Patents

Literature

164results about How to "Reduce acid and alkali consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

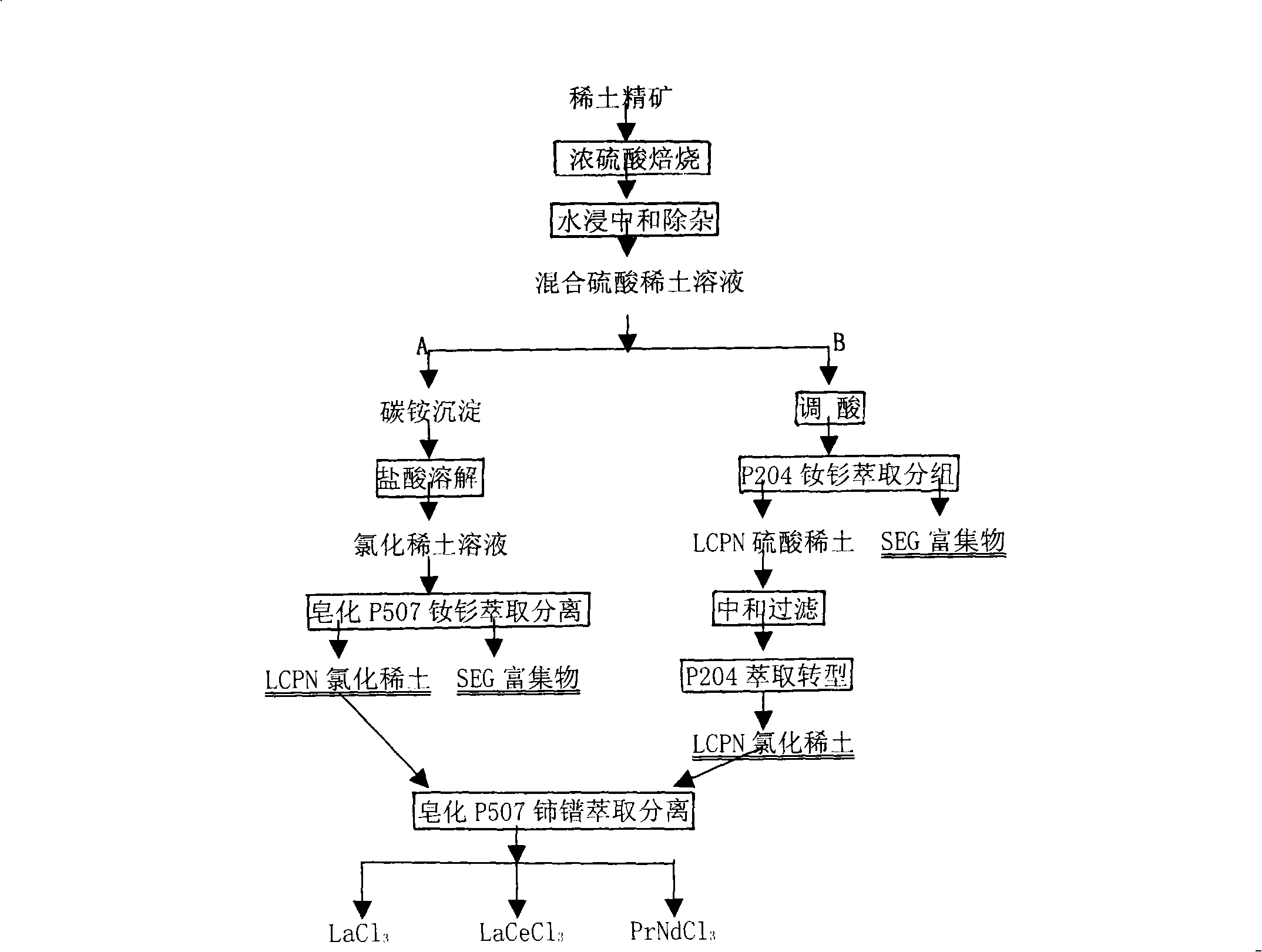

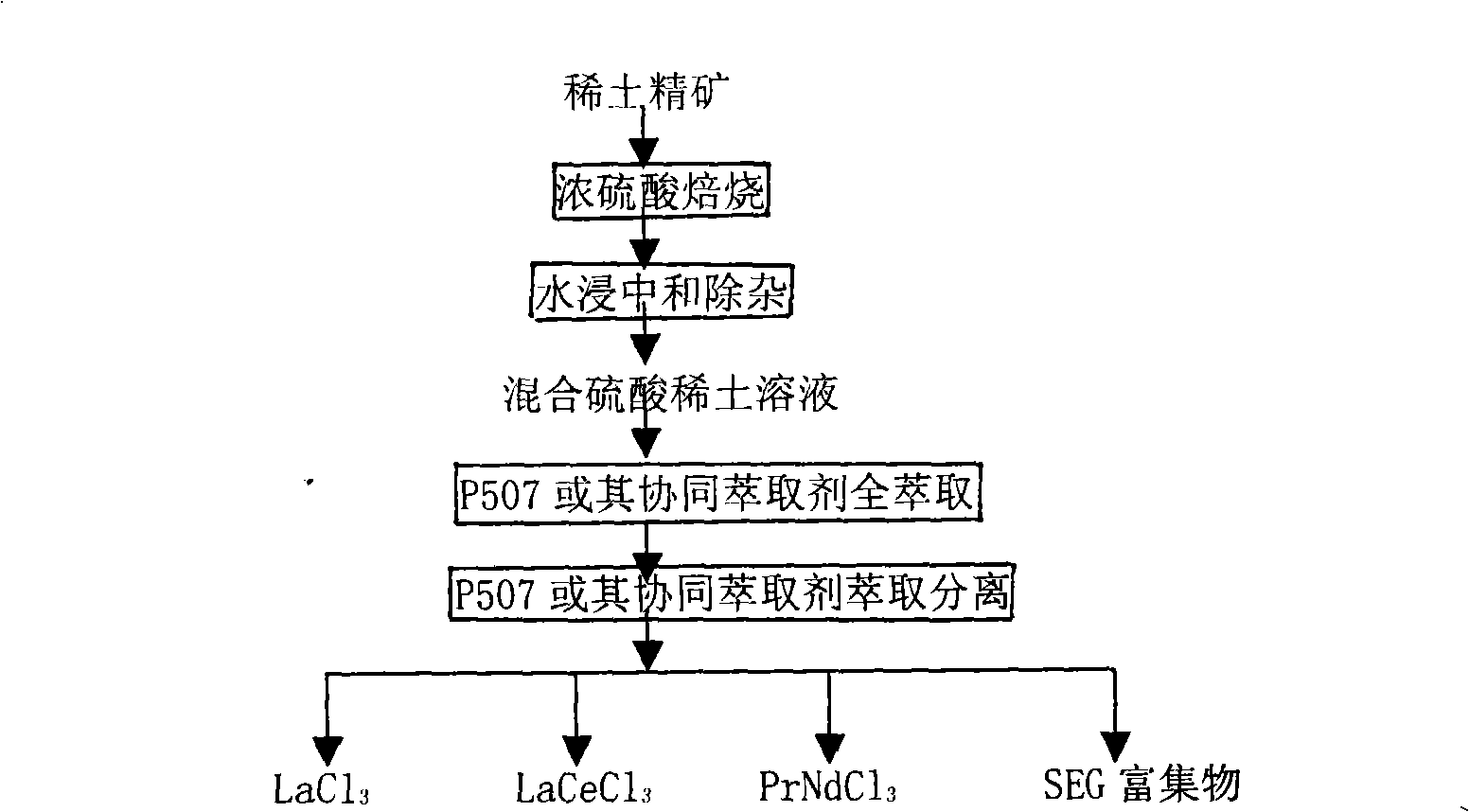

Process for solvent extraction separation purification of rare earth element

ActiveCN101319275AStripping is easyReduce acid and alkali consumptionProcess efficiency improvementRare-earth elementNitrate

The invention provides a process method for separating and purifying rare earth elements by solvent extraction. The method takes a mixed rare earth sulfate solution obtained from a rare earth ore treated by sulphuric acid as a raw material, directly adopts a nonsaponifiable P507 extraction agent or a synergistic extraction agent containing the P507 to completely extract rare earth in a material liquid into an organic phase, and then takes the organic phase as a rare earth material liquid to extract, separate and purify the rare earth or directly backextract to produce mixed chlorinated rare earth or rare earth nitrate. The process method is simple and flexible, does not saponify the organic phase during the extraction and separation process, does not produce ammonia nitrogen waste water, is easy to backextract middle and heavy rare earths, and has less consumption of acid and base and low production cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

