Patents

Literature

317 results about "Carbon monofluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

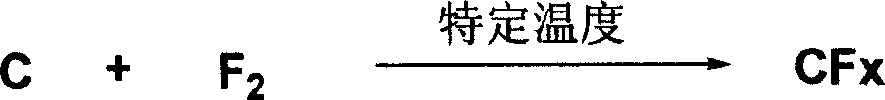

Carbon monofluoride (CF, CFₓ, or (CF)ₓ), also called polycarbon monofluoride (PMF), polycarbon fluoride, poly(carbon monofluoride), and graphite fluoride, is a material formed by high-temperature reaction of fluorine gas with graphite, charcoal, or pyrolytic carbon powder. It is a highly hydrophobic microcrystalline powder. Its CAS number is 51311-17-2. In contrast to graphite intercalation compounds it is a covalent graphite compound.

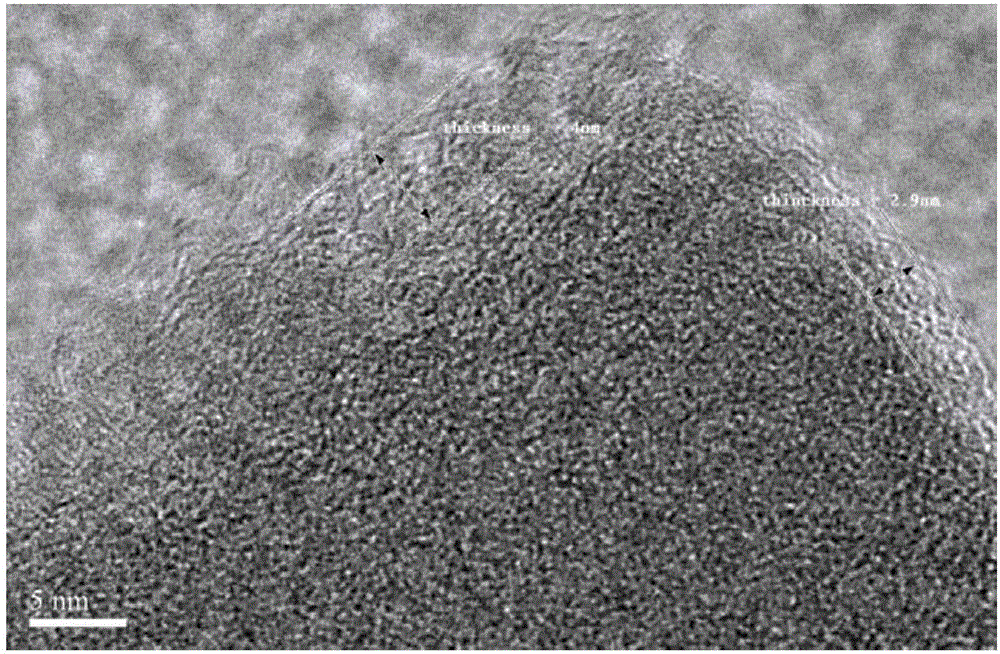

Method for preparing high-performance doped diamond-like film

InactiveCN101748381AImprove overall performanceImprove performanceChemical vapor deposition coatingIon beam depositionPhysics

The invention discloses a method for preparing a high-performance doped diamond-like film. The method is characterized by comprising the following steps: firstly, utilizing ultrasonic cleaning technology to remove a polluted layer on the surface of a substrate; utilizing ion beam assisted deposition technology to prepare a gradient transition layer; and finally utilizing ion beam deposition and magnetron sputtering to synthesize a multi-element doped DLC film, wherein except any one of carbonaceous gases, such as methane, acetylene, benzene, ethanol, acetone and the like, any gas containing non-carbon elements, such as silicon hydride, boron hydride, phosphorane, carbon tetrafluoride and the like, is simultaneously introduced, and a metal sputtering source is opened for the doping of metal elements. The method has the advantages of synthesizing the multi-element doped DLC film which is simultaneously doped with the metal elements and the nonmetal elements, fully developing the complementary advantages of the doped metal elements and the doped nonmetal elements and remarkably improving the combination properties of the DLC film.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

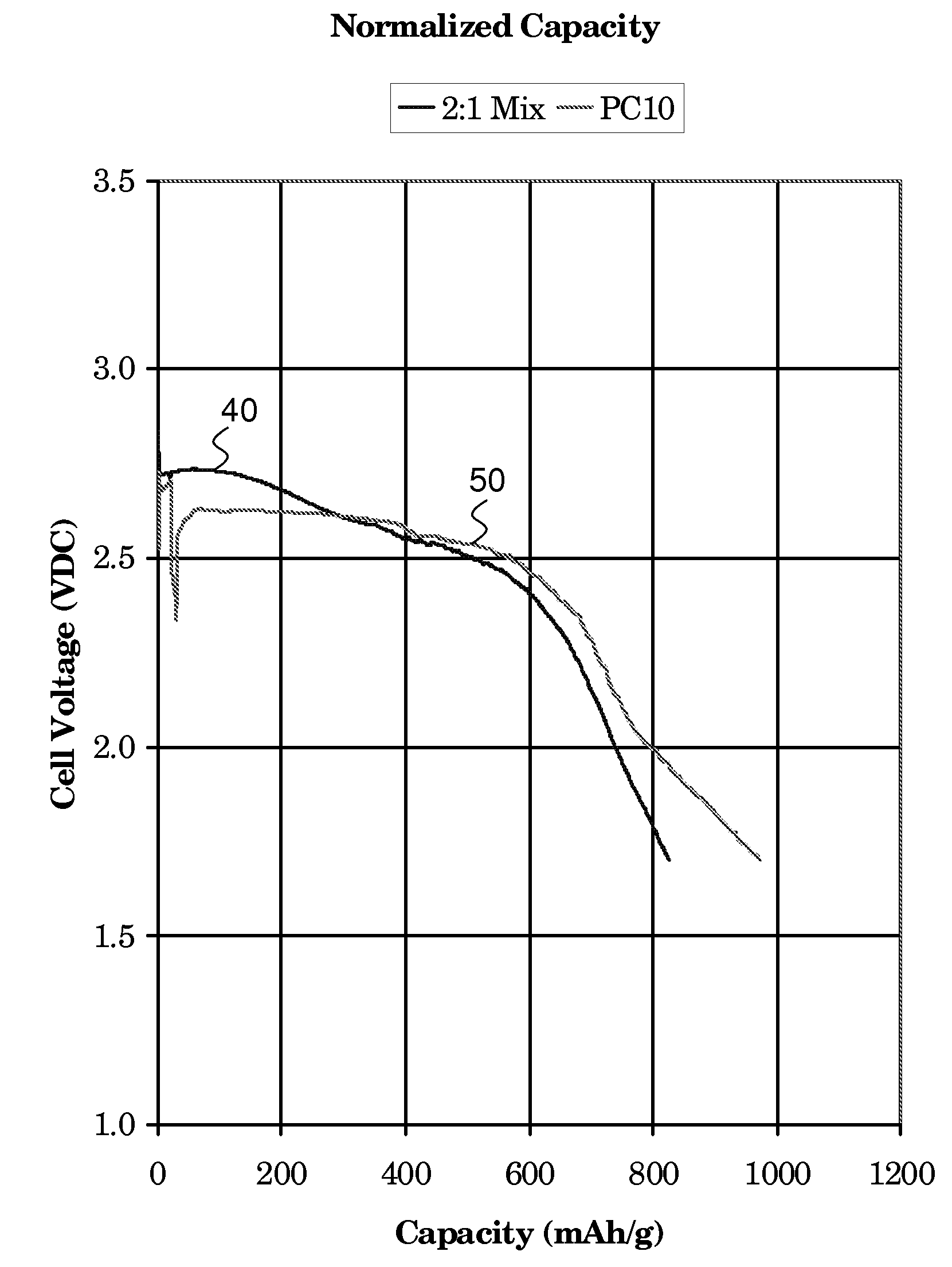

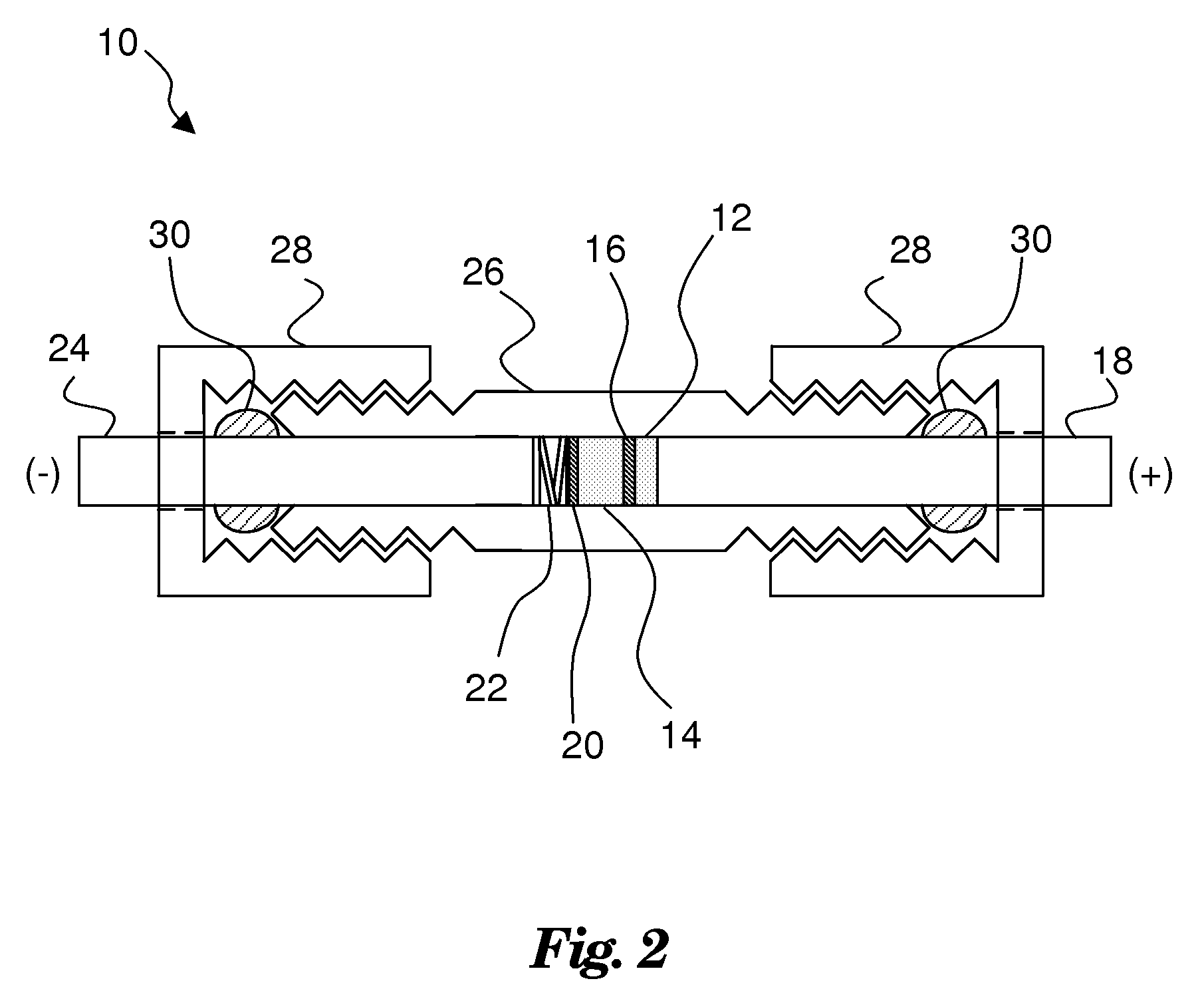

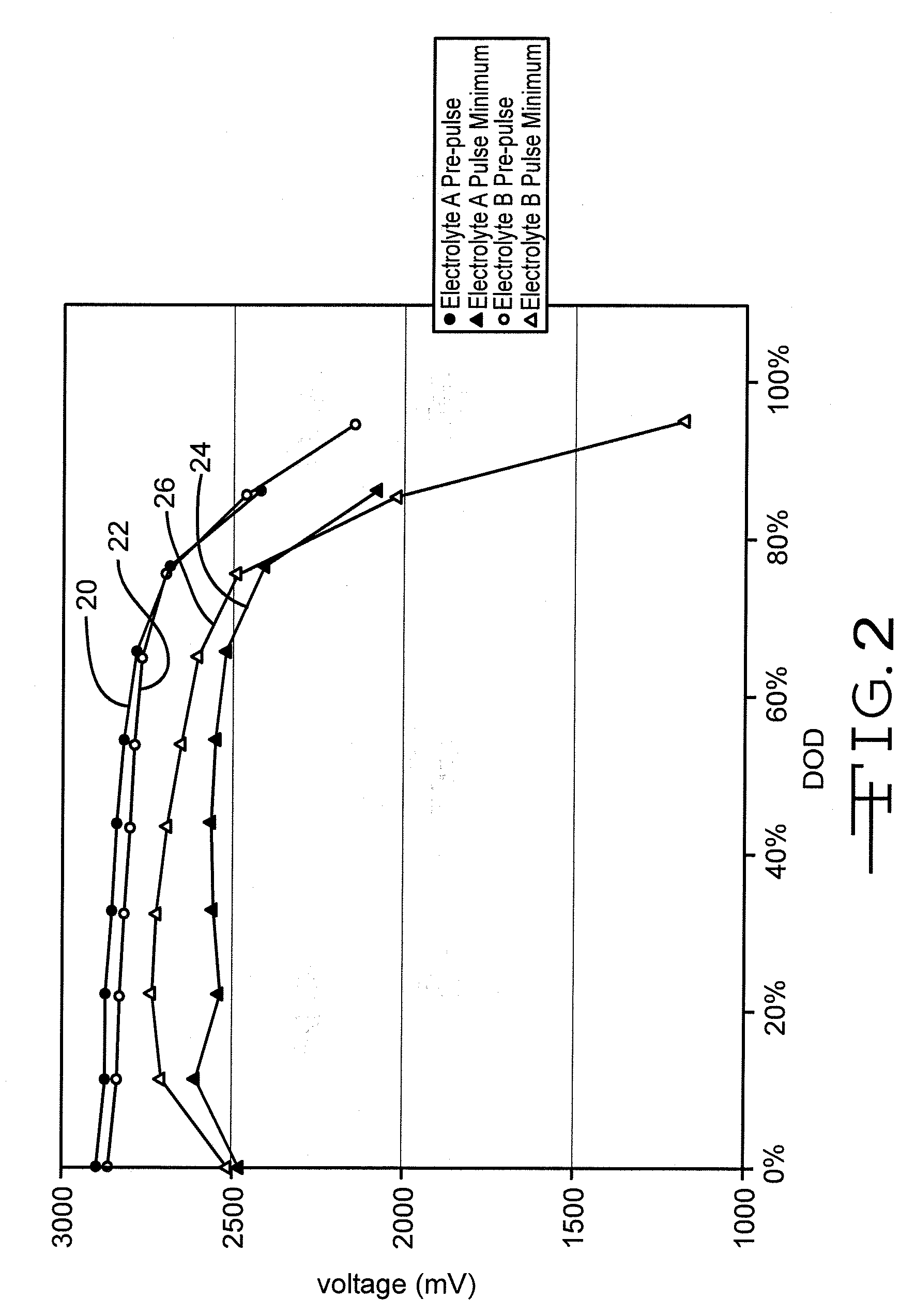

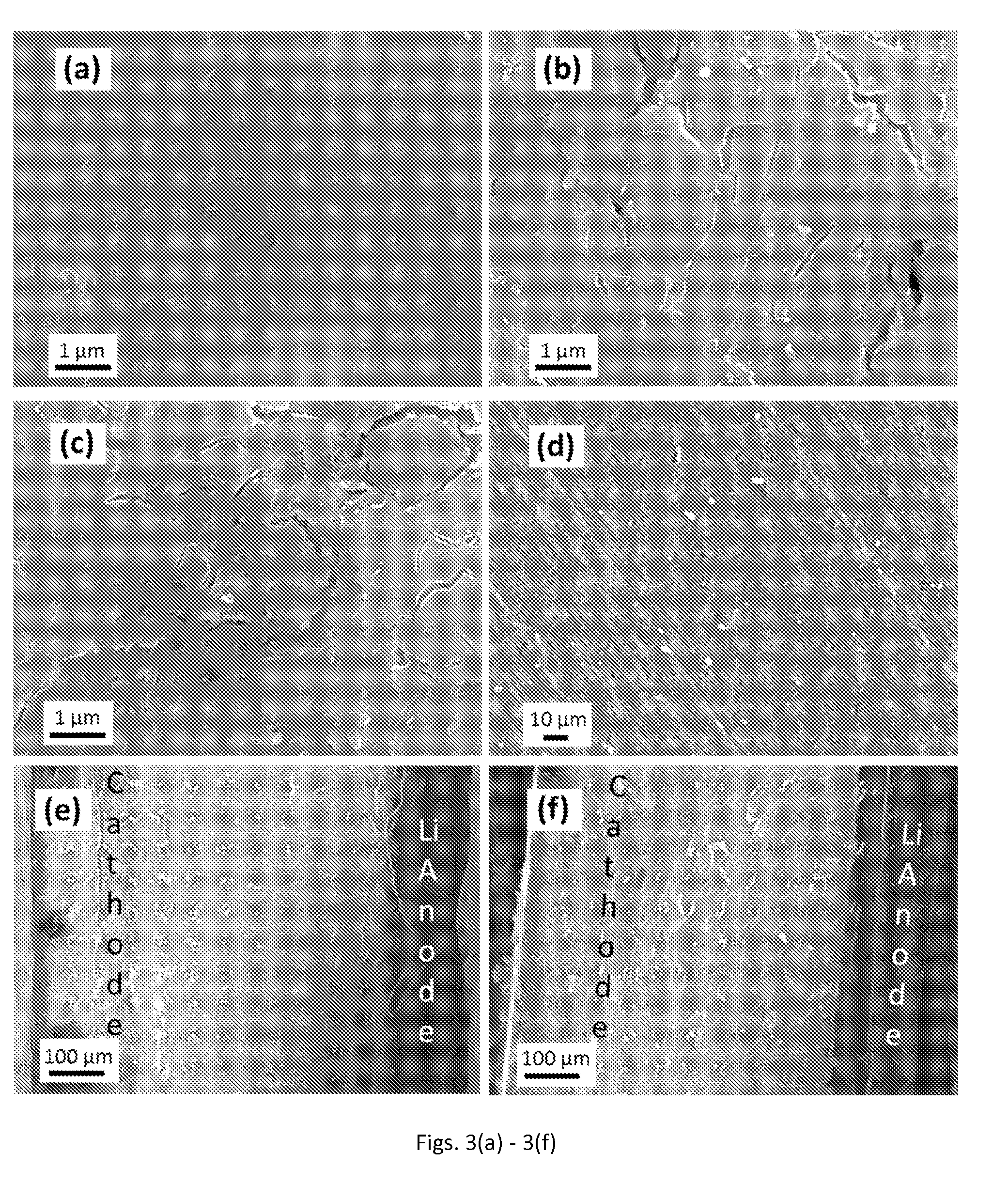

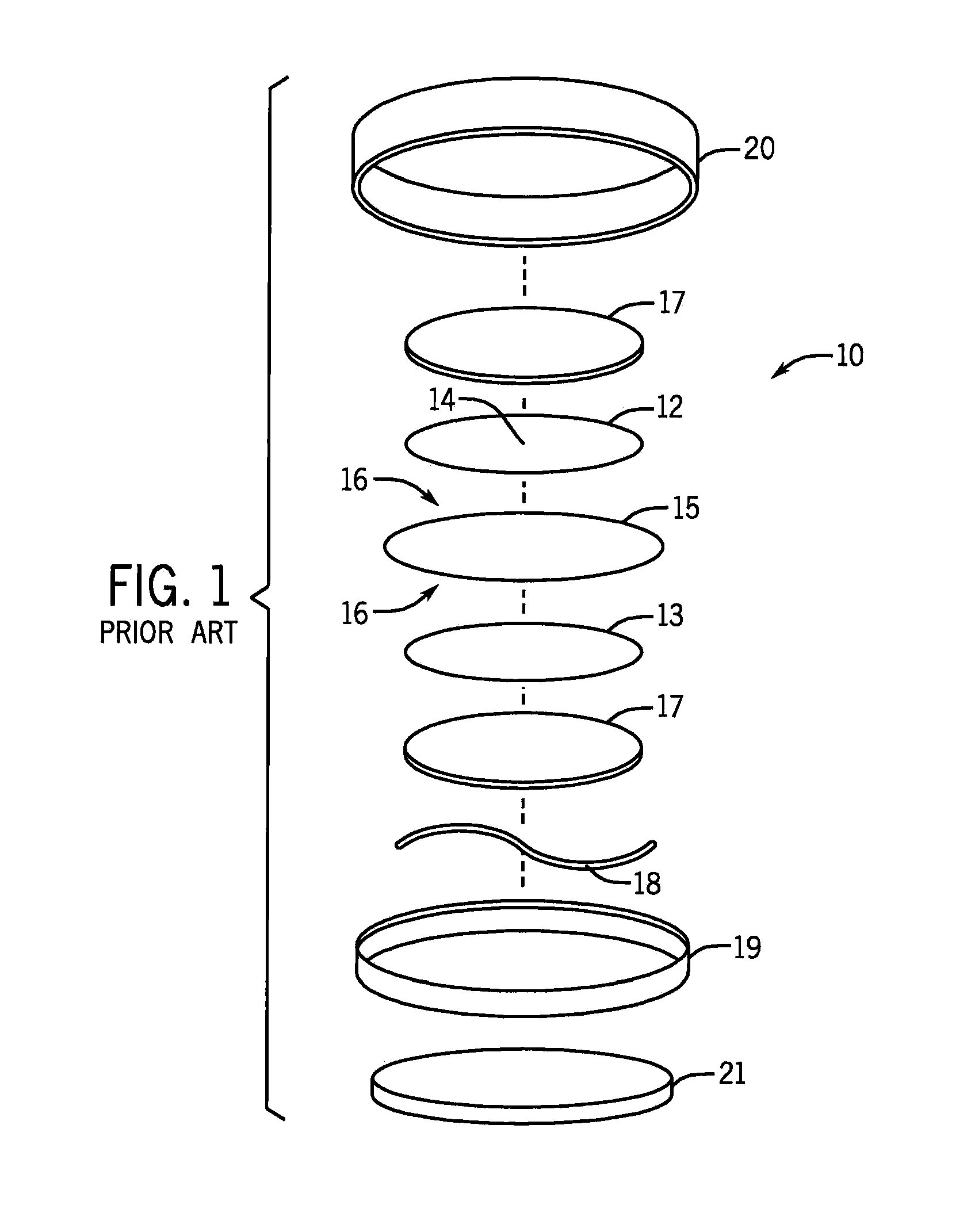

Carbon Monofluoride Cathode Materials Providing Simplified Elective Replacement Indication

InactiveUS20070281213A1Organic electrolyte cellsHeart stimulatorsCarbon monofluorideElectrochemical cell

An electrochemical cell includes an anode, a cathode and an electrolyte operatively associated with the anode and the cathode. The cathode comprises a blend of a first electrochemically active fluorinated carbon material and one or more additional electrochemically active fluorinated carbon materials. The fluorinated carbon materials provide an electrochemical cell voltage characteristic that may be used to predict remaining energy capacity as the electrochemical cell discharges during service. Advantageously, the cathode does not require other electrochemically active materials to achieve the desired voltage characteristic, thereby preserving the favorable energy density properties of fluorinated carbon.

