Monomer and polymer for gel electrolyte material, and preparation methods and applications of monomer and polymer

A gel electrolyte and monomer technology, which is used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of difficult control of production process, difficulty in post-processing of products, and energy consumption in the preparation process. , to achieve the effect of improving energy storage and energy utilization, improving plasticity, and strong storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

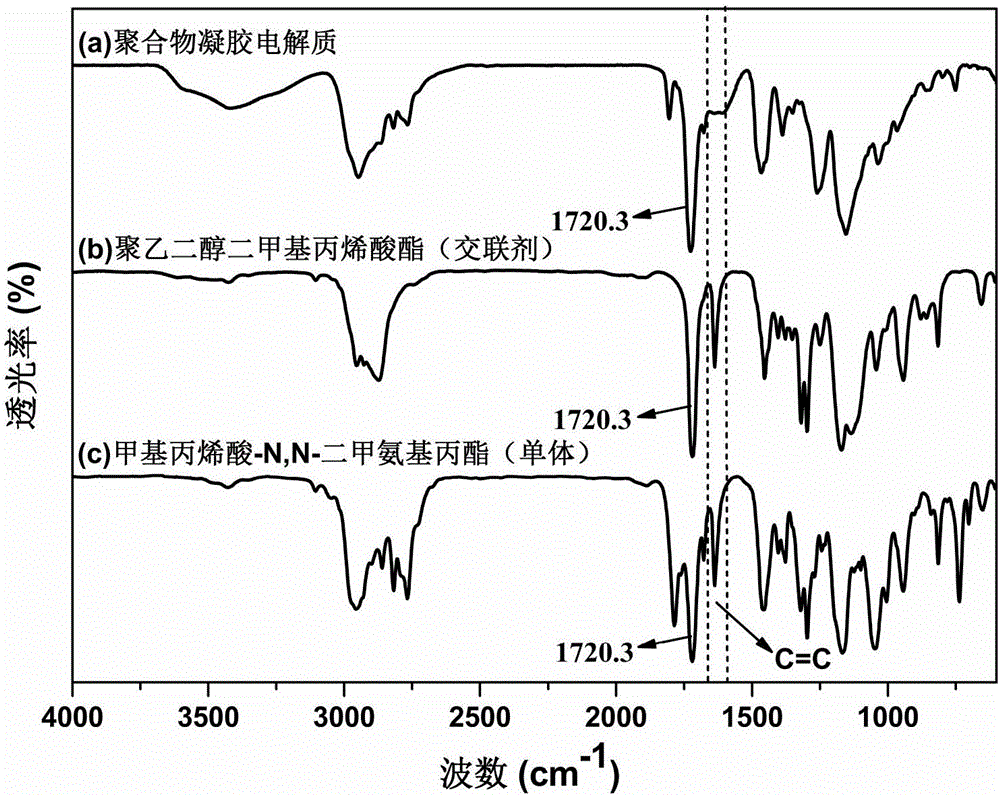

[0048] Embodiment 1, preparation lithium-ion battery gel electrolyte monomer

[0049]

[0050] In a 500mL two-necked bottle, add 200mL of dichloromethane, pump and change the air 3 times, replace the solution system with a nitrogen atmosphere, add 3-dimethylamino-1-propanol (30mmol, 3.60mL) into the system, and stir thoroughly , under an ice-water bath, triethylamine (60mmol, 8.32mL) was added, stirred thoroughly, and methacryloyl chloride (60mmol, 5.38mL) was added dropwise within 30min. After stirring at room temperature for 5 h, the system changed from a colorless liquid to an orange liquid. The resulting liquid was fully extracted with saturated sodium bicarbonate and saturated sodium chloride, the organic phase was fully dried over anhydrous sodium sulfate, and the organic solvent was spun off to obtain an orange oily product (methacrylic acid-N,N-dimethylaminopropyl , the yield is about 80%).

Embodiment 2

[0051] Embodiment 2, preparation lithium ion battery gel electrolyte

[0052] Polymethacrylic acid-N,N-dimethylaminopropyl ester-lithium hexafluorophosphate polymer gel electrolyte (PDMP-Li GPE) is a methacrylic acid-N,N-dimethylaminopropyl ester monomer polymerized and cross-linked by gamma rays preparation. Dissolve 0.75mol / L methacrylic acid-N,N-dimethylaminopropyl ester monomer in a mixed solution with a volume ratio of ethylene carbonate and diethyl carbonate of 1:1, and then add 0.05mol / L Joint agent polyethylene glycol dimethacrylate and 1mol / L LiPF 6 , after mixing evenly, ultrasonically degassed to form an orange-yellow transparent and clear solution. After γ-ray irradiation, under the condition of dose rate of 80Gy / min and absorbed dose of 10kGy, the polymerization and crosslinking of the system are initiated to form polymethacrylic acid-N,N-dimethylaminopropyl ester-lithium hexafluorophosphate polymer gel Electrolyte (PDMP-Li GPE).