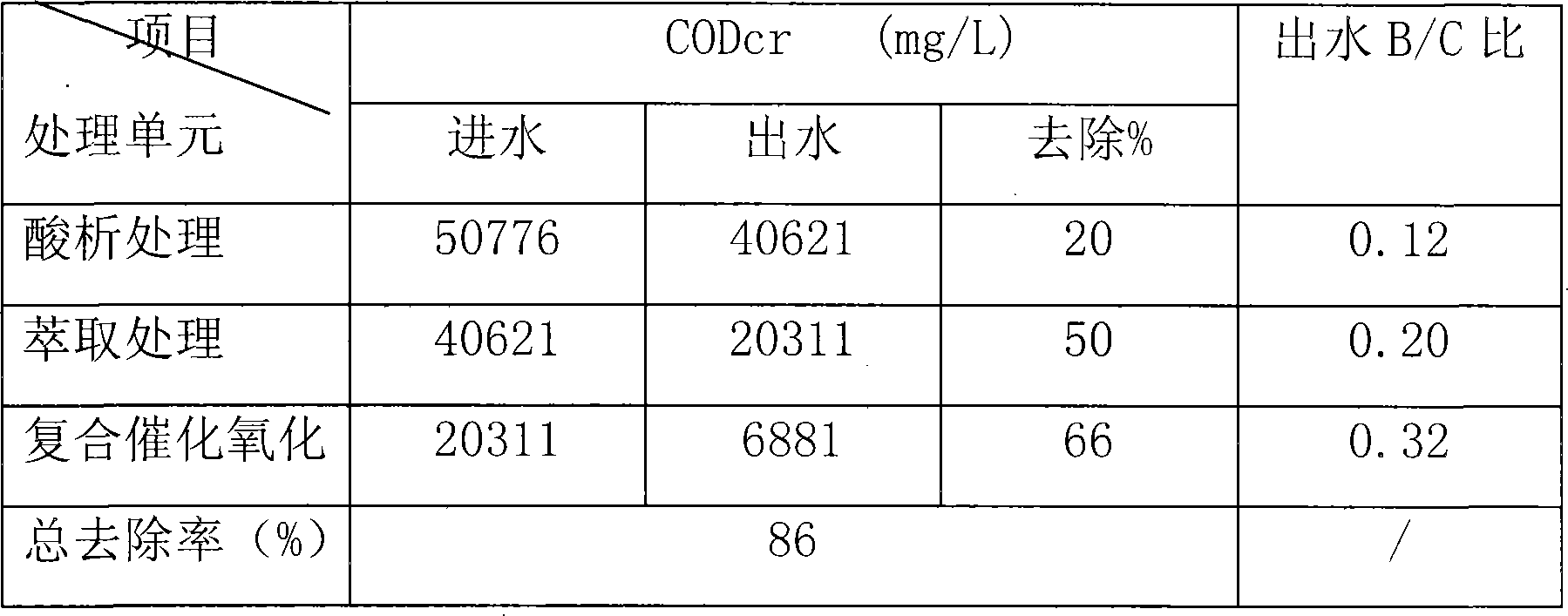

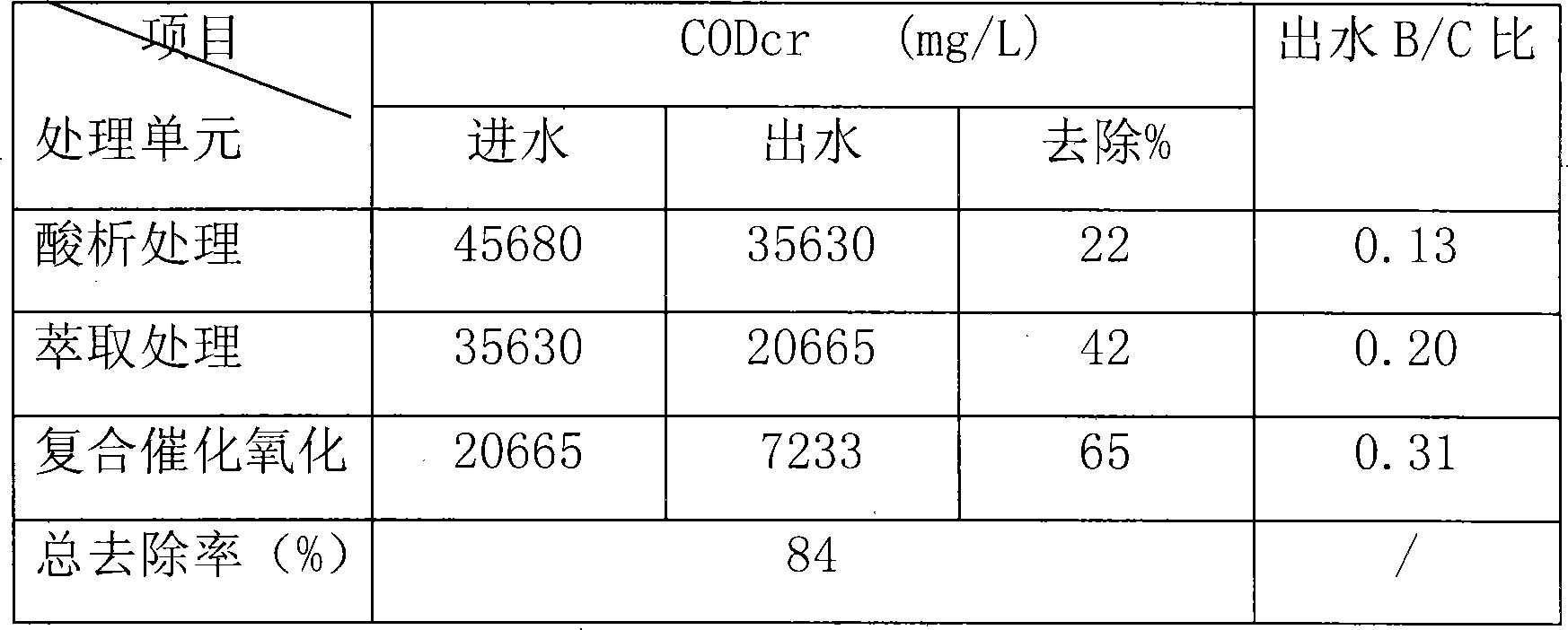

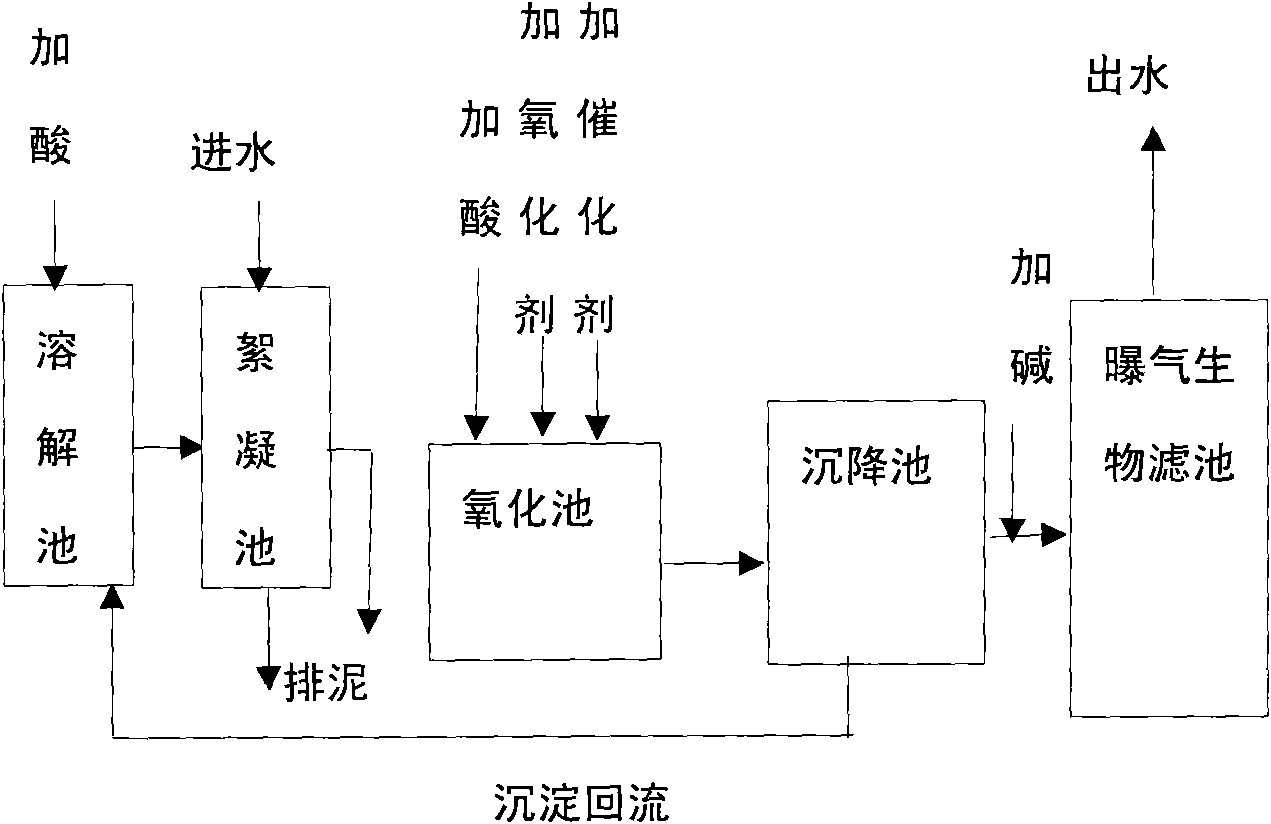

Chlopyrifos pesticides waste water treatment process

InactiveCN101172728APromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCatalytic oxidationPendimethalin

The invention discloses a treatment process of waste water polluted by the pesticide of Dursban, and the process includes the procedures of acid eduction, complexation and extraction, Fenton oxidation and catalytic oxidation. The invention is characterized in that Dursban waste water and herbicide Pendimethalin waste water are comprehensively treated, thereby achieving the proposal of waste controlled by the waste, decreasing the load of organic pollutant being hard to be graded in the waste water, improving the biological degradability of the waste water, removing the pollutant from the waste water, and increasing the biochemical performance of the waste water. Besides, the invention has the advantages of safe and advanced technique, clean operation and low waste water treatment cost.

Owner:山东华阳农药化工集团有限公司

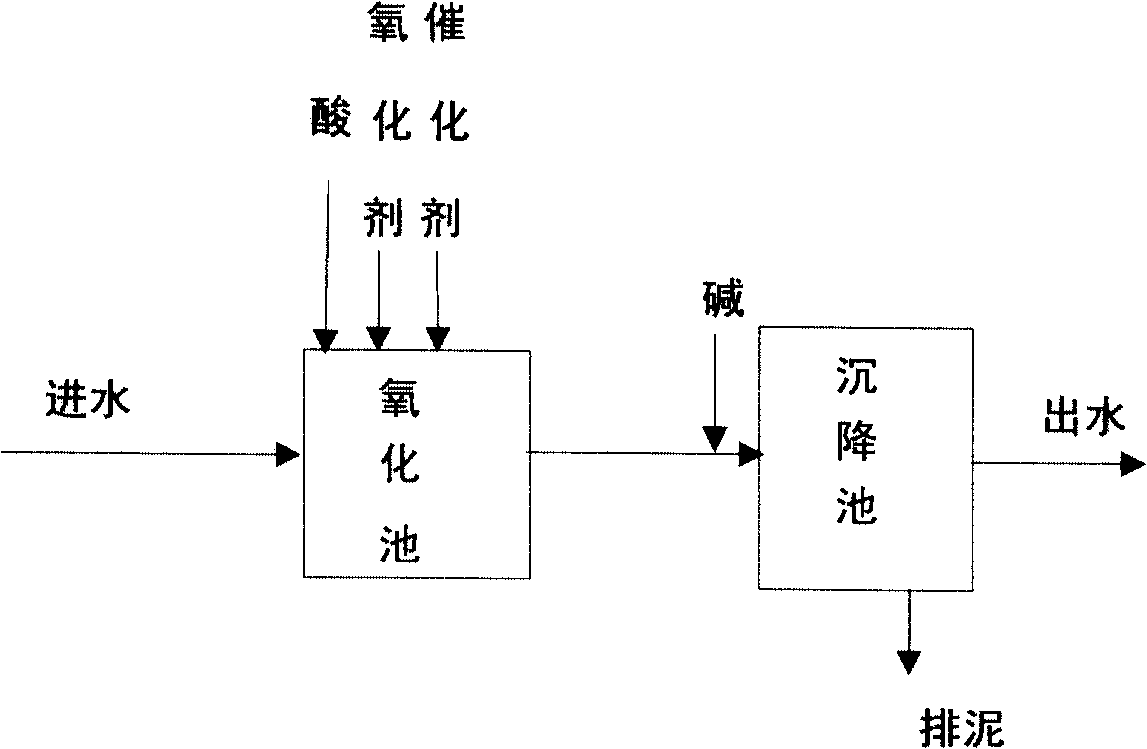

Method for processing waste water by fenton oxidation

InactiveCN101570368AReduce the amount addedReduce consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationWater processing

The invention relates to a method for processing waster water by fenton oxidation, comprising the following steps: (1) enabling alkaline waste water to be processed to enter a flocculation pond so as to be flocculated and precipitated; (2) enabling the flocculated waste water to enter an oxidation pond so as to be oxidized for fenton oxidation reaction; (3) enabling oxidized waste water to enter a precipitation pond so as to be precipitated; (4) adding alkali to supernatant discharged from precipitated waste water to adjust the pH value of the waste water till the waste waster is neutralized, and directly discharging the waste waster or processing the waste water by the next step; and (5) enabling acid precipitate obtained in the step (4) to return to a mixer in a refluxing way to be mixed with total or part of waste water to be processed. With the method for processing waster water through fenton oxidation, the consumption of acid and the alkali can be greatly reduced and content of salt in the waste water can be reduced so that the waste water processing effect is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

