Patents

Literature

213results about How to "Avoid pinholes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

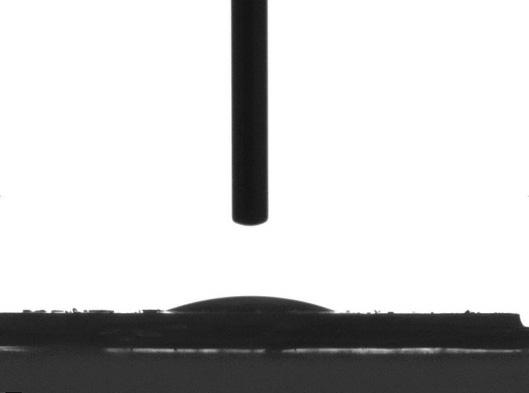

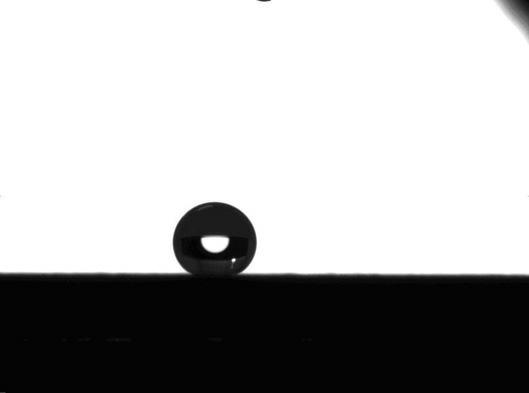

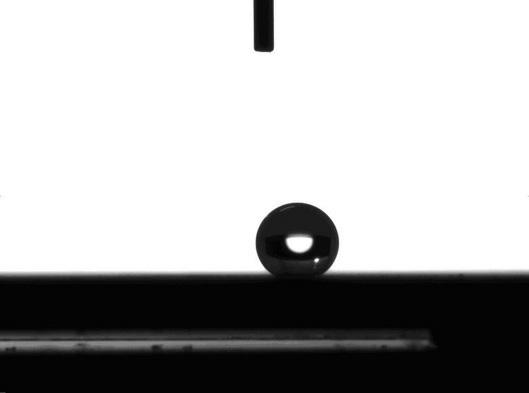

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

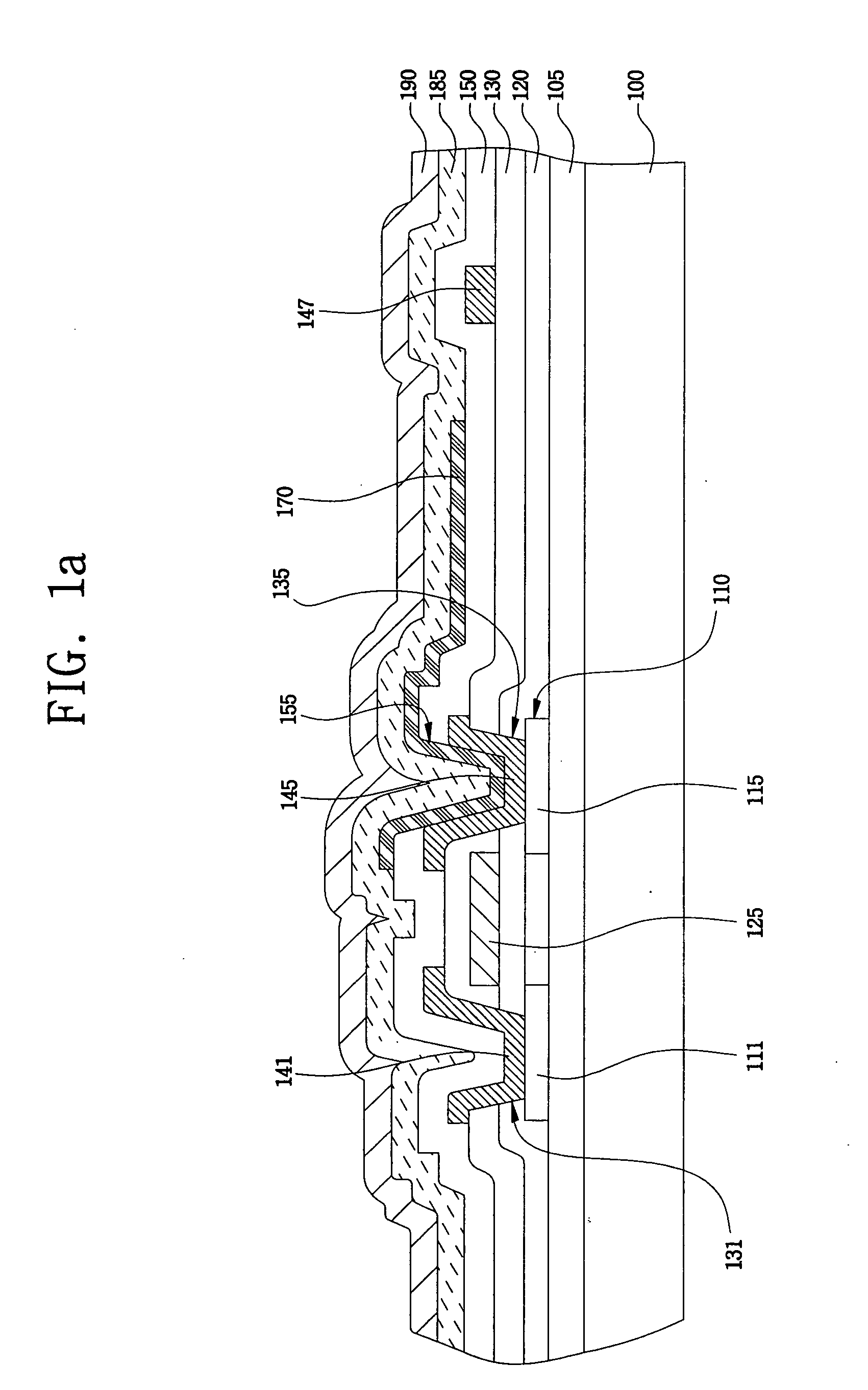

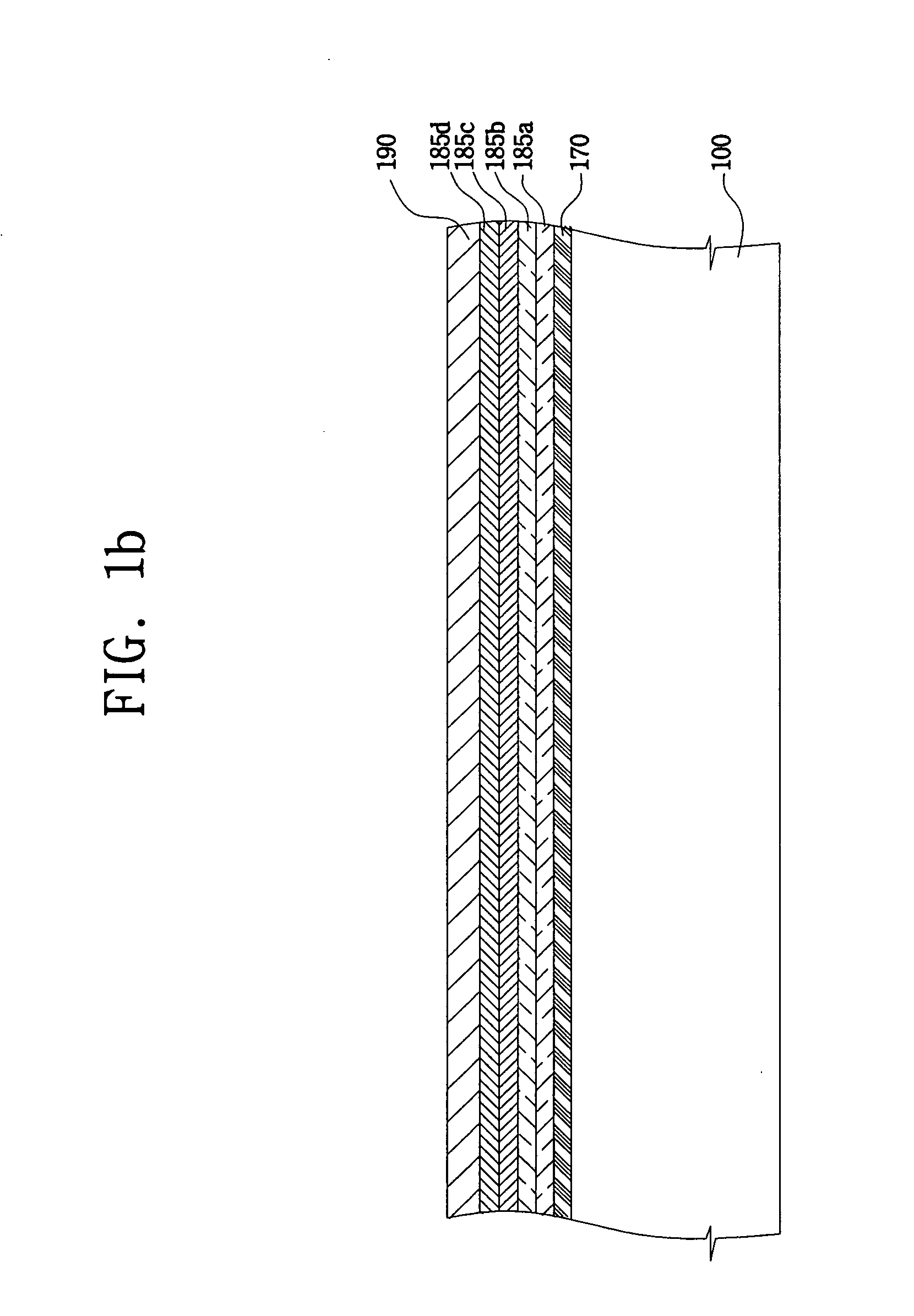

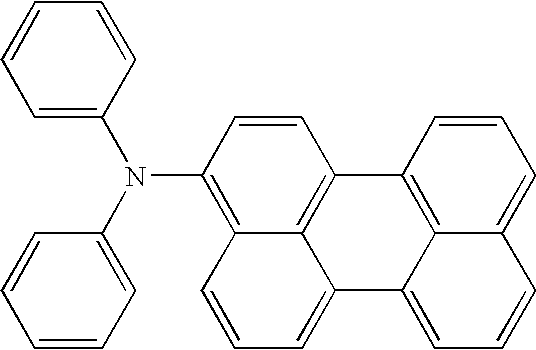

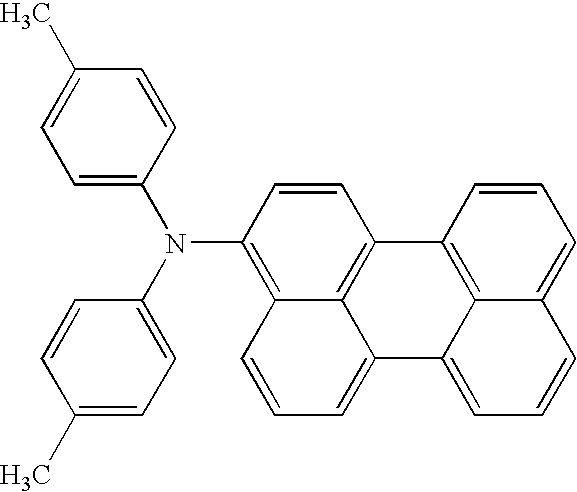

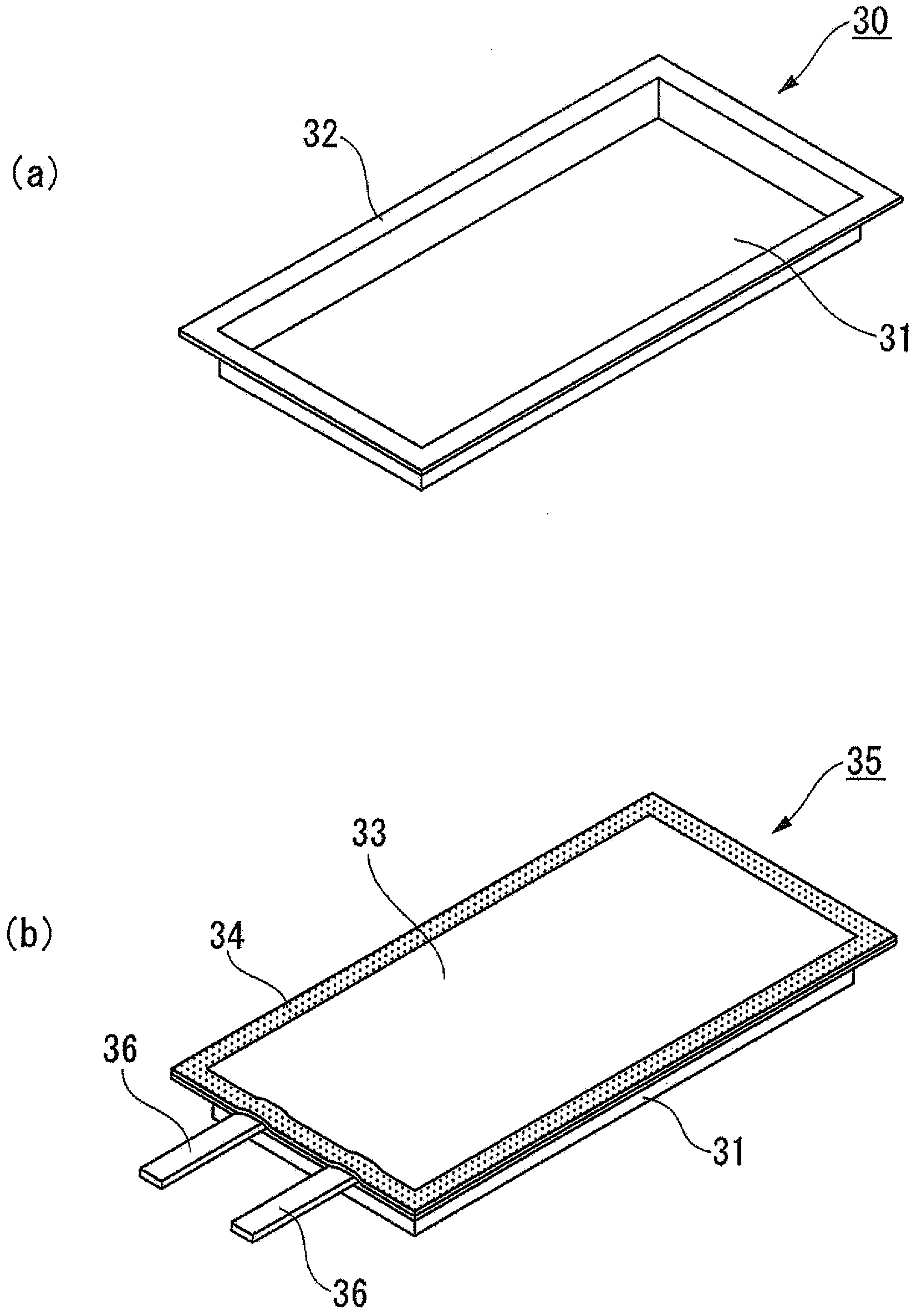

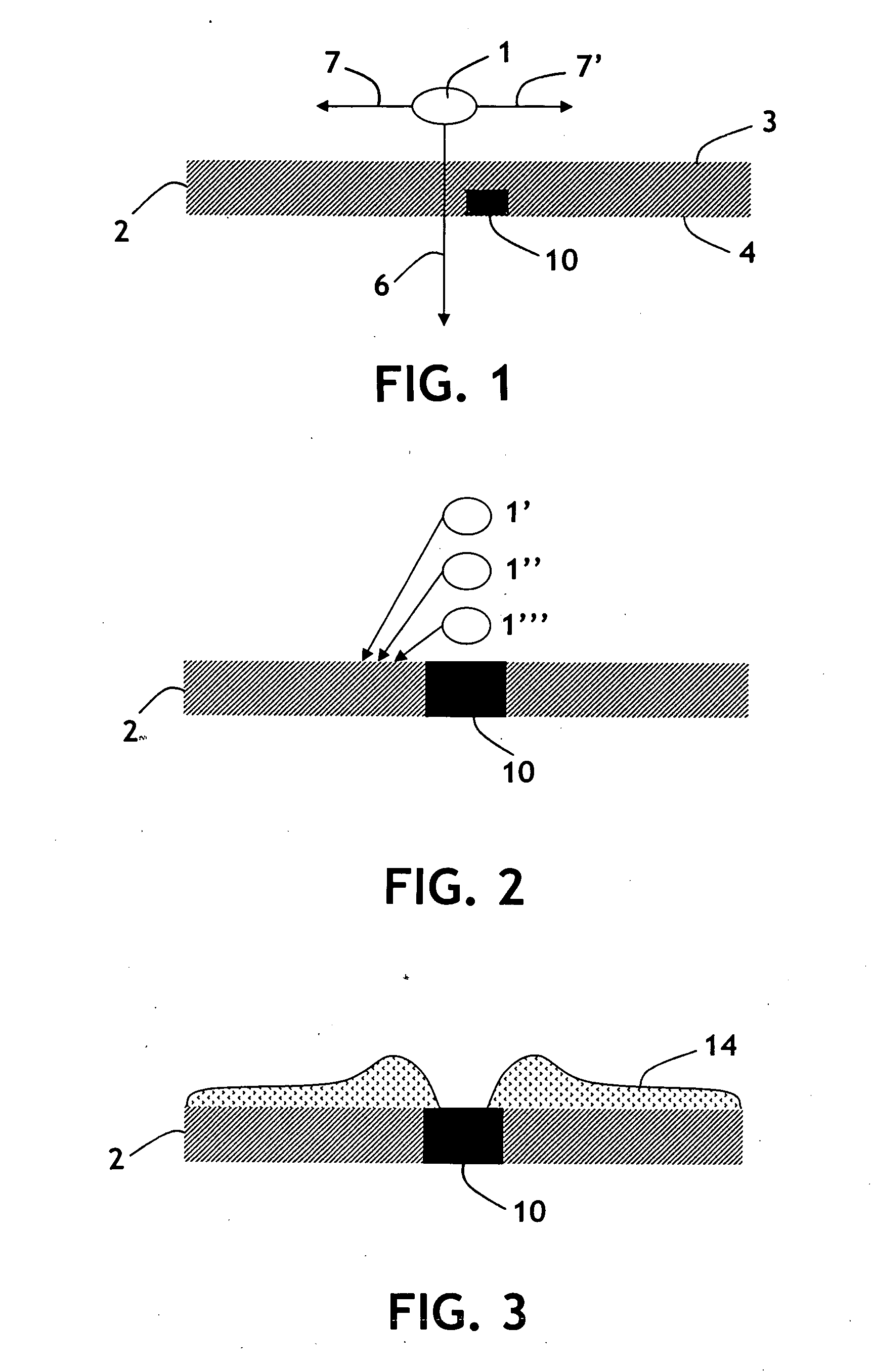

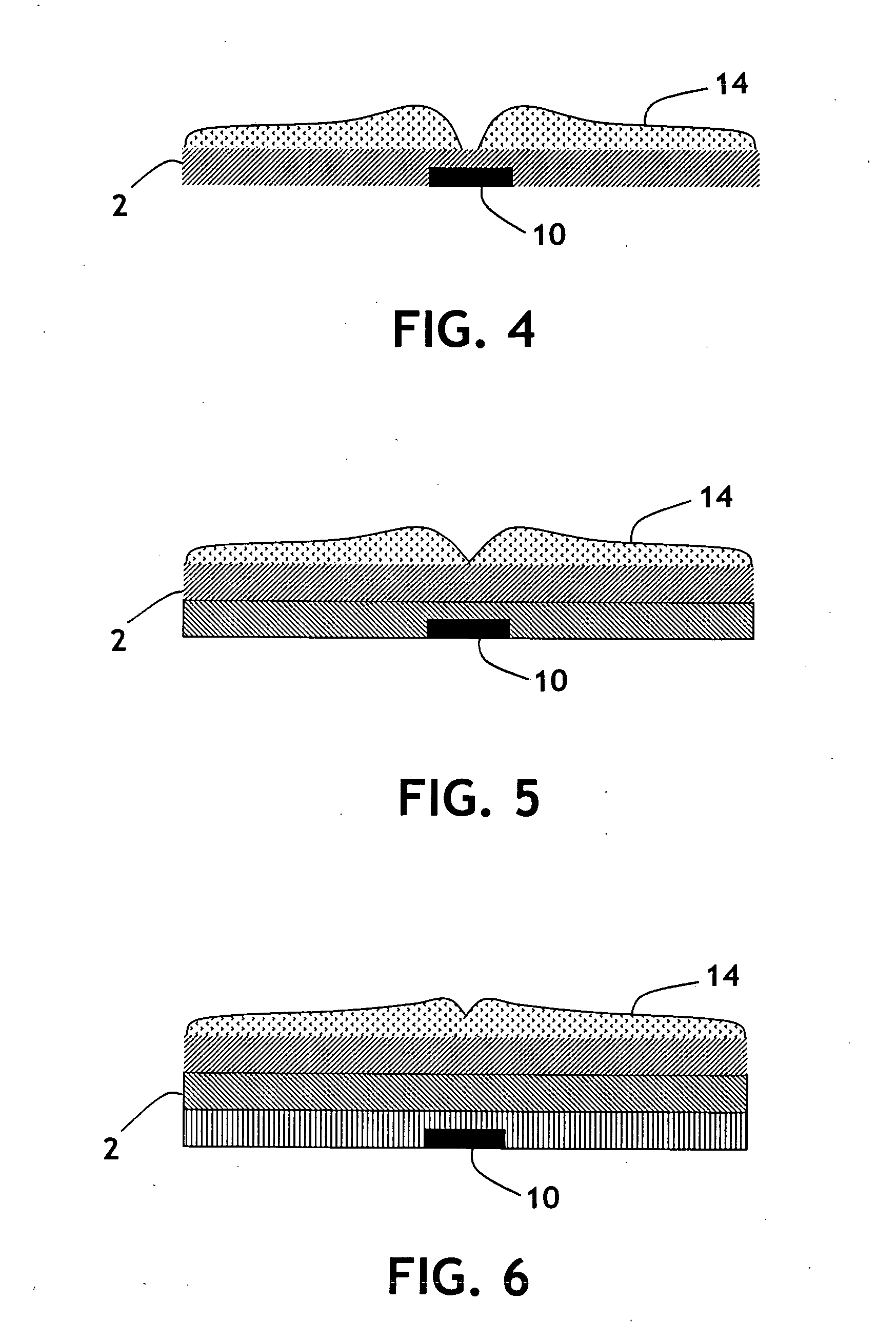

Flat panel display

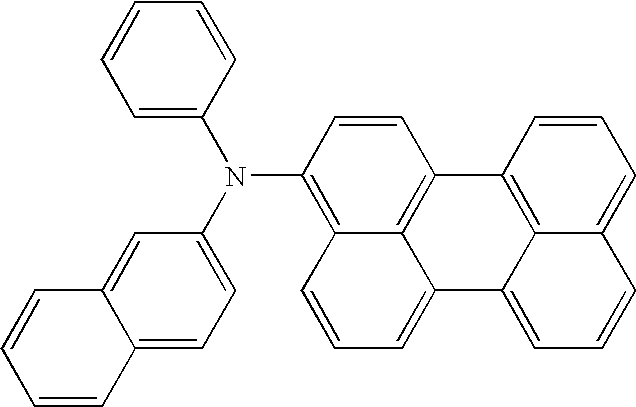

ActiveUS20050116240A1Avoid pinholesImprove picture qualityDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerDisplay device

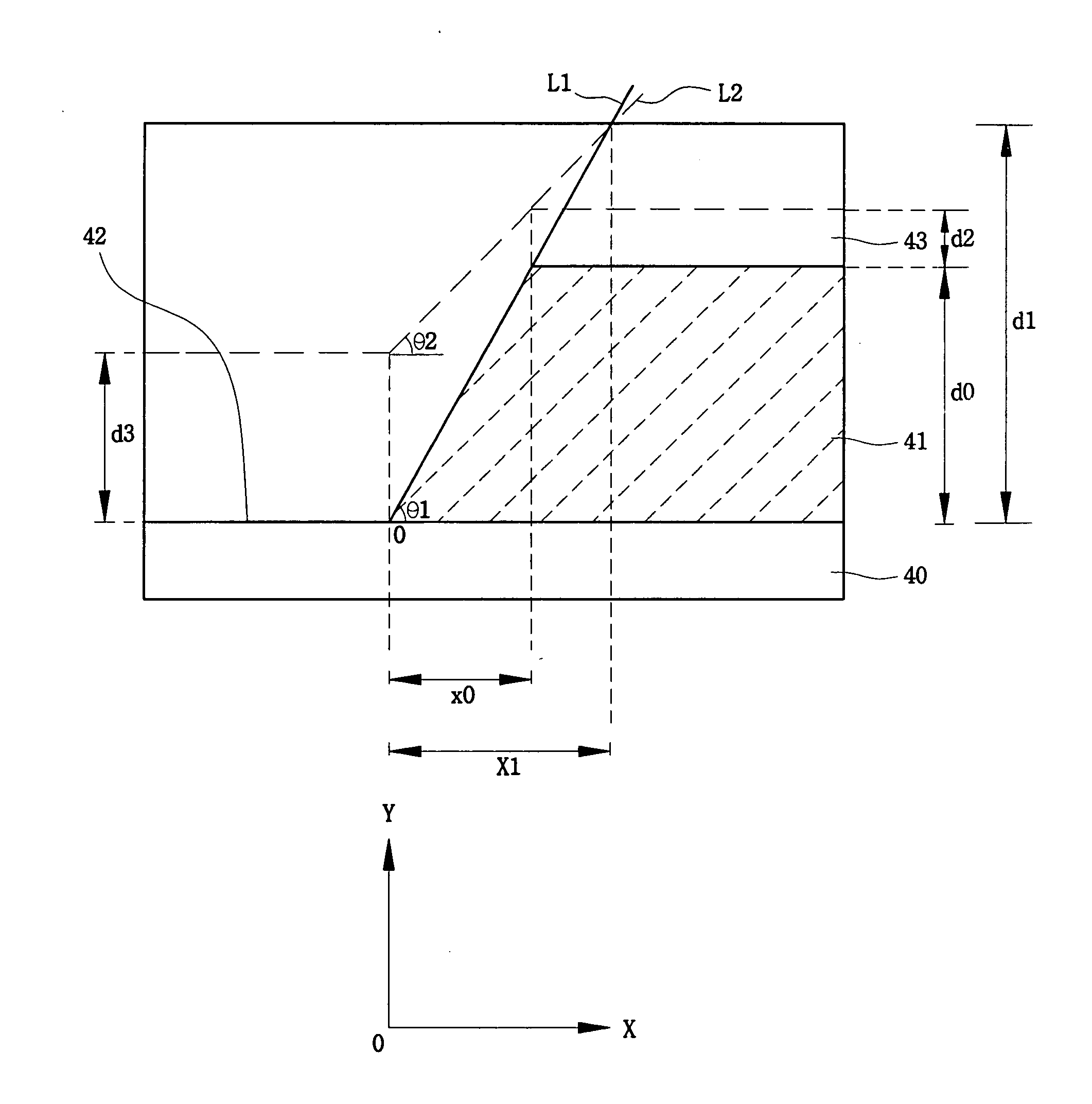

The present invention discloses an organic light emitting device for preventing element defects and improving picture quality by reducing a taper angle of a substrate surface. The flat panel display of the present invention comprises, an insulating substrate, a lower layer formed on the insulating substrate and having a first step and a first taper angle with respect to the substrate surface, and an upper layer formed on the insulating substrate and for reducing the taper angle of the lower layer. The upper layer has a second taper angle smaller than the first taper angle of the lower layer. The upper layer is a conductive layer that may be applied by a wet coating method, has a charge transporting capability, and is selected from at least one of a small-molecule organic layer including a carbazole-based, arylamine-based, hydrazone-based, stilbene-based, oxadiazole-based, starburst-based derivatives, and a polymer organic layer including PEDOT, PANI, carbazole-based, arylamine-based, perylene-based, pyrrole-based, oxadiazole-based derivatives.

