Patents

Literature

65 results about "Process chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process chemistry is the arm of pharmaceutical chemistry concerned with the development and optimization of a synthetic scheme and pilot plant procedure to manufacture compounds for the drug development phase. Process chemistry is distinguished from medicinal chemistry, which is the arm of pharmaceutical chemistry tasked with designing and synthesizing molecules on small scale in the early drug discovery phase.

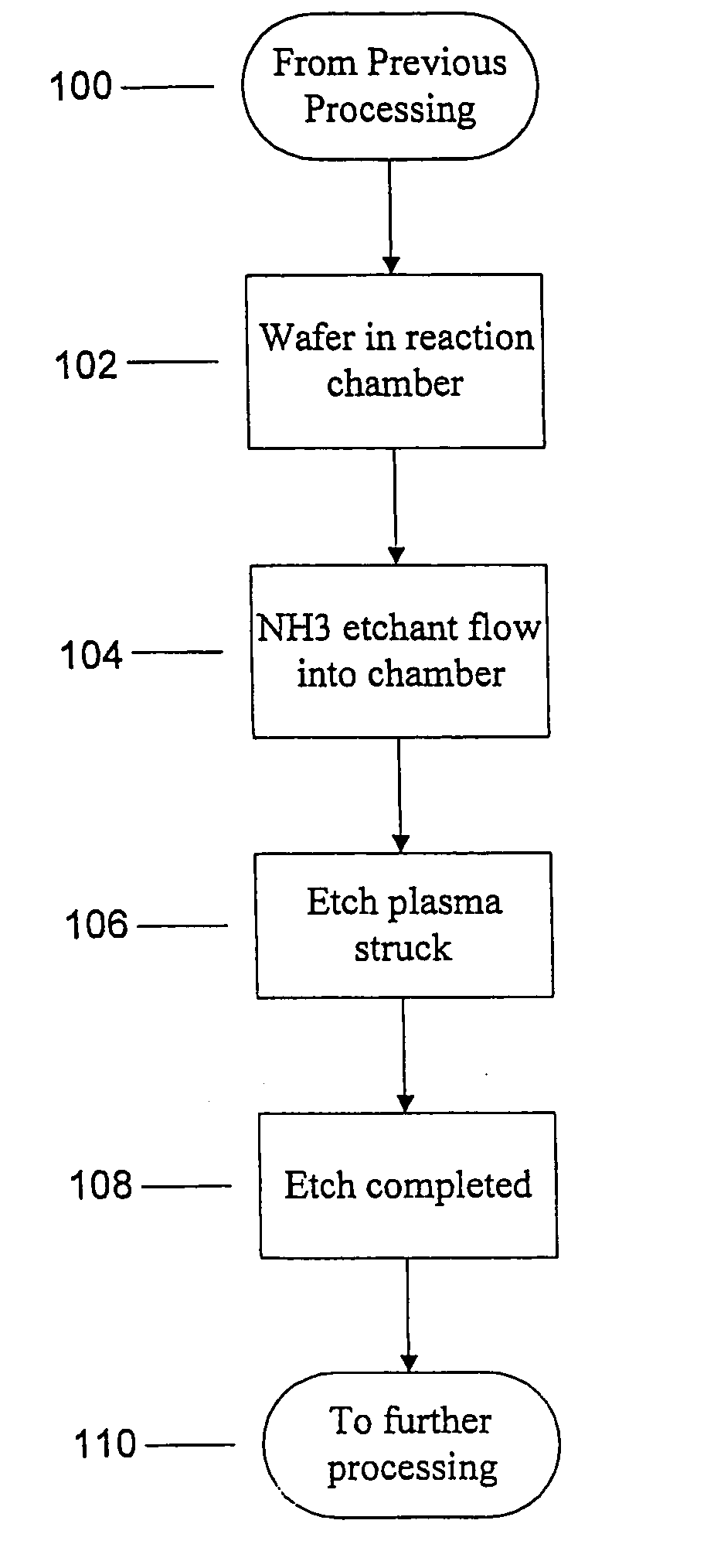

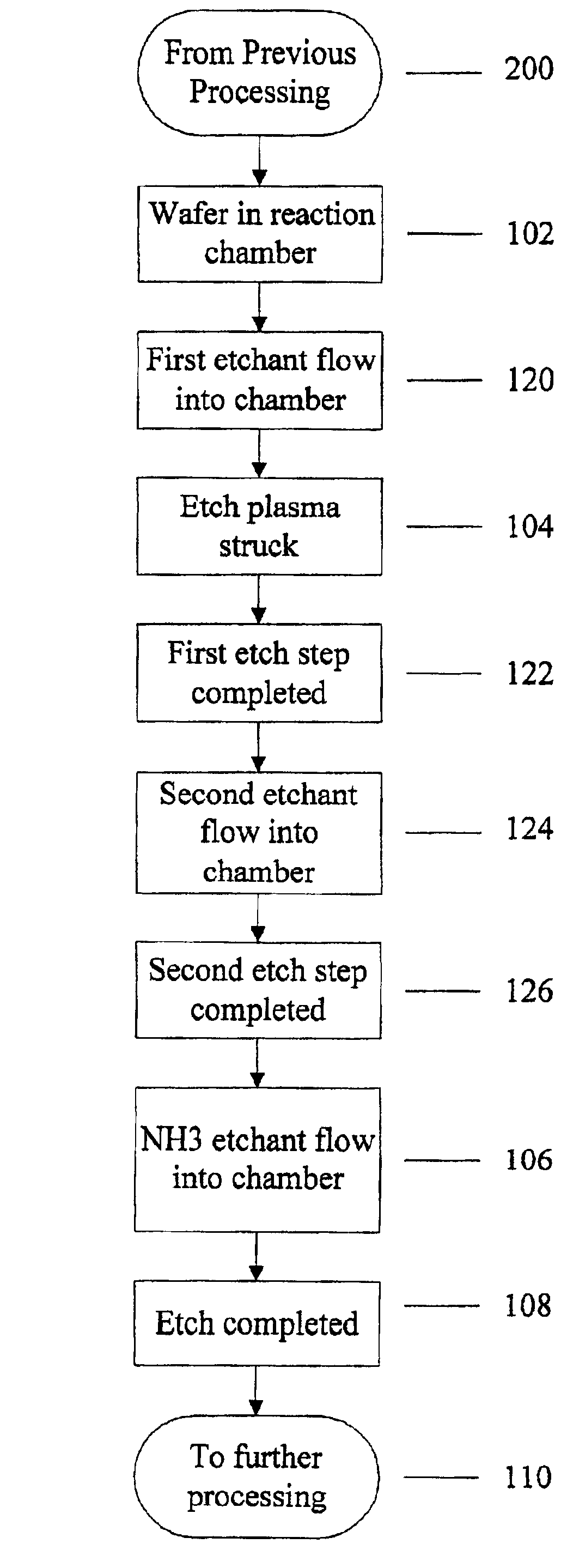

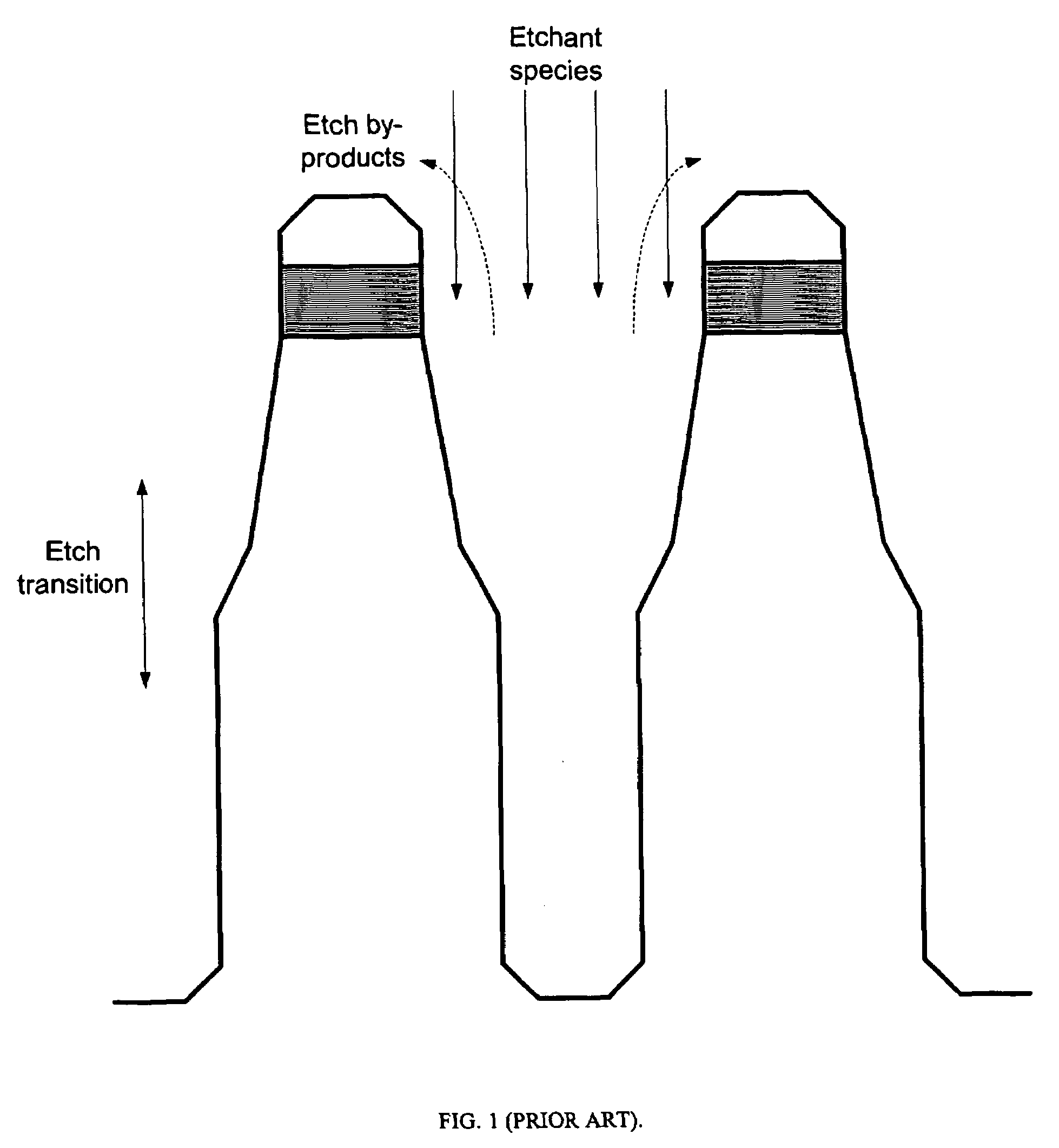

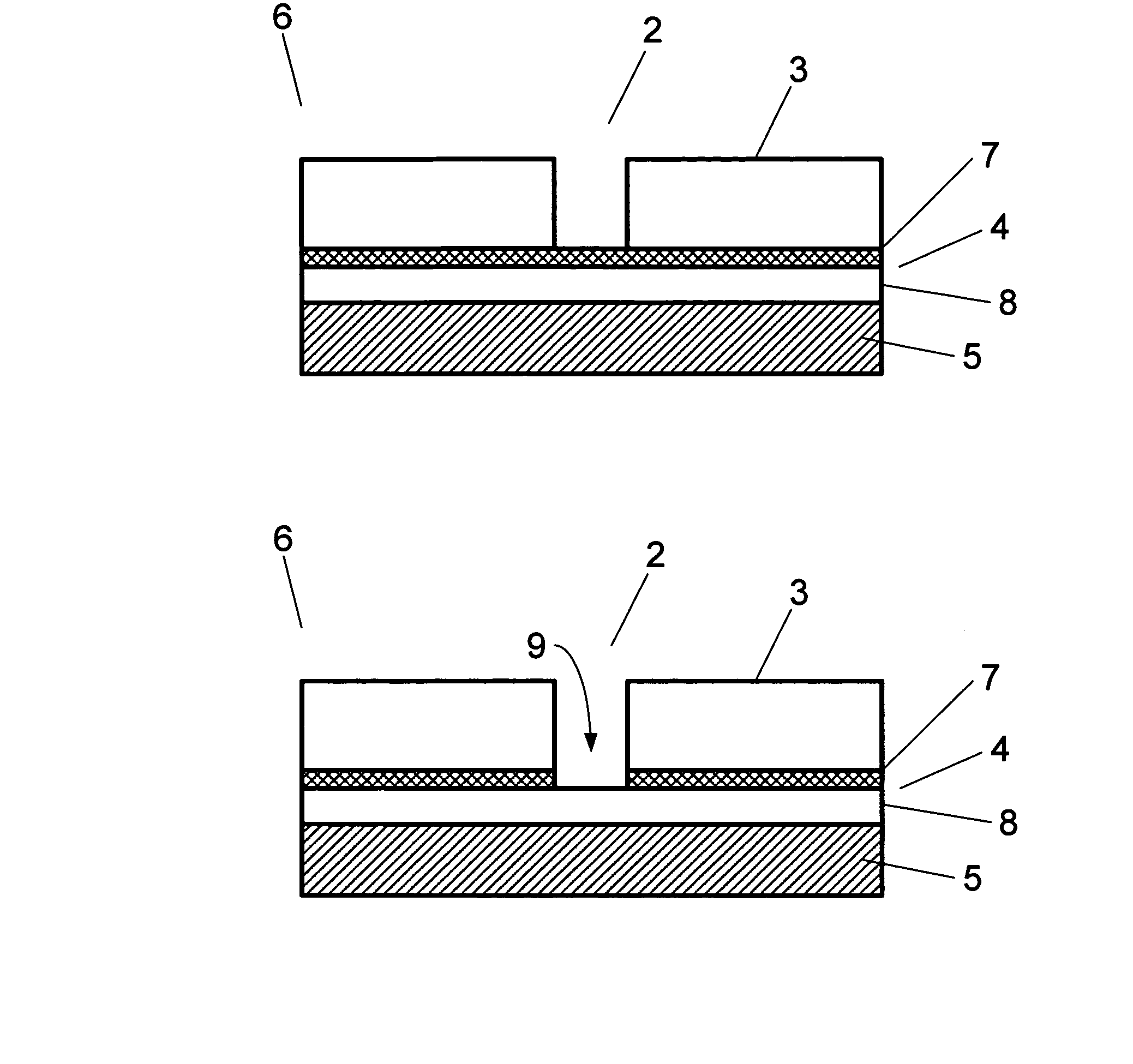

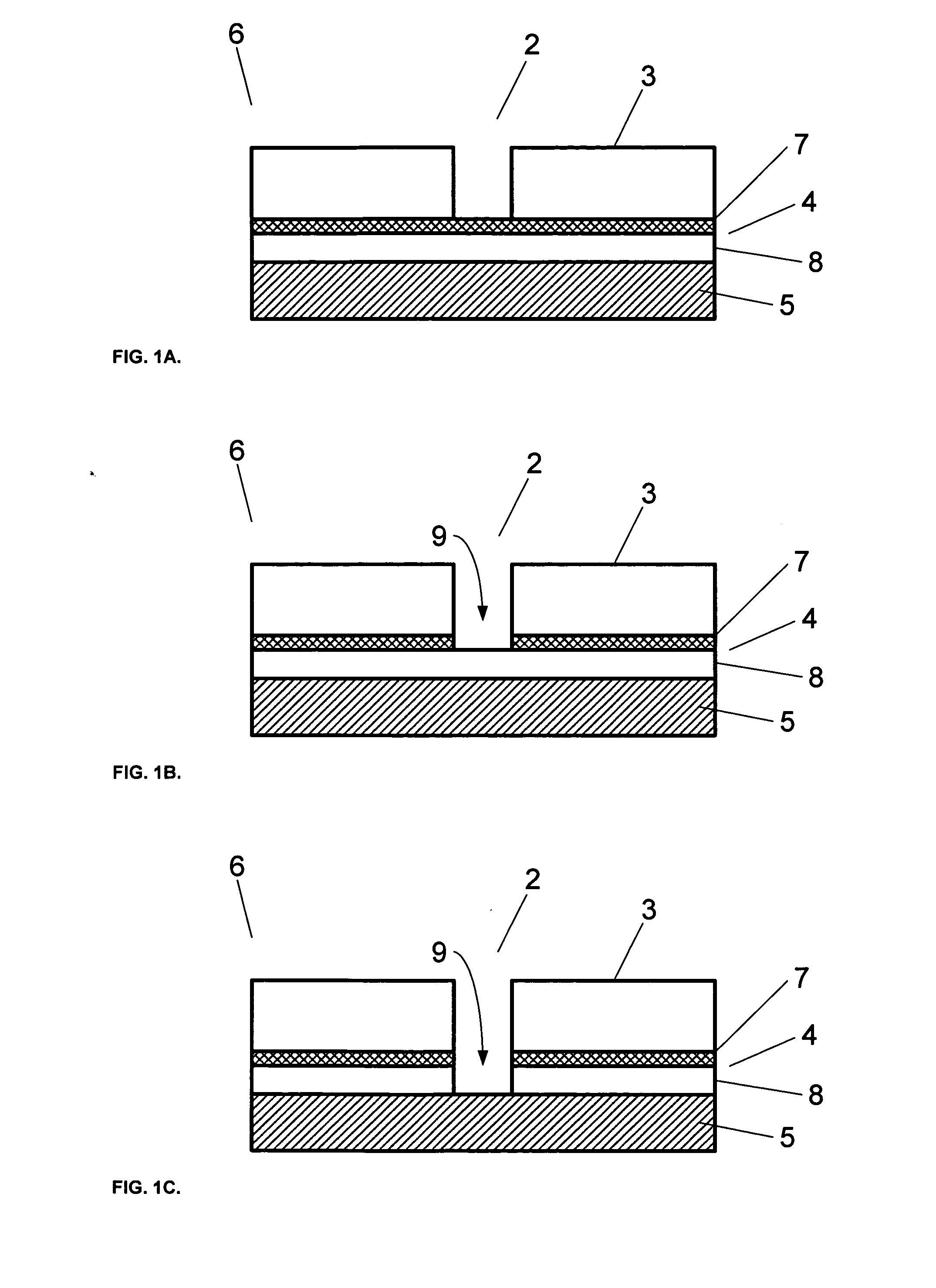

Use of ammonia for etching organic low-k dielectrics

InactiveUS20050003676A1Increase etch rateHigh selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingProcess chemistryElectricity

