Patents

Literature

49results about How to "Good curing properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

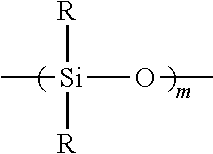

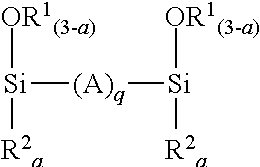

Curable composition

InactiveUS20090182091A1Less discolorationGood adhesivenessOther chemical processesEster polymer adhesivesSilylenePlasticizer

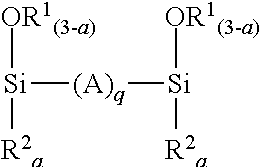

The present invention has its object to provide a curable composition which comprises a guanidine compound as a non-organotin type catalyst, is less discolored, has good surface curability, depth curability, strength rise and adhesiveness, and can retain the curability even after storage; the above object can be achieved by a curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiX3 (1) (wherein X represents a hydroxyl group or a hydrolyzable group and the three X groups may be mutually the same or different), (B) a guanidine compound (B-1) as a silanol condensation catalyst, and (C) a plasticizer, wherein the content of the component (B-1) is not lower than 0.1 part by weight but lower than 8 parts by weight per 100 parts by weight of the component (A), and a non-phthalate ester plasticizer accounts for 80 to 100% by weight of the (C) component plasticizer.

Owner:KANEKA CORP

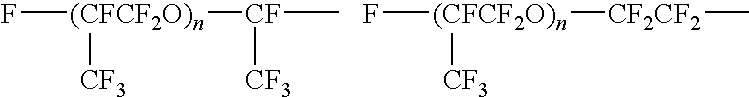

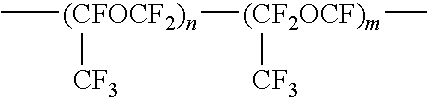

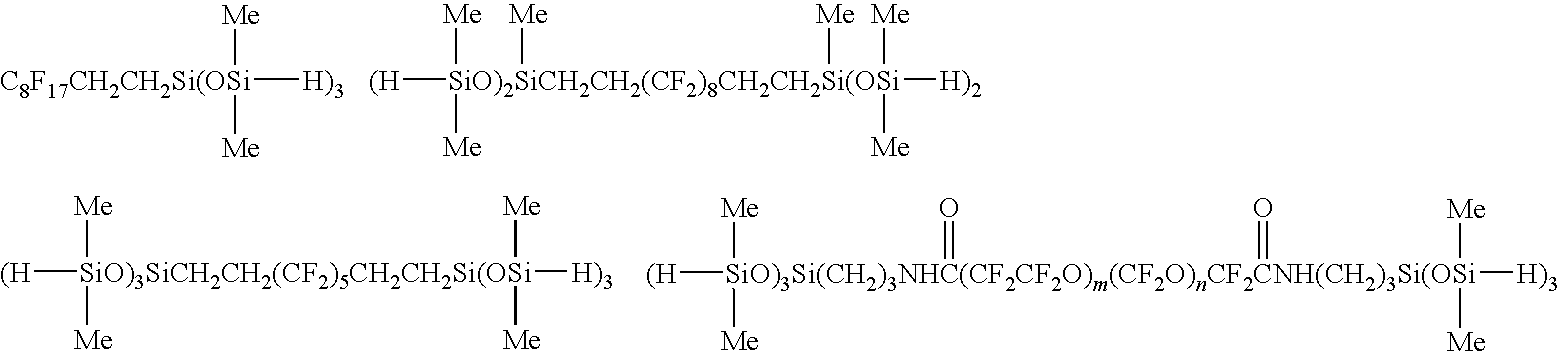

Fluorine-containing polymer composition and cured body

InactiveUS20060052546A1Reduce pointsExcellent mechanical propertiesOther chemical processesPolymer scienceFluoropolymer

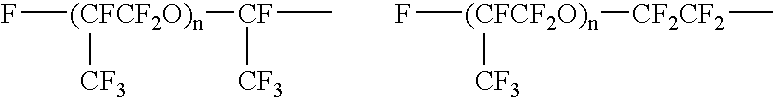

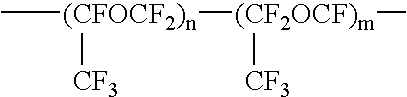

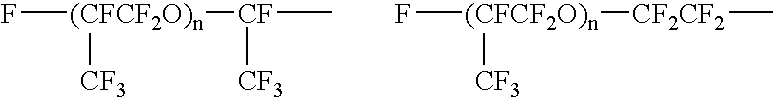

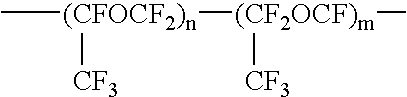

The invention provides a fluoropolymer composition capable of improving the characteristics of the cured material obtained therefrom. A fluoropolymer composition comprising a methylene group-containing fluoropolymer (A) and a hydrosilylation catalyst (B), wherein the methylene group-containing fluoropolymer (A) has methylene group-containing repeating units in the main chain thereof and is capable of hydrosilylation in the presence of the hydrosilylation catalyst (B) and one terminus of the chain is a carbon-carbon double bond or an Si—H group and the other terminus of the chain is an Si—H group or a carbon-carbon double bond.

Owner:DAIKIN IND LTD

One part epoxy resin including a low profile additive

InactiveUS20110253943A1Improve abilitiesImprove connection reliability and consistencyPrinted circuit assemblingConductive materialPolymer scienceResin matrix

An adhesive composition comprising: (i) a one part curable epoxy adhesive and (ii) a low profile additive (LPA), the low profile additive being a polymer that is compatible with the epoxy adhesive such that it forms a single phase when admixed with the adhesive composition and that separates from the adhesive to form a network of stress-absorbing nodules therein when the adhesive is cured, the low profile additive being present in an amount sufficient to prevent or reduce shrinkage and / or the formation of voids or cracks when the adhesive is cured. In one embodiment the LPA is a block copolymer including at least one flexible block and at least one rigid block that makes the low profile additive compatible with the epoxy adhesive such that a mixture of the uncured epoxy resin and the low profile additive forms a homogenous solution and as the epoxy resin is cured, the low profile additive forms a stress absorbing network of nodules in the cured epoxy resin matrix.