Owner:GENTCORP

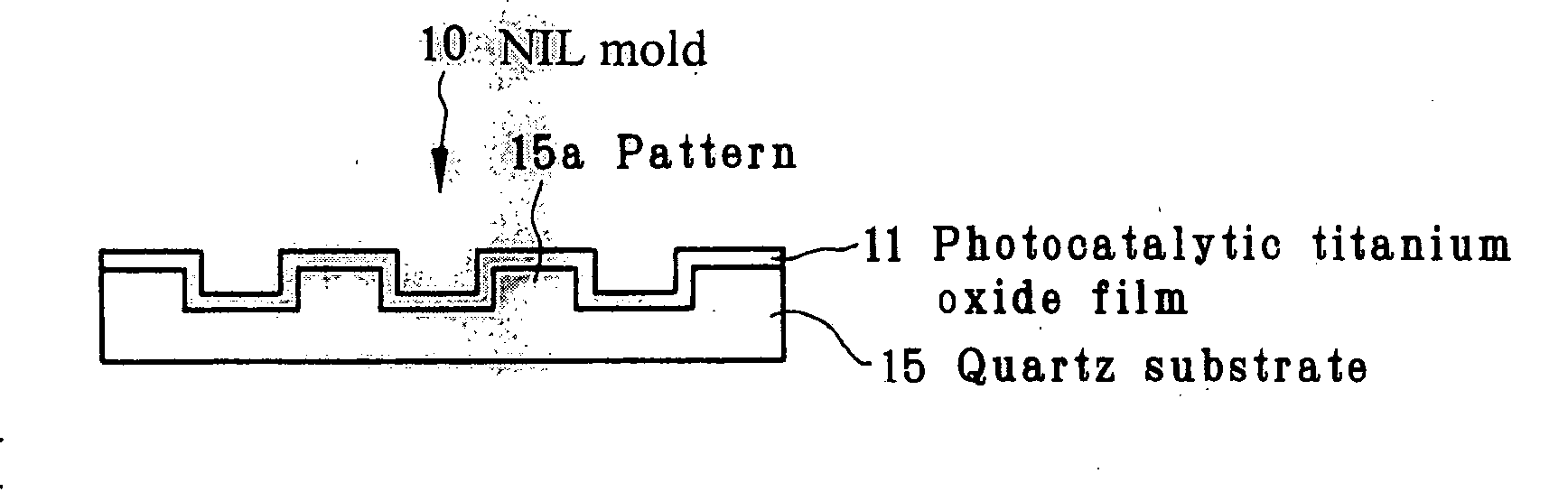

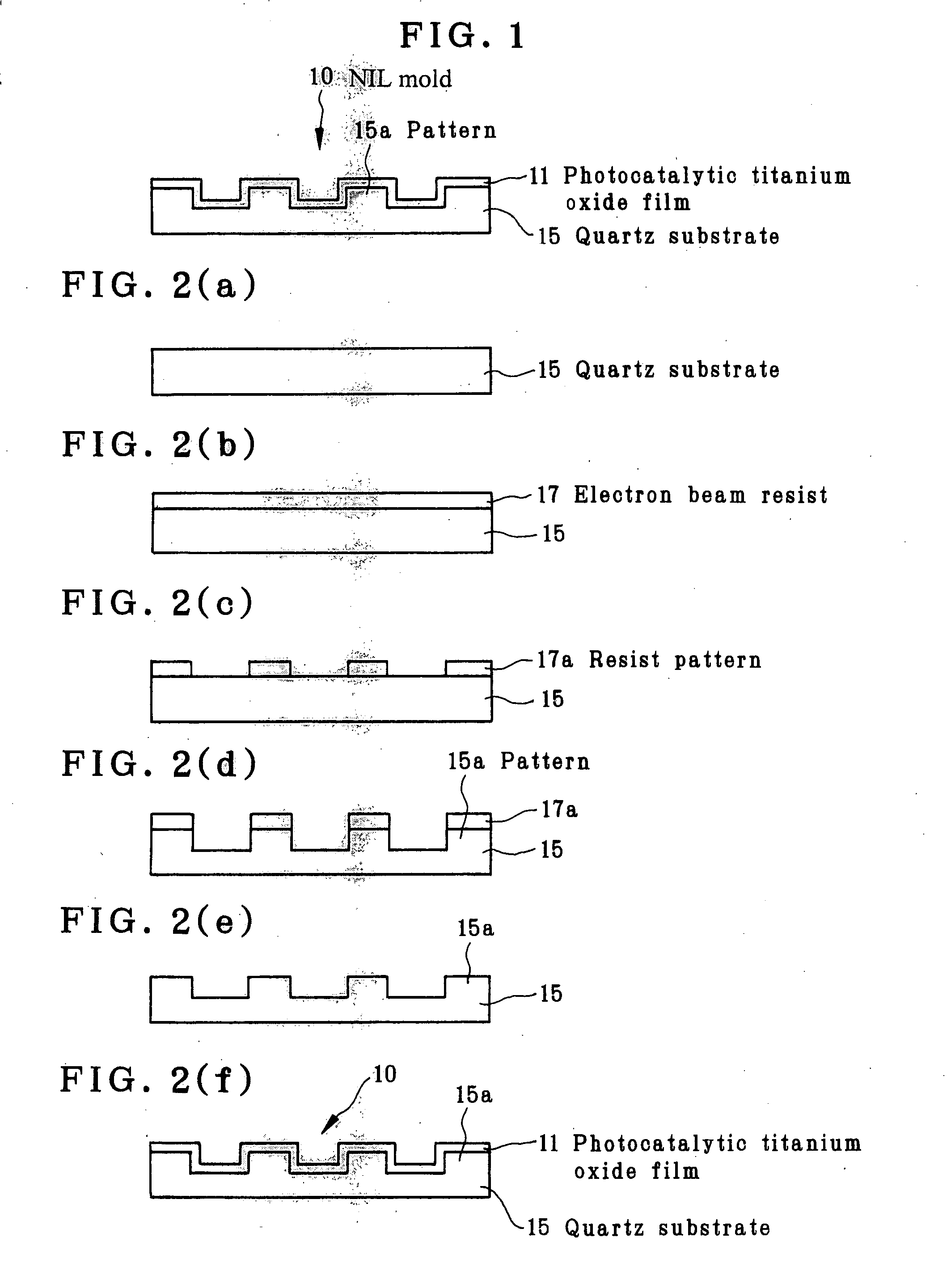

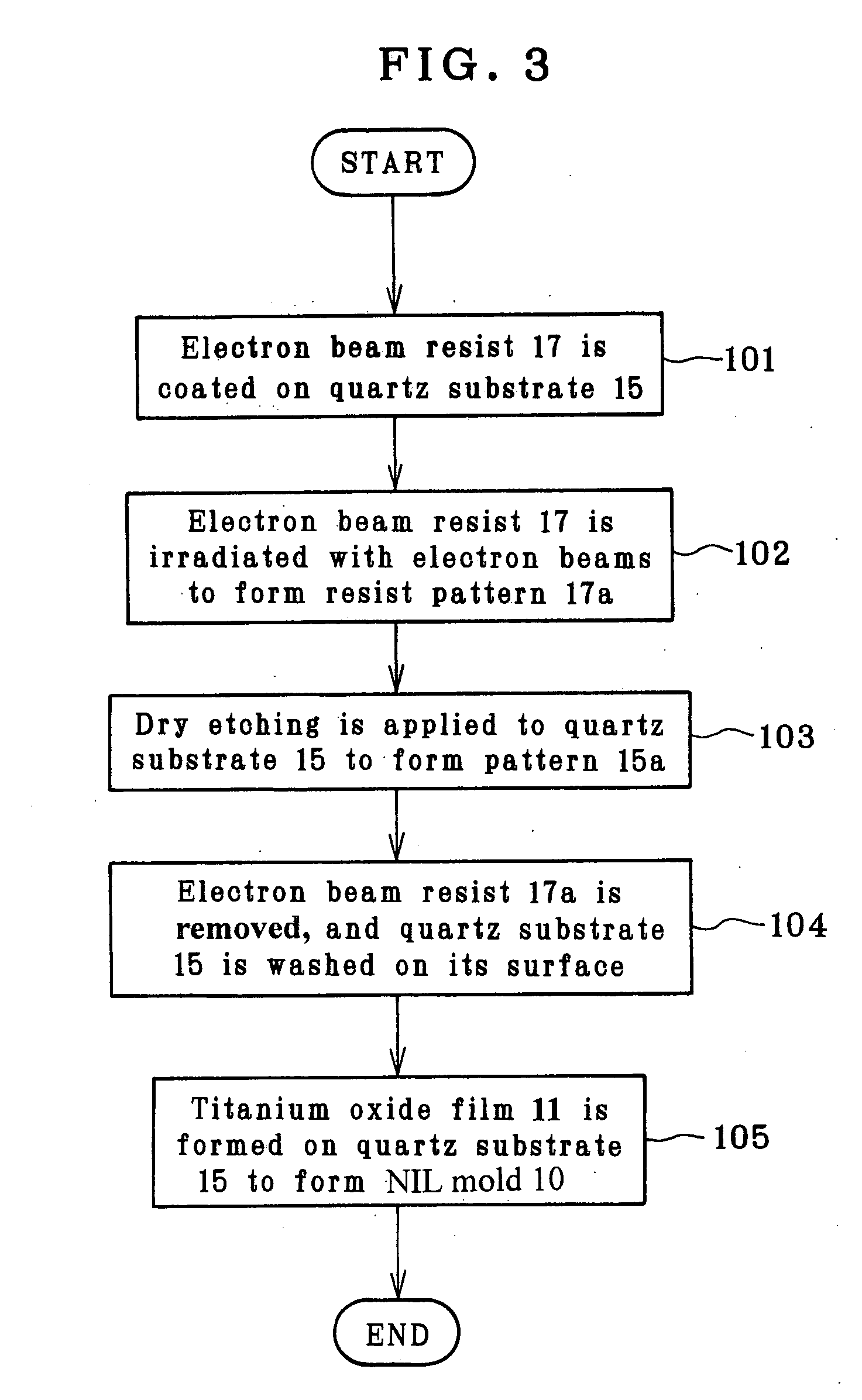

Mold for photocuring nano-imprint and its fabrication process

InactiveUS20070267764A1Improve reliabilityImprove robustnessNanoinformaticsFoundry mouldsCarbon monofluorideUltraviolet lights

The invention relates to a mold that has an improved releasability for a photocured resin and an improved robustness. First, an electron beam resist 17 is coated on a quartz substrate 15 having the nature of being transmissive to ultraviolet light. A resist pattern 17a is formed by irradiation with electron beams. Thereafter, the quartz substrate is dry etched using etching gas such as carbon tetrafluoride to form a pattern 15a on the quartz substrate 15. A photocatalytic titanium oxide film 11 is formed as by sputtering on the surface of the quartz substrate 15 with the pattern 15a formed on it to fabricate an NIL mold 10.

Owner:DAI NIPPON PRINTING CO LTD

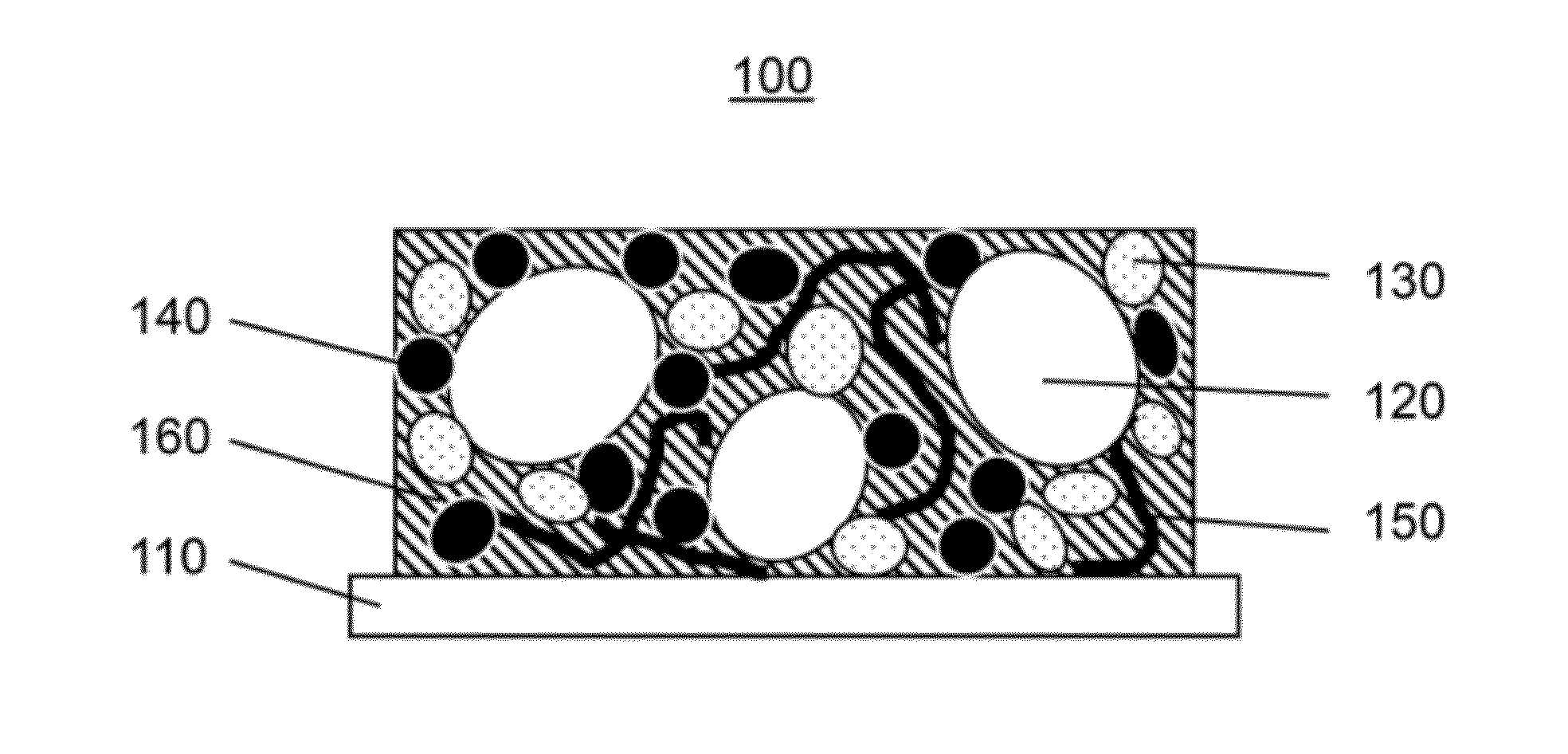

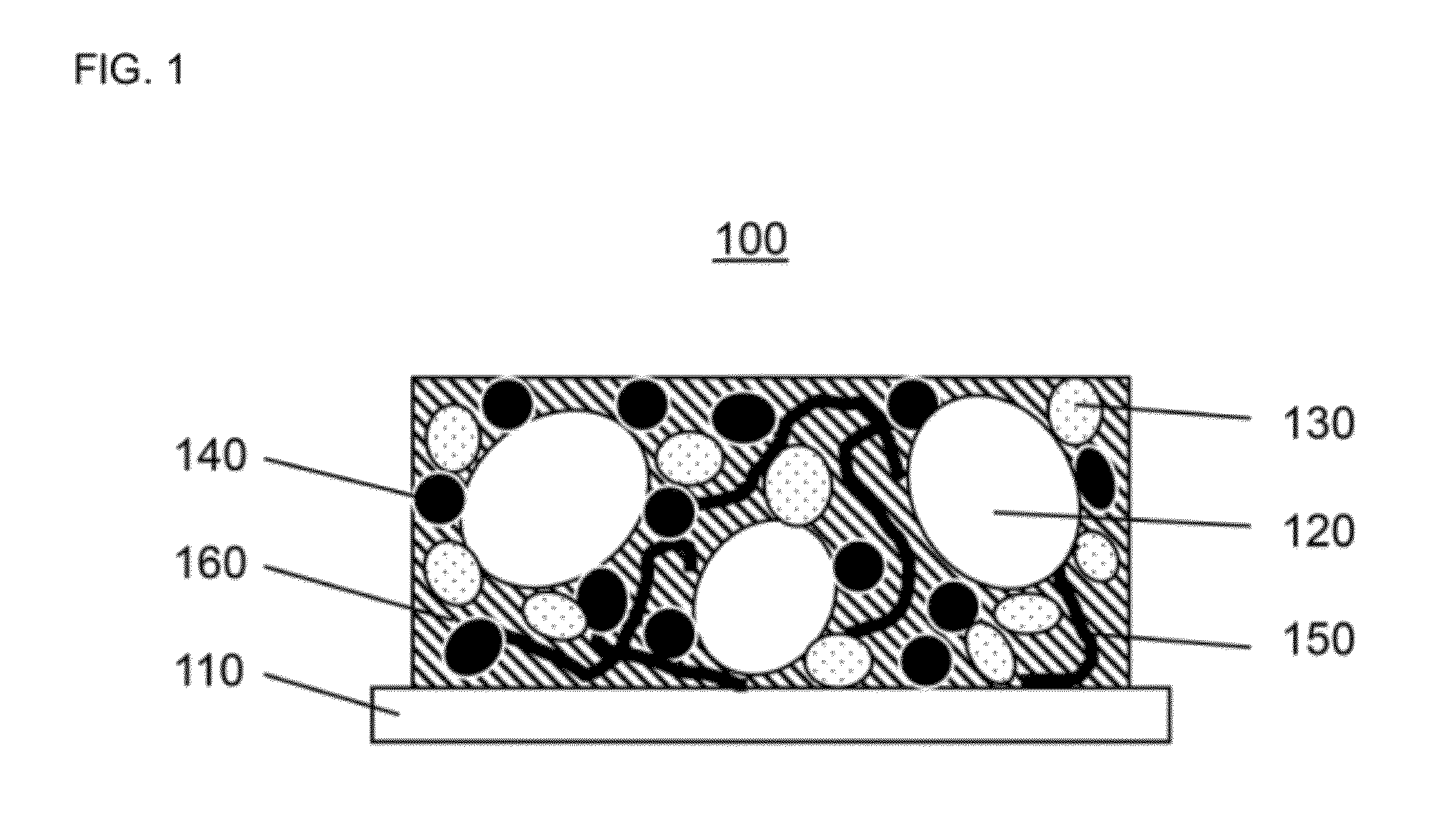

Fluorinated carbon composite cathode for a high-energy lithium battery

InactiveUS20120126182A1Reduce voltage dropNon-metal conductorsElectric discharge heatingCarbon compositesCarbon monofluoride

A lithium / fluorinated carbon (Li / CFx) battery having a composite cathode including an electroactive cathode material, a non-electroactive additive, a conductive agent, and a binder. The electroactive cathode material is a single fluorinated carbon having a general formula of CFx, whereby x is an averaged value ranging from about 0.5 to about 1.2. The non-electroactive additive is at least one or a mixture of two or more oxides selected from the group comprising Mg, B, Al, Si, Cu, Zn, Y, Ti, Zr, Fe, Co, or Ni. The conductive agent is selected from the group comprising carbon, metals, and mixtures thereof. Finally, the binder is an amorphous polymer selected from the group comprising fluorinated polymers, ethylene-propylene-diene (EPDM) rubbers, styrene butadiene rubbers (SBR), poly (acrylonitrile-methyl methacrylate), carboxymethyl celluloses (CMC), and polyvinyl alcohol (PVA). Also, a method of reducing the initial voltage drop of a lithium / fluorinated carbon (Li / CFx) battery by providing a composite cathode which includes an electroactive cathode material having a general formula of CFx, whereby x is an averaged value ranging from about 0.5 to about 1.2, a non-electroactive additive, a conductive agent, and a binder.

