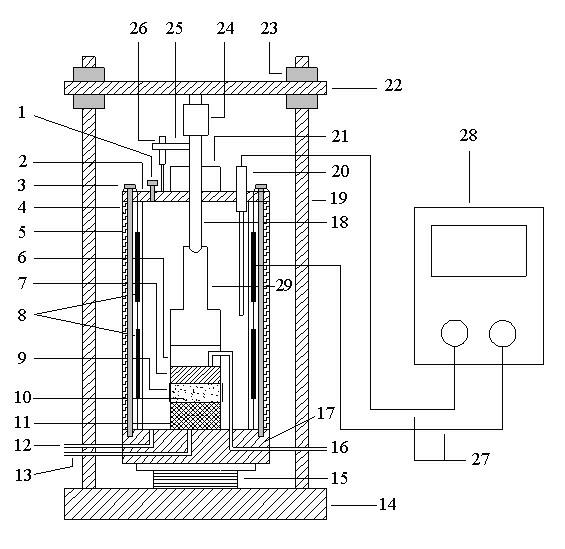

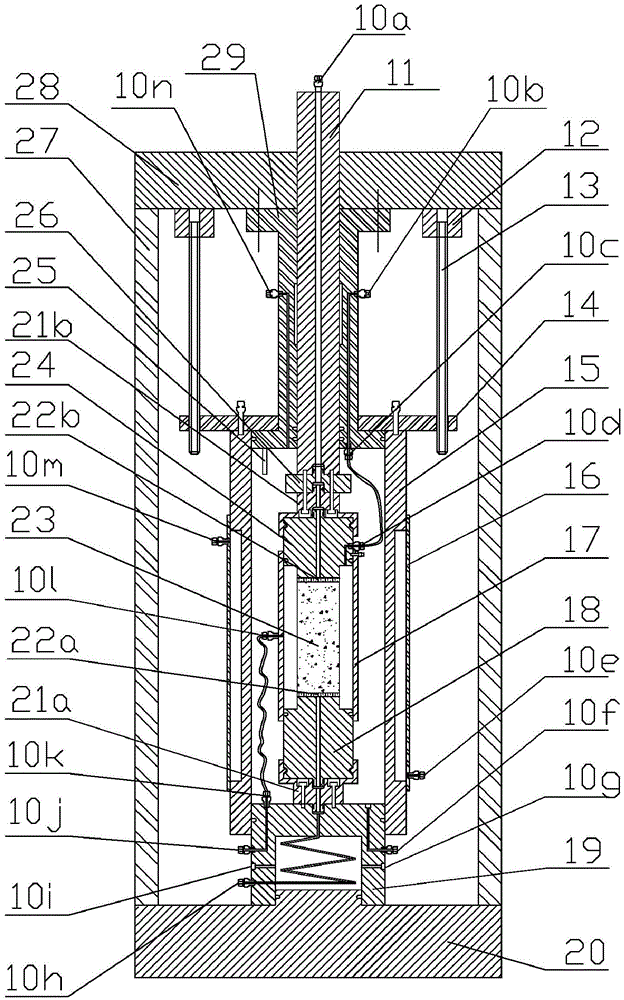

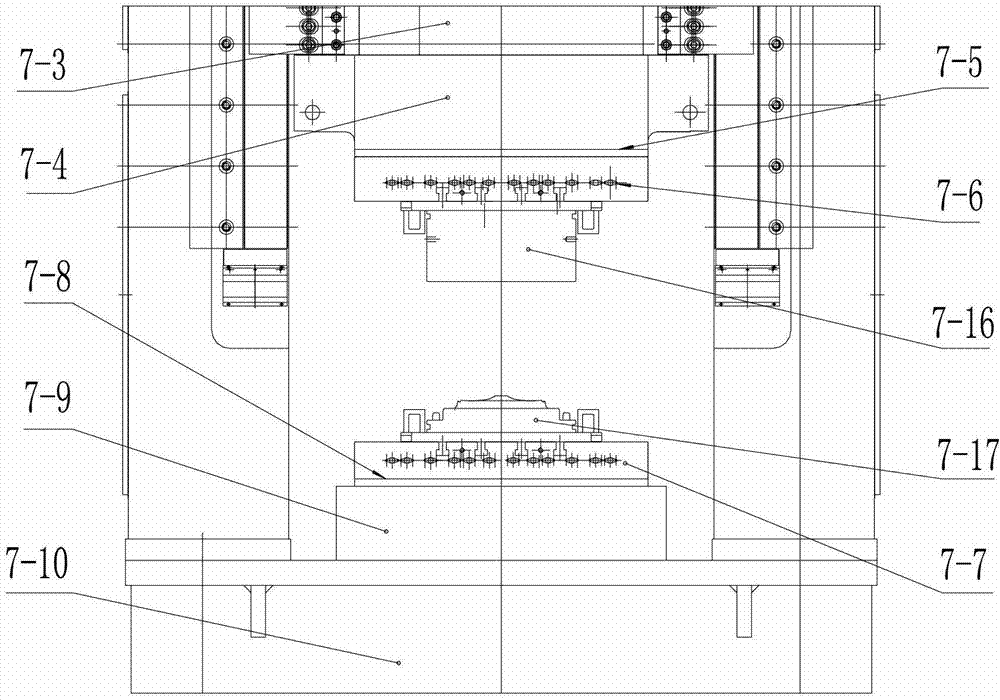

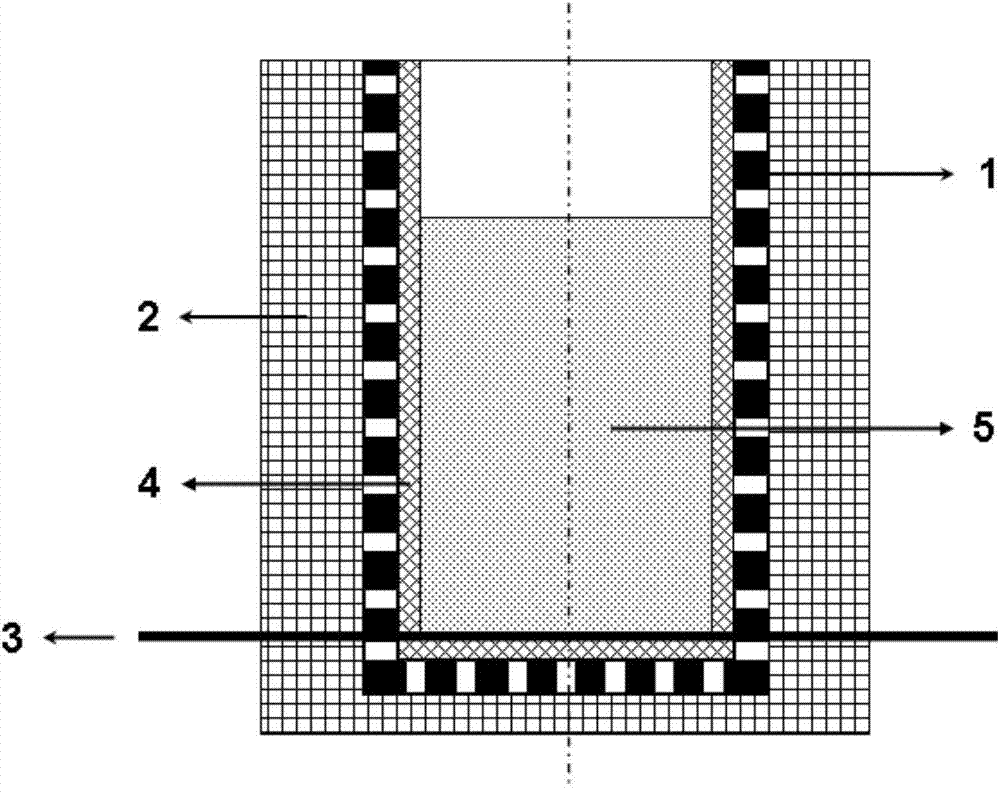

Rock-soil body temperature-control dynamic characteristic test system and test method

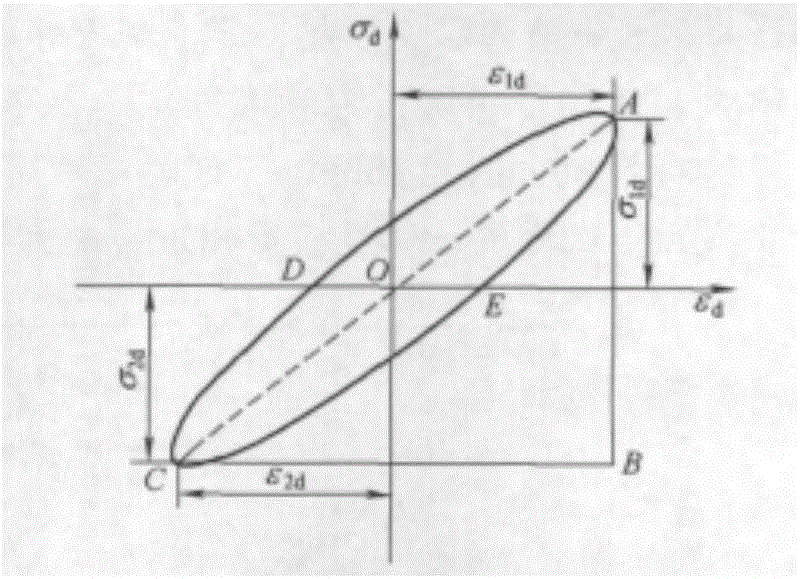

ActiveCN104596852AEasy loading and unloadingImprove suitabilityMaterial strength using tensile/compressive forcesStatic stressHeating temperature

The invention discloses a rock-soil body temperature-control dynamic characteristic test system and method, is characterized in that the system includes a dynamic triaxial pressure chamber and a temperature control device; the dynamic triaxial pressure chamber comprises a pressure chamber cylinder body, a piston rod and an upper dowel bar; a sample is arranged between the lower end of the upper dowel bar and the upper end of the piston rod; the dynamic triaxial pressure chamber also includes a pressure sensor, an axial displacement sensor, a deformation sensor, a confining pressure sensor, a lateral displacement sensor and a pore pressure sensor; the temperature control device includes a temperature sensor, a temperature controller and an arc plate type heater symmetrically coating the outer wall of the pressure chamber cylinder body. The temperature-control dynamic characteristic test method mainly includes installing the sample, setting the temperature control device, carrying out drainage consolidation of the sample, applying dynamic / static stress, and completing a temperature-control dynamic / static triaxial test, to determine the cumulative plastic strain, dynamic damping ratio, dynamic elastic modulus and other indexes of a rock-soil body under different temperatures. The system and the method have the advantages of uniform heating temperature, short heating time and low cost, and can accurately control the temperature in the pressure chamber.

Owner:NINGBO UNIV

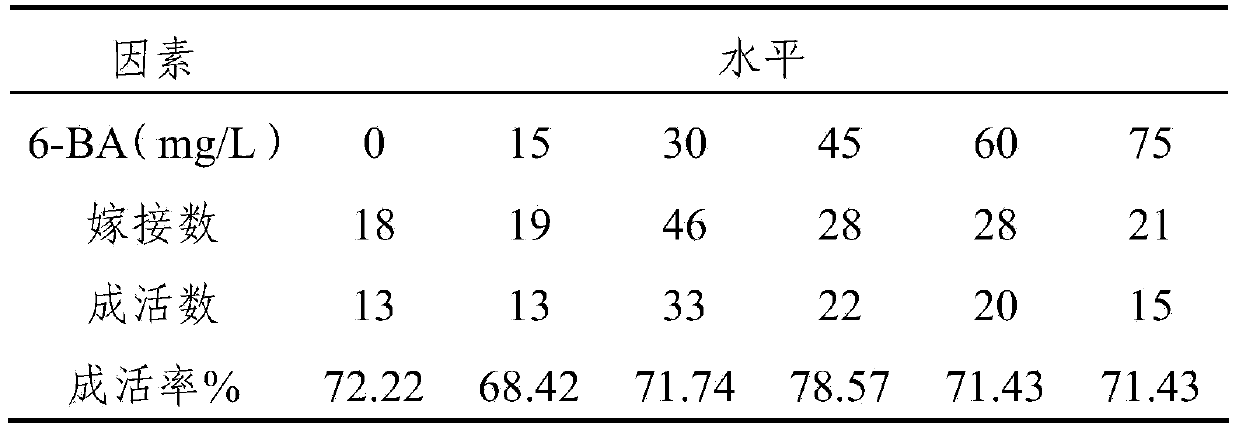

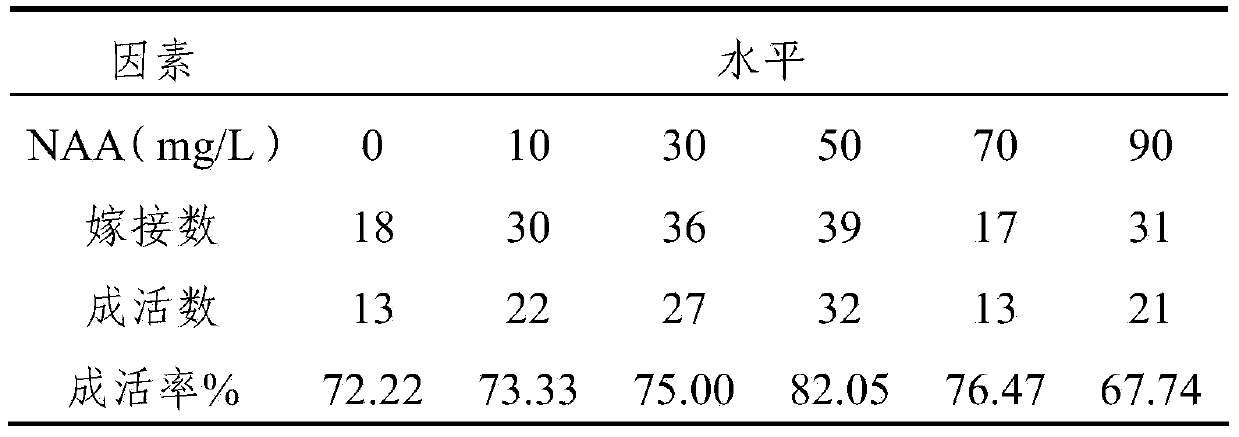

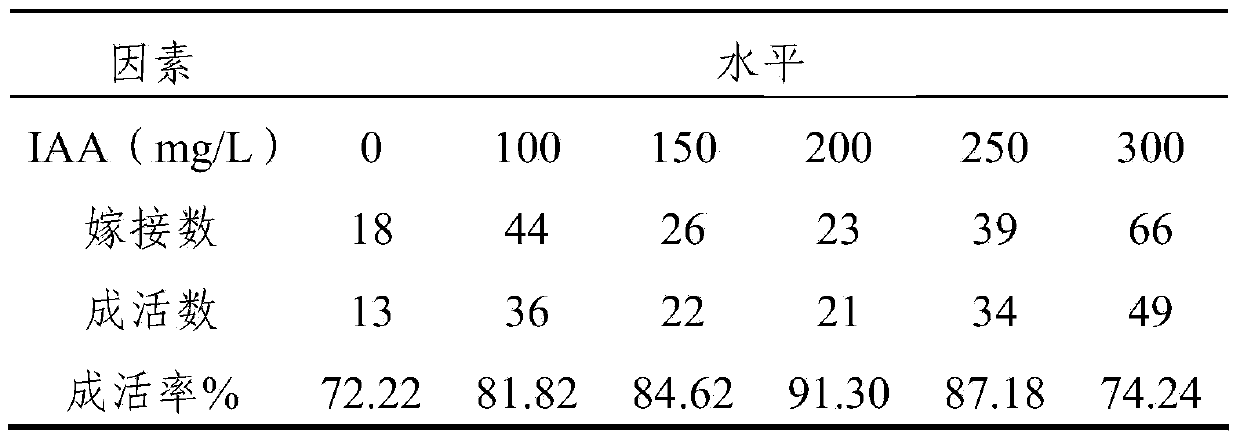

Healing agent for jujube grafting and application method thereof

InactiveCN103739402AAvoid getting lostImprove the bactericidal effectHorticultureFertilizer mixturesPlant regulatorsCallus formation

The invention relates to a healing agent for jujube grafting and an application method thereof, and belongs to a plant regulator. The healing agent comprises an agent A, an agent B and an agent C, wherein the agent A comprises naphthylacetic acid, heteroauxin and gibberellin; the agent B is carbendazim; the agent C is a nutrient. The application method comprises the following steps: dissolving the agent A into 60-85% of alcohol, mixing with the agent B and the agent C to prepare a healing solvent solution; soaking a jujube scion into the healing agent solution for 5-20 minutes and then using. By adopting the healing agent, a plant graft union growth regulator, nutrient, sterilization and moisture are achieved at the same time, and the healing agent has the functions of promoting callus formation, disinfecting, sterilizing, supplying nutrients, preventing moisture loss and the like. Not only is the jujube grafting survival rate improved by adopting a scion soaking method, but also the grafting speed is obviously improved, the labor intensity is reduced, and the grafting cost is saved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

