Process for recovering fluorine and zinc from steelmaking soot

A soot and process technology, which is applied in the field of comprehensive recovery of metallurgical waste residues, can solve the problems of limited use range of defluorination agents, low fluorine removal efficiency, and difficulty in wide-scale popularization and application, and achieves clean production requirements and solves technical problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

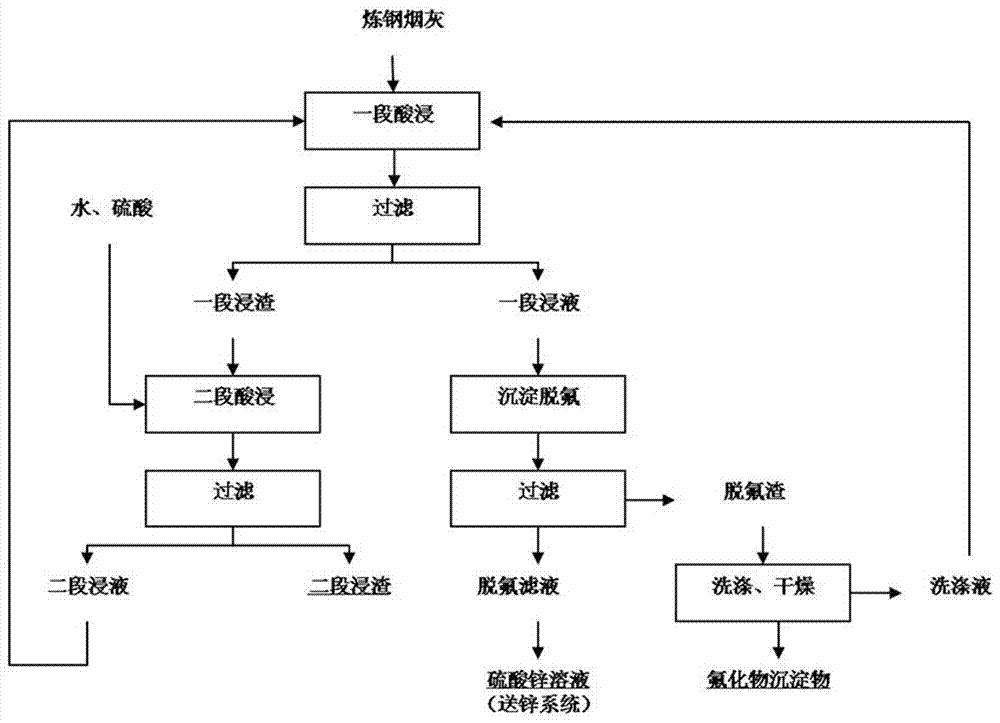

[0024] The process for recovering fluorine and zinc from steelmaking soot comprises the following steps:

[0025] (1) One-stage leaching: Slurry the steelmaking soot with water and add it to the one-stage leaching tank, detect the concentration of fluoride ions in the steelmaking soot, calculate the amount of its substance, add manganese dioxide, sodium sulfite and one-stage leaching agent, manganese dioxide The molar ratio of fluoride ion is 0.6:1, the amount of sodium sulfite and manganese dioxide is the same, then add concentrated sulfuric acid to an initial concentration of 180g / L, control the liquid-solid weight ratio to 4:1, temperature 60°C, leaching time 60 minutes , carry out the leaching reaction, obtain a section of leachate and a section of leaching residue after filtration;

[0026] (2) Second-stage leaching: Slurry the first-stage leaching residue with water and add it to the second-stage leaching tank, control the liquid-solid ratio to 3:1, add concentrated sulf...

Embodiment 2

[0030] The process for recovering fluorine and zinc from steelmaking soot comprises the following steps:

[0031] (1) One-stage leaching: the specific operating parameters are as follows:

[0032] The molar ratio of manganese dioxide to fluoride ion is 1:1, and the ratio of sodium sulfite to manganese dioxide is

[0033] the same amount,

[0034] Add concentrated sulfuric acid to an initial concentration of 180g / L;

[0035] Control the liquid-solid weight ratio to 3:1;

[0036] The leaching temperature is 60°C;

[0037] The leaching time was 60 minutes, and all the other steps were the same as in Example 1.

[0038] (2) Two-stage leaching: the specific operating parameters are as follows:

[0039] The liquid-solid ratio is 2:1;

[0040] Add concentrated sulfuric acid to an initial mass concentration of 250g / L;

[0041] The leaching temperature is 80°C;

[0042] The leaching time was 90 minutes, and all the other steps were the same as in Example 1.

[0043] And the se...

Embodiment 3

[0050] The process for recovering fluorine and zinc from steelmaking soot comprises the following steps:

[0051] (1) One-stage leaching: the specific operating parameters are as follows:

[0052] The molar ratio of manganese dioxide to fluoride ion is 0.7:1, and the amount of sodium sulfite and manganese dioxide is the same.

[0053] Add concentrated sulfuric acid to an initial concentration of 180g / L;

[0054] Control the liquid-solid weight ratio to 4:1;

[0055] The leaching temperature is 50°C;

[0056] The leaching time was 40 minutes, and all the other steps were the same as in Example 1.

[0057] (2) Two-stage leaching: the specific operating parameters are as follows:

[0058] The liquid-solid ratio is 3:1;

[0059] Add concentrated sulfuric acid to an initial mass concentration of 250g / L;

[0060] The leaching temperature is 70°C;

[0061] The leaching time was 60 minutes, and all the other steps were the same as in Example 1.

[0062] And the second-stage leac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com