Owner:ARMY US SEC THE

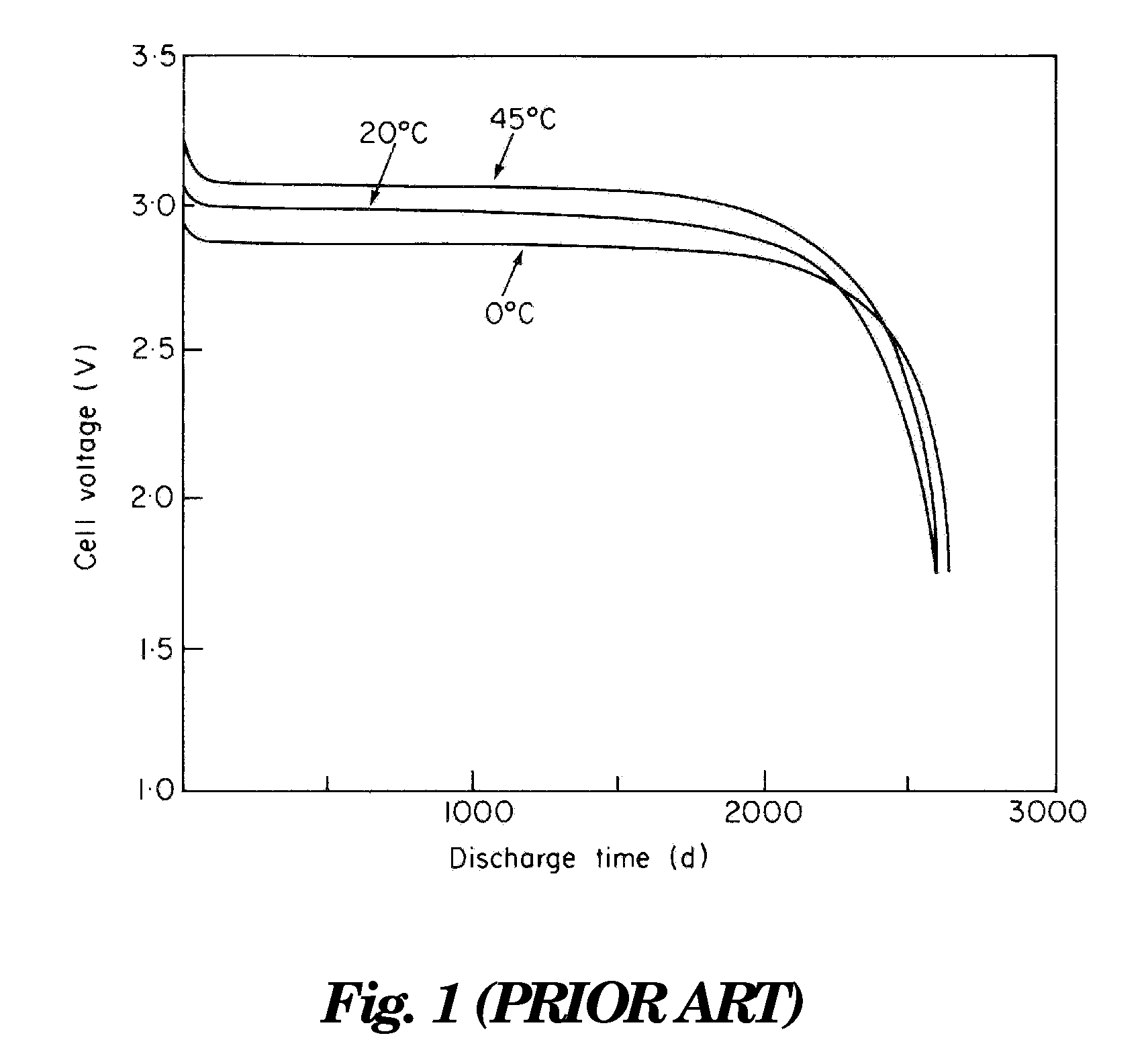

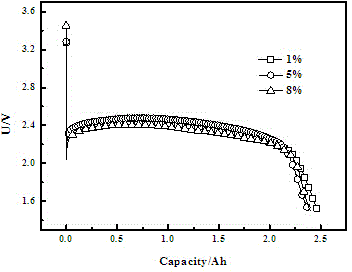

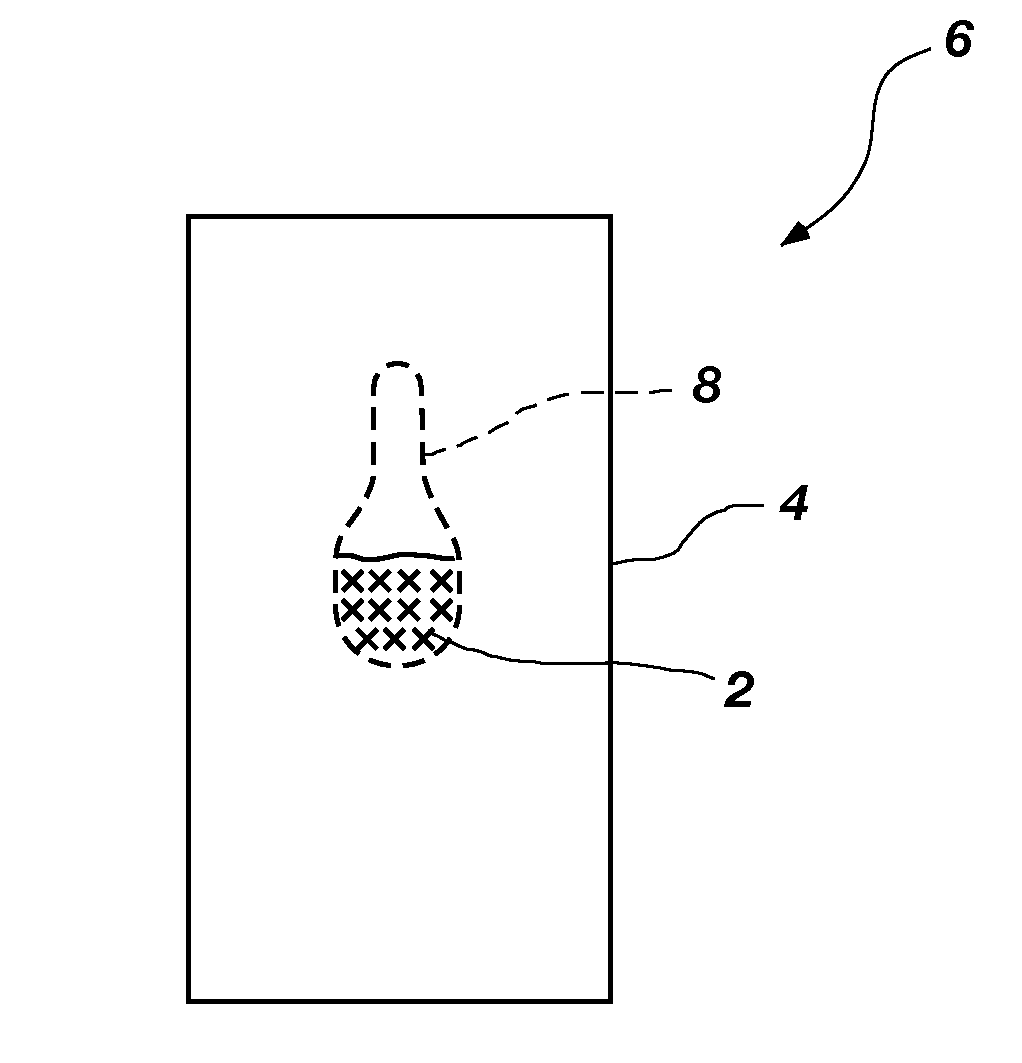

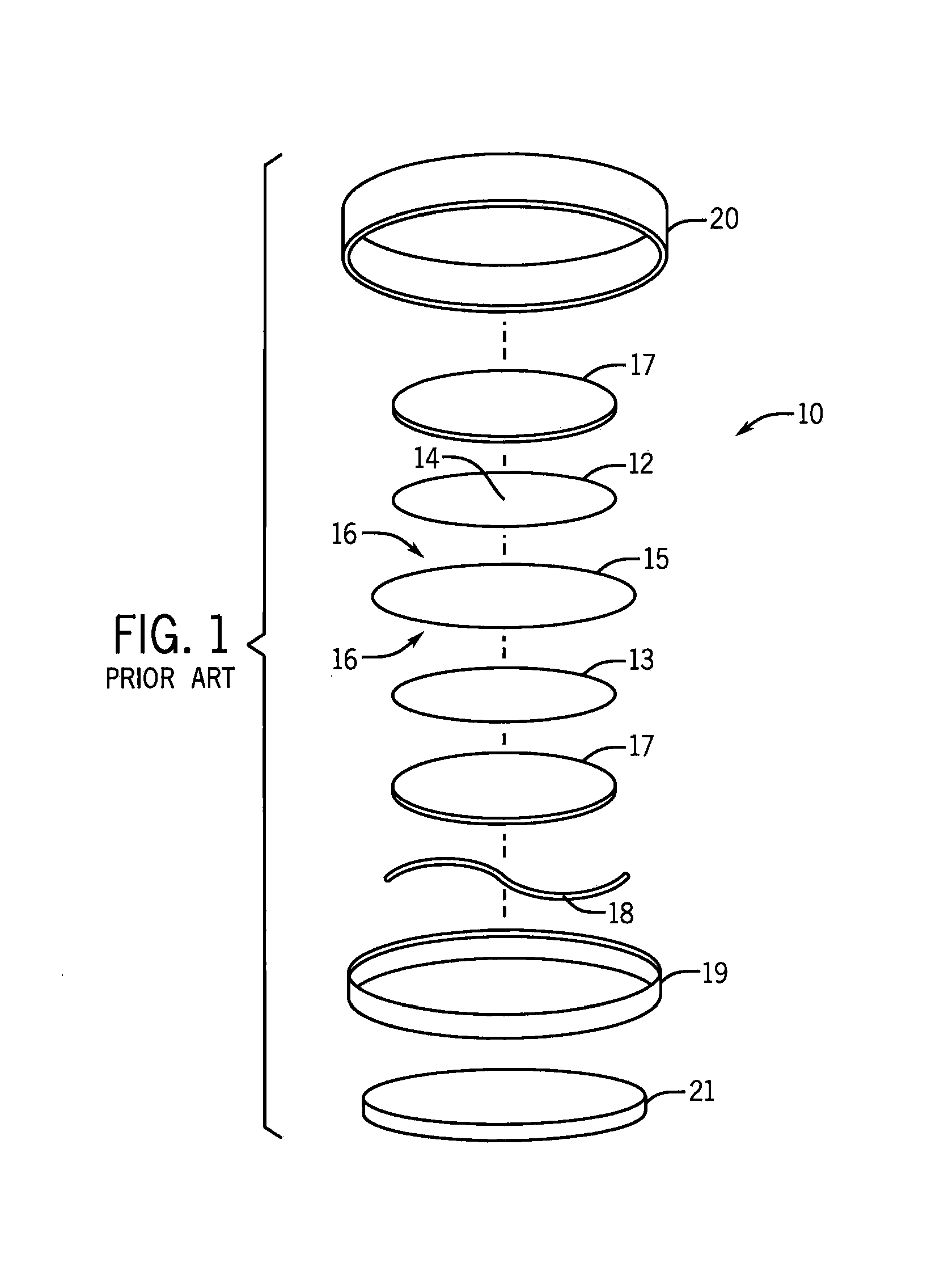

Lithium/Fluorinated Carbon Cell For High-Rate Pulsatlie Applications

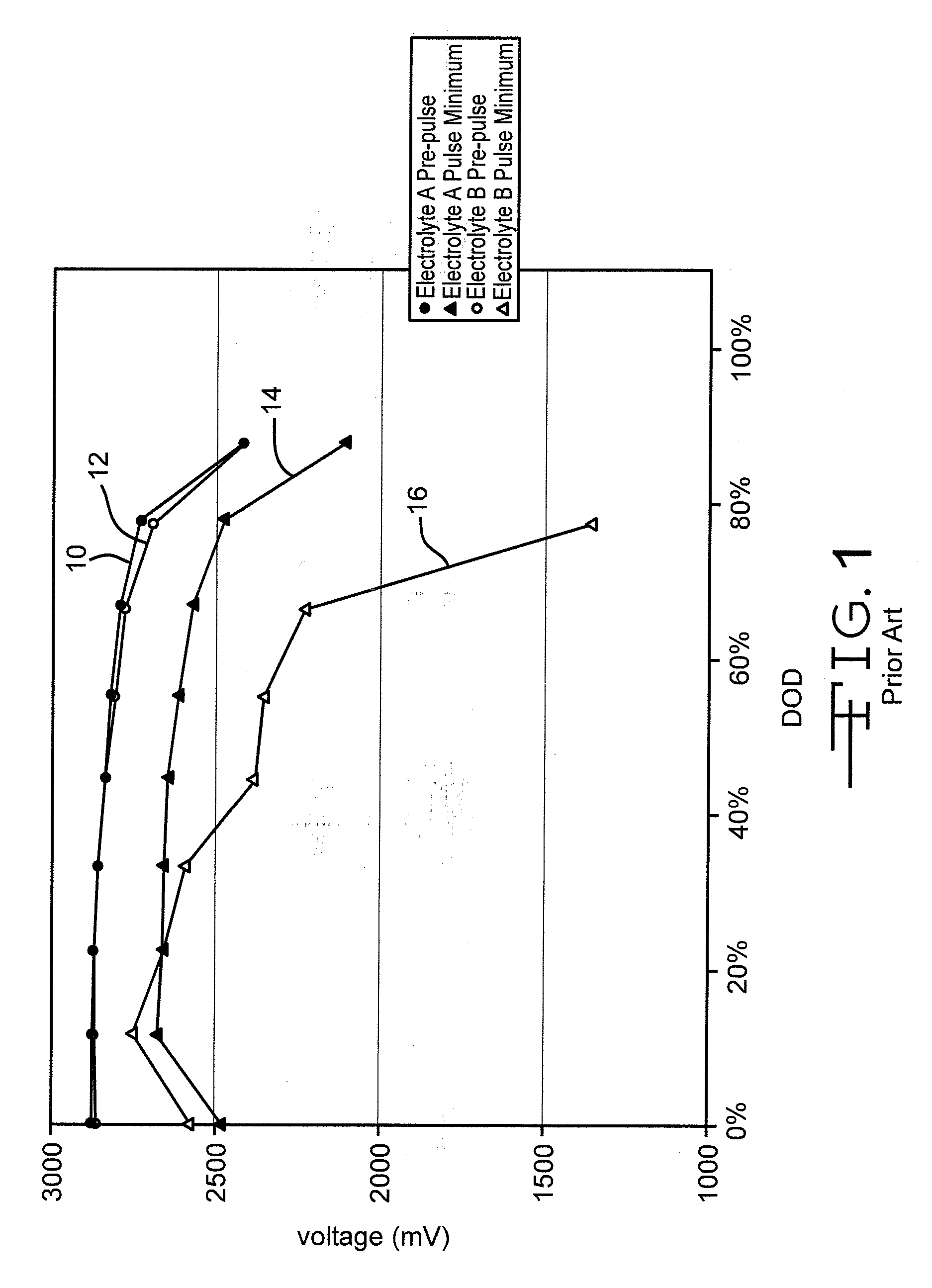

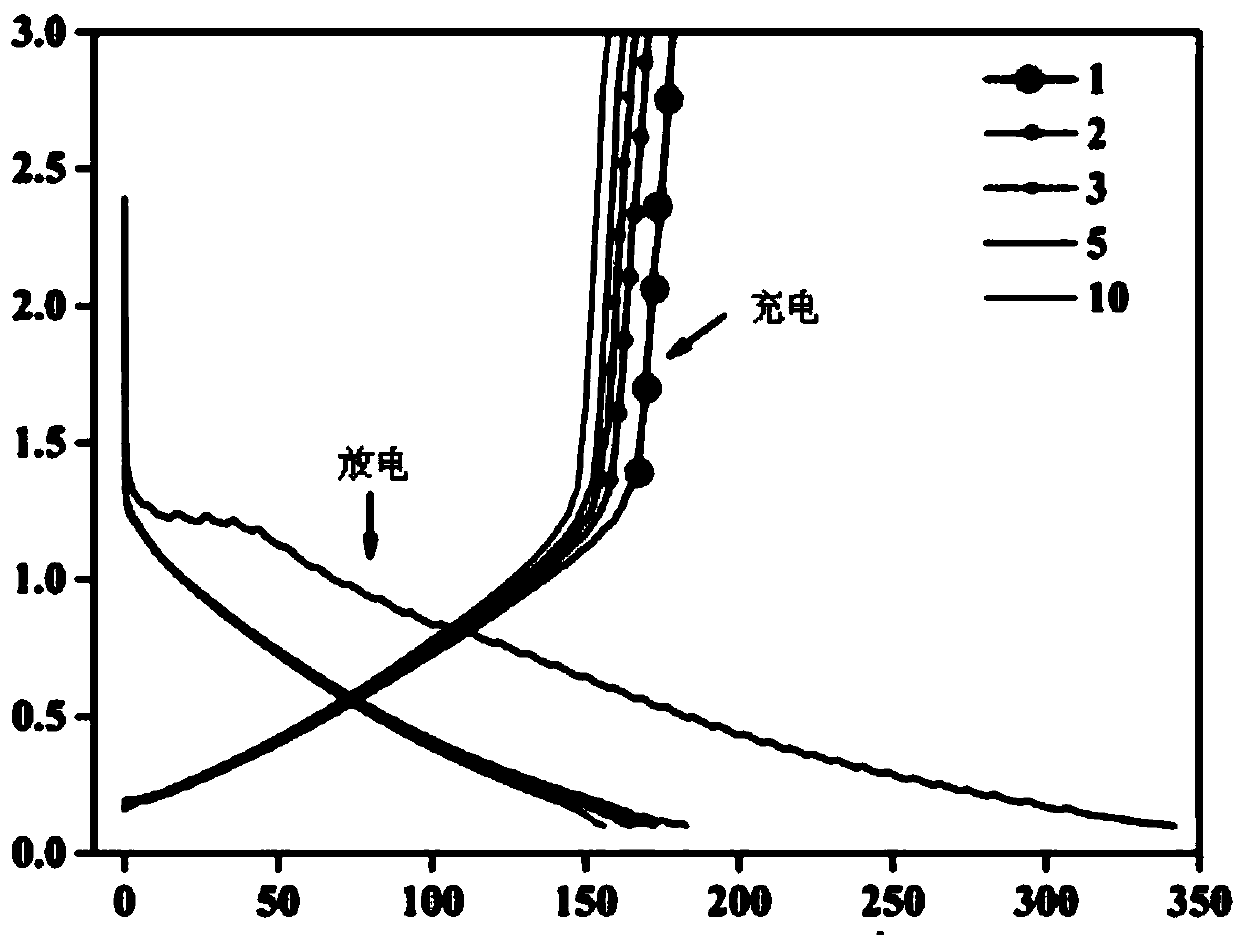

The current invention describes a lithium / carbon monofluoride (Li / CFx) cell capable of delivering sufficient power to supply an ICD or similar demanding device. The cell exhibits the typical excellent long-term stability and predictability of the CFx system, as well as its high energy density (greater than about 300 Ah / cc, greater than about 600 Wh / cc). Additionally, the cell is capable of delivering about 0.5 W / cc of cathode volume for greater than 5 seconds with a voltage above 1.70 V (FIG. 1). The following invention embodiments can be applied individually or in conjunction with each other.

Owner:WILSON GREATBATCH LTD

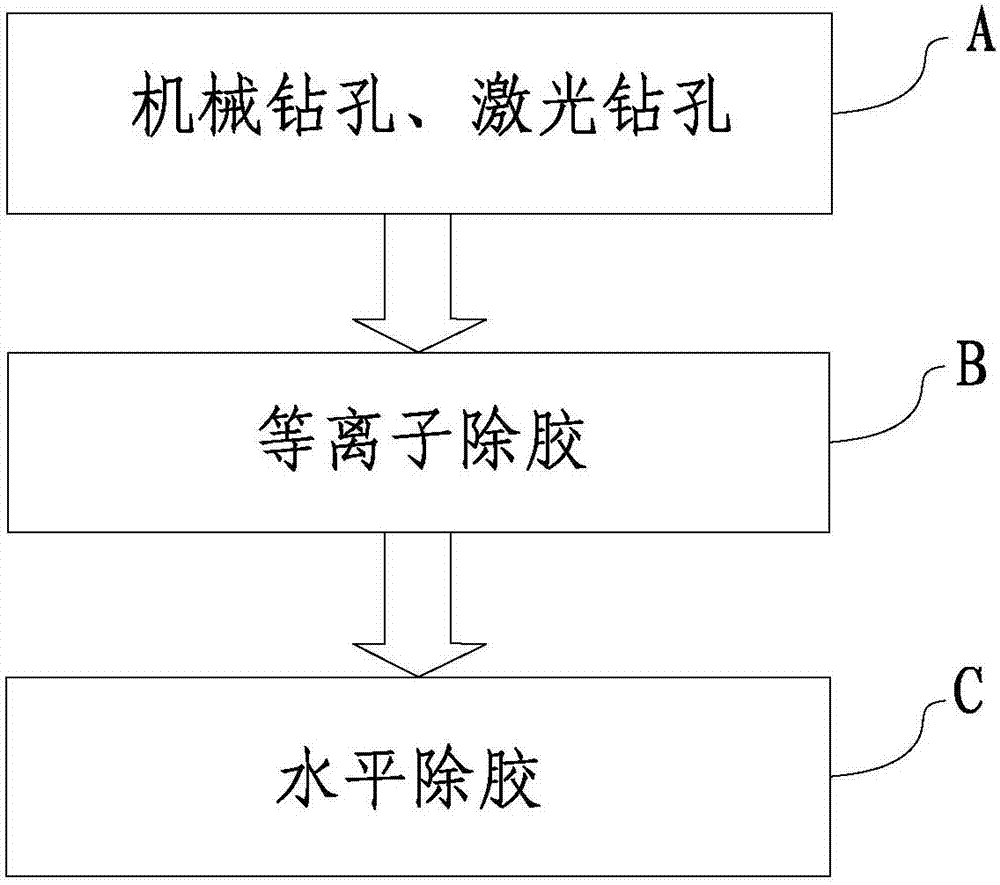

Adhesive-removal method for printed circuit board HDI (high density interconnection) product

ActiveCN102833952AEasy to cleanEfficient removalPrinted circuit manufactureCarbon monofluorideAdhesive

The invention relates to the technical field of the printed circuit board, in particular to an adhesive-removal method for a printed circuit board HDI (high density interconnection) product. The adhesive-removal method comprises the following steps of: A) mechanical drilling and laser drilling: carrying out mechanical drilling on an HDI product, and carrying out laser drilling on the HDI product to form a through hole and a blind hole; B) plasma adhesive removal: generating a plasma by oxygen and carbon tetrafluoride under the action of the nitrogen environment and an RF electric field, and enabling the plasma to react with resin on the walls of the through hole and the blind hole to generate carbon dioxide, hydrogen fluoride and water; and C) horizontal adhesive removal: processing the through hole and the blind hole by chemical potion in a horizontal adhesive removal method. Firstly, the blind hole and the through hole are subjected to the plasma adhesive removal, the generated carbon dioxide, hydrogen fluoride and water can be absorbed without residuals in the blind hole, and then the blind hole and the through hole are subjected to horizontal adhesive removal to effectively remove tiny residual adhesives on the bottom of the blind hole and clean the blind hole.