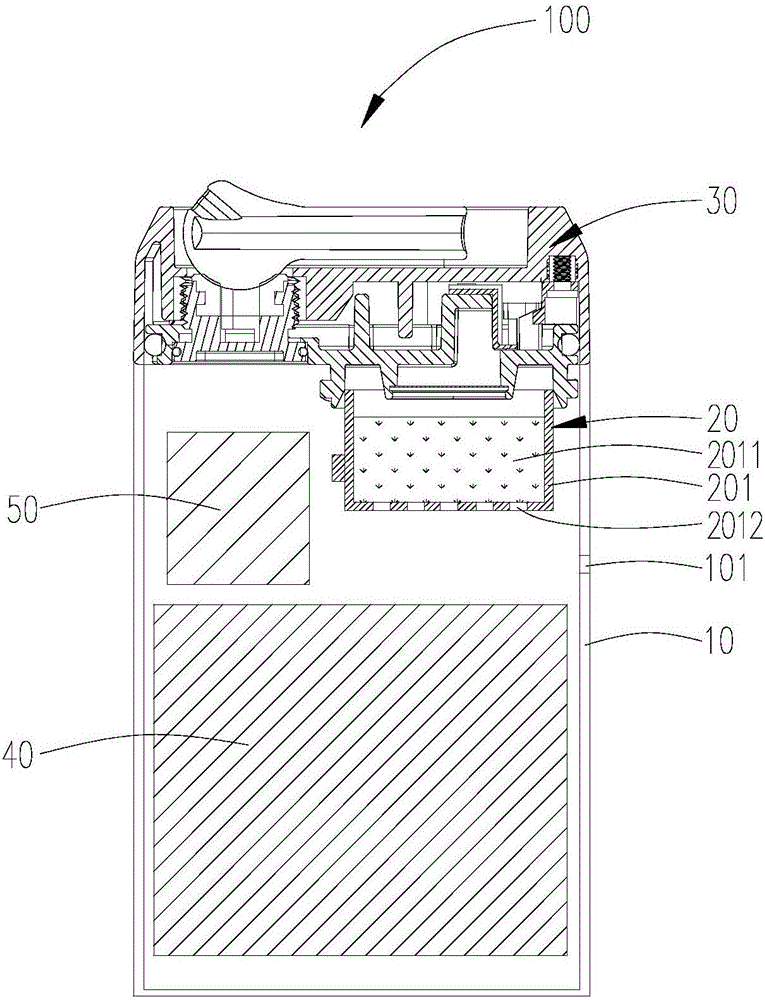

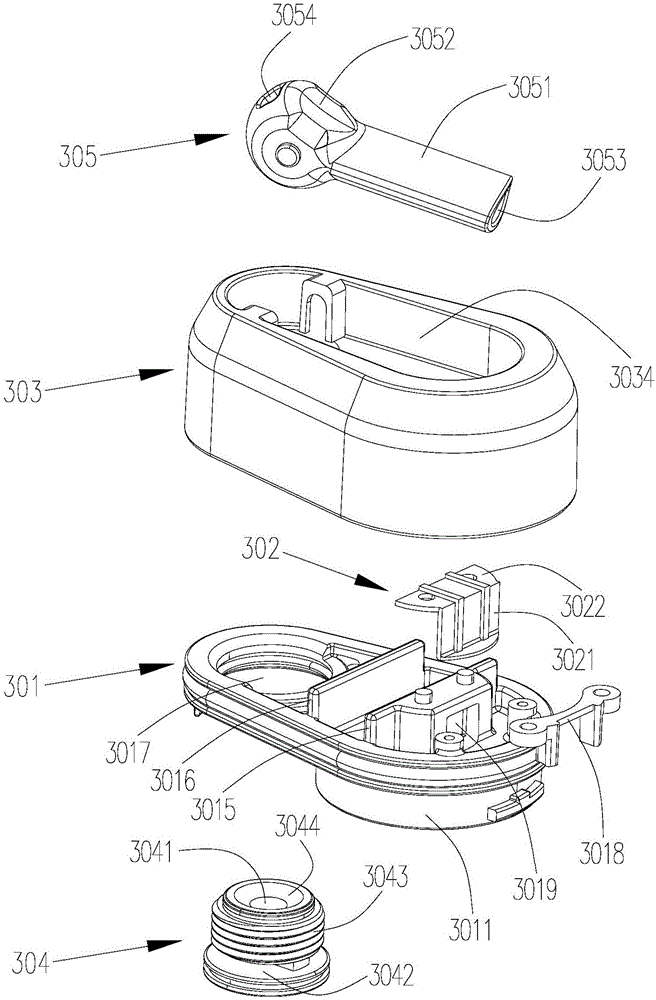

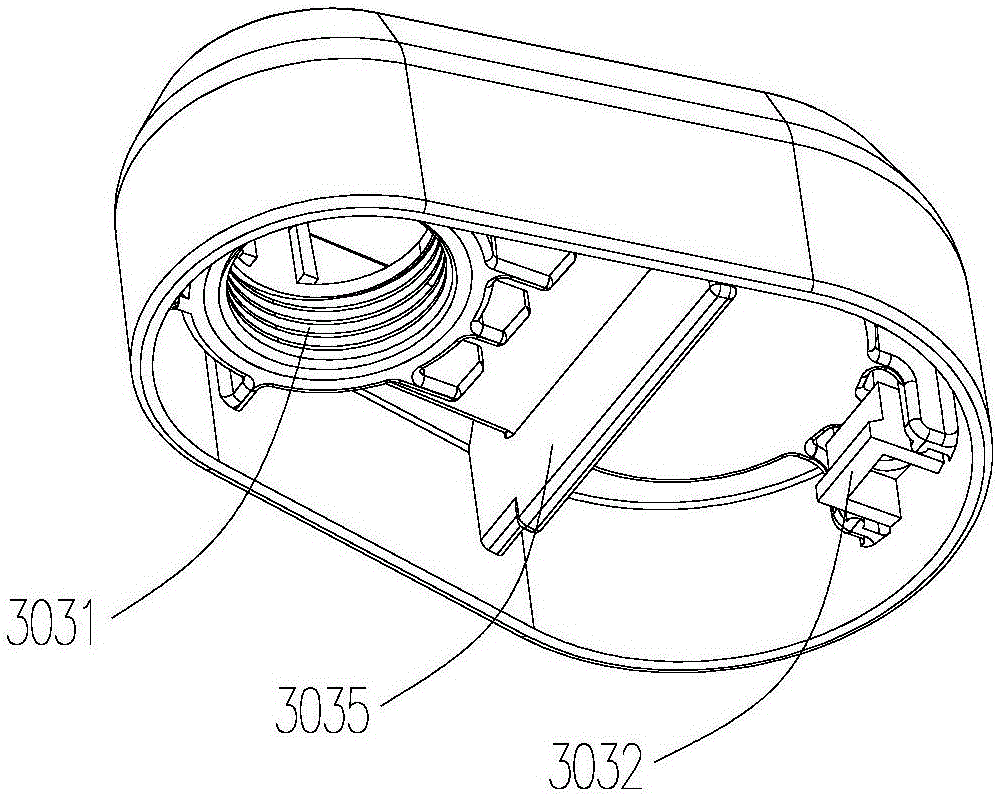

Electronic cigarette

ActiveCN106723379AAffect user experienceAvoid getting lostRespiratorsMedical devicesMouth pieceElectronic cigarette

The invention provides an electronic cigarette, comprising an atomizer, a controller, a sensor and a reminding device; the atomizer comprises an atomizing component and a cigarette holder component arranged at one end of the atomizing component; an atomizing cavity for heating gas sole and forming a matrix to generate smoke is arranged in the atomizing component; the cigarette holder component comprises a cigarette holder, an air flow channel arranged between the cigarette holder and the atomizing cavity and an unidirectional valve mounted in the air flow channel; the sensor, the controller and the reminding device are cooperated to remind user of suction or not; under the suction function, the unidirectional valve opens the airflow channel; when the suction function is stopped, the unidirectional valve closes the airflow channel. When related physical volume of smoke reaches the first preset value, the electronic cigarette reminds user of suction; when the user is sucked, the atomizing cavity and the cigarette holder can be connected through the airflow channel, the smoke can be flowed out from the cigarette holder; compared with the traditional structure, the electronic cigarette prevents waste and heat lost caused by the self-flow of the smoke.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

Temperature-control pressure chamber system for unsaturated soil tri-axial apparatus

InactiveCN102175539AEffective controlEvenly heatedMaterial strength using tensile/compressive forcesTemperature controlControl system

The invention relates to a temperature-control pressure chamber system for an unsaturated soil tri-axial apparatus, and the system comprises a loading platform and a pressure cover, wherein the pressure cover is fixedly arranged on the loading platform; the pressure chamber system further comprises a temperature control system which is connected to the pressure cover; the pressure cover comprisesa top cover and an outer wall; the outer wall has a sandwich structure; the temperature control system comprises an electric heating plate, a lead, a temperature controller and a temperature sensor; the electric heating plate is arranged in the sandwich layer of the outer wall and is connected to the temperature controller through the lead; the temperature sensor is fixed on the top cover of the pressure cover through a fixing nut; and one end of the temperature sensor is arranged in the pressure cover while the other end is connected to the temperature controller through the lead. The systemis used for realizing the precise control and measurement for the test temperature on the basis of the conventional unsaturated soil tri-axial apparatus and is used for carrying on various unsaturated soil tests at different temperatures, thereby promoting the universality of the ordinary unsaturated soil tri-axial apparatus. Besides, the temperature control is automated and the measured data is accurate.

Owner:BEIJING JIAOTONG UNIV

Method for coal bed methane mining by multi-element thermal fluid foam displacement

ActiveCN103061730AImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for starting application and terminal

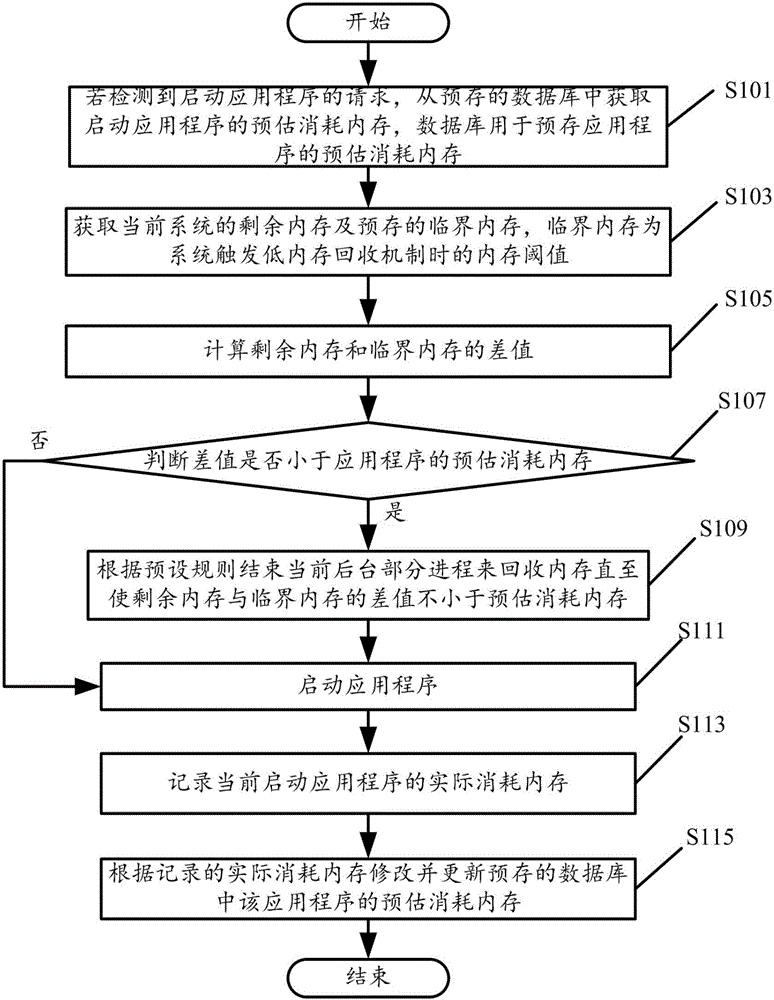

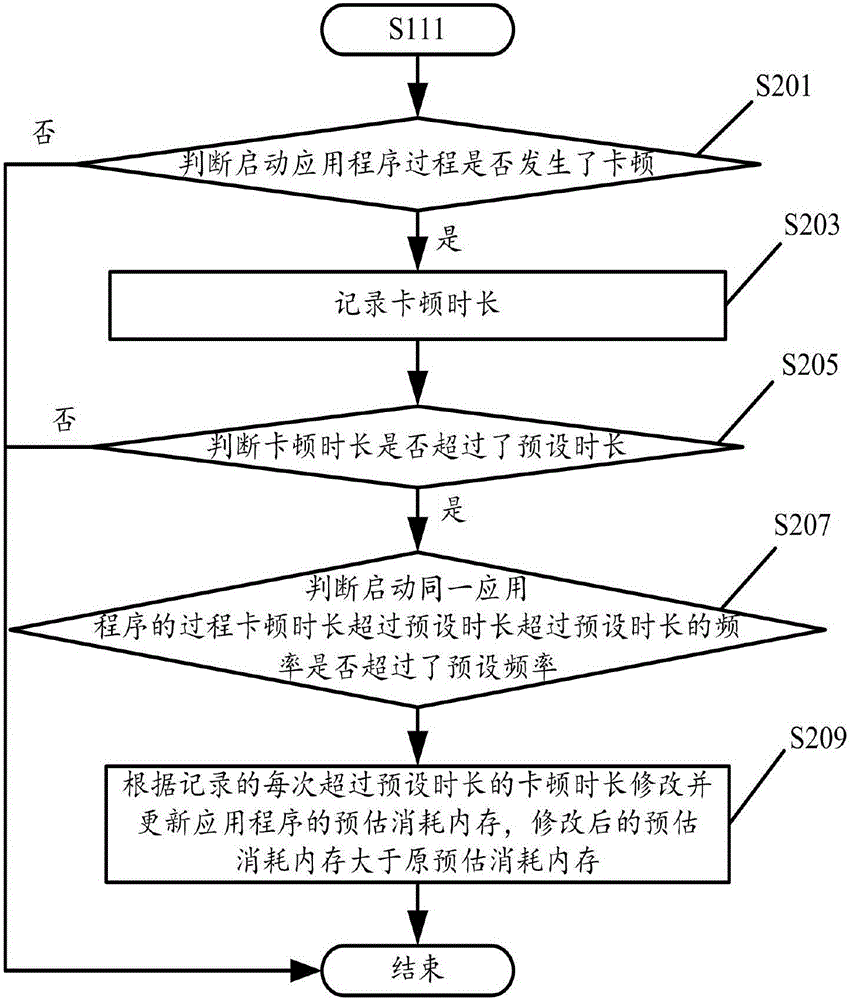

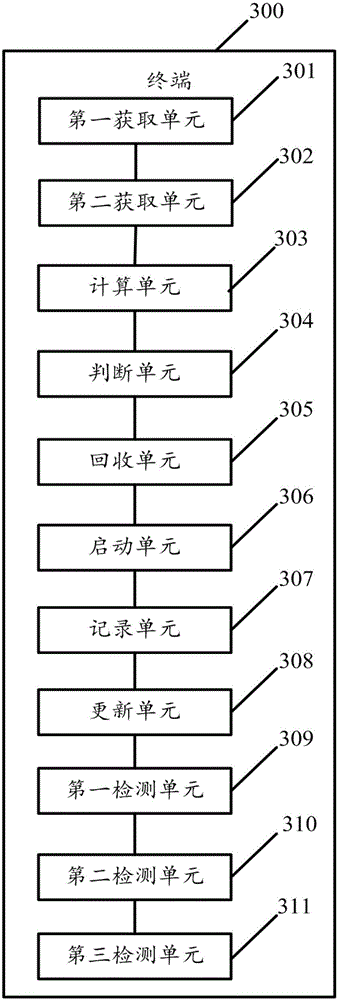

InactiveCN106528216AMeet memory requirementsAvoid getting lostProgram loading/initiatingBackground processComputer science

Embodiments of the present invention disclose a method for starting an application and a terminal. The method comprises: if a request for starting an application is detected, acquiring an estimated consumption memory for starting the application from a database used for pre-storing; acquiring a remaining memory of a current system and a pre-stored critical memory; calculating a difference between the remaining memory and the critical memory; determining whether the difference is less than the estimated consumption memory of the application; if the difference is less than the estimated consumption memory of the application, ending a part of current background processes according to a preset rule to recover the memory until the difference between the remaining memory and the critical memory is not less than the estimated consumption memory; and if the difference is not less than the estimated consumption memory, starting the application. Whether the memory needs to be recovered currently to satisfy a memory demand of the currently started application is detected, therefore, not only can the memory be provided for the started application, but also loss of a part of background application functions when the memory is idle can be prevented.

Owner:SHENZHEN GIONEE COMM EQUIP

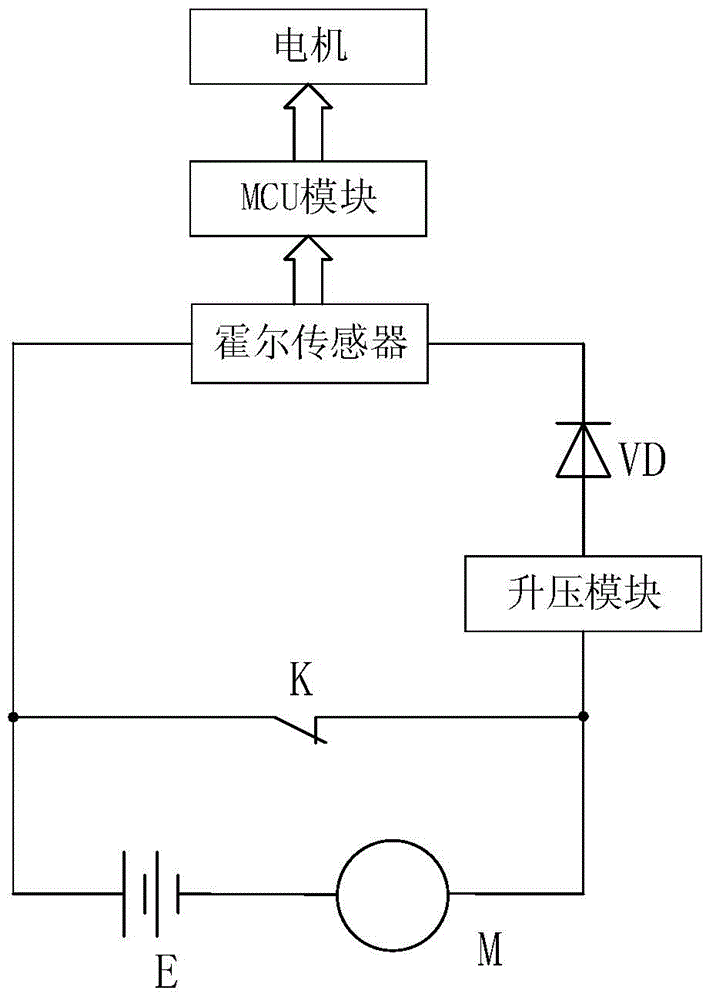

Working method of real scene navigation system

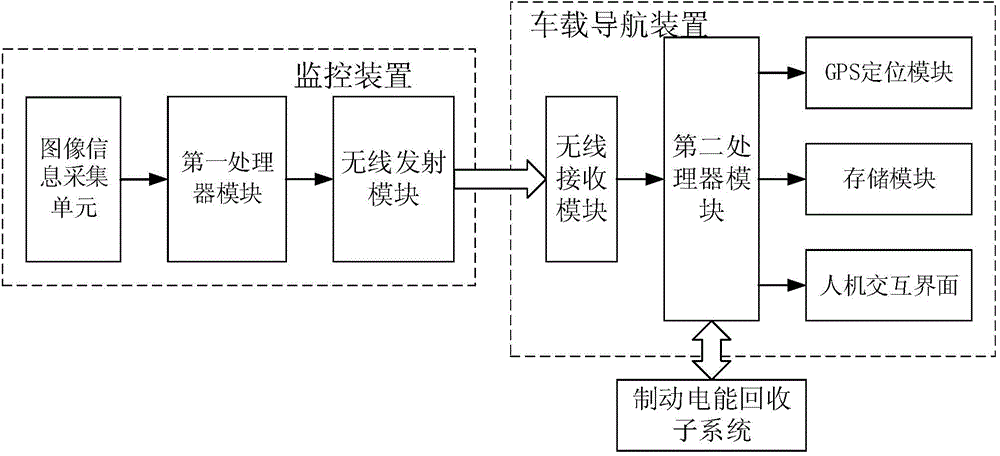

ActiveCN104990555AAvoid getting lostGood real-time performanceInstruments for road network navigationBatteries circuit arrangementsData memoryMarine navigation

The present invention discloses a working method of a real scene navigation system. The navigation system comprises a navigation device and an imaging device. The working method comprises that when a vehicle drives according to a preset navigation path, the imaging device follows the vehicle and real-timely shoots the real-time image around the current vehicle; if a complex intersection exists in front of the vehicle, a processor module matches the real-time image and the street scene image of corresponding position and pre-stored in a data memory, combines the preset navigation path, and determines the position, the road and the right driving direction of the current vehicle; and a display module is controlled to display the corresponding navigation images, wherein the real-time image in front of the current vehicle, and the vehicle driving direction matched with the navigation path and labeled by the arrow are contained in the navigation image.

