Patents

Literature

267 results about "TVEX-PHOR resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The use of TVEX-PHOR resin for the sorption of praseodymium (III), holmium (III) and cobalt (II) from nitrate medium was carried out using batch and column techniques.

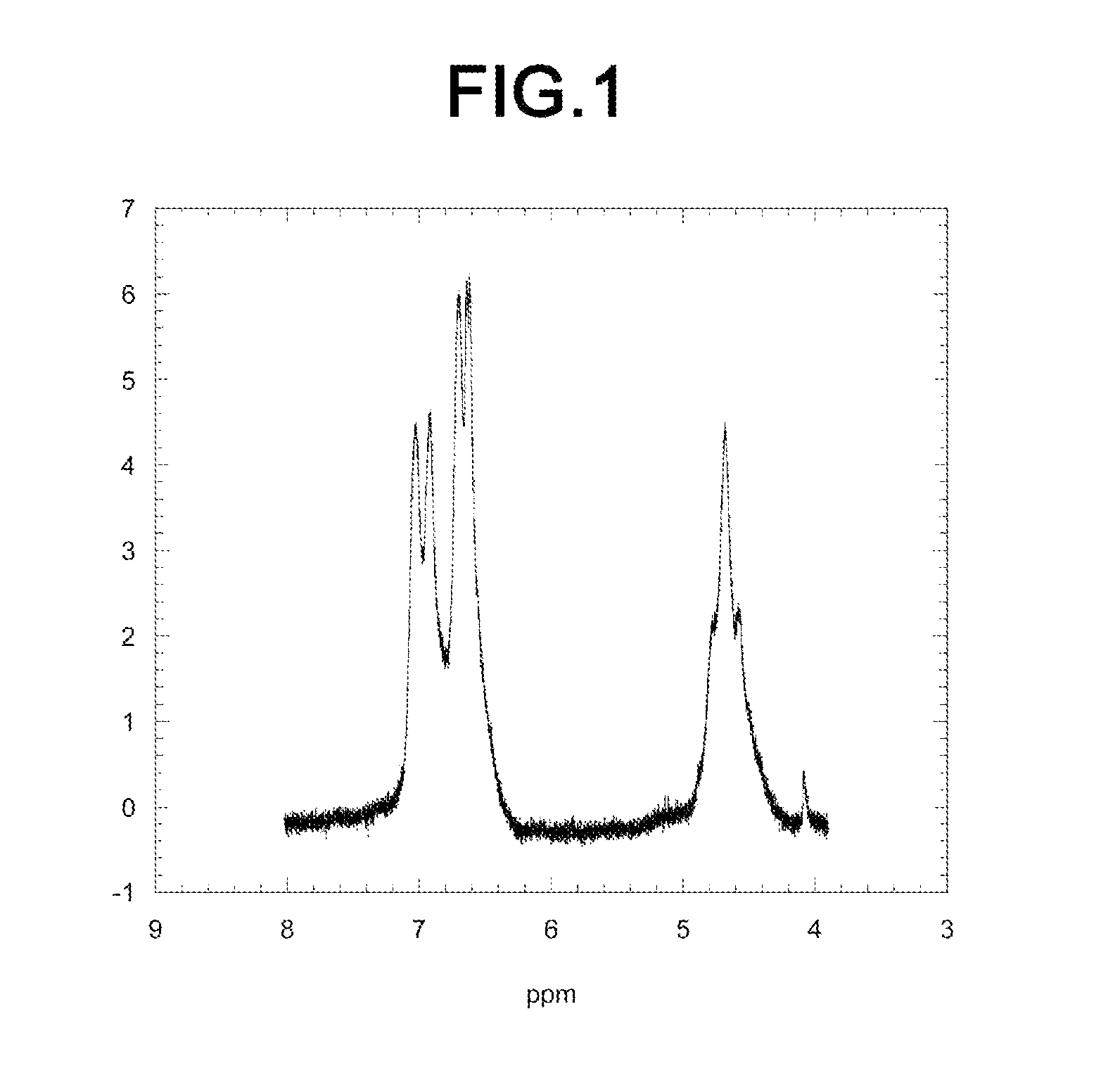

Epoxy Acid Thermoset Resins and Composites that Can Be Hot-Fashioned and Recycled

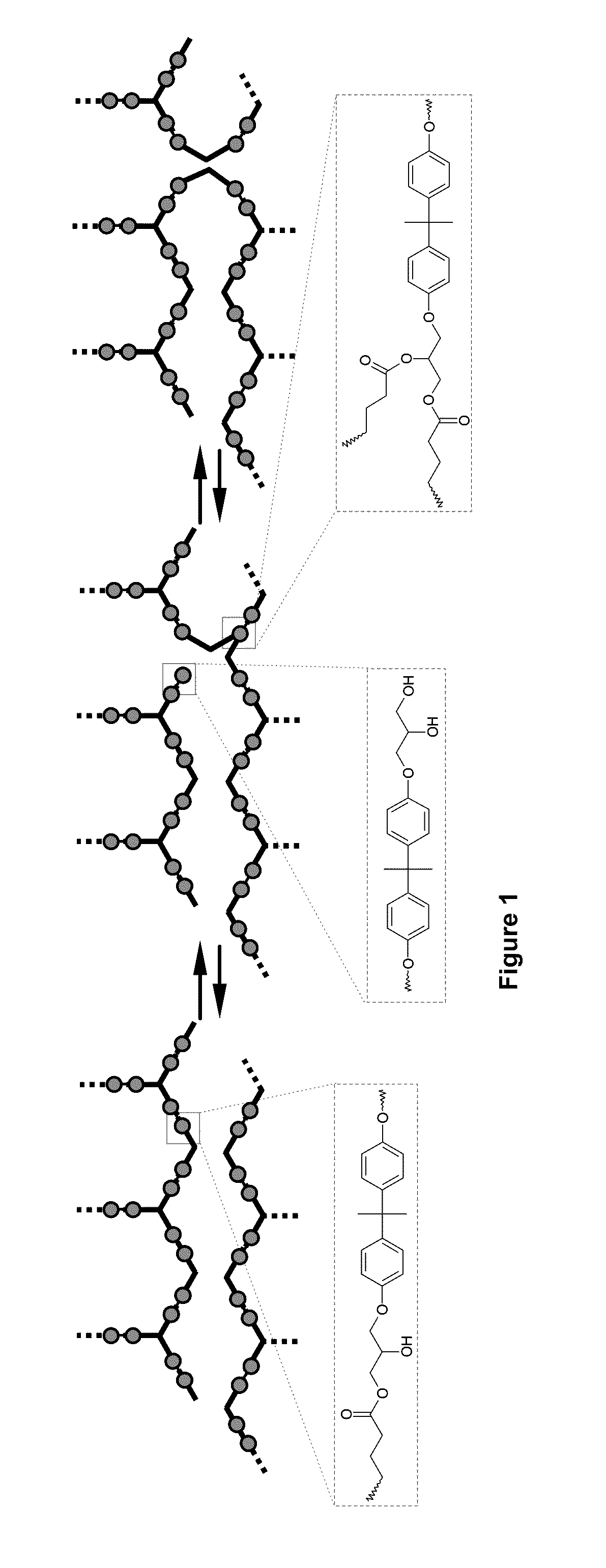

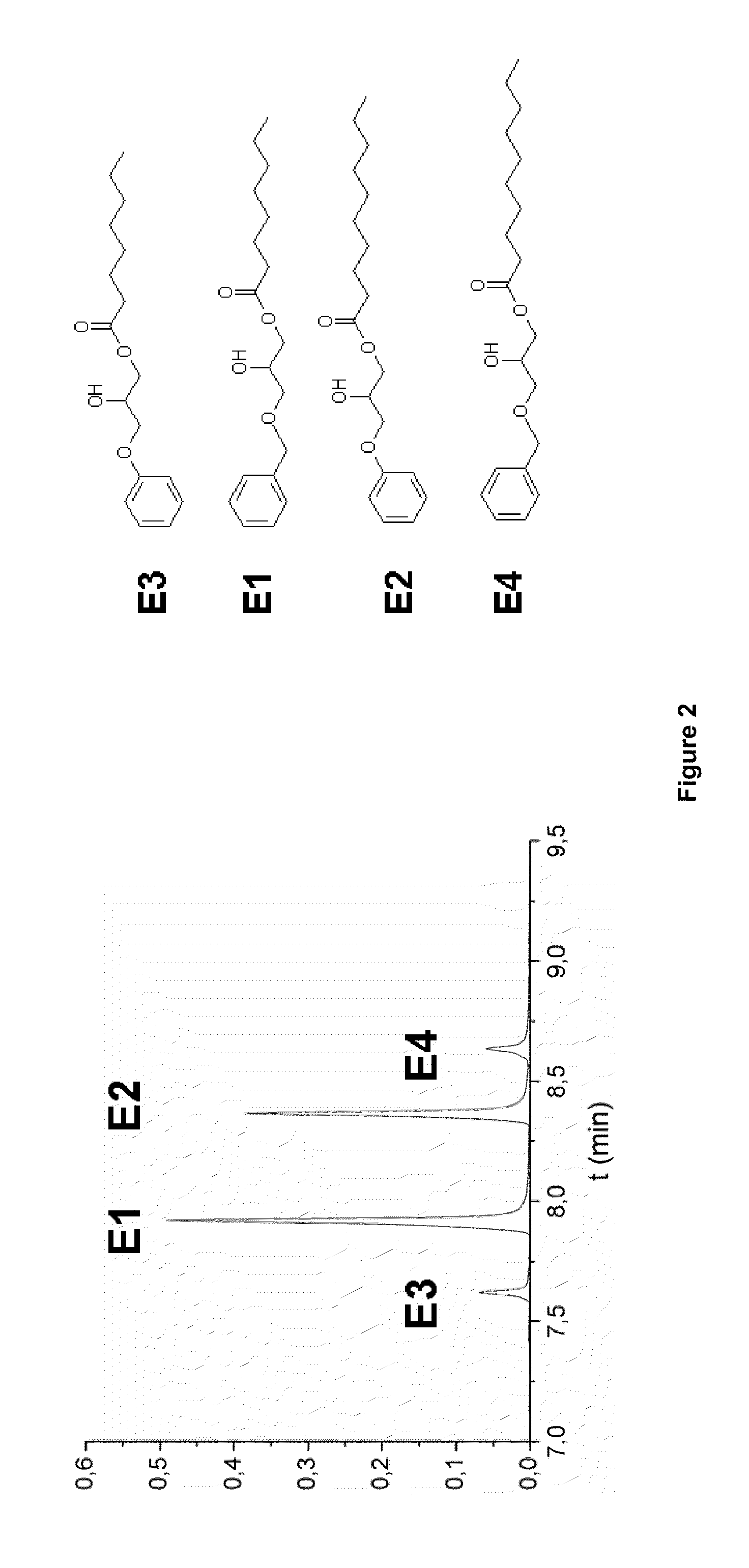

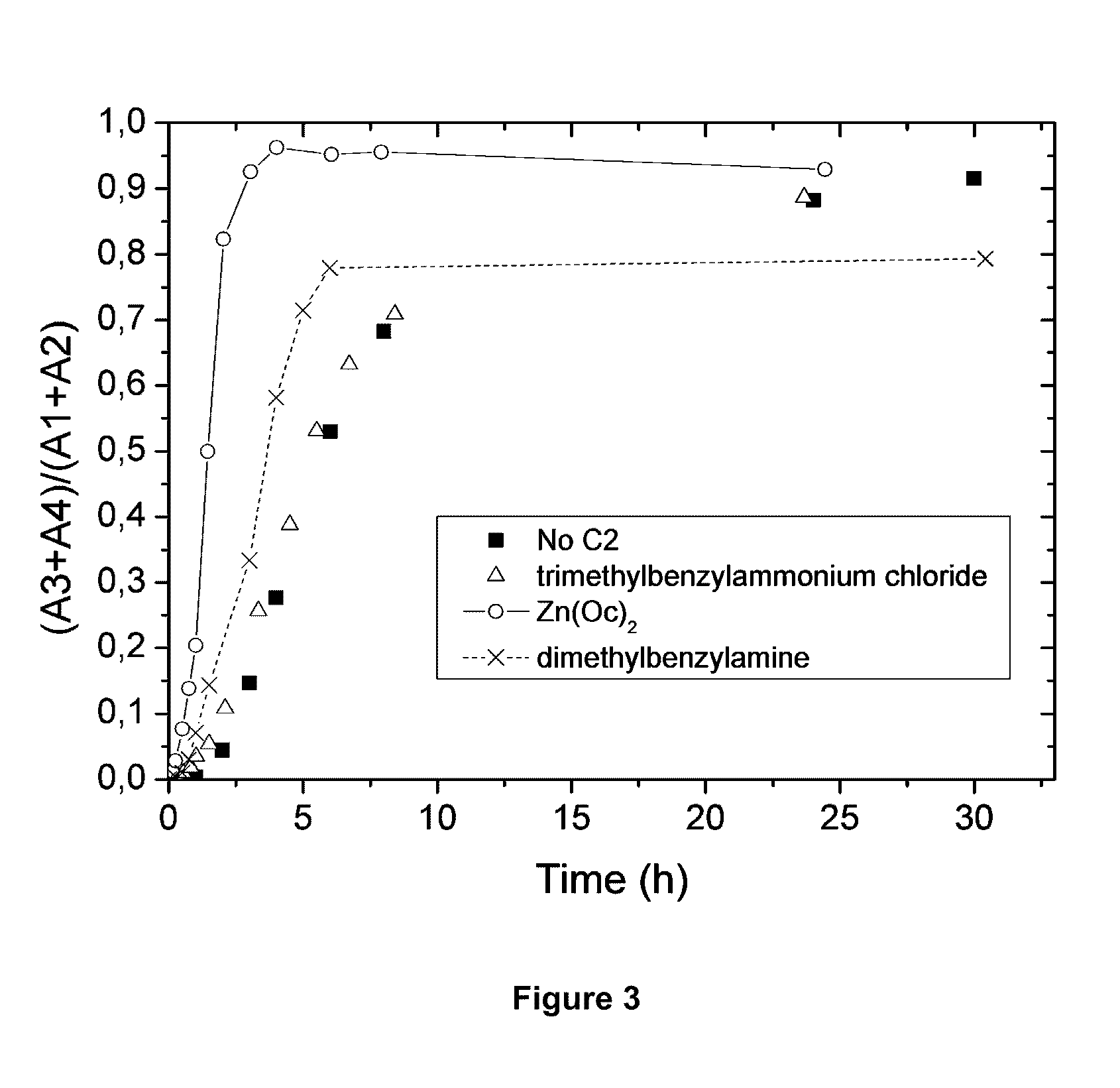

Resins and thermoset composites comprising them, these materials being able to be hot-fashioned. These compositions resulting from placing at least one thermosetting resin precursor, this thermosetting resin precursor comprising hydroxyl functions and / or epoxy groups, and optionally ester functions, in contact with at least one hardener chosen from carboxylic acids, in the presence of at least one transesterification catalyst whose total molar amount is between 5% and 25% of the total molar amount of hydroxyl and epoxy contained in the thermosetting resin precursor. Process for manufacturing these materials, process for transforming and process for recycling these materials. New solid forms of resins and of thermoset composites that may be used in the implementation of these processes.

