Patents

Literature

1190 results about "Electron beam irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

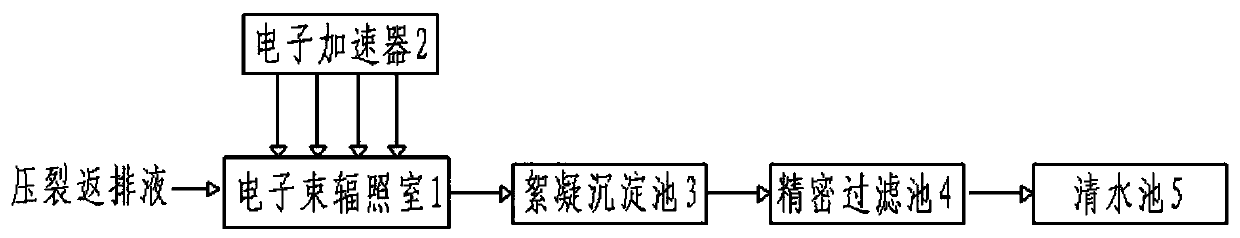

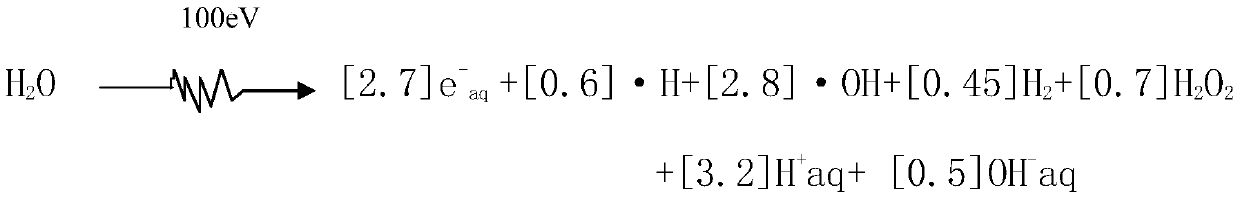

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

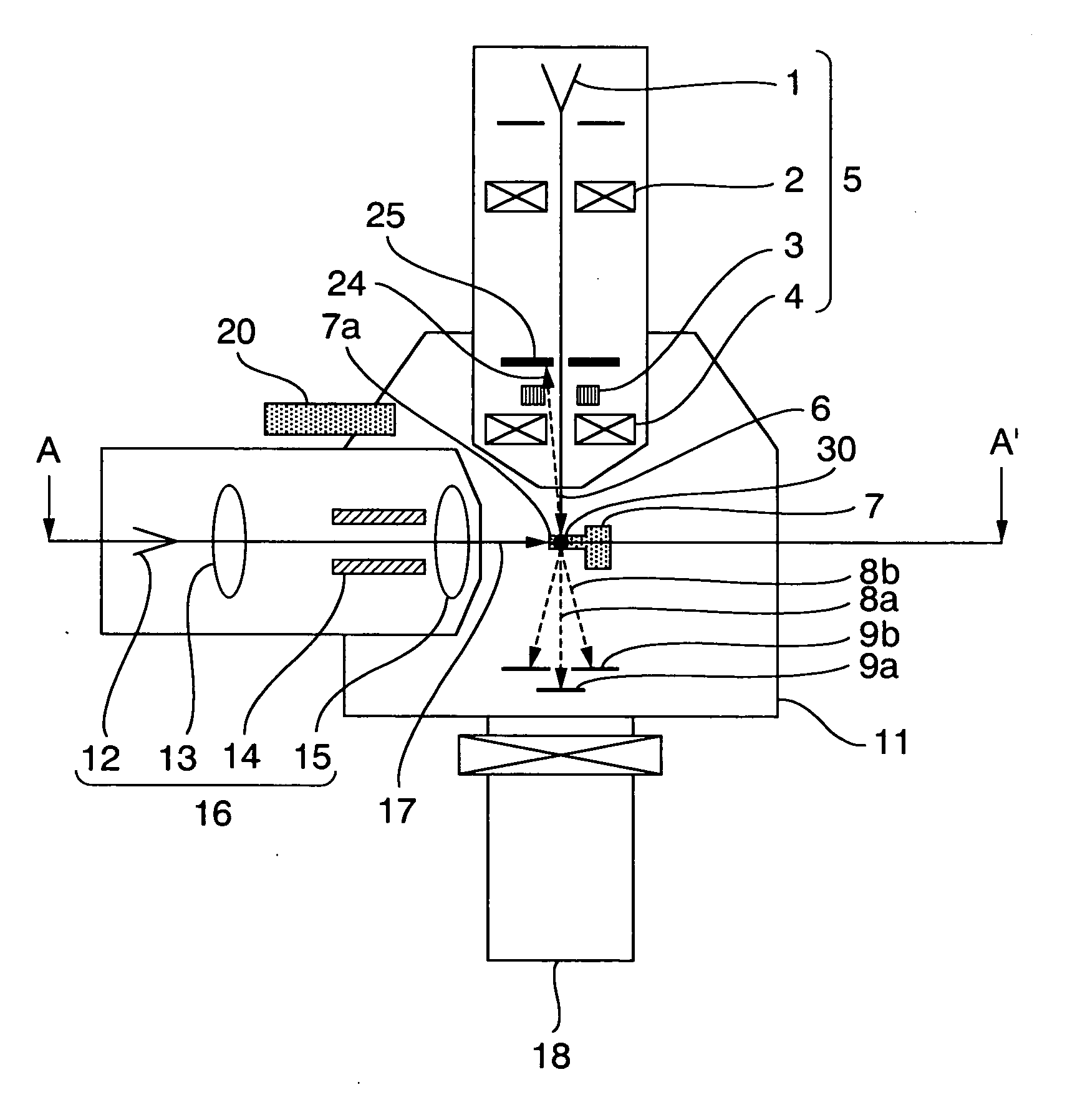

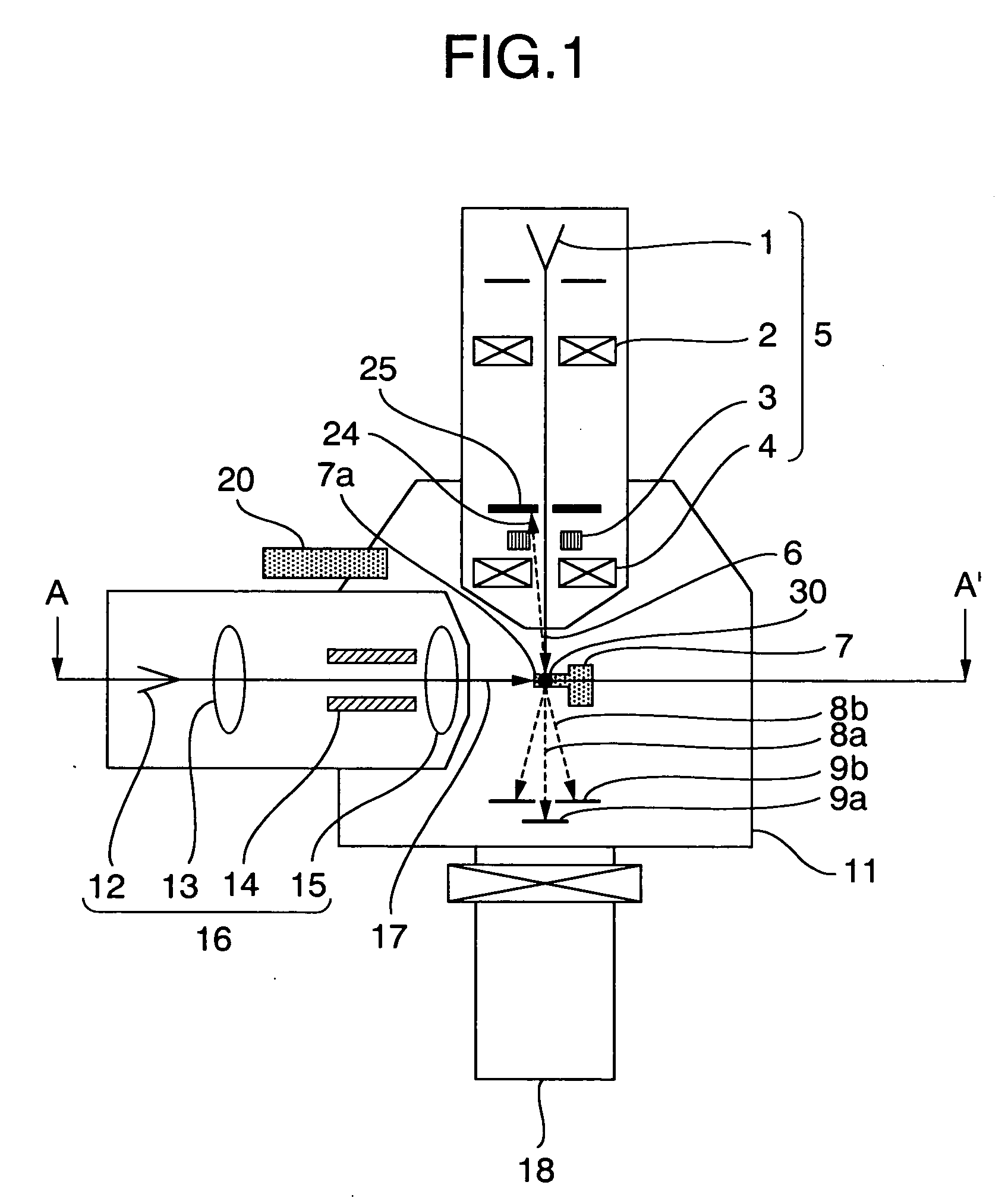

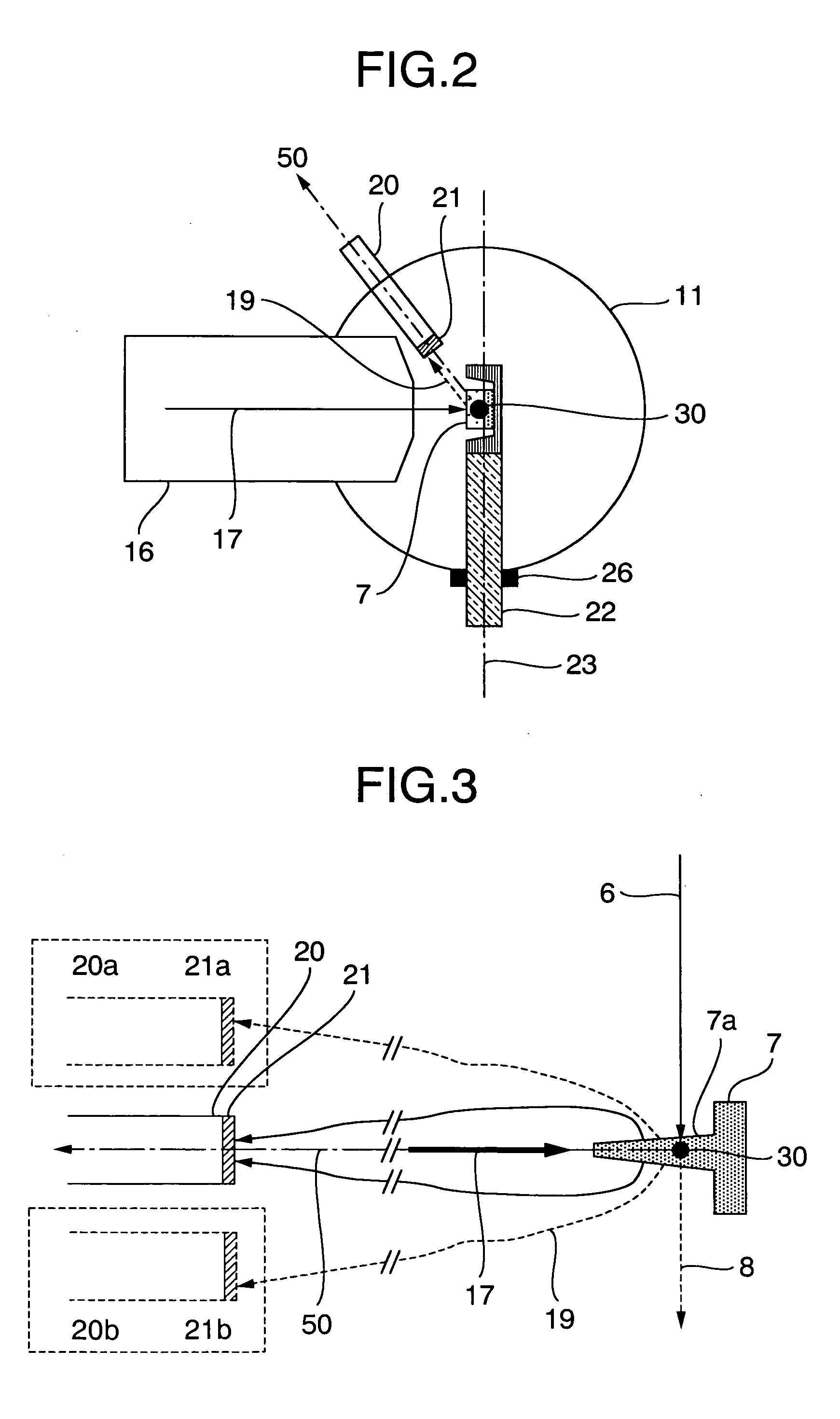

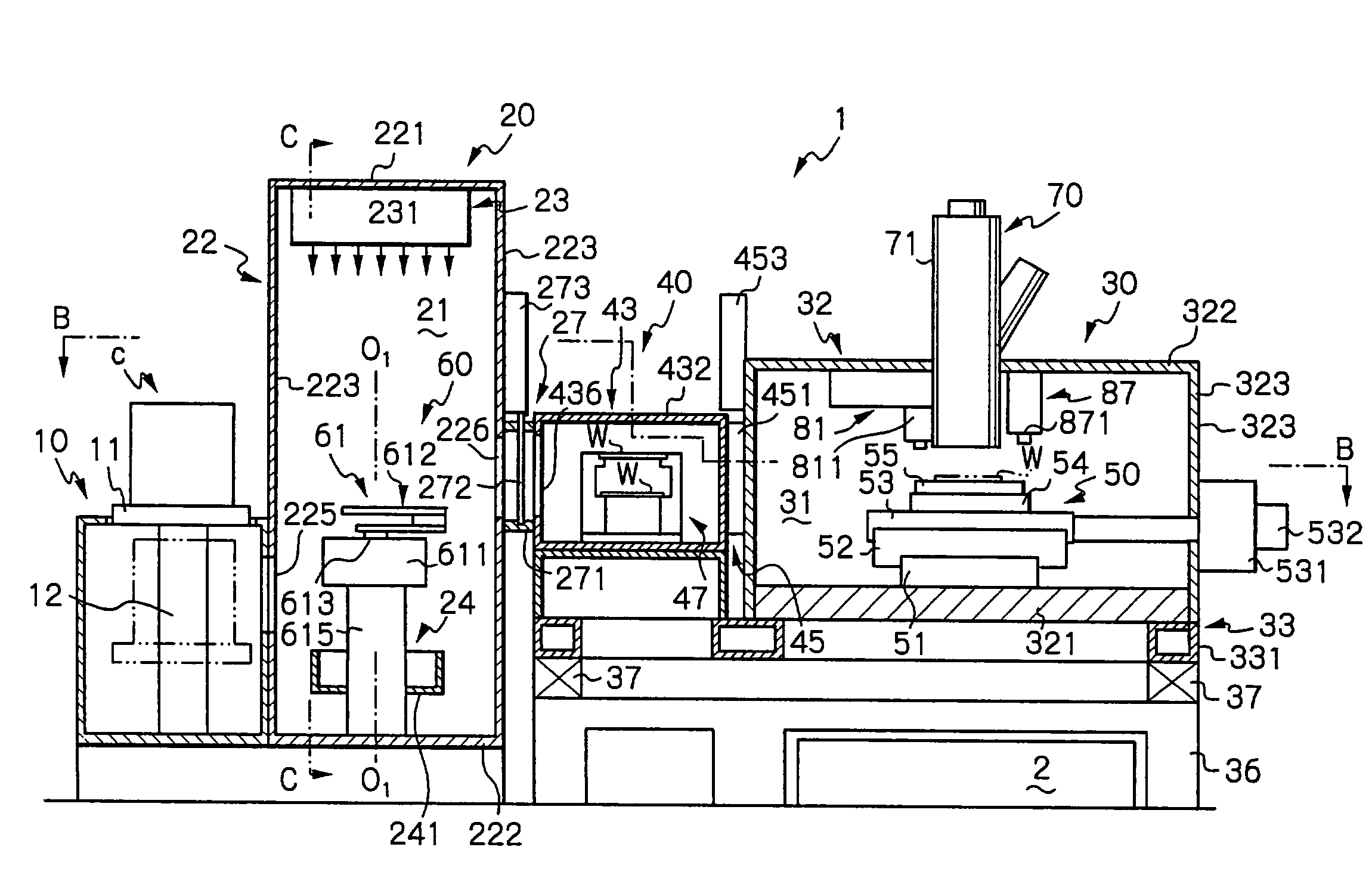

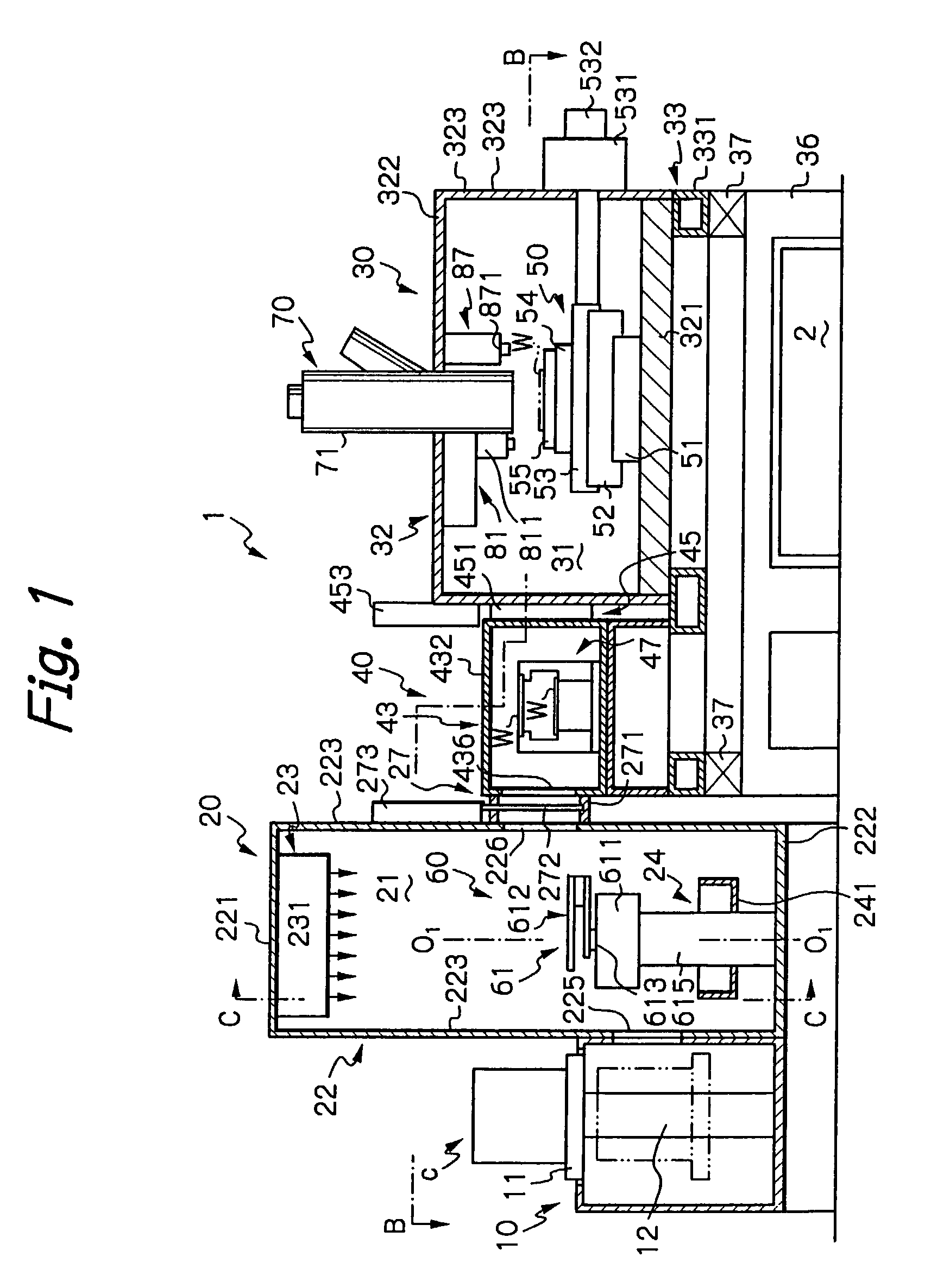

Charged particle beam apparatus and sample manufacturing method

ActiveUS20060097166A1Simplifying sample thickness optimization workReduced beam diameterMaterial analysis using wave/particle radiationElectric discharge tubesElectron beam irradiationIon beam irradiation

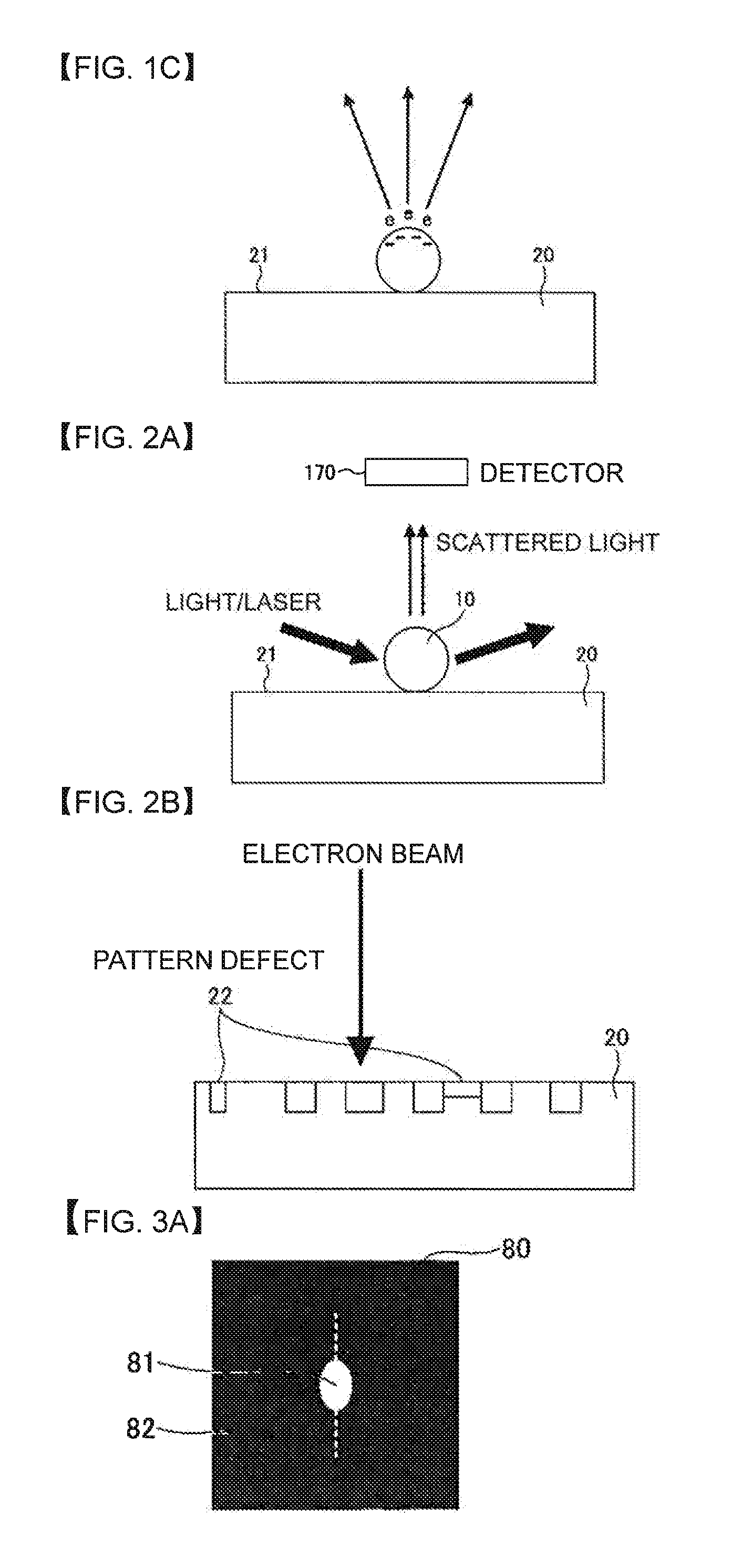

It is possible to carry out a highly accurate thin film machining by irradiation of an ion beam to a sample and a high-resolution STEM observation of the sample by irradiating an electron beam with a high throughput almost without moving the sample. The FIB irradiation system has an irradiation axis almost orthogonally intersecting an irradiation axis of the STEM observation electron beam irradiation system. The sample is arranged at the intersection point of the irradiation axes. The FIB machining plane of the sample is extracted from the thin film plane of the STEM observation sample. The transmitting / scattered beam detector are arranged at backward of the sample on the electron beam irradiation axis viewed from the electron beam irradiation direction.

Owner:HITACHI HIGH-TECH CORP

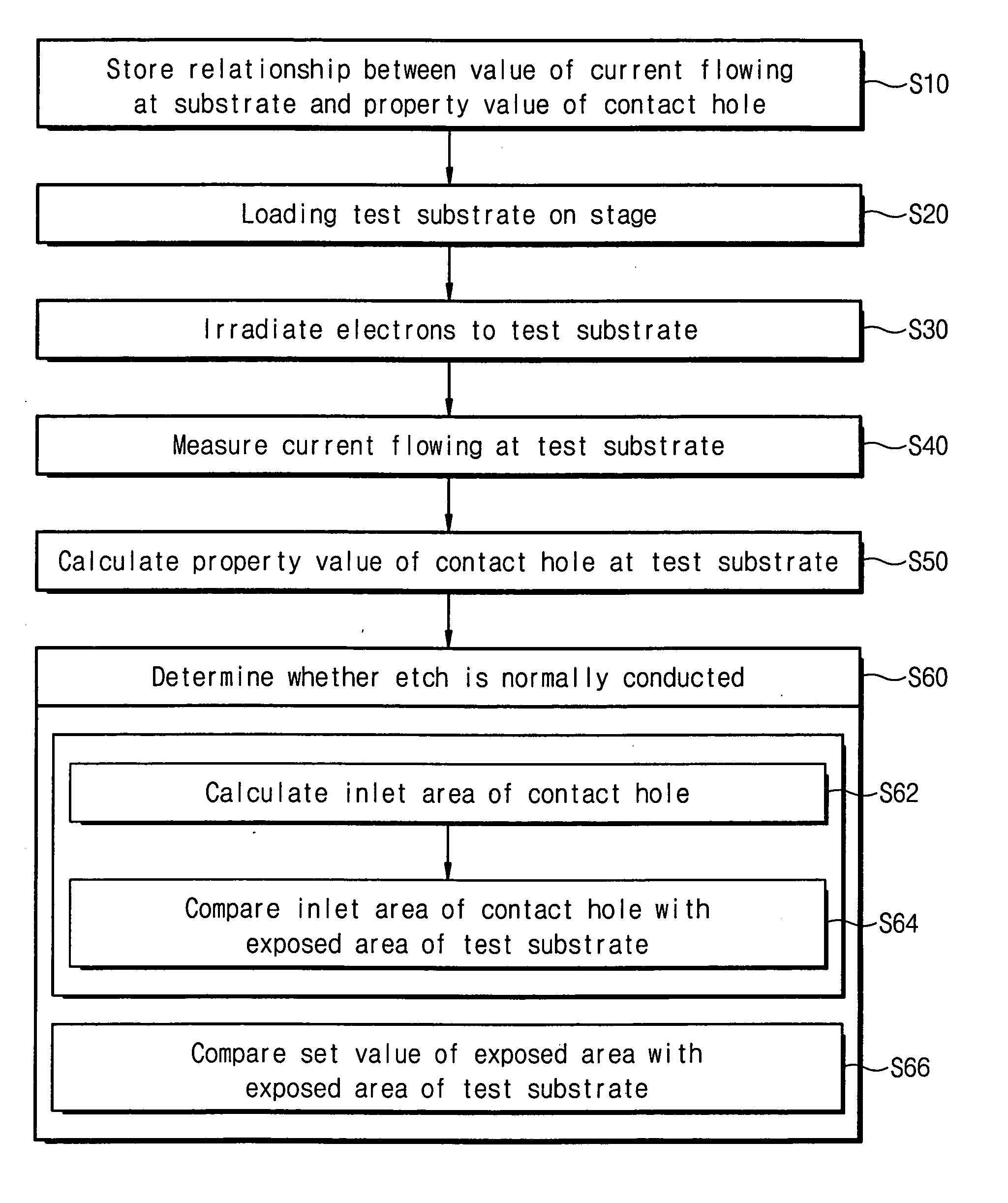

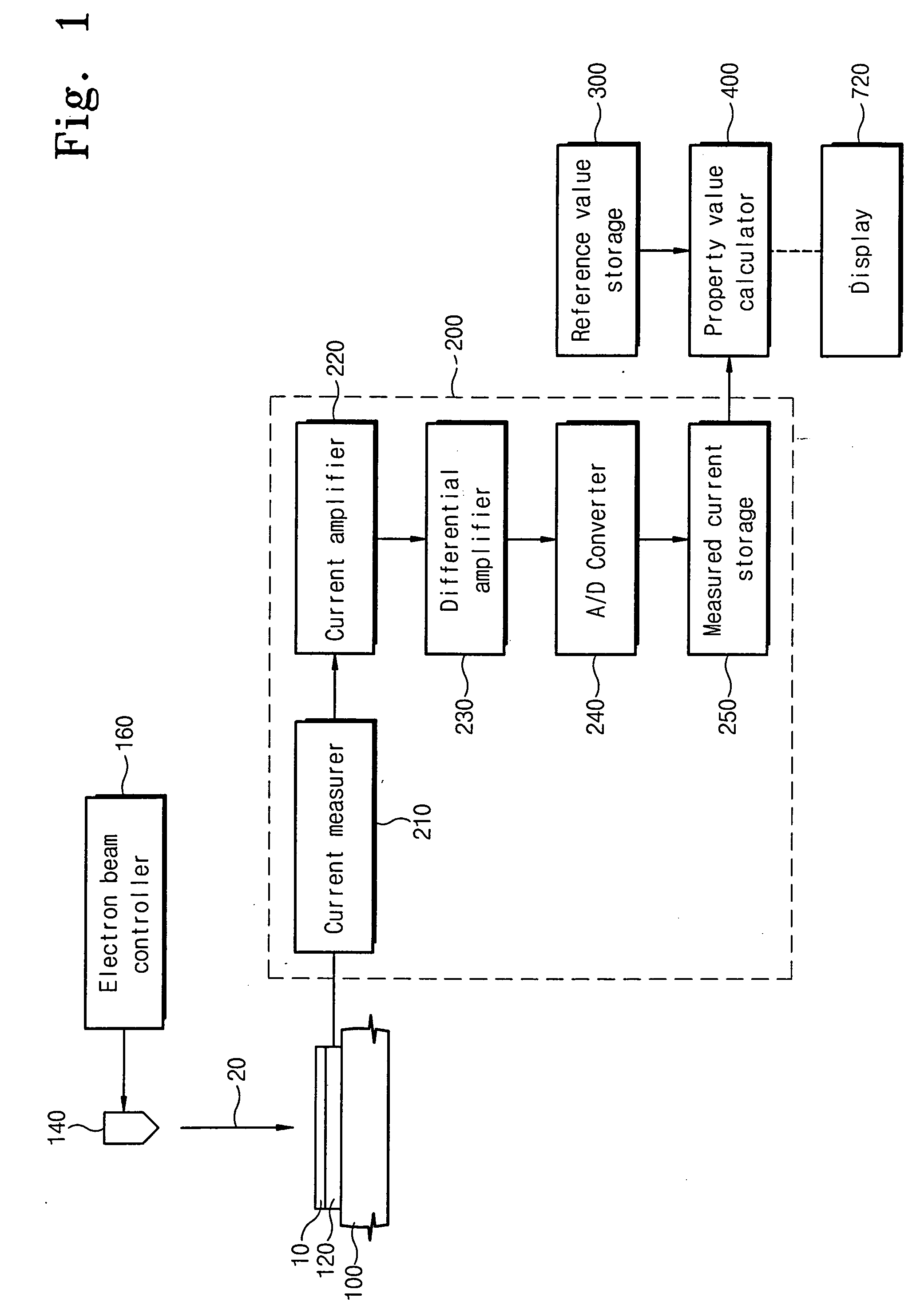

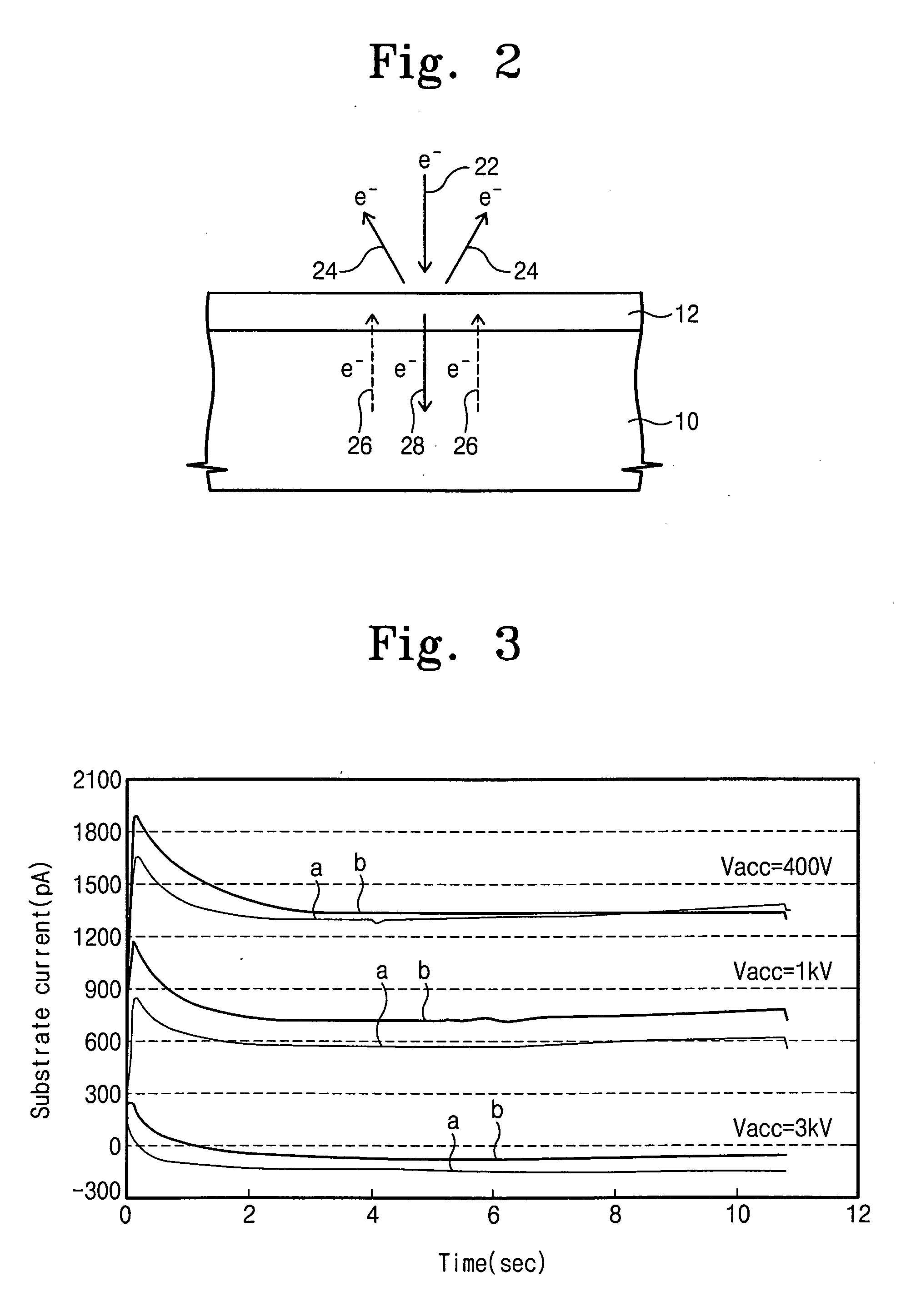

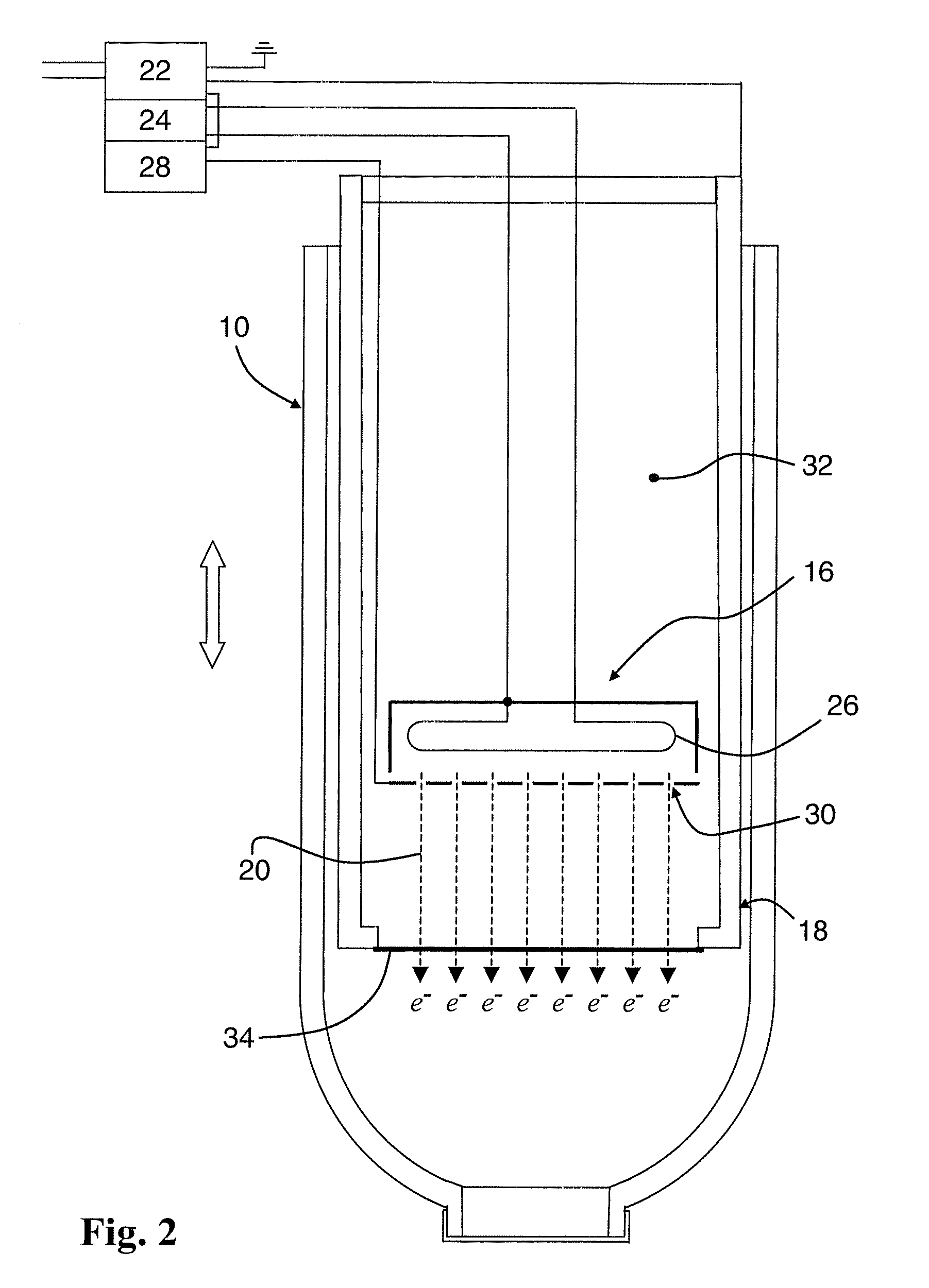

Apparatus and method for measuring substrates

InactiveUS20050191768A1Semiconductor/solid-state device testing/measurementElectric discharge tubesComputational physicsMeasurement device

A substrate measuring apparatus includes a reference value storage unit, an electron irradiator, a current measuring device, and a property value calculating device. The reference value storage unit stores data on the relationship between current flow in a sample substrate with a contact hole of known characteristics that is irradiated by an electron beam. The current measuring device measures current flow in a test substrate. The property value calculating device calculates the property value of the contact hole formed in a material layer of the test substrate using the current flow in the test substrate and the data stored in the reference value storage unit. The property values of the contact hole may be a surface area of underlying substrate exposed by a contact hole or an amount of residual material remaining in the contact hole.