Owner:TRILLION SCI INC

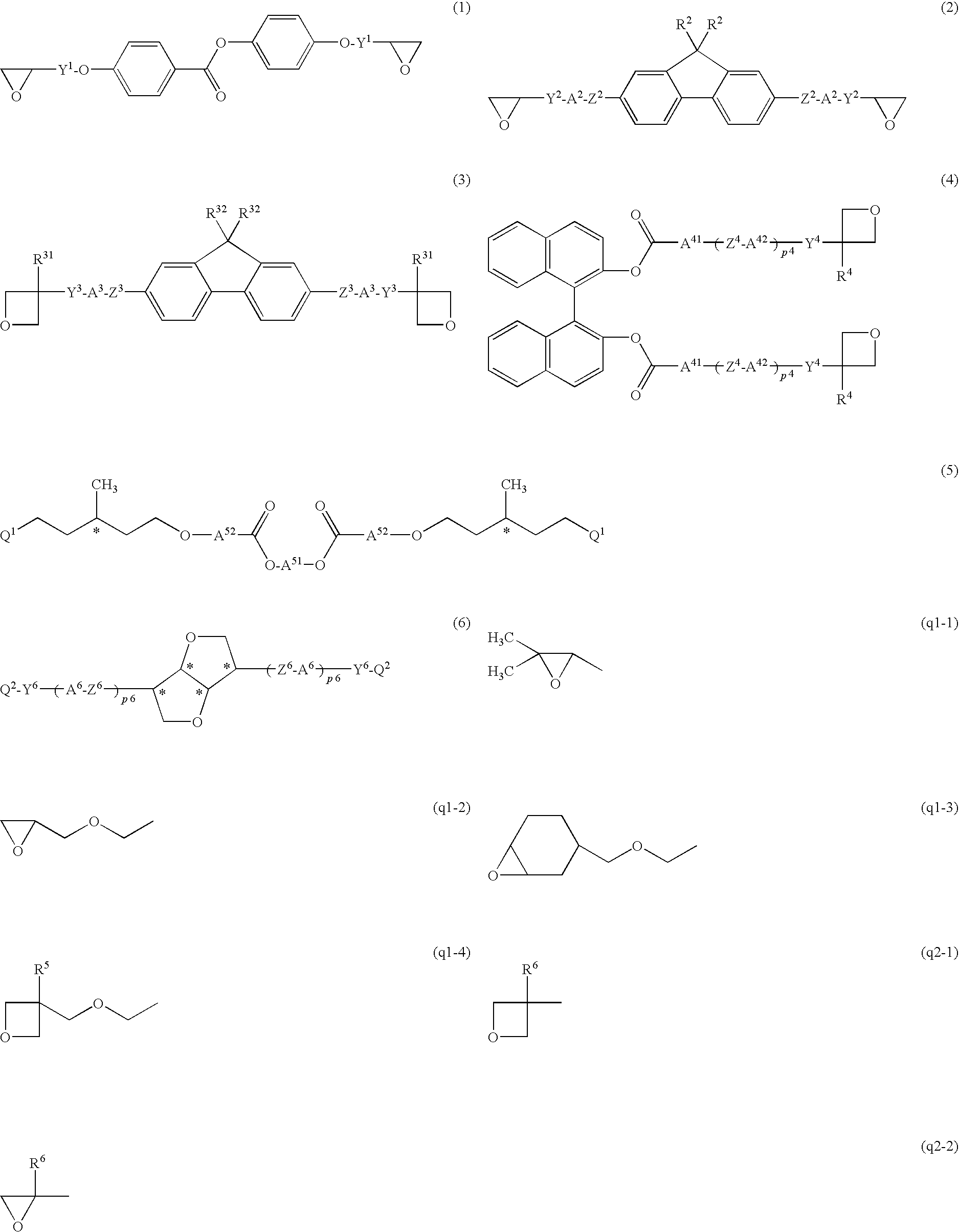

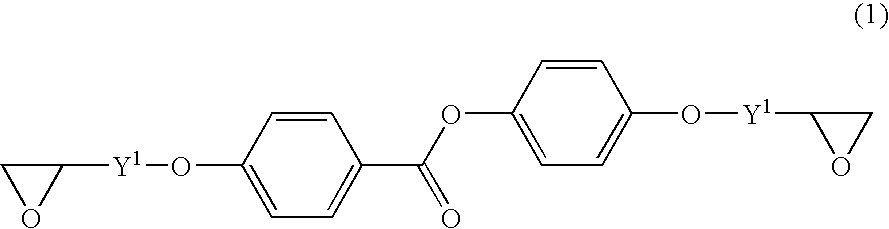

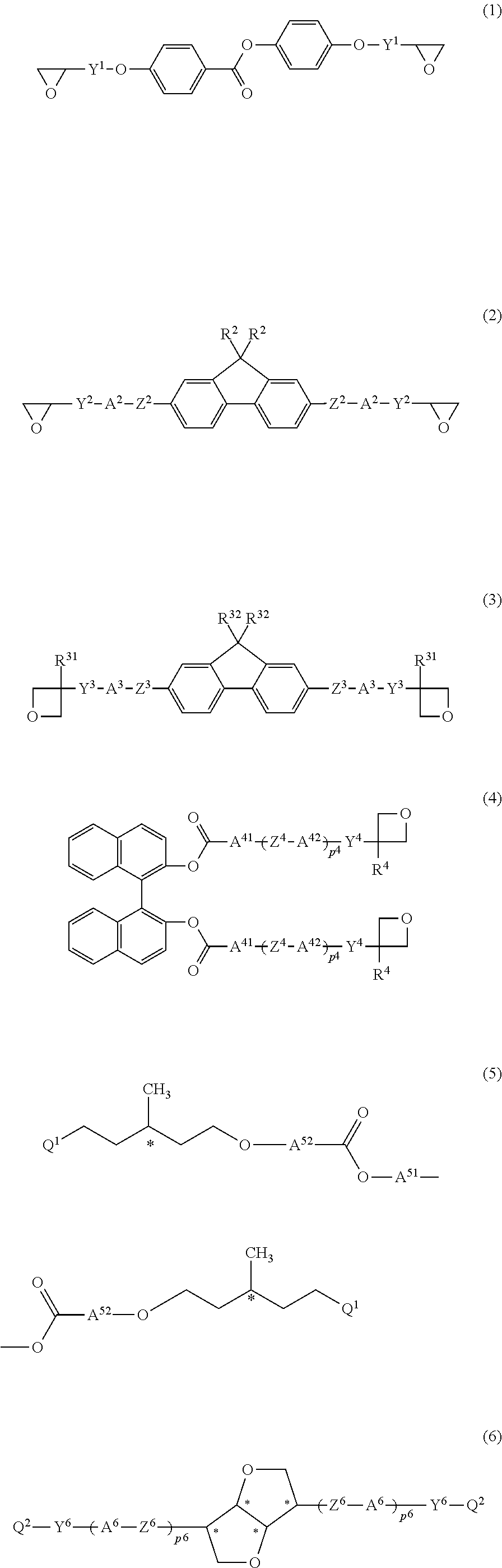

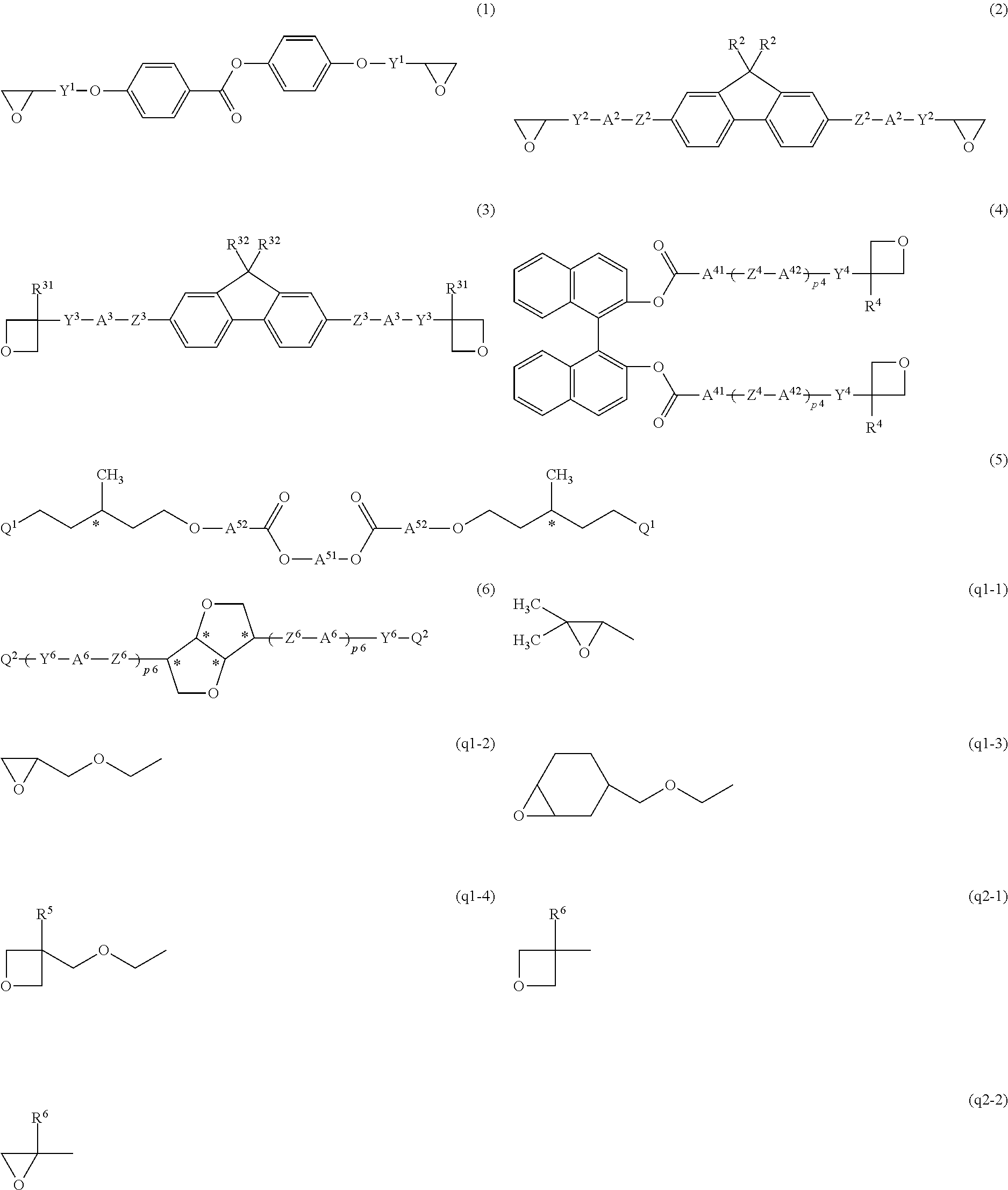

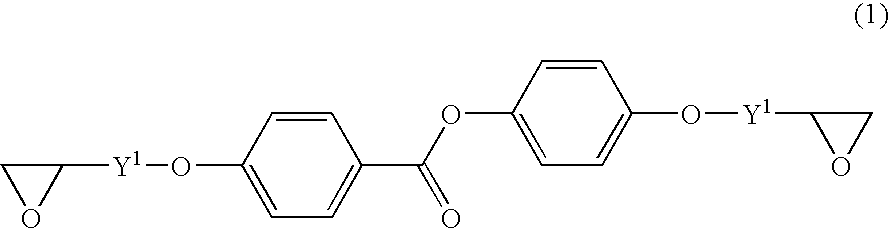

Polymerizable liquid crystal composition

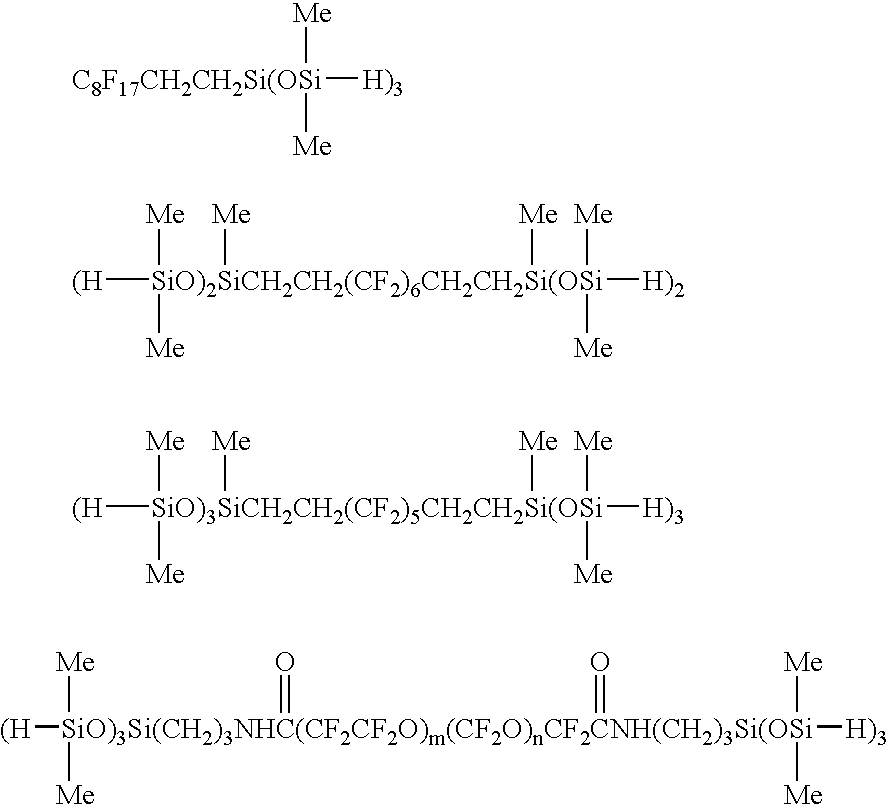

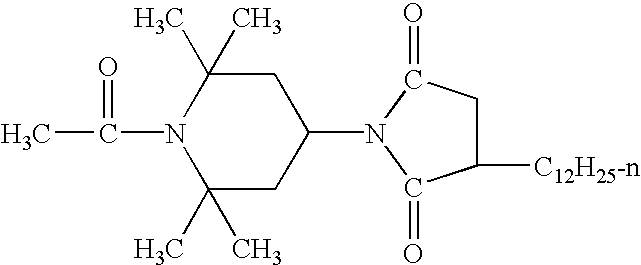

InactiveUS20100117027A1Good curing propertiesImprove homogeneityLiquid crystal compositionsThin material handlingHalogenSelective reflection

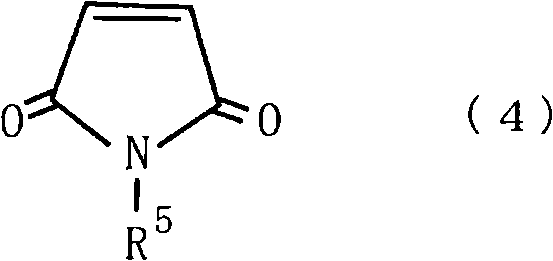

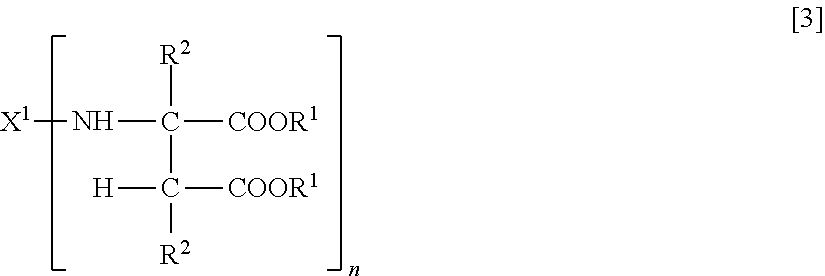

A polymerizable liquid crystal composition is provided that is excellent in UV curing characteristics in the air and is excellent in orientation homogeneity, and a polymer film as a selective reflection film is provided that is obtained by orienting and polymerizing the composition on a supporting substrate. The liquid crystal composition contains a compound (1), a compound (2), a compound (3), a compound selected from a group of compounds represented by the formulae (4) to (6), and a surfactant. In the following formulae Y1 to Y4 and Y6 are each alkylene, A2, A3, A41, A42, A51, A52 and A6 are each a cyclic group, Z2 to Z4 and Z6 are each a bonding group, P4 and P6 are each an integer of from 0 to 3, R2, R31 and R32 are each hydrogen, halogen or alkyl, and Q1 and Q2 are each a polymerizable group.

Owner:JNC PETROCHEM CORP +1

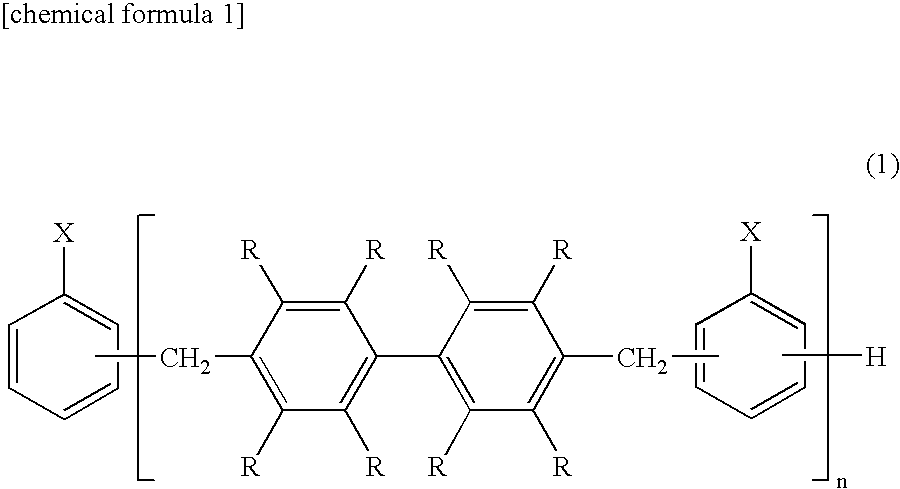

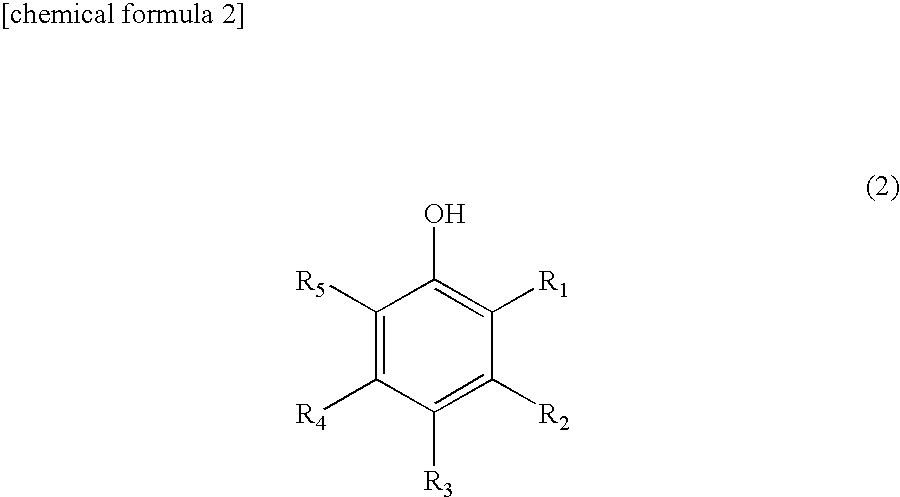

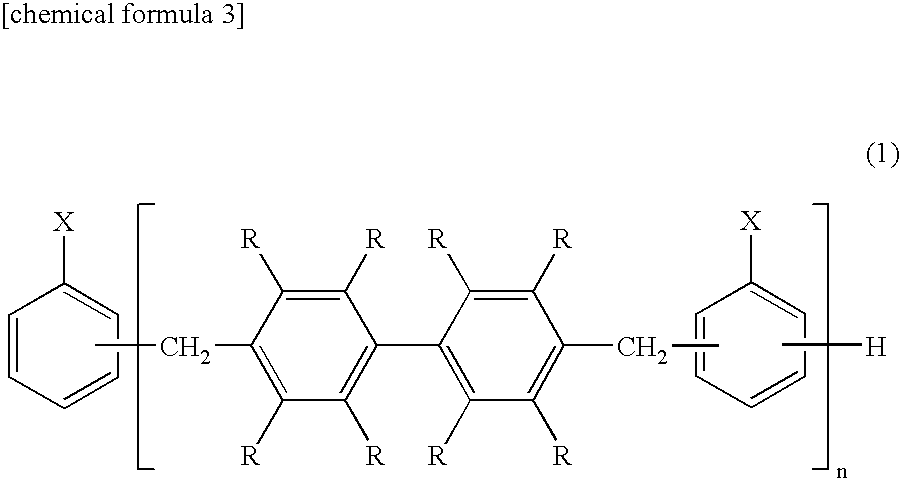

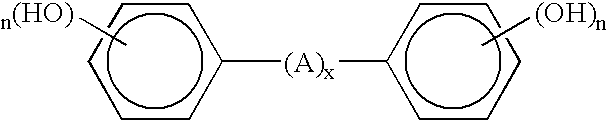

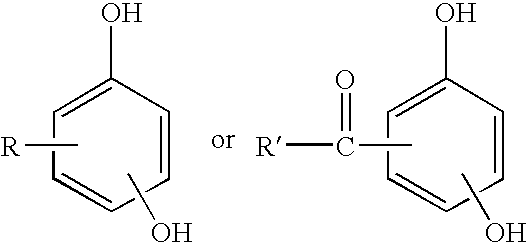

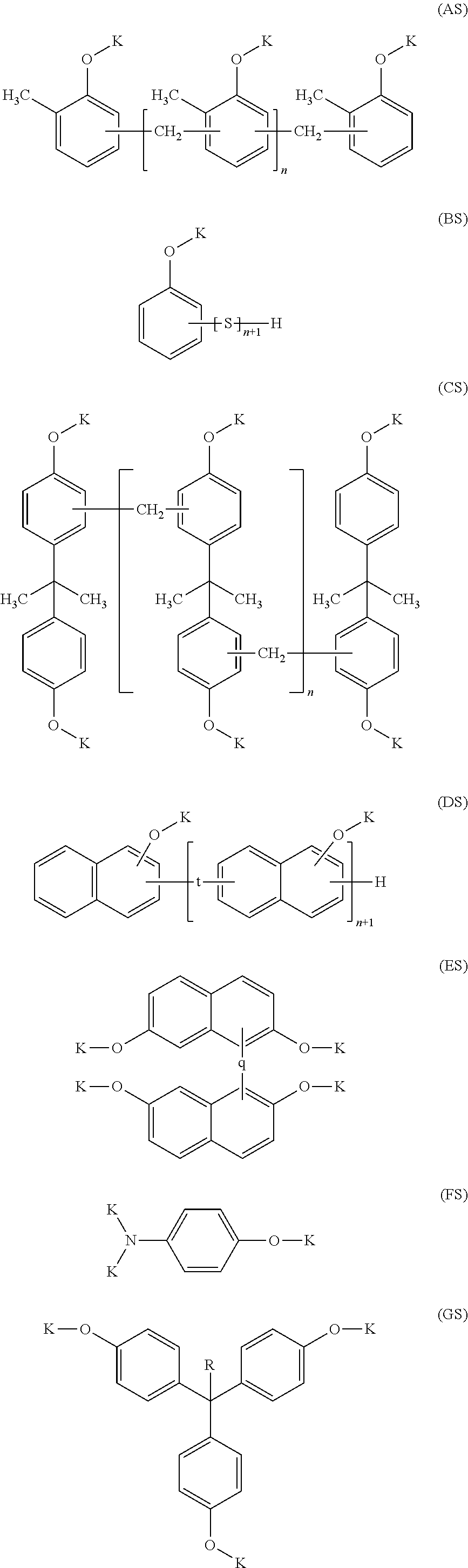

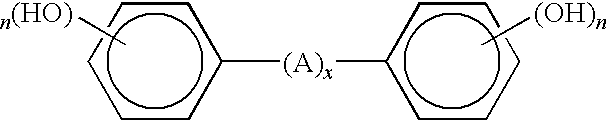

Epoxy resin composition for encapsulating semiconductor chip and semiconductor device

InactiveUS20070043166A1Improve flowabilityImprove mold releaseabilitySemiconductor/solid-state device detailsSolid-state devicesParaffin waxPOLYETHYLENE WAX

An epoxy resin composition for encapsulating a semiconductor chip having an improved flowability, an improved sequential moldability and the like, and additionally having improved characteristics of a cured product thereof, such as an improved mold-releaseability, an improved resistance to reflow soldering heat and the like, and a semiconductor device that is formed by encapsulating a semiconductor chip with the epoxy resin composition. An epoxy resin composition for encapsulating a semiconductor chip containing essential components of: (A) an epoxy resin, (B) a phenolic resin, (C) a cure accelerator, (D)an inorganic filler, (E) a mold releasing agent, (F) a silane coupling agent and (G) a chemical compound having aromatic ring that has hydroxyl groups, each of which is bound to respective two or more adjacent carbon atoms that composes the aromatic ring. At least one of said (A) epoxy resin and said (B) phenolic resin contains resin of novolac structure, in which biphenylene skeleton is included in its main chain, and said (E) mold releasing agent includes one or more chemical compound(s) selected from a group consisting of (E1) oxidized polyethylene wax, (E2) glycerin tri-fatty acid ester and (E3) oxidized paraffin wax, and further, said (E) mold releasing agent is contained in the amount of 0.01 wt % to 1 wt % both inclusive, and said (G)chemical compound is contained in the amount of 0.01 wt % to 1 wt % both inclusive, in the total epoxy resin composition.