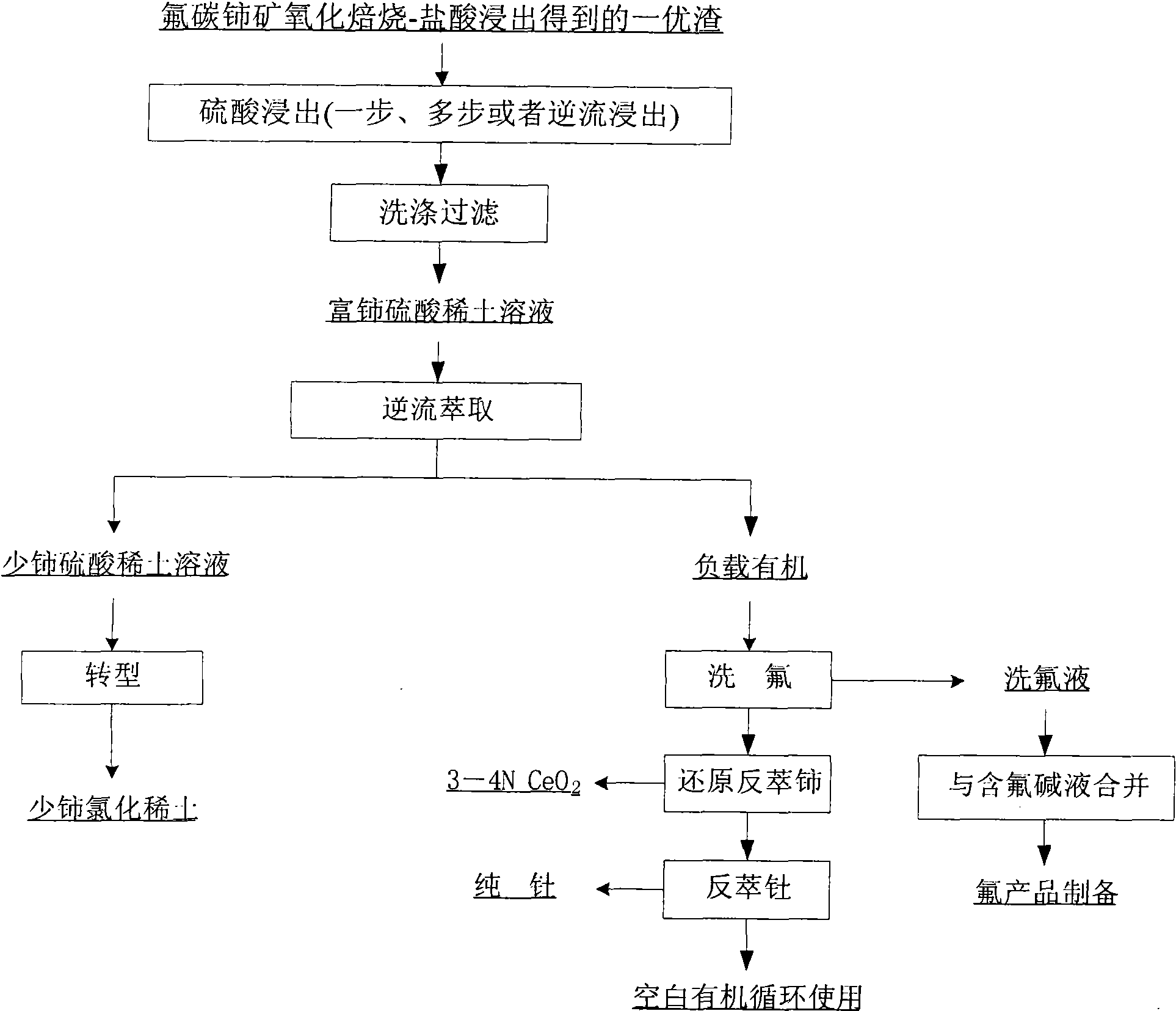

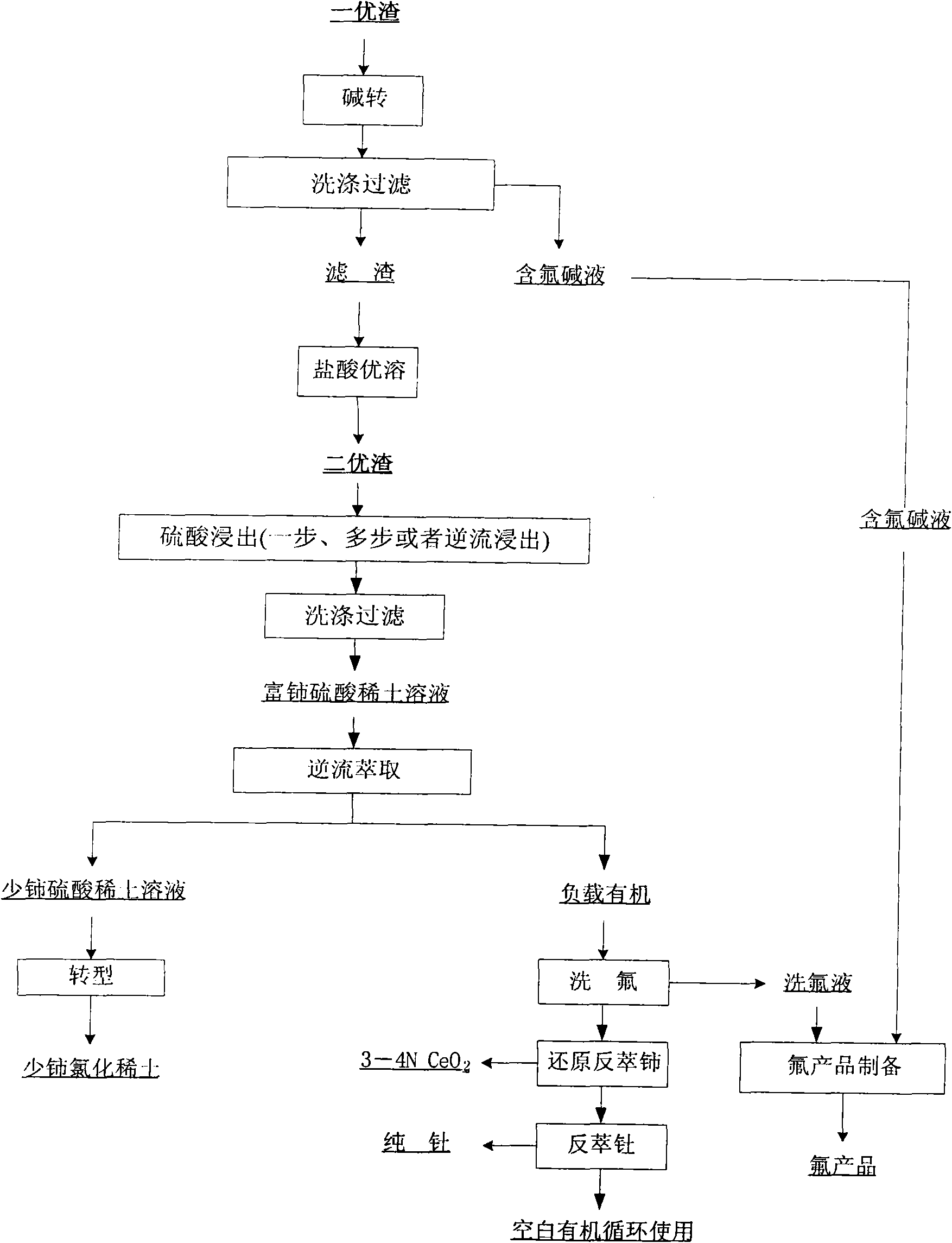

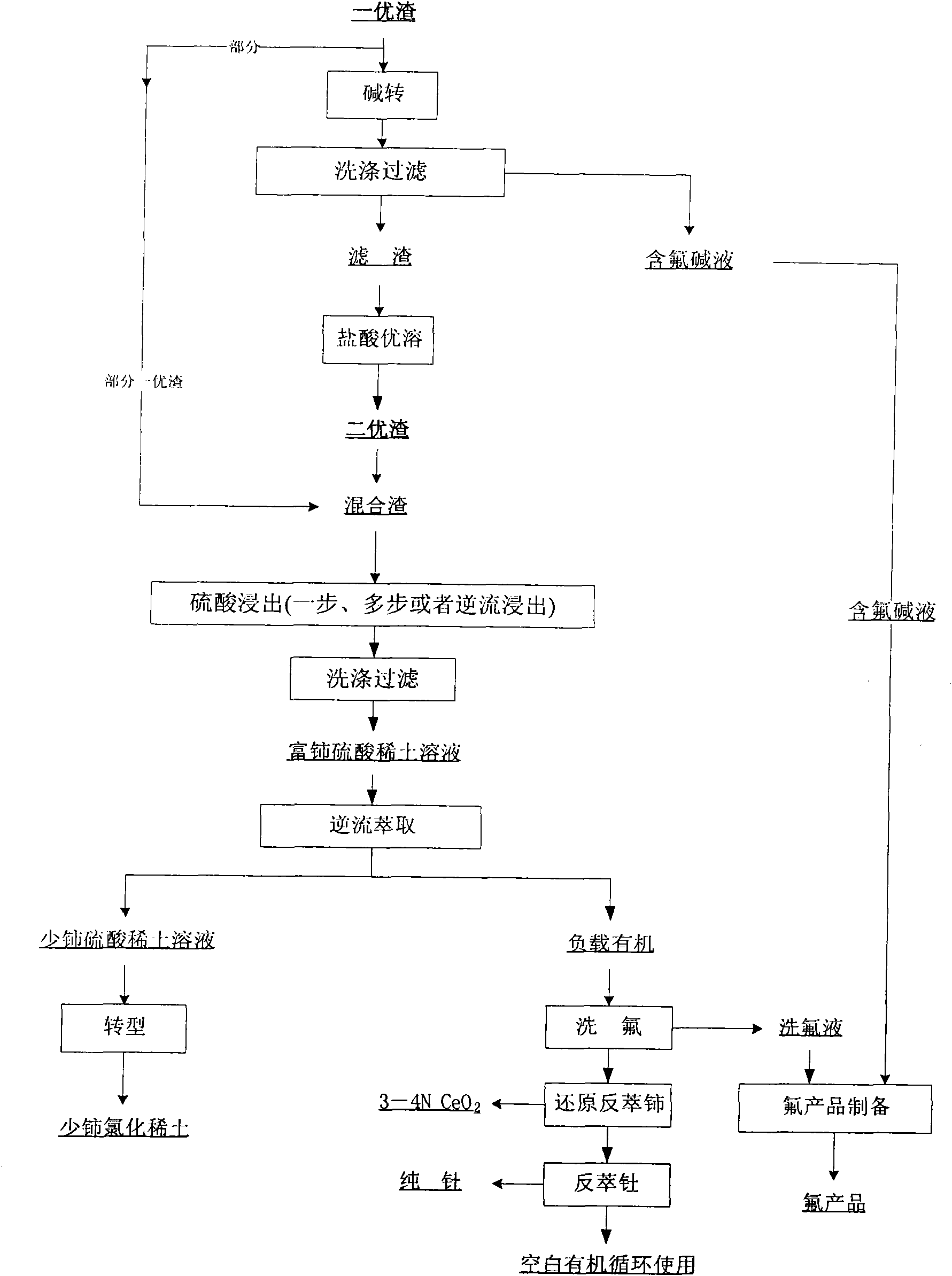

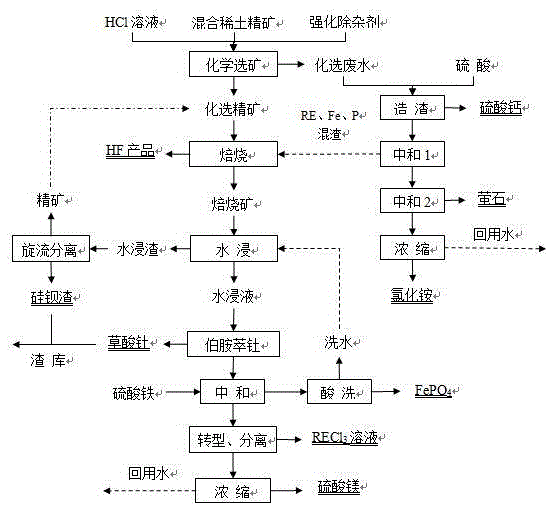

Hamartite smelting separation process

ActiveCN102146512AAchieve recyclingIncrease the added value of resourcesFluoride preparationProcess efficiency improvementFluoride productsSlag

The invention discloses a hamartite smelting separation process. First optimal slag or / and second optimal slag mainly containing cerium (IV), thorium (IV) and fluorine, obtained by oxidative roasted salt acid leaching of hamartite, is / are used as raw materials, and extraction and separation of rare earth are performed. The process comprises the following steps of: 1) leaching the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the second optimal slag obtained by alkali conversion-hydrochloric acid dissolution of the first optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; or leaching the mixed slag of the first optimal slag and the second optimal slag by using sulfuric acid to obtain sulfuric acid-rare earth solution and filter residue; 2) performing extraction separation on the sulfuric acid-rare earth solution obtained in the step 1) to obtain a rare earth compound,fluorine washing liquor, a pure cerium product and a thorium product; and 3) synthesizing a fluoride product by using the fluorine-containing alkali wastewater obtained by alkali conversion in the step 1) and the fluorine washing liquor obtained by the extraction separation in the step 2). The process has the advantages that: the recovery rate of the rare earth is obviously improved, the fluorineand the thorium (IV) are effectively reclaimed in a product form, the high-purity cerium product is obtained, reclamation of the rare earth and associated resources is realized, and the additional values of the resources are improved; and the process flow is simple, the consumption of acid and alkali is low, the production cost is low, and the process is environmentally-friendly.

Owner:GRIREM ADVANCED MATERIALS CO LTD

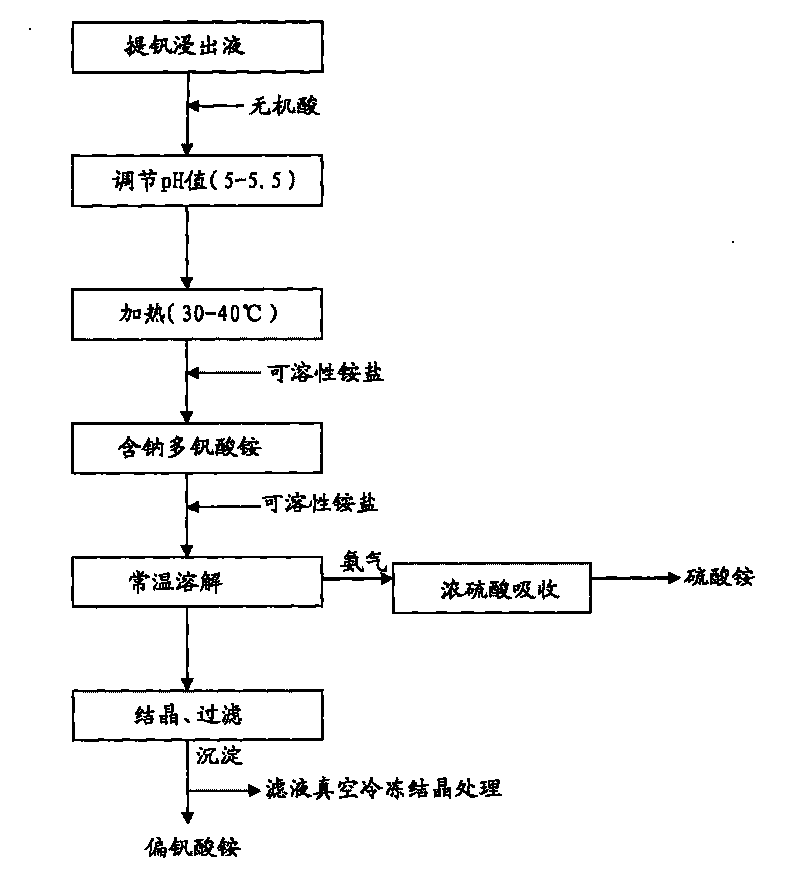

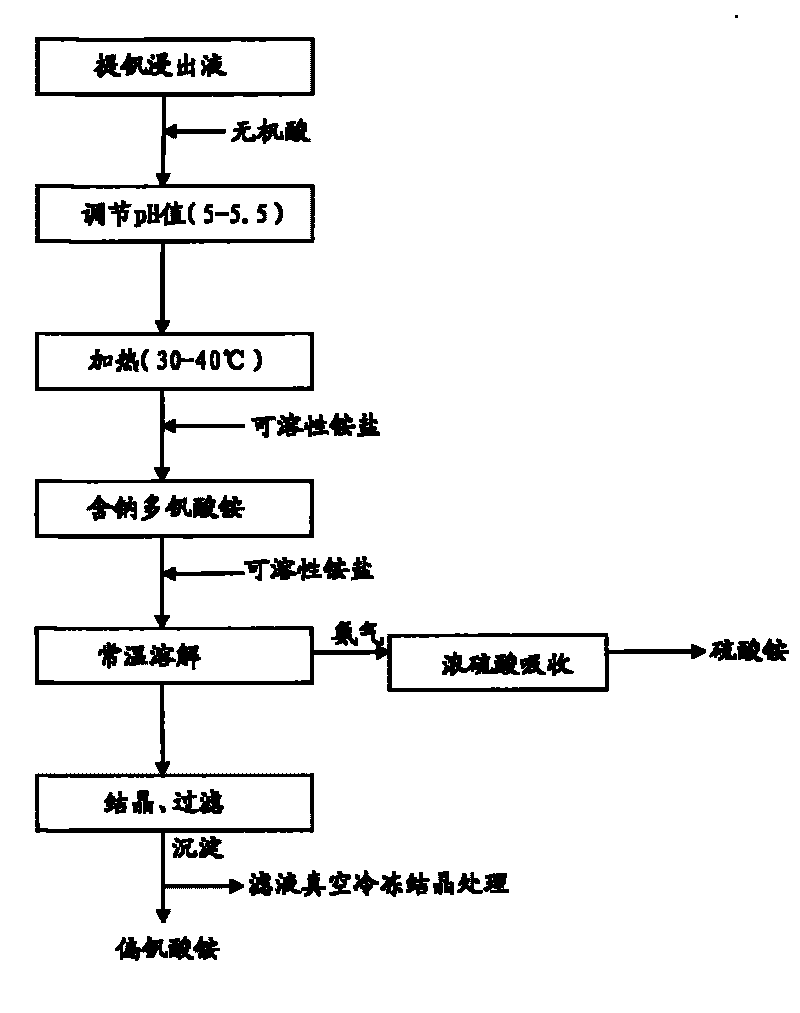

Method for preparing ammonium metavanadate from vanadium extraction leaching solution

InactiveCN101748297AIncrease sedimentation rateIncrease productivityVanadium compoundsRoom temperatureAmmonium metavanadate

The invention discloses a method for preparing ammonium metavanadate from a vanadium extraction leaching solution, comprising the following steps of: adjusting the pH value of the vanadium extraction leaching solution to 5-5.5 by using inorganic acid, then heating to the temperature of 30-40 DEG C, subsequently adding a soluble ammonium salt into the solution according to the mass ratio of NH4+:V=2.0-3.0, fully and uniformly stirring, and obtaining ammonium polyvanadate containing sodium after the reaction is finished; putting the obtained ammonium polyvanadate containing sodium into a sealed reactor, adding the soluble ammonium salt into the reactor according to the mol ratio of NH4+:V=3.0-5.0, slowly, uniformly stirring under the room temperature by controlling the pH value in the range of 7.5-8.5 and filtering the obtained solution after the reaction is finished to obtain an ammonium metavanadate solid.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

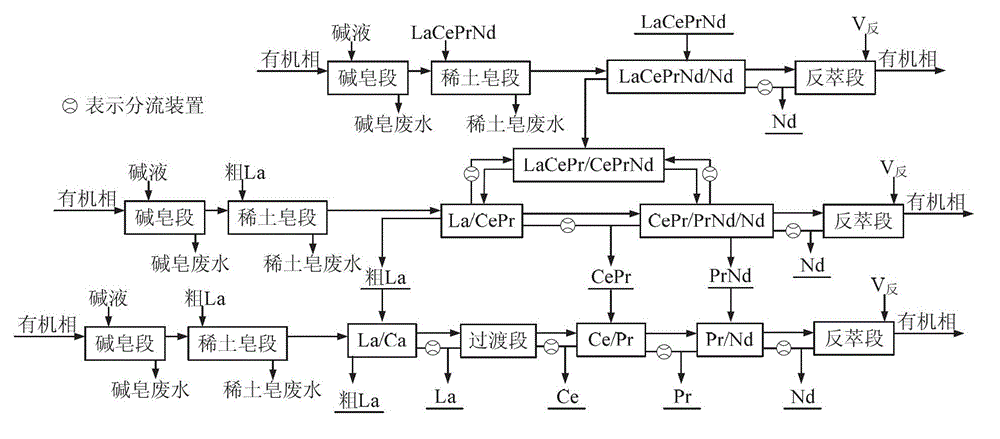

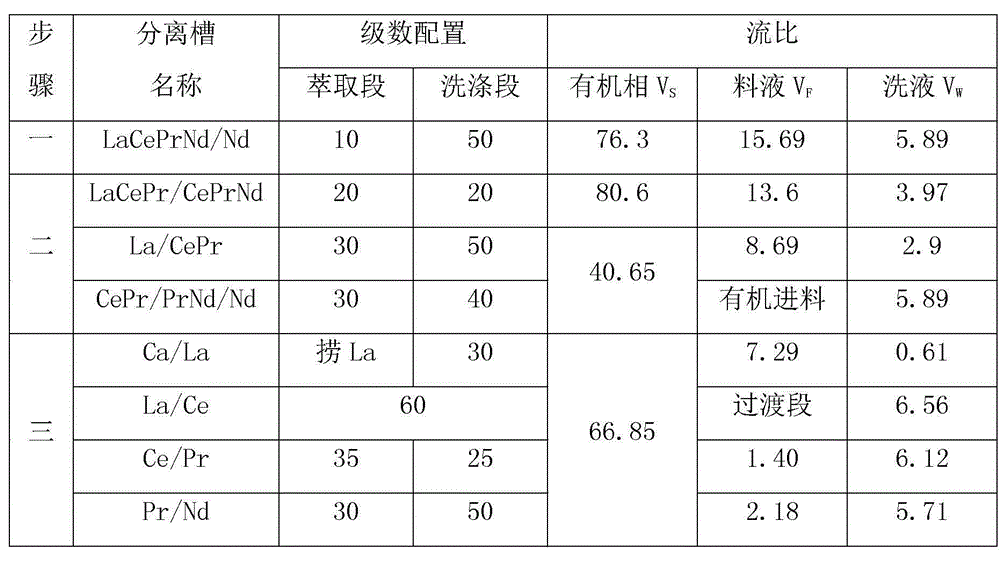

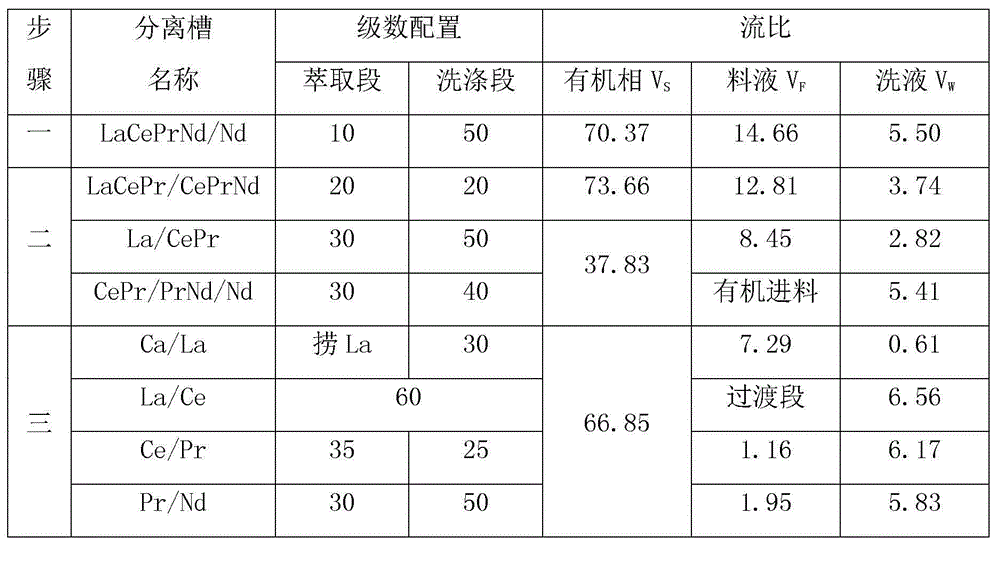

Method for extracting and separating light rare earth

ActiveCN102912157AEmission reductionAdvanced and reasonable processProcess efficiency improvementMultiplexingRare-earth element

The invention discloses a method for extracting and separating light rare earth and aims at providing an extracting and separating technology with low separation cost and less one-time investment for the light rare earth. The key points of the technical scheme provided by the invention are as follows: light rare earth materials containing La, Ce, Pr and Nd elements are separated into single elements of the La, the Ce, the Pr and the Nd; and due to the utilization of a fuzzy separation technology, a separation module combined linkage technology, a displacement extraction technology, an extraction amount and washing mount multiplexing technology, an organic feeding technology, a three-outlet technology, a washing and acid regurgitation operating technology, a rare earth washing technology, a diversion technology, an organic phase extraction tank continuous saponification technology and an extraction tank continuous rare earth saponification technology for optimization, more materials filled in the tank for extracting and separating the light rare earth are saved, the production cost is lower and less waste water is produced. The method disclosed by the invention is used for extracting and separating light rare earth elements and belongs to a rare earth separation technology.