Owner:SAMSUNG ELECTRONICS CO LTD

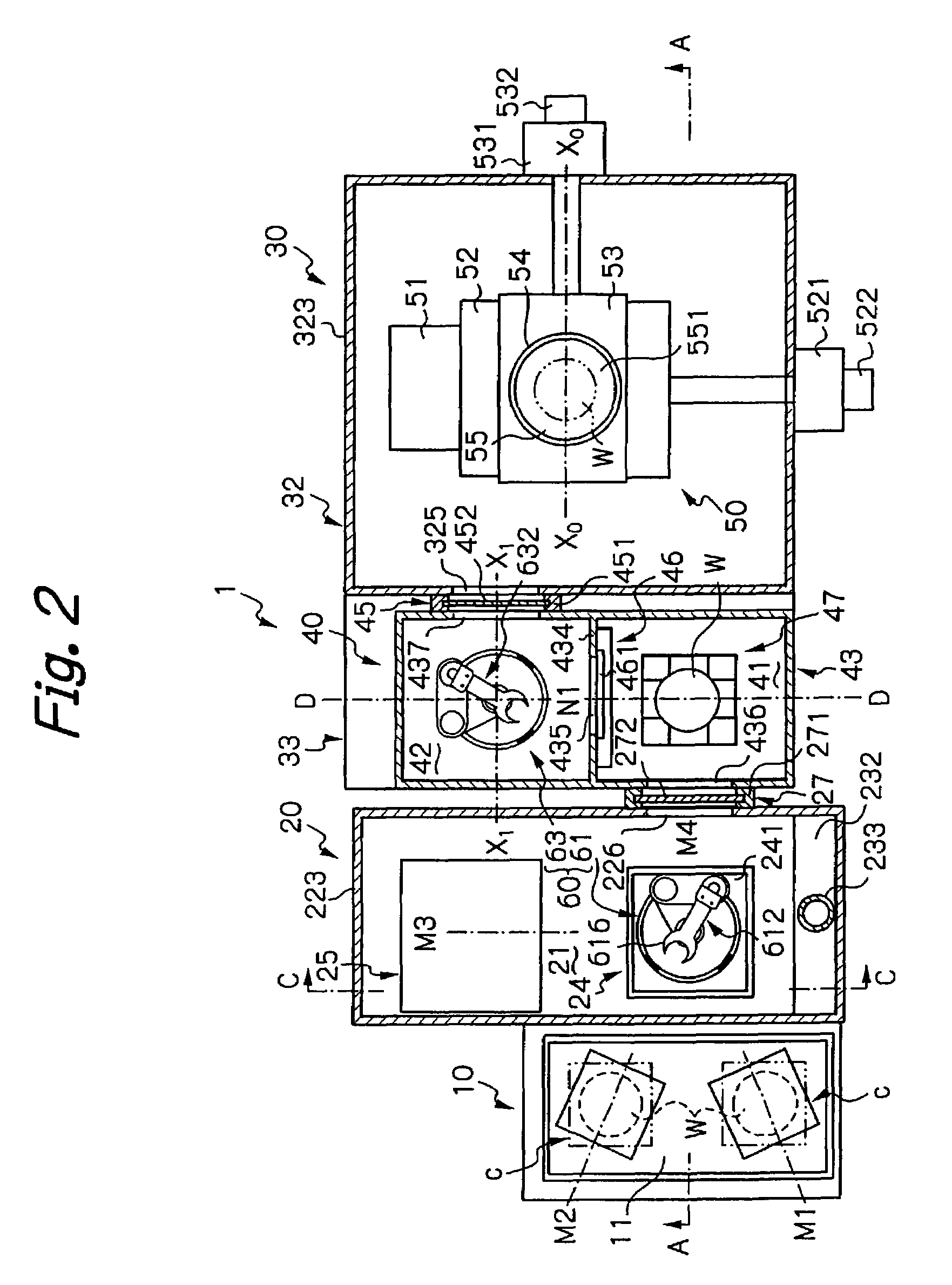

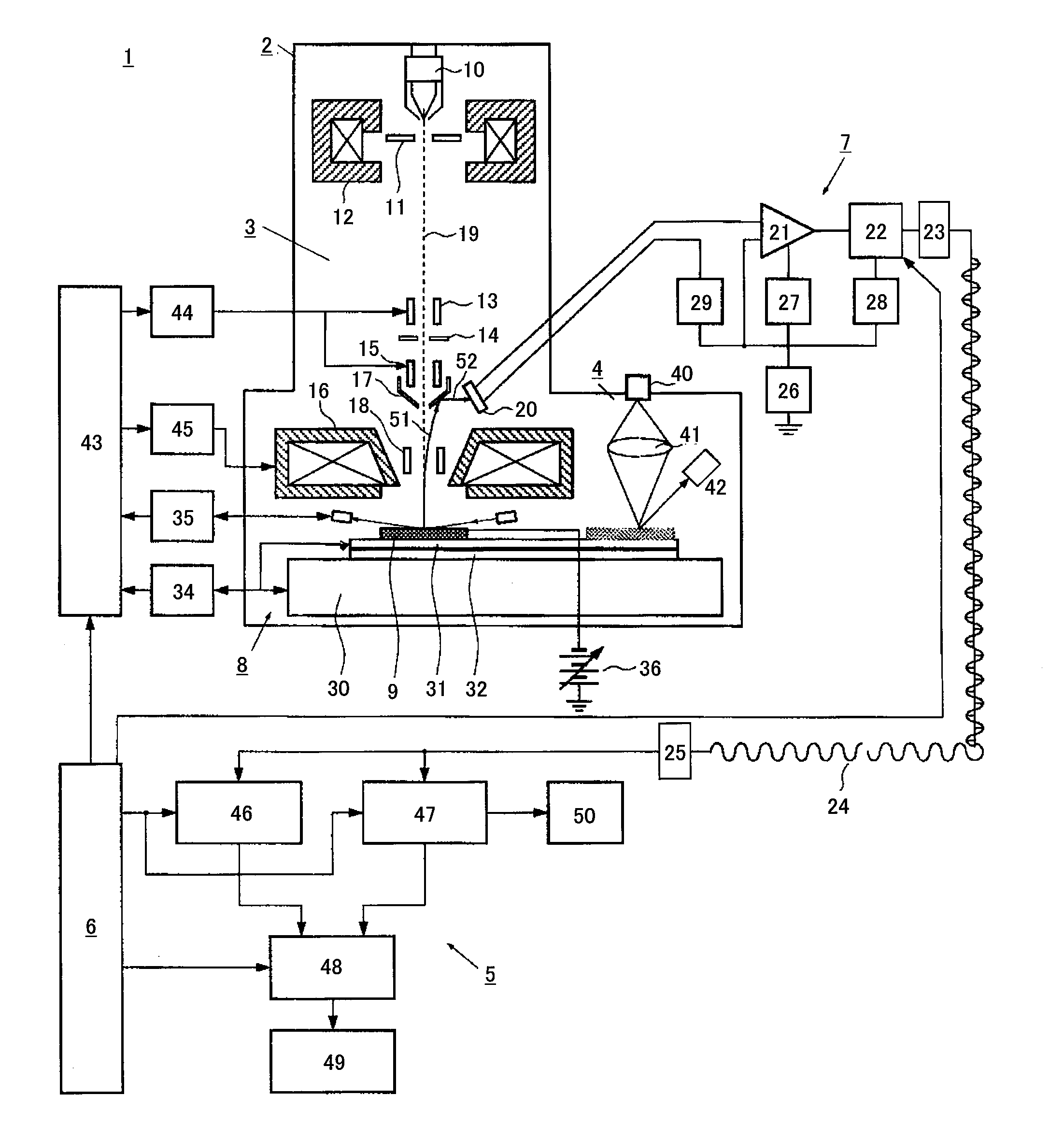

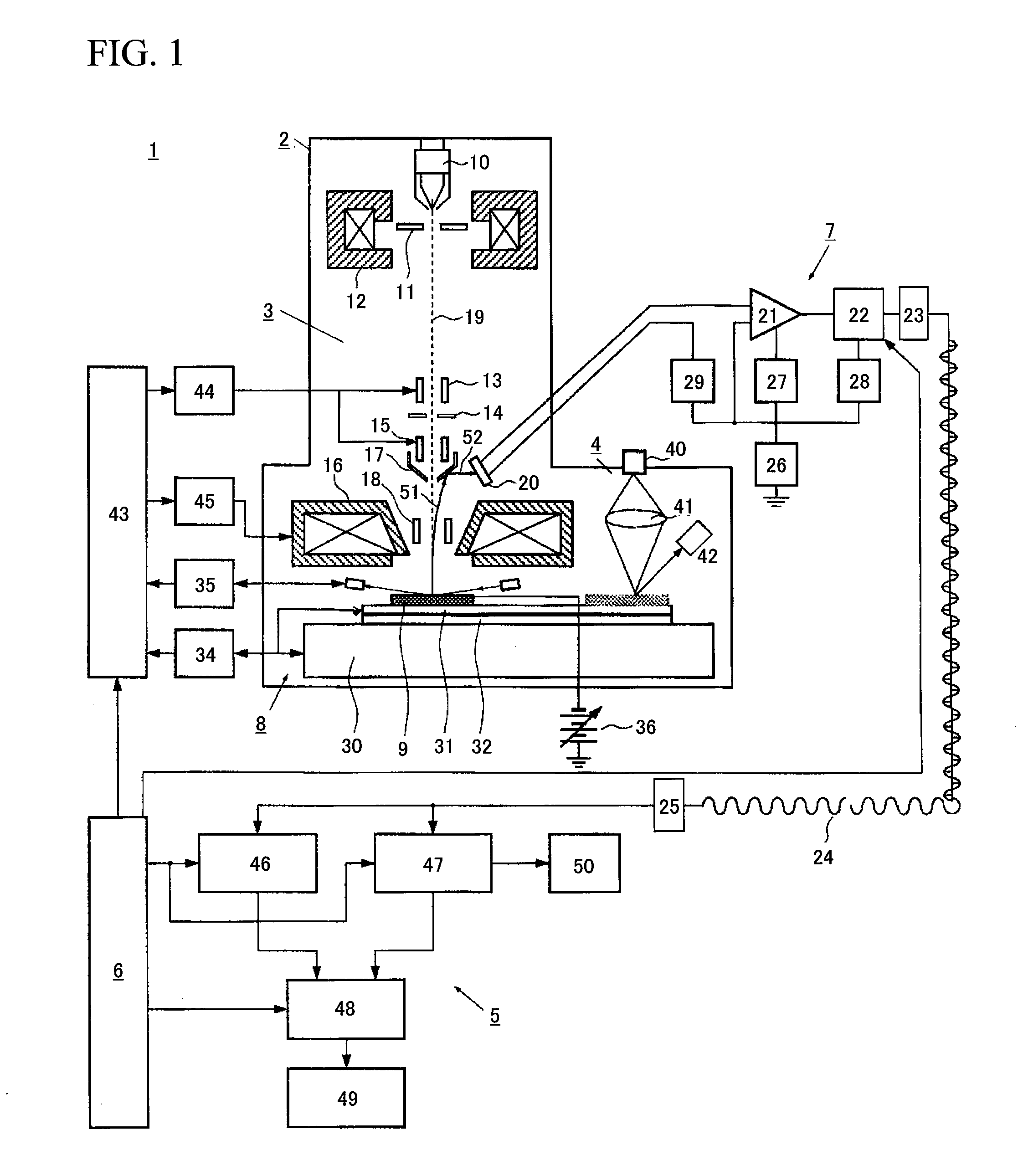

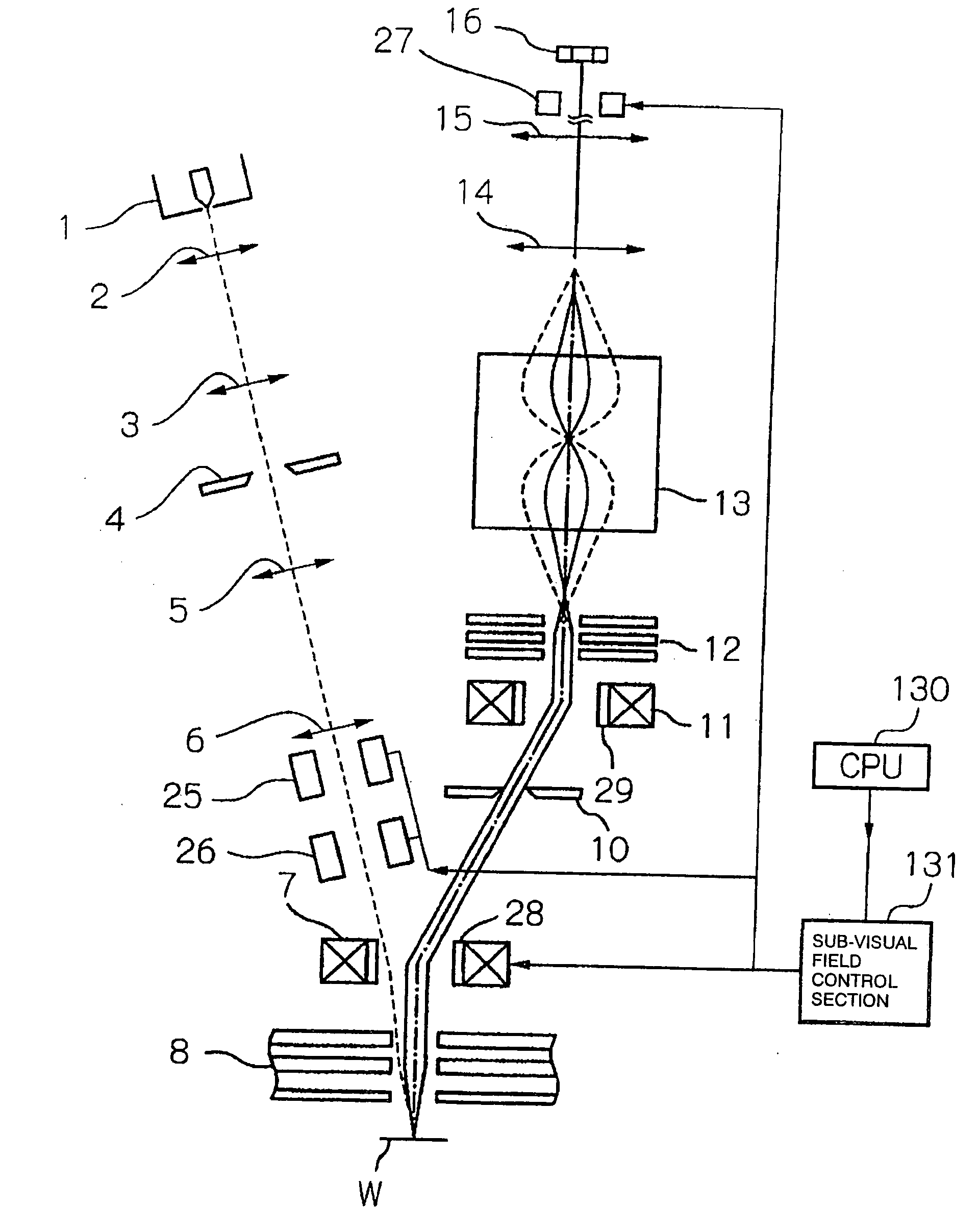

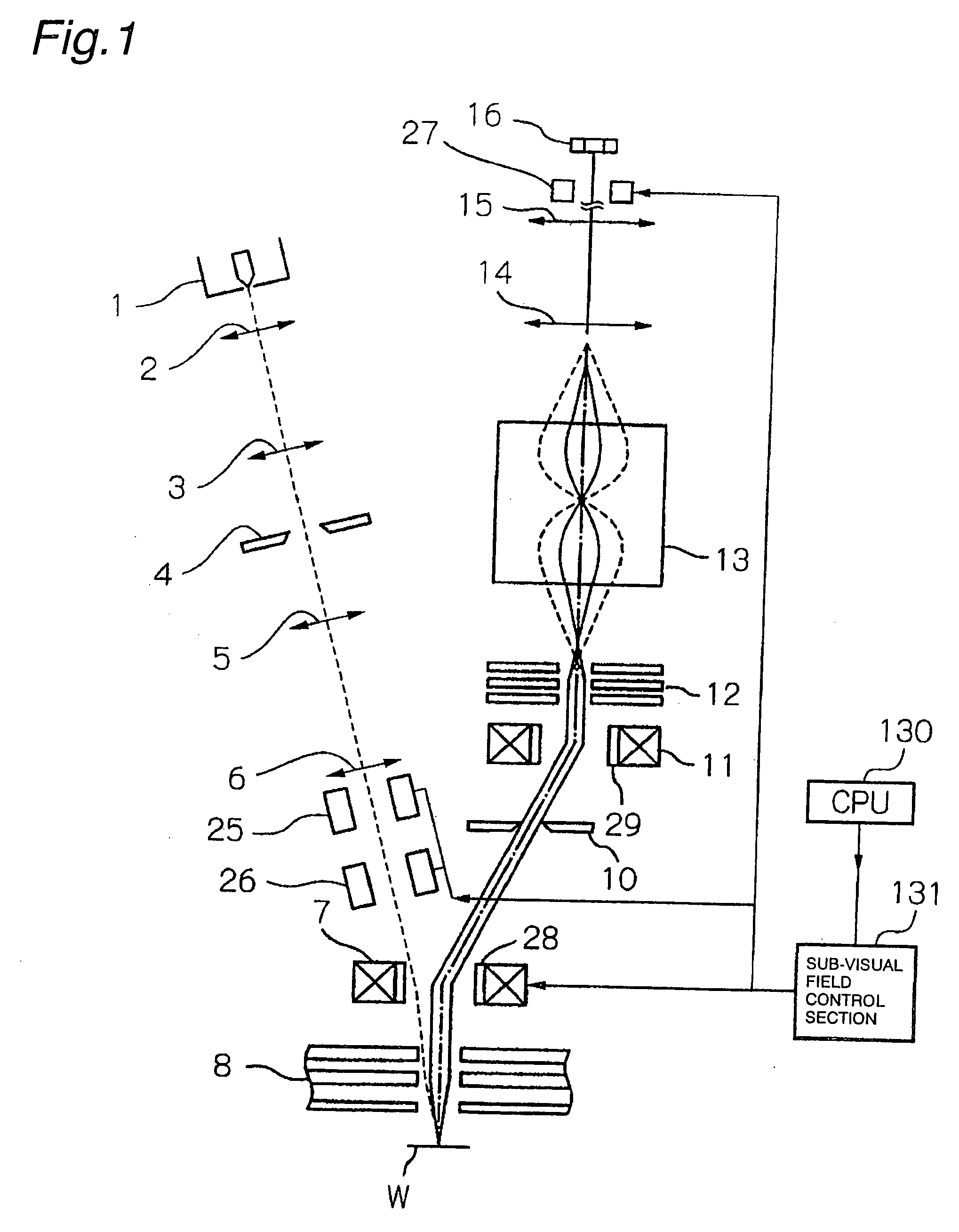

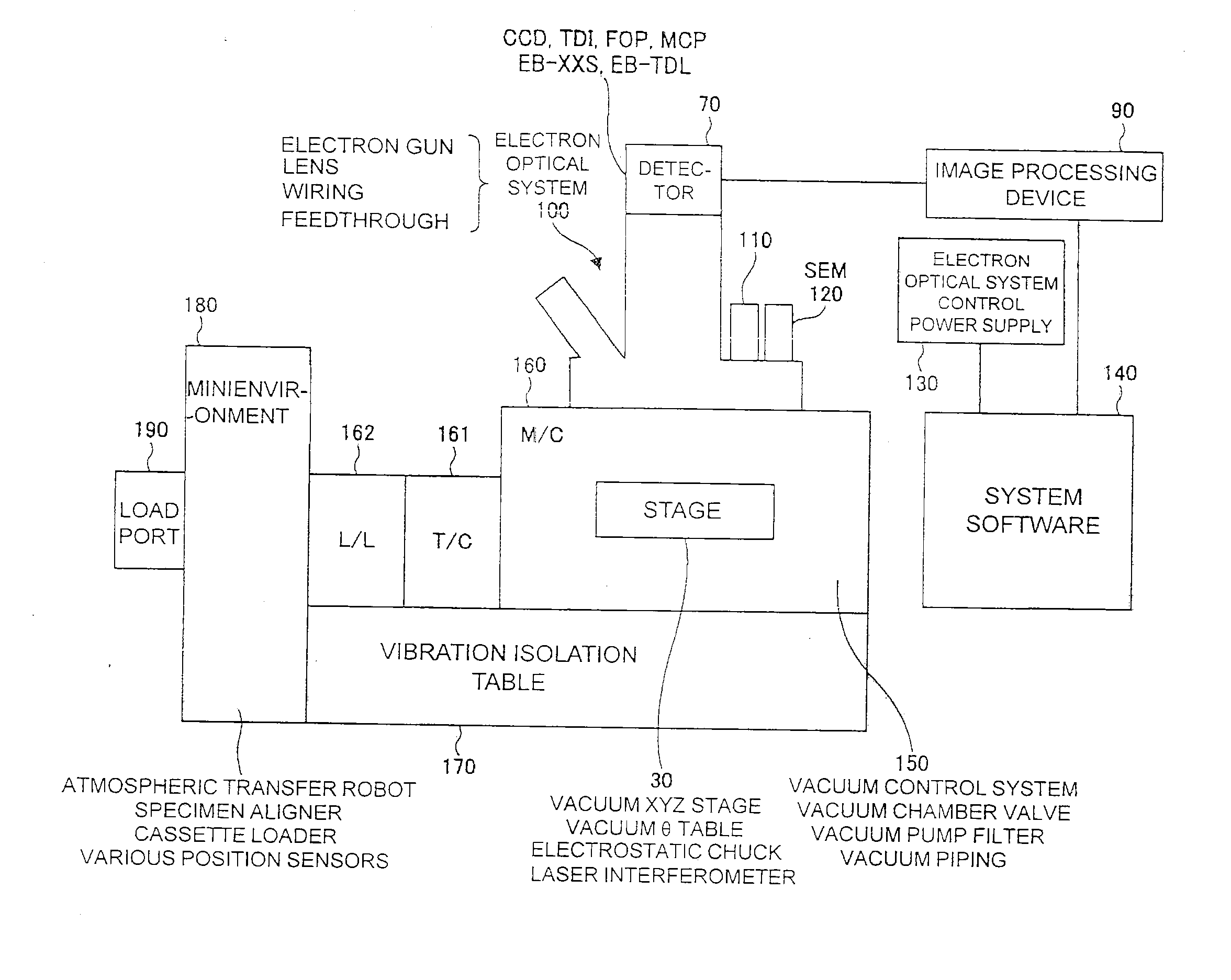

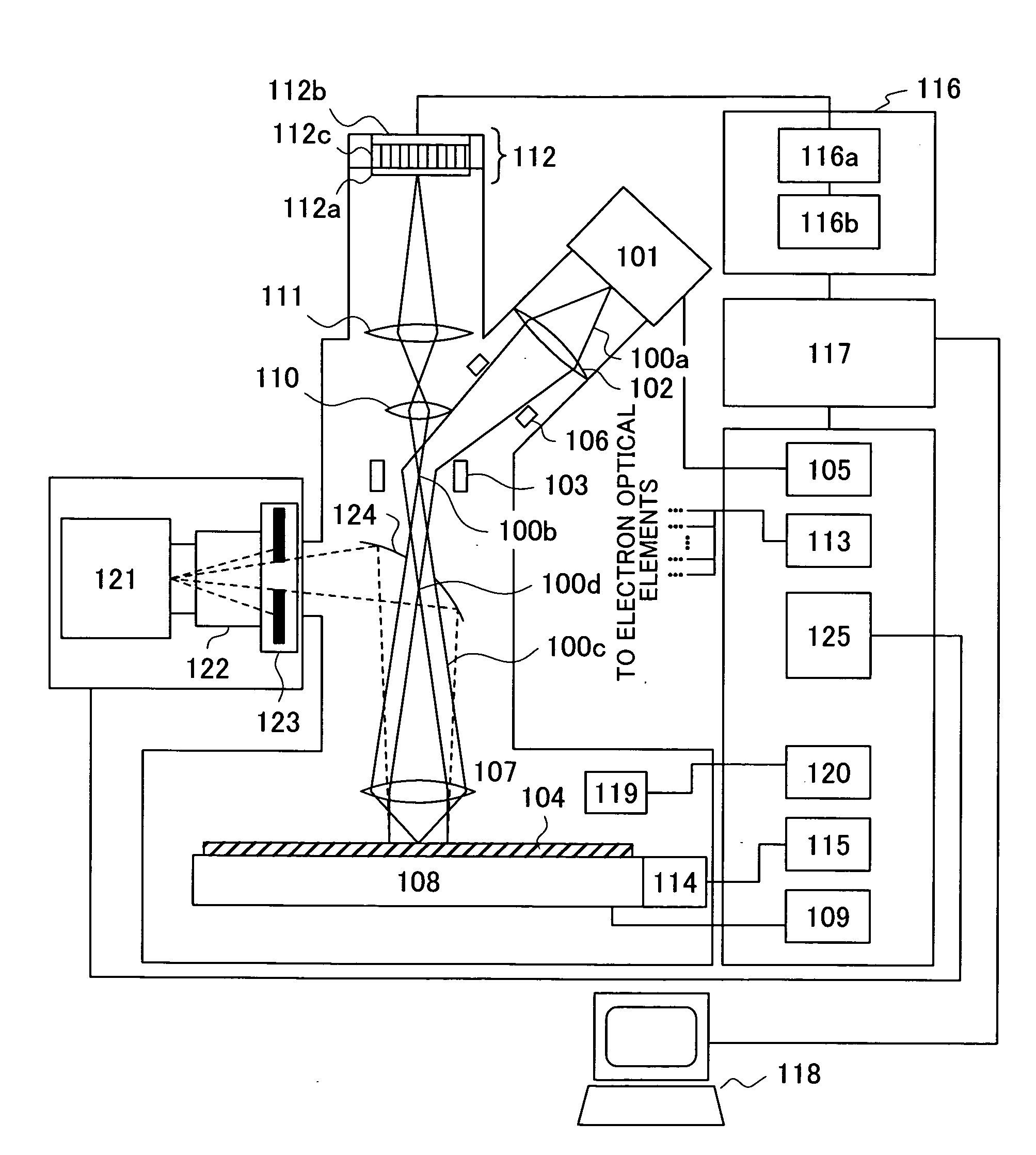

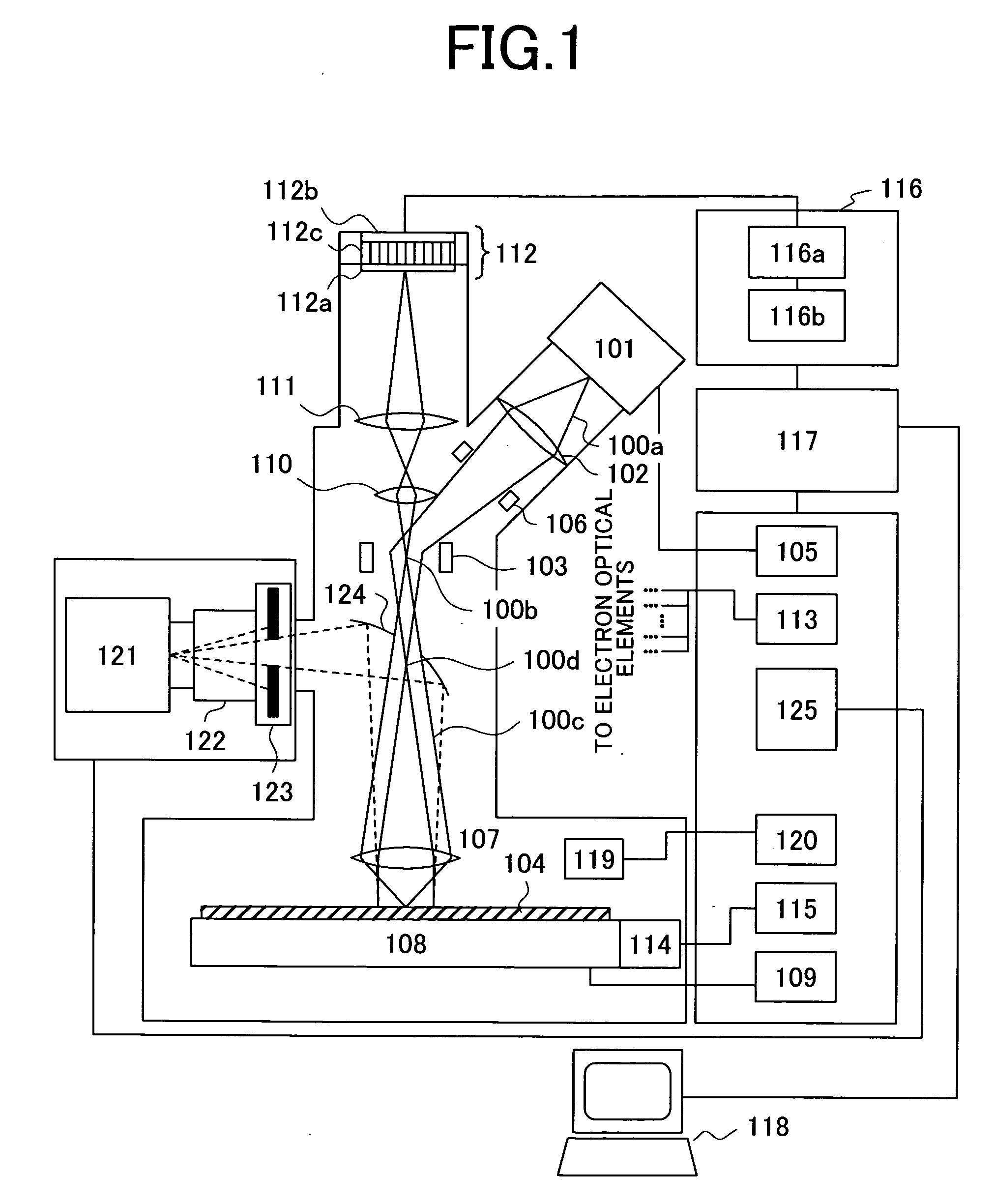

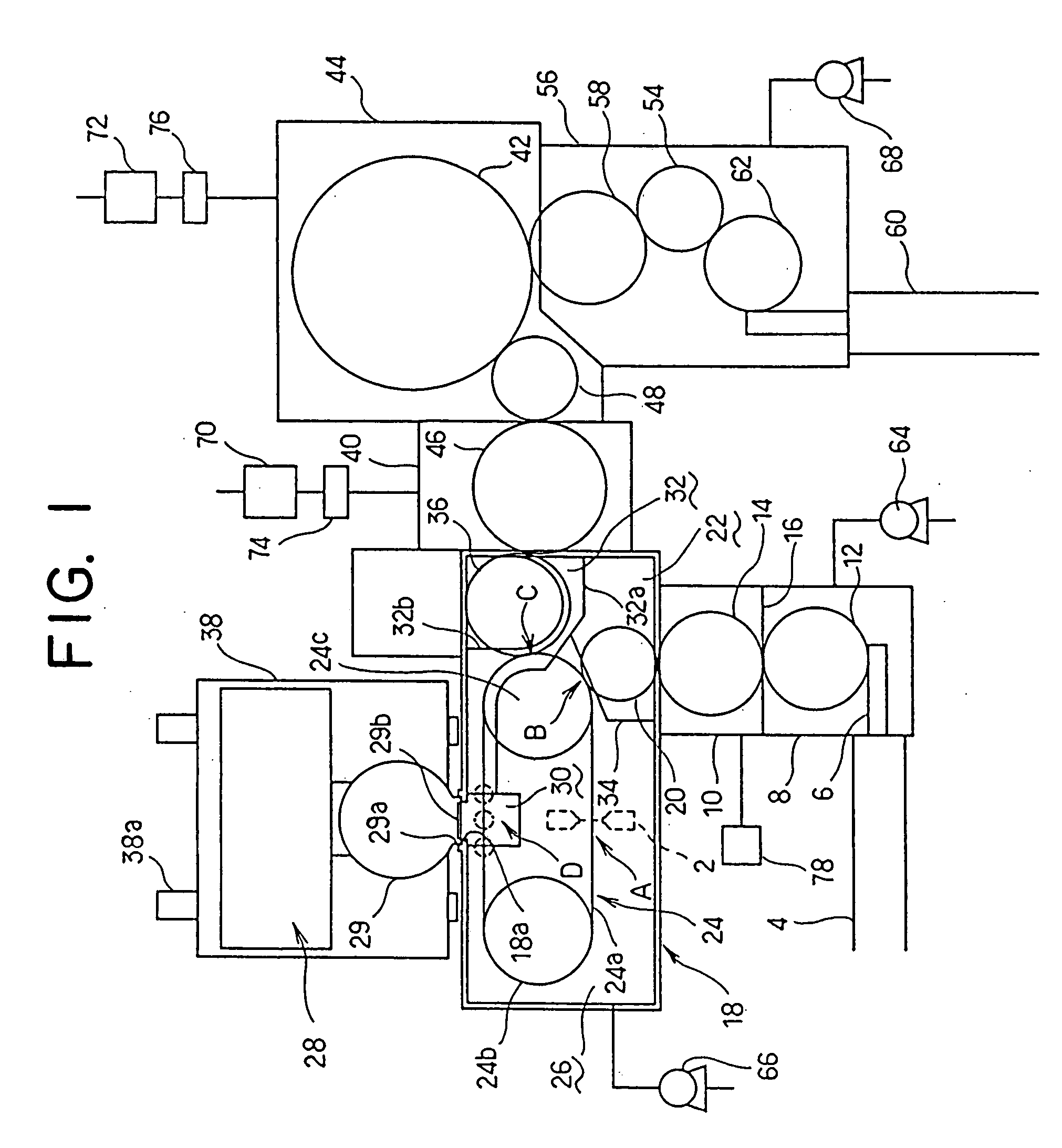

Electron beam apparatus and device fabrication method using the electron beam apparatus

InactiveUS7244932B2Improve throughputImprove accuracyThermometer detailsStability-of-path spectrometersSecondary electronsThroughput

The purpose of the invention is to provide an improved electron beam apparatus with improvements in throughput, accuracy, etc. One of the characterizing features of the electron beam apparatus of the present invention is that it has a plurality of optical systems, each of which comprises a primary electron optical system for scanning and irradiating a sample with a plurality of primary electron beams; a detector device for detecting a plurality of secondary beams emitted by irradiating the sample with the primary electron beams; and a secondary electron optical system for guiding the secondary electron beams from the sample to the detector device; all configured so that the plurality of optical systems scan different regions of the sample with their primary electron beams, and detect the respective secondary electron beams emitted from each of the respective regions. This is what makes higher throughput possible. To provide high accuracy, the apparatus is configured such that the axes of its optical systems can be aligned, and aberrations corrected, by a variety of methods.

