Compound steamed-bread preserving modifier

An anti-aging and improving agent technology, applied in baking, dough processing, food preparation, etc., can solve the problems of increased number of colonies, secondary pollution of steamed bread, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1, steamed bread preservation and anti-aging compound improver is composed of the following raw materials in weight percentage: 2% fungal α-amylase, 3% xylanase, 4% phospholipase, 50% calcium sodium stearoyl lactylate, monohard Fatty acid glyceride 10%, sodium carboxymethyl cellulose 27%, tricalcium phosphate 4%.

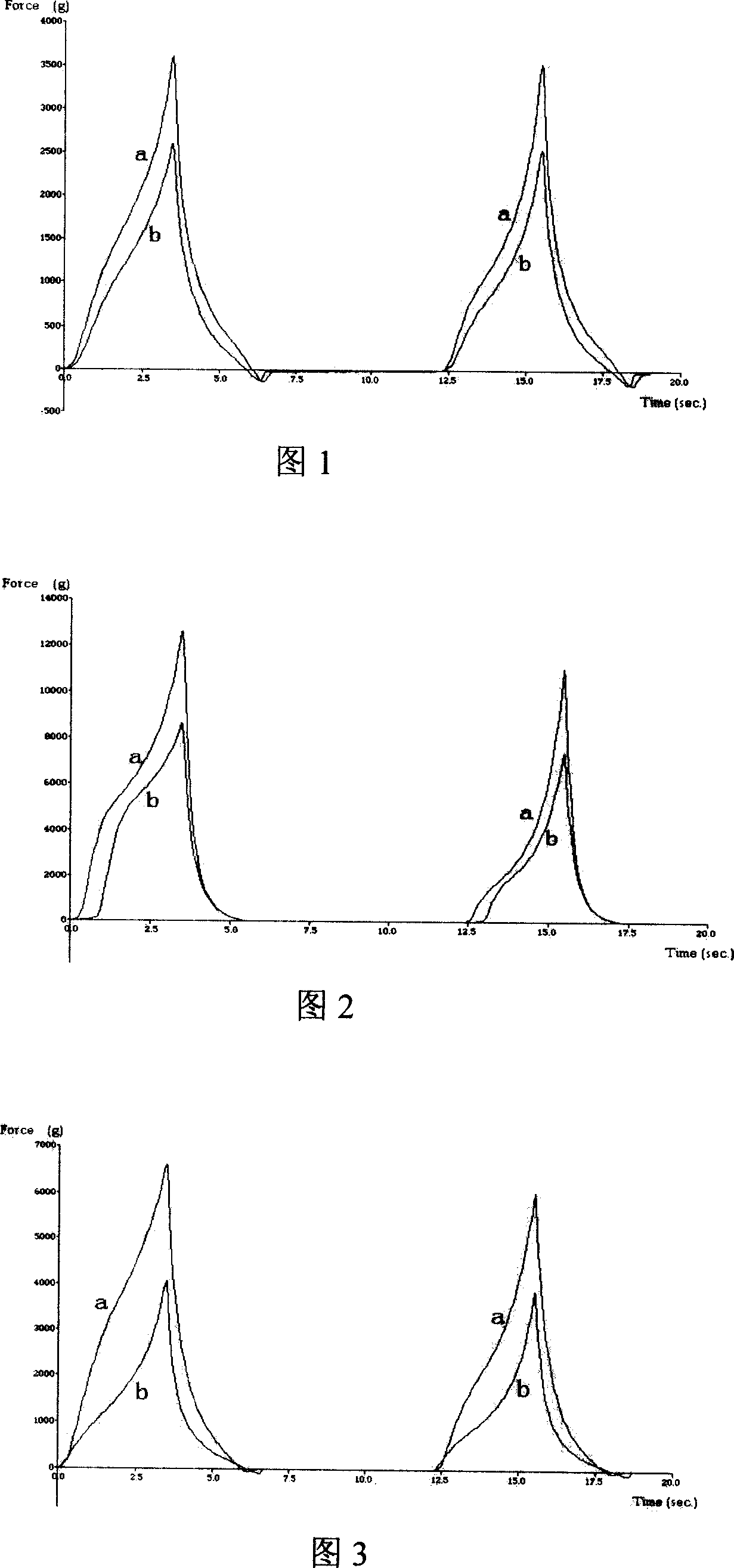

[0028] Fig. 1 is the curve of the softness of steamed buns tested by a physical property tester, b is a fresh-keeping steamed bun sample steamed with flour added with a steamed bun fresh-keeping anti-aging compound improver, a is a control sample, and the storage days are 2 days, compared with the improvement rate of steamed bun softness of the present invention was 39.2%.

Embodiment 2

[0029] Example 2, steamed bread preservation and anti-aging compound improver is composed of the following raw materials in weight percentage: 1% bacterial α-amylase, 7% xylanase, 3% lipohydrolase, 60% calcium sodium stearoyl lactylate, carboxylate Sodium Methylcellulose 25%, Silicon Dioxide 4%.

