Patents

Literature

37 results about "Fluoride products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the United States, water fluoridation is not the only form of fluoride delivery that is effective in preventing tooth decay in people of all ages. Use the information listed below to compare the other fluoride products that may lower the risk for tooth decay, especially for people who are at ...

Hamartite smelting separation process

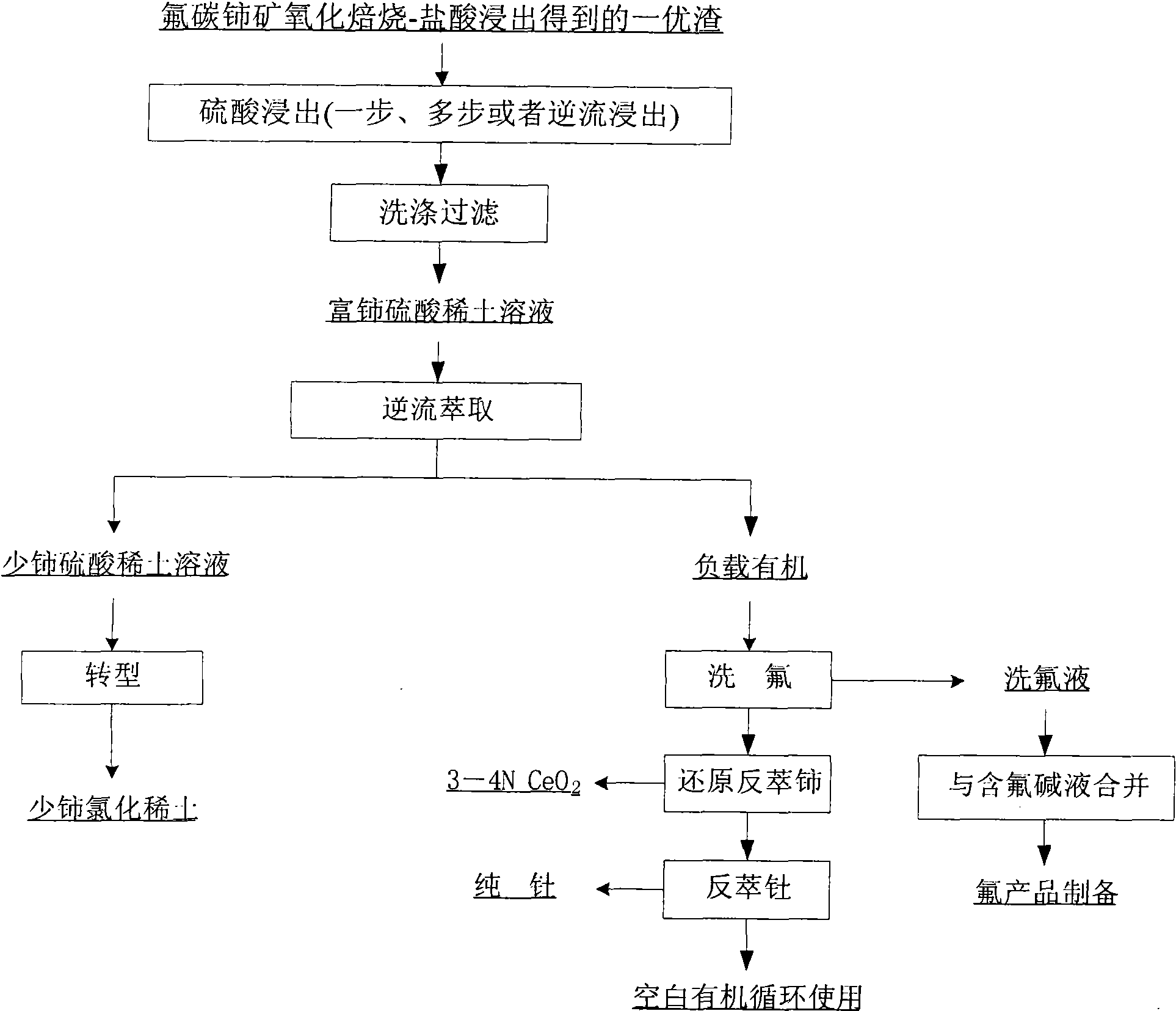

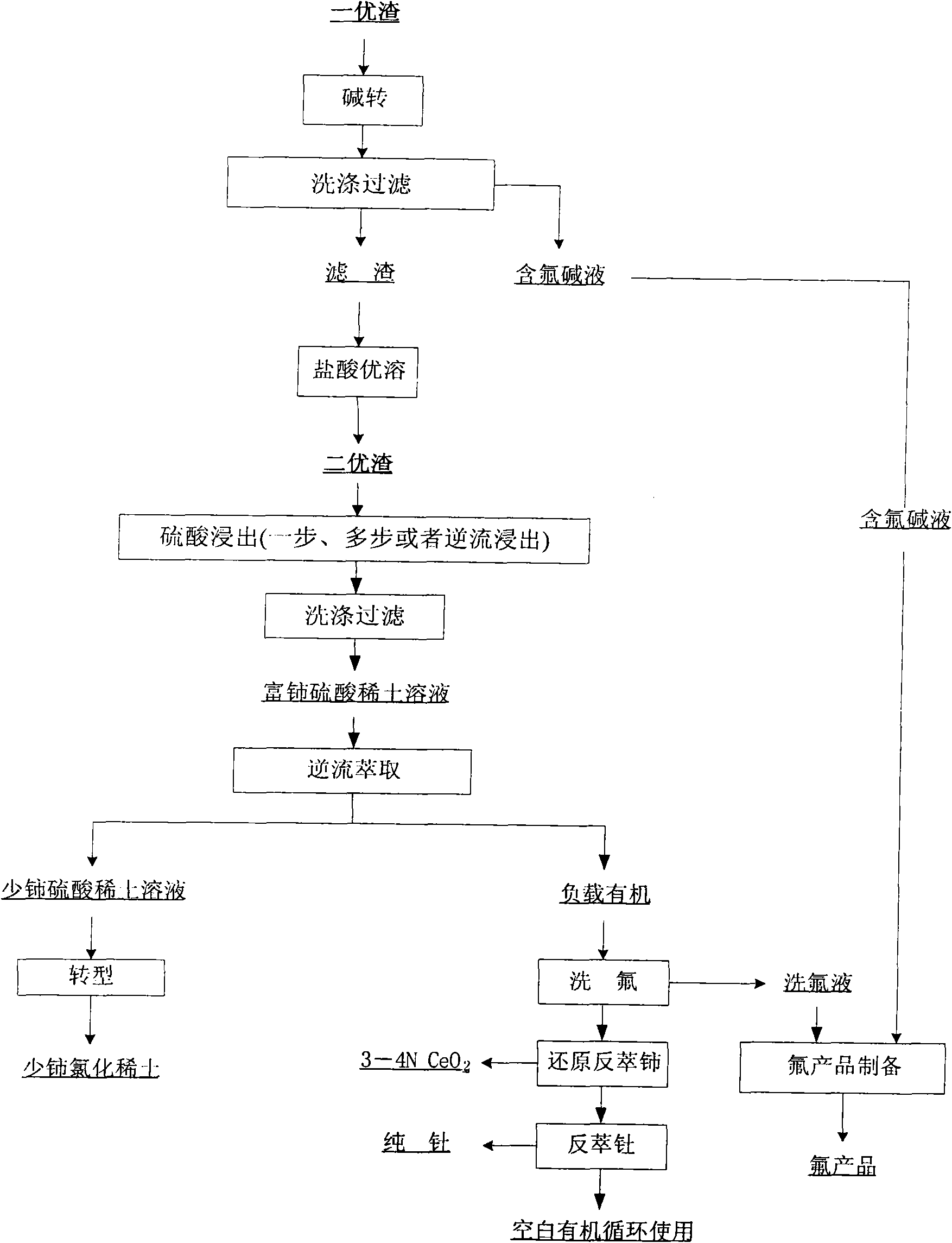

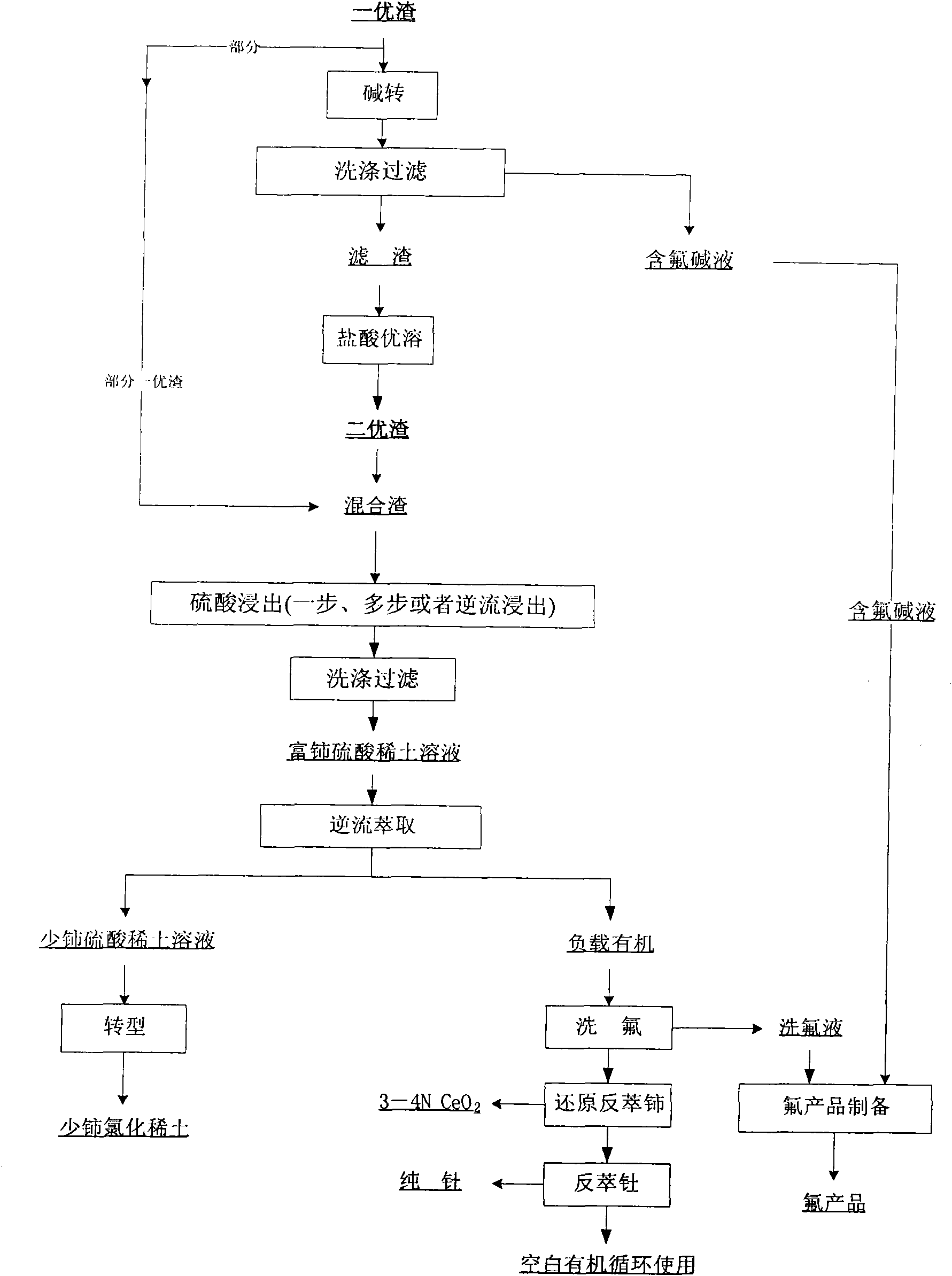

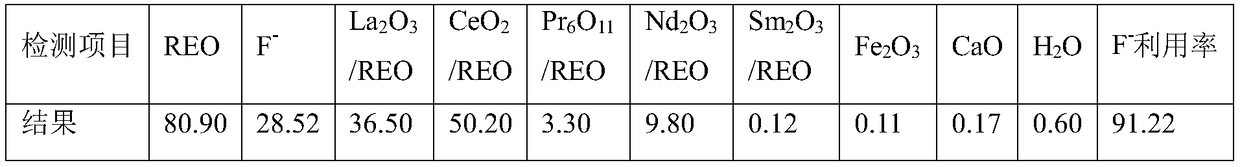

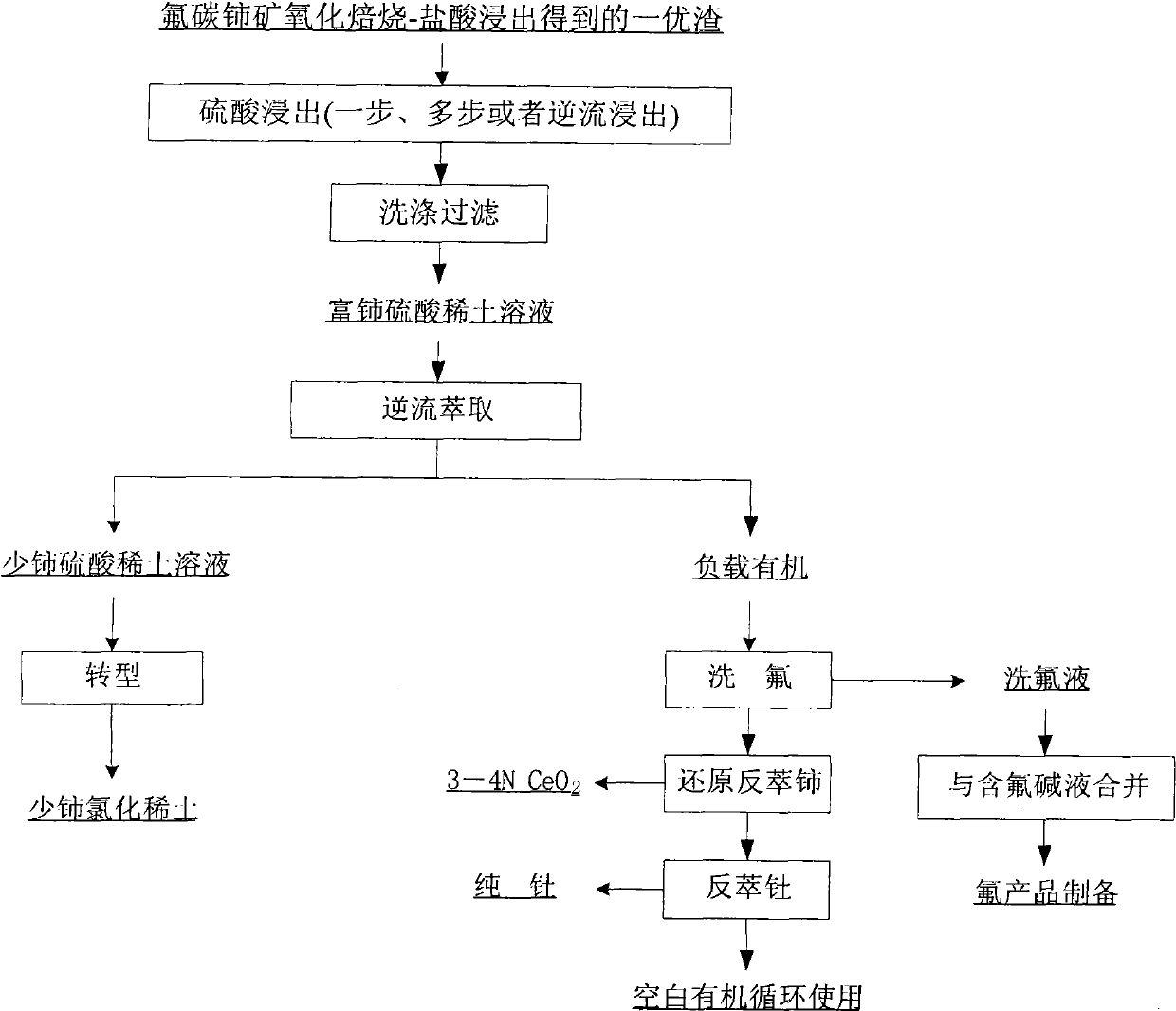

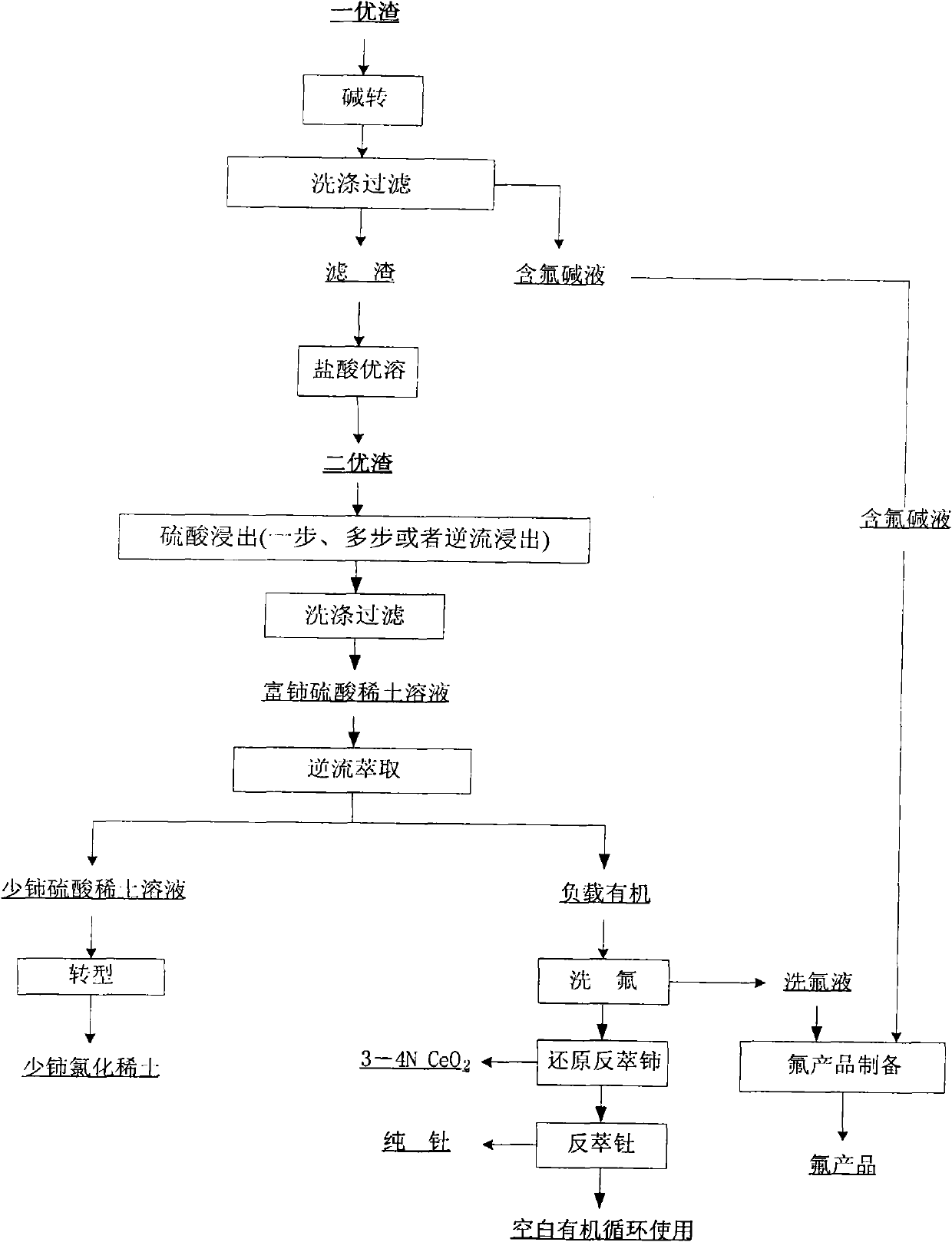

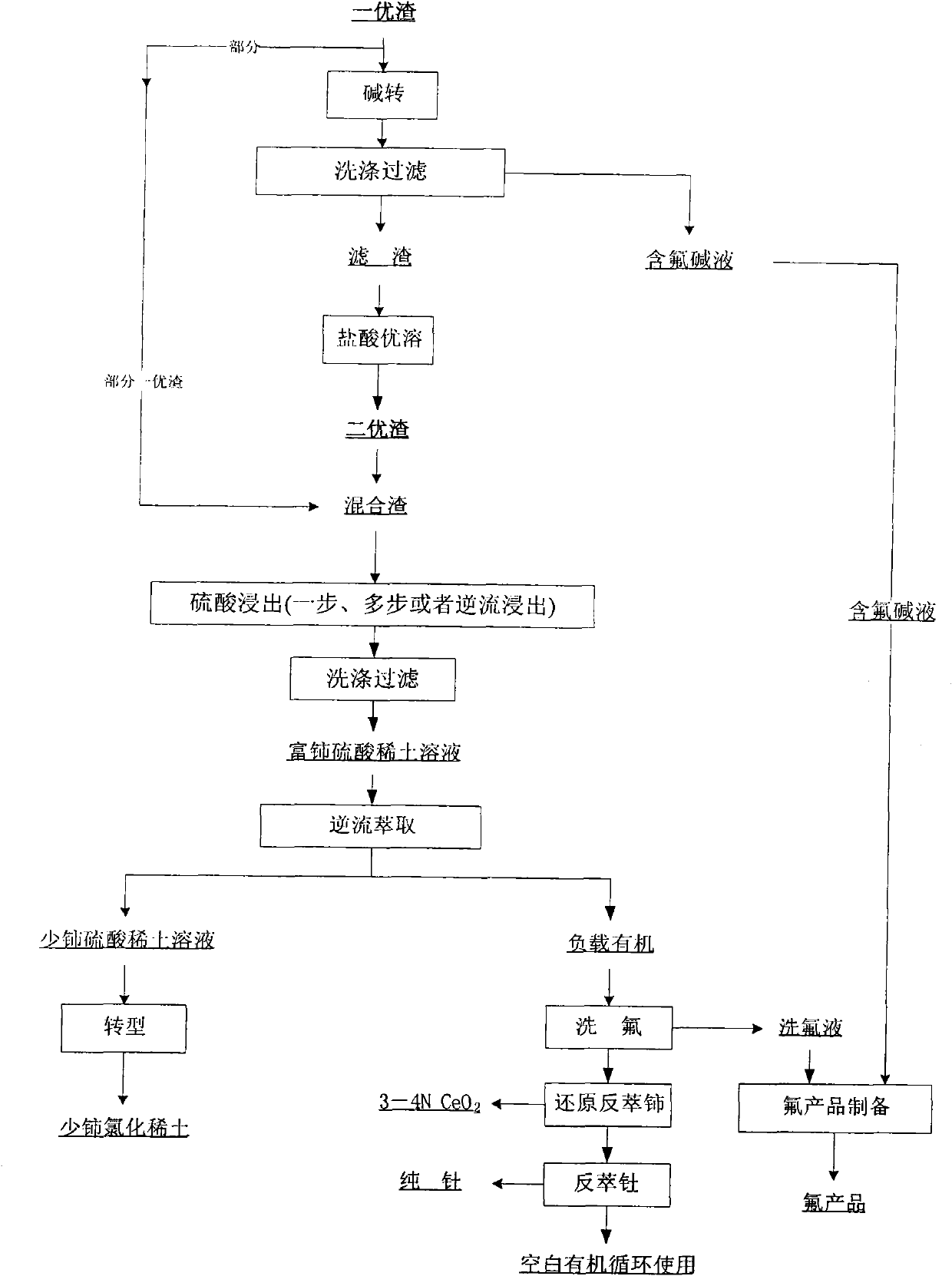

ActiveCN102146512AAchieve recyclingIncrease the added value of resourcesFluoride preparationProcess efficiency improvementFluoride productsSlag

The invention discloses a hamartite smelting separation process. First optimal slag or / and second optimal slag mainly containing cerium (IV), thorium (IV) and fluorine, obtained by oxidative roasted salt acid leaching of hamartite, is / are used as raw materials, and extraction and separation of rare earth are performed. The process comprises the following steps of: 1) leaching the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the second optimal slag obtained by alkali conversion-hydrochloric acid dissolution of the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the mixed slag of the first optimal slag and the second optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; 2) performing extraction separation on the sulfuric acid-rare earth solution obtained in the step 1) to obtain a rare earth compound,fluorine washing liquor, a pure cerium product and a thorium product; and 3) synthesizing a fluoride product by using the fluorine-containing alkali wastewater obtained by alkali conversion in the step 1) and the fluorine washing liquor obtained by the extraction separation in the step 2). The process has the advantages that: the recovery rate of the rare earth is obviously improved, the fluorineand the thorium (IV) are effectively reclaimed in a product form, the high-purity cerium product is obtained, reclamation of the rare earth and associated resources is realized, and the additional values of the resources are improved; and the process flow is simple, the consumption of acid and alkali is low, the production cost is low, and the process is environmentally-friendly.