Owner:广东省富远稀土有限公司

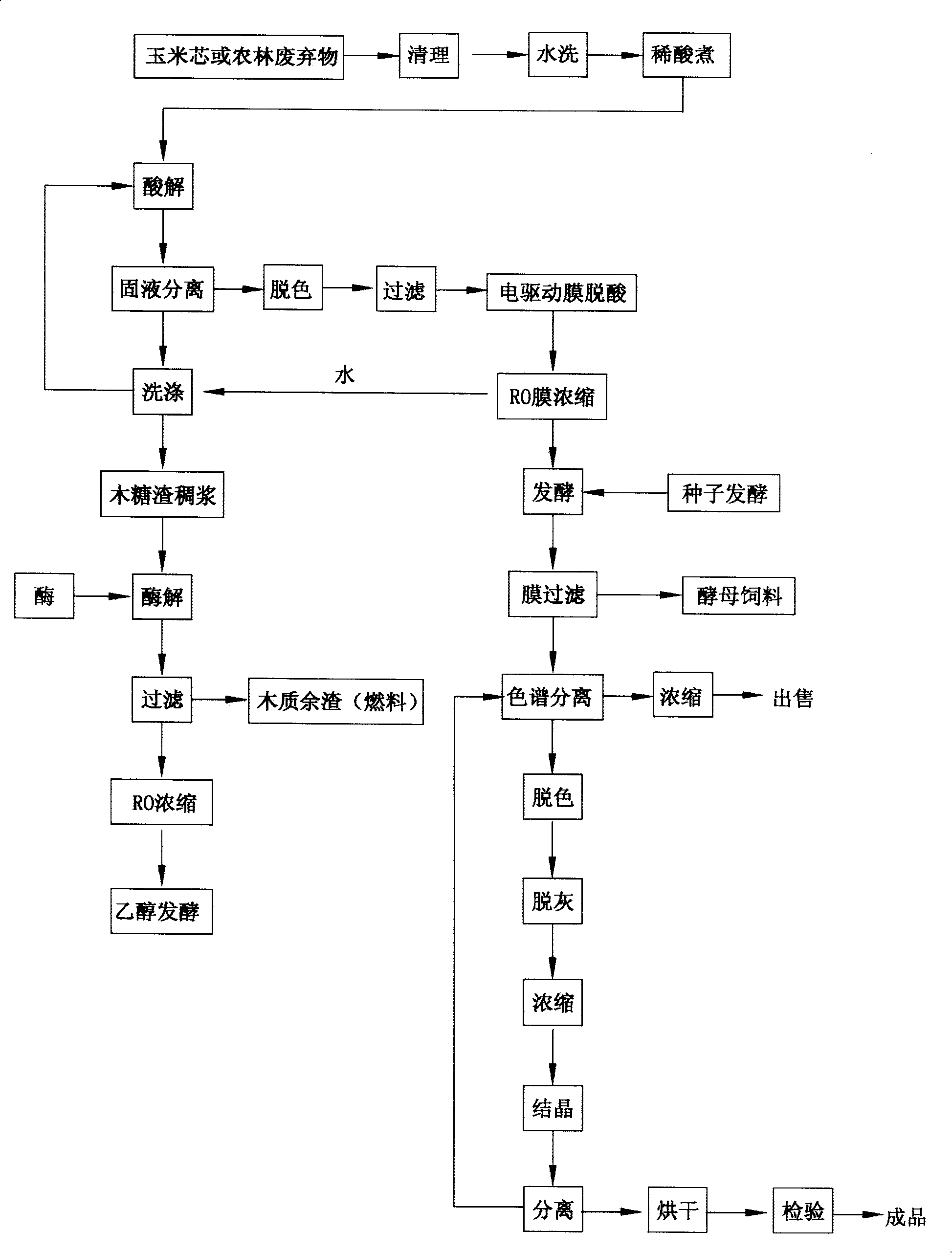

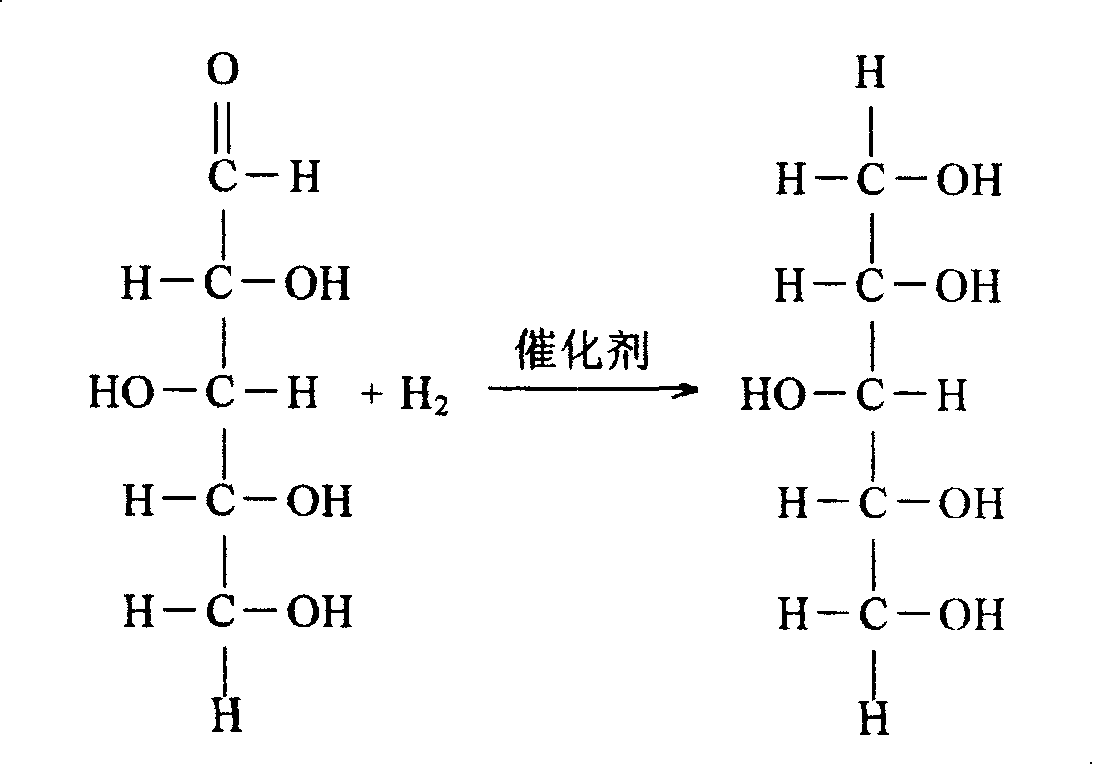

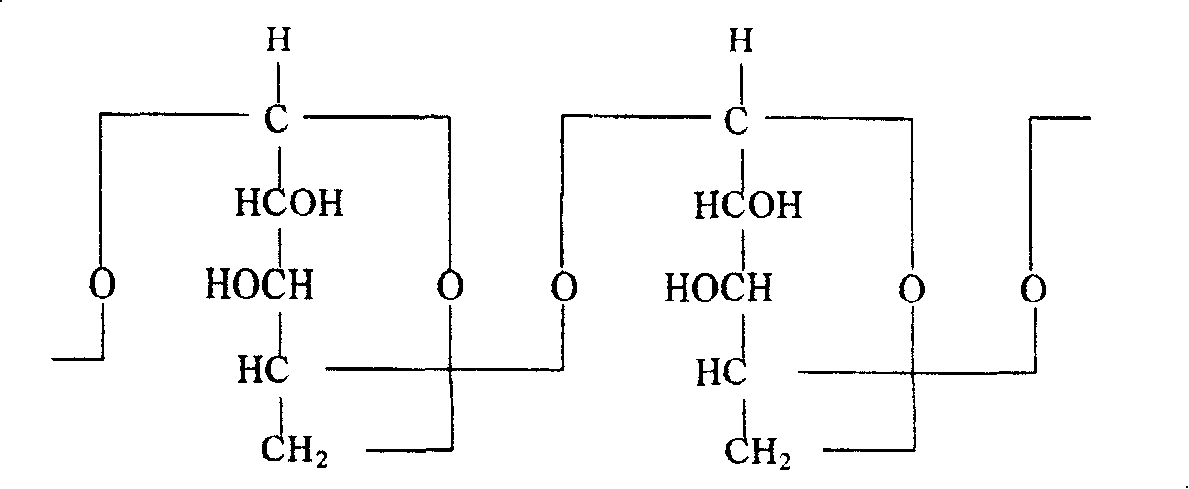

Process for preparing xylitol by using corn core or agriculture and forestry castoff

ActiveCN101220381AEliminate the crystallization processIncrease profitMicroorganism based processesFermentationChromatographic separationFiltration

The invention provides a xylitol production method by utilizing corn cobs or agro-forestry waste, such as, stalks, as raw materials. The method includes the pretreatment of the raw materials, the diluted acid treatment of the raw materials and the solid-liquid separation, the ingredients of obtained liquid phase are treated with decolorization, filtration, deacidification and RO concentration, then a yeast is utilized for fermentation so as to obtain a xylitol. A relatively pure xylitol liquid is obtained after the bacteria removal, the concentration and the chromatographic separation of the fermentation liquid, then a solid finished product xylitol is obtained by decolorization, ash removal, concentration, crystallization, separation and drying, and a crystal parent solution returns to the chromatographic separation. In addition, the invention carries out the pulp conditioning of solid phase components which are obtained by the solid-liquid separation after acidolysis, then the solid phase components are used for ethanol fermentation after the enzymolysis; the lignin residue which is obtained after the filtration of the products of the enzymolysis can be taken as fuel or be used for the development of the deep-processed products of the lignin. The xylitol production method of the invention can greatly reduce the cost of the industrial production of the xylitol and lead all the components of the raw materials to be utilized effectively.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