Owner:东莞市若美电子科技有限公司

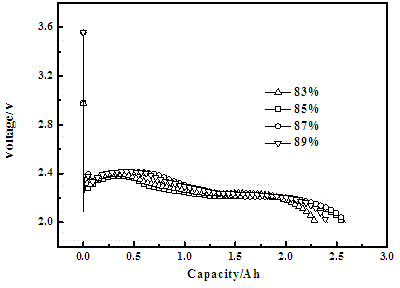

Modified lithium/carbon fluoride battery

InactiveCN104538650AImprove electronic conductivityImprove discharge performanceCell electrodesOrganic electrolyte cellsCarbon monofluorideModified carbon

The invention discloses a modified lithium / carbon fluoride battery which is characterized by comprising the following anode materials in percentage by weight: 80-90% of manganese dioxide modified carbon monofluoride, 3-13% of a conductive agent and 7% of a bonding agent. The electronic conductivity of a material is improved by using manganese dioxide modified carbon polymonofluoride, and during high-current discharge of the battery, the internal resistance is reduced, the polarization phenomenon is reduced, and the discharge capacity of the battery is improved. Therefore, the invention can provide a high-current primary battery which has strong discharge capacity and has great industrial and commercial values.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

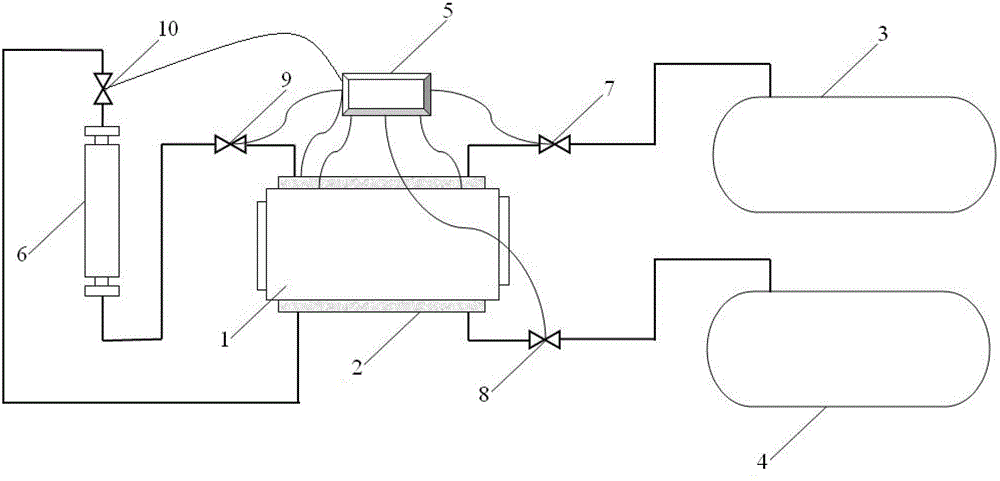

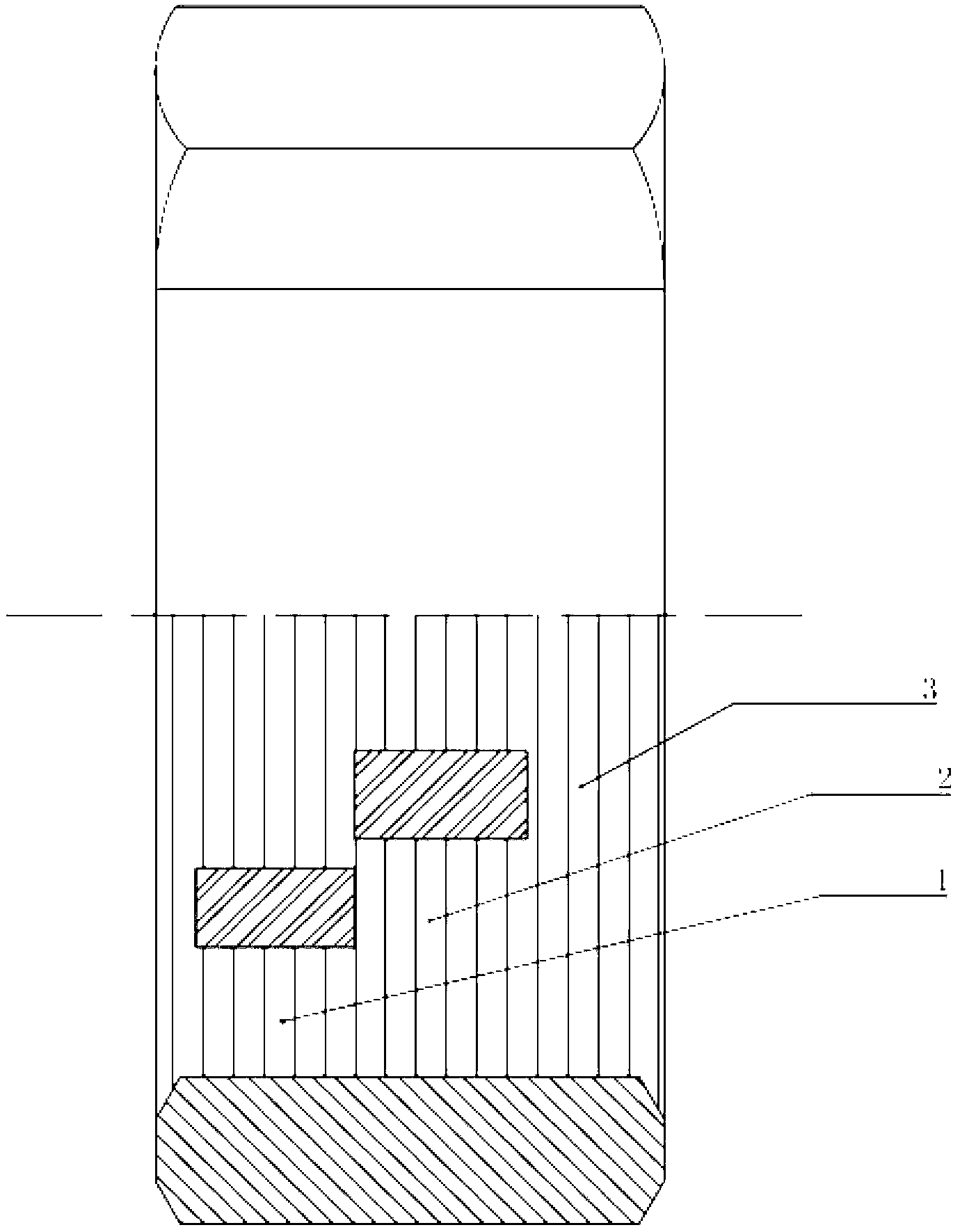

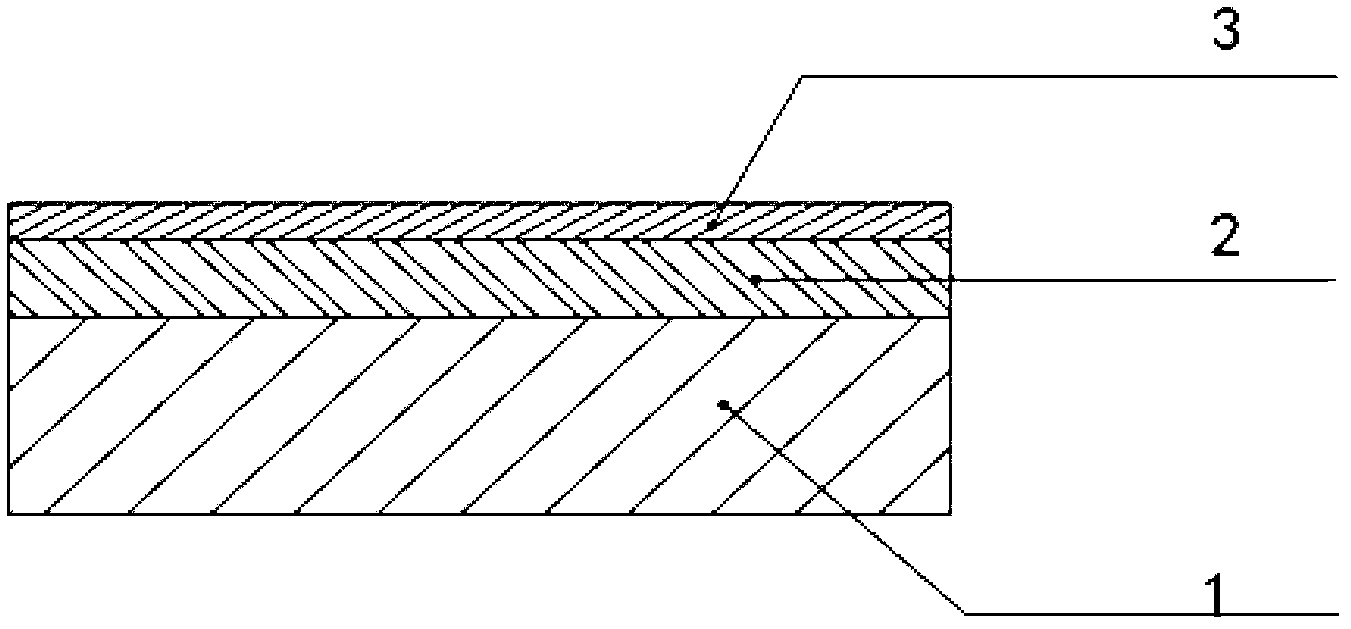

Method for preparing carbon monofluoride or fluorocarbon through inner circulation of fluorine

InactiveCN103332669ALow costReduce manufacturing costCarbon fluoridesCarbon monofluorideHigh concentration

The invention provides a method for preparing carbon monofluoride or fluorocarbon through inner circulation of fluorine. The method comprises the following steps of: (1) firstly passivating a reaction system, and then loading the pretreated graphite or carbon material into a reaction kettle with a cycling passage; (2) adding argon or nitrogen into the reaction kettle, adding fluorine to obtain the fluorine nitrogen or fluorine argon mixed gas; (3) heating the reaction kettle, setting and maintaining a reaction temperature and reaction pressure, and stopping the heating after the reaction is carried out for 1 to 70h under the inner circulation working condition; and (4) taking out the carbon monofluoride or fluorocarbon when the reaction kettle is cooled to the room temperature. The invention also provides a synthesizing device for preparing the carbon monofluoride or fluorocarbon through the inner circulation of the fluorine. The carbon monofluoride or fluorocarbon is synthesized by adopting the fluorine nitrogen mixed gas with high concentration of fluorine, the passivated reaction system, automatic control of a remote computer and a novel fluorine inner circulation process. The cost is low, the safety is high, the yield is high, and the fluorine-carbon ratio of a product is precisely controlled.

Owner:HUBEI ZHUOXI FLUOROCHEM

Screw cap with solid lubricating coating and production method of screw cap

ActiveCN103214911AMeet demanding requirementsImprove reliabilityNutsPretreated surfacesEpoxyCarbon monofluoride

The invention relates to a screw cap with a solid lubricating coating. The lubricating coating is 15-30mum thick, and the solid lubricating paint comprises the following ingredients in percentage by weight: 2-12% of molybdenum disulfide, 3-6% of polytetrafluorethylene, 1-7% of graphite, 0-3% of graphene, 12-18% of tungsten disulfide, 8-12% of carbon monofluoride, 16-34% of epoxy resin, 18-29% of nitroresin, and 3-9% of paint additives. The lubricating coating has excellent self-lubricating property, and anti-loosening and anti-occlusion properties. The screw cap with the solid lubricating coating realizes low torque coefficient of 0.1-0.13, and high torque coefficient of 0.14-0.17, thereby meeting the special requirements of automobiles, shipbuilding, power generation and other industries on the screw cap.

Owner:SHANGHAI YILIN LUBRICATING MATERIAL

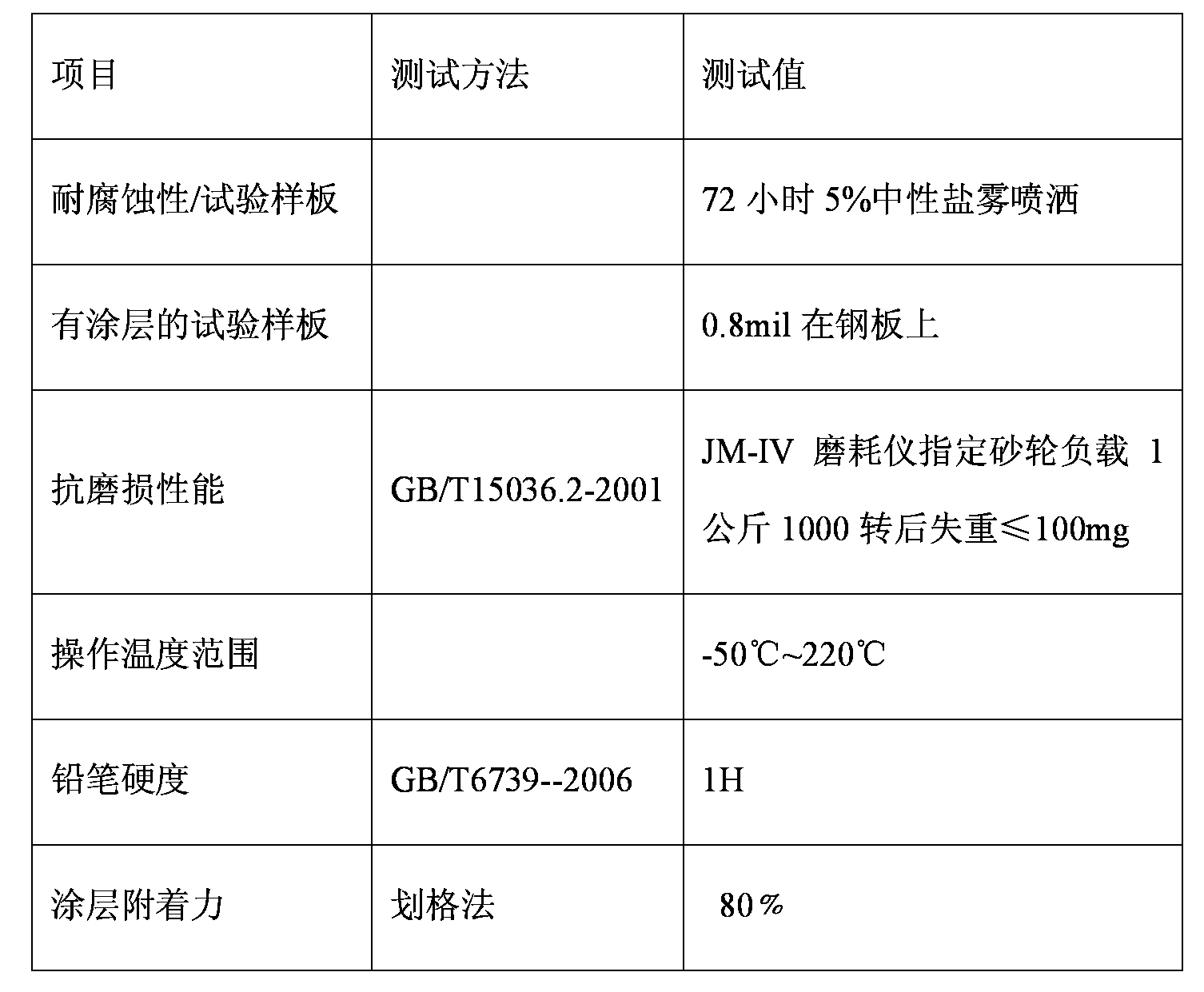

Abrasion-resistant paint and preparation method thereof

InactiveCN104231831AImprove the lubrication effectImprove wear resistanceEpoxy resin coatingsCarbon monofluoridePolymer science

The invention discloses abrasion-resistant paint and a preparation method thereof. The paint comprises a first component and a second component, wherein the first component is double-component composition formed by mixing of a component A and a component B in a ratio of 1:1, the component A in the first component comprises components as follows: E-20 epoxy resin, silicon carbide micro powder, carbon monofluoride and a coupling agent; the component B in the first component comprises components as follows: methyl methacrylate, butyl acrylate, aluminum isopropoxide, triethoxy vinyl silane and 20-25 parts of a solvent; the second component comprises components as follows: a curing agent, an antifoaming agent, a leveling agent and a solvent. The components A and B in the first component are prepared separately and then mixed, and finally, the first and second components are cured to obtain the abrasion-resistant paint.

Owner:JIANGSU MARINE VICTORY COATING

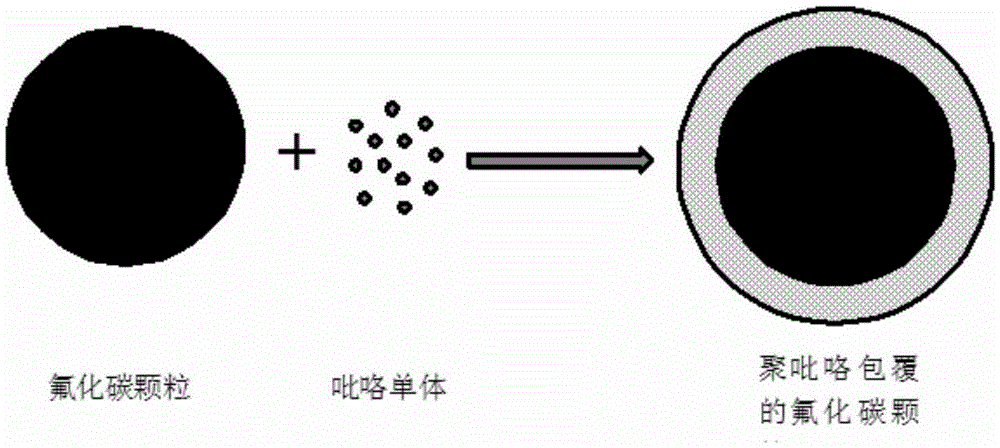

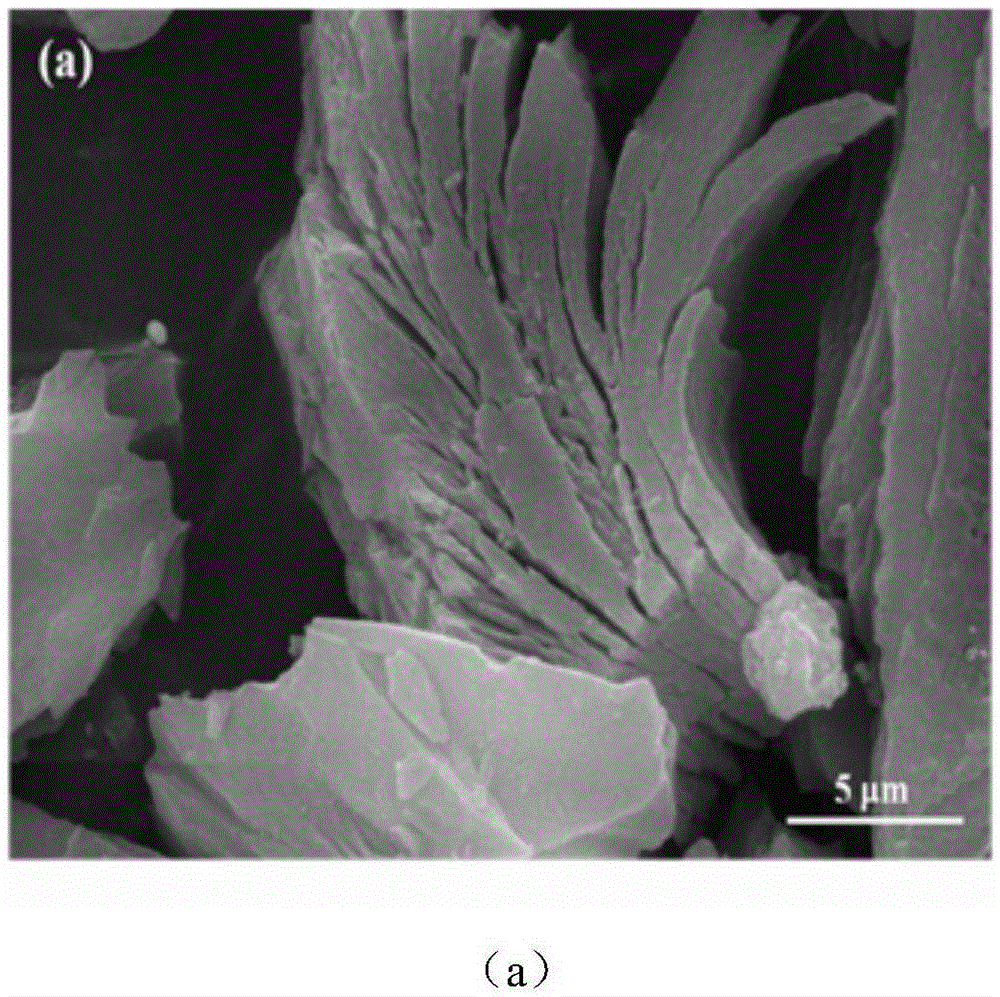

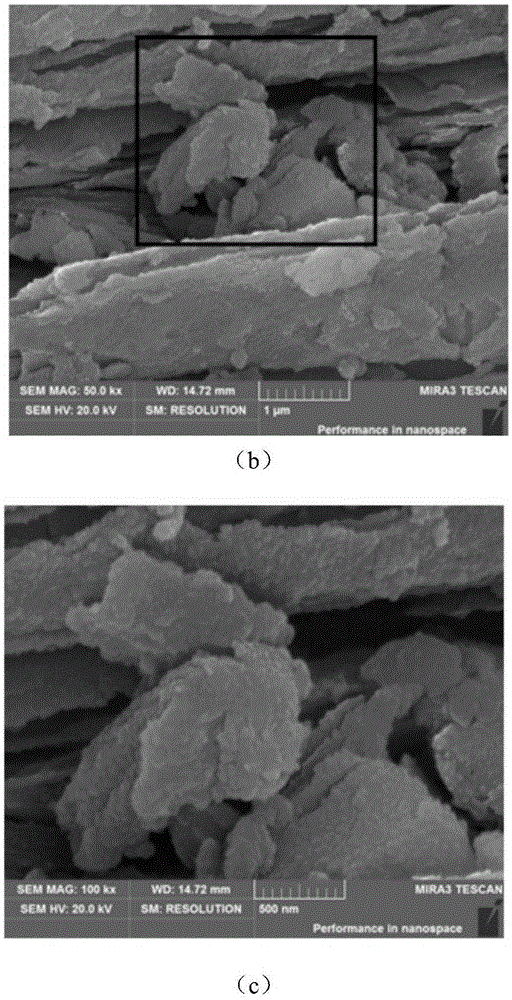

Preparation method and application of polypyrrole-coated carbon fluoride positive electrode material

ActiveCN105336928AImprove conductivityImprove discharge ratePrimary cell electrodesEnvironmental resistanceInorganic salts

The present invention discloses a preparation method and application of a polypyrrole-coated carbon fluoride positive electrode material, the preparation of the positive electrode material is as follows: carbon fluoride particles are dispersed in water in the surfactant role, pyrrole monomer is added for evenly mixing to obtain carbon fluoride / pyrrole suspension; an inorganic salt oxidizing agent-containing acidic solution is added dropwise into the obtained carbon fluoride / pyrrole suspension for stirring for reaction, and the reaction product is successively washed and dried to obtain the polypyrrole-coated carbon fluoride positive electrode material. The preparation method is simple, avoids the use of toxic organic solvents, is non-toxic and environmentally friendly and low in cost, and can meet the requirements of industrial production; the polypyrrole layer of the obtained polypyrrole-coated carbon fluoride positive electrode material is evenly coated, the obtained polypyrrole-coated carbon fluoride positive electrode material has good conductivity, and can improve the rate discharge performance of a one-shot battery.