Owner:SUMITOMO BAKELITE CO LTD

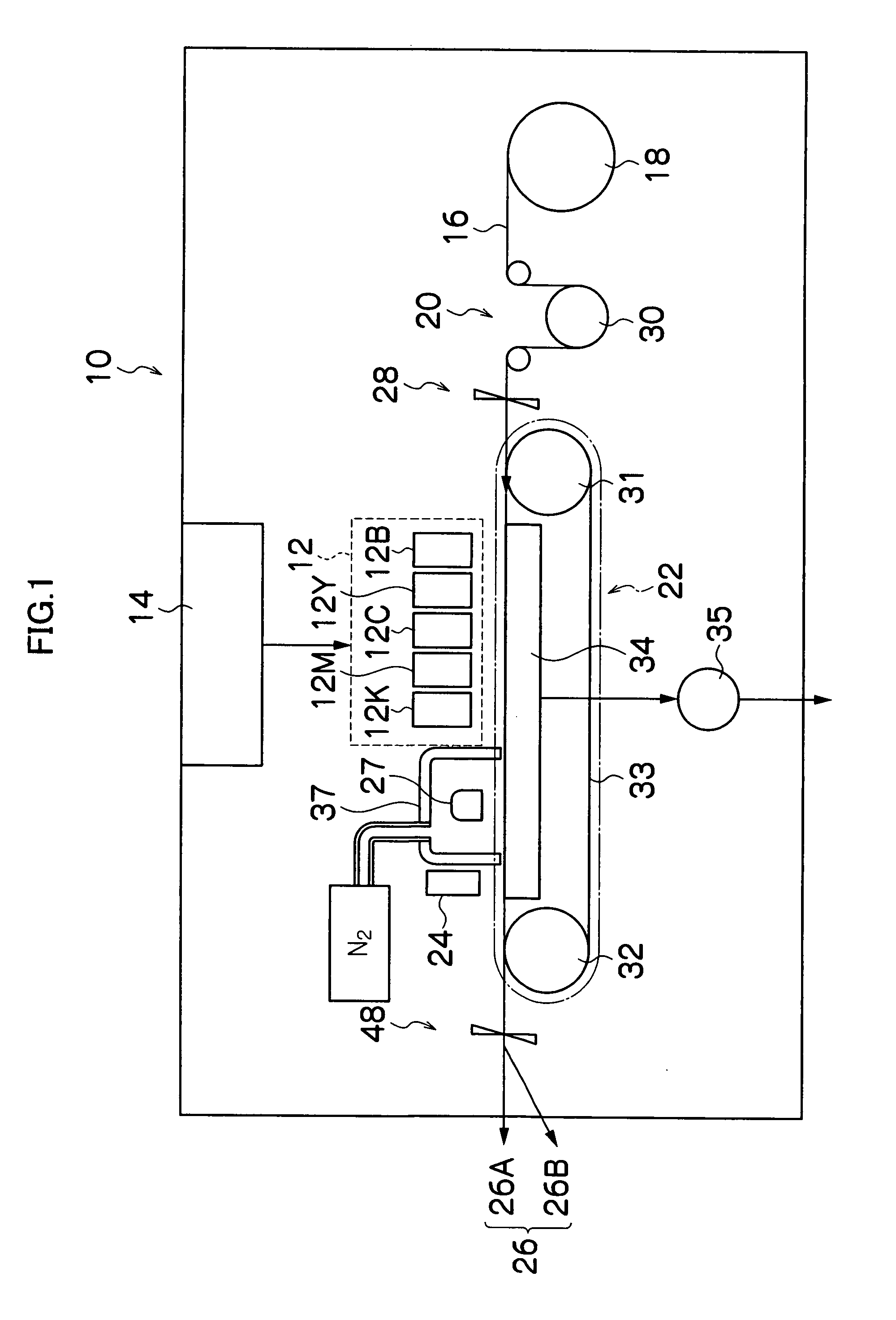

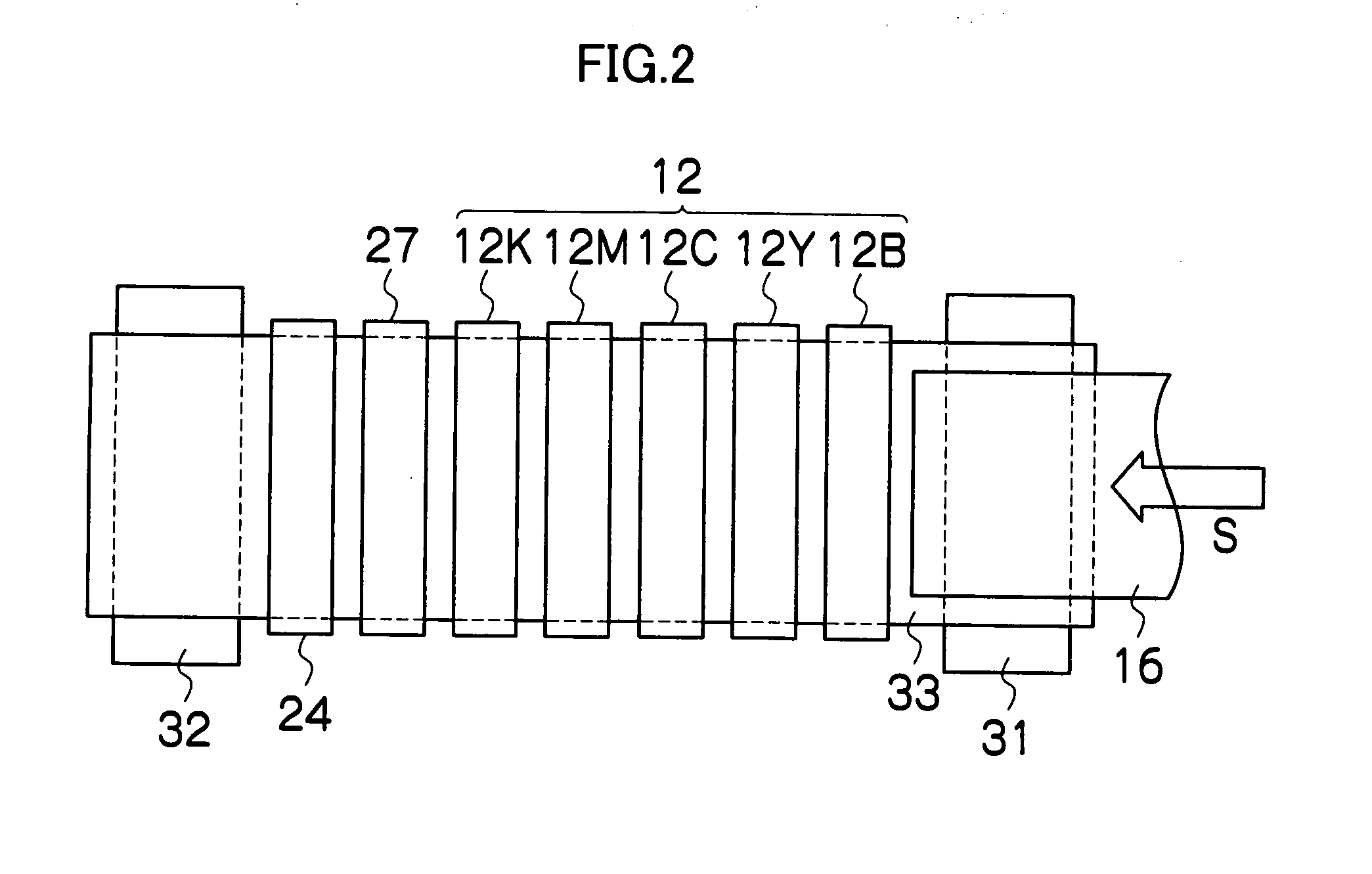

Inkjet recording apparatus

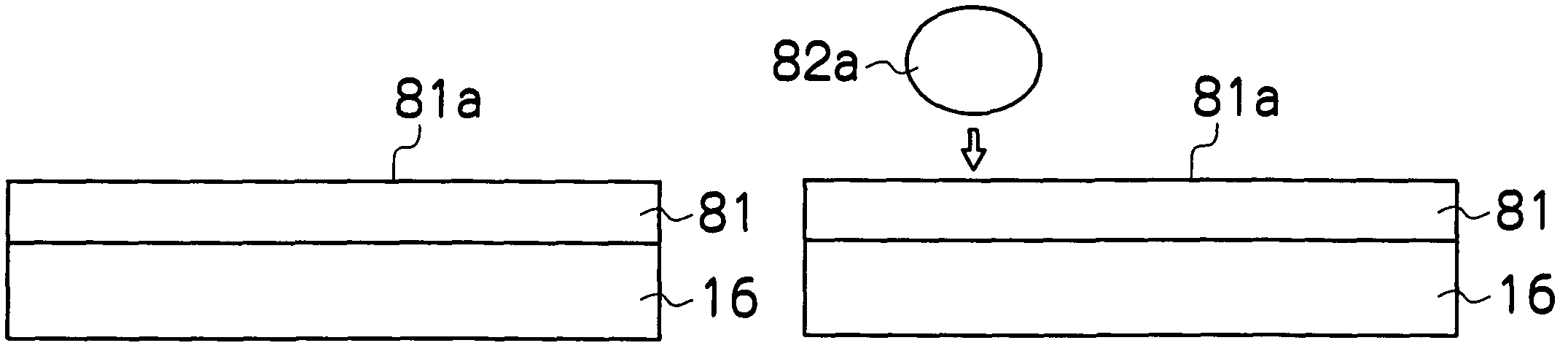

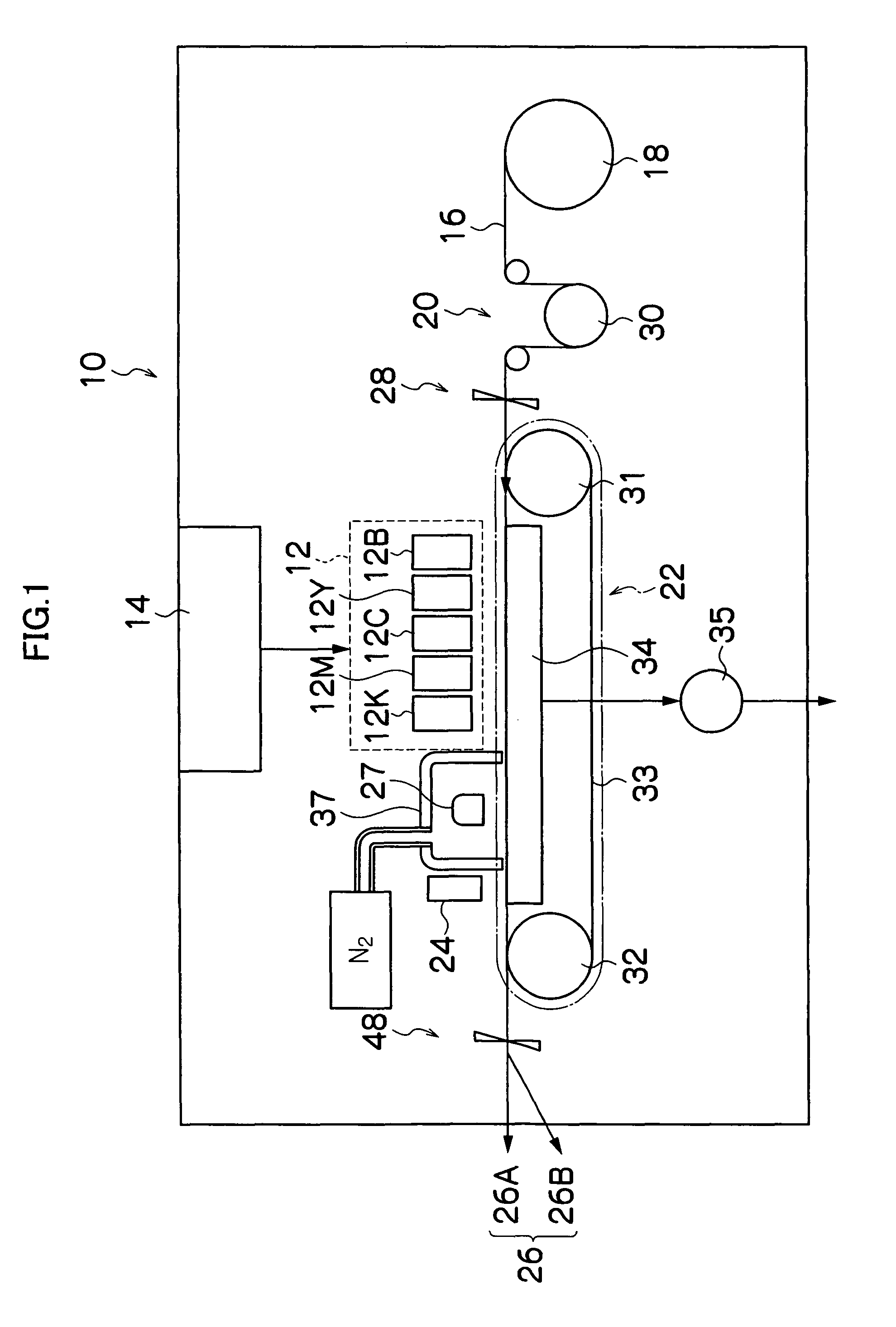

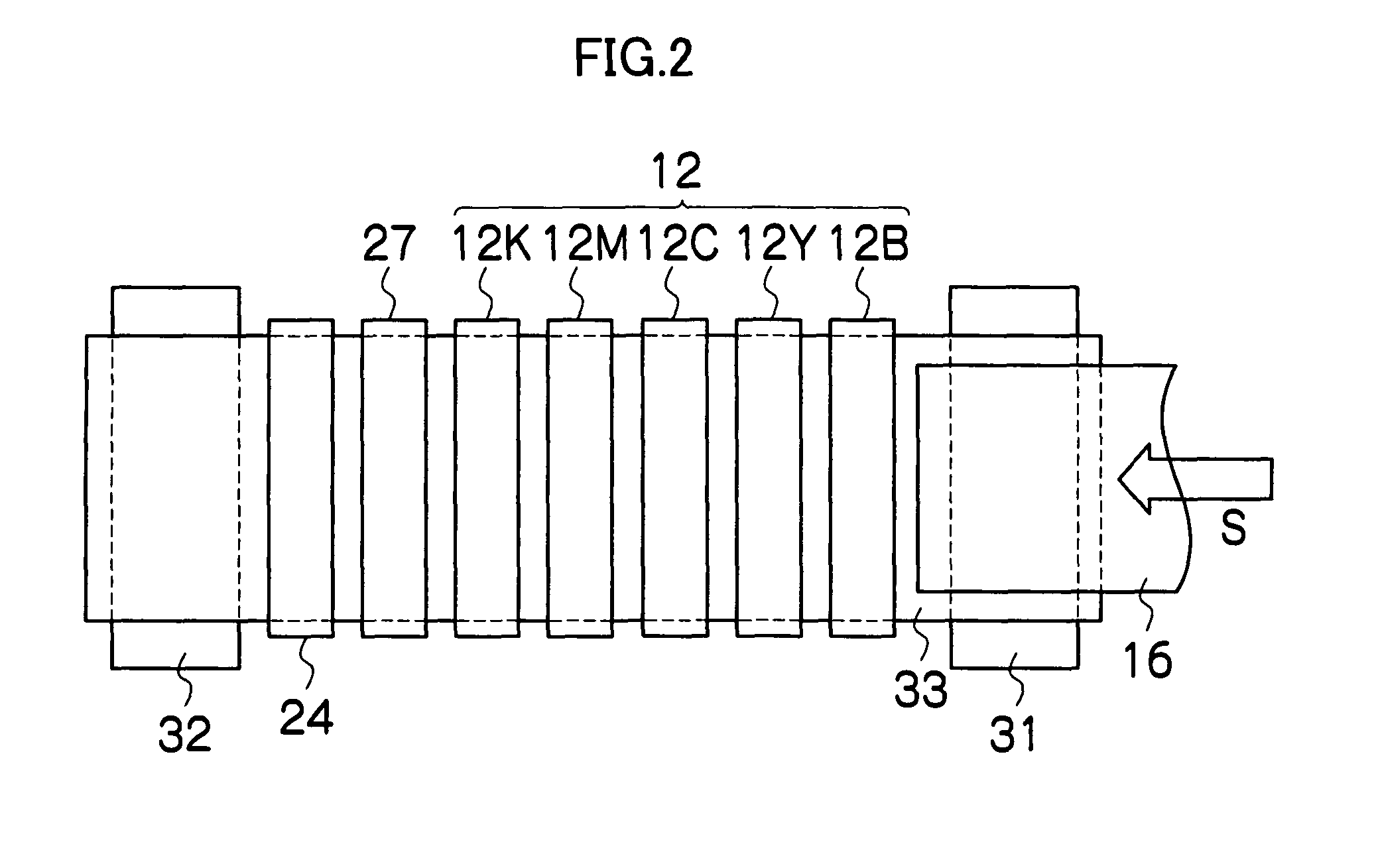

InactiveUS20080018695A1Disturbance of image can be suppressedSuppress interferenceInking apparatusDuplicating/marking methodsAcceleration voltageElectron

The inkjet recording apparatus which forms an image on a recording medium by applying a first liquid containing coloring material and a second liquid containing no coloring material or the coloring material of not greater than 0.1 wt %, on the recording medium, includes: a liquid application device which applies the second liquid on the recording medium and then ejects droplets of the first liquid toward the second liquid applied on the recording medium; and an electron beam irradiation device which radiates an electron beam on the first liquid and the second liquid on the recording medium, wherein: at least one of the first liquid and the second liquid contains a polymerizable compound which is polymerized when irradiated with the electron beam; and the electron beam irradiation device radiates the electron beam at an acceleration voltage of 40 kV through 60 kV.