Owner:GRIREM ADVANCED MATERIALS CO LTD

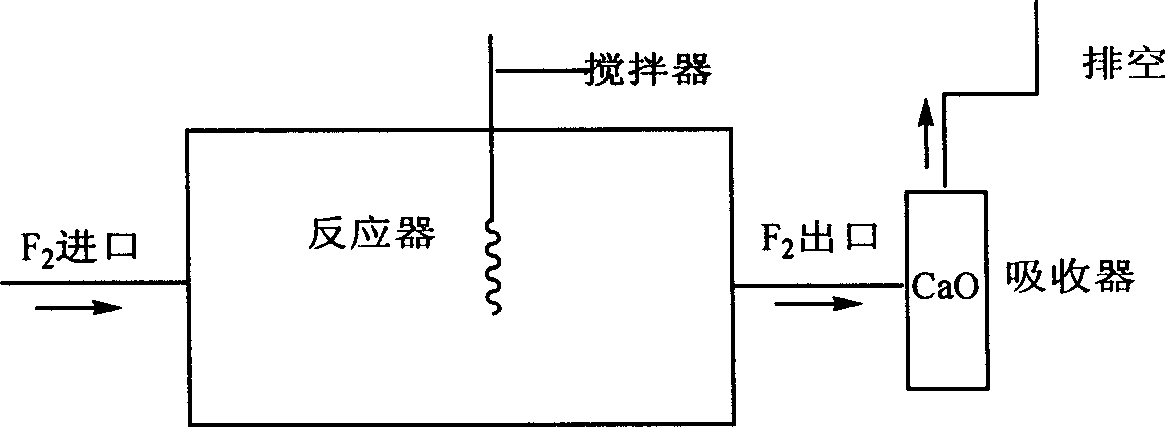

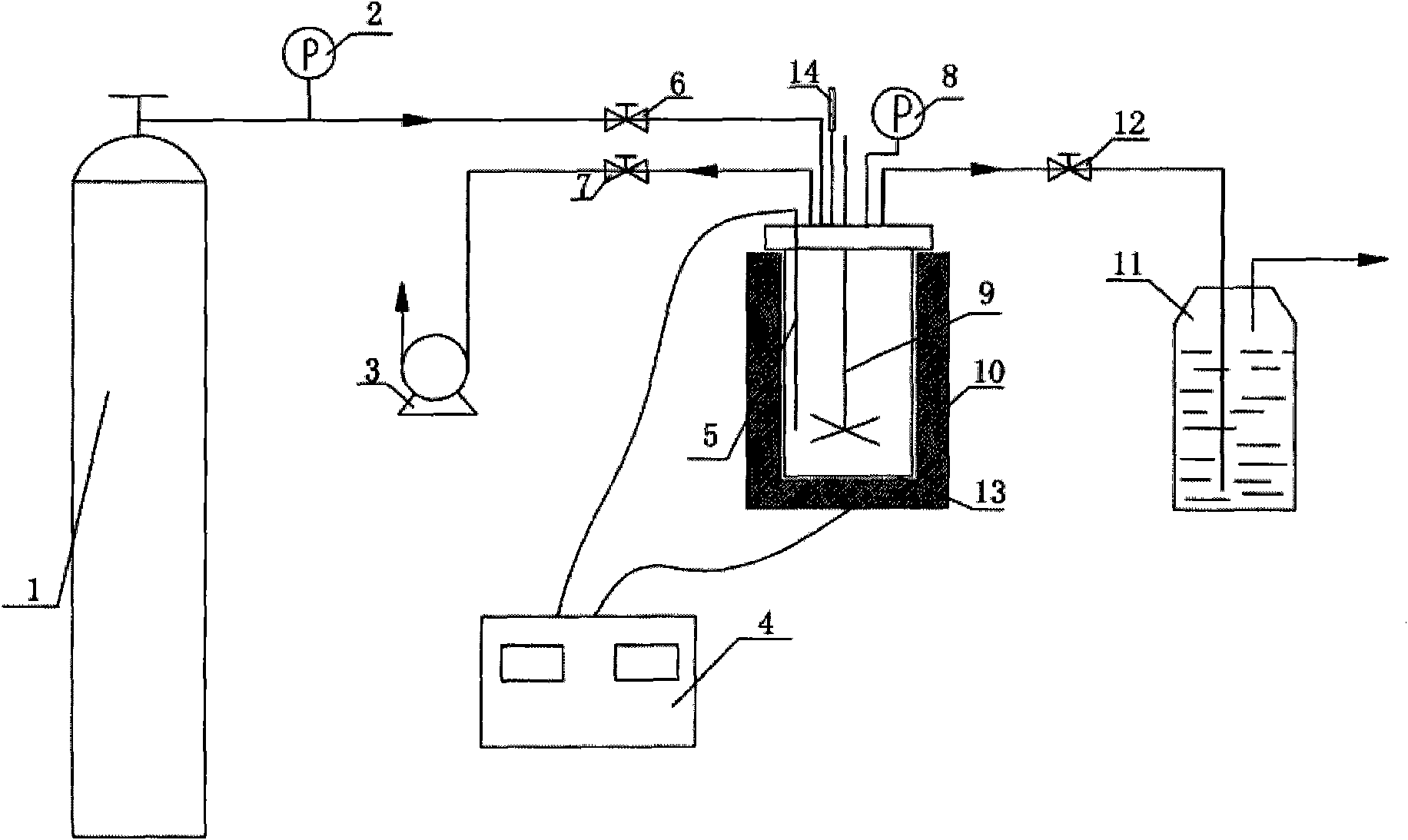

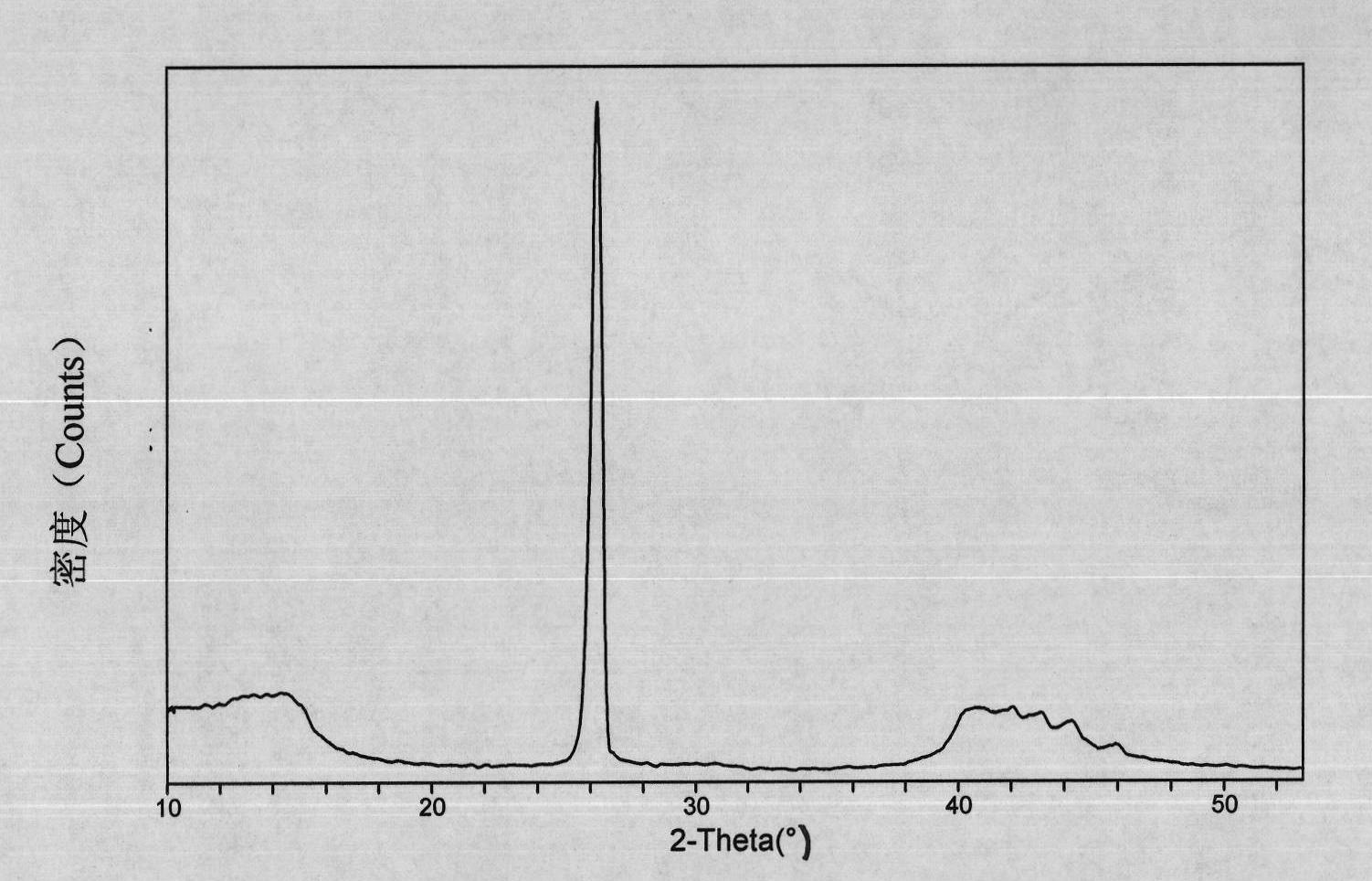

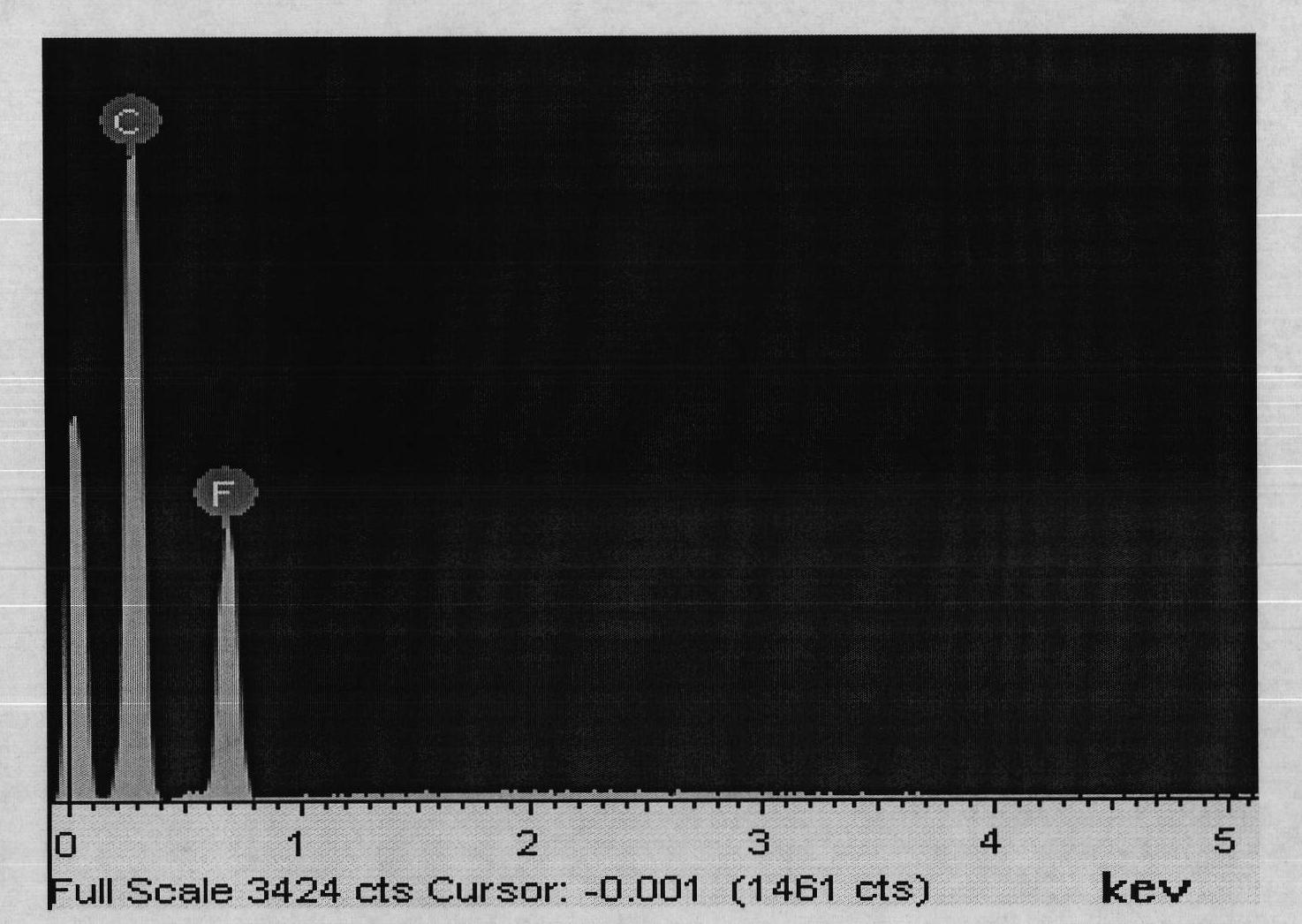

Industrial novel method for synthesizing graphite fluoride

The invention discloses an industrial synthesis method for graphite fluoride. Fluorine gas or the mixture of fluorine gas and inert gas is led into a specific reaction container filled with graphite at certain flow speed and pressure; and then graphite fluoride with various specifications of more than 50 percent is obtained by controlling reaction temperature, reaction pressure and reaction speed. Compared with methods specified in other relevant patents, the method has simple operation and can carry out industrial production safely. The obtained graphite fluoride products are mainly applied to the electrode materials of novel high-energy lithium ion battery and solid lubricant material.

Owner:杨先金 +2

Method for preparing graphite fluoride

The invention discloses a method for preparing graphite fluoride. The graphite fluoride is prepared from inorganic composite fluridizer and graphite as raw materials by heating and reaction in the presence of high-purity nitrogen, wherein the inorganic composite fluridizer is the mixture of potassium hexafluoromanganate and antimony pentafluoride. Due to the adoption of the method, the fluorine content of the finally obtained graphite fluoride can reach 59%, and the graphite fluoride can be used as the anode material and the solid lubricating material of lithium ion batteries; the purity of the graphite fluoride product prepared by a solid phase method is greater than 