Owner:CENT NAT DE LA RECHERCHE SCI +1

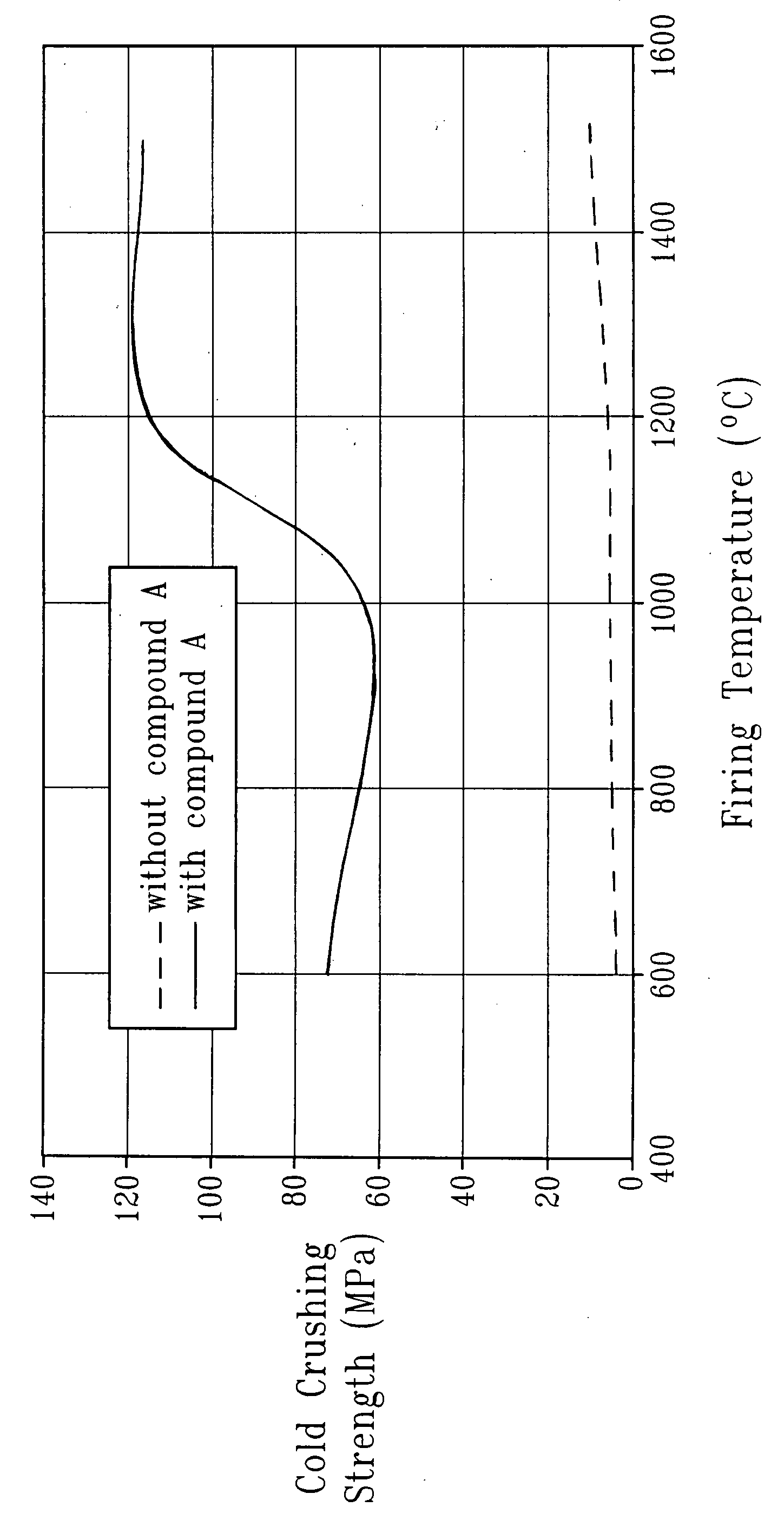

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Biodegradable resin composition for molding and molded object obtained by molding the same

InactiveUS20050043462A1Improve heat resistanceHigh mechanical strengthDyeing processPhosphoniumPhosphonium salt

A biodegradable resin composition and an object molded or formed from the composition. The resin composition comprises: 100 parts by weight of a biodegradable polyester resin comprising not smaller than 50% by weight of polylactic acid having a melting point of not lower than 160° C., the biodegradable polyester resin having a melt flow rate of 0.1 to 50 g / 10 min as measured under a load of 21.2 N at 190° C.; and 0.1 to 20 parts by weight of a phyllosilicate containing a primary, secondary or tertiary amine salt, a quaternary ammonium salt or a phosphonium salt ionically bonded between layers thereof.

Owner:UNITIKA LTD

Polyolefin-based adhesive resins and method of making adhesive resins

InactiveUS7064163B2Speed up the processReduce the amount requiredAdhesive processesMacromolecular adhesive additivesMonomer compositionPolyolefin

A method for producing polyolefin-based adhesive resins having improved physical and optical properties and the improved adhesive resins thereby produced, eliminates at least one reheating and melting of polyolefin polymer, comprises polymerizing a monomer composition of at least one olefin, mixing the polymerization product without pelletizing the polyolefin polymer with at least one graft polymer or copolymer in a heated mixing device at a temperature above the melting point of the components, and recovering the resulting polyolefin-based adhesive resin.

Owner:MSI TECH LLC

Anhydride and resorcinol latent catalyst system for improving cure characteristics of phenolic resins

An anhydride and resorcinol latent catalyst system for a phenolic resole resin provides a resin having long pot life and long shelf life, yet cures quickly thereafter.

Owner:GEORGIA PACIFIC CHEM LLC

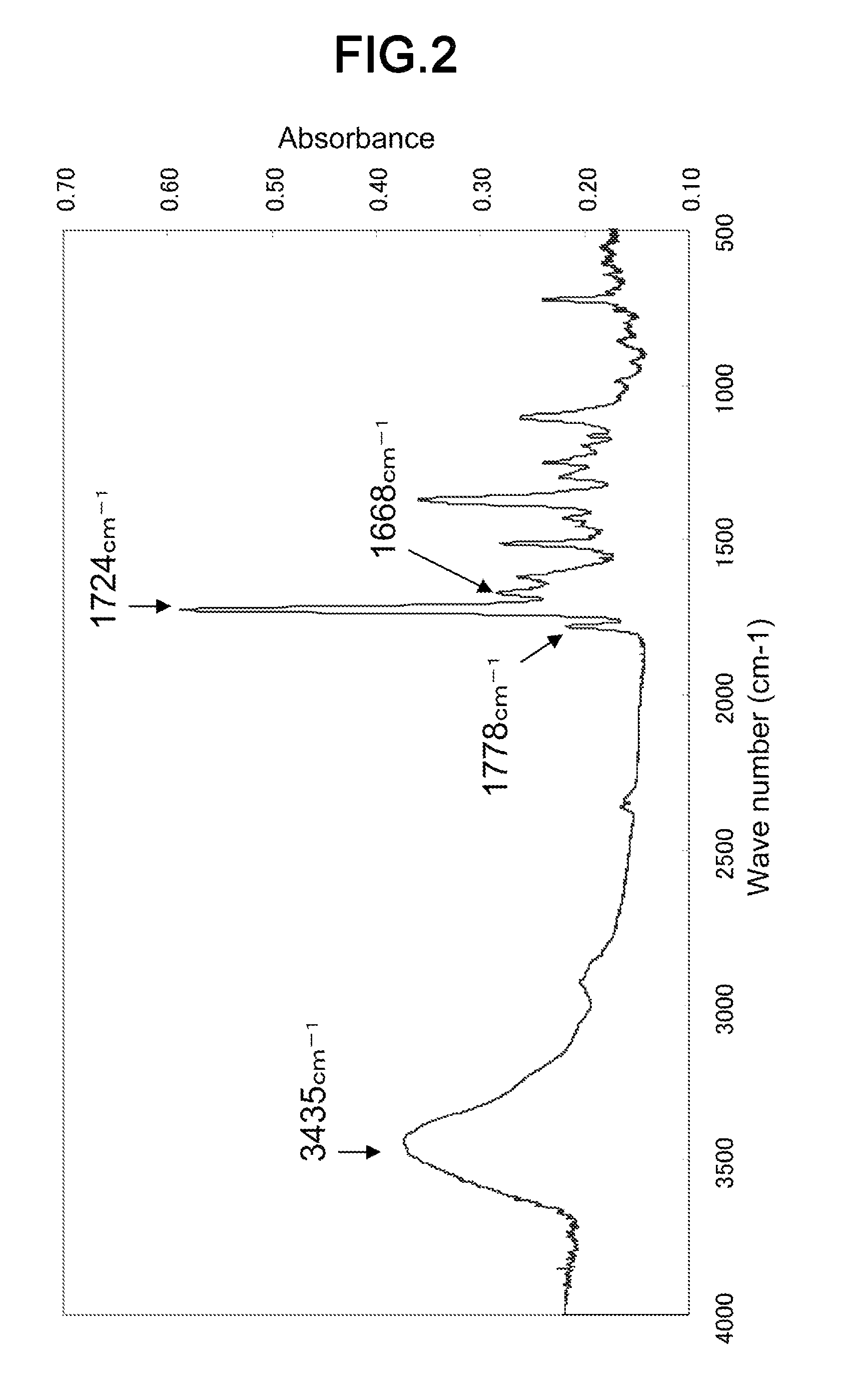

High thermal-conductive, halogen-free, flame-retardant resin composition, and prepreg and coating thereof

ActiveUS20100163783A1Improve flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsEpoxyHalogen

A high thermal-conductive, halogen-free and flame-retardant resin composition used as a dielectric layer of a printed circuit board comprises 5% to 70% of phosphorus-containing epoxy resin, at most 50% of multifunctional or bifunctional epoxy resin, 1% to 20% of curing agent, 0.01% to 10% of accelerant, at most 20% of inorganic powder, 5% to 85% of high thermal conductivity powder and 0.01% to 10% of processing aids, which resin composition has excellent thermal conductivity, heat resistance and flame retardancy as well as being environmentally friendly for free of halogen flame retardant and no toxic or corrosive gases when burning; the resin composition is used to form as a high thermal-conductive prepreg by impregnation or form as a high thermal-conductive coating by coating and then further used as a dielectric layer on a printed circuit board for demonstrating if electronic components formed thereon the printed circuit board has high thermal-conductivity and efficient heat dissipation capable of improving long service life and enhanced stability of electronic components.

Owner:NANYA PLASTICS CORP

Modified epoxy resins comprising the reaction product of a biomass derived compound and an epoxy resin, and aqueous dispersions and coatings comprising such resins

Modified epoxy resins comprising the reaction product of a cycloaliphatic, polycyclic and / or aromatic biomass derived compound and an epoxy resin are disclosed. Aqueous dispersions and coatings comprising these reaction products are also disclosed.

Owner:PPG IND OHIO INC

Polyester resin and purposes thereof

InactiveUS20110257273A1Increase elasticityCosmetic preparationsOrganic chemistryMonomer compositionPolyol

A low-molecular-weight polyester resin which can elasticize a resin suitably and can be used for various purposes, various resins obtained by using the resin, and the purposes thereof. The polyester resin is obtained by polymerizing a monomer composition containing 10 to 90 weight % of a linear dicarboxylic acid and / or diol having at least 8 carbon atoms (I), 5 to 80 weight % of a branched dicarboxylic acid and / or diol having at least 4 carbon atoms (II-1) and / or 2 to 40 weight % of at least one polyfunctional monomer (II-2) selected from the group consisting of polyols, polycarboxylic acids and hydroxycarboxylic acids having 3 or more functional groups respectively and which has the number average molecular weight of 500 to 5000 and is amorphous.

Owner:NIPPON BEE CHEM

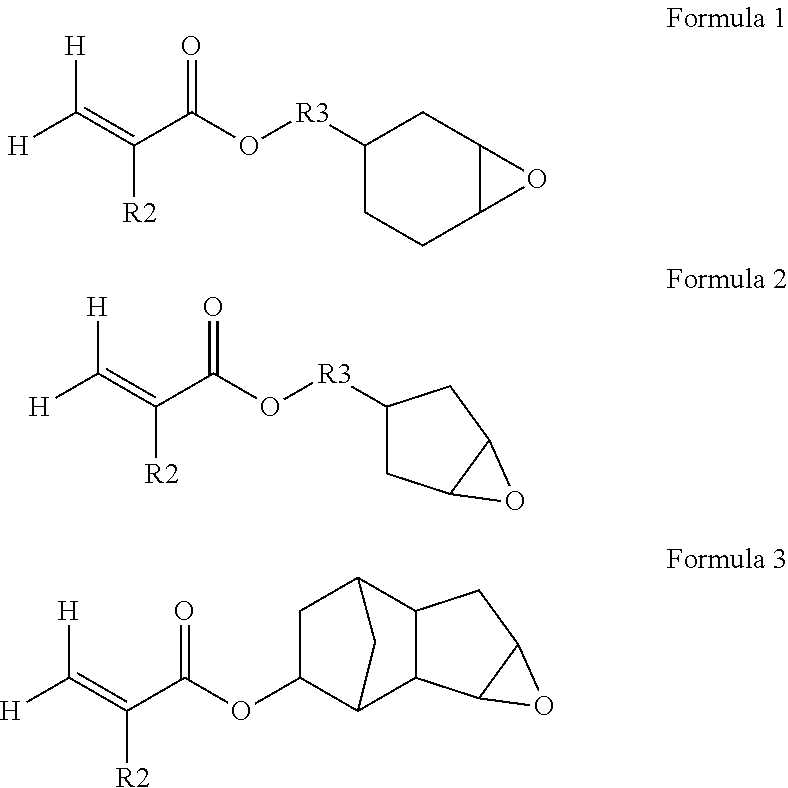

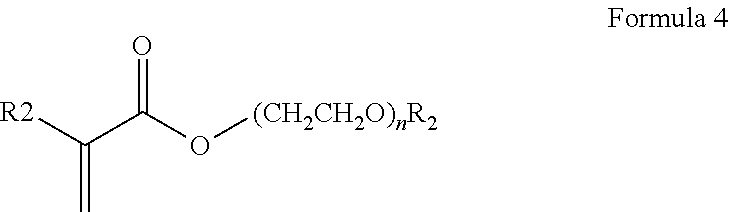

Thermally curable resin composition with good coatability and re-coatability

InactiveUS20140011916A1Good coating effectHigh surface energyCoatingsLiquid-crystal displayEthylene oxide

The present invention relates to a thermally curable binder resin including an epoxy group-containing ethylenic unsaturated monomer and an aqueous monomer including an ethylene oxide group; or an epoxy group-containing ethylenic unsaturated monomer, a compound including an acidic component, and an aqueous monomer including an ethylene oxide group, a thermally curable resin composition including the same, a cured film prepared therefrom, a color filter, and a liquid crystal display device. The thermally curable binder resin of the present invention may significantly enhance the coatability of a cured film forming composition and increase the surface energy of a coated protective film to significantly enhance the recoating properties in subsequent processes after formation of the protective film.