Owner:SHANGHAI ANYO NAVINFO INFORMATION TECH

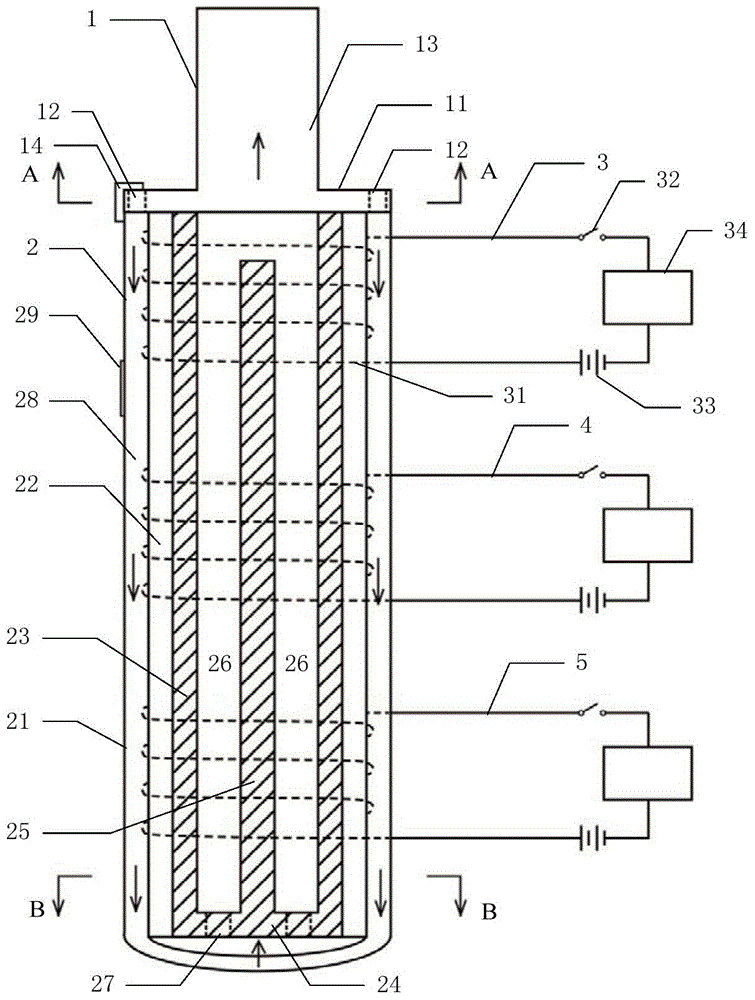

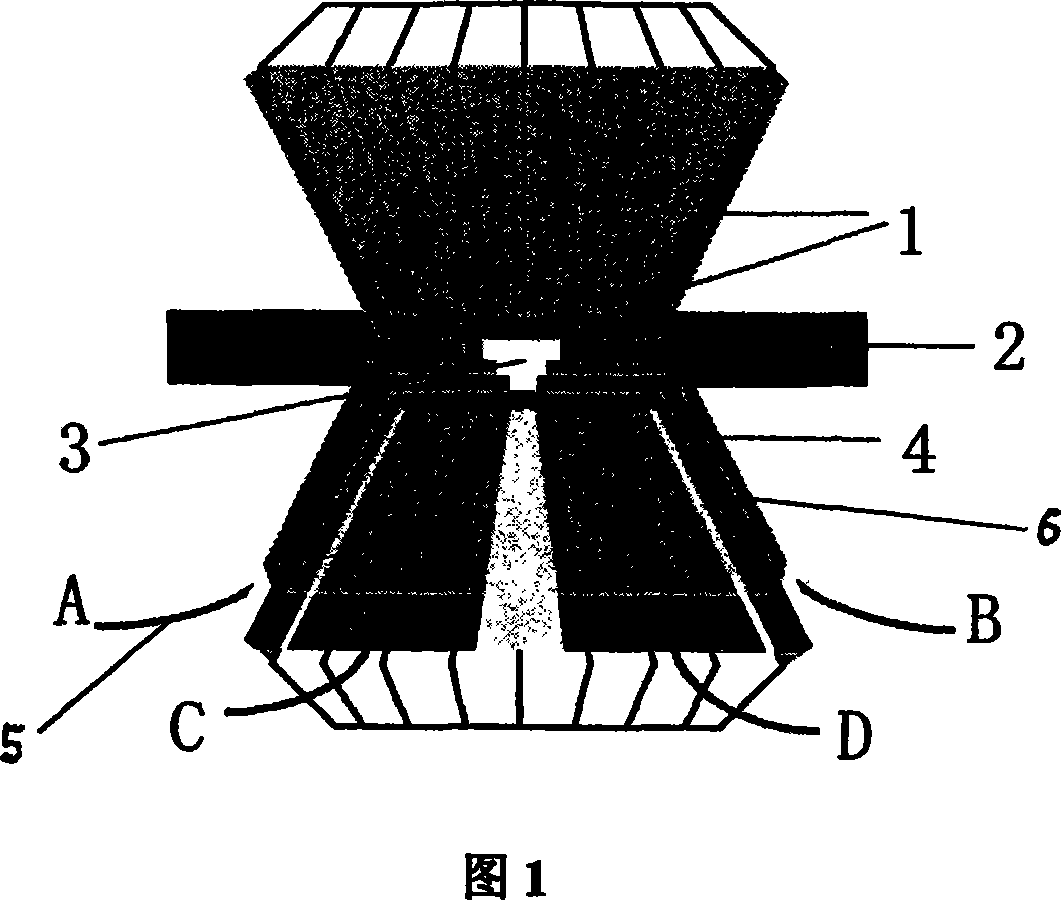

Tobacco suction system based on electromagnetic heating

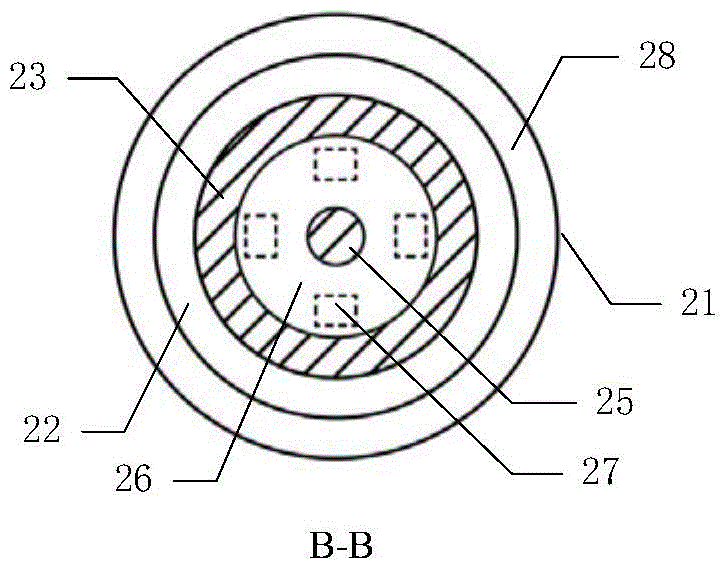

The invention discloses a tobacco suction system based on electromagnetic heating, which is characterized in that it comprises an end cover (1), a heater (2) and an electromagnetic induction system, and the end cover (1) is detachably connected to the heater ( 2) above; the end cap (1) includes a round cover (11) and a filter tip (13); the heater (2) includes a shell (21), an inner tank (23) and a chassis (24) and a cylindrical Iron core (25); the electromagnetic induction system includes a heating liner (23), a chassis (24), a cylindrical iron core (25), an induction coil and a temperature control circuit. The present invention can increase the heating speed and high thermal efficiency through the electromagnetic induction system to heat the liner, the chassis and the cylindrical iron core, and can also realize instantaneous heating, so as to better meet the needs of the suction taste; the cylindrical iron core The setting can realize the uniform heating of the tobacco products, so that the tobacco products can be fully heated, which can prevent the waste caused by insufficient heating of the tobacco products, and is suitable for popularization and use.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

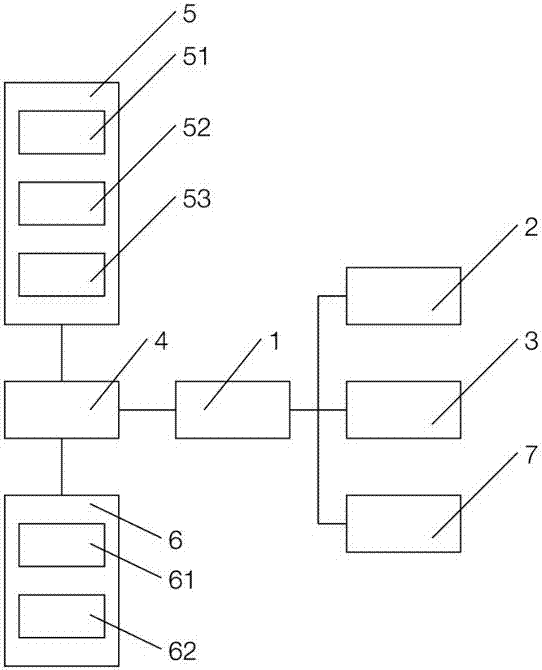

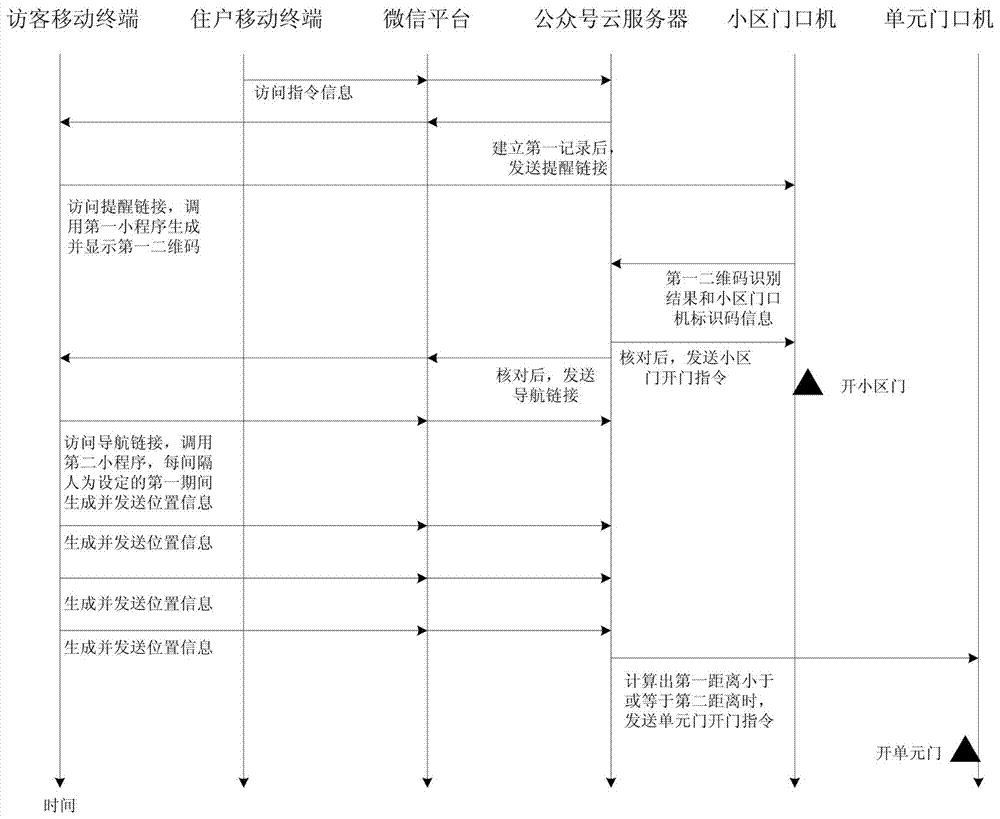

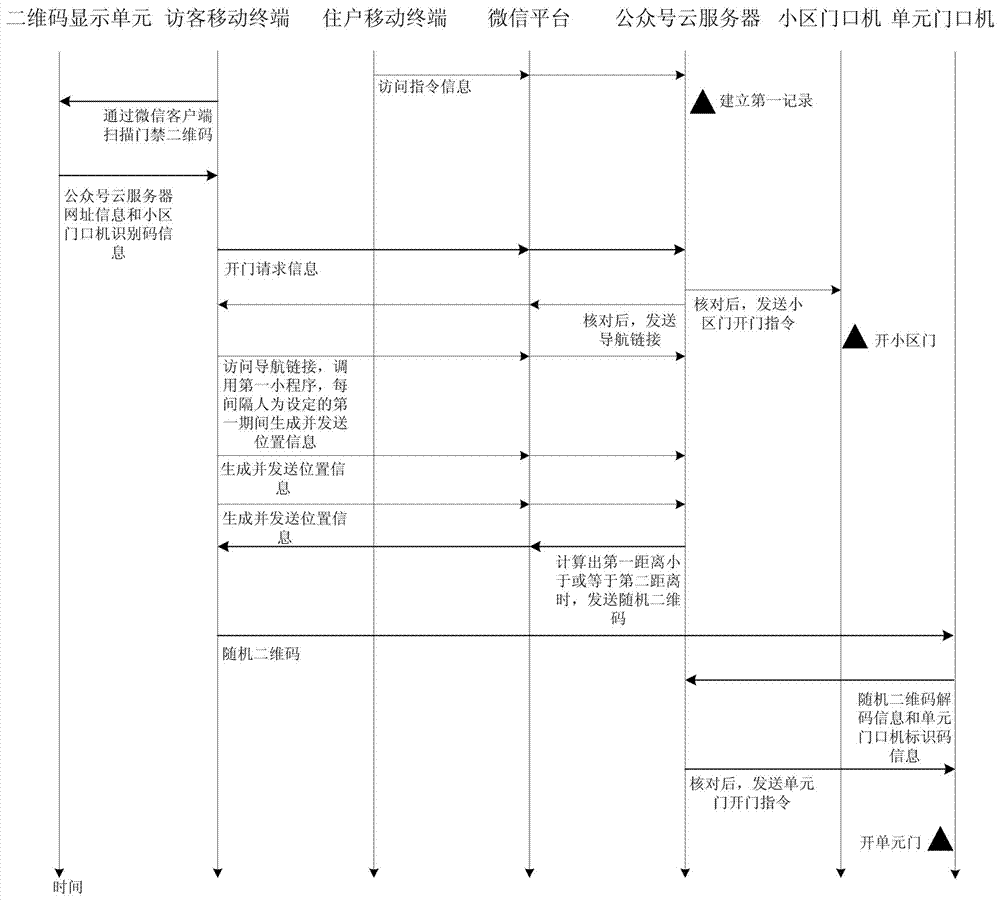

Cloud service-based community access control system and door opening method

ActiveCN107492168AImplement authorizationWide range of servicesIndividual entry/exit registersTransmissionAccess timeMarine navigation

The invention discloses a cloud service-based community access control system and a door opening method. The cloud service-based community access control system comprises a WeChat platform, a resident mobile terminal platform, a visitor mobile terminals, an official account cloud server, a community entrance machine and an apartment entrance machine, an access control cloud service WeChat official account is followed through the resident mobile terminal and the visitor mobile terminal to realize the communication of the official account cloud server with the resident mobile terminal and the visitor mobile terminal. In the relevant door opening method, a resident can pre-authorize and restrict the access time of visitors; and the check of the visitor's identity can be realized, navigation from the community entrance machine to the apartment entrance machine is provided for the visitor, and an apartment door is automatically opened when the visitor is close to the apartment door.

Owner:XIAMEN DNAKE INTELLIGENT TECH CO LTD

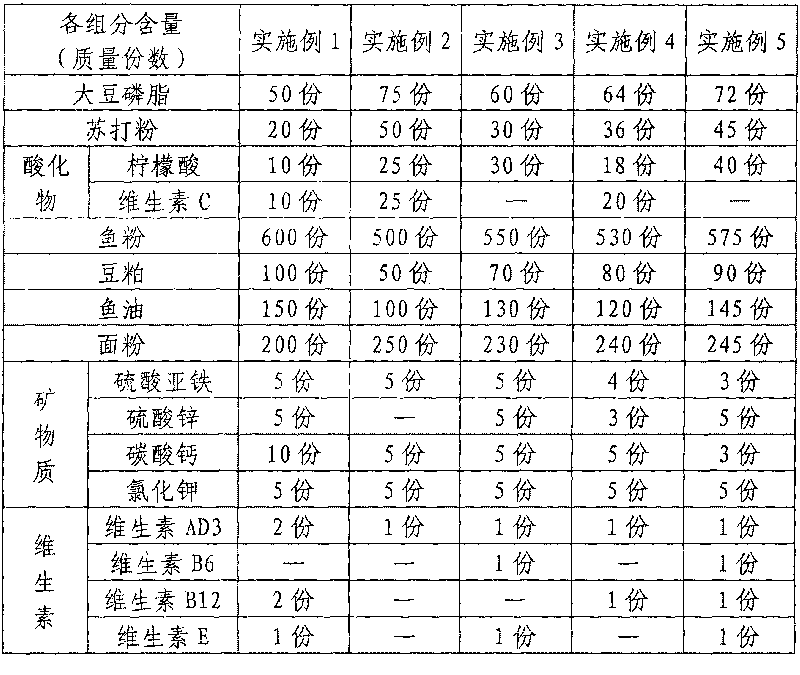

Slowly floating aquatic product feed and production process thereof

InactiveCN101715890AObserve feedingPrevent leakageClimate change adaptationAnimal feeding stuffAquatic productFish oil

The invention relates to a slowly floating aquatic product feed, which is characterized by comprising the following components in part by mass: 50 to 75 parts of soybean lecithin, 20 to 50 parts of soda powder, 20 to 50 parts of acidifying substances, 100 to 150 parts of fish oil, 500 to 600 fish meal, 50 to 100 parts of bean pulp and 200 to 250 parts of flour. The slowly floating aquatic product feed is convenient for a user to observe ingestion condition, and has the advantages of good ingestion and less water body pollution.

