Temperature-control pressure chamber system for unsaturated soil tri-axial apparatus

A technology of temperature control system and pressure chamber, applied in instruments, using stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve problems such as unsatisfactory and ineffective temperature control, so as to prevent heat loss and ensure Uniformity, Measurement, and Acquisition Automated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

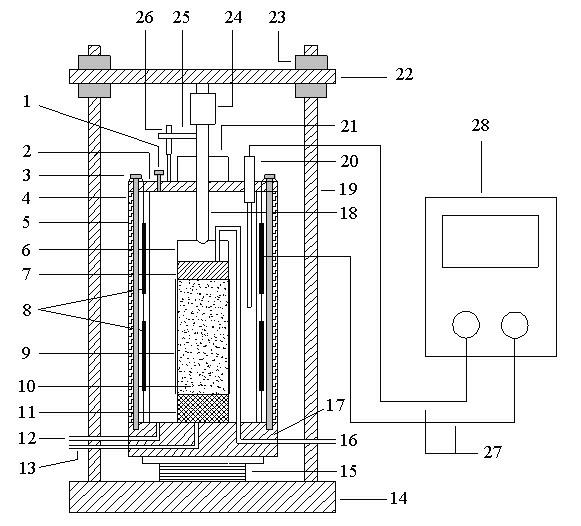

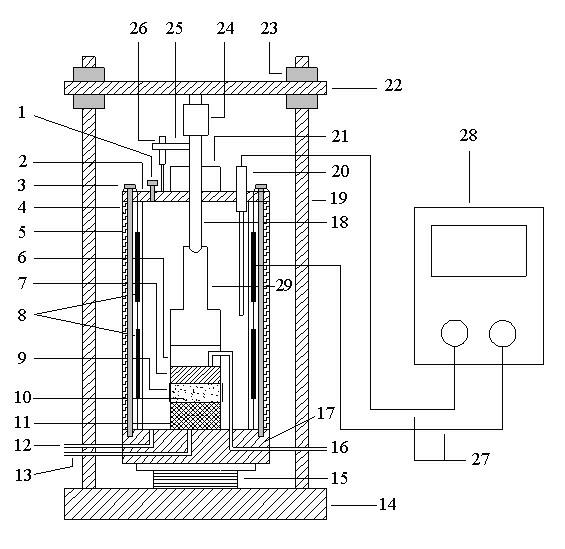

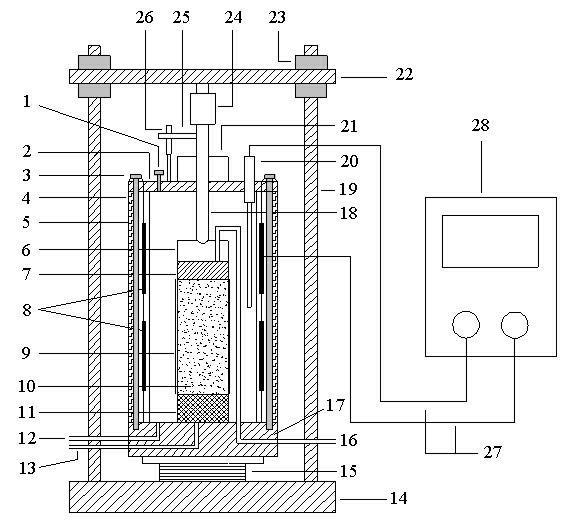

[0026] Such as figure 1 As shown, the pressure chamber system of the temperature-controlled unsaturated soil triaxial instrument of the present invention includes a loading platform, a pressure cover, and a temperature control system;

[0027] The loading platform includes a bearing platform 14, a lifting platform 15, a base 17, two struts 19, a beam 22 and an axial load sensor 24, a bracket 25 and an axial displacement sensor 26; the lower end of the two struts 19 and the bearing platform 14 Fixed connection, the upper end passes through the two ends of the beam 22 and is fixedly connected by fixing bolts 23; the upper end of the axial load sensor 24 is connected to the midpoint of the beam, and the lower end is in contact with the piston rod 18; the lower end of the axial displacement sensor 26 is connected to the top cover 2 are in contact, the upper end is connected to the piston rod 18 through the bracket 25;

[0028] The pressure cover includes a top cover 2, an outer wall 4 ...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that when the unsaturated soil-soil-water characteristic curve is tested, in order to shorten the test time while ensuring the same accuracy and test results, the axial piston rod 18 and the organic glass sample A height-increasing pad 29 is arranged between the caps 6, so that a sample with a smaller height can be used. The heightening pad 29 is composed of two upper and lower cylinders with different diameters, the top of which is in contact with the axial piston rod 18, and the semicircular groove on the top has the same radius as the semicircular protrusion on the top of the axial piston rod 18. The bottom is in contact with the organic glass sample cap 6, and the diameter of the two is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com