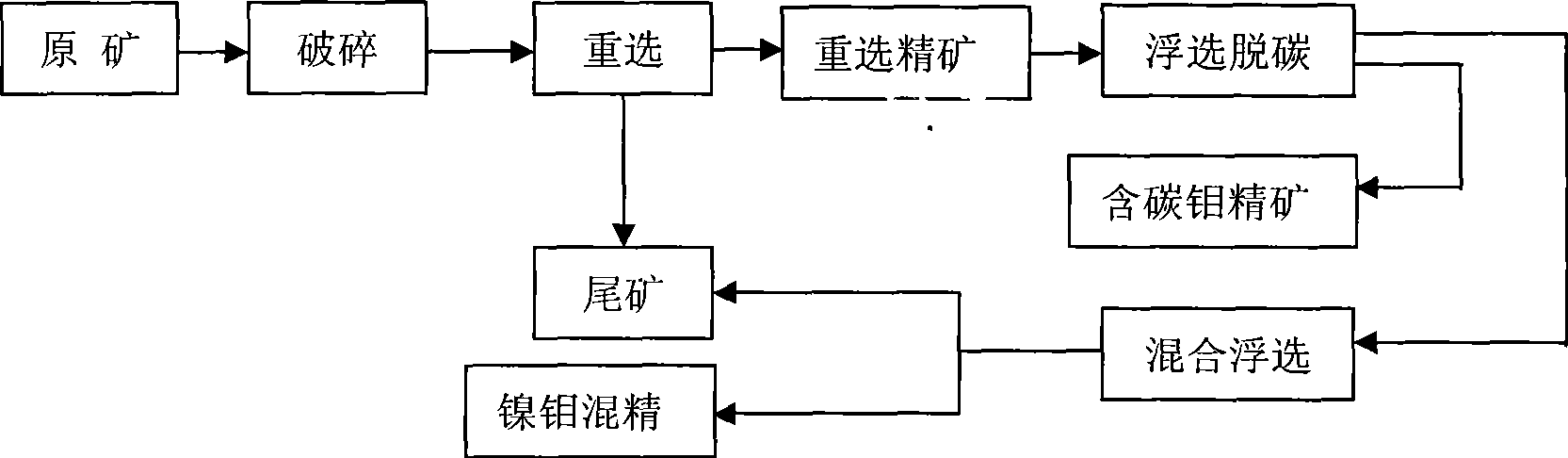

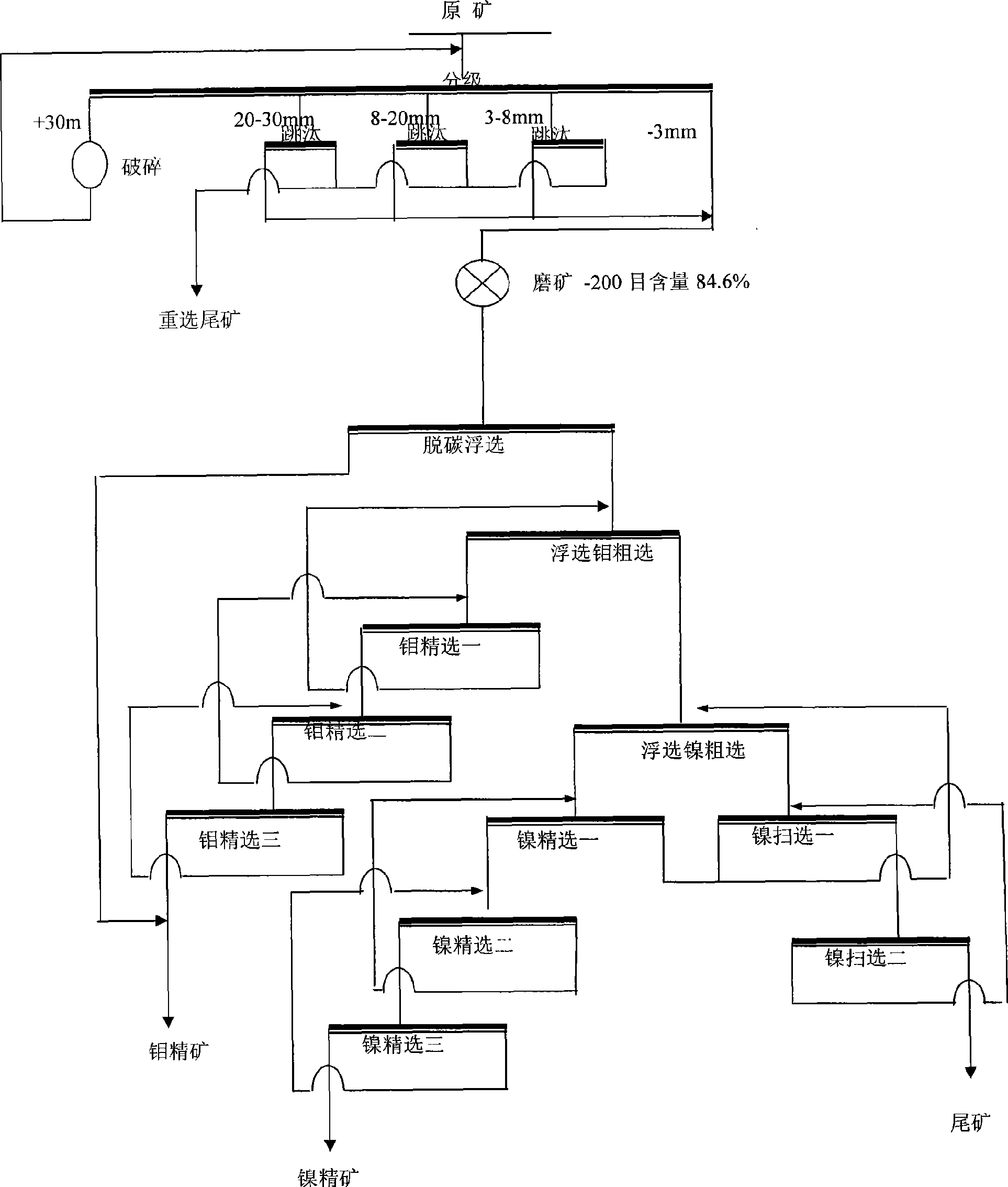

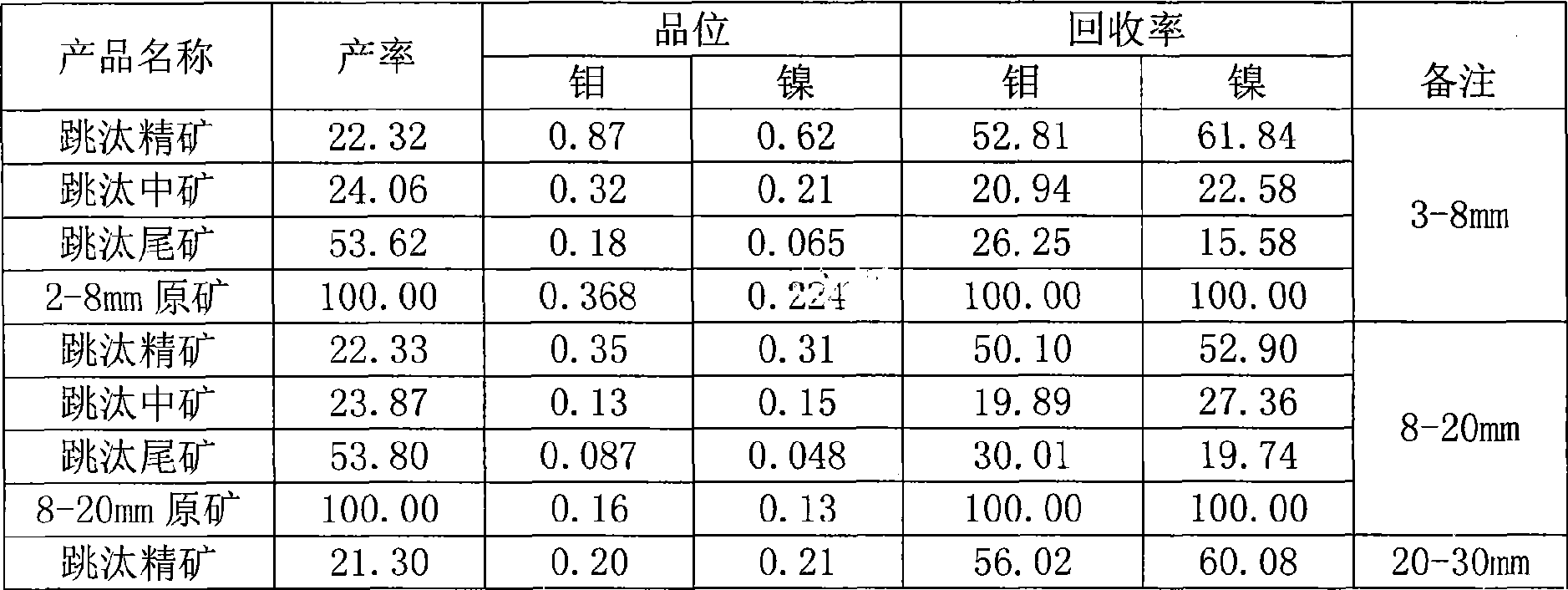

Mineral separation process of high-carbon molybdenum-nickel ore

The invention provides a beneficiation method for a high-carbon molybdenum nickel ore, which adopts floatation decarbonization so as to eliminate the influence of high-content carbon substances on subsequent nickel floatation. Furthermore, the beneficiation process adopts sieve classification with jigging and tail throwing so as to enhance the floatation and selected grade, then rough concentrates are selected again and treated by floatation after being ground, and the ore concentrates are selected again with tail throwing to enhance the floatation and selected grade without ore grinding. The invention can greatly reduce the floatation quantity, has good beneficiation index and provides a new way for developing a low-grade high-carbon molybdenum nickel ore.

Owner:HUNAN RES INST FOR NONFERROUS METALS

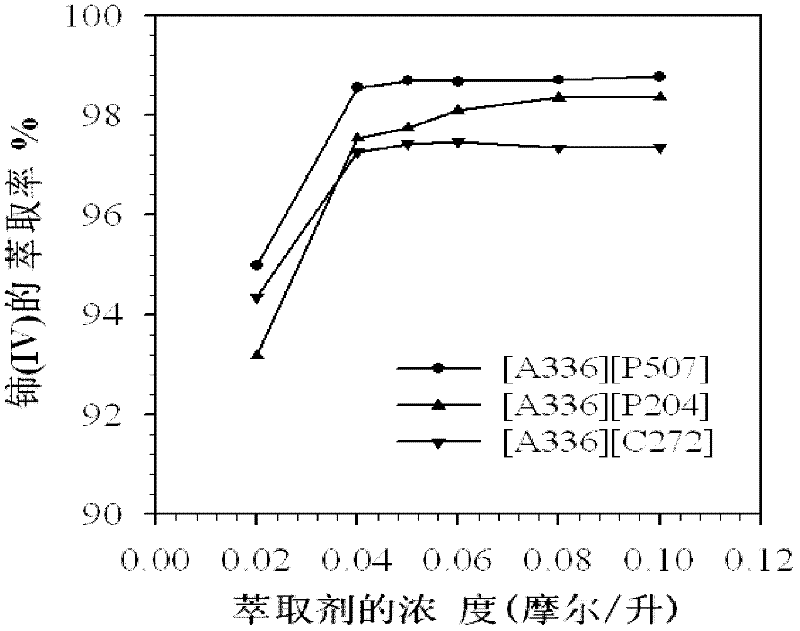

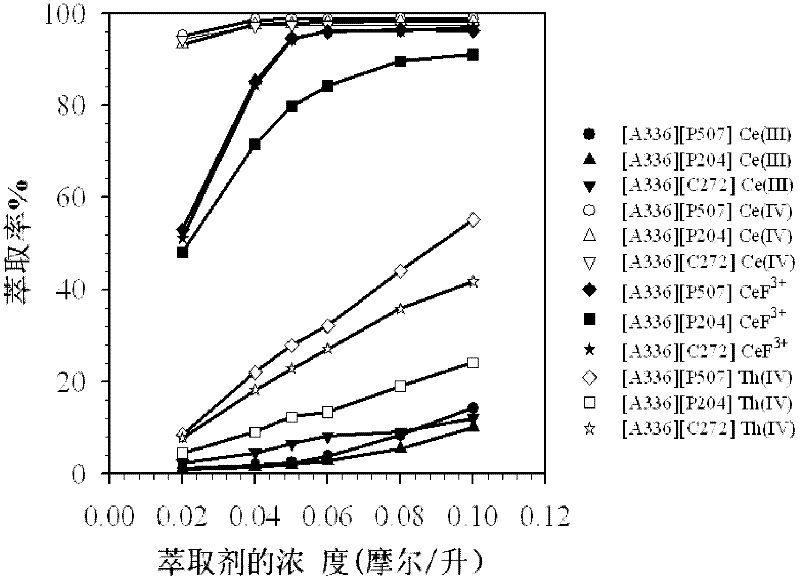

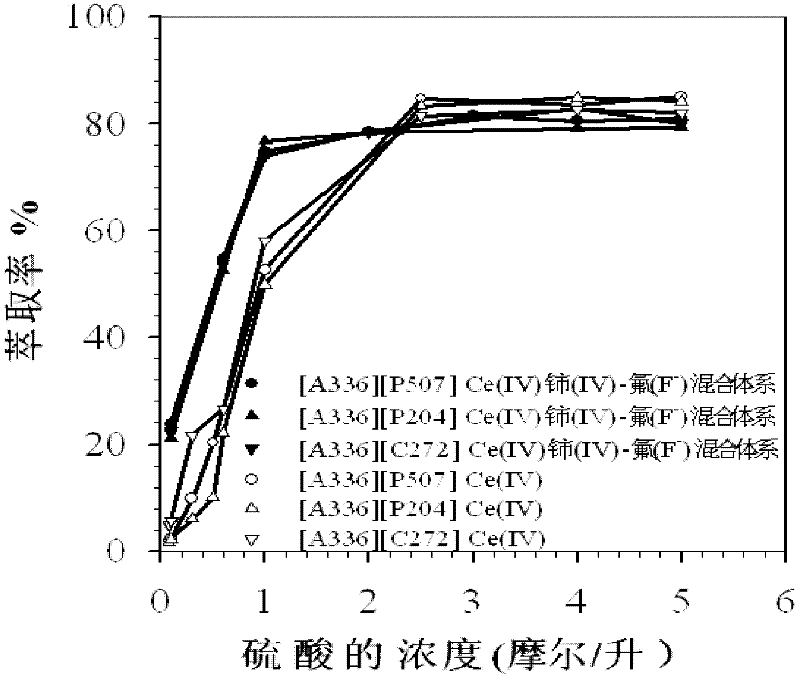

Method for separating tetravalent cerium or tetravalent cerium and fluorine

InactiveCN102409172AReduce pollutionImprove extraction efficiencyProcess efficiency improvementProtonationQuaternary ammonium cation

The invention provides a method for separating tetravalent cerium. The method comprises the following steps: a) providing feed liquor, wherein the feed liquor contains tetravalent cerium ions, trivalent rare earth ions and sulphuric acid and the concentration of sulphuric acid in the feed liquor is 0.06mol / L-0.5mol / L; b) extracting the feed liquor in the step a) with a mixed solution of ionic liquid and a diluent to obtain extract liquor and raffinate, wherein the cations of the ionic liquid are quaternary ammonium cations and the anions of the ionic liquid are anions obtained by deprotonating an acidic phosphine extractant; and c) performing back extraction on the extract liquor obtained in the step b) by using dilute sulphuric acid as the back-extractant to obtain back extraction liquor containing tetravalent cerium. The invention also provides a method for separating tetravalent cerium and fluorine. The method for separating tetravalent cerium and fluorine, provided by the invention, has lower extraction acidity and back-extractant acidity, thus the consumptions of acid and base can be reduced, the production cost can be saved and the environmental pollution can be reduced.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

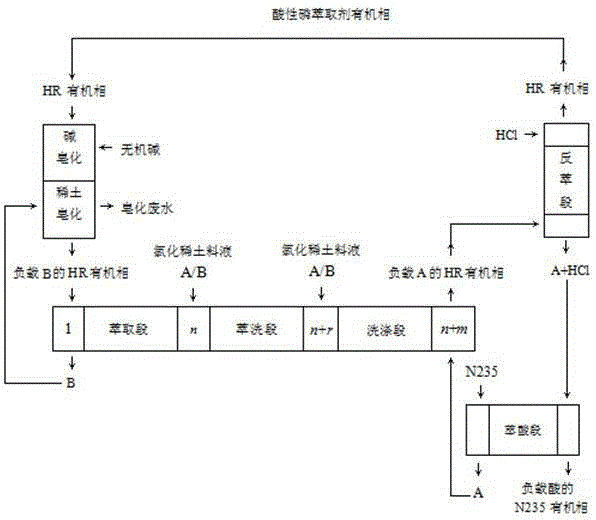

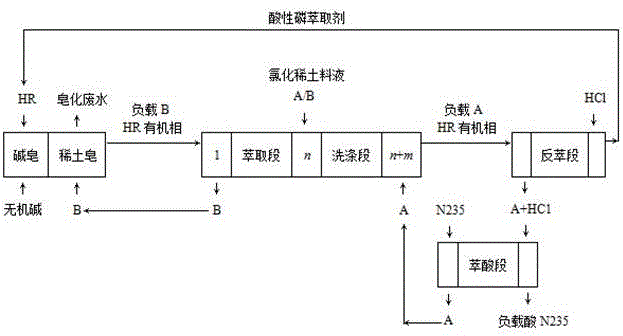

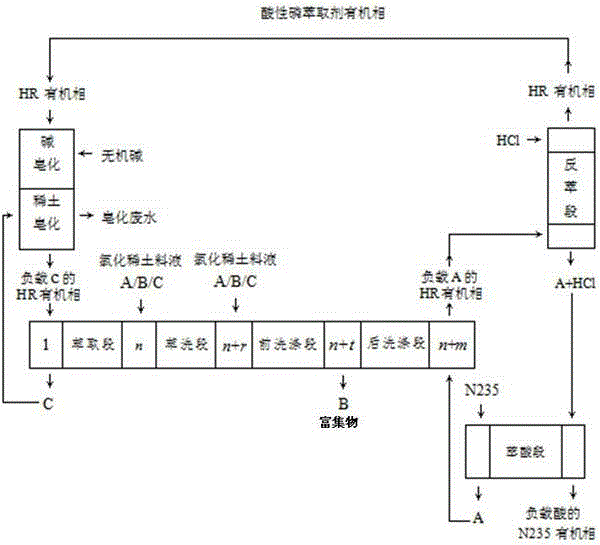

Two-feeding-opening fully-loaded rare earth fractional extraction separation process method

InactiveCN104561546AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSide effectTotal investment

The invention discloses a two-feeding-opening fully-loaded rare earth fractional extraction separation process method. According to the method, P507 serves as a rare earth extracting agent; in a two-feeding-opening fractional extraction separation process, an acid extraction section which takes N235 as an acid extracting agent and takes trioctyl phosphate as an N235 organic phase demulsifying agent is arranged, and the side effect of hydrogen ions can be eliminated through the acid extracting effect of the N235, so that not only is the rare earth separation coefficient not reduced, but also the extracting amount of rare earth in a two-feeding-opening fractional extraction system is not lower than the saponification amount of the rare earth. Compared with the existing two-feeding-opening fractional extraction process, the consumption of acid and alkali in a rare earth separation process can be greatly reduced, wherein the consumption amount of an alkaline reagent is reduced by 39 to 51 percent, and the consumption amount of hydrochloric acid can be reduced by 17 to 26 percent; the waste water discharging amount in the rare earth extraction separation process is greatly reduced; the green degree of rare earth separation is greatly improved; the stage number of extracting tanks can be reduced by 32 to 38 percent; the total investment of the rare earth extraction separation process is reduced. Therefore, the separation cost is remarkably reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

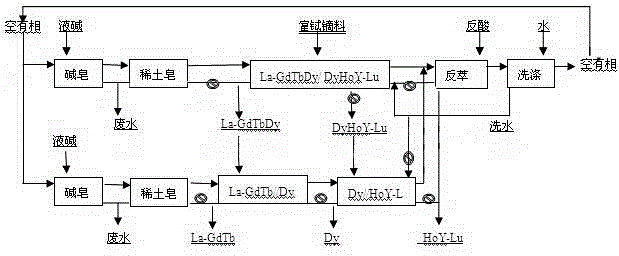

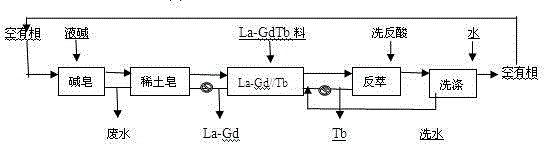

Method for extracting and separating high-purity dysprosium oxide and terbium oxide from terbium-dysprosium rare earth enrichment matters

ActiveCN104087748ALess groove volumeReduce commissioning costsProcess efficiency improvementPhysical chemistryDysprosium

The invention relates to a rare earth separation method, and in particular relates to a method for extracting and separating high-purity dysprosium oxide and terbium oxide from various terbium-dysprosium rare earth enrichment materials. The invention aims to provide the method for extracting and separating high-purity dysprosium oxide and terbium oxide from various terbium-dysprosium rare earth enrichment matters which are easily-balanced in system, low in debugging cost, small in acid and alkali consumption, low in production cost as well as low in quantity of high-price terbium element pressing grooves, and saves one-time investment. The method for extracting and separating high-purity dysprosium oxide and terbium oxide from the terbium-dysprosium rare earth enrichment matters comprises the following steps: (1) a continuous saponification and continuous rare earth soap manufacturing process; (2) a pre-grouping process; (3) a tandem separation process; and (4) a two outlets-Gd / / Tb separation process. The method provided by the invention has the advantages that 1, the quality of high-price terbium element pressing grooves is less; 2, the method is easily-balanced in system, low in debugging cost, small in acid and alkali consumption and low in production cost, and saves the one-time investment.

