Hamartite smelting separation process

A bastnaesite and process technology, which is applied in the field of bastnaestite smelting and separation to achieve the effects of improved recovery, simple process flow, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

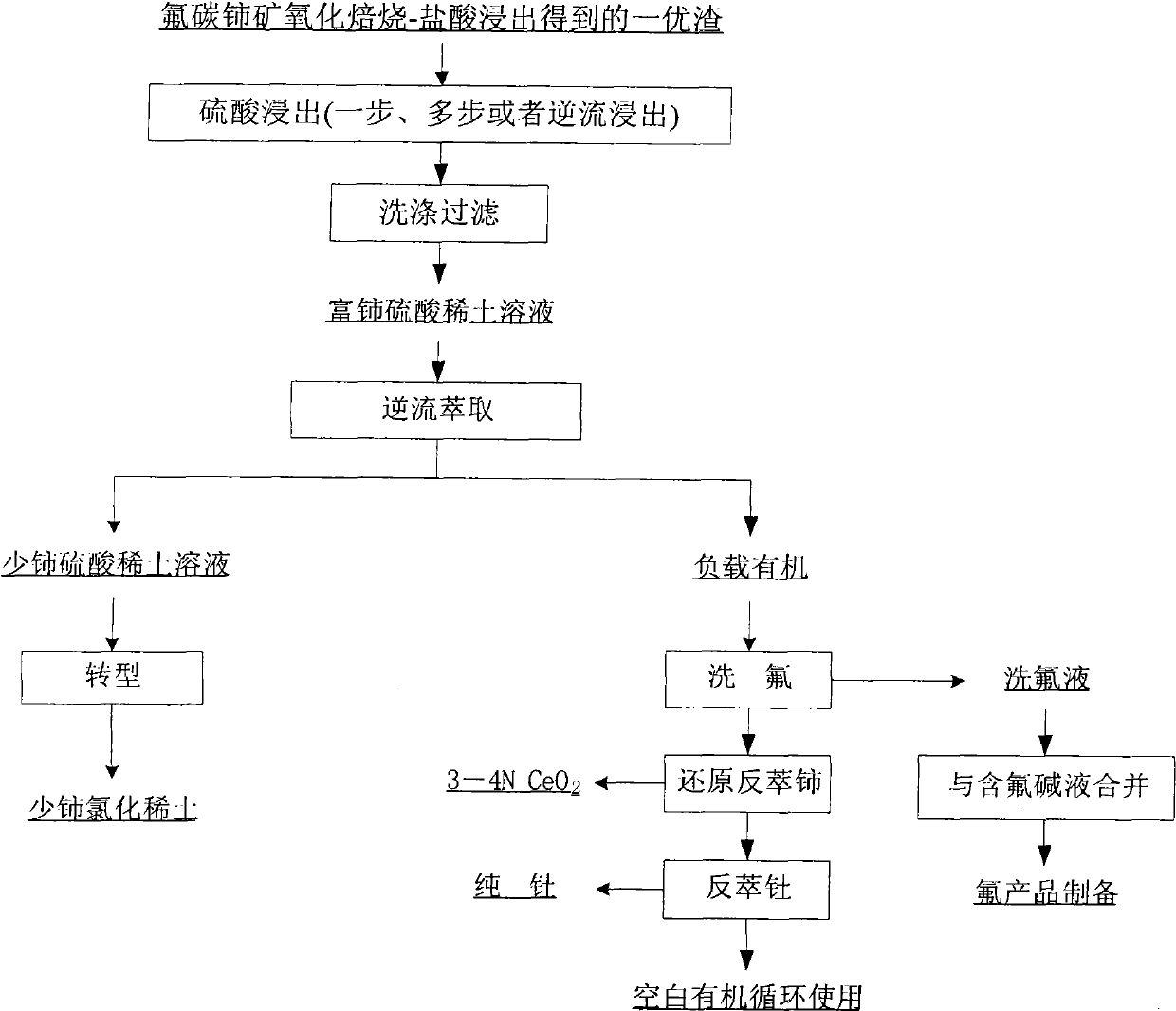

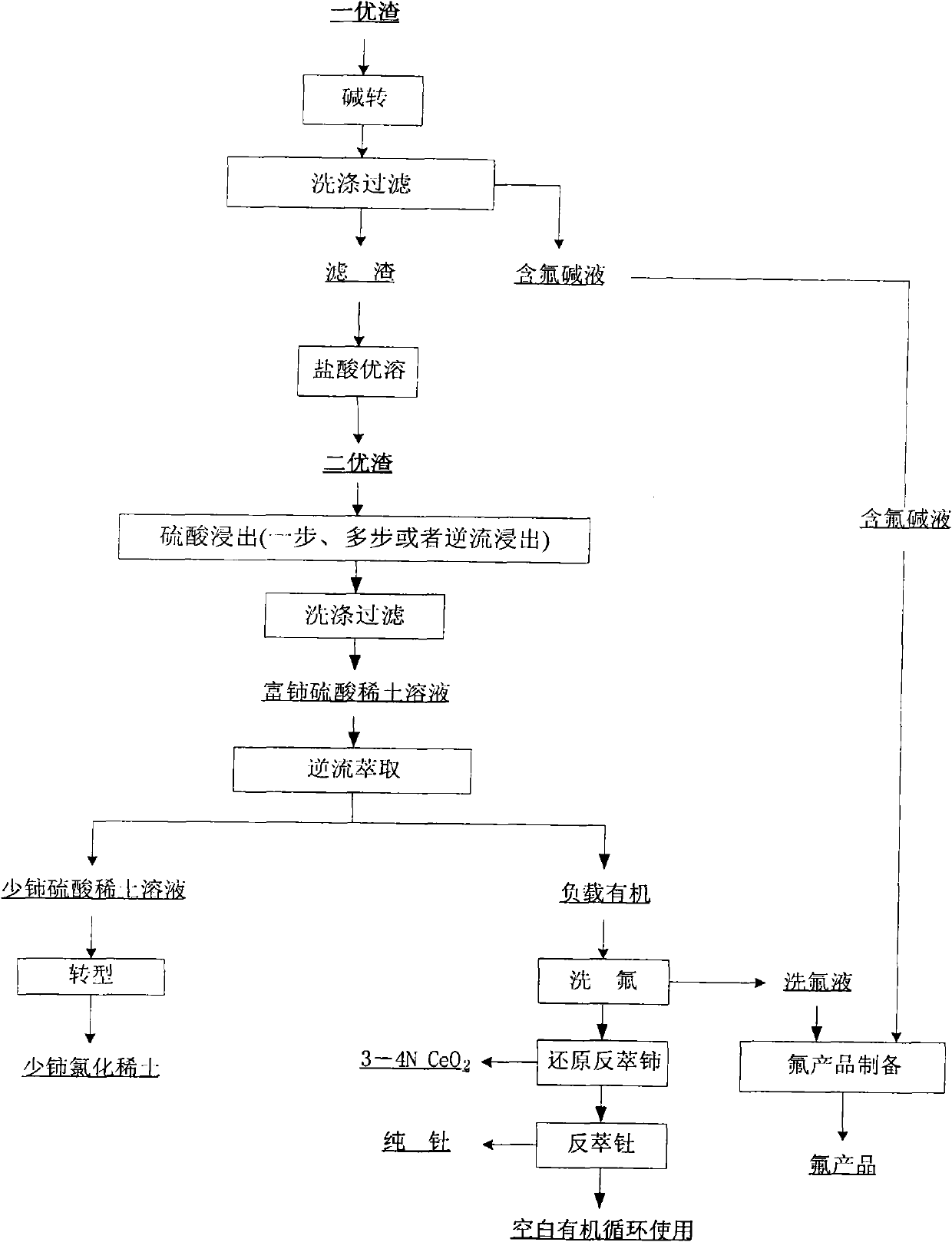

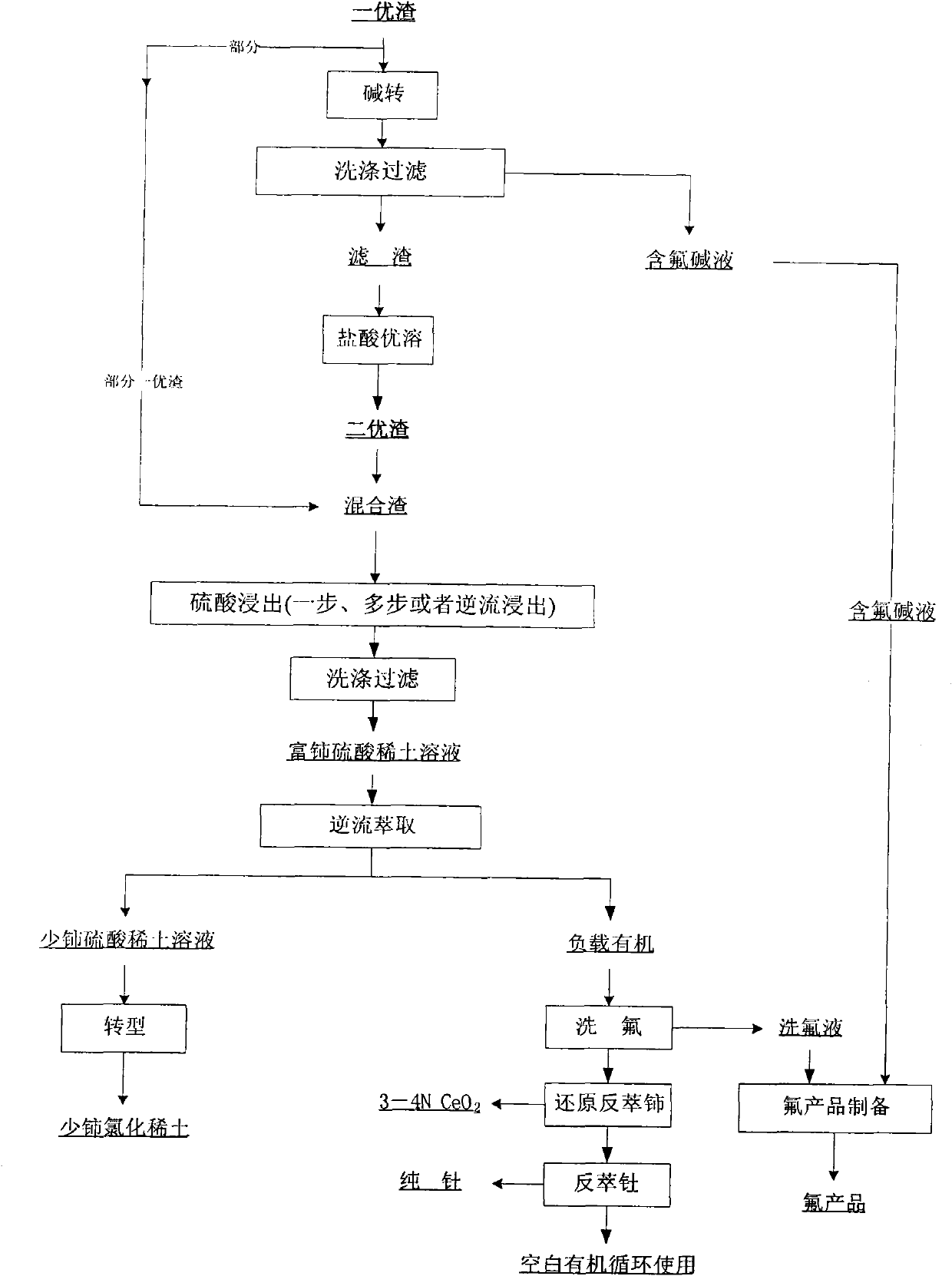

Method used

Image

Examples

Embodiment 1

[0034] Bastnaesite is leached with hydrochloric acid through oxidative roasting to obtain a high-quality slag 1 ton, wherein REO content is 30wt%, CeO 2 / TREO is 60%, the weight content of fluorine is 3.0wt%, ThO 2 The content is 0.1 wt%. Be that the sulfuric acid solution of 2 washes with pH, the chloride ion content in the excellent slag after washing is 0.01%, then at room temperature, be 12: 1 (weight ratio) with the sulfuric acid of 0.5mol / L with liquid-solid ratio, to A fine slag was leached for 10 hours, the rare earth leaching rate was 93%, and the obtained sulfuric acid rare earth solution was 14.4m 3 , wherein the rare earth content is 19.4g / L in terms of REO, of which CeO 2 / TREO is 85%, F - The concentration is 1.9g / L, ThO 2 It is 0.03g / L.