99%, and the use value is high; moreover, the invention is simple in operation and has high safety without needing external fluorine; and the properties of hexafluoromanganate and antimony pentafluoride are stable at normal temperature and therefore the safety is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Large scale synthesis process of carbon fluorides

The present invention is large scale synthesis process of carbon fluoride as one new type of functional material. Carbon fluoride material is white or grey, non-toxic, nonflammable, non-corrosive and chemically stable. It may be used as insulating material, waterproofing material, lubricant material and electrode material for high energy lithium battery, and has excellent performance and superiority of being used in the conditions of high temperature, high pressure, high load, strong acid and alkali environment. Carbon fluoride material is prepared through introducing fluorine gas or mixed gas of fluorine and nitrogen or other inert gas into special solidifying bed with various kinds of carbon process so as to produce reaction in certain temperature to generate carbon fluoride product of different sizes.

Owner:彭海燕

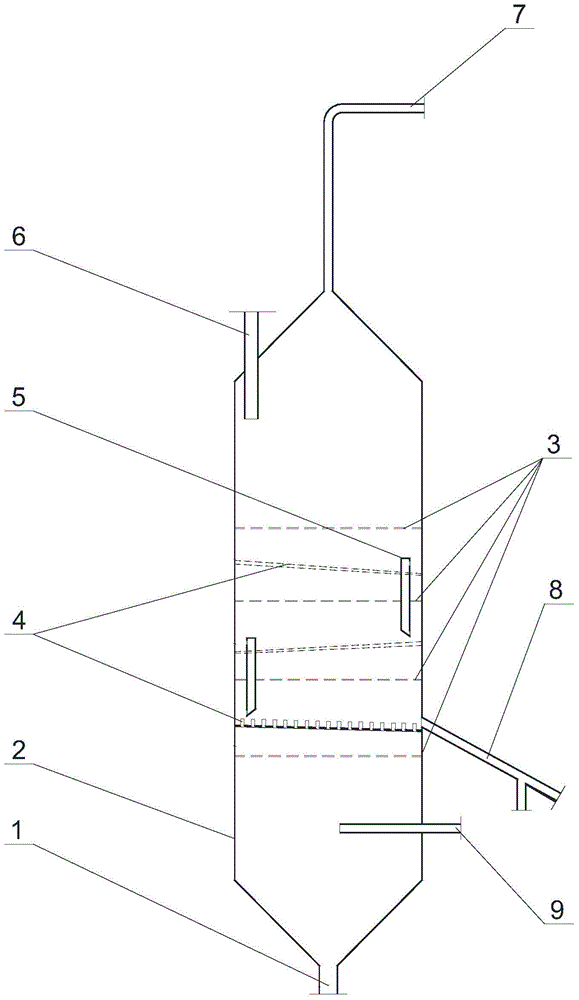

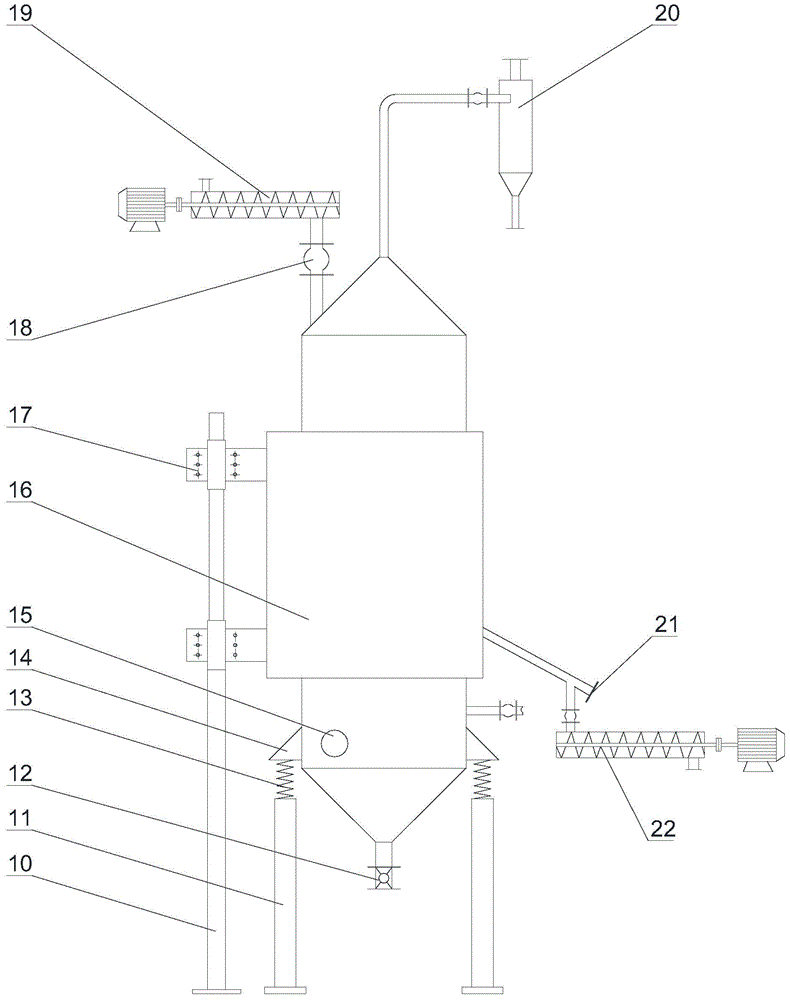

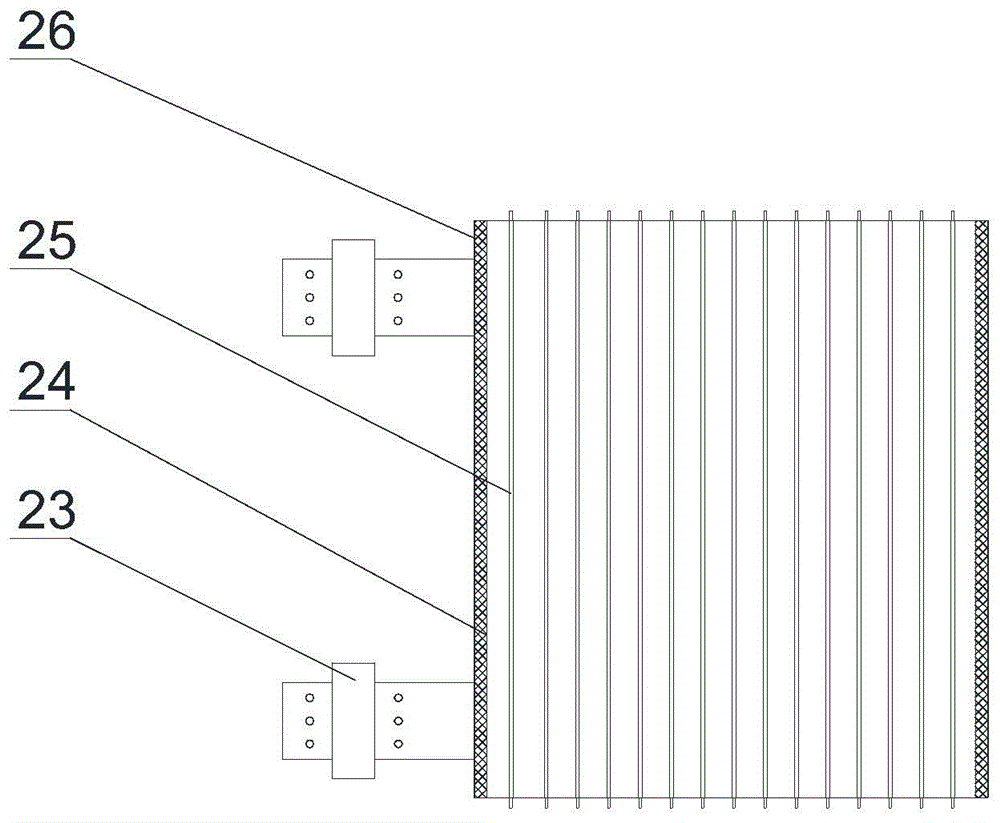

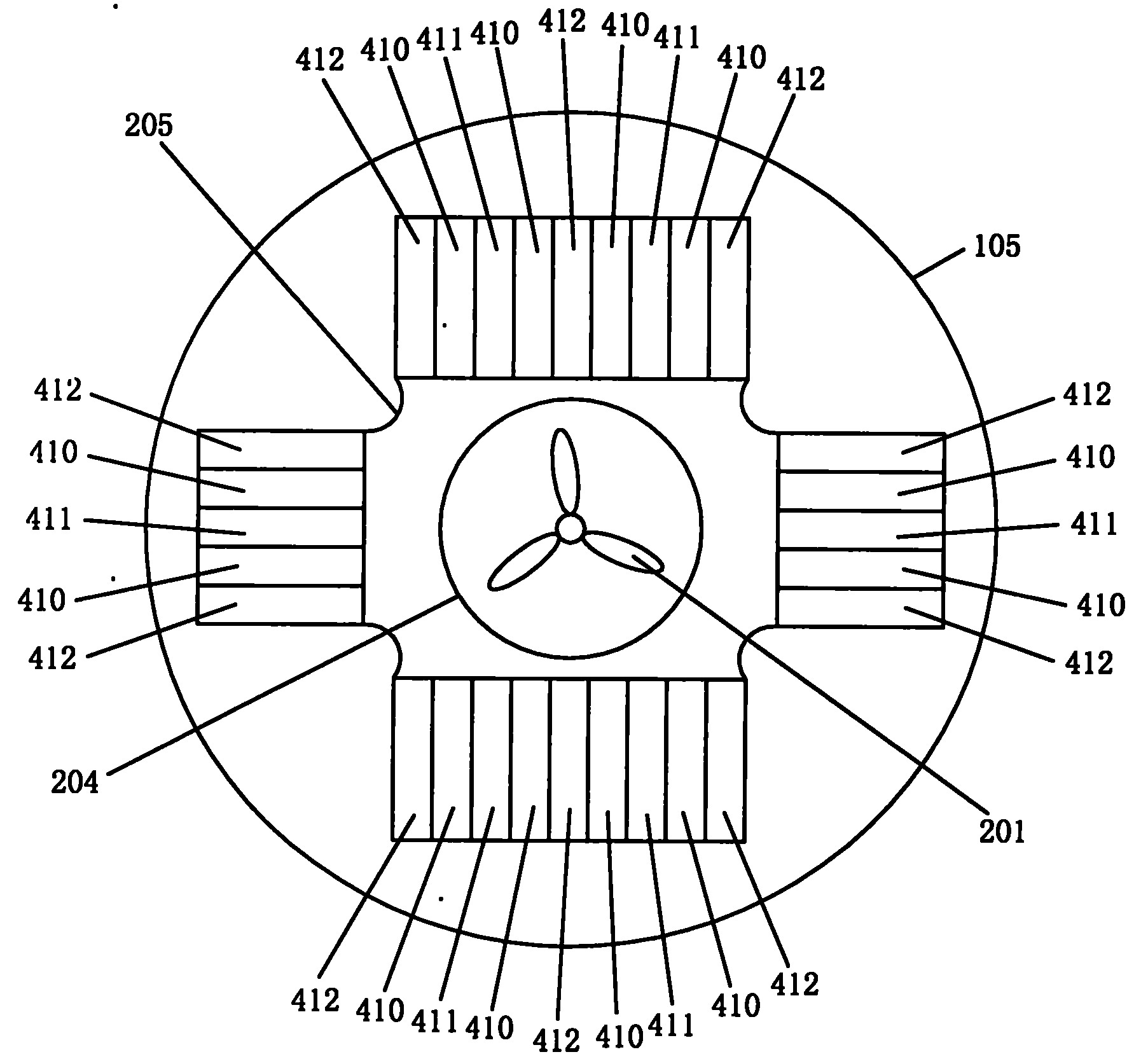

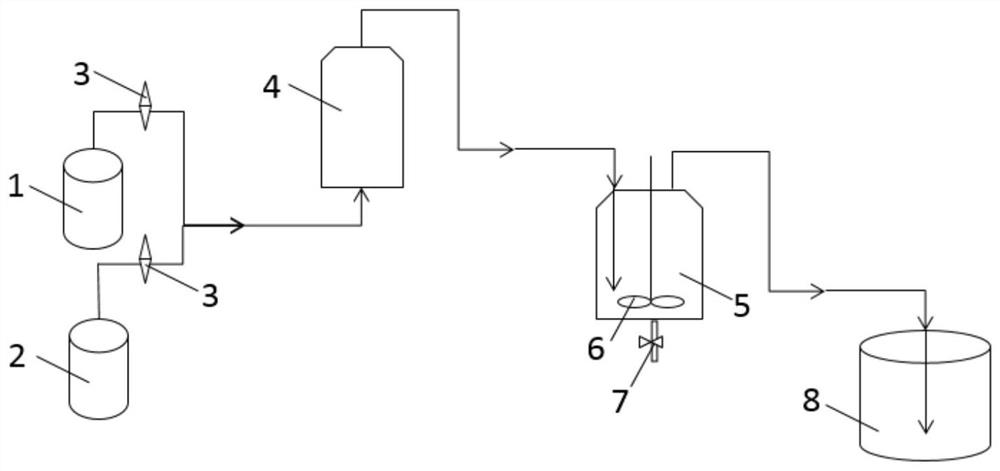

Vibratory fluidized bed reactor for continuous production of rare earth fluorides and production method

InactiveCN104084095AImprove fluidization qualityOptimizing the gas-solid fluidization reaction processRare earth metal compoundsChemical/physical processesHydrogen fluorideFluoride products