Owner:LG CHEM LTD

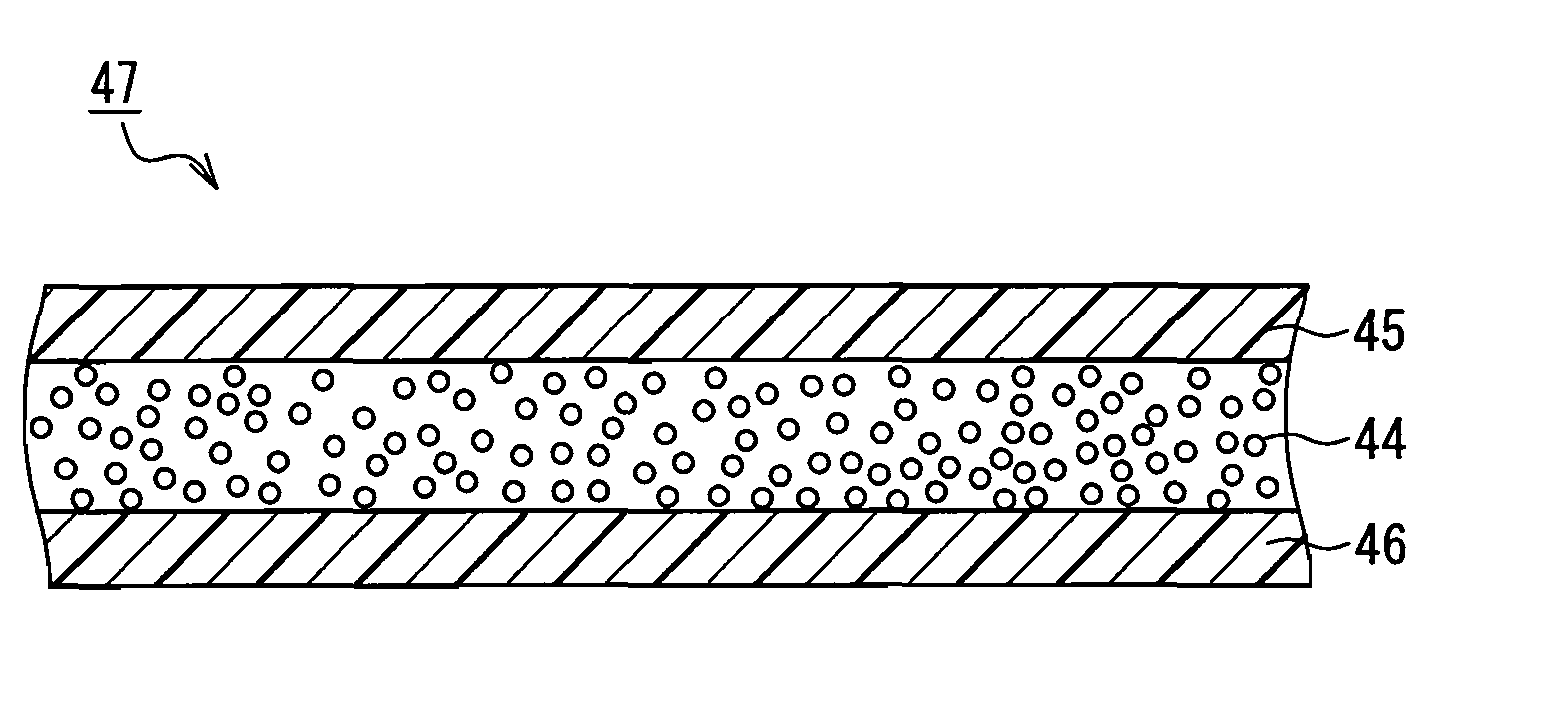

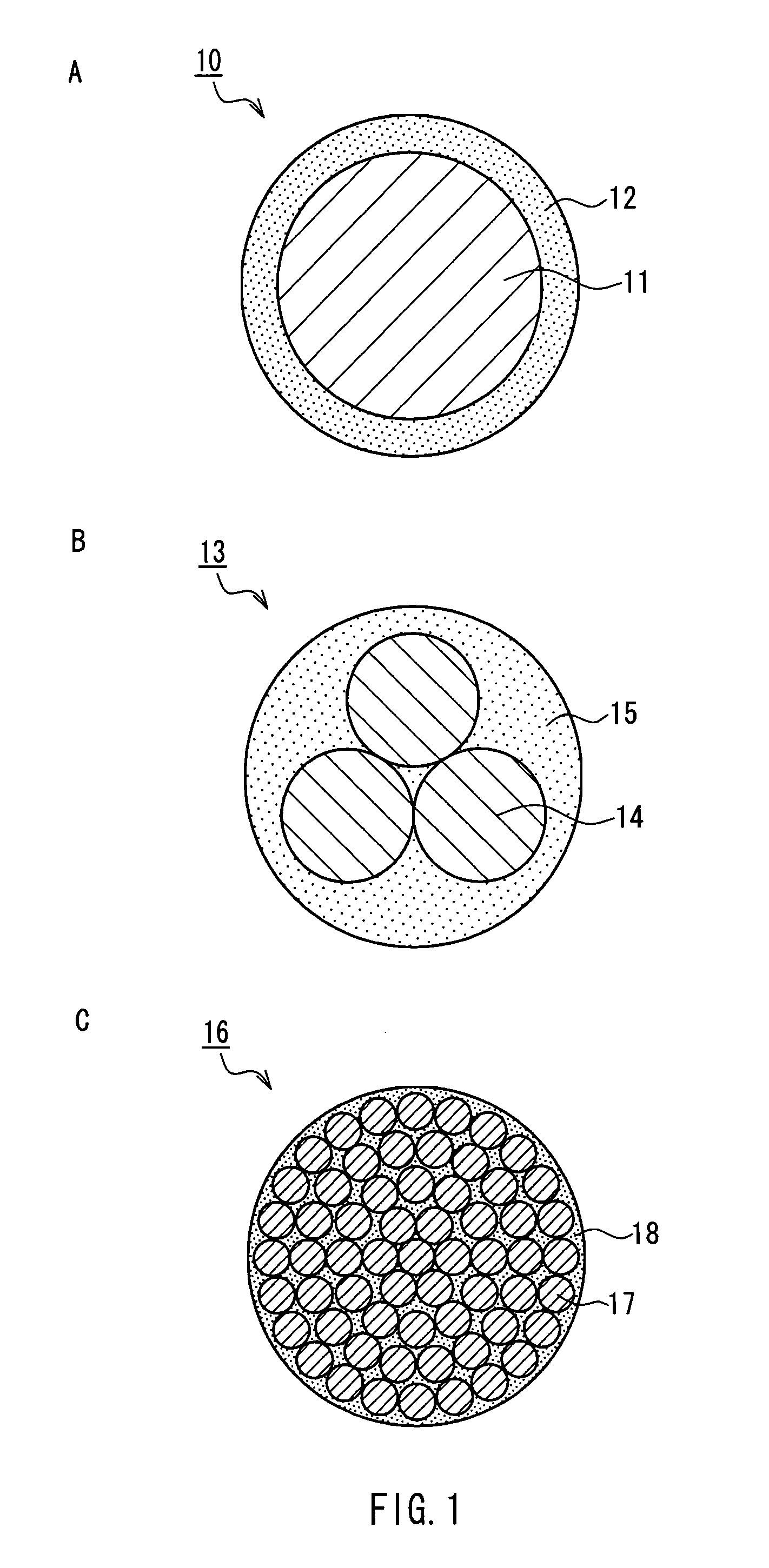

Epoxy resin composition for fiber-reinforced composite materials, prepreg, and fiber-reinforced composite material

Provided are: a fiber-reinforced composite material which has mode I interlaminar fracture toughness, mode II interlaminar fracture toughness and compressive strength under heat and humidity conditions at the same time; an epoxy resin composition for obtaining the fiber-reinforced composite material; and a prepreg which is obtained using the epoxy resin composition. An epoxy resin composition for fiber-reinforced composite materials, which contains at least the following constituent elements (A), (B), (C) and (D). (A) An epoxy resin (B) Resin particles that satisfy the following conditions (b1)-(b3) and are insoluble in an epoxy resin (b1) The particle size distribution index is 1.0-1.8. (b2) The particle sphericity is 90 or more. (b3) The glass transition temperature of the particles is 80-180° C. (C) At least one elastomer component that is selected from among block copolymers containing a block having a glass transition temperature of 20° C. or less and rubber particles (D) An epoxy resin curing agent

Owner:TORAY IND INC

Polyvinyl acetal-based resin composition

ActiveUS20150240067A1High mechanical strengthGlass/slag layered productsDynamic viscoelasticityPolyvinyl alcohol

The present invention provides a polyvinyl acetal resin composition exerting excellent mechanical strength over a wide temperature range from low temperatures to high temperatures. The present invention provides a polyvinyl acetal resin composition containing a polyvinyl acetal resin and a resin having a crosslinked structure, the polyvinyl acetal resin composition having a structure in which the resin having a crosslinked structure is dispersed as a dispersed phase in the polyvinyl acetal resin as a continuous phase, the polyvinyl acetal resin composition having a maximum value of a loss tangent derived from the polyvinyl acetal resin at 40° C. or higher and a maximum value of a loss tangent derived from the resin having a crosslinked structure at 10° C. or lower in measurement of a dynamic viscoelasticity spectrum at a frequency of 10 Hz.

