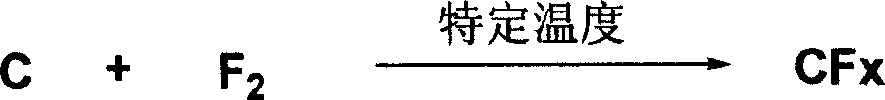

Large scale synthesis process of carbon fluorides

A carbon fluoride, large-scale technology, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve the problems of immature fluorinated carbon technology, and achieve the effect of good lubricity and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] Add 2-4Kg of petroleum coke into the solidified bed, and then raise the temperature to about 200 degrees under the condition of vacuuming the oil pump for half an hour, fill with nitrogen to drive out the air, and repeat three times. Raise the temperature of the reaction kettle to 500-600 degrees, slowly introduce fluorine gas, control the flow rate of fluorine gas added by a fluorine gas flow meter to be 100-300 ml / second, continue to react for 6-10 hours, stop heating, let The temperature of the reaction kettle is naturally cooled to room temperature, and nitrogen gas is passed into the reaction kettle after cooling to room temperature to drive away residual fluorine gas in the reaction kettle, and the reaction ends. During the reaction process, the gas outlet after the reactor is connected to two absorption towers equipped with potassium hydroxide or other lye to absorb complete fluorine gas. Open the reaction kettle and take out the solid powder in the solidified be...

example 2

[0013] Add 2-4Kg of petroleum coke into the solidified bed, and then raise the temperature to about 200 degrees under the condition of vacuuming the oil pump for half an hour, fill with nitrogen to drive out the air, and repeat three times. Raise the temperature of the reactor to 300-500 degrees, slowly introduce fluorine gas, control the flow of fluorine gas to 100-300 ml / second through the fluorine gas flowmeter, continue to react for 4-8 hours, stop heating, let The temperature of the reaction kettle is naturally cooled to room temperature, and nitrogen gas is passed into the reaction kettle after cooling to room temperature to drive away residual fluorine gas in the reaction kettle, and the reaction ends. During the reaction process, the gas outlet after the reactor is connected to two absorption towers equipped with potassium hydroxide or other lye to absorb complete fluorine gas. Open the reaction kettle and take out the solid powder in the solidified bed, most of which ...

example 3

[0015] Add 2-4Kg of graphite into the solidified bed, heat up to about 200 degrees under the condition of vacuuming by the oil pump for half an hour, fill with nitrogen to drive out the air, and repeat three times. Raise the temperature of the reactor to 500 to 600 degrees, slowly feed the mixed gas of fluorine gas and nitrogen gas with a ratio of 1:1, and control the flow of fluorine gas added to 100-300 ml / second through the fluorine gas flow meter, continue React for 6-10 hours; then stop heating, allow the temperature of the reactor to cool down to room temperature naturally, feed nitrogen into the reactor after cooling to room temperature, drive away the residual fluorine gas in the reactor, and the reaction ends. During the reaction process, the gas outlet after the reactor is connected to two absorption towers equipped with potassium hydroxide or other lye to absorb complete fluorine gas. Open the reaction kettle, take out the solid powder in the solidified bed, the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com