The invention discloses a vibratory fluidized bed reactor for continuous production of rare earth fluorides. The vibratory fluidized bed reactor comprises a feeding device, a discharging device, a fluidized bed, a vibrator and a heating device, wherein a rare-earth-containing material feeding hole is formed in the upper part of a fluidized bed body; a rare earth fluoride product discharge opening communicated with the discharging device is formed in the lower part of the fluidized bed body; a hydrogen-fluoride-containing gas inlet is formed in the bottom of the fluidized bed body; gas distribution plates through which hydrogen-fluoride-containing gas passes and uniform air distribution is realized are arranged in the cavity of the fluidized bed body; an exhaust pipe is arranged on the top of the fluidized bed body; the heating device is arranged on the outer side of the fluidized bed body and covers the fluidized bed body; the vibrator is arranged on the outer wall of the fluidized bed body; the bottom of the fluidized bed body is connected to supports through elastic supporting pieces. According to the scheme in the invention, the fluidization quality can be improved, the mass transfer and heat transfer effects are improved, the production efficiency is high, and the product is uniform and stable in quality, high in fluorination rate and low in process cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

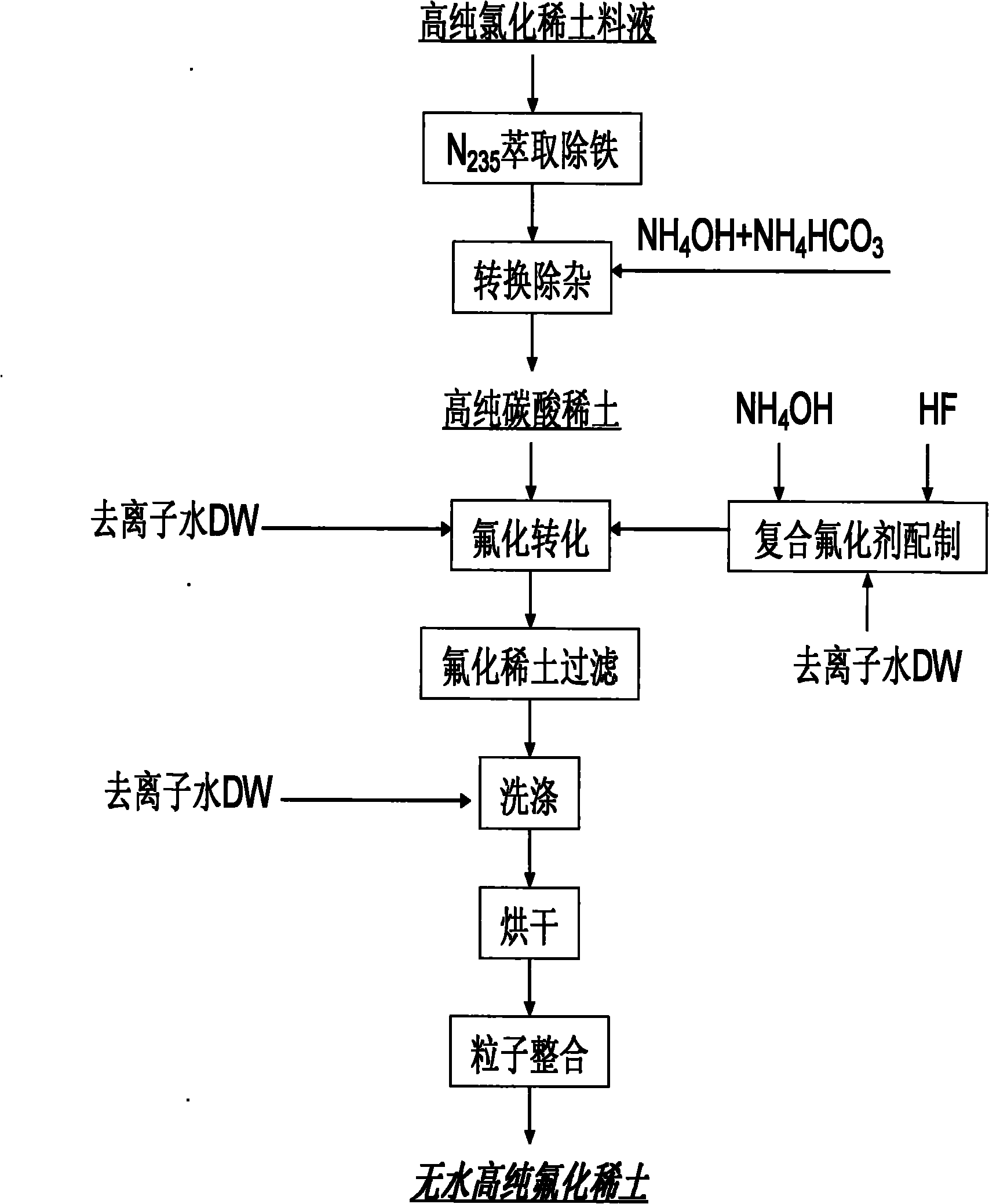

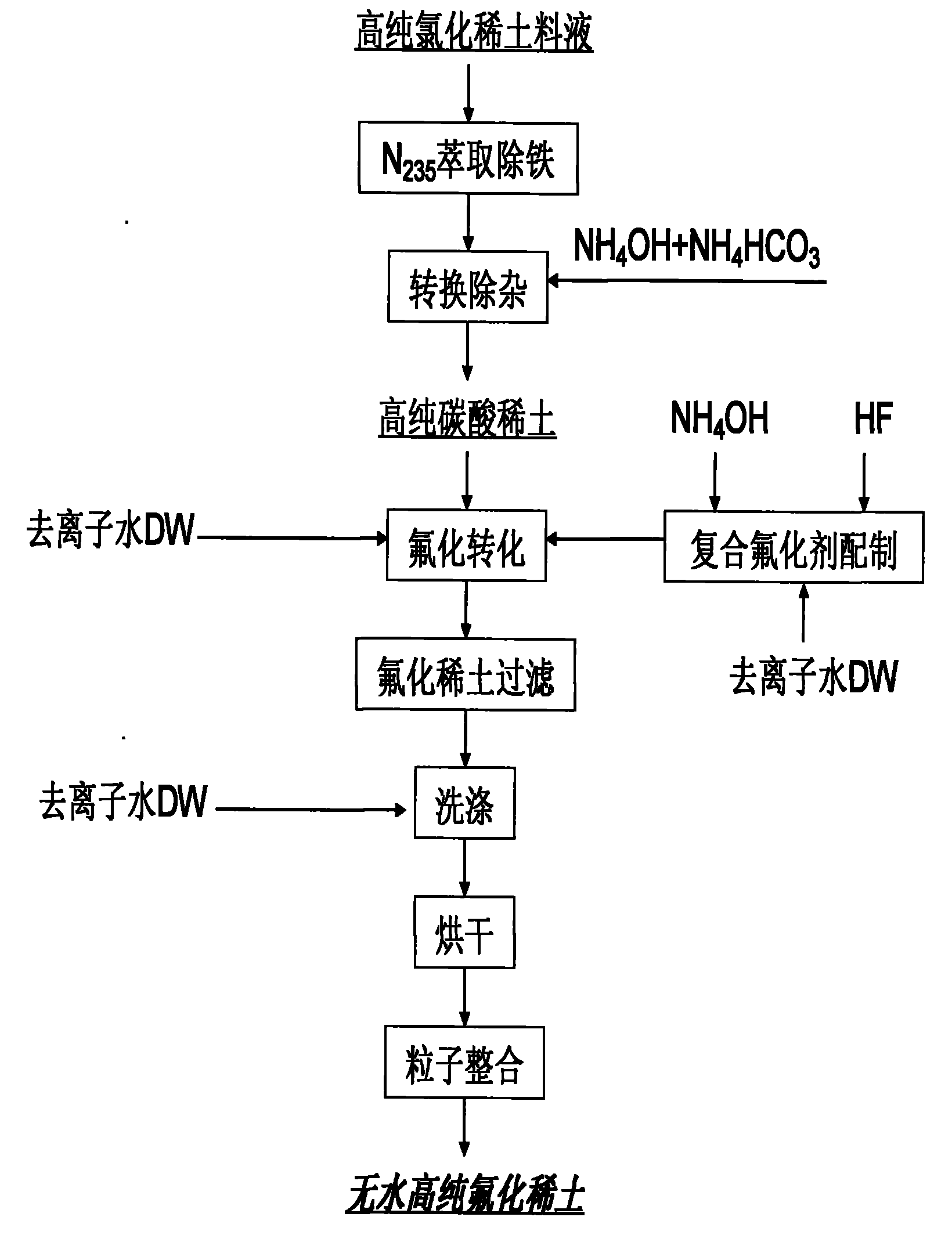

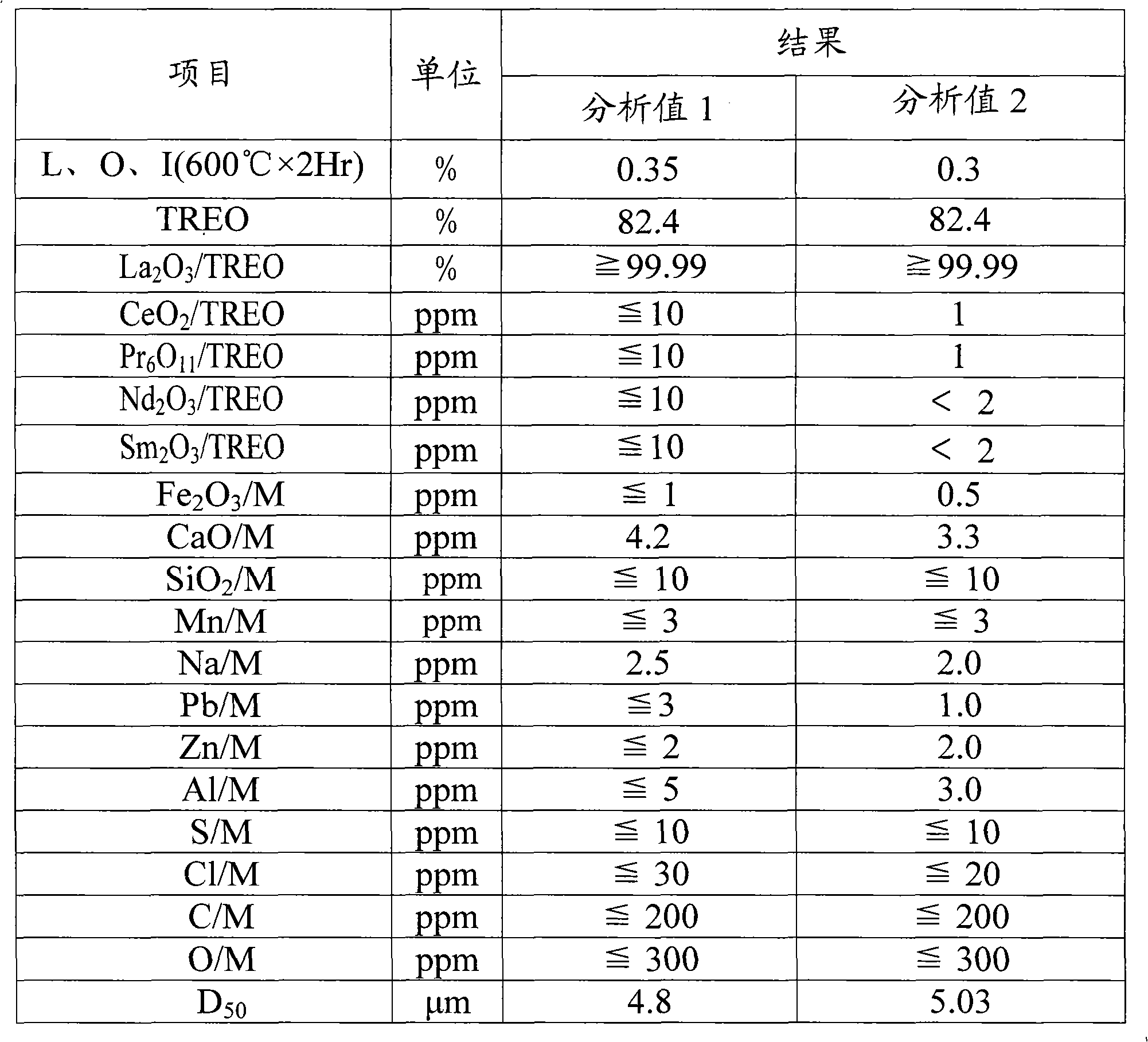

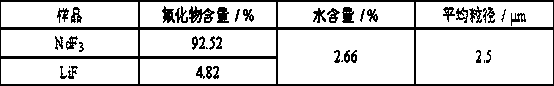

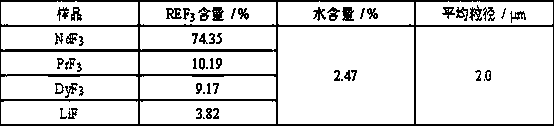

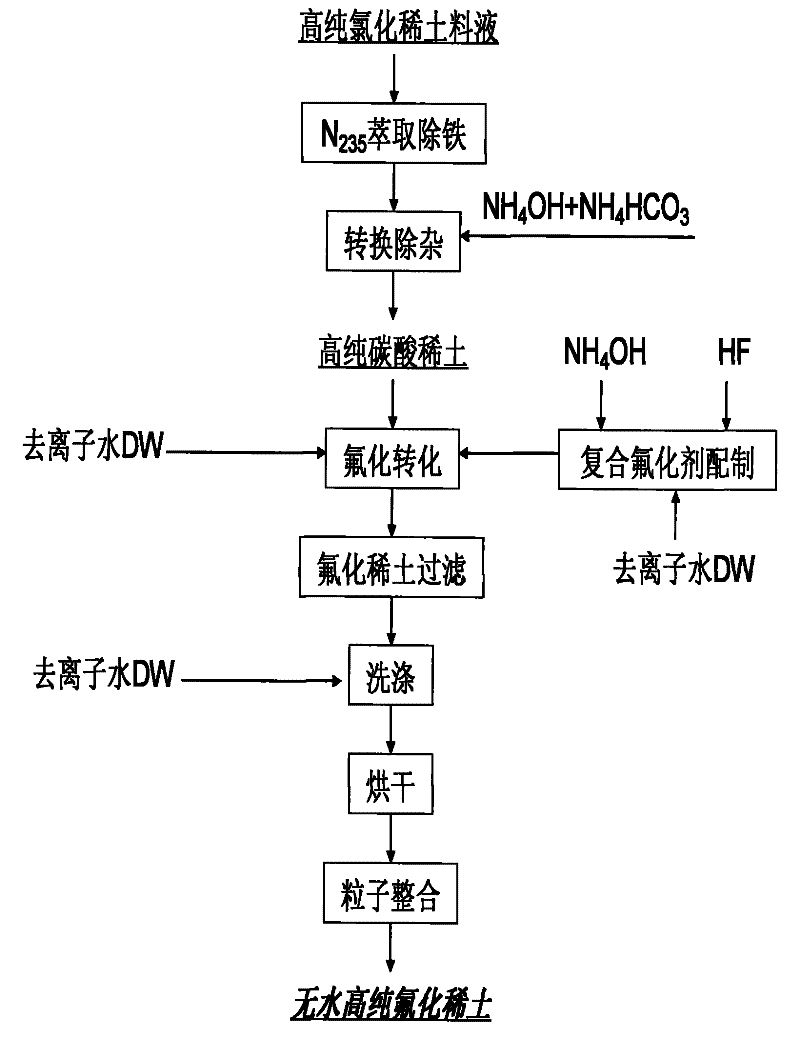

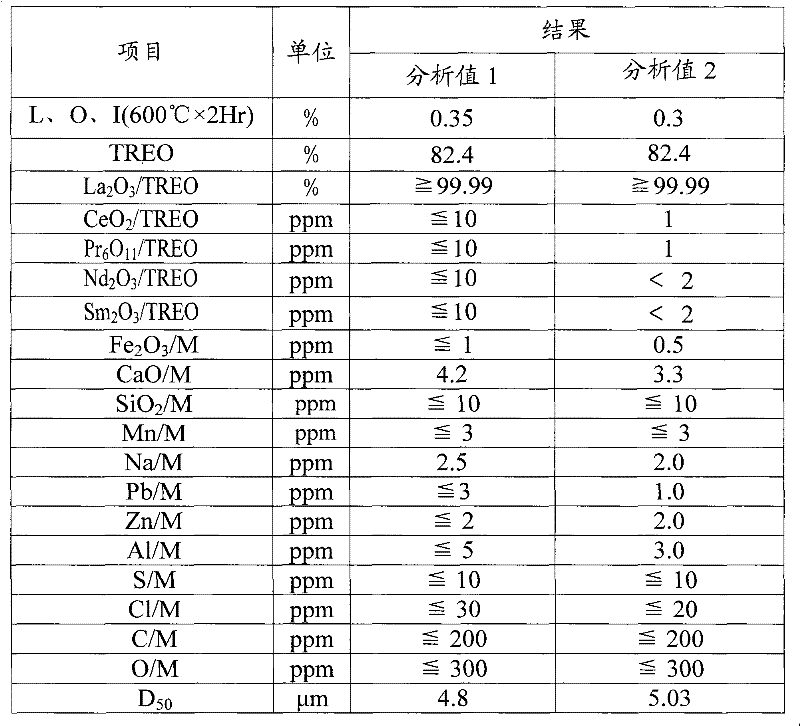

Anhydrous high-purity rare earth fluoride and preparation method thereof

The invention discloses an anhydrous high-purity rare earth fluoride and a preparation method thereof. The anhydrous high-purity rare earth fluoride mainly comprises minim non-rare earth impurity iron (Fe2O3<=1ppm), calcium (CaO<=10ppm), silicon (SiO2<=10ppm), carbon (C<=200ppm), oxygen (O<=200ppm), chloride (Cl<=30ppm), sulfur (S<=10ppm) and the like and has ignition loss not more than 0.5%. The product is mainly applied in the field of electronic and luminescent materials. The preparation method is characterized by pre-removing the non-rare earth impurity by enhancement on the basis of the traditional process and then carrying out conversion in the form of compound fluorinating agents; strictly controlling the feed liquor concentration and acidity, fluorinating agent addition, fluorination temperature and time, etc and obtaining the rare-earth fluoride which is coarse in fluorinated particles, fast in sedimentation and easy to wash and filter; and finally obtaining the anhydrous high-purity rare earth fluoride product through subsequent drying and particle integration.