Owner:GANZHOU ZHANHAI IND & TRADING +2

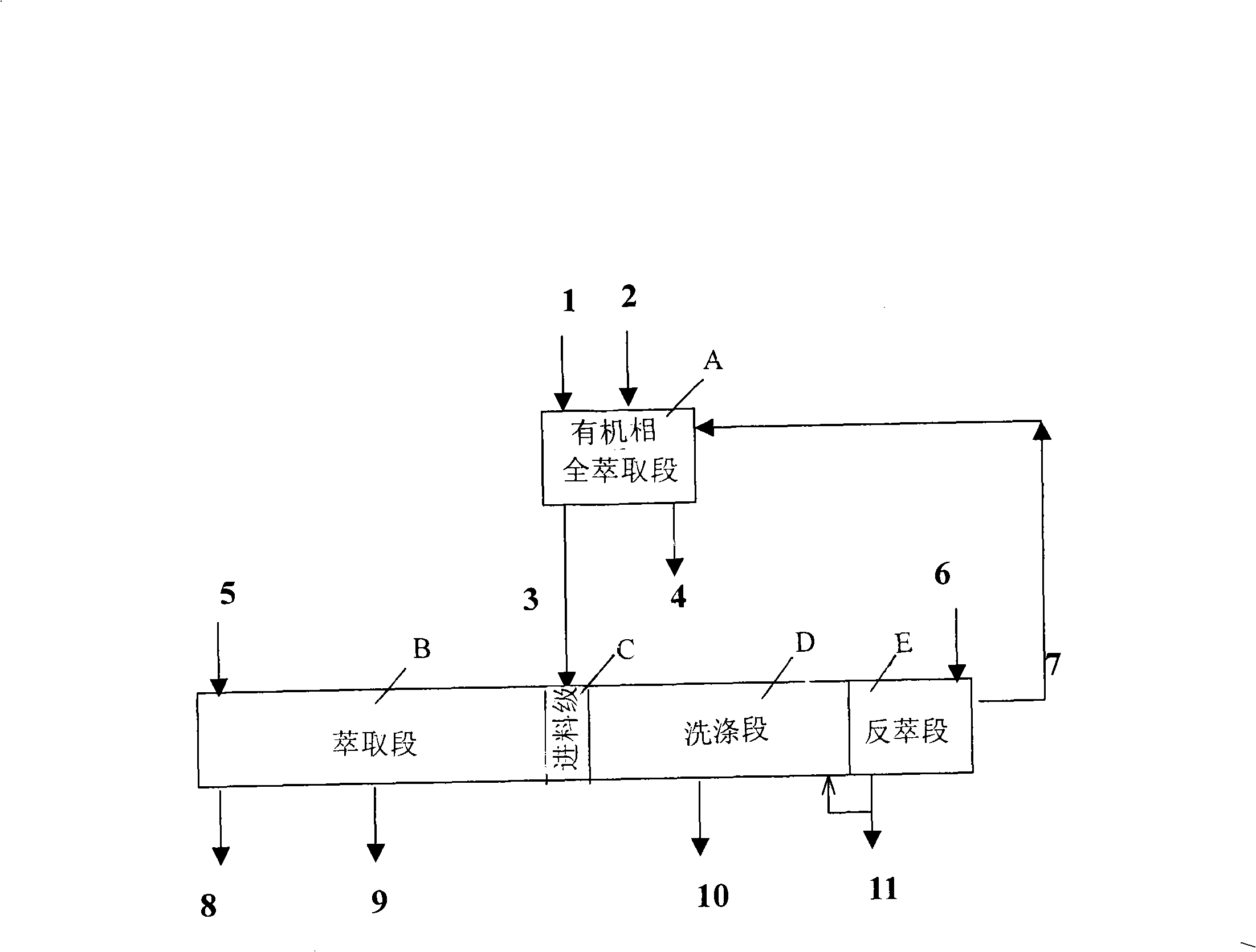

Technological method of full load fractional extracting and separating rare earths

InactiveCN104532022AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementSeparation factorWater discharge

The invention relates to a technological method of full load fractional extracting and separating rare earths. According to the technological method disclosed by the invention, P507 or P204 serves as a rare earth extractant; in a fractional extraction separation technology, N235 serves as an acid extraction agent, and a mixed alcohol serves as an acid extraction segment of an N235 organic phase regulator; an easily-extracted rare earth component solution with a pH value to be 1-4 serves as a washing solution; by virtue of the acid extraction action of the N235 in the acid extraction segment, the side effects of hydrogen ion washing are eliminated, so that the separation factor of the rare earths is ensured not to be lowered, and the extraction quantity of the extractant in a fractional extraction system is also ensured. Compared with the traditional fractional extraction separation technology, the acid and alkali consumption in the process of the rare earth separation technology can be greatly lowered, wherein the consumption of a basic reagent is lowered by 34-62 percent, and the consumption of hydrochloride is lowered by 16-29 percent; the waste water discharge in the process of the rare earth extraction separation technology is greatly reduced, the greening degree of rare earth separation is greatly increased; the grade amount of extraction tank is reduced by 22-46 percent, the total investment of the rare earth extraction separation technology is lowered; the separation cost is greatly lowered.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing beta-alanine by coupled enzymatic reaction

InactiveCN103320480ALow costReduce equipment investmentFermentationEnzyme catalysisIon-exchange resin

The invention belongs to the biotechnical field, and in particular relates to a method for preparing beta-alanine by a coupled enzymatic reaction. The method comprises the following steps: by using ammonium fumarate as a raw material, mixing bacterial cells respectively comprising aspartase and aspartic acid-alpah-decarboxylase or a crude enzyme liquor of the two enzymes with an ammonium fumarate aqueous liquor, wherein pH of the ammonium fumarate aqueous liquor is 7.0-7.5; performing enzymatic reaction at 25-55 DEG C; obtaining high purity beta-alanine by separating converted products by isoelectric point crystallization or a method combining isoelectric point crystallization or ion exchange resin. The beta-alanine is prepared by coupled enzymatic reaction, and the method has the advantages of wide source of raw materials, low cost, simplicity and convenience in operation, short enzymatic conversion time, low production cost and the like.

Owner:NANJING UNIV

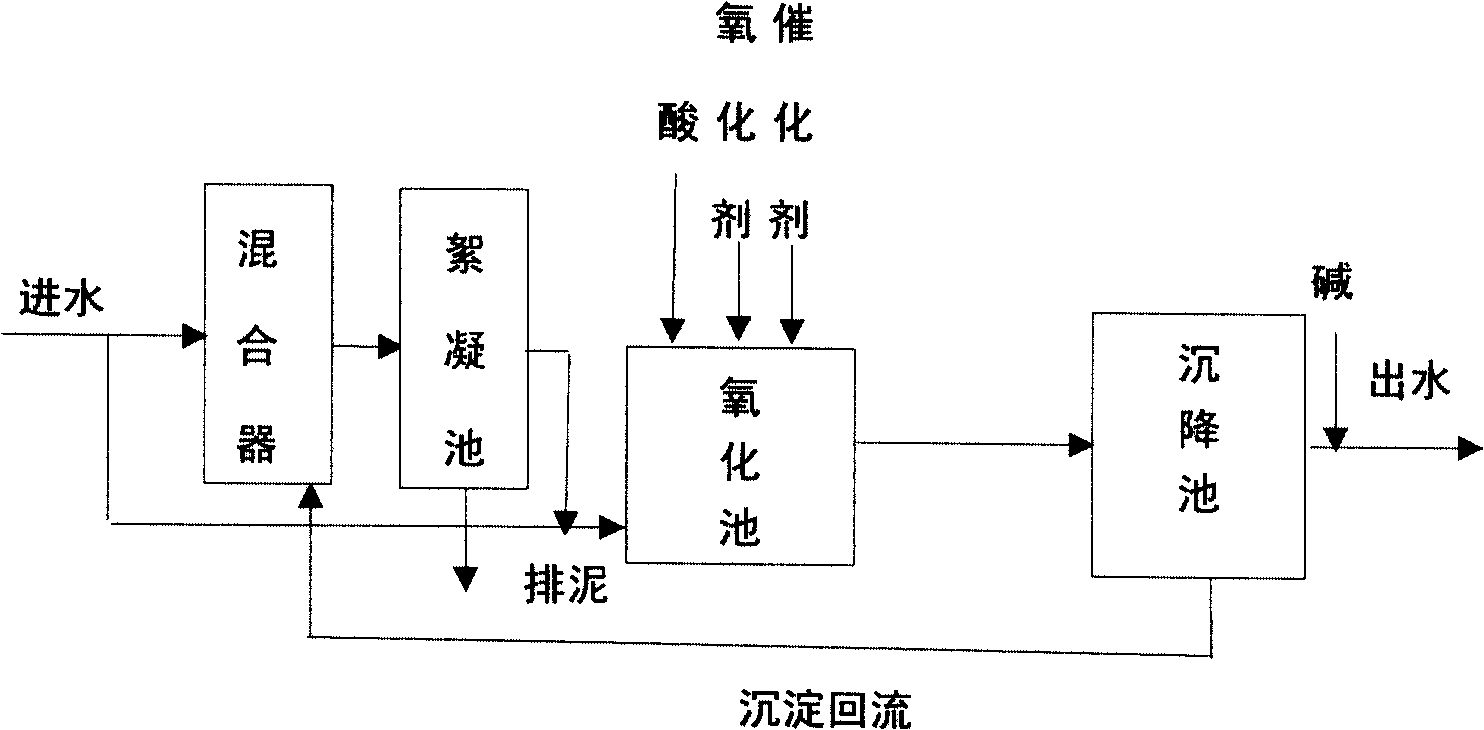

Method for treating wastewater by combining catalytic oxidation with biological aerated filter

ActiveCN102040308AImprove processing effectReduce acid and alkali consumptionMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemistrySediment flow

The invention relates to a method for treating wastewater by combining catalytic oxidation with a biological aerated filter, which sequentially comprises the following steps of: 1) adding all or part of the wastewater to be treated into a flocculating tank, performing flocculation sedimentation, and adding into an oxidation tank; 2) adding acid into the oxidation tank to regulate the pH value of the wastewater to be 0 to 6, adding an oxidant and a catalyst and performing catalytic oxidation reaction; and 3) adding the oxidized wastewater into a settling tank for settling, discharging supernatant, adding alkali to regulate the pH value to be 6 to 9, adding into the biological aerated filter for treating, and discharging; and making settled acidic sediments flow back to a dissolving tank, adding the acid to regulate the pH value until the sediments are completely dissolved, adding solution into the flocculating tank and performing flocculation sedimentation reaction on the solution and all or part of the wastewater to be treated. Compared with the prior art, the method reduces the consumption of the acid and the alkali and treatment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

InactiveCN105568006AImprove dissolution rateIncrease dissolution rateProcess efficiency improvementResource recoveryWastewater

The invention relates to a method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid. The method is characterized by comprising the following steps of chemically selecting and gathering mixed rare earth concentrate by use of a hydrochloric acid solution and a reinforced impurity remover, mixing the chemically-selected concrete with the concentrated sulfuric acid to roast at a low temperature, carrying out water leaching on roasted concentrate, carrying out resource recovery on a water leaching fluid, carrying out tail gas absorption, and recycling chemical-selected wastewater resources. The method has the advantages that the source of three wastes of a current concentrated sulfuric acid high-temperature roasting process is solved at the front end of concentrate treatment, so that various problems in a low-temperature acid method are solved, the follow-up three-waste treatment difficulty is greatly reduced, the rare earth direct recovery rate is increased, and the purpose of comprehensively recycling various resources in the concentrate and auxiliary materials is finally realized.

Owner:BAOTOU RES INST OF RARE EARTHS

Method for separating and refining high-purity L-arabinose and D-xylose with simulated moving bed

ActiveCN103113422AReduce demandReduce generationSugar derivativesSugar derivatives preparationSimulated moving bedHigh sugar

The invention discloses a method for separating and refining high-purity L-arabinose and D-xylose with a simulated moving bed, which comprises the following steps: by using bagasse, bagasse pith or sugarcane leaf as a raw material, hydrolyzing, purifying, separating with a simulated moving bed chromatographic separator to obtain an L-arabinose solution with the purity of higher than 90% and a D-xylose solution with the purity of higher than 85%, and crystallizing to obtain the L-arabinose and D-xylose with the purity of up to 99%. The method has the advantages of simple technological operation, high sugar purity, high yield, low cost and high equipment stability, and is suitable for industrial production.

Owner:广西轻工业科学技术研究院有限公司

Method for treating nickel-containing laterite by microwave reducing roasting-goethite precipitation conversion method

InactiveCN101392320AFast heatingImprove energy efficiencyProcess efficiency improvementSlurryHigh pressure

The invention relates to a method for processing laterite comprising nickel by means of microwave reduction roasting-goethite deposit transformation, which is characterized in that the method comprises the following steps: (1) a carbonaceous reducing agent is added into the laterite, and heated for 5min to 20min under microwave radiation after even blending so as to obtain laterite calcine; and (2) the laterite calcine is blended into slurry and leached, the concentration of the mine slurry is 10wt percent to 30wt percent, the leaching temperature is 80 DEG C to 120 DEG C, the duration for leaching is 2h to 5h, and nickel cobalt in the laterite enters the leached liquid, with iron transformed to goethite deposit. The method consumes less acid which is equal to that of the high-pressure acid leaching method, but the operation temperature and pressure at the leaching stage are greatly lowered by reduction roasting, which is favorable to the decrease in manufacturing cost of leaching equipment.

