Patents

Literature

91results about How to "Improve oxidation reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

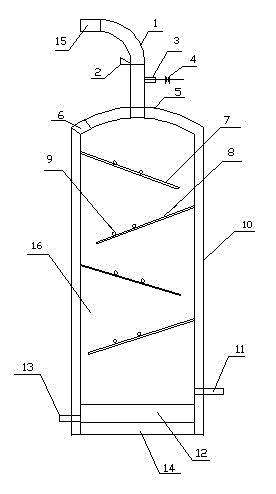

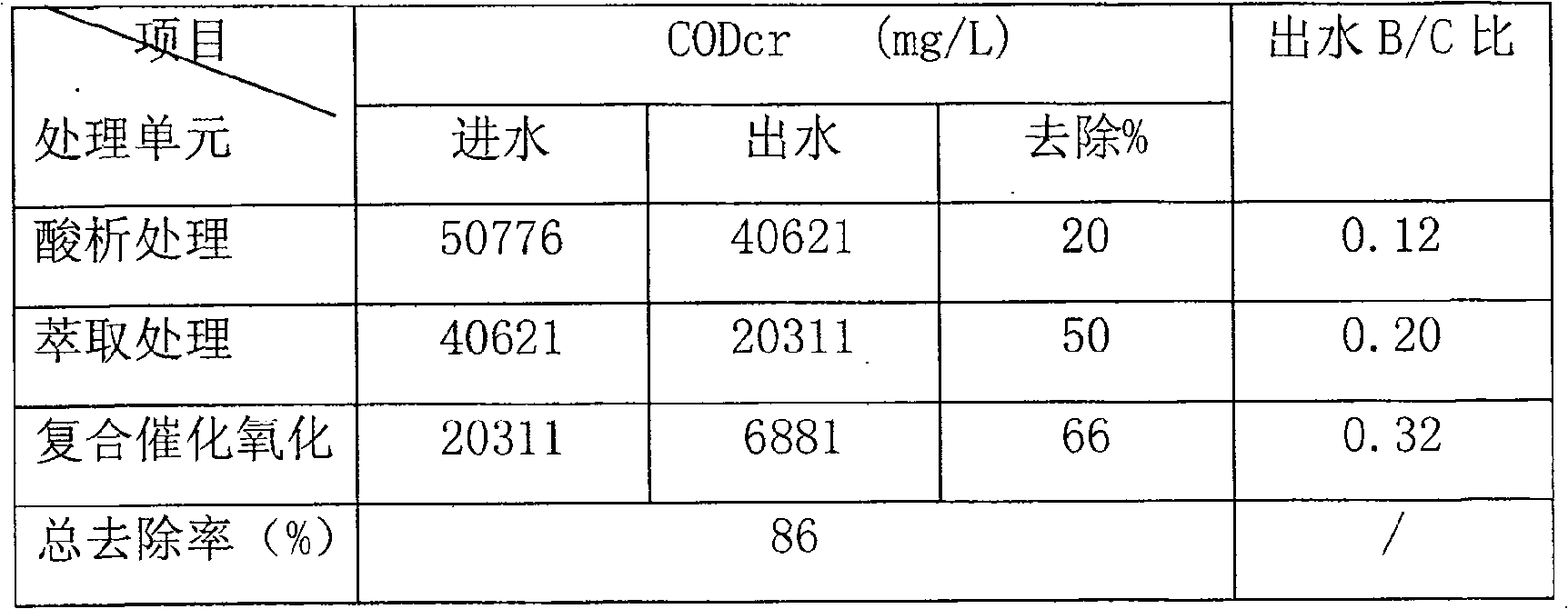

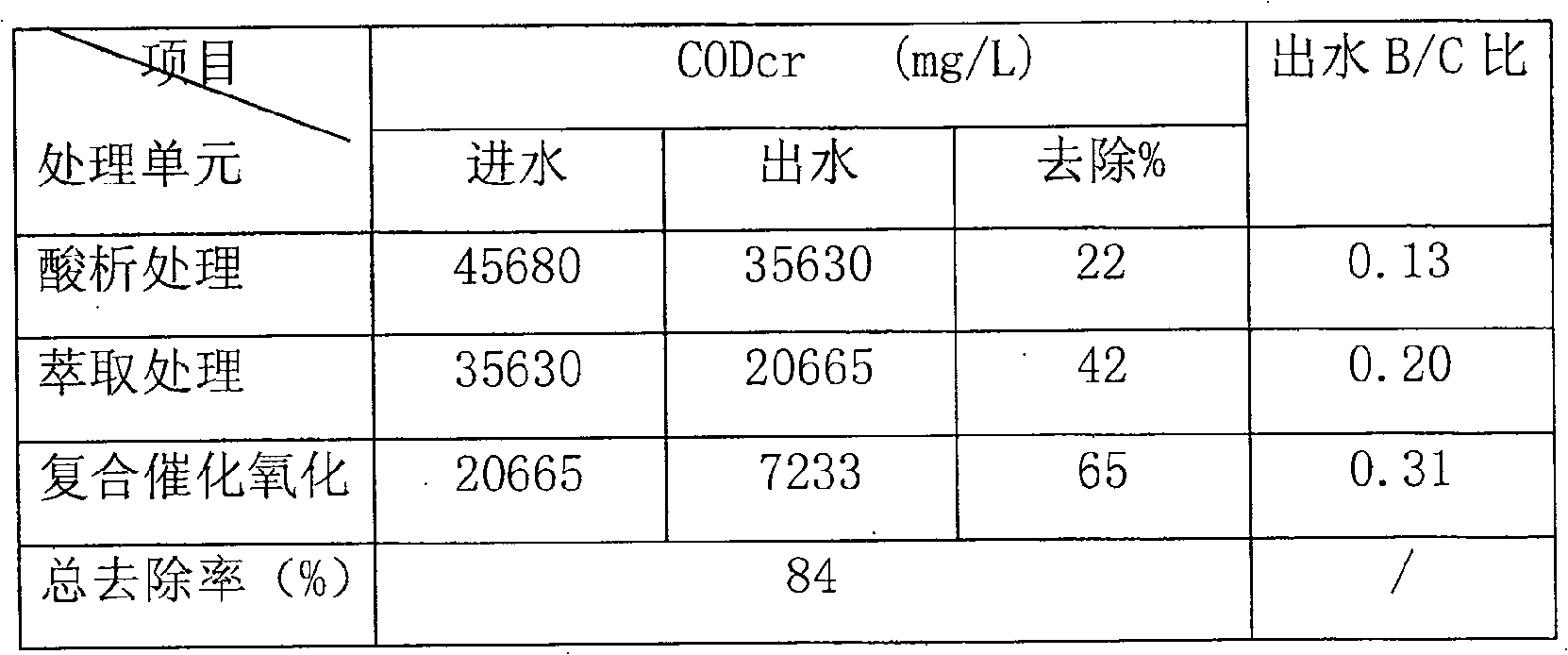

Chlopyrifos pesticides waste water treatment process

InactiveCN101172728APromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCatalytic oxidationPendimethalin

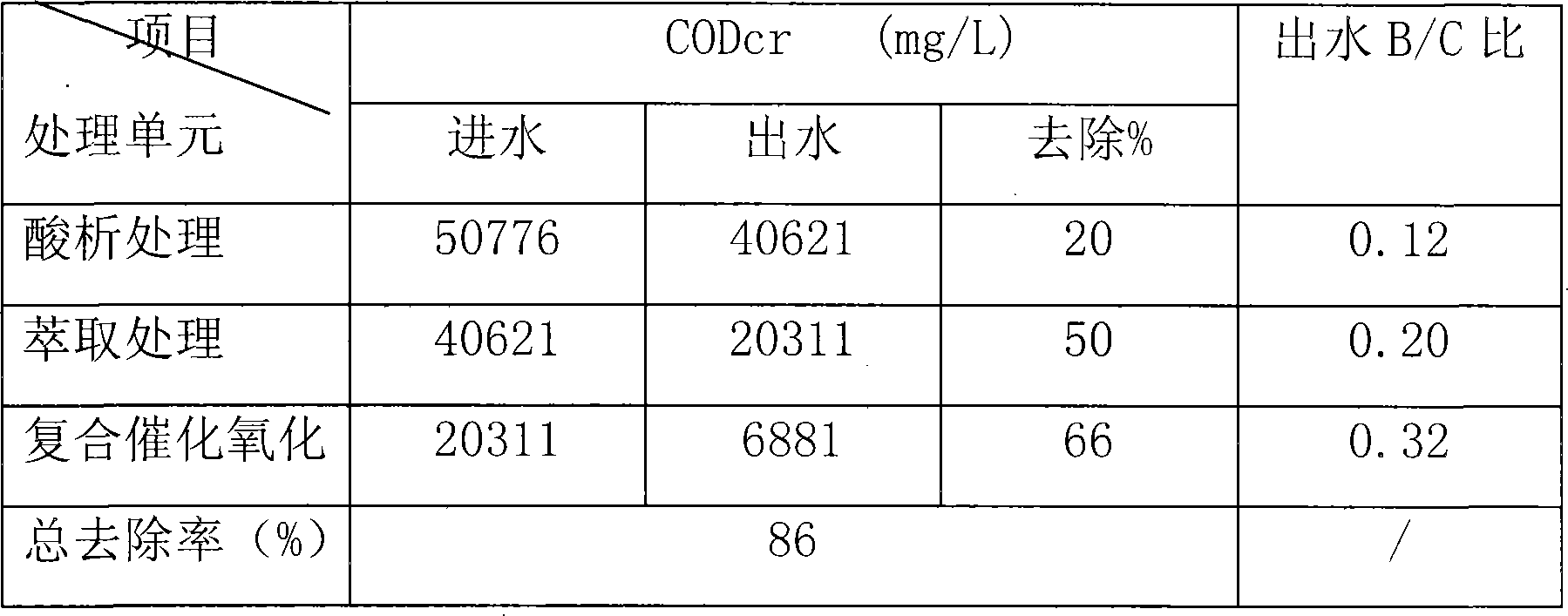

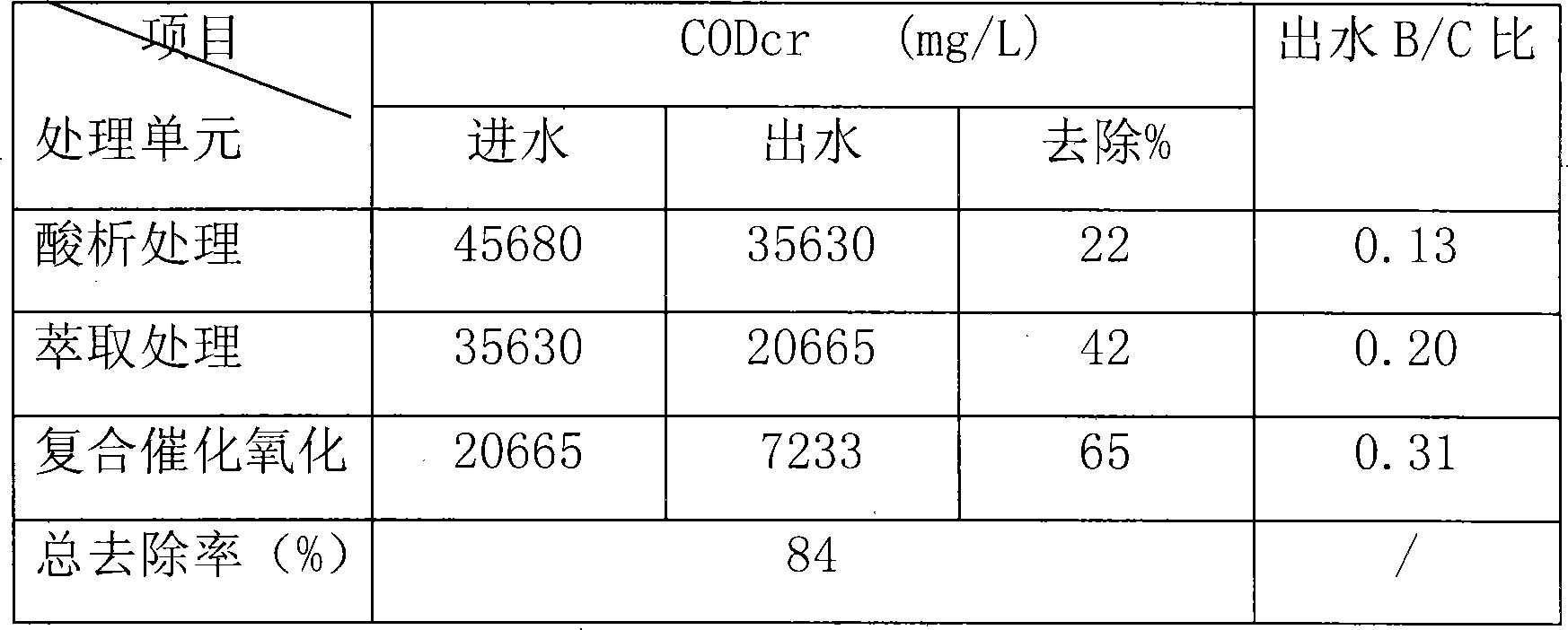

The invention discloses a treatment process of waste water polluted by the pesticide of Dursban, and the process includes the procedures of acid eduction, complexation and extraction, Fenton oxidation and catalytic oxidation. The invention is characterized in that Dursban waste water and herbicide Pendimethalin waste water are comprehensively treated, thereby achieving the proposal of waste controlled by the waste, decreasing the load of organic pollutant being hard to be graded in the waste water, improving the biological degradability of the waste water, removing the pollutant from the waste water, and increasing the biochemical performance of the waste water. Besides, the invention has the advantages of safe and advanced technique, clean operation and low waste water treatment cost.

Owner:山东华阳农药化工集团有限公司

Preparation method for nano-cellulose

ActiveCN104047198APromote swellingFacilitate dissociationPulping with organic solventsPlant fibreWastewater

The invention relates to a preparation method for nano-cellulose. The method comprises the steps of: providing a plant fiber pulp; untwining the plant fiber pulp to separate the plant fiber into single fiber; conducting pre-defiberization treatment on the untwined plant fiber pulp, and simultaneously adding a TEMPO catalytic oxidation system to oxidize the fiber; when the freeness of the plant fiber pulp reaches 150-450ml, separating the oxidized fiber and wastewater; conducting defiberization treatment on the oxidized fiber again to freeness of 50ml and below, thus obtaining defiberized oxidized fiber; and carrying out nanocrystallization treatment on the defiberized oxidized fiber so as to obtain a nano-cellulose solution. The method is easier to realize wastewater separation and recovery of chemicals, at the same time can save pulping energy consumption by 20%-82%, and is easier to obtain nano-cellulose with uniform size and low cost.

Owner:GOLD EAST PAPER JIANGSU

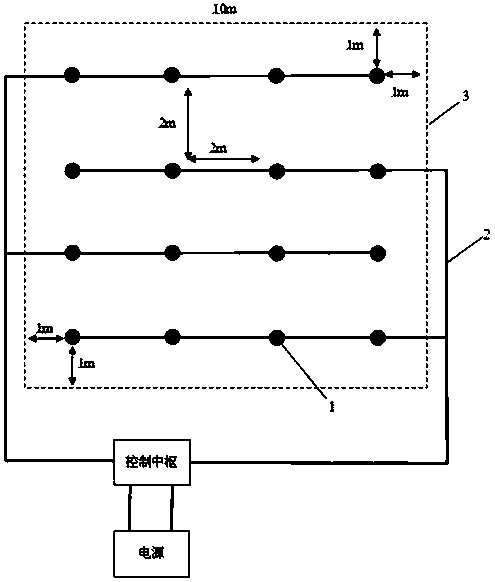

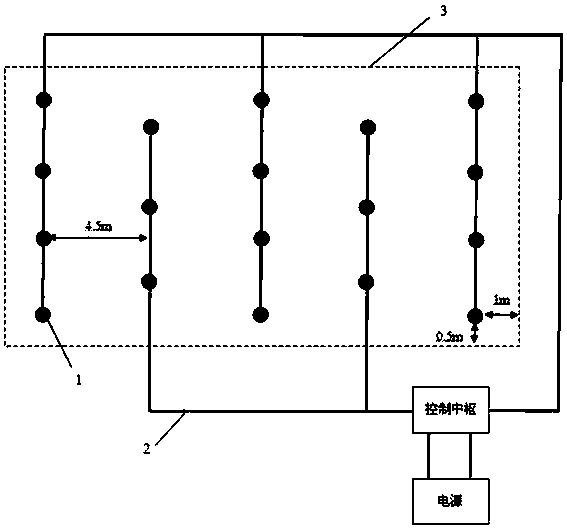

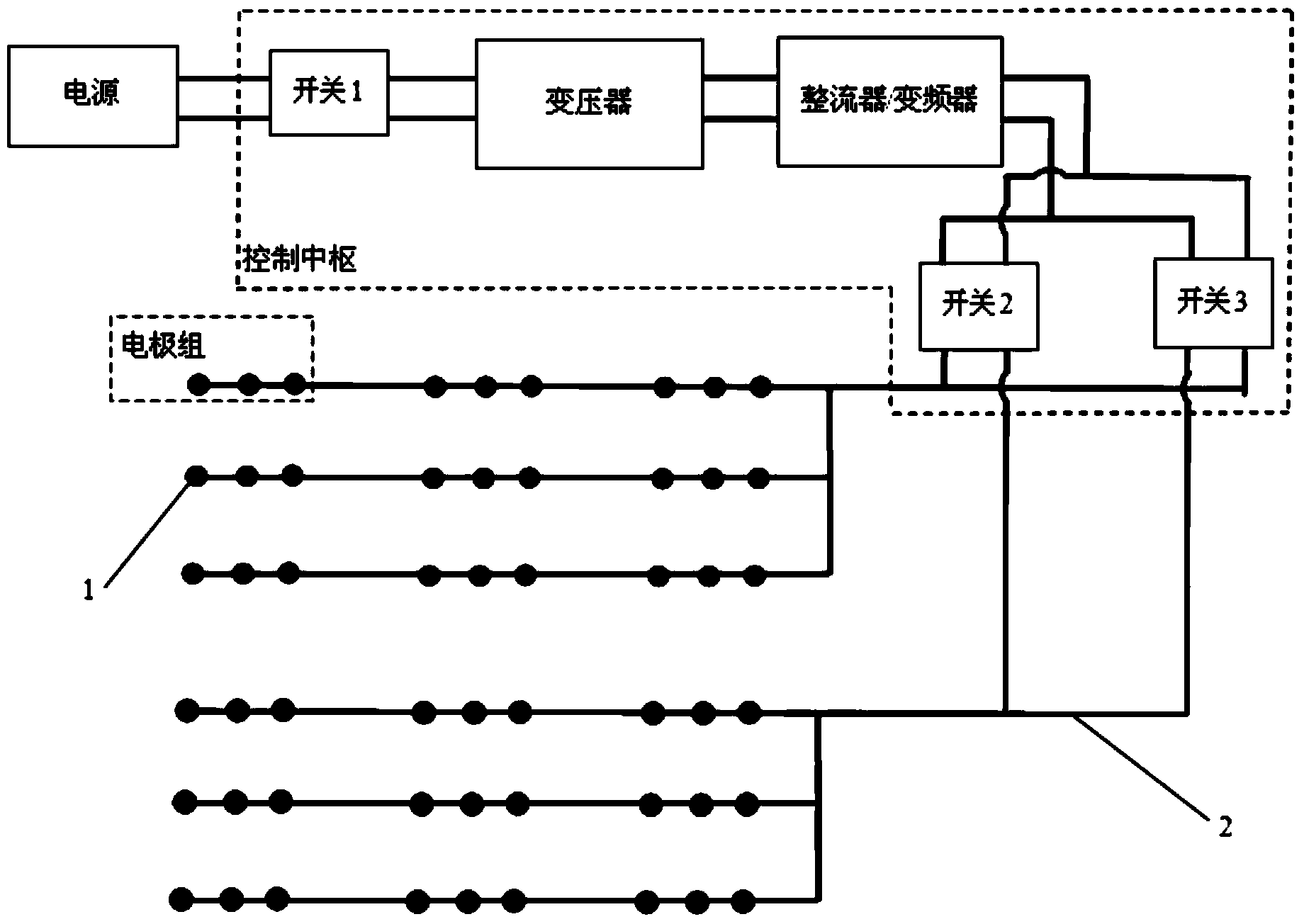

Electrochemical device for treating pollution caused by organic matters and inorganic matters in soil and underground water and application of electrochemical device

ActiveCN103896369AOvercoming limitations of in situ useImprove efficiencyWater/sewage treatment by electrochemical methodsContaminated soil reclamationPower flowElectrical polarity

The invention discloses an electrochemical device for treating pollution caused by organic matters and inorganic matters in soil and underground water and an application thereof. The device is characterized by being a control circuit which consists of a power supply, a control pivot and an electrode pack or electrodes, which are sequentially connected in series through leads, wherein the electrode pack or the electrodes are embedded into a pollution medium, and a conductive ionic catalytic liquid is added into the pollution medium; the control pivot receiving current output by the power supply adjusts output to the electrode pack or the electrodes so as to control the voltage, the polarity and / or the current direction of the electrode pack or the electrodes. The device disclosed by the invention can effectively promote degradation of pollutants in soil and underground water and improve the degradation efficiency of the pollutants without secondary pollution, so that the purpose of repairing soil is realized by treating organic and inorganic pollutants in soil and underground water.