Owner:QIANDONG RARE EARTH GRP

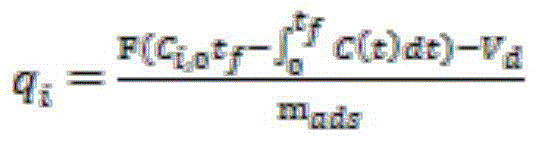

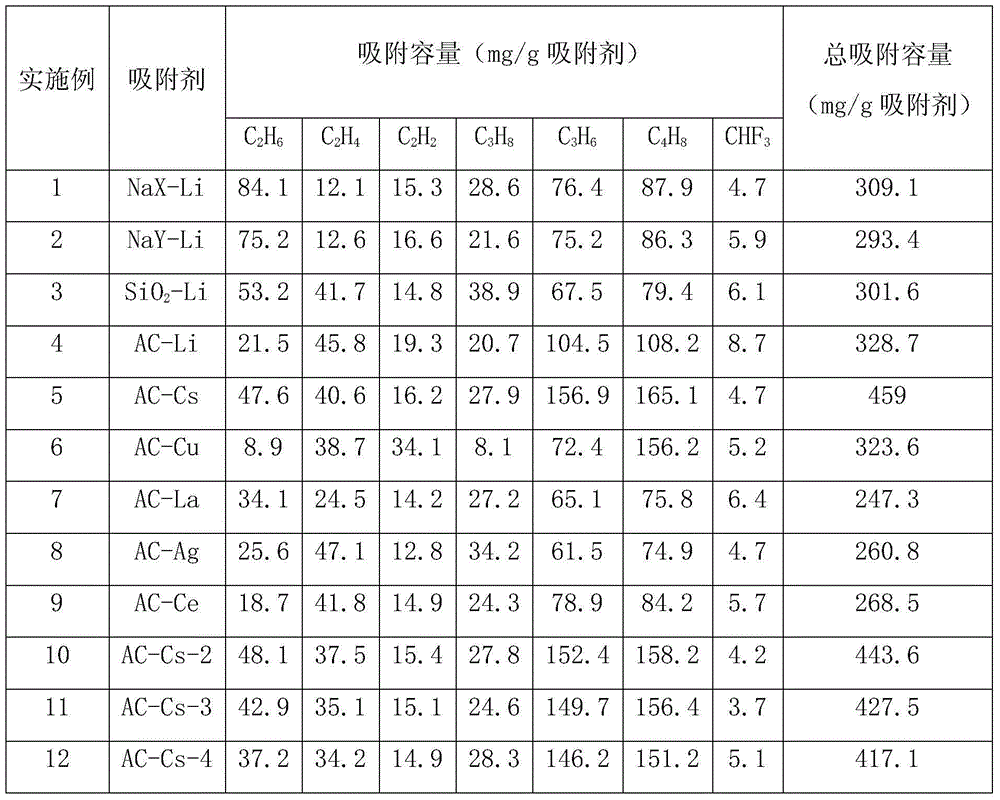

Modified adsorbent and applications of modified adsorbent in ultra-high purity methyl fluoride preparation

ActiveCN105363407AImprove adsorption efficiencyLarge adsorption capacityOther chemical processesSilicon compoundsMolecular sieveFluoride products

The present invention discloses an adsorbent modified through an ion exchange method, ball mill method or impregnating method, wherein the adsorbent is selected from an A type molecular sieve, an X type molecular sieve, a Y type molecular sieve, SiO2, Al2O3 or active carbon AC. According to the present invention, the modified adsorbent is suitable for removal of organic impurities from the methyl fluoride crude product so as to obtain the ultra-high purity methyl fluoride product with a purity of more than or equal to 99.999%.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +2

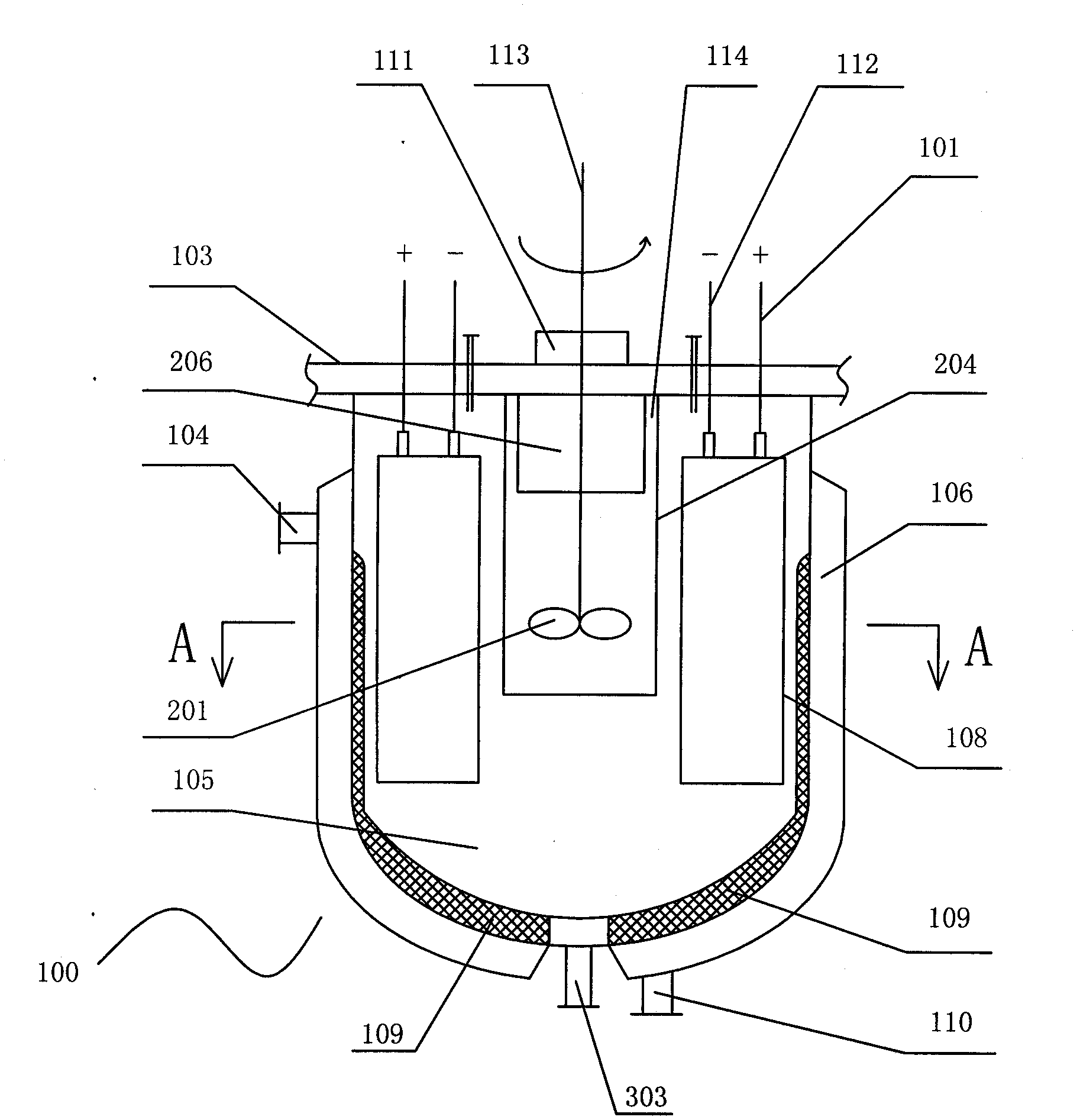

Compulsory internal recycle fluorination electrolysis reactor

InactiveCN102839384ASpeed up the flowControl enrichment dischargeCellsElectrolytic organic productionElectricityElectrolysis

The invention discloses a fluorination electrolysis reactor, which comprises a reaction kettle with an inner chamber, a pair of negative electrode and positive electrode leading-out terminals, a plurality of negative and positive plates, a mixer, a rotating shaft and a motor. The positive plates and negative plates are all flat rectangles, and are alternately arranged at preset interval into electrode stacks; the mixer is connected to the motor through the rotating shaft; the electrode stacks are arranged around the mixer into a ring; and the gap between the electrode plates generally orient the mixer. Adjacent electrode stacks can be arranged in choking connection to prevent flow of the electrolyte along the gaps between the stacks. The simple equipment employs a compulsory internal recycle mode; electrolysis products are easily controlled and derived in an electrolytic reaction process, so as to facilitate enrichment discharge of the reaction products; and the reactor effectively increases product yield, expands the varieties of fluoride products from the electrolytic reaction and the usage scope of the electrolytic tank.

Owner:叶姝菡 +1

Method for preparing aluminum fluoride

The present invention relates to process of producing aluminum fluoride with ammonium fluoroaluminate and aluminum hydroxide as material. The process includes the following steps: mixing solid ammonium fluoroaluminate and solid aluminum hydroxide in the reaction ratio inside a reactor to react at 500-600 deg.c to produce solid aluminum fluoride product, and condensating the mixed gas of ammonia and water vapor the reaction produces to obtain ammonia water. The process is simple, and has low cost and high aluminum fluoride product quality.

Owner:DO FLUORIDE CHEM CO LTD

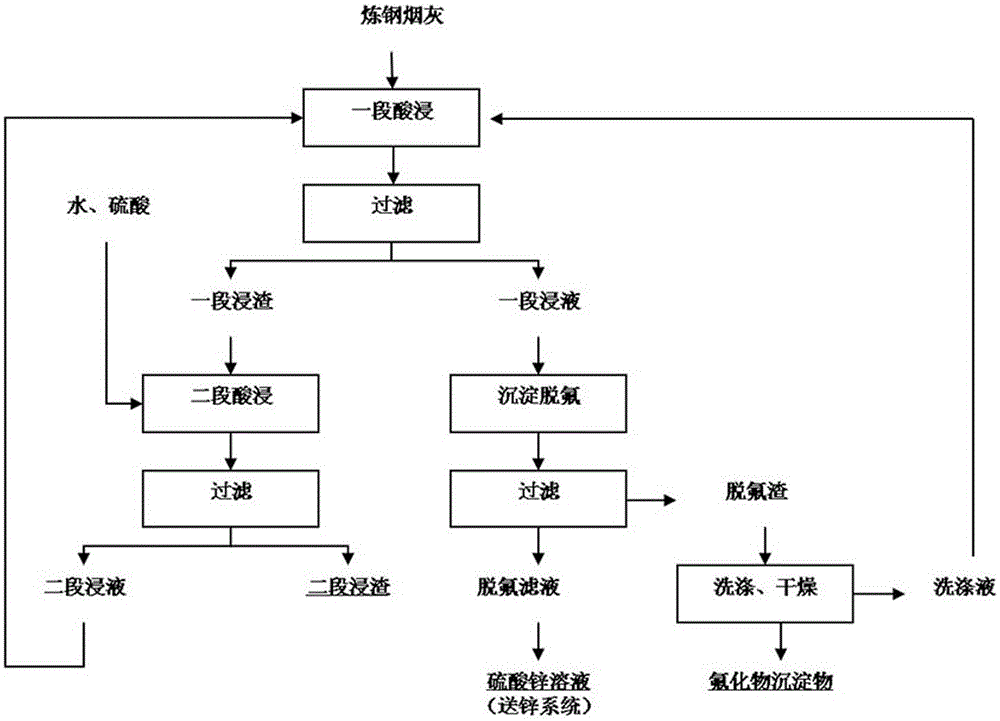

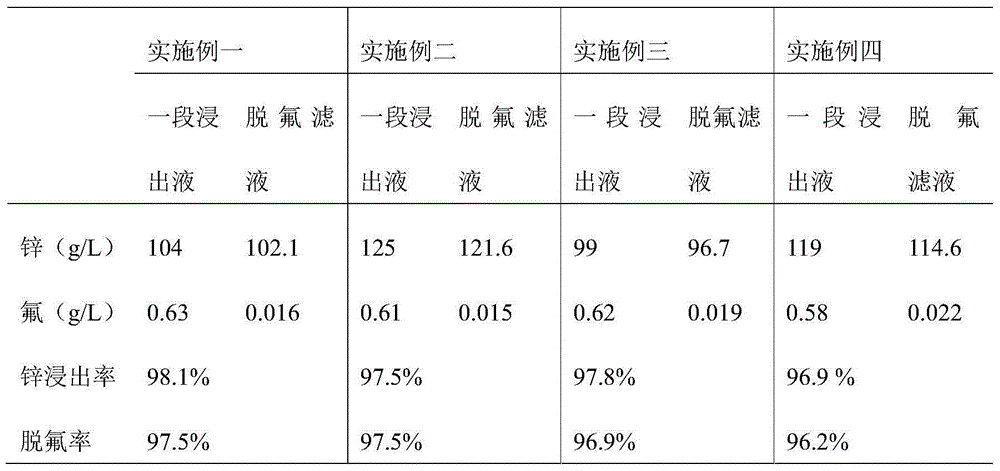

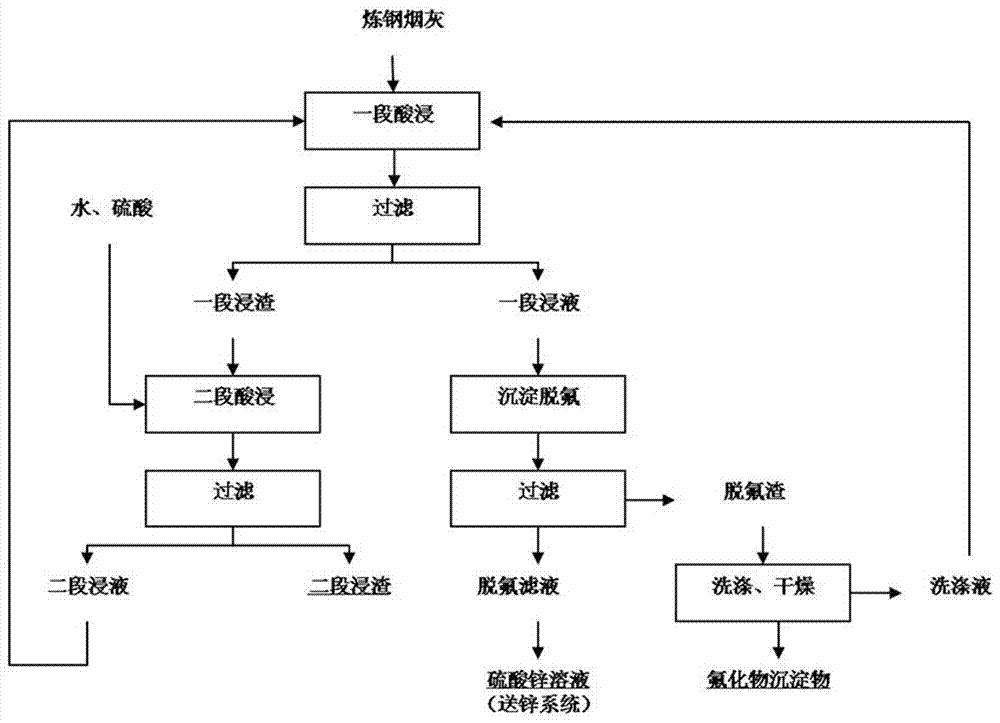

Technology capable of recycling fluorine and zinc from steelmaking soot

ActiveCN105154681AAchieve recyclingNo emissionsProcess efficiency improvementIron halidesSteelmakingFluoride products

The invention relates to a technology capable of recycling fluorine and zinc from steelmaking soot. Two-segment acid leaching is adopted for enabling zinc, fluorine and iron in the steelmaking soot to be dissolved in a solution, and then a precipitation method is adopted for enabling harmful element fluorine in the solution to be separated from the solution; and defluorination filtering liquid enters a zinc smelting system, and according to the normal technology, electrolytic zinc is produced. Fluorine-contained precipitation is washed, filtered and dried, and then a fluoride product is obtained. after the technological treatment is carried out, the zinc in the steelmaking soot can be recycled in a manner of a product of excellent cathode zinc, the harmful element fluorine is comprehensively utilized in a manner of an auxiliary product, and the environment pollution caused in the long-term stacking and storing or take-out transportation process of the soot in the steelmaking industry can be eliminated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

