High-precision LED support material belt online detection punching system

An LED bracket, high-precision technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, reduced production costs, affecting the overall quality of products, etc., to improve shooting clarity and brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make those skilled in the technical field of the present invention understand the present invention more clearly, the technical solutions of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

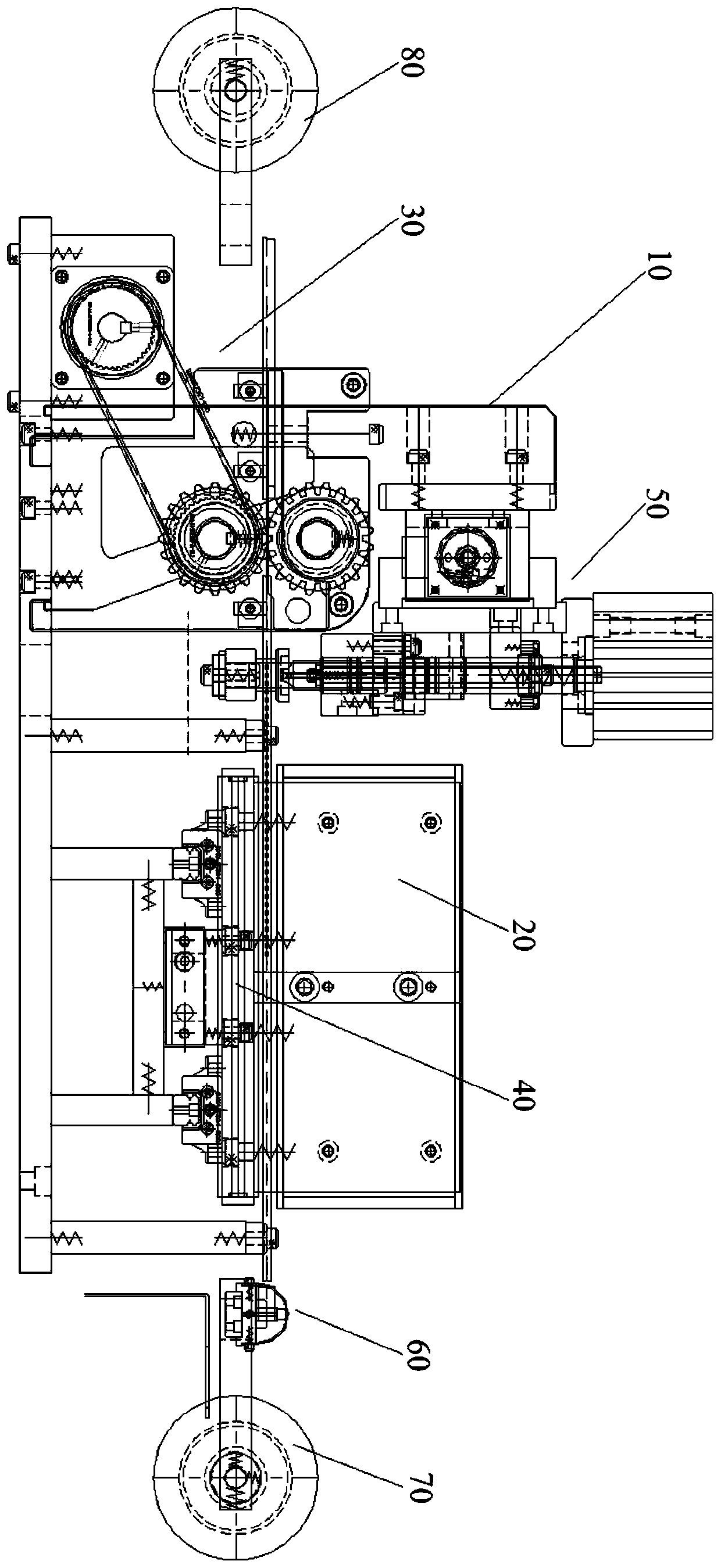

[0034] In an embodiment of the present invention, a high-precision LED bracket strip on-line detection and punching system is used for on-line inspection of the LED bracket strip after glue application and before bending, and detects and removes defective products lacking glue. A feeder 70 and a rewinder 80 are arranged at the front and rear of the system respectively, which are respectively used for automatically unrolling the LED bracket material tape roll and automatically rewinding the LED bracket material tape.