[0035] Rare earth sulfate solution using P 507 and P 204 The synergistic extractant is carried out in accordance with the ratio of 1.5:1 for 5-stage countercurrent extraction, extracting cerium (IV), thorium (IV), and ...

Embodiment 2

[0039] Bastnaesite is leached with hydrochloric acid through oxidative roasting to obtain 1 ton of excellent slag, wherein REO content is 75wt%, CeO 2 / TREO is 85%, fluorine content is 10wt%, ThO 2 Content is 0.8wt%, is 4 sulfuric acid solution with pH, washes, and the chloride ion content in the excellent slag after washing is 0.1%, then under 80 degree, is 5.5 with the sulfuric acid of 4mol / L with liquid-solid ratio: 1 (weight ratio) leaching a high-quality slag, leaching for 1 hour, filtering, washing the filter cake with water, the leaching rate of rare earth is 95%, and the rare earth content in the rare earth sulfate solution obtained is 108g / L in terms of REO, wherein CeO 2 / TREO is 80%, F - The concentration is 14.4g / L, ThO 2 The concentration is 1.15g / L.

[0040] The obtained sulfuric acid rare earth solution adopts P 507 and P 204 The synergistic extractant is subjected to 10-stage countercurrent extraction according to the ratio of 8:1, cerium (IV), thorium (...

Embodiment 3

[0044] Bastnaesite is leached with hydrochloric acid through oxidative roasting to obtain a high-quality slag 1 ton, wherein REO content is 40wt%, CeO 2 / TREO is 85%, fluorine content is 4.5wt%, ThO 2 Content is 0.3wt%, with the sulfuric acid solution that pH is 2, wash, and the chloride ion content in the slag after washing is 0.01%, then under 100 ℃, with the sulfuric acid of 6.0mol / L, liquid-solid ratio is 2 : 1 (weight ratio) leaching a fine slag, leaching 2 hours, filtering, water washing filter cake, the leaching rate of rare earth is 95%, and rare earth content in the sulfuric acid rare earth solution obtained is 158g / L with REO, wherein CeO 2 / TREO is 85%, F - The concentration is 17.8g / L, ThO 2 The concentration is 1.19g / L.

[0045] Rare earth sulfate solution using P 507 Carry out 6-stage countercurrent extraction according to the ratio of 12:1, cerium (IV), thorium (IV), fluorine and iron are extracted into the organic phase, and the trivalent rare earths are le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com