Owner:XIANGTAN UNIV

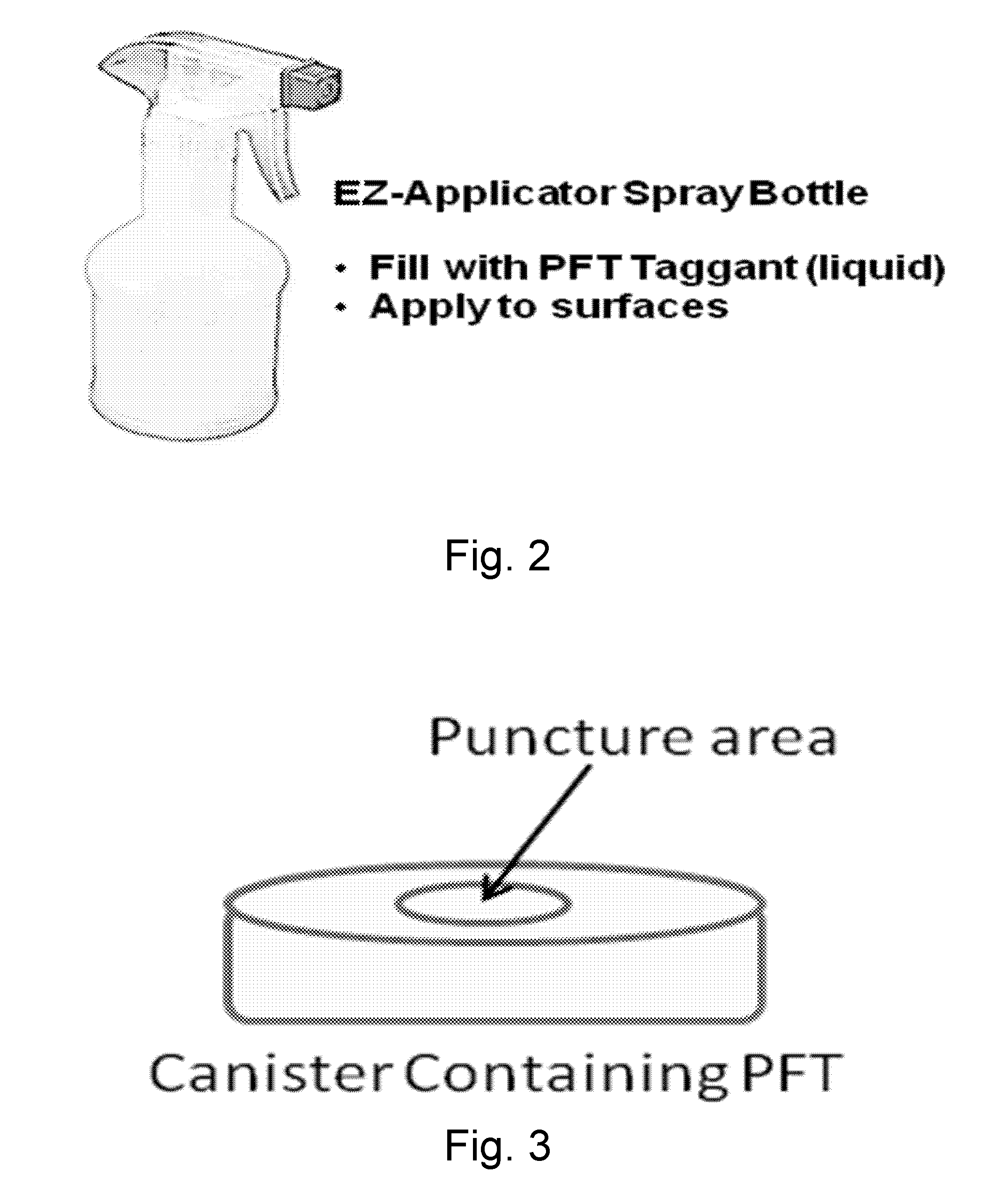

Taggants, method for forming a taggant, and a method for detecting an object

InactiveUS20110100091A1Optical radiation measurementParticle separator tubesChemical structurePolonium

A taggant comprising at least one perfluorocarbon compound surrounded by a polyphosphazene compound. The polyphosphazene compound has the chemical structure:wherein G1 and G2 are pendant groups having different polarities, m is an integer greater than or equal to 100, and each of A and B is independently selected from hydrogen, an alkyl, an alkene, an alkoxide, a polyether, a polythioether, a siloxane, and —X(CH2)nY1(CH2)p1Y2(CH2)p2 . . . Yi(CH2)piCH3, where n ranges from 1 to 6, X and Y are independently selected from oxygen, sulfur, selenium, tellurium, and polonium, and p1 through pi range from 1 to 6. Cyclic polyphosphazene compounds lacking the A and B groups are also disclosed, as are methods of forming the taggant and of detecting an object.

Owner:BATTELLE ENERGY ALLIANCE LLC

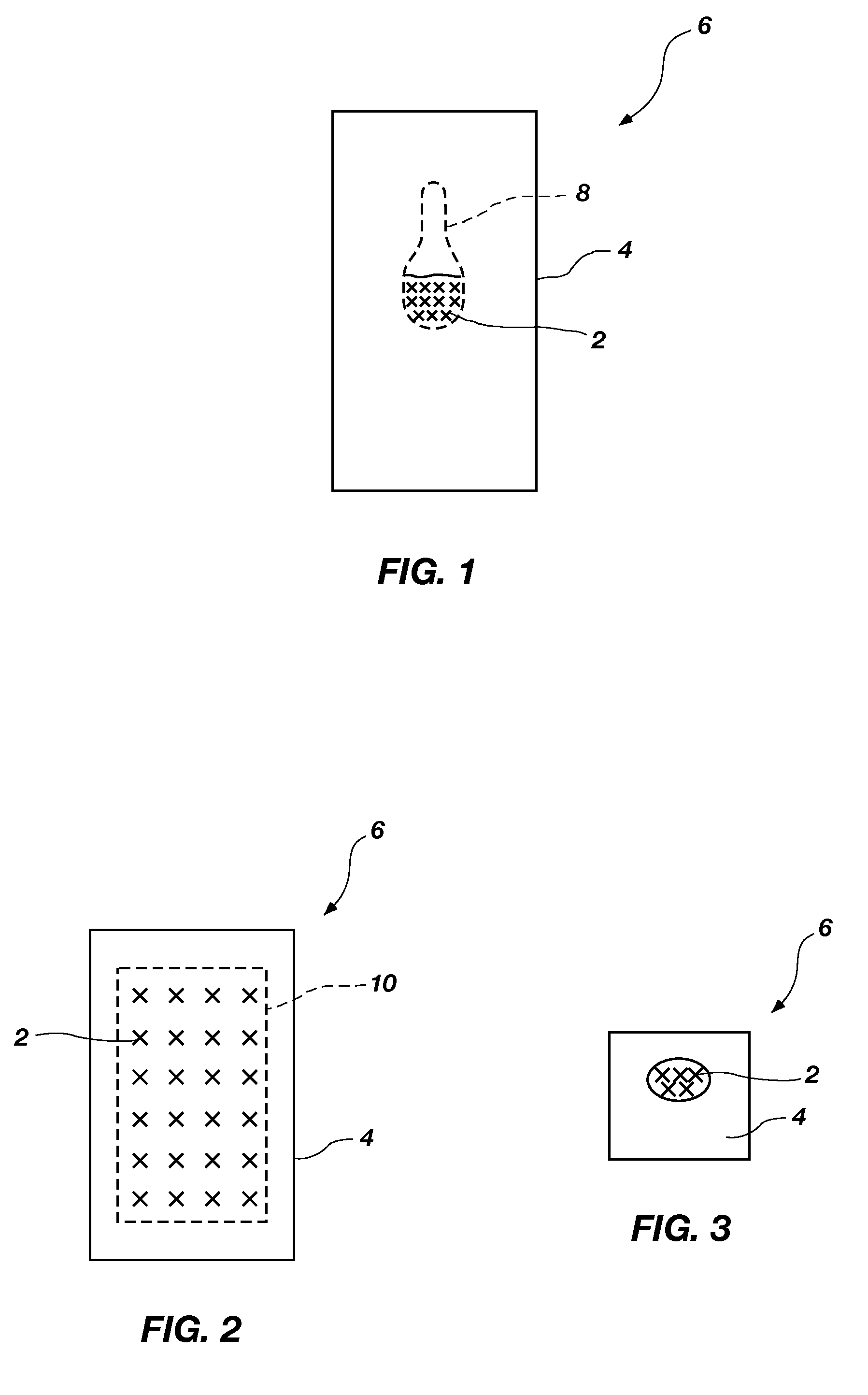

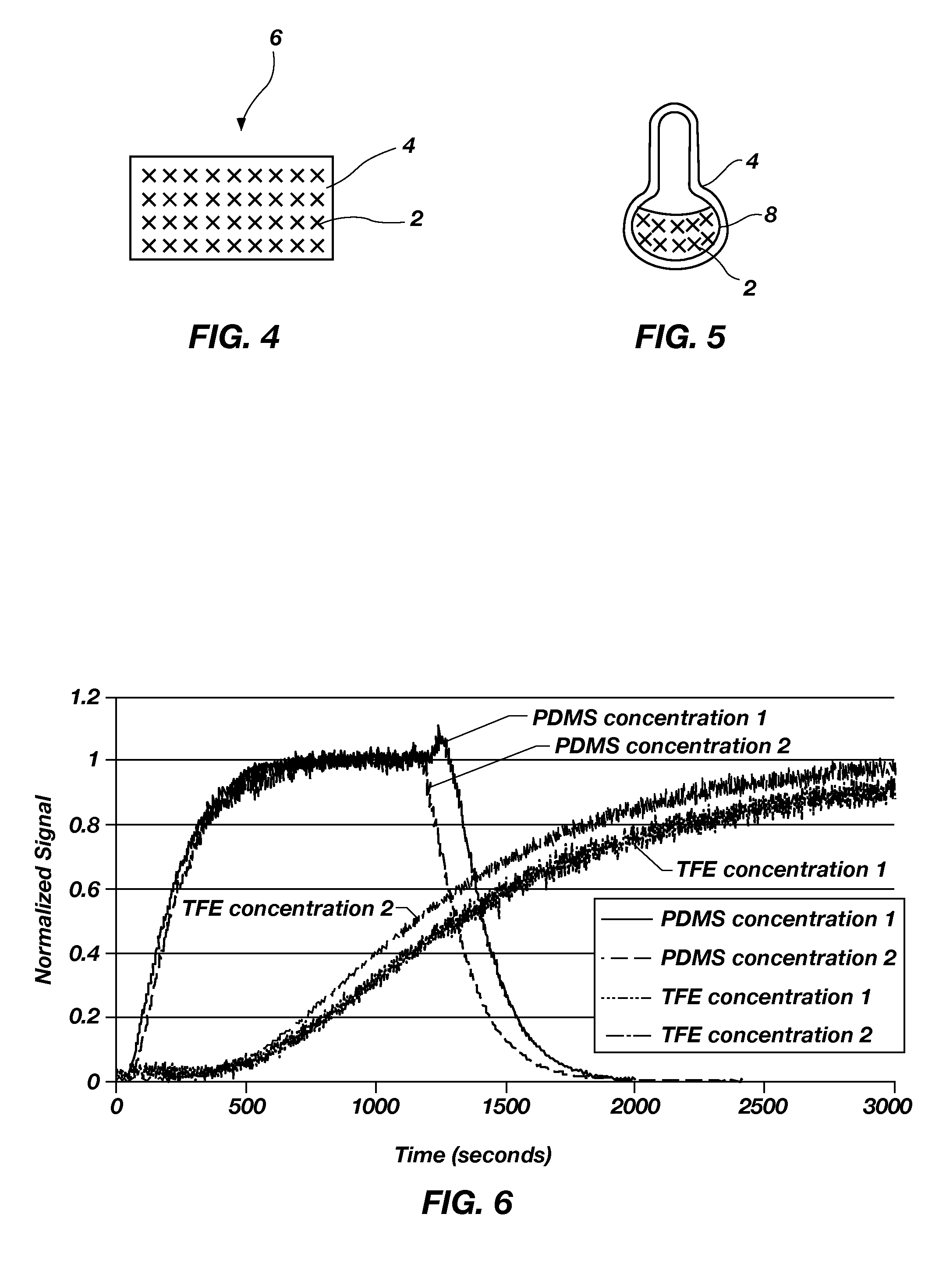

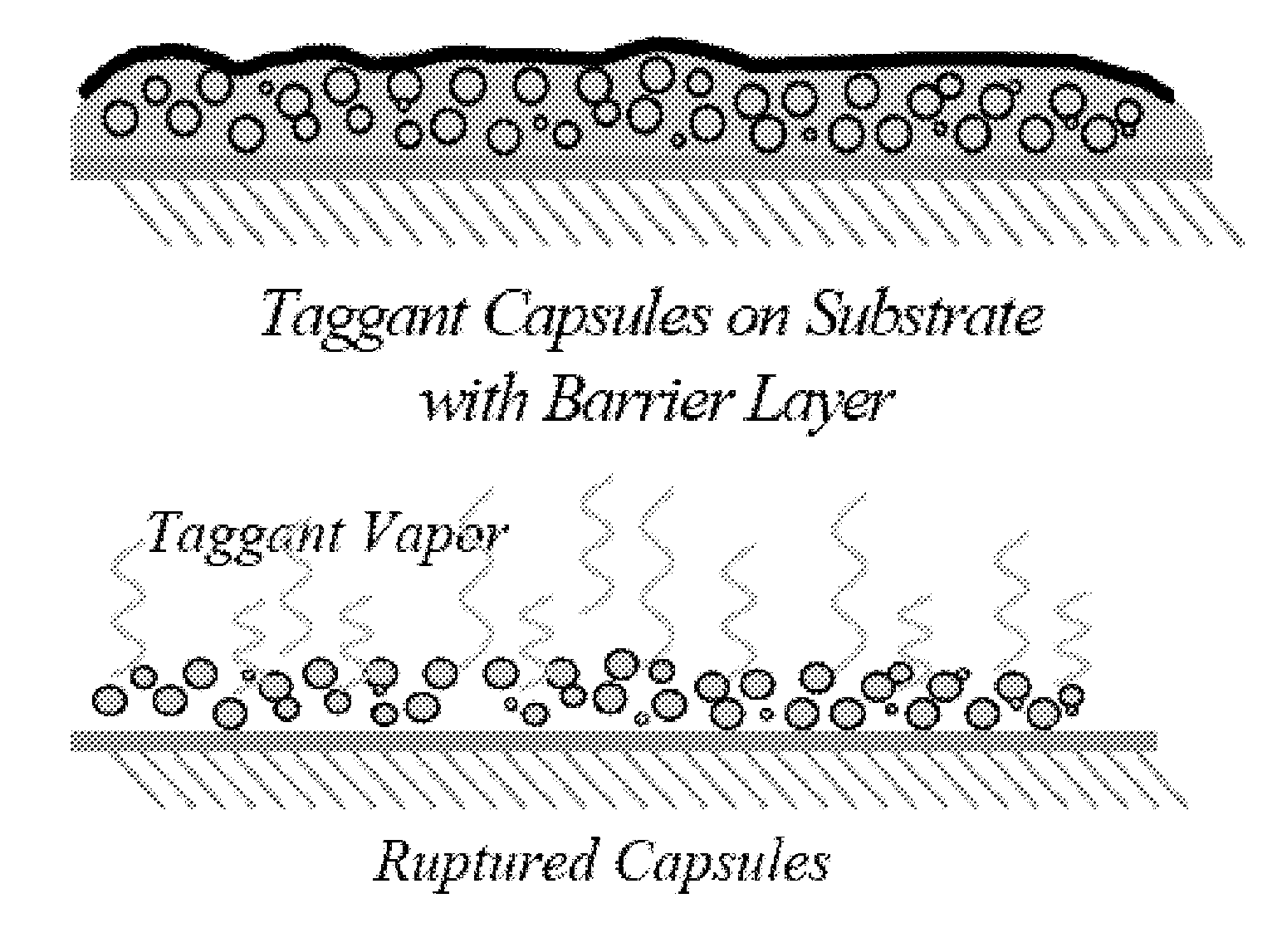

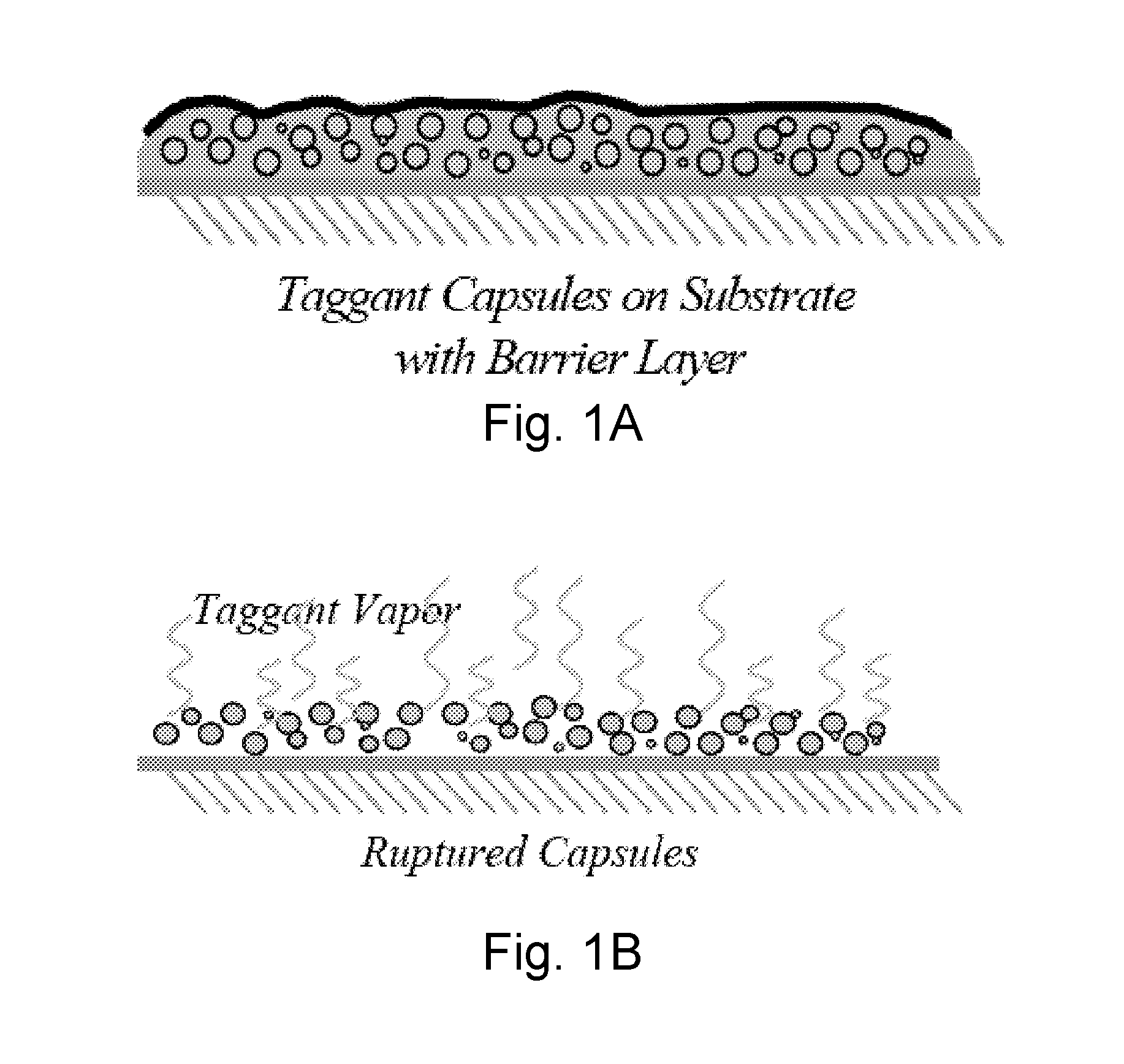

Methods of delivery of encapsulated perfluorocarbon taggants

InactiveUS9057712B1Material analysis using wave/particle radiationSpray nozzlesControlled releasePerfluorocarbon tracer

A system and method for tagging, tracking, locating and identifying people and vehicles transporting people using Perfluorocarbon tracers. An on-going problem faced by military as well as law enforcement personnel is that of friendly fire incidents. To prevent possible friendly-fire incidents, troops would separate the two layers of the uniform patch, thereby releasing a controlled release of the Perfluorocarbon vapors. Other “friendly” troops, equipped with sensors tuned to the specific perfluorocarbon characteristics would thus be able to literally view a plume around the tagged person or object. The system may conversely be used to tag enemies. Formulations of mixed perfluorocarbons may be used to provide coding of emissions.

Owner:COPILOT VENTURES FUND III

Adsorbent for purifying perfluorocarbon, process for producing same, high purity octafluoropropane and octafluorocyclobutane, and use thereof

To provide a purification adsorbent capable of effectively removing impurities contained in a perfluorocarbon and obtaining a perfluorocarbon reduced in the impurity content to 1 ppm by mass or less; a process for producing the adsorbent; high-purity octafluoropropane or octafluorocyclobutane; processes for purifying and for producing the octafluoropropane or octafluorocyclobutane; and uses thereof. Purification is performed using a purification adsorbent produced by a method comprising (1) washing an original coal with an acid and then with water, (2) deoxidizing and / or dehydrating the original coal, (3) re-carbonizing the original coal at a temperature of from 500 to 700° C. and (4) activating the original coal at a temperature of from 700 to 900° C. in a mixed gas stream containing an inert gas, carbon dioxide and water vapor.

Owner:SHOWA DENKO KK

Large scale synthesis process of carbon fluorides

The present invention is large scale synthesis process of carbon fluoride as one new type of functional material. Carbon fluoride material is white or grey, non-toxic, nonflammable, non-corrosive and chemically stable. It may be used as insulating material, waterproofing material, lubricant material and electrode material for high energy lithium battery, and has excellent performance and superiority of being used in the conditions of high temperature, high pressure, high load, strong acid and alkali environment. Carbon fluoride material is prepared through introducing fluorine gas or mixed gas of fluorine and nitrogen or other inert gas into special solidifying bed with various kinds of carbon process so as to produce reaction in certain temperature to generate carbon fluoride product of different sizes.

Owner:彭海燕

Method for preparing wear-resistant non-stick pan coating

ActiveCN109820429AGood non-stickExtended service lifeCooking-vessel materialsPretreated surfacesCarbon monofluorideWear resistant

The invention relates to the field of surface treatment of cookware, in particular to a method for preparing a wear-resistant non-stick pan coating. By weight, 100 parts of water, 20-40 parts of polytetrafluoroethylene, 24-40 parts of polyethersulfone resin, 6-12 parts of polyetheretherketone, 2-5 parts of polymethylvinylsiloxane and 0.003-0.1 part of an alane N,N-dimethylethylamine complex are heated to 450-550 DEG C and stirred for 5-10 h, then 1-3 parts of nano graphene oxide, 2-4 parts of carbon monofluoride, 2-4 parts of mica powder and 0.5-1 part of distearyloxyisopropoxyaluminate are added, stirring is carried out for 2-5 h, then 1.5-3.5 parts of a coating reinforcing agent is added, and a wear-resistant non-stick pan paint is obtained; then the obtained wear-resistant non-stick panpaint is applied to the inner surface of a pretreated metal pan, then the metal pan is placed in a constant-temperature drying oven, drying is carried out for 15-30 min at 250-350 DEG C, and the wear-resistant non-stick pan is obtained.