Owner:佛山市顺德区全兴水产饲料有限公司

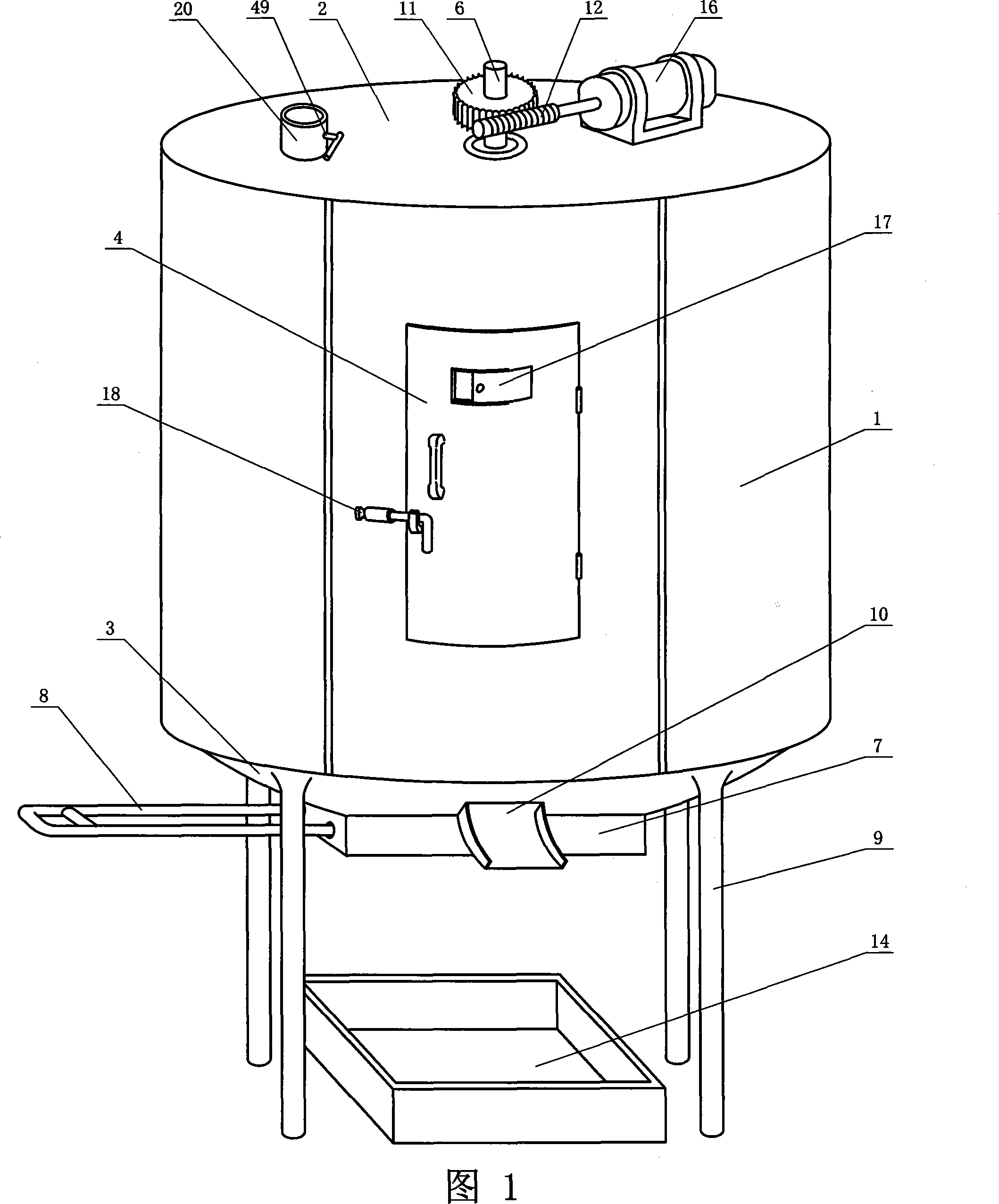

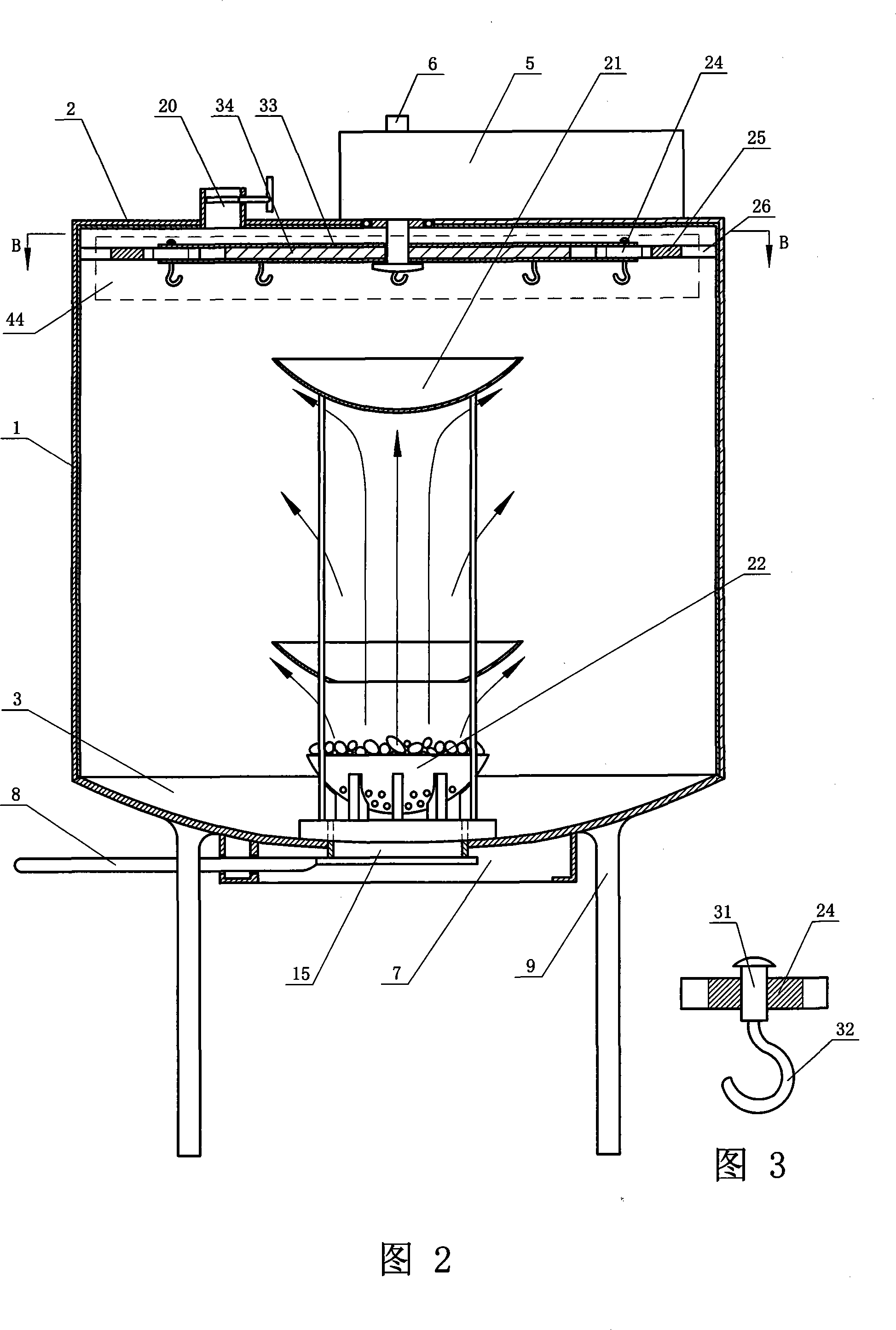

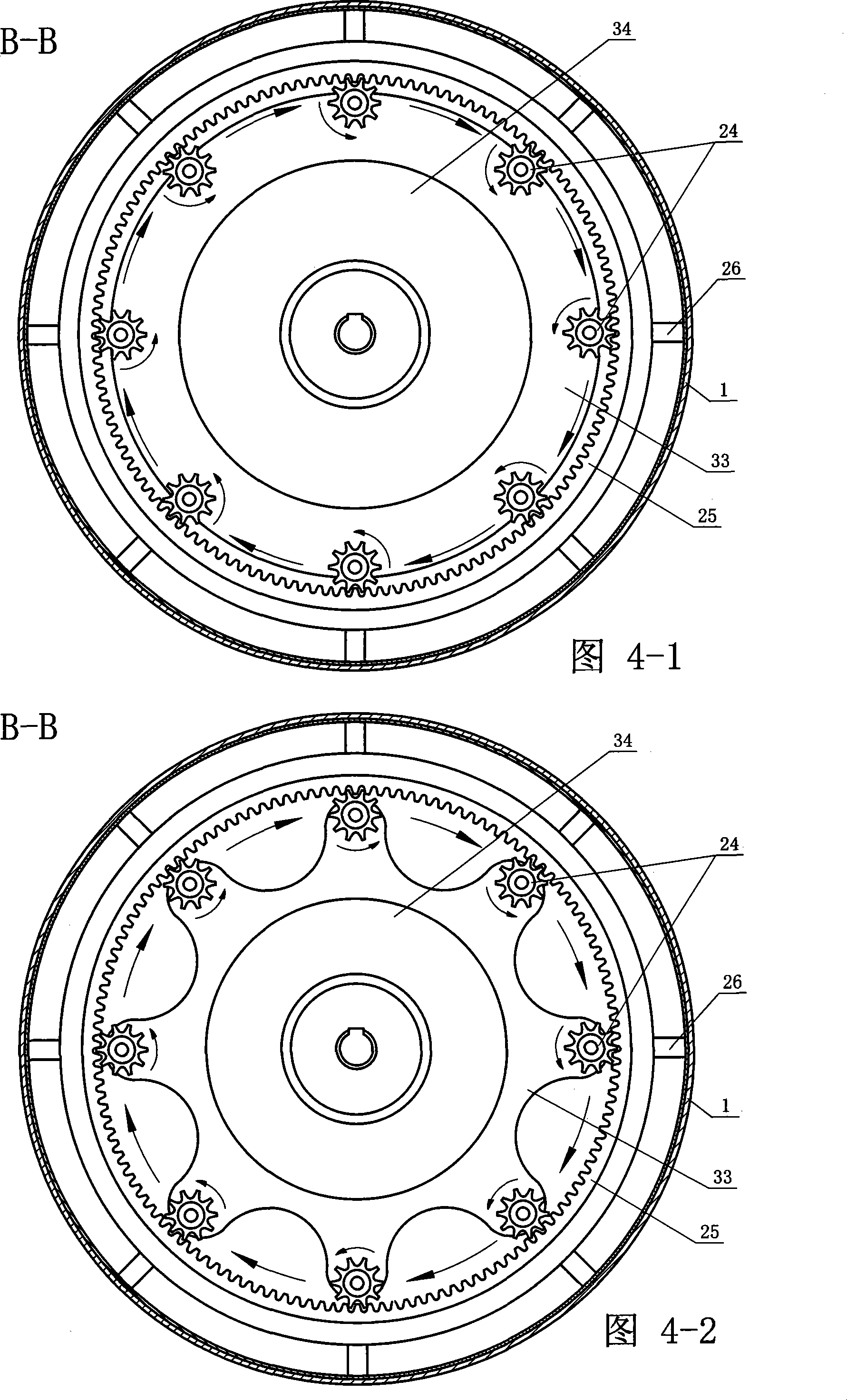

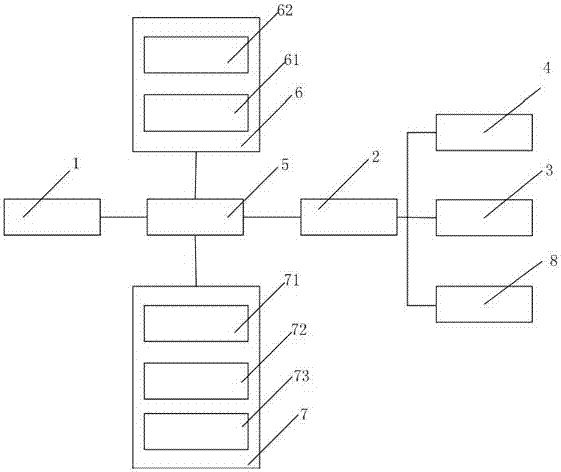

High-efficiency energy-saving environment-protection barbecue machine

InactiveCN101218979AImprove sealingAvoid getting lostFood processingClimate change adaptationEngineeringSmall footprint

The invention relates to a high effective and energy saving green barbecue machine which comprises a machine case with a stand, a heating device which is arranged in the machine case, a power mechanism which is fixedly arranged at the outer side of the machine case, an air outlet, an air intake mechanism and an oven door at the side wall of the machine case. The machine case is a vertical column shell or at least one assembled column shell. An upper end cover and a lower base plate are respectively and closely arranged on the upper end and the lower end of the column shell; the power mechanism is arranged on the upper surface of the upper end cover of the shell and the center of the inner side of the lower base plate; an air inlet is arranged on the lower end of the heating device; and a temperature controller is arranged in the machine case which is on the upper end of the heating device; an output shaft of the power mechanism runs through a central shaft hole of the upper end cover and a rotating mechanism which comprises a revolution mechanism and an auto-rotation mechanism is arranged on the shaft part at the inner side of the machine case. The high effective and energy saving green barbecue machine of the invention can prevent oil from the meat from dropping to fires and the secondary pollution by the oil smoke, thus reducing disease sources and preventing dust and ash pollution to the air during the barbecue; in addition, the machine occupies less area and is semi-automate, therefore, one person can control a plurality of barbecue machines and the machine is beneficial for popularization.

Owner:河南御寨山庄有限公司

Processing method of green bud tea

The invention discloses a processing method of green bud tea, comprising the following steps: paving tea leaves on a tea groove, wherein the paving thickness is 10-15cm; ventilating with an assistant blower, wherein the paving time is 10-14h; water-removing the tea leaves, wherein the cylinder temperature of the tea inlet end is 269-275 DEG C, the middle section temperature is 253-260 DEG C, the tea outlet end temperature is 219-225 DEG C, the leaves temperature is 102-108 DEG C, and; the water removing time is 1min25s-1min30s; directly putting the water removed tea leaves to a vibration groove, and putting the tea leaves into a wind selector, sending the selected tea leaves to a microwave water removing machine through a transporter, wherein the temperature of the water removing machine is 120 DEG C, the tea leaves temperature is 46-49 DEG C, the rotary speed is 1100r / min, and the water removing time is 50s; grading, carding, shaping, drying, infrared flavor enhancing. The method canincrease the shape, color and smell of green bud tea.

Owner:贵州湄潭兰馨茶业有限公司

Community access control system based on WeChat and door opening method

ActiveCN107507305AWide range of servicesLow costIndividual entry/exit registersData switching networksAccess timeComputer terminal

The invention discloses a community access control system based on WeChat and a door opening method. The community access control system based on WeChat comprises a two-dimensional code display unit, a WeChat platform, a household mobile terminal, a visitor mobile terminal, an official account cloud server, a community entrance machine and a unit entrance machine. By subscribing an access control cloud service WeChat official account through the household mobile terminal and the visitor mobile terminal, communication of the official account cloud server and the household mobile terminal with the visitor mobile terminal can be realized. In the relevant door opening method, the household can carry out pre-authorization and limit the access time of a visitor, also the method can achieve identity verification of the visitor, also can provide navigation for the visitor from the community entrance machine to the unit entrance machine, and enhances the door opening experience of the household and visitor.

Owner:XIAMEN DNAKE INTELLIGENT TECH CO LTD

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458AReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

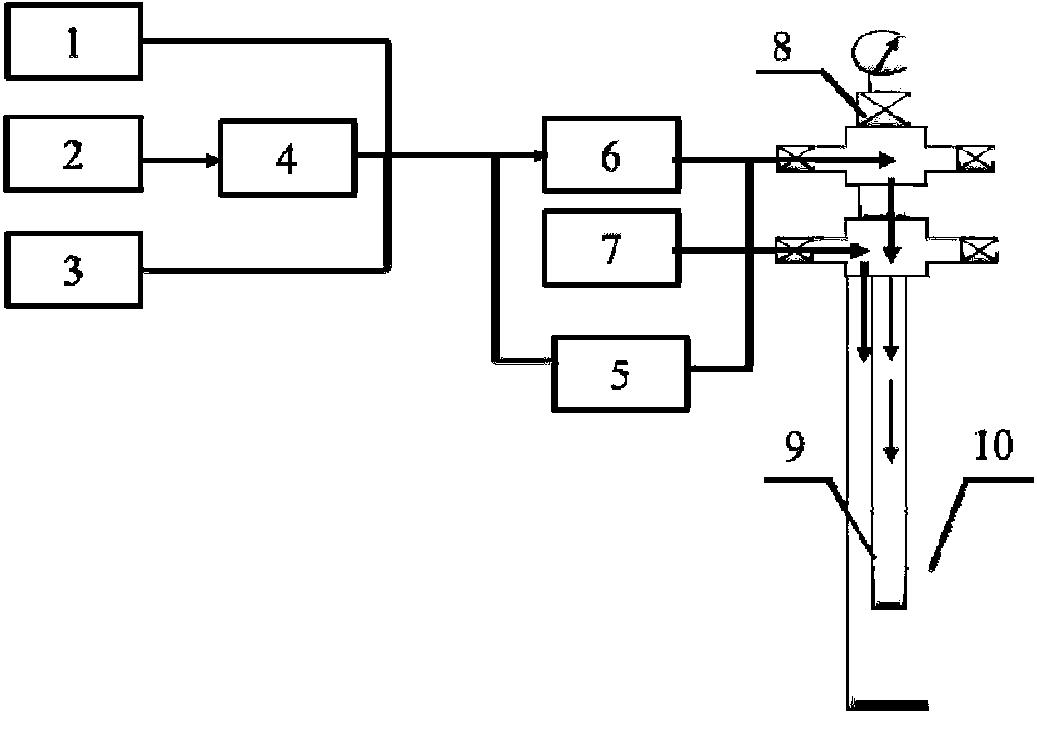

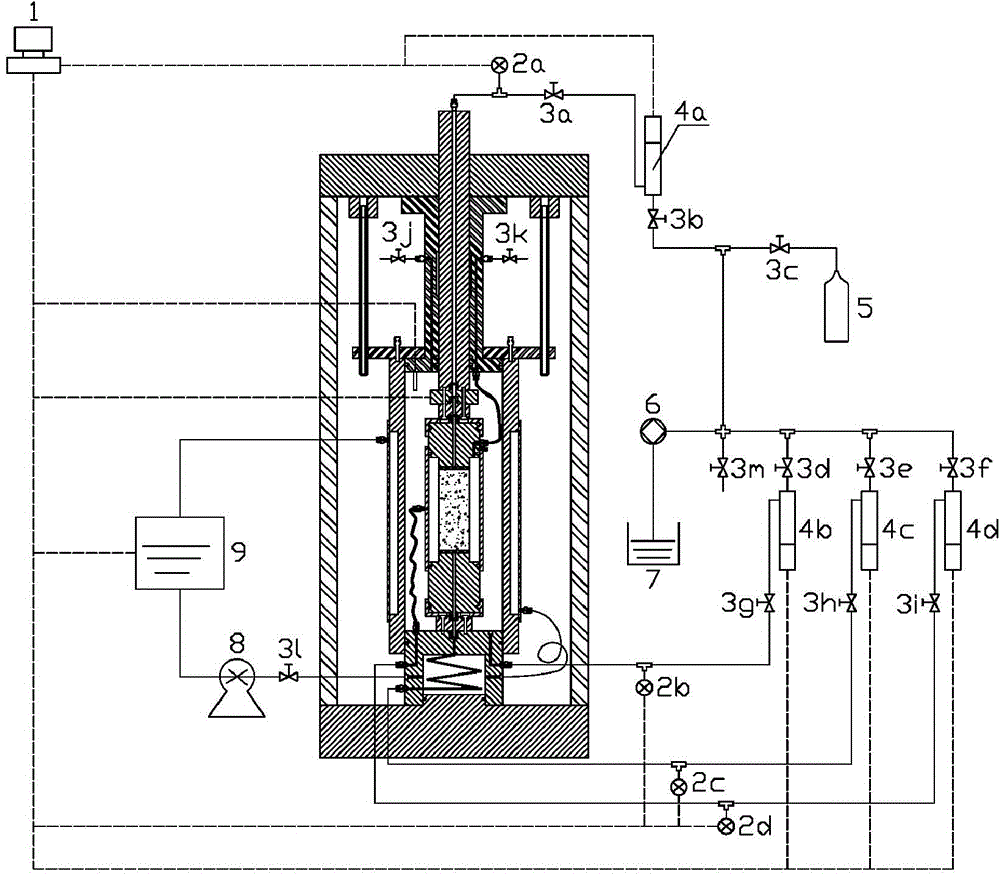

Natural gas hydrate sediment triaxial test device

ActiveCN104833582AApplicable volumetric measurementGain body changeMaterial strength using tensile/compressive forcesDecompositionData acquisition

The invention discloses a natural gas hydrate sediment triaxial test device, and belongs to the field of testing the mechanical properties of natural gas hydrate sediment. The device comprises a triaxial test device main machine, a temperature control system, a pore pressure control system, a confining pressure control system and a computer data acquisition and control system. The triaxial test device main machine, which is in a dual-pressure-chamber structure, can be used for accurately measuring volume change in the sediment in a natural gas hydrate decomposing process; a load sensor is arranged inside the pressure chamber and is capable of improving the precision of intensity data; a pre-cooling hollow cavity is formed inside a base to pre-cool pore gas and pore water which enter a sample, so as to relieve the decomposition of the natural gas hydrate in a saturated water process and to improve the precision of temperature control; in a sample installation process, a quick coupling is adopted for connection, so that the operation is convenient and rapid. The device can simulate the natural gas hydrate decomposing process under mining conditions, so as to achieve the high-precision temperature control, and accurate measurement of intensity and volume change; and the device has great significances for understanding the mechanical properties of the natural gas hydrate sediment and assessing the stability of a reservoir.