Owner:SEKISUI CHEM CO LTD

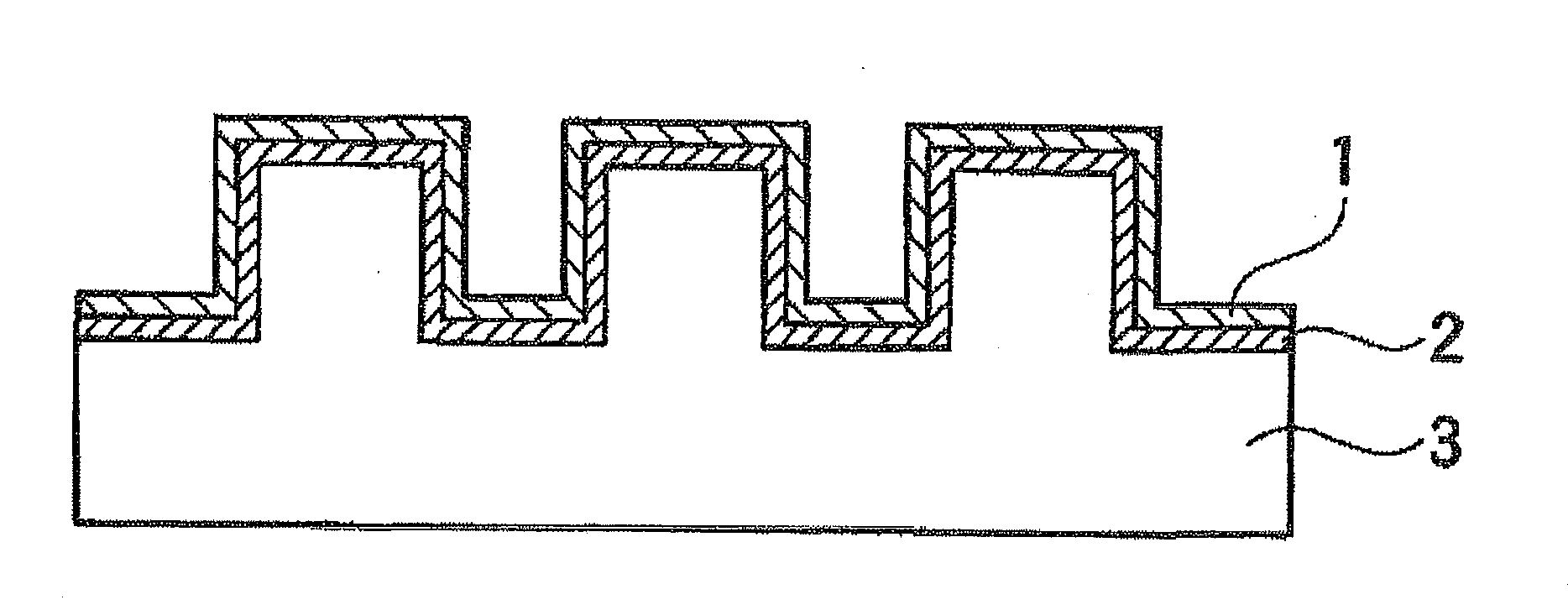

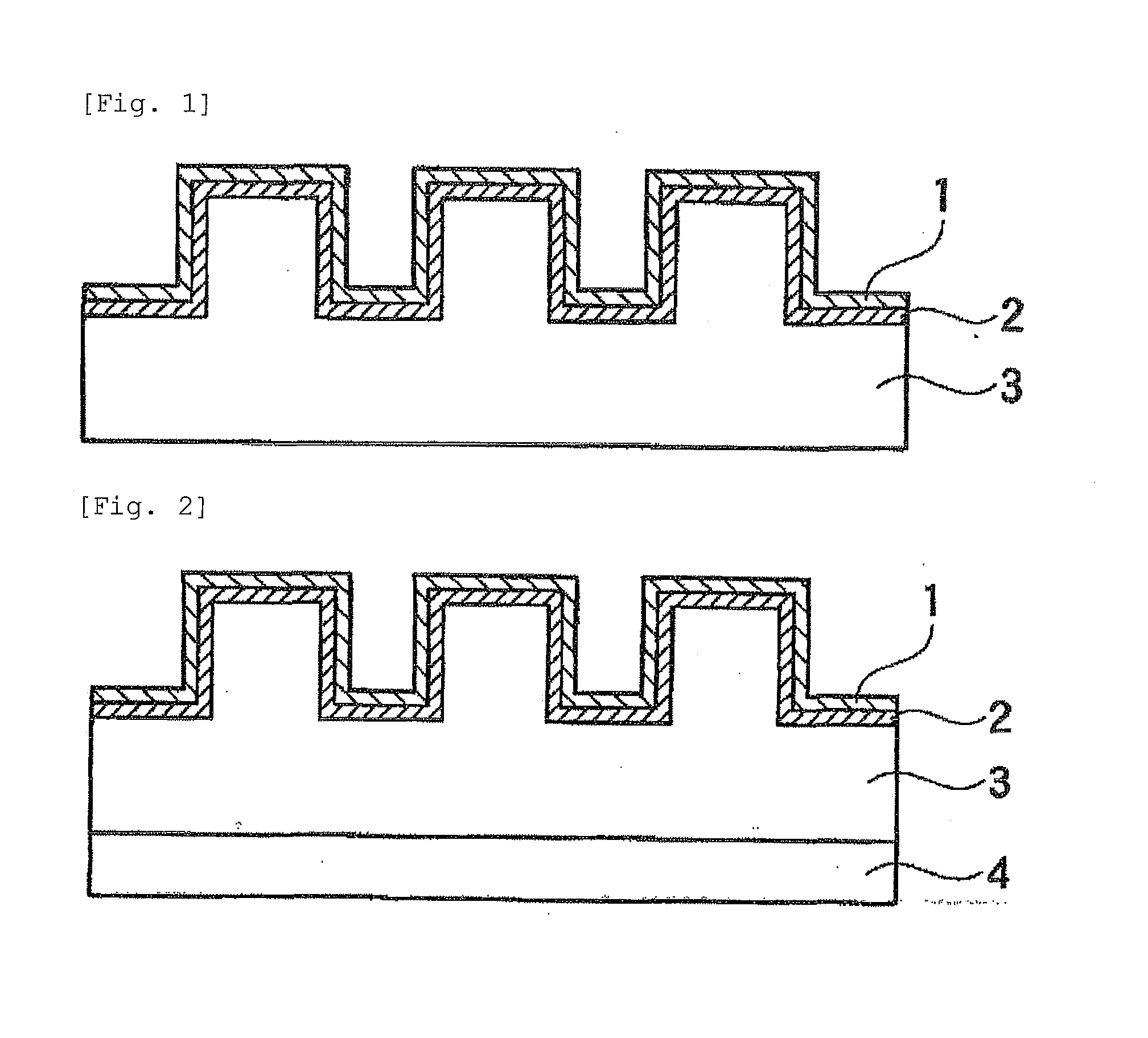

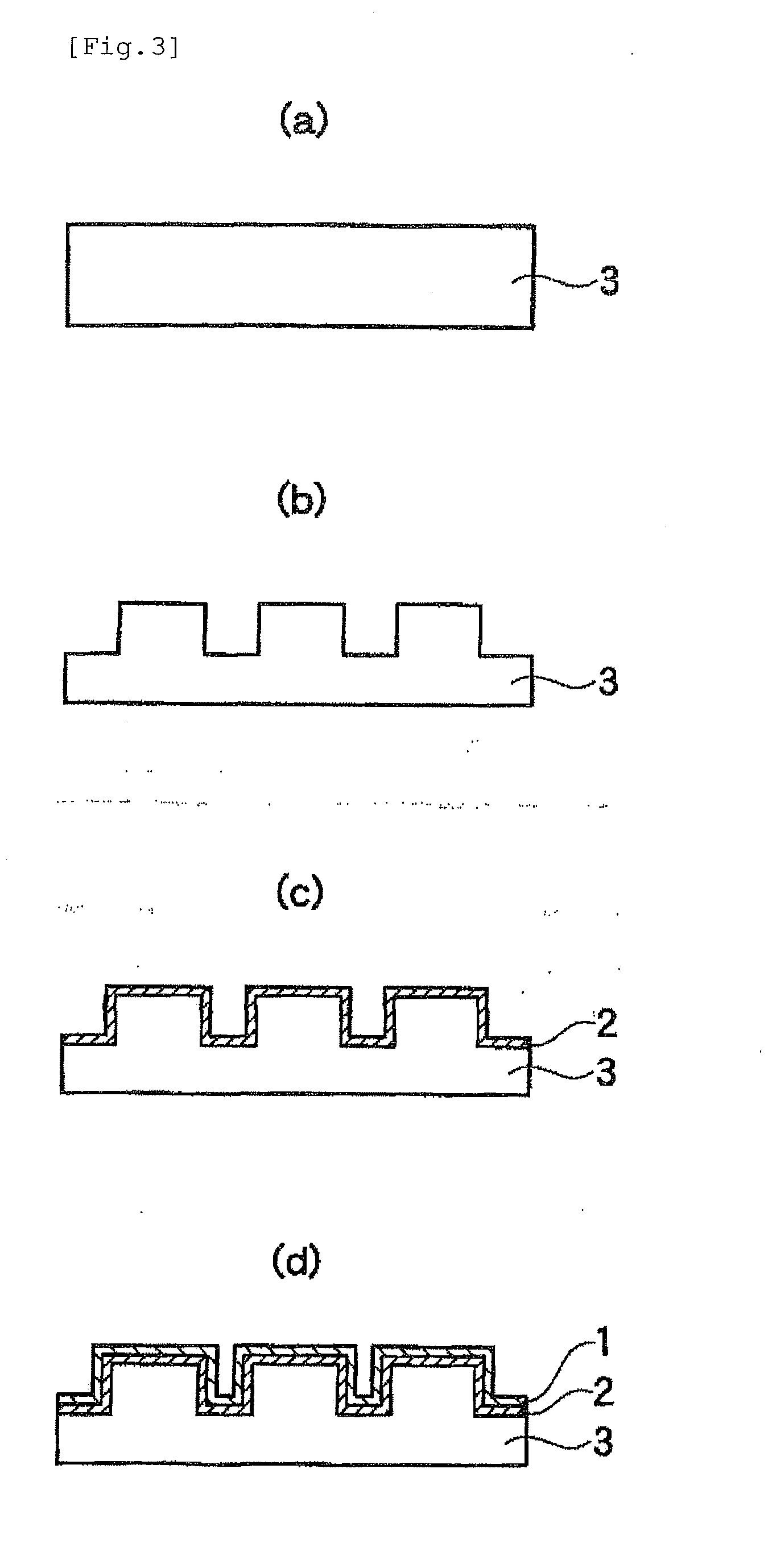

Resin Mold for Imprinting and Method for Producing the Same

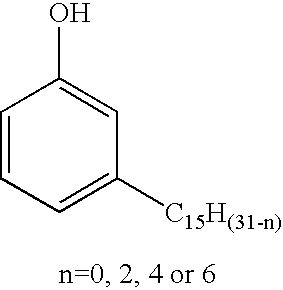

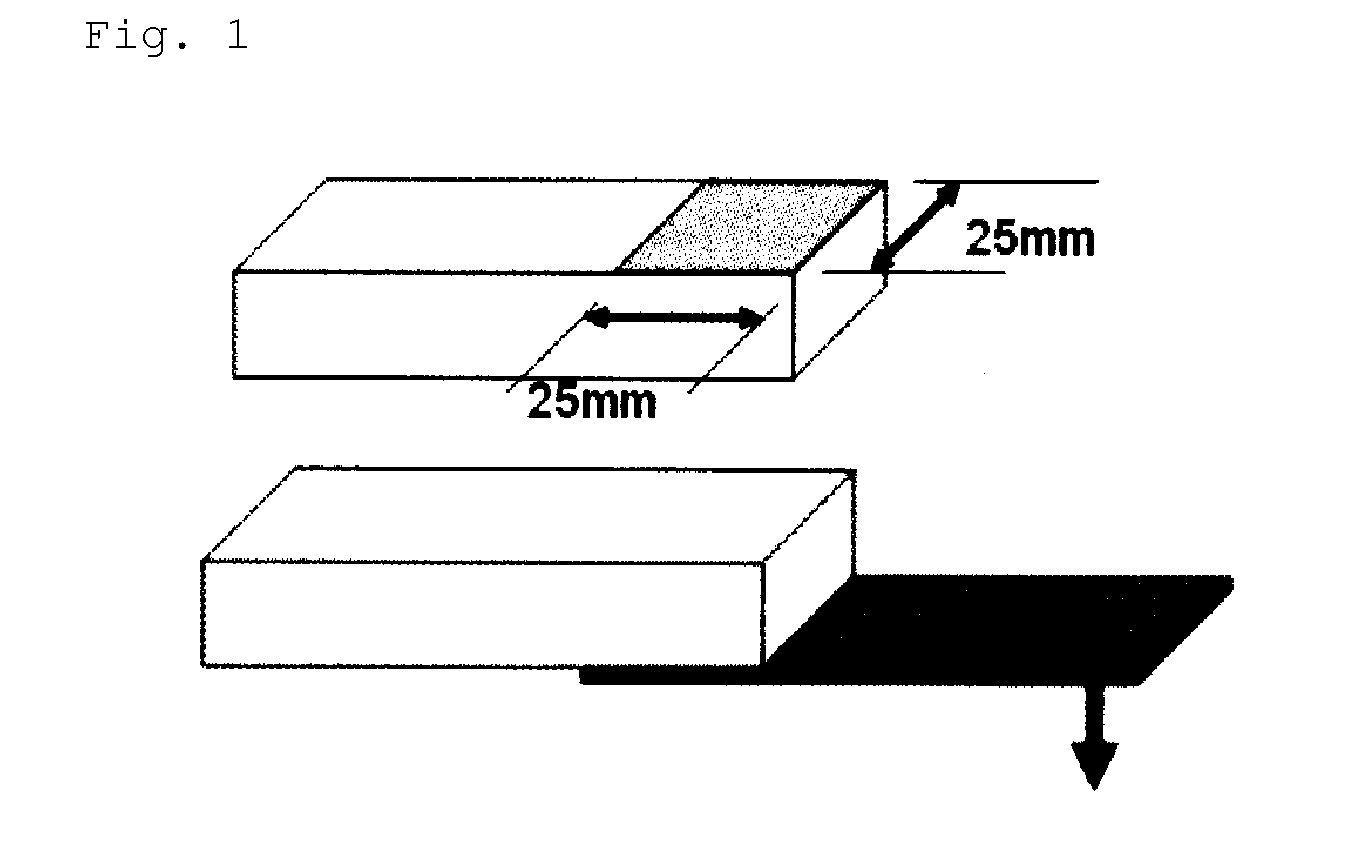

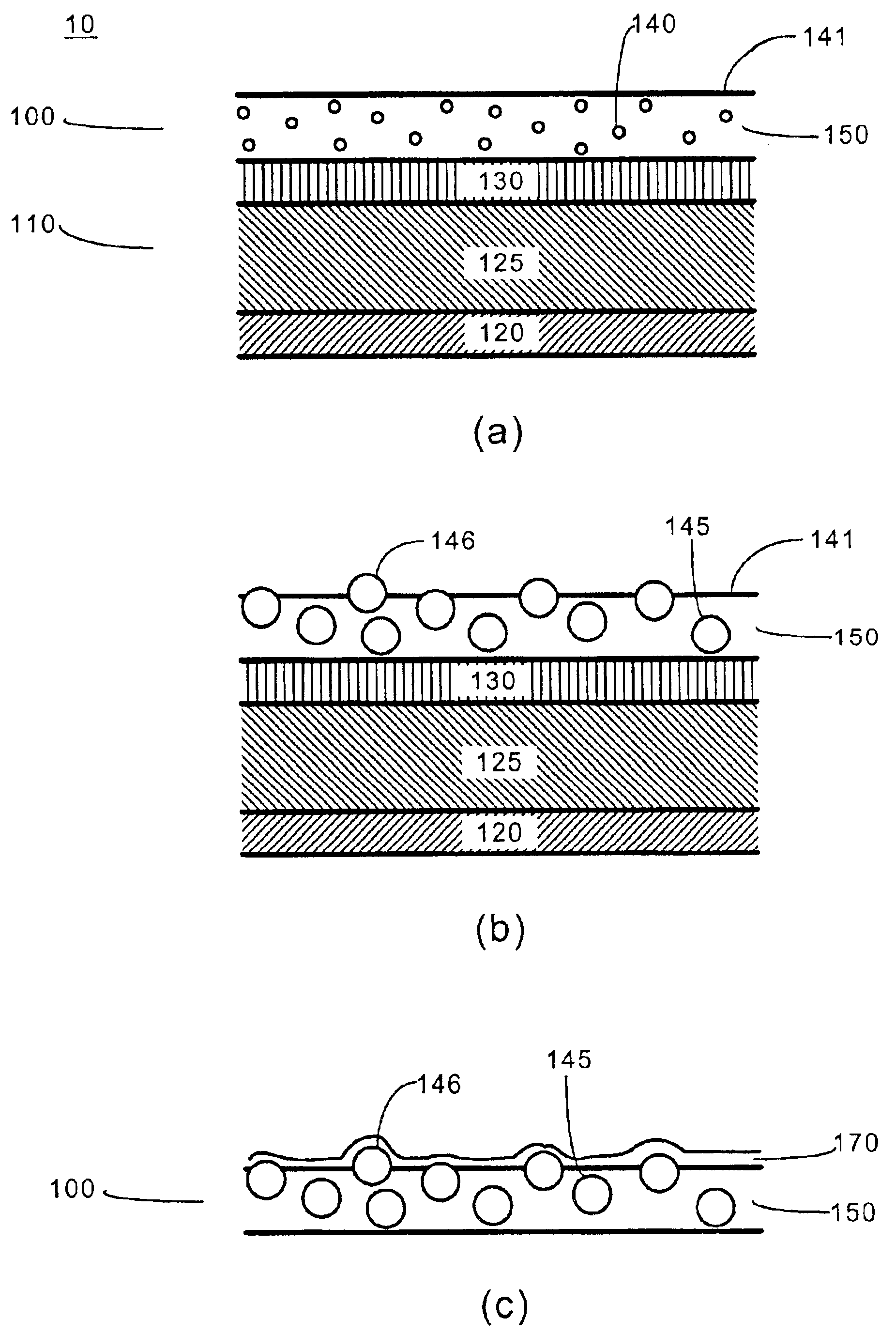

ActiveUS20120133077A1Improve adhesionGood release effectNanoinformaticsConfectioneryInorganic materialsTVEX-PHOR resin

Provided is a resin mold for imprinting which is free from transfer defects, has excellent releasability from a resin subjected to imprinting, and does not cause any defect by imprinting. The resin mold for imprinting includes a resin layer having a recessed and projected pattern surface, an inorganic material layer formed with a uniform thickness on at least the recessed and projected pattern surface of the resin layer, and a release agent layer formed with a uniform thickness on at least the recessed and projected pattern surface of the inorganic material layer.