Method for etching organic low-k dielectric using ammonia, NH3, as an active etchant. Processes using ammonia results in at least double the etch rate of organic low-k dielectric materials than processes using N2 / H2 chemistries, at similar process conditions. The difference is due to the much lower ionization potential of NH3 versus N2 in the process chemistry, which results in significantly higher plasma densities and etchant concentrations at similar process conditions.

Owner:LAM RES CORP

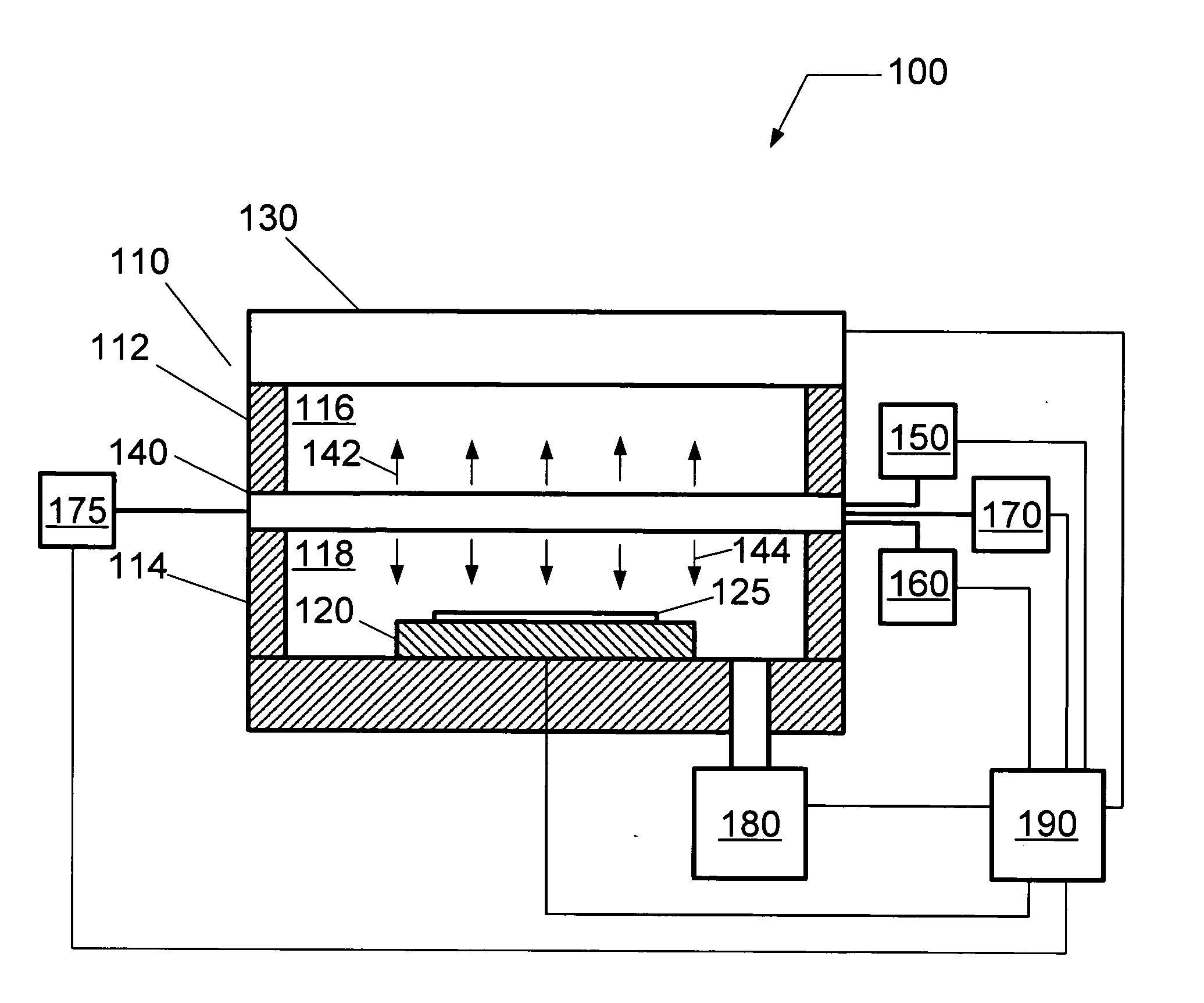

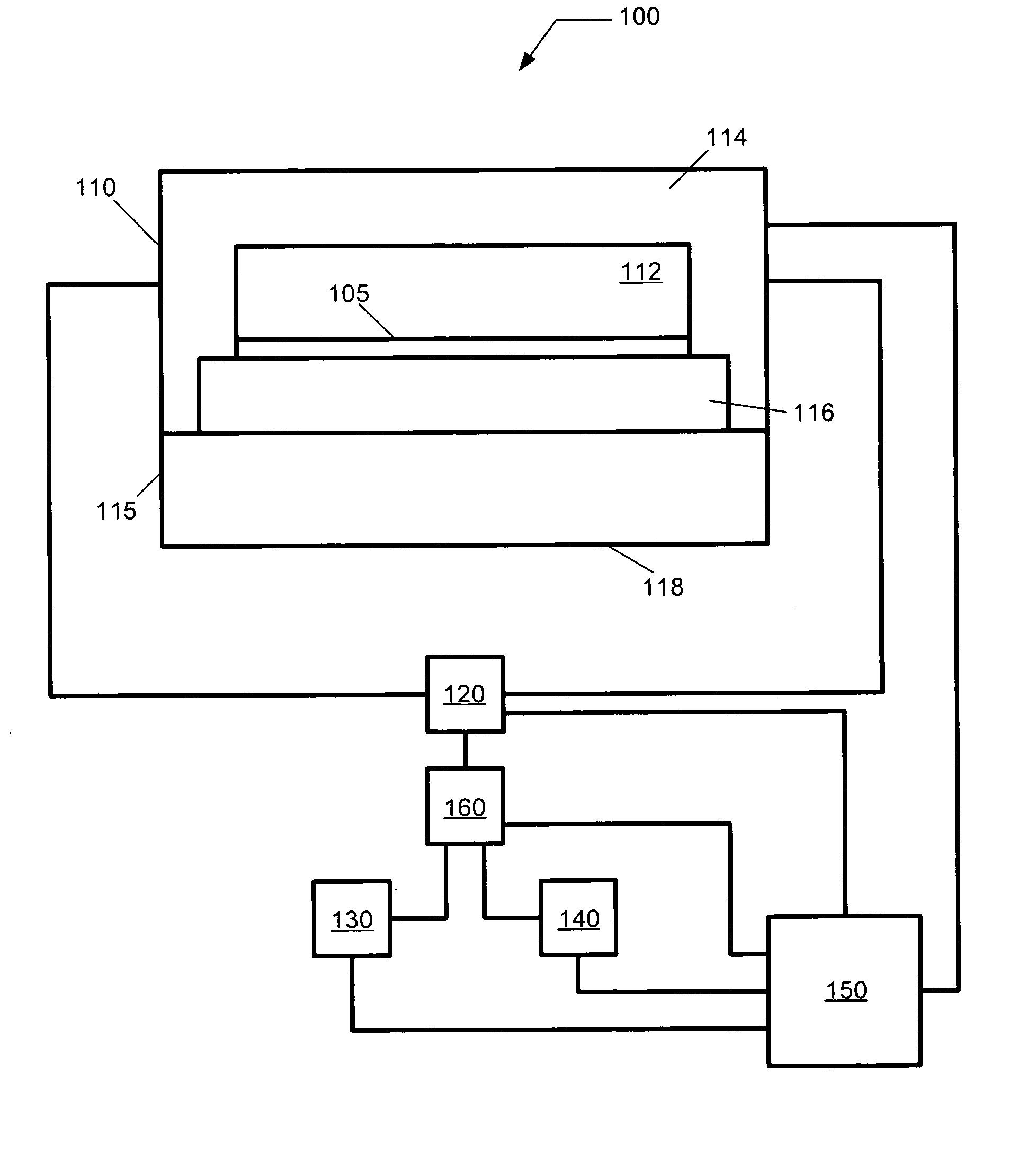

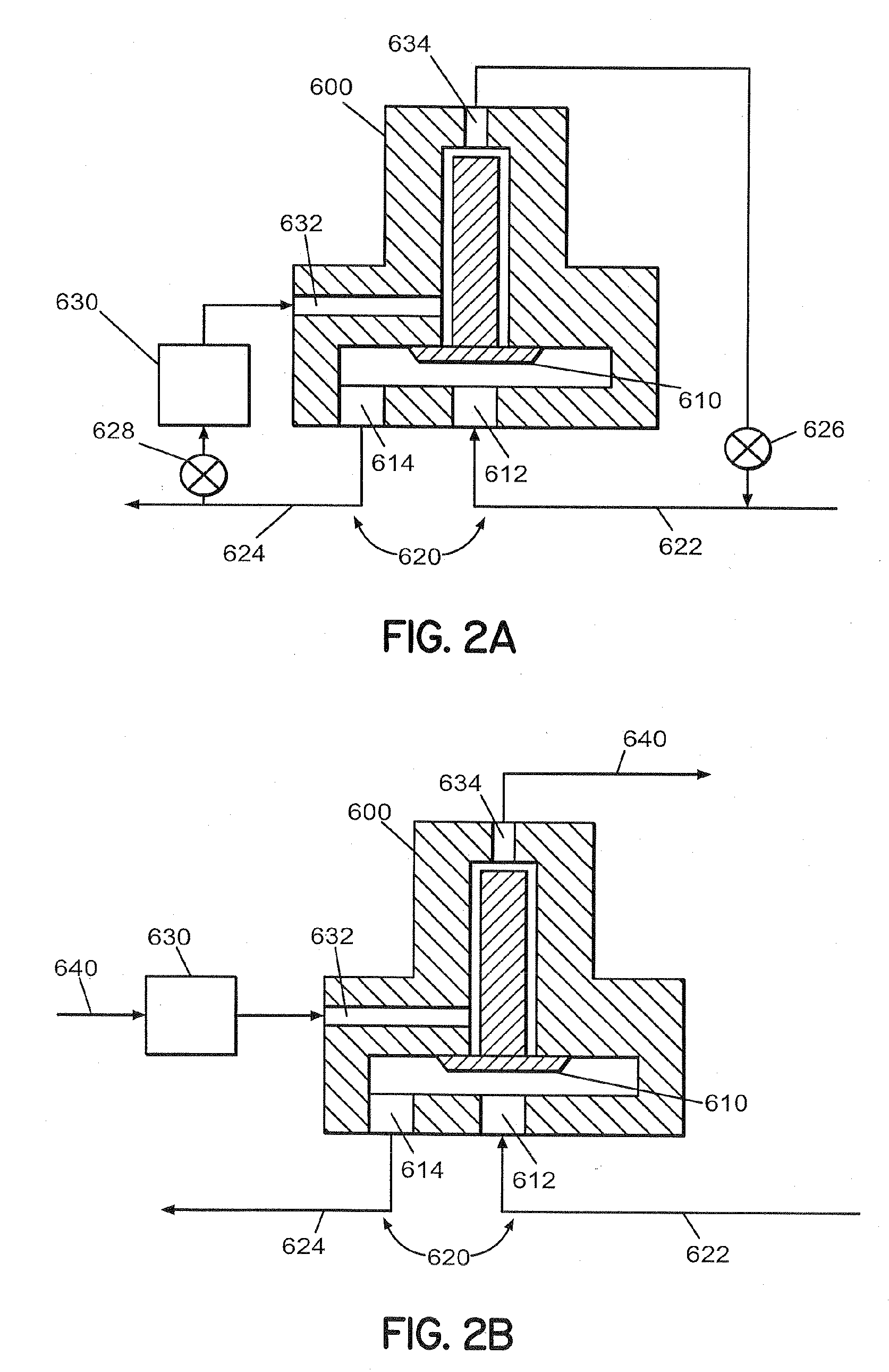

Method for treating a substrate

InactiveUS20060065629A1Reduce harmReduce the possibility of damageElectric discharge tubesDecorative surface effectsProcess chemistryEngineering