Owner:陈亮

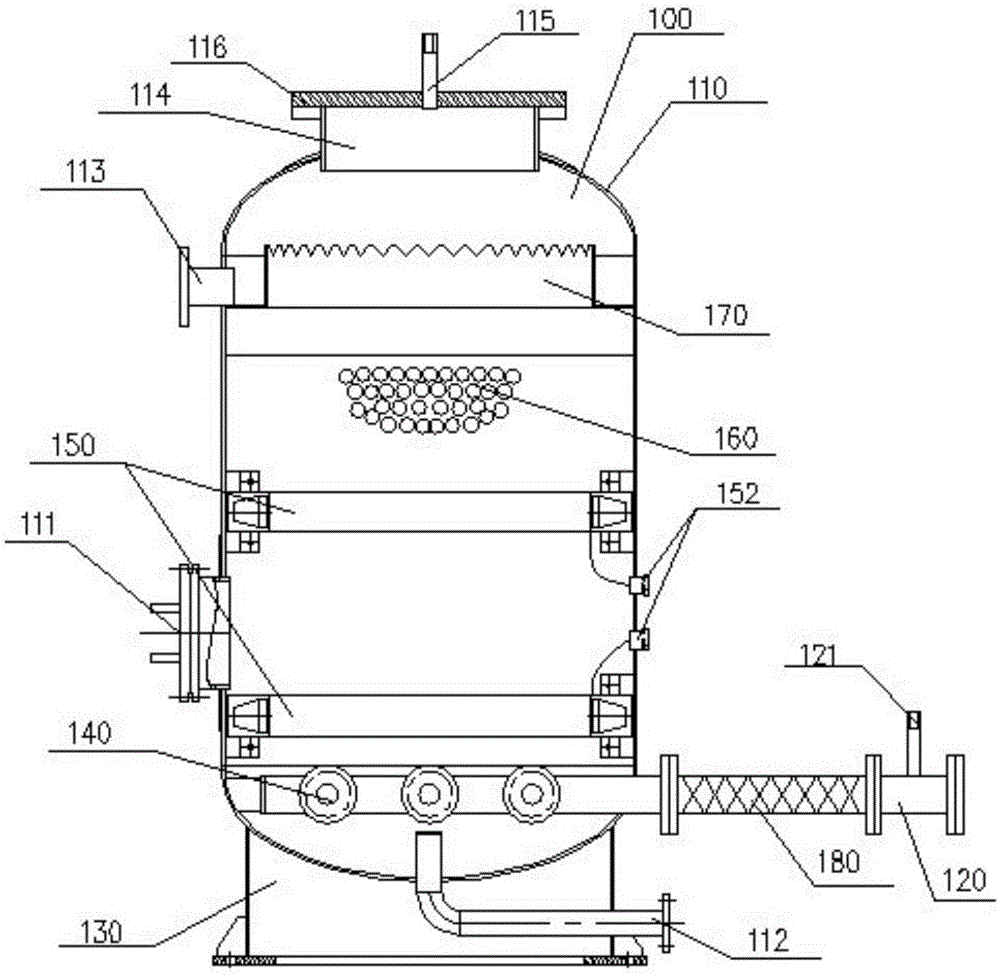

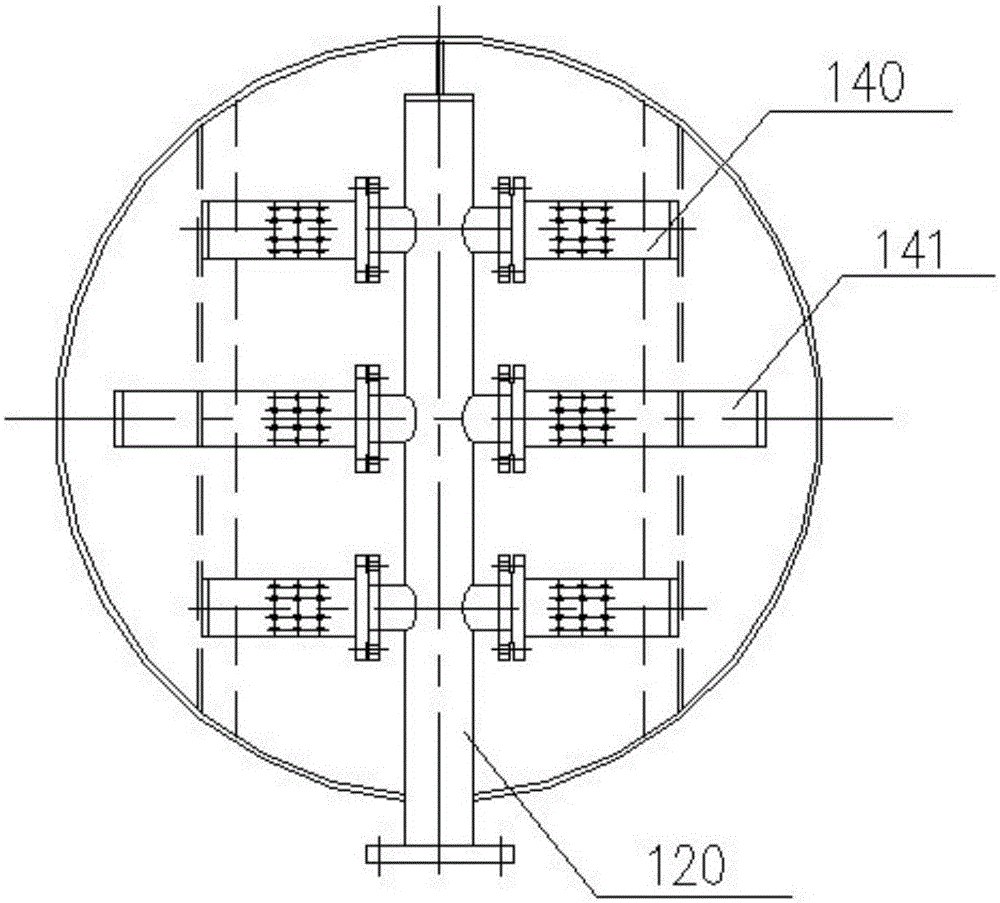

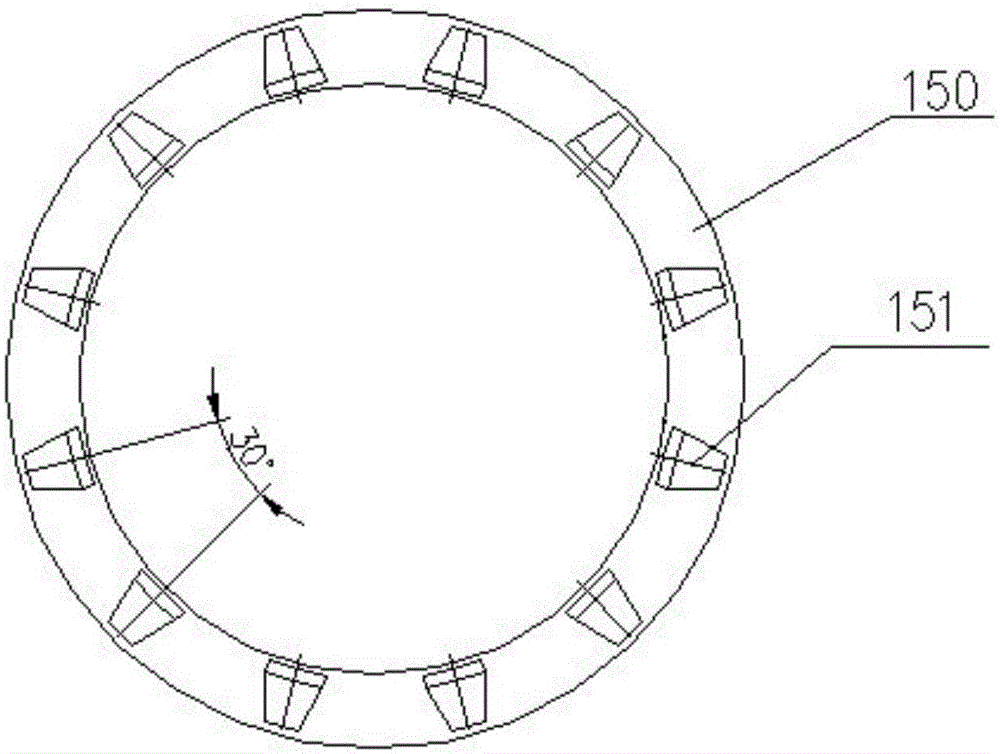

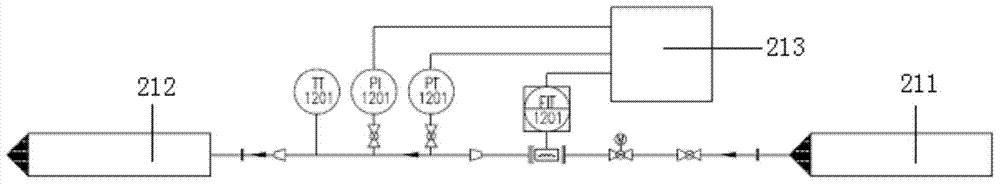

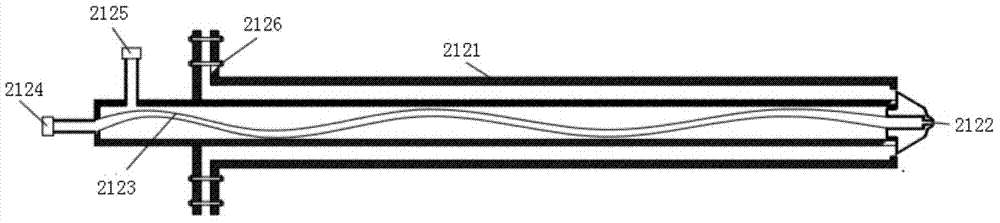

Ozone oxidation reactor

ActiveCN105000627AReal-time processingEasy to moveWaste water treatment from quariesWater/sewage treatment with mechanical oscillationsChemical oxygen demandUltrasonic cavitation

The invention discloses an ozone oxidation reactor. The ozone oxidation reactor comprises a tank body and a water inlet pipe communicated with the tank body. The water inlet pipe is provided with a water inlet and an ozone inlet. Ozone is fed in the ozone inlet. A hydrodynamic cavitation device allowing water and the ozone to generate hydrodynamic cavitation is arranged in the water inlet pipe. Ultrasonic oscillators allowing the water and the ozone to generate ultrasound cavitation are arranged in tank body and connected with an ultrasonic generator. A cavity of the tank body is filled with catalysts for motivating the ozone to generate hydroxyl radical. According to the ozone oxidation reactor, ozone oxidation is combined with an ultrasonic cavitation technology and a hydrodynamic cavitation technology to form a synergetic catalytic ozonation technology, the hydroxyl radical with the higher oxidation performance and lower reaction selectivity is generated, the oxidation potential of the hydroxyl radical can reach 2.8 V, the hydroxyl radical can generate a chain reaction with most of organic pollutants unselectively, hazardous substances are converted into CO2, H2O and mineral salt, the chemical oxygen demand is lowered, and meanwhile secondary pollution is avoided.

Owner:INST OF SINOPEC OILFIELD EQUIP CORP +1

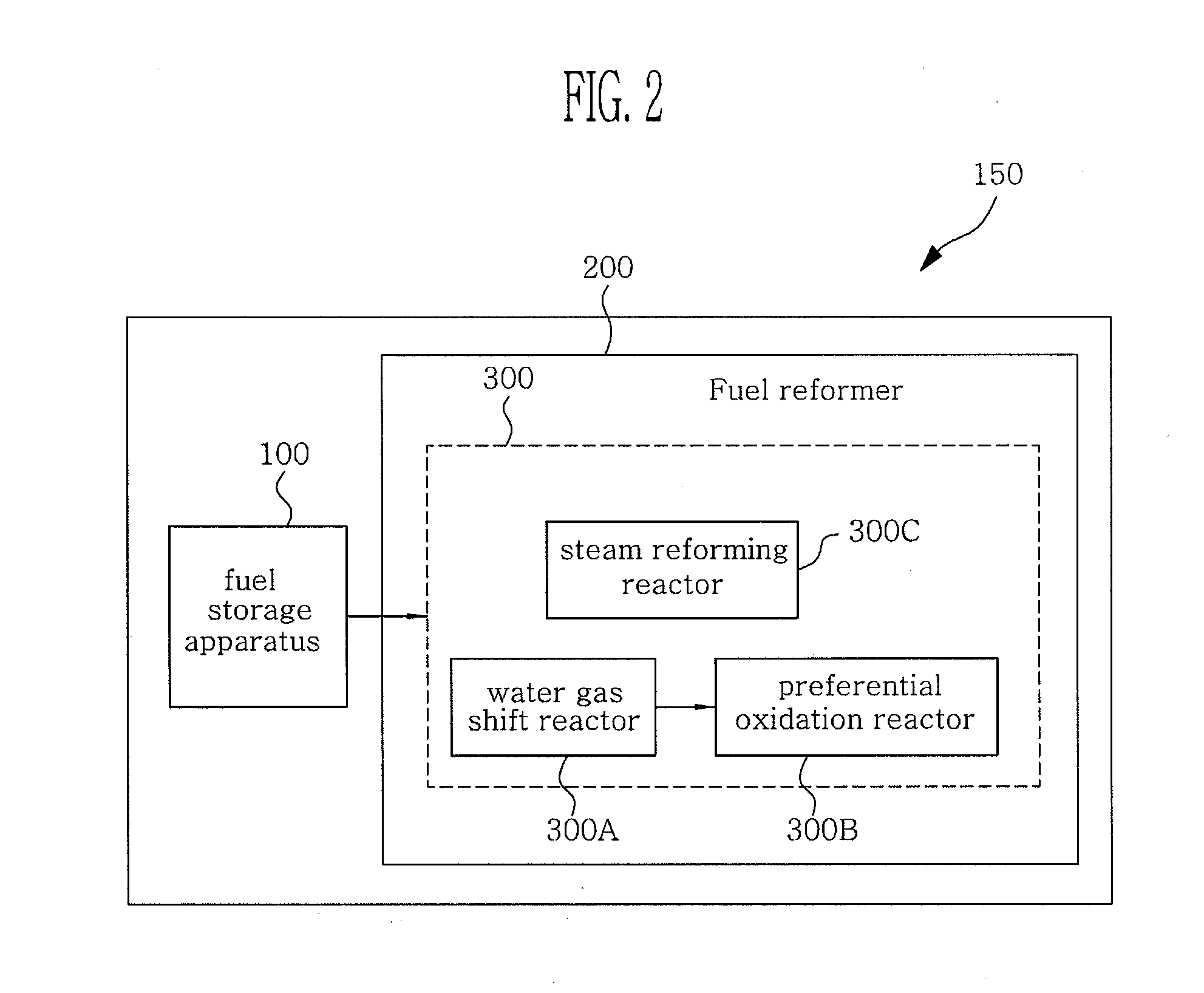

Fuel reforming apparatus and fuel cell system

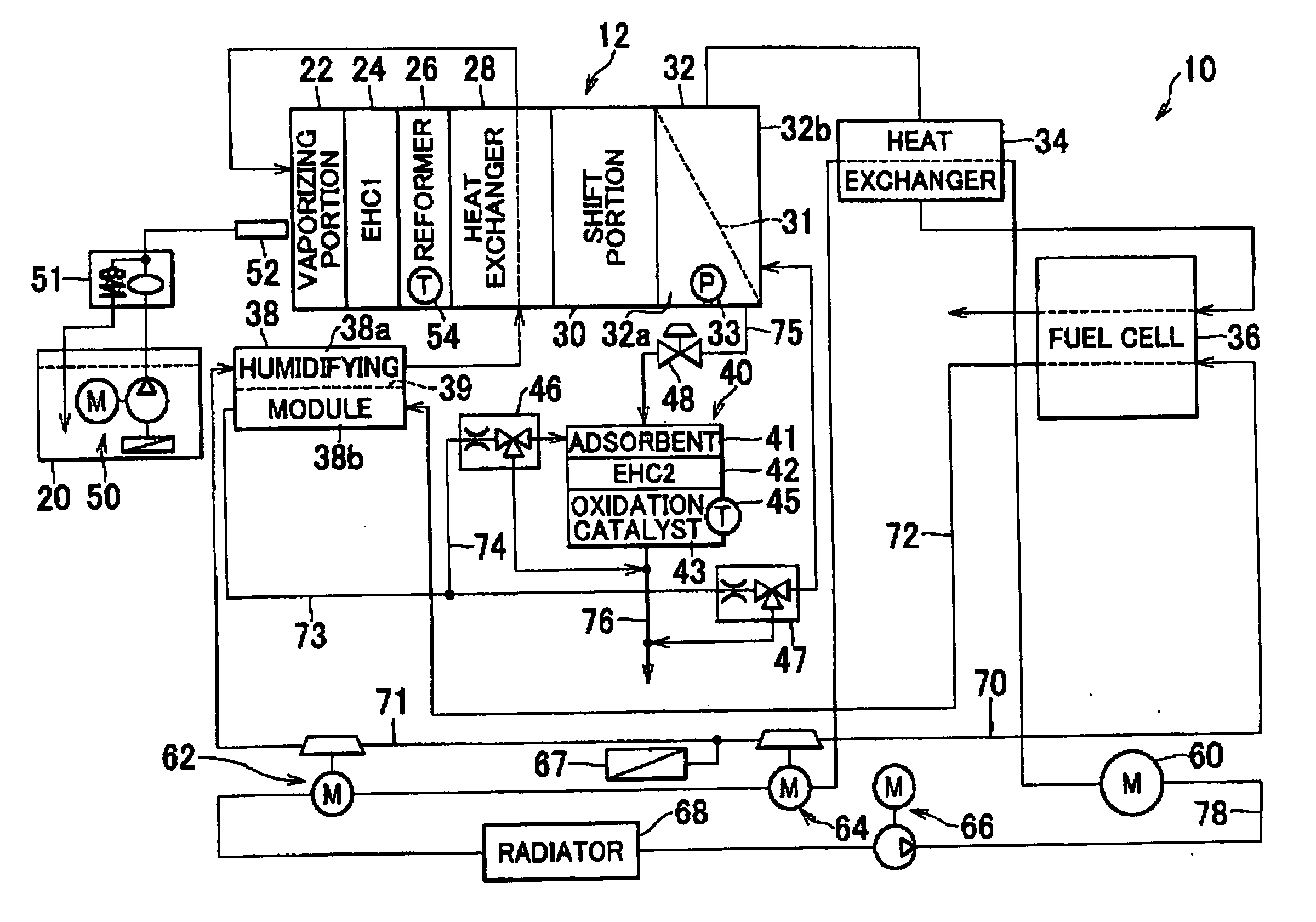

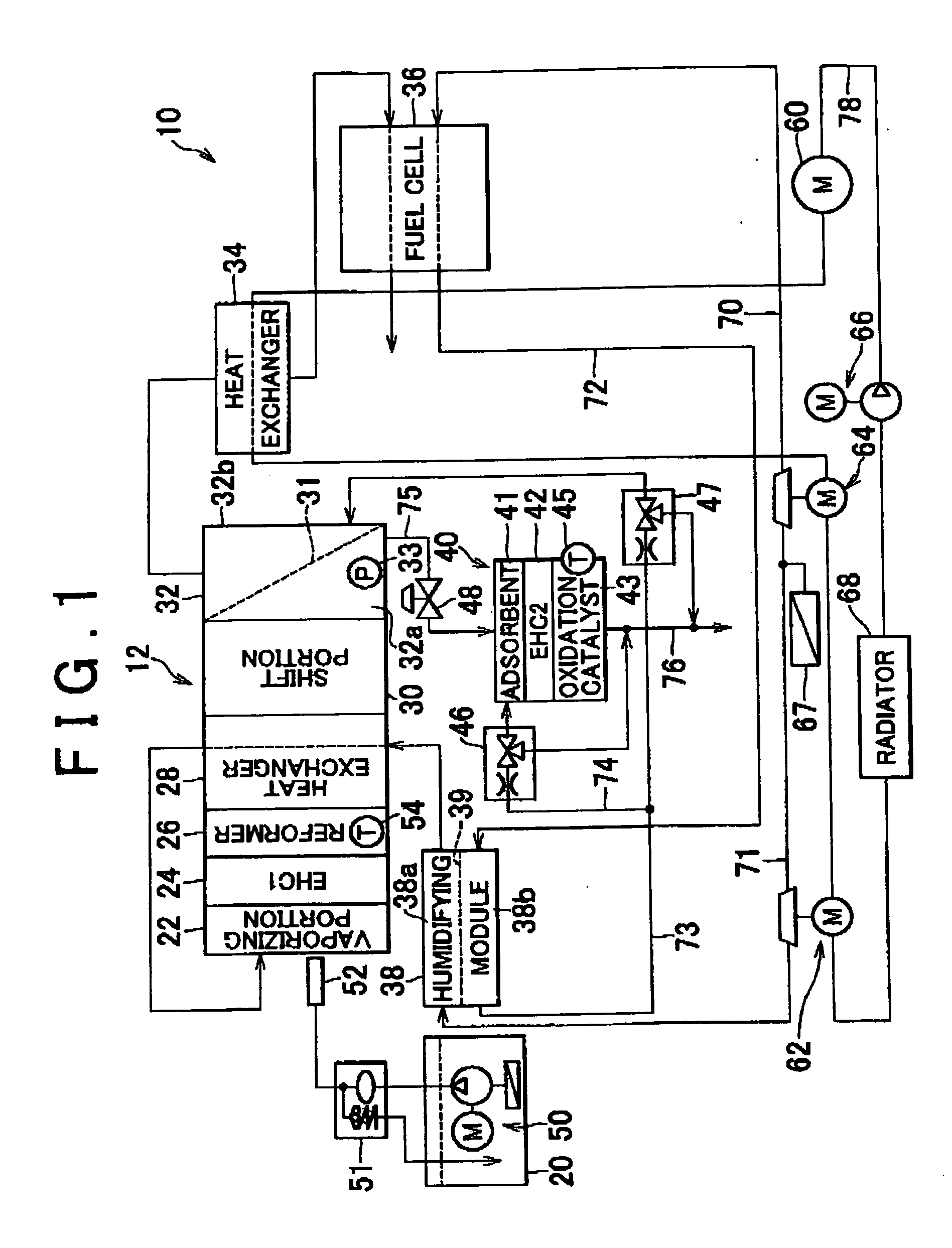

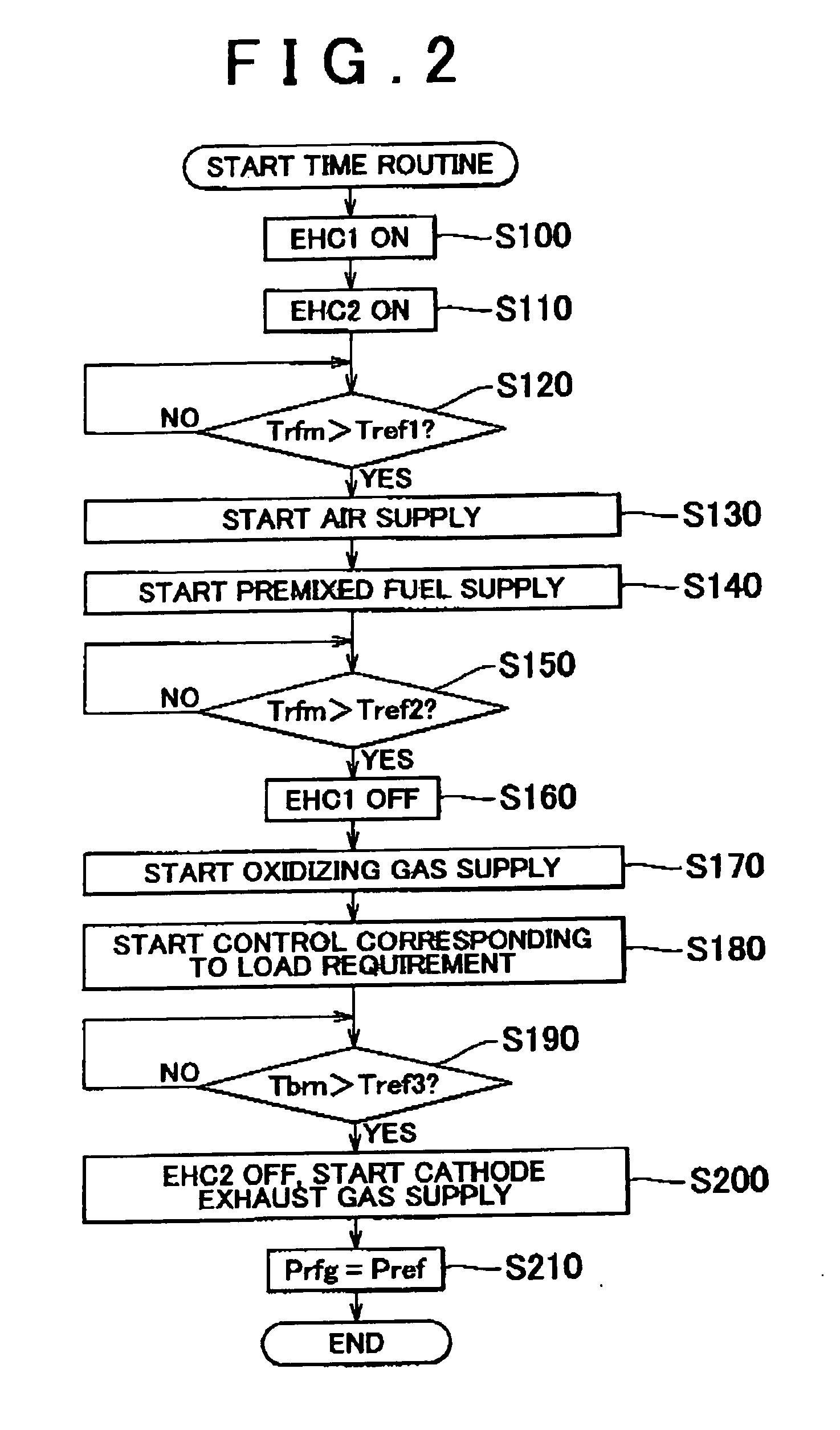

InactiveUS20040226218A1Easy to evaporateStable stateThermal non-catalytic crackingProcess control/regulationFuel cellsGasoline