Owner:FUJIFILM CORP

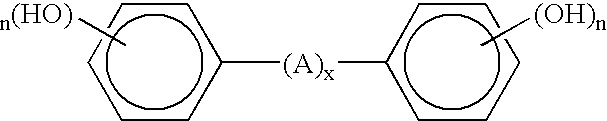

Curable base-resistant fluoroelastomers

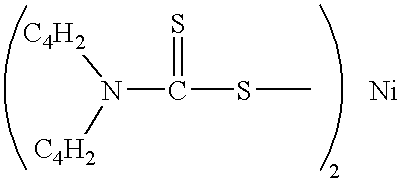

InactiveUS20080207861A1Good curing propertiesImprove adhesionFibre treatmentSpecial tyresPolymer scienceEnd-group

Compositions of fluoroelastomers containing copolymerized units of tetrafluoroethylene, propylene, a first cure site selected from the group consisting of i) trifluoroethylene, ii) 3,3,3-trifluoropropene-1, iii) 1,2,3,3,3-pentafluoropropylene, iv) 1,1,3,3,3-pentafluoropropylene, and v) 2,3,3,3-tetrafluoropropene, and a second cure site selected from the group consisting of i) copolymerized units of a brominated cure site monomer, ii) copolymerized units of an iodinated cure site monomer, iii) copolymerized units of a chlorinated cure site monomer, iv) brominated endgroups, v) iodinated endgroups and vi) a combination of any of i)-v) are readily curable with polyhydroxy curing systems. The resulting cured articles have a combination of excellent resistance to alkaline fluids, superior tensile properties and compression set resistance, and excellent adhesion to metal substrates. Optionally, the fluoroelastomers may be dual cured by both a polyhydroxy system and an organic peroxide system.

Owner:THE CHEMOURS CO FC LLC

Anhydride and resorcinol latent catalyst system for improving cure characteristics of phenolic resins

An anhydride and resorcinol latent catalyst system for a phenolic resole resin provides a resin having long pot life and long shelf life, yet cures quickly thereafter.

Owner:GEORGIA PACIFIC CHEM LLC

Fluorine-containing polymer composition and cured body

InactiveUS20090176953A1Reduce pointsDelay transitionOther chemical processesPolymer scienceFluoropolymer

The invention provides a fluoropolymer composition capable of improving the characteristics of the cured material obtained therefrom. A fluoropolymer composition comprising a methylene group-containing fluoropolymer (A) and a hydrosilylation catalyst (B), wherein the methylene group-containing fluoropolymer (A) has methylene group-containing repeating units in the main chain thereof and is capable of hydrosilylation in the presence of the hydrosilylation catalyst (B) and one terminus of the chain is a carbon-carbon double bond or an Si—H group and the other terminus of the chain is an Si—H group or a carbon-carbon double bond.

Owner:DAIKIN IND LTD

Curable silicone compositions containing reactive non-siloxane-containing resins

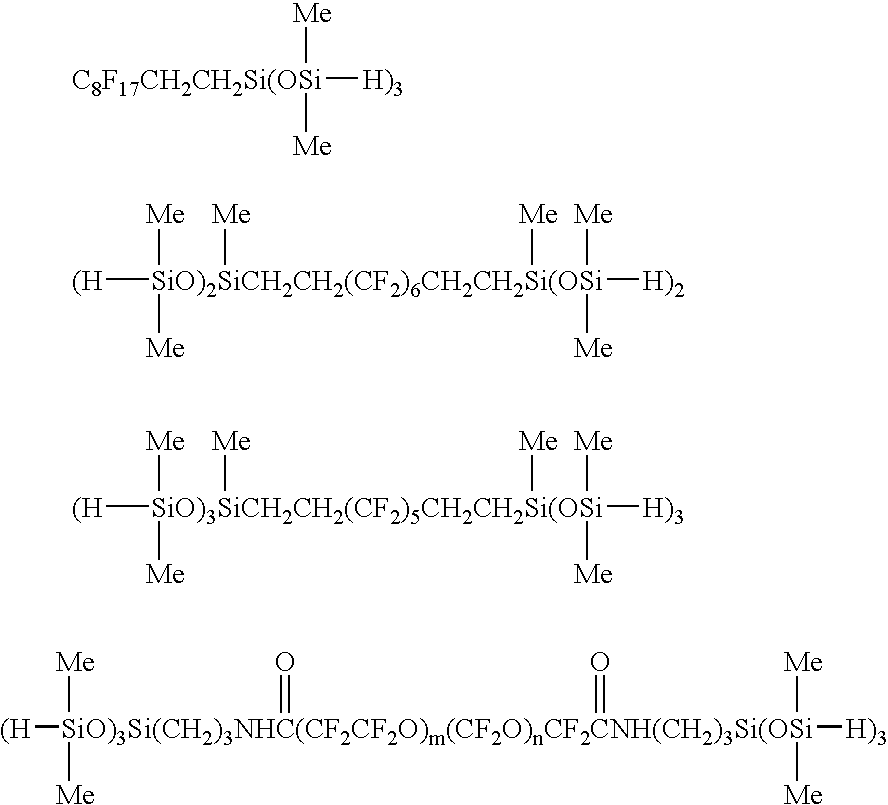

ActiveUS20120111498A1Provide strengthEliminate the problemFilm/foil adhesivesLaminationRoom temperatureMoisture

The present invention relates to two-part moisture curing compositions useful for adhesive, sealing, potting and other applications. In particular, the present invention relates to two-part room temperature vulcanizing (RTV) compositions which include in one of the parts a moisture curing organic polymer which is substantially free or does not contain siloxane bonds in its backbone.

Owner:HENKEL KGAA

Tire compositions comprising epoxidized natural rubber and a functionalized polyolefin

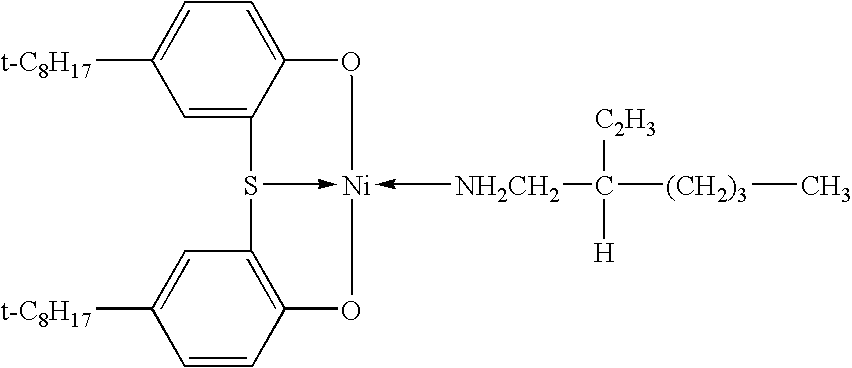

InactiveUS6845797B2Good curing propertiesImprove rolling resistanceSpecial tyresTyresPolyolefinSilicon dioxide

A tire comprising a tread, where said tread includes a vulcanized rubber, where said vulcanized rubber includes from about 0.5 to about 40 weight percent epoxidized rubber; from about 1 to about 35 parts by weight of a functionalized polyolefin per 100 parts by weight of said vulcanized rubber; and from about 1 to about 100 parts by weight silica per 100 parts by weight of said vulcanized rubber.

Owner:BRIDGESTONE CORP

Transparent silicone film-forming composition and method for curing same

There is provided a transparent silicone film-forming composition which forms an ultraviolet-absorbing and infrared-screening film exhibiting a film hardness of 6H to 9H or more after curing on a transparent substrate such as glass and plastic. The transparent silicone film-forming composition contains a reaction product of an alkoxysilane having an epoxy group and alkoxysilane having an amino group with an active hydrogen, an acid catalyst, a finely ground ITO cocatalyst and at least one solvent selected from organic solvents. The transparent silicone film-forming composition can also contain a reaction product of an alkoxysilane having an epoxy group and alkoxysilane having an amino group with an active hydrogen as well as tri- or dialkyloxysilane mixed with monoalkoxysilane and / or glycidesilane, an acid catalyst, a finely ground ITO cocatalyst and at least one solvent selected from organic solvents.

Owner:SATOSHI SAWAMURA

Polymerizable liquid crystal composition

InactiveUS8419972B2Good curing propertiesImprove homogeneityLiquid crystal compositionsThin material handlingCrystallographyUV curing

Owner:JNC PETROCHEM CORP +1

Polyurethane resin composition for sealing optoelectric conversion devices

InactiveCN1365370AImprove thermal stabilityHigh elastic modulusSemiconductor/solid-state device detailsSolid-state devicesHydroxy compoundChemistry

A urethane resin composition for sealing optoelectric conversion devices which is prepared from a component (A) containing an isocyanate compound and a component (B) containing a hydroxyl compound, characterized in that the isocyanate compound is at least one compound selected from the group consisting of aromatic isocyanates having structures where none of the isocyanate groups are bonded directly to the benzene rings, aliphatic isocyanates, alicyclic isocyanates, and mixture of them.

Owner:MITSUI CHEM INC

Composition containing a surface-deactivated polyisocyanate and curing in two stages

InactiveCN102421817AEasy to stretchHigh strengthPolyureas/polyurethane adhesivesAdhesive processes with adhesive heatingAdhesiveMoisture

The present invention relates to single-component compositions that can be cured in two stages, wherein in the first curing stage, compositions pre-cured by means of moisture and having in particular plastic properties are formed, and wherein in the second curing stage, compositions cured by means of heat and having in particular elastic properties are formed. Said two-stage compositions are suitable in particular as adhesives and have the great advantage that thanks to said two-stage compositions, an adhesive can be applied to a substrate, said adhesive cures by means of moisture in such a way that it can be handled and stored without problems, and said adhesive can be cured easily in an adhering step by means of heat only when needed.