Owner:EBARA CORP

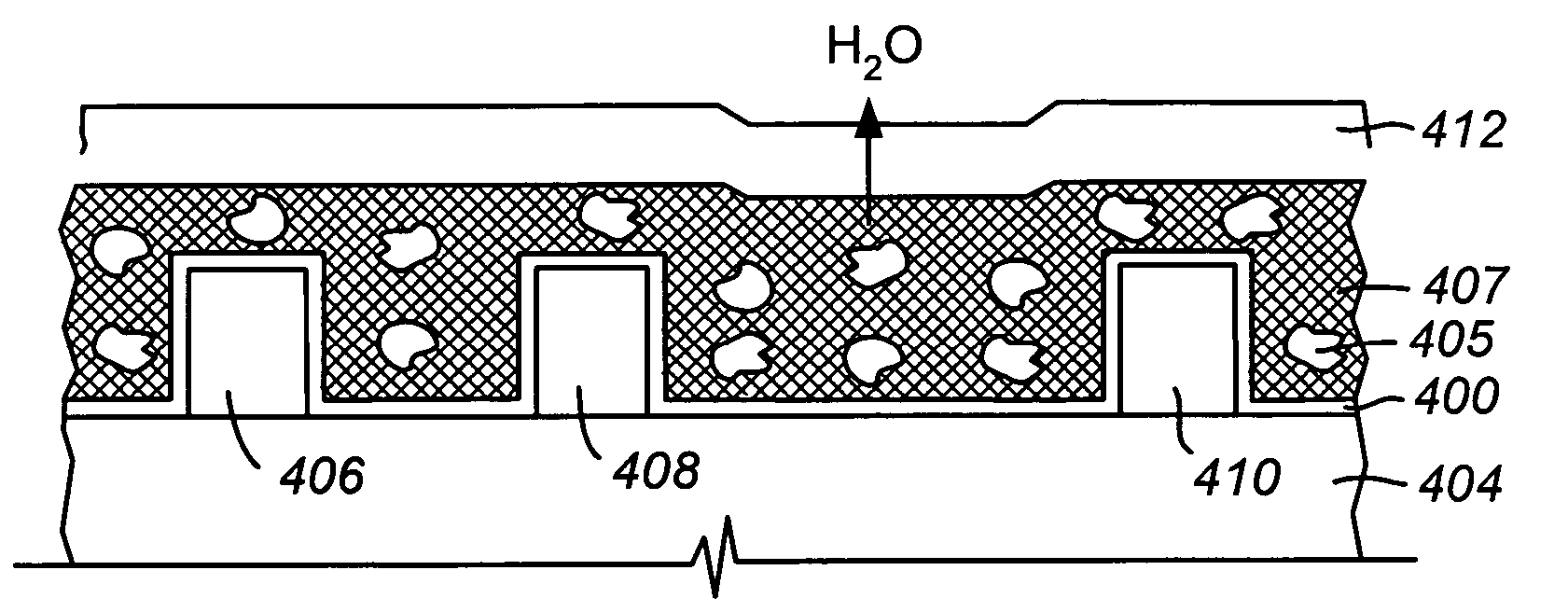

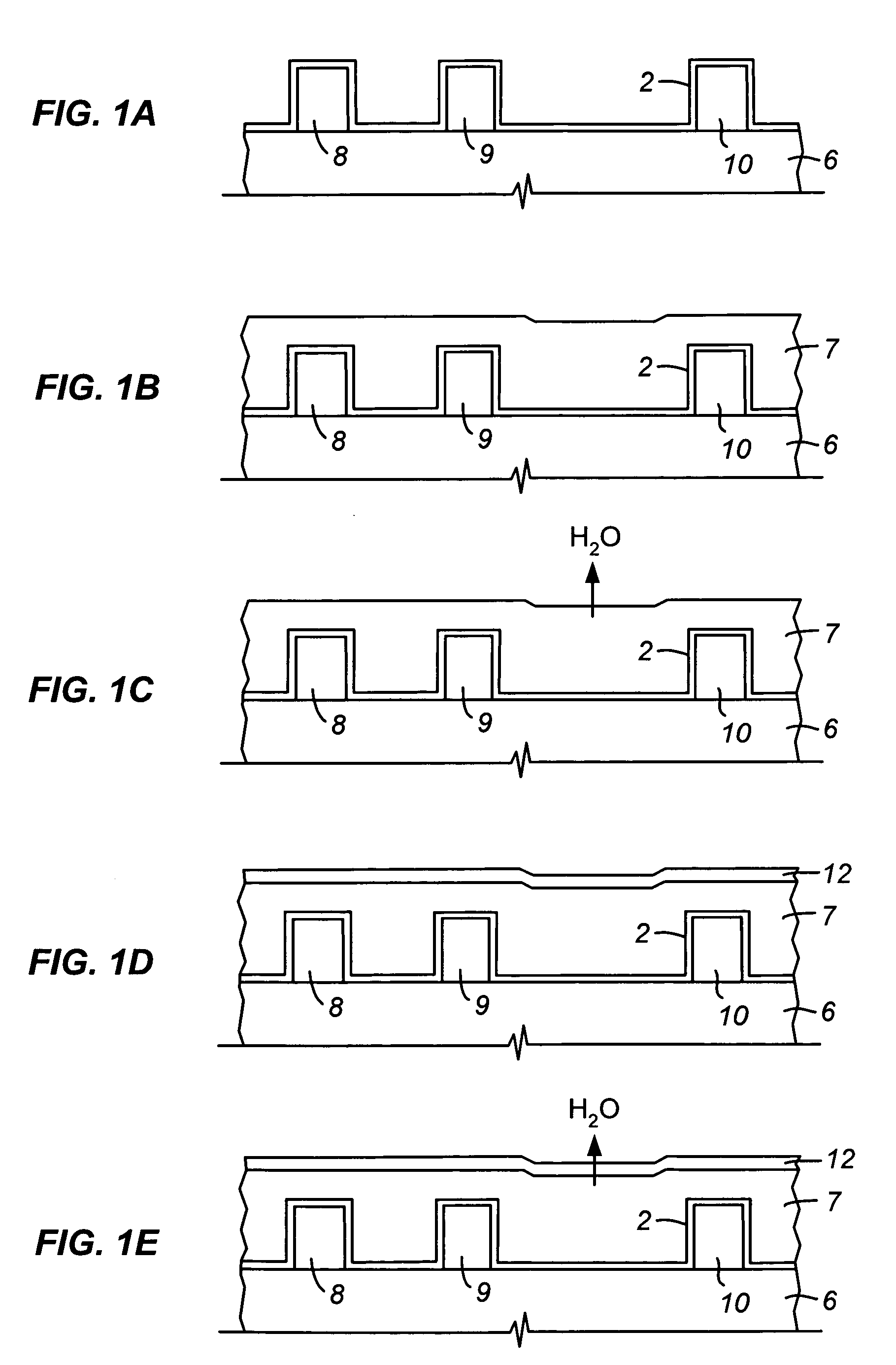

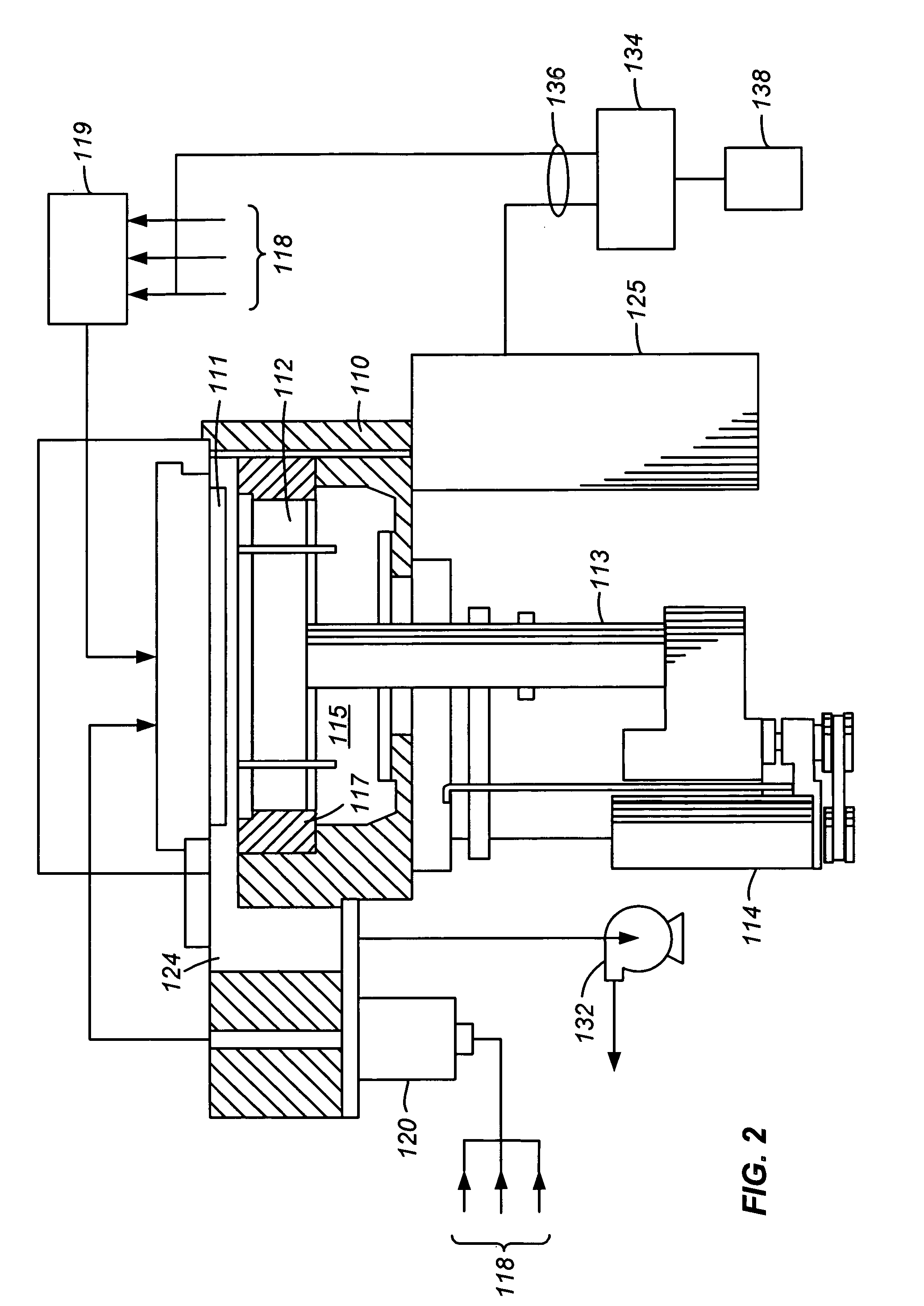

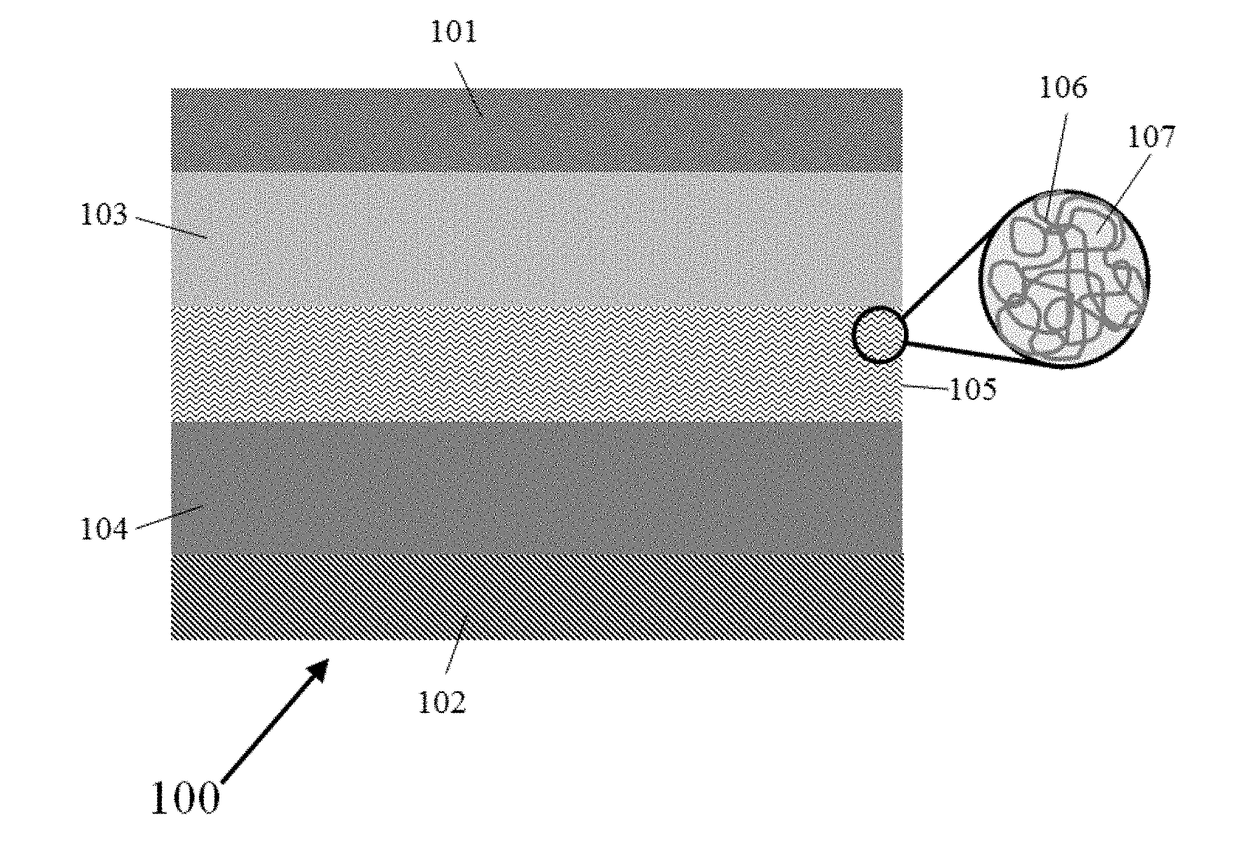

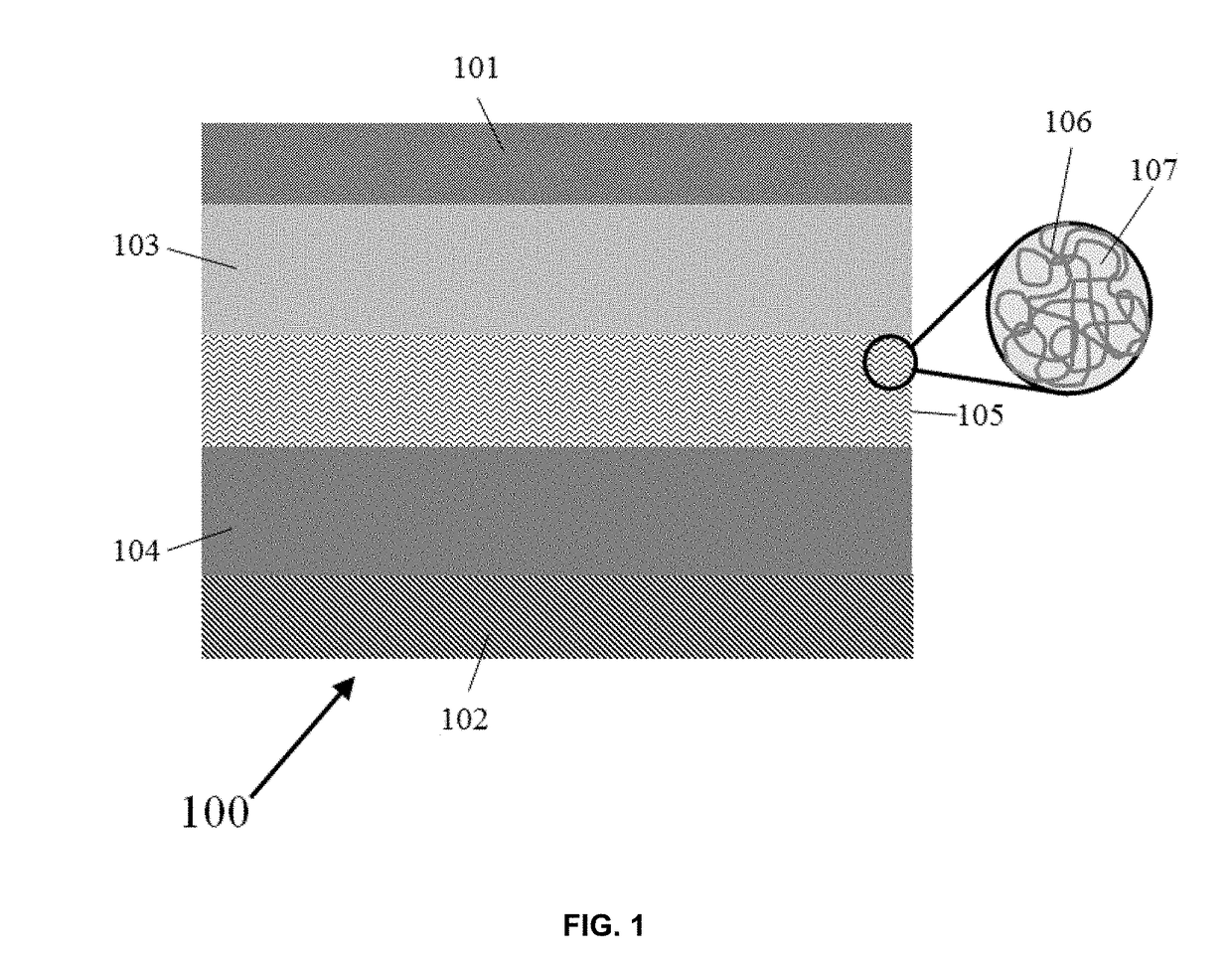

Multi-stage curing of low K nano-porous films

InactiveUS20050230834A1Semiconductor/solid-state device detailsSolid-state devicesThermal energyGas phase

Embodiments in accordance with the present invention relate to multi-stage curing processes for chemical vapor deposited low K materials. In certain embodiments, a combination of electron beam irradiation and thermal exposure steps may be employed to control selective outgassing of porogens incorporated into the film, resulting in the formation of nanopores. In accordance with one specific embodiment, a low K layer resulting from reaction between a silicon-containing component and a non-silicon containing component featuring labile groups, may be cured by the initial application of thermal energy, followed by the application of radiation in the form of an electron beam.