A fuel reforming apparatus includes a premixed fuel tank. In the premixed fuel tank, premixed fuel which is formed by emulsifying gasoline and water that are mixed with each other at a predetermined ratio, using a emulsifier. The premixed fuel is sprayed into a vaporizing portion through a nozzle. Heat can be supplied to the vaporizing portion by the reformer in which oxidation reaction proceeds, a first heating portion, and air supplied to the vaporizing portion through a heat exchanger. The premixed fuel sprayed into the vaporizing portion is vaporized immediately by the thus supplied heat, and is supplied to the reformer. In addition, air which has been humidified in a humidifying module cam be supplied to the vaporizing portion.

Owner:TOYOTA JIDOSHA KK

Zero discharge system for treating flue gas of boiler and method

ActiveCN104841256AReduce consumptionImprove oxidation reaction efficiencyLighting and heating apparatusDispersed particle separationOzone generatorFlue gas

The invention discloses a zero discharge system for treating a flue gas of a boiler and a method. The zero discharge system comprises a boiler, an oxidation reactor and a desulfurizing tower, wherein the boiler is used for generating a flue gas; the oxidation reactor and the desulfurizing tower are sequentially connected with the boiler through a pipeline; the oxidation reactor is also connected with an ozone preparation and distribution unit; the ozone preparation and distribution unit comprises an ozone generator and at least two spray guns; the spray guns are connected with the ozone generator, and extend into the oxidation reactor; and furthermore, the ozone injection quantity in various spray guns and the positions of the various spray guns in the oxidation reactor can be adjusted by the system according to the concentration of nitric oxide and sulfur oxide in the flue gas in the oxidation reactor within the injection ranges of the spray guns. According to the zero discharge system and the method, the quantity and the distribution positions of the spray guns, and the ozone injection quantity in the spray guns can be adjusted according to the concentration differences of flue gas pollutants in various reaction regions in the flue; adjustable control on the ozone quantity within each reaction region is realized; the oxidation reaction efficiency is improved; and the treatment cost is reduced.

Owner:北京宜泽环保科技有限责任公司

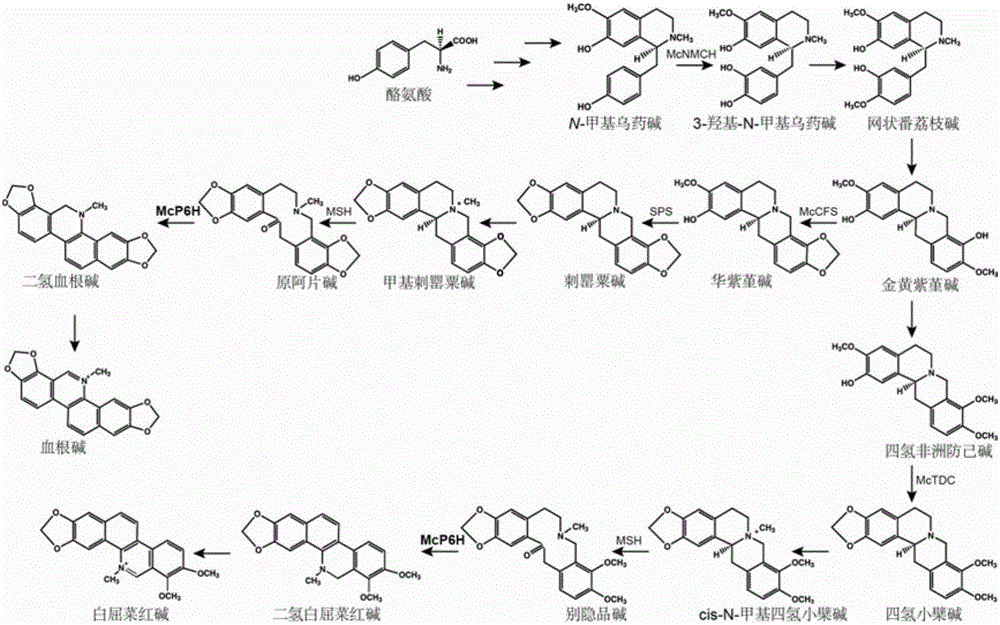

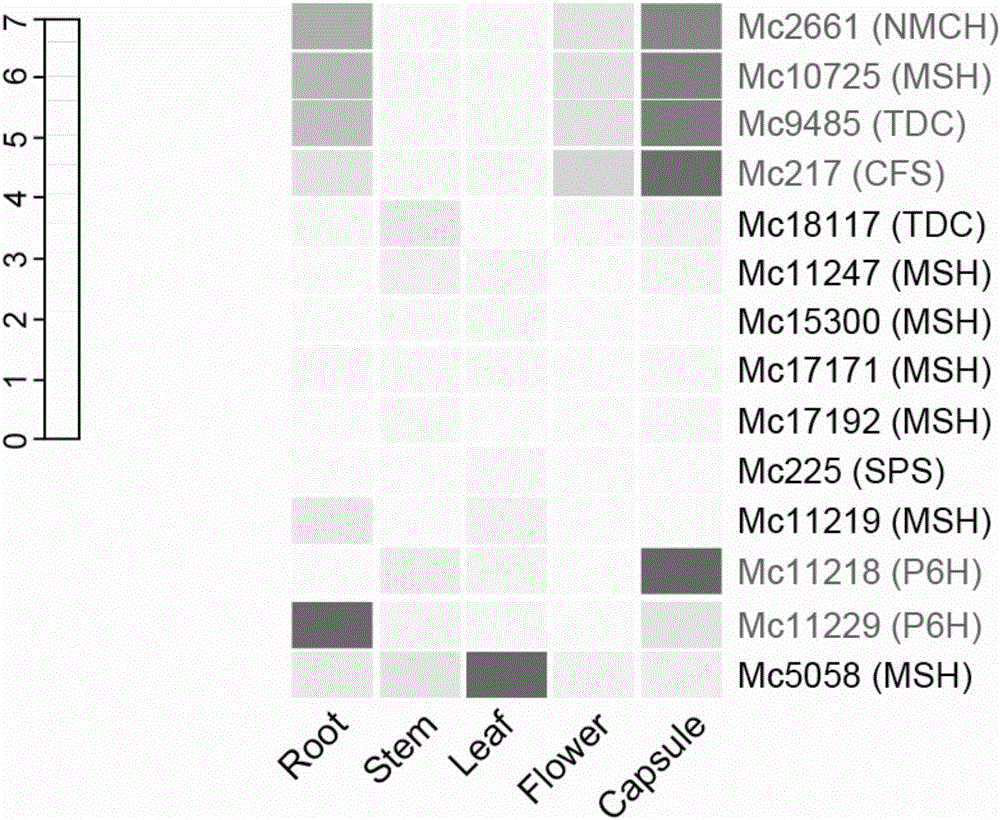

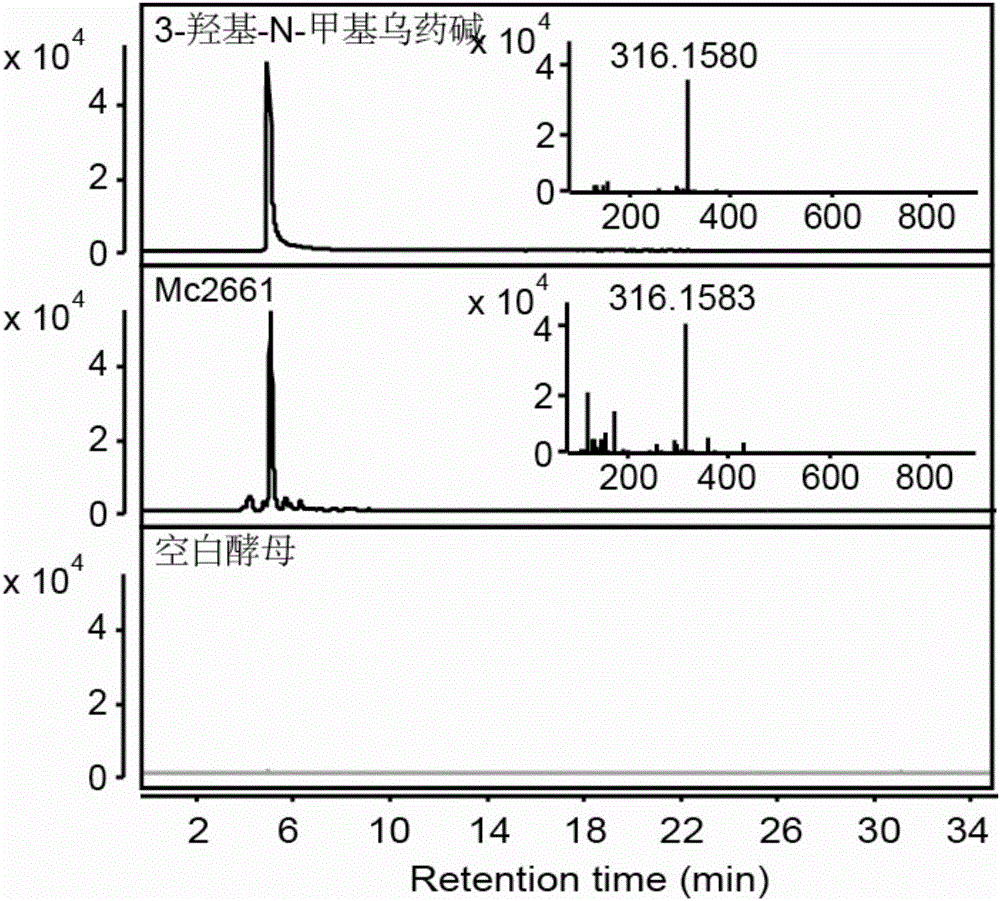

Cytochrome P450 enzyme gene for taking part in sanguinarine and chelerythrine synthesis in macleaya cordata and application of cytochrome P450 enzyme gene

ActiveCN106119265AAchieve synthesisAchieve in vitro synthesisTransferasesOxidoreductasesSanguinarineChelerythrine

The invention discloses cytochrome P450 enzyme gene for taking part in sanguinarine and chelerythrine synthesis in macleaya cordata and application of the cytochrome P450 enzyme gene. For the first time, five cytochrome P450 enzyme genes taking part in sanguinarine and chelerythrine synthesis are found in macleaya cordata genome and comprise gene Mc9485, gene Mc2661, gene Mc217, gene MC11229 and gene Mc11218. A brewer's yeast system verifies that the steps of reaction are respectively verified by upstream precursor feeding and synthesis of sanguinarine and chelerythrine intermediate is achieved. According to the cytochrome P450 enzyme gene, the conversion efficiencies of the same function genes in the macleaya cordata, the papaver somniferum and the eschscholzia californica are compared by the brewer's yeast heterogeneous expression system, and the conversion efficiency of the macleaya cordata is obviously higher than those of the papaver somniferum and the eschscholzia californica. According to the cytochrome P450 enzyme gene, a molecular mechanism of the sanguinarine synthesis in the macleaya cordata is further revealed. Thus, a theoretical basis and a molecular assistant breeding target are provided for the breeding of the macleaya cordata with high sanguinarine and chelerythrine content. Meanwhile, valuable experience is provided for in-vitro artificial synthesis of the sanguinarine and the chelerythrine.

Owner:MICOLTA BIORESOURCE INC LTD

Process for the catalytic oxidation of hydrocarbons

InactiveUS7074838B2Improve oxidation reaction efficiencySpeed up the flowOrganic chemistry methodsCarboxylic acid esters preparationPartial oxidationCatalytic oxidation

Owner:INEOS EURO LTD

A preparing process of energy-saving environmental-friendly type modified polymeric ferric sulfate

ActiveCN104761002AIncrease added valueGood flocculation effectChemical industryIron sulfatesSlagTurbidity

The invention relates to a preparing process of energy-saving environmental-friendly type modified polymeric ferric sulfate. The process includes following steps: adding polyaluminum chloride waste slag and a sulfuric acid type ferrous sulfate-acid mixture into a pretreatment kettle, heating, stirring, reacting and performing filter pressing to obtain a first reaction liquid material; adding green vitriol and a sulfuric acid type ferrous sulfate-acid mixture into a pretreatment kettle and stirring to obtain a second reaction liquid material; and adding the first and second reaction liquid materials into a sealed acid-resistant pressure-resistant reactor, adding a catalyst solution and a cocatalyst solution, feeding oxygen, heating, reacting, and cooling to obtain a modified polymeric ferric sulfate solution. The beneficial effects of the process are that the polymeric ferric sulfate containing a trace amount of aluminum and silicon is high in added value, has flocculation effects superior to flocculation effects of polymeric ferric sulfate, and can be used for treatment of high-turbidity high-COD printing and dying waste water; production raw materials are all industrial waste materials; the raw material cost is reduced; reaction time is shortened; and the time cost is saved.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

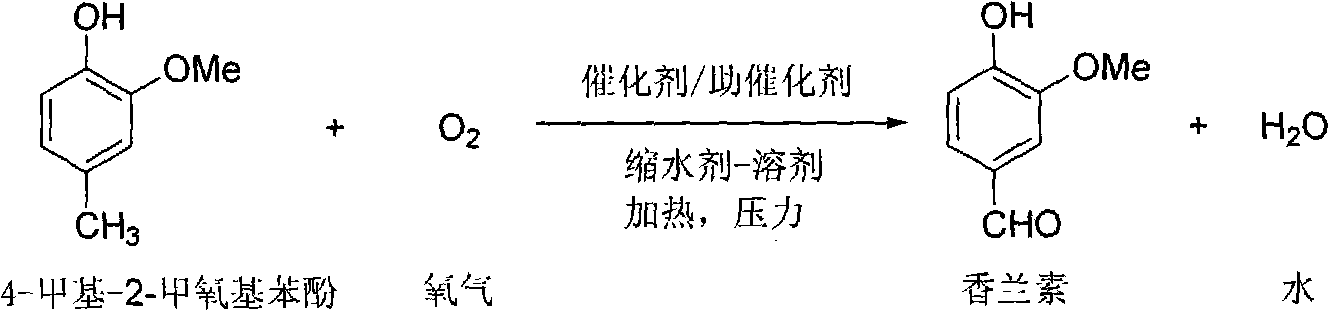

Method for synthesizing vanillin

InactiveCN102030625AAvoiding Explosion HazardsAvoid deep oxidationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorVanillin synthesis

The invention relates to a method for synthesizing vanillin, comprising the following steps of: carrying out material thermal pretreatment by adopting a pressured reaction axe, and then pouring the materials into a cannular slurry reactor for vanillin synthetic oxidation reaction; and by using 4-methyl-2-metoxyphenol as a raw material, using ethylene glycol monomethyl ether or ethylene glycol monoethyl ether as a solvent and using oxygen as an oxidant, carrying out the oxidation reaction for synthesizing vanillin in a way of intermittently feeding oxygen. The conversion rate of the 4-methyl-2-metoxyphenol as the raw material reaches more than 99%, the selectivity of the vanillin reaches more than 93%, and the separation yield reaches about 82%. The oxidation test carried out in the cannular slurry reactor proves that the oxidation reaction of the 4-methyl-2-metoxyphenol can be successfully carried out in the reactor under a milder condition to synthesize vanillin, and the method avoids a danger of easy explosion of the traditional axe type oxidation technology process for synthesizing vanillin by using methanol as the reaction solvent and has the advantages of environmental-protection process and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

Apparatus for treating discharge gas and system for treating discharge gas

InactiveCN102099096AIncrease contact timeImprove oxidation reaction efficiencyNitrous oxide captureGas treatmentNitrogen oxidesHoneycomb

Owner:MITSUBISHI HEAVY IND LTD

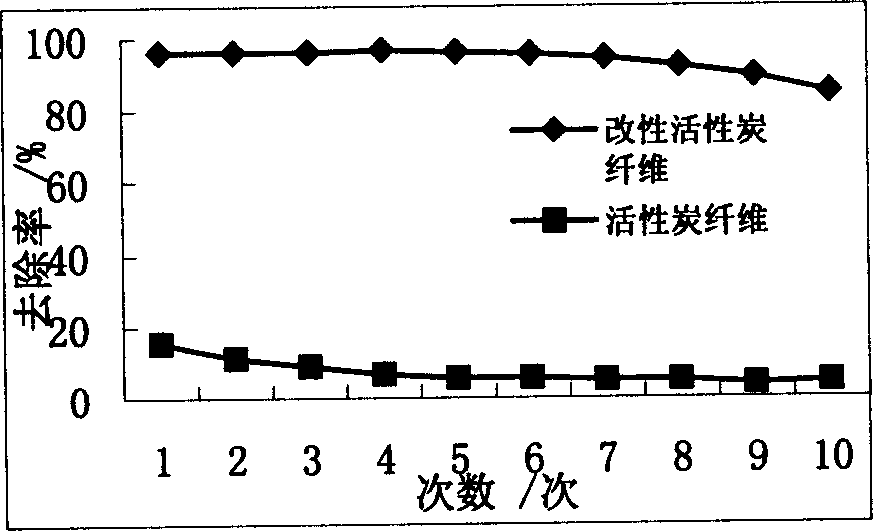

Process for preparing Fe-Sn modified active carbon fibre catalyst for microwave induced oxidation

InactiveCN1602996APromote absorptionReduce dosagePhysical/chemical process catalystsMuffle furnaceUrea

A method uses to preparate the MIOP hard tin modified activated carbon textile fiber catalyst, it involves one kind of preparing method of the catalyst.It is realized like this; A.Soaks the activated carbon textile fiber into the mix solution which includes Fe2+, the Sn2+, then joins the urea; B.Lays the above mixture under 50~90deg.C for 10~15hours, clear washes off the settling attaches onto the surface of the activated carbon textile fiber, dry it then get the catalyst forerunner body; C.Roastes it in the muffle furnace then colds it to the room temperature, obtains the modified activated carbon textile fiber catalyst.The method choose the activated carbon textile fiber as the substrate of the MIOP catalyst,by carries on the process chemistry modification MIOP to the activated carbon textile fiber surface, strengthens its absorbancy to the microwave, reduces the catalyst amount used and lengthens the age of catalyst.The invention effectively enhances the MIOP catalyst efficiency (approximately 5~10to double), lengthenes the MIOP catalyst service life (experimental repetitely use for above 10times, it removeing efficiency still may maintains above 80%) reduces the catalyst amount used (its amount used only is 1, / 10of the pellet activated charcoal).