Owner:SOKEN CHEM & ENG CO LTD

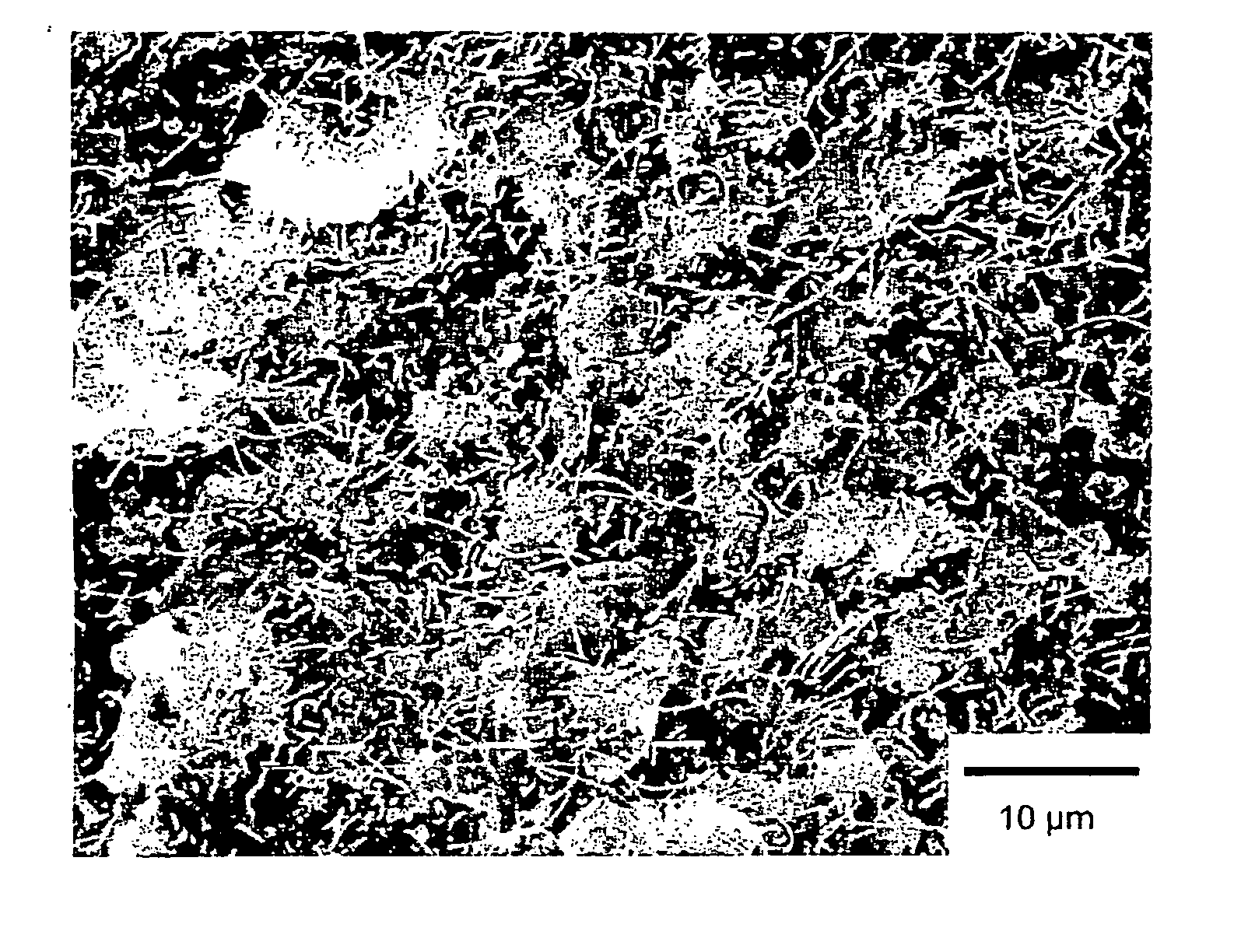

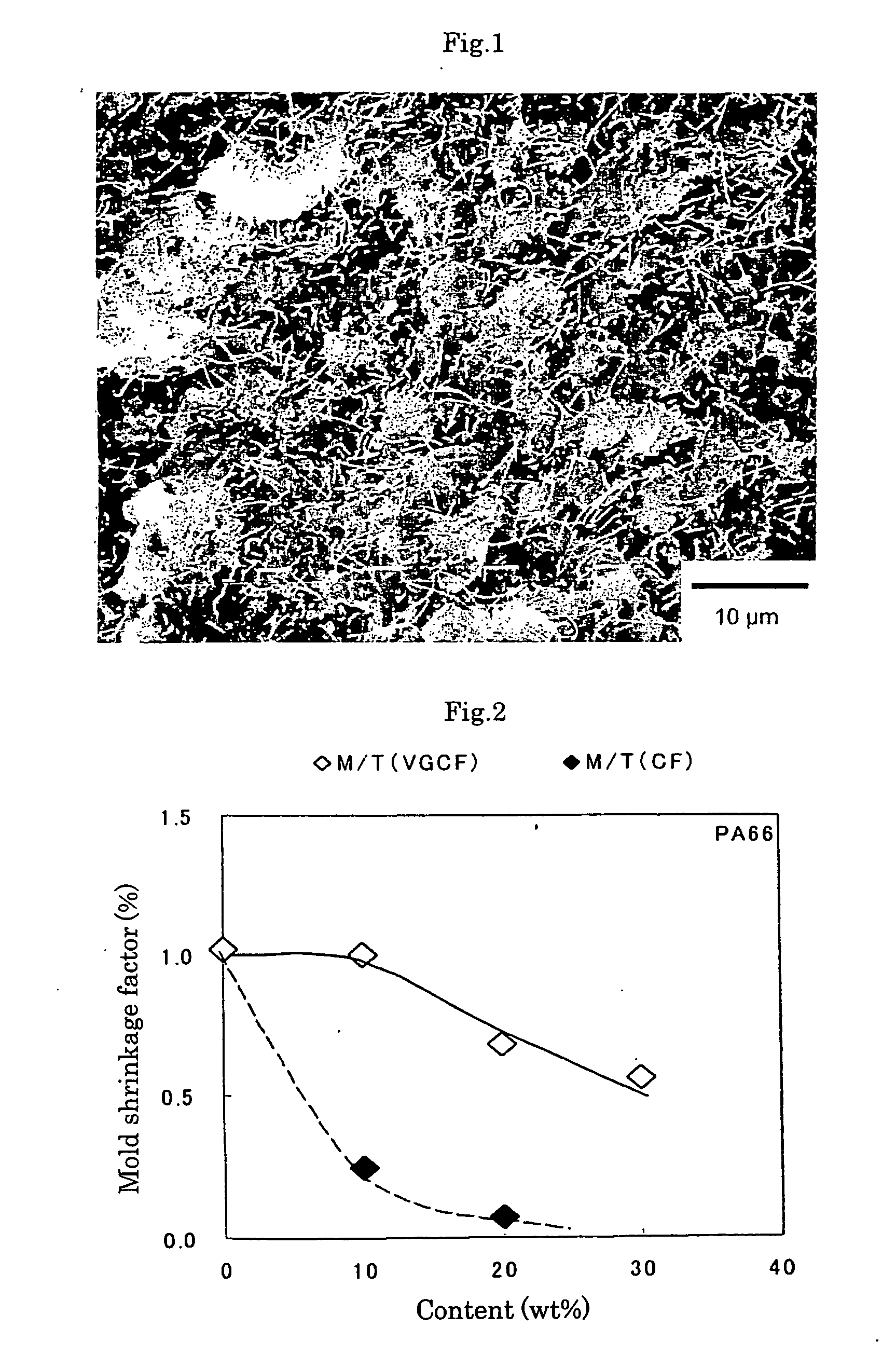

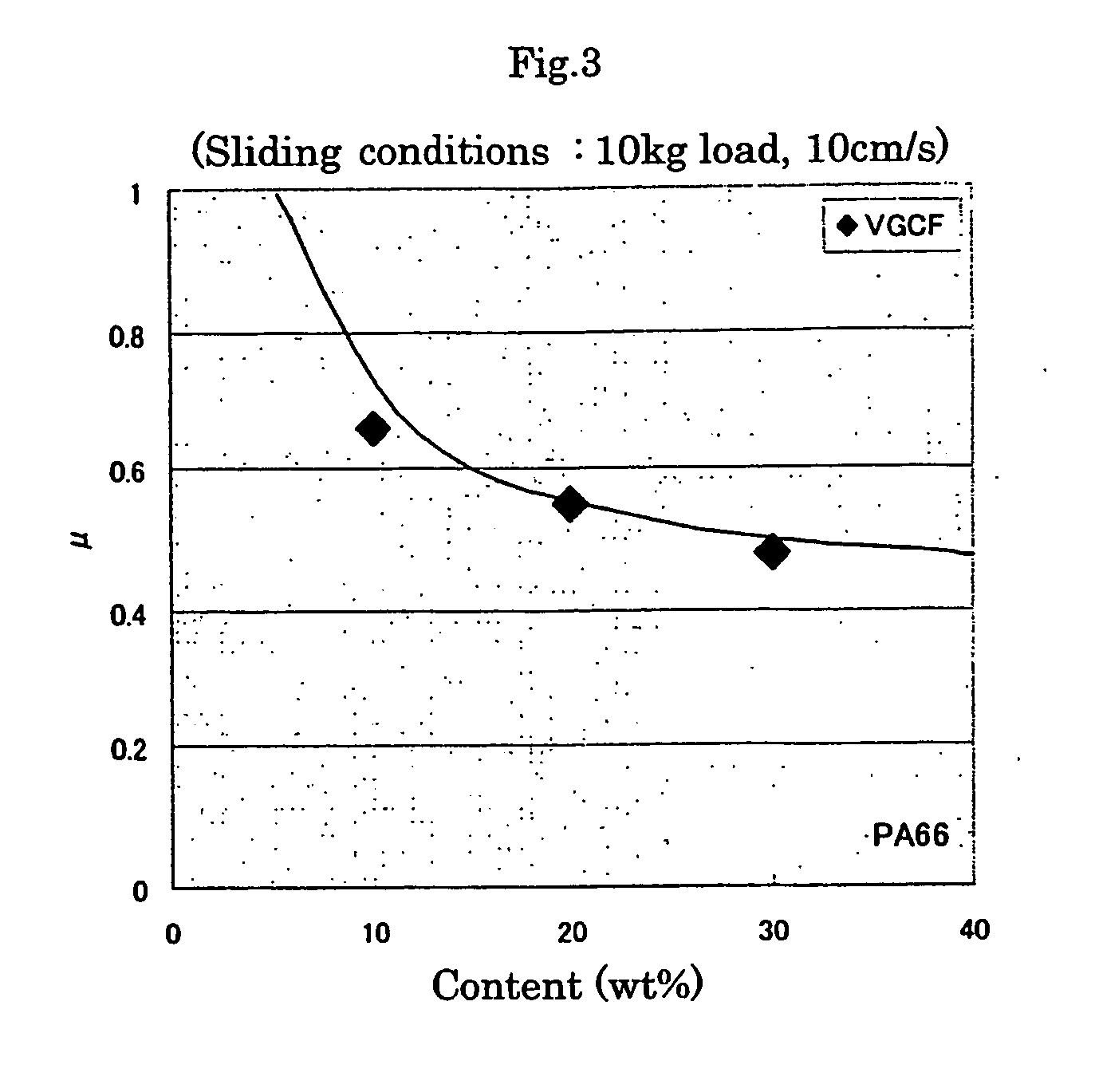

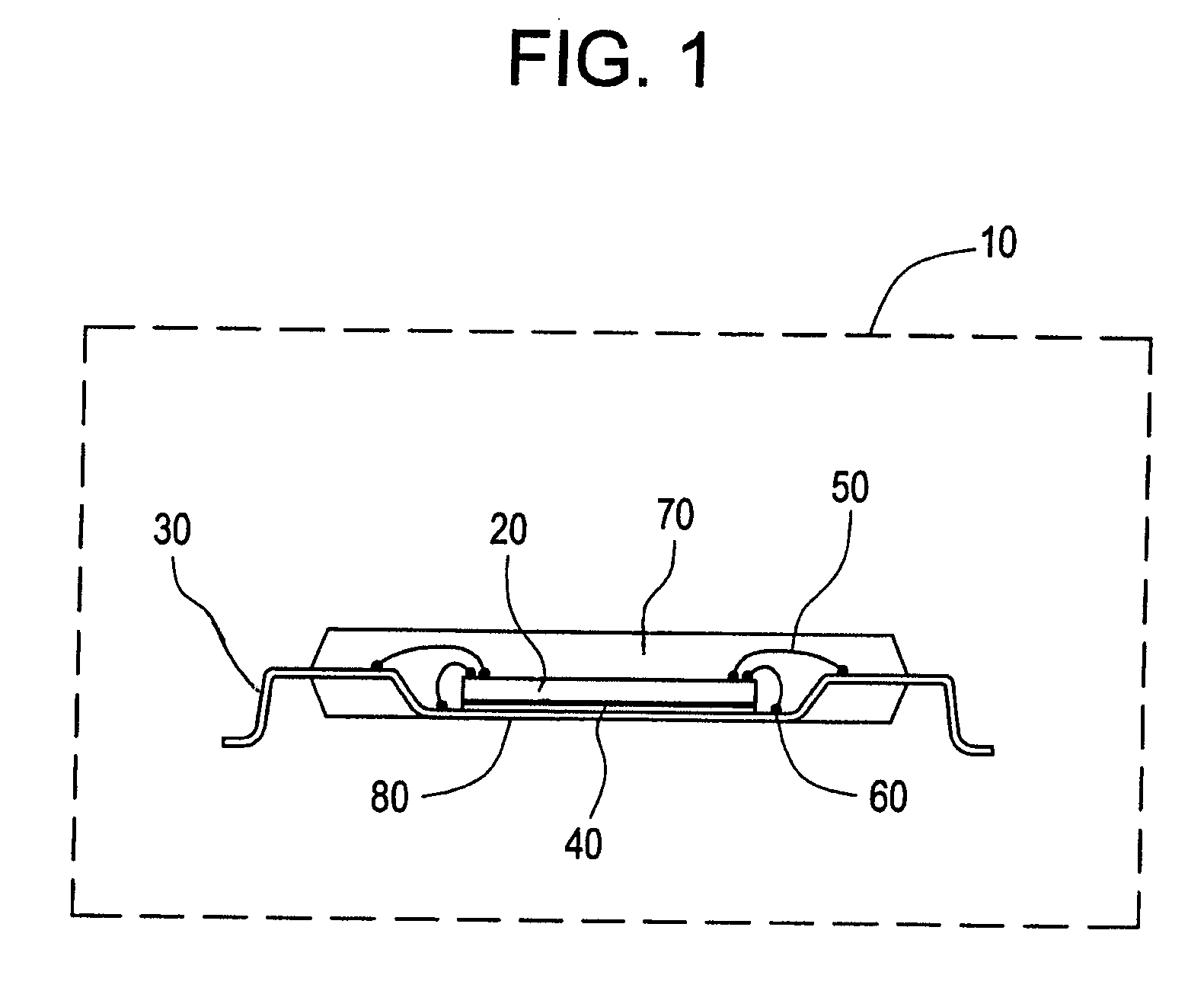

Carbon-based electrically conducting filler, composition and use thereof

InactiveUS20070181855A1Less deteriorationImprove conductivityNon-insulated conductorsConductive materialCarbon fibersFiber diameter

A conductive composition comprising a vapor grown carbon fiber having an aspect ratio of 40 to 1,000, preferably 65 to 1,000, and a specific surface area or fiber diameter of the fiber within a predetermined range, and a preferable peak intensity ratio (I0=I1360 / I1580) of 0.1 to 1, wherein I1580 represents a peak height at 1,580 cm−1 and I1360 represents a peak height at 1,360 cm−1 in a Raman scattering spectrum; and a resin composition containing the composition; and a production method thereof. The present invention provides: i) a composition which exhibits stable conductivity and less deterioration in physical properties during any molding methods in a conductive plastic in which a conductive filler is dispersed in a polymer; ii) a composite material composition for precision molding which enables production of a molded product with low warpage and is excellent in mechanical properties and performance during the injection molding; and iii) a sliding member composition which exhibits durability under high temperature and heavy load and has a low friction coefficient.

Owner:SHOWA DENKO KK

Curable composition and method

A curable resin composition useful for encapsulating solid state devices is described. The composition includes an epoxy resin, a poly(arylene ether) resin, a latent cationic cure catalyst effective to cure the epoxy resin, and about 70 to about 95 weight percent of an inorganic filler, based on the total weight of the curable composition. A method of encapsulating a solid state device with the composition and encapsulated devices prepared with the composition are also described.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Synergistic filler compositions and low density sheet molding compounds therefrom

InactiveUS20060252869A1Improve efficiencyHigh resin contentMaterial nanotechnologySheet moulding compoundLow density

The present disclosure relates generally to resin formulations for sheet molding compounds. Particularly, but not by way of limitation, the disclosure relates to low-density thermosetting sheet molding compounds (SMC) comprising a treated inorganic clay, a thermosetting resin, a low profile agent, a reinforcing agent, a low-density filler, and substantially the absence of calcium carbonate. The thermosetting SMC are used to prepare exterior and structural thermoset articles, e.g. auto parts and panels, etc that have Class A Surface Quality.

Owner:ASHLAND LICENSING & INTPROP LLC

Phenol-formaldehyde resin having low concentration of tetradimer

A phenol-formaldehyde resin, having a low concentration of tetradimer, making the resin suitable for preparing a binder composition for making non-woven fiber products, such as fiberglass insulation, prepared by reacting phenol and formaldehyde in the presence of a sulfite source.

Owner:GEORGIA PACIFIC CHEM LLC

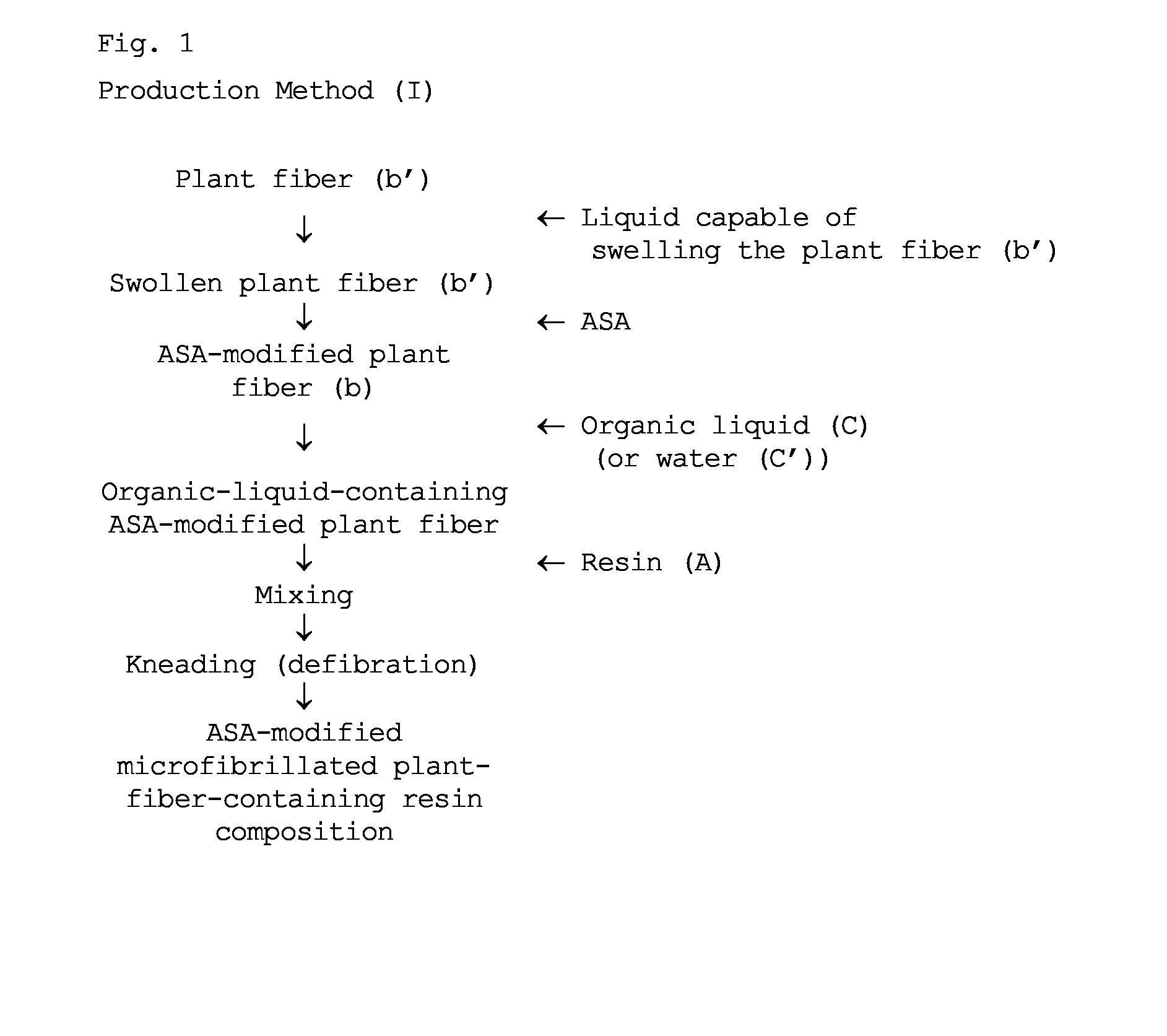

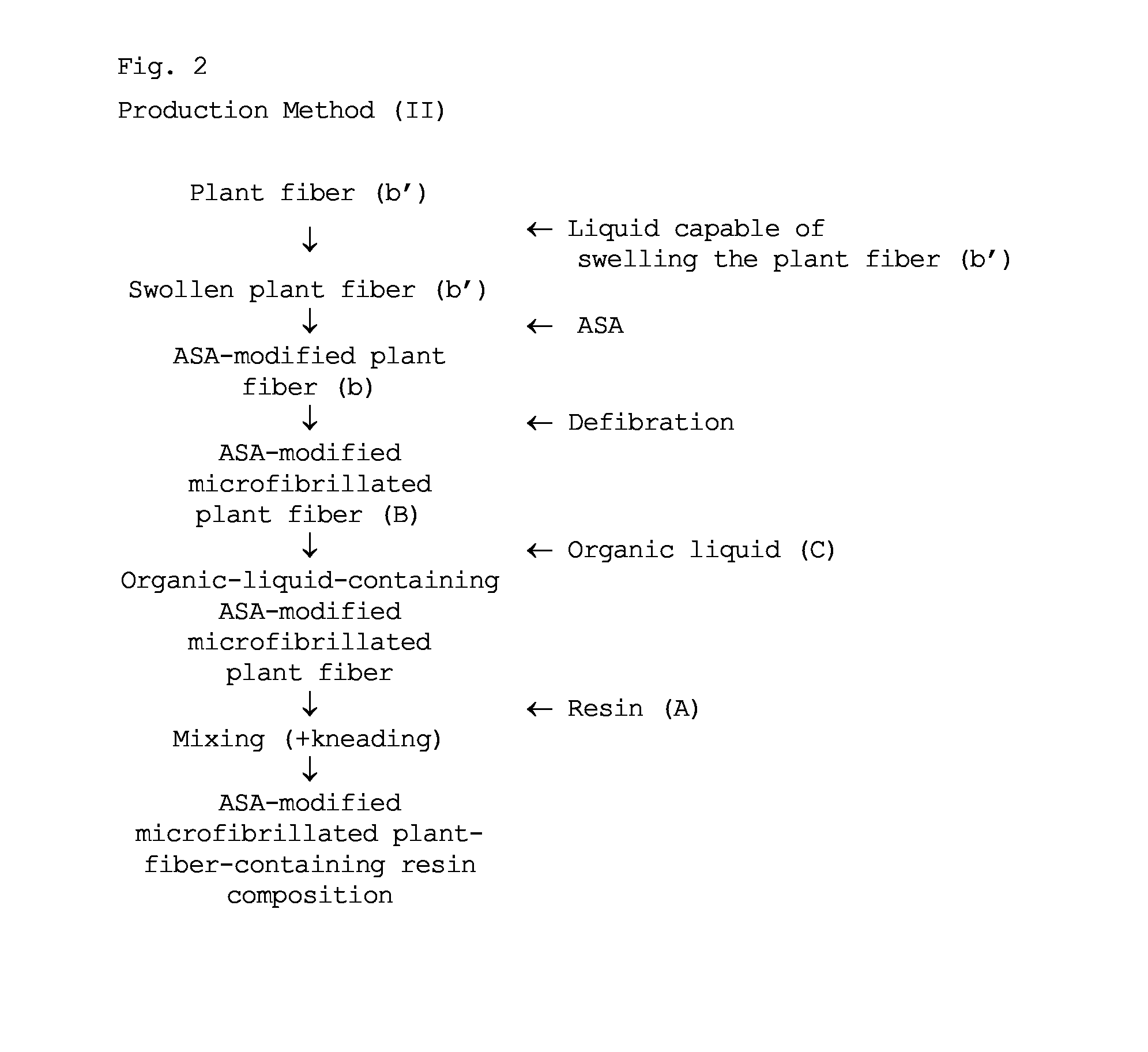

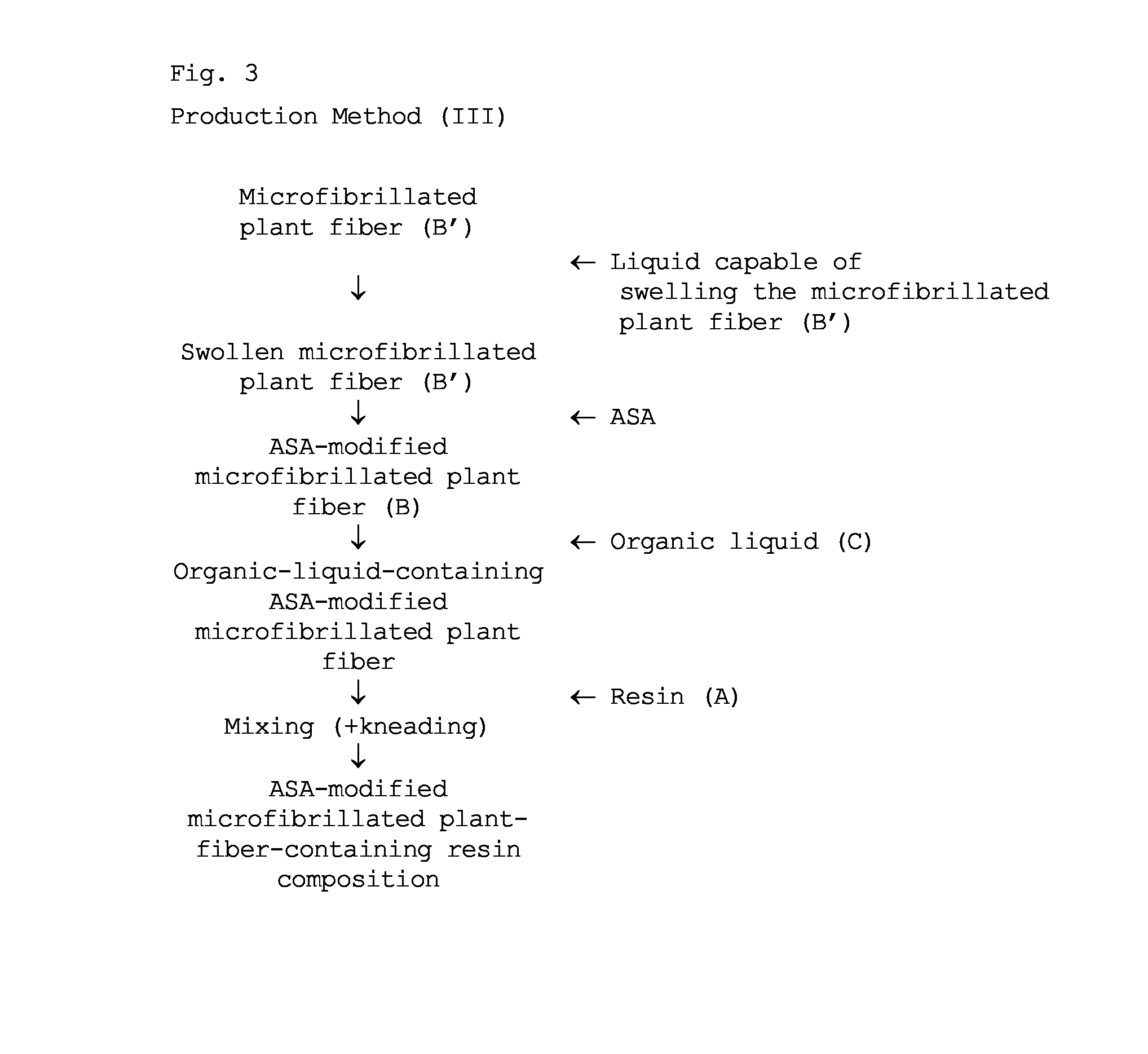

Method for producing resin composition comprising modified microfibrillated plant fibers, and same resin composition

ActiveUS20150105499A1High mechanical strengthSimple stepsImpression capsDentistry preparationsFiberHeat resistance

The present invention provides a method for producing a resin composition, which, by means of simple steps, can uniformly disperse microfibrillated plant fiber in a highly hydrophobic resin and can impart enhanced mechanical strength to a molding material obtained by molding the resin composition. The present invention further provides a resin composition having excellent heat resistance and low linear thermal expansion. The present invention relates to a method for producing a resin composition, the method including a step of mixing a thermoplastic resin or thermosetting resin (A), and modified plant fiber (b) or modified microfibrillated plant fiber (B), in the presence of an organic liquid (C), the modified plant fiber (b) or modified microfibrillated plant fiber (B) being obtained by modification with an alkyl or alkenyl succinic anhydride in a liquid capable of swelling microfibrillated plant fiber (B′) or plant fiber (b).