Owner:SIKA TECH AG

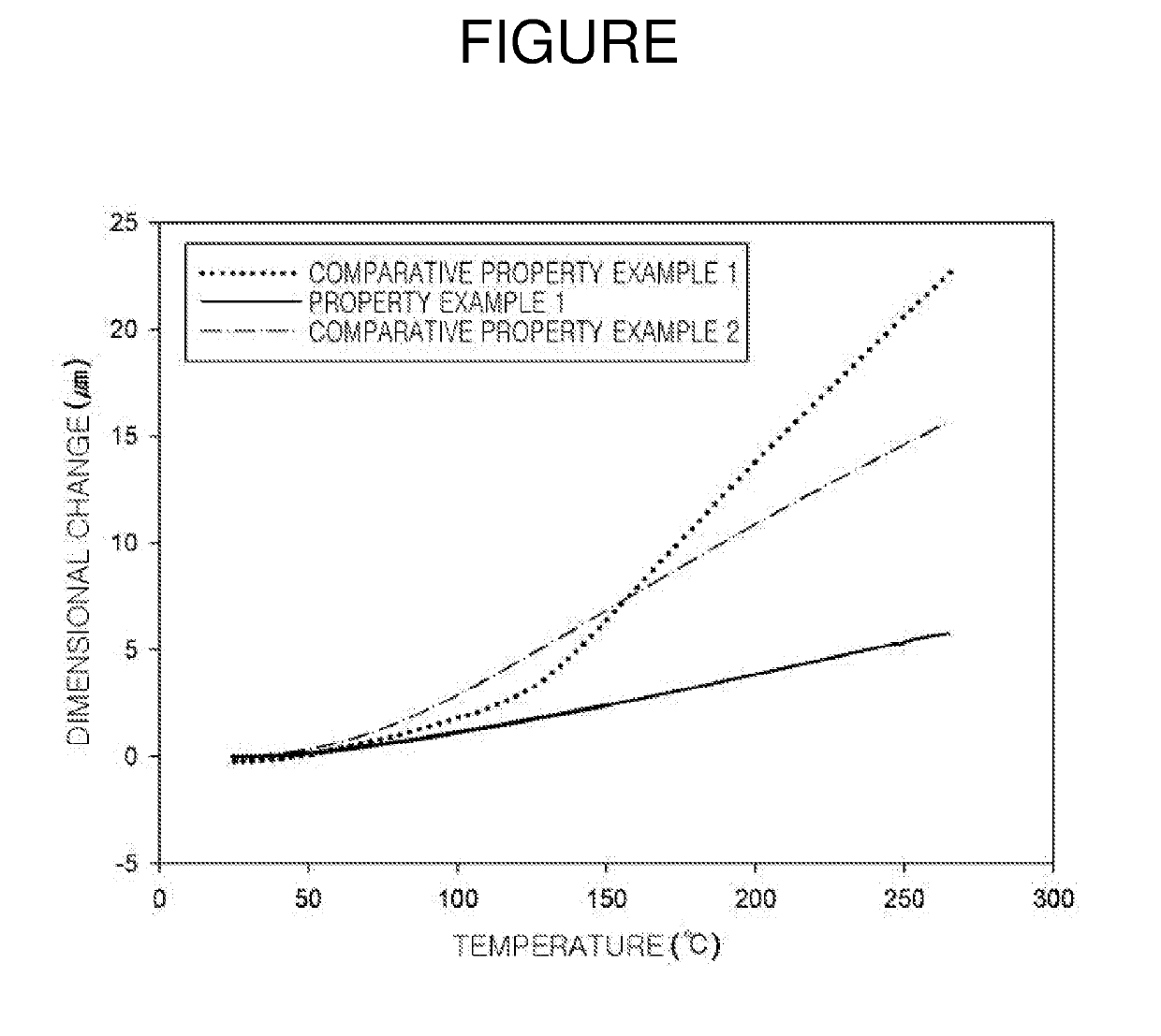

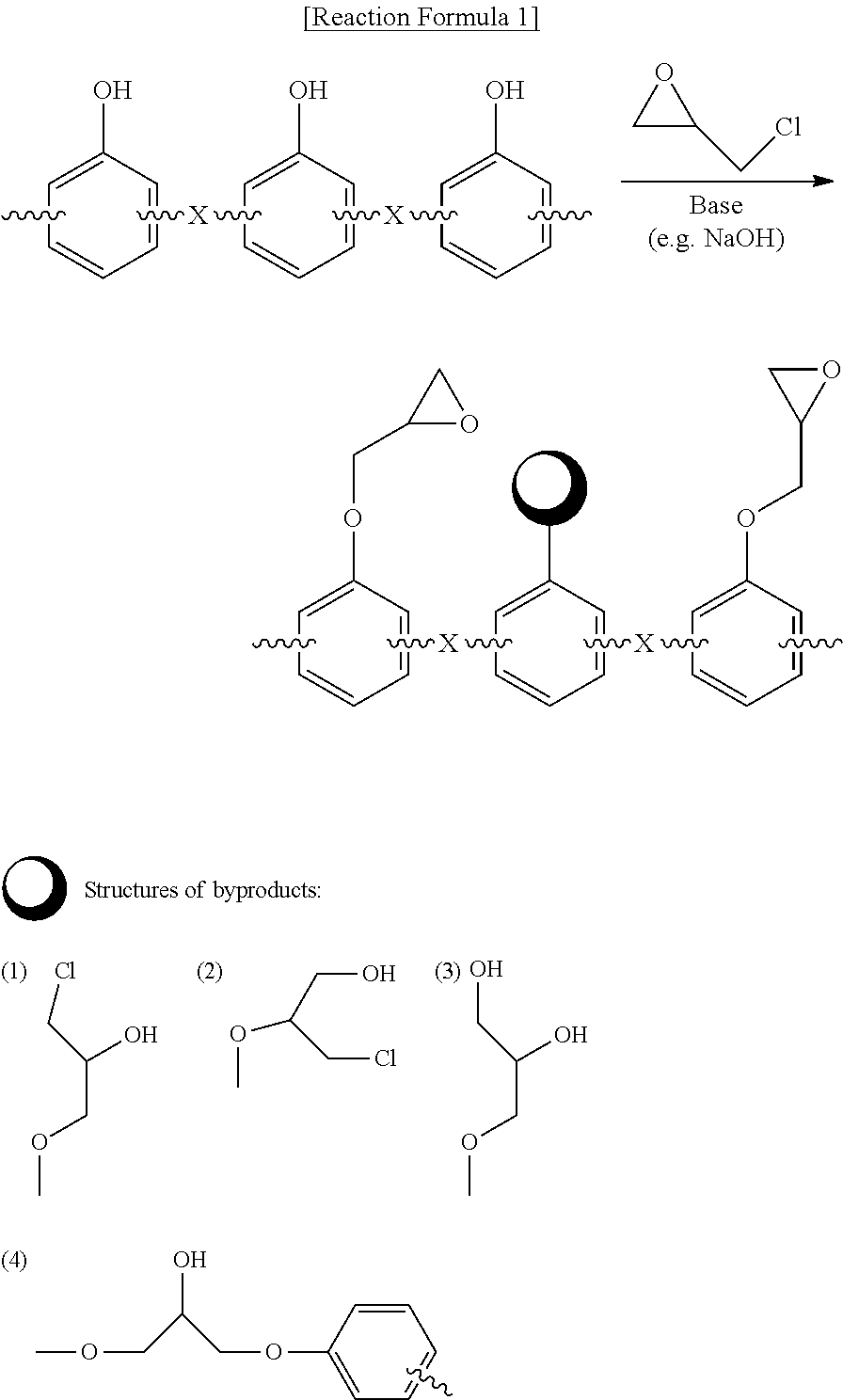

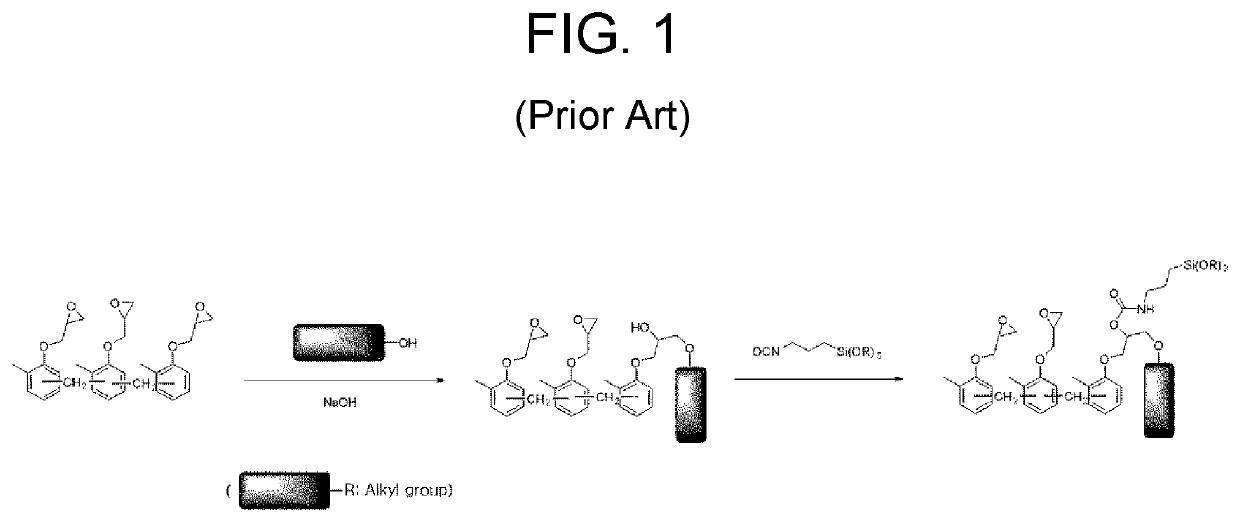

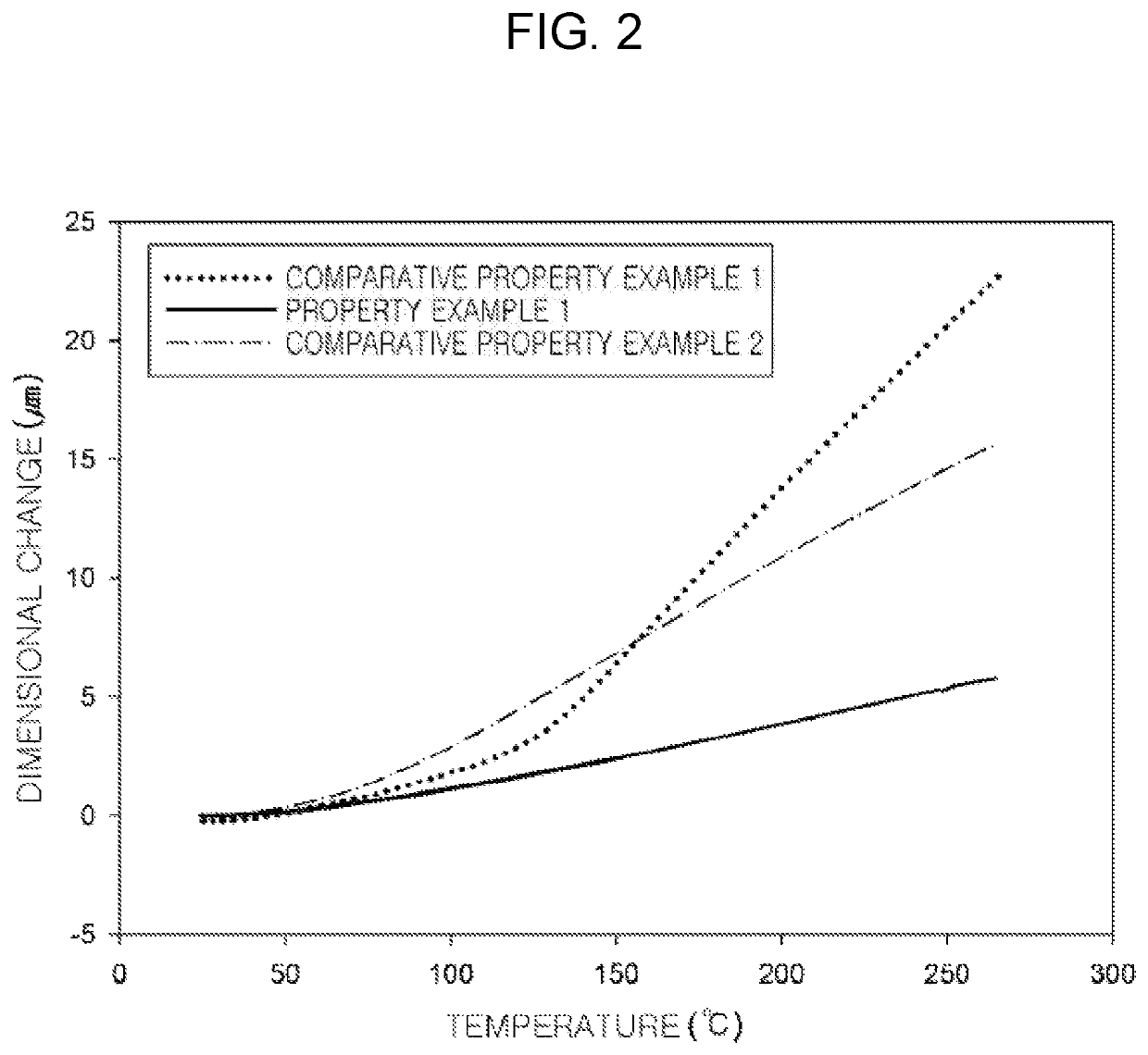

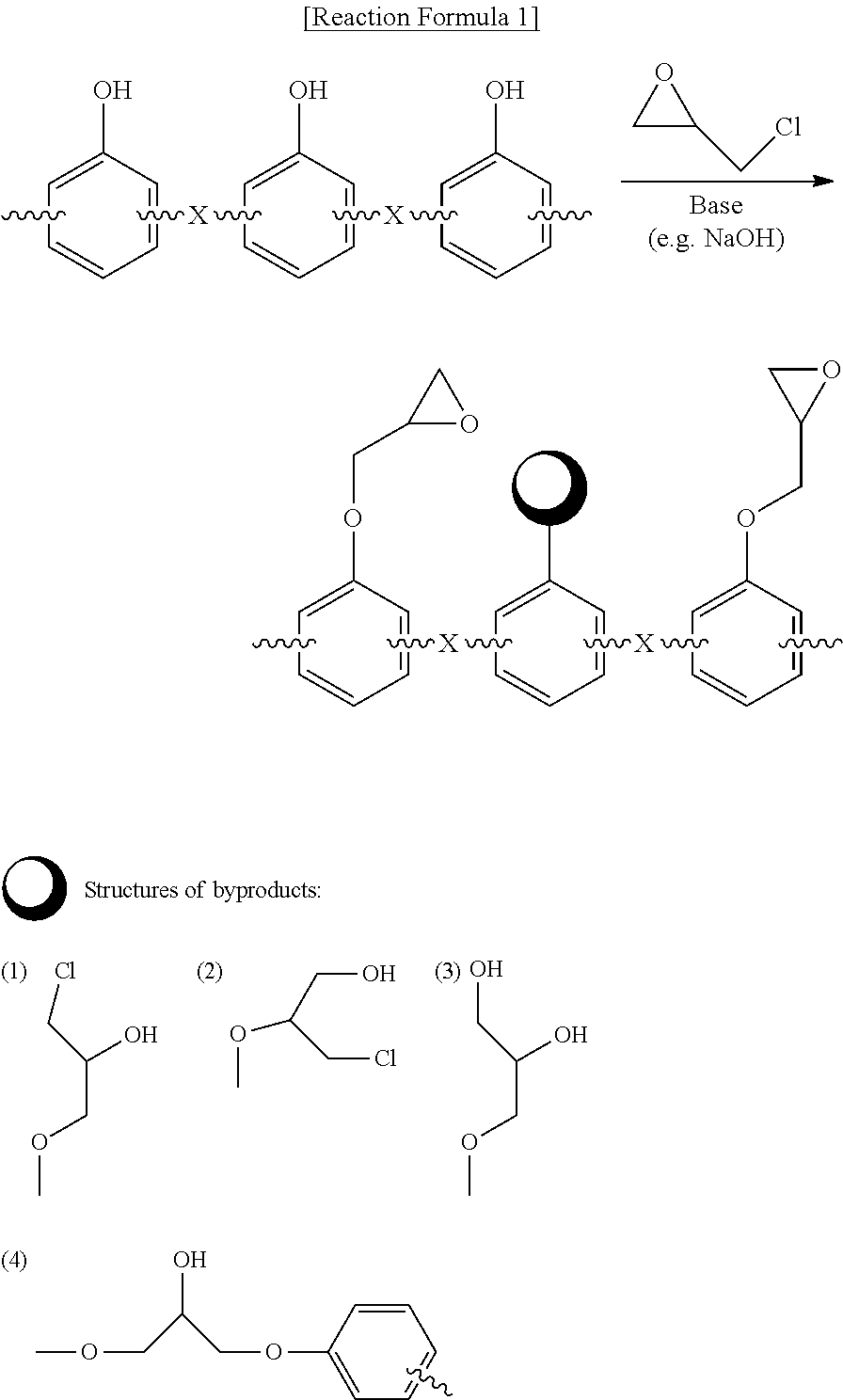

Preparation method of epoxy compound having alkoxysilyl group, epoxy compound having alkoxysilyl group, composition comprising the same, and use thereof

ActiveUS20190135970A1Improve compoundGood curing propertiesGroup 4/14 element organic compoundsCarbamic acid derivatives preparationEpoxyPolymer science

Provided are a preparation method of an epoxy compound having an alkoxysilyl group in which an increase in the epoxy equivalent weight (EEW) of the epoxy compound is minimized because alkoxysilylation occurs through a simple one-step reaction using a hydroxyl group formed during the synthesis of the epoxy compound, an epoxy compound having an alkoxysilyl group prepared by the method, a composition comprising the same, and a use thereof. The method includes the reaction of an epoxy compound having a hydroxyl group with an isocyanate alkoxysilane in the presence of amine-based base catalyst, wherein the epoxy compound having an alkoxysilyl group has a mole ratio of [epoxide group]:[alkoxysilyl group] of n:1 ranging from 2:1 to 10:1, and an EEW increase of the epoxy compound having an alkoxysilyl group is less than 260 / n. The epoxy compound has good physical properties when being cured.