Owner:HARBIN INST OF TECH

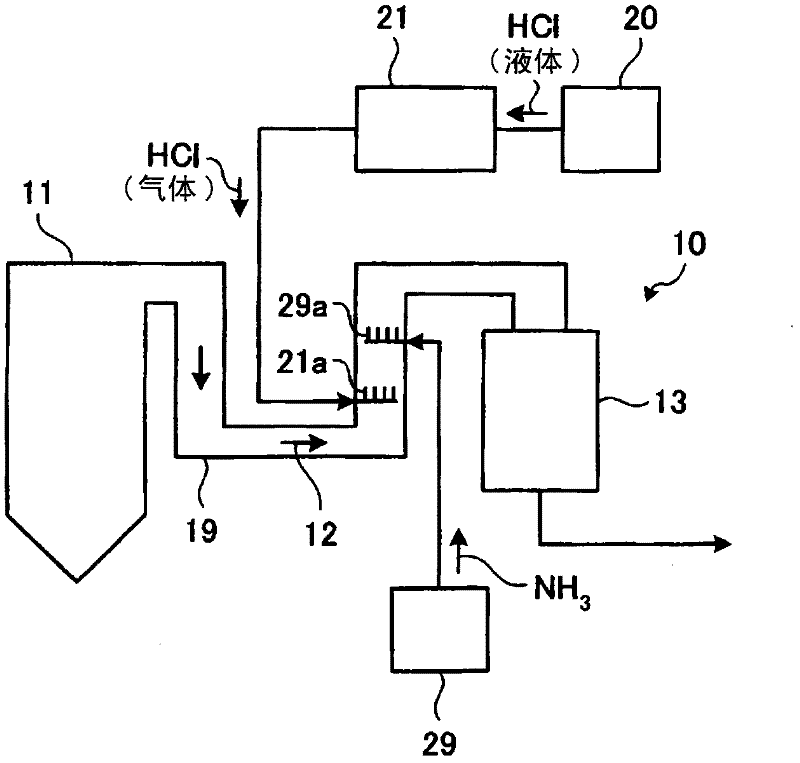

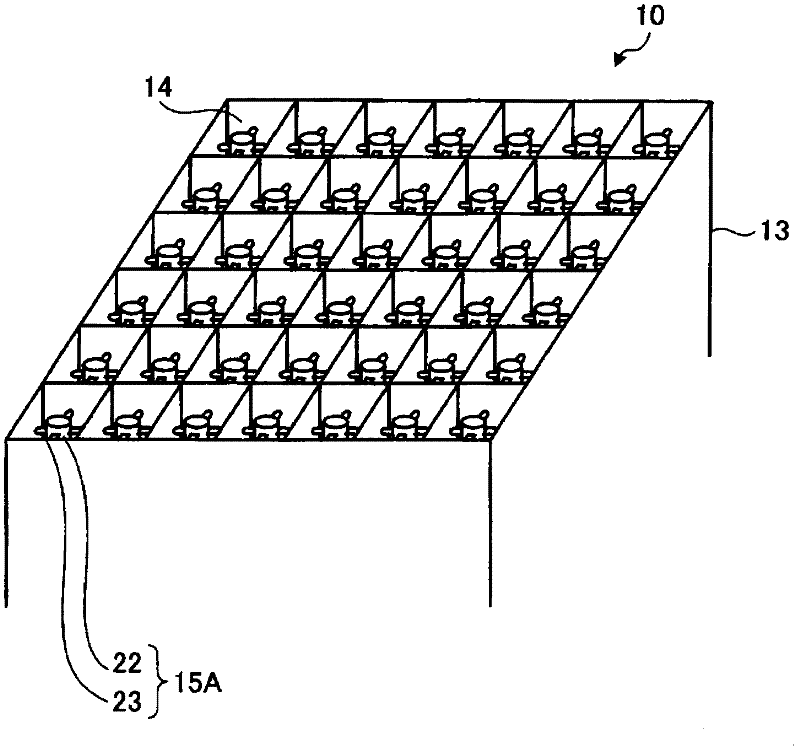

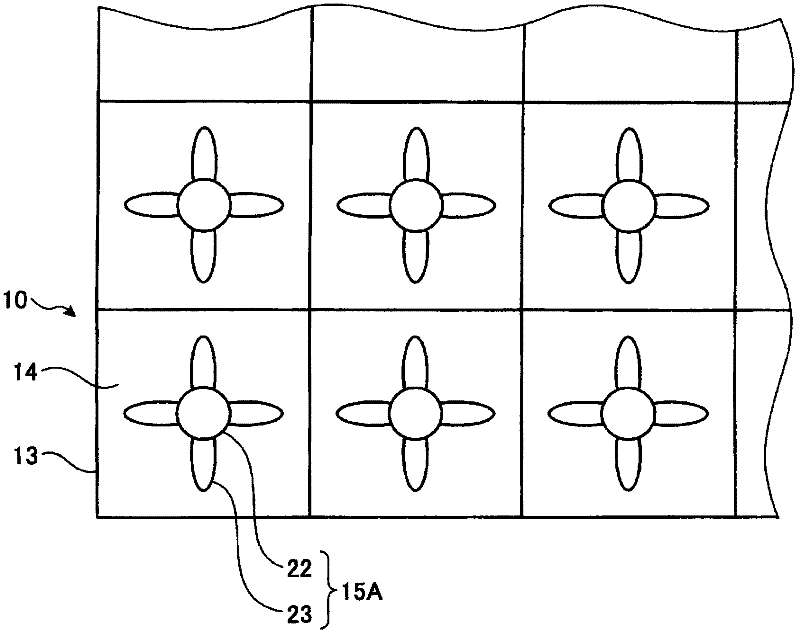

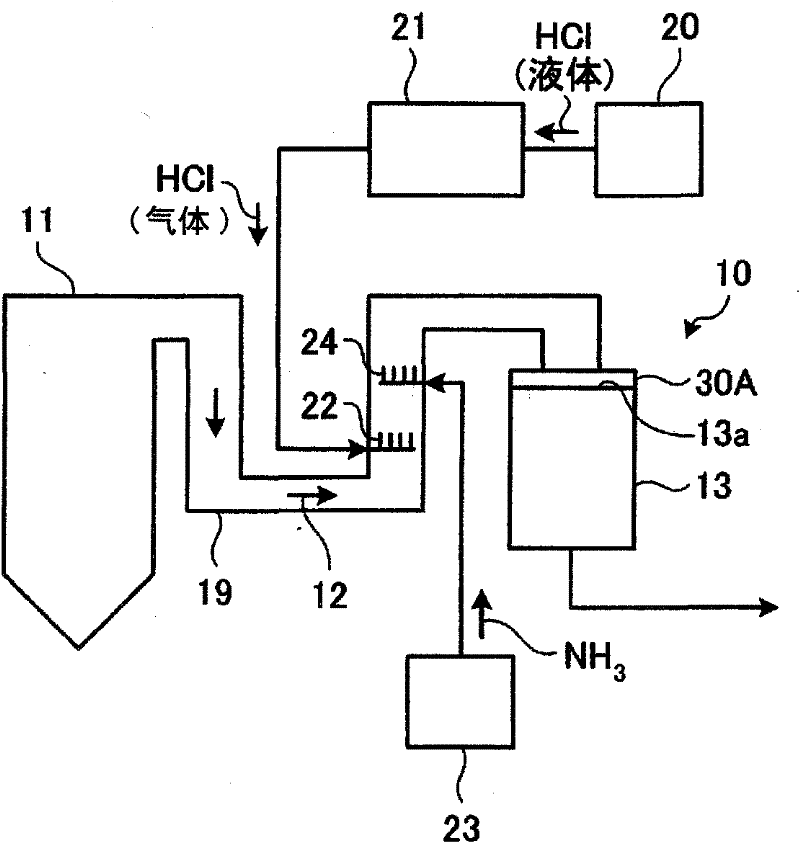

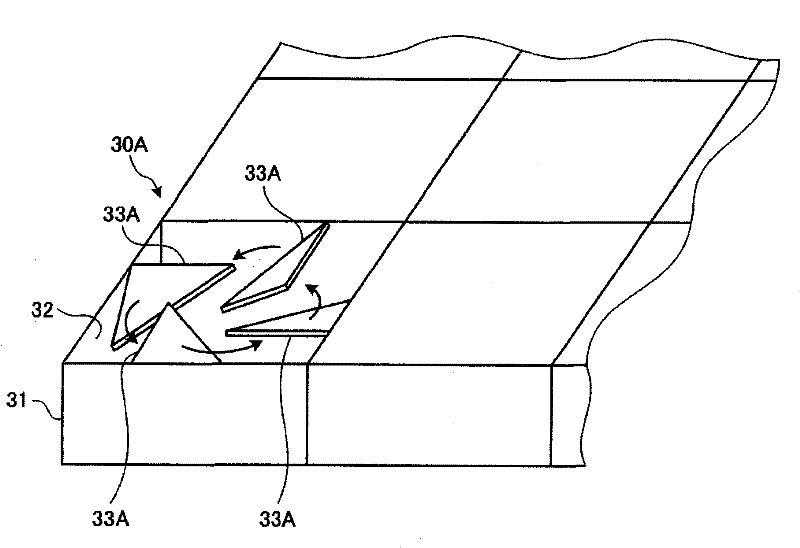

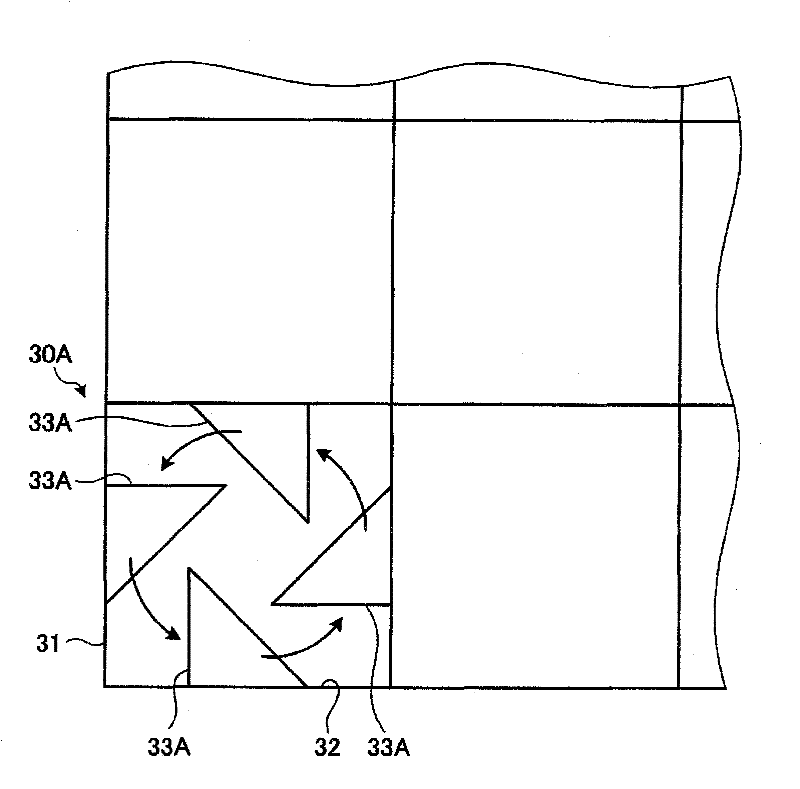

Apparatus for treating discharge gas and system for treating discharge gas

InactiveCN102099097AIncrease contact timeEfficient removalGas treatmentPhysical/chemical process catalystsEnvironmental engineeringSpiral flow

An apparatus for discharge gas treatment (10) having a denitration catalyst layer (13) which removes NOX from a discharge gas (12) and in which HCl is sprayed in the discharge gas (12) to oxidize mercury. The apparatus has a spiral-flow generation member (30A) disposed on an inlet (13a) side of the denitration catalyst layer (13). The member (30A) is constituted of: a spiral-flow generation member main body which has been partitioned so as to correspond to individual passages of the denitration catalyst layer (13); and a plurality of spiral-flow generation blades which have been disposed on the inner walls of each of the separated chambers and cause a turbulent flow. This configuration changes the flow of the discharge gas (12), which is a laminar flow in a flue (19), into a spiral flow inside the denitration catalyst layer (13). The time period of contact of the discharge gas (12) with the denitration catalyst can hence be prolonged to improve the efficiency of the oxidation reaction of the mercury contained in the discharge gas (12) with the denitration catalyst.

Owner:MITSUBISHI HEAVY IND LTD

Preparation method of formaldehyde-free flame retardant fiberboard

ActiveCN107586461AImprove oxidation reaction efficiencyReduce dosageWood working apparatusDomestic articlesFiberSolubility

The invention relates to the technical field of resource utilization of starch and fiber wastes, and specifically relates to a preparation method of a formaldehyde-free flame retardant fiberboard. Thepreparation method comprises the following steps: adding starch, sodium periodate, and magnesium salts into a ball mill to carry out solid phase activation to prepare dialdehyde starch; then mixing dialdehyde starch with a glue making aid to prepare a dialdehyde starch adhesive; mixing the dialdehyde starch adhesive with fiber wastes, and pressing the mixture in a vulcanizing press to obtain theformaldehyde-free flame retardant fiberboard. The dialdehyde starch is prepared by solid phase mechanical active oxidation reactions, the using amount of sodium periodate is little, and the oxidationreaction efficiency is high. The aldehyde group of dialdehyde starch reaches 1.15-2.45. The solubility reaches 40-50 g / 100g water. The prepared dialdehyde starch adhesive has the advantages of low cost, good dispersibility, low viscosity, and high bonding strength. The prepared fiberboard does not release formaldehyde, is safe and environmentally friendly, and has a good flame retardant performance.

