Organic hydrophilic resin for odorless hydrophilic coating, coating composition and application thereof

A technology of hydrophilic coating and hydrophilic resin, which is applied in the direction of coating, etc., can solve the problems of coating, poor punching performance, and large wear of abrasive tools without considering the problem of coating odor, so as to reduce the risk of coating odor , good brewing performance, and the effect of reducing the adsorption of peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

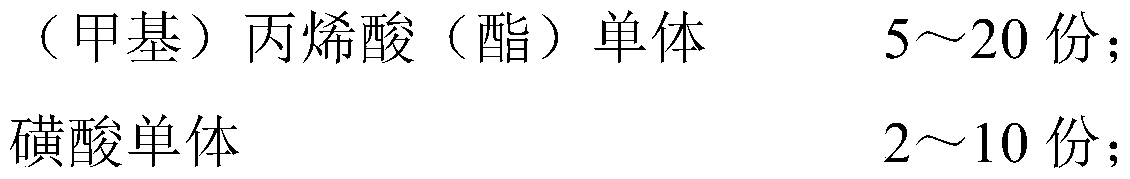

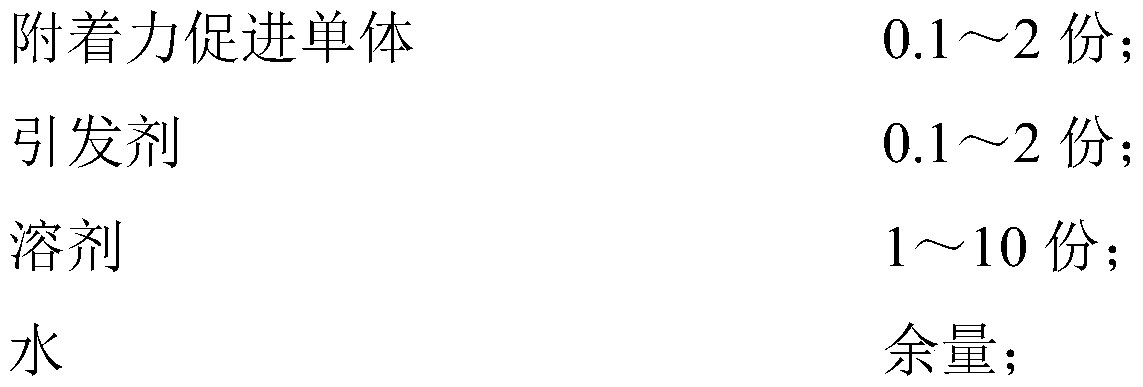

[0041] (1) The organic hydrophilic resin A for the odorless hydrophilic coating comprises the following components by mass: 5 parts of acrylic acid; 10 parts of p-styrenesulfonic acid; 0.2 part of IBOA; 0.2 part of sodium persulfate; 1 part; balance water.

[0042] Dissolve sodium persulfate in water to make a 1% initiator solution, add the remaining water and butyl glycol ether into the reaction kettle, heat to 80°C, add acrylic acid, p-styrenesulfonic acid and IBOA while stirring, After being stirred evenly, start to add the initiator solution dropwise, finish the dropwise addition within 2 hours, continue heating and stirring for 5 hours, obtain the organic hydrophilic resin A for odorless hydrophilic coating after cooling, and measure it with gel permeation chromatography (GPC). The obtained molecular weight was 210,000.

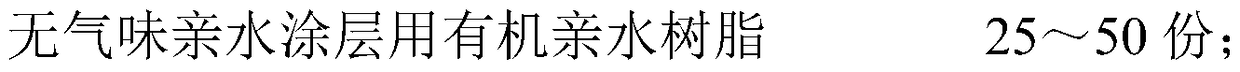

[0043](2) The coating composition comprises the following components in parts by mass: 35 parts of resin A; 0.1 part of titanate coupling agent; 0.05 p...

Embodiment 2

[0046] (1) Organic hydrophilic resin B for an odorless hydrophilic coating comprises the following components by mass: 20 parts of acrylic acid; 2 parts of sodium vinyl sulfonate; 0.5 part of IBOA; 0.5 part of potassium persulfate; 3 parts of isopropanol ; water balance.

[0047] Dissolve potassium persulfate in water to make a 0.5% initiator solution, add the remaining water and isopropanol to the reaction kettle, heat to 70°C, add acrylic acid, sodium vinyl sulfonate and IBOA while stirring, and wait to stir After uniformity, the initiator solution was added dropwise, and the dropwise addition was completed within 3 hours, and then continued heating and stirring for 4 hours, and after cooling, the organic hydrophilic resin B for an odorless hydrophilic coating was obtained, with a molecular weight of 260,000.

[0048] (2) The coating composition comprises the following components in parts by mass: 48 parts of resin B; 0.5 part of zirconate coupling agent; 0.1 part of fatty a...

Embodiment 3

[0051] (1) The organic hydrophilic resin C for an odorless hydrophilic coating comprises the following components by mass: 10 parts of sodium methacrylate; 10 parts of allylsulfonic acid; 2 parts of IBOA; 0.1 part of potassium persulfate; 5 parts of ethanol portion; water balance.

[0052] Dissolve potassium persulfate in water to make a 0.1% initiator solution, add remaining water and ethanol to the reaction kettle, heat to 75°C, add sodium methacrylate, allyl sulfonic acid and IBOA while stirring, wait until After stirring evenly, start to add the initiator solution dropwise, finish the dropwise addition within 1 hour, then continue to heat and stir for 6 hours, and after cooling, an organic hydrophilic resin C for an odorless hydrophilic coating is obtained, with a molecular weight of 500,000.

[0053] (2) The coating composition comprises the following components in parts by mass: 50 parts of resin C; 0.2 parts of aluminate coupling agent; 0.2 parts of fatty acid polyoxyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com