Owner:KOREA INST OF IND TECH

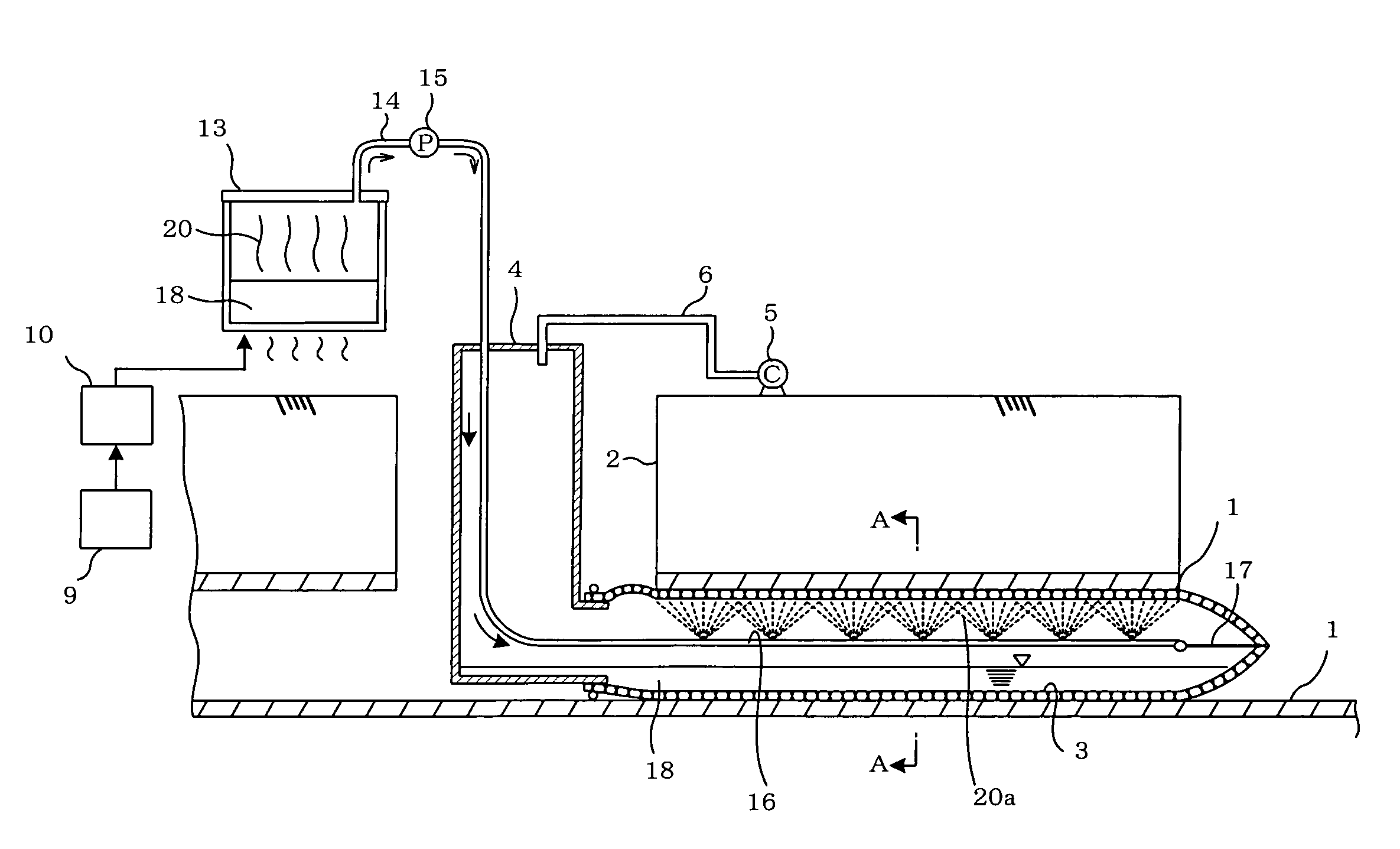

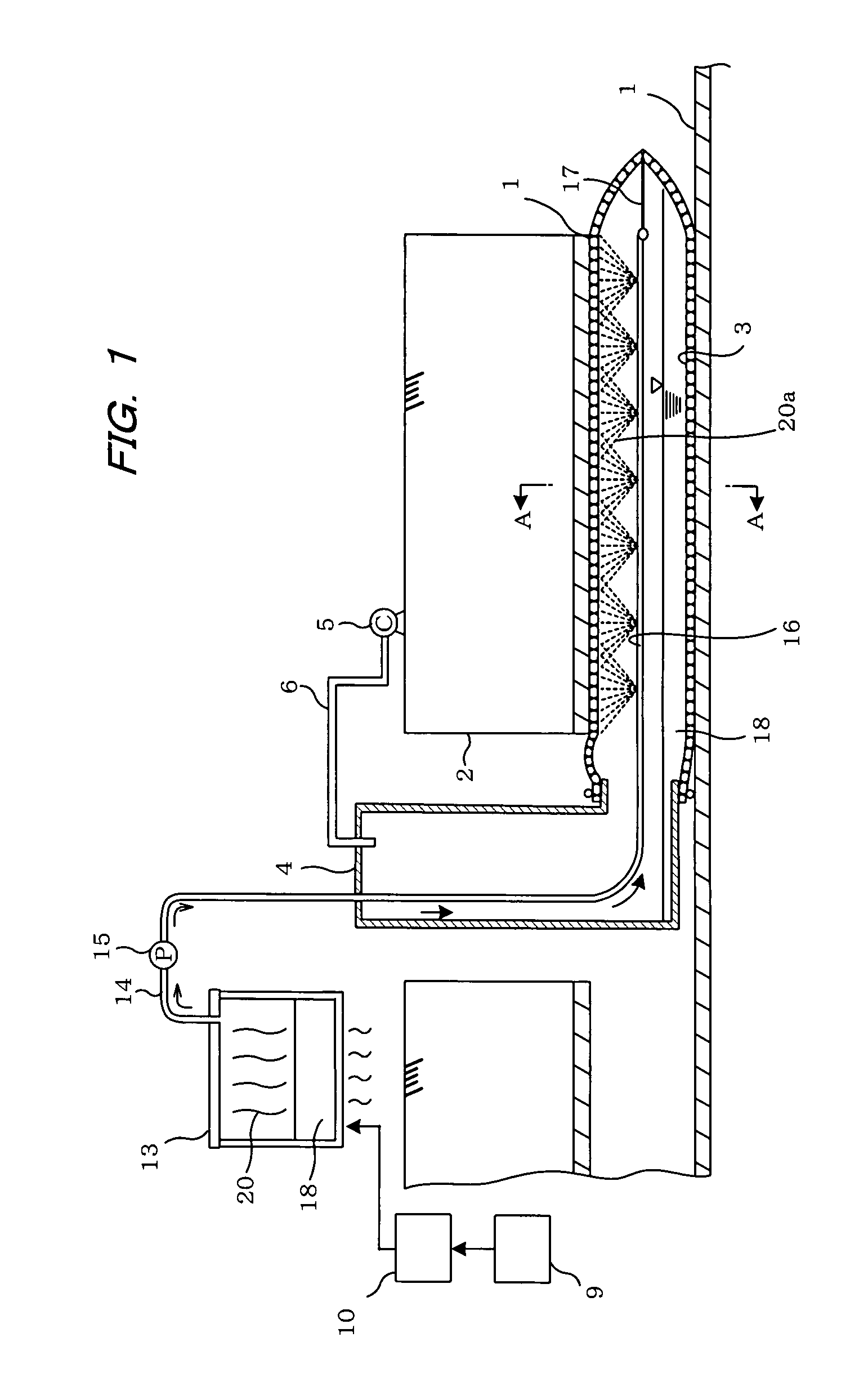

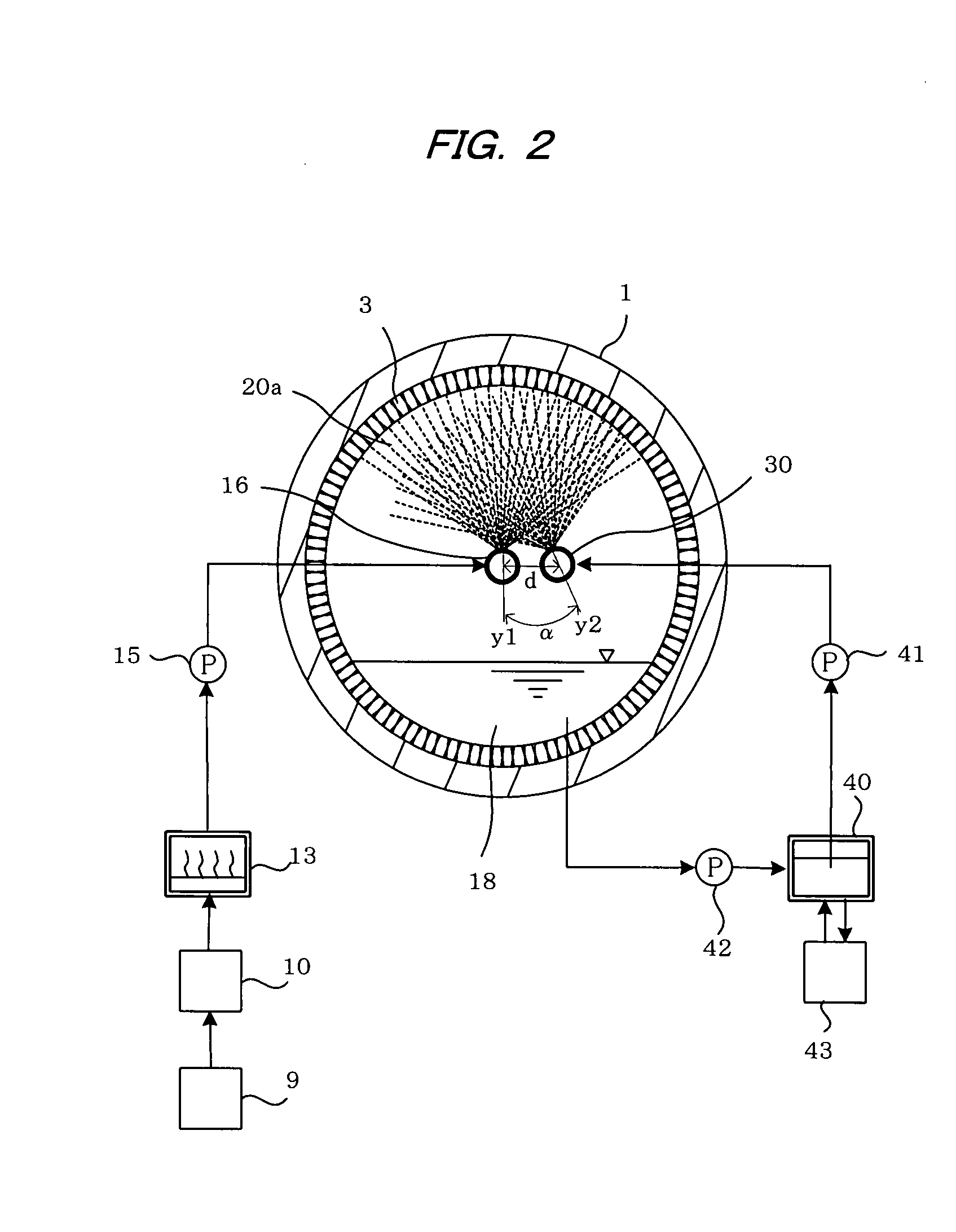

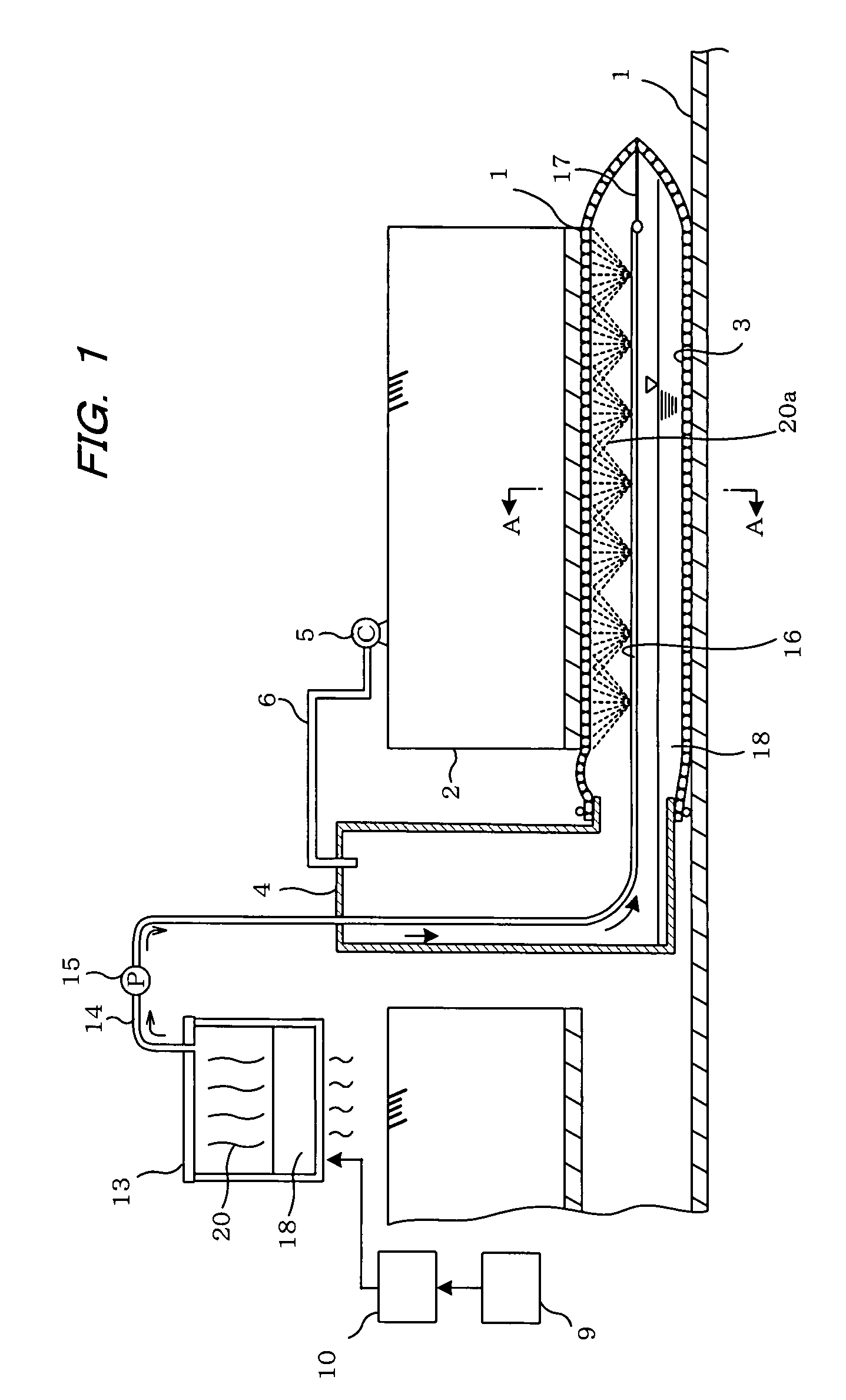

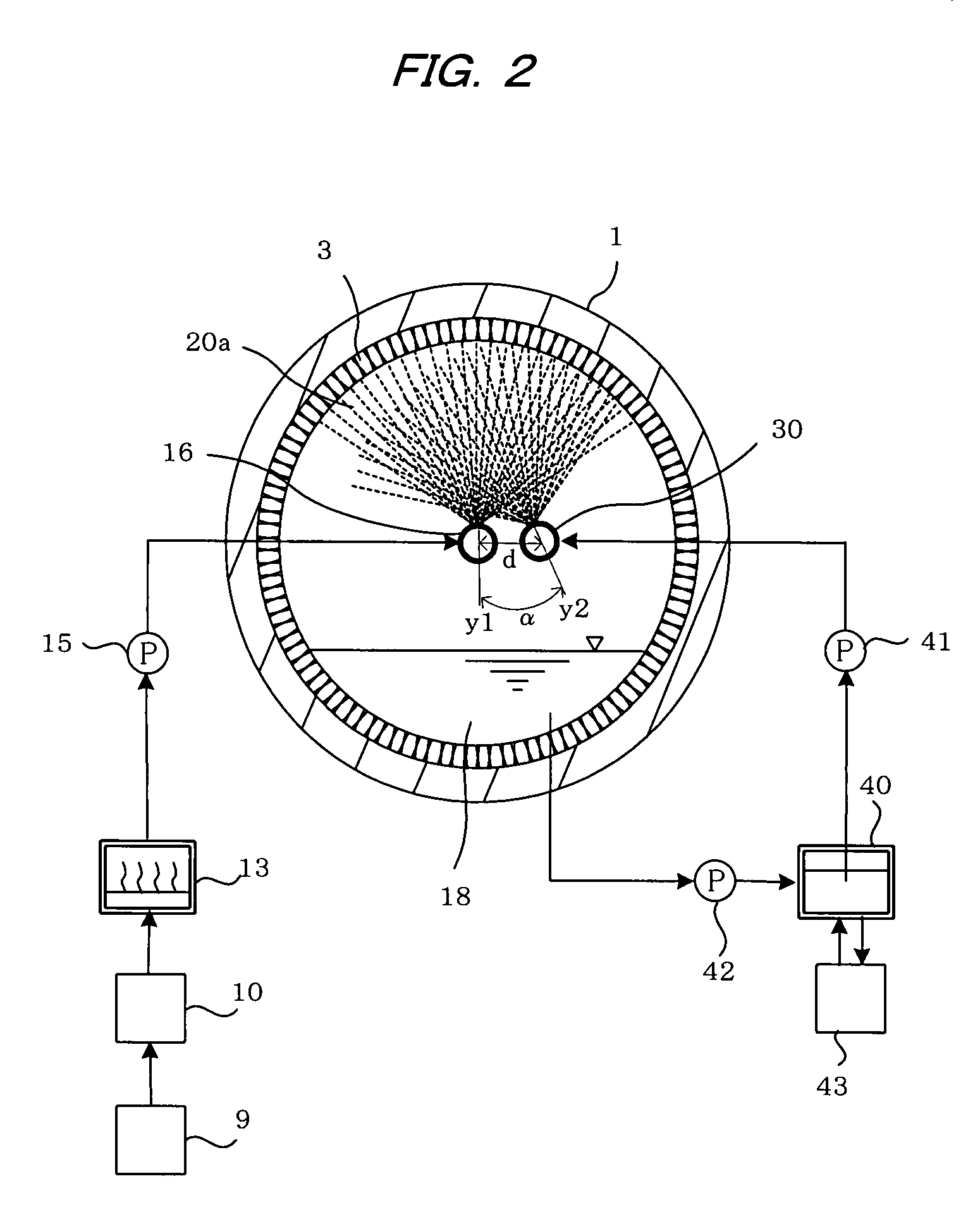

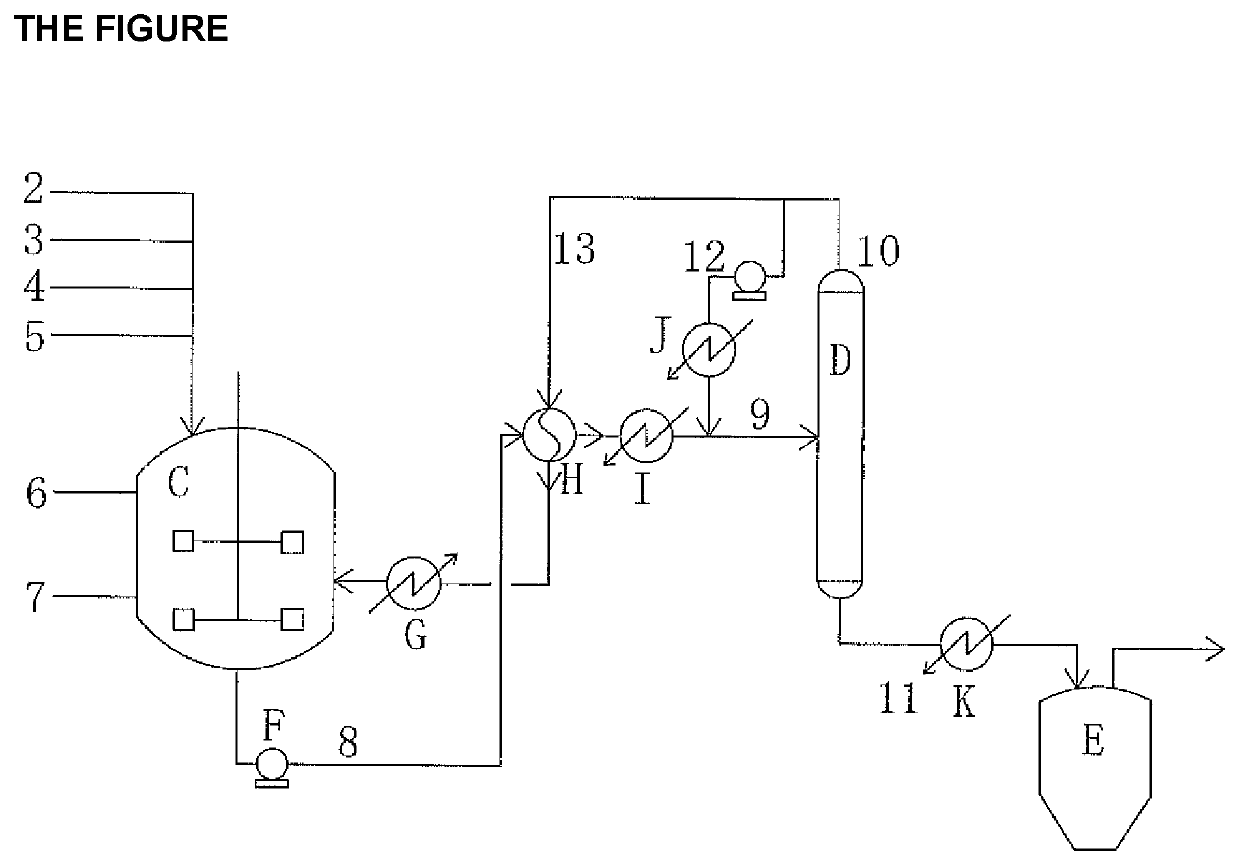

Pipeline lining method

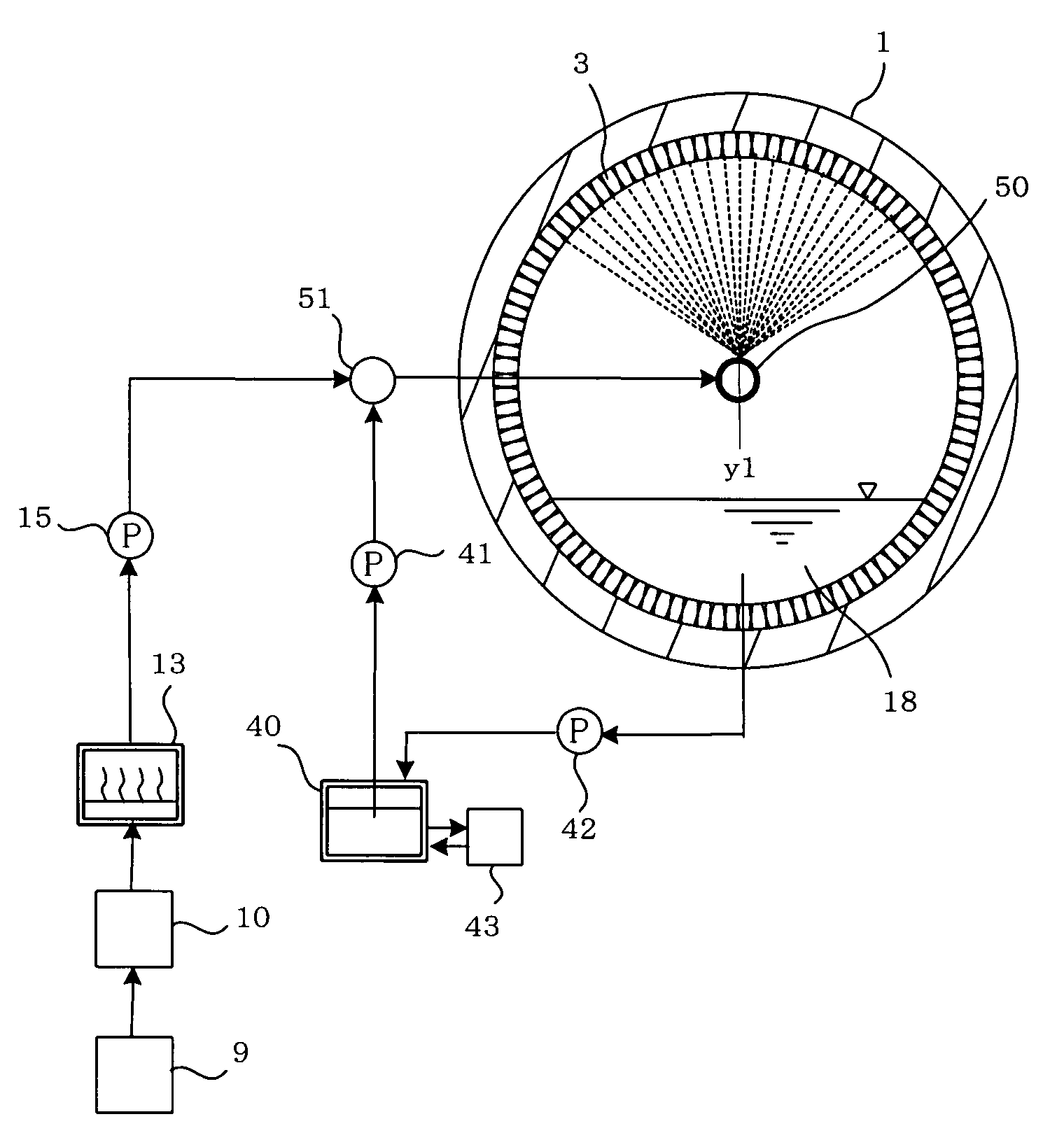

InactiveUS20070275162A1Reduce the amount requiredMinimize amount of waterLiquid surface applicatorsLaminationWater wheelThermal water

A tubular pipe lining material impregnated with a thermosetting resin is inserted into a pipeline and made to expand and press against an inner peripheral surface thereof. Hot water or steam is sprayed onto the pipe lining material to cure the thermosetting resin impregnated therein. Hot water that has accumulated in a bottom part of the pipe lining material is pumped out to an external location by a pump and cooled by a cooling device to generate cool water, which is then sprayed via a hose onto the cured pipe lining material to thereby cool the heated pipe lining material. This enables the thermally cured pipeline lining material to be reliably cooled and rendering a water truck unnecessary that is required at a construction site to supply additional cooling water.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

Fluorine-containing polymer composition and cured body

InactiveUS7521509B2Reduce pointsDelay transitionOther chemical processesPolymer sciencePtru catalyst

Owner:DAIKIN IND LTD

Pipeline lining method

InactiveUS7713374B2Reduce the amount requiredMinimize amount of waterLaminationLamination apparatusThermal waterMechanical engineering

A pipe lining material is inserted into a pipeline and expanded to press against an inner peripheral surface of the pipeline. Hot water from a first fluid source is sprayed onto the pipe lining material via a hose to cure the thermosetting resin impregnated therein and thereby cure the pipe lining material, with the sprayed hot water being accumulated in a bottom part of the pipe lining material. The hot water accumulated in the bottom part of the pipe lining material is delivered to a second fluid source separate and independent from the first fluid source, cooled in the second fluid source to provide cooling water, and supplied to the hose. The cooling water is sprayed onto the cured pipe lining material via the hose to cool the cured pipe lining material.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