Owner:GUANGXI UNIV

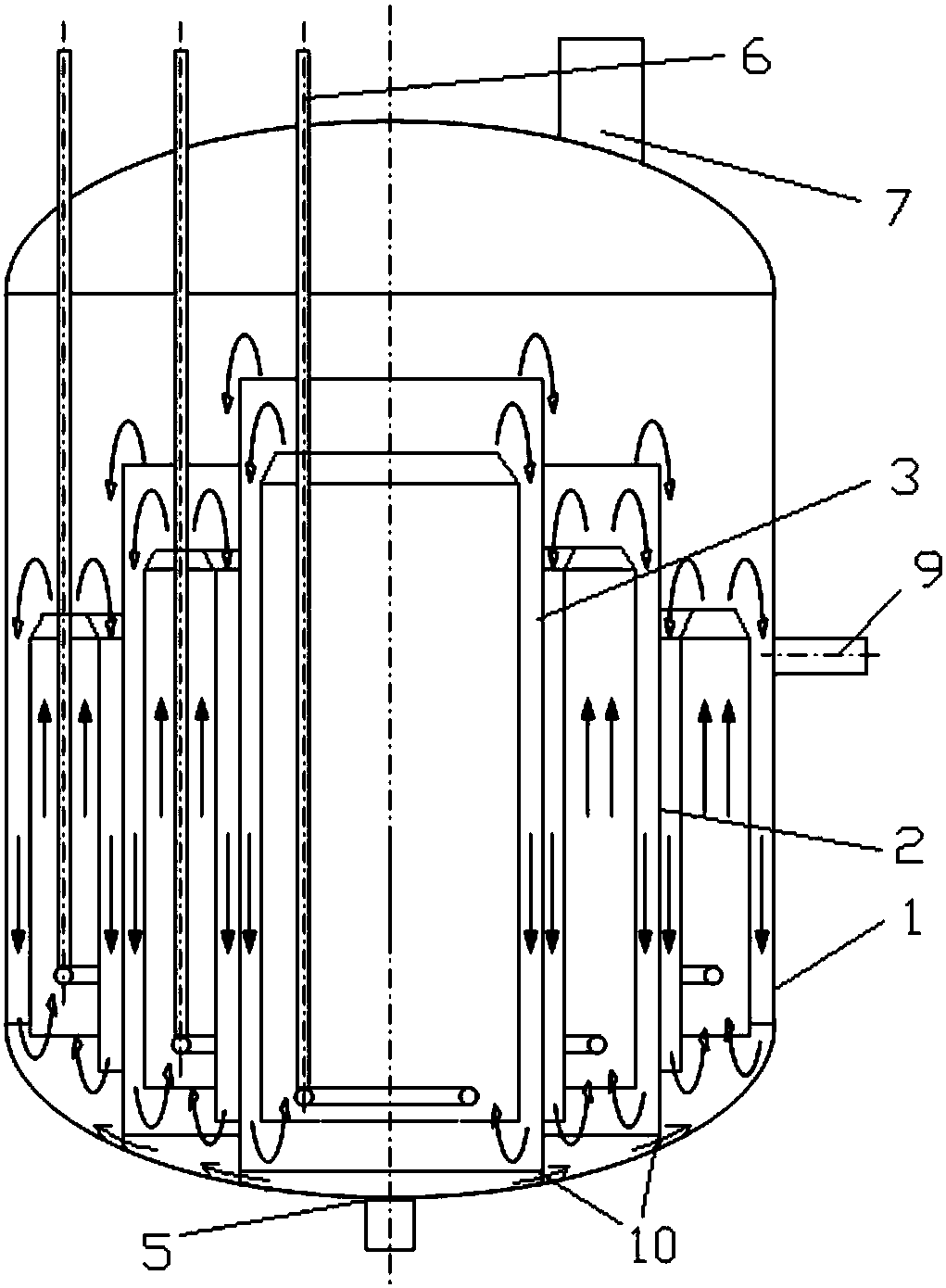

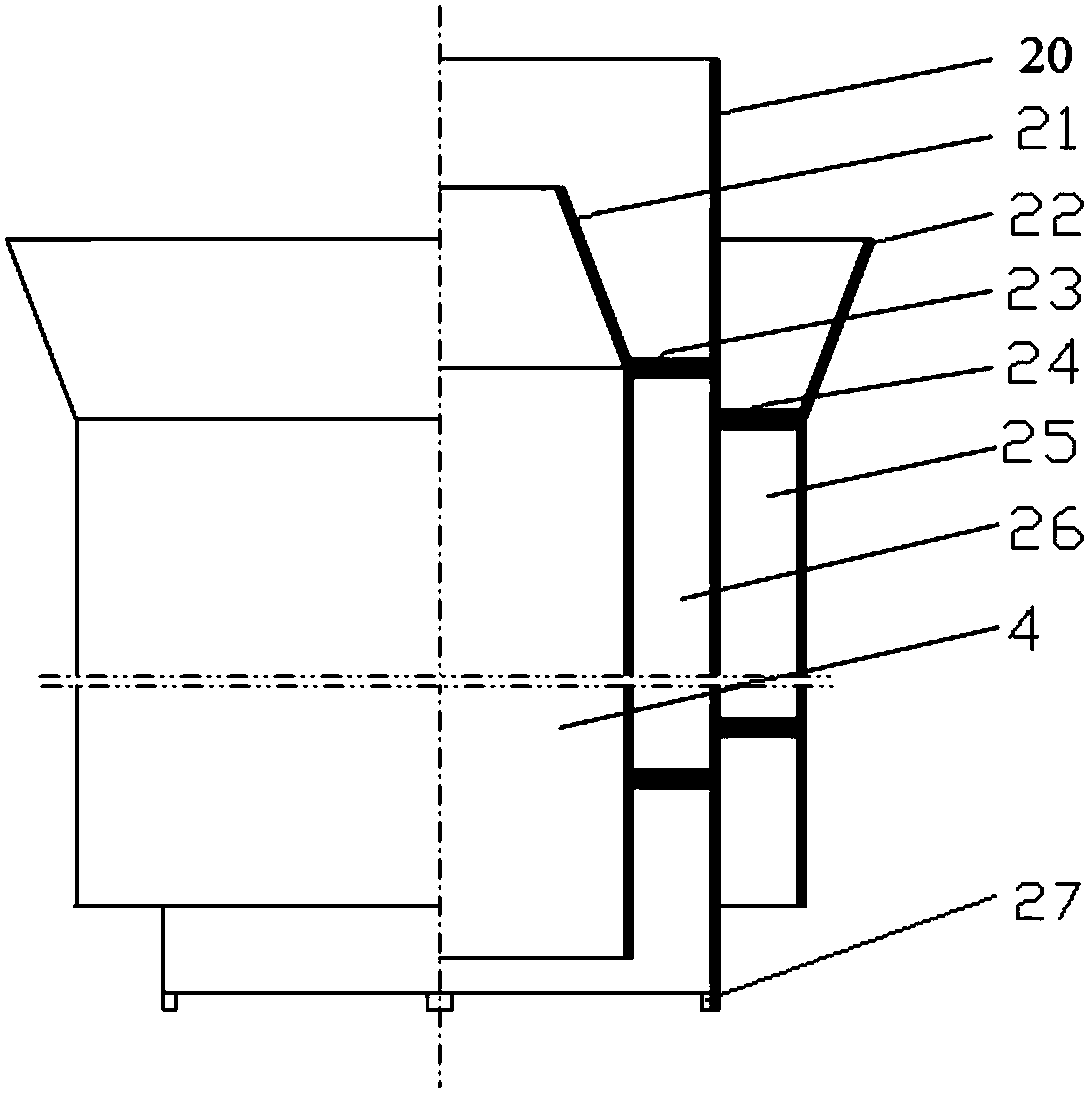

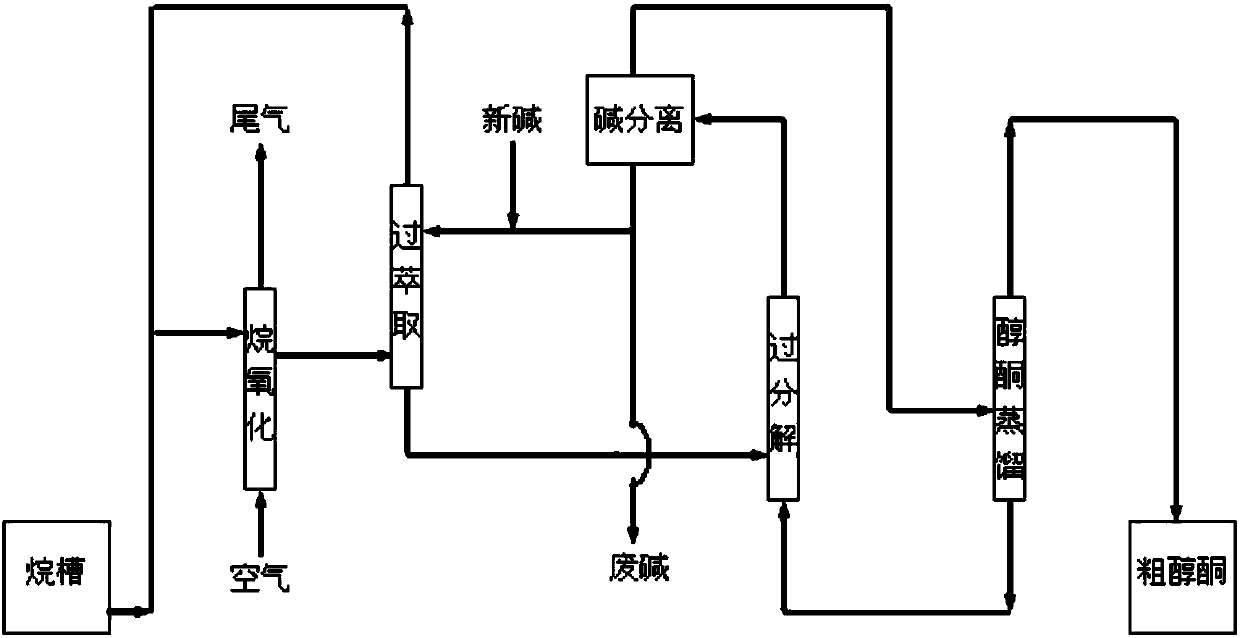

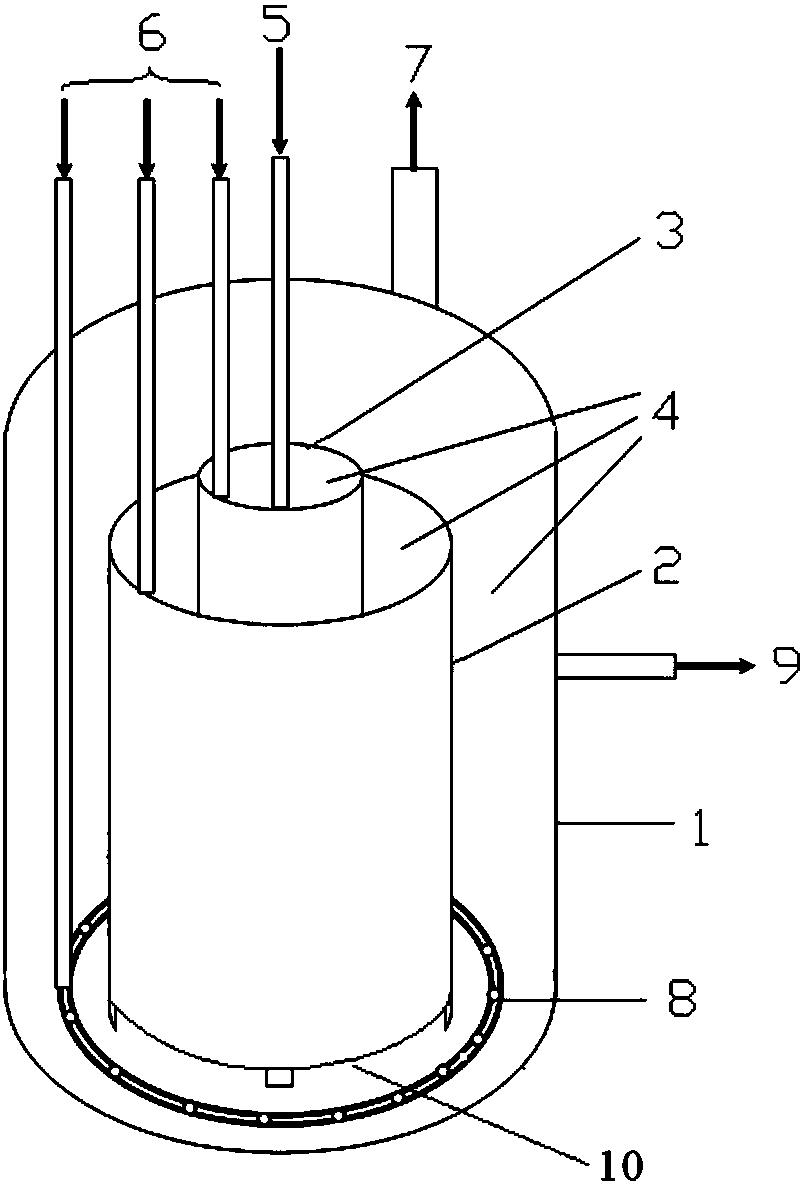

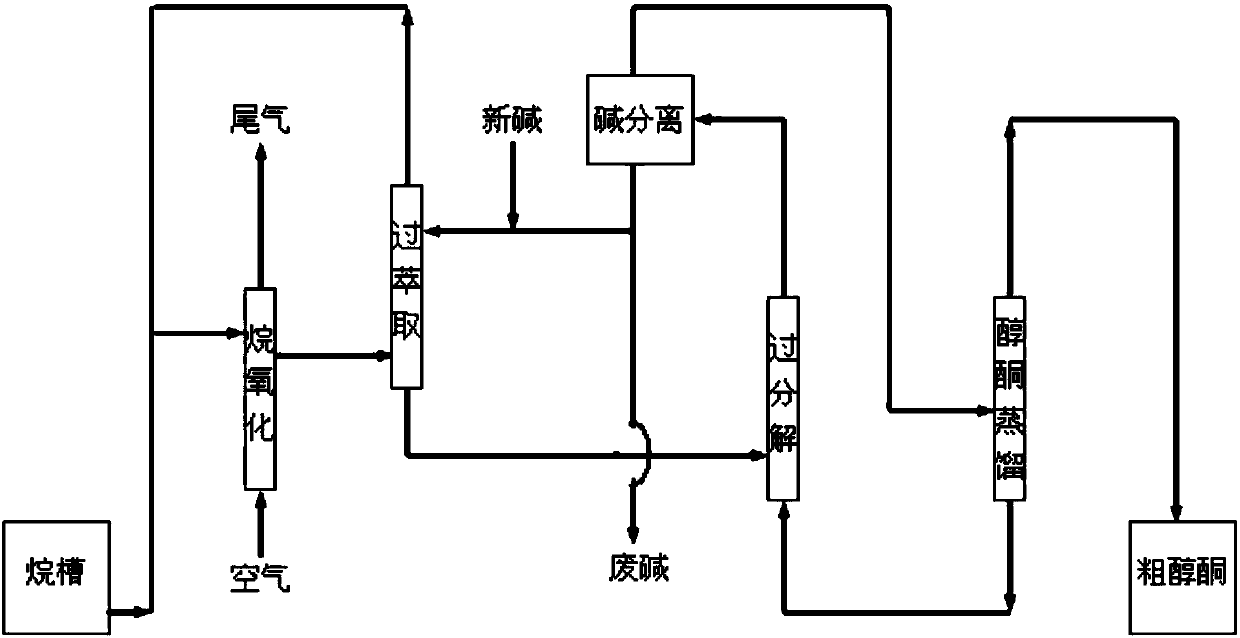

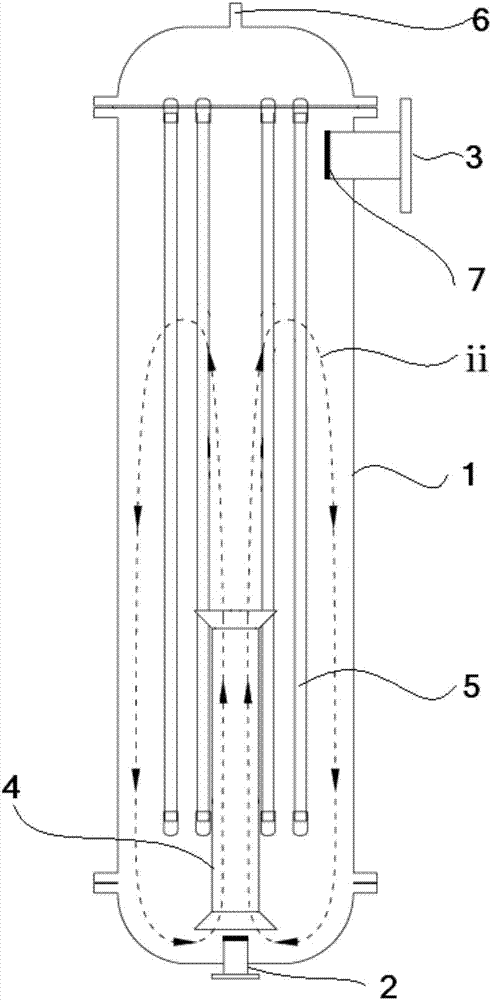

Method for preparing cyclohexanol and cyclohexanone based on multi-layer annular flow guide cylinder bubbling reactor

ActiveCN107778131AAvoid backmixingReduce backmixingOxygen-containing compound preparationLiquid-gas reaction as foam/aerosol/bubblesCyclohexanoneDistillation

The invention discloses a method for preparing cyclohexanol and cyclohexanone based on a multi-layer annular flow guide cylinder bubbling reactor. The method comprises the following steps: in a multi-layer annular flow guide cylinder bubbling reactor, oxidizing cyclohexane with an oxygen-containing gas to generate a cyclohexyl hydroperoxide-containing oxidation liquid, extracting an oxidation liquid with a strong base solution so as to obtain a cyclohexyl hydroperoxide-containing alkali water phase and a cyclohexane organic phase, performing a decomposition reaction on the cyclohexyl hydroperoxide-containing alkali water phase in the presence of a high-melting point solvent, performing sedimentation separation on a decomposition liquid, distilling the cyclohexane organic phase so as to obtain a mixture of cyclohexanol and cyclohexanone, and feeding back the extracted cyclohexane solution to the cyclohexane oxidation reaction process. By adopting the method, the oxidation selectivity and the reaction efficiency of the cyclohexane can be greatly improved, and the cyclohexane distillation energy consumption can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

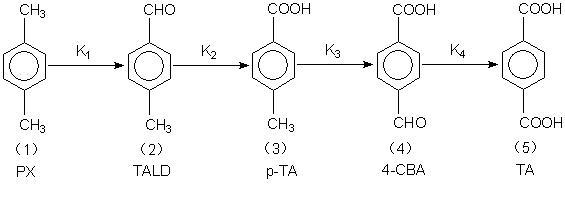

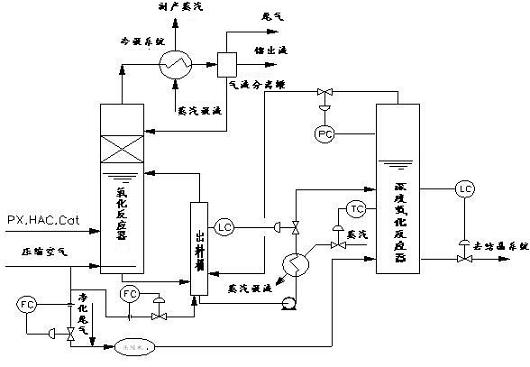

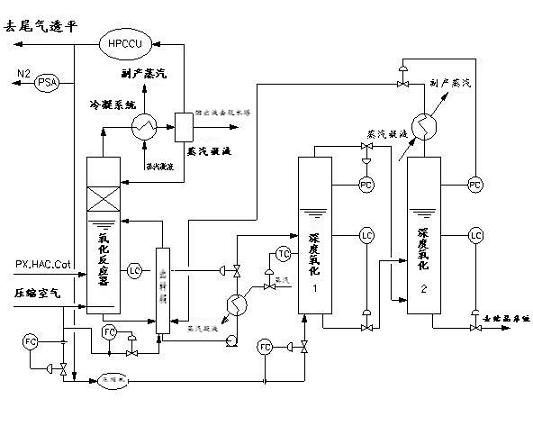

Deep oxidation method and deep oxidation device in KPTA (Kunlun pure terephthalic acid) production

ActiveCN102675090APrevent precipitationIncrease gas contentOrganic compound preparationCarboxylic compound preparationSlurrySolvent

The invention relates to a deep oxidation method and a deep oxidation device in KPTA (Kunlun pure terephthalic acid) production; the method comprises the following steps of: (1) oxidizing: oxidizing PX (p-Xylene) with oxygen in solvent HAC (ethanoic acid) in case of catalysis; (2) deeply oxidizing: further deeply oxidizing the slurry obtained in the step (1) through oxidizing with oxygen to improve the TA (terephthalic acid) content; and (3) crystallizing and separating: crystallizing and separating TA from the slurry obtained in the step (2). The system comprises an oxidation reactor, a reactor discharge tank, a deep oxidation reactor and a crystallizing and separating system, wherein a slurry outlet of the oxidation reactor is connected with a slurry inlet of the discharge tank, a slurry outlet of the discharge tank is connected with a slurry inlet of the deep oxidation reactor, and a slurry outlet of the deep oxidation reactor is connected with a slurry inlet of the crystallizing and separating system. The method provided by the invention not only can guarantee the product quality, but also can reduce the requirement on equipment, and stirring equipment is omitted, so that the equipment investment can be reduced, and the power consumption can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

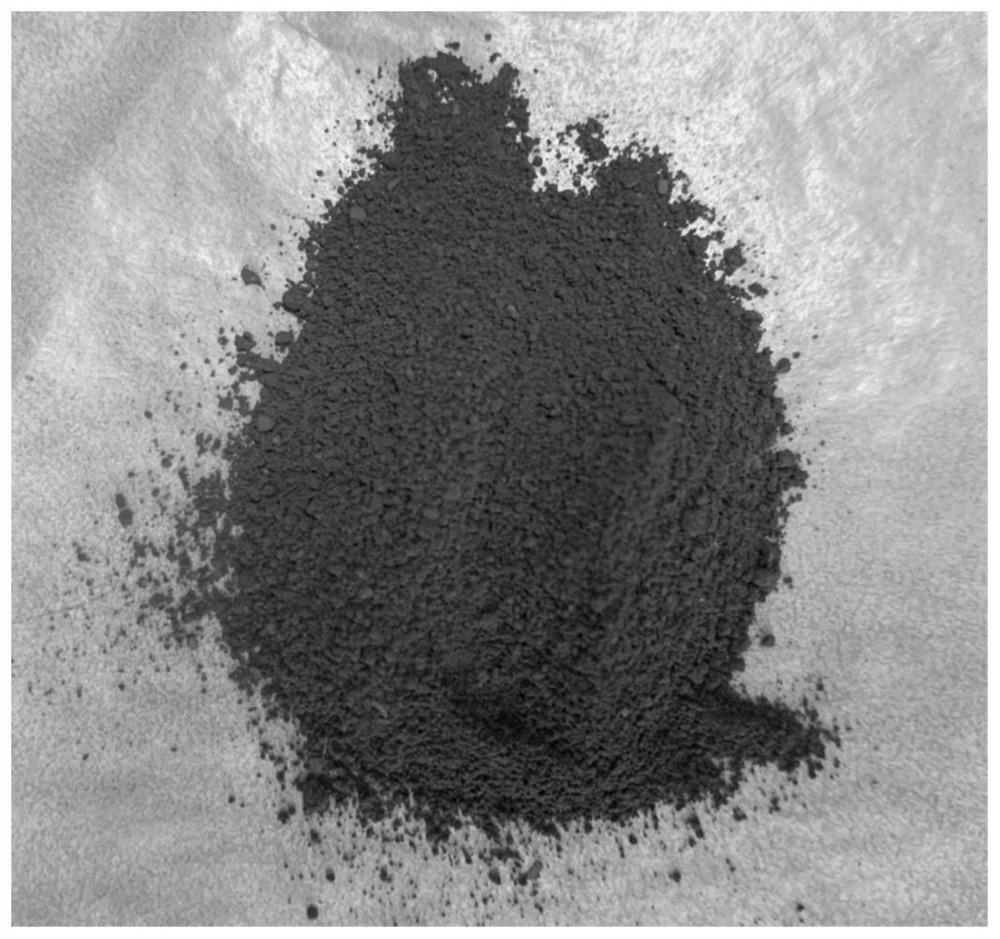

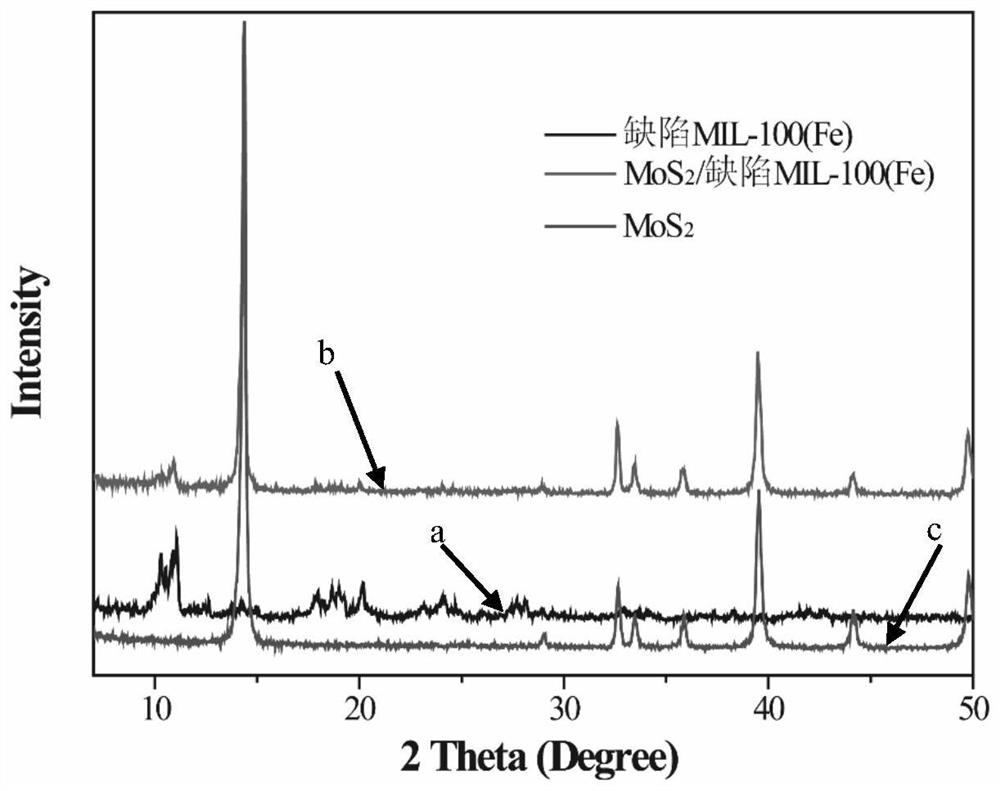

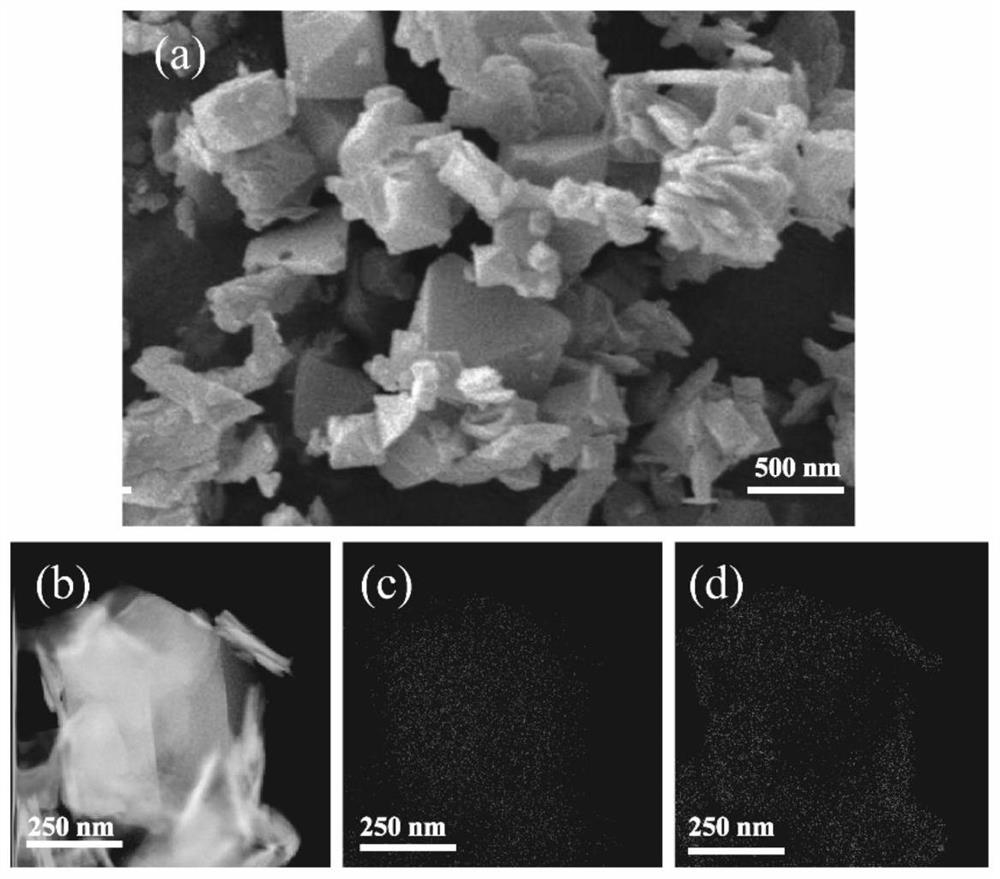

Composite catalyst of MoS2/defective MIL-100 (Fe) and preparation method and application thereof

ActiveCN111659468AOvercoming Mass Transfer Limiting ProblemsWide pH rangeWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMaterials science

The invention discloses a composite catalyst of MoS2 / defective MIL-100 (Fe) and a preparation method and application thereof. According to the composite catalys, MIL-100 (Fe) grows on MOS2 in situ toobtain a MoS2 / MIL-100 (Fe) material, the MoS2 / MIL-100 (Fe) material is activated at a high temperature to obtain the composite catalyst, the composite catalyst is formed by bonding MOS2 and MIL-100 (Fe), and the mass ratio of MOS2 to MIL-100 (Fe) is 0.2-0.8: 1. According to the composite catalyst, the reduction effect of Mo < 4 + > is utilized; meanwhile, the iron-based active component exposed bythe defective MIL-100 (FE) is utilized, good physicochemical properties of MoS2 and the defect type MIL-100 (Fe) are considered at the same time; a favorable way is provided for diffusion of pollutant molecules and H2O2 molecules in a Fenton-like system; the defect that the promotion effect of MoS2 composite catalysts on Fenton-like compounds in the prior art needs to depend on light conditions is overcome, the oxidation reaction promotion efficiency is improved, the pH application range is wide, and good catalytic degradation performance is still kept under the neutral pH condition.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing cyclohexanol and cyclohexanone based on multi-layer guide cylinder bubbling reactor

ActiveCN107778132AImprove circulation rateImprove oxidation reaction efficiencyOrganic compound preparationOxygen compounds purification/separationCyclohexanoneDistillation

The invention discloses a method for preparing cyclohexanol and cyclohexanone based on a multi-layer guide cylinder bubbling reactor. The method comprises the following steps: in a multi-layer guide cylinder bubbling reactor, oxidizing cyclohexane with an oxygen-containing gas to generate a cyclohexyl hydroperoxide-containing oxidation liquid, extracting an oxidation liquid with a strong base solution so as to obtain a cyclohexyl hydroperoxide-containing alkali water phase and a cyclohexane organic phase, performing a decomposition reaction on the cyclohexyl hydroperoxide-containing alkali water phase in the presence of a high-melting point solvent, performing sedimentation separation on a decomposition liquid, distilling the cyclohexane organic phase so as to obtain a mixture of cyclohexanol and cyclohexanone, and feeding back the extracted cyclohexane solution to the cyclohexane oxidation reaction process. By adopting the method, the oxidation selectivity and the reaction efficiencyof the cyclohexane can be greatly improved, and the cyclohexane distillation energy consumption can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