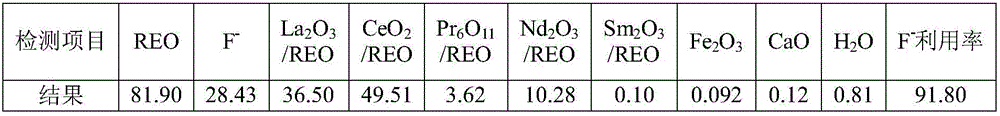

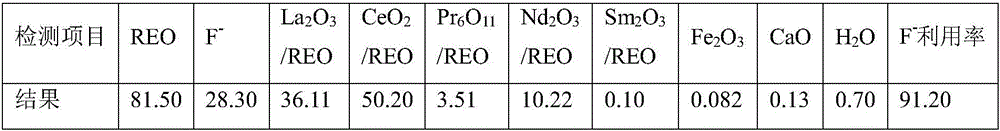

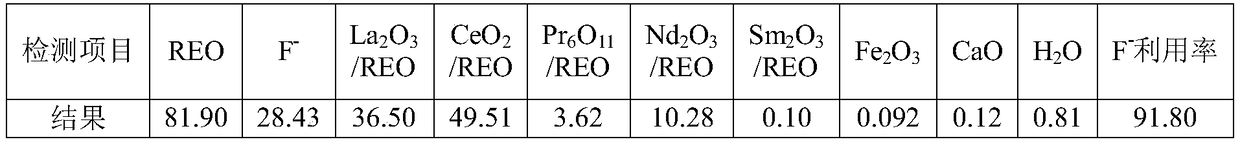

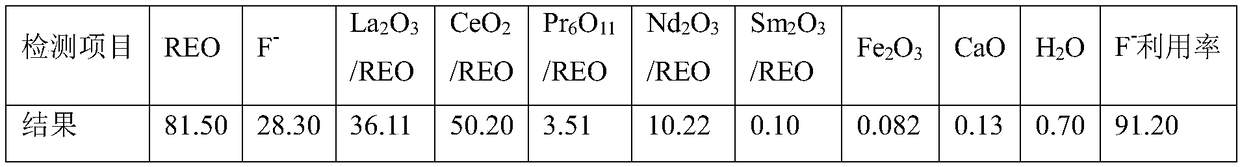

Method for producing rare earth fluoride from bastnasite

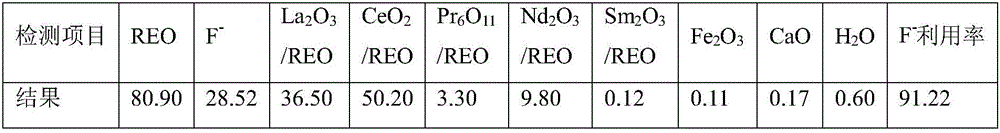

ActiveCN106811609AIncrease profitMeet market requirementsProcess efficiency improvementFluoride productsFiltration

The invention discloses a method for producing rare earth fluoride from bastnasite. The method comprises the following steps that 1, bastnasite is burnt, decarburized and oxidized; 2, the burnt, decarburized and oxidized bastnasite is added into a hydrochloric acid water solution with a complexing agent for acid leaching; 3, after acid leaching, a flocculating agent is added for solid-liquid separation, a fluorine-containing rare earth material and leached residue are obtained, and the leached residue is washed and recycled; 4, the fluorine-containing rare earth material is heated to be boiled and kept warm, standing is carried out after the reaction is finished, solid-liquid separation is carried out after clarification, and a fluorinated rare earth solid phase and a rare earth chloride clear liquid phase are obtained; and 5, the fluorinated rare earth solid phase is washed till pH is 6-7, heating and dehydration are carried out after filtration, and therefore rare earth fluoride is obtained. Rare earth ore is decomposed, the rare earth fluoride product is obtained, the leaching rate of rare earth in the rare earth ore is larger than 94%, and the utilization rate of fluorine resources in rare earth ore is larger than 91%. Fluorine resources in rare earth ore concentrate are sufficiently utilized, rare earth fluoride is produced, and a remarkable effect is obtained in the aspects of cost, energy saving and consumption reducing, environmental protection and the like.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Perfluoropolyether end group fluorination method

The invention provides a perfluoropolyether end group fluorination method which comprises the following steps: (1) irradiating mixed gas of fluorine gas and inert gas by using ultraviolet light, and activating; and (2) introducing the activated mixed gas into a reaction kettle filled with perfluoropolyether acyl fluoride, and reacting to obtain the end group fluorinated perfluoropolyether. According to the method disclosed by the invention, the fluorination reaction can be carried out at normal temperature, the obtained perfluoropolyether is easy to post-treat, the low-molecular-weight perfluoropolyether acyl fluoride product is less in loss, and the structure, the average molecular weight, the viscosity and the like of the fluorinated product are not changed.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

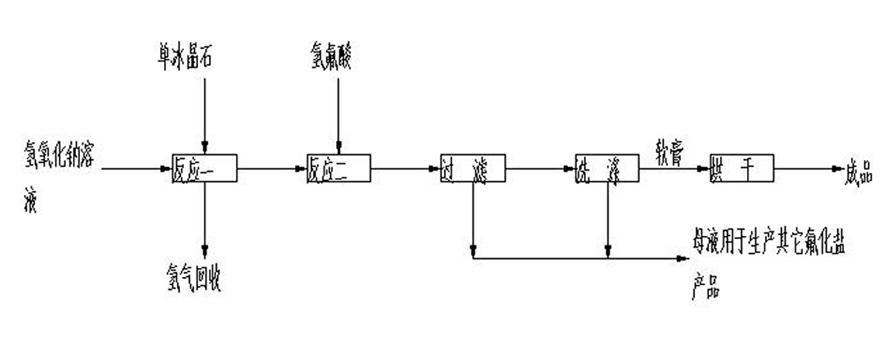

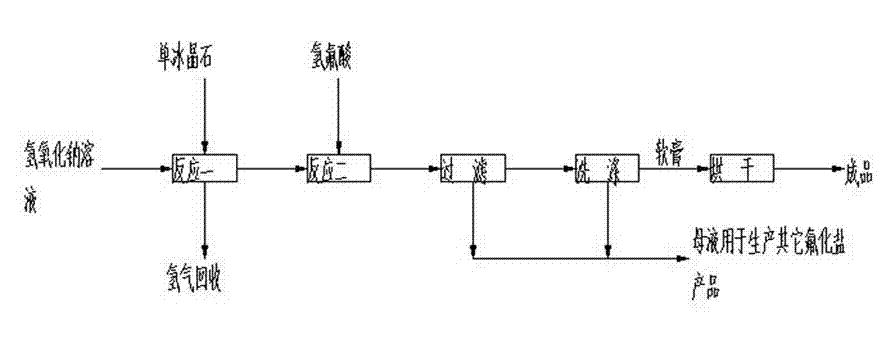

Method for comprehensively utilizing chemical byproduct single cryolite

ActiveCN102107900ALow impurity contentIncrease profitHydrogen productionAluminium fluoridesHydrofluoric acidFluoride products

The invention belongs to the technical field of polysilicon production, in particular to a method for comprehensively utilizing a chemical byproduct single cryolite during production of polysilicon. The method comprises the following steps of: reacting the single cryolite with sodium hydroxide solution to generate hydrogen and sodium aluminate slurry; and reacting the sodium aluminate slurry withhydrofluoric acid to prepare cryolite for aluminum, wherein the byproduct, namely hydrogen in the reaction process is purified and recovered to serve as a byproduct; and mother liquid is used for producing other fluoride products, or being neutralized by adding lime and then being discharged. The byproduct, namely single cryolite, of polysilicon is used for producing cryolite for aluminum, so rawmaterials are readily available, cost is low and the utilization ratio of the raw materials is high; the produced cryolite for aluminum has low impurity content and meets national standard; and wasteis changed into treasure, which accords with production ideas of comprehensive utilization of resources, energy conservation and environmental protection.

Owner:BAIYIN ZHONGTIAN CHEM

Perfluorooctanoic acid fluoride preparation method

InactiveCN106336355ALow reaction temperatureMild responseCarboxylic acid halides preparationFluoride productsReaction temperature

The invention relates to a perfluorooctanoic acid fluoride preparation method. According to the invention, fluorine gas is diluted by inert gas and is subjected to caprylyl chloride under low temperature condition to prepare perfluorooctanoic acid fluoride. The technical means such as inert gas dilution, reaction temperature reduction, stirring or filling material increasing can be carried out so that the reaction of fluorine gas and caprylyl chloride is milder and more uniform, control is easy, yield of perfluorooctanoic acid fluoride is greatly increased, usage of an electrolytic tank metal anode is avoided, and the generation of a solid waste material is basically eliminated. Direct reaction of fluorine gas and caprylyl chloride can avoid the energy waste, increases perfluorooctanoic acid fluoride yield, reduces the generation of by products such as low fluorine carbon due to a scission reaction of long-chain carbon atoms, quality of the perfluorooctanoic acid fluoride product is guaranteed, and the method has great meaning for perfluorocapylic acid production enterprises.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

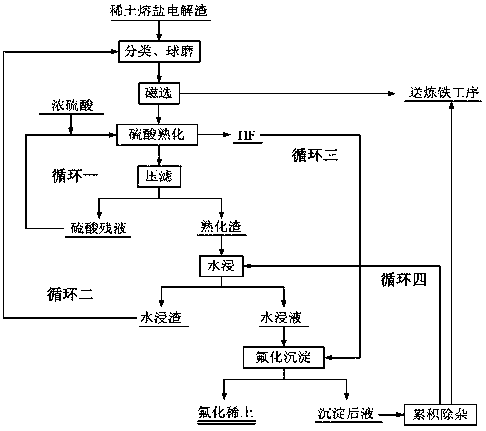

Rare earth fluoride molten salt electrolysis slag treatment method

InactiveCN109487089AEfficient separationRealize full recyclingHydrogen fluorideProcess efficiency improvementFluoride productsElectrolysis

The invention discloses a rare earth fluoride molten salt electrolysis slag treatment method. The rare earth fluoride molten salt electrolysis slag treatment method comprises the following steps thatball milling is carried out on rare earth molten salt electrolytic slag to a certain particle size; the electrolytic slag obtained after ball milling is subjected to magnetic separation, and magneticseparation tailings and magnetic separation concentrates are obtained; the magnetic separation tailings and concentrated sulfuric acid are mixed to make a heating reaction, and curing residues and HFgas (preparing an HF solution with water absorption) are obtained; the sulfuric acid curing residues are leached with water, and water leaching liquid is obtained; and the water leaching liquid obtained in the fourth step is subjected to fluoride precipitation with the HF solution obtained in the step three, and a rare earth fluoride product is obtained after liquid-solid separation is carried. The rare earth fluoride molten salt electrolysis slag treatment method is environment-friendly and economical, and solves the problem about separation of molten salt electrolysis slag rare earth and fluorine; meanwhile, the fluorine is finally recycled into a reaction system to react with rare earth to form precipitate, and green production and high-efficiency recovery of rare earth and iron from rare earth molten salt electrolysis slag are realized.

Owner:JIANGXI UNIV OF SCI & TECH

Anhydrous high-purity rare earth fluoride and preparation method thereof

Owner:QIANDONG RARE EARTH GRP

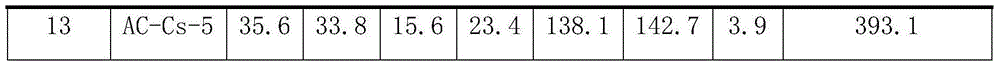

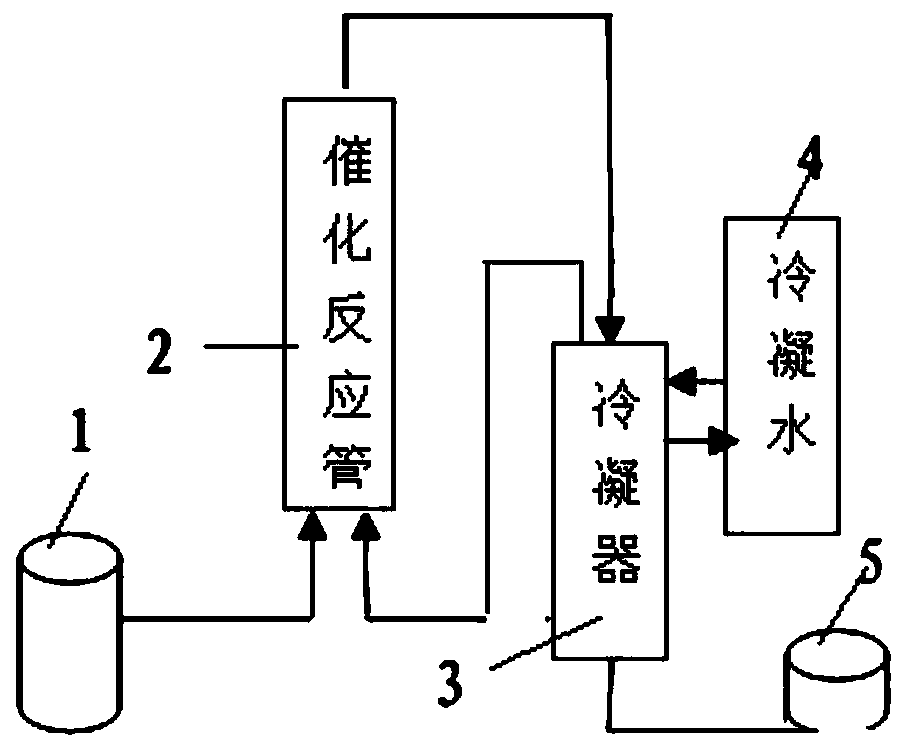

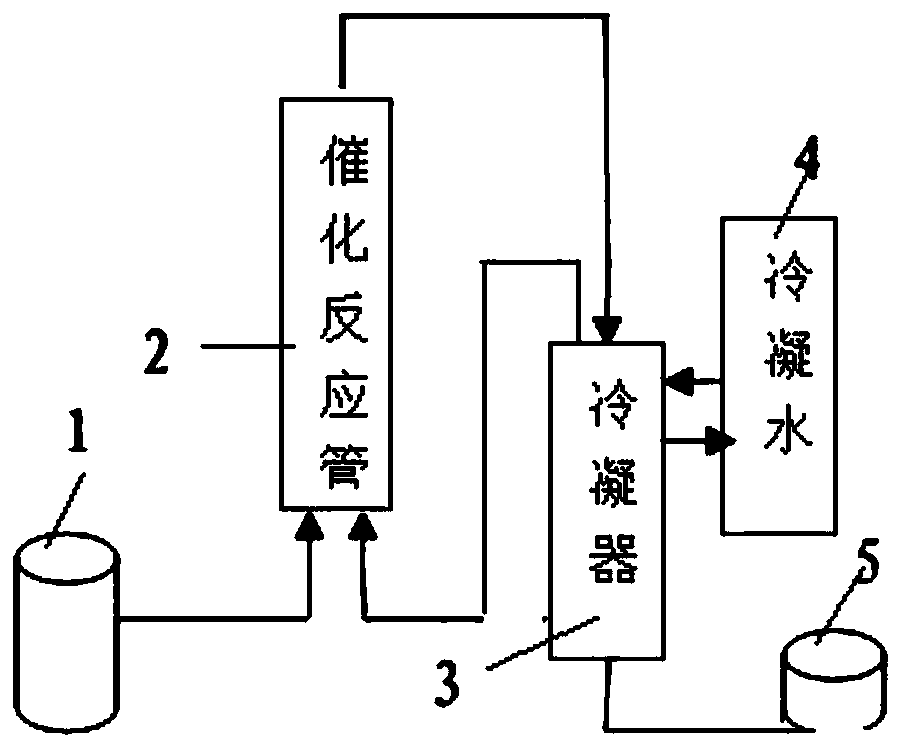

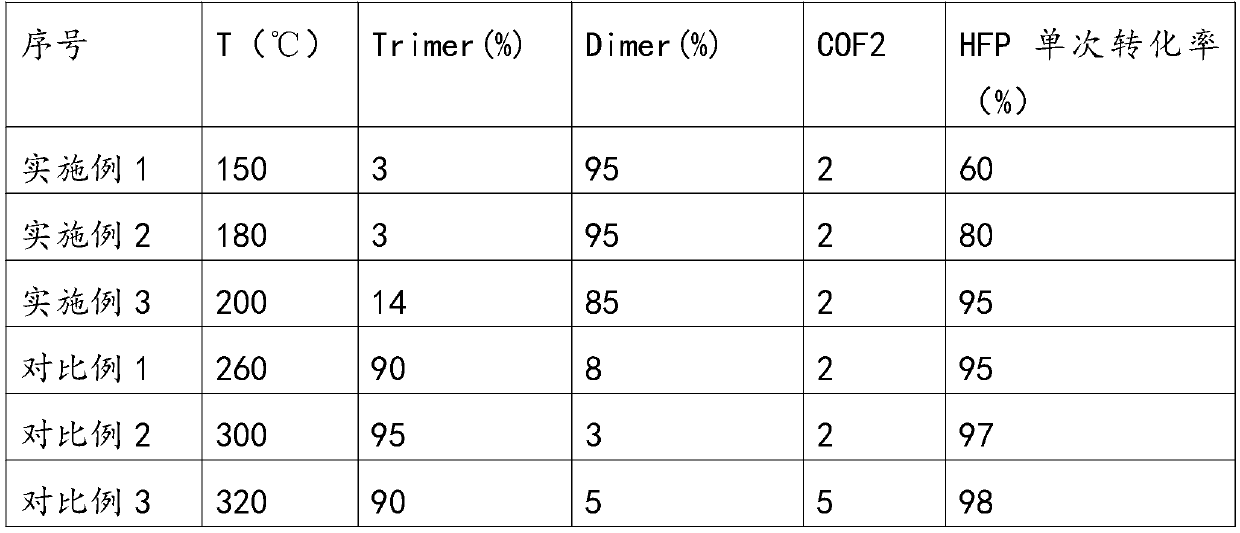

Controllable polymerization method and device of hexafluoropropene trimer

InactiveCN109734552AHigh yieldStrong productivityHalogenated hydrocarbon preparationFluoride productsHexafluoropropylene

The invention belongs to the field of fluorine chemical engineering and particularly relates to a controllable polymerization method and device of hexafluoropropene trimer. The hexafluoropropene trimer is made by gaseous reaction of hexafluoropropene under the catalysis of a supported ionic fluoride; the reaction temperature is 260-320 DEG C; contact time is 0.1-30 s; the ionic fluoride supportingcapacity is 10-20%; a supporter is activated carbon, aluminum trioxide, silicon dioxide or magnesium oxide; the ionic fluoride is AgF, NaF, KF, RbF or CsF. The novel route herein is suitable for existing manufacturers of fluoride products and the advantages of long-term reusability, low cost and significant economic benefit.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