Owner:DALIAN UNIV OF TECH

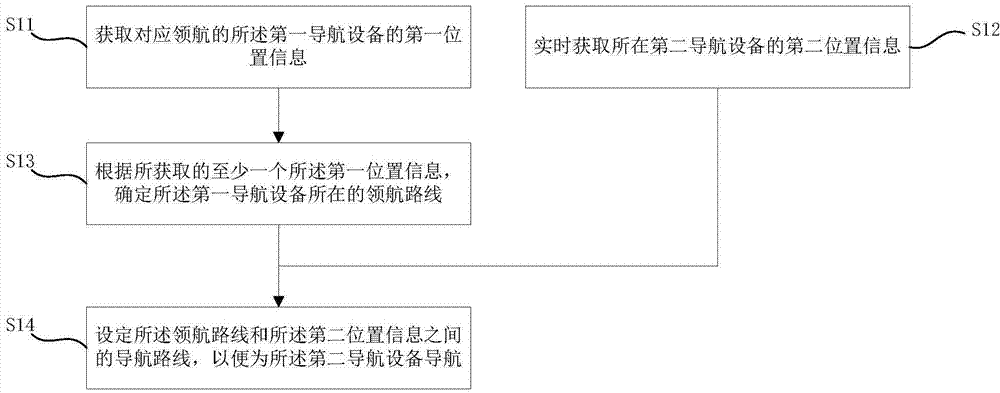

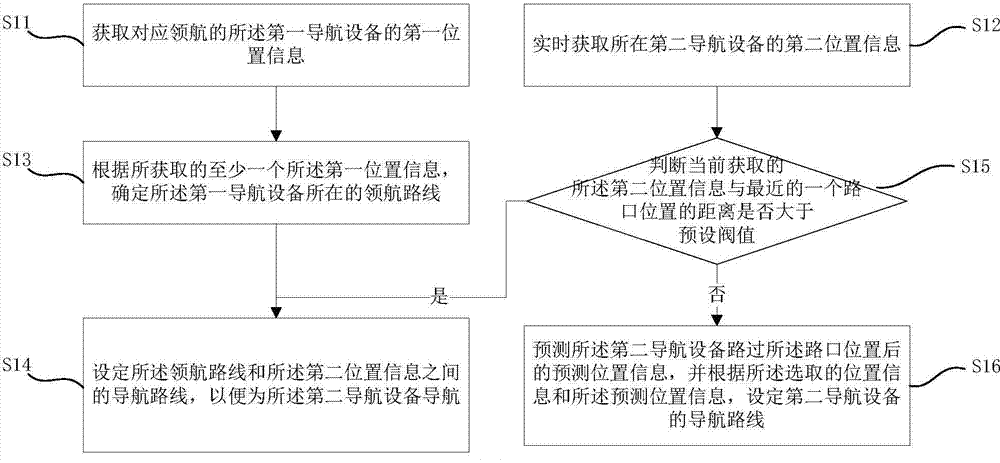

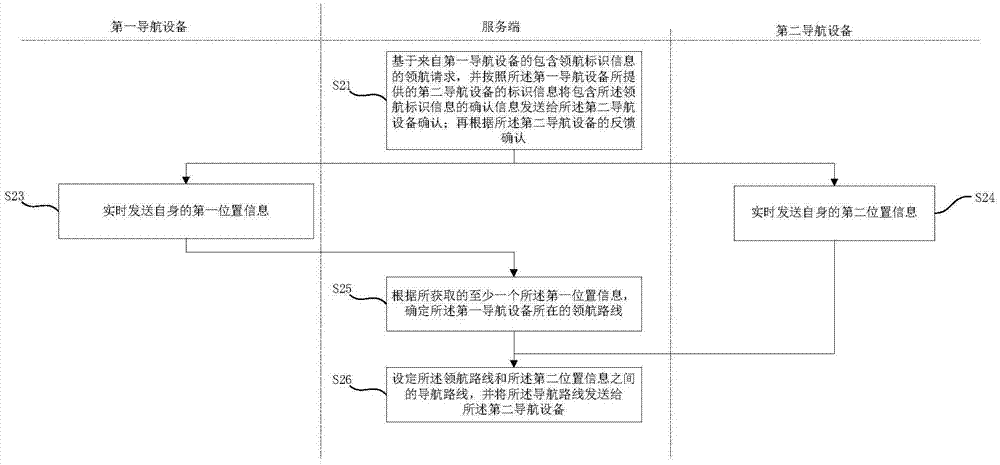

Car following navigation method and system and navigation system

ActiveCN104776854AReduce confusionEasy to findInstruments for road network navigationNavigation systemMarine navigation

The invention provides a car following navigation method and system and a navigation system. The method comprises the steps that the navigation system obtains the first position information corresponding to a piloting first navigation device in real time and obtaining the second position information corresponding to a following second navigation device in real time at the same time; a piloting route where the first navigation device is located is determined according to at least one piece of obtained first position information; a navigation route between the piloting route and the second position information is set, so that the second navigation device conducts navigation. By means of the car following navigation method and system and the navigation system, the function of car following navigating is achieved on the second navigation device when two vehicles run at the same time.

Owner:SHANGHAI DROI TECH CO LTD

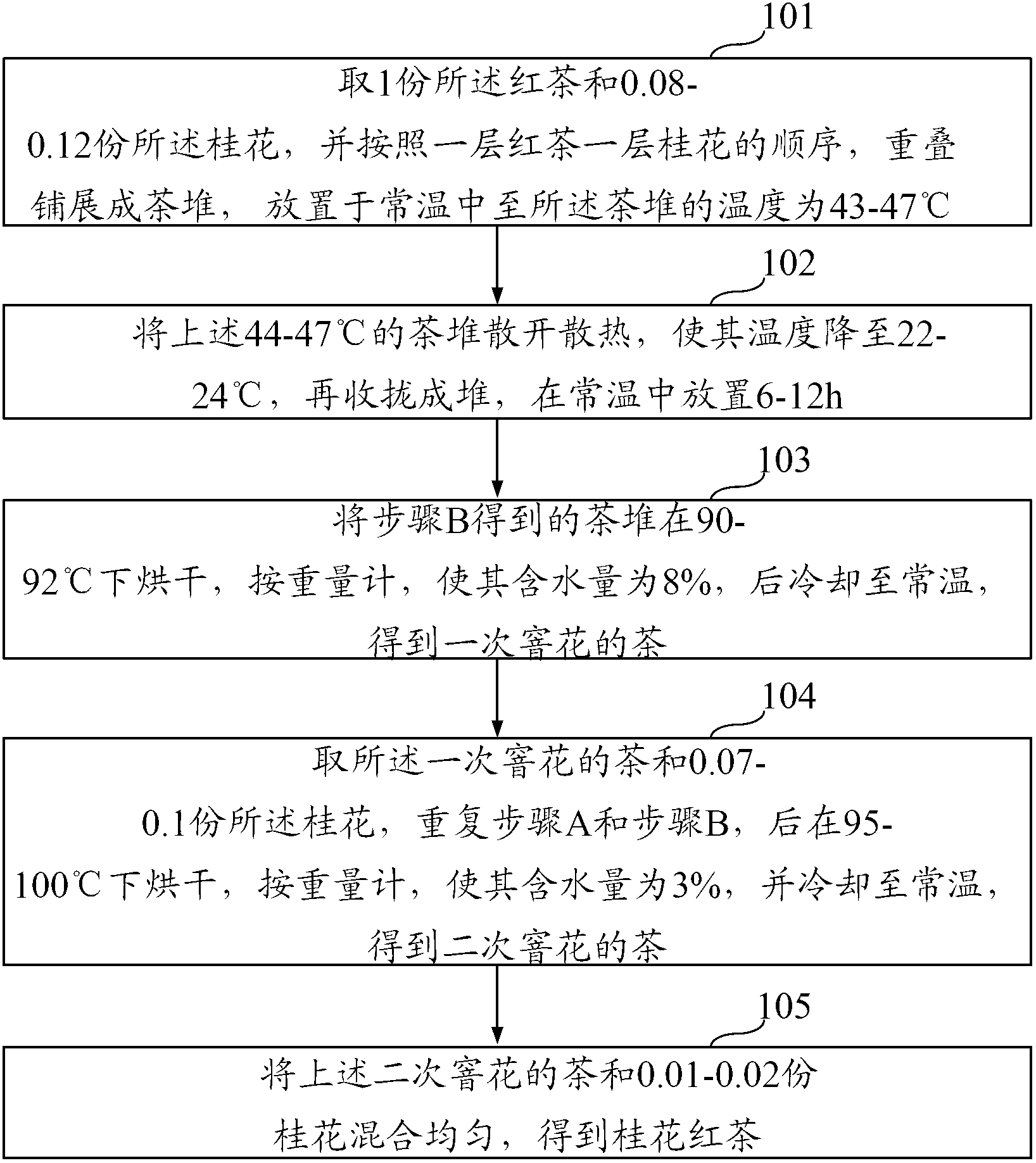

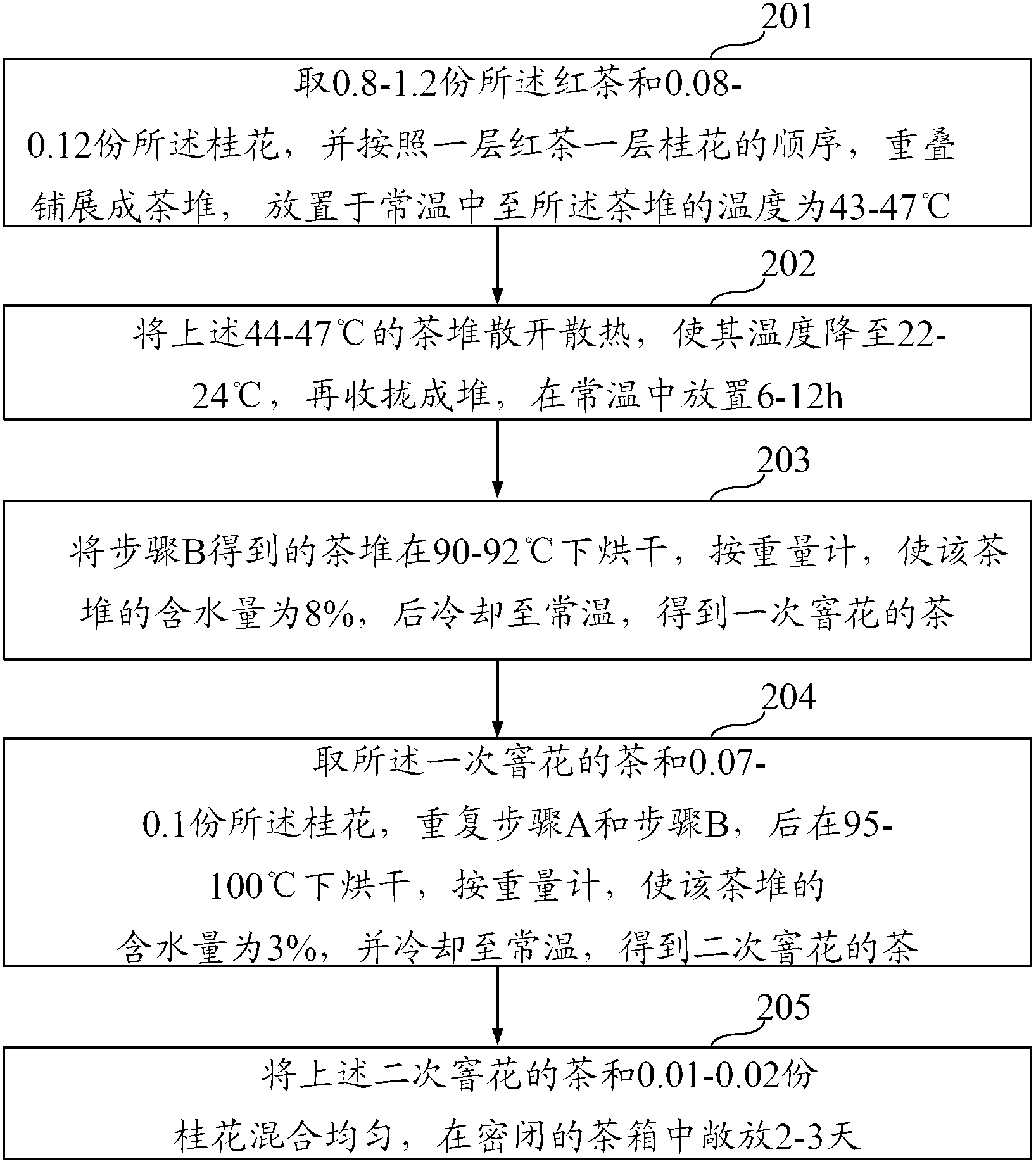

Black tea with sweet osmanthus and scenting method thereof

The invention belongs to the field of making of tea leaves, and particularly relates to black tea with sweet osmanthus and a scenting method thereof. The black tea with sweet osmanthus comprises the following components in parts by weight: 0.8-1.2 parts of black tea and 0.16-0.24 parts of sweet osmanthus. The scenting method comprises the following steps of: spreading 1 part of black tea and 0.08-0.12 parts of sweet osmanthus layer after layer alternatively to form a tea pile, and standing at the normal temperature till the temperature of the tea pile is 43-47 DEG C; spreading for dissipating heat till the temperature is lowered to 22-24 DEG C, gathering into a pile, and standing at the normal temperature for 6-12 hours; drying at the temperature of 90-92 DEG C, and cooling to obtain primarily-scented tea; adding 0.07-1 part of sweet osmanthus, repeating the previous steps, drying at the temperature of 95-100 DEG C and cooling to obtain secondly-scented tea; and adding the left sweet osmanthus, and mixing to obtain the black tea with sweet osmanthus. The black tea with the sweet osmanthus is prepared manually, so that damages of a mechanical way to nutritional ingredients are avoided, and the natural values of the black tea and the sweet osmanthus are kept.