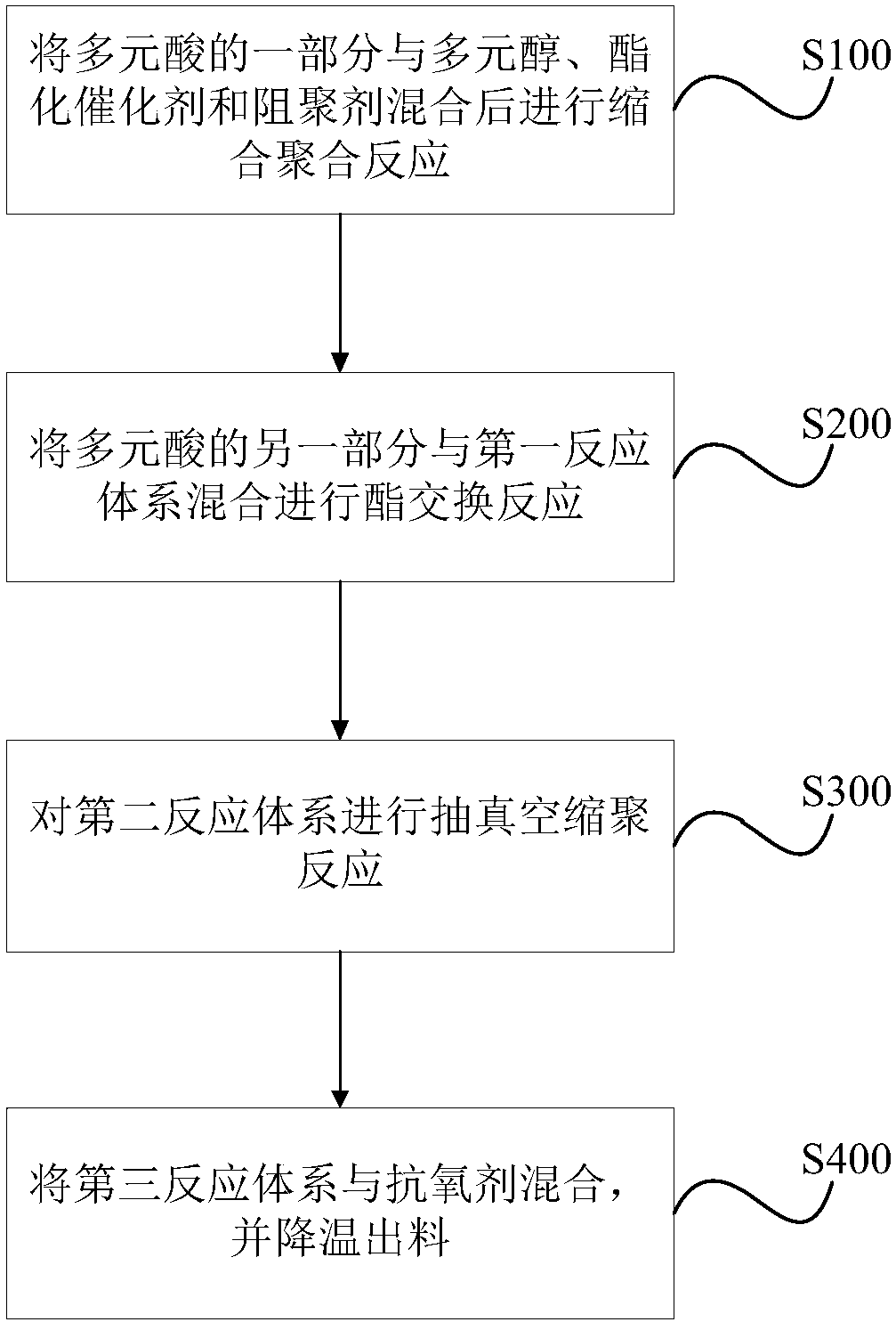

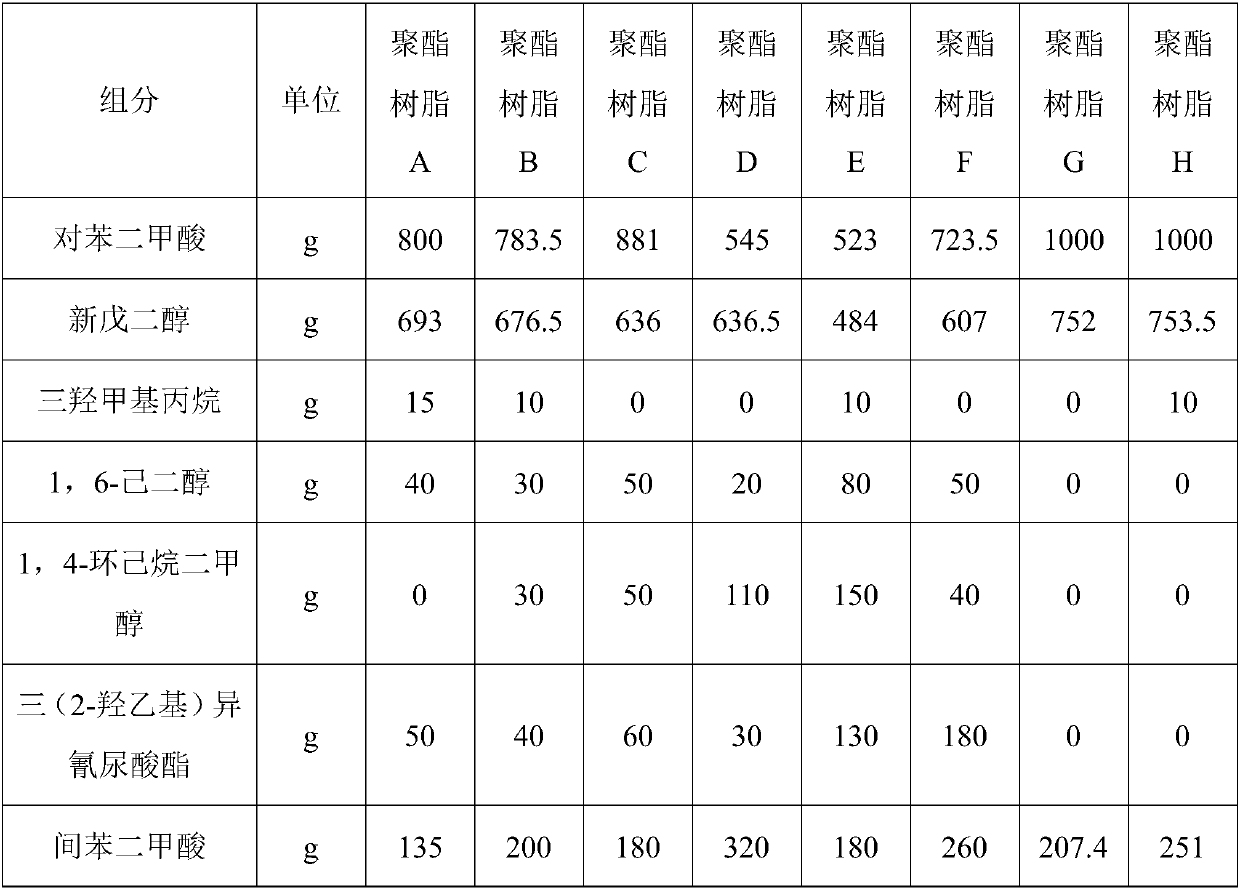

Long-term anti-yellowing polyester resin as well as preparation method and application thereof

InactiveCN107868234AImprove anti-yellowing effectGood long-term anti-yellowing performancePowdery paintsPolyester coatingsTO-18Alcohol

The invention discloses long-term anti-yellowing polyester resin as well as a preparation method and application thereof. The method comprises the following steps: mixing and performing condensation polymerization on one part of polyatomic acid, polyatomic alcohol, an esterification catalyst and a polymerization inhibitor, so as to obtain a first reaction system with the acid value being 10 to 18mg KOH / g; mixing the other part of the polyatomic acid and the first reaction system and performing transesterification, so as to obtain a second reaction system with the acid value being 48 to 56 mgKOH / g; performing vacuumizing condensation polymerization on the second reaction system, so as to obtain a third reaction system with the acid value being 28 to 35 mg KOH / g and the viscosity being 5000 to 15000 mPa.s; mixing the third reaction system and an antioxidant, and cooling and discharging, so as to obtain the long-term anti-yellowing polyester resin. Through the adoption of the method, the polyester resin with long-term anti-yellowing property can be obtained, is used for preparing white system powder coating, and has a wide application prospect in the field of white household appliances.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

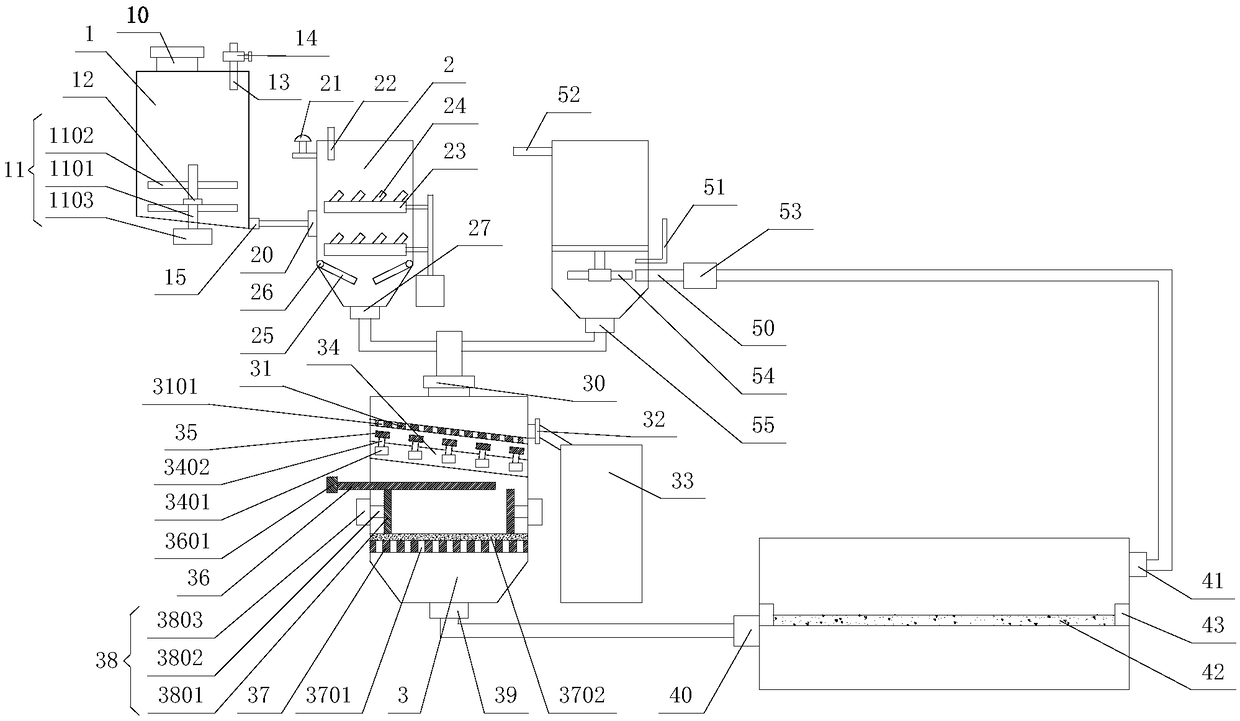

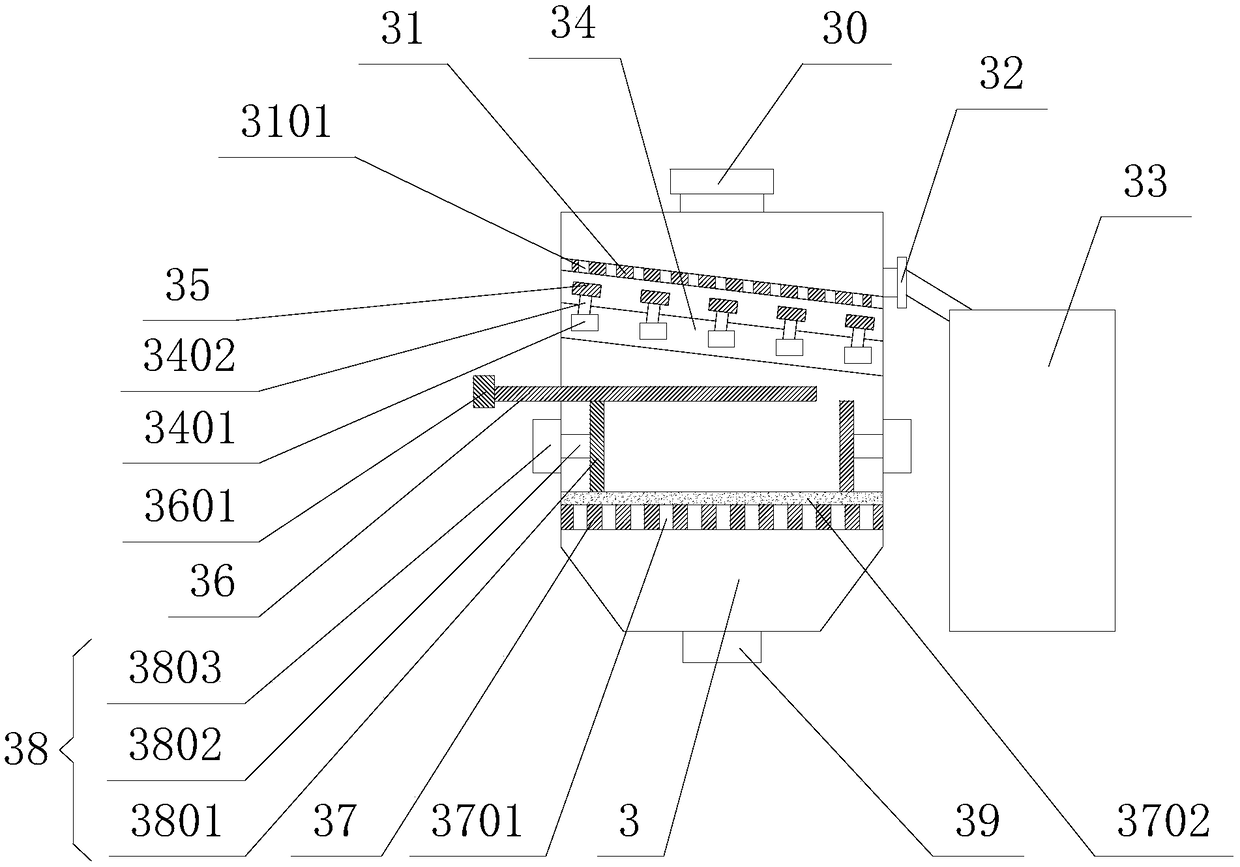

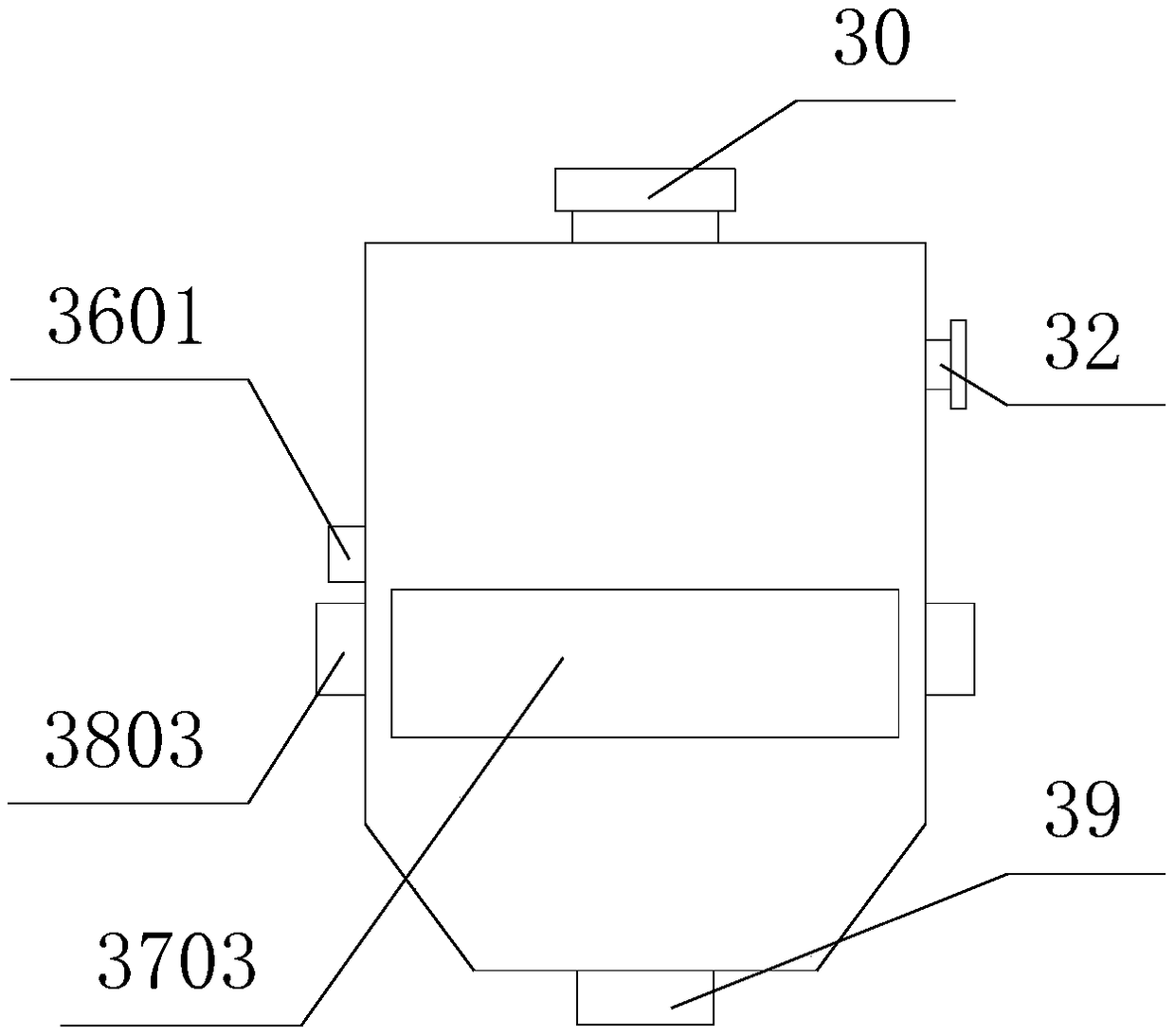

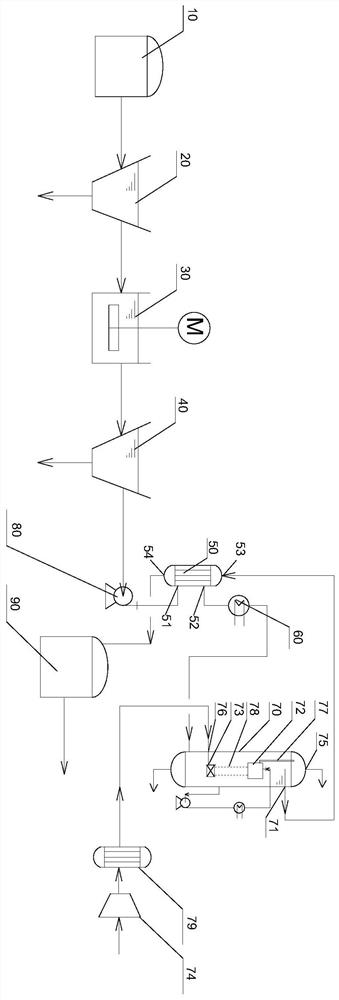

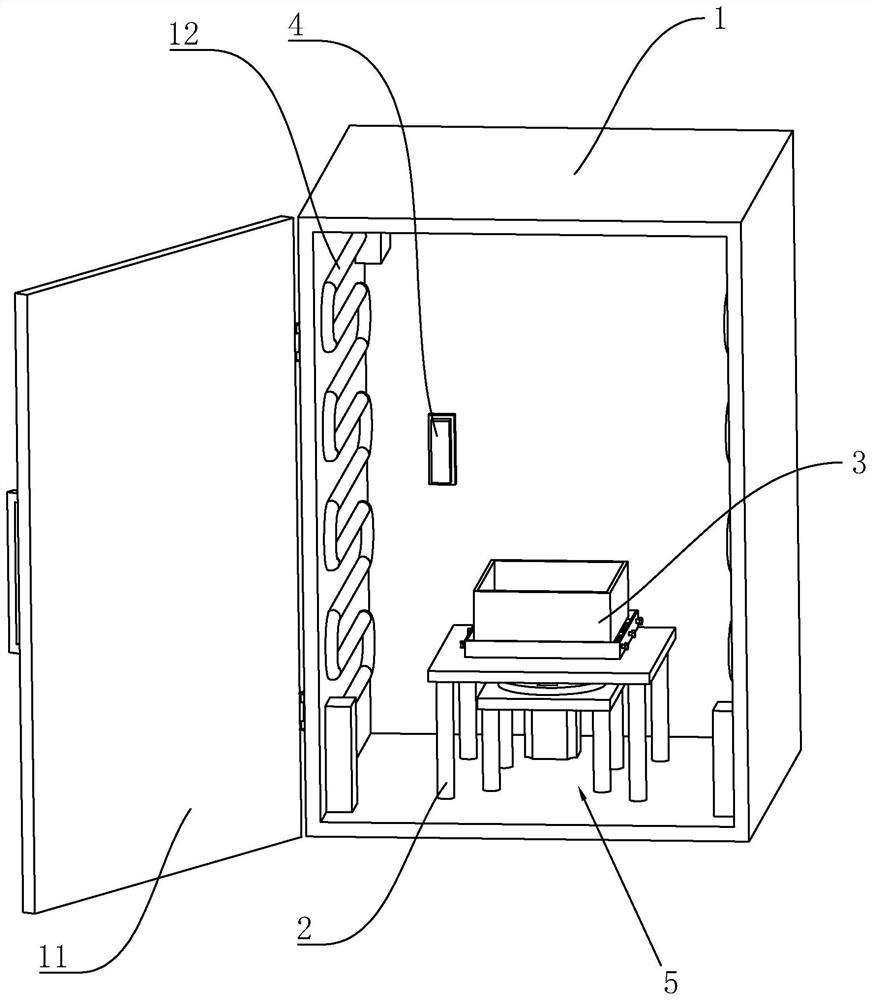

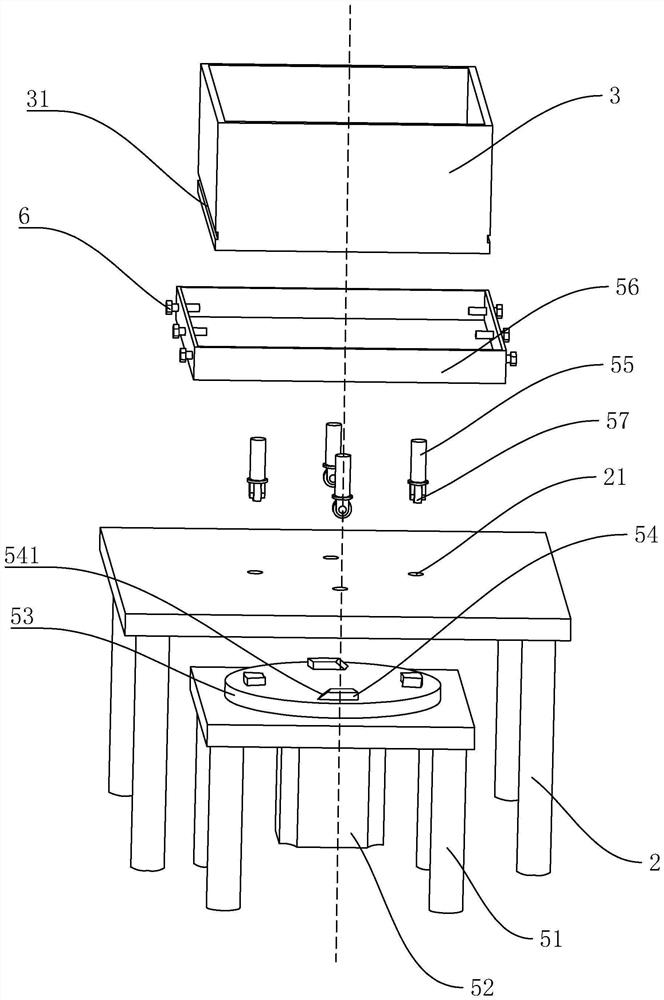

Waste discharging treatment system for trimanganese tetraoxide production

ActiveCN109231584AImprove oxidation reaction efficiencyEasy to recycleWater treatment parameter controlWater treatment compoundsFilter pressManganese(II,III) oxide

The invention discloses a waste discharging treatment system for trimanganese tetraoxide production. The waste discharging treatment system comprises a collecting tank, an oxidizing tank, a filter pressing tank, a precipitating pond and a manganese precipitating tank, wherein a collected wastewater outlet of the collecting tank is communicated with an oxidized wastewater inlet of the oxidizing tank through a pipeline; an oxidized wastewater outlet of the oxidizing tank is communicated with a material inlet of the filter pressing tank through a pipeline; a filtered water outlet of the filter pressing tank is communicated with a liquid inlet pipe of the precipitating pond through the pipeline; a liquid outlet pipe of the precipitating tank is communicated with a clear liquid inlet pipe through a pipeline; a precipitate discharging opening of the manganese precipitating tank is communicated with the material inlet of the filter pressing tank through a pipeline. According to the waste discharging treatment system disclosed by the invention, through twice manganese precipitating, the treatment on manganese ions in manganese-containing wastewater is greatly increased, and the wastewatertreating effect is better; meanwhile, the manganese ions in the wastewater are precipitated for twice and are recycled and reutilized, and the production cost is greatly saved.