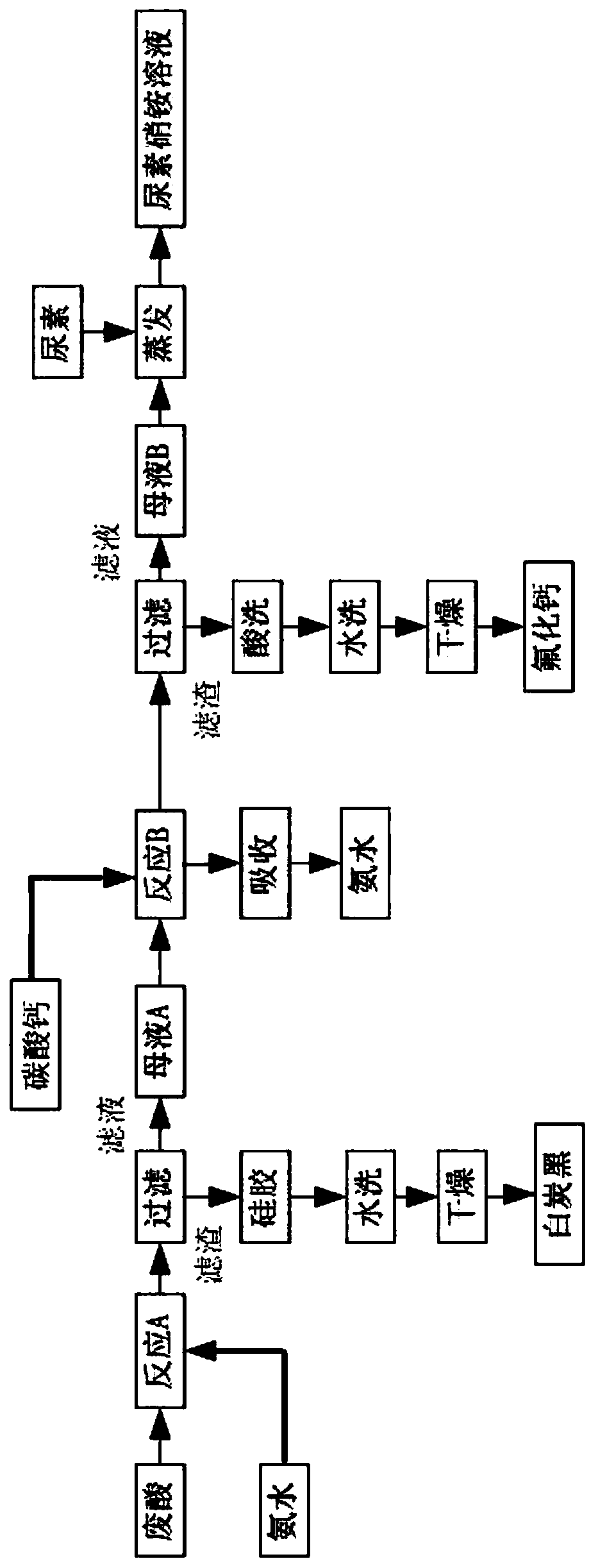

Fluorine-containing wastewater resource treatment and utilization method

InactiveCN110902883AEfficient recyclingMild process conditionsWater contaminantsTreatment involving filtrationFluoride productsWater resources

The invention relates to a fluorine-containing wastewater resource treatment and utilization method. The method includes the steps of: 1, slowly adding a first precipitant into fluorine-containing wastewater, carrying out reaction, controlling the pH value of the wastewater at 7-14, and performing filtering to obtain a first mother solution and silica sol, and conducting washing and drying on thesilica sol to obtain white carbon black; 2, adding a second precipitant into the first mother solution, carrying out reaction, and then performing filtering to obtain a second mother solution and a fluoride, conducting pickling, washing and drying on the fluoride, and then performing recovery; and 3, carrying out wastewater treatment on the second mother solution. The fluorine-containing wastewater resource treatment and utilization method provided by the invention can enable effective recycling of fluorine, silicon, nitrogen and other elements in the wastewater, for example, silicon is converted into a precipitated white carbon black product meeting the industrial standard, and fluorine is converted into a fluoride product meeting the national standard; and the method is mild in process conditions and simple in equipment, thus being easy to realize industrialization.

Owner:中广核环境科技(深圳)有限责任公司

Aluminum fluoride preparation method

InactiveCN107697937ASimple processReliable workmanshipAluminium fluoridesHydrofluoric acidAluminum fluoride

The invention discloses an aluminum fluoride preparation method which comprises the following steps: enabling recycled materials generated in the production process of dry-method aluminum fluoride toreact with hydrofluoric acid, and performing crystallization, filtration, separation, drying and dehydration, thereby obtaining an aluminum fluoride product. By adopting the technical scheme that thealuminum fluoride product is prepared from the recycled materials generated in the production process of dry-method aluminum fluoride and hydrofluoric acid through common processes and equipment, thedefects that the product quality can be seriously affected if recycled aluminum fluoride materials are put into an aluminum fluoride product after being dried, or great waste and serious environment pollution can be caused if the recycled aluminum fluoride materials are discarded, are overcome; and the aluminum fluoride preparation method is applicable to preparation of inorganic fluorides, and isparticularly applicable to preparation of aluminum fluoride prepared from a raw material, namely the recycled materials generated in the production process of dry-method aluminum fluoride.

Owner:达州励志环保科技有限公司

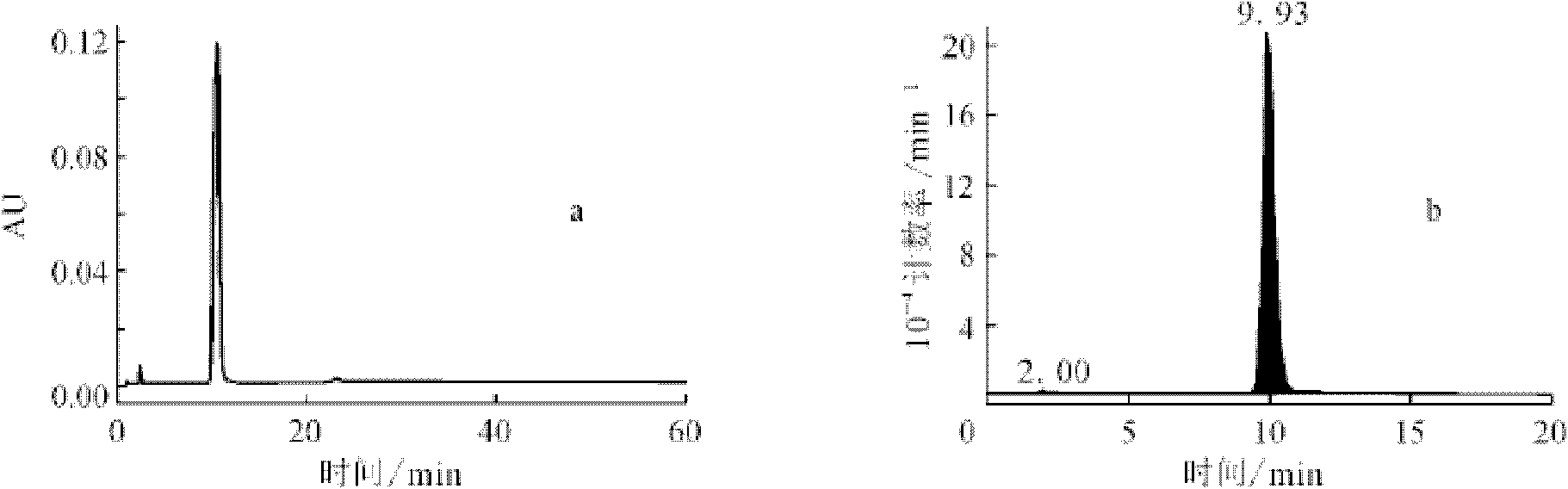

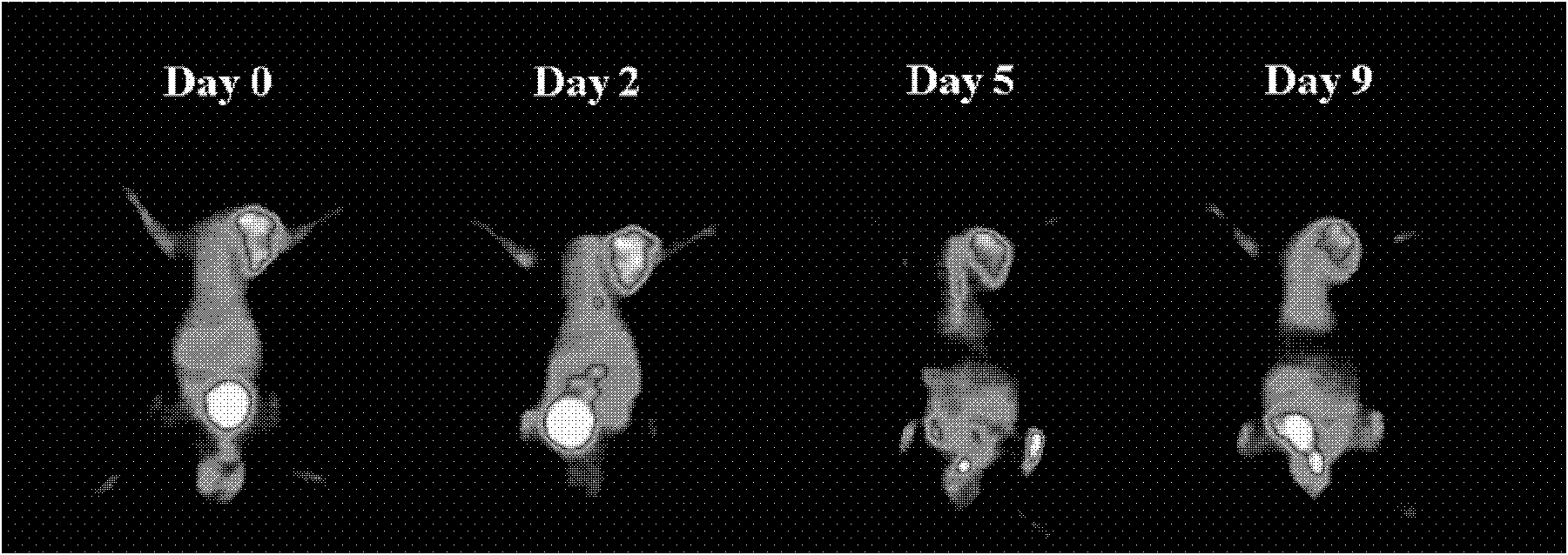

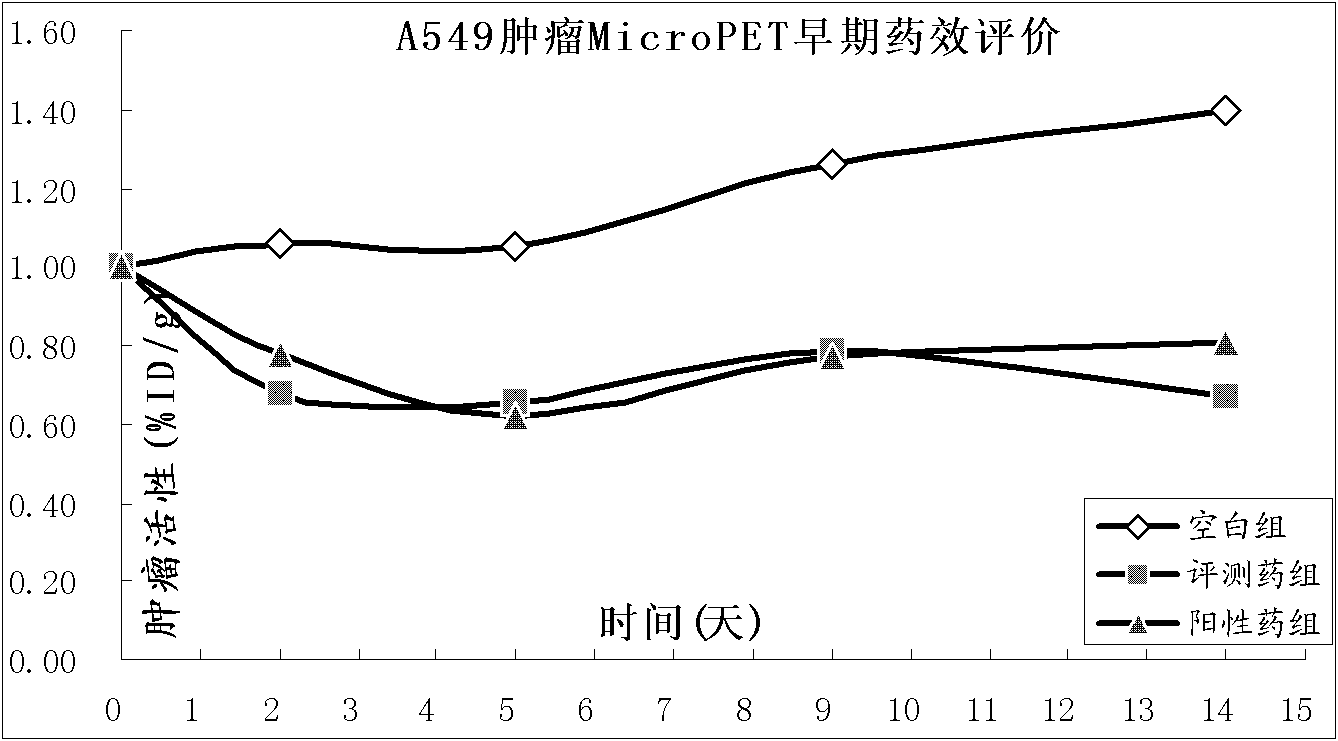

Process for preparing 18F-FLT and self-contained reagent kit

InactiveCN102329359AImprove stabilityHigh puritySugar derivativesSugar derivatives preparationFluoride productsCarbonate

The invention relates to a process for preparing 18F-FLT and a self-contained reagent kit, relating to the preparation of positron medicine and a reagent kit thereof and belonging to the technical field of radiopharmaceuticals and nuclear medicine. The process comprises the following steps of: a, catching 18F- generated by an accelerator by using a QMA column, then leaching the 18F- on the QMA column into a reaction tube by using quaternary ammonium salt TEABC (Triethyl Ammonium Bicarbonate) or a TBAHCO3 (Tetrabutylammonium Hydrogen Carbonate) solution; b, dehydrating the obtained 18F- after being leached in the step a; c, dissolving a precursor MTR-Nos-Boc-LT of 18F-FLT through a protic solvent, and adding into the 18F- obtained in the step b to carry out a nucleophilic fluorination reaction; d, hysrolyzing a nucleophilic fluoride product obtained in the step c through a hydrochloric acid solution, and neutralizing through an alkaline buffer solution; and e, edulcorating a neutralized liquid obtained in the step d to obtain a product 18F-FLT. Compared with the traditional synthesis technology, the process provided by the invention is a 18F-FLT synthesis technology with high efficiency, high stability and high purity, and can be used for making novel 18F-FLT and other positron medicine synthesis modules.

Owner:无锡米度生物技术有限公司

Rare earth fluoride and its production method

InactiveCN103922381AQuality improvementLow elemental contentRare earth metal compoundsFluoride productsPurification methods

The invention discloses a rare earth fluoride, and the purpose of obtaining a high-quality rare earth fluoride can be achieved by using a distillation purification method to reduce non rare earth impurities in a commercially available rare earth fluoride. A production method of the rare earth fluoride is simple, and the rare earth fluoride product quality is stable. The development and application of high pure rare earth metals and alloys and rare earth fluoride function materials can be facilitated.