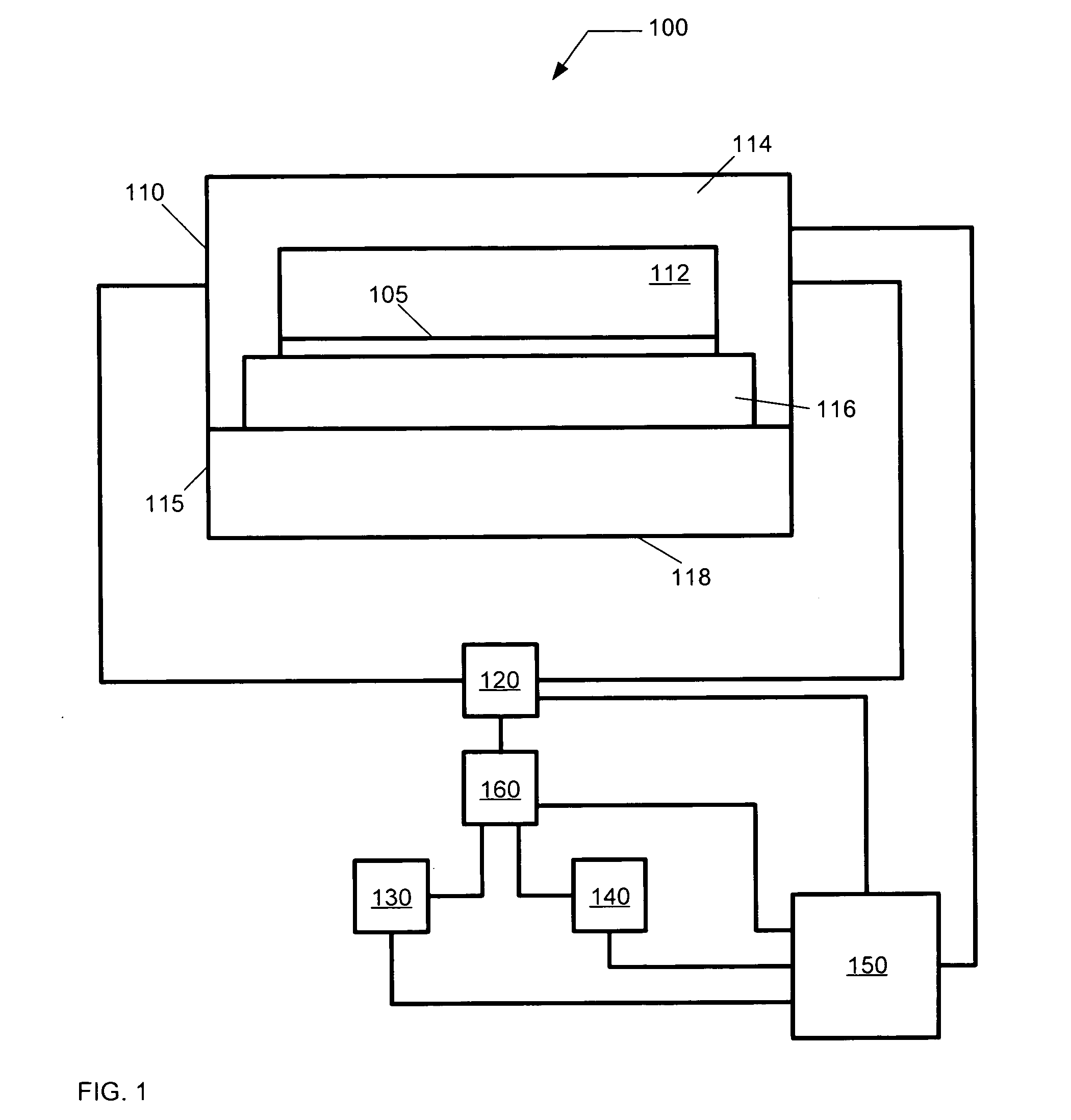

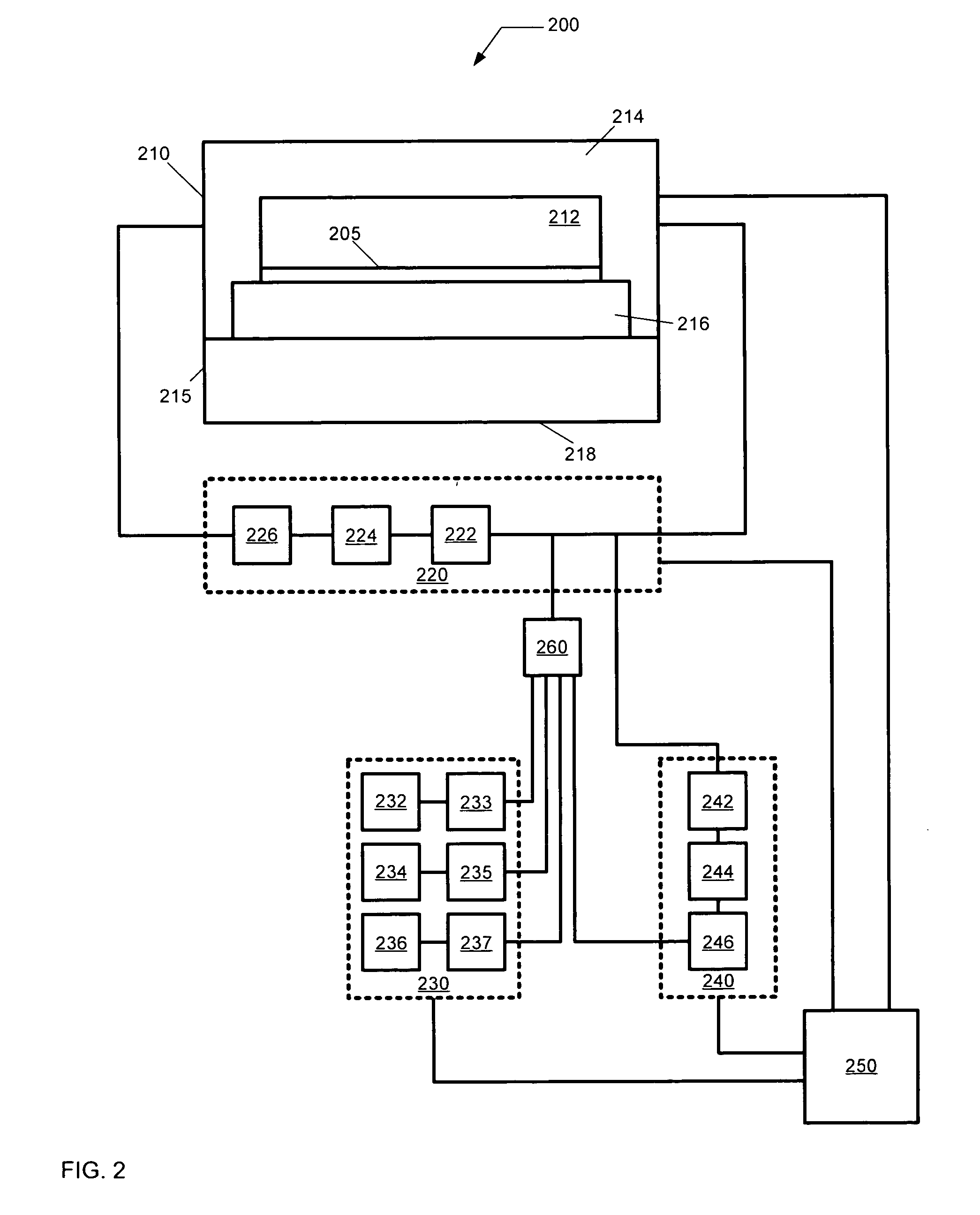

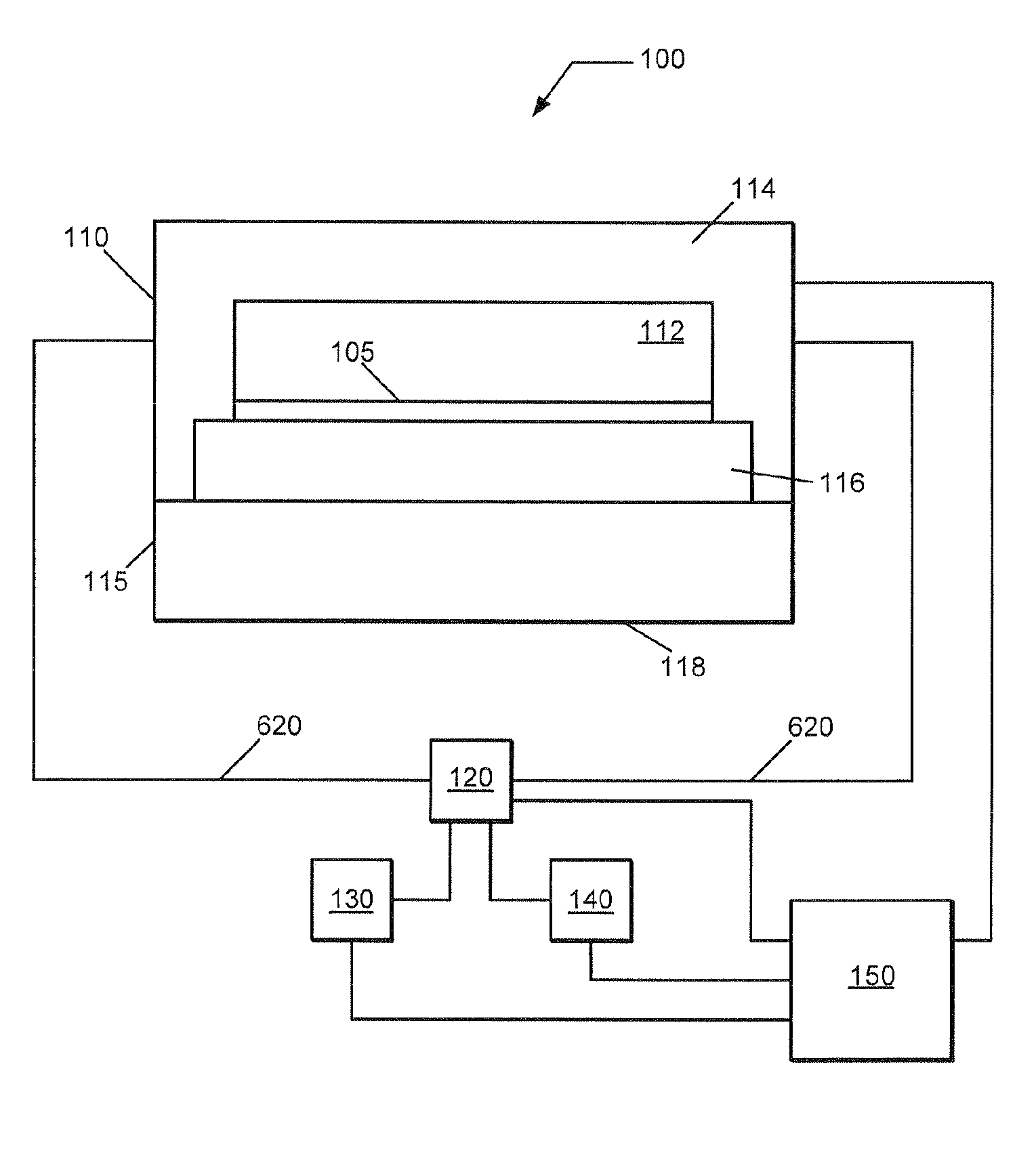

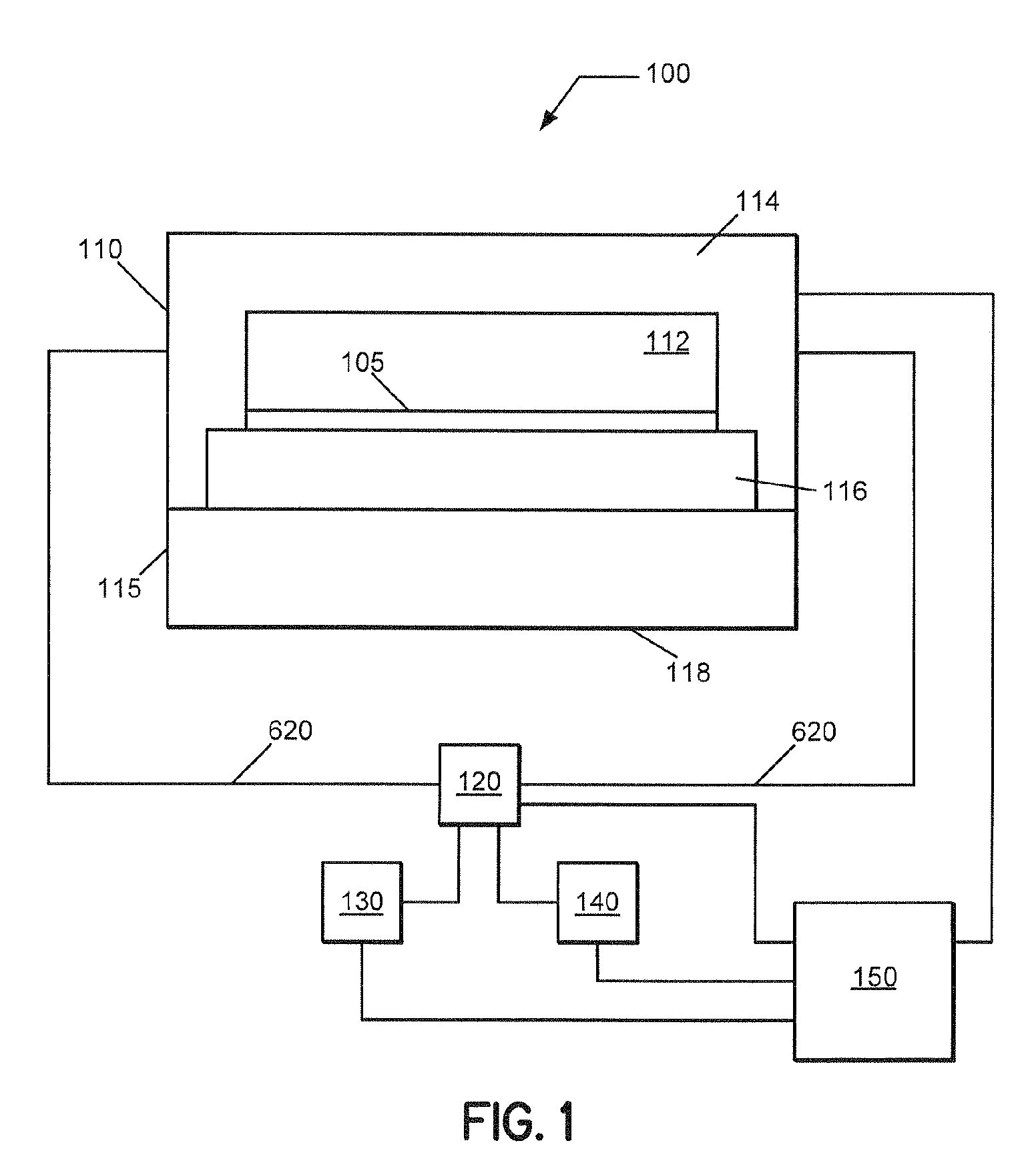

A method of treating a substrate includes disposing the substrate in a processing chamber having a first chamber portion configured to define a plasma space and a second chamber portion configured to define a process space, introducing a first gas to the plasma space and introducing a second gas to the process space. A plasma is formed in the plasma space from the first gas using a plasma source coupled to the upper chamber portion, and a process chemistry for treating the substrate is formed in the process space by providing a grid positioned between the first chamber portion and the second chamber portion such that the plasma can diffuse from the plasma space to the process space.