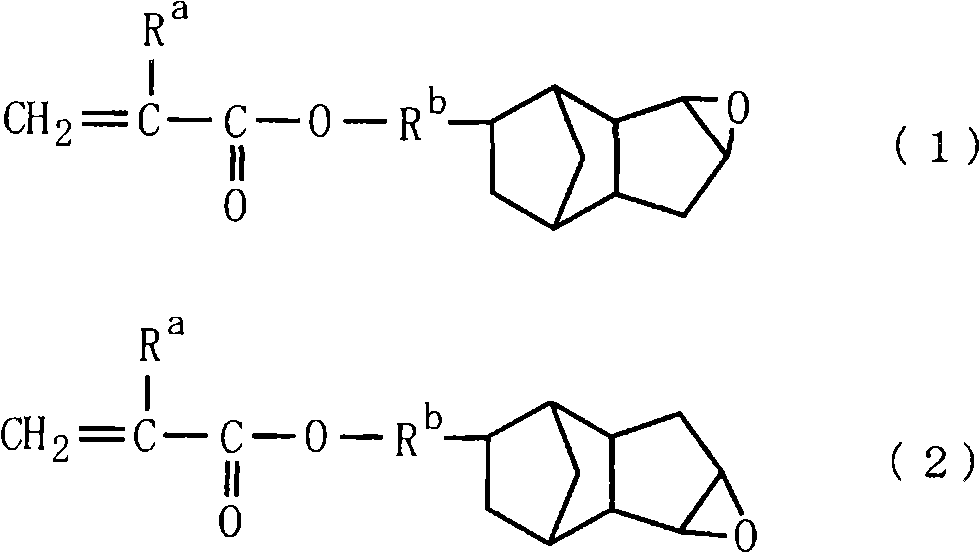

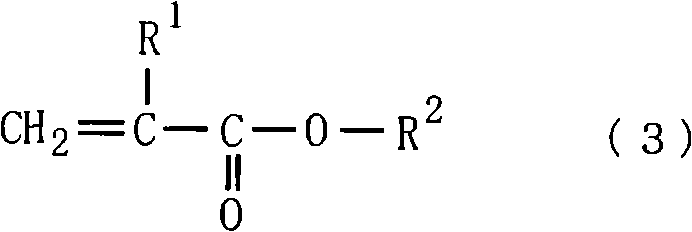

Photo- and/or thermo-curable copolymer, curable resin compositions, and cured articles

A photo- and / or thermo-curable copolymer having polymerizable unsaturated groups in side chains, prepared from both a copolymer (P) comprising monomer units derived from a carboxyl-containing polymerizable unsaturated compound (A) and monomer units derived from at least one epoxy-containing polymerizable unsaturated compound (B) represented by the general formula (1) or (2) and an epoxy-containingpolymerizable unsaturated compound (C) through addition reaction of part of the carboxyl groups of the copolymer (P) with the epoxy group of the compound (C) (wherein R's are each hydrogen or alkyl having 1 to 4 carbon atoms; and R's are each a single bond or C1-12 alkylene which may contain a heteroatom). The curable copolymer exhibits excellent synthesis stability and storage stability and excellent curing characteristics and permits both epoxy crosslinking and radical crosslinking.

Owner:DAICEL CORP

Coating compositions incorporating ingredients having secondary amine, hydroxyl and isocyanate functionality

ActiveUS20130231441A1Excellent performanceExcellent mold release characteristicSynthetic resin layered productsPolyurea/polyurethane coatingsIsocyanateVolatile organic compound

The present invention provides coating compositions with excellent curing performance. Curing can occur very rapidly for excellent cycle time, yet with minimal (if any) foaming. A preferred catalyst system helps to provide excellent initial and follow through cure through the entirety of the coating thickness, even with respect to in-mold coating (IMC) applications. Preferred aspects of the invention provide a composition having zero, or nearly zero, emissions of volatile organic compounds (VOC) when applied and cured.