Owner:李德芬

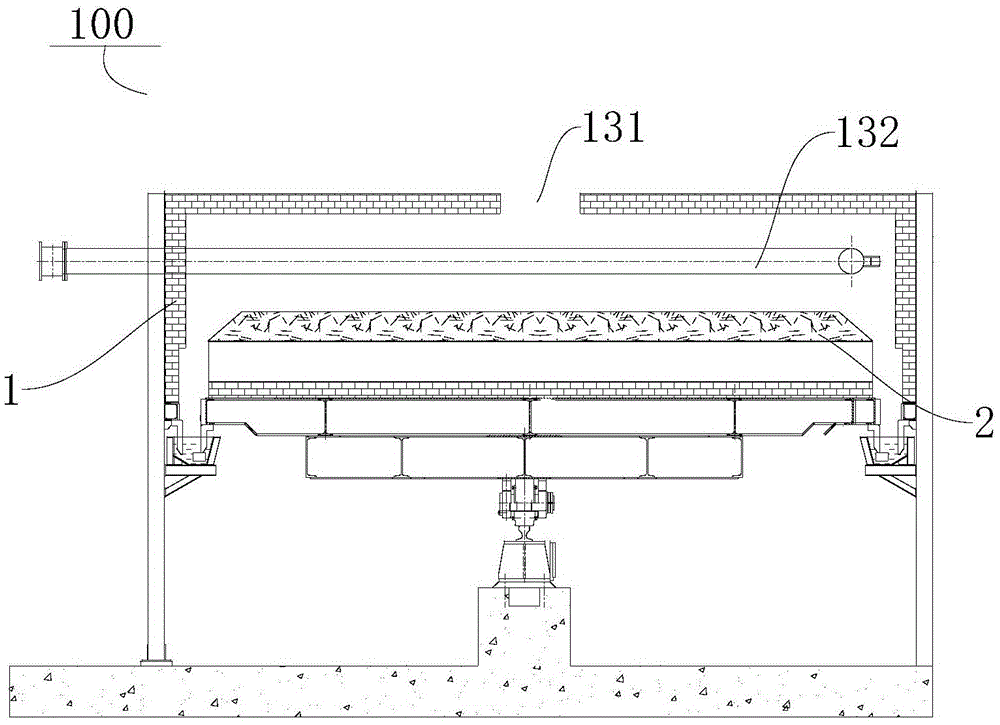

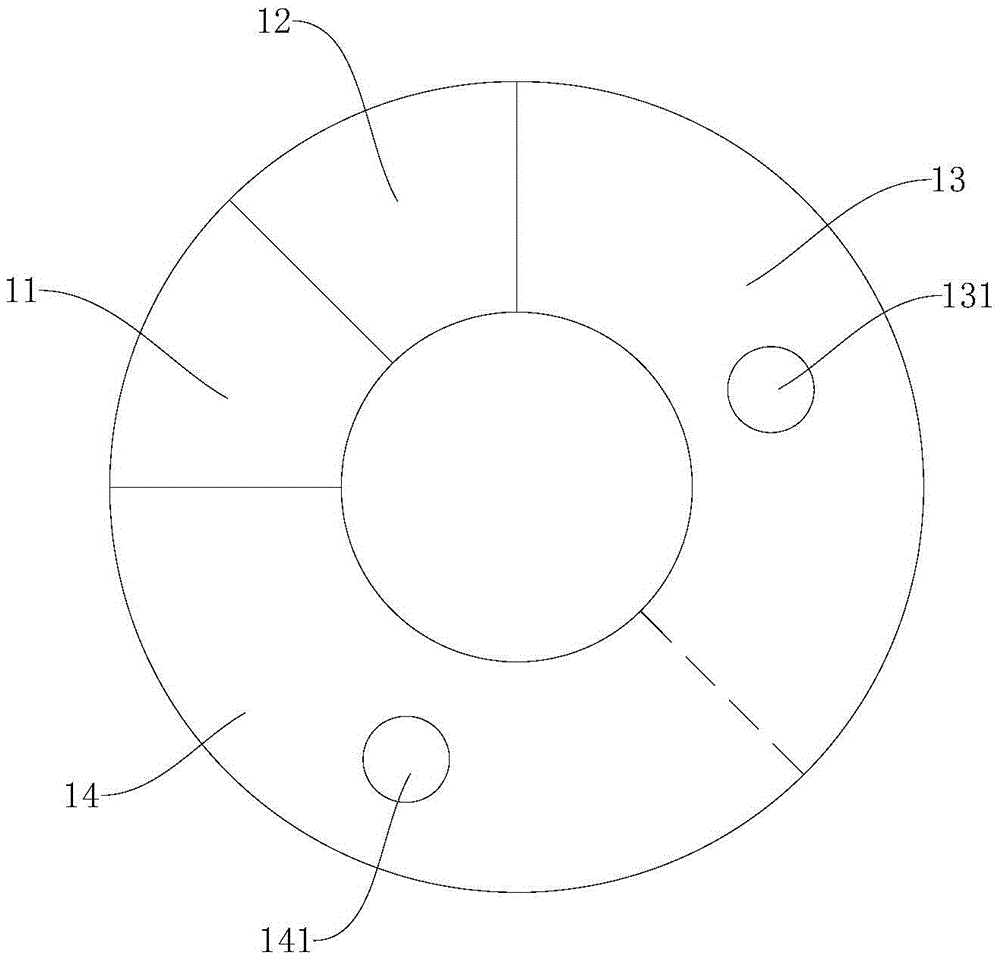

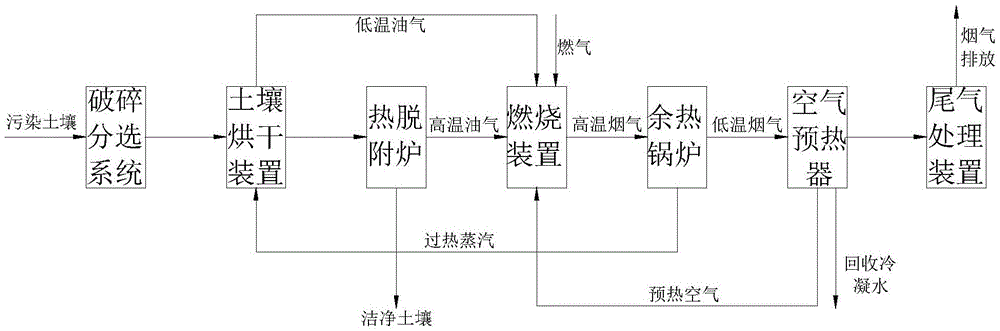

Soil restoration system and soil restoration method thereof

PendingCN105583221AAvoid getting lostAvoid wastingContaminated soil reclamationIndirect carbon-dioxide mitigationFistCombustion chamber

The invention discloses a soil restoration system and a soil restoration method thereof. The soil restoration system comprises a thermal desorption furnace, a combustion device and a waste heat boiler. The thermal desorption furnace comprises a furnace body, a material distributing plate and a first radiant pipe combustor. A thermal desorption region is arranged in the furnace body. The first radiant pipe combustor is arranged on the side wall of the furnace wall so as to provide thermal desorption heat for soil in the thermal desorption region. The position, corresponding to the thermal desorption region, of the furnace body is provided with a volatile gas outlet. The combustion device is provided with a combustion chamber used for combusting gas. The combustion chamber is provided with a fuel gas inlet, a first flue gas inlet and a first flue gas outlet. The fist flue gas inlet communicates with the volatile gas outlet. The waste heat boiler is provided with a second flue gas inlet and a second flue gas outlet. The second flue gas outlet communicates with the first flue gas outlet. According to the soil restoration system, heat in high-temperature oil gas generated in the thermal desorption furnace can be repeatedly used, and loss of lots of heat and energy waste are avoided.

Owner:SHENWU TECH GRP CO LTD

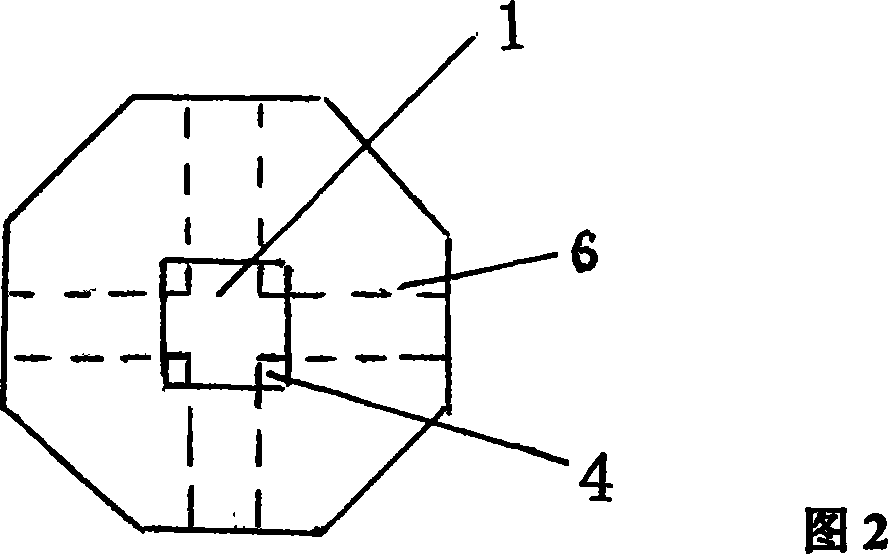

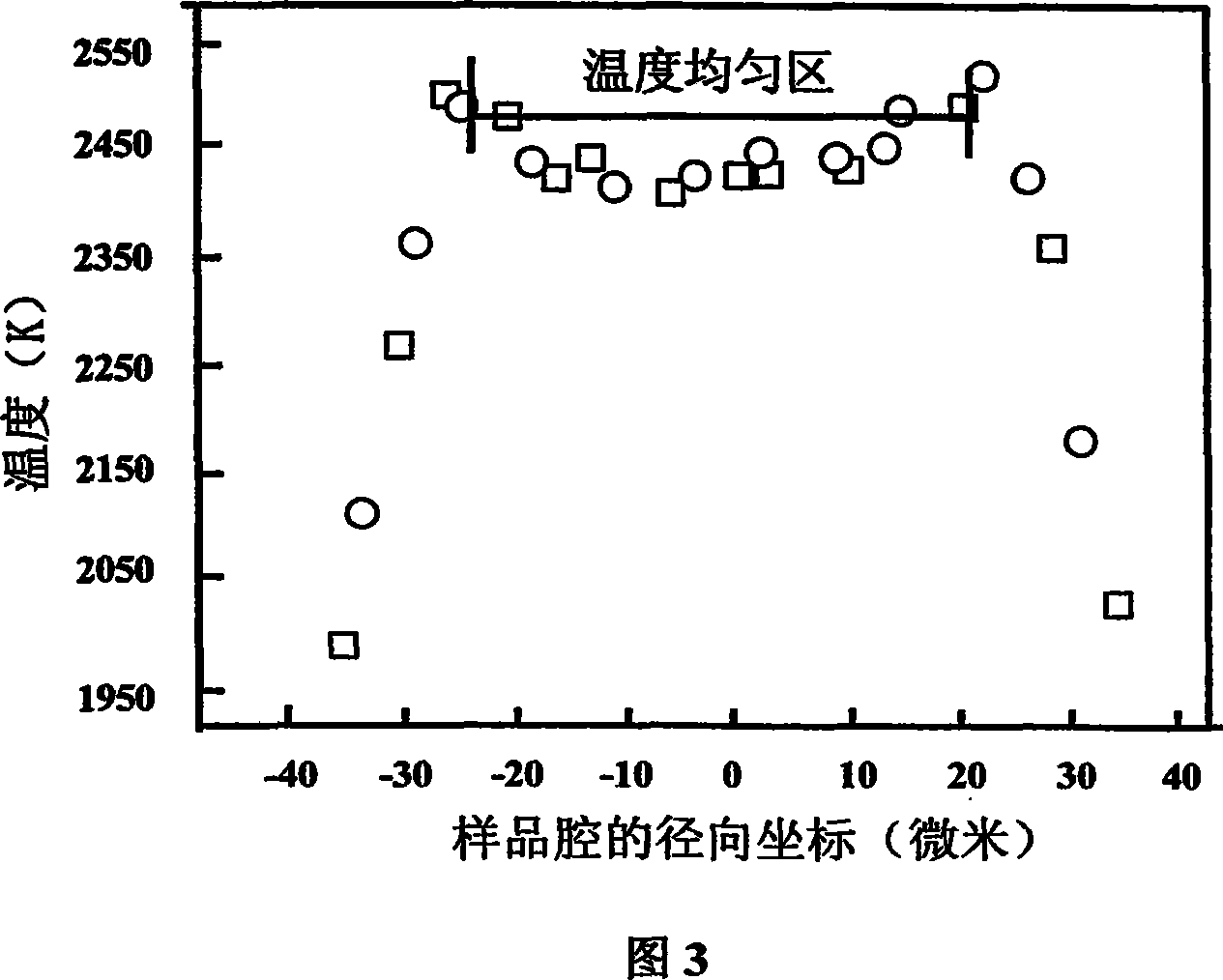

Diamond anvil for electrical quantity in-situ measurement and its production method

InactiveCN101078703APrevent heat lossReduce temperature gradientMaterial analysis by electric/magnetic meansPhotolithographyDiamond anvil cell

The invention relates to a diamond anvil cell for measuring electronic quantity in situ and the manufacturing method, belonging to the technology field of high-temperature and high-pressure device. Heat insulation layer of aluminum oxide 1, two to four mutual insulated electrodes 4 and protecting layer of aluminum oxide 6 are deposited in turn on anvil face and side face of diamond anvil. The distribution of each electrode 4 is from the anvil face to the side face. The end of electrode 4 at the anvil face is bare and is in the sample cavity 3 of diamond anvil cell. The end of electrode 4 at the side face is bare and is connected with electrode leader 5. Heat insulation layer of aluminum oxide 1, electrode 4, protecting layer 6 are integrated on the diamond anvil in turn by film deposition technology and photolithographic method. Heat insulation layer and electrode designed in the invention can prevent loss of heat quantity effectively and decrease temperature gradient in sample cavity obviously so that the measurement of electronic quantity can be realized under high temperature and high pressure and measuring accuracy can be guaranteed.

Owner:JILIN UNIV

Method for producing organic fertilizer by processing pig manure

InactiveCN101279861AStart fastShort startup timeBio-organic fraction processingEnergy inputFiberZymogen

Disclosed is a method for treating pig manures to produce an organic fertilizer, which inoculates horse manures in pig manures and purifies and amplifies high temperature fiber bacteria thereof to prepare a zymogen agent through two times of high temperature fermentation, then composts are inoculated in a solar energy isolation greenhouse to produce the organic fertilizer. The method has advantages of fast compost starting, low cost of nitrogen protecting and deodorization agent, broad sources and good effects; and the whole process for producing the organic fertilizer is conducted in the solar energy isolation greenhouse, thereby effectively preventing secondary pollutions such as pig manures and diffusion of nutrients and realizing the clean treatment to the pig manures and production to the organic fertilizer. The method is suitable for the southwest area and the like in China abound with rain and moisture and with rather low temperature in winter, and has advantages of low investment, low energy consumption, low cost, simple operation, strong practicability and easy promotion.

Owner:SOUTHWEST UNIVERSITY

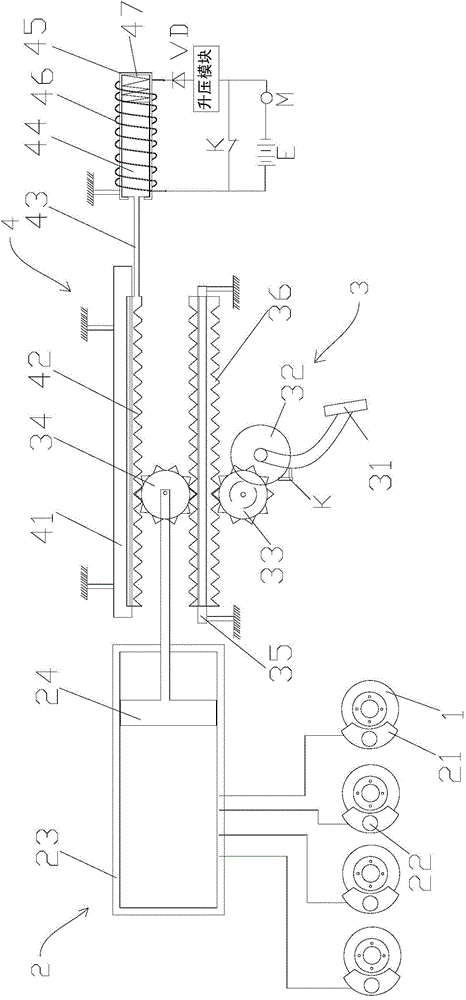

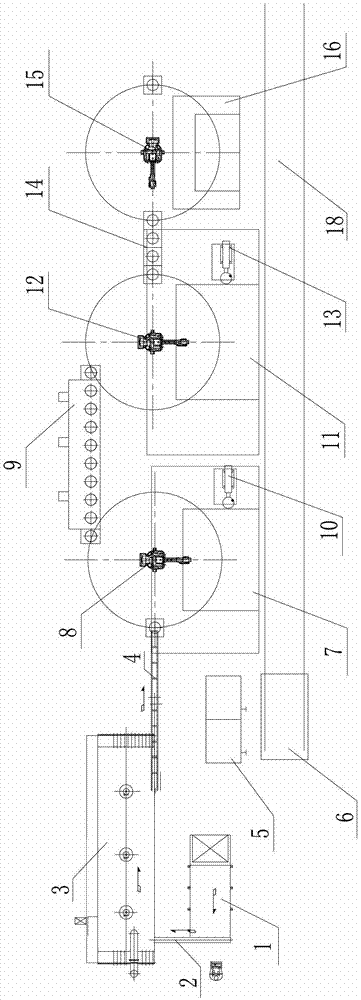

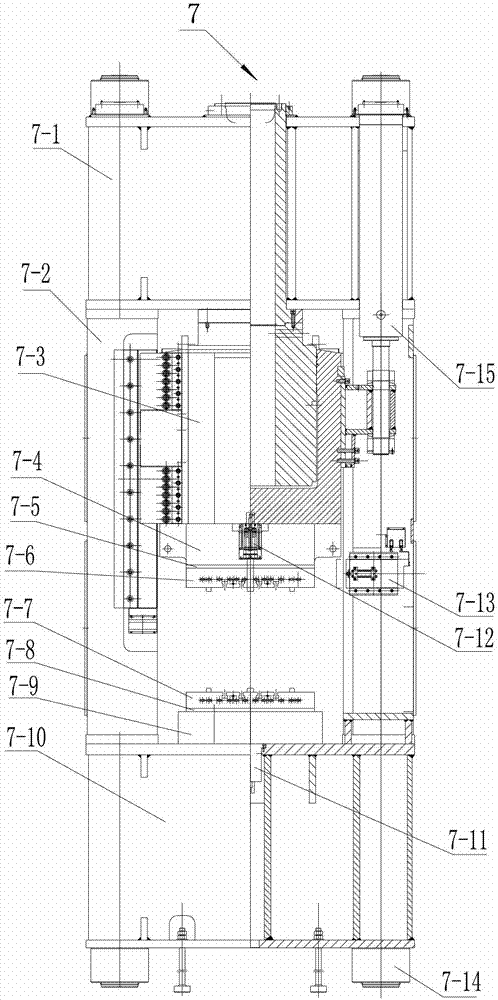

Large-scale aluminum alloy hub isothermal forging production line

ActiveCN102873253ASimplify the pressing processRealize visual operationShaping safety devicesForging/hammering/pressing machinesProduction lineHeating furnace

The invention relates to a large-scale aluminum alloy hub isothermal forging production line. The large-scale aluminum alloy hub isothermal forging production line is characterized by comprising a bar cutting machine, a bar heating furnace, a plurality of delivery manipulators, a pre-forging hydraulic press, a hub finish-forging hydraulic press, an aluminum alloy hub broaching and trimming hydraulic press and a pressing die. A cold material conveying roller table is arranged between the bar cutting machine and the bar heating furnace, a hot material conveying roller table is arranged between the other end of the bar heating furnace and the delivery manipulators, a die heating furnace, a die change trolley and a change trolley rail are arranged on one side of the pre-forging hydraulic press, a pre-forging lubrication spraying device is arranged on the other side of the pre-forging hydraulic press, a middle heating furnace or a delivery roller table is arranged between each two manipulators, and a finish-forging lubrication spraying device is arranged on one side of the hub finish-forging hydraulic press. The large-scale aluminum alloy hub isothermal forging production line has the advantages that by means of structural and technical combination of hot die forging, broaching and trimming, one-time pressing of aluminum alloy hubs can be realized, the pressing process of the aluminum alloy hubs is simplified, cost, time and labor for later-stage secondary processing and shaping can be greatly saved, and production efficiency is improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Compound steamed-bread preserving modifier

The present invention belongs to the field of food preserving technology, and is especially one kind of compound steamed bread preserving modifier comprising starch hydrolase 1-7 wt%, hemicellulase 3-7 wt%, lipase 3-7 wt%, emulsifier 40-70 wt%, hydrophilic colloid 15-40 wt%, and coagulation inhibitor 2-6 wt%. The compound steamed bread preserving modifier can improve the internal structure of steamed bread, soften core, promote the form of cellular gluten structure, raise the antiageing performance, raise total water content and delay water-losing ageing of steamed bread.