Owner:TOKYO ELECTRON LTD

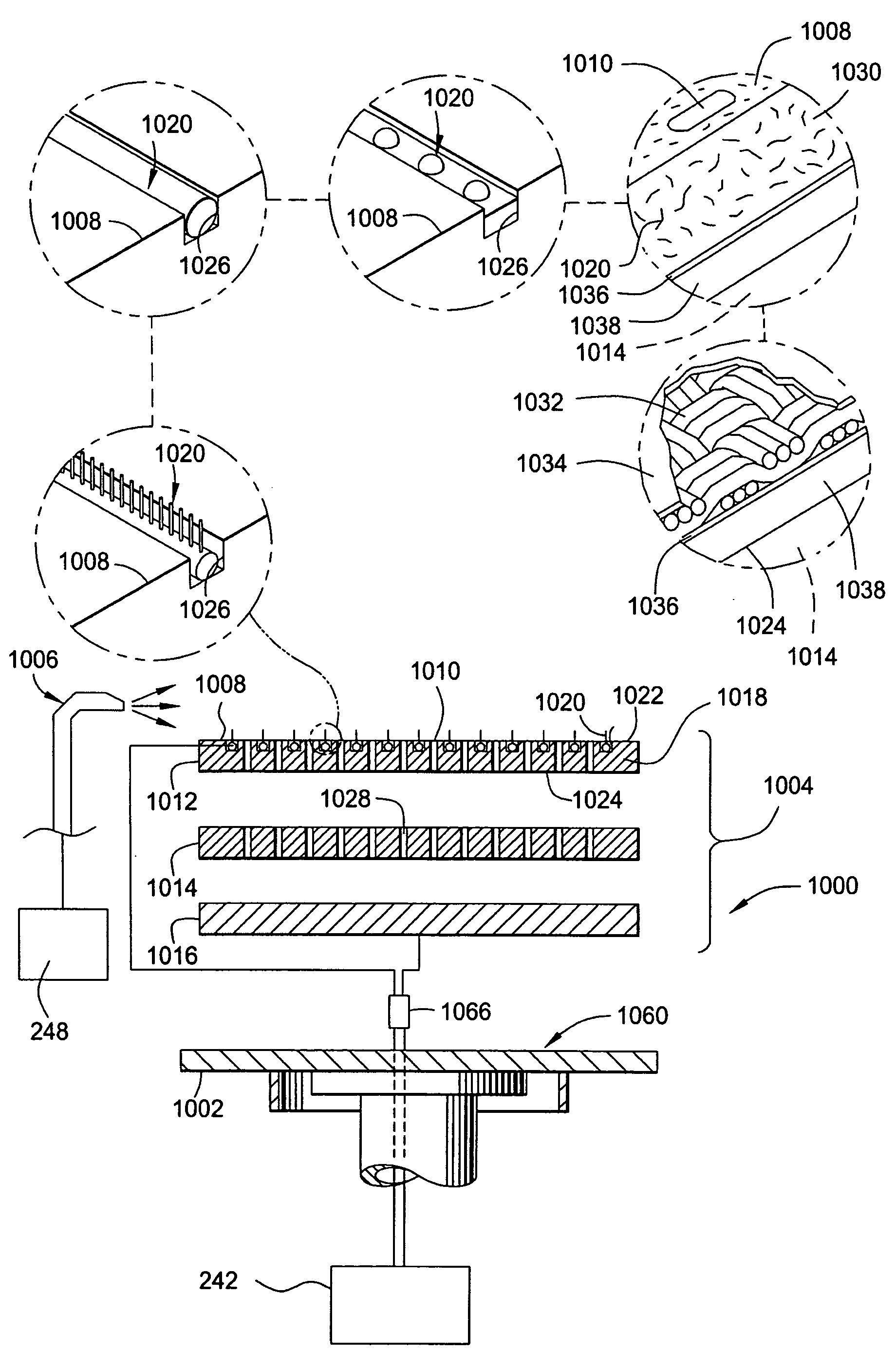

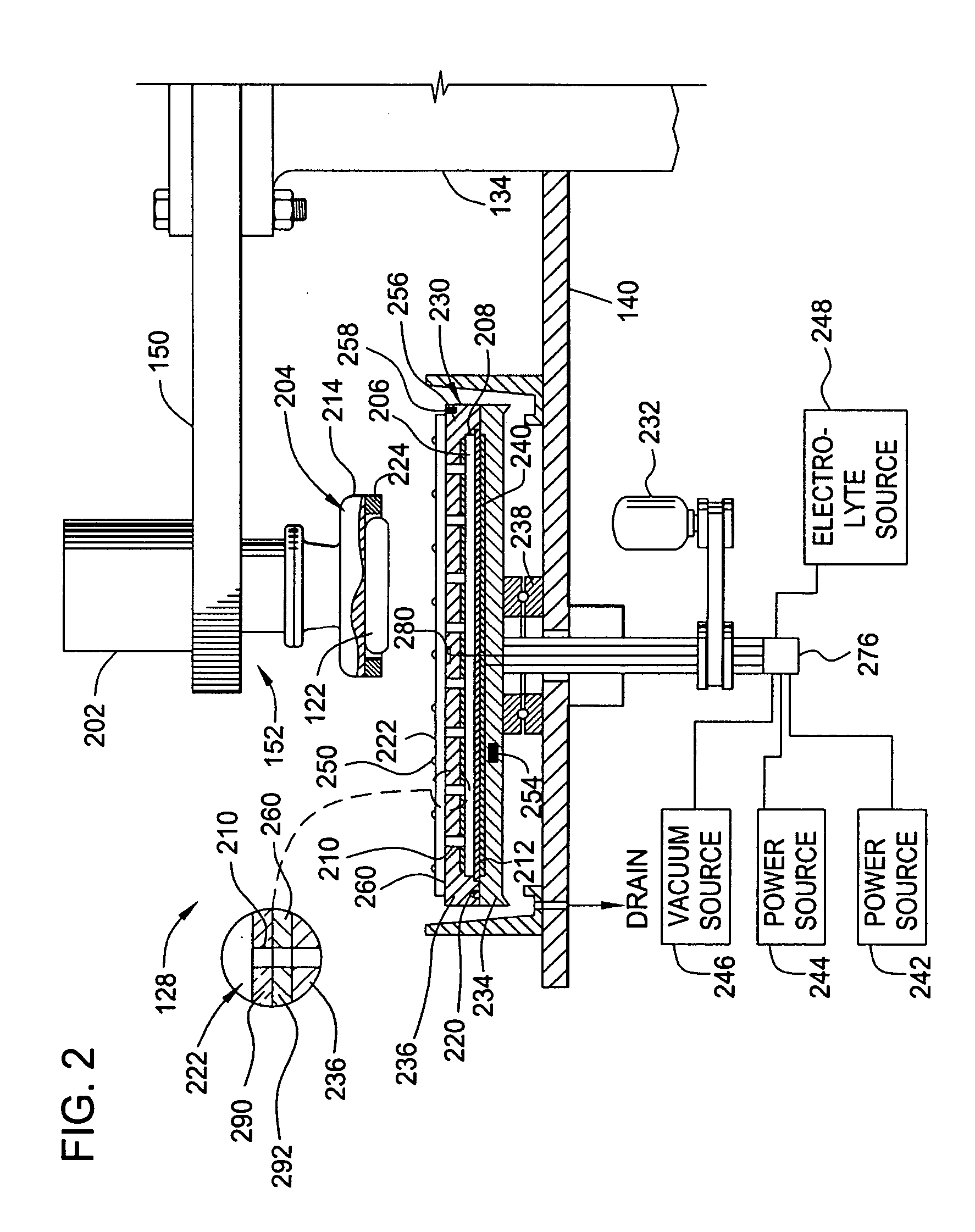

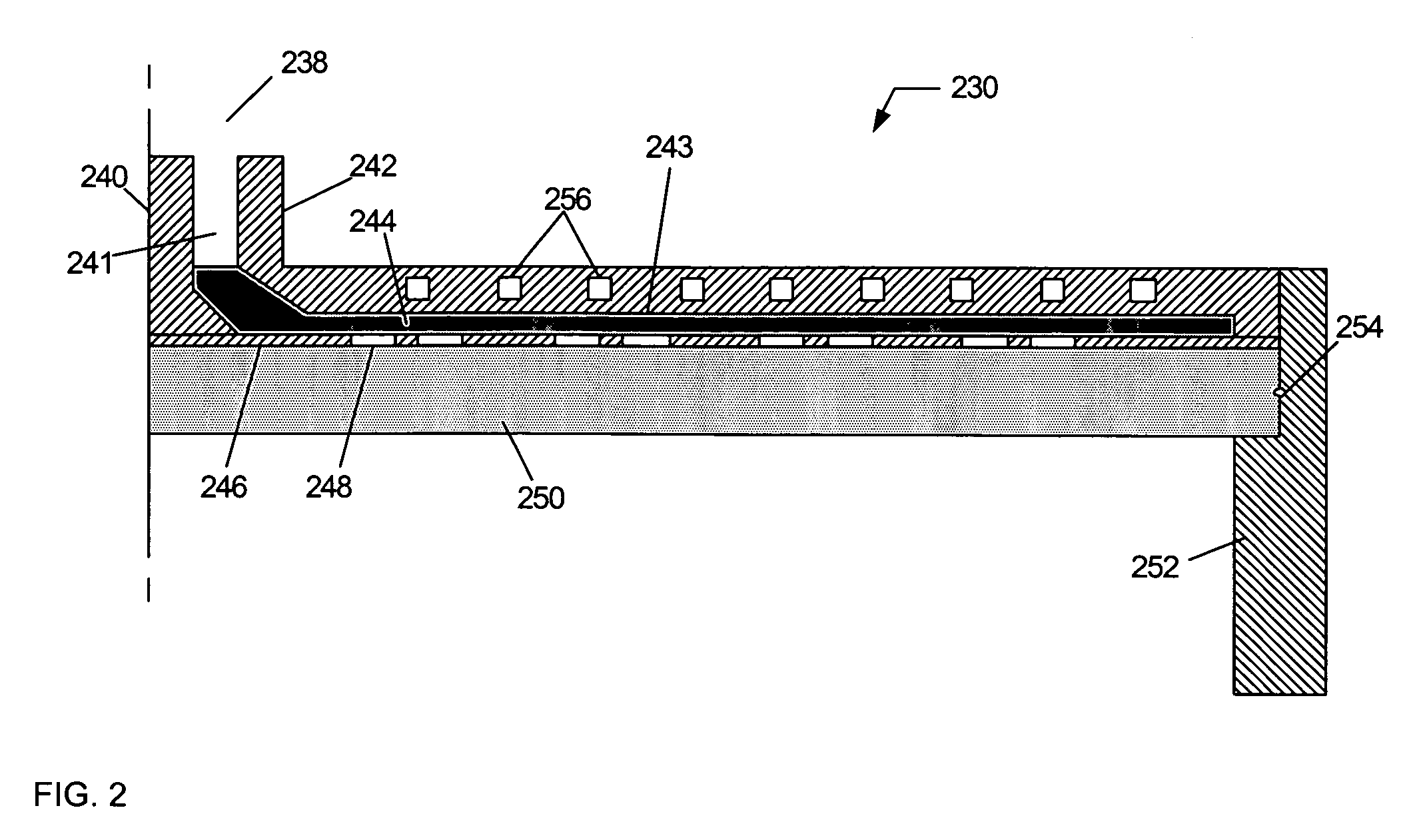

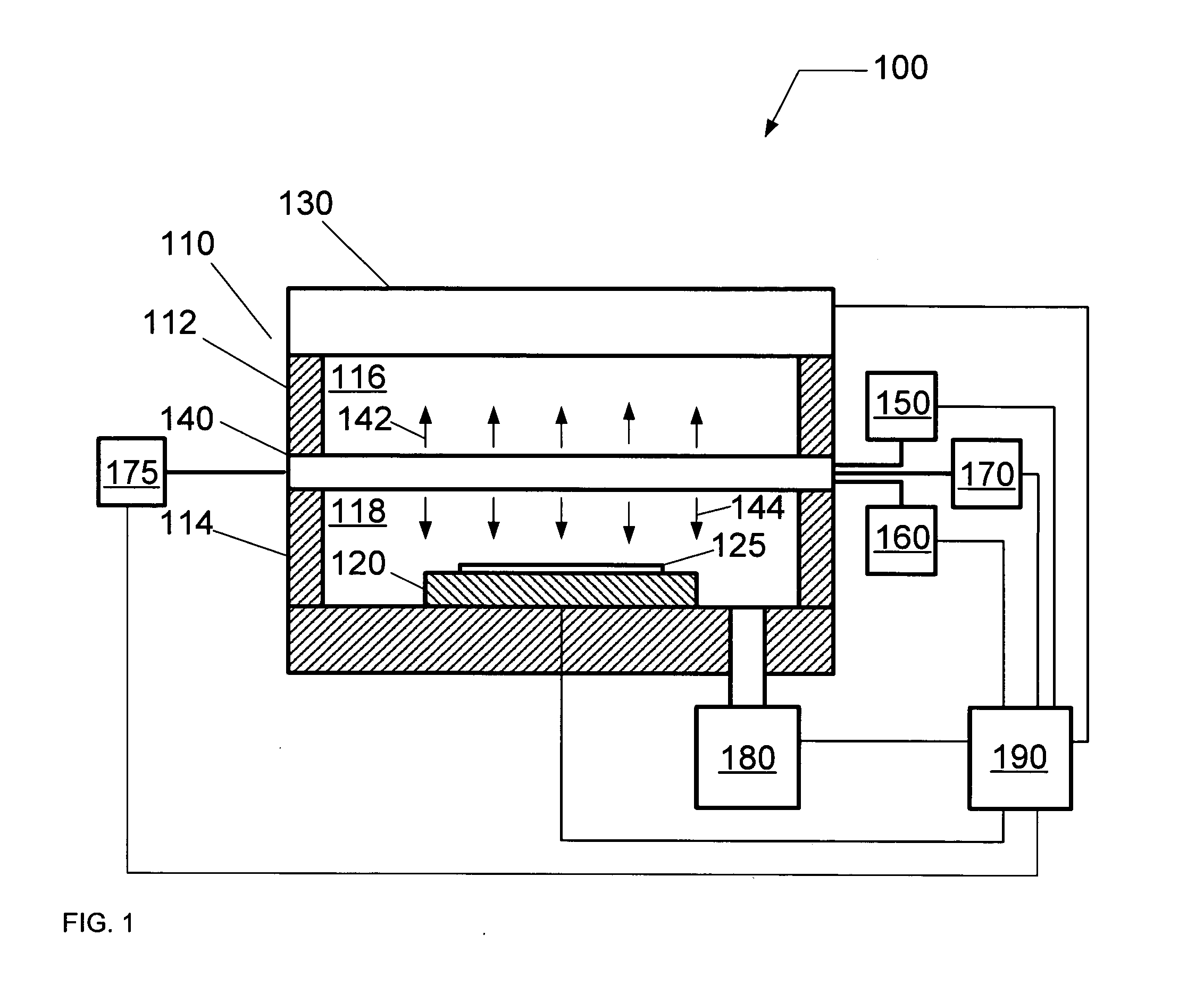

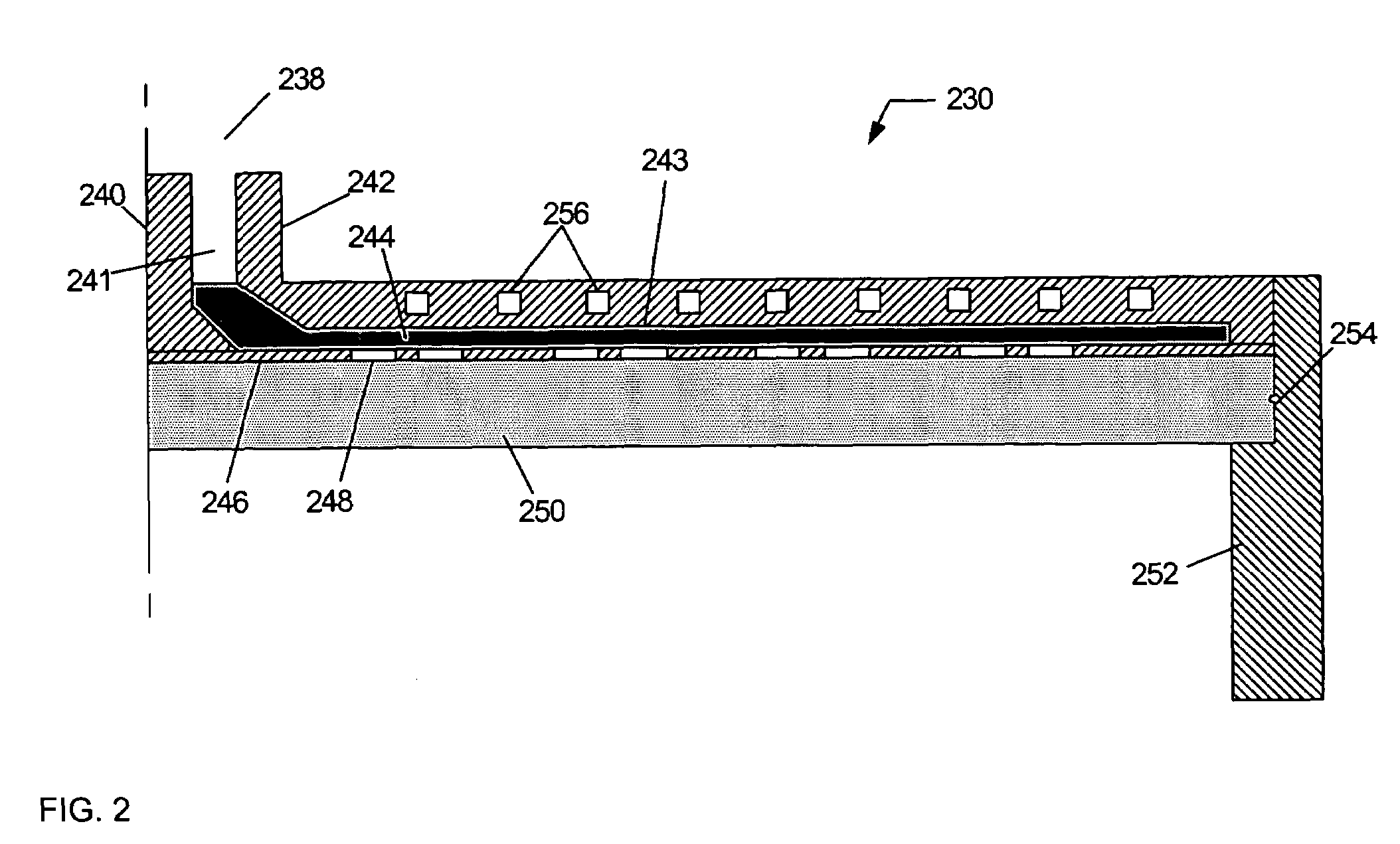

Method and apparatus for electrochemical mechanical processing

InactiveUS20050000801A1CellsSemiconductor/solid-state device manufacturingProcess chemistryEngineering