Owner:QIANDONG RARE EARTH GRP

Method and device for controllable polymerization of hexafluoropropylene dimer

InactiveCN109651075AIncrease productionIncrease profitHalogenated hydrocarbon preparationChemical industryActivated carbon

The invention belongs to the field of fluorine chemical industry, and concretely relates to a method and a device for controllable polymerization of a hexafluoropropylene dimer. The hexafluoropropylene dimer is obtained by a gas phase reaction of hexafluoropropylene under the catalysis of a supported ionic fluoride; the reaction temperature is 150-220 DEG C; the contact time is 0.1-30 s; the loadcapacity of the ionic fluoride is 10-20%; the carrier is activated carbon, alumina, silica or magnesia; and the ionic fluoride is AgF, NaF, KF, RbF Or CsF. The above new route is suitable for existingenterprises for producing fluoride products, and realizes the characteristics of long-term recycling, low cost and remarkable economic benefit.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

A method for producing rare earth fluoride from bastnaesite

ActiveCN106811609BIncrease profitMeet market requirementsProcess efficiency improvementFluoride productsFiltration

The invention discloses a method for producing rare earth fluoride from bastnasite. The method comprises the following steps that 1, bastnasite is burnt, decarburized and oxidized; 2, the burnt, decarburized and oxidized bastnasite is added into a hydrochloric acid water solution with a complexing agent for acid leaching; 3, after acid leaching, a flocculating agent is added for solid-liquid separation, a fluorine-containing rare earth material and leached residue are obtained, and the leached residue is washed and recycled; 4, the fluorine-containing rare earth material is heated to be boiled and kept warm, standing is carried out after the reaction is finished, solid-liquid separation is carried out after clarification, and a fluorinated rare earth solid phase and a rare earth chloride clear liquid phase are obtained; and 5, the fluorinated rare earth solid phase is washed till pH is 6-7, heating and dehydration are carried out after filtration, and therefore rare earth fluoride is obtained. Rare earth ore is decomposed, the rare earth fluoride product is obtained, the leaching rate of rare earth in the rare earth ore is larger than 94%, and the utilization rate of fluorine resources in rare earth ore is larger than 91%. Fluorine resources in rare earth ore concentrate are sufficiently utilized, rare earth fluoride is produced, and a remarkable effect is obtained in the aspects of cost, energy saving and consumption reducing, environmental protection and the like.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Hamartite smelting separation process

ActiveCN102146512BAchieve recyclingIncrease the added value of resourcesFluoride preparationProcess efficiency improvementFluoride productsSlag

The invention discloses a hamartite smelting separation process. First optimal slag or / and second optimal slag mainly containing cerium (IV), thorium (IV) and fluorine, obtained by oxidative roasted salt acid leaching of hamartite, is / are used as raw materials, and extraction and separation of rare earth are performed. The process comprises the following steps of: 1) leaching the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the second optimal slag obtained by alkali conversion-hydrochloric acid dissolution of the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the mixed slag of the first optimal slag and the second optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; 2) performing extraction separation on the sulfuric acid-rare earth solution obtained in the step 1) to obtain a rare earth compound,fluorine washing liquor, a pure cerium product and a thorium product; and 3) synthesizing a fluoride product by using the fluorine-containing alkali wastewater obtained by alkali conversion in the step 1) and the fluorine washing liquor obtained by the extraction separation in the step 2). The process has the advantages that: the recovery rate of the rare earth is obviously improved, the fluorineand the thorium (IV) are effectively reclaimed in a product form, the high-purity cerium product is obtained, reclamation of the rare earth and associated resources is realized, and the additional values of the resources are improved; and the process flow is simple, the consumption of acid and alkali is low, the production cost is low, and the process is environmentally-friendly.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Phosphorus removal method for aluminun fluoride solution

ActiveCN101423238AWide variety of sourcesTake advantage ofAluminium fluoridesAluminum fluorideFluoride products

The invention relates to a dephosphorization method of aluminum fluoride solution, P2O5 in the aluminum fluoride solution is reacted with a dephosphorization agent to prepare a product, and the method comprises the following steps: I. the aluminum fluoride solution containing phosphorus is selected; II. the aluminum fluoride solution containing the phosphorus is put in a reaction tank, steam is introduced, and the temperature is increased; III. slurry with the weight ratio of 1:1 is prepared by the dephosphorization agent and put in the reaction tank, the reaction time is 0.5h-1h, and mixture is generated by the reaction; and IV. the mixture is filtered, sediments are separated, and the qualified product is obtained; the dephosphorization method adopts the technical proposal of adopting P2O5 in the aluminum fluoride solution to be reacted with Fe in the dephosphorization agent so as to further prepare aluminum fluoride or cryolite and other fluoride products, thereby overcoming the shortcomings of single raw material, long technology flow, complicated process, strict requirements on phosphorus content in the fluosilicic acid raw material, and the like of the existing preparation method of the aluminum fluoride, the cryolite and other fluoride products. The dephosphorization method is applicable to the preparation of inorganic fluorides and especially applicable to the prepration of the aluminum fluoride or the cryolite and other fluoride products with the need of the treatment of the fluosilicic acid.

Owner:云南云天化氟化学有限公司

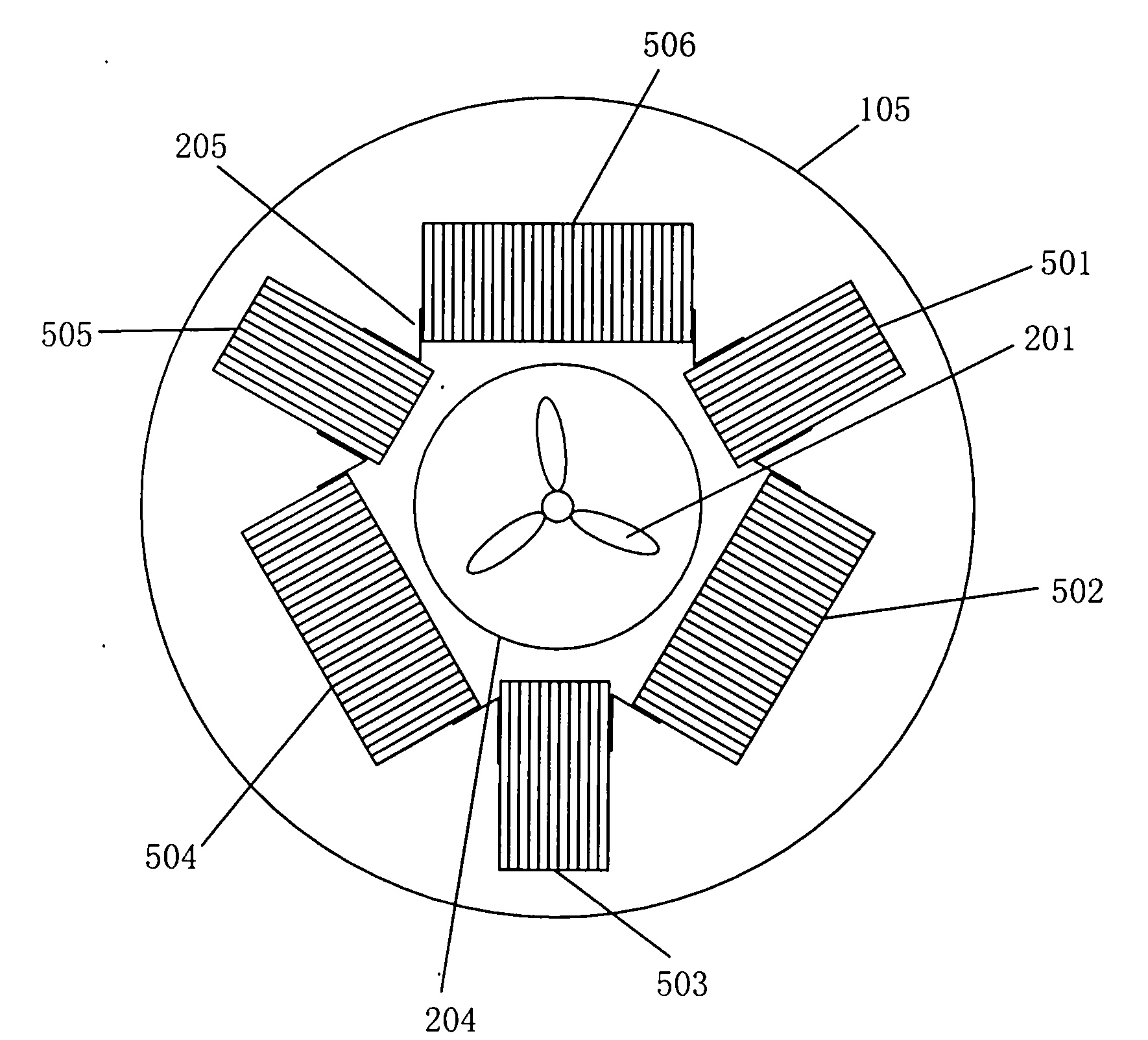

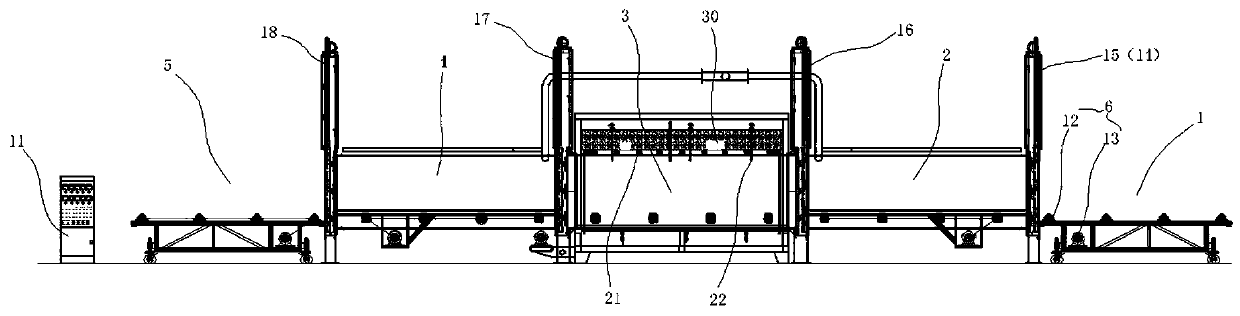

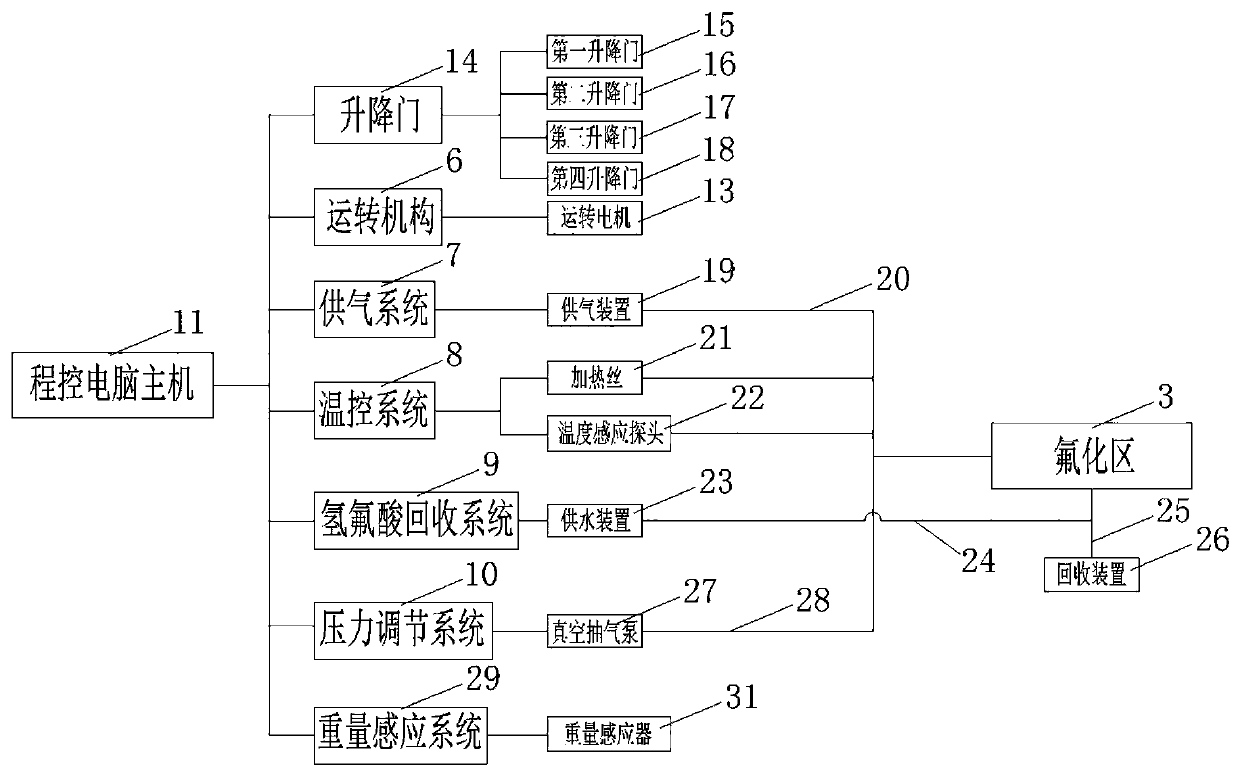

Automatic rare earth oxide fluorination transformation system

PendingCN111115676AAvoid pollutionQuality improvementRare earth metal fluoridesAutomatic controlFluoride products

The invention discloses an automatic rare earth oxide fluorination transformation system. The automatic rare earth oxide fluorination transformation system comprises a feeding area, a material preparation area, a fluorination area, a cooling area and a discharging area which are arranged in sequence, wherein the feeding area, the material preparation area, the fluorination area, the cooling area and the discharging area are gradually fed through an operation mechanism, the fluorination area is provided with an air supply system, a temperature control system, a hydrofluoric acid recovery systemand a pressure adjusting system, and the operation mechanism, the air supply system, the temperature control system, the hydrofluoric acid recovery system and the pressure adjusting system are in communication connection with a program control computer host. Through the system, the whole fluorination process can be carried out in a closed environment; therefore, a fluoride product with stable quality and a good working environment are ensured; the system can effectively recover byproduct hydrofluoric acid so as to prevent the hydrofluoric acid from being discharged into the air to pollute theenvironment, the recovered byproduct can be reutilized, automatic control can be realized through the system, the whole fluorination efficiency is improved, and the labor cost is saved.

Owner:NINGBO FUNENG NEW MATERIAL

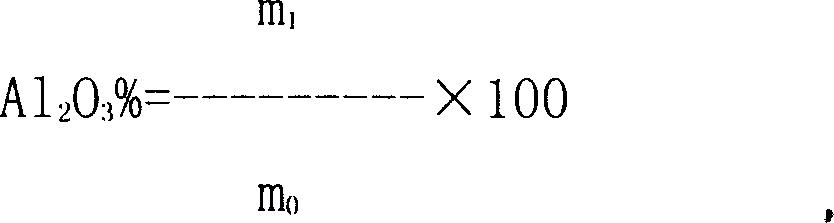

Method for measuring alumina in aluminium fluoride

ActiveCN100386617CAccurate measurementRapid determinationWeighing by removing componentPreparing sample for investigationAluminum fluorideFluoride products

The invention is the testing method of the alumina in Al fluoride and relates to the chemical analyzing and testing technology, especially the testing of alumina content in Al fluoride products. The invention comprises the collocation of the reagent, the black test, the refining of the samples, the measurement of the samples, the dissolving of the samples, the abstersion of the deposits, the burning condition of the deposits, the cooling of the deposits and the metage process. The invention can fast and precisely test the alumina content in Al fluoride and can accelerate the speed by 5 times and lower the cost by 80% and the analyzing error by 60%.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Process for recovering fluorine and zinc from steelmaking soot

ActiveCN105154681BAchieve recyclingNo emissionsIron halidesProcess efficiency improvementSteelmakingFluoride products

The invention relates to a technology capable of recycling fluorine and zinc from steelmaking soot. Two-segment acid leaching is adopted for enabling zinc, fluorine and iron in the steelmaking soot to be dissolved in a solution, and then a precipitation method is adopted for enabling harmful element fluorine in the solution to be separated from the solution; and defluorination filtering liquid enters a zinc smelting system, and according to the normal technology, electrolytic zinc is produced. Fluorine-contained precipitation is washed, filtered and dried, and then a fluoride product is obtained. after the technological treatment is carried out, the zinc in the steelmaking soot can be recycled in a manner of a product of excellent cathode zinc, the harmful element fluorine is comprehensively utilized in a manner of an auxiliary product, and the environment pollution caused in the long-term stacking and storing or take-out transportation process of the soot in the steelmaking industry can be eliminated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for comprehensively utilizing chemical byproduct single cryolite

ActiveCN102107900BLow impurity contentIncrease profitHydrogen productionAluminium fluoridesFluoride productsSodium aluminate

Owner:BAIYIN ZHONGTIAN CHEM

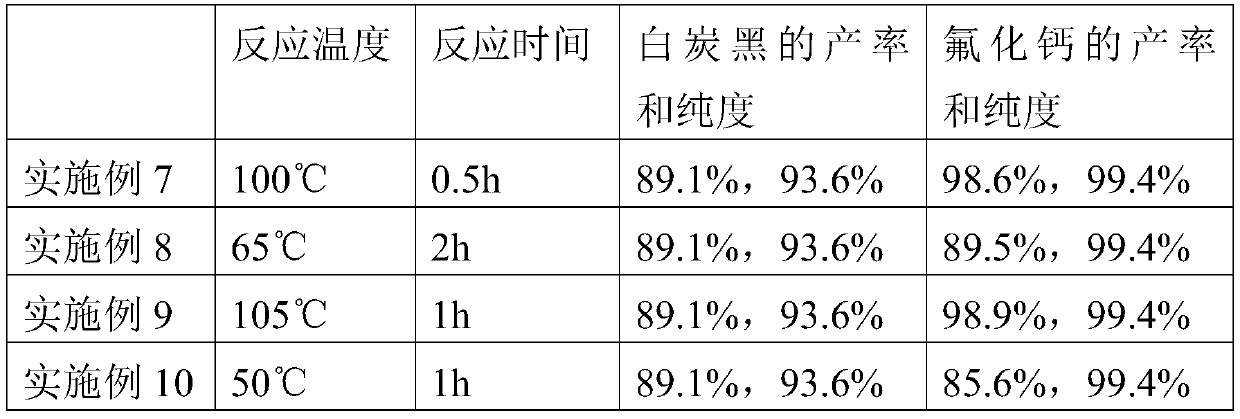

A method for preparing high-purity calcium fluoride and calcium chloride by using fluorine-chlorine mixed acid separated from dirty acid

ActiveCN111634934BIncrease added valueAchieving Sensitive JudgmentCalcium/strontium/barium chloridesCalcium/strontium/barium fluoridesFluoride productsChloride

The invention discloses a method for preparing high-purity calcium fluoride and calcium chloride by using fluorine-chlorine mixed acid separated from polluted acid, which comprises the following steps: (1) adding fluorine-chlorine mixed acid to a neutralizer to carry out a stage of neutralization , control the pH value of one section of neutralization end point to 1.5-3, obtain a section of neutralization slag and a section of neutralization filtrate through solid-liquid separation; (2) mix a section of neutralization slag and water to obtain an aqueous solution, then add a flocculant to settle and filter to obtain a high Pure calcium fluoride product and cleaning solution; (3) Collect the mixed solution obtained from the first-stage neutralization filtrate and cleaning solution, add a neutralizer to carry out second-stage neutralization and deep defluorination, and separate solid-liquid to obtain calcium chloride-rich solution and second-stage neutralization solution. and slag; (4) the calcium chloride-rich solution is subjected to cyclic evaporation crystallization and solid-liquid separation to obtain a high-purity calcium chloride product. The invention can recycle the fluorine-chloride mixed acid separated from the polluted acid step by step, and the obtained high-purity calcium fluoride has a purity of ≥99%, and the high-purity calcium chloride has a purity of ≥99%, both of which meet the national Class I standard.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com