Owner:SAMSUNG DISPLAY CO LTD

Composition for organic electroluminescene element and organic electroluminescent using the same

InactiveUS20040151944A1Improve film formationAvoid pinholesDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceOrganic layer

There are disclosed an organic electroluminescent (EL) device composition that includes a compound (A) having a perylene ring and a compound (B) having a diketopyrrolopyrrole skeleton, and an organic EL device that includes a pair of electrodes consisting of an anode and a cathode, and one or more organic layers including a light-emitting layer formed between the electrodes, at least one of the organic layers being a layer formed from the organic EL device composition. Furthermore, there are disclosed an organic EL device composition that includes a compound (C) having, as a solid film, a fluorescence spectrum peak wavelength of 550 nm or longer, and a compound (D) having, as a solid film in which Compound (D) is contained at 5 wt % in Compound (C), an area at a wavelength of 600 nm or shorter in a fluorescence spectrum region of 500 to 800 nm of 20% or less of the entire area, and an organic EL device including a light-emitting layer formed from this composition.

Owner:TOYO INK SC HOLD CO LTD

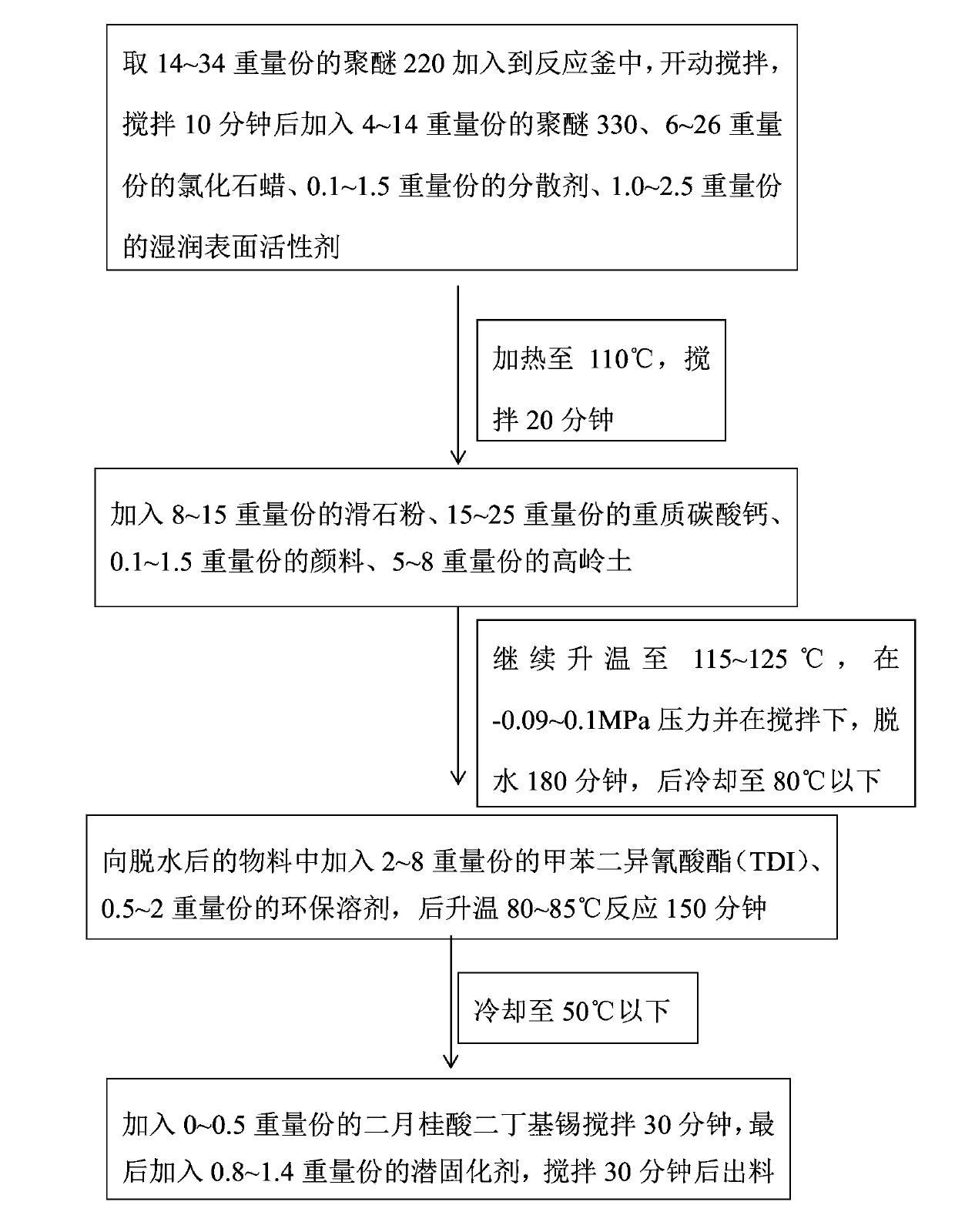

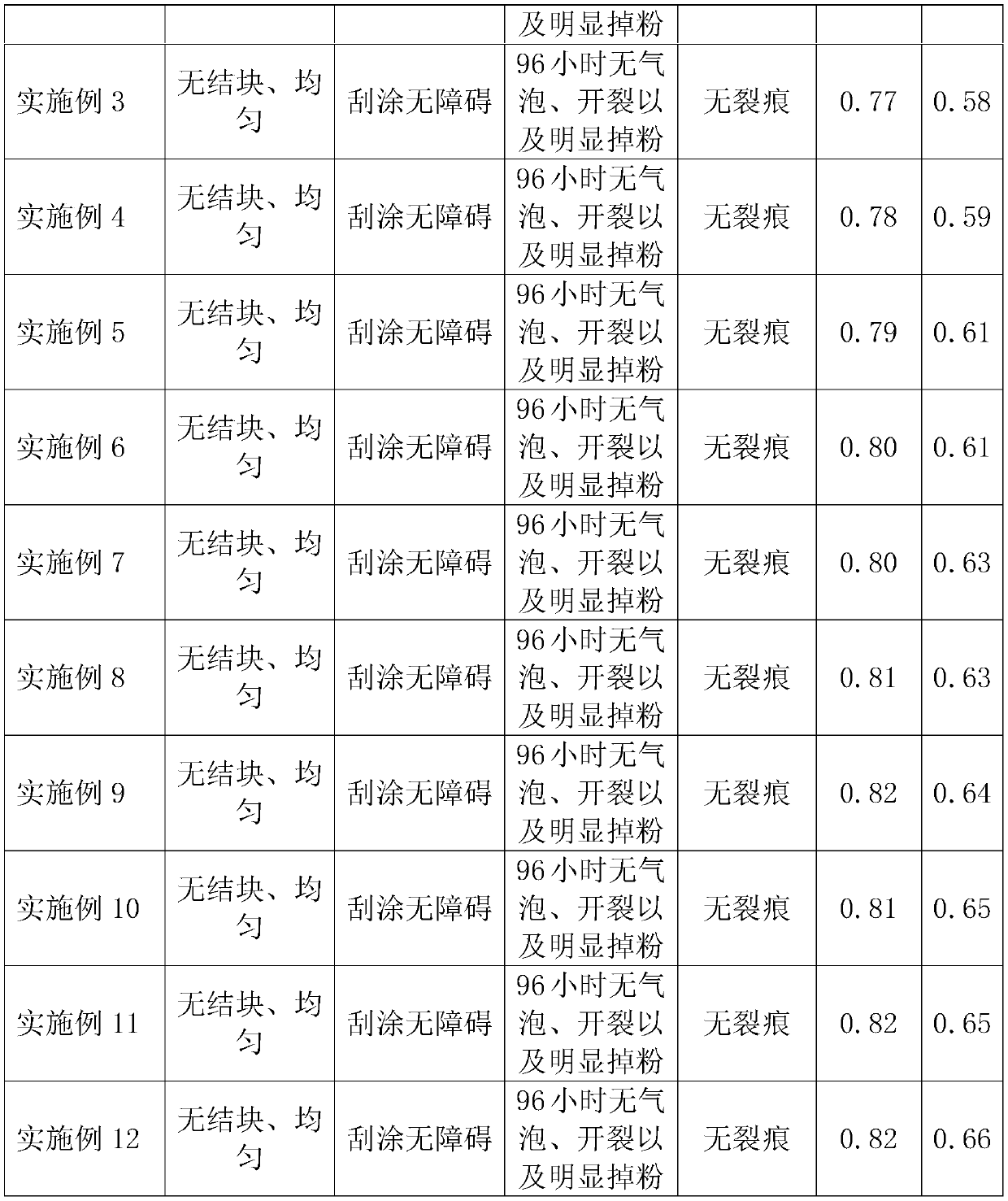

Single-component moisture curable polyurethane waterproof coating and preparation method thereof