Owner:四川中哲新材料科技有限公司

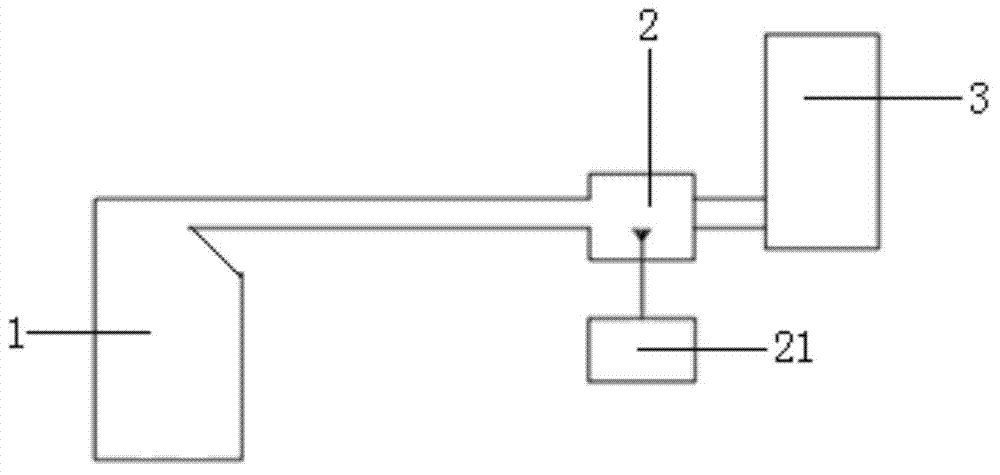

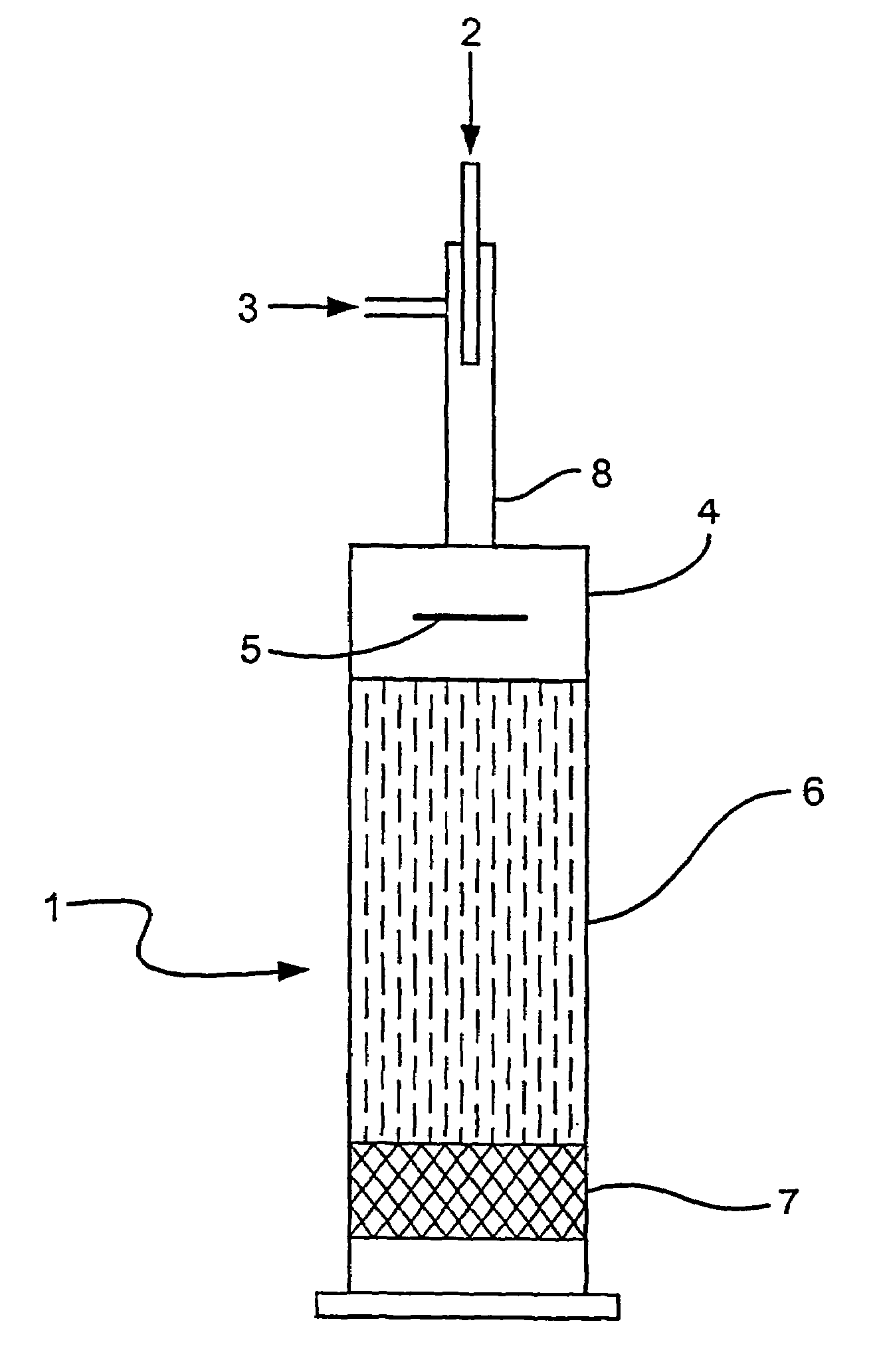

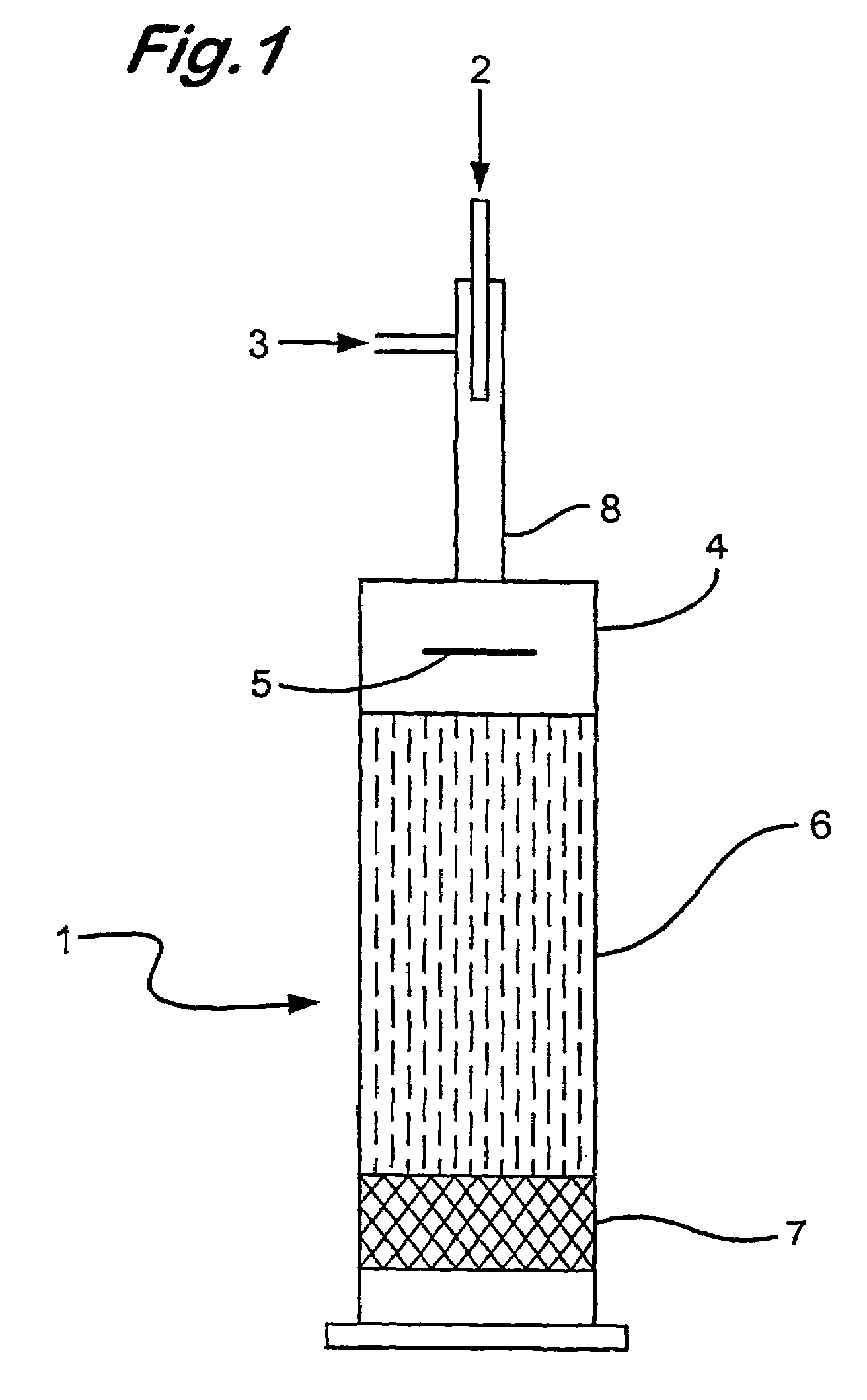

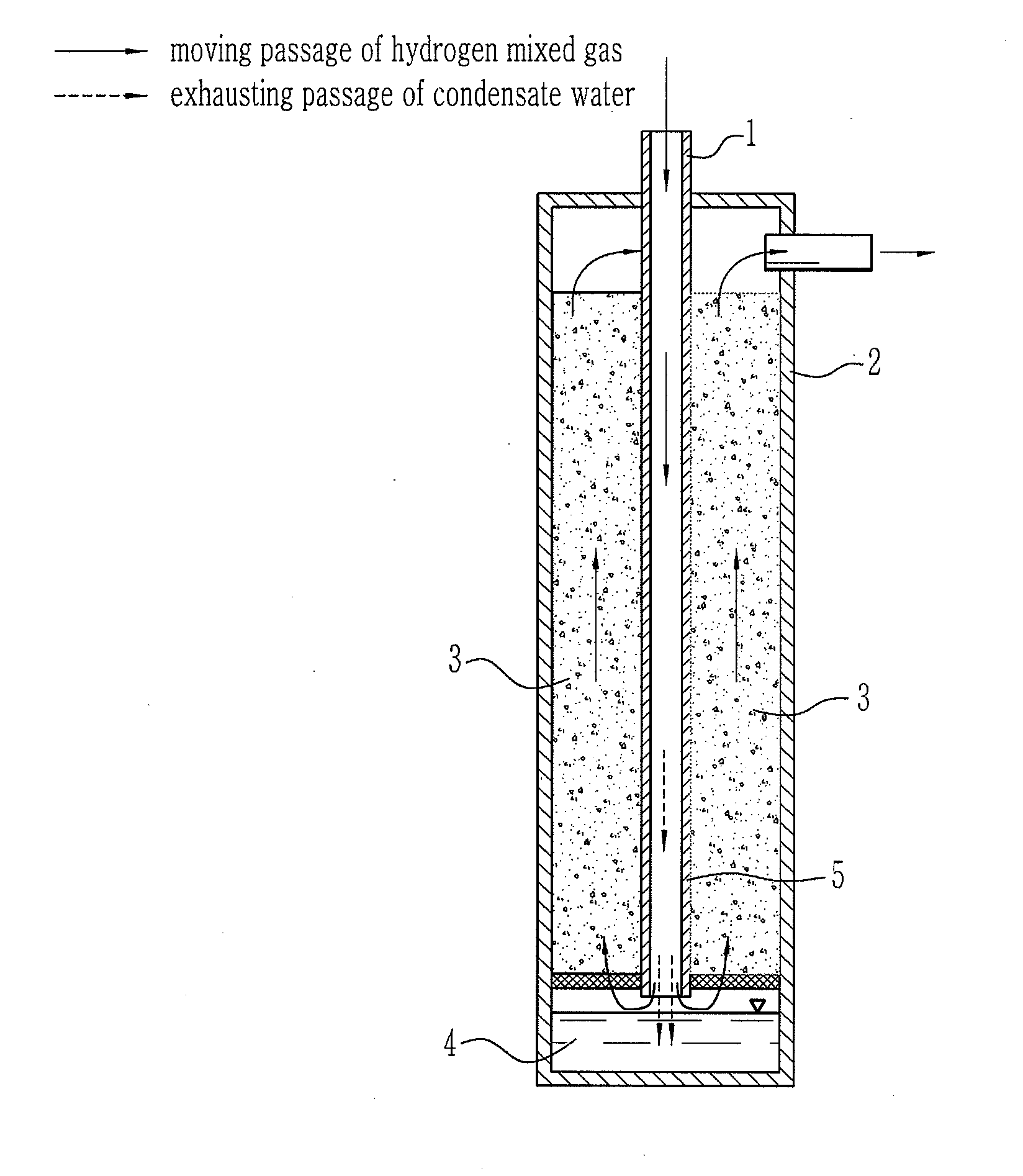

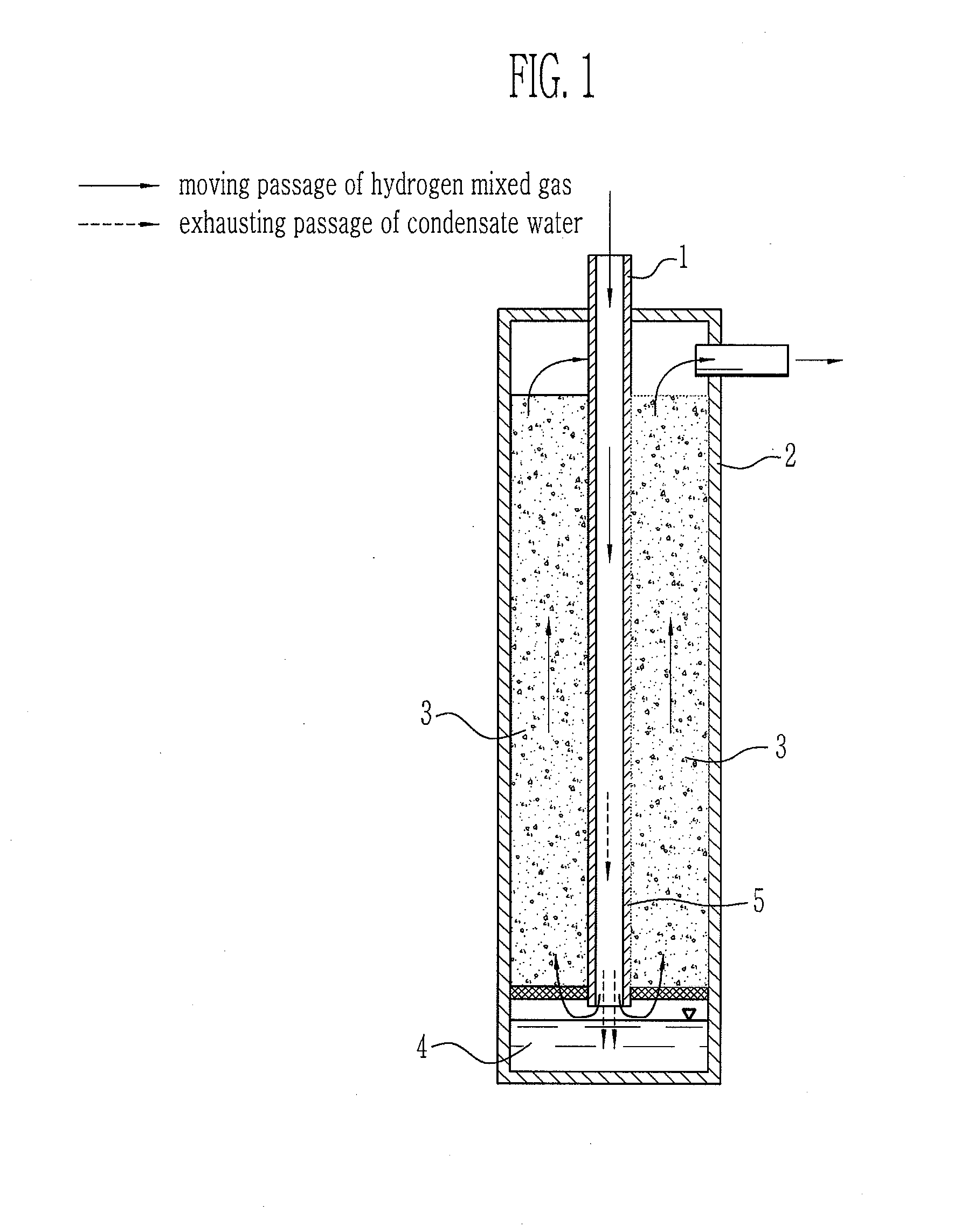

Preferential oxidation reactor and fuel cell system using the same

InactiveUS20110281188A1Improve oxidation reaction efficiencyPrevent wettingHydrogenPhysical/chemical process catalystsHydrogenFuel cells

A preferential oxidation reactor for removing carbon monoxide in a hydrogen mixture gas is disclosed. The preferential oxidation reactor may include a housing having a catalytic layer provided therein, a mixture gas supply portion inserted into the interior of the housing and penetrating the catalytic layer, a condensate receiving portion contained within the housing and in fluid communication with a gas outlet port of the mixture gas supply portion and condensate control tubes arranged in the catalytic layer of the housing and in fluid communication with the condensate receiving portion. The condensate control tubes may have a capillary structure. A fuel cell system including the preferential oxidation reactor is also disclosed.

