Chrome vanadizing process of automotive chain pin shaft

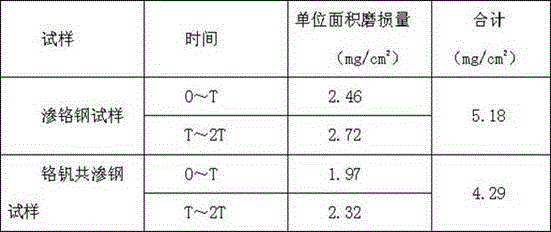

A chrome vanadium co-infiltration and pinning technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of inability to withstand large loads, low hardness, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

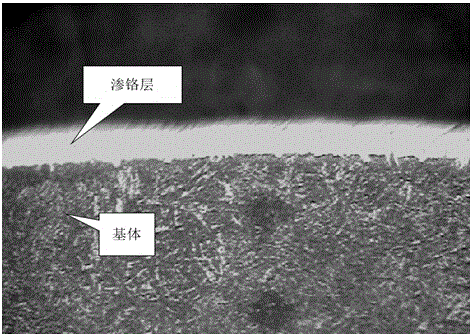

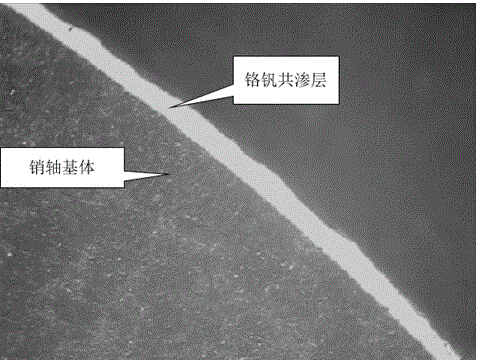

[0022] Embodiment 1: with reference to attached figure 2 . A chrome-vanadium co-infiltration process for automobile chain pin shafts, which is characterized in that: the finely ground pin shafts are placed in a converter, and 60% to 70% of anhydrous borax is added to the converter at the same time, and 10% to 15% Cr 2 o 3 , 8% to 15% of V 2 o 5 As an infiltrating agent, a certain amount of reducing agent is used to keep the converter in a rotating state, and it is kept at 1000°C±2°C for 10 hours to carry out chrome-vanadium co-infiltration. Boiling water boils off the residual waste salt on the surface; when adding a reducing agent to the salt bath, vanadium is first reduced, and if the reducing agent is excessive, it is possible to reduce chromium at the same time, and active vanadium, vanadium, and Chromium vanadium and chromium vanadium boron atoms, in order to realize steel vanadium, chromium vanadium binary co-drilling and chromium vanadium boron three-way co-infilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com