Owner:APPLIED MATERIALS INC

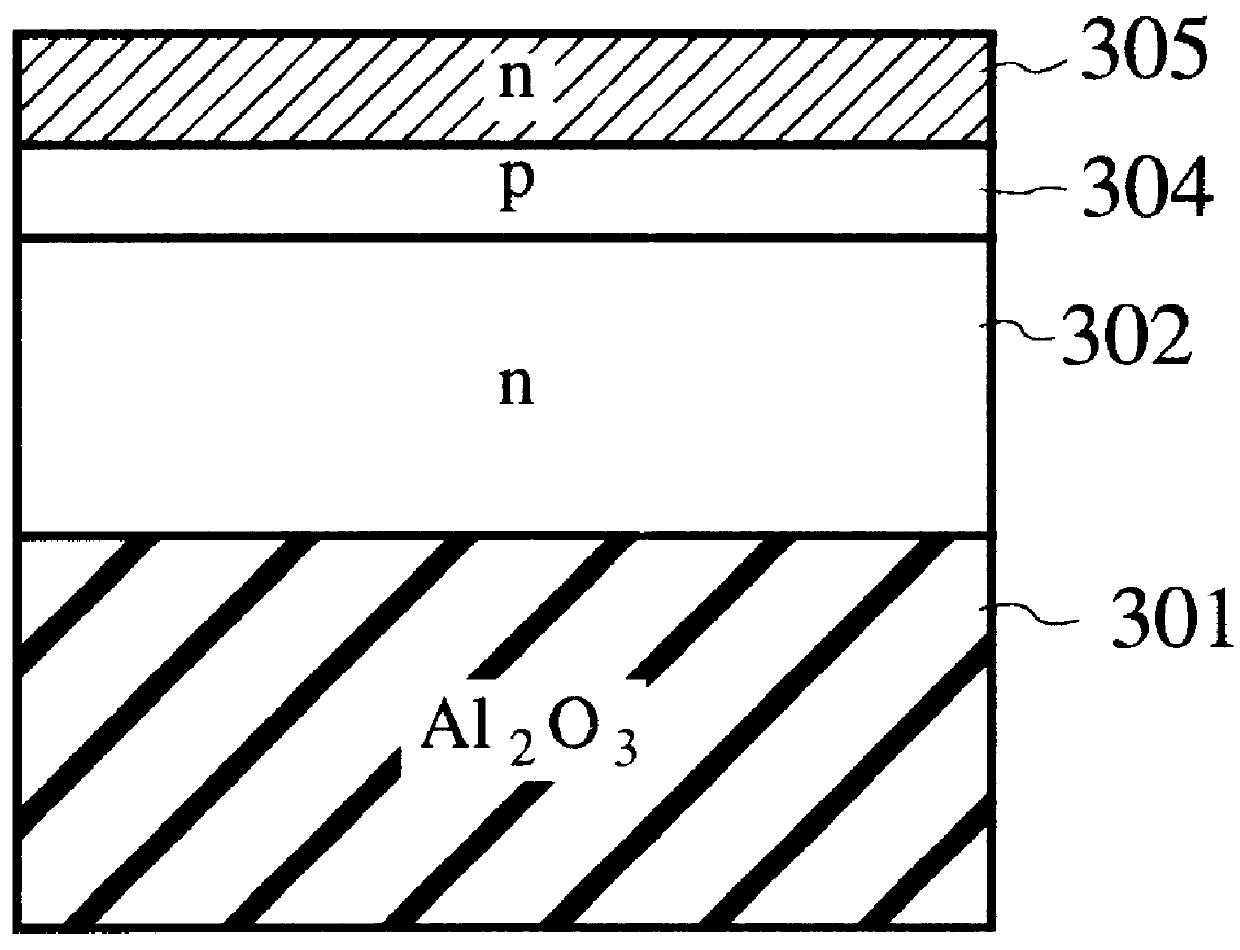

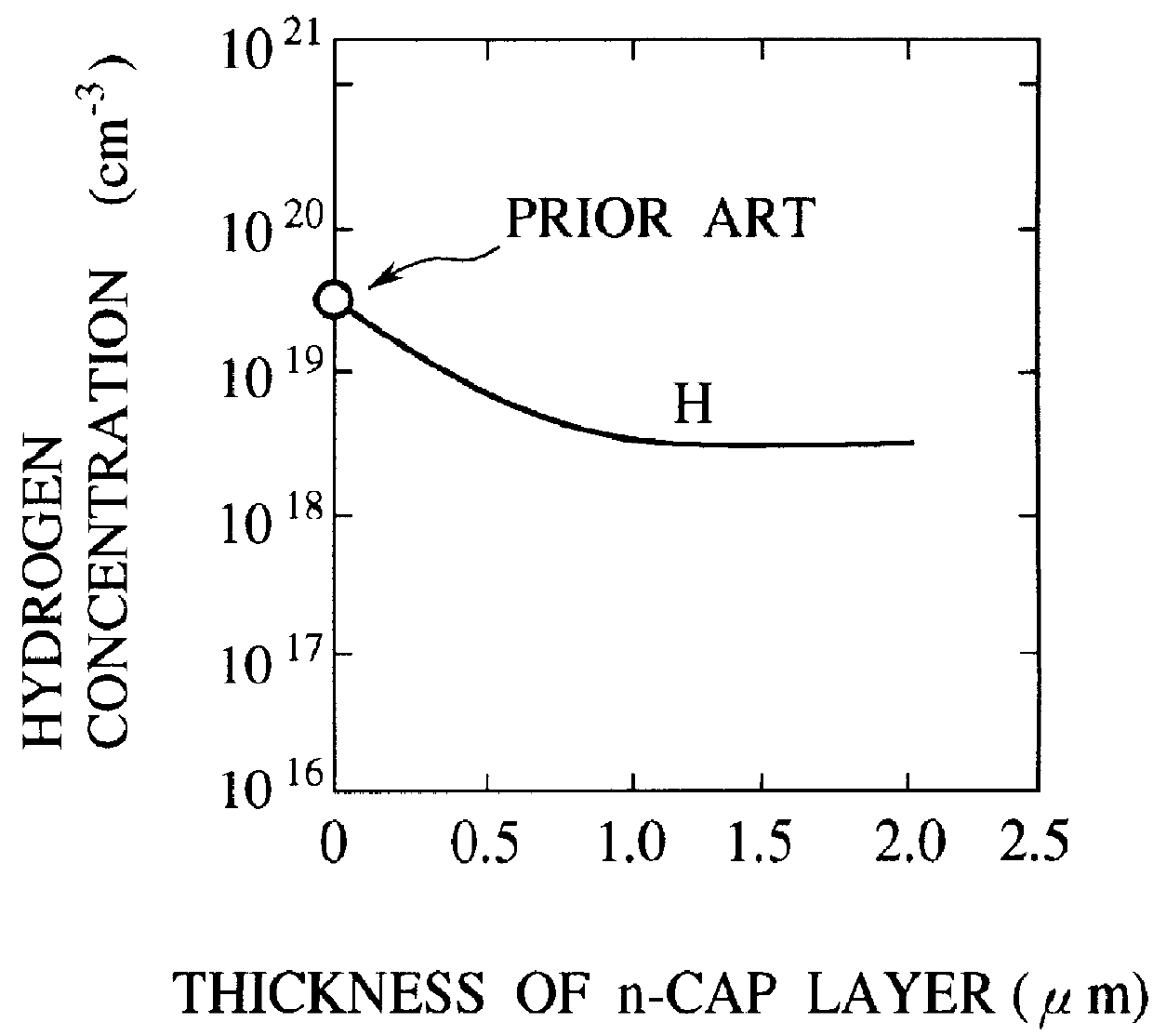

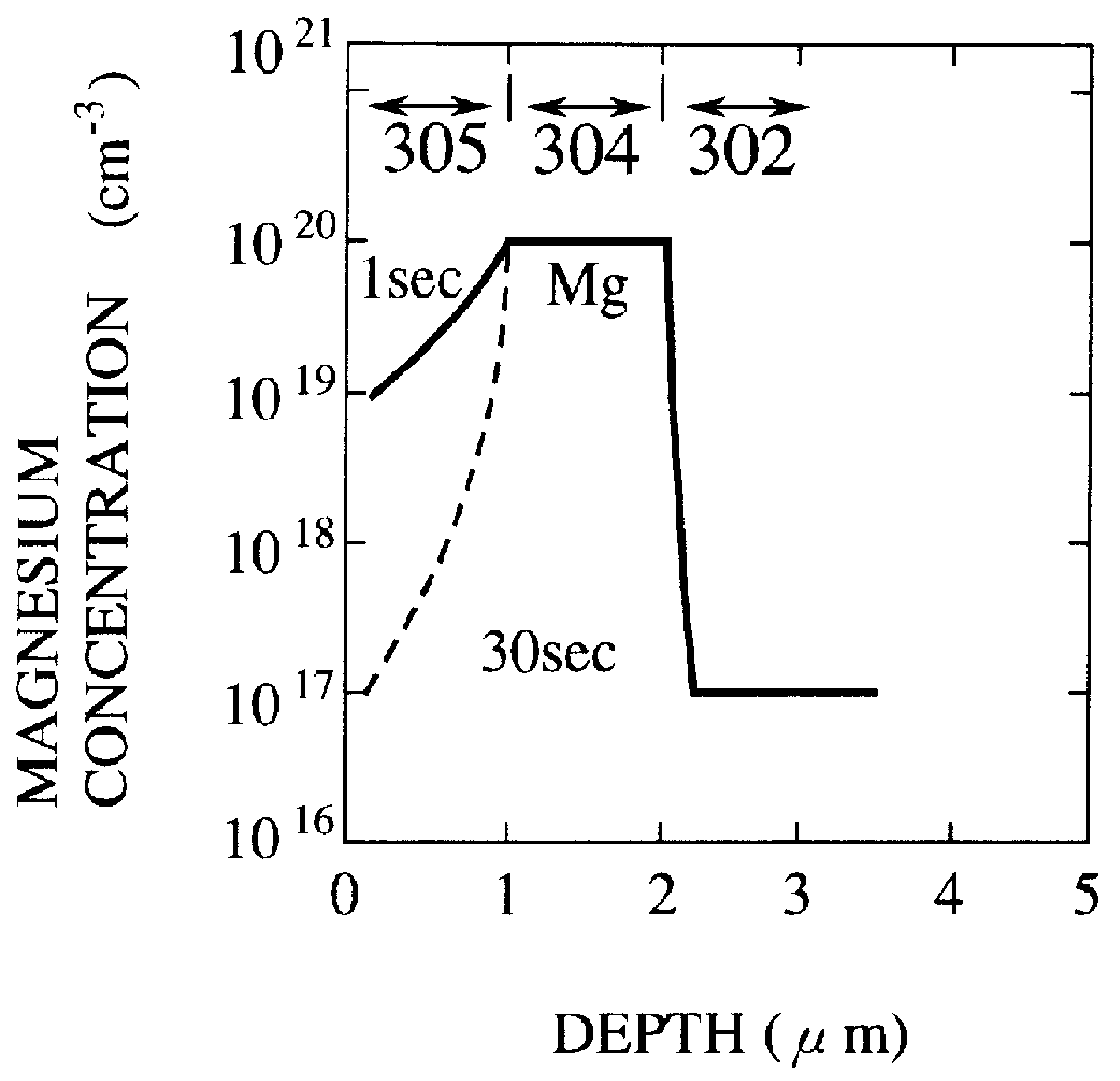

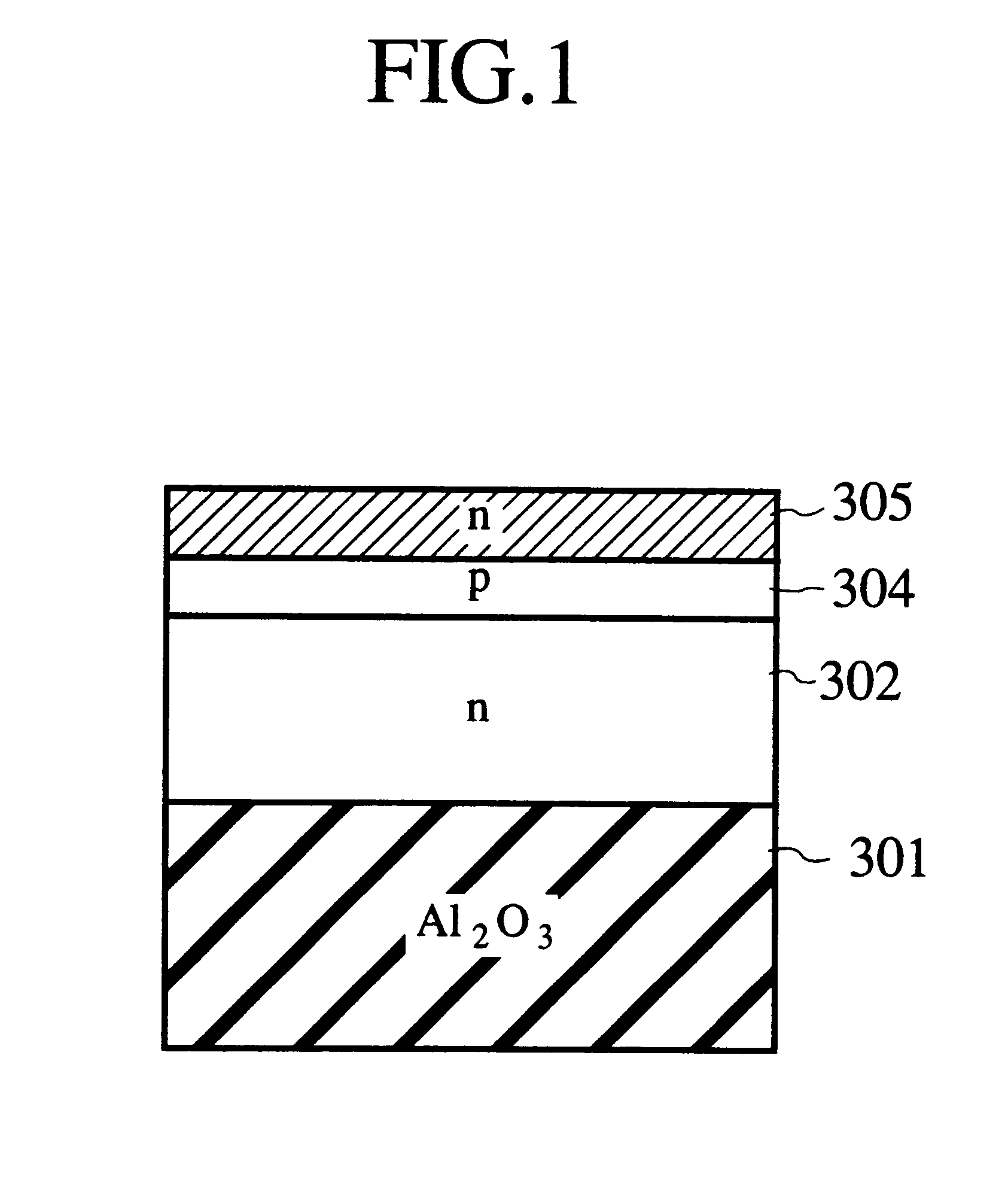

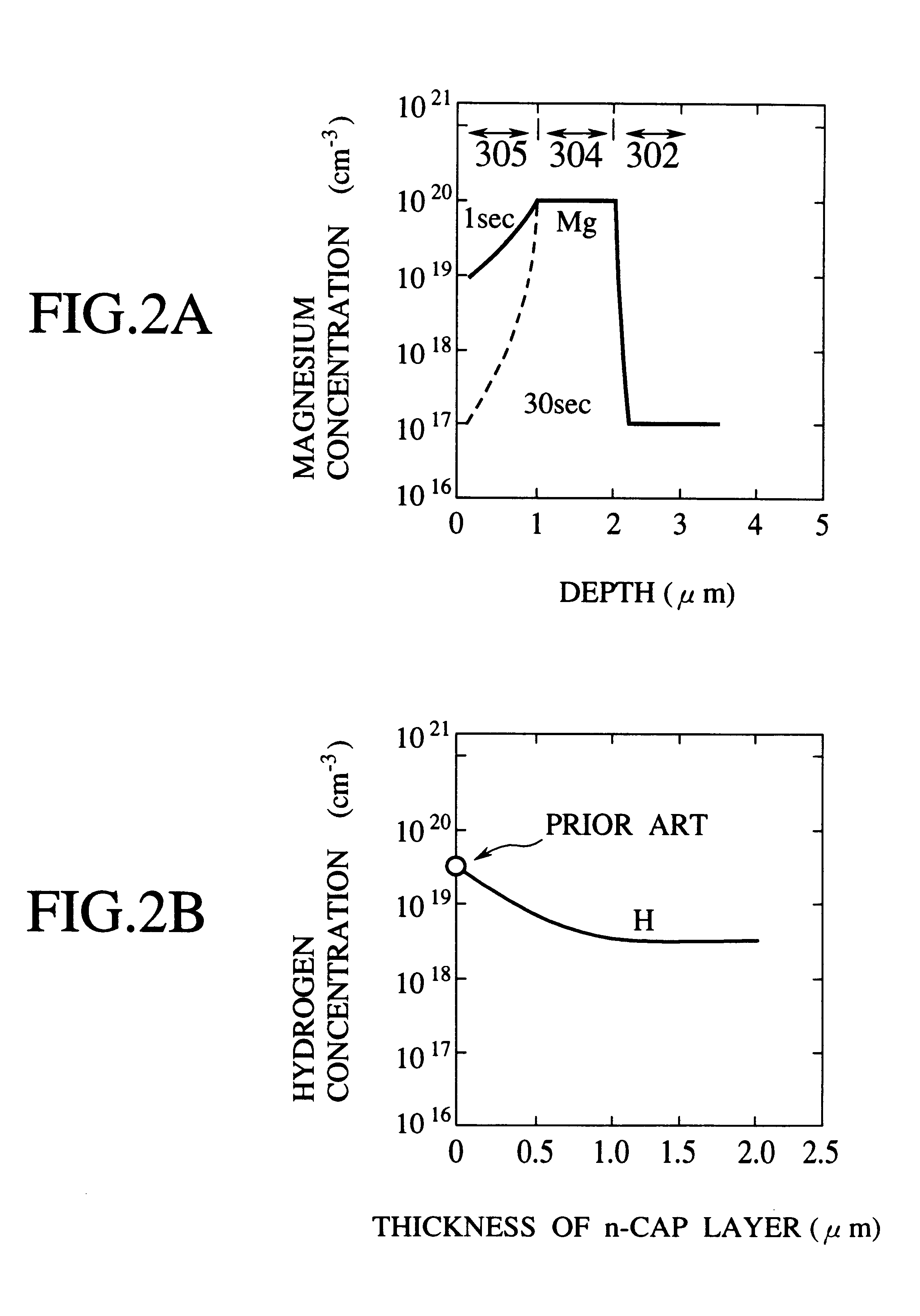

GaN based optoelectronic device and method for manufacturing the same

InactiveUS6020602AImprove extraction efficiencyImprove luminous performanceLaser detailsLaser active region structureCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

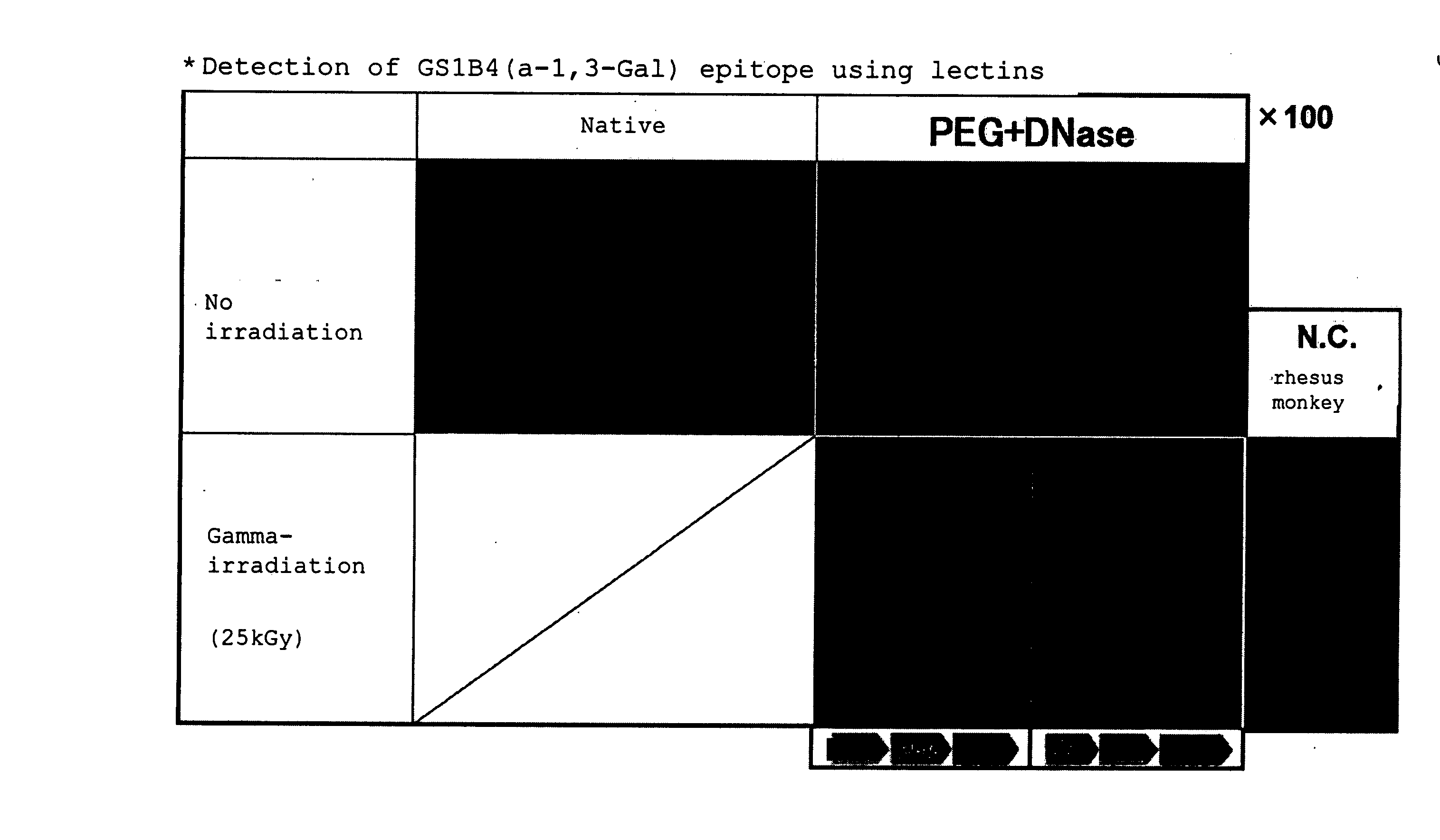

Decellularized Tissue and Method of Preparing the Same

InactiveUS20070244568A1Improve efficiencyGood effectMammal material medical ingredientsProsthesisUltravioletSolvent

Decellularization of tissue by means of an amphipathic solvent a well-established practice. However, situations exist where the provision of enhanced decellularization is preferred. There is a demand for treating methods for coping with such situations. Thus, it is intended to provide a method for enhancing decellularization. The method comprises not only the immersing of a tissue in a solution containing an amphiphilic molecule in non-micellar form (for example, 1,2-epoxide polymer) but also performing a radical reaction (for example, treatment selected from the group consisting of exposure to gamma-ray irradiation, ultraviolet irradiation, a free radical supply source, ultrasonication, electron beam irradiation, and X-ray irradiation).

Owner:CARDIO +1

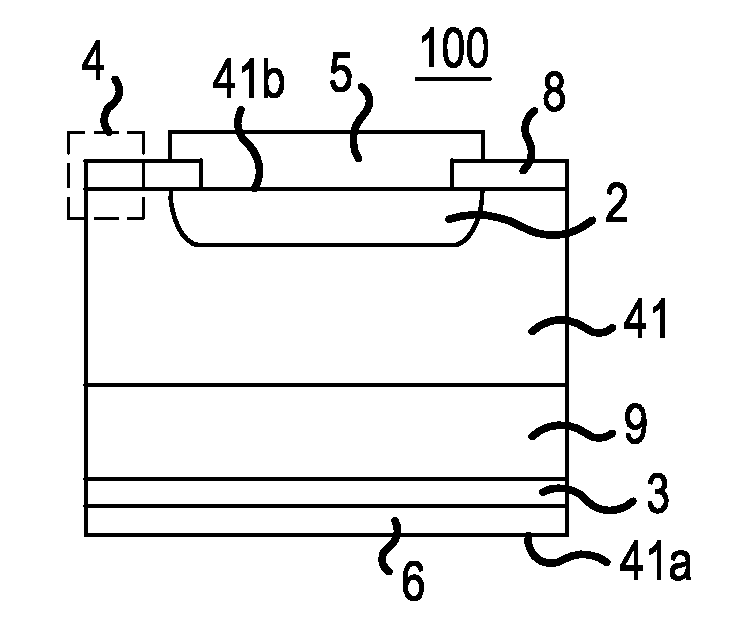

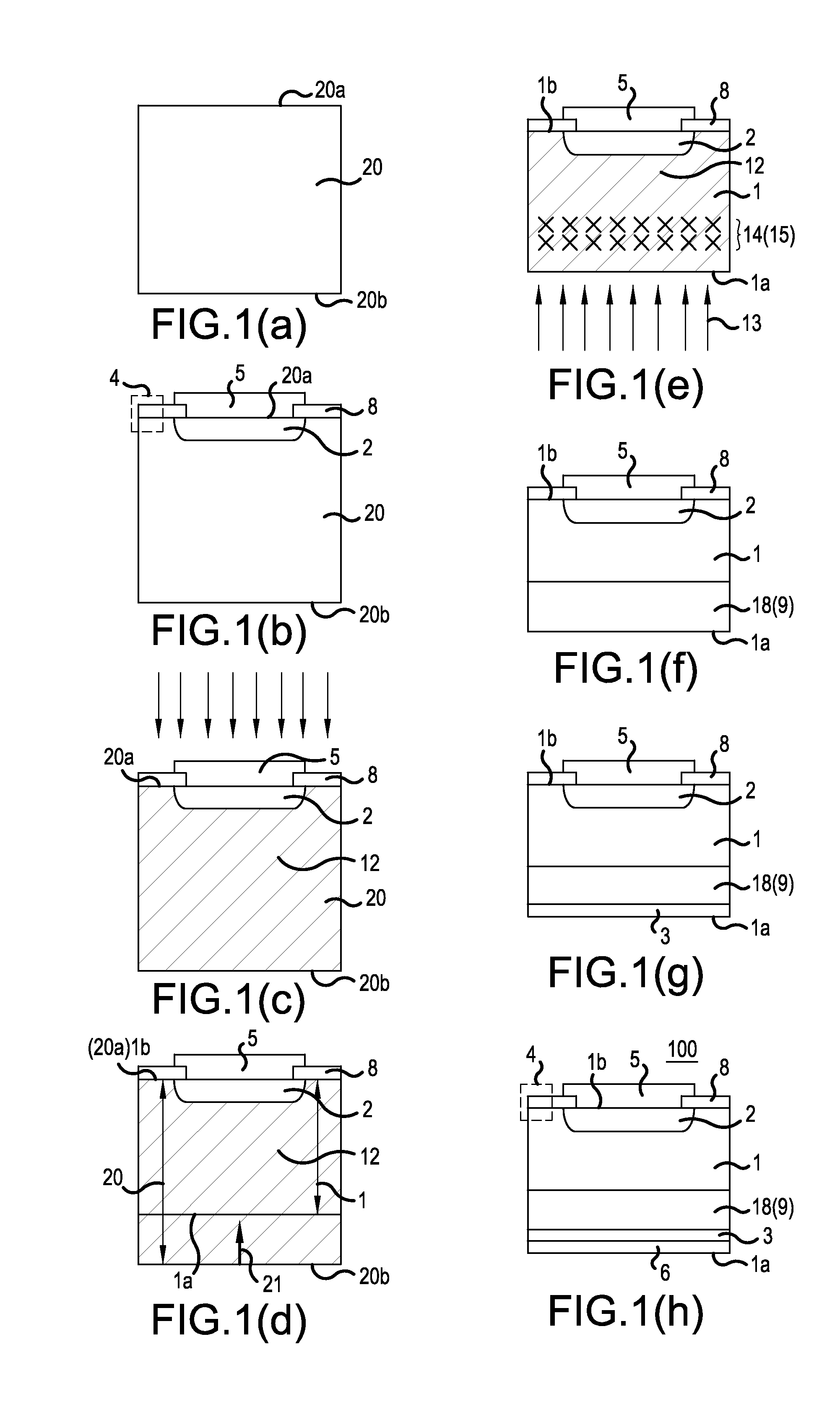

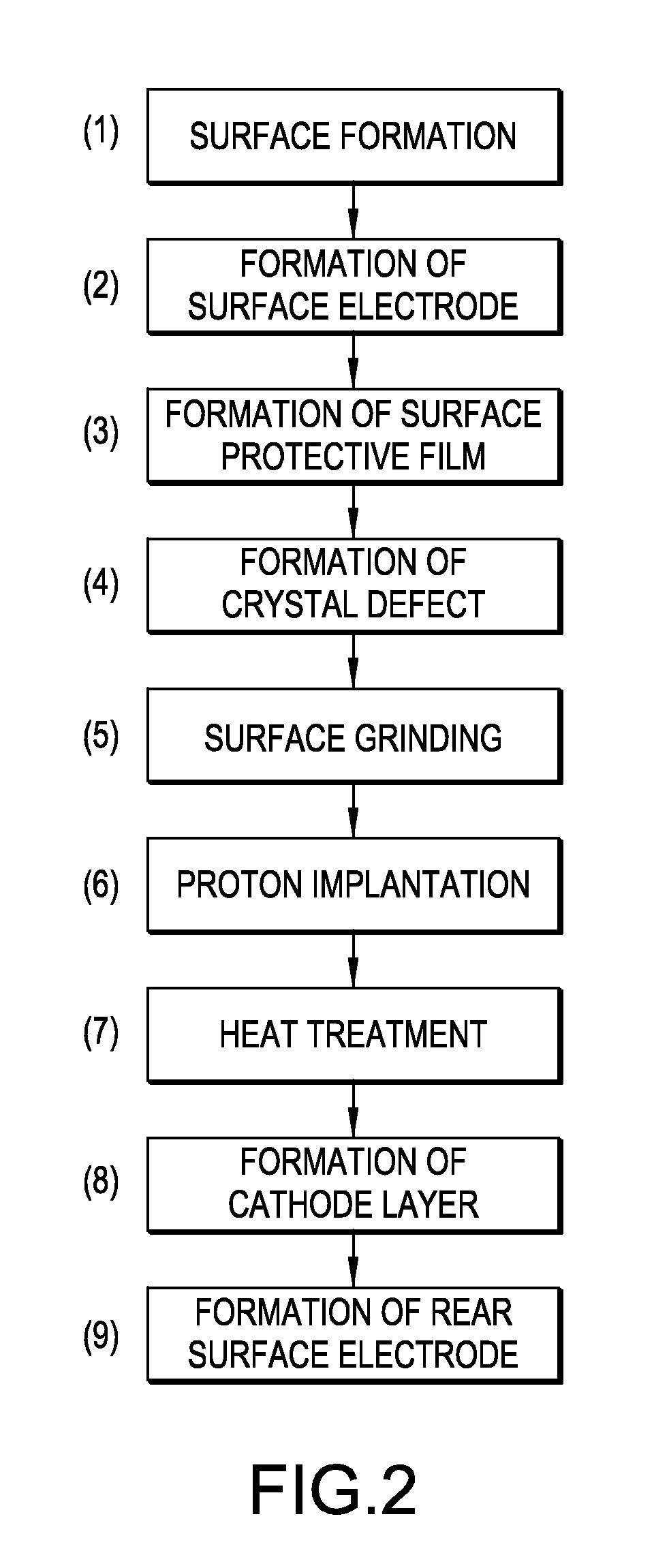

Semiconductor device and method for producing semiconductor device

ActiveUS20140246755A1Limited amountIncrease spawn rateSemiconductor/solid-state device manufacturingSemiconductor devicesProton implantationGeneration rate

Hydrogen atoms and crystal defects are introduced into an n− semiconductor substrate by proton implantation. The crystal defects are generated in the n− semiconductor substrate by electron beam irradiation before or after the proton implantation. Then, a heat treatment for generating donors is performed. The amount of crystal defects is appropriately controlled during the heat treatment for generating donors to increase a donor generation rate. In addition, when the heat treatment for generating donors ends, the crystal defects formed by the electron beam irradiation and the proton implantation are recovered and controlled to an appropriate amount of crystal defects. Therefore, for example, it is possible to improve a breakdown voltage and reduce a leakage current.

Owner:FUJI ELECTRIC CO LTD

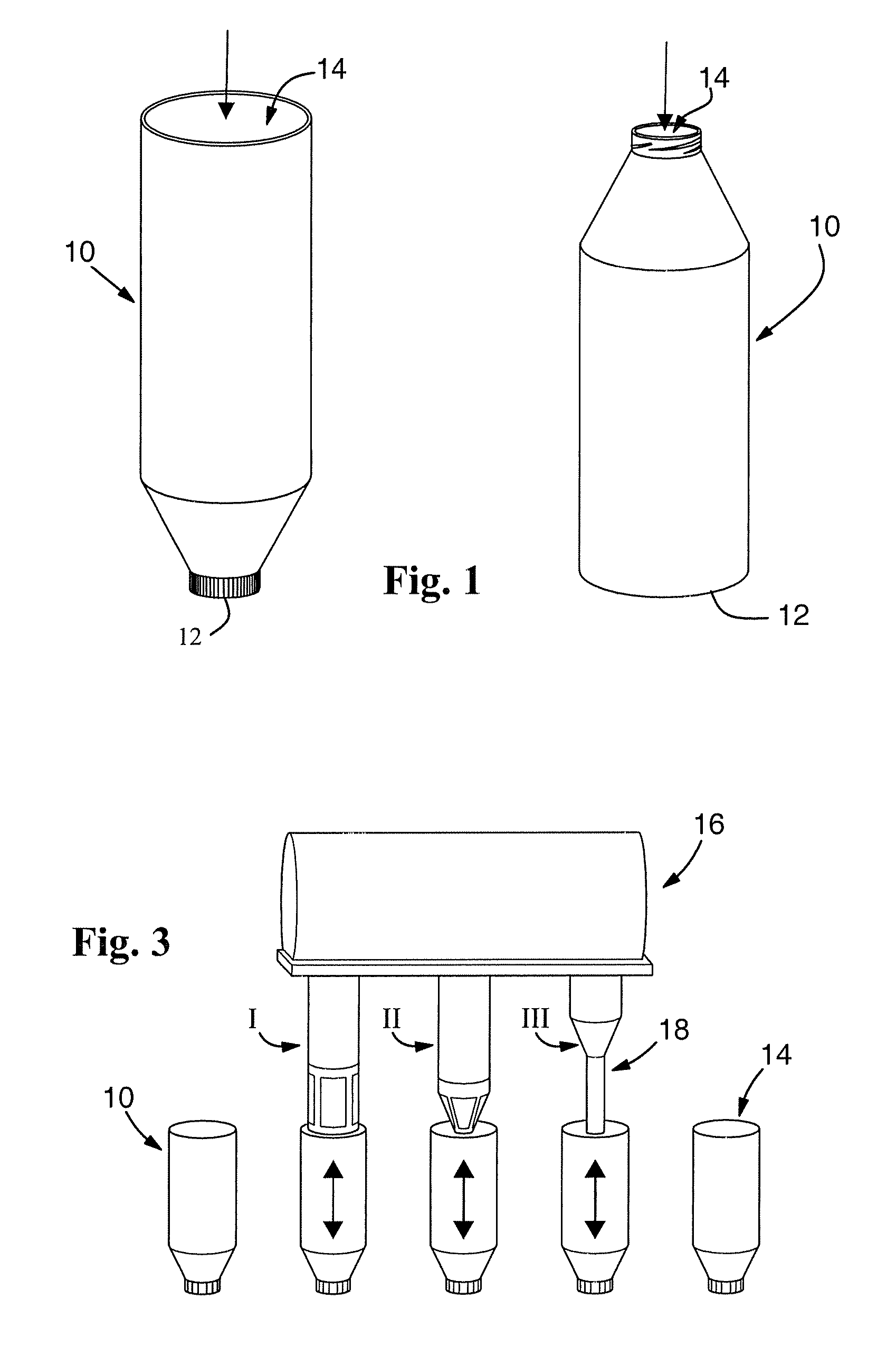

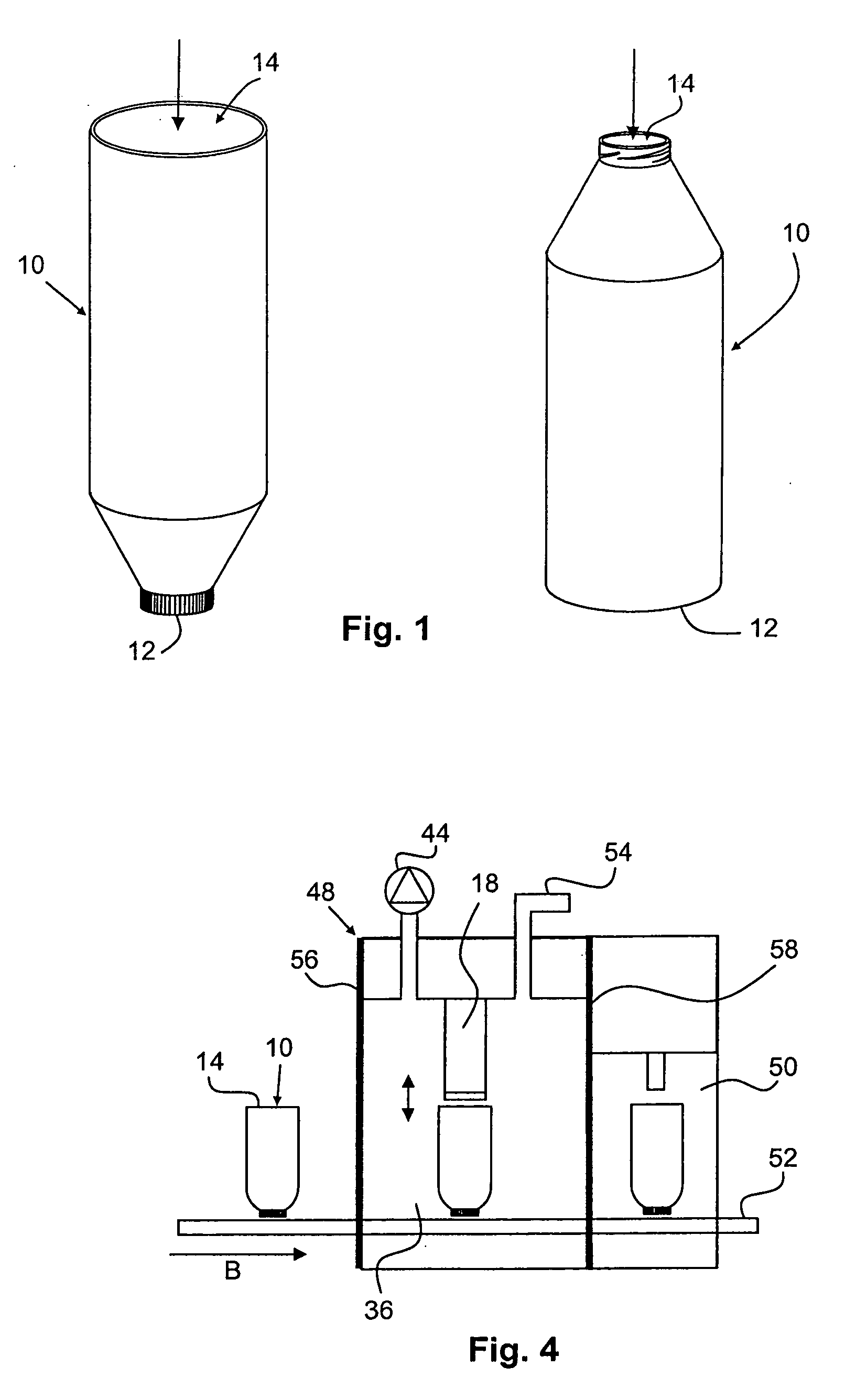

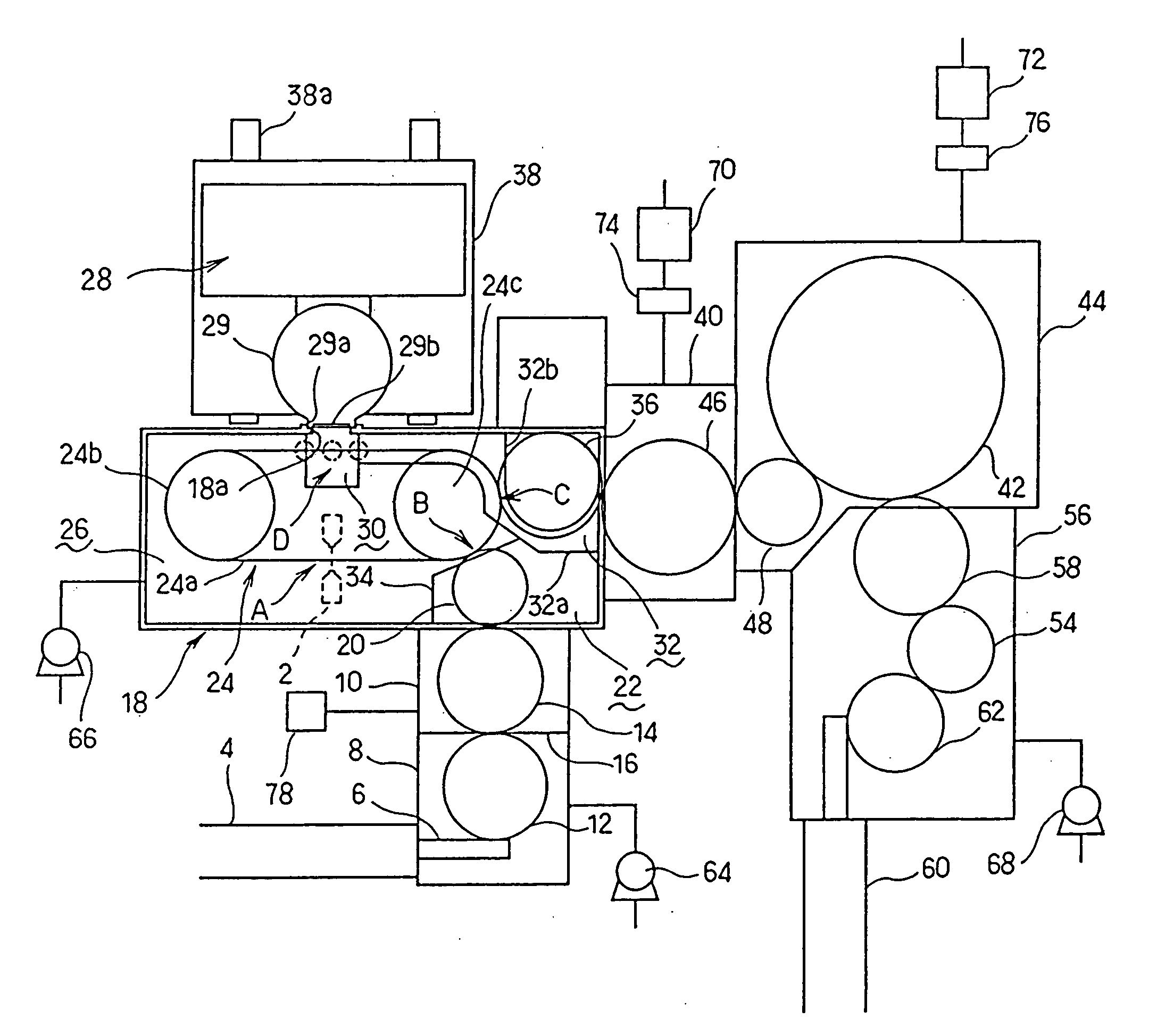

Method of sterilizing packages

ActiveUS20070283667A1Even dosePackage sterilisationLavatory sanitoryPhysicsElectron beam irradiation

A method for sterilizing at least partly formed packages with electron beam irradiation in a packaging machine involves sterilizing each of at least two at least partially separate areas of the package by way of a respective electron beam sterilizing device, with each of the sterilizing devices being adapted to characteristics of each respective one of the two areas, and also performing a respective relative movement between the package and each of the electron beam sterilizing devices, which movements are adapted for the sterilization of each respective one of the two areas with the sterilizing devices.