InactiveCN103965765ASolve the problem that the construction quality is difficult to guaranteeGood storage stabilityPolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a single-component moisture curable polyurethane waterproof coating and a preparation method thereof. The single-component moisture curable polyurethane waterproof coating comprises the following raw materials by weight: 14-34 part of polyether 220, 4-14 parts of polyether 330, 6-26 parts of chlorinated paraffin, 0.1-1.5 parts of a dispersing agent, 1.0-2.5 parts of a wetting surfactant, 8-15 parts of talcum powder, 15-25 parts of heavy calcium carbonate, 0.1-1.5 parts of a pigment, 5-8 parts of kaolin, 2-8 parts of toluene diisocyanate (TDI), 0.5-2 parts of environment-friendly solvent, 0-0.5 part of dibutyltin dilaurate, and 0.8-1.4 parts of a latent curing agent. In the preparation process of the polyurethane coating, the wetting surfactant and the latent curing agent are added, so that even if a fundamental plane with a lot of dust is encountered in a construction process of the coating, sand holes and other problems cannot arise. Adding of the latent curing agent can prevent the coating from undergoing micro-foaming during construction.

Owner:YANTAI DONGJU WATERPROOF THERMAL INSULATION ENG CO LTD

Aluminum alloy for wheel hub and preparation method thereof, and aluminum alloy wheel hub

The invention discloses an aluminum alloy for a wheel hub and a preparation method thereof, and an aluminum alloy wheel hub. The preparation method comprises the following steps: a, melting an aluminum ingot so as to prepare a primary aluminum liquid; b, mixing a slag-clearing agent with the primary aluminum liquid, and discharging molten slag so as to prepare a second-stage aluminum liquid; c, mixing a refining agent with the second-stage aluminum liquid in the presence of nitrogen and then carrying out standing and slagging so as to prepare a third-stage aluminum liquid; d, mixing a refiner and a modifier with the third-stage aluminum liquid so as to prepare a fourth-stage aluminum liquid; E, spreading the slag-clearing agent onto the surface of the fourth-stage aluminum liquid to clear slag so as to prepare a fifth-stage aluminum liquid; and f, spreading the slag-clearing agent on the surface of the fifth-stage aluminum liquid, and carrying out degassing treatment so as to prepare the aluminum alloy for the wheel hub. According to the invention, the contents of hydrogen and impurities in the aluminum alloy for the wheel hub are low, so the aluminum alloy for the wheel hub has excellent fluidity and shrinkage during solidification; therefore, the surface of the aluminum alloy wheel hub prepared from the aluminum alloy used for the wheel hub is free of pin holes and slag holes.

Owner:WUHU HUANGYAN IND

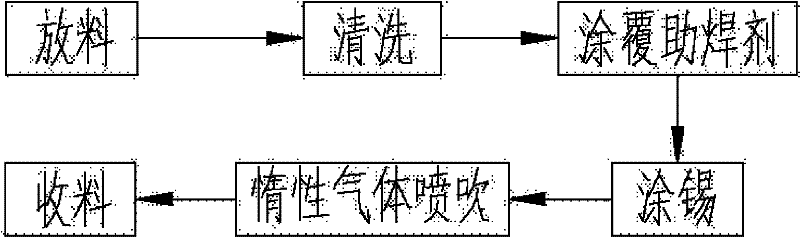

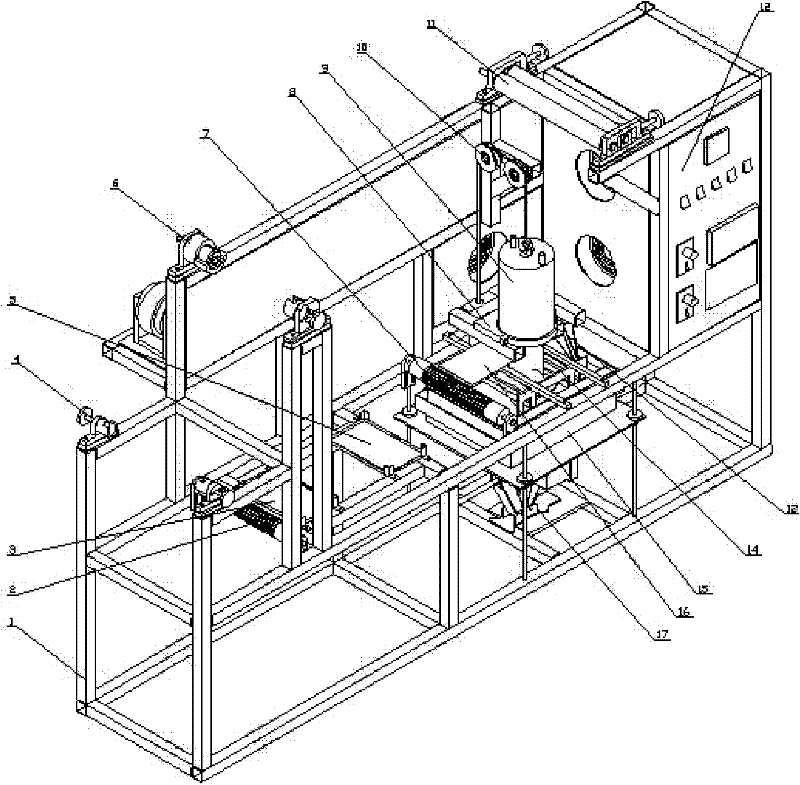

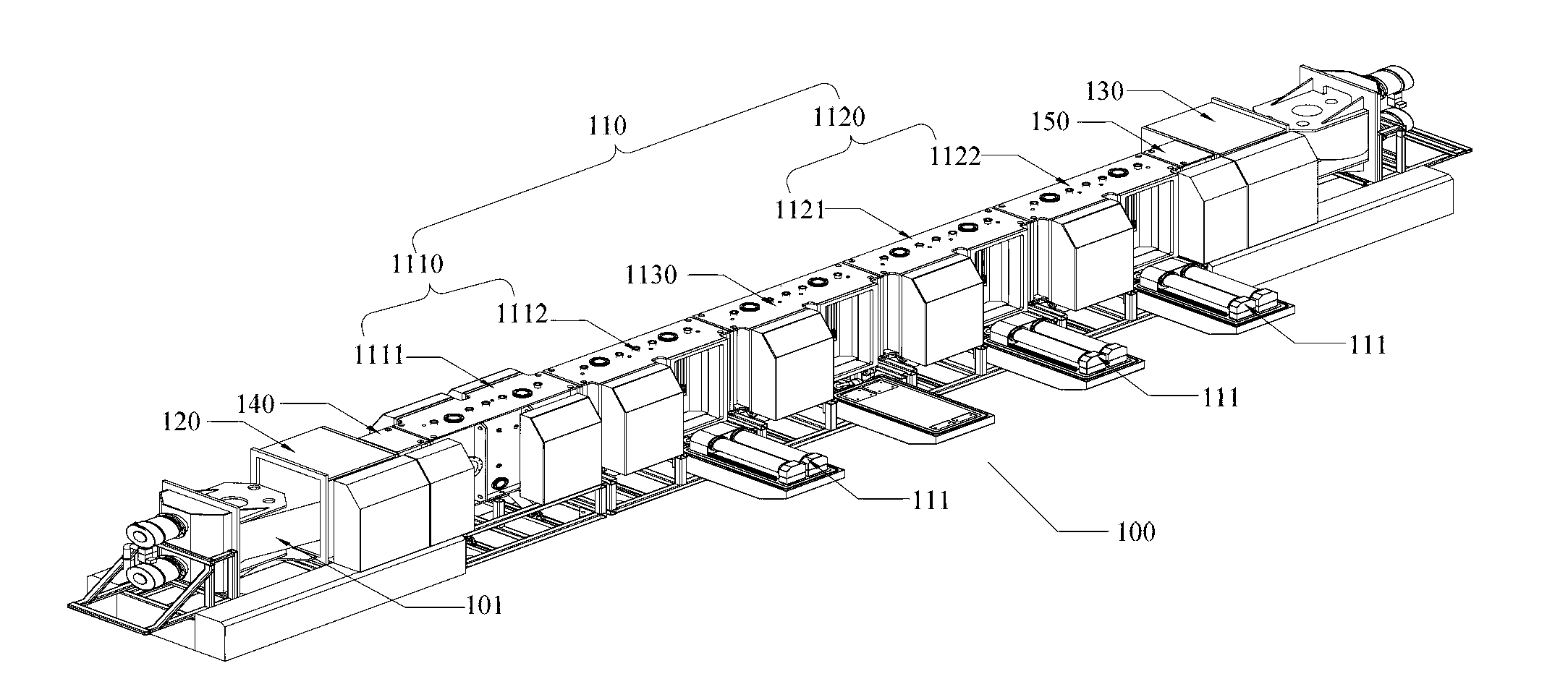

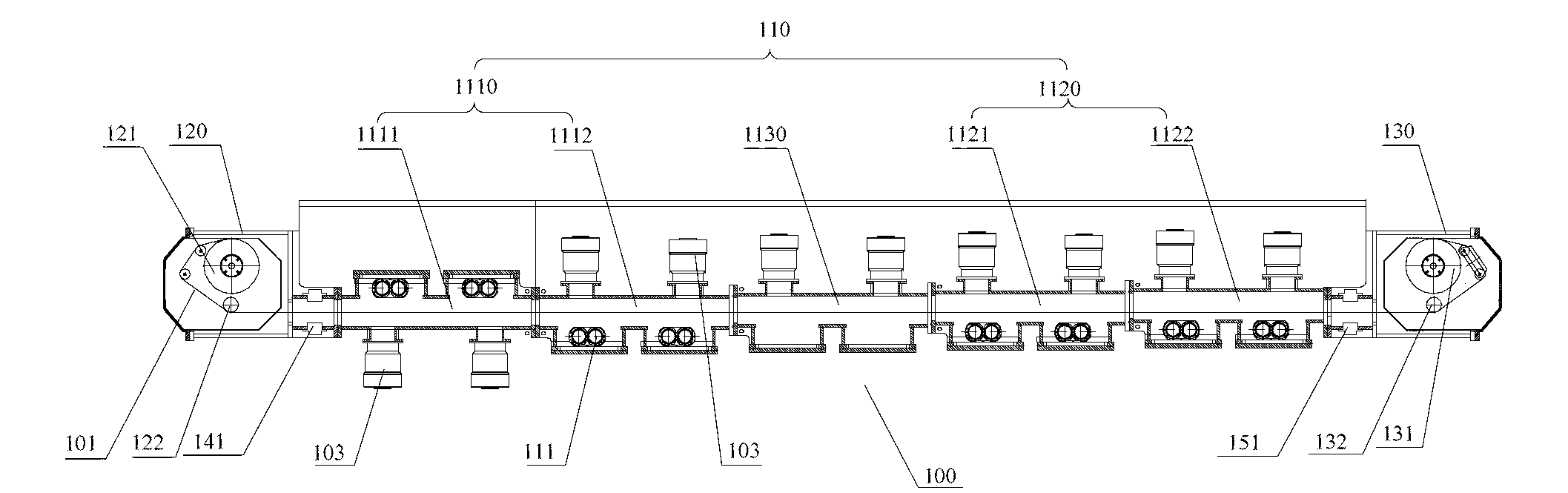

Manufacturing method of photovoltaic welding strip and tin coating machine thereof

ActiveCN102226259AAvoid pinholesQuality improvementHot-dipping/immersion processesFinal product manufactureSlagTransducer

The invention provides a manufacturing method of a photovoltaic welding strip and a tin coating machine thereof. The method comprises the following steps: A, carrying out a simple pretreatment on a copper strip; B, sending the pretreated copper strip into a plating solution of a tin furnace for tin coating, when tin coating, carrying out an ultrasonication to the copper strip with ultrasonic waveemitted by an ultrasonic wave transducer arranged above the tin furnace; C, blowing tin with inert gases, and D, receiving materials. According to the invention, by adding ultrasonic wave in the tin coating process, tin liquor can rapidly form an alloy layer of copper and tin on the surface of the copper strip by the sound pressure effect of the ultrasonic wave, the production efficiency of the photovoltaic welding strip is increased, the transporting speed of the copper strip reaches to 10-80m / min; by removing grease and oxide layer on the copper strip surface, reducing the usage of chemicalreagents, simplifying the pretreatment before coating, and utilizing the ultrasonic wave to crush clusters of tin oxide, the defects of pinhole and tin slag of the welding strip is prevented, the quality of the welding strip is improved, and the production efficiency is raised greatly.