Owner:NORTHEASTERN UNIV

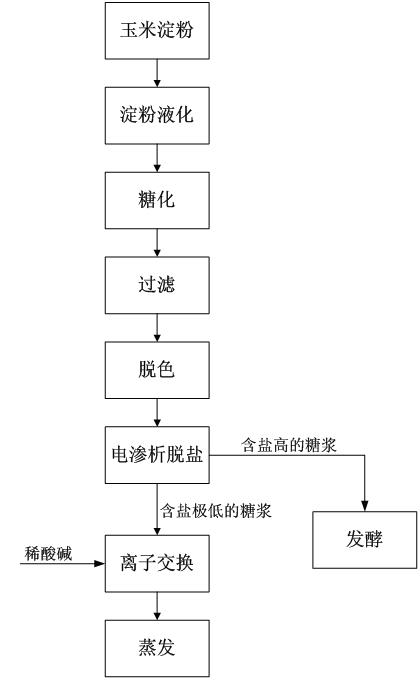

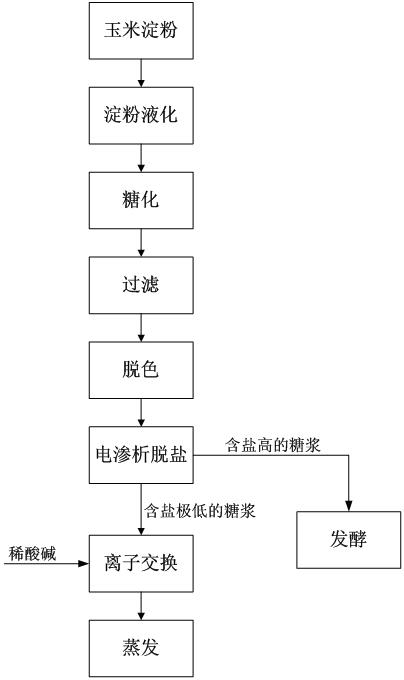

Desalting method for syrup and production method for glucose syrup

The invention discloses a desalting method for syrup and a production method for glucose syrup. The desalting method is used for desalting syrup by utilizing the electrodialysis process, and comprises the following steps: the syrup of which the salinity is to be desorbed is divided into a part A and a part B according to the ratio A : B = 1 to 4 : 6 to 9; the part A of the syrup enters into one side of the ion-exchange membrane of an electrodialysis device; the part B of the syrup enters into the other side of the ion-exchange membrane of the electrodialysis device; and the ions of the part Bof the syrup shift to the part A of the syrup due to the migration action of an electric field. As the desalting method is adopted during the desalting of a syrup preparation process, the cost of each ton of syrup is reduced by 22 percent than that of the prior art, which greatly reduces the production cost of the starch sugar of enterprises, reduces sewage discharge generated during the traditional desalting process, and veritably realizes the purposes of energy conservation, consumption reduction, sewage discharge reduction and cleaner production. Therefore, the invention has a wide popularization value.

Owner:CHANGCHUN DACHENG NEW RESOURCE GROUP

Method for treating nickel-containing laterite by microwave reducing roasting-hematite precipitation conversion method

InactiveCN101392321AFast heatingImprove energy efficiencyProcess efficiency improvementSulfate radicalsSlurry

The invention relates to a method for processing laterite ore comprising nickel by means of microwave reduction roasting-hematite deposit transformation, which is characterized in that the method comprises the following steps: (1) a carbonaceous reducing agent is added into the laterite ore, and heated for 5min to 20min under microwave radiation after even blending so as to obtain laterite ore calcine; and (2) the laterite ore calcine is leached in a high-pressure container. The concentration of ore slurry leached is 10 percent to 30 percent, and the ore slurry is fed into oxygen-enriched air or pure oxygen to carry out oxidation leaching reaction. Nickel cobalt in the laterite ore enters the leached liquid, with iron transformed to hematite deposit. The method consumes less acid, with the leaching temperature greatly lower than that of the existing high-pressure acid leaching method, thereby being favorable to the decrease in manufacturing cost of leaching equipment; simultaneously, the scale in equipment is greatly decreased, the content of sulfate radical in the leaching residue is accordingly lowered, thus being favorable to the comprehensive utilization of the leaching residue.

Owner:NORTHEASTERN UNIV

Method of separating thulium, ytterbium and lutetium through extraction

ActiveCN107099666AReduce acidityReduce saltRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentLutetiumThulium

The invention discloses a method of separating thulium, ytterbium and lutetium through extraction, and belongs to the technical field of rare earth metal extraction. The method includes the steps of: (1) separating a TmYbLu chloride solution with an organic phase, which supports a TmYb water phase, and a (YbLu)Cl3 solution; (2) separating the TmYb water phase with the organic phase and a YbCl3 solution to obtain a pure Tm water phase and a Yb organic phase, and dividing the supported organic phase and feeding the supported organic phase into the step (1) to separate the TmYbLu chloride solution; (3) separating a YbLu organic phase with a LuCl3 solution and the Yb organic phase, and feeding a part of a pure Yb water phase to the step (2); (4) in a Yb / Lu separation trough, dividing a part of a YbLu water phase and feeding the YbLu water phase into the step (1). The method is used for extraction separation of high-purity thulium, ytterbium and lutetium, is low in separation cost and generates less separation wastewater, has high product recovery rate and is short in separation time.

Owner:广东省富远稀土有限公司

Extraction separation method for rare earth and zinc in reverse extraction raffinate obtained in reduction extraction separation of europium

ActiveCN103922383AHigh extraction rateImprove the extraction and separation effectLiquid solutions solvent extractionRare earth metal compoundsChlorideSamarium

The invention relates to an extraction separation method for rare earth and zinc in reverse extraction raffinate obtained in reduction extraction separation of europium, belonging to the field of hydro-metallurgy of rare earth. According to the invention, the reverse extraction raffinate obtained in reduction extraction separation of europium is mixed solution of rare earth chloride and zinc chloride; ammonia water is added into the reverse extraction raffinate to neutralize spent acid, then NH4Cl is added, and then the reverse extraction raffinate with NH4Cl is used as a feed liquid, wherein the concentration of NH4Cl in the feed liquid is 3 mol / L; an organic phase is composed of P507-kerosene with a concentration of 1.5 mol / L; a GdCl3 solution with NH4Cl is used as a washing liquid, and the concentration of NH4Cl in the washing liquid is 3 mol / L; after multistage extraction separation, raffinate containing zinc and an organic phase with loaded rare earth are obtained, wherein the raffinate containing zinc is used as a raw material for preparation of zinc carbonate, and the organic phase with loaded rare earth is directly used as a feed liquid for extraction separation of samarium, europium and gadolinium. NH4Cl is added into the extraction separation feed liquid for rare earth and zinc and into the washing liquid, so a separating factor for rare earth and zinc is improved, the stages of extraction separation in industrial production and the volume of a mixing chamber can be reduced, and consumption of acid and alkali is decreased at the same time.

Owner:BAOTOU RES INST OF RARE EARTHS +1

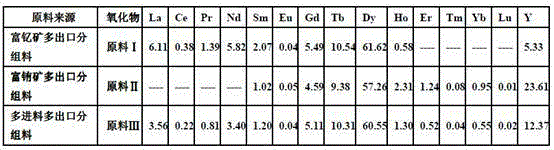

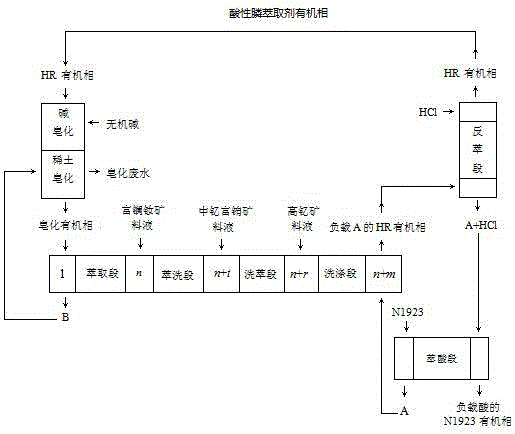

Method for fractionation and extraction separation of mischmetal through three feeding openings

InactiveCN106498191AReduce acid and alkali consumptionHigh degree of greeningProcess efficiency improvementChemistryYttrium

The invention discloses a method for fractionation and extraction separation of mischmetal through three feeding openings. According to the method for fractionation and extraction separation of mischmetal through the three feeding openings, P507 is used as a rare extraction agent, primary amine N1923 is used as an acid extraction agent, and TOP is used as an organic phase modifier; the three feeding openings are arranged in a fractionation and extraction system, Gd / Tb grouped separation is conducted to treat three kinds of rare earth chloride feed liquid of lanthanum-neodymium-rich ore, yttrium-intermediate europium-rich ore and high-yttrium ore at the same time, and then a light and middle rare earth product and a heavy rare earth product are obtained; the lanthanum-neodymium-rich ore feed liquid enters the fractionation and extraction system from the first feeding opening; the yttrium-intermediate europium-rich ore feed liquid enters the fractionation and extraction system from the second feeding opening; and the high-yttrium ore feed liquid enters the fractionation and extraction system from the third opening. The light and middle rare earth product with the purity being 5N is obtained from the water phase of an outlet of a first-level extraction tank of the fractionation and extraction system; and the heavy rare earth product with the purity being 5N is obtained from the extraction raffinate water phase of an acid extraction section. Compared with an existing traditional fractionation and extraction technology, the consumption amount of organic-phase saponification alkaline is lowered by 39%-52%, the consumption amount of pickling acid is lowered by 66%-80%, and the total number of levels of extraction tanks is reduced by 30%-60%.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for separating rare earth by using two-inlet three-outlet full-load fractionation and extraction

InactiveCN104561612AReduce acid and alkali consumptionReduce consumptionProcess efficiency improvementChemistryFoam fractionation

The invention discloses a method for separating rare earth by using two-inlet three-outlet full-load fractionation and extraction. According to the method, P507 serves as a rare earth extraction agent, rare earth chloride serves as a raw material, a third outlet is formed in a scrubbing section of a two-inlet three-outlet fractionation and extraction system, and an acid extraction section which takes N235 as an acid extraction agent and takes TBP as a demulsifying agent is arranged between the scrubbing section and the stripping section. According to the acid extraction action of N235, side effects of hydrogen ions are eliminated, so that the rare earth separation coefficient is not reduced, and the extraction amount of rare earth is not lower than the rare earth saponification amount. Compared with the conventional two-inlet three-outlet fractionation and extraction process, the method disclosed by the invention has the advantages that the acid-base consumption in the rare earth separation process can be greatly reduced, the consumption of alkaline reagents is reduced by 54.6-58.8 percent, and the consumption of hydrochloric acid is reduced by 16.1-23.7 percent; the wastewater discharge amount in the rare earth extraction and separation process is greatly reduced, and the greening degree of rare earth separation is greatly improved; and moreover, the grade number of the extraction tank can be reduced by 9.5-24.6 percent, and the total investment of the rare earth extraction and separation process is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

Separation and purification process for producing branched chain amino acid by using fermentation method

InactiveCN103951572AReduce consumptionEmission reductionOrganic compound preparationAmino-carboxyl compound preparationIon exchangeBranched-chain amino acid

The invention discloses a separation and purification process for producing branched chain amino acid by using a fermentation method. The process comprises the following steps: 1) preparing a rough product; 2) preparing branched chain amino acid salt by using a hydrochloric acid technique; 3) desalting to purify a multi-membrane combined system. As a rough fermentation finished product is adopted to prepare hydrochloride firstly, secondly, other amino acids are separated and purified, and subsequently the multi-membrane combination technique is adopted to replace an ion exchange technique, the acid and alkali consumption is reduced, the wastewater emission is reduced, and clean production, energy conservation and emission reduction are achieved; a fermentation liquid is partially desalted by using an electrodialysis technique in the multi-membrane combination technique, and the salt is removed by coupling the electrodialysis technique with the ion exchange technique, the problems of use amount of ion exchange resin recycled acid and alkali and salt contamination are effectively solved, and the water consumption is reduced.

Owner:WUXI JINGHAI AMINO ACID

Clean chitin production process with physical separation and biological enzymolysis

InactiveCN103524641AReduce acid and alkali consumptionAcid-base decreaseBiotechnologyChemical treatment

The invention discloses a clean chitin production process with physical separation and biological enzymolysis and belongs to the field of chitin processing. The chitin clean production process comprises the following steps of: with fresh shrimp and crab shells as raw material, carrying out extrusion pretreatment on the fresh shrimp and crab shells in an extruding device firstly, then carrying out enzymolysis on proteins in the shrimp and crab shells by virtue of protease, filtering out protein enzymatic hydrolysate to obtain solid substances, and carrying out the operations of calcium removal by virtue of aeration picking, closed-type degreasing by virtue of soda boiling, washing and drying on the solid substances by virtue of a closed tank to obtain a chitin product, wherein the filtered protein enzymatic hydrolysate is treated by technical processes of standing precipitation, centrifugation, drying and the like to obtain a protein product, and the protein product can be used in feed additives. With the adoption of the clean chitin production process, as the biomasses in the chitin raw materials are basically removed by virtue of a physical separation and biological extraction method before chemical treatment, and then acid-base chemical treatment is adopted to carry out the production process to comprehensively utilize the shrimp and crab shells, the acid-base consumption can be further lowered, the acid-base dosage in subsequent chemical treatment is greatly lowered, and the product yield is high.

Owner:YANGZHOU RIXING BIO TECH +1

Novel process for preparing highland barley flavone extract and application thereof in health wine

ActiveCN101696381AAnti-fatigueFunctionalSugar derivativesAlcoholic beverage preparationSolventImpurity

The invention relates to a novel process for preparing highland barley flavone extract, comprising the following steps of extracting flavonoids form highland barley seedlings by a normal hydrous alcohol solvent reflux extraction method; removing particular impurities such as dusts by a tubular centrifuge; carrying out the procedures of filtering for clarification through a ceramic membrane, interception for separation through anultrfiltration membrane, desalination for concentration through a nanofiltration membrane and the like; and finally drying by spraying or microwave to obtain the highland barley flavone extract containing 8.1-14.9 percent of total flavone . Meanwhile, the invention also discloses the application of the highland barley flavone extract prepared by the process in health wine. In the invention, purification and separation are carried out in a combined membrane separation mode, so that the invention has the advantages of good separation effect, high yield of effective substances and good stability of the product.

Owner:青海金麦杞生物科技有限公司

Method for purifying long-chain diacid

ActiveCN110272341AReduce acid and alkali consumptionReduce inorganic salt pollutionCarboxylic compound separation/purificationChemistryLiquid ammonia

A method for purifying a long-chain diacid comprises the following steps: controlling the pH value of a long-chain diacid fermentation liquid to be 7.0 or above by using ammonia water, liquid ammonia or ammonia gas during or after fermentation in order to obtain a fermentation liquid containing long-chain diacid ammonium salt, performing membrane filtration, heating the filtered fermentation liquid, carrying out solid-liquid separation, and extracting the long-chain diacid. The method effectively reduces the content of inorganic salts in the fermentation liquid under the premise of maintaining the high yield of long-chain dibacid product, so the sewage treatment pressure is greatly reduced.