Owner:TETRA LAVAL HLDG & FINANCE SA

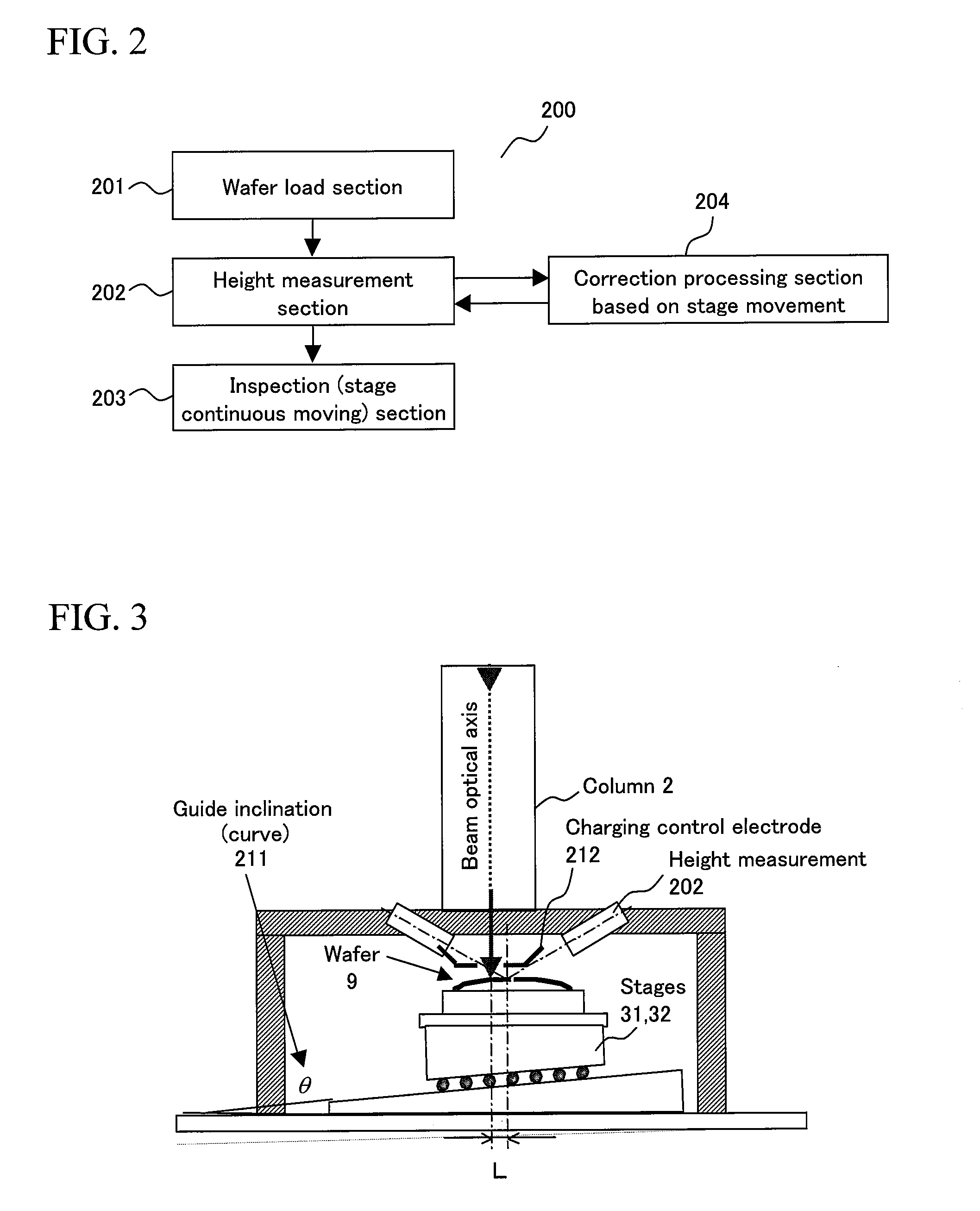

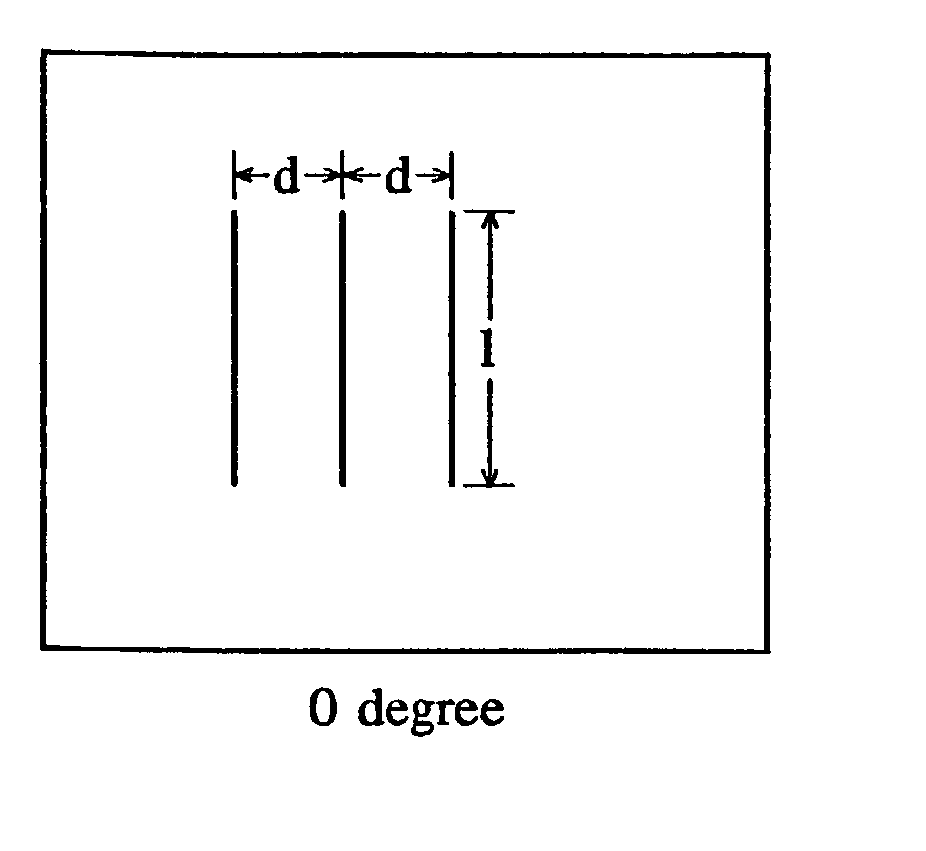

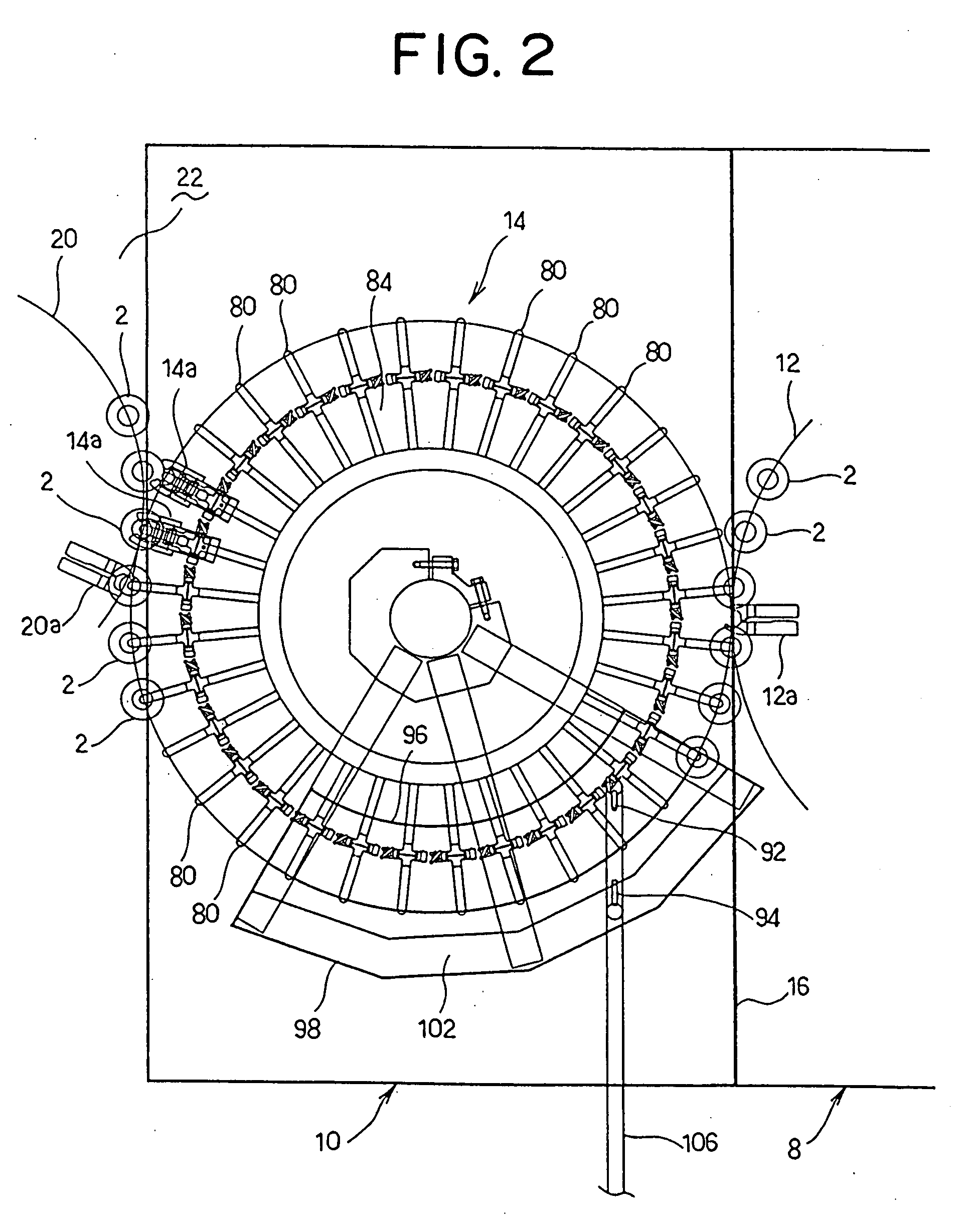

Apparatus for inspecting a substrate, a method of inspecting a substrate, a scanning electron microscope, and a method of producing an image using a scanning electron microscope

InactiveUS20090309022A1Excellent substrate inspectionSensitive defect detecting capabilityStability-of-path spectrometersMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

An object of the present invention provides an inspection apparatus and an inspection method which use an electron beam image to accurately detect a defect that is difficult to detect in an optical image, the apparatus and method also enabling prevention of a possible decrease in focus accuracy of an inspection image which affect the defect detection. To accomplish the object, the present invention includes a height measurement section which measures height of the electron beam irradiation position on the substrate after the substrate is loaded onto a movable stage, a height correction processing section which corrects the measured height, and a control section which adjusts a focus of the electron beam according to the height corrected by the height correction processing section, wherein a stage position set when the height measurement section measures the height differs from a stage position set when the substrate is irradiated with the electron beam, and the height correction processing section corrects a possible deviation in height resulting from movement from the stage position for the height measurement to the stage position for the electron beam irradiation.

Owner:HITACHI HIGH-TECH CORP

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

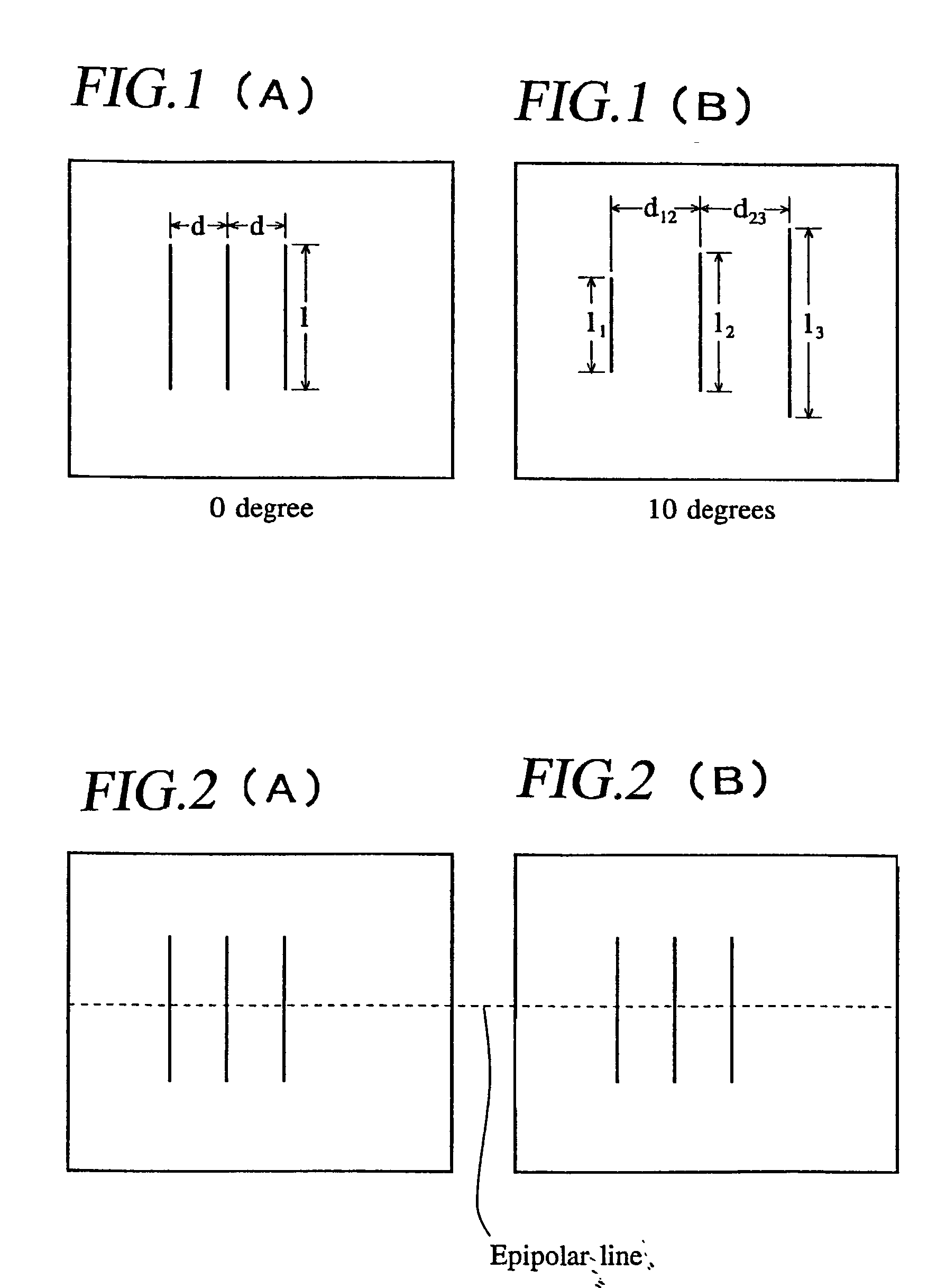

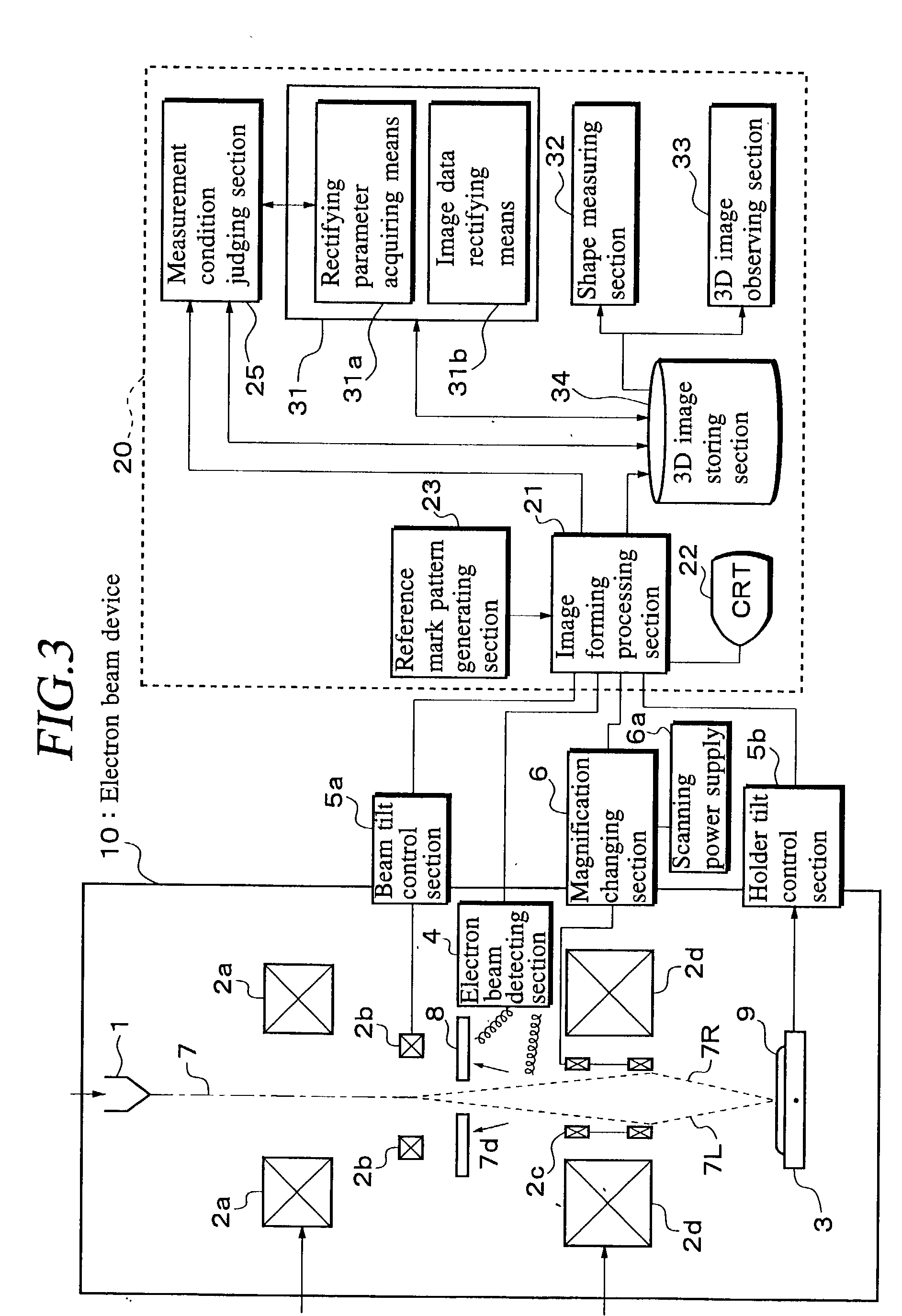

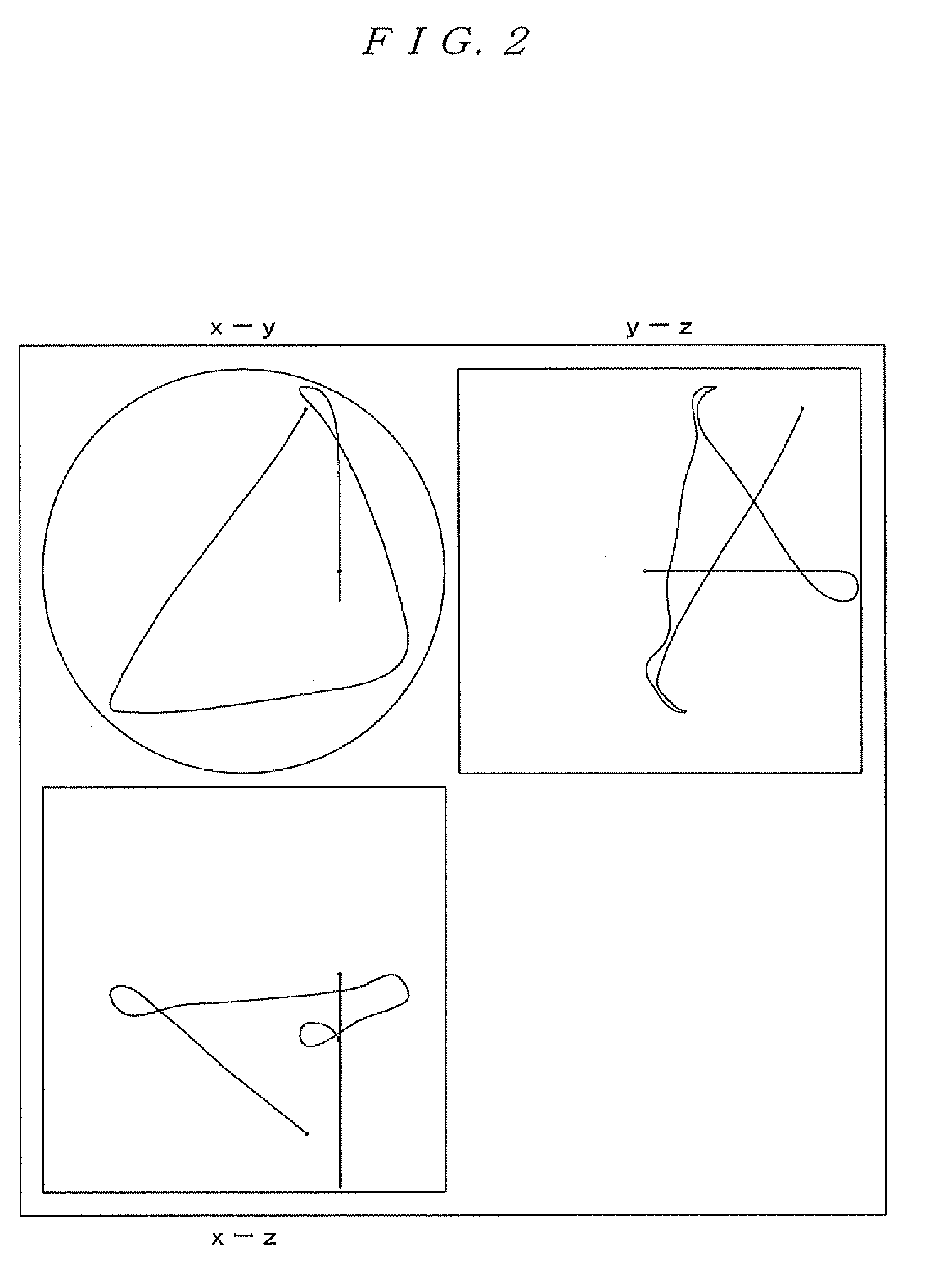

Electron beam device and method for stereoscopic measurements

InactiveUS20020179812A1Accurate rectifying parametersMaterial analysis using wave/particle radiationMicrobiological testing/measurementBeam sourceParticle physics

An electron beam device according to the present invention is made up of an electron beam source for emitting an electron beam, an electron optical system for irradiating the electron beam onto a specimen, a specimen holder for holding the specimen, a specimen tilting section for producing relative tilt angles between the specimen holder and the electron beam, an electron beam detecting section for detecting electron beam emitted from the specimen, and a data correcting section for correcting the three-dimensional detection data to have specified relationship under the condition of a relative tilt angle between the specimen holder and the electron beam.

Owner:KK TOPCON

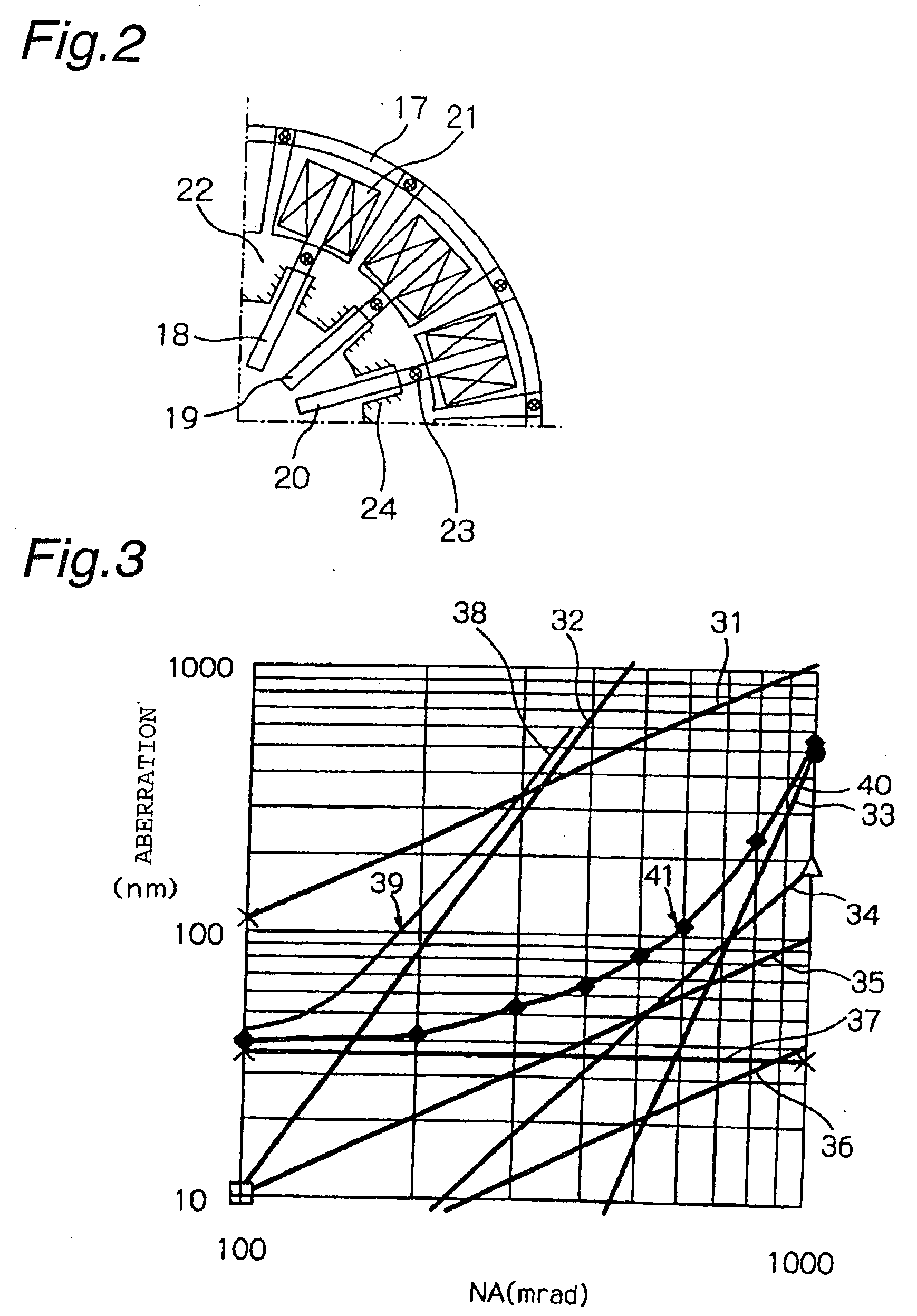

Electron beam apparatus

InactiveUS20090014649A1Reduce aberrationHigh-precision image data whose aberration is reducedMaterial analysis using wave/particle radiationElectric discharge tubesOptical axisLight beam

Secondary electrons emitted from a sample (W) by an electron beam irradiation is deflected by a beam separator (77), and is deflected again in a perpendicular direction by an aberration correction electrostatic deflector (711) to form a magnified image on the principal plane of an auxiliary lens (712). The secondary electron beam diverged from the auxiliary lens (712) passes through axial chromatic aberration correction lenses (714-717) and images on a principal plane of an auxiliary lens (718) for a magnifying lens (719). The magnified image is formed in a position spaced apart from the optical axis. Therefore, when the secondary electron beam diverged from the auxiliary lens (712) is incident on the axial chromatic aberration correction lenses without any change, large abaxial aberration occurs. To avoid it, the auxiliary lens (712) is used to form the image of an NA aperture (724) in substantially a middle (723) in the light axis direction of the axial chromatic aberration correction lenses (714-717).

Owner:KK TOSHIBA

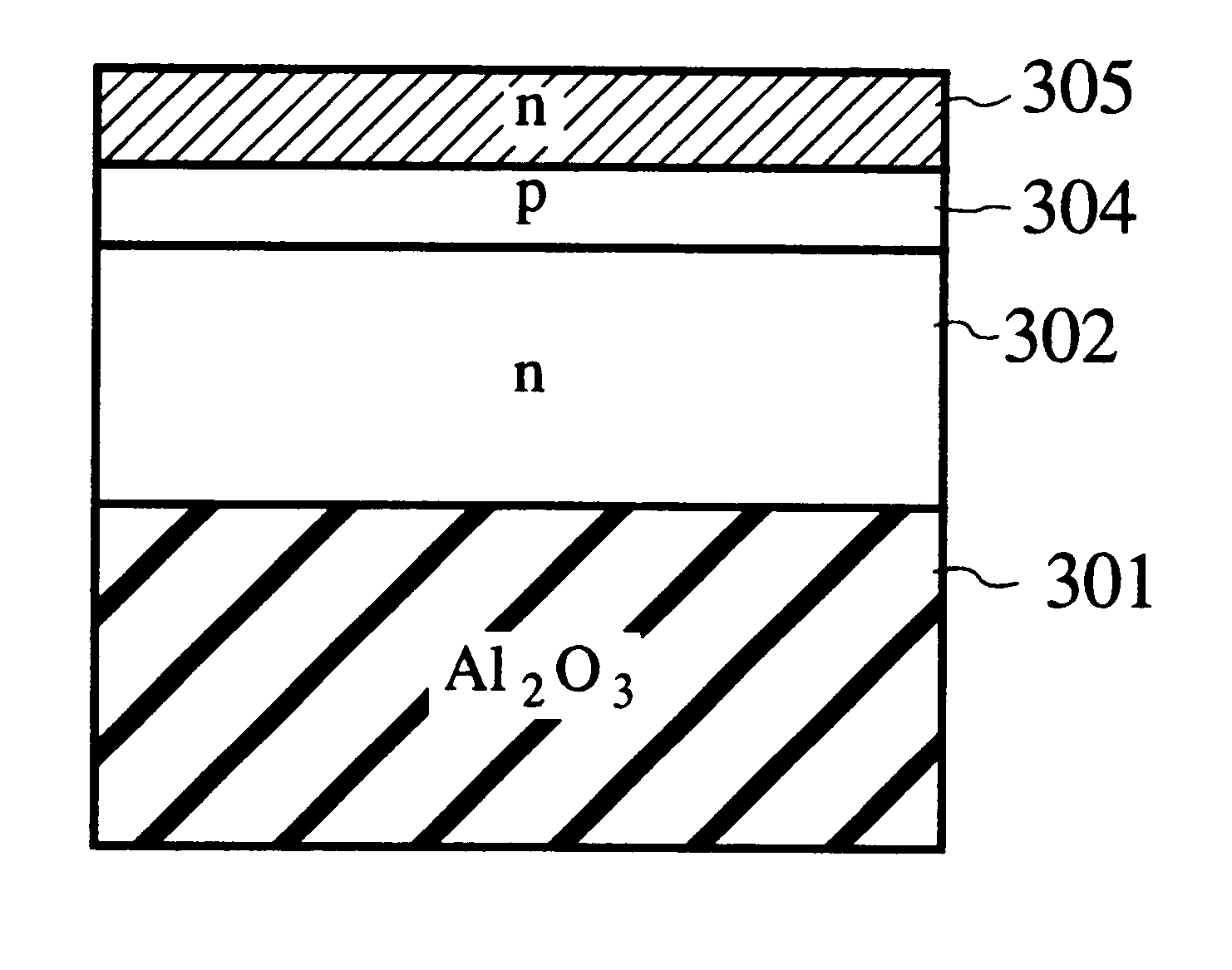

GaN based optoelectronic device and method for manufacturing the same

InactiveUS6221684B1Improve extraction efficiencyImprove luminous performanceLaser active region structureSemiconductor/solid-state device manufacturingCharge carrierAcceptor impurity

An n-cap layer is formed on a top surface of p-type clad layers, the p-type clad layer is a top layer of a stacked structure having a pn-junction for emitting carriers into light-emitting region of a GaN based light-emitting device, thus increasing the activation ratio of acceptor impurities in the p-type clad layers. The n-cap layer is used also as a current blocking layer, thereby constructing a current-blocked structure. The n-cap layer should preferably be made of InuAlvGa1-u-vN (0<u, v<1) deposited as thick as 1.0 micron or more. The present invention will easily provide a high luminous efficiency GaN based semiconductor light-emitting device without using any complicated processes such as electron-beam irradiation or thermal annealing.

Owner:KK TOSHIBA

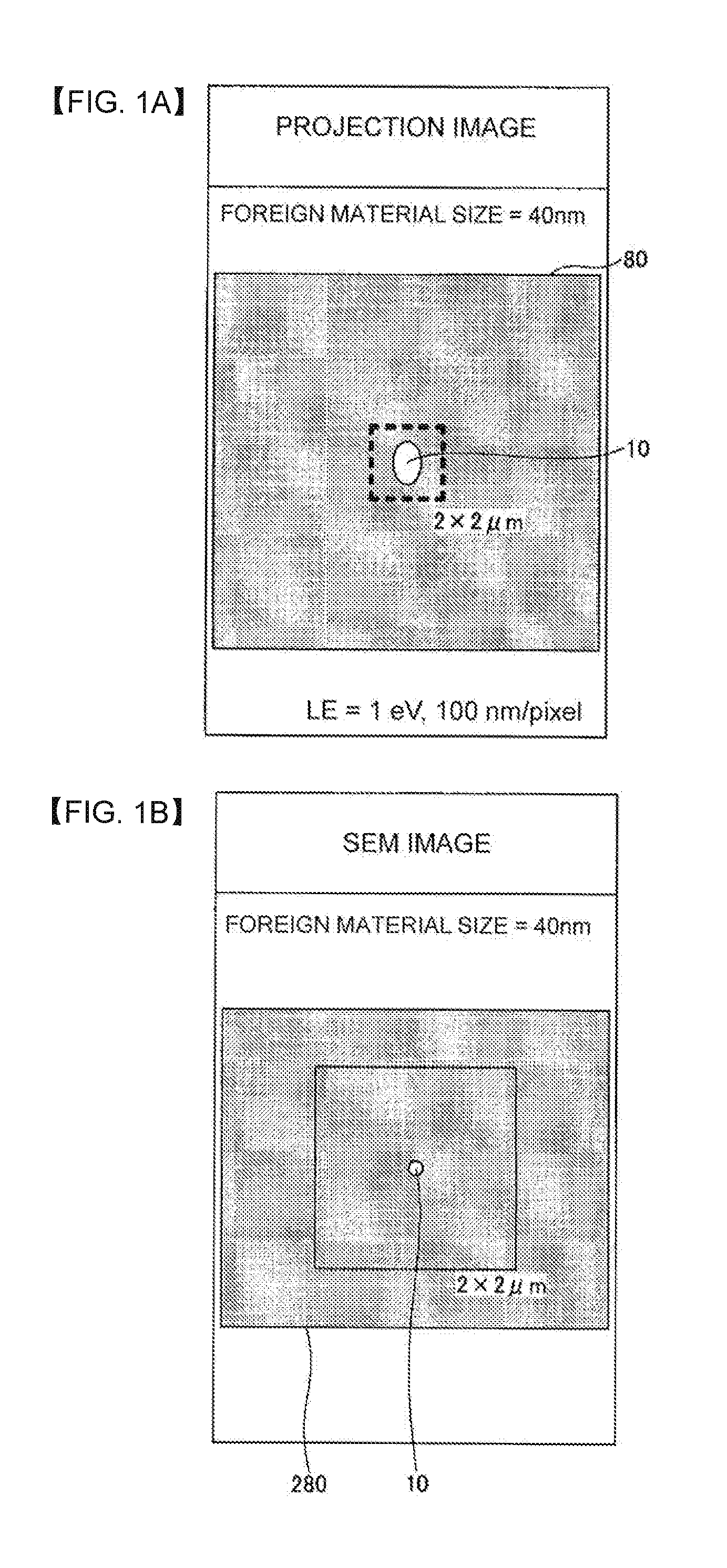

Specimen observation method and device, and inspection method and device using the method and device

ActiveUS20110155905A1Material analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementForeign matterPerformed Observation

A technique capable of improving the ability to observe a specimen using an electron beam in an energy region which has not been conventionally given attention is provided. This specimen observation method comprises: irradiating the specimen with an electron beam; detecting electrons to be observed which have been generated and have obtained information on the specimen by the electron beam irradiation; and generating an image of the specimen from the detected electrons to be observed. The electron beam irradiation comprises irradiating the specimen with the electron beam with a landing energy set in a transition region between a secondary emission electron region in which secondary emission electrons are detected and a mirror electron region in which mirror electrons are detected, thereby causing the secondary emission electrons and the mirror electrons to be mixed as the electrons to be observed. The detection of the electrons to be observed comprises performing the detection in a state where the secondary emission electrons and the mirror electrons are mixed. Observation and inspection can be quickly carried out for a fine foreign material and pattern of 100 nm or less.

Owner:EBARA CORP

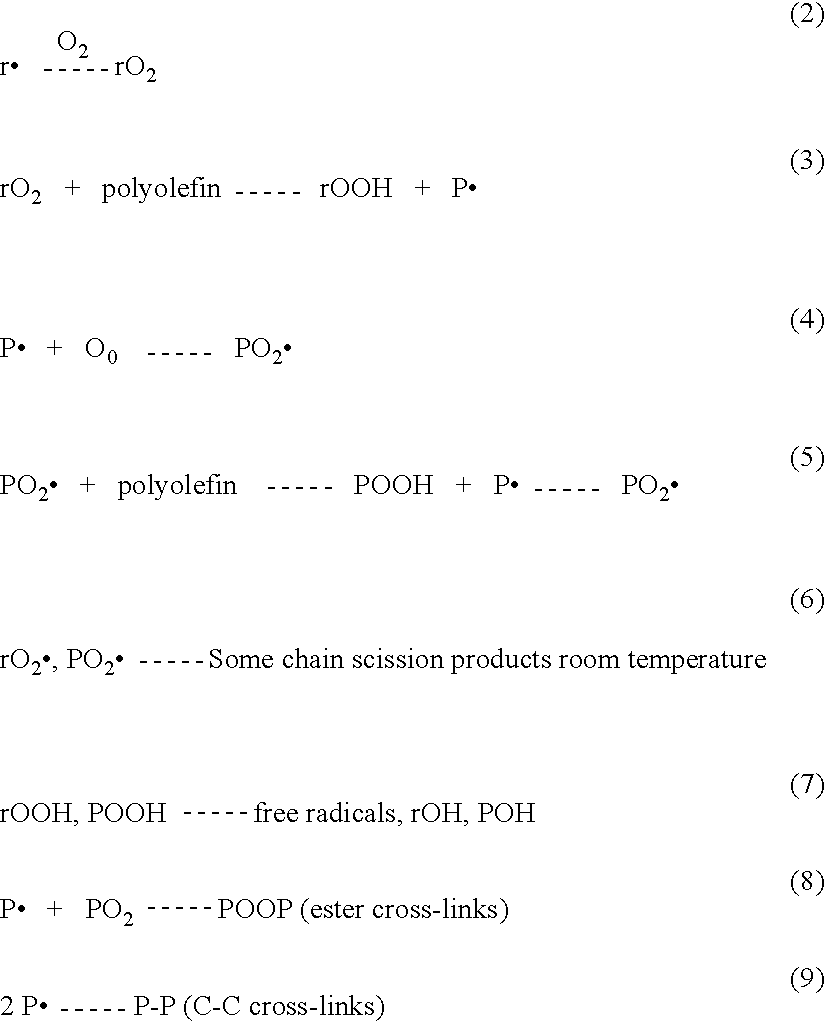

Polyethylene cross-linked with an anthocyanin

ActiveUS20100036491A1Improve wear resistanceReduced chain-scissionLavatory sanitoryMedical waste disposalCross-linkUltimate tensile strength

A method for manufacturing of ultrahigh molecular weight polyethylene (UHMWPE) for implants, where the implants have been machined out of UHMWPE blocks or extruded rods, has anthocyanin dispersely imbedded in the polyethylene. The implant is then exposed to γ ray or electron beam irradiation in an amount of at least 2.5 Mrad followed by a heat treatment to prevent the implant from becoming brittle in the long term as well as to improve strength and wear. The method includes mixing a powder or granulate resin of UHMWPE with an aqueous liquid that contains anthocyanin in a predetermined amount. The water is then evaporated in order to deposit the anthocyanin in a predetermined concentration on the polyethylene particles. The doped UHMWPE particles are compressed into blocks at temperatures in a range of approximately 135° C.-250° C. and pressures in a range of approximately 2-70 MPa. Medical implants are made from the blocks.