Owner:江苏威腾新材料科技有限公司

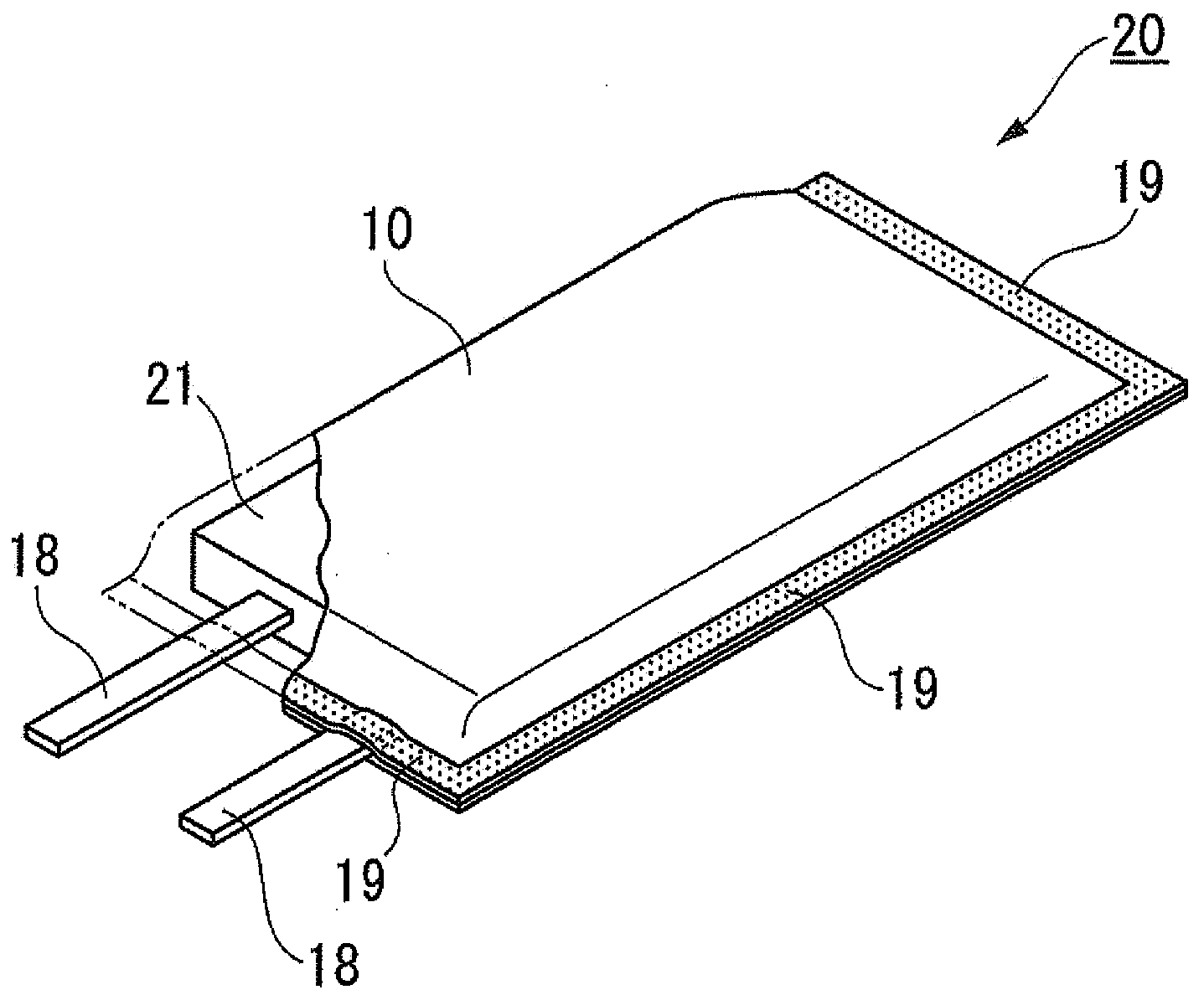

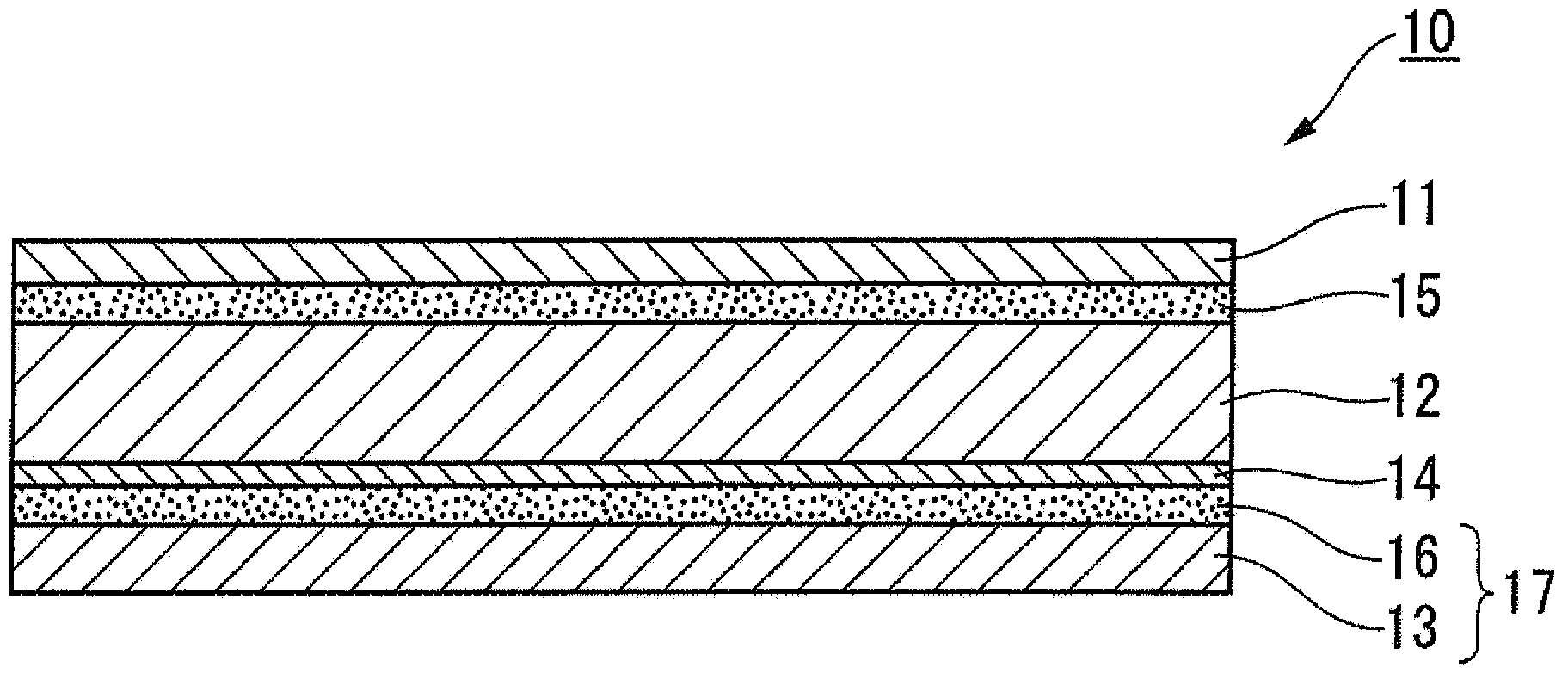

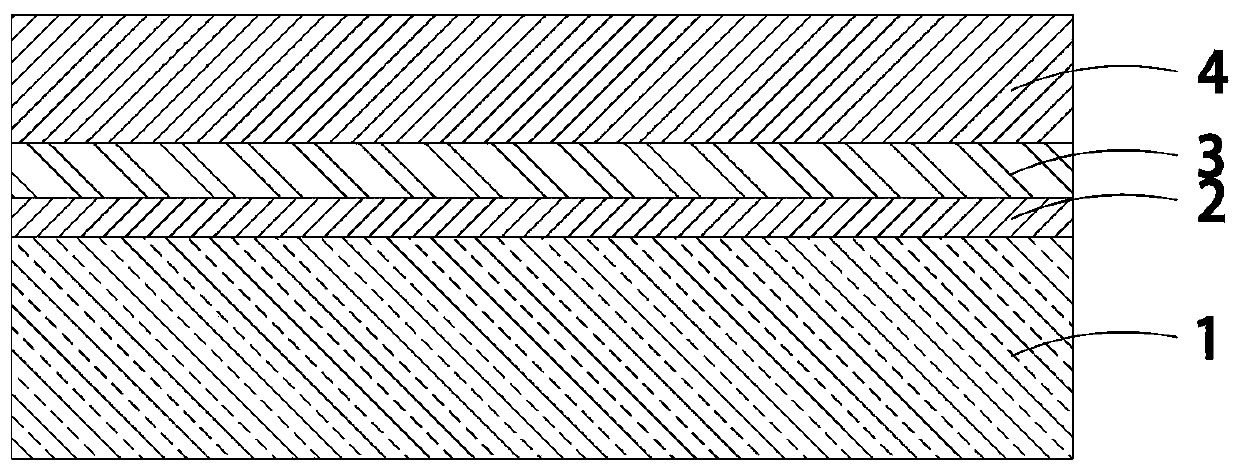

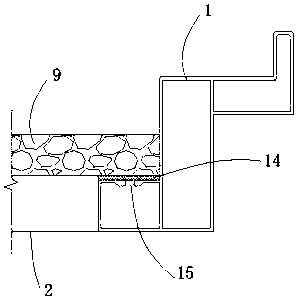

Battery packaging laminate

ActiveCN104051678APrevent peelingAvoid pinholesJackets/cases materialsElectrical equipmentCorrosion resistantLithium electrode

The invention aims to provide a battery packaging laminate at a low cost, wherein the laminate can reduce reduction of the laminate strength between aluminum foil and a multilayer sealant film and interlayer peeling induced by electrolyte deterioration of a lithium ion battery and can produce a packaging container with a high yield. A substrate layer (11), aluminum foil (12), and a multilayer sealant film (17) formed by lamination of a metal-object heat-adhesive resin layer (16) and a polyolefin resin layer (13), are laminated in the battery packaging laminate (10). A corrosion-resistant coating layer (14) is formed at least on the surface of the aluminum foil (12) attached to the multilayer sealant film (17). The multilayer sealant film (17) is attached to the corrosion-resistant coating layer (14) through the metal-object heat-adhesive resin layer (16), the melting heat of which is smaller than 25 mJ / mg.

Owner:FUJIMORI KOGYO CO LTD

Lithium ion battery pole piece drying device

InactiveCN105486059AEasy to assembleEasy to moveDrying gas arrangementsDrying machines with progressive movementsElectrical batterySmall footprint

The invention relates to the technical field of lithium batteries and in particular to a lithium ion battery pole piece drying device. The lithium ion battery pole piece drying device comprises a cabinet. The cabinet is sequentially divided into a heating chamber I, a heating chamber II and a heating chamber III. Turning rolls I and infrared heaters are arranged in the heating chamber I. A first transmission port is formed in the upper end of the heating chamber I and formed in a heat insulation board I. Turning rolls II and fans are arranged in the heating chamber II. Turning rolls III are arranged in the heating chamber III and a vacuum pump and a vent valve are arranged at the upper end of the heating chamber III. A rotary roll is arranged at the lower end of the heating chamber III. The lithium ion battery pole piece drying device is safe, reliable, convenient to assemble and move, small in occupied area, high in drying speed and capable of solving the problem that bubbles, needle holes and chaps are generated and greatly improving production efficiency.

Owner:SHANDONG PEARSON POWER NEW ENERGY

Pre-coated sand with high strength and low gas evolution rate and preparation method thereof

InactiveCN103567362AHigh strengthImprove heat resistanceFoundry mouldsFoundry coresSilanesNitrogen gas

The invention discloses pre-coated sand with high strength and a low gas evolution rate and a preparation method thereof. The pre-coated sand with high strength and low gas evolution rate is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 15-20 parts of celestite, 5-10 parts of wollastonite, 0.4-0.8 parts of ethenyl tri(beta-methoxyethyoxyl) silane, 4-6 parts of pentaerythritol oleate, 3-5 parts of epoxy soybean oil, 2-3 parts of nano magnesium oxide, 0.5-1.5 parts of bisphenol A epoxy resin, 1-2 parts of thermosetting phenol resin, 3-6 parts of diaminodiphenyl methane, 5-10 parts of urotropine, 4-8 parts of calcium stearate and 3-5 parts of composite powder. Compared with the conventional pre-coated sand, the pre-coated sand disclosed by the invention is not only high in strength, good in heat resistance, good in mobility and small in roughness, but also good in gas permeability and low in gas evolution rate, so that a casting piece can be effectively prevented from generating defects such as pin holes, nitrogen gas holes and burnt-on sand, and therefore, the yield of the casting piece is greatly improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