Embodiments of the invention generally provide a method and apparatus for processing a substrate in an electrochemical mechanical planarizing system. In one embodiment, a cell for polishing a substrate includes a processing pad disposed on a top surface of a platen assembly. A plurality of conductive elements are arranged in a spaced-apart relation across the upper planarizing surface and adapted to bias the substrate relative to an electrode disposed between the pad and the platen assembly. A plurality of passages are formed through the platen assembly between the top surface and a plenum defined within the platen assembly. In another embodiment, a system is provided having a bulk processing cell and a residual processing cell. The residual processing cell includes a biased conductive planarizing surface. In further embodiments, the conductive element is protected from attack by process chemistries.

Owner:APPLIED MATERIALS INC

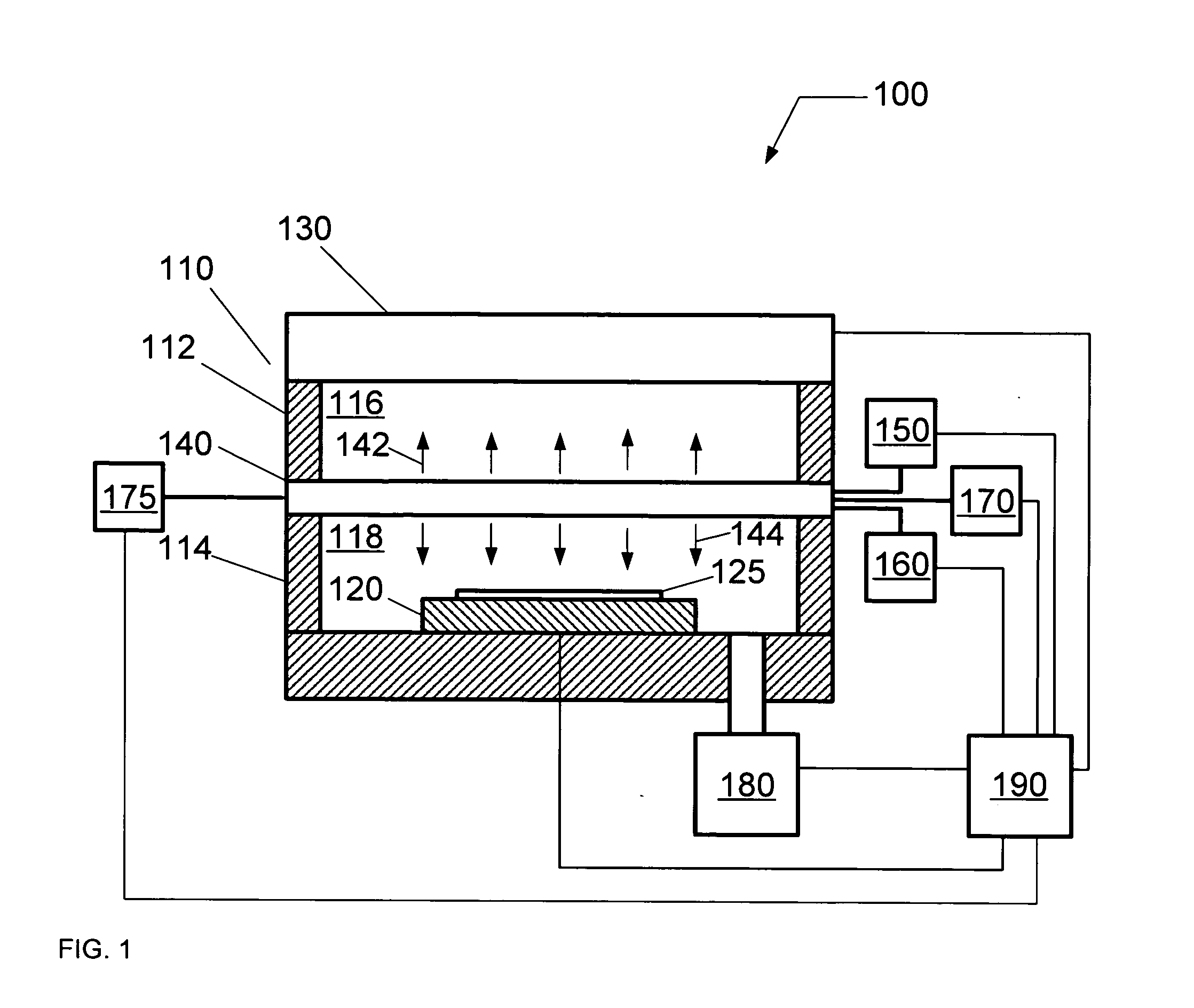