Owner:浙江乐太新材料有限公司

Anti-adhesion surgical device

InactiveCN102090923AImprove performanceSurgical instrument detailsCoatingsSemiconductor materialsDiamond-like carbon

The invention discloses an anti-adhesion surgical device which comprises a power generator, a handheld control unit and a working head. The anti-adhesion surgical device is characterized in that the surface or a part of the working head is provided with at least one layer of nano or micron fluorinated diamond-like carbon film, fluorinated silicon-doped diamond-like carbon film, fluorinated silicon doped diamond-like film, fluorinated silicon and boron doped diamond-like film or fluorinated silicon, boron and nitrogen doped diamond-like film deposited by using a perfluocarbon compound, a high purity graphite target or a cathode, a carbon nano tube and / or semiconductor materials including materials which can form n-type or p-type semiconductors together with silicon. The working head of the surgical device provided by the invention has extremely strong hydrophobicity and can still have low friction coefficient and self-lubricating property under laparoscopic surgery environment with high relative humidity, and the cutting and anti-adhesion capabilities are enhanced.

Owner:冷博

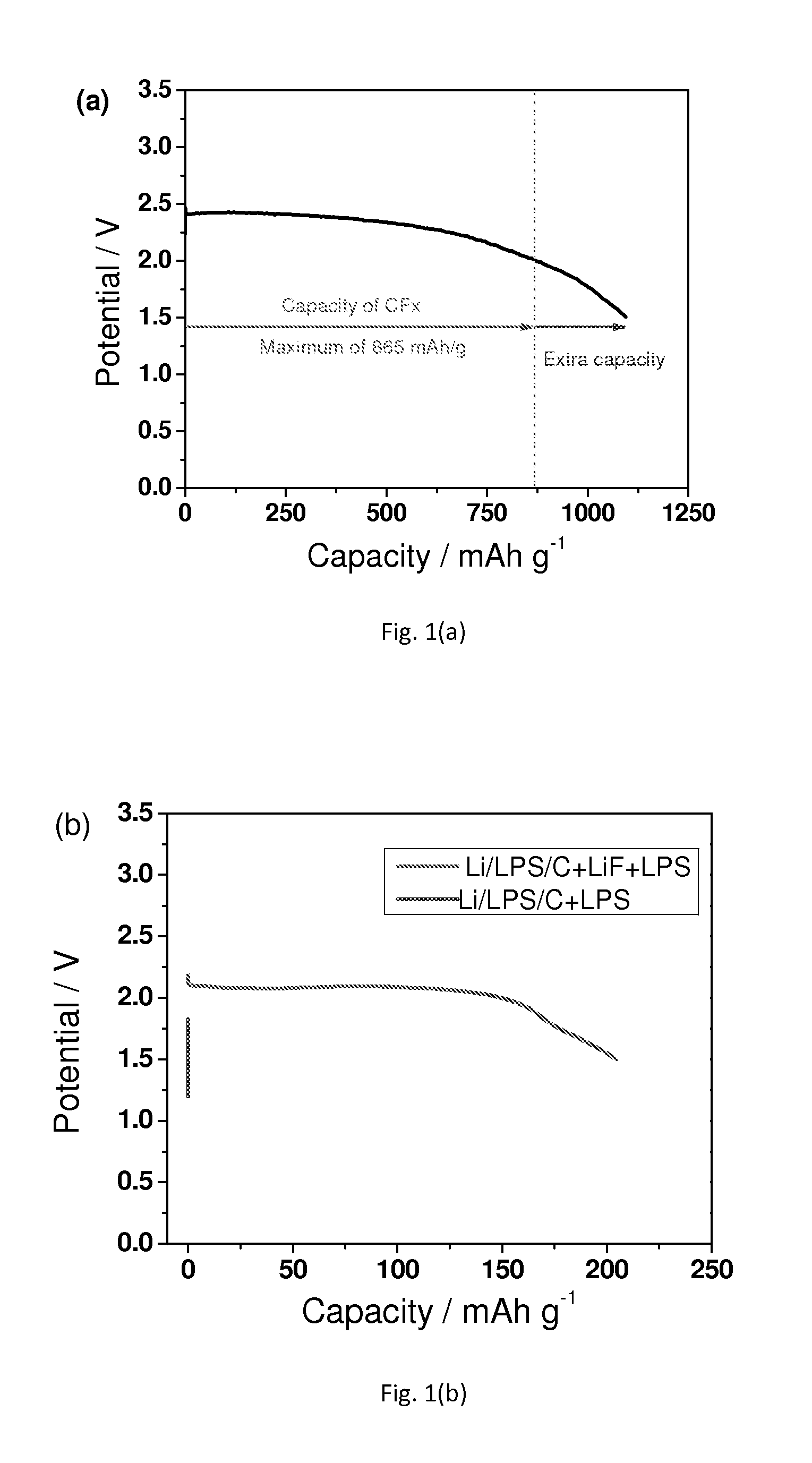

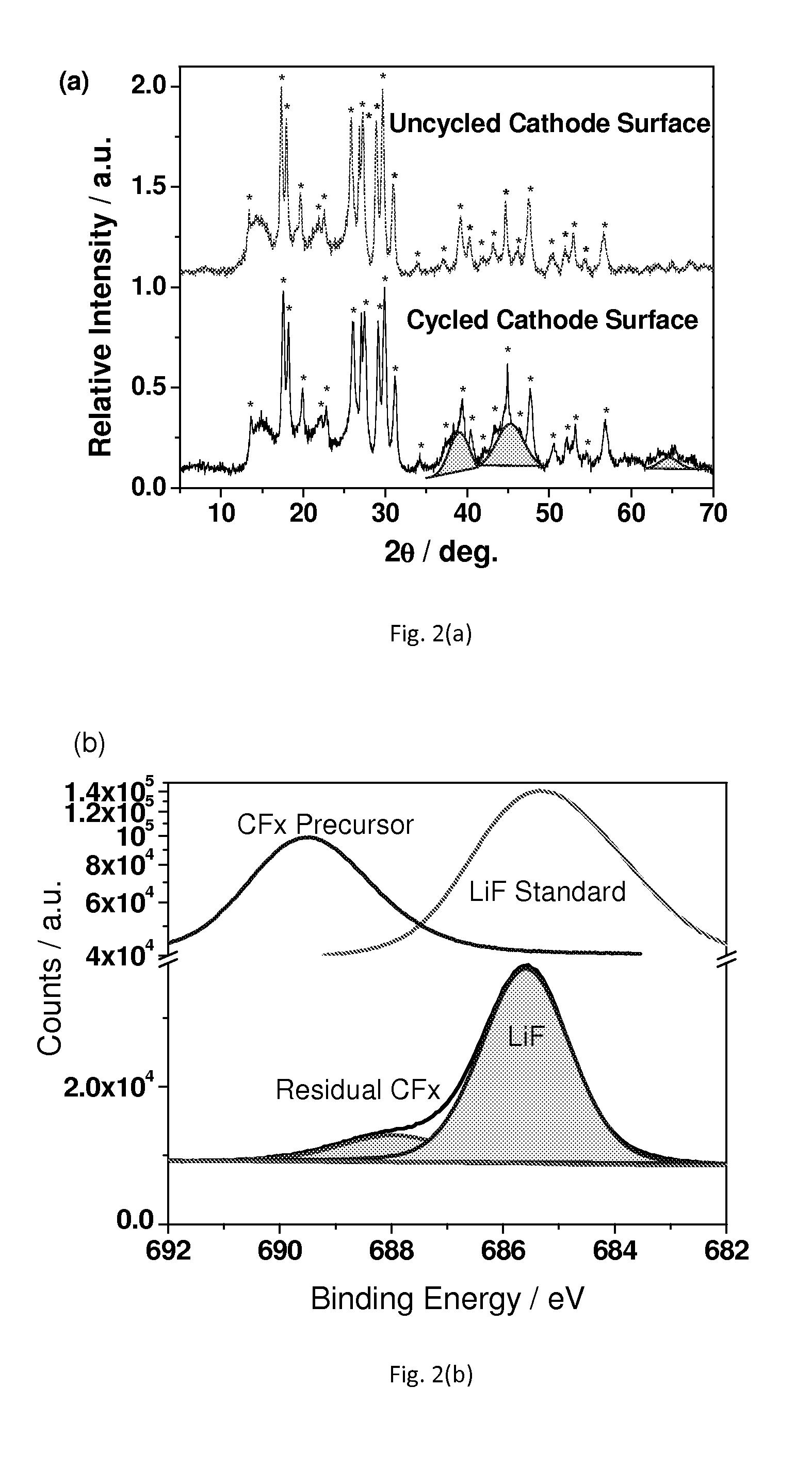

All-solid state lithium carbon monofluoride batteries

A solid state lithium carbon monofluoride battery includes an anode comprising Li, a solid electrolyte, and a cathode including CFx and LPS. The cathode can also include a carbon compound. The solid electrolyte can include LPS. The LPS can include β-Li3PS4. The cathode LPS can include β-Li3PS4. A method of making a battery is also disclosed.

Owner:UT BATTELLE LLC

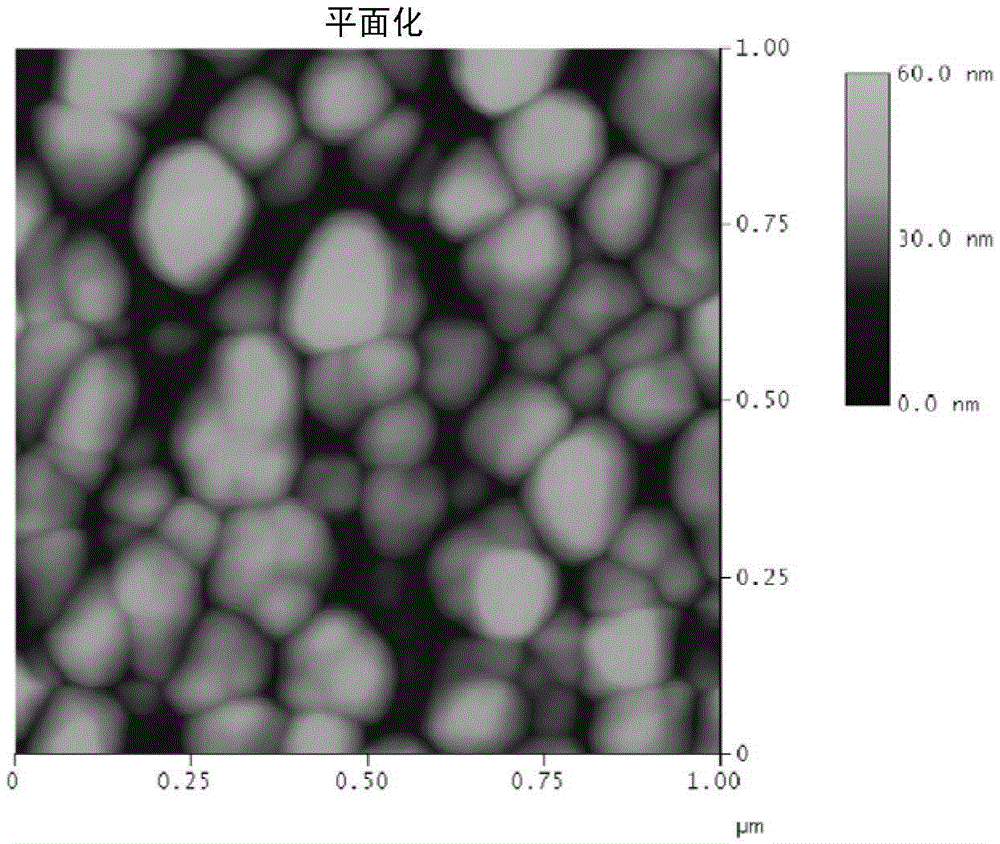

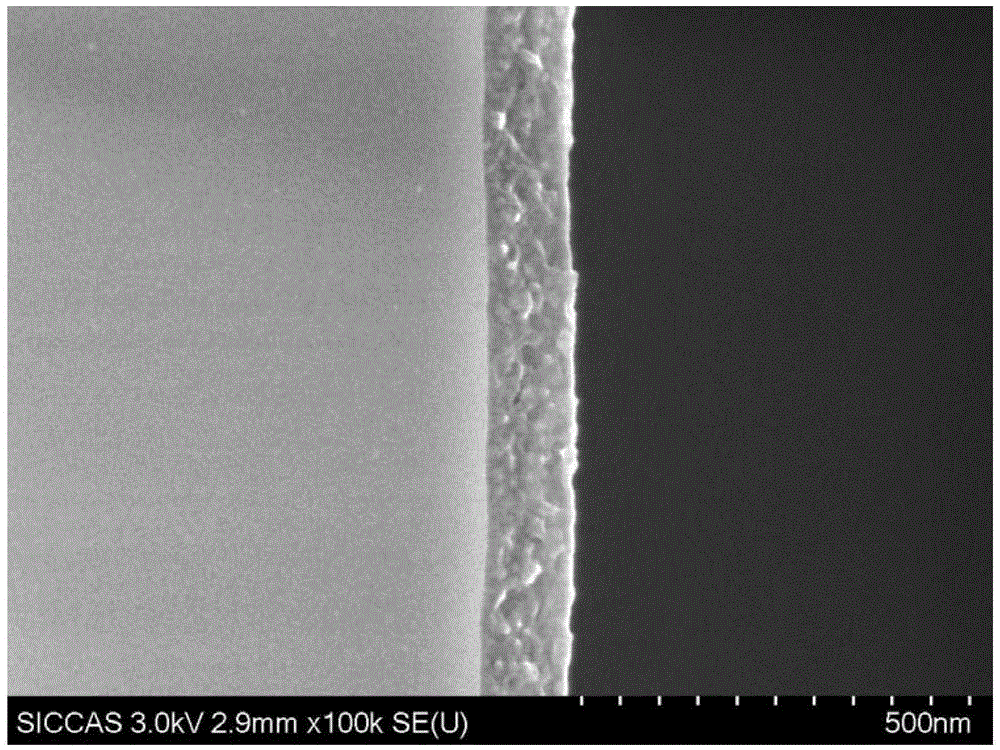

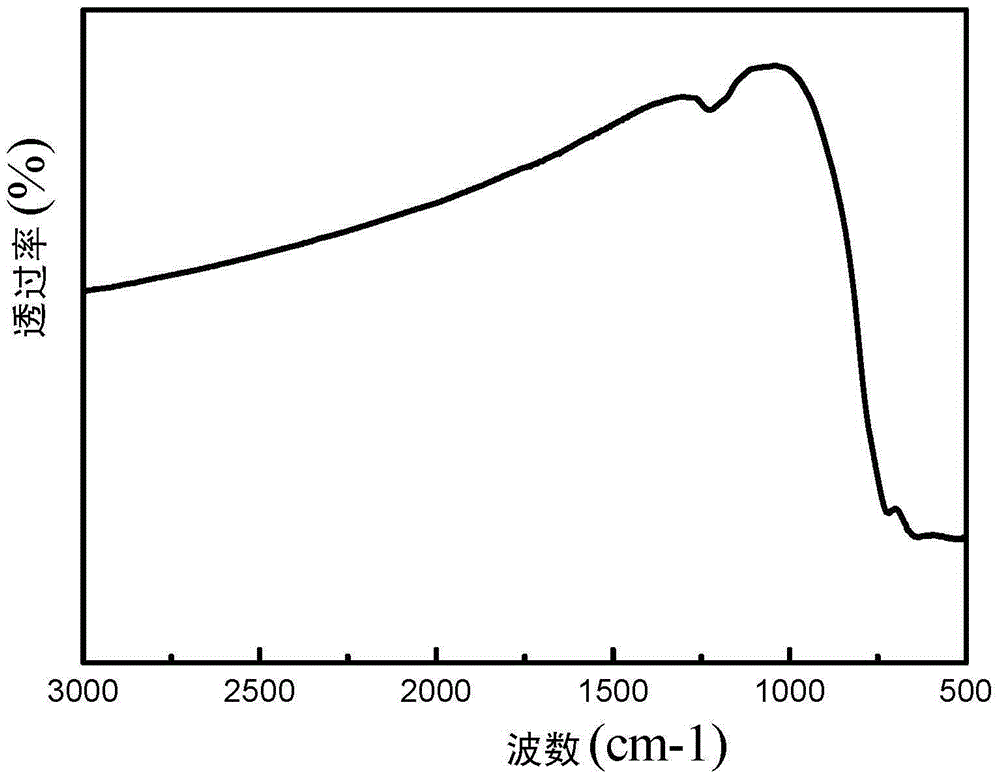

Teflon thin film with high light transmitting and dewatering functions and preparation method and application thereof

InactiveCN106676473AImprove adhesionIncrease deposition rateVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringOptoelectronics

The invention relates to a teflon thin film with the high light transmitting and dewatering functions and a preparation method and application thereof. According to the preparation method, a radio frequency magnetron sputtering method is adopted for sputtering the teflon thin film on a substrate. The method includes the preparation conditions that background vacuum pressure is 1*10<6>-2*10<3>Pa, the volume proportion of argon pumped in to carbon tetrafluoride is 10:1-100:1, and working air pressure is 0.5-2.0Pa; and sputtering power is 10-100W, the substrate temperature is 25-300 DEG C, and sputtering time is 15-60 minutes. By means of the teflon thin film with the high light transmitting and dewatering functions and the preparation method and application thereof, the radio frequency magnetron sputtering method is adopted for depositing the teflon thin film on the substrate, so that adhesive force to the substrate by the thin film is increased; and moreover, fluorocarbon gas like CF4 is added into Ar flow, and thus the deposition rate and fluorine content of the thin film can be effectively increased. A certain proportion of CF4 gas is mixed into the argon carrier gas pumped in to serve as supplemental gas, and the problems that F ions at the C-F chain breaking part lose due to glow discharging and thin film quality is lowered are solved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Coating material for preventing engine crankshaft from being locked, and preparation method and application method of coating material

InactiveCN103710116AGood synergyImprove flame retardant performanceBase-materialsCarbon monofluorideEpoxy

The invention discloses a coating material for preventing an engine crankshaft from being locked, and a preparation method and an application method of the coating material. The coating material comprises the following raw materials in parts by weight: PAG (Polyalkylene Glycol ethers) polyether base oil, modified plant-based synthetic ester oxide sunflower oil, epoxy resin, organic molybdenum, tungsten disulfide powder, tungsten diselenide powder, carbon monofluoride powder, polyphenyl, a fire retardant, an antiwear agent and an antioxidant. The coating material is coated on a crankshaft neck surface and / or bearing bush surface between a crankshaft neck and a bearing bush (tile), so that a protective coating which is lubricant enough, and not easy to wash off or damage, and can bearing extremely high temperature is provided under the condition that the engine oil cannot provide effective lubricating due to poor quality, or cannot provide an enough lubricating effect between the crankshaft and a connecting rod due to reduction of the engine oil, the coating material has excellent waterproof properties, anti-rust characteristics, anti-corrosion property, and micro-grinding resistance on metal parts, can form solid dry film lubrication under the environment above 200 DEG C, and can play the roles in lubricating and preventing metal from being locked by sintering at the temperature which can be up to 1400 DEG C, and the locking phenomenon between the crankshaft and the connecting rod caused by dry friction between the tile and the crankshaft is effectively avoided.