Owner:CATHAY R&D CENT CO LTD +1

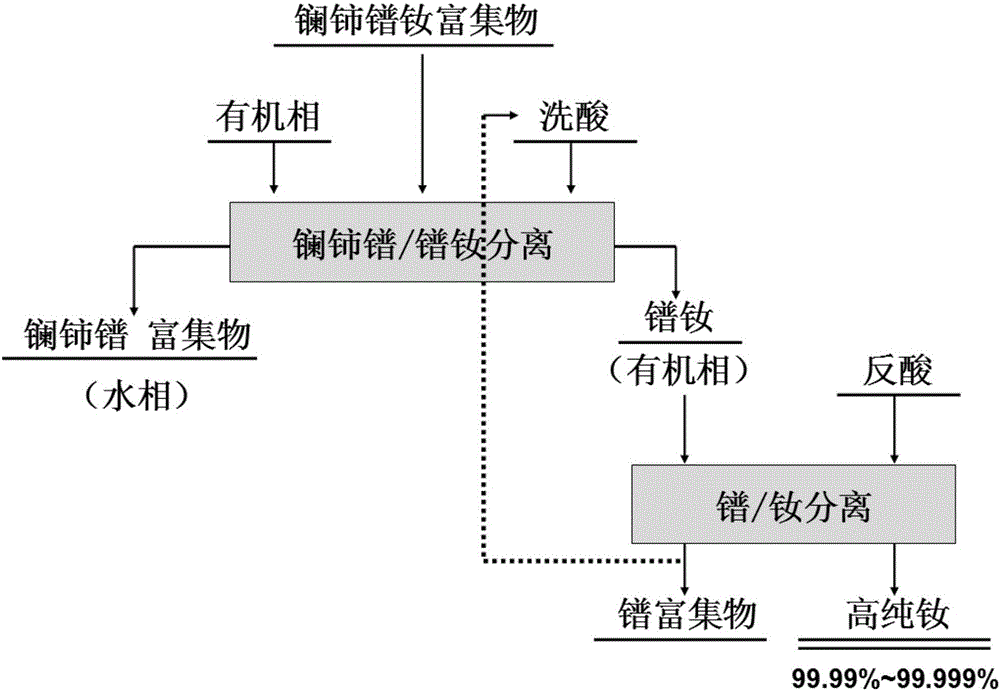

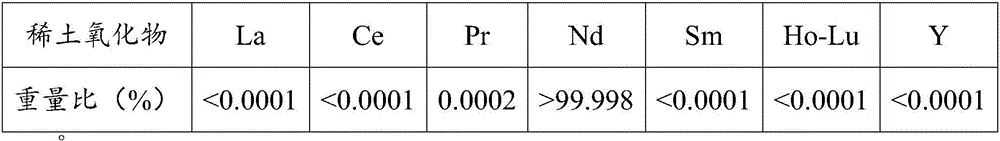

Method for industrialized production of high-purity neodymium oxide

ActiveCN105883889AReduce the number of seriesHigh purityRare earth metal oxides/hydroxidesRare earth metal compounds preparation/treatmentCeriumLanthanum

The invention discloses a method for industrialized production of high-purity neodymium oxide. The method comprises the following steps that 1, enrichment material liquid containing lanthanum, cerium, praseodymium and neodymium is mixed with an organic phase, extraction is performed through a lanthanum-praseodymium-cerium / praseodymium-neodymium fuzzy extraction module, an outlet water phase of the fuzzy extraction module contains lanthanum, cerium and praseodymium, and the outlet organic phase washed with washing liquid contains praseodymium and neodymium; 2, the praseodymium and neodymium of the organic material liquid containing praseodymium and neodymium obtained in the step 1 are separated through a praseodymium / neodymium separating module, an outlet water phase of the praseodymium / neodymium separating module is an enriched product of praseodymium and serves as the washing liquid used for the lanthanum-praseodymium-cerium / praseodymium-neodymium fuzzy extraction module in the step 1, the outlet water phase of the praseodymium / neodymium separating module contains high-purity neodymium, and the purity is 99.99%-99.999%; 3, the neodymium containing material liquid inn the step 2 is subjected to precipitation, calcinations and packaging to obtain a high-purity neodymium oxide produce. The method has the advantages of being low in production cost, high in product purity and capable of performing large-scale continuous production.

Owner:赣州稀土(龙南)有色金属有限公司 +1

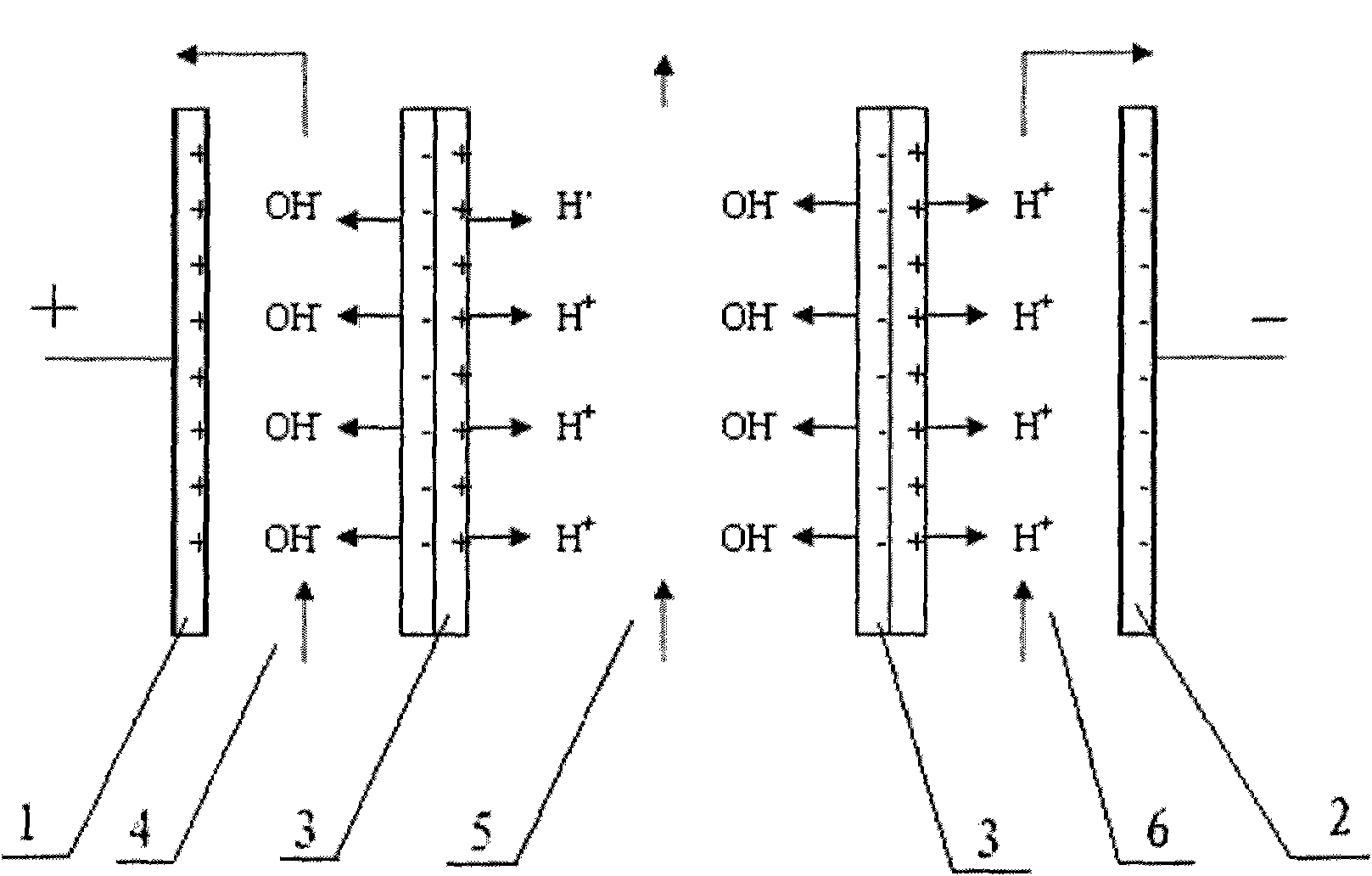

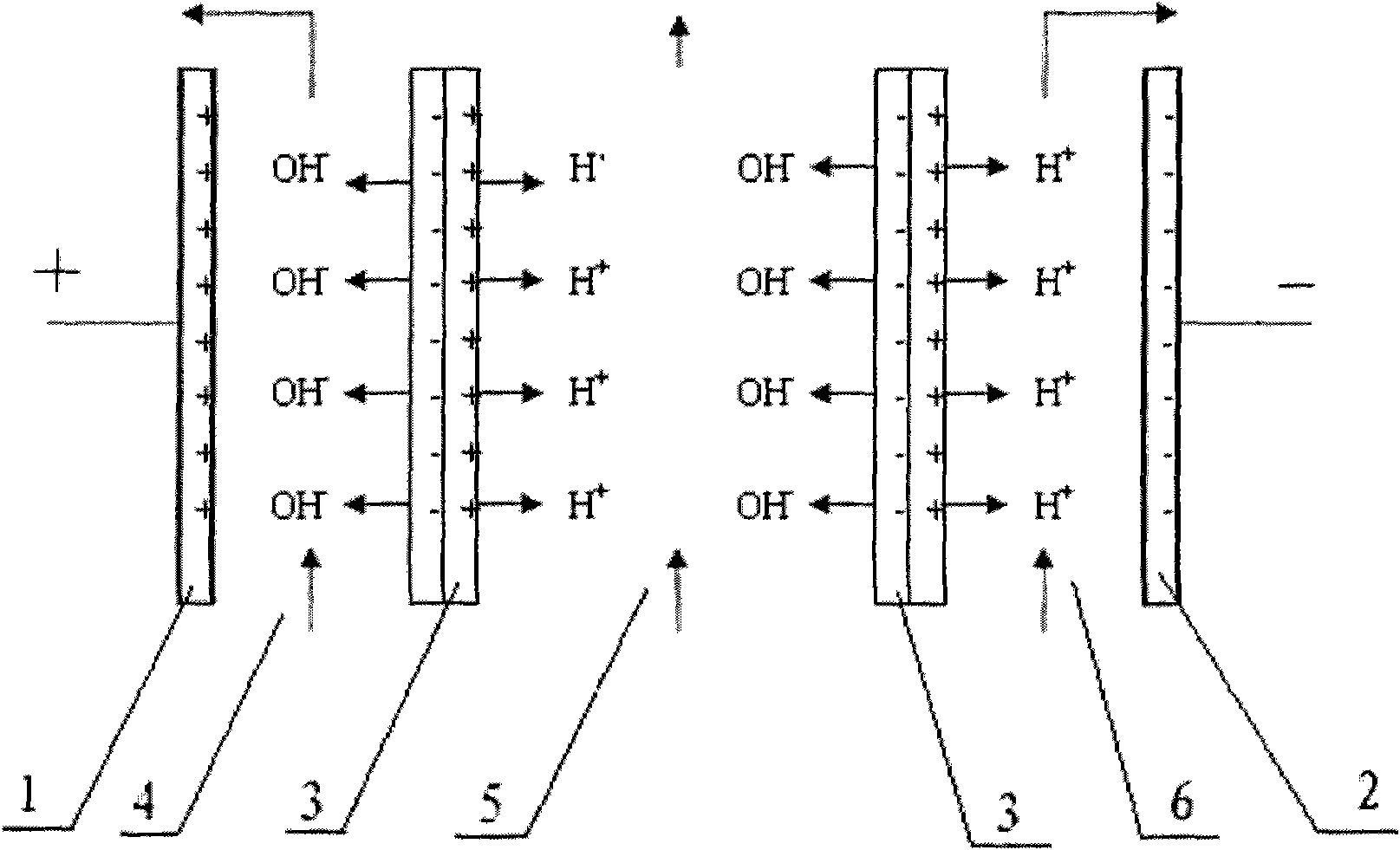

Bipolar membrane electrolysis method for ester-type hydrolysis

ActiveCN101812700ASimplify the production processReduce acid and alkali consumptionElectrolysis componentsElectrolytic organic productionIonizationChemistry

The invention discloses a bipolar membrane electrolysis method for ester-type hydrolysis. The method is based on a bipolar membrane electrolysis technique and adopts bipolar membrane and electrodes to form a hydrolysis device in order to promote the hydrolysis of esters. The method comprises the following specific steps: a, pumping electrolyte into an anode chamber and a cathode chamber respectively, pumping ester-type solution into a hydrolysis chamber and performing circulation; b, applying a DC power source between an anode and a cathode to electrolyze water; and c, moving hydrolysis products out from the device in time to perform separation and obtain acid and alcohol. The method utilizes bipolar membrane ionization water to catalyze the hydrolysis of esters in order to directly obtain clean acid and alcohol products, and has the advantages of no need for any catalysts, high material utilization rate, no pollutant emission, capability of being operated at normal temperature under normal pressure, simple process flow, high volume utilization rate of equipment, safety and energy conservation.

Owner:淮安芯存集成电路有限公司

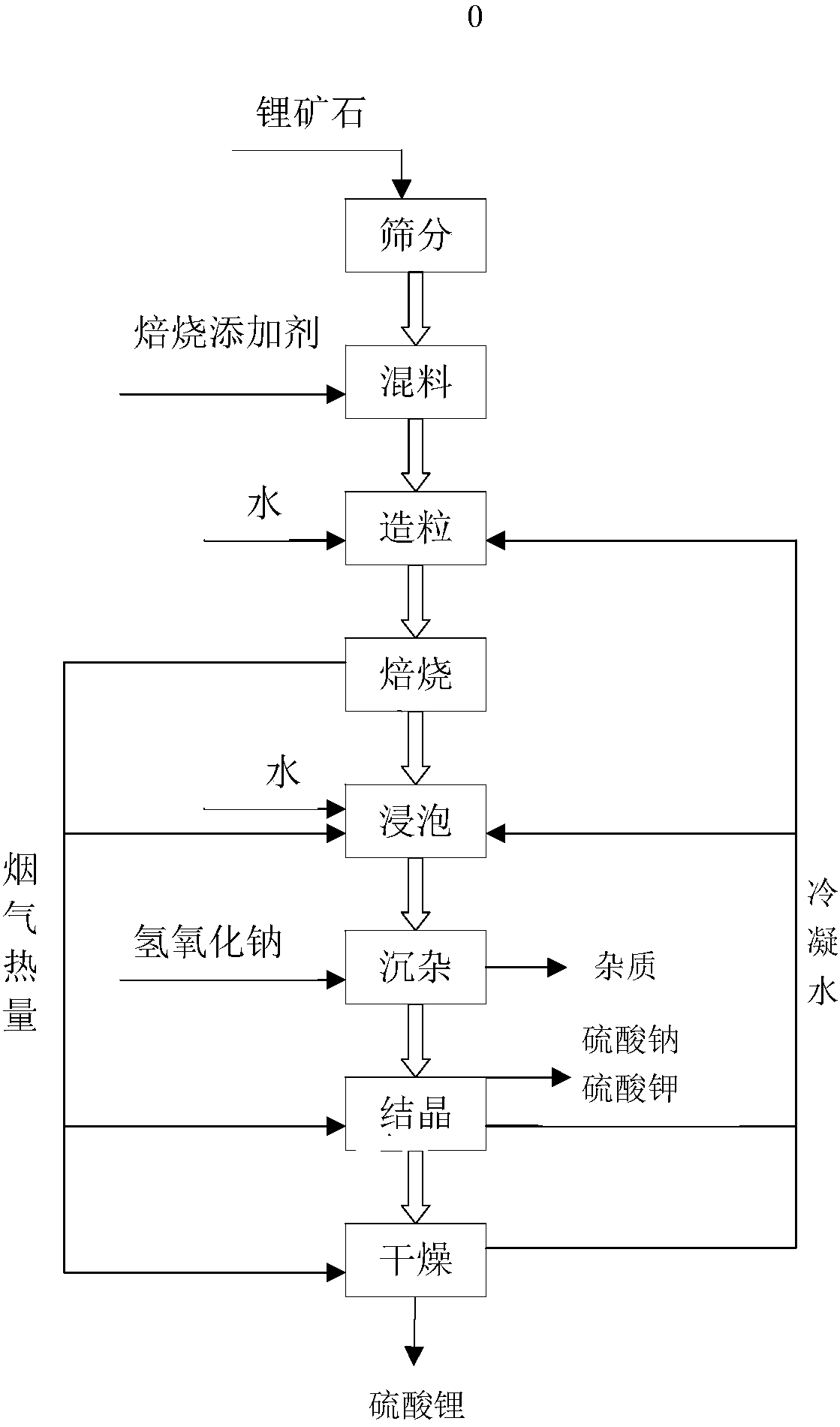

Clean production technology and method for lithium sulfate

InactiveCN108383140AImprove conversion rateImprove leaching rateLithium sulfates/sulfitesLithium sulphatePregnant leach solution

The invention provides a clean production technology and method for lithium sulfate. A technique and a roasting additive are used. The production process comprises the steps of sieving, mixing, granulating, roasting, soaking, impurity deposition, crystalizing, drying and the like, and the roasting additive comprises components including Na2SO4, K2SO4, CaCO3, CaO and the like. By the clean production technology and method for lithium sulfate, the roasting conversion rate and leaching rate of lithium can be increased, moreover, acid is not used, types and contents of impurities in leaching liquid are less, a follow-up impurity removal process is simple, and acid and alkali consumption is low. The production process is simple, the lithium extracting rate is high, energy and materials are reused, and thus, the clean production technology and method are suitable for large-scale production.

Owner:天津二八科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com