Embodiment 3

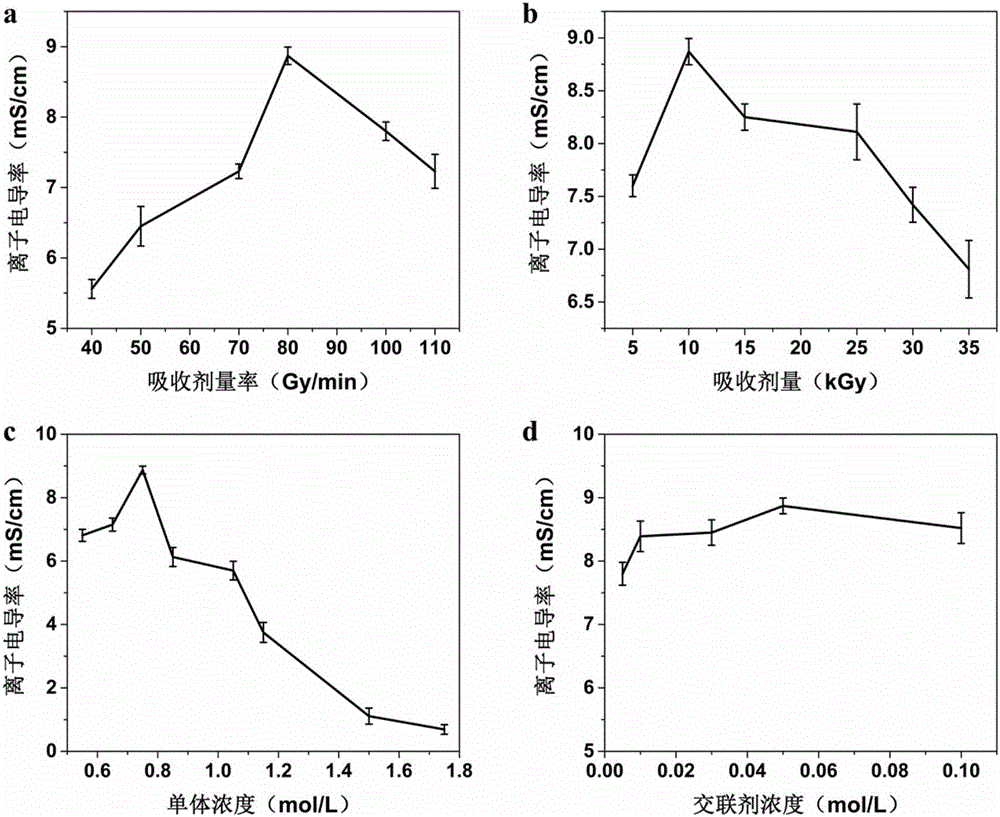

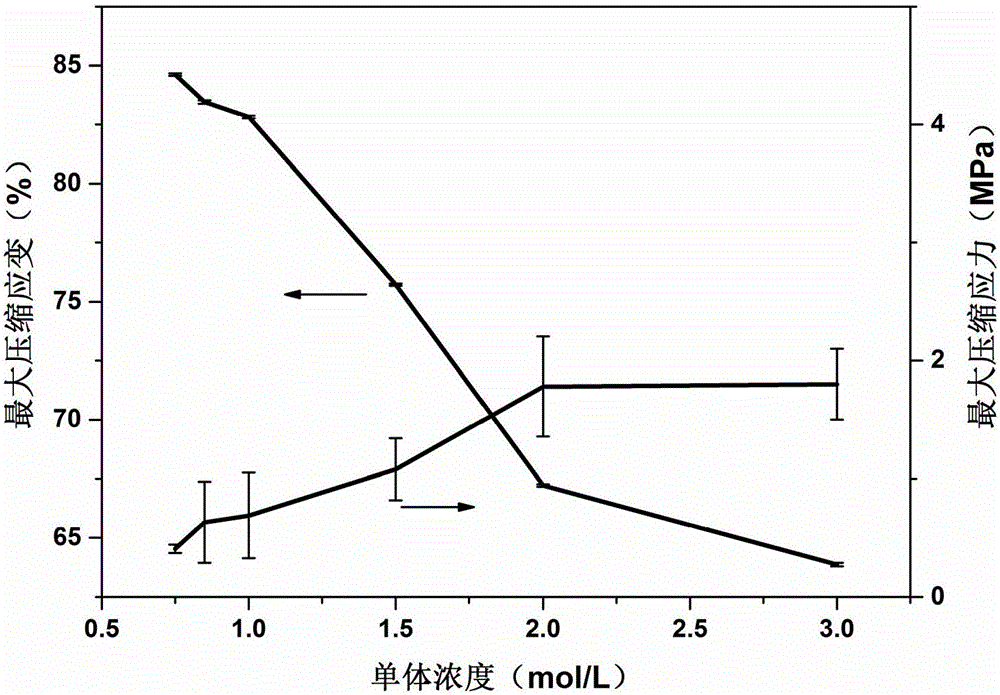

[0053] Embodiment 3, prepare the ionic conductivity test of lithium-ion battery gel electrolyte

[0054] At room temperature, put the lithium-ion battery gel electrolyte in Example 2 (or Examples 7-27) into stainless steel electrodes, and use Shanghai Zhenhua 604D electrochemical workstation to test respectively. Measure the ion conductivity of the lithium ion battery gel of each example and comparative example, as figure 2 shown. It can be found that when the dose rate is 80Gy / min, the absorbed dose is 10kGy, the concentration of methacrylic-N,N-dimethylaminopropyl ester monomer is 0.75mol / L, and the polyethylene glycol dimethacrylate crosslinking agent When the concentration is 0.05mol / L, the ionic conductivity reaches the maximum value of 8.88×10 -3 S cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com