Rapid treatment method for fracturing flowback fluid

A fracturing flowback fluid and treatment method technology, applied in filtration treatment, precipitation treatment, multi-stage water treatment, etc., can solve the problems of long period of biological gel breaking, high equipment investment cost and large floor space, etc. Realize online processing, improve glue breaking speed and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

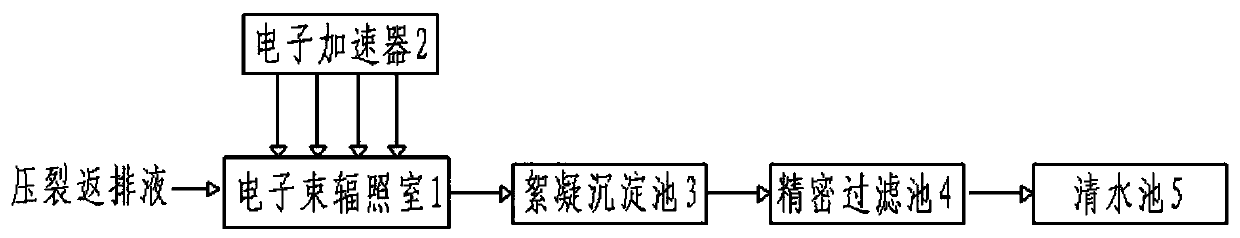

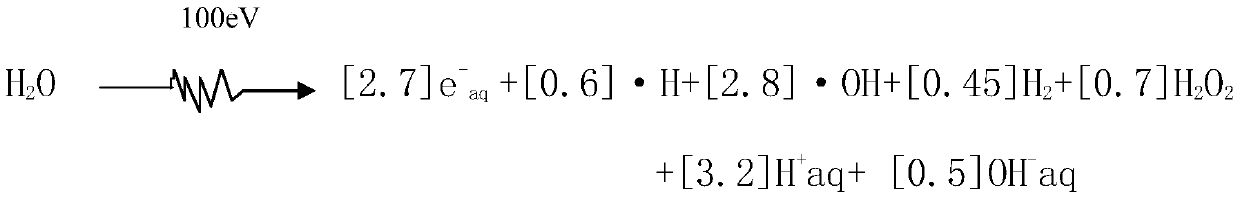

Method used

Image

Examples

Embodiment 1

[0037]The fracturing flowback fluid to be treated is the guar gum system fracturing flowback fluid in the Dingbian area of Shaanxi. The oil content in the fracturing flowback fluid is 85mg / L, the suspension content is 280mg / L, the viscosity is 22mPa·s, COD2080mg / L, B 2.1 mg / L, pH 6.89, SRB 25 pieces / mL, under the condition that the irradiation dose of the electron beam irradiation reactor is 15KGy and the residence time is 20s, the viscosity is reduced to below 1.5mPa·s, and the COD is 2512mg / L. Obvious gel breaking effect. During the gel breaking process, a part of recessive COD is converted into dominant, resulting in an apparent increase in COD content. Add PAFC100mg / L, PAM5mg / L, settle in the aggregation sedimentation tank for 20min, and filter with a 3μm oil-resistant bag filter. Final product water: oil 1.5mg / L, suspended matter 2.0mg / L, viscosity 1mPa·s, COD 45mg / L, B 0.3mg / L, bacteria 0 / mL. Sludge produced during the process is higher than the local reinjection sta...

Embodiment 2

[0039] The fracturing flowback fluid to be treated is sewage from the drying pool of Changqing Oilfield. The raw water is black and thick liquid with peculiar smell, and there are dissolution and emulsification phenomena. Detected raw water oil content 186mg / L, suspended matter 411mg / L, pH 5.5, sulfate reducing bacteria 250 / mL, iron bacteria 2.5×103 / mL saprophytic bacteria 150 / mL, viscosity 15mPa·s, in electron beam When the irradiation dose of the irradiation reactor is 8KGy and the residence time is 30s, the viscosity is reduced to below 1.5mPa·s, and the bacteria content is zero. Adjust the pH to neutral, add PAFC80mg / L, PAM10mg / L, settle in the aggregation sedimentation tank for 15min, and filter with a 5μm oil-resistant bag filter. Final product water: oil content 2.5mg / L, suspended matter 8mg / L, viscosity<2mPa·s, bacteria content 0 / mL, higher than the local reuse standard (oil content≤5.0mg / L, suspended matter≤5.0mg / L , viscosity≤1.5mpa·S, pH6-9, sulfide≤2.0mg / L) and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com