Owner:DAINIPPON INK & CHEM INC +3

Filler-dispersed melt-kneaded products, molded resin products thereof, and production method thereof

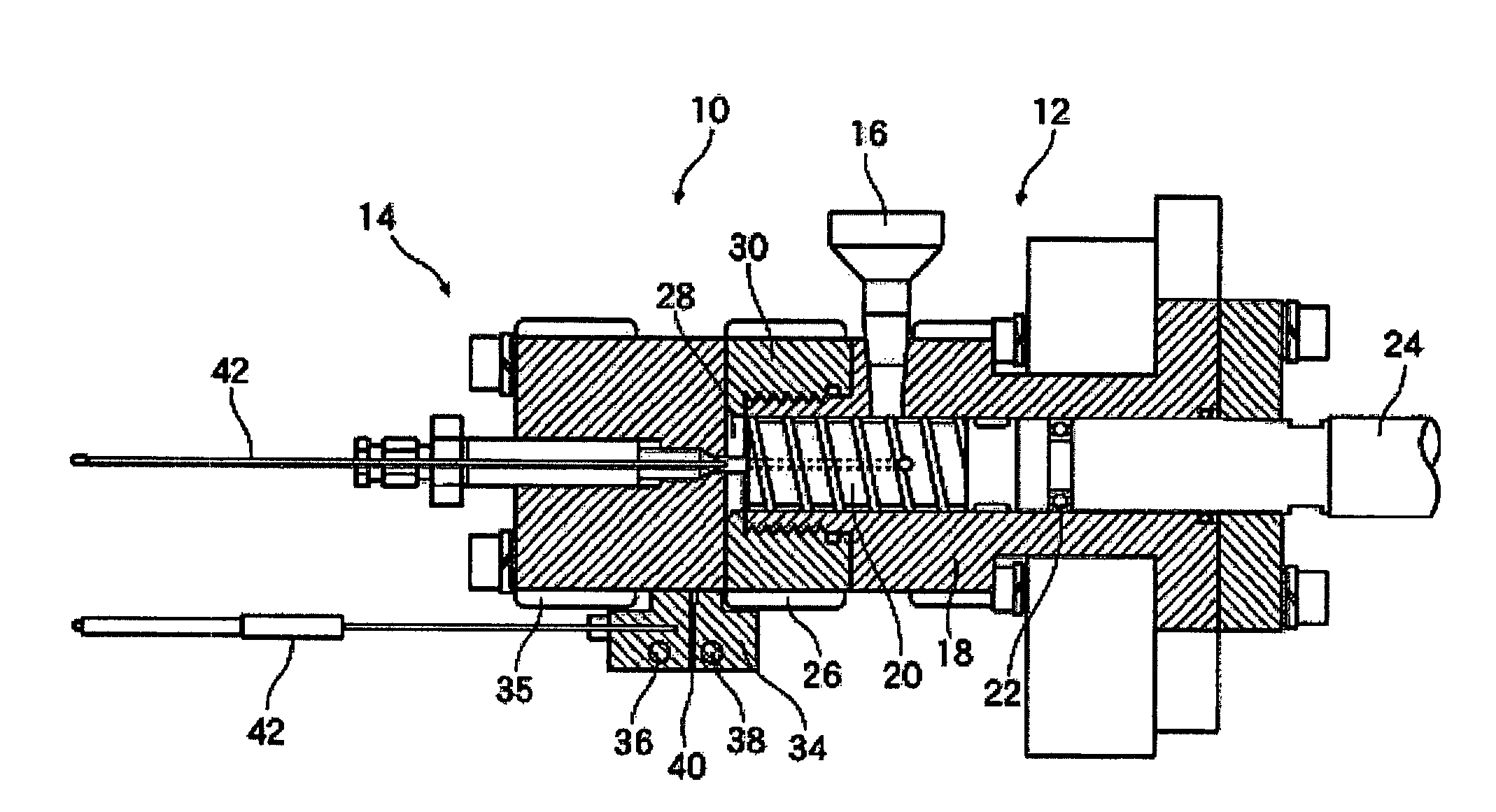

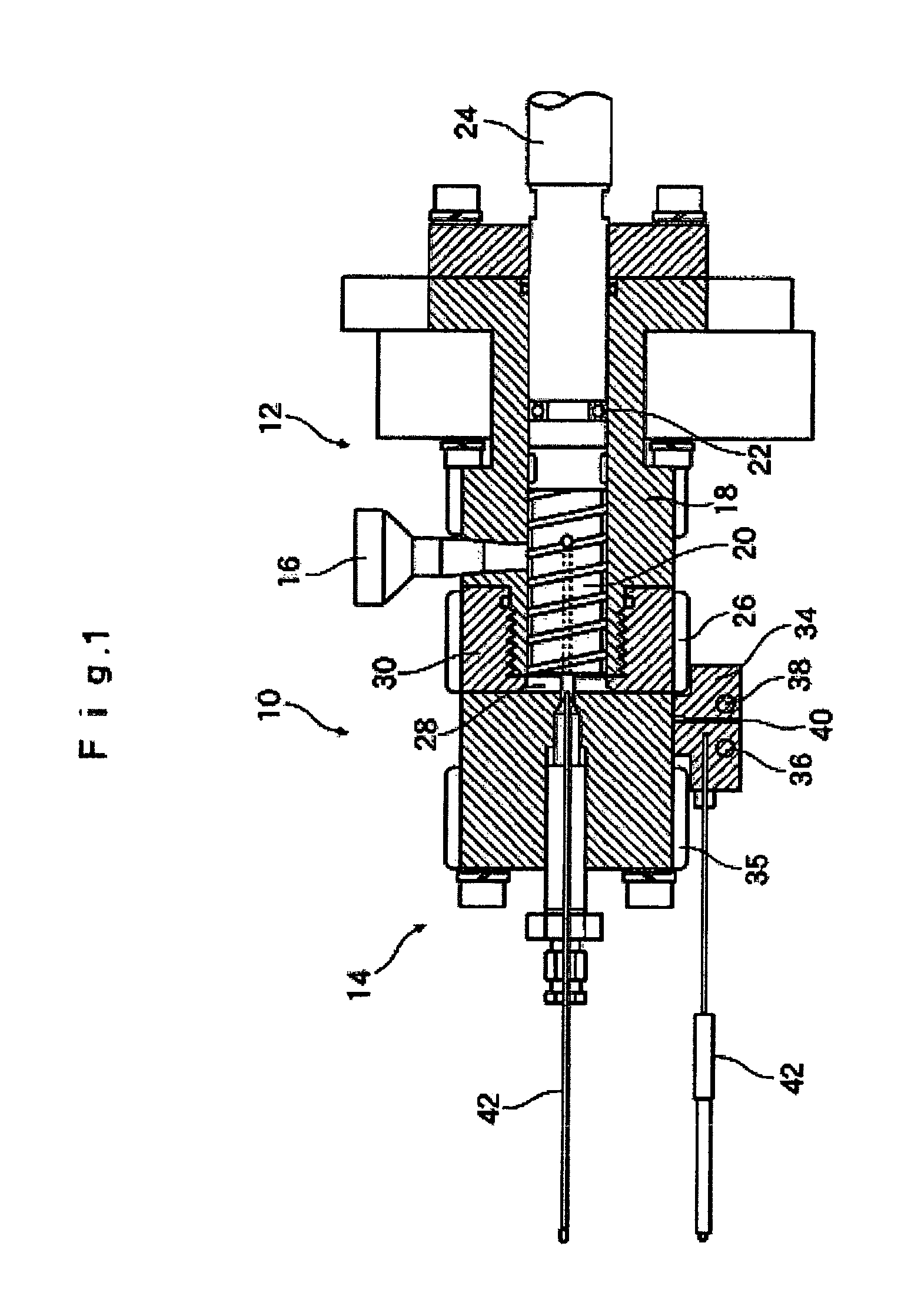

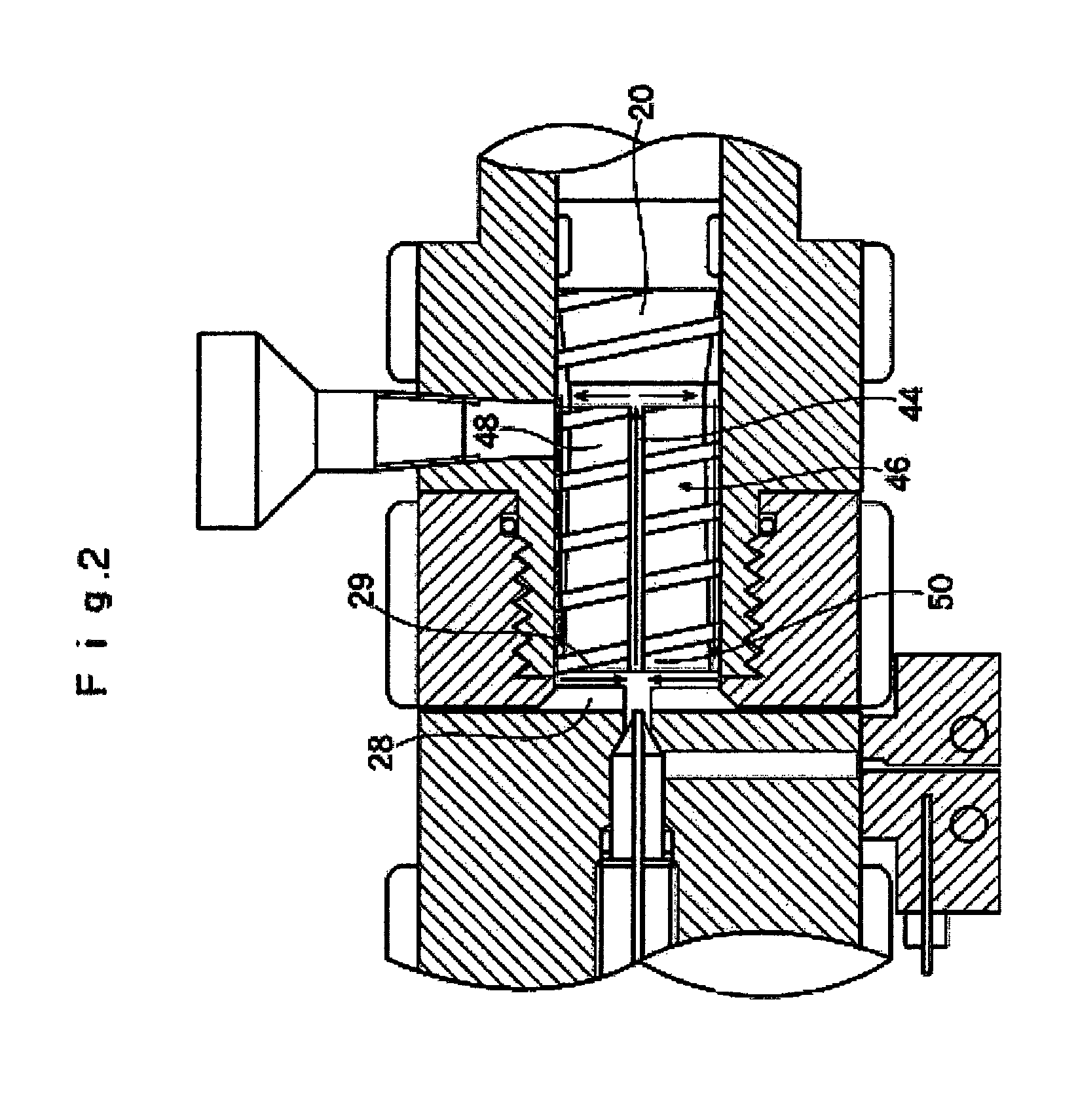

A melt-kneading method for filling material-containing resin or elastomer includes: a step of preparing a filling material as a filler and a resin or elastomer comprising an incompatible blend; and a step of introducing the filling material-containing resin or elastomer into a material feed part provided at an end of a cylindrical melt-kneading part having a heater and provided with a screw, and then melt-kneading the filling material-containing resin or elastomer under conditions where the rotation speed of the screw is about 600 rpm to about 3,000 rpm and its shear rate is about 900 to about 4,500 sec−1, thereby forming a co-continuous structure comprising the incompatible blend.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Reactive liquid ceramic binder resin

InactiveUS20080034794A1High green strengthWeaken energyGlass shaping apparatusAryl radicalMaterials science

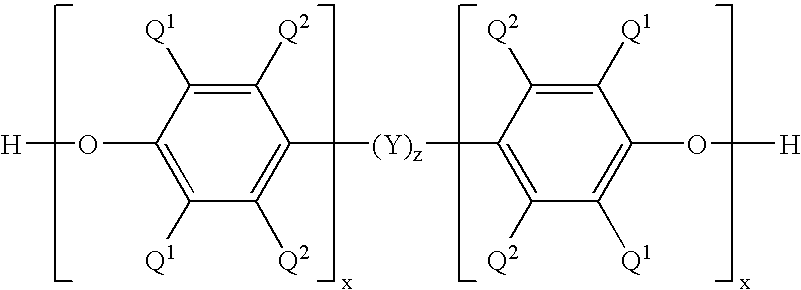

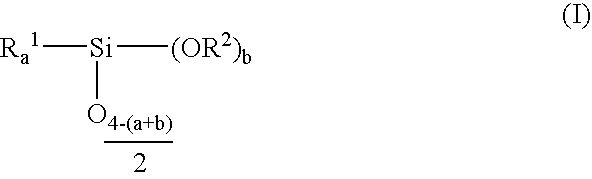

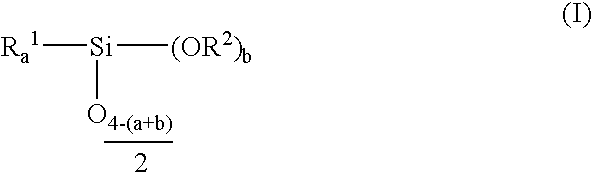

A reactive liquid ceramic binder suitable for the production of ceramic products from ceramic powders is provided. The reactive liquid ceramic binder contains organo-modified siloxane compounds, wherein the liquid organo-modified siloxane compounds contain organoalkoxysiloxane units according to general formula (I)whereinR1=alkyl radical and / or aryl radical,R2═H and / or alkyl radical with 1 to 4 carbon atoms,a≧0 and ≦2, andb<0 and ≦3,with the proviso that a+b≧1 and ≦4.