Owner:杨毅

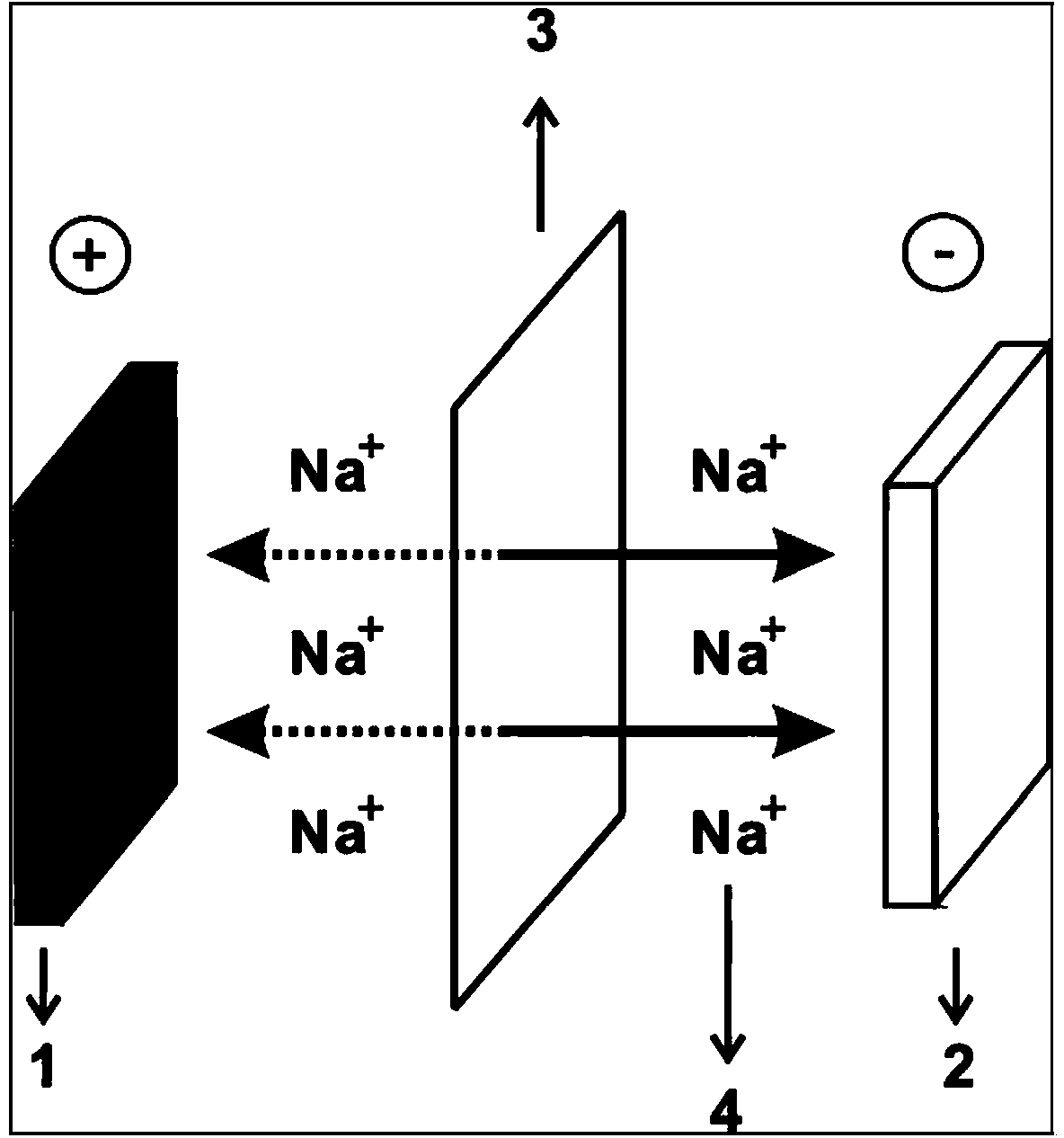

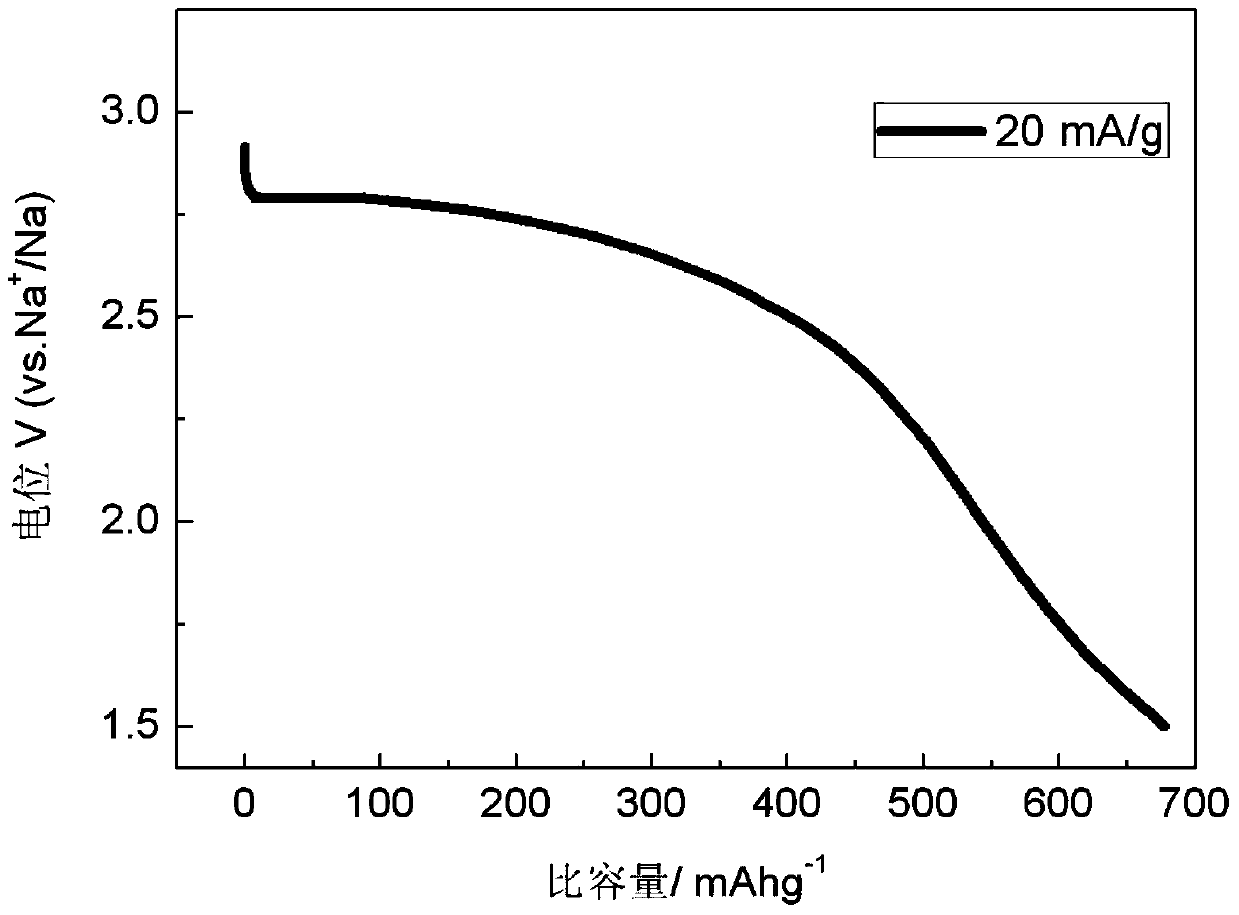

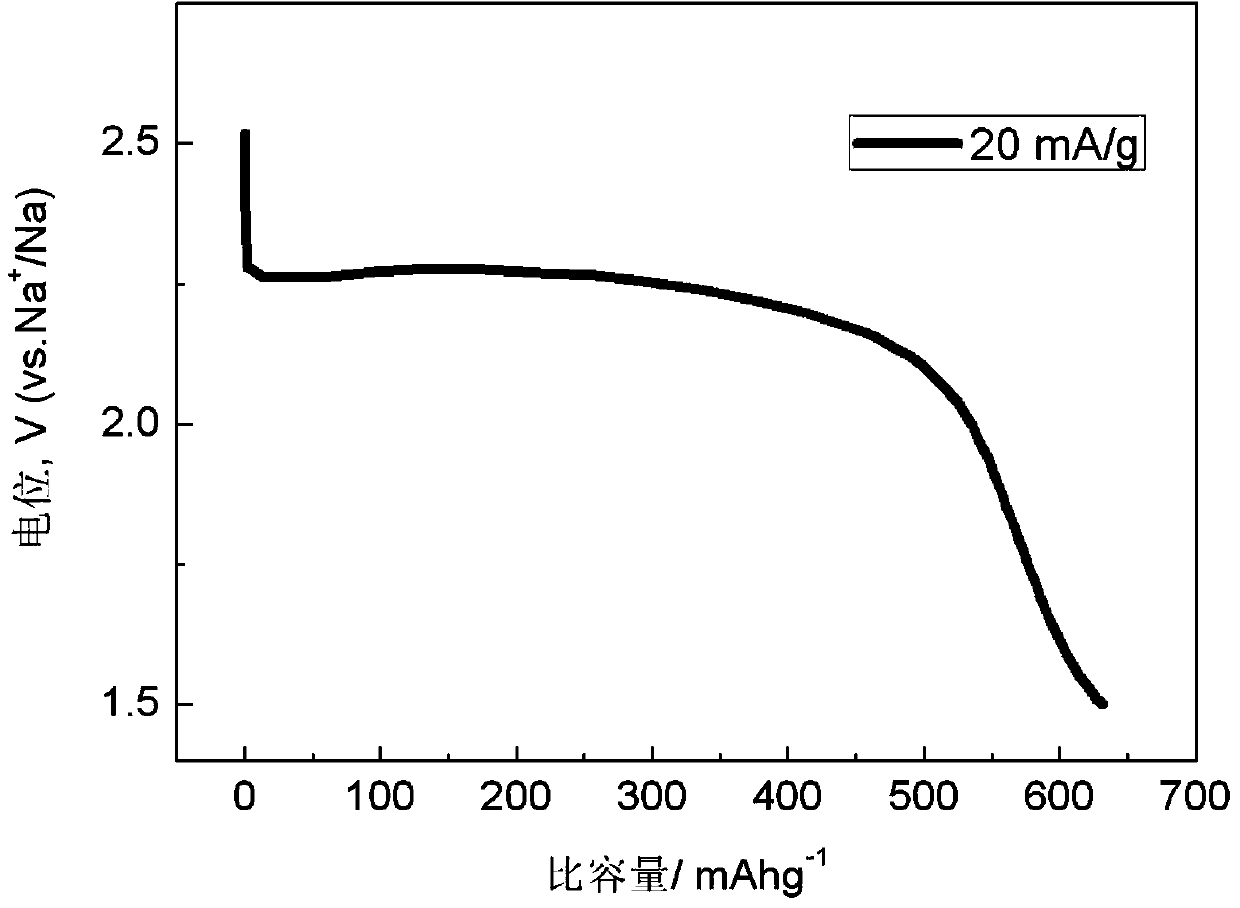

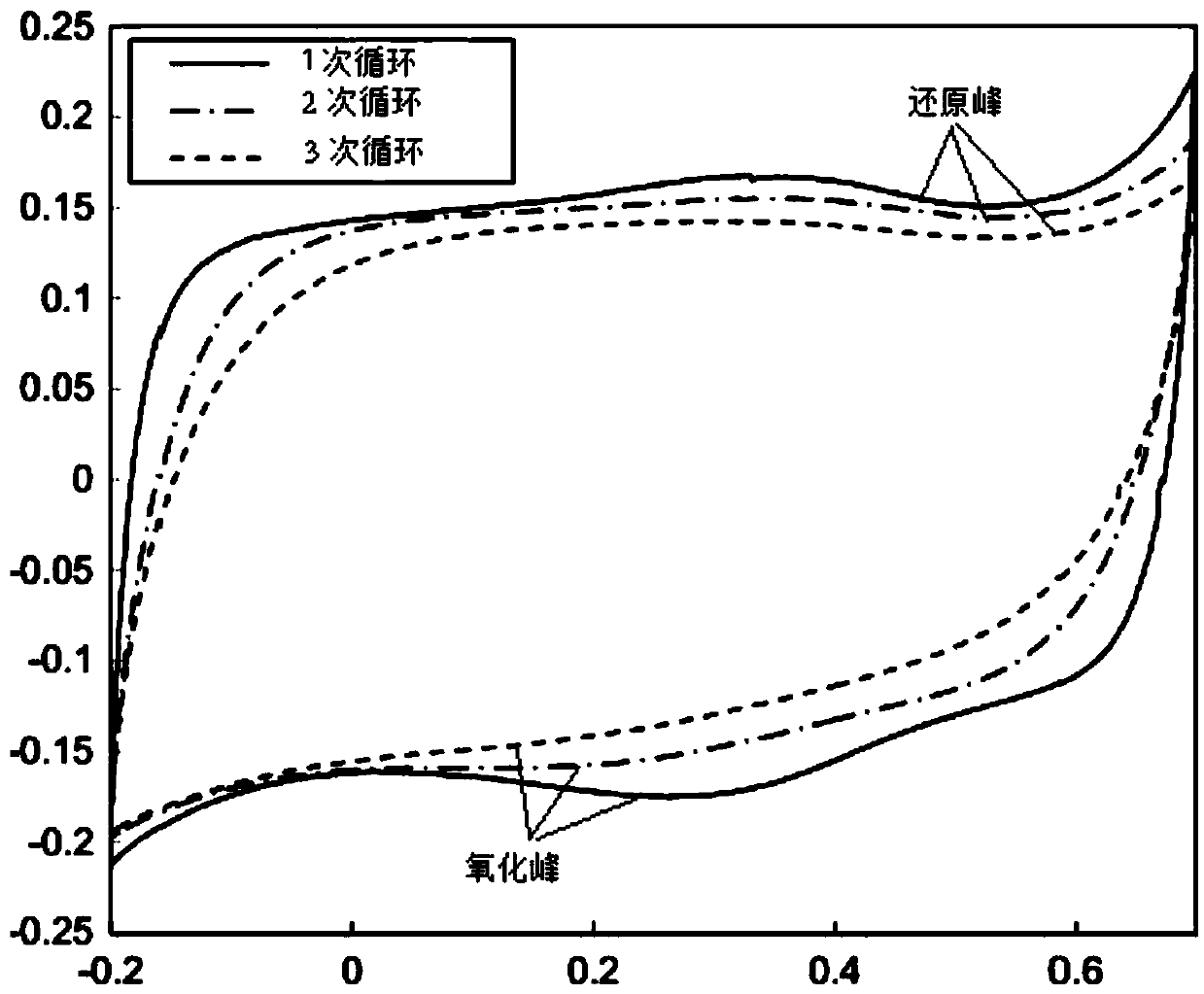

Sodium-perfluorocarbon primary battery

ActiveCN103700858AImprove discharge capacityDischarge potential is stablePrimary cellsPrimary cell electrodesFiberCarbon monofluoride

The invention discloses a sodium-perfluorocarbon primary battery and relates to a sodium battery. The sodium-perfluorocarbon primary battery is provided with a positive electrode, a negative electrode, a diaphragm and an electrolyte solution, wherein the positive electrode takes perfluorocarbon as an active substance; a main body of the perfluorocarbon is (CFx), and x is ranged from 0.2-1.2; the active substance comprises 20-100 percent of perfluorocarbon by mass; the electrolyte consists of a solvent, an electrolyte and an additive. The commercial perfluorocarbon, including carbon monofluoride, fluoride petroleum coke, fluoride carbon nano tube, fluoride carbon fibers, fluoride graphene and the like, is used as a main body active substance of the positive electrode of the sodium-perfluorocarbon primary battery; the sodium metal is used as the negative electrode; the electrolyte solution which takes an organic solution as the solvent and contains the sodium salt electrolyte and the diaphragm form a primary battery system which discharges at the constant current density of 20mA / g, and the mass specific capacity can be more than 800mAh / g. The sodium-perfluorocarbon primary battery has the characteristics of high discharging capacity, steady discharging level, environment friendliness and the like.

Owner:XIAMEN UNIV +1

Preparation method of high-performance fluorinated peanut shell hard carbon electrode material

InactiveCN110880599AIncrease capacityLow costCell electrodesSecondary cellsCarbon monofluorideHigh energy

The invention discloses a preparation method of a high-performance fluorinated peanut shell hard carbon electrode material. The method comprises the following steps of pulverizing peanut shells, and cleaning the peanut shells with deionized water once to remove the water-soluble impurities; soaking the peanut shells in a KOH solution, activating, drying, carrying out high-temperature pyrolysis for4-6 hours under the protection of inert gas, and after the pyrolysis is finished, cooling to room temperature so as to obtain a pyrolytic carbon material; washing the pyrolytic carbon material to beneutral, drying, grinding the pyrolytic carbon material into powder, fluorinating the pyrolytic carbon material obtained in the step 4 by adopting a gas-phase fluorination method, wherein the fluorination gas is mixed gas of fluorine gas and nitrogen gas; keeping the fluorination temperature at 200-300 DEG C for 3-5 hours, and cooling to obtain a carbon fluoride material; uniformly mixing the carbon fluoride material with carbon black and a binder in proportion, uniformly coating an aluminum foil with an NMP, and drying to obtain the high-performance fluorinated peanut shell hard carbon electrode material. The high-energy-density carbon fluoride material can be obtained and used for a lithium primary battery, and the specific capacity of a battery can be remarkably improved.

Owner:TIANJIN UNIV

Fluorocarbon-modified super-hydrophobic material and preparation method thereof

InactiveCN102382366ASuper hydrophobic effect is remarkableSimple processing methodOther chemical processesBenzoic acidCarbon monofluoride

The invention discloses a fluorocarbon-modified super-hydrophobic material, which is prepared from silicon rubber, a vulcanizing agent, a fluorocarbon material, polypropylene and an aid serving as raw materials, wherein the static contact angles of the raw materials are respectively greater than 150 degrees, and the drift angles are respectively smaller than 10 degrees; the vulcanizing agent is one or more of TMTD (Tetramethylthiuram Disulfide), PDM (N,N'-m-Phenylenedimaleimide), t-butyl perbenzoate and tertiary capryl peroxyester; the fluorocarbon material is prepared by fluorating a carbon material; the carbon material is one or more of carbon black, active carbon, coke, a carbon nanotube and graphene; and the aid is one or more of stearic acid, magnesium stearate and zinc stearate. A preparation method of the fluorocarbon-modified super-hydrophobic material comprises the following steps of: (1) smelting a premix compound; (2) fluorating a carbon material; (3) extruding and pelletizing; (4), performing hot pressing and cold pressing; and (5) grinding and removing scraps. The super-hydrophobic material has a remarkable super-hydrophobic effect, a simple processing method and a good application prospect. Moreover, the inside and the surface of a product substrate are provided with the same component, so that a needed super-hydrophobic surface can be formed by grinding once again when the surface is damaged.

Owner:WENGFU (GRP) CO LTD +1

Method of forming a (CFx)n containing absorbent composition, intermediate materials employed in conducting the method and method of using the composition for preferential separation of a fluorine-containing gas from a gas stream containing the same

InactiveUS20040084793A1Other chemical processesTransportation and packagingCarbon monofluorideFluorinated gases

Method of forming a (CF.sub.X).sub.n containing adsorbent composition by combining a fine particle (CF.sub.X).sub.n starting material with a non-fluorinated carbonaceous material prior to the formation of a solid body and intermediate materials employed in conducting the method.