Owner:河南兴泰科技实业有限公司

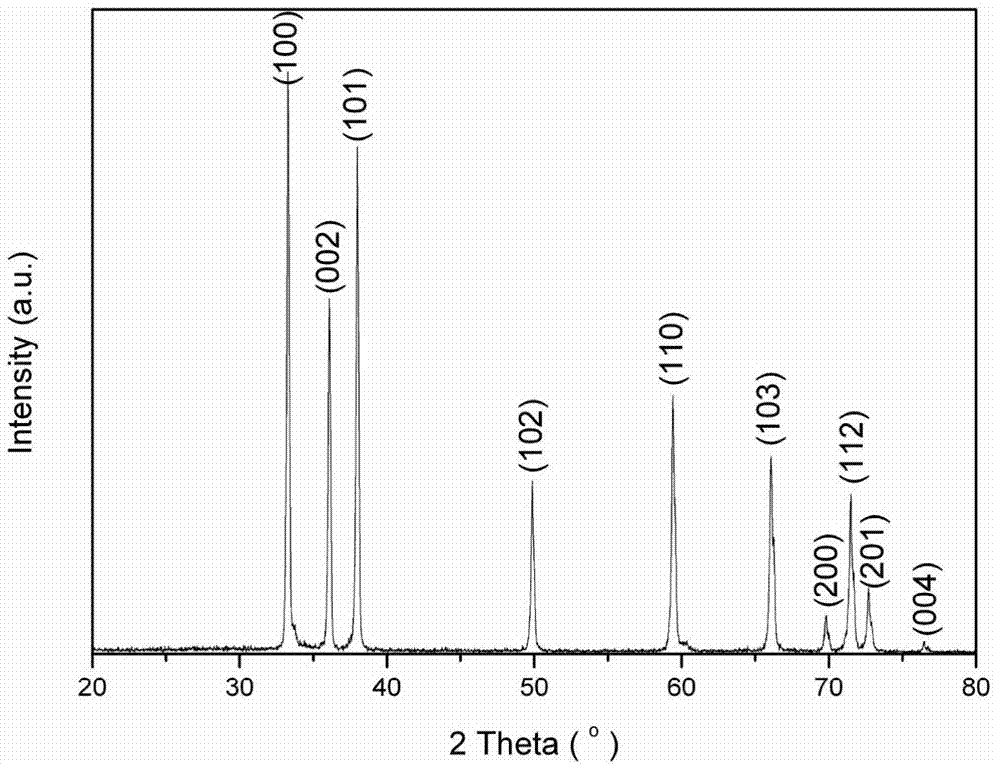

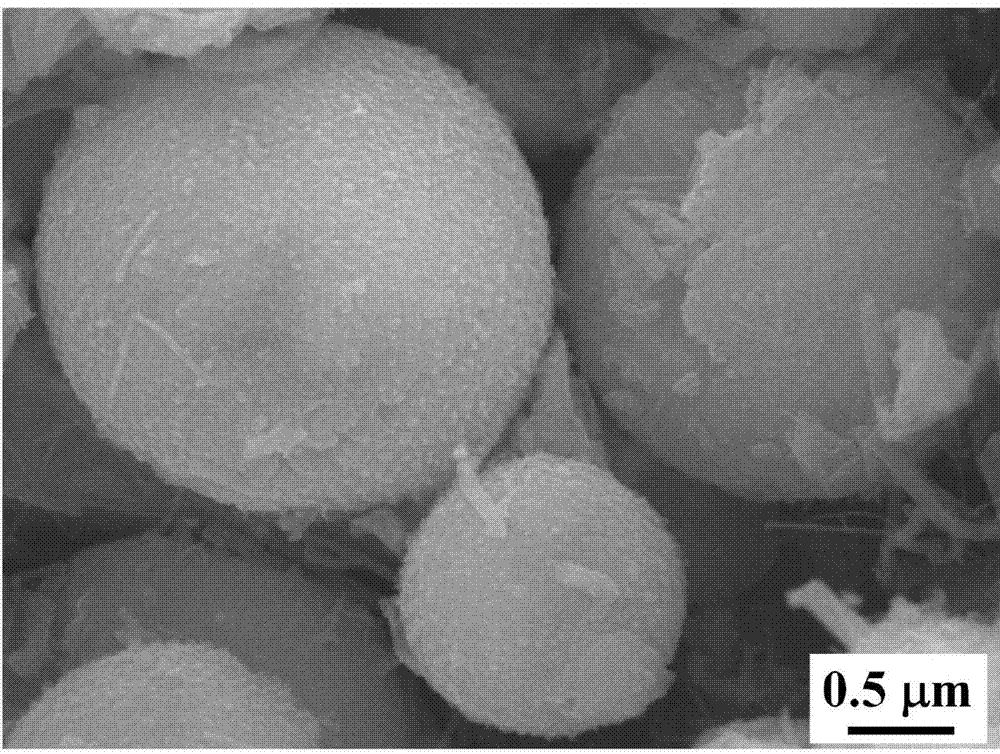

Method for preparing spherical aluminum nitride powder

The invention provides a method for preparing a spherical aluminum nitride powder. The method comprises the following steps of: 1, mixing aluminum powder with aluminum nitride powder and ammonium chloride powder, putting the mixture into a mortar for grinding, wherein the aluminum powder is spherical aluminum powder having the particle size range from 0.5 micron to 3 microns; and the aluminum nitride powder is prepared from an aluminum source which is spherical aluminum powder having the same particle size with the raw material aluminum powder through in-situ nitrogenation; 2, putting the evenly ground powder in a porous graphite crucible with a graphitic carbon felt exterior heat preservation layer and an interior protective layer and reacting in a reaction device; 3, electrifying graphite paper, and igniting the powder from bottom to cause a combustion reaction; 4, after natural cooling, releasing nitrogen in the reaction chamber, and opening the reaction device, and obtaining an off-white powder in the porous graphite crucible, namely the spherical aluminum nitride powder; and 5, controlling the particle size of the spherical aluminum nitride powder through the particle size of the spherical aluminum powder. The method provided by the invention has the characteristics of low energy consumption, simple process and low cost; and the prepared spherical aluminum nitride powder is good in homogeneity and controllable in particle size.

Owner:咸阳瞪羚谷新材料科技有限公司

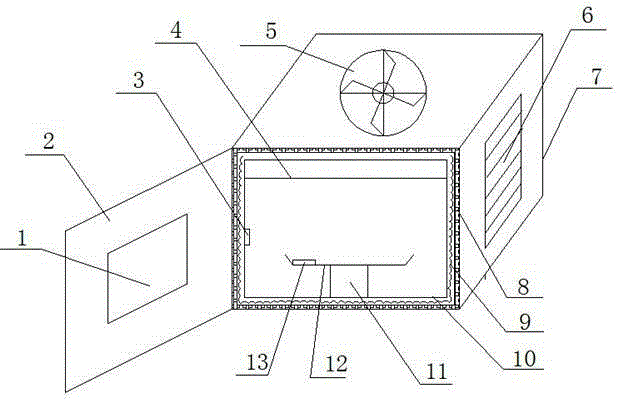

Electrothermal blowing dry box

InactiveCN105180604AAvoid getting lostIncrease profitDrying gas arrangementsDrying machines with local agitationLiquid-crystal displayEngineering

The invention discloses an electrothermal blowing dry box. The electrothermal blowing dry box comprises a box door, an air blower and a box body, wherein the air blower is arranged at the top of the box body; a radiating window is arranged at the right side of the box body; a rotating platform is arranged in the box body; a tray is arranged above the rotating platform; a humidity inductor is arranged on the tray; a temperature inductor is arranged on the inner wall of the box body; a protection plate is arranged at the upper part of the box body; air dispersing holes are uniformly distributed on the protection plate; the box door is arranged at the left side of the box body; an observation window is arranged at the middle part of the box door; a liquid crystal display screen is arranged at the left side of the box door; and an operation panel is arranged below the liquid crystal display screen. The electrothermal blowing dry box is reasonable in structure and practical in function; as the rotating platform is arranged, products are uniformly heated, and the temperature in the box is low in disturbance; electric heating wires are used for heating, so that the temperature adjustment is convenient and precise; and as the heat preservation layer is arranged, the heat loss can be effectively prevented, and the energy utilization rate is largely improved.

Owner:湖州周吴鼎盛化工有限公司

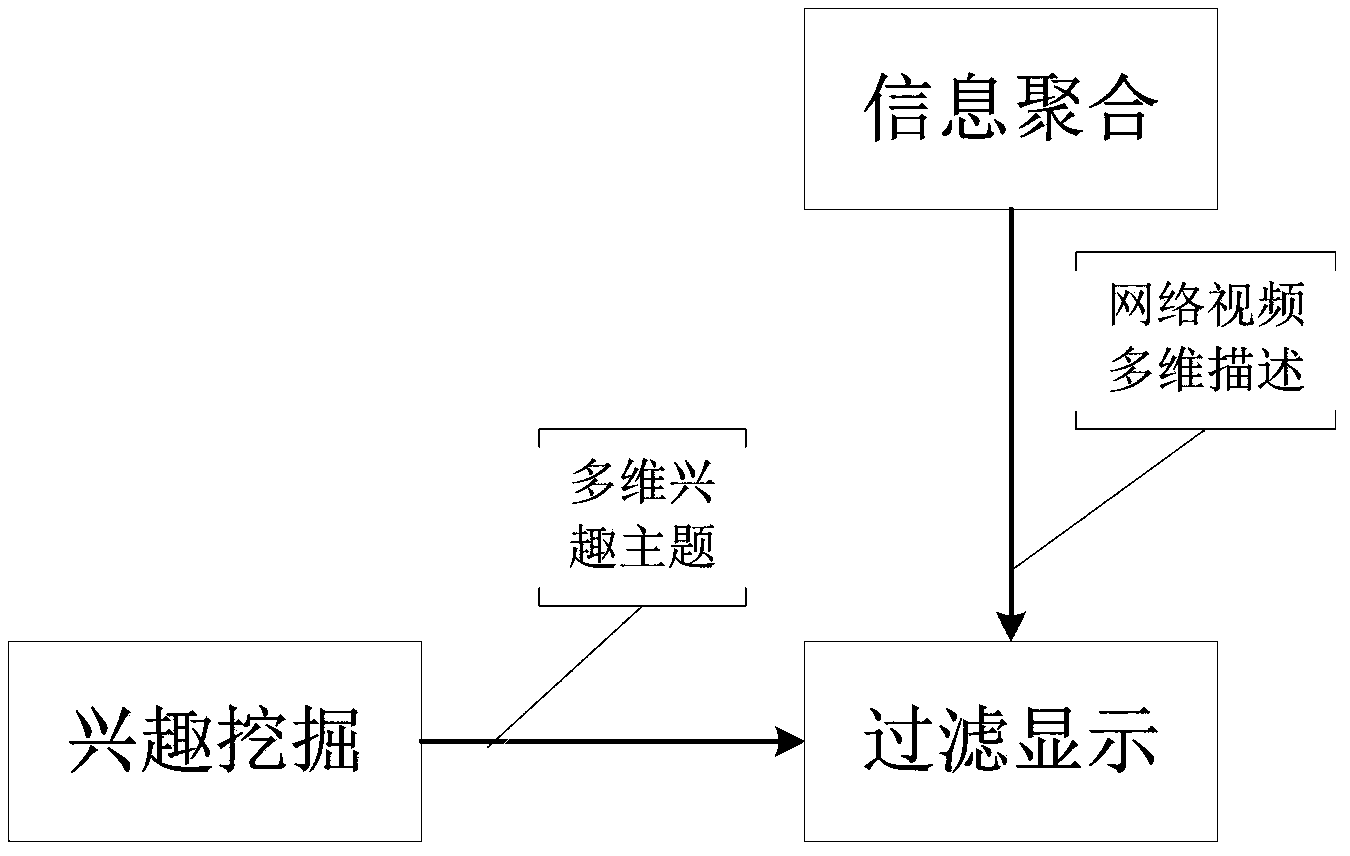

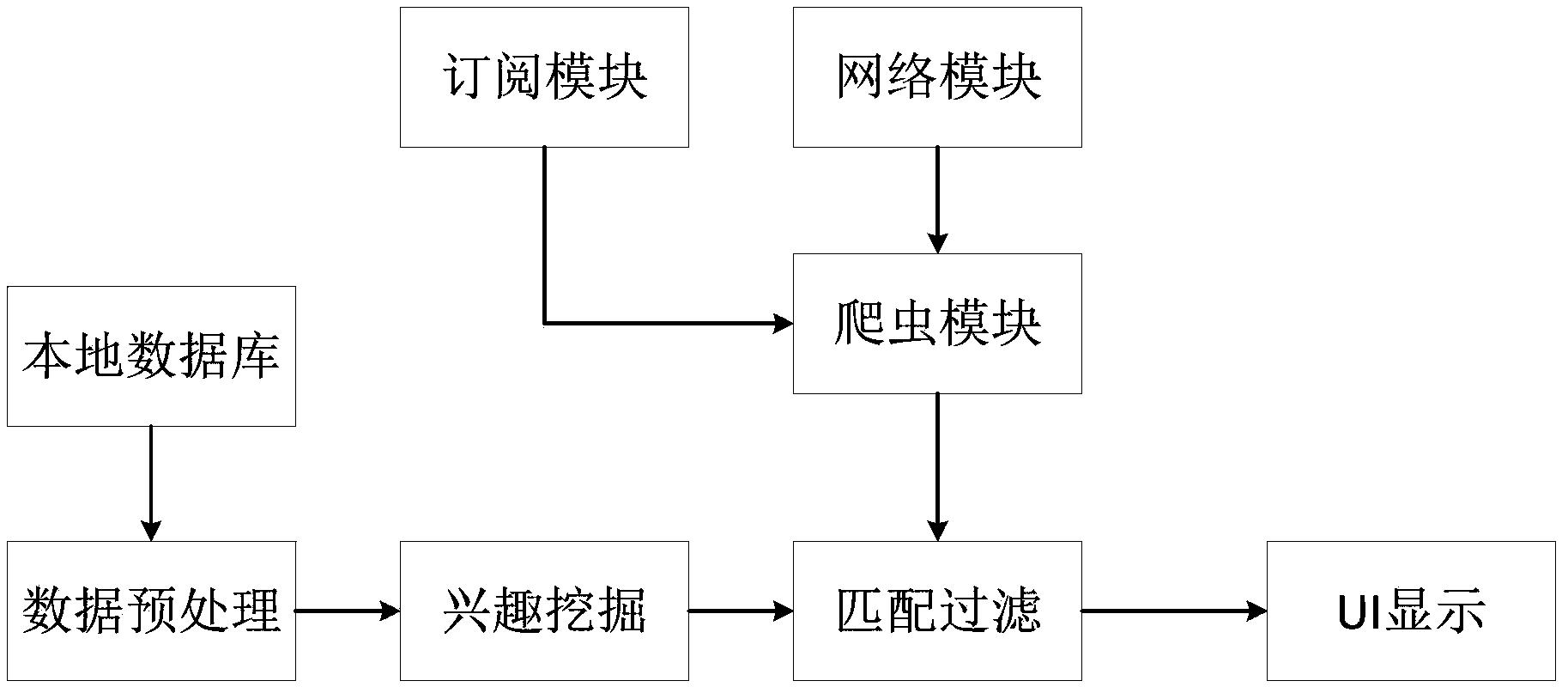

Terminal aggregation method and system for network videos

InactiveCN104144181AExtended Web Video SourcesAvoid choosing trekTransmissionSpecial data processing applicationsMultiple dimensionMetadata

The invention discloses a terminal aggregation method and system for network videos. The method and system are particularly suitable for intelligent television terminals. The system comprises a subscription module, a crawler module, a local database module, a preprocessing module, an interest mining module, a matching filtering module and a UI display module. The subscription module is used for specifying a source for network video aggregation. The crawler module is used for extracting metadata of the network videos. The local database module is used for storing local playing records and local video information. The preprocessing module is used for preprocessing local database data so as to be adaptive to the mining need for interest. The interest mining module is used for mining multi-dimension interest subjects according to a local database. The matching filtering module is used for filtering and sequencing the network videos according to the matching degree of the network videos and user interest. The UI display module is used for displaying a network video list which is obtained through filtering and sequencing. According to the method, the rich playing records of the user on a terminal are used for mining the multi-dimension interest subjects of the user, and the network videos meeting the user interest are aggregated from the massive quantity of network video resources by the utilization of subscription, interest and other limiting conditions.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI +1

