Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

A moisture-proof coating and radome technology, which is applied in coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc., can solve the difficulties in processing large-area special-shaped surfaces, poor adhesion and film-forming properties, and processing of heterogeneous surfaces Difficulties and other problems, to achieve the effect of excellent bonding performance, good friction resistance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a high-transmission super-hydrophobic moisture-proof coating of a radome material, comprising the following steps:

[0038] (1) Preparation of sealing emulsion:

[0039] Take 14g of polytetrafluoroethylene with a particle size of 20 μm and 5.5g of silicon dioxide with a particle size of 60 μm, and disperse them in 70.4g of acetone solvent, then add 9g of E51 type epoxy resin and 1.1g of triethanolamine, and stir them evenly to obtain Sealing emulsion;

[0040] (2) Preparation of superhydrophobic moisture-proof emulsion:

[0041] Take 12.5g ethyl orthosilicate, dissolve in 50g of absolute ethanol, and make solution A;

[0042] Take 9.1g of ammonia solution and dissolve it in a mixed solution of 18g of water and 80g of absolute ethanol, then add 3g of 20μm polytetrafluoroethylene and 7g of polymethylsilicone to the mixed solution, stir and disperse evenly to obtain emulsion B ;

[0043] Take 10.7g of methyltriethoxysiloxane, dissolve it in 40g ...

Embodiment 2

[0049] A preparation method of a high-transmission super-hydrophobic moisture-proof coating of a radome material, comprising the following steps:

[0050] (1) Preparation of sealing emulsion:

[0051] Take 14g of polytetrafluoroethylene with a particle size of 20 μm and 5.5g of silicon dioxide with a particle size of 60 μm, and disperse them in 70.4g of acetone solvent, then add 9g of E51 type epoxy resin and 1.1g of triethanolamine, and stir them evenly to obtain Sealing emulsion;

[0052] (2) Preparation of superhydrophobic moisture-proof emulsion:

[0053] Take 12.5g ethyl orthosilicate, dissolve in 50g of absolute ethanol, and make solution A;

[0054] Take 9.1g of ammonia solution and dissolve it in a mixed solution of 18g of water and 80g of absolute ethanol, then add 3g of 20μm polytetrafluoroethylene and 7g of polymethylsilicone to the mixed solution, stir and disperse evenly to obtain emulsion B ;

[0055] Take 10.7g of methyltriethoxysiloxane, dissolve it in 40g ...

Embodiment 3

[0061] A preparation method of a high-transmission super-hydrophobic moisture-proof coating of a radome material, comprising the following steps:

[0062] (1) Preparation of sealing emulsion:

[0063] Take 15g of polyvinylidene fluoride with a particle size of 30μm and 5.6g of silicon dioxide with a particle size of 80μm, and disperse them in 68.2g of acetone solvent, then add 10g of E44 epoxy resin and 1.2g of triethylamine, and stir them evenly Obtain the sealing emulsion;

[0064] (2) Preparation of superhydrophobic moisture-proof emulsion:

[0065] Take 12.5g ethyl orthosilicate, dissolve in 50g of absolute ethanol, and make solution A;

[0066] Take 9.1g of ammonia solution and dissolve it in a mixed solution of 18g of water and 80g of absolute ethanol, then add 2g of 30μm polyvinylidene fluoride and 8g of polymethylphenylsilicone resin to the mixed solution, stir and disperse evenly to obtain an emulsion B;

[0067] Take 10.7g of dimethyldiethoxysiloxane, dissolve it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

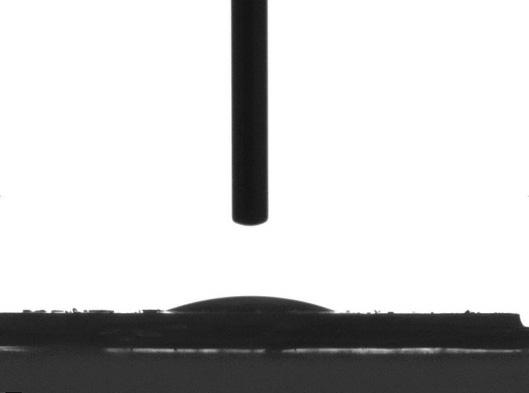

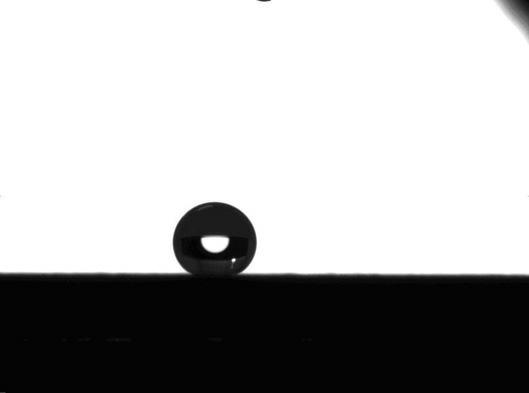

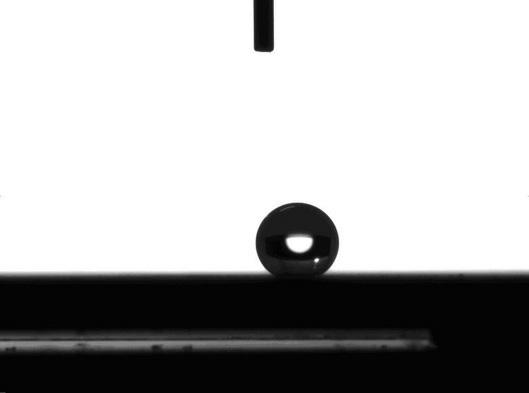

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com