Owner:HOWMEDICA OSTEONICS CORP

Shrink film, process for producing the same, printing ink, print produced therewith and process for producing print

InactiveUS20050191439A1Short timeIncrease production capacityLayered productsDuplicating/marking methodsPrinting inkPlastic film

A coating material of an electron beam curable type is printed or coated onto a substrate of a heat shrinkable plastic film. Then, the coating material is cured by electron beam irradiation to form a coating layer. As a consequence, a shrinkable film including the substrate and the coating layer disposed thereon is obtained.

Owner:TOYO INK SC HOLD CO LTD +1

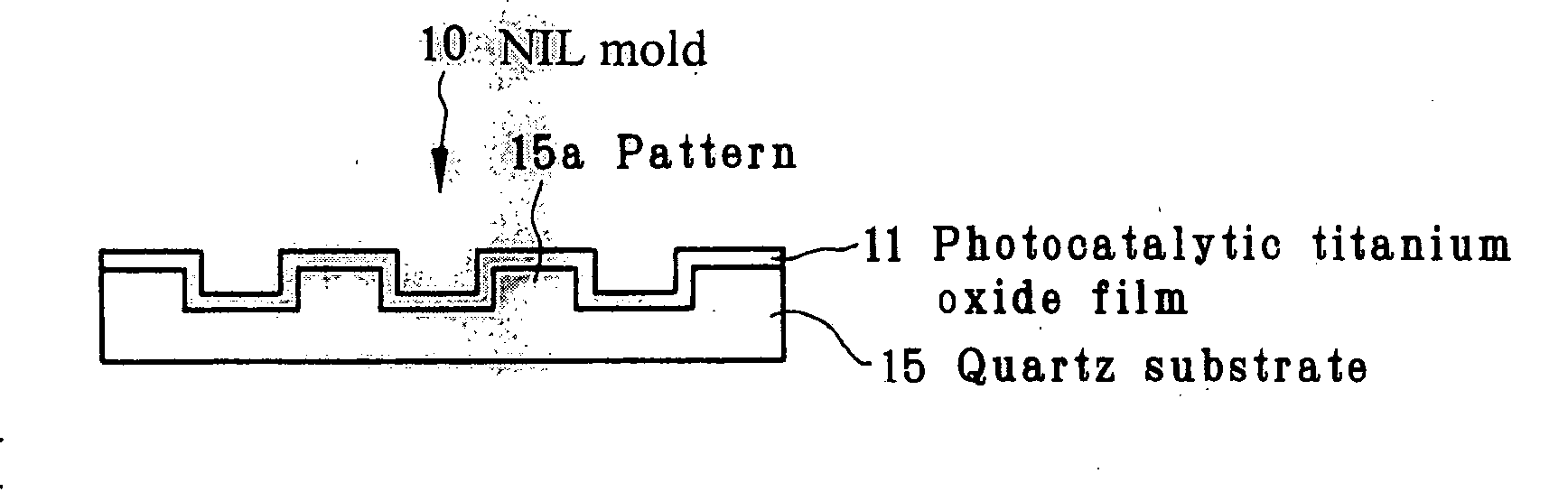

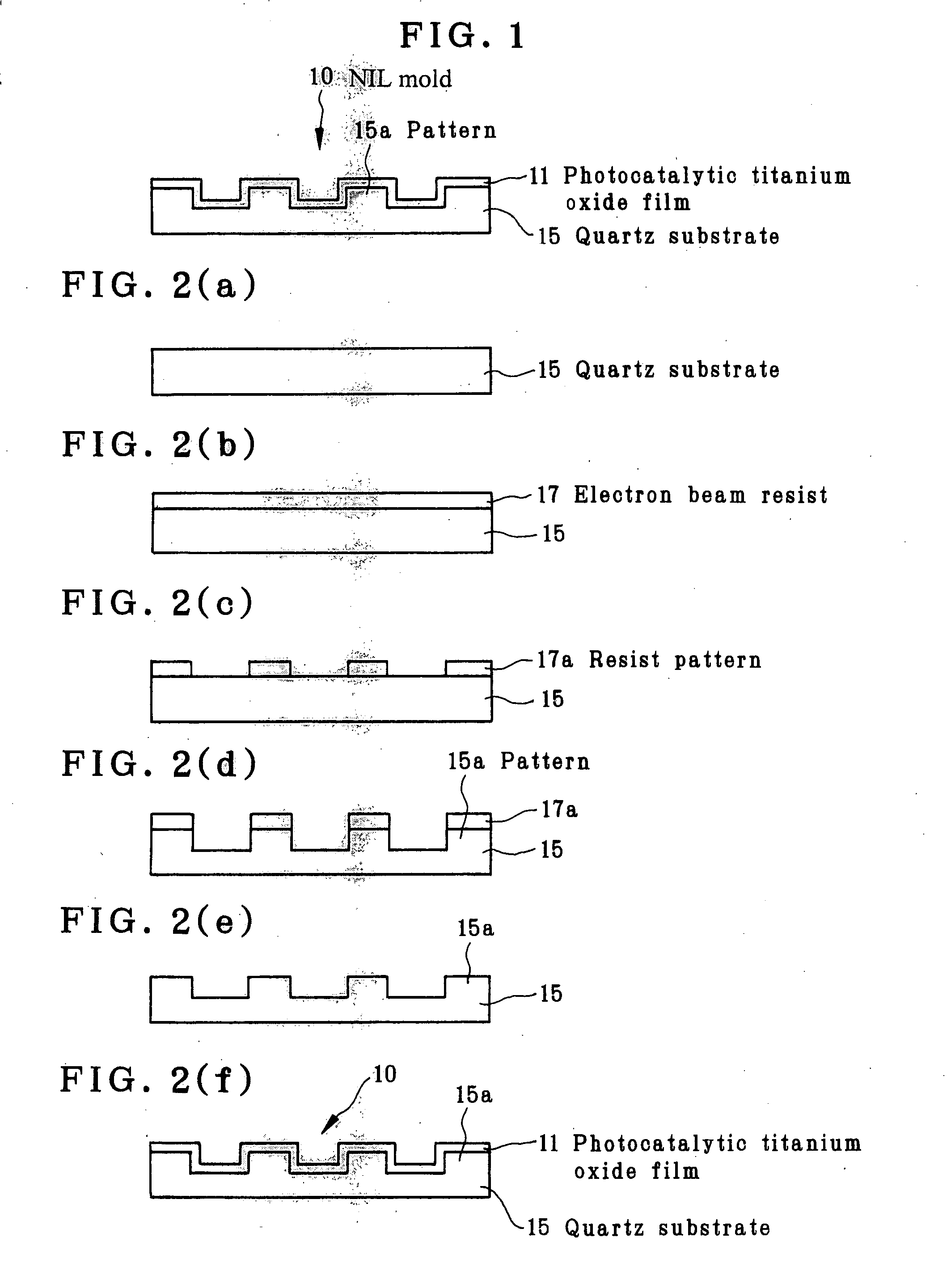

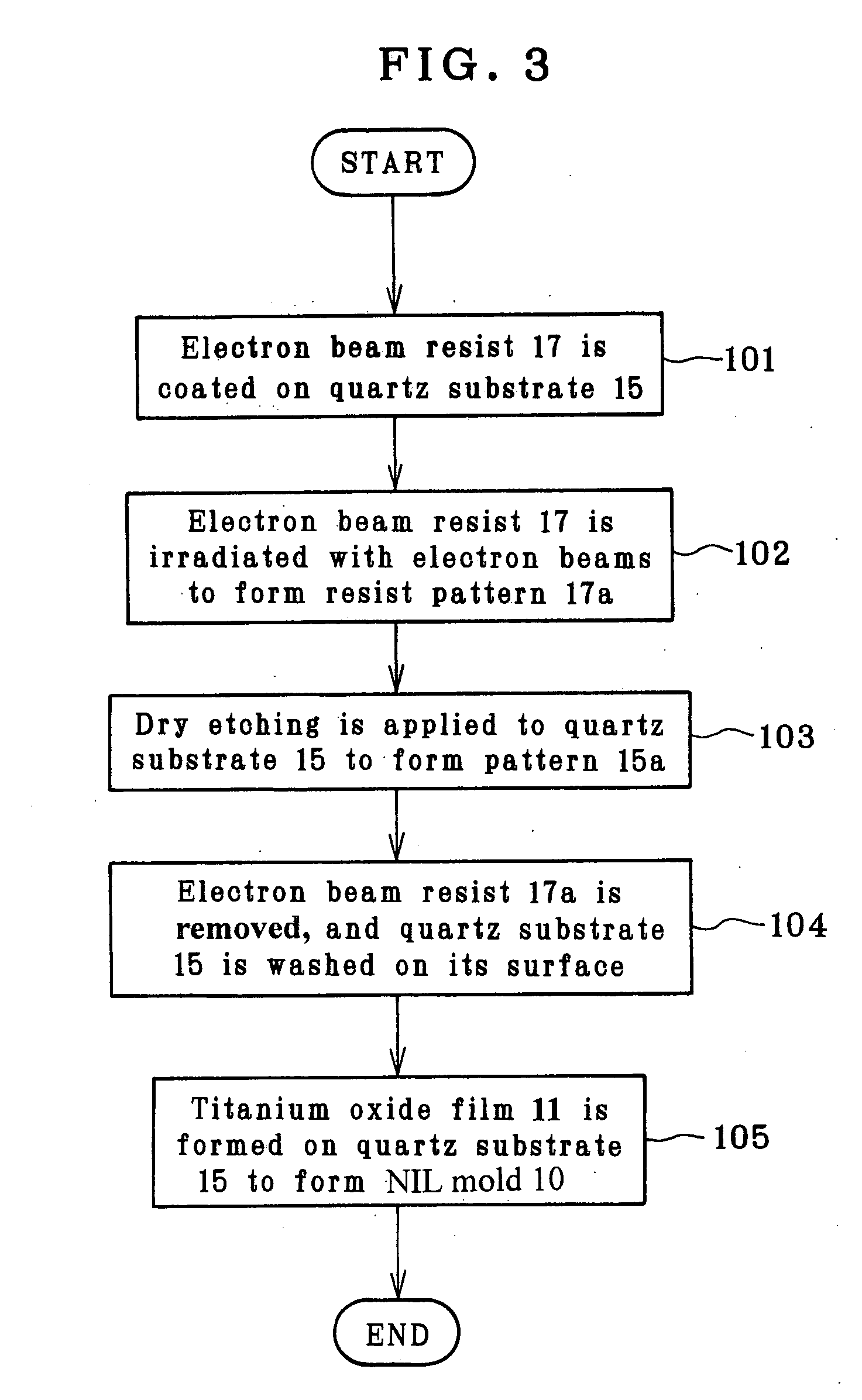

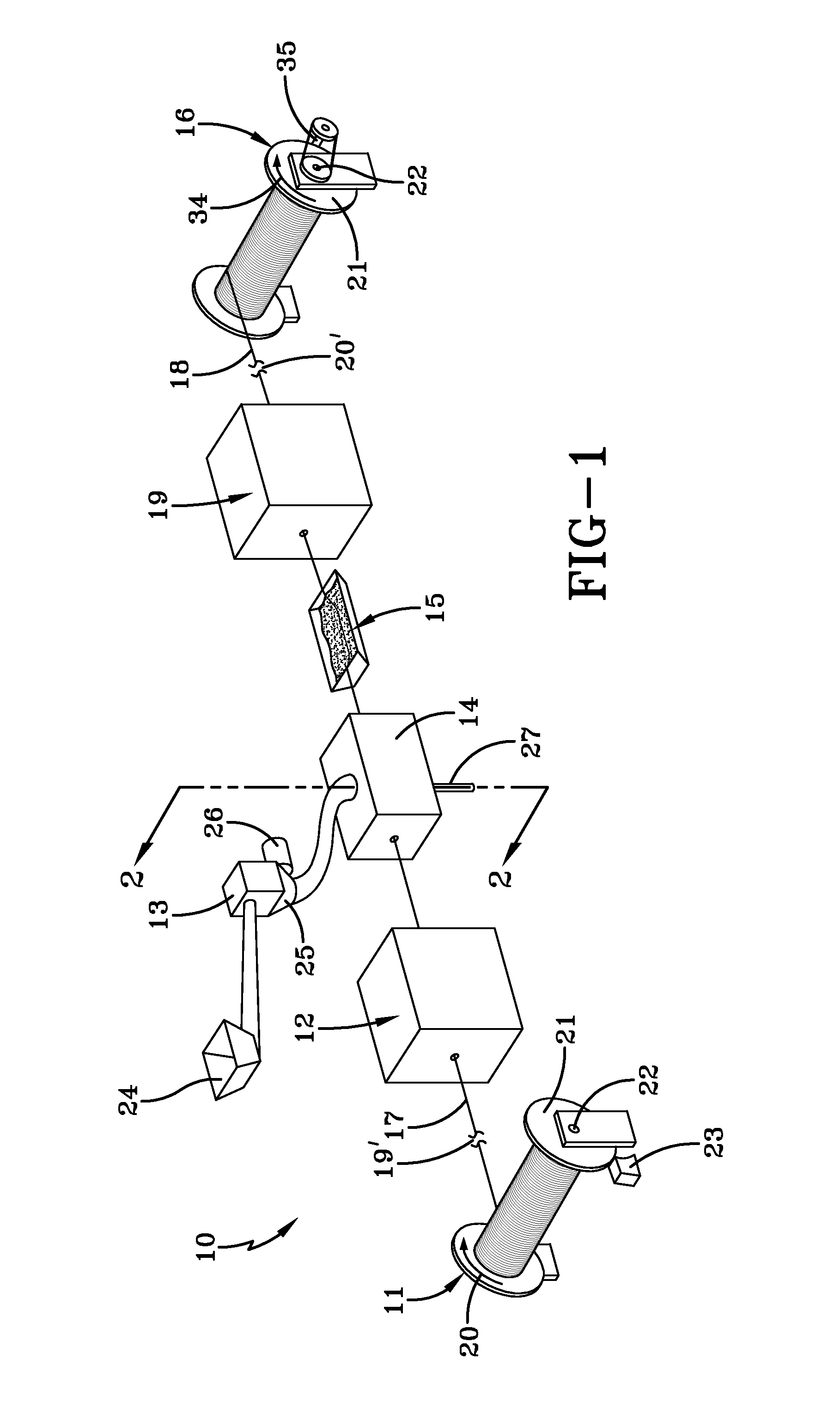

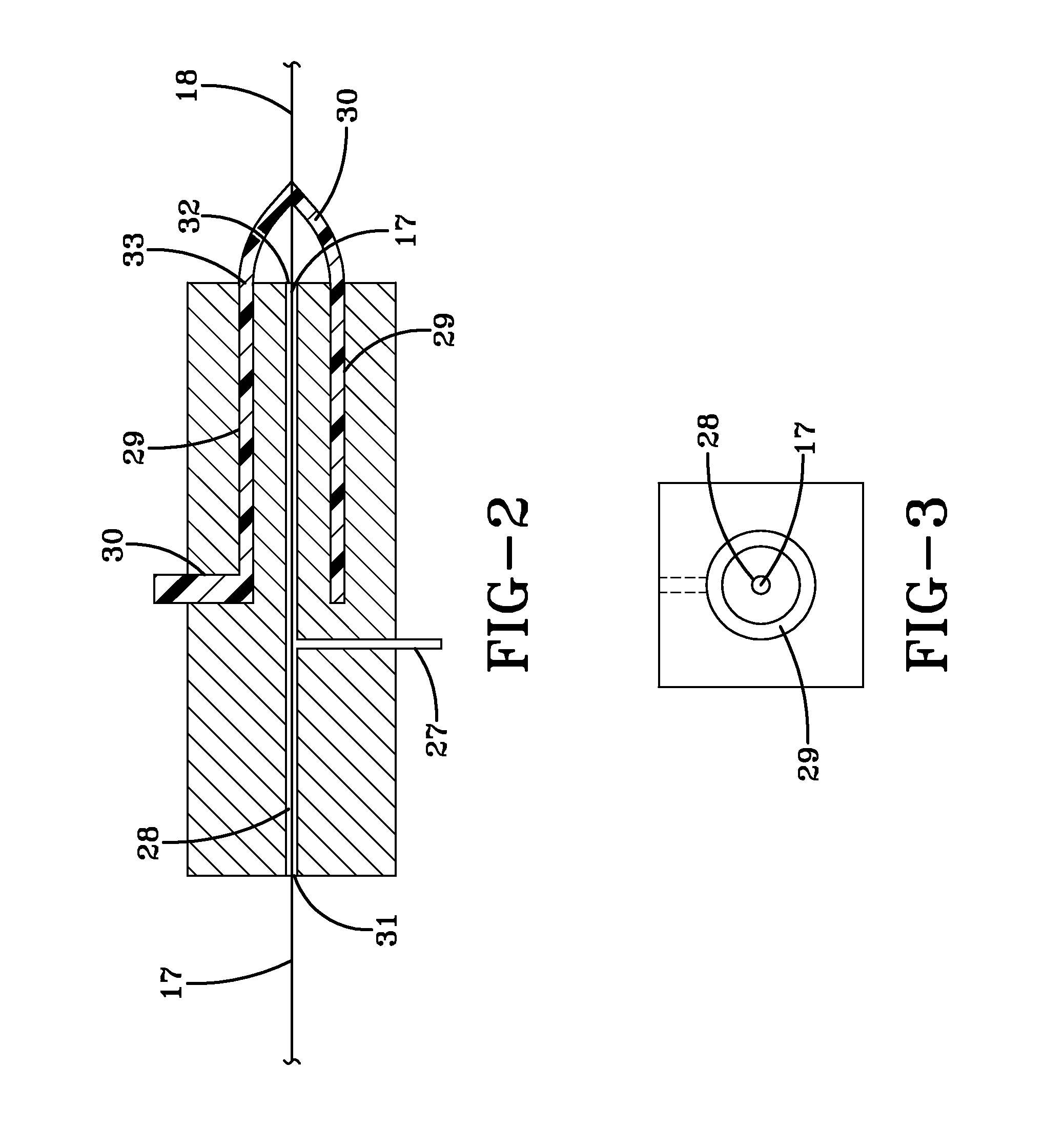

Mold for photocuring nano-imprint and its fabrication process

InactiveUS20070267764A1Improve reliabilityImprove robustnessNanoinformaticsFoundry mouldsCarbon monofluorideUltraviolet lights

The invention relates to a mold that has an improved releasability for a photocured resin and an improved robustness. First, an electron beam resist 17 is coated on a quartz substrate 15 having the nature of being transmissive to ultraviolet light. A resist pattern 17a is formed by irradiation with electron beams. Thereafter, the quartz substrate is dry etched using etching gas such as carbon tetrafluoride to form a pattern 15a on the quartz substrate 15. A photocatalytic titanium oxide film 11 is formed as by sputtering on the surface of the quartz substrate 15 with the pattern 15a formed on it to fabricate an NIL mold 10.

Owner:DAI NIPPON PRINTING CO LTD

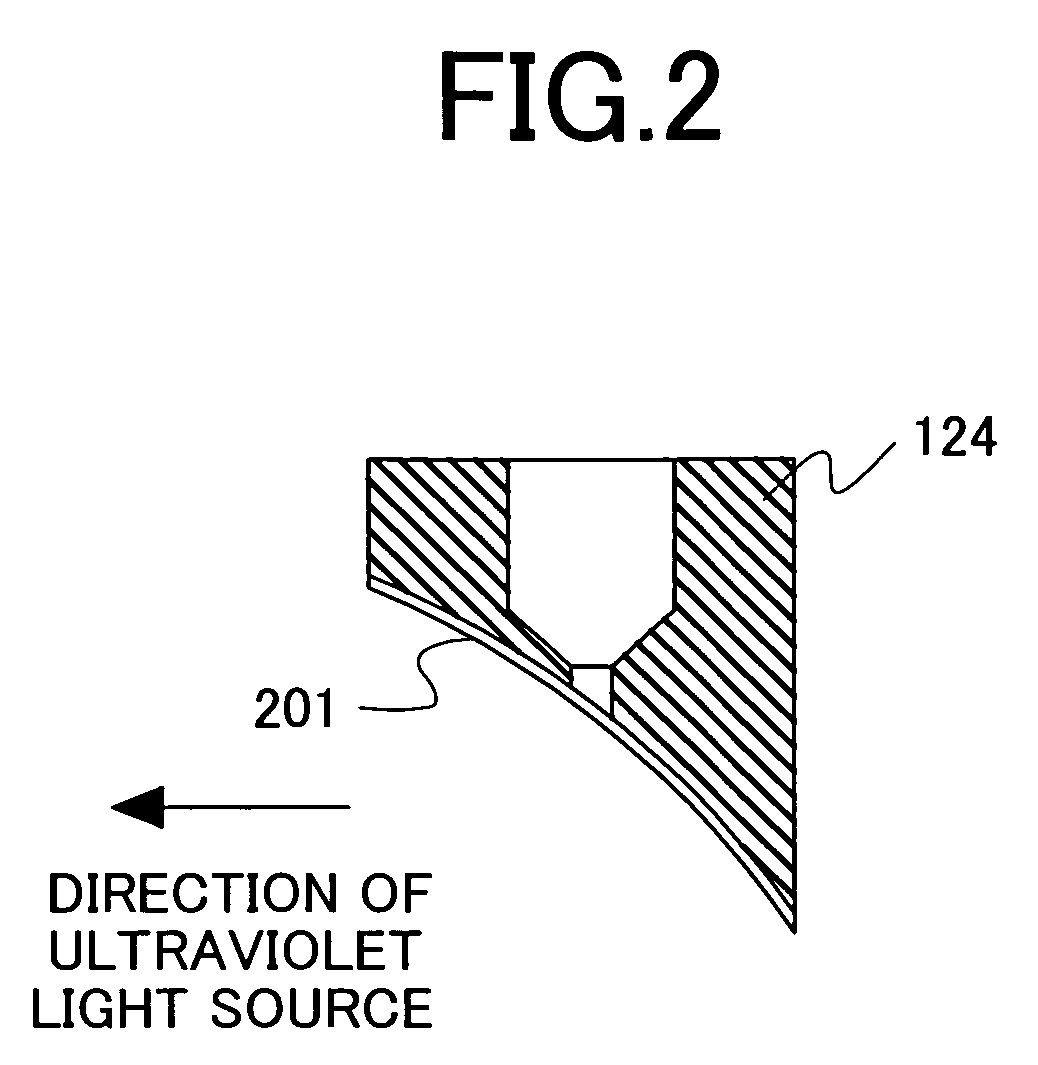

Electron beam inspection method and electron beam inspection apparatus

InactiveUS20080315093A1Highly sensitively detectedIncrease speedMaterial analysis using wave/particle radiationElectric discharge tubesImaging conditionUltraviolet

An electron beam inspection apparatus images reflected electrons and cancels negative charging derived from electron-beam irradiation. Ultraviolet rays are irradiated and an irradiated area of ultraviolet rays is displayed as a photoelectron image. The photoelectron image and a reflected-electron image are displayed on a monitor while being superposed on each other, to easily grasp the positional relationship between the images and the difference in size between them. Specifically, the shape of the irradiated area of an electron beam includes the shape of the irradiated area of ultraviolet rays on a display screen. The intensity of the ultraviolet rays in the irradiated area of the electron beam is adjusted while the reflected-electron imaging conditions for the reflected-electron image are sustained. Moreover, an amount-of-ultraviolet ray adjustment mechanism is controlled on the monitor so that an amount of the ultraviolet rays is adjusted while observing a reflected-electron image obtained during ultraviolet irradiation.

Owner:HITACHI LTD

Separator For Use in Electrochemical Cells and Method of Fabrication Thereof

InactiveUS20170263908A1Improve performanceImprove securityHybrid capacitor separatorsSecondary cellsParticulatesCross-link

An electrochemical cell, such as a capacitor or a secondary battery, is formed with a heat-resistant separator comprising a crosslinked membrane. The heat resistant separator is formed by exposing a polymeric membrane to a suitable condition, such as electron beam irradiation, to form the cross linked separator. In certain embodiments, the heat-resistant separator can be in the form of a laminate. In other embodiments, the heat-resistant separator includes inorganic particulate additives. The separator improves both safety and electrochemical performance of electrochemical cells, including lithium-ion batteries, such as by protecting against off-normal thermal abuse conditions and internal shorts from dendrite formation. The heat-resistant separator also provides improvements in high-rate and power density performance capabilities of secondary batteries.