Owner:EVONIK DEGUSSA GMBH

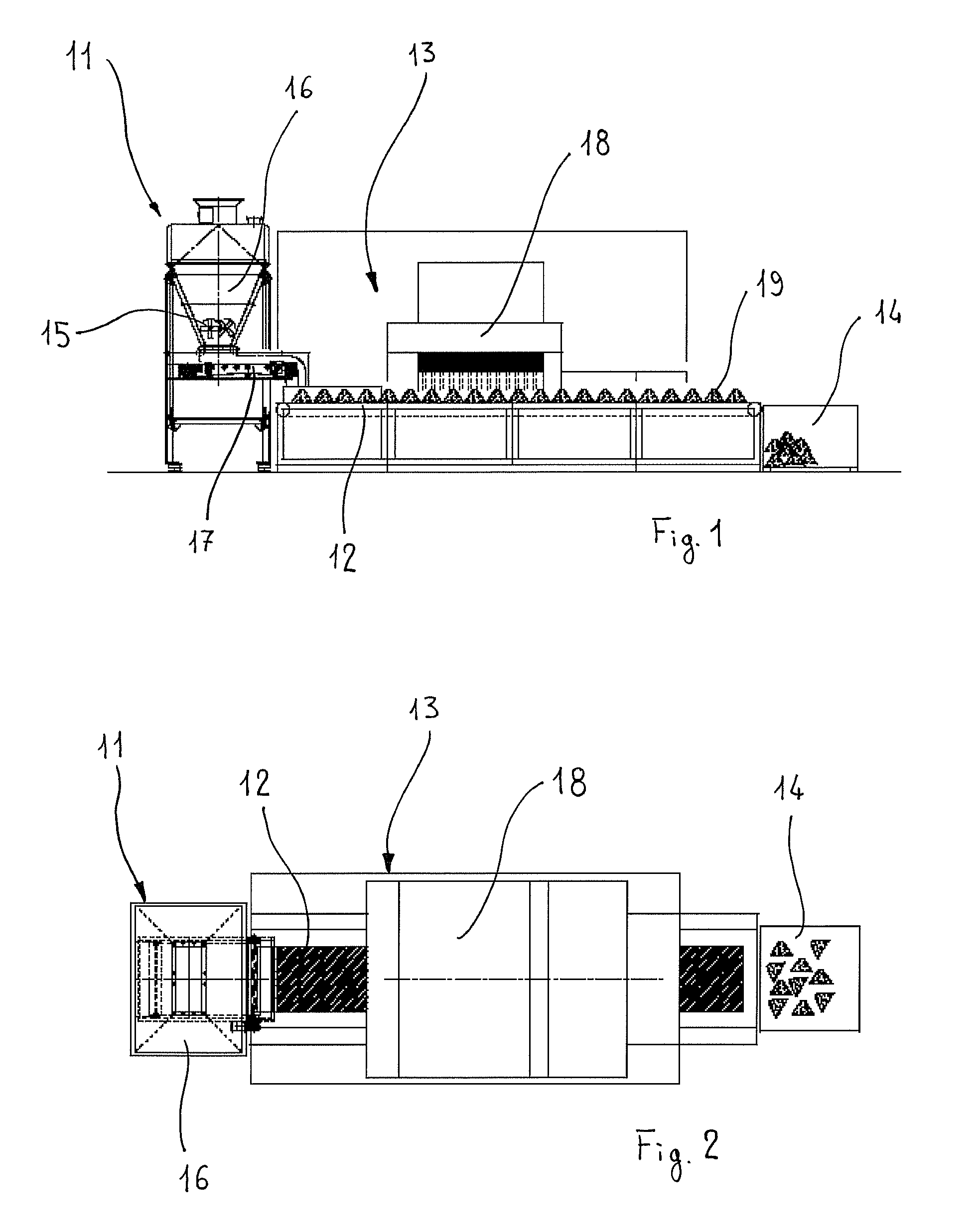

Method and plant for rendering inert toxic substances in uncompacted residual material containing hardenable resin and aggregrates

ActiveUS8030441B2Eliminate the risk of contaminationDielectric heating circuitsSolid waste disposalOrganic solventToxic material

A loose mixture formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz. A plant for implements a method where a loose mixture is formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz.

Owner:TONCELLI DARIO

Water-absorbing resin composition

ActiveUS7868075B2Suppress emissionSynthetic resin layered productsConductive materialFiberCompound (substance)

The object of the present invention is to provide a water-absorbing resin compound, wherein the water-absorbing resin compound can retain antibacterial properties of an antibacterial metal to suppress the emission of unpleasant odors even when an organic material exists in a system in the case of using an eluting-type antibacterial agent. Thus, the present invention relates to a water-absorbing resin compound, which comprises a water-absorbing resin, an antibacterial agent having a porous material incorporating an antibacterial metal, and a metal chelating agent. Further, the present invention also relates to an absorbing material, which comprises a water-absorbing resin compound of the present invention, and a hydrophilic fiber as well as an absorbing product, which comprises a liquid-permeable sheet and a liquid-non-permeable sheet, and an absorbing material comprising a water-absorbing resin compound of the present invention, and a hydrophilic fiber between the liquid-permeable sheet and the liquid-non-permeable sheet.

Owner:SUMITOMO SEIKA CHEM CO LTD

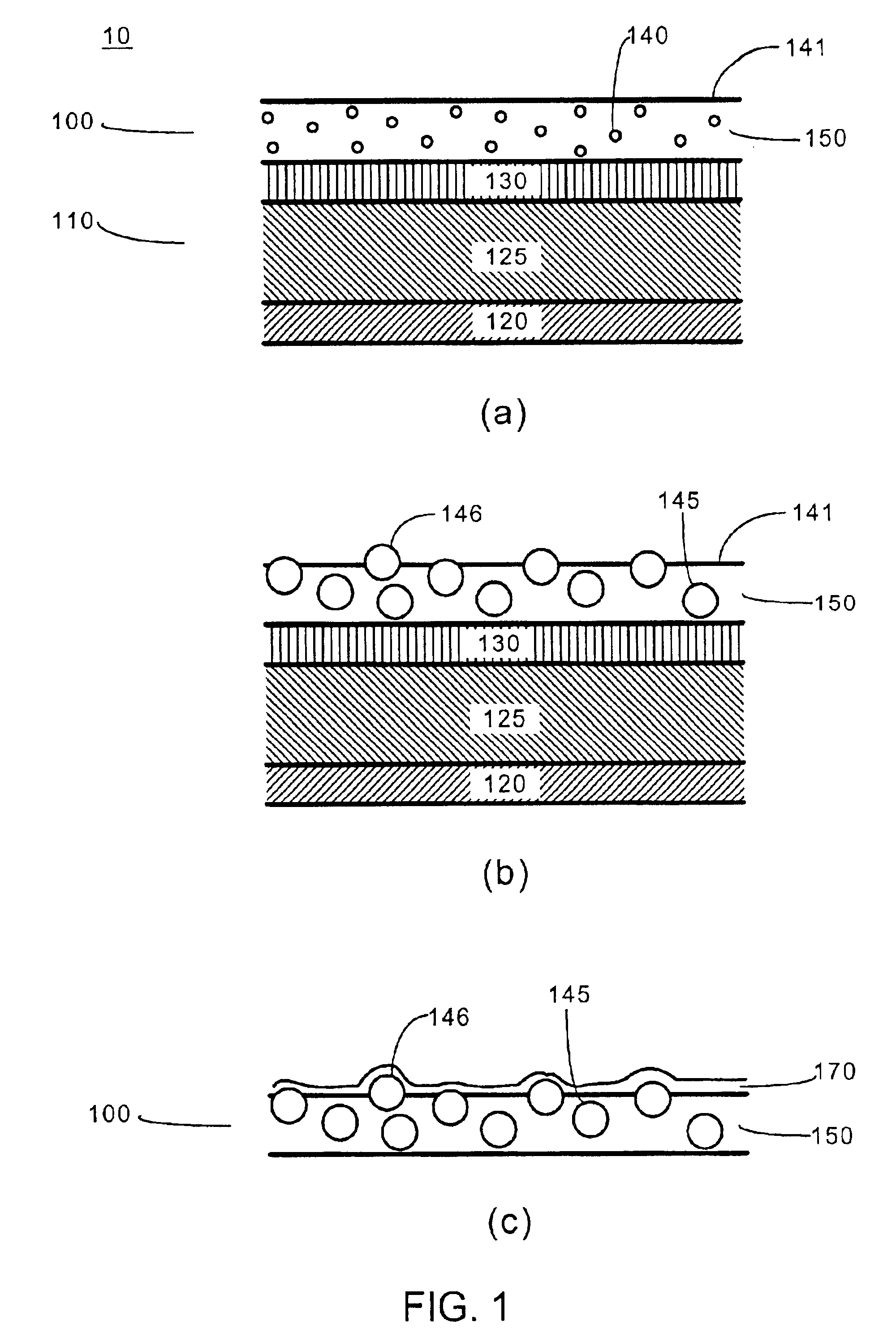

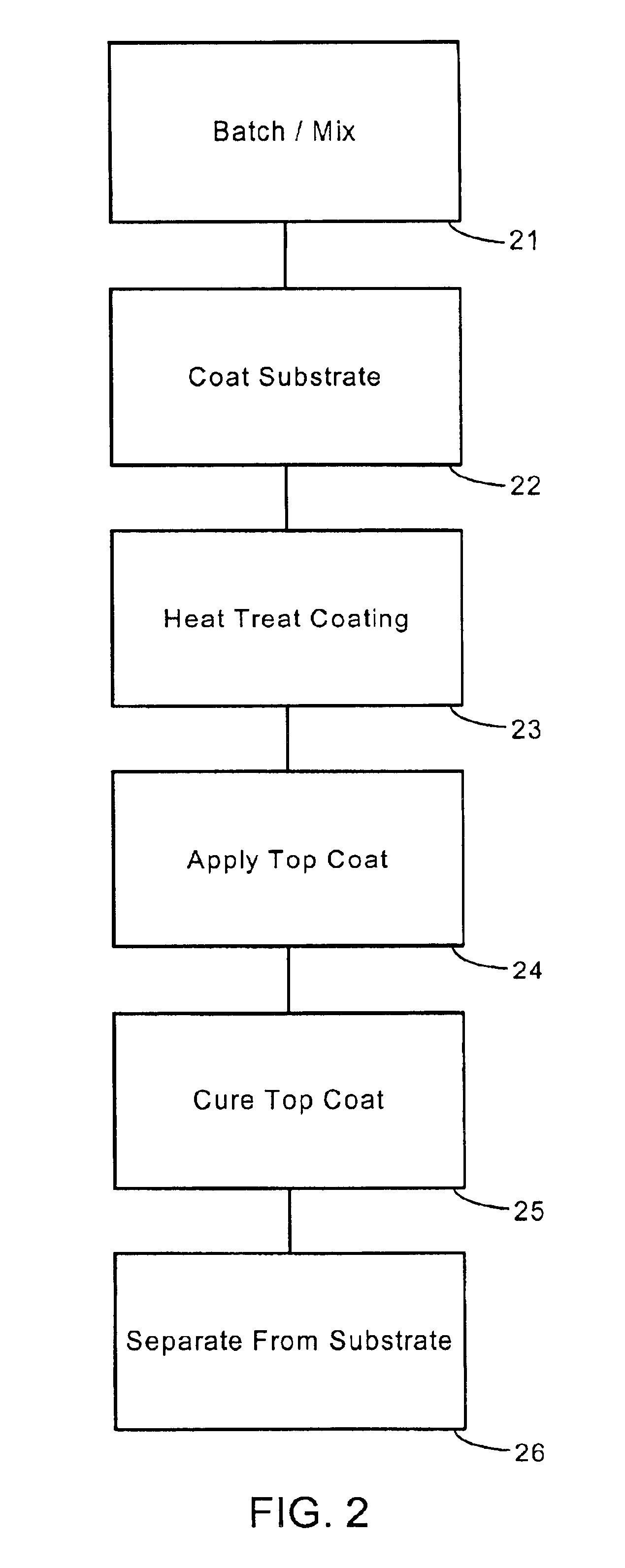

Heat activated coating texture

A process for making a textured coating on a substrate and compositions for such coatings are disclosed wherein coating mixtures comprising un-expanded micro-capsules and a plastisol or other suitable resins are applied to the substrate and subsequently heat treated to expand the micro-capsules within the coating. The expanded micro-capsules create an aesthetically pleasing surface texture in the coating while retaining the desired wear-resistant properties of the coating.

Owner:LAW DEBENTURE TRUST COMPANY OF NEW YORK

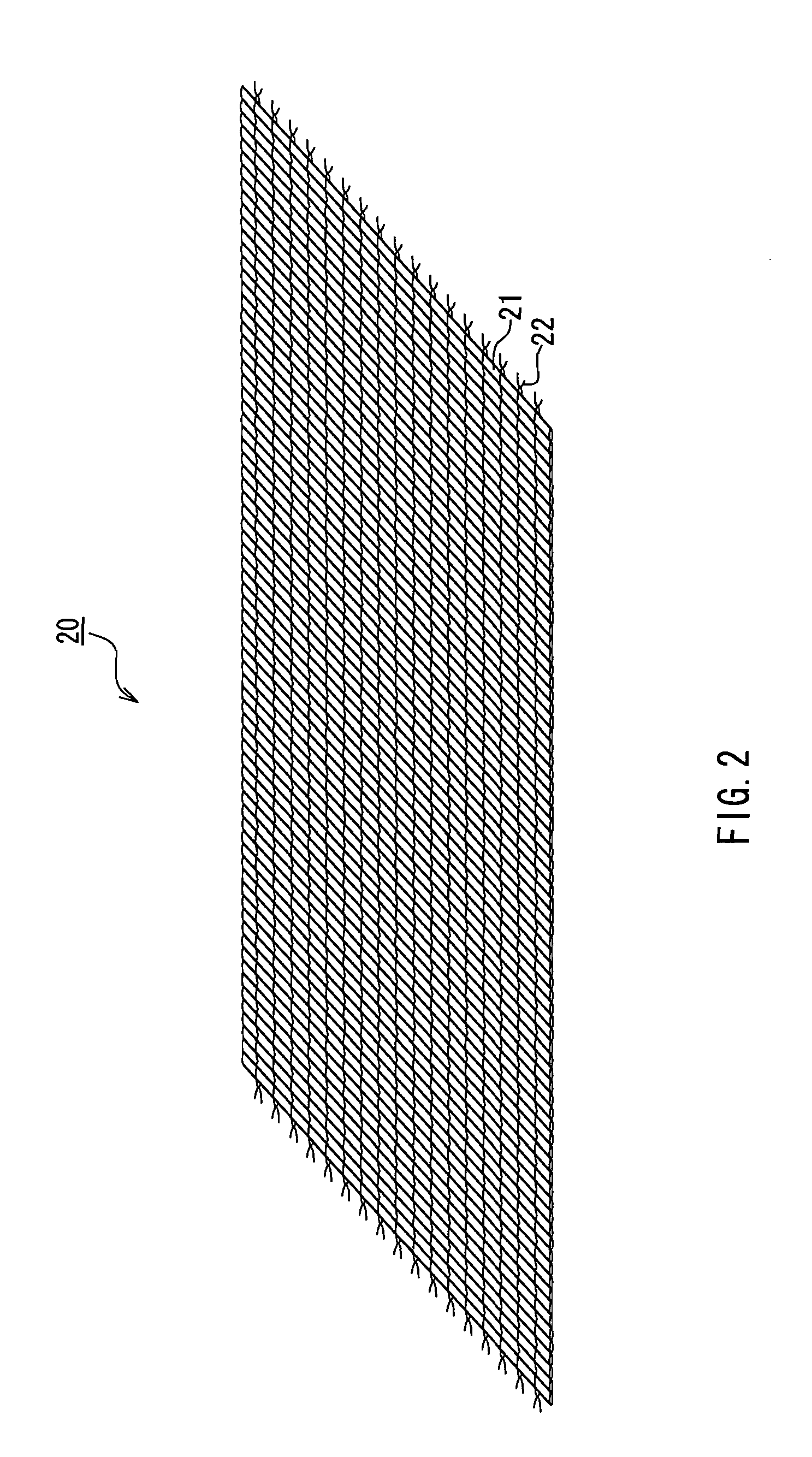

Sheet for fiber-reinforced resin and fiber-reinforced resin molded article using the same

InactiveUS20120302118A1Improve adhesionHigh proportionWarp knittingWood working apparatusCompression moldingPolymer science

A sheet for a fiber-reinforced resin according to the present invention includes a conjugate fiber that contains a low melting point polymer component and a high melting point polymer component. The low melting point polymer component and the high melting point polymer component are polymers of the same type. When the sheet is formed into a fiber-reinforced resin molded article, the low melting point polymer component serves as a matrix resin, while the high melting point polymer component serves as a reinforcing fiber. The conjugate fiber is arranged in at least one direction. A fiber-reinforced resin molded article according to the present invention is obtained by heating the sheet for a fiber-reinforced resin to a temperature equal to or higher than the melting point of the low melting point polymer component and lower than the melting point of the high melting point polymer component, followed by compression molding.

