Technology research and development of organic and inorganic composite silicon steel plate insulating paint

A technology for compounding silicon steel and insulating coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of not meeting the high-temperature application performance of silicon steel sheets, personal hazards, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

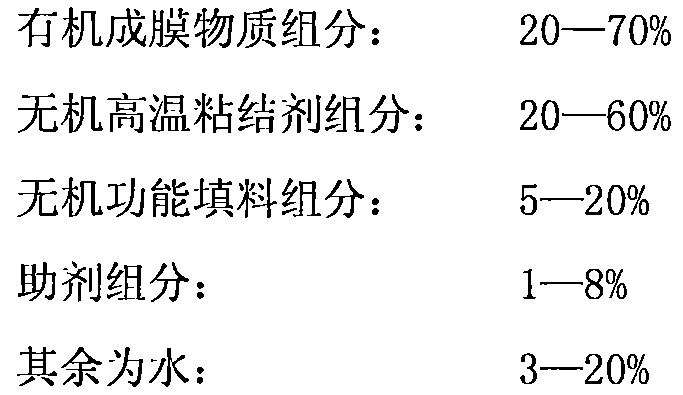

Method used

Image

Examples

Embodiment 1

[0018] Example 1, preparation of inorganic mixed solution: add 20kg of water, 1kg of defoamer, 1kg of water-based dispersant, 0.5kg of wetting agent, 0.5kg of adhesion promoter in the reaction kettle and carry out high-speed shearing and stirring at the same time Add 5kg of mica powder with a particle size of about 6um, 4.5kg of titanium dioxide, 0.5kg of boron nitride, and 13kg of lead-free low-temperature glass powder in batches, and stir at high speed. Preparation of organic mixed solution: 2kg of water-based acrylic synthetic emulsion, 18kg of water-based silicone resin, and 1kg of coupling agent were mixed uniformly at a medium-low speed, and then gradually added to the pre-prepared inorganic mixed solution in batches, and fully stirred at a medium speed. Obtain a uniform and stable organic-inorganic composite silicon steel sheet insulation coating.

Embodiment 2

[0019] Example 2, preparation of inorganic mixed solution: add 10kg of water, 0.5kg of defoamer, 1kg of water-based dispersant, and 0.5kg of wetting agent in the reaction kettle in sequence, then carry out high-speed shearing and stirring, and add the particle size in batches at the same time 4kg of mica powder of about 6um, 1.5kg of titanium dioxide, 0.5kg of silicon nitride, 2kg of quartz fiber powder, 30kg of lead-free low-temperature glass powder, high-speed stirring, after the components are fully mixed, and finally add 20kg of alkaline silica sol. Preparation of organic mixed solution: 5kg of water-based acrylic synthetic emulsion, 15kg of water-based epoxy resin, and 10kg of silicone resin. A uniform and stable organic-inorganic composite silicon steel sheet insulation coating is obtained.

Embodiment 3

[0020] Example 3, preparation of inorganic mixed solution: add 10kg of water, 0.5kg of defoamer, 0.5kg of water-based dispersant, and 1kg of emulsifier in the reaction kettle, and then carry out high-speed shearing and stirring, and at the same time, add in batches with a particle size of 6um About 3kg of mica powder, 2kg of glass fiber, 4kg of titanium dioxide, 2kg of talcum powder, 1kg of boron nitride, 24kg of lead-free low-temperature glass powder, stir at high speed, and after the components are fully mixed, add 14kg of alkaline silica sol. Preparation of organic mixed solution: 10kg of water-based acrylic synthetic emulsion, 18kg of water-based silicone resin, and 10kg of water-based epoxy resin are uniformly mixed at medium and low speeds, and then gradually added to the pre-prepared inorganic mixed solution in batches, fully stirred and mixed at a medium speed, and finally A uniform and stable organic-inorganic composite silicon steel sheet insulation coating is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com