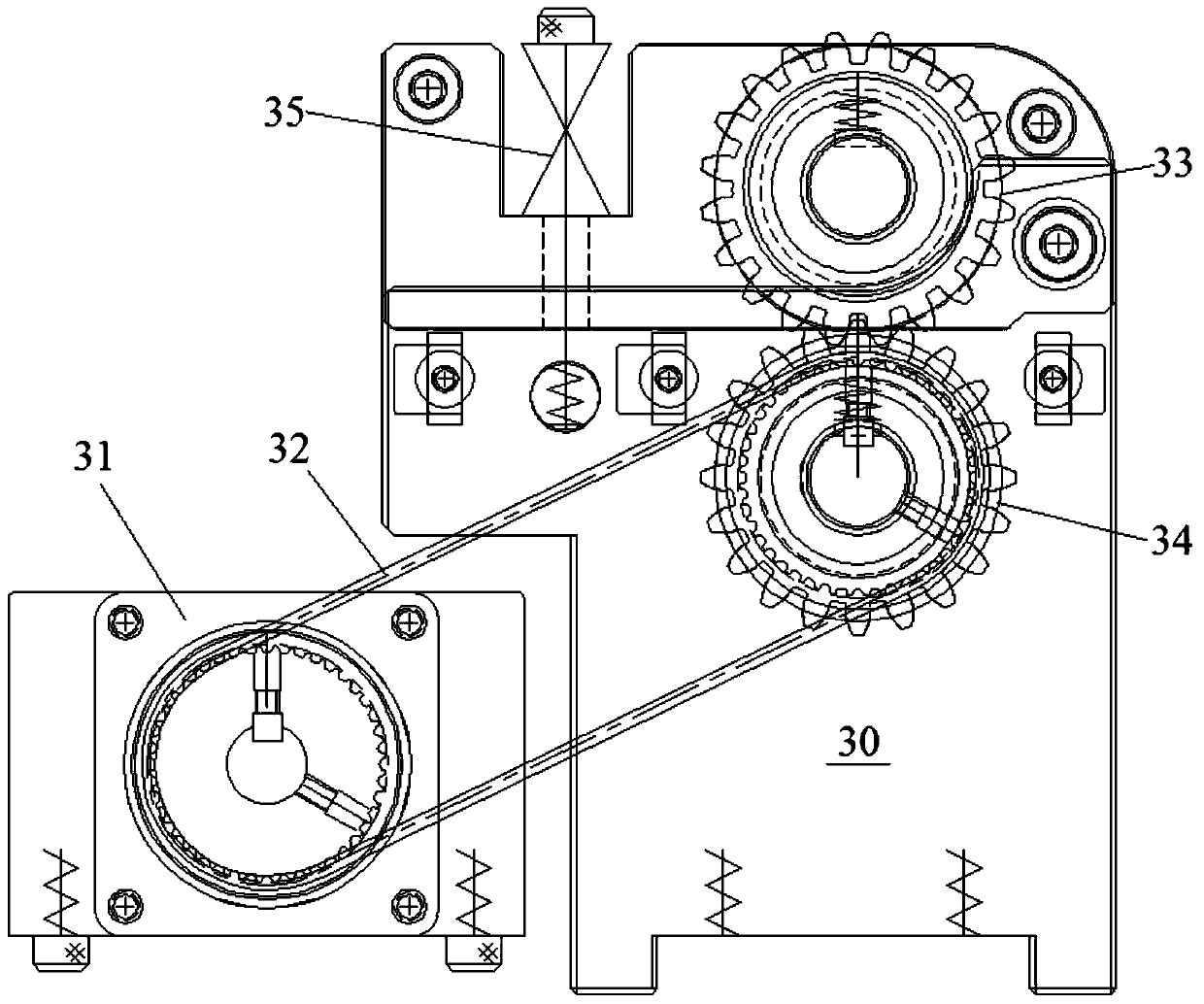

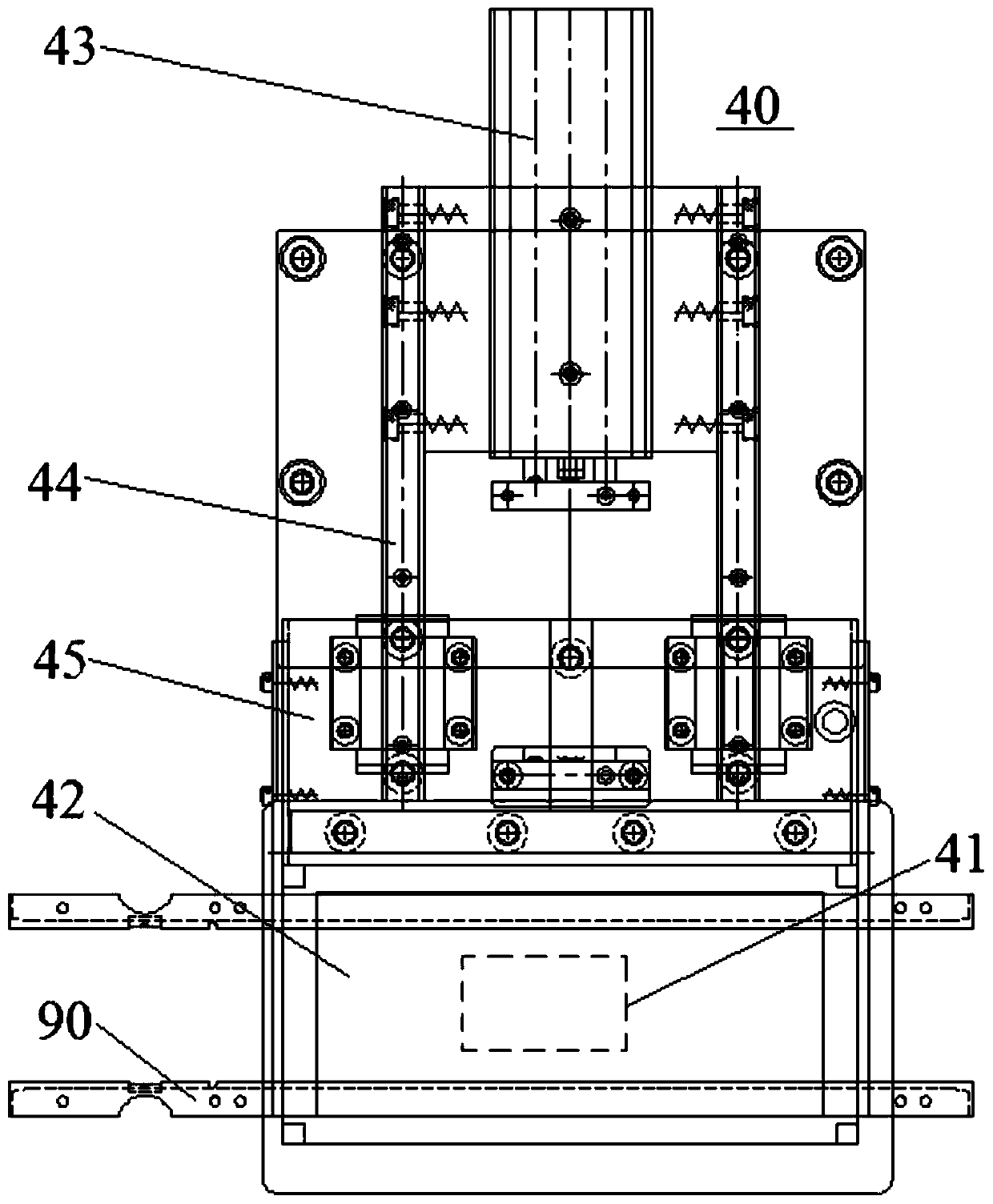

[0035] see figure 1 , the system includes a frame 10, a controller 20, and a feeding unit 30, an online detection unit 40 and a punching unit 50 installed on the frame 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com