Owner:KURASHIKI BOSEKI KK

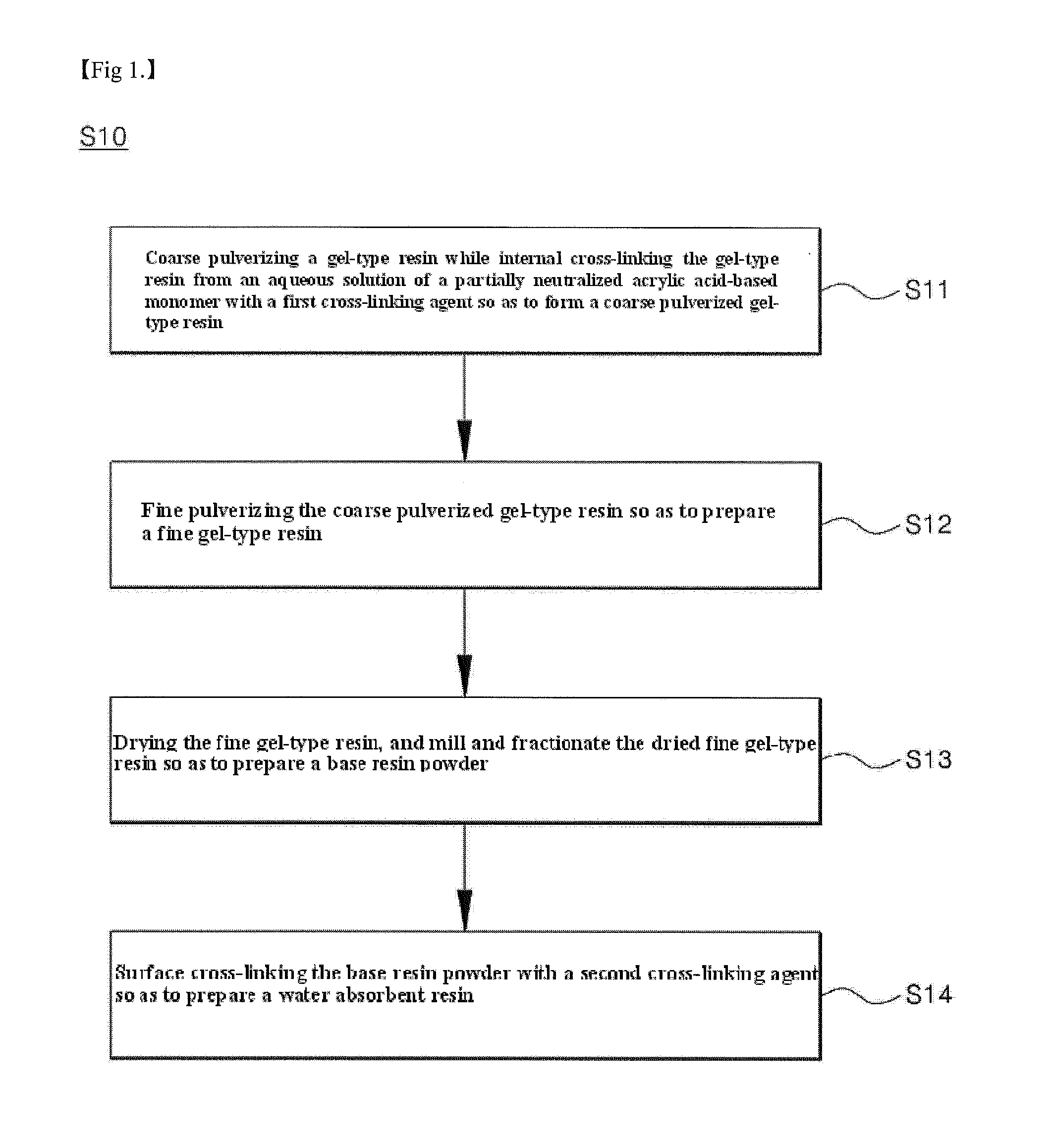

Process for preparing water absorbent resin with high performance

The present invention relates to a process for preparing a water absorbent resin, particularly to a process for preparing a water absorbent resin which can resolve the uneven size of the fine pulverized gel-type resin and long pulverizing time those are the problems of prior process for preparing the water absorbent resin, by carrying out the pulverizing process of the gel-type resin divided into the coarse pulverizing process which is carried out with the internal cross-linking polymerization, and the fine pulverizing process. According to the preparation process, it is possible to mass-produce the water absorbent resin showing excellent absorption under pressure and low extractable content.

Owner:LG CHEM LTD

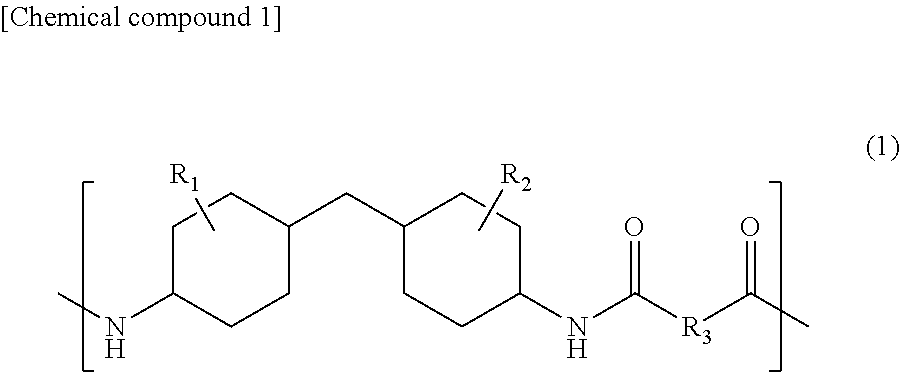

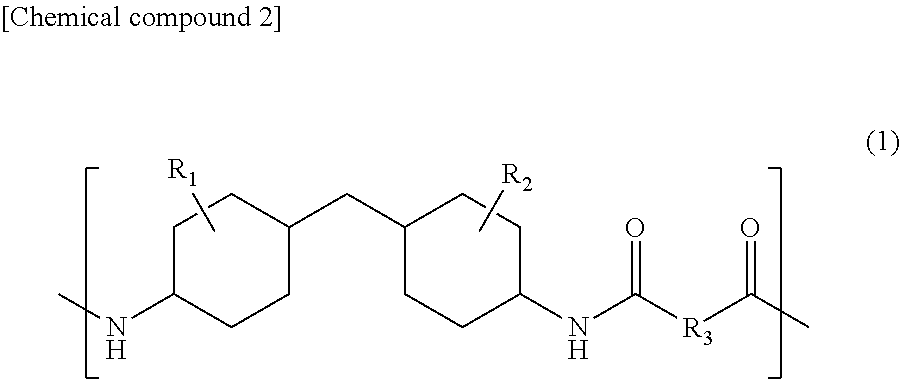

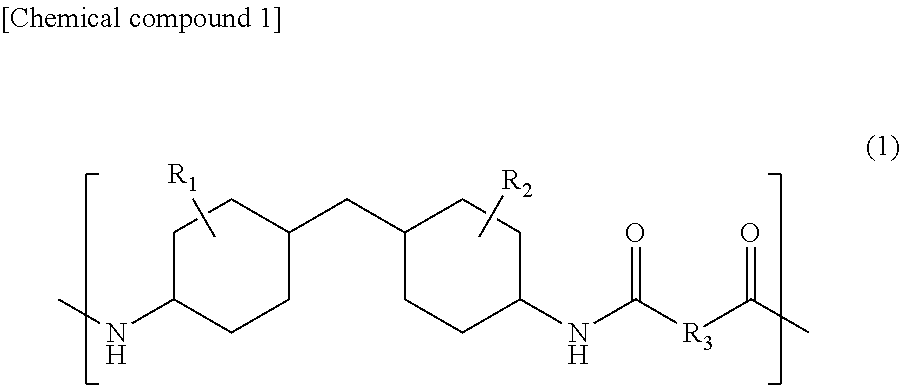

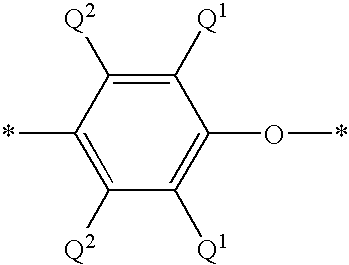

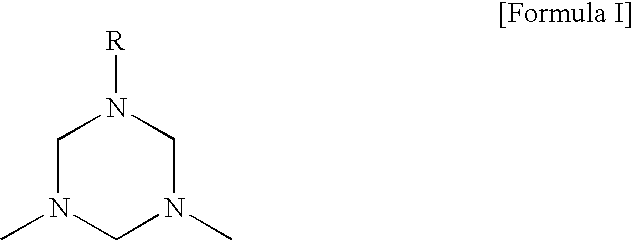

Diamine polymer and resin composition thereof

A diamine polymer comprising a repeat unit represented by the following formula (I) in which diamine is linked to form a triaza ring;wherein R represents a monoamine residue.

Owner:SEKISUI CHEM CO LTD +1

Puroduction method for readily dispersible cellulose composition, readily dispersible cellulose composition, cellulose dispersion resin composition, and prodaction method for water-based dispersant for cellulose

ActiveUS20170002182A1Readily dispersibleStable preparationTransportation and packagingMixingWater basedPolymer science

An object of the present invention is to provide a technology of dispersing cellulose readily in a hydrophobic substance such as a resin by treating cellulose being a hydrophilic substance in a system that contains water as a main medium with a polymer dispersant, which has been developed for dispersing a fine and hydrophobic substance such as a pigment, in a simple and efficient manner without conducting surface modification of nanocellulose or other treatments. The object is solved by a process for producing a readily dispersible cellulose composition, the process including dissolving a polymer dispersant having a block copolymer structure having a resin-affinitive segment A and a cellulose-adsorptive segment B in a hydrophilic organic solvent solution, adding a surface active agent to the resultant solution, thereafter adding water to the resultant mixture to prepare an aqueous dispersion treatment agent containing the polymer dispersant, and adding the obtained aqueous dispersion treatment agent to cellulose in a water-containing state or in a dry state, thereby obtaining a readily dispersible cellulose composition. The object is also solved by a process for producing an aqueous dispersion treatment agent for use in the process for producing a readily dispersible cellulose composition, the readily dispersible cellulose composition, and a cellulose-dispersed resin composition using the readily dispersible cellulose composition.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

Polyethylene compositions having improved printability

Polyethylene compositions having improved printability are provided. The compositions which are comprised of a polyethylene base resin, polyethylene glycol and polyethylene modified with carboxylic acid or carboxylic acid derivative functionality are melt blended under conditions of mixing and shear to increase their melt elasticity.

Owner:EQUSR CHEM LP

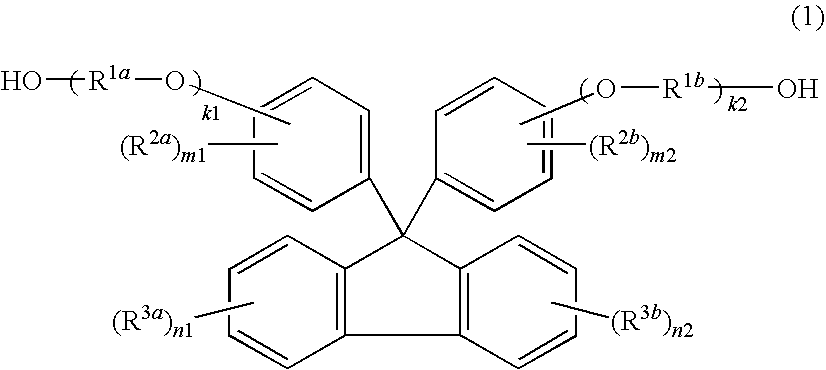

Resin composition and molded articles thereof

ActiveUS7781540B2Improve the immunityImprove liquidityOrganic dyesEnvironmental resistanceRefractive index

A resin composition, and molded articles thereof, where the resin composition simultaneously satisfies resistances, such as heat and environmental resistance, and moldability at high levels, and has excellent optical properties, such as high refractivity and low birefringence. The resin composition contains a polyester resin formed from a dicarboxylic acid component and a diol component (a) and a polycarbonate resin formed from a carbonate-forming component and a diol component (b), the diol component (a) containing a specific fluorene-containing compound and the diol component (b) containing a specific fluorene-containing compound.

Owner:OSAKA GAS CO LTD

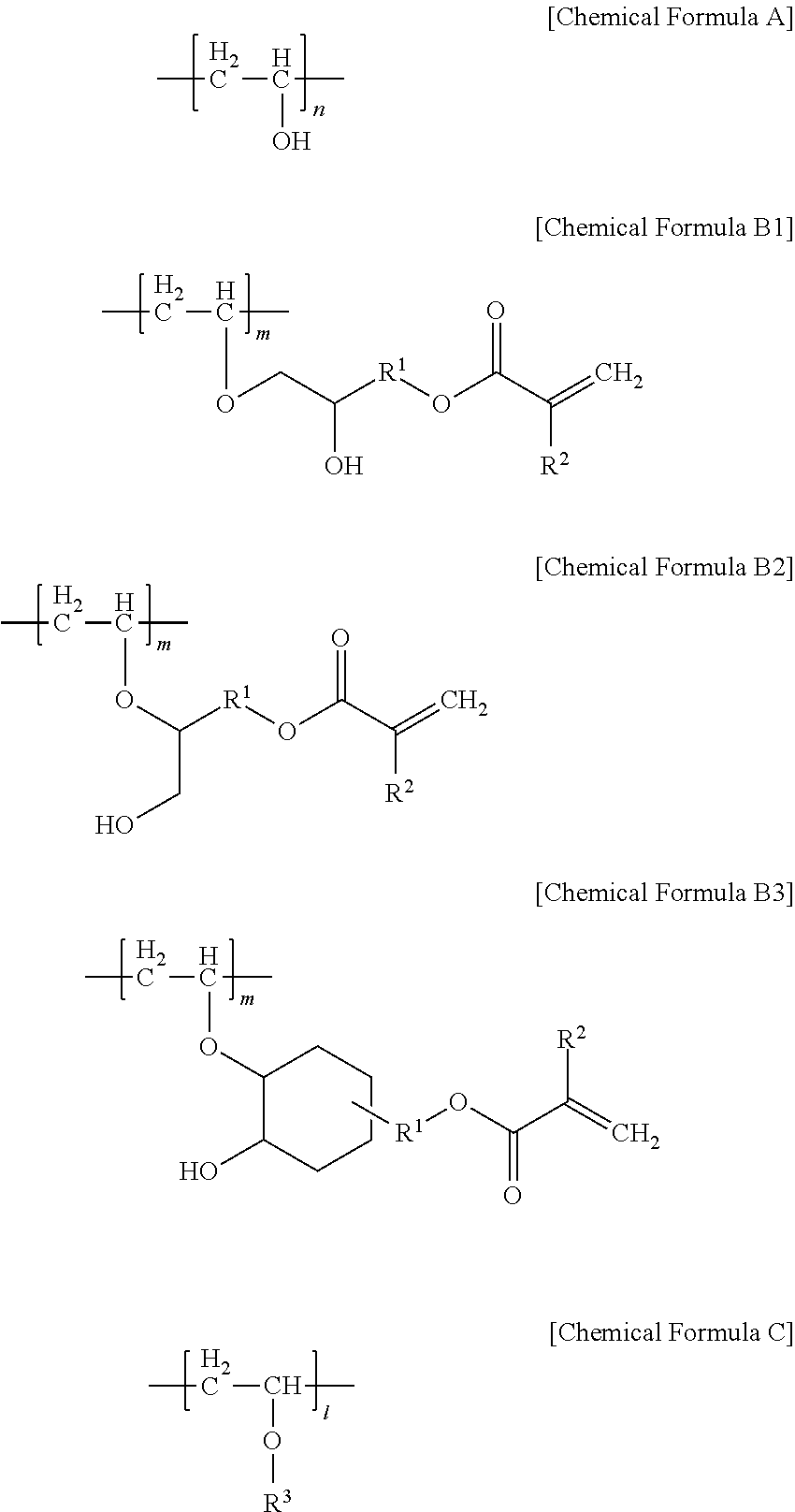

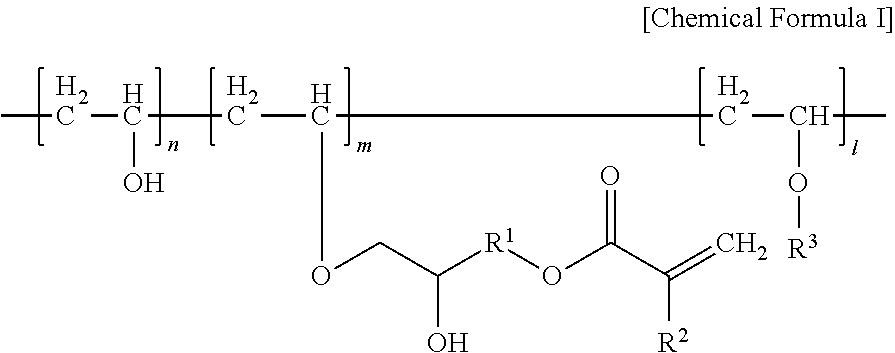

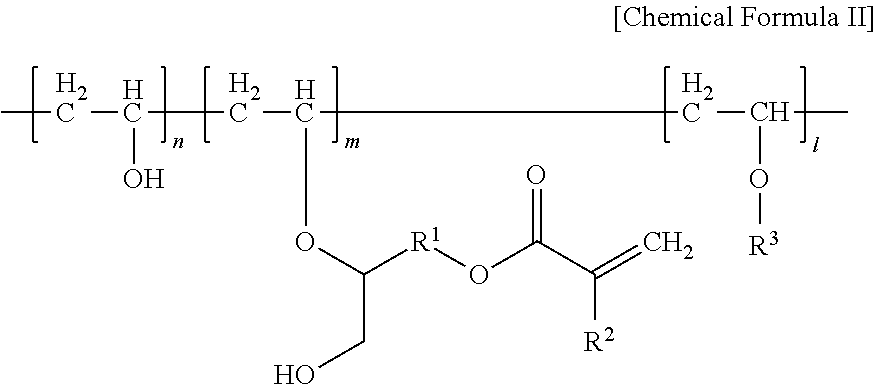

Modified polyvinyl alcohol resins and adhesive, polarizer, and display device containing the same

InactiveUS20110300387A1Improve adhesionExcellent humidity resistanceSynthetic resin layered productsPolarising elementsSolubilityAdhesive

Provided are a modified polyvinyl alcohol-based resin with an acrylic group introduced thereto and including a hydroxyl group formed during the introduction of the acrylic group, an adhesive including the modified polyvinyl alcohol-based resin having excellent adhesion, humidity resistance, and water resistance, an adhesive including a polyvinyl alcohol-based resin, and a compound having an epoxy group, and an acrylic group, a polarizing plate and an image display device including the adhesive. The adhesive for a polarizing plate according to an embodiment of the present invention has excellent adhesion, humidity resistance, and water resistance as well as having excellent solubility with respect to water and an increase in adhesion while physical properties of a typical polyvinyl alcohol-based resin are maintained.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com