Owner:GINER INC

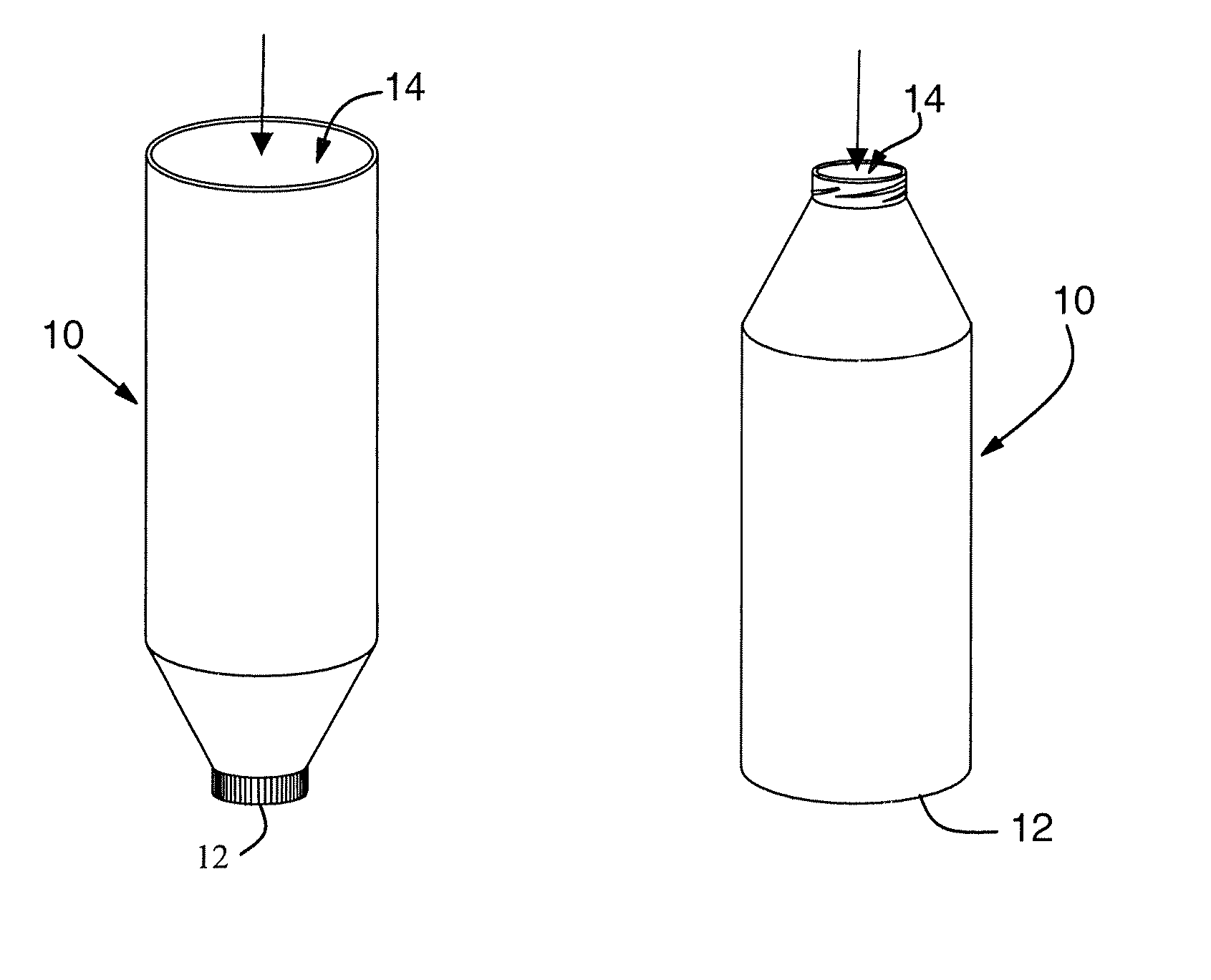

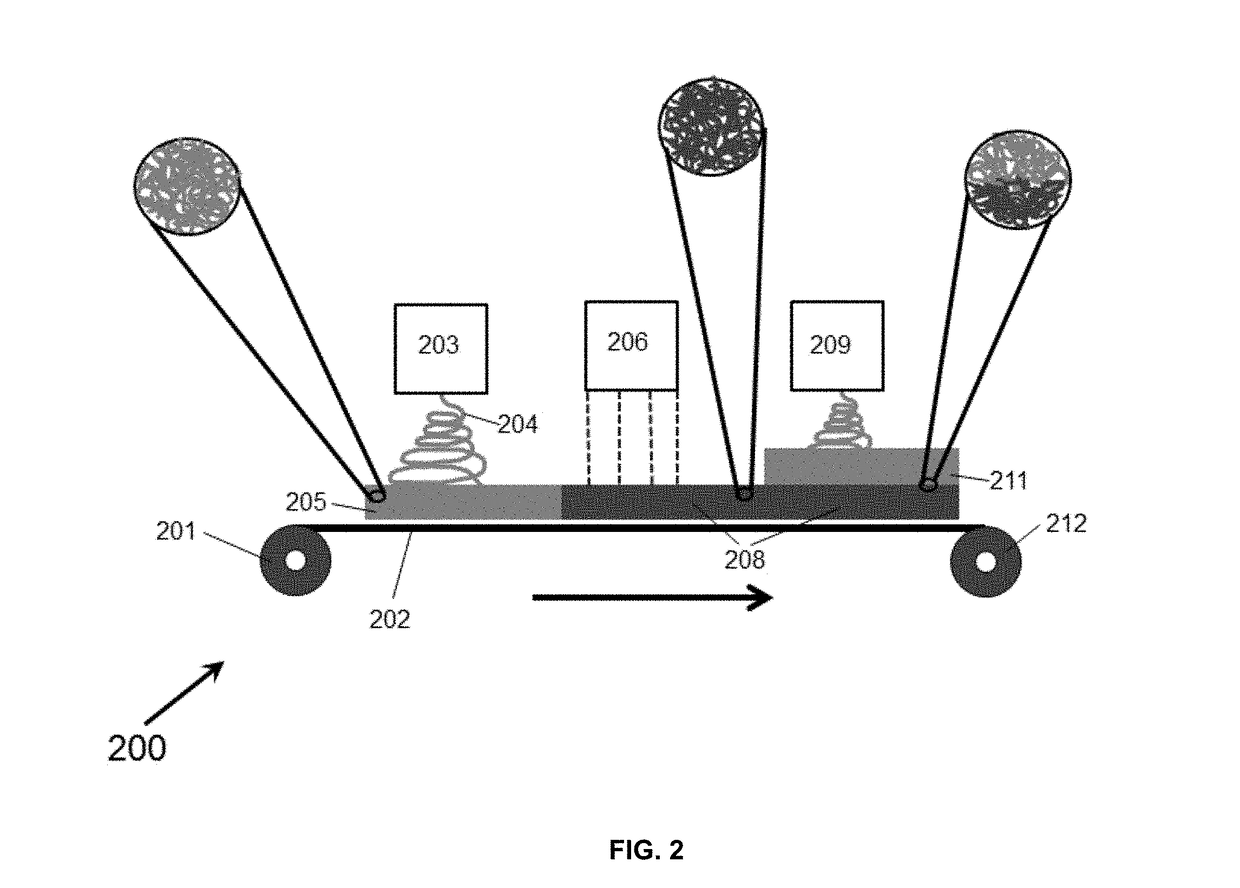

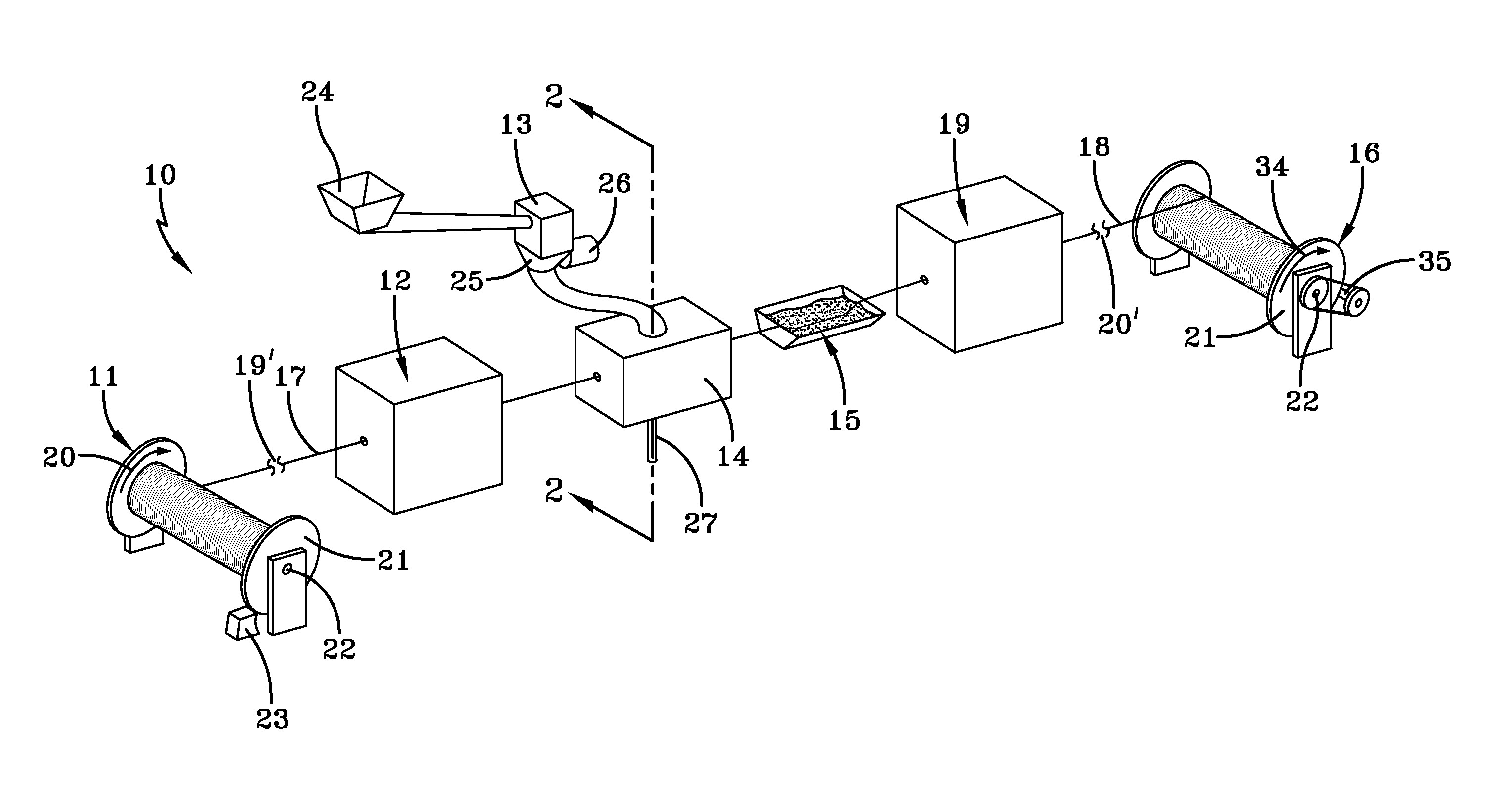

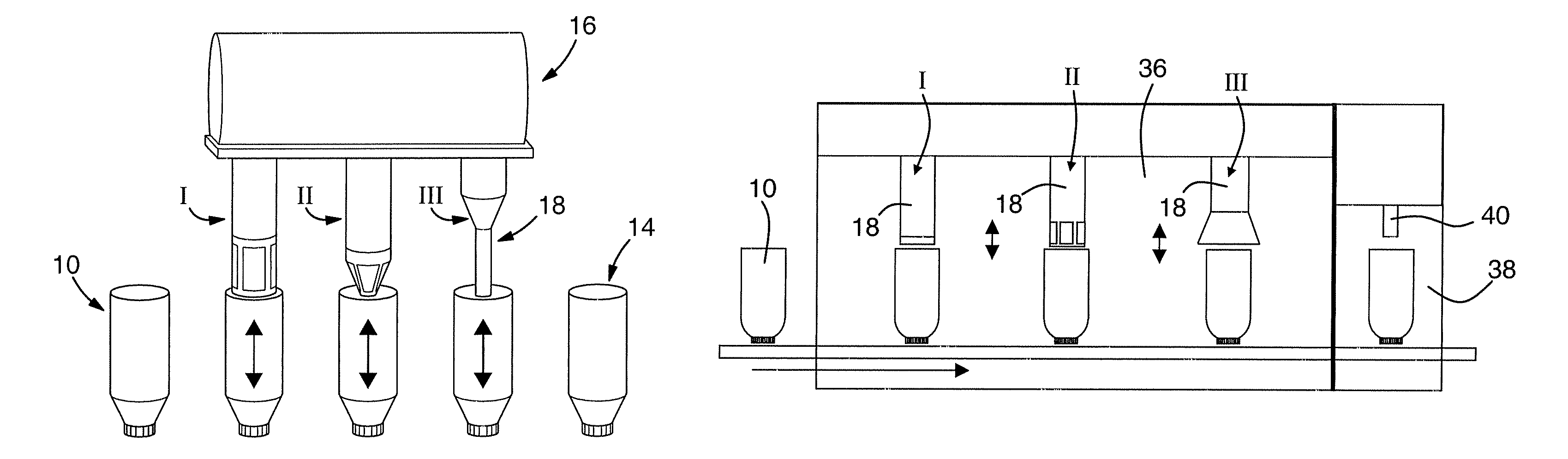

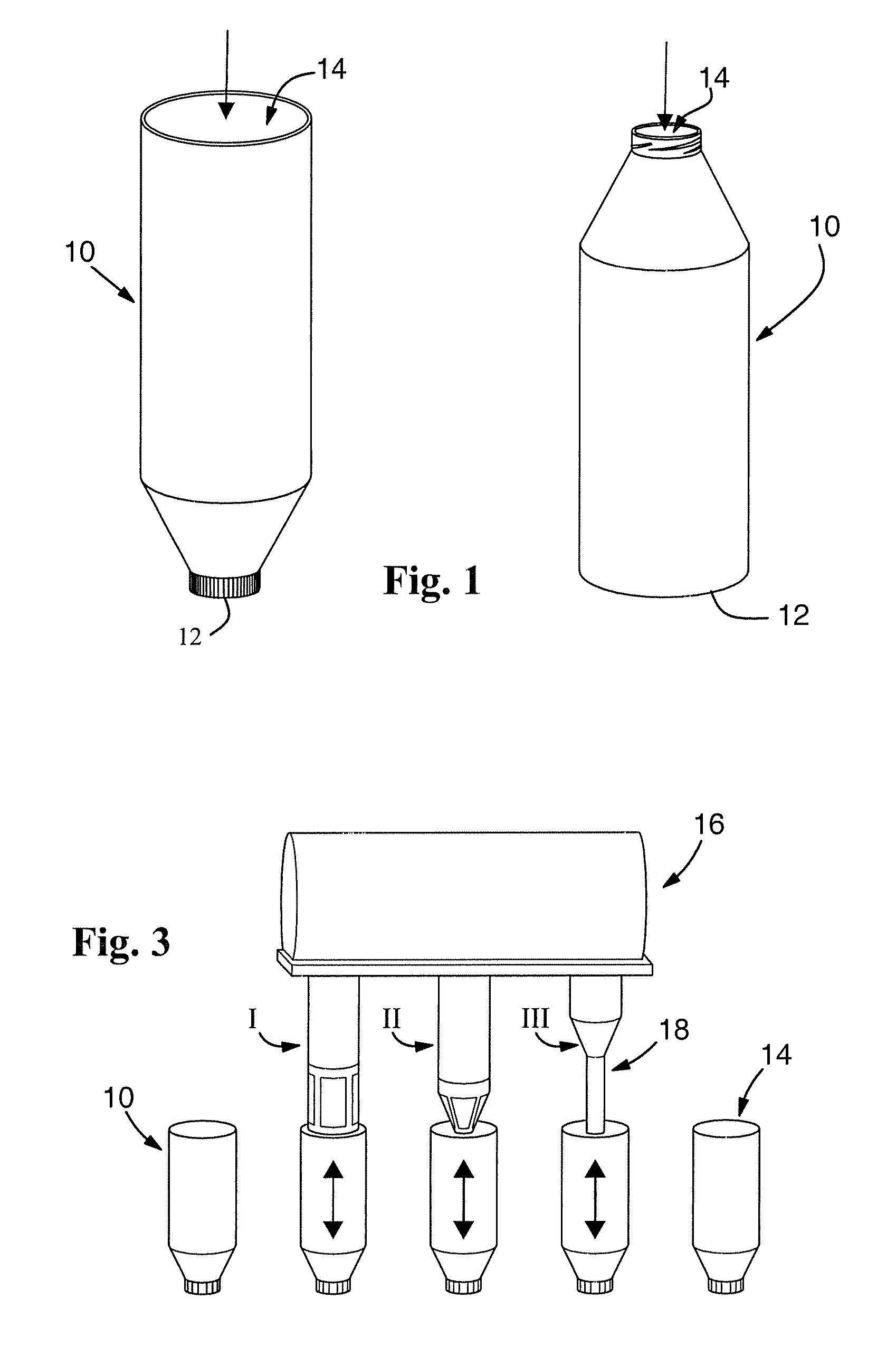

Method for irradiating objects

InactiveUS20080138243A1Short timeEven dosePackage sterilisationScattering properties measurementsIrradiationElectron

The invention relates to a method for irradiating partly formed packages (10) with electron beam irradiation from at least one electron beam sterilizing device (18), characterized in that it comprises: providing at least one partly formed package (10) to be irradiated in a gaseous environment, and exposing the gaseous environment to a pre-determined pressure regulation cycle and exposing the partly formed package (10) to irradiation at least during a portion of said pressure regulation cycle. The invention also relates to a device for realizing said method. The invention further relates irradiation of a packaging material web.

Owner:TETRA LAVAL HLDG & FINANCE SA

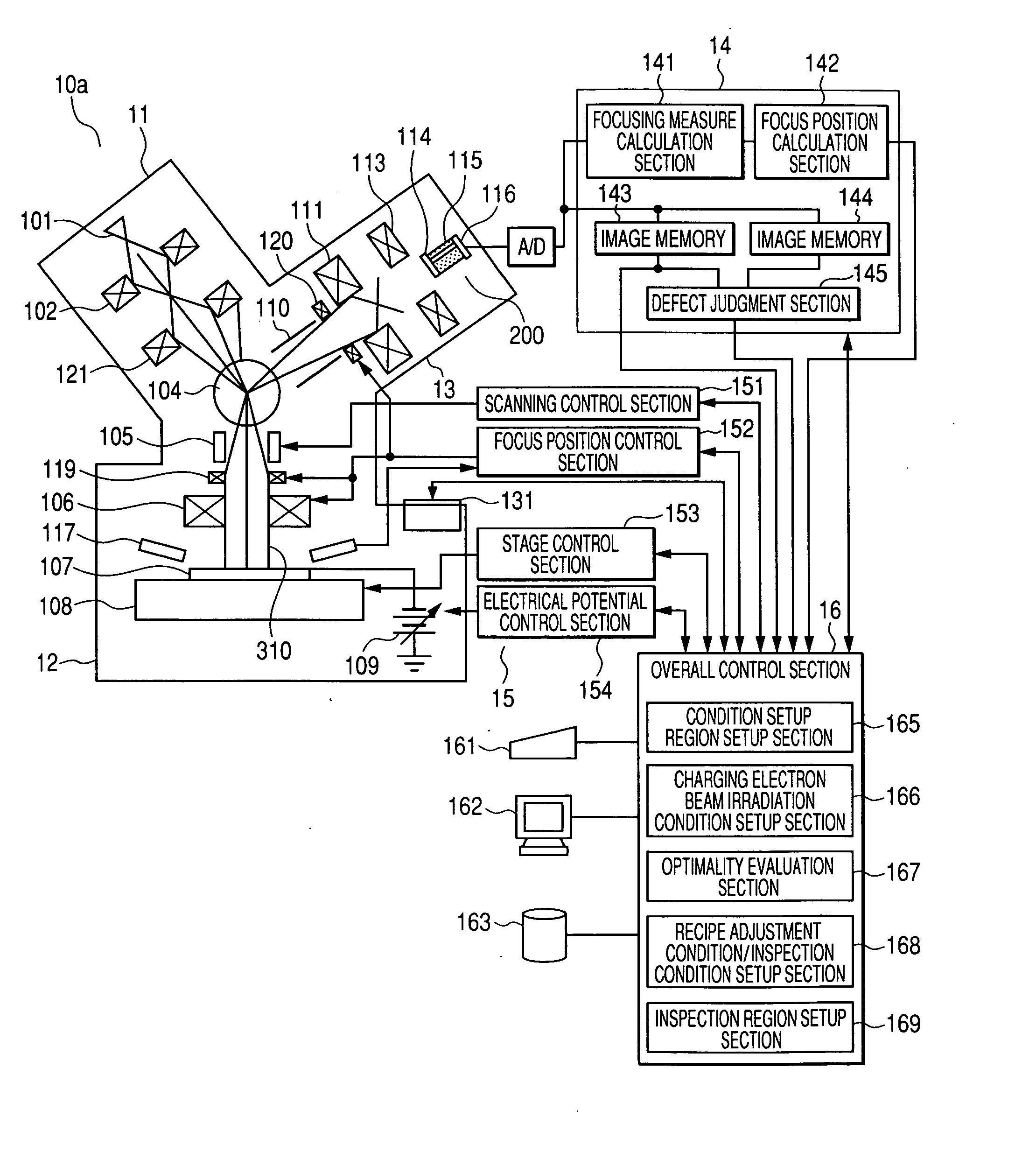

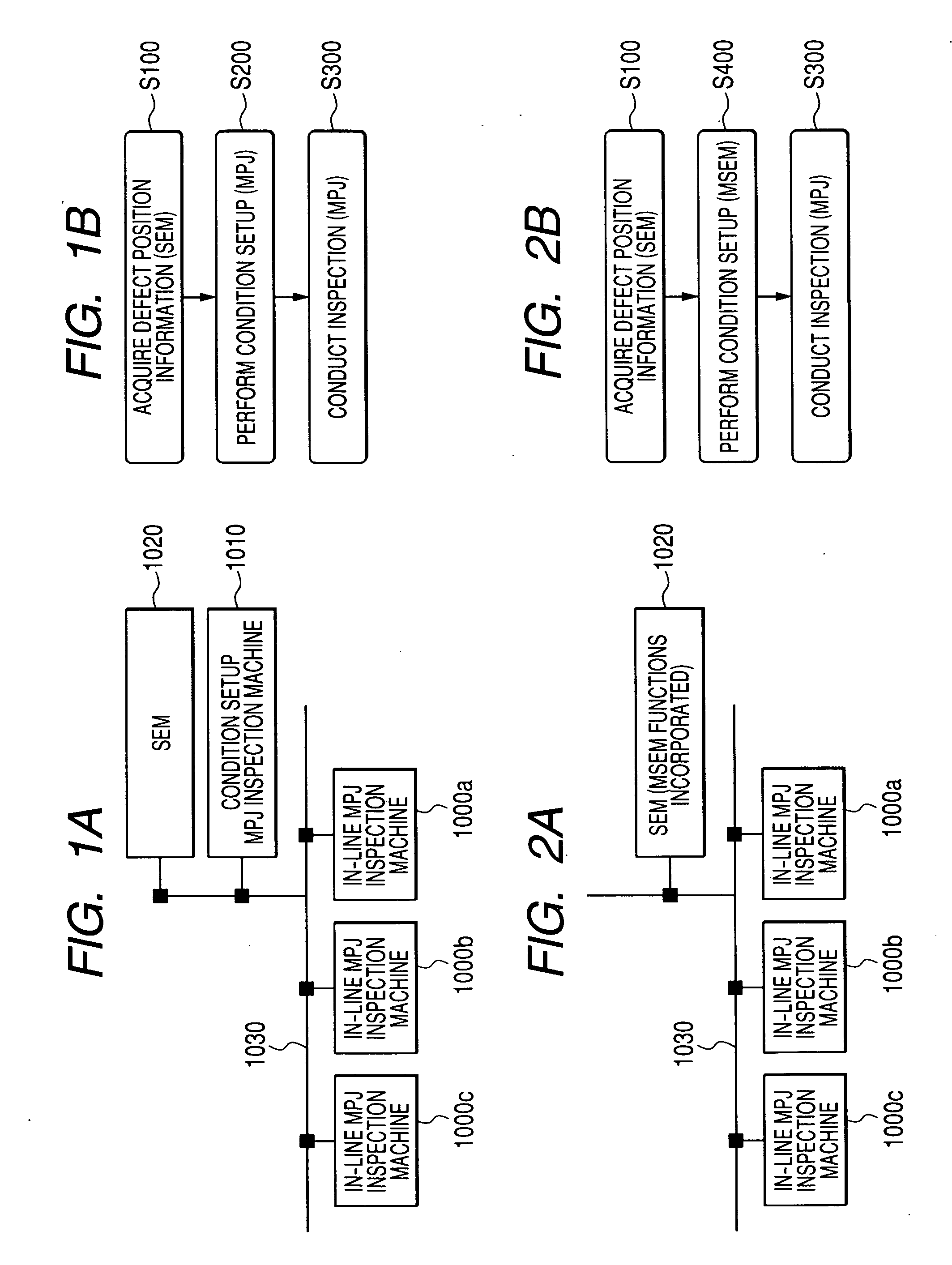

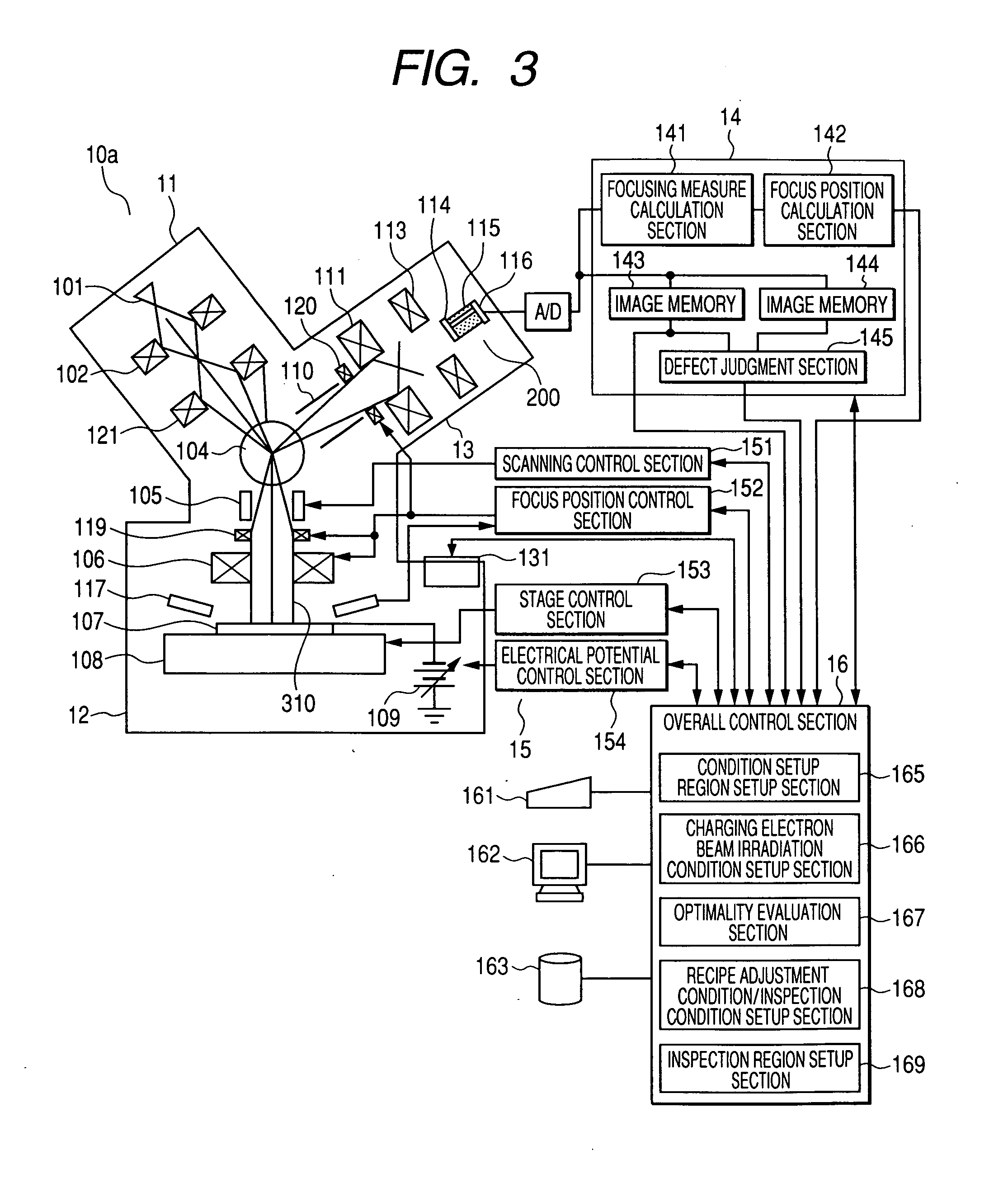

Method and apparatus for inspecting pattern defects and mirror electron projection Type or multi-beam scanning type electron beam apparatus

ActiveUS20070194229A1Quick checkMaterial analysis using wave/particle radiationElectric discharge tubesDevice typeLight beam

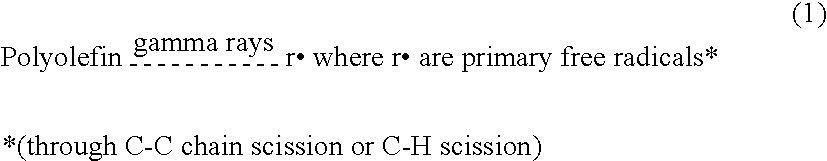

The present invention provides a mirror electron projection (MPJ) type (SEPJ type included) scanning electron beam apparatus that is capable of performing condition setup, and a method and apparatus for inspecting pattern defects with the scanning electron beam apparatus. A mirror electron projection type defect inspection apparatus, which comprises a charging device for emitting a charging electron beam, electron beam irradiation means for shedding a mirror electron projection electron beam onto an inspection region near which an electrical potential distribution is formed, detection means for detecting secondary electrons or reflected electrons generated from a surface and proximity of the specimen, and defect detection means for detecting a defect by processing a mirror image signal that is detected by the detection means, includes irradiation condition optimization means for optimizing charging electron beam irradiation conditions.

Owner:HITACHI HIGH-TECH CORP

Crosslinkable Thermoplastic Polyurethane

ActiveUS20110186329A1Improve the heating effectMaintain good propertiesElectric discharge tubesInsulated cablesThermoplasticPolymer science

The TPU of this invention contains unsaturation in its polymeric backbone. The unsaturation can be present in the soft segment or in the hard segment or in both the soft and hard segments of the TPU. The TPU can be molded like a thermoplastic, and can be subsequently crosslinked by exposure to electron beam irradiation into thermoset articles having excellent chemical resistance, dimensional stability, set properties, heat resistance, oxidative resistance, and creep resistance. In one embodiment, the TPUs of this invention are the reaction product (1) a hydroxyl terminated intermediate, (2) a polyisocyanate, (3) a saturated glycol chain extender, and (4) a glycol chain extender containing carbon-carbon double bonds, such as the allyl moieties present in trimethylolpropane monoallyl ether. In another embodiment of this invention, the thermoplastic polyurethane which is crosslinkable by e-beam irradiation is comprised of the reaction product of (1) a saturated hydroxyl terminated intermediate, (2) an unsaturated hydroxyl terminated intermediate, wherein the unsaturated hydroxyl terminated intermediate contains carbon-carbon double bonds, (3) a polyisocyanate, and (4) a saturated glycol chain extender.

Owner:LUBRIZOL ADVANCED MATERIALS INC

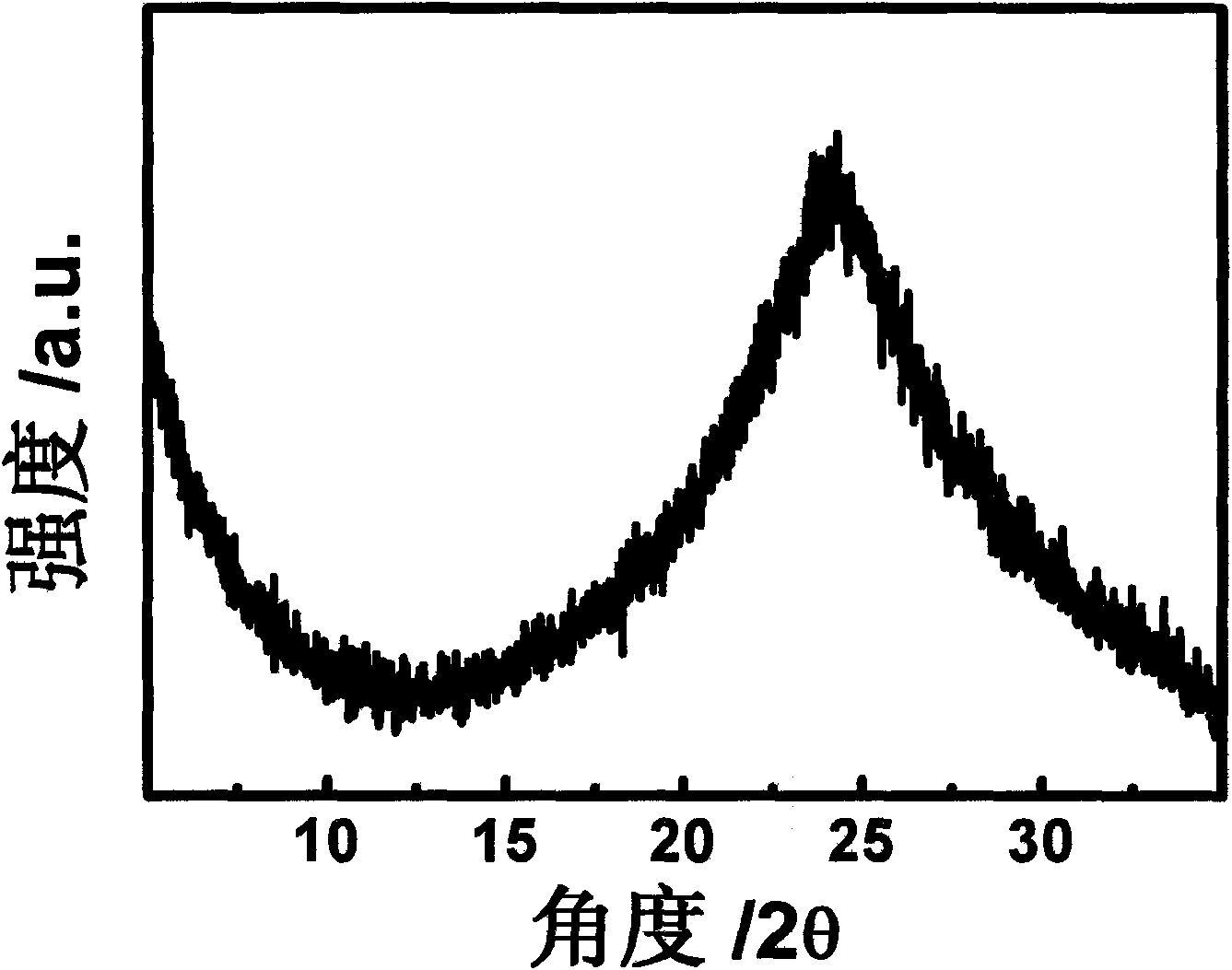

Method for preparing graphite alkenyl nanometer materials by electron beam irradiation method

InactiveCN101559941AHigh reversible lithium storage capacityImprove performanceNanostructure manufactureSolution stateCvd graphene

The invention relates to a method for preparing graphite alkenyl nanometer materials by an electron beam irradiation method. The method comprises the following steps: firstly, oxidizing natural graphite to obtain oxidized graphite; secondly, realizing the stripping between layers of the oxidized graphite by ultrasonic sound at the state of solution; and finally reducing the oxidized graphite through certain dosage of electron beam irradiation, and obtaining the graphite alkenyl nanometer materials. The method has simple preparation process, short preparation period and high yield, can be operated at normal temperature, does not add any catalyst and chemical initiator, and can be applied on a large scale.