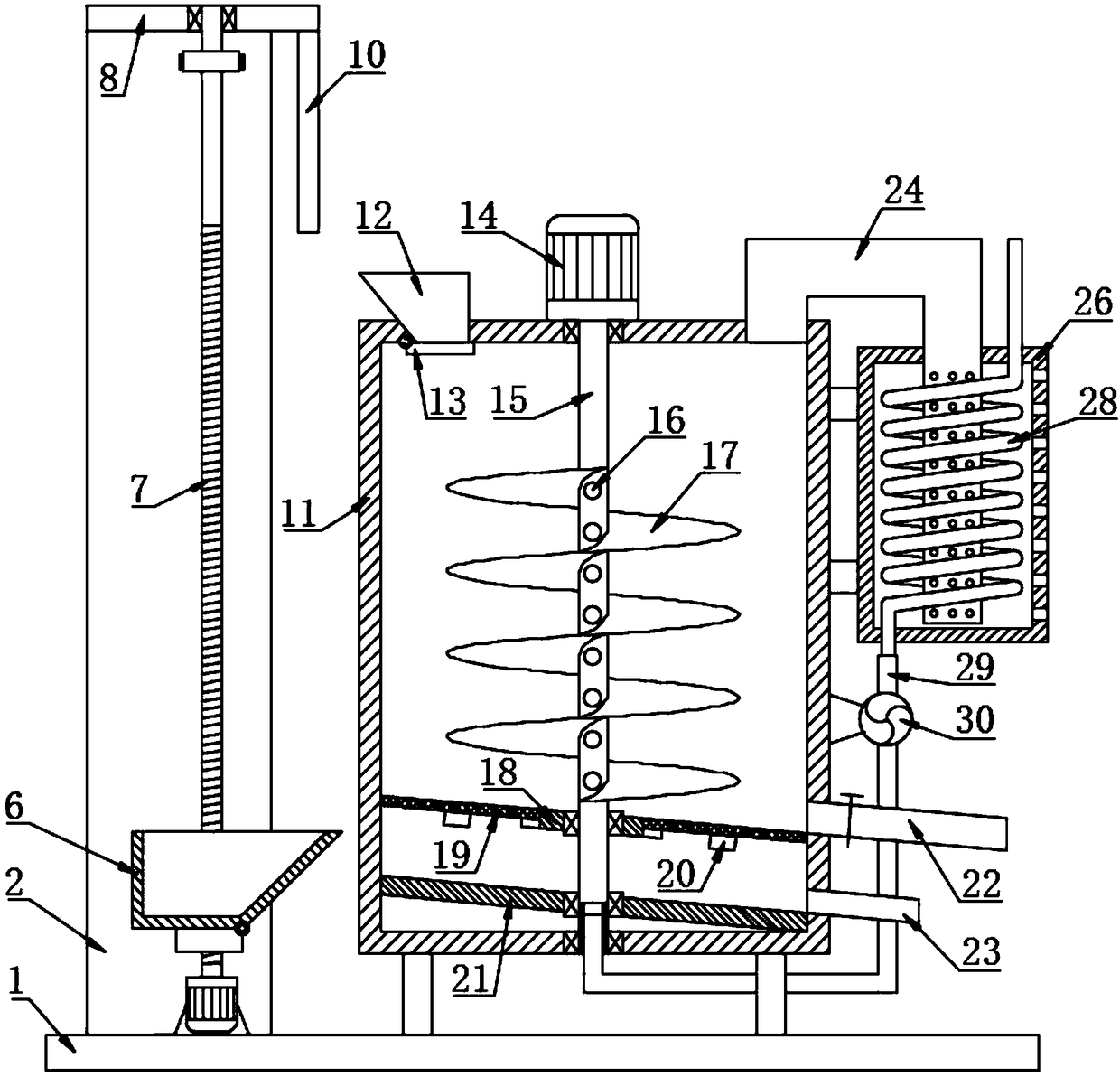

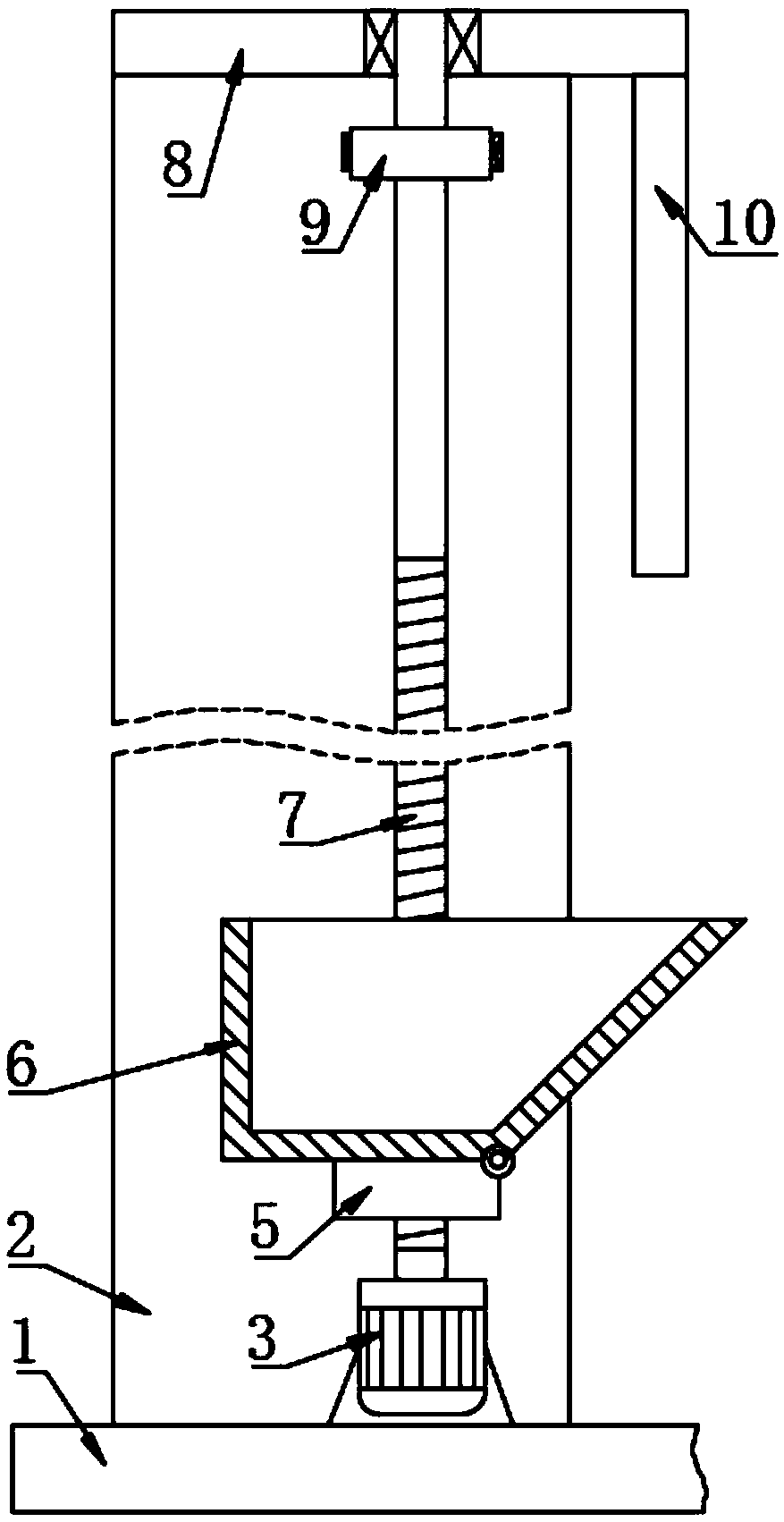

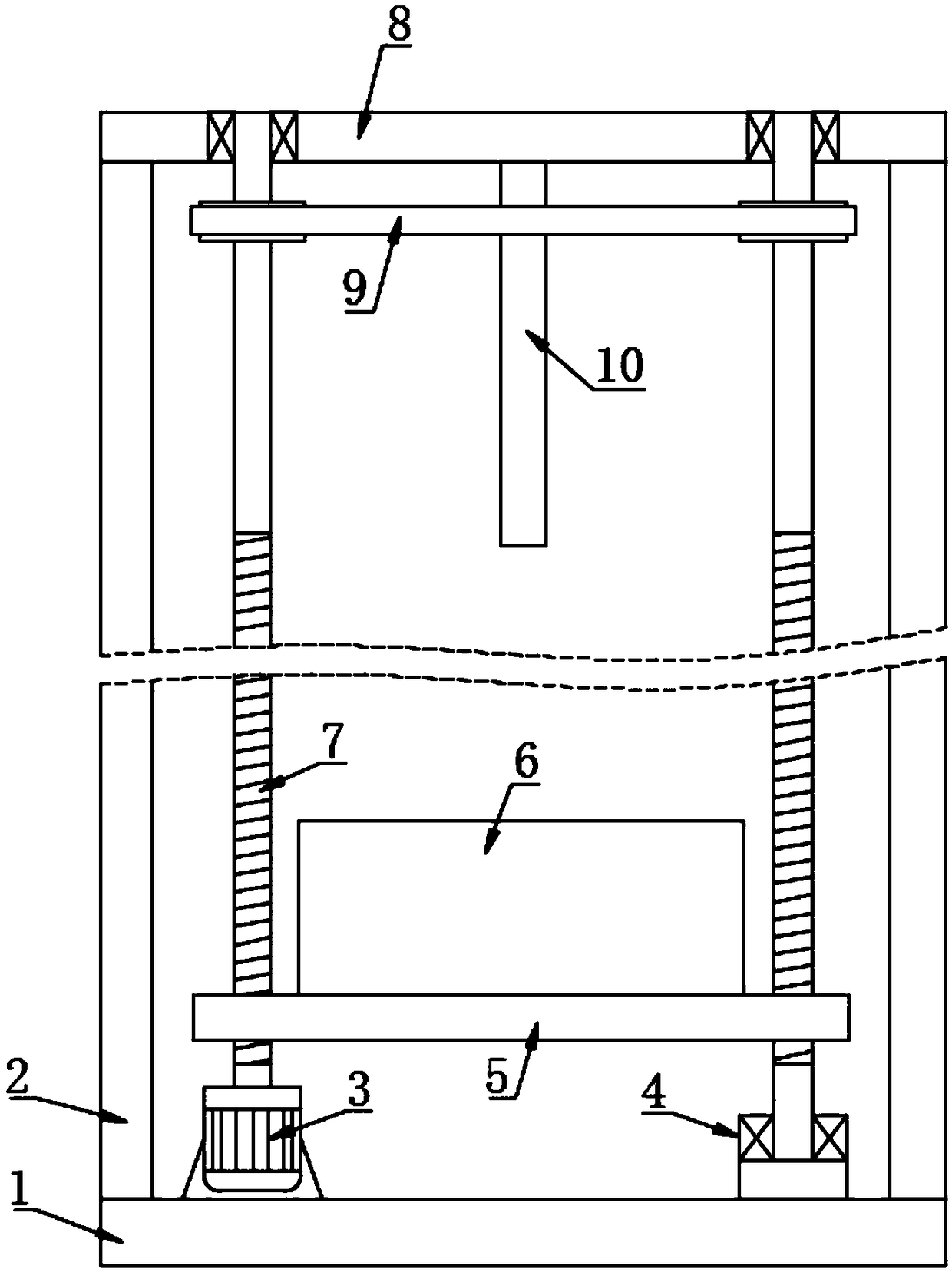

Self-feeding type energy-saving grain drying device

InactiveCN108800832AEvenly heatedImprove drying effectFood processingDrying gas arrangementsSpiral bladePulp and paper industry

The invention discloses a self-feeding type energy-saving grain drying device comprising a base. A drying barrel is fixed to the top of the base through a support, a rotating tube is arranged in the center in the drying barrel, and the upper end and the lower end of the rotating tube are rotationally connected with the top wall and the bottom wall of the drying barrel correspondingly. A second speed reducing motor is fixedly arranged at the center of the top of the drying barrel, a motor shaft at the bottom end of the second speed reducing motor is fixedly connected with the top end of the rotating tube, and spiral blades are fixedly mounted at the tube section, located above a screen plate, of the rotating tube. A plurality of one-way air outlet holes are uniformly formed in the tube section, between the spiral blades, of the rotating tube. A hot air blower is fixedly arranged at the right part of the side wall of the drying barrel, the air inlet end and the air outlet end of the hotair blower are connected with hot air tubes correspondingly, and the air outlet end of each hot air tube is connected into the rotating tube. The hot air blower is used for introducing hot air into the rotating tube, the hot air is discharged from the one-way air outlet holes to dry grains, and the heat is uniformly distributed; and the spiral blades are driven by the rotating tube to rotate to drive the grains to roll, so that the grains are heated more uniformly when dried, and the drying effect is good.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

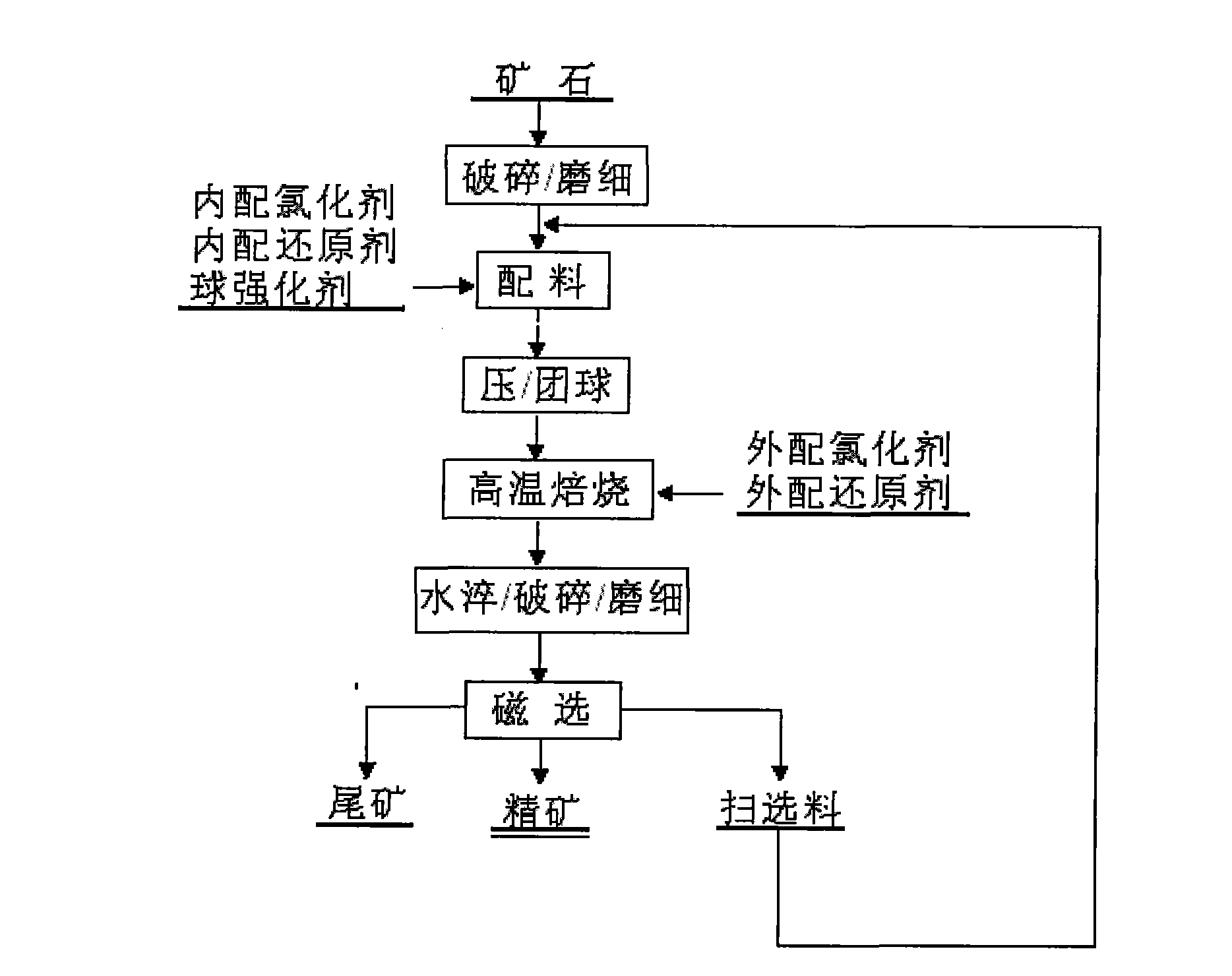

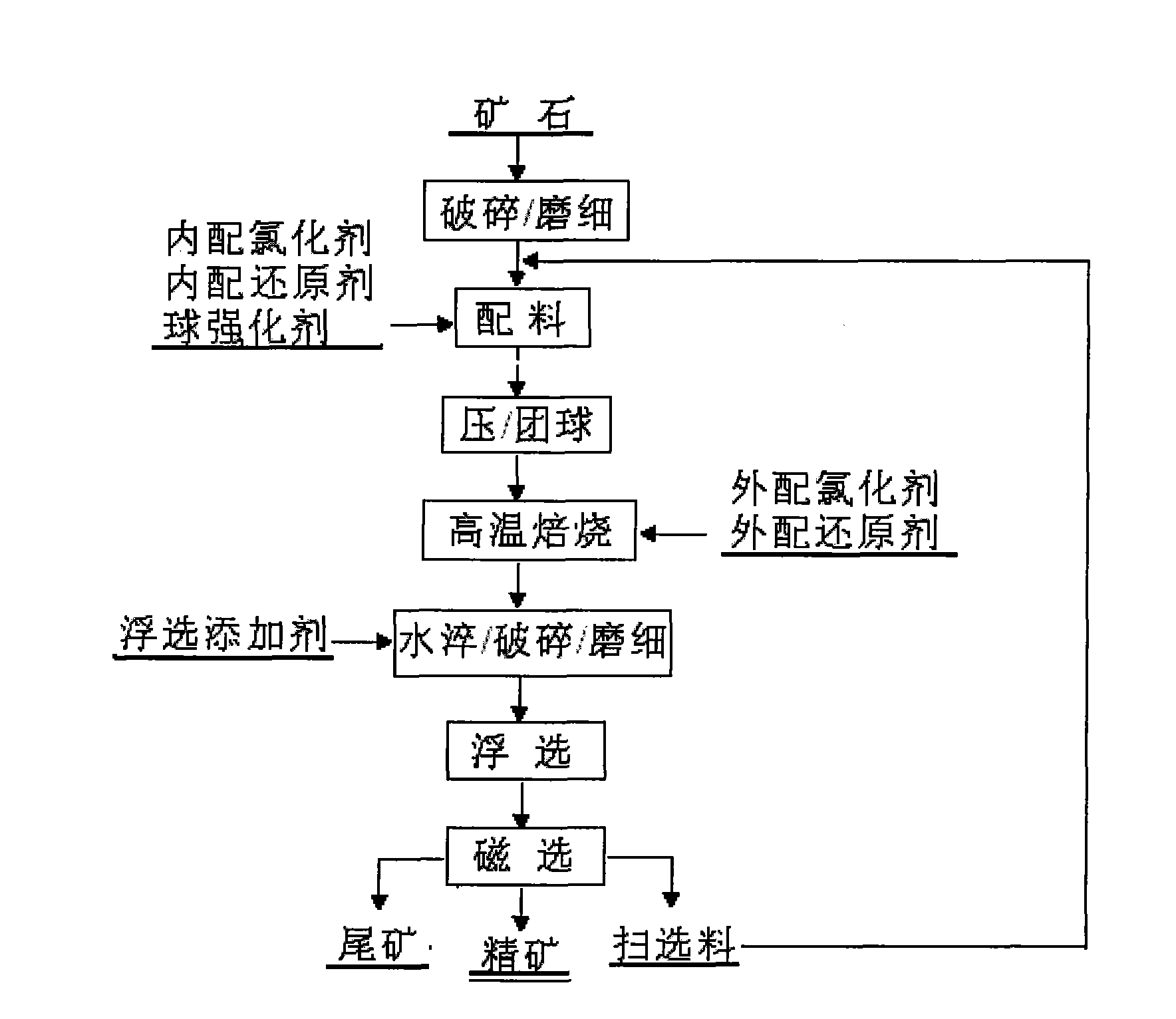

Method for efficiently concentrating cobalt and nickel from low-grade nickeliferous laterite ore

InactiveCN101514401ASimple processPractical processMagnetic separationWet separationLower gradeAlloy

The invention provides a method for efficiently concentrating cobalt and nickel from a low-grade nickeliferous laterite ore. The method is based on mine-phase reconstruction, and the ore is subject to physical treatment, high temperature chlorination and reduction roasting to convert the nickel and the cobalt in the ore from oxide or composite oxide (silicate and ferrite) mineral into magnetic metal or alloy, magnetic separation method or combined floatation-magnetic separation method is used for separation to concentrate the cobalt and the nickel. The method is used for treating the low-grade nickeliferous laterite ore (Ni is 0.2-2.0%), contents of the nickel ore concentrate is more than ten times of that of the crude nickel ore; and the nickel recovery is more than 80%.

Owner:CENT SOUTH UNIV

Composition for forming transparent polysiloxane coating and solidification thereof

There is provided a transparent silicone film-forming composition which forms a ultraviolet absorbing and infrared screening film exhibiting film hardness of 6H to 9H or more after curing on a transparent substrate such as glass and plastic. A transparent silicone film-forming composition comprises (a) a reaction product of alkoxysilane (A) having an epoxy group and alkoxylsilane (B) having an amino group with active hydrogen, (b) an acid catalyst, (c) a finely ground ITO cocatalyst and (d) at least one solvent selected from organic solvents. A transparent silicone film-forming composition comprising a reaction product of alkoxysilane (A) having an epoxy group and alkoxylsilane (B) having an amino group with active hydrogen as well as tri- or dialkoxysilane (C) mixed with monoalkoxysilane (D) and / or glycidsilane (E), (b) an acid catalyst, (c) a finely ground ITO cocatalyst and (d) at least one solvent selected from organic solvents.

Owner:泽村聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com