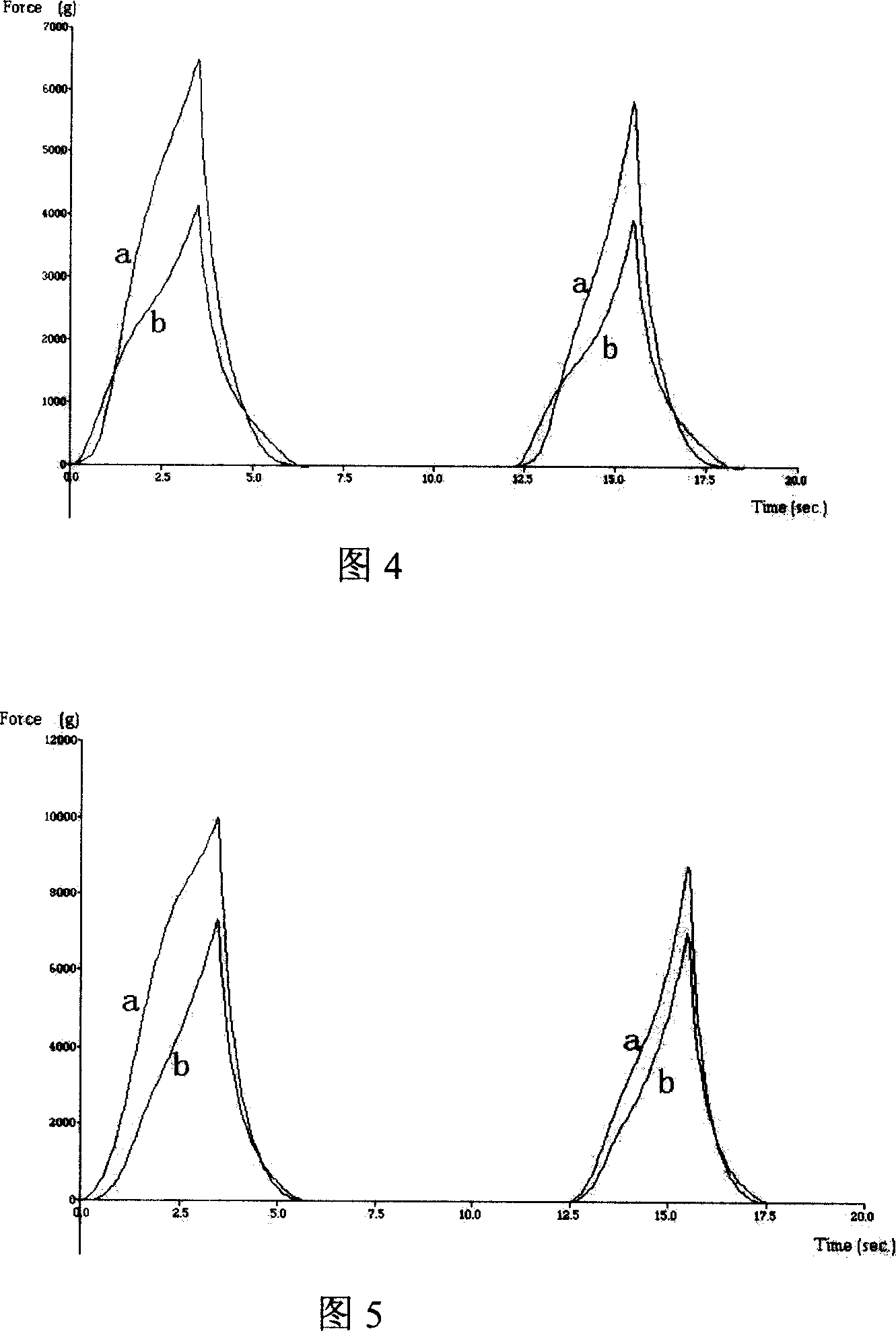

[0030] Figure 2 is the curve of the softness of steamed buns tested by the physical property tester, b is the fresh-keeping steamed bun sample steamed with flour added with steamed bun fresh-keeping anti-aging compound improver, a is the control sample, and the storage days are 7 days, compared with the improvement rate of steamed bun softness of the present invention was 41.4%.

Embodiment 3

[0031] Example 3, steamed bread preservation and anti-aging compound improver is composed of the following raw materials in weight percentage: glucoamylase 3%, pentosanase 5%, phospholipase 7%, diacetyl tartaric acid monoglyceride 19%, monostearic acid Glyceride 20%, Tripolyglyceride 20%, Konjac Flour 20%, Tricalcium Phosphate 6%.

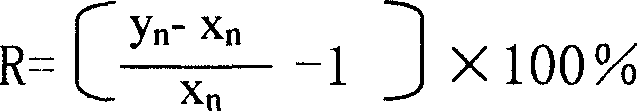

[0032] Figure 3 is the curve of the softness of steamed buns tested by the physical property tester, b is the fresh-keeping steamed bun sample steamed with flour added with the fresh-keeping and anti-aging compound improver of steamed buns, a is the control sample, and the storage days are 5 days, compared with the improvement rate of steamed bun softness of the present invention 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com