Owner:BOC GRP INC

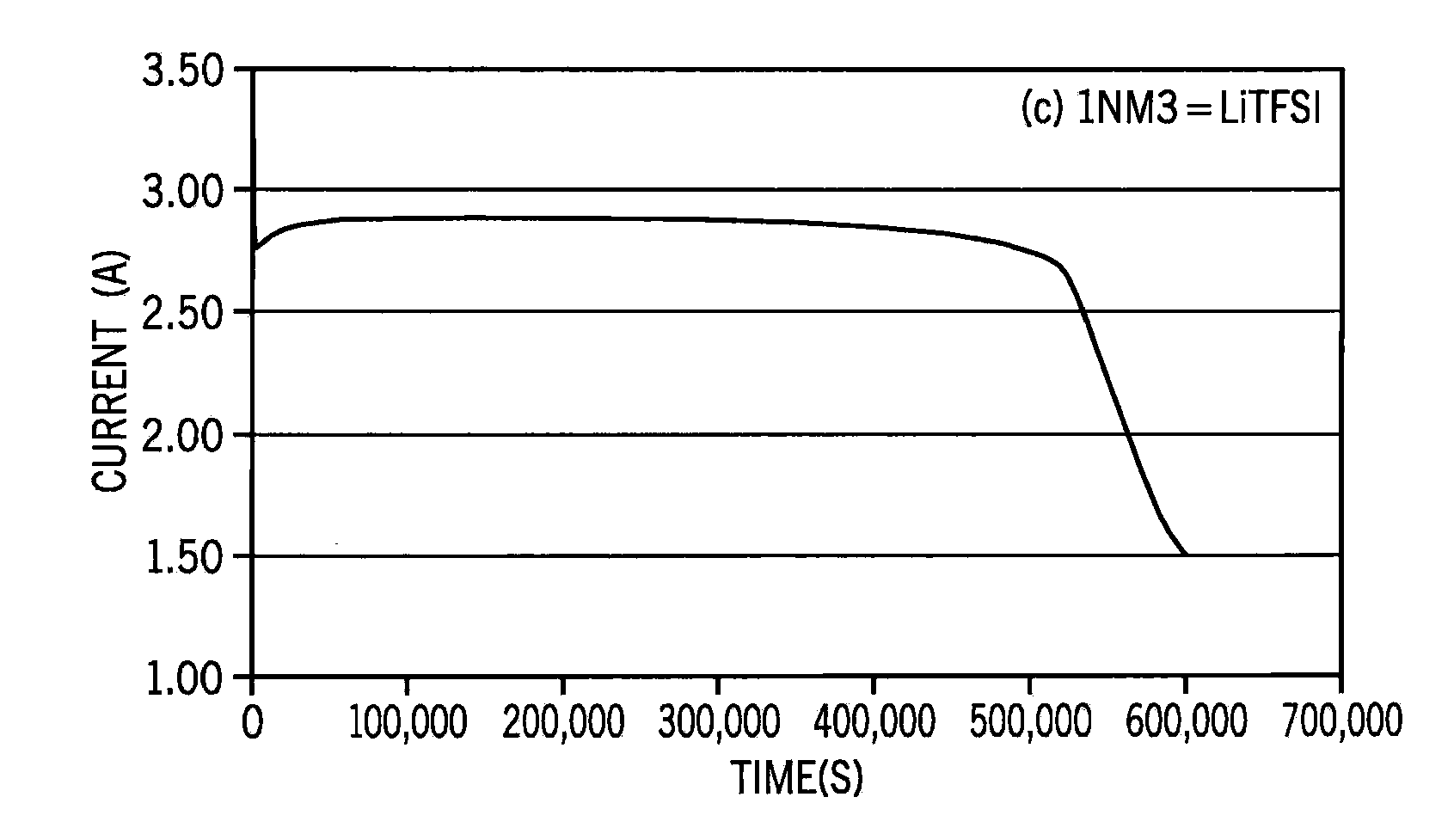

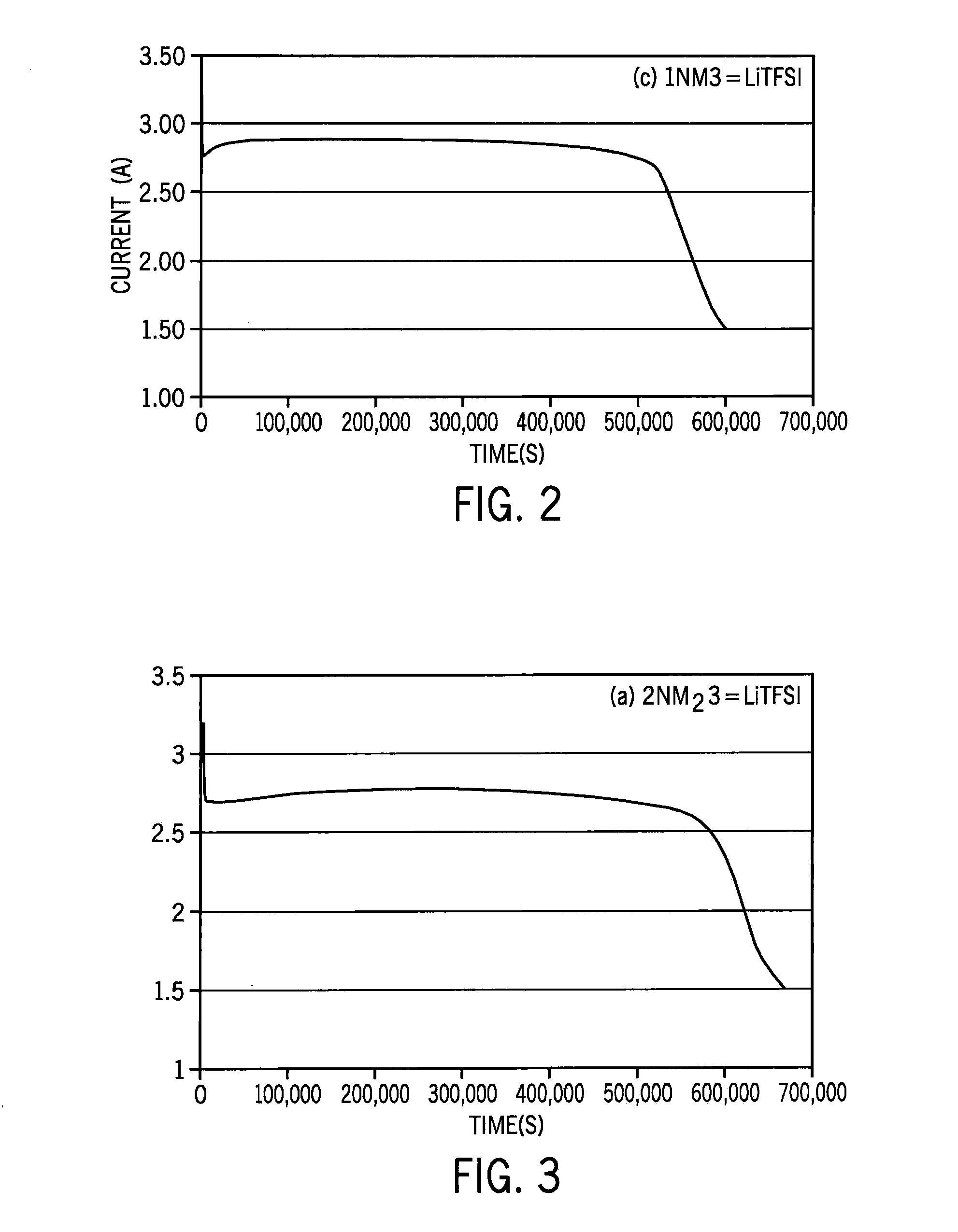

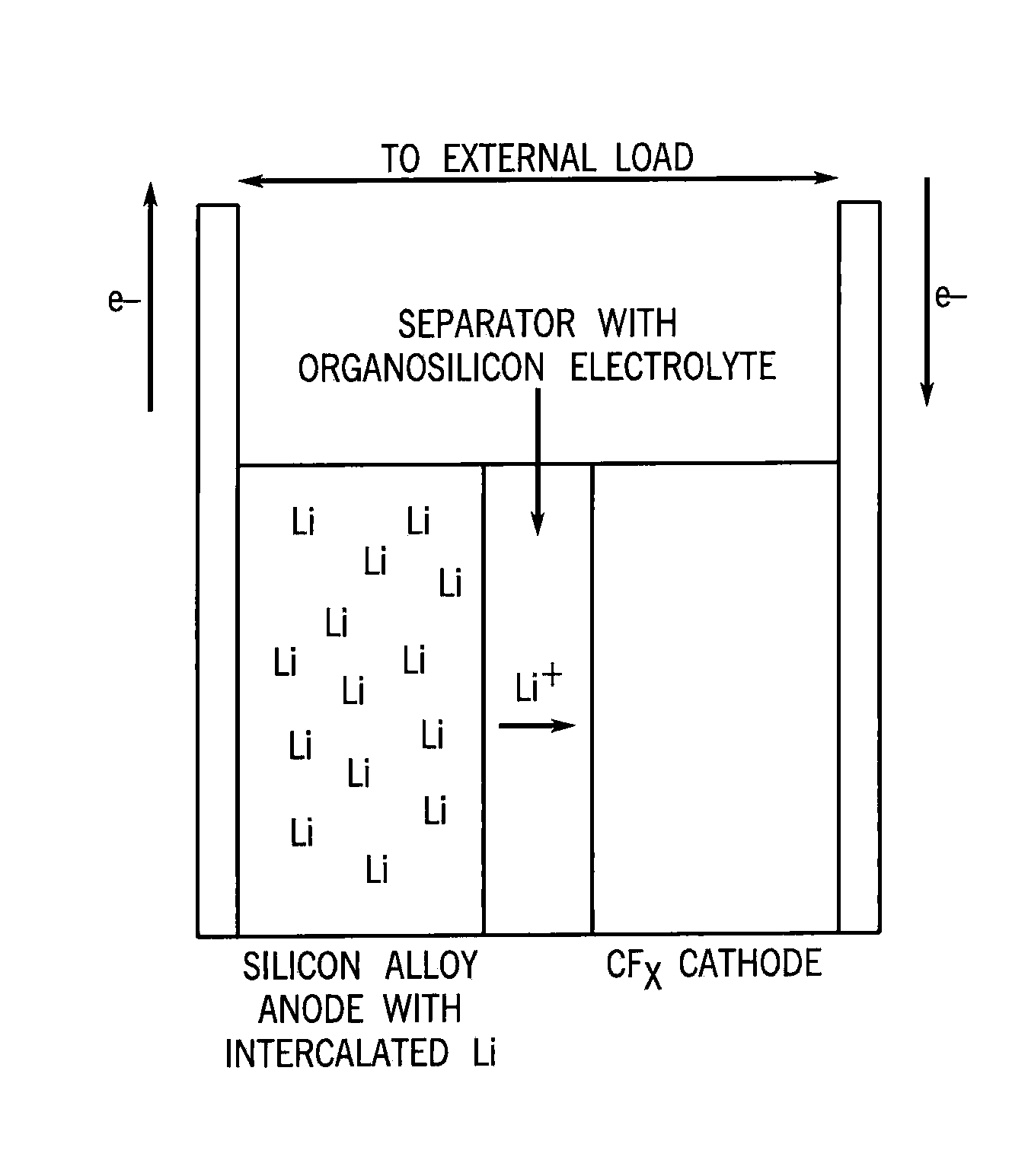

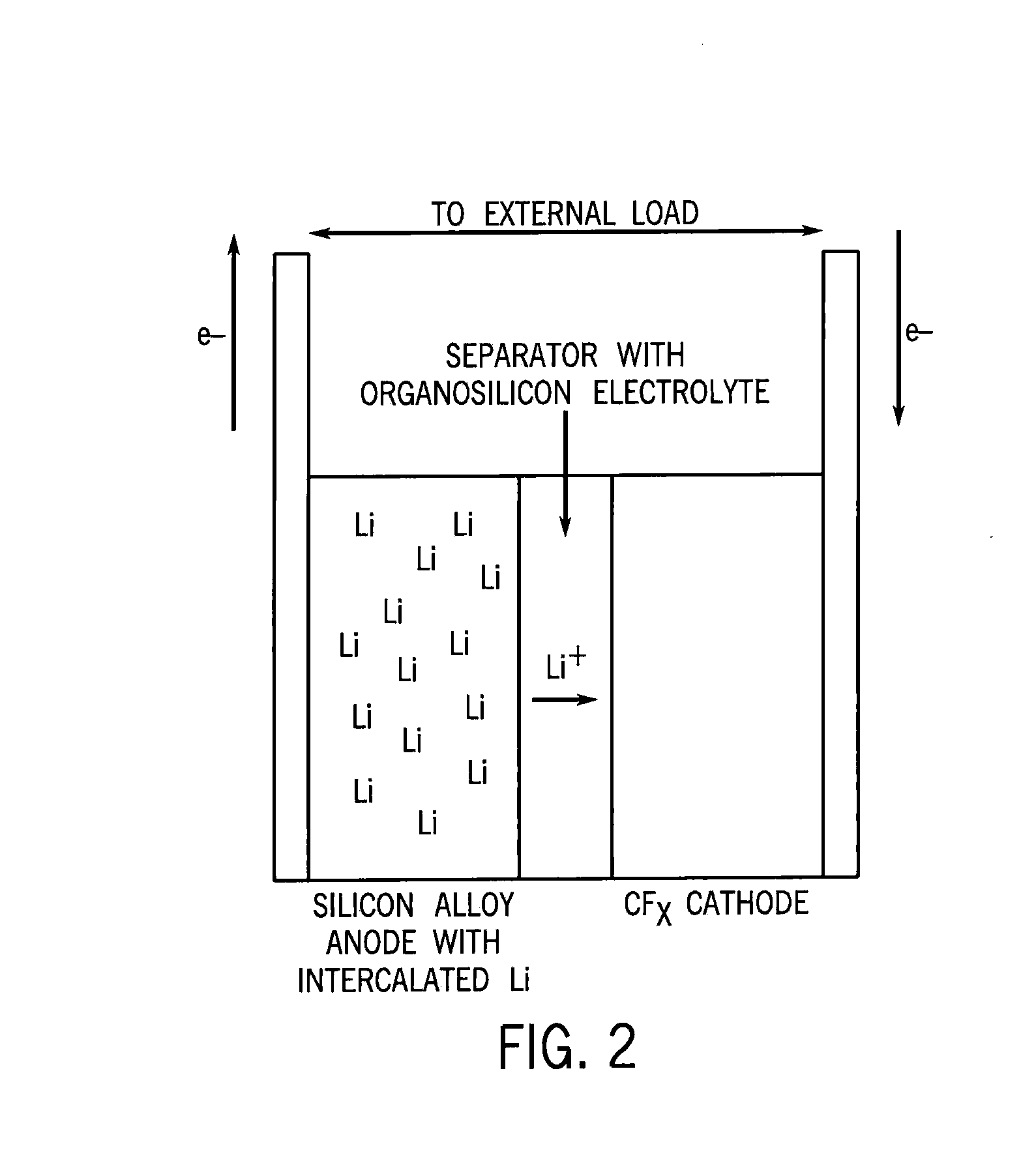

Lithium/Carbon Monofluoride Batteries With Organosilicon Electrolytes

ActiveUS20110274985A1Acceptable costEasy to useCell electrodesOrganic electrolyte cellsCarbon monofluorideElectrolyte

Disclosed are lithium / carbon monofluoride batteries suitable for long term use at highly elevated temperatures. Organosilicon electrolytes having low vapor pressure and high flash points are used, along with lithium salts and ceramic separators. Methods of using these batteries at high temperatures are also disclosed.

Owner:WISCONSIN ALUMNI RES FOUND

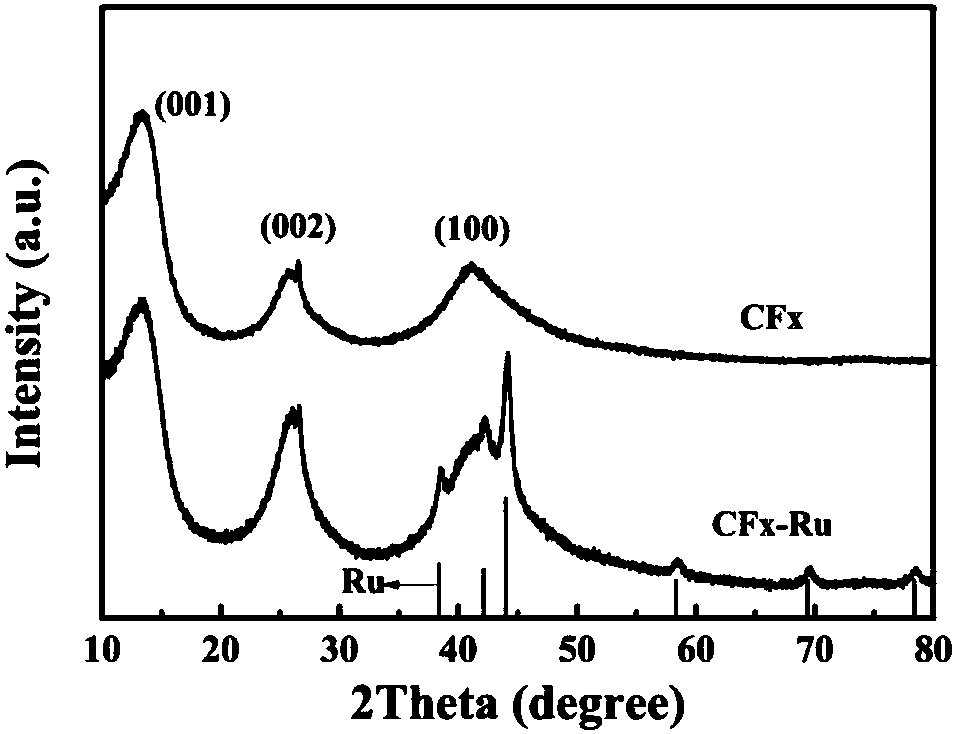

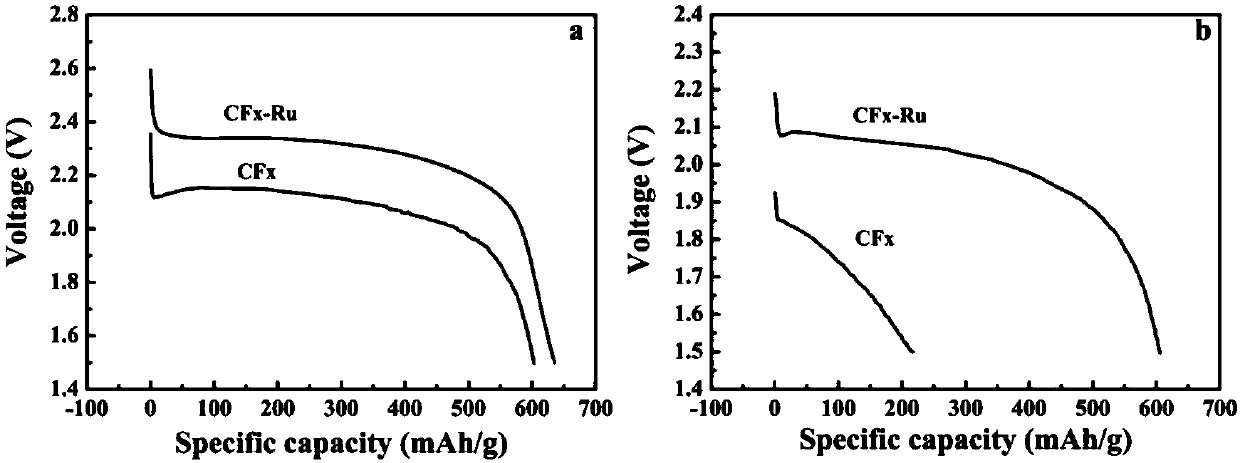

Ruthenium-modified carbon fluoride material, and preparation method and application thereof

ActiveCN107910521AEasy to prepareMild conditionsCell electrodesOrganic electrolyte cellsHigh rateModified carbon

The invention discloses a ruthenium-modified carbon fluoride material, and a preparation method and an application thereof, and belongs to the technical field of a battery. A synthetic process comprises the steps of (1) enabling a CF<X> positive electrode material to be dispersed into a mixed solution of deionized water and ethyl alcohol; (2) adding RuCl<3> and carbon fluoride into a suspension liquid based on a certain proportion, and next, adding a NaOH solution to adjust pH to be 8-9; (3) performing suction filtration on the suspension liquid, and performing washing by deionized water and ethyl alcohol for multiple times to form a mixture; (4) performing drying on the mixture to obtain mixture powder; and (5) putting the mixture powder into an atmosphere furnace, performing high-temperature treatment, and cooling to the room temperature to obtain the ruthenium-modified carbon fluoride material. By virtue of the preparation method, metal ruthenium is introduced successfully, so thatthe discharging voltage platform of a lithium carbon fluoride battery is greatly improved, and voltage lagging is lowered; and particularly, in high-rate discharge, the discharging voltage platform and the specific capacity of the ruthenium-modified carbon fluoride material are far higher than those of the original carbon fluoride.

Owner:BEIJING UNIV OF TECH

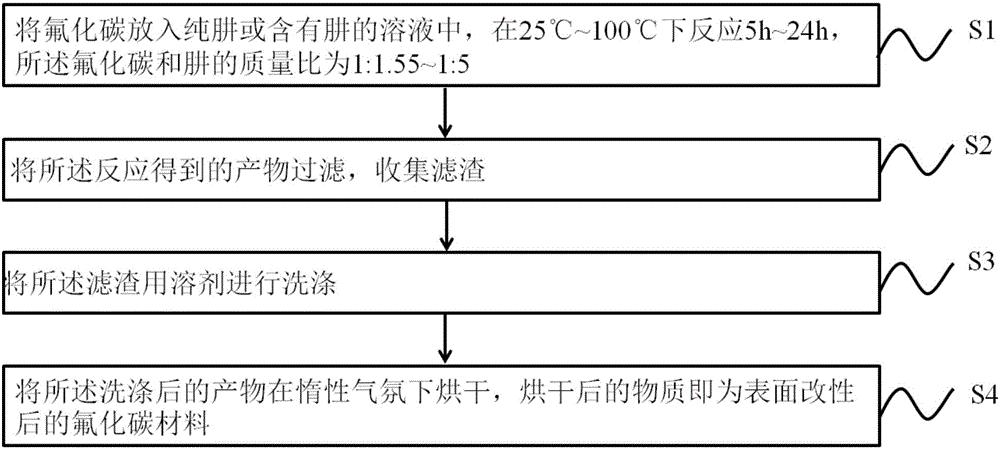

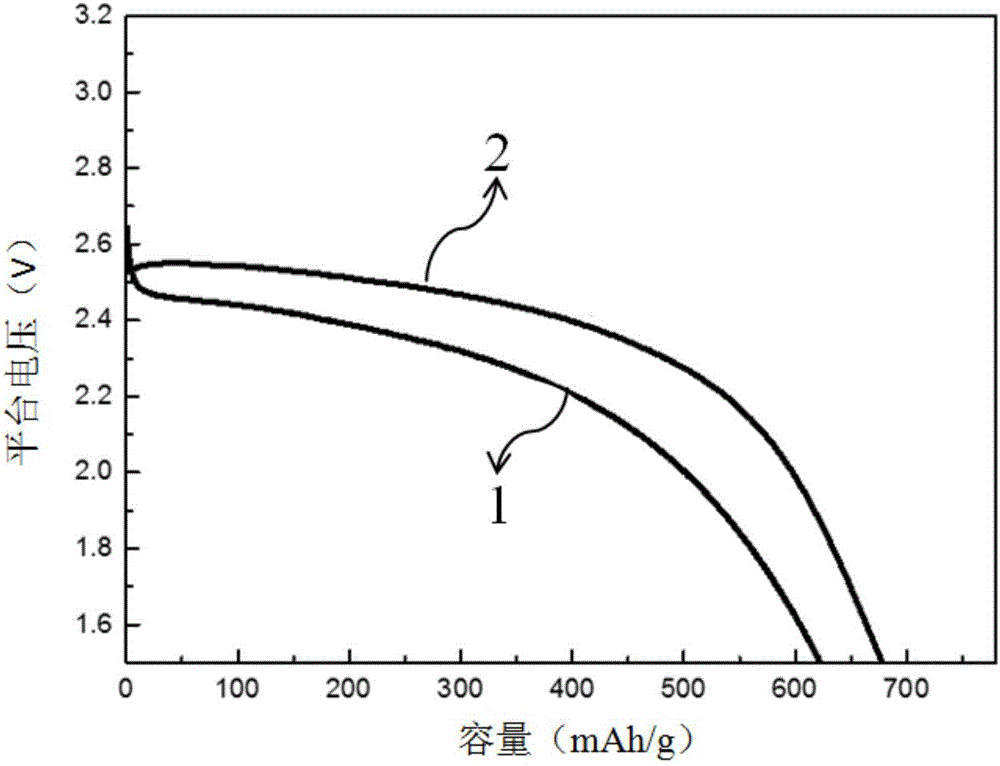

Carbon fluoride material surface modification method and product and application thereof

InactiveCN106229511AReduce voltage lagImprove high rate discharge performanceCell electrodesLi-accumulatorsDry matterSolvent

The invention relates to a carbon fluoride material surface modification method and a product and application thereof. The surface modification method comprises the following steps: putting carbon fluoride in a pure hydrazine solution or a solution containing hydrazine, and reacting for 5-24 hours at the temperature of 25-100 DEG C, wherein the mass ratio of the carbon fluoride to the hydrazine is 1:1.55-1:5; filtering a product obtained through the reaction, collecting a filter residue, washing the filter residue by using a solvent, and drying the washed product under an inert atmosphere, wherein the dried matter is a surface modified carbon fluoride material. The surface modified carbon fluoride material provided by the invention effectively reduces the voltage delay of the carbon fluoride and greatly improves the high-rate discharge performance of the carbon fluoride.

Owner:江苏超电新能源科技发展有限公司

Copper base powder metallurgy friction reducing material and preparing method of copper base powder metallurgy friction reducing material

The invention discloses a copper base powder metallurgy friction reducing material and a preparing method of the copper base powder metallurgy friction reducing material. The material is prepared from the following ingredients in parts by weight: 72 to 75 parts of mixing copper powder, 5 to 8 parts of lead powder, 3 to 7 parts of zinc oxide, 2 to 5 parts of metallurgy carbon black, 4 to 8 parts of carbon monofluoride, 4 to 8 parts of micro wax powder, 3 to 7 parts of molybdenum powder, 10 to 14 parts of iron powder, 2 to 5 parts of cobalt powder and 3 to 6 parts of silicon carbide powder. The preparing method comprises the following steps of mixing, pressing, sintering, shaping and oil soaking processing. The method has the advantages that the raw materials can be easily obtained, the price is low, the preparing process is simple, the parameters can be easily controlled, the production process is safe, the environment is protected, the method is suitable for large-scale industrial production, and the like.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

High-Temperature Resistant Carbon Monofluoride Batteries Having Lithiated Anode

InactiveUS20140093754A1Reliable for long-term useAcceptable costOrganic electrolyte cellsSolid electrolyte cellsCarbon monofluorideMaterials science

Disclosed are carbon monofluoride cathode batteries suitable for use at highly elevated temperatures. Rather than using a pure lithium anode, the anode has a base material selected from the group consisting of silicon, germanium and tin, where the base material is lithiated. This renders the anode more resistant to heat. Selected electrolytes are used which also contain lithium salts. Methods for using these batteries at high temperatures are also disclosed.

Owner:WISCONSIN ALUMNI RES FOUND

Self-lubricating fluorinated diamond-like carbon electric massage antibacterial shaver

InactiveCN102085672AGuaranteed BondingSurface treatment exempt fromVacuum evaporation coatingSputtering coatingCarbon monofluorideCarbon nanotube

The invention discloses a self-lubricating fluorinated diamond-like carbon electric massage antibacterial shaver, which is characterized in that: a plurality of layers of razor blades comprise at least one layer of fluorinated diamond membrane or fluorinated silicon-doped and / or boron diamond-like carbon membrane which is deposited by a perfluorocarbon compound, a high-purity graphite target or a cathode and / or a carbon nano tube on the surface of a cutting edge part and has the thickness of a nanometer or micrometer level. A frictional factor of the razor blades is between 0.001 and 0.04, and the shaver has ultrastrong self-lubricating properties which exceed those of the ordinary diamond-like carbon membrane and polytetrafluoroethylene, so that the shaving experience is smoother, and has a natural antibacterial effect. The shaver is an updating and upgrading product.

Owner:冷博

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com