Owner:SAMSUNG SDI CO LTD

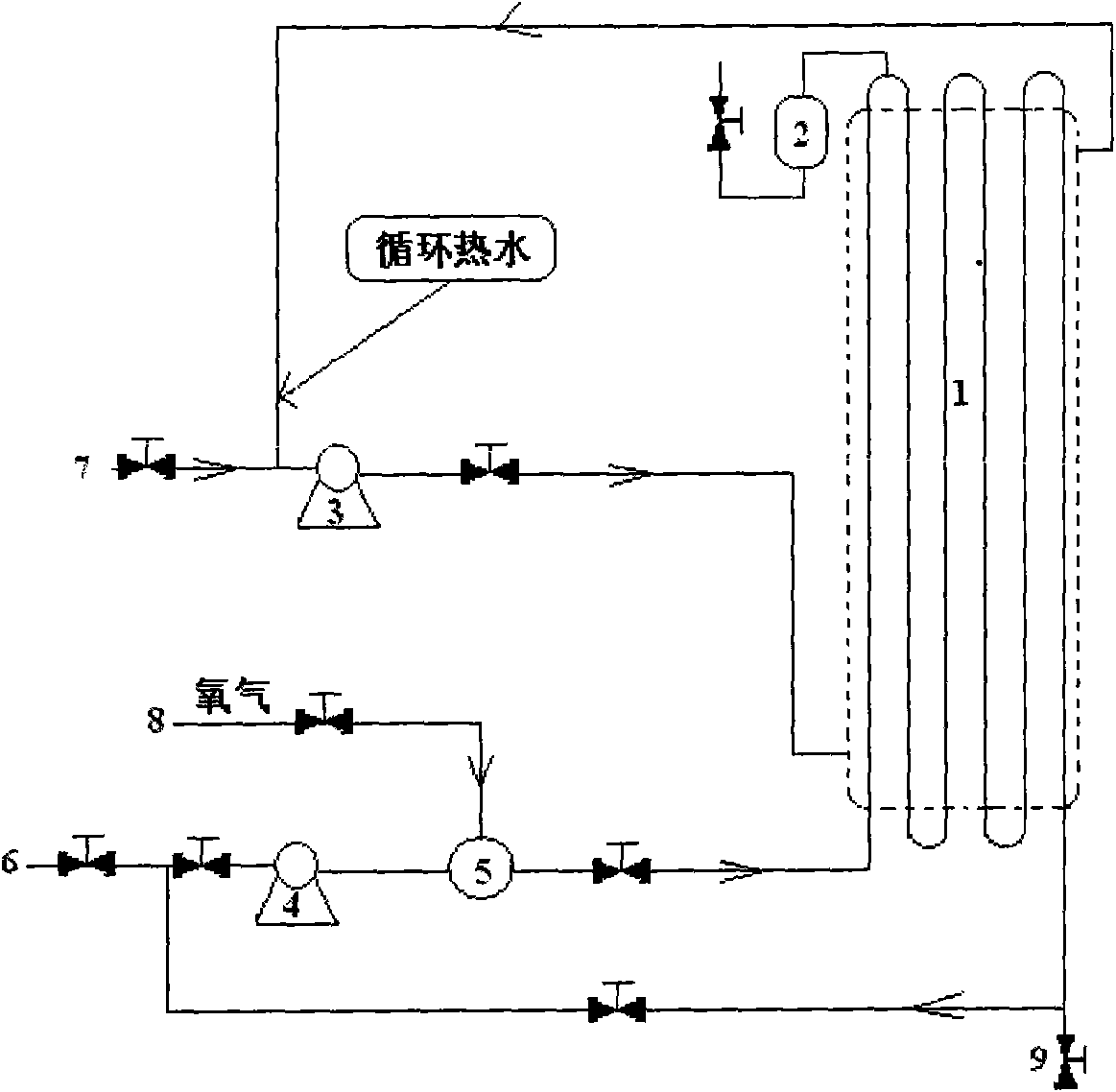

Method and device for oxidative conversion of sodium sulfide in alkali fusant

ActiveCN102874769AIncrease the areaImprove oxidation reaction efficiencySulfur compoundsAlkali metal carbonatesSodium carbonateSulfur dioxide

The invention discloses method and device for oxidative conversion of sodium sulfide in alkali fusant. The method includes the steps of guiding alkali fusant generated in black liquor combustion from the bottom of an alkali recovery furnace into a furnace chamber; guiding out hot exhaust from a hearth of the alkali recovery furnace by an insulating pipe, mixing the hot exhaust with air and sending the mixture into the furnace chamber; allowing the alkali fusant to transverse spread to form a thin fluid layer under the action of a guide plate, allowing sodium sulfide in the thin fluid layer to contact with oxygen in the hot mixed gas to cause oxidation so as to generate sulfur dioxide and sodium carbonate. The sulfur dioxide and sodium carbonate subjected to subsequent treatment are reusable. The invention further discloses the device for oxidative conversion of sodium sulfide in alkali fusant. Automatic spreading of high-temperature fluid is achieved, oxidizing efficiency is improved, and the alkali fusant is guaranteed to exist in fluid form to facilitate flowing and outflowing from a furnace body.

Owner:GUANGXI UNIV

Three-phase catalytic oxidization wastewater treatment method and reactor

InactiveCN107055678AFully contactedImprove oxidation reaction efficiencyWater/sewage treatment by irradiationWater/sewage treatment apparatusUltravioletActive carbon

The invention provides a three-phase catalytic oxidization wastewater treatment method and a reactor; ozone is added to wastewater to be treated, the wastewater to be treated is brought in contact with a solid catalyst in ultraviolet and is driven to move up in fluidized form under the joint action of flotation of adhering microbubbles and a flow of central tube incoming liquid so as to carry out reaction, the ozone is consumed by organic pollutants, the solid catalyst precipitates, and biorefractory organic matters are removed effectively. A guide reaction barrel is arranged in the reactor and is not in full contact with the bottom of a shell, the height of the guide reaction barrel is not less than that of the shell, and a plurality of ultraviolet generators are arranged around the guide reaction barrel within the shell. Dissolved gas wastewater containing massive ozone microbubble s is formed by using ozone dissolved gas, the dissolved gas wastewater is subjected to contact reaction with the active carbon solid catalyst that carries catalytic ingredients such as TIO2, ultraviolet irradiation assists in catalysis, simultaneous full contact of solid, liquid and gas is achieved, and oxidative reaction efficiency is improved.

Owner:中化学朗正环保科技有限公司

Chlopyrifos pesticides waste water treatment process

InactiveCN100546926CPromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationChlorpyrifosCatalytic oxidation

The invention discloses a process for treating chlorpyrifos pesticide wastewater, which comprises the process steps of acid analysis, complex extraction, Fenton oxidation, catalytic oxidation and the like. The present invention selects chlorpyrifos wastewater and the herbicide pendimethalin wastewater for mixed treatment, achieves waste treatment with waste, reduces the load of refractory organic pollutants in waste water, improves the biodegradability of waste water, and removes pollutants in waste water, For the purpose of improving the biodegradability of wastewater, the process is safe, advanced, clean and has low wastewater treatment cost.

Owner:山东华阳农药化工集团有限公司

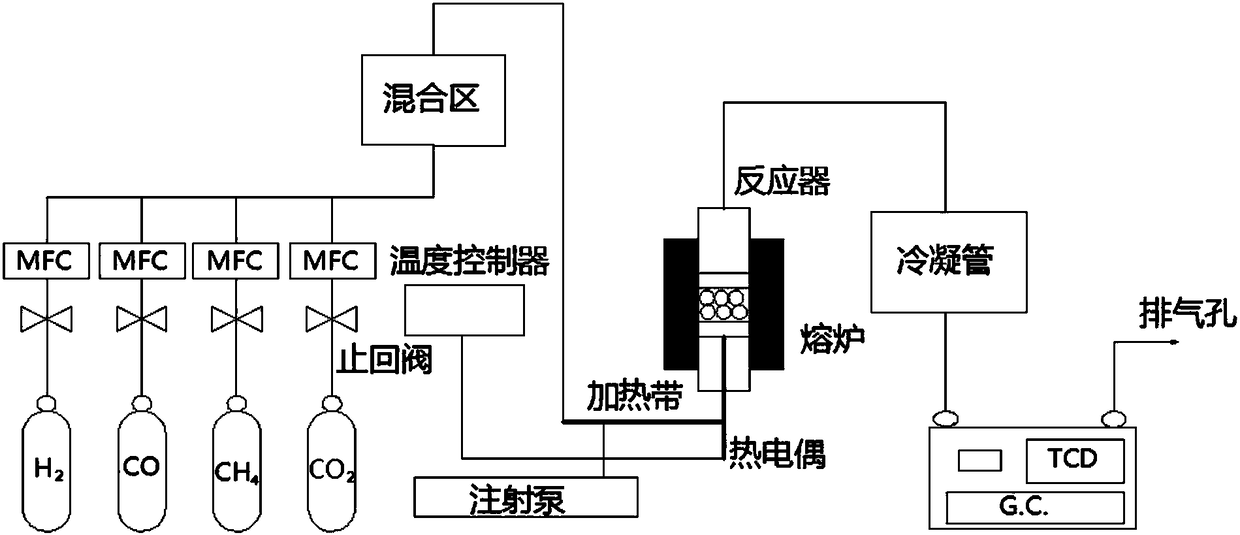

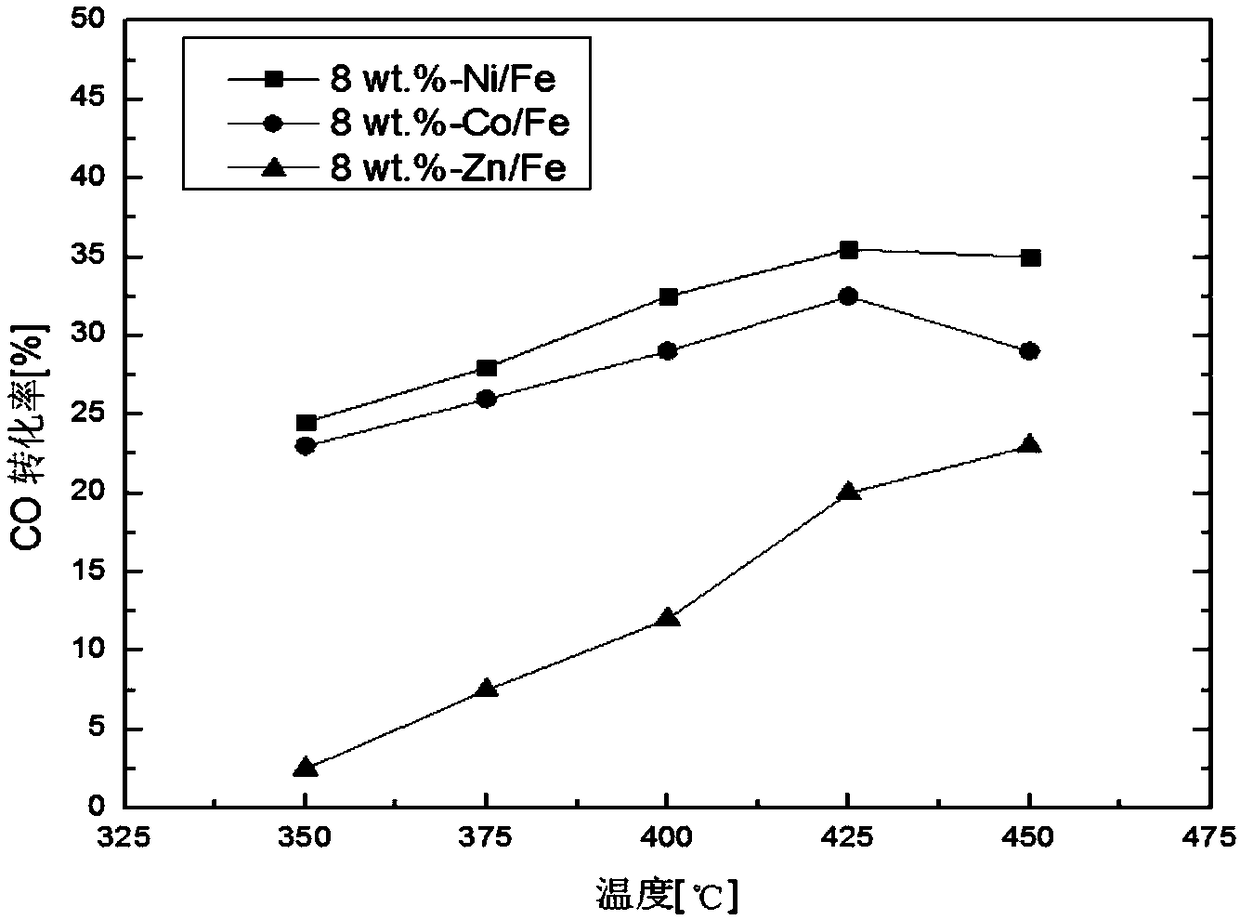

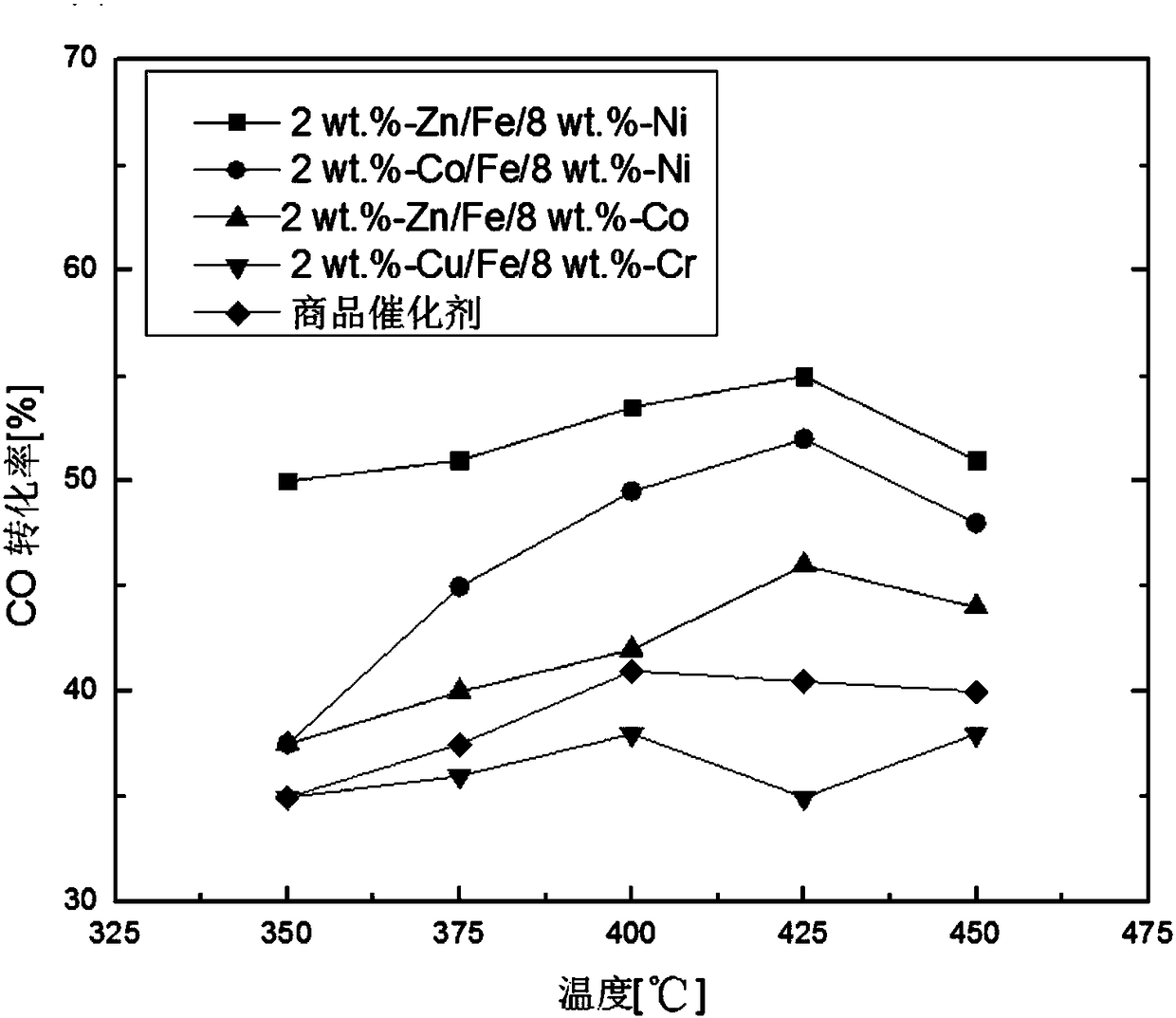

Catalyst for high-temperature water gas conversion reaction and manufacturing method thereof

InactiveCN108479785AImprove oxidation reaction efficiencyImprove economyHydrogenCombustible gas catalytic treatmentChromium freeCobalt

The invention discloses a catalyst for high-temperature water gas conversion reaction. The catalyst is prepared from iron and two ingredients selected from nickel, cobalt and zinc. During the preparation, iron precursors are added into distilled water; stirring is performed through a magnetic stirring machine; two ingredients are selected from nickel precursors, cobalt precursors and zinc precursors; then, stirring is performed; a distilled water and sodium carbonate mixed solution are added; then, drying is performed; a distilled water and sodium hydroxide mixed solution is added; washing isperformed; solid obtained after the washing is dried; pyrolysis treatment is performed. The catalyst belongs to a chromium-free three-ingredient series composite catalyst containing iron and two ingredients selected from nickel, cobalt and zinc, and is applied to high-temperature water gas conversion reaction. Compared with the iron- chromium series catalyst, the catalyst has the advantages that the oxidization reaction efficiency of carbonic oxide is high; non-noble metal is used for replacing high-price noble metal, so that the economic performance and the practicability are higher.

Owner:深圳市国能环保科技有限公司

Caprolactam production wastewater treatment system and method

ActiveCN113087252AIncreased phase boundary areaImprove mass transfer effectWater contaminantsMultistage water/sewage treatmentPtru catalystThermodynamics

The invention provides a caprolactam production wastewater treatment system and method. The treatment system comprises a raw water tank, a wastewater heat exchanger, a wastewater heater and an oxidation reactor which are sequentially connected, wherein a material inlet, a material outlet, a heat source inlet and a heat source outlet are formed in the wastewater heat exchanger; oxidized water from the oxidation reactor enters the wastewater heat exchanger from the heat source inlet, the heat source outlet is connected with a finished product tank, the material inlet is connected with the raw water tank, the material outlet is connected with the wastewater heater, a micro-interface generation system is arranged in the oxidation reactor, and the micro-interface generation system is used for dispersing the crushed gas into bubbles. According to the treatment system, after the micro-interface generator is arranged, the contact of thereaction phase interface is improved, and a good wastewater treatment effect can be obtained without using a catalyst or by adding a small amount of the catalyst.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Production process of N-benzyl hydroxylamine hydrochloride

InactiveCN114292207AGood catalytic effectImprove efficiencyOrganic chemistryDrying machines with non-progressive movementsSide productOrganic synthesis

The invention relates to an organic synthesis intermediate, and particularly discloses a production process of N-benzyl hydroxylamine hydrochloride, which comprises the following steps: oxidation: dissolving dibenzylamine in a solvent, and adding an oxidizing agent for oxidation reaction under the catalysis of a metal oxide to obtain an oxide; ammonolysis: dissolving the oxide in an ether solvent, adding an ammonolysis solution, and carrying out ammonolysis to obtain N-benzyl hydroxylamine hydrochloride; the ammonolysis solution is a mixture of methanol and hydroxylamine hydrochloride. According to the preparation method of the N-benzyl hydroxylamine hydrochloride, few byproducts are obtained, the metal oxide is used as the catalyst, the catalytic effect is good, the oxidation reaction efficiency and the oxidation reaction conversion rate are improved, the oxide is dissolved in the ether solvent, the ammonolysis reaction conversion rate is improved, and the yield of the N-benzyl hydroxylamine hydrochloride is improved. Therefore, the yield of the N-benzyl hydroxylamine hydrochloride is improved.

Owner:苏州诚和医药化学有限公司

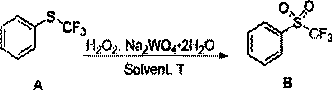

Trifluoroalkyl sulfone compound preparation method

ActiveCN110683999AHigh yieldImprove oxidation reaction efficiencyProcess control/regulationSequential/parallel process reactionsThioetherSulfone

The invention provides a trifluoroalkyl sulfone compound preparation method, which comprises: continuously feeding a trifluoroalkyl thioether compound, sodium tungstate dihydrate and a hydrogen peroxide solution into a continuous reactor through feeding equipment, and carrying out an oxidation reaction on the trifluoroalkyl thioether compound to obtain a product system containing the trifluoroalkyl sulfone compound, wherein the trifluoroalkyl thioether compound has a structure represented by a structural formula, R is any one selected from the following groups: linear alkyl, branched alkyl, substituted aryl, non-substituted aryl, substituted heterocyclic aryl, non-substituted heterocyclic aryl, non-substituted cyclic alkyl and substituted cyclic alkyl, and the temperature of the oxidationreaction is 25-50 DEG C. According to the invention, by using the continuous feeding, the material contact effect is improved, so that the thioether oxidation reaction can be carried out at a low temperature; and the oxidation reaction temperature is reduced to effectively reduce the decomposition of hydrogen peroxide and reduce the pressure resistance requirement on the continuous reactor.

Owner:ASYMCHEM LIFE SCI TIANJIN

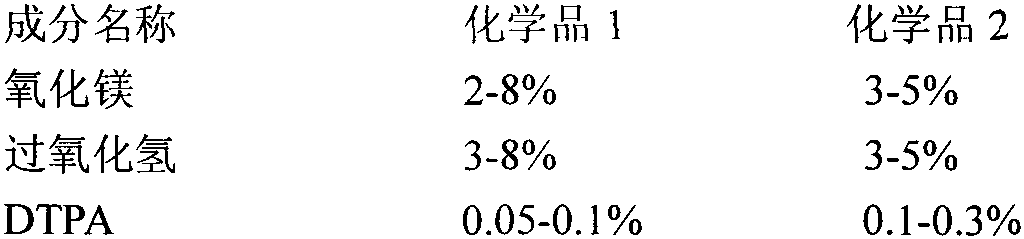

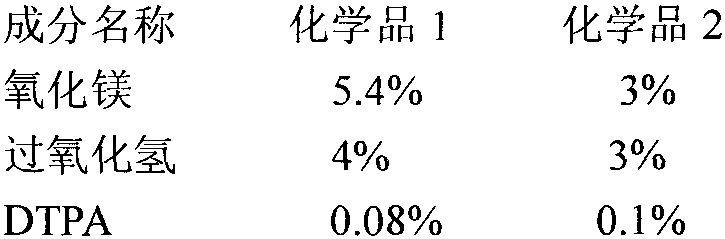

Hydrogen peroxide oxidation bleaching process pH value stabilizing technology

InactiveCN110725148AStable pHImprove oxidation reaction efficiencyPulp bleachingFood sciencePapermakingBuffering agent

The invention relates to a hydrogen peroxide oxidation bleaching process pH value stabilizing technology, which is mainly used in multiple fields of textiles, papermaking, foods and the like related to hydrogen peroxide bleaching under alkaline conditions. According to the method, magnesium oxide is used as a single alkali source to replace caustic soda, sodium silicate and other alkali sources and buffer agents in conventional hydrogen peroxide bleaching, and the magnesium oxide is slightly dissolved and gradually converted into magnesium hydroxide is utilized to provide a stable pH value forhydrogen peroxide bleaching, so that the effect of the pH value buffer solution is achieved; Mg(OH)2 belongs to a weakly alkaline compound, and the actually measured pH value of the suspension prepared from MgO mineral powder is about 10.24, so that the initial pH value of bleaching is low, the moderate alkali extraction effect is achieved, the COD generation amount in the bleaching process is small, the pollutant generation is reduced, and the material consumption is reduced; and by using magnesium oxide to replace sodium silicate, the problems of bleaching waste liquid viscosity rising andequipment scaling caused by silicon are avoided while the problem of silicon interference in the process for treating the bleaching waste liquid through the heat pump or evaporation concentration method at present is fundamentally avoided.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com