Owner:THE SHERWIN WILLIAMS HEADQUARTERS CO

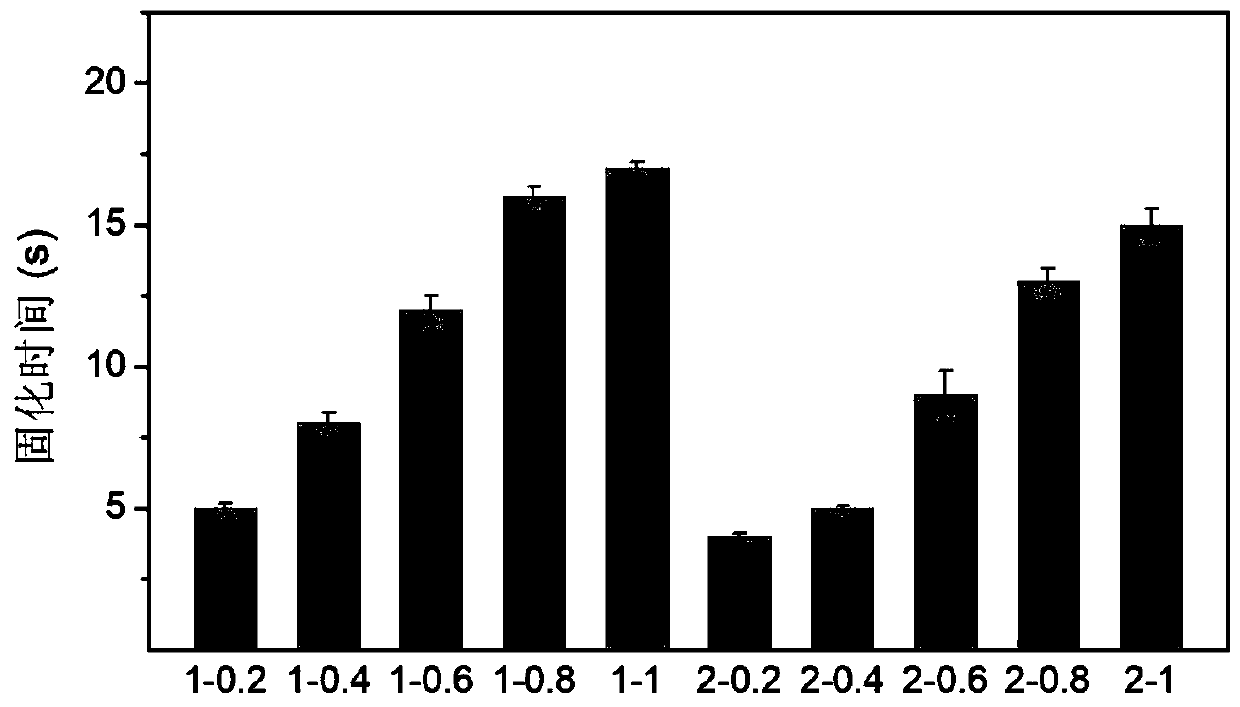

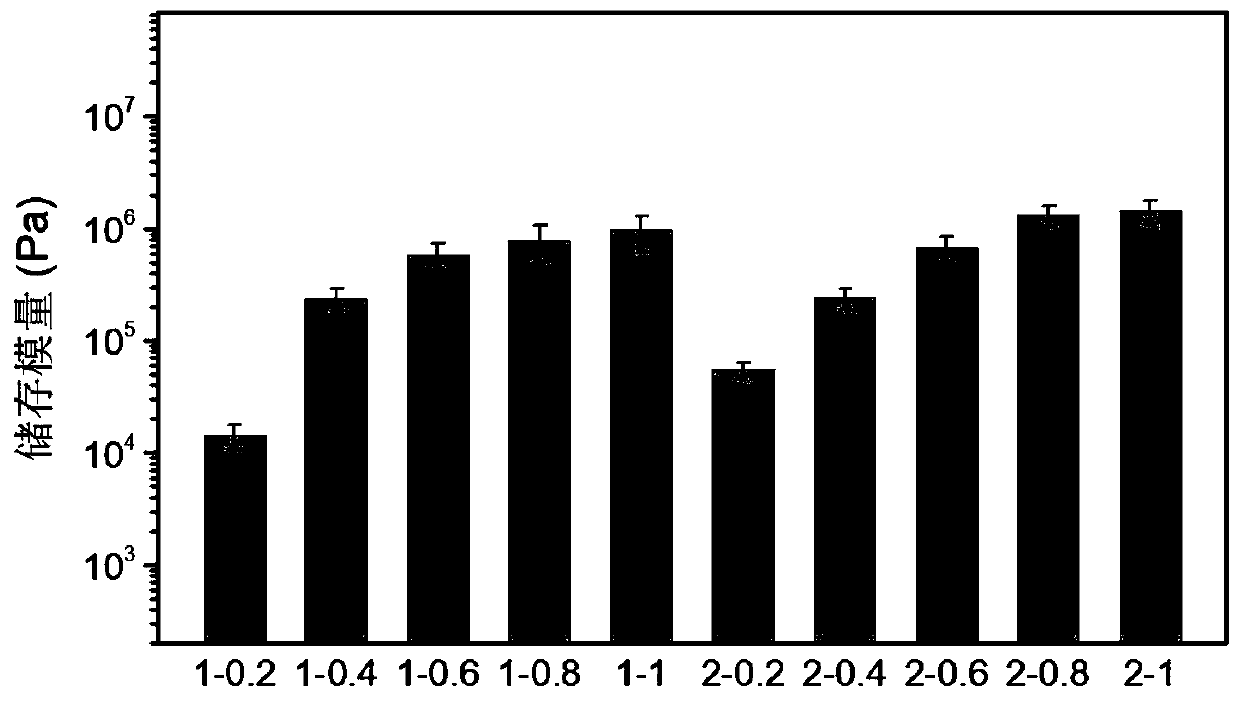

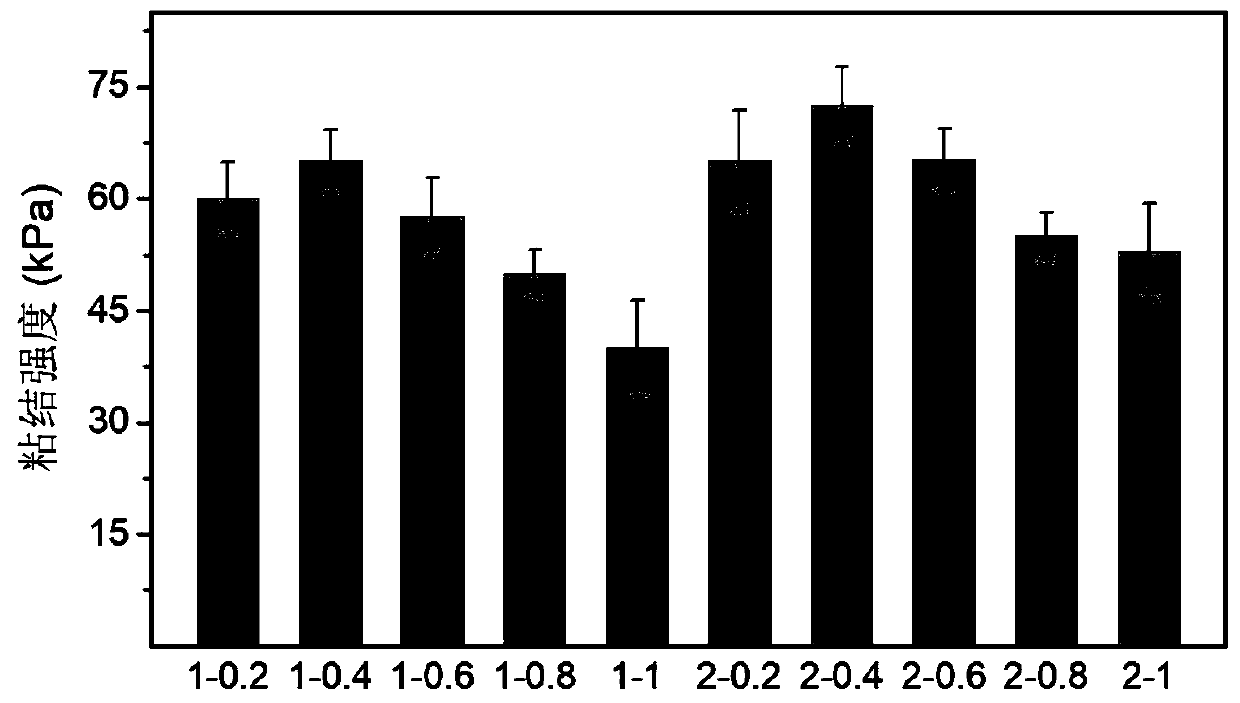

Preparation method of medical adhesive

The invention provides a preparation method of a medical adhesive, and belongs to the field of biomedical materials. The solvent-free UV-excited medical adhesive which is liquid at room temperature isprepared by mixing a thiol-terminated hyperbranched polymer and a small amount of polyethylene glycol containing unsaturated double bonds. Due to the hydrophobicity of the hyperbranched polymer, multiple thiol groups at the tail end and flowability without a solvent, the adhesive shows high adhesive strength. The adhesive provided by the invention can be quickly cured under low-dose ultraviolet light, so that the damage of high-dose ultraviolet light to surrounding healthy tissues is reduced. In addition, the adhesive has an elastic modulus close to that of human soft tissues, so that the comfort of a patient is improved; and meanwhile, the adhesive shows low swelling property and low cytotoxicity, and has a great application prospect as a medical adhesive.

Owner:JIANGNAN UNIV

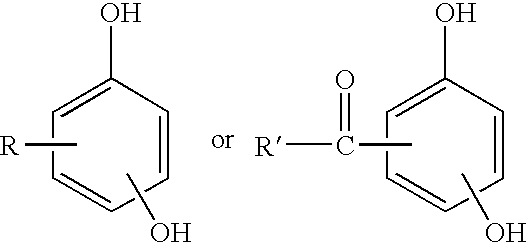

Synthesis method for beta-naphthol modified phenolic resin

The invention discloses a synthesis method for beta-naphthol modified phenolic resin. The synthesis method comprises the following steps: adding beta naphthol and phenol in an batch reactor according to the ratio of (1:2)-(1:6), adding hydrochloric acid, wherein the mole dosage of hydrogen chloride or sulfuric acid accounts for 6-20% of that of the phenol and water is used as a solvent, heating to 80-90 DEG C, adding paraformaldehyde or a formaldehyde aqueous solution, wherein the mole dosage of formaldehyde is two times of that of the phenol. According to the invention, since beta-naphthol is used as modified material of phenolic resin, compared with common melamine, lignin or cardanol modification, the following advantages are achieved: the final bonding density of the phenolic resin is enhanced, the curing characteristic of phenolic resin is improved, and for the curing condition, high temperature curing is changed into room temperature curing; in addition, compared with original resorcinol modified phenolic resin, the beta-naphthol modified phenolic resin has the advantages that application time is obviously prolonged, and fire-proof coating construction of high-rise buildings is facilitated.

Owner:江苏常州酞青新材料科技有限公司

Curable base-resistant fluoroelastomers

InactiveUS7576164B2Improve adhesionExcellent characteristicsFibre treatmentSpecial tyresTetrafluoroethyleneDual cure

Compositions of fluoroelastomers containing copolymerized units of tetrafluoroethylene, propylene, a first cure site selected from the group consisting of i) trifluoroethylene, ii) 3,3,3-trifluoropropene-1, iii) 1,2,3,3,3-pentafluoropropylene, iv) 1,1,3,3,3-pentafluoropropylene, and v) 2,3,3,3-tetrafluoropropene, and a second cure site selected from the group consisting of i) copolymerized units of a brominated cure site monomer, ii) copolymerized units of an iodinated cure site monomer, iii) copolymerized units of a chlorinated cure site monomer, iv) brominated endgroups, v) iodinated endgroups and vi) a combination of any of i)-v) are readily curable with polyhydroxy curing systems. The resulting cured articles have a combination of excellent resistance to alkaline fluids, superior tensile properties and compression set resistance, and excellent adhesion to metal substrates. Optionally, the fluoroelastomers may be dual cured by both a polyhydroxy system and an organic peroxide system.

Owner:THE CHEMOURS CO FC LLC

One part epoxy resin including acrylic block copolymer

InactiveUS20130146816A1Improve abilitiesImprove moisture resistanceConductive materialSolid-state devicesEpoxyAnisotropic conductive film

An adhesive composition comprising a phenoxy resin, a latent hardener, an acrylic block co-polymer dispersant and a weak solvent wherein the dispersant enables the phenoxy resin to be dispersed in a weak solvent that does not attack the latent hardener thereby providing a composition with good shelf life. The compositions are useful in making anisotropic conductive films.

Owner:TRILLION SCI INC

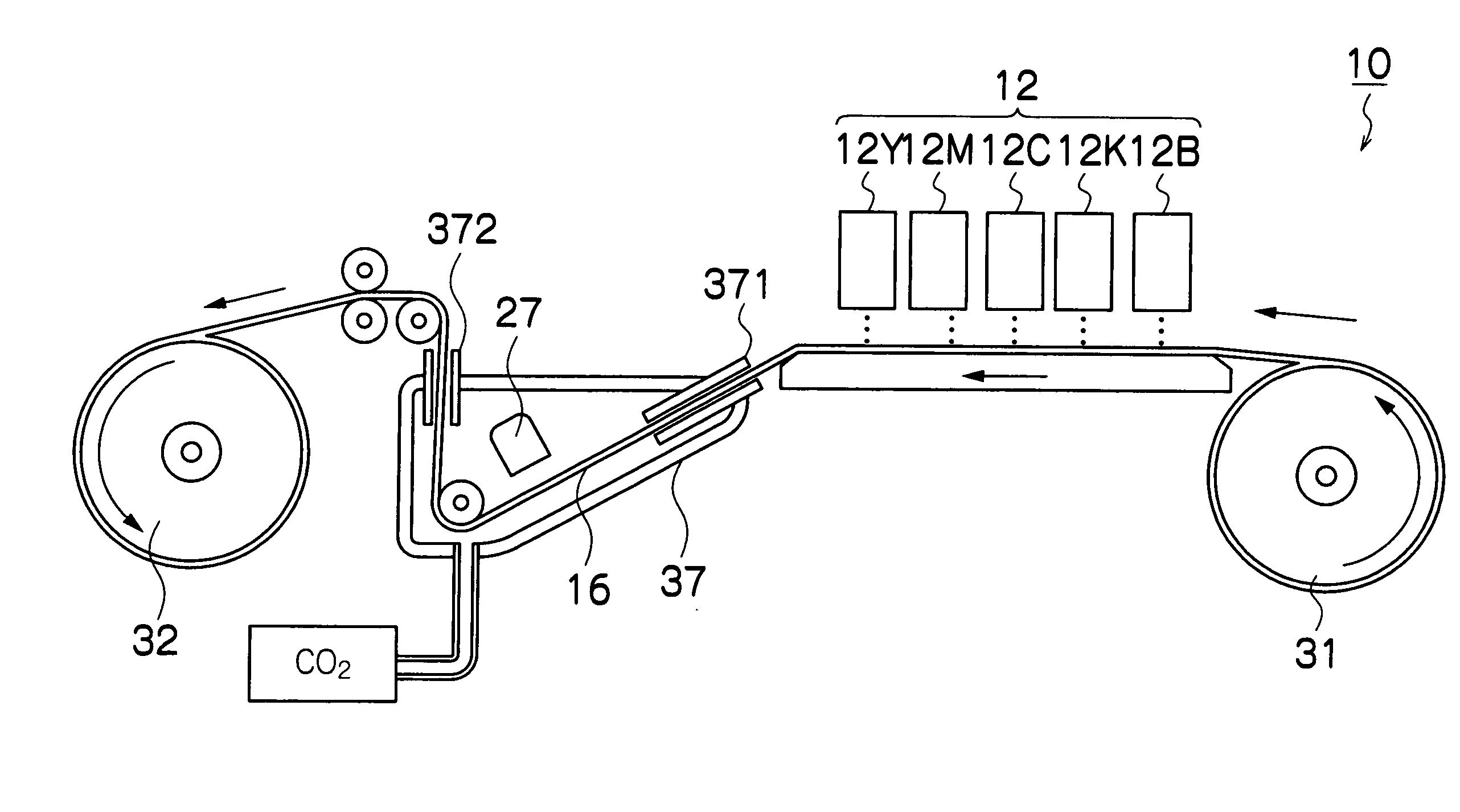

Inkjet recording apparatus

InactiveUS7806514B2Preventing Image Quality DeteriorationAvoid interferenceInking apparatusDuplicating/marking methodsAcceleration voltageElectron

The inkjet recording apparatus which forms an image on a recording medium by applying a first liquid containing coloring material and a second liquid containing no coloring material or the coloring material of not greater than 0.1 wt %, on the recording medium, includes: a liquid application device which applies the second liquid on the recording medium and then ejects droplets of the first liquid toward the second liquid applied on the recording medium; and an electron beam irradiation device which radiates an electron beam on the first liquid and the second liquid on the recording medium, wherein: at least one of the first liquid and the second liquid contains a polymerizable compound which is polymerized when irradiated with the electron beam; and the electron beam irradiation device radiates the electron beam at an acceleration voltage of 40 kV through 60 kV.

Owner:FUJIFILM CORP

Coating compositions incorporating ingredients having secondary amine, hydroxyl and isocyanate functionality

ActiveUS9469779B2Facilitated releaseImprove curing effectSynthetic resin layered productsPolyurea/polyurethane coatingsAdditive ingredientCycle time

The present invention provides coating compositions with excellent curing performance. Curing can occur very rapidly for excellent cycle time, yet with minimal (if any) foaming. A preferred catalyst system helps to provide excellent initial and follow through cure through the entirety of the coating thickness, even with respect to in-mold coating (IMC) applications. Preferred aspects of the invention provide a composition having zero, or nearly zero, emissions of volatile organic compounds (VOC) when applied and cured.

Owner:SWIMC LLC

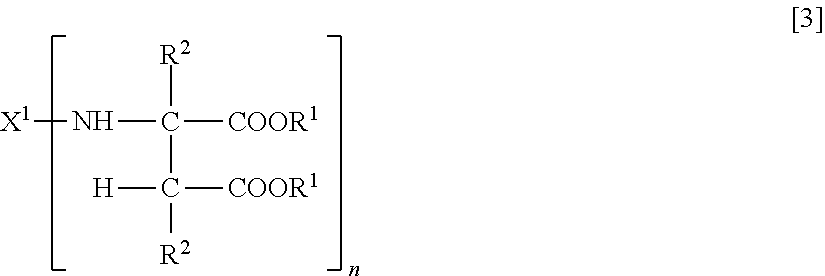

ETHYLENE/alpha-OLEFIN/NON-CONJUGATED POLYENE COPOLYMER, METHOD FOR PRODUCING THE SAME, AND USE THEREOF

PendingUS20210009730A1Low long-chain branching contentGood curing propertiesSpecial tyresPolymer scienceAlkene

An object of the present invention is to provide a novel ethylene / α-olefin / non-conjugated polyene copolymer containing a certain non-conjugated polyene such as VNB as a copolymerization component, having a low long-chain branching content, excellent in cure characteristics in the case of crosslinking by using peroxide, and having good processability. The ethylene / α-olefin / non-conjugated polyene copolymer according to the present invention has constitutional units derived from ethylene (A), an α-olefin (B) having 3 to 20 carbon atoms, and a non-conjugated polyene (C) having a total of two or more partial structures selected from the group consisting of the following general formulas (I) and (II) in a molecule, and satisfies certain requirements.

Owner:MITSUI CHEM INC

Preparation method of epoxy compound having alkoxysilyl group, epoxy compound having alkoxysilyl group, composition comprising the same, and use thereof

ActiveUS10968308B2Improve compoundMinimizing an EEW increaseGroup 4/14 element organic compoundsCarbamic acid derivatives preparationEpoxyPolymer science

Provided are a preparation method of an epoxy compound having an alkoxysilyl group in which an increase in the epoxy equivalent weight (EEW) of the epoxy compound is minimized because alkoxysilylation occurs through a simple one-step reaction using a hydroxyl group formed during the synthesis of the epoxy compound, an epoxy compound having an alkoxysilyl group prepared by the method, a composition comprising the same, and a use thereof. The method includes the reaction of an epoxy compound having a hydroxyl group with an isocyanate alkoxysilane in the presence of amine-based base catalyst, wherein the epoxy compound having an alkoxysilyl group has a mole ratio of [epoxide group]:[alkoxysilyl group] of n:1 ranging from 2:1 to 10:1, and an EEW increase of the epoxy compound having an alkoxysilyl group is less than 260 / n. The epoxy compound has good physical properties when being cured.

Owner:KOREA INST OF IND TECH

A kind of preparation method of medical adhesive

ActiveCN111269427BHydrophobicHigh bonding strengthSurgical adhesivesPolyethylene glycolUltraviolet lights

The invention provides a preparation method of a medical adhesive, which belongs to the field of biomedical materials. A solvent-free, liquid UV-excited medical adhesive at room temperature was prepared by mixing a hyperbranched polymer with a thiol group at the end and a small amount of polyethylene glycol containing unsaturated double bonds. Due to the hydrophobicity of the hyperbranched polymer, the multiple thiol groups at the end, and the solvent-free flowability, the adhesive exhibits high adhesive strength. The adhesive provided by the invention can be quickly cured under low doses of ultraviolet light, thereby reducing the damage of large doses of ultraviolet light to surrounding healthy tissues. In addition, the adhesive has an elastic modulus close to that of human soft tissue, which increases the patient's comfort; at the same time, the adhesive exhibits low swelling and low cytotoxicity, and has great application prospects as a medical adhesive.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com