Owner:SHANGHAI UNIV

Method of sterilizing packages

Owner:TETRA LAVAL HLDG & FINANCE SA

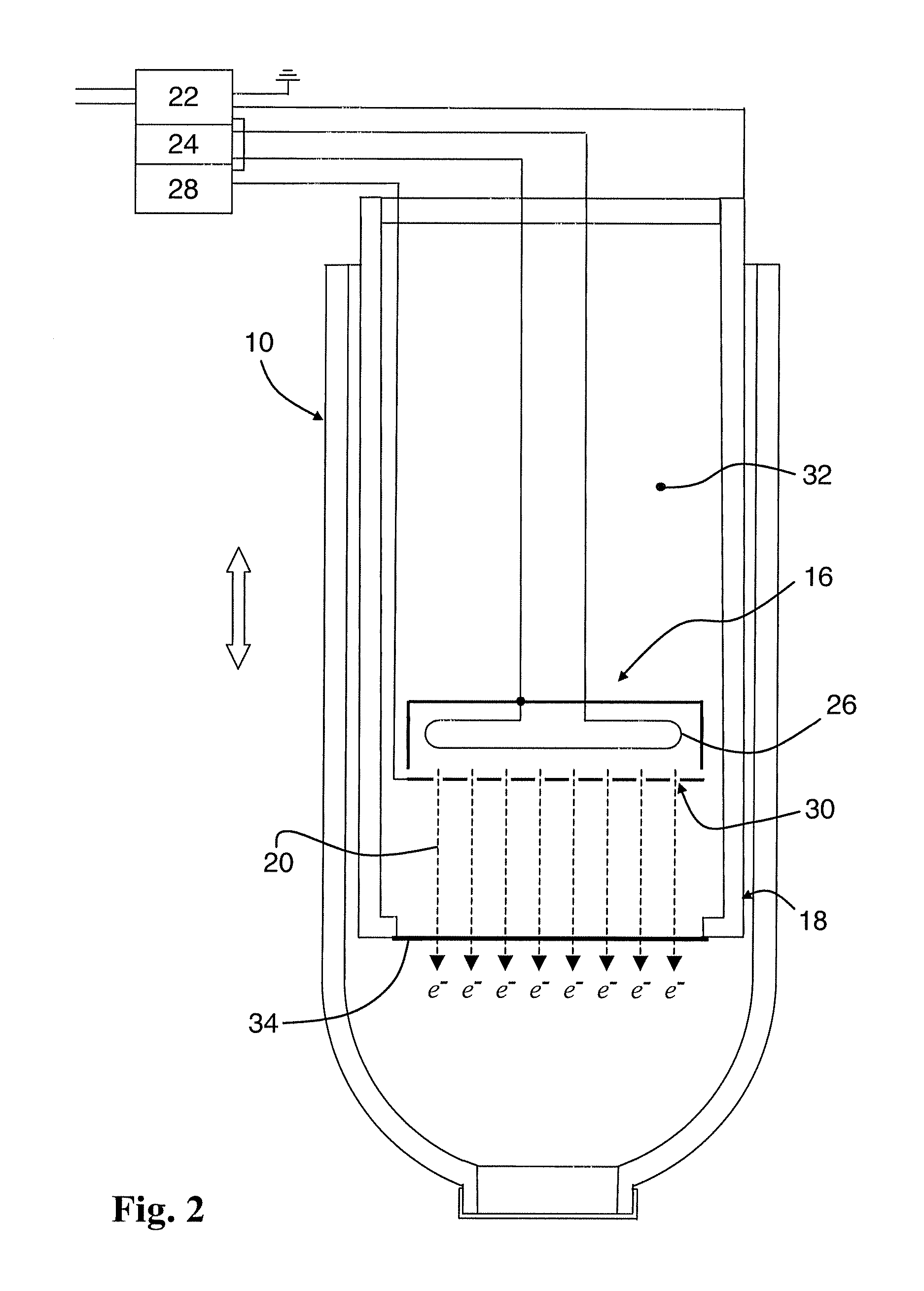

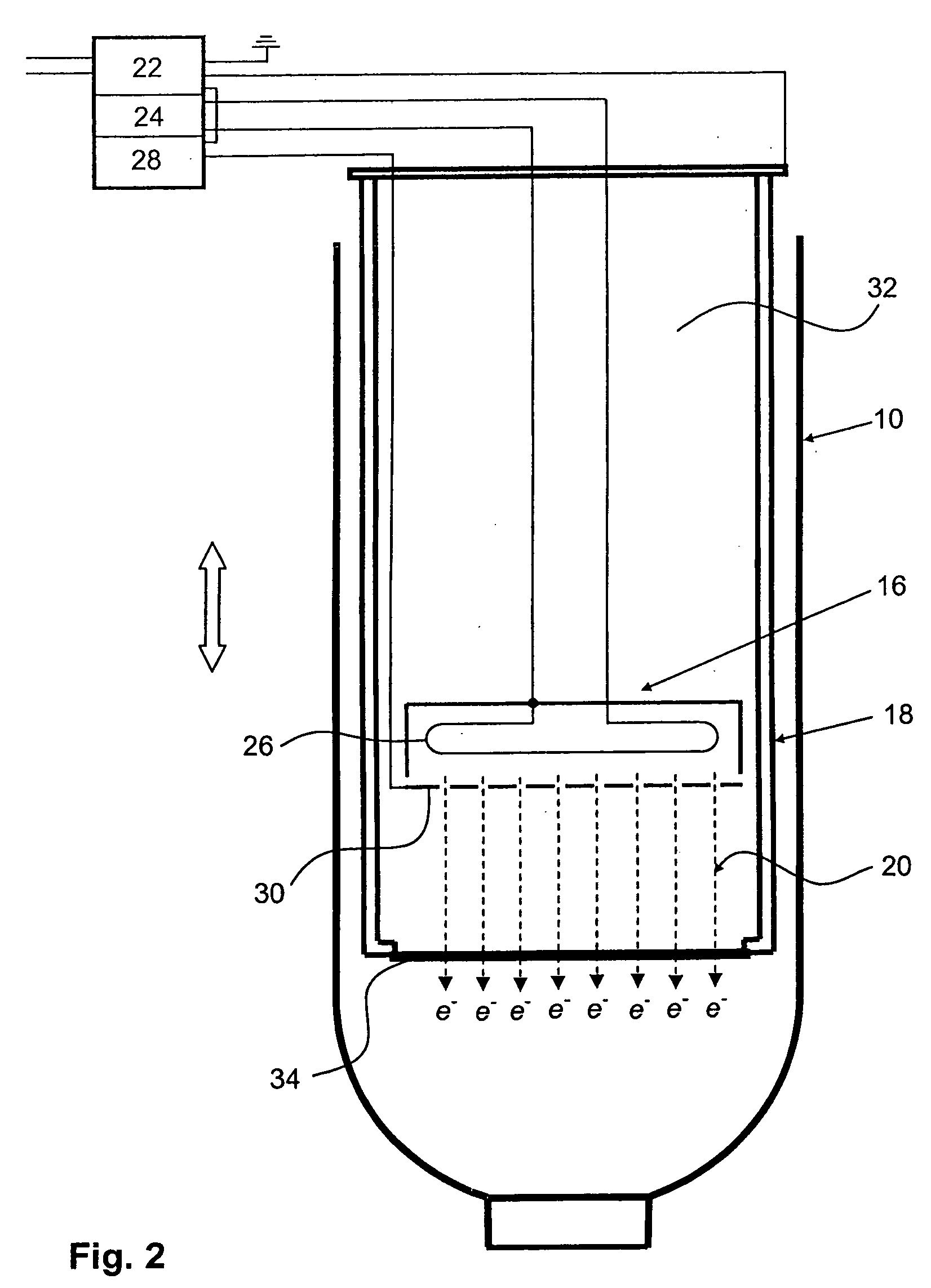

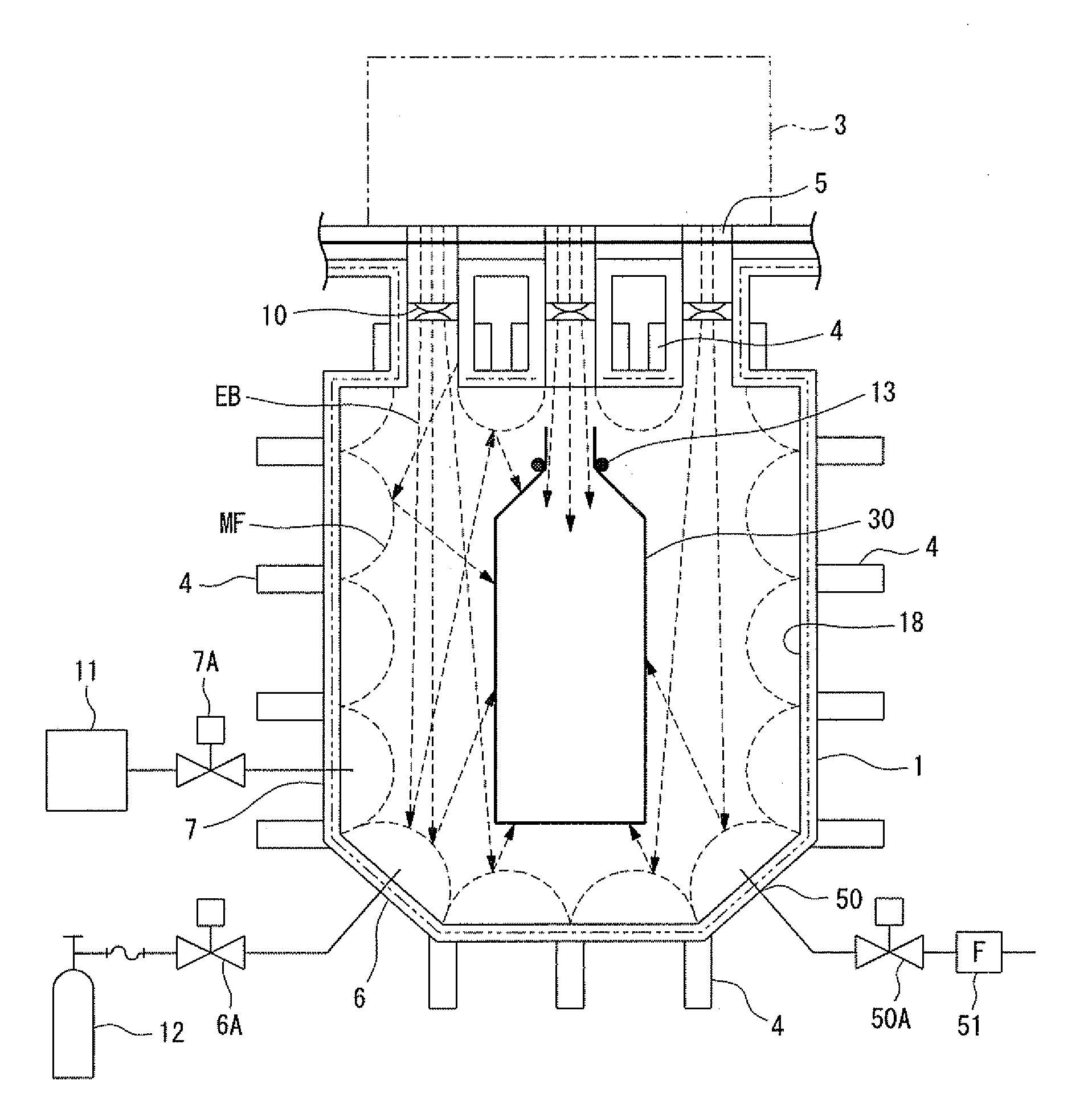

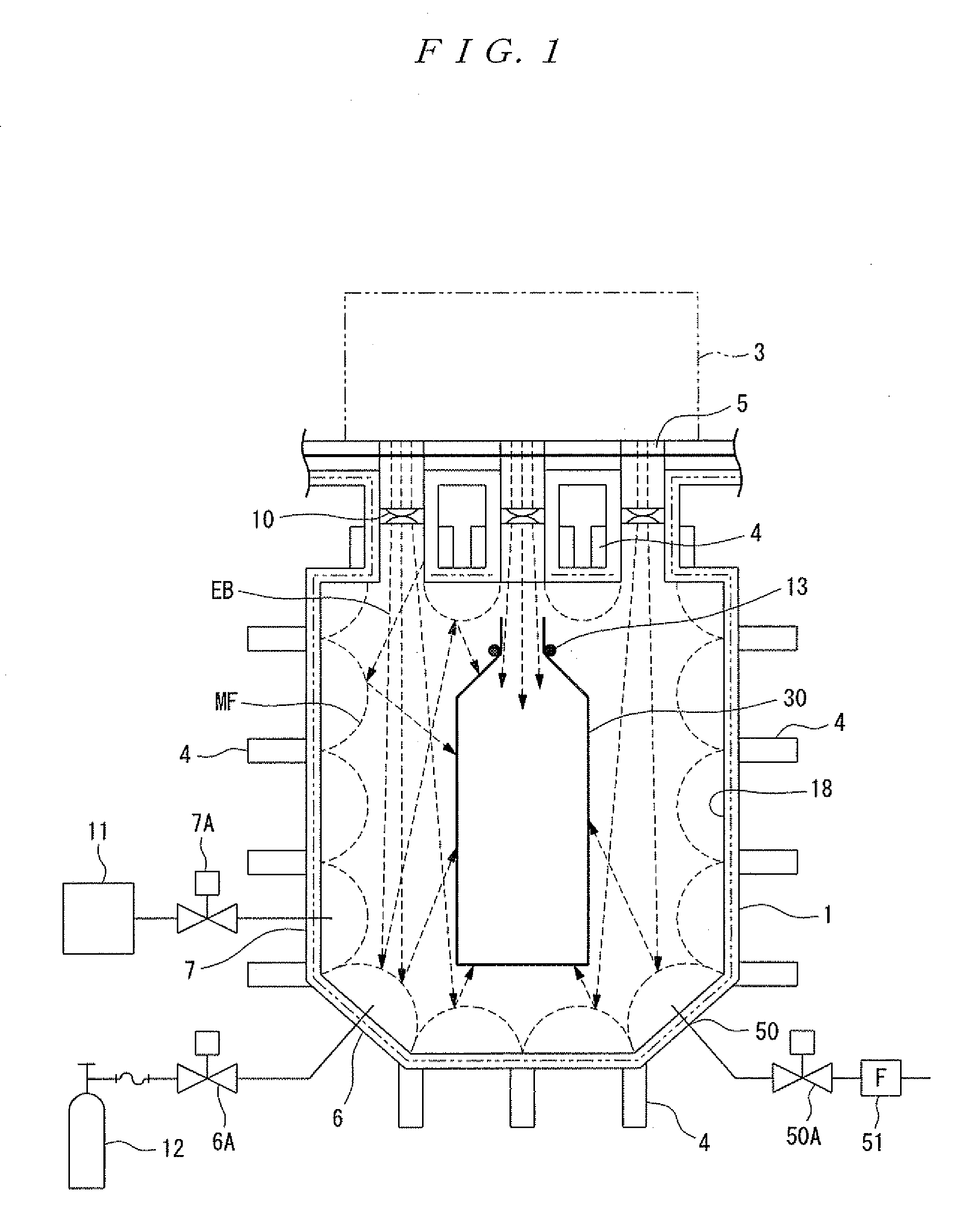

Electron Beam Irradiation Method, Electron Beam Irradiation Apparatus, and Electron Beam Irradiation Apparatus for Open-Mouthed Container

InactiveUS20090134338A1Reduce chanceSlightly wornParticle separator tubesPackage sterilisationMagnetic barrierElectron

There are provided an electron beam application method and an electron beam application device capable of uniformly applying electron beams to an object even if the electron beams have a low energy. For this, electron beams (EB) are applied to a beverage container (30) (object) within a magnetic barrier (MF) formed by combining a plurality of magnetic fields generated in an electron beam application region.

Owner:JAPAN AE POWER SYST

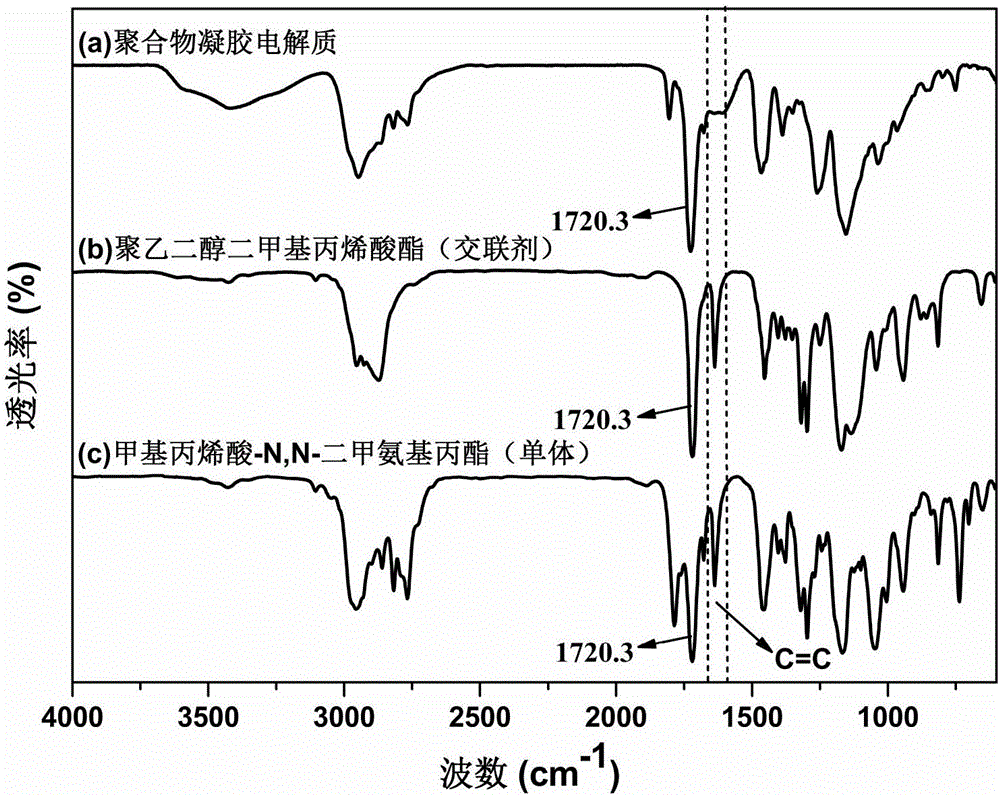

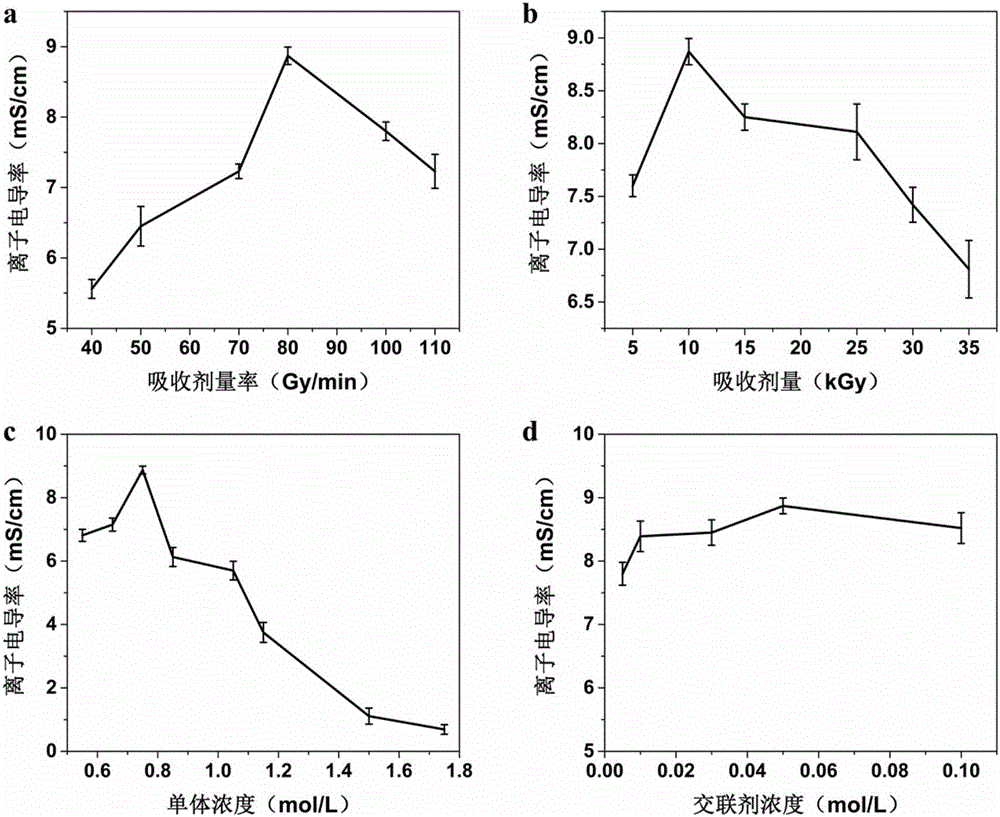

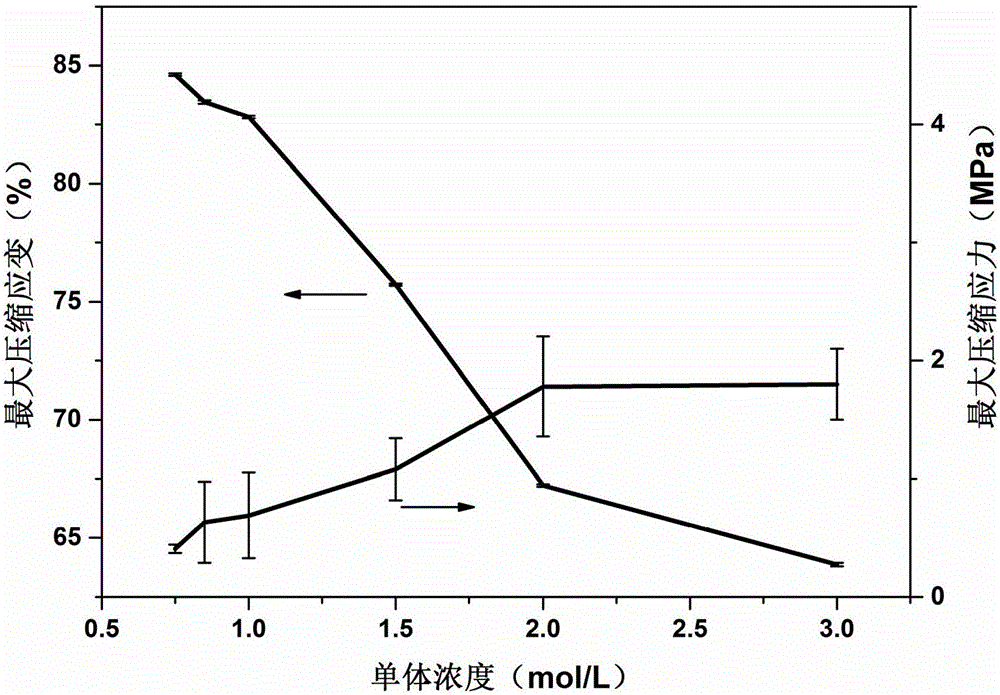

Monomer and polymer for gel electrolyte material, and preparation methods and applications of monomer and polymer

ActiveCN106374139AImprove ionic conductivityGood chemistryFinal product manufactureElectrolyte accumulators manufactureGamma rayLithium-ion battery

The invention discloses a monomer and polymer for a gel electrolyte material, and preparation methods and applications of the monomer and the polymer. By a gamma ray or electron beam-induced polymerization crosslinking method, a hydrophobic oleophilic monomer and an acrylic ester crosslinking agent are polymerized and crosslinked in an organic solvent containing a lithium salt to obtain a polymer gel electrolyte. Compared with a traditional lithium-ion battery, the lithium-ion battery of using the gel electrolyte has higher ionic conductivity (8.88*10<-3>S cm<-1>); liquid leakage can be effectively prevented; the dangers of explosion, combustion and the like caused by liquid leakage are avoided; and the safety factor is high. Meanwhile, a traditional chemical method is replaced with a gamma ray or electron beam irradiation method, so that the preparation method is simpler, safe, environment-friendly and low in energy consumption and is very suitable for industrialized production.

Owner:PEKING UNIV

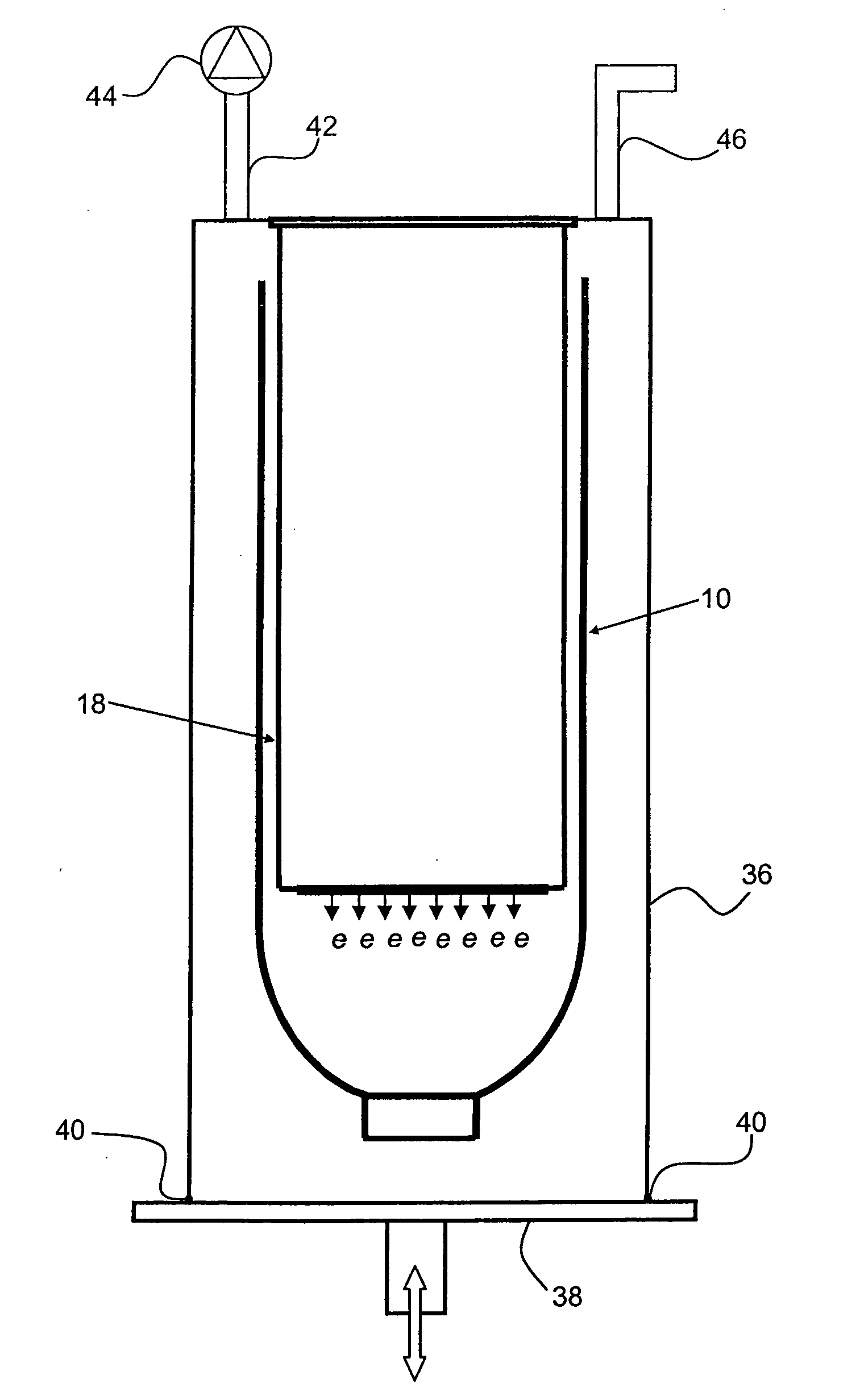

Vessel sterilization apparatus

InactiveUS20090110613A1Improve reliabilityPreventing a vessel from being deformedPackage sterilisationEnergy based chemical/physical/physico-chemical processesMarine engineeringElectron beam irradiation

A vessel sterilizing apparatus includes a vessel conveying unit for conveying a vessel, and an electron beam irradiation unit for irradiating the vessel with an electron beam. The sterilizing apparatus further includes a sterilization area in which the vessel is irradiated with the electron beam, a first chamber surrounding the sterilization area so as to separate the sterilization area from an external portion, a supply area disposed upstream side of the sterilization area in a vessel conveying direction and provided with an opening through which the vessel passes, a second chamber surrounding the supply area so as to separate the supply area from an external portion, and a sterilizing medium supplying unit for supplying a sterilizing medium to the supply area.

Owner:SHIBUYA IND CO LTD

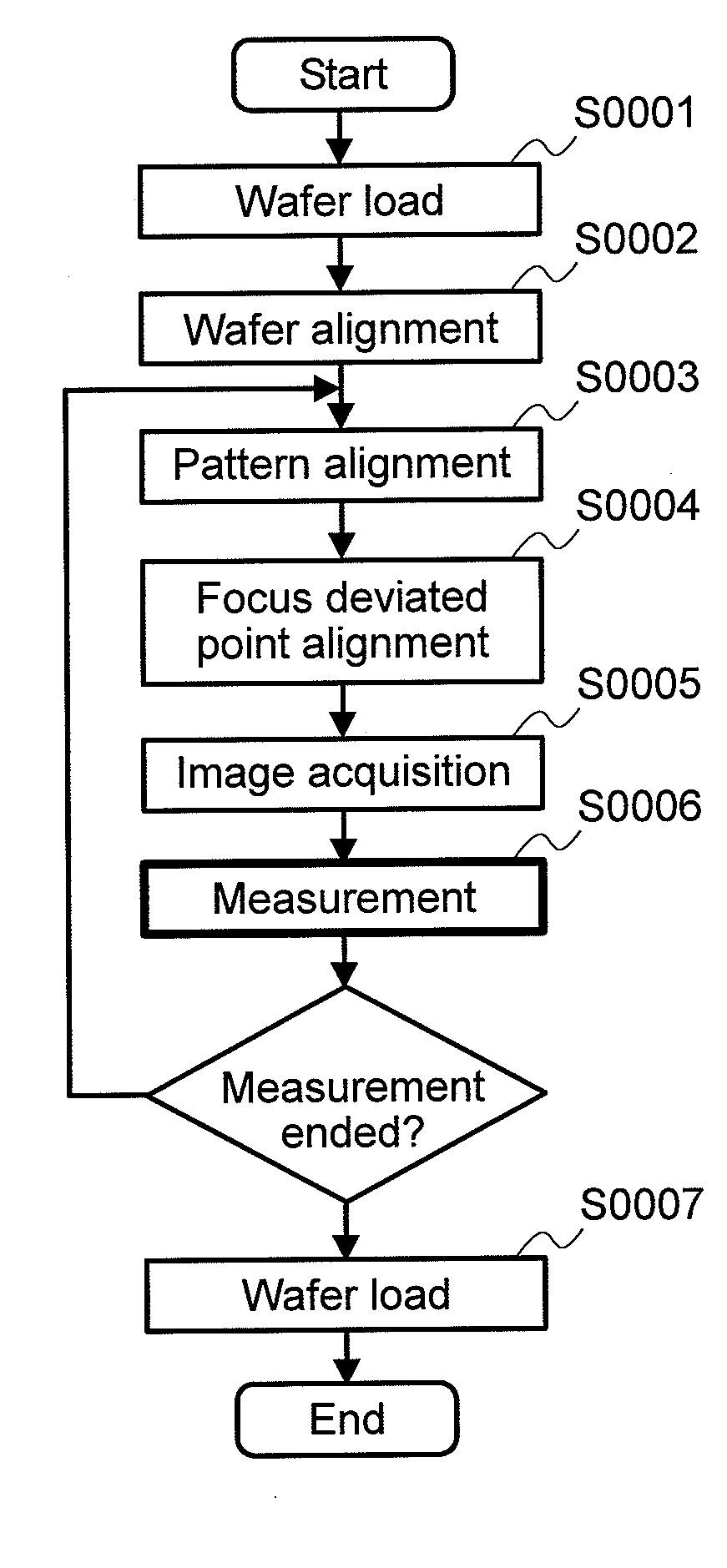

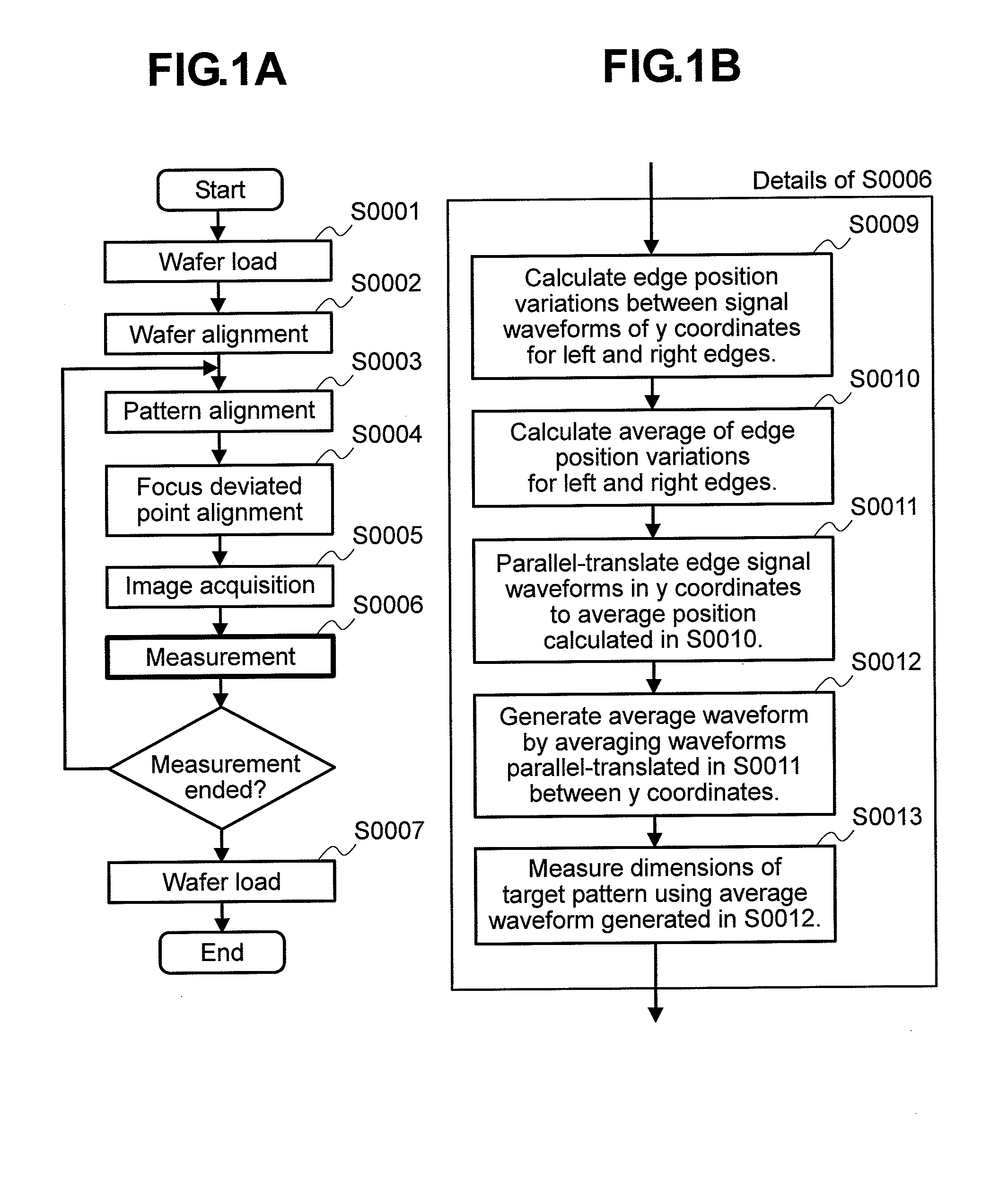

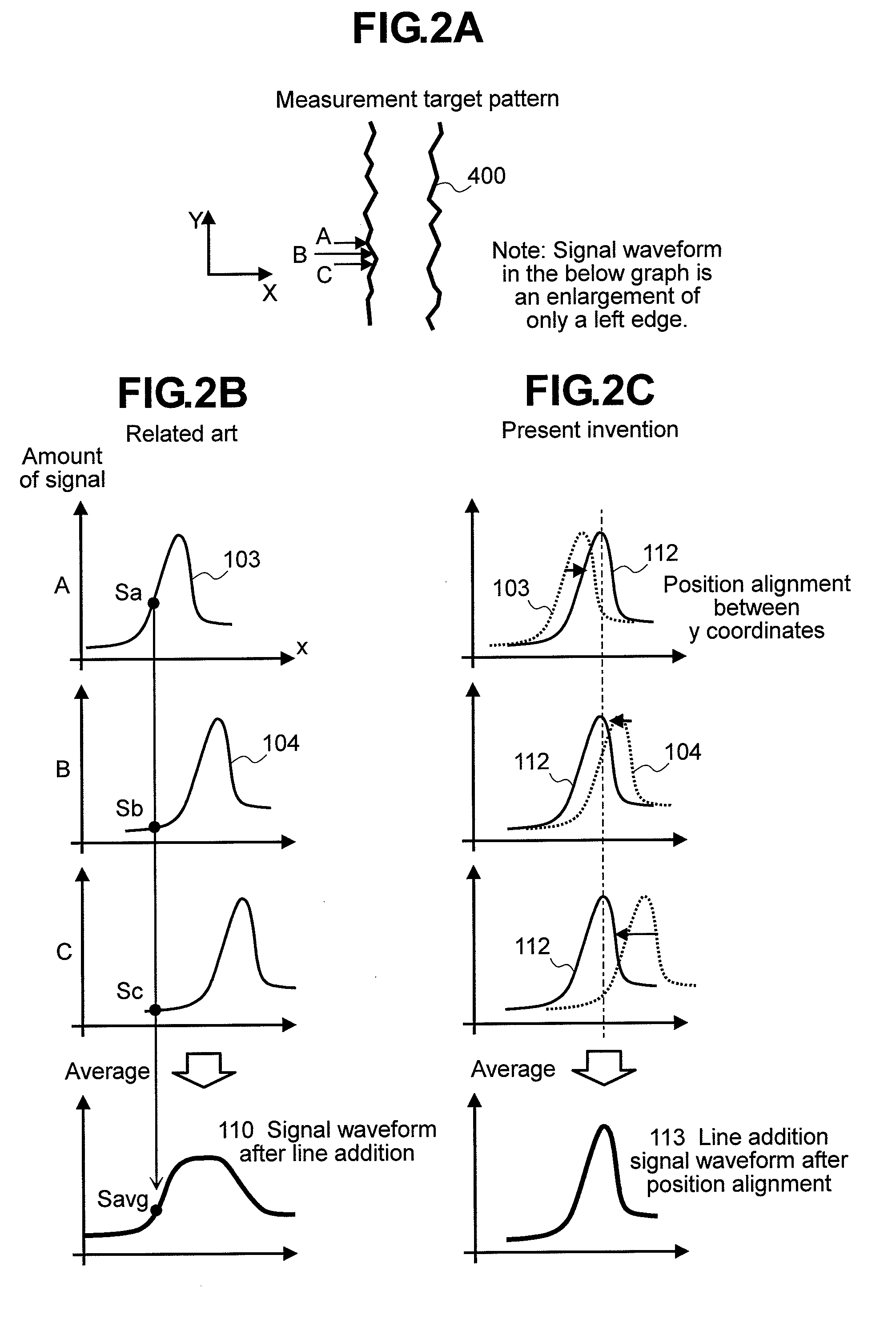

Method and apparatus for measuring pattern dimensions

InactiveUS20080197280A1Reduce impactRepeatability of measurementSemiconductor/solid-state device testing/measurementRadiation applicationsObservational errorImage averaging

It is difficult for a material having low resistance to electron beam irradiation to obtain an electron microscopic image having a high S / N ratio. A conventional image smoothing process can improve stability of measurement, but this process has a problem of measurement errors for absolute values, reduction of sensitivity, deterioration of quality of cubic shape information and the like. In the present invention, by performing an image averaging process without deteriorating cubic shape information of a signal waveform in consideration of dimension deviation of a measurement target pattern, measurement stability is compatible with improvement of precision and sensitivity. Accordingly, it is possible to realize measurement of pattern dimensions and shapes with high precision and control of a highly sensitive semiconductor manufacturing process using the measurement.

Owner:HITACHI HIGH-TECH CORP

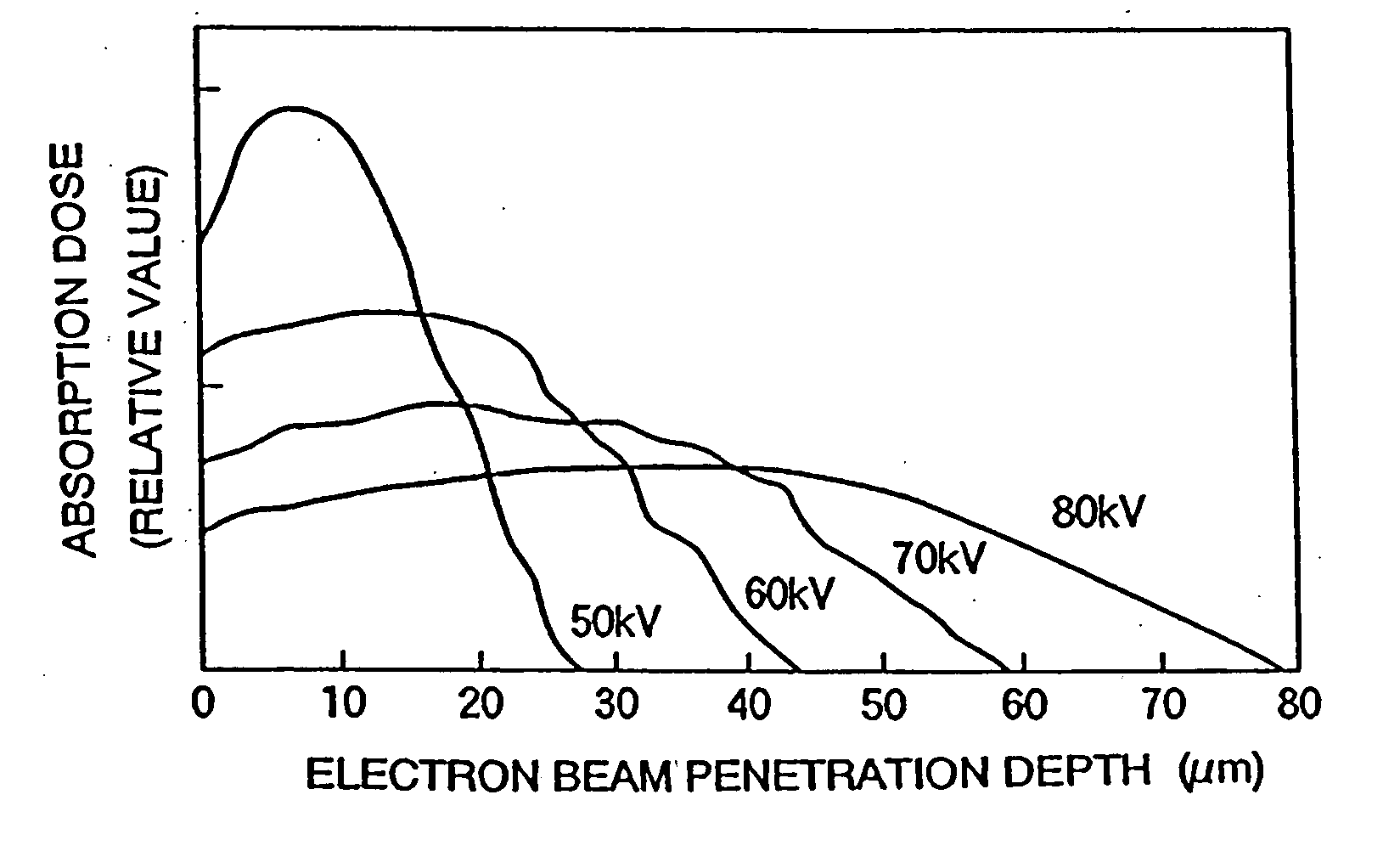

Methods for manufacturing multi-wall carbon nanotubes

InactiveUS7291318B2Few defectEfficient preparationMaterial nanotechnologyFullerenesDouble wallIrradiation

A method is presented for effectively manufacturing multi-wall (double-wall, etc.) carbon nanotubes (CNTs) having a structure whereby interior tubes are formed within the CNTs. In this manufacturing method, fullerene / CNT hybrid structures are prepared, wherein assembled fullerenes, these being fullerenes that are linked, have been housed within single-wall CNTs. The interior tubes are formed from the assembled fullerenes by subjecting the hybrid structures to electron beam irradiation while in a heated state. It is preferred that irradiation with the electron beams occurs at a temperature of 100˜500° C. and with the electron beams having an accelerating voltage of 80˜250 kV. According to the manufacturing method of the present invention, multi-wall CNTs with few defects can be manufactured at lower temperatures and in a shorter period than in the case where the fullerene / CNT hybrid structures are only maintained under high temperature conditions (and electron beam irradiation is not performed).

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com