Treatment method and treatment device of chemical exhaust

A chemical tail gas and treatment method technology, applied in the direction of gas treatment, chemical instruments and methods, separation devices, etc., can solve the problems that the chemical tail gas treatment method is difficult to meet the environmental protection requirements, the chemical tail gas is difficult to meet the environmental protection emission standards, and the processing equipment is complicated. , to achieve the effect of solving the non-compliance of tail gas emission, realizing simplified design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

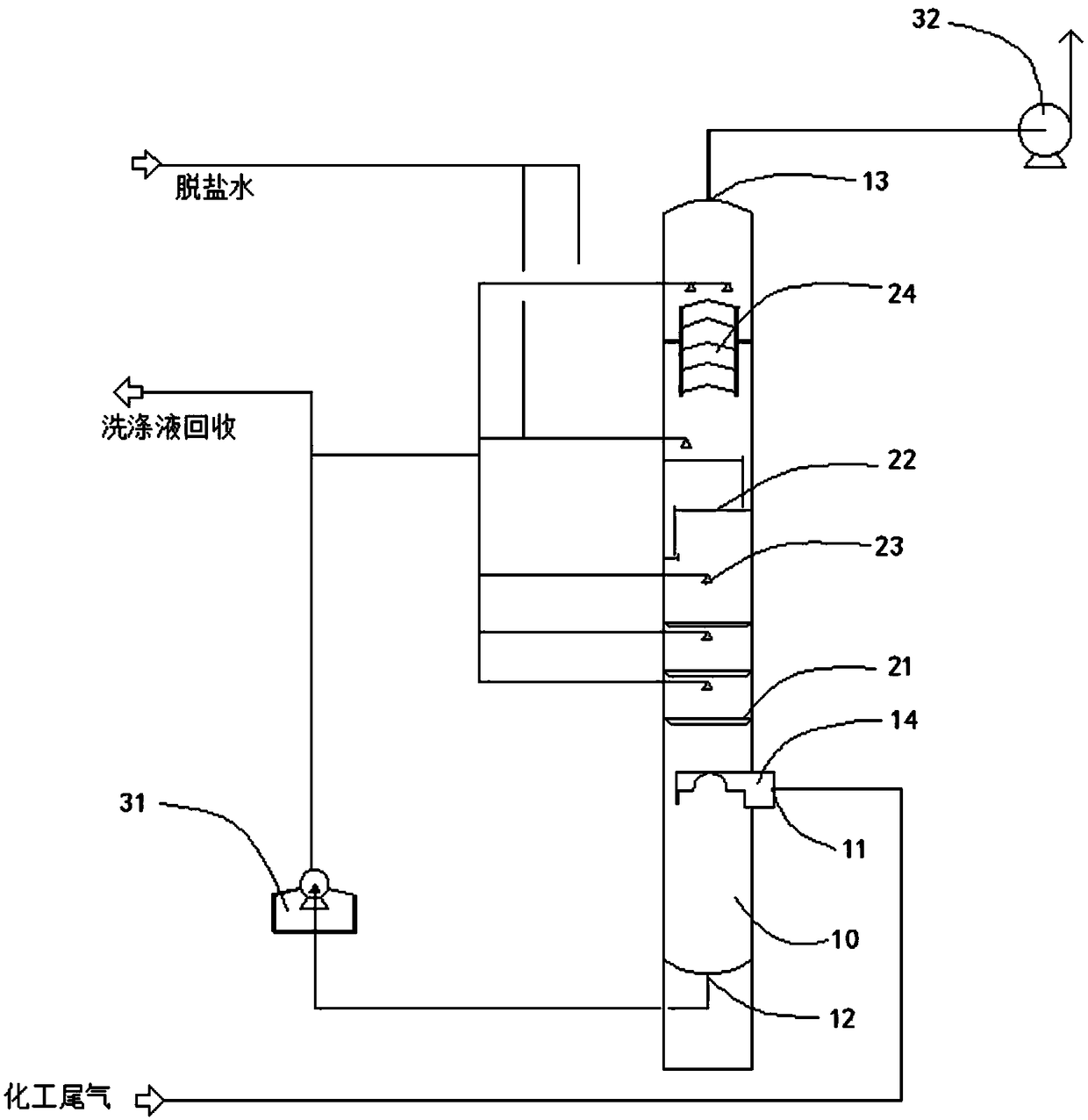

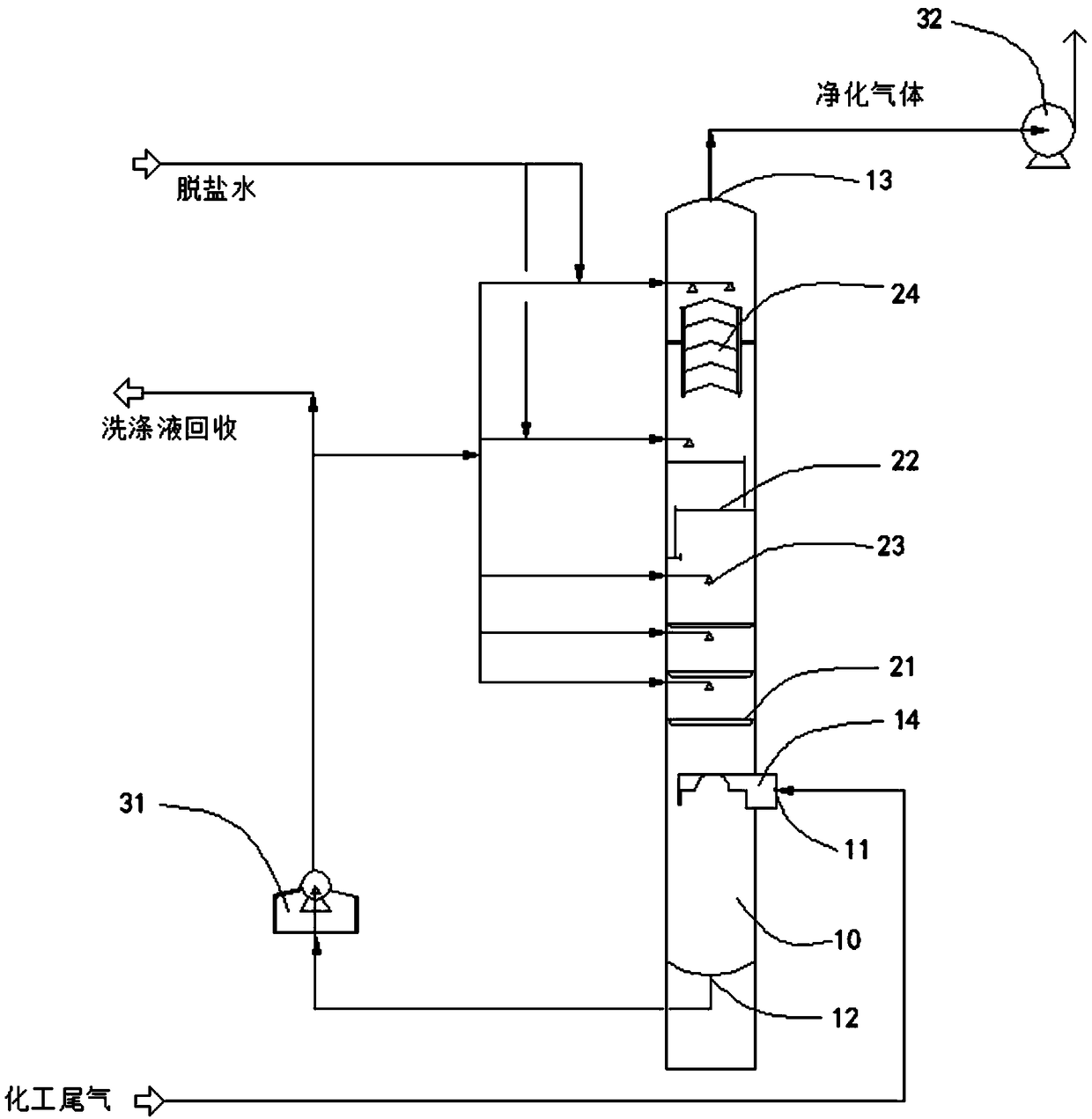

[0070] like figure 2 As shown, the present embodiment is a treatment method for chemical tail gas containing a large amount of dust and ammonia, and the treatment device used in the treatment method includes:

[0071] Empty tower 10, the lower part of the empty tower 10 is provided with a gas inlet 11, the chemical tail gas enters through the gas inlet, the bottom is provided with a liquid outlet 12, and the washing liquid generated during the spray washing process flows out from the liquid outlet, and the top is provided with a gas Outlet 13, the purified gas after treatment flows out from this gas outlet 13;

[0072] In the empty tower 10, the lower part is provided with a gas distributor 14, and the setting position of the gas distributor 14 corresponds to the gas inlet 11 of the empty tower 10;

[0073] Three gas redistributors 21 are arranged in sequence above the gas distributor 14, and a plurality of nozzles 23 are arranged above each gas redistributor 21, and the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com