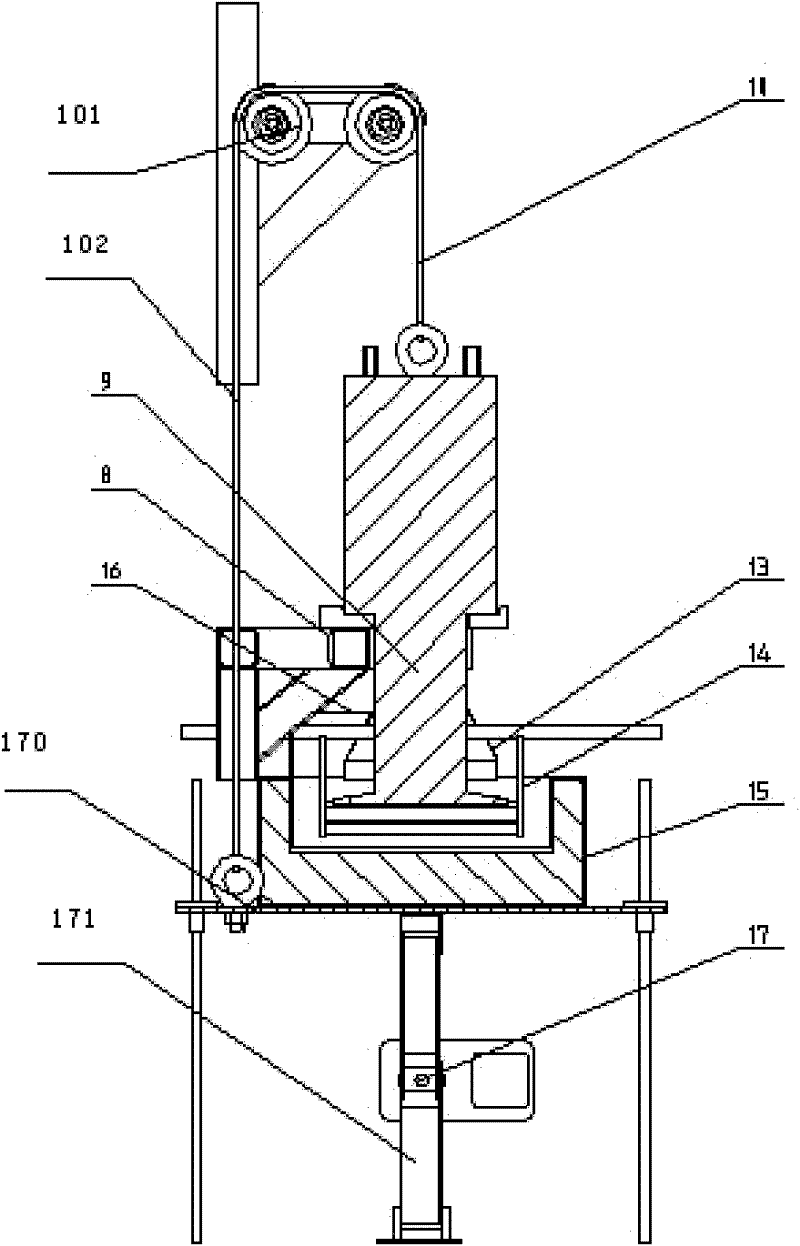

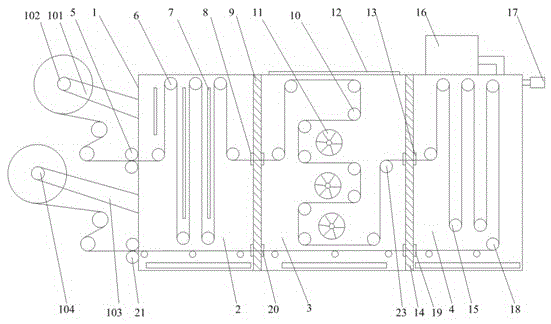

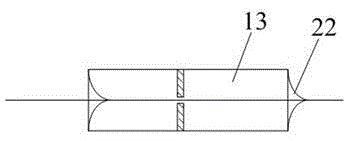

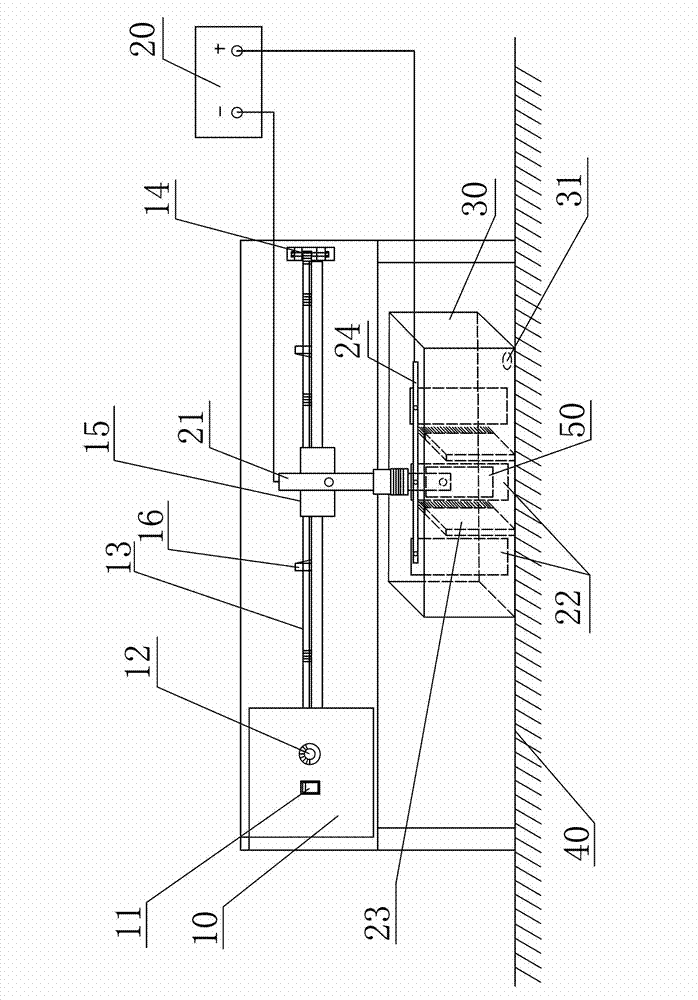

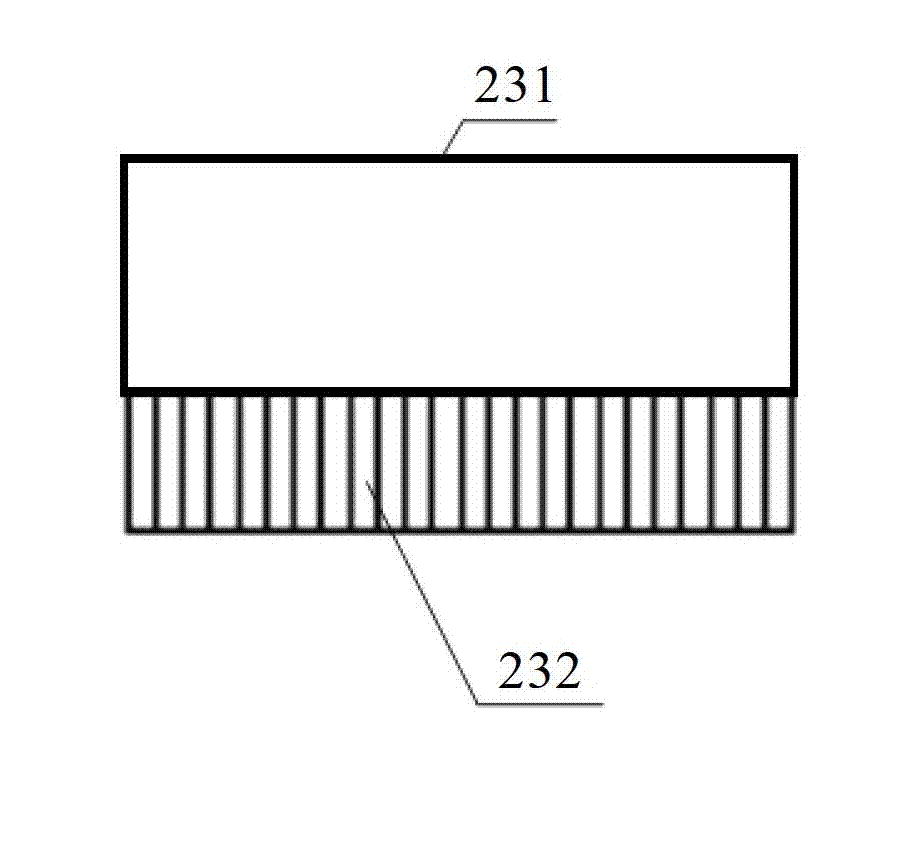

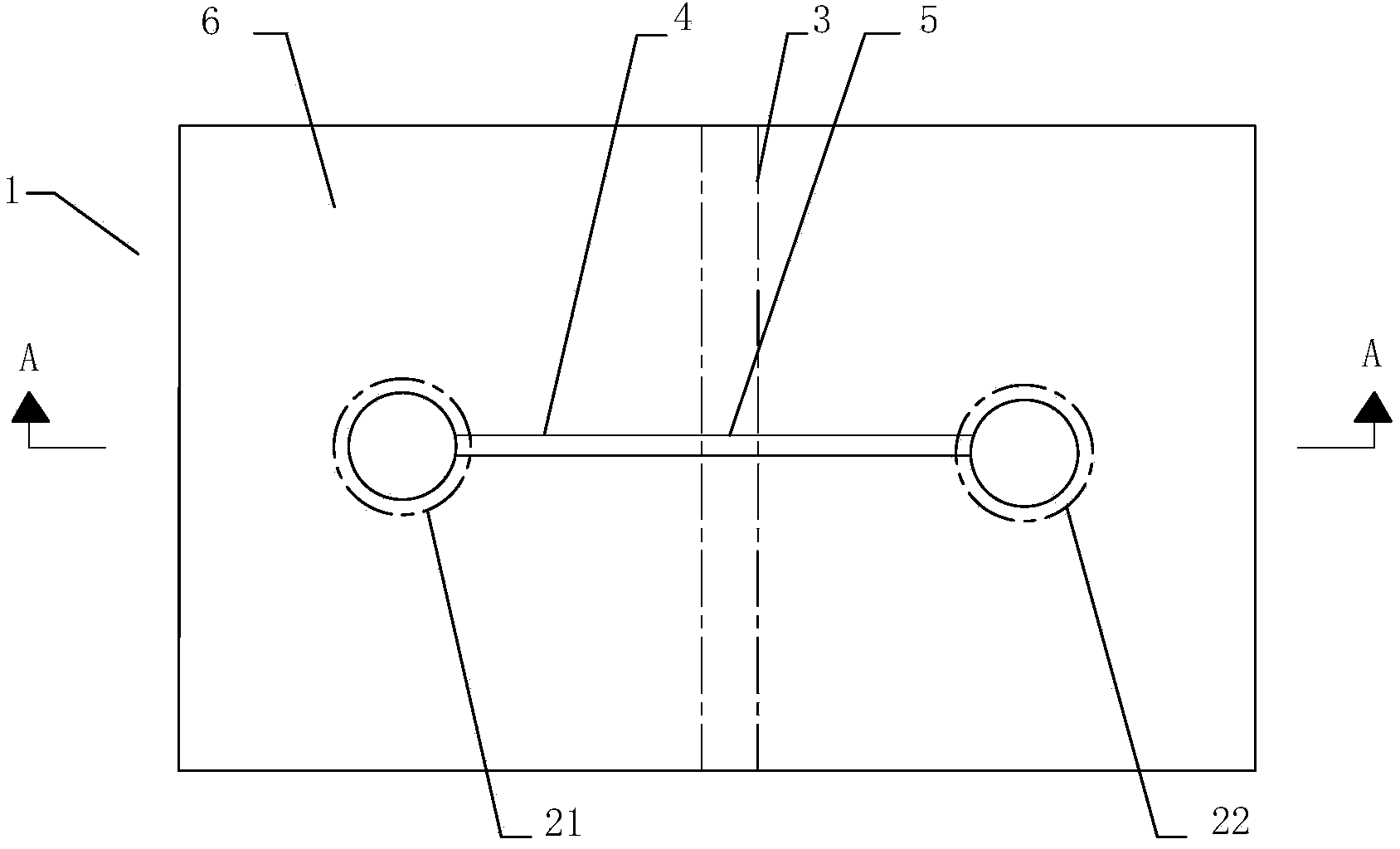

Electric brush plating device of flat plate type metal component

The invention discloses an electric brush plating device of a flat plate type metal component. The electric brush plating device comprises a movement control device, a brush, an anode plate and an electric brush plating groove, wherein the brush and the anode plate are fixedly mounted in the electric brush plating groove; a plating component is mounted on the movement control device and is positioned in the electric brush plating groove; the plated surface of the plating component is opposite to the anode plate; the plating component and the anode plate are respectively connected with the cathode and the anode of a direct-current power supply; the bristles of the brush face the plated surface of the plating component; the movement control device controls the plating component to do horizontal reciprocating rectilinear movement in the electric brush plating groove; when the plating component moves in front of the brush, the plated surface of the plating component do friction movement relative to the bristles of the brush. According to the electric brush plating device, the brush and the plating component do relative flexible friction movement in partial time during the whole electric brush plating process, so that the electric deposition speed is accelerated effectively; and a plating layer is prevented from generating pinholes, pocking marks, nodules and the like. Therefore, the quality of the plating layer is improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Composite plating manufacturing method of high-precision irregular grinding wheel

ActiveCN106584299AImprove wear resistanceHigh hardnessLiquid/solution decomposition chemical coatingGrinding devicesChemical platingGrinding wheel

The invention discloses a composite plating manufacturing method of a high-precision irregular grinding wheel. The manufacturing method comprises the following steps of preparing of a substrate and abrasives, treating before plating of the abrasives, preparing of a plating solution, treating before plating and preplating of the substrate, mould cavity abrasive grain dispensing, chemical plating thickening, passivating treatment after plating, testing and packing. The manufacturing method has the advantages that the compositely-plated grinding wheel has the characteristic of high profiling, and the consistency of abrasive molding surfaces reaches up to 95% or above; the height uniformity of the abrasives subjected to plating solidification is high, the abrasives can be used for grinding simultaneously to the largest extent, and machining efficiency is improved; and the shape preserving property is good, and the shape of the grinding wheel curve surface almost does not change under the continuous grinding condition, so that the grinding efficiency and the machining precision of the grinding wheel are guaranteed, and the service life of the grinding wheel is prolonged greatly.

Owner:郑州众邦超硬工具有限公司

Metal bipolar plate for fuel cell and fabrication method of metal bipolar plate

ActiveCN105047975AImprove corrosion resistanceExtended service lifeCell electrodesSolid electrolyte fuel cellsThermal sprayingFuel cells

The invention discloses a metal bipolar plate for a fuel cell. The metal bipolar plate comprises a stainless steel substrate and a surface modification layer, wherein the surface modification layer comprises a continuous insulating layer and discontinuous conductive particles; and the continuous insulating layer and the discontinuous conductive particles are attached to the surface of the stainless steel substrate. According to the metal bipolar plate for the fuel cell disclosed by the invention, through a surface treatment technology of depositing the continuous insulating layer and the discontinuous conductive particles in combination on the surface, a compact protection layer can be formed; the corrosion rate of the metal bipolar plate is greatly reduced; the contact resistance can be reduced; and the service life of the metal bipolar plate is prolonged. The discontinuous conductive particles are deposited through a plasma thermal spraying technique; micro metallurgic bonding can be formed by the conductive particles and the stainless steel substrate; the adhesive force of the discontinuous conductive particles is improved; and the fabrication cost is reduced.

Owner:北京长征天民高科技有限公司

High-covering black UV silkscreen printing ink

The invention discloses a high-covering black UV silkscreen printing ink. A preparation method for the high-covering black UV silkscreen printing ink comprises the following steps: preheating acrylate and then mixing the preheated acrylate with a part of active monomer; then adding a dispersant and carrying out primary dispersion; then successively adding pigment and a filling material and carrying out secondary dispersion; carrying out grinding to obtain color paste; mixing a phosphine oxide photoinitiator with residual active monomer; and adding the color paste, an organosilicon antifoaming agent and an organosilicon leveling agent and carrying out uniform dispersion so as to obtain the high-covering black UV silkscreen printing ink. The high-covering black UV silkscreen printing ink provided by the invention is reasonable in composition; all the components are in good compatibility; and the prepared printing ink has excellent comprehensive properties and good storage performance, and the viscosity of the printing ink is suitable for silkscreen printing. The printing ink does not need increase in the usage amounts of components like carbon black, prevents unfavorable influence of the components on the appearance and light shading performance of a product, and can meet light shading requirements of the product after only one printing and under the condition of a thickness of 7 to 8 micrometers, so unexpected technical effects are obtained.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

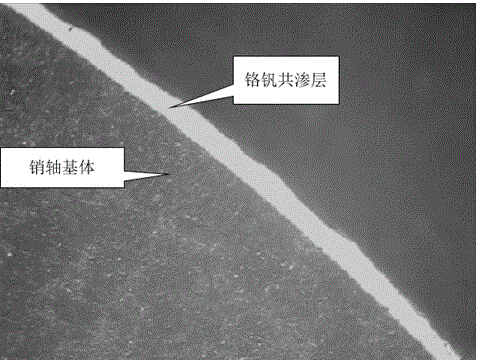

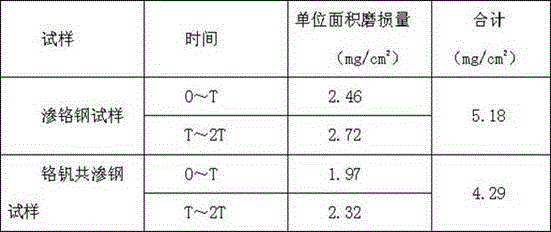

Chrome vanadizing process of automotive chain pin shaft

ActiveCN104404445AImprove wear resistanceStrong scratch resistanceSolid state diffusion coatingBoronWear resistance

The invention relates to a chrome vanadizing process of an automotive chain pin shaft with the advantages of larger load, wear resistance, corrosion resistance, oxidation resistance, good fatigue property and long service life. The finely-ground pin shaft is arranged in a converter, 60-70 percent of anhydrous borax, 10-15 percent of Cr2O3, 8-15 percent of V2O5 as a penetrating agent and a certain amount of reducing agent are simultaneously added into the converter, the converter is kept to be in a rotating state and is subjected to heat preservation for 10 hours at a temperature of 1000 plus or minus 2 DEG C, chrome vanadizing is performed, the pin shaft subjected to chrome vanadizing is poured into quenching oil to be quenched, and residual waste salt on the surface is boiled by using boiled water; after the reducing agent is added into salt bath, vanadium is reduced firstly, chrome is likely to be simultaneously reduced only when the reducing agent is excessive, and active vanadium, chrome alum and chrome vanadium boron atoms can be respectively obtained according to different consumptions of the reducing agent so as to realize vanadinizing, chrome vanadizing and chrome vanadium boronizing of steel.

Owner:HANGZHOU CHIZHENG TECH

Preparation method of wet-process dry-grain polished crystal brick and polished crystal brick

ActiveCN110981197AEasy to recycleEasy to adjust the glaze amountCeramic shaping apparatusTextile printerProduction line

The invention discloses a preparation method of a wet-process dry-grain polished crystal brick and the polished crystal brick. The preparation method comprises the following steps: preparing a green brick; performing drying for the first time; applying surface glaze; performing ink-jet printing; applying dry particle protective glaze; performing drying for the second time; and performing firing and molding. The wet-process dry-grain polished crystal brick sequentially comprises a green brick layer, a cover glaze layer, a printing layer and a dry-grain protective glaze layer from bottom to top.The polished crystal brick with excellent performance is prepared by controlling production process parameters and the setting of proper components and proportion of dry particles and dry particle protective glaze. The method is suitable for existing production equipment, and a production line does not need to be modified; a glaze spraying process is adopted, a glaze layer is more uniform, and abell jar is adopted for glaze spraying, so that the glaze amount is more convenient to adjust, and the recycle is easy; the required glaze layer is thinner and is only 1 / 5 of the dosage of dry-processdry particles, so that the dosage is lower, the firing period is shorter, the production cost is reduced, and the production efficiency is improved; meanwhile, compared with a dry method, the defectsof bubbles, pinholes and the like of the glaze layer are fewer, and color development is finer and richer.

Owner:FOSHAN OCEANO CERAMICS

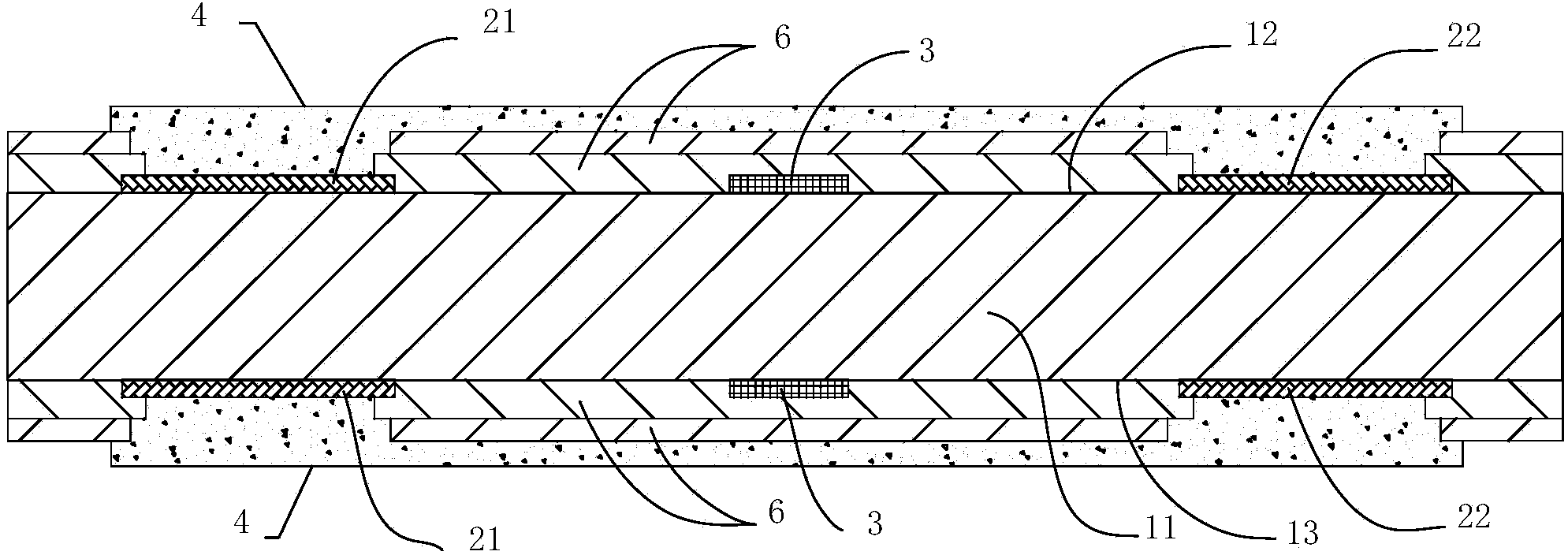

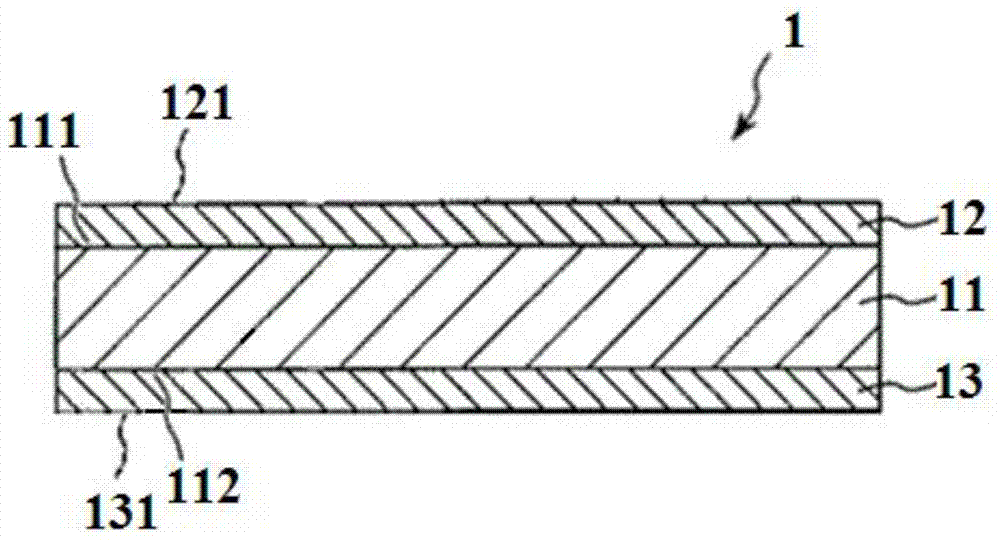

Printed circuit board and manufacturing method thereof

InactiveCN103763854AIncrease the number of layers of conductive linesReduce thicknessPrinted circuit detailsConductive pattern formationMiniaturizationConductive materials

The invention discloses a printed circuit board and a manufacturing method of the printed circuit board. The printed circuit board comprises a substrate and is characterized in that at least one surface of the substrate is provided with two or more layers of conductive circuits which are overlaid vertically and arranged in a cross mode, an insulation material layer is arranged between every two vertically adjacent layers of conductive circuits, and the conductive circuits are isolated through the insulation material layers. According to the printed circuit board, conductive ink is adopted as conductive material for manufacturing the conductive circuits, and the multiple layers of conductive circuits arranged on the substrate in an overlaid mode are isolated through the insulation material layers, so that the layer number of the conductive circuits of the printed circuit board is increased, a laminated insulation hard board is not needed, the thickness of the printed circuit board is greatly reduced, and the printed circuit board is more adaptive to miniaturization electronic devices.

Owner:SHANGHAI MEADVILLE ELECTRONICS

Photovoltaic solder strip manufacturing method

InactiveCN102747313AHigh densityLarge amount of deformationHot-dipping/immersion processesMetal-working apparatusPre treatmentCopper

The invention provides a manufacturing method of a photovoltaic solder strip. According to the invention, a copper strip is subjected to simple pre-treatments, tin coating, and rewinding. The copper strip is subjected to the pre-treatments including heating, forging, and heat treatments, such that the density of copper strip is increased. Because the copper strip is forged, the density of the copper strip is increased, deformation amount of the copper strip is increased, and excessive oxidation speed during the copper tin-coating process is avoided. Therefore, the quality of the solder strip is improved, and a qualification rate of the solder strip is higher than 99.9%.

Owner:江苏金苇电气科技有限公司

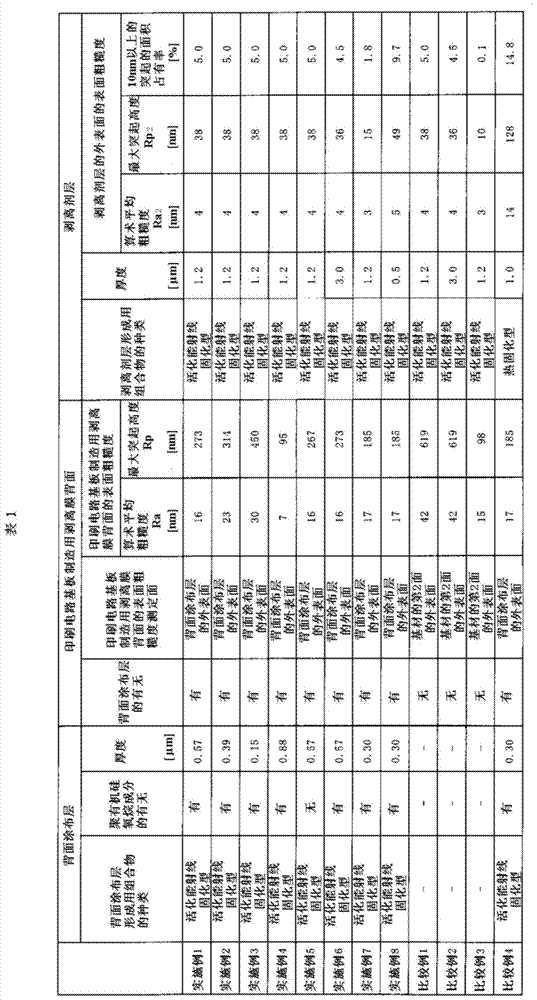

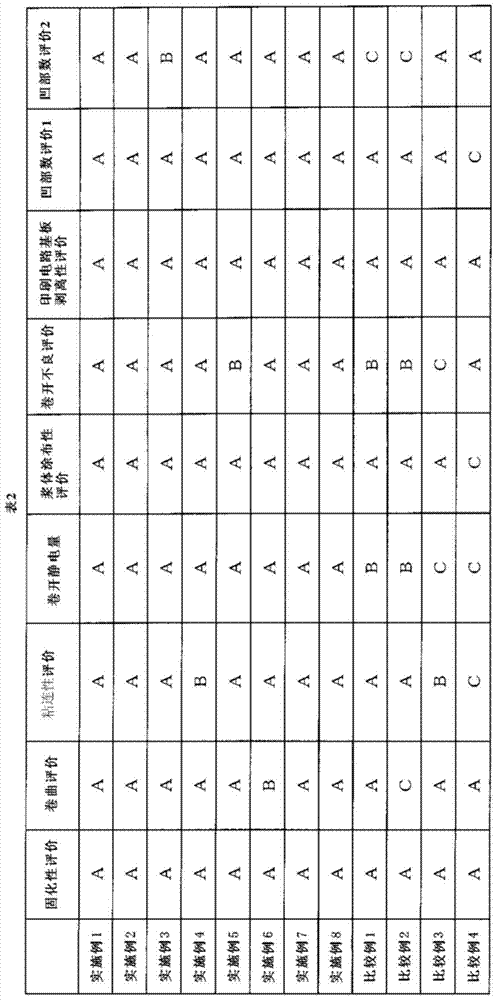

Release film for use in producing green sheet

ActiveCN104245263AAvoid pinholesInhibition thicknessSynthetic resin layered productsCeramic shaping apparatusPartial thicknessMaterials science

Owner:LINTEC CORP

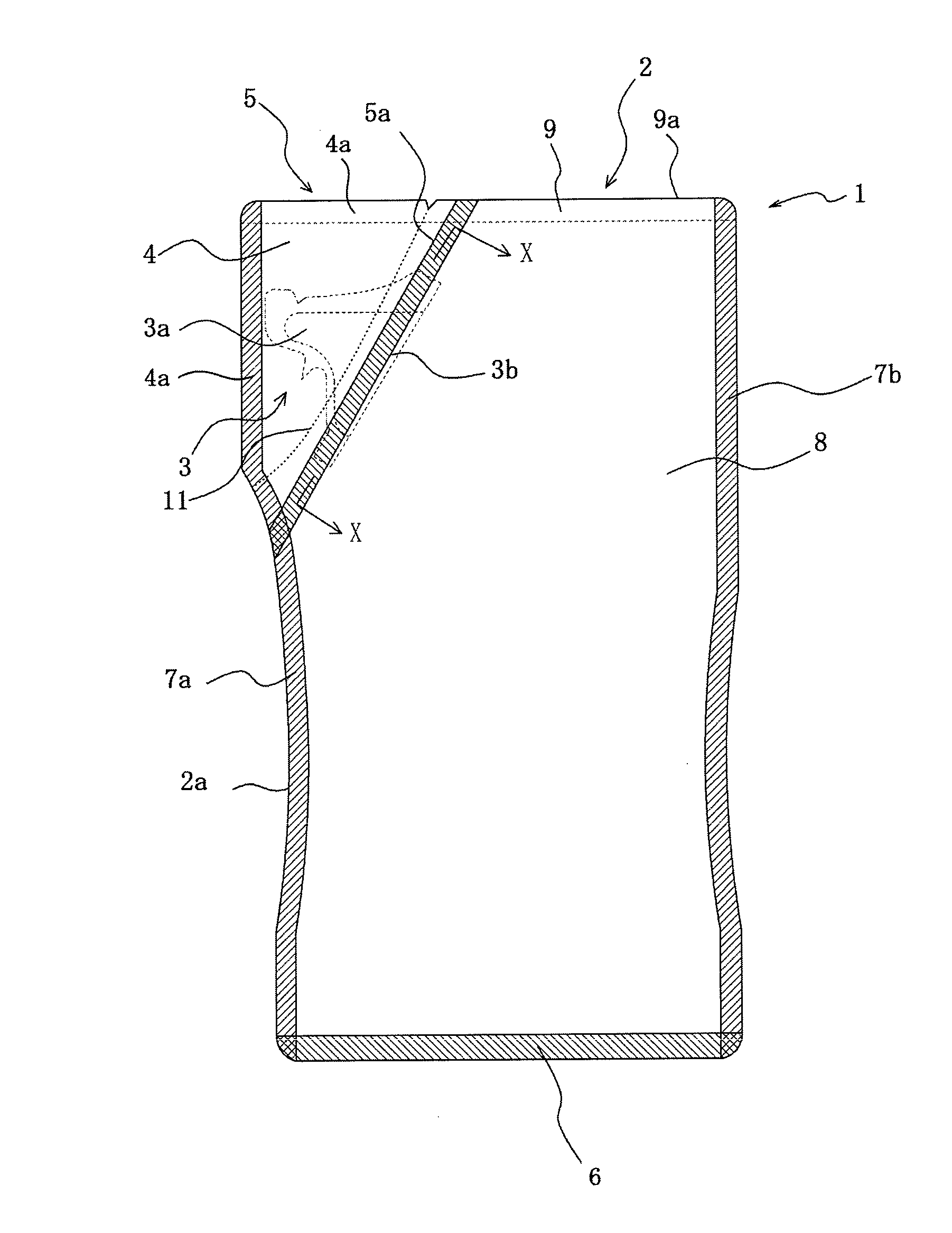

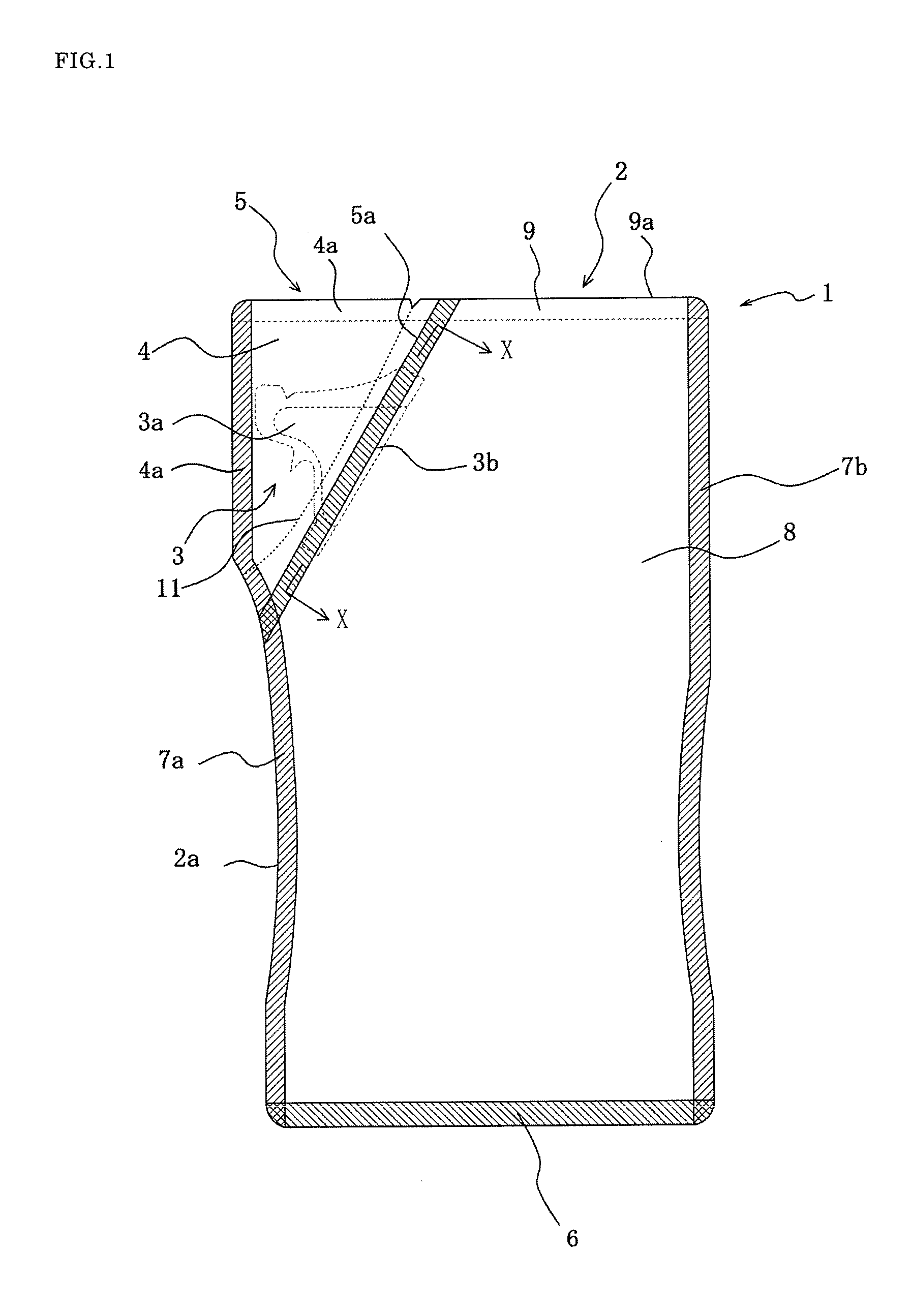

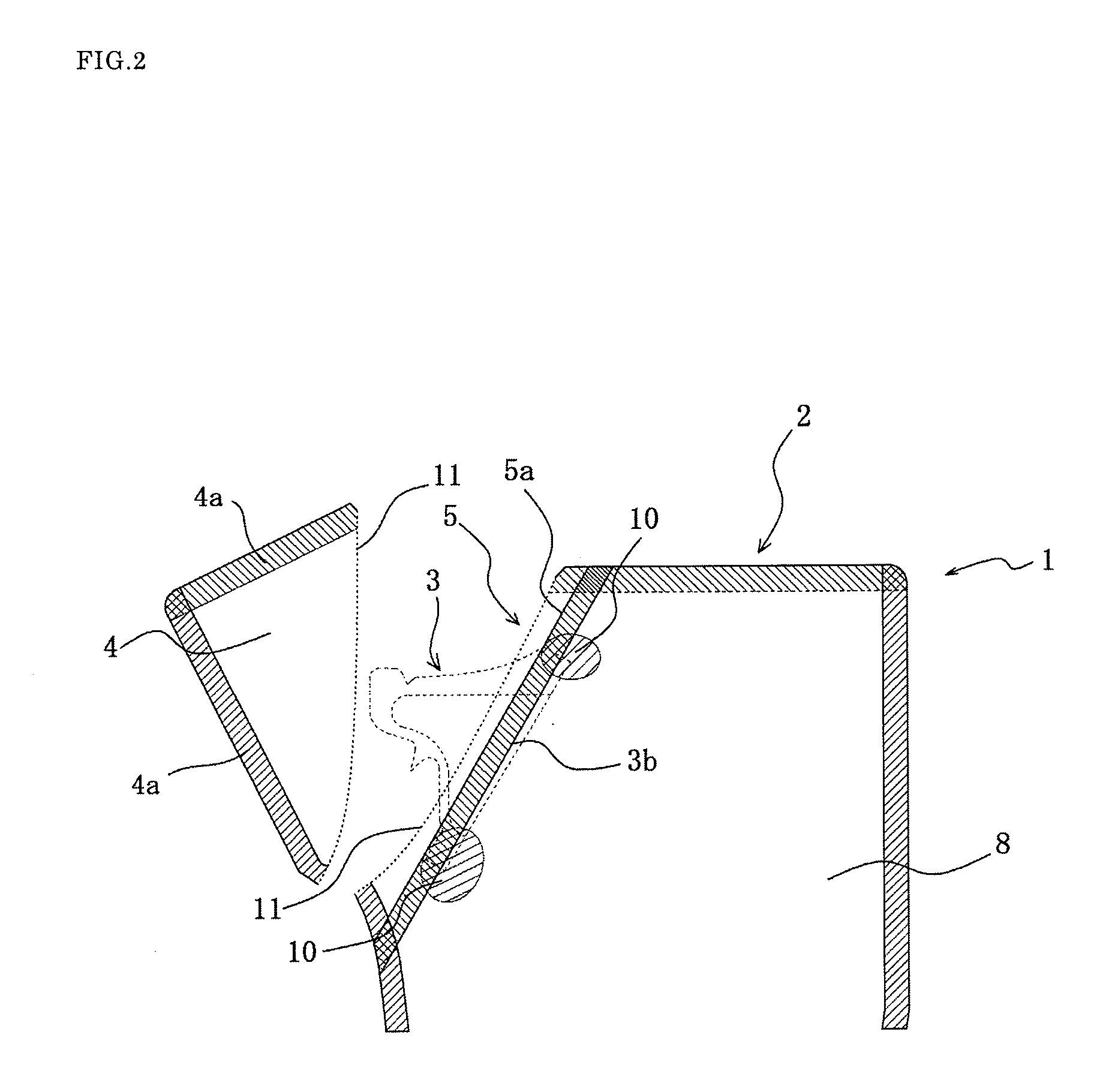

Packaging bag

ActiveUS20170043926A1No fear of bending and breakingReduce spacingFlexible coversWrappersBiomedical engineering

In packaging bag including a main bag body made of laminate films and a film-shaped pouring nozzle made of laminate films being thinner than the laminate film for the main bag body and developing a self-sealing function, the main bag body is provided on an edge part of a portion formed by cutting out at least a shoulder part with a notch part for fixing and holding the film-shaped pouring nozzle, and the notch part is formed as a protect cover separateably connected to the cutout edge part to house the film-shaped pouring nozzle therein, and an outer face of a base part of the pouring nozzle is fusion-joined to an inner face of the cutout edge part of the main bag body and connected to the main bag body.

Owner:YUSHIN

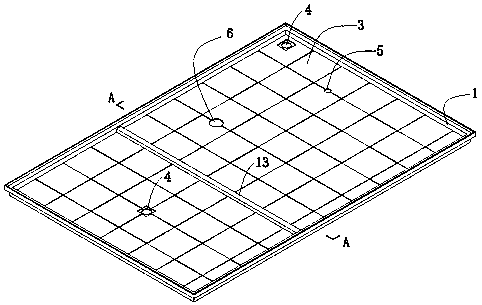

Waterproof base plate of fabricated integral bathroom

The invention discloses a waterproof base plate of a fabricated integral bathroom. The waterproof base plate comprises an aluminum frame, a plate core and a surface layer. The aluminum frame is a quadrilateral frame formed by aluminum welding-on of aluminum sectional materials, and flat-head screw hole sites are reserved in the surfaces of the aluminum sectional materials; the aluminum frame is hollow, and aluminum box sections are welded to the aluminum frame horizontally and vertically for reinforcing; the plate core can adopt a cement fiber board, specifically, the cement fiber board is bonded on the aluminum frame through epoxy resin glue, the cement fiber board and the aluminum frame are connected in a reinforced mode through countersink flat-head screws, waterproof glue and tile glueare smeared on the surface of the cement fiber board, and then the cement fiber board is bonded with tiles to form the waterproof base plate; and the plate core can also adopt an aluminum honeycomb core, specifically, aluminum sheets are arranged on the upper face layer and the lower face layer of the aluminum honeycomb core through high-temperature hot-pressing, thus an aluminum honeycomb composite board is formed, bonded on the aluminum frame through epoxy resin glue and reinforced through self-tapping screws, the face layer of the aluminum honeycomb composite board is painted with waterproof glue and epoxy resin glue, and then the aluminum honeycomb composite board is bonded with tiles to from the waterproof base plate. The waterproof base plate has the characteristics of being good inwaterproof property, light, high in rigidity and long in service life, is produced in a factory according to the site structure and not limited by the number and can be assembled after being transported to a site.

Owner:ZHUHAI SINGYES GREEN BUILDING TECH +2

Method of forming decorative tissue sheets

InactiveUS20060102302A1High strengthThe process is simple and effectiveNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineering

Forming fabrics for making tissue webs are provided with structural icons on the side of the fabric that does not contact the tissue web during formation. The resulting tissue web has good formation without pinholes, yet contains a watermark corresponding to the shape of the structural icon.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Roll-to-roll vertical type magnetic control film plating device

ActiveCN103290385AAvoid pollutionFree from pollutionVacuum evaporation coatingSputtering coatingEngineeringImpurity

The invention discloses a roll-to-roll vertical type magnetic control film plating device. The roll-to-roll vertical type magnetic control film plating device comprises a film plating chamber, wherein one end of the film plating chamber is connected with an unreeling chamber; the unreeling chamber is internally provided with an unreeling roller and a guide roller with vertical shafts; the other end of the film plating chamber is connected with a reeling chamber; the reeling chamber is provided with a reeling roller and a first guide roller with vertical shafts; the side wall of the film plating chamber is provided with a magnetron sputtering target; the target face of the magnetron sputtering target is vertical and is parallel to a plane of a flexible substrate; slits, through which the flexible substrate passes, are respectively arranged between the unreeling chamber and the film plating chamber, and between the film plating chamber and the reeling chamber; the unreeling chamber, the film plating chamber and the reeling chamber are respectively provided with an independent air exhausting system. The device disclosed by the invention can prevent foreign gas from polluting the film plating chamber so as to guarantee that a film layer is not polluted by impurities; meanwhile, fine powder and grains generated in a chamber body are prevented from falling onto the surface of the flexible substrate and the target face of the magnetron sputtering target, thereby avoiding a needle hole in the film layer and guaranteeing the quality of the film layer.

Owner:GUANGDONG SHENGBOER PHOTOELECTRIC TECH CO LTD

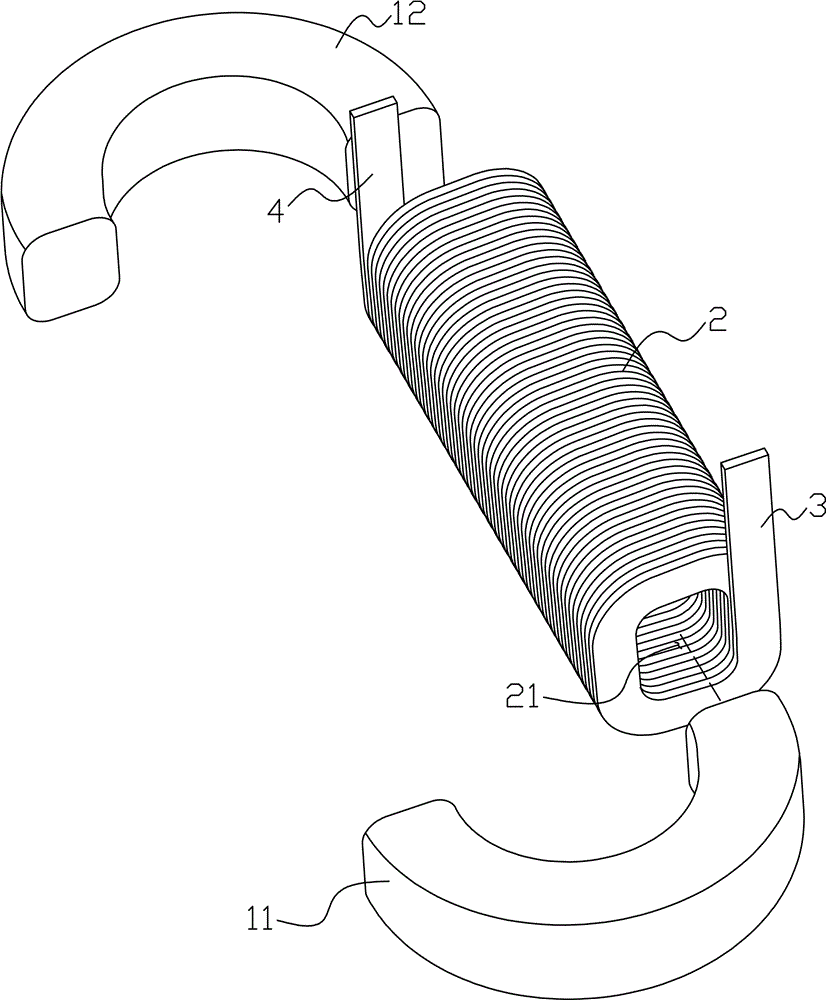

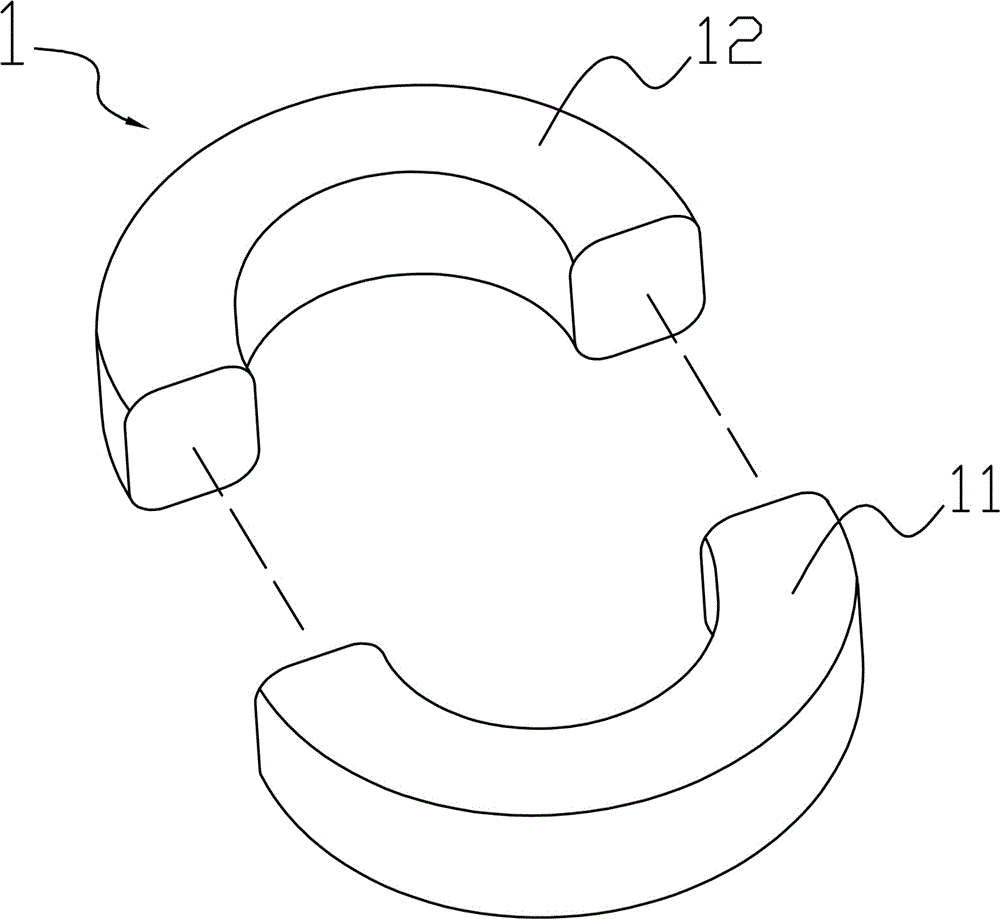

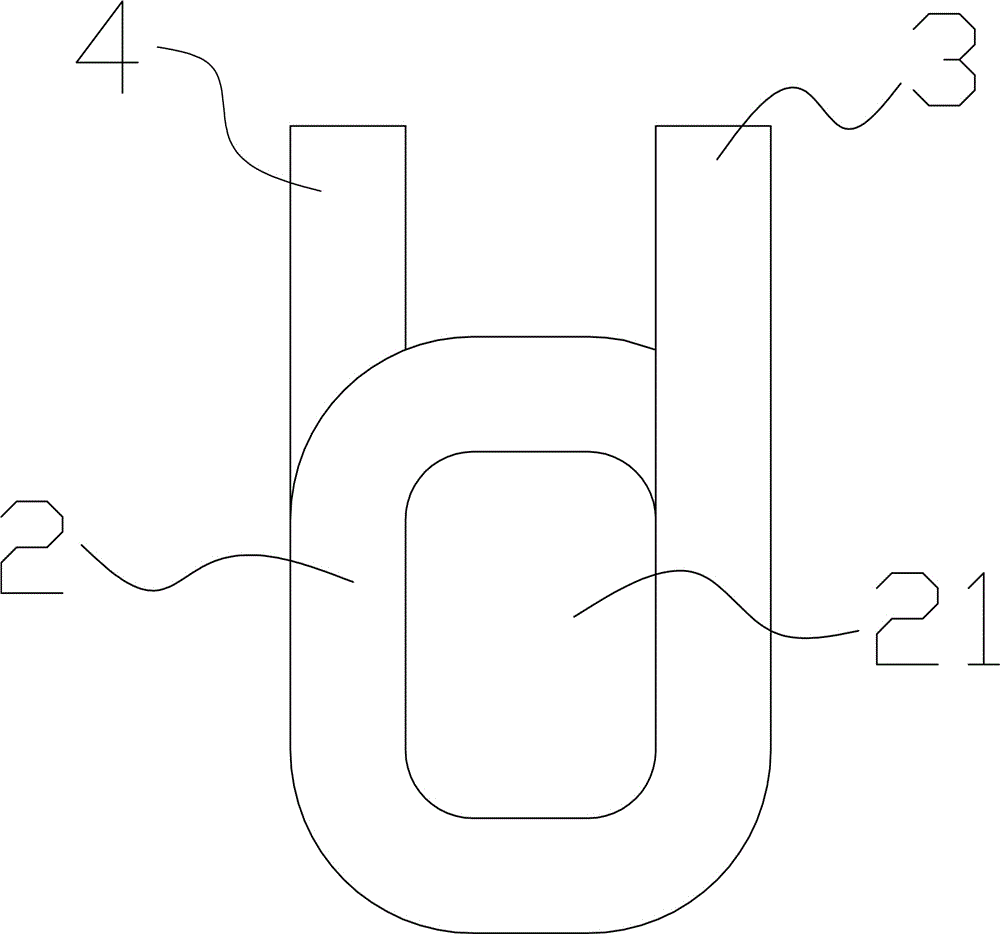

Annular differential-mode inductor and production method thereof

InactiveCN105825998AReduce labor intensityAvoid damageTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectricityWinding machine

The present invention relates to the field of magnetoelectric technology, in particular to a ring-shaped differential-mode inductor and a production method thereof. The ring-shaped differential-mode inductor includes a ring-shaped magnetic core and a coil, and the ring-shaped magnetic core is connected by a first magnetic core and a second magnetic core. In combination, the window in the middle of each turn coil forms a magnetic core channel, and the first and second magnetic cores are inserted into the magnetic core channel and then docked. The production method of the annular differential mode inductor comprises the following steps: winding the coil by a winding machine, respectively passing the first and second magnetic cores through the coil, while the second magnetic core is passed through the other end of the coil core channel, and the The starting and tail wires are stripped and soldered. In the present invention, the coil passes through the magnetic core after being wound by a winding machine. The winding process is simple, which solves the problem that the wire diameter is too large and cannot be wound. At the same time, it reduces the labor intensity of workers and improves production efficiency; The copper wire will be damaged or have pinholes during the process, which improves the yield.

Owner:湖口健诚电子电器有限公司

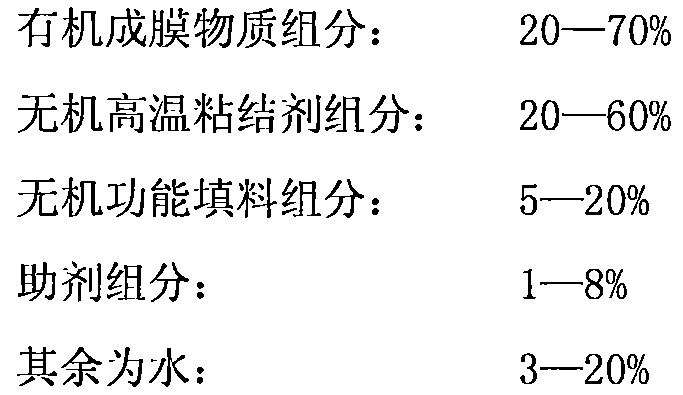

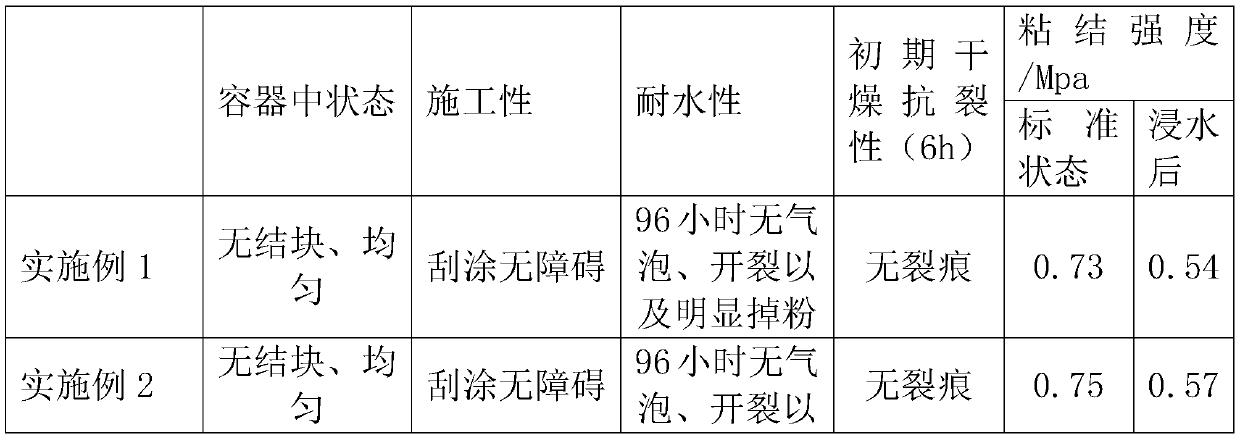

Technology research and development of organic and inorganic composite silicon steel plate insulating paint

InactiveCN106590324AGood punching performanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsOrganic filmEpoxy

The invention discloses organic and inorganic composite silicon steel plate insulating paint. The paint comprises the following components in percentages by weight: 20-70% of an organic film forming substance component, 20-60% of an inorganic high temperature binder, 5-20% of an inorganic functional filling material component, 1-8% of an auxiliary agent component, and 3-20% of water. The organic film forming substance comprises the following components according to a certain proportion: aqueous epoxy resin, an aqueous acrylic acid synthetic emulsion, one or several kinds of aqueous organic silicone resin; the inorganic binder comprises low temperature leadless glass powder and alkaline silica sol; and particle sizes of an inorganic functional filling material and a functional auxiliary agent are 6[mu]m or below. The paint guarantees film forming ability, impact resistance, water proofness and other performances of the coating in a low temperature condition, guarantees adhesive force and insulating properties of the coating in a high temperature working environment, the paint does not have chromate and mother toxic components, and the paint has usage safety and reliability.

Owner:天津市硅酸盐研究所有限公司

House roof indoor decoration method

The invention relates to the field of building decoration, in particular to a house roof indoor decoration method. The house roof indoor decoration method comprises the following steps that S1, wall surface treatment is carried out, specifically, dust, oil pollution and ash slag on the wall surface are cleaned, local concave and convex parts of the wall surface are filled and compacted by using gypsum, and flattening and polishing with sandpaper are carried out after drying; S2, the wall surface is coated with clean water first to moisturize the wall surface, and then an interface agent is evenly brushed on the wall surface; S3, after the interface agent on the wall surface is dried, glue is evenly sprayed and brushed on the wall surface; S4, putty is prepared; S5, the putty is batch scraped, transverse batch scraping is carried out during the first batch scraping putty, a scraping board is tightly connected to a scraping board, rafts are not left at joints, and a putty layer is polished with the sandpaper after drying the putty for the first time; the putty is batch scraped vertically when the putty is batch scraped the second time, and the putty layer is polished with the sandpaper after drying the second time; S6, primer paint is evenly brushed; S7, the first time of finishing coat is uniformed, and after an interval of 3-5 hours, the finishing coat is brushed for the secondtime. The house roof indoor decoration method has the advantage of good anti-cracking effect of the putty layer.

Owner:GUANGZHOU NO 4 DECORATION CO LTD

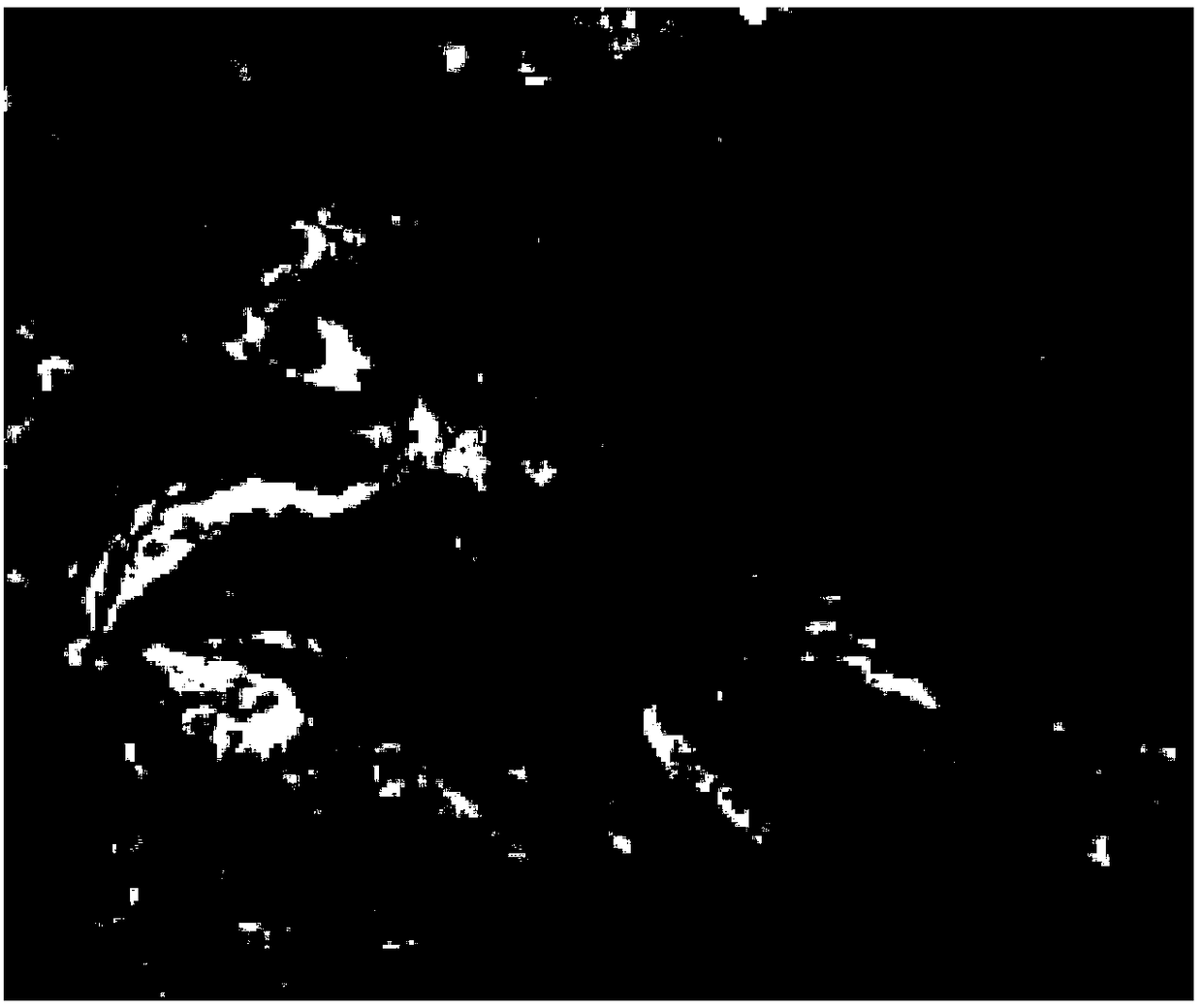

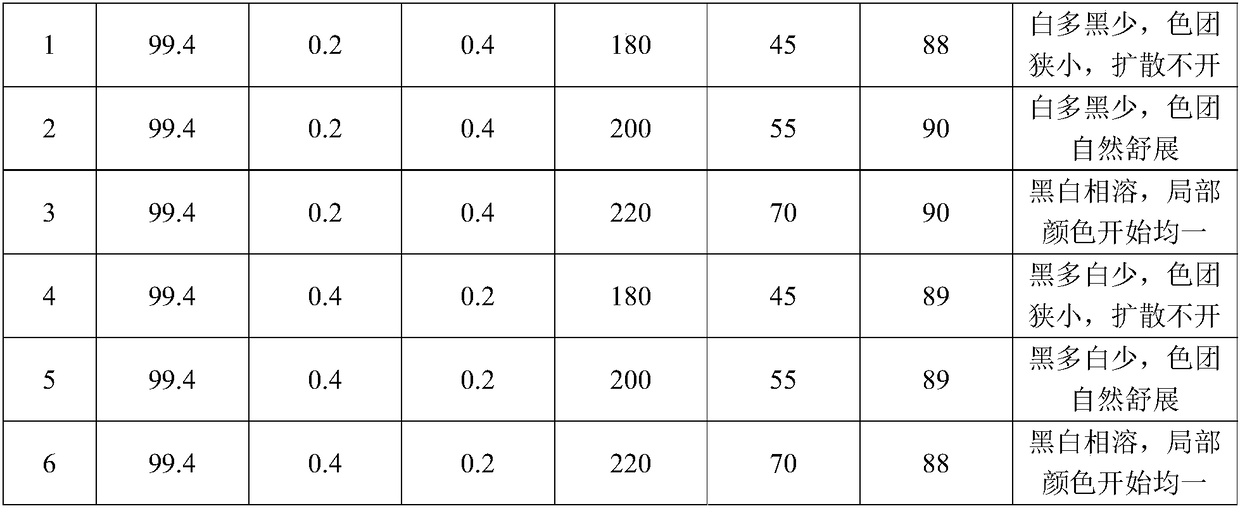

Spray-free polypropylene material with marble black and white grains and preparation method thereof

The invention discloses a spray-free polypropylene material with marble black and white grains and a preparation method thereof. The spray-free polypropylene material is prepared from, by mass, 99.2-99.6% of matrix, 0.2-0.4% of black master batches and 0.2-0.4% of white master batches. The invention further discloses the preparation method of the spray-free polypropylene material with marble blackand white grains. Compared with the prior art, due to the obtained black or white master batches, the complexity of a traditional technology matrix is lowered, pinholes or hard spots are prevented from appearing in the surface of the highlight PP matrix resin, and the size, number and the like of white and black lines are effectively regulated by adjusting the ratio of black master batches to white master batches and controlling the injection molding temperature. The preparation method is simple, the technology operation is easy to implement, and the obtained PP composite material can be usedfor the fields of individualized home appliance shells, kitchen appliances, automobile materials and the like with the strict requirement for appearances.

Owner:GUANGDONG JUSHI CHEM CO LTD

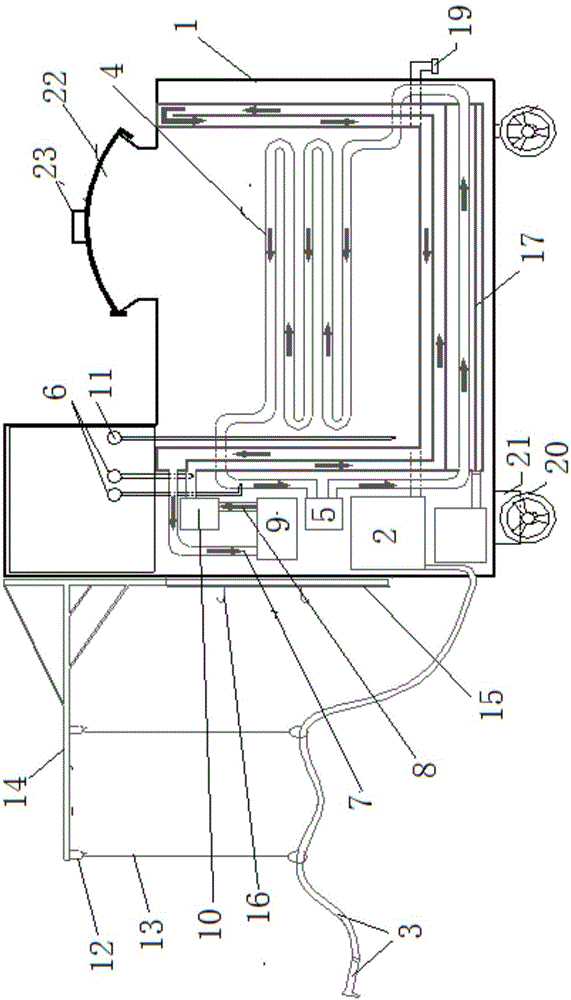

Construction equipment for spraying non-curing rubber asphalt

ActiveCN105863218AConducive to low temperature constructionNo damageWorking-up pitch/asphalt/bitumen by meltingBuilding constructionsMechanical indexEngineering

The invention relates to construction equipment for heating and spraying non-curing rubber asphalt. The construction equipment comprises a storage tank; the storage tank serves as an important component part of the equipment and a zone for conducting heating and temperature adjusting and preserving on asphalt paint and divided into two areas, the upper portion is a heating area, and the lower portion is a temperature lowering and preserving area. A first conduction oil heating system is placed in the heating area and used for heating and melting the non-curing asphalt paint, after being heated, the paint enters the temperature lowering and preserving area, and a second heating system is mounted in the temperature preserving area and used for conducting temperature adjusting and preserving treatment on the heated and molten paint; a paint spraying machine is connected with the temperature lowering and preserving area and used for implementing spraying operation. According to the construction equipment, temperature adjusting and control are conducted on the paint in the temperature lowering and preserving area, so that the paint is constructed in the low temperature state, it is guaranteed that mechanical indexes of a material are not damaged, the situation that a coating layer has the pinhole phenomenon due to high temperature of the paint is avoided, or the phenomenon that when the pain is in the high temperature state, smoke occurs in the site construction process is avoided.

Owner:中科建通工程技术有限公司

Red-base golden-dot ceramic glaze and preparation method thereof

The invention relates to a red-base golden-dot ceramic glaze and a preparation method thereof, belonging to the technical field of ceramics. The red-base golden-dot ceramic glaze comprises the following raw materials in percentage by mass: 30-35.5% of fusion cake, 21.5-27% of potassium feldspar powder, 14.5-19% of silicon dioxide, 6.6-7% of lithium carbonate and 21.9-27.4% of ferric oxide. The fusion cake comprises the following raw materials in percentage by mass: 1.5-2% of potassium oxide, 15.5-17.5% of sodium oxide, 6.9-8% of calcium oxide, 2.1-3.1% of barium oxide, 2.4-3.4% of aluminum oxide and 66-71.6% of silicon dioxide. The red-base golden-dot ceramic glaze can also contain 1% of manganese peroxide. The glaze color of the red-base golden-dot ceramic glaze has the artistic effects of the particular ceramic glaze material, and the red-base golden-dot ceramic glaze has the golden or orange metal bright dot grains on the dark red ceramic glaze surface. After a long-time experiment under the temperature condition of -30 DEG C, cracking or shedding does not appear on the glaze surface, and the glaze can resist corrosion of common acids and alkalis.

Owner:SHENYANG JIANZHU UNIVERSITY

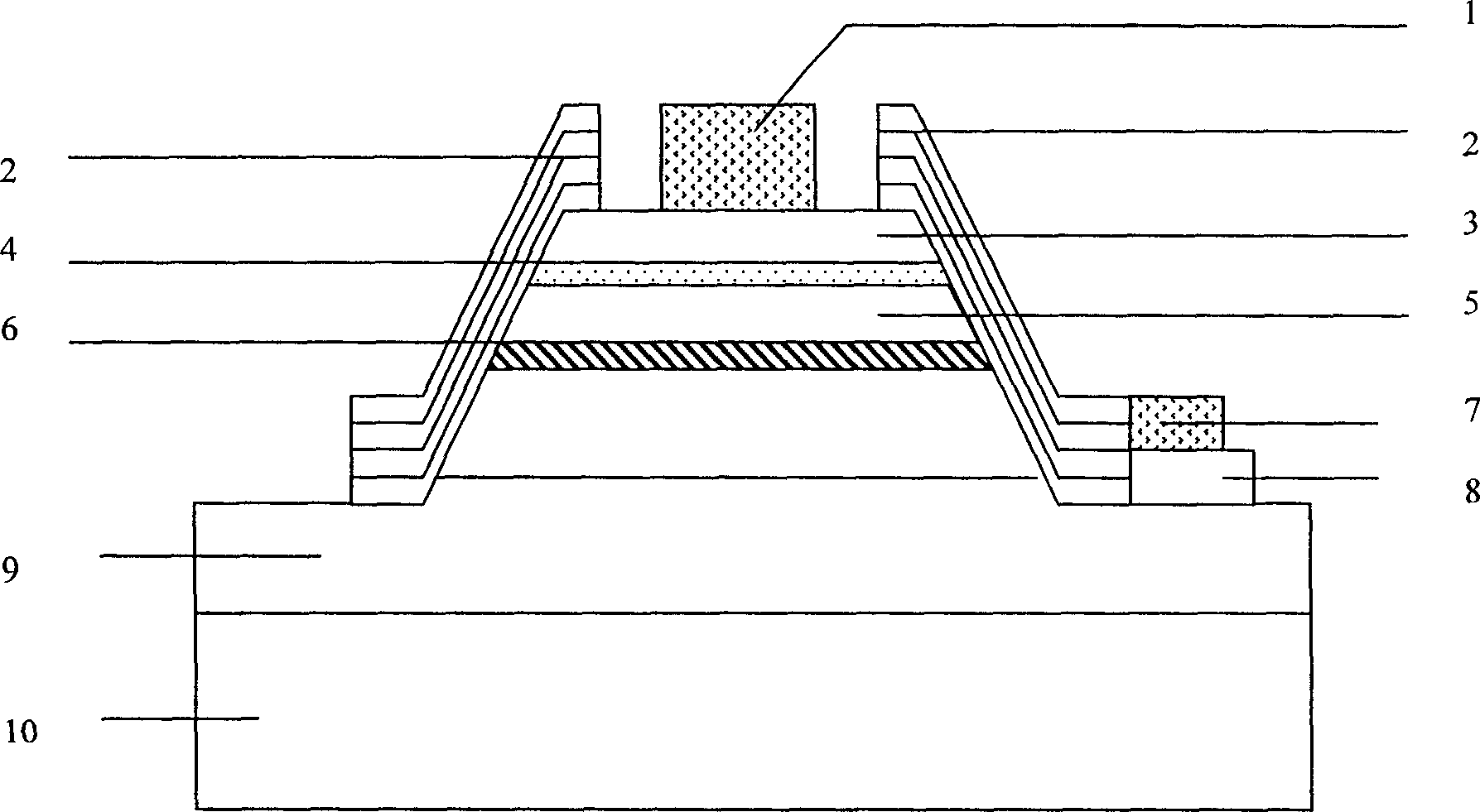

LED with high light extracting efficiency and preparing method thereof

InactiveCN1825643AQuality improvementPrevent leakageSemiconductor devicesRefractive indexContact layer

The invention is a light-emitting diode (LED) for improving light pickup efficiency, comprising: thickened P electrode, high reflecting metallic mirror, P electrode Ohm contact layer, P-type semiconductor, multi-quantum trap active region, thickened N electrode, N electrode Ohm contact layer, N-type semiconductor, and substrate, where the P-type semiconductor, multi-quantum trap active region, N-type semiconductor compose a table of the LED from the top down, and the substrate is a light outgoing side; and it is characterized by alternatively growing high and low refractivity materials on the LED side wall to form a high reflecting multilayer dielectric film. And the preparing method of the LED is characterized by preparing the high reflecting multilayer dielectric film after preparing the high reflecting metallic mirror. And the invention makes one-time growth of the high reflecting multilayer dielectric film while passivating the side wall. And the process is simple and the light output is improved at least by 20%.

Owner:BEIJING TIMESLED TECH CO LTD

Water-base foundry coating and preparation technology thereof

InactiveCN103586402AImprove high temperature resistanceImprove bindingFoundry mouldsFoundry coresFoundryWater based

A water-base foundry coating comprises quartz powder, and also comprises the components: diatomite for removing crystal water and accounting for 8%-12% by mass of quartz powder, silica sol accounting for 6%-10% by mass of quartz powder, white mud accounting for 0.6%-1%by mass of quartz powder, carboxymethyl cellulose sodium accounting for 6%-10% by mass of quartz powder, bentonite accounting for 6%-10% by mass of quartz powder, and the balance additive. The water-base foundry coating is good in high temperature resistance and combining performance, has capabilities of storing gas and exhausting gas, and helps to avoid disadvantages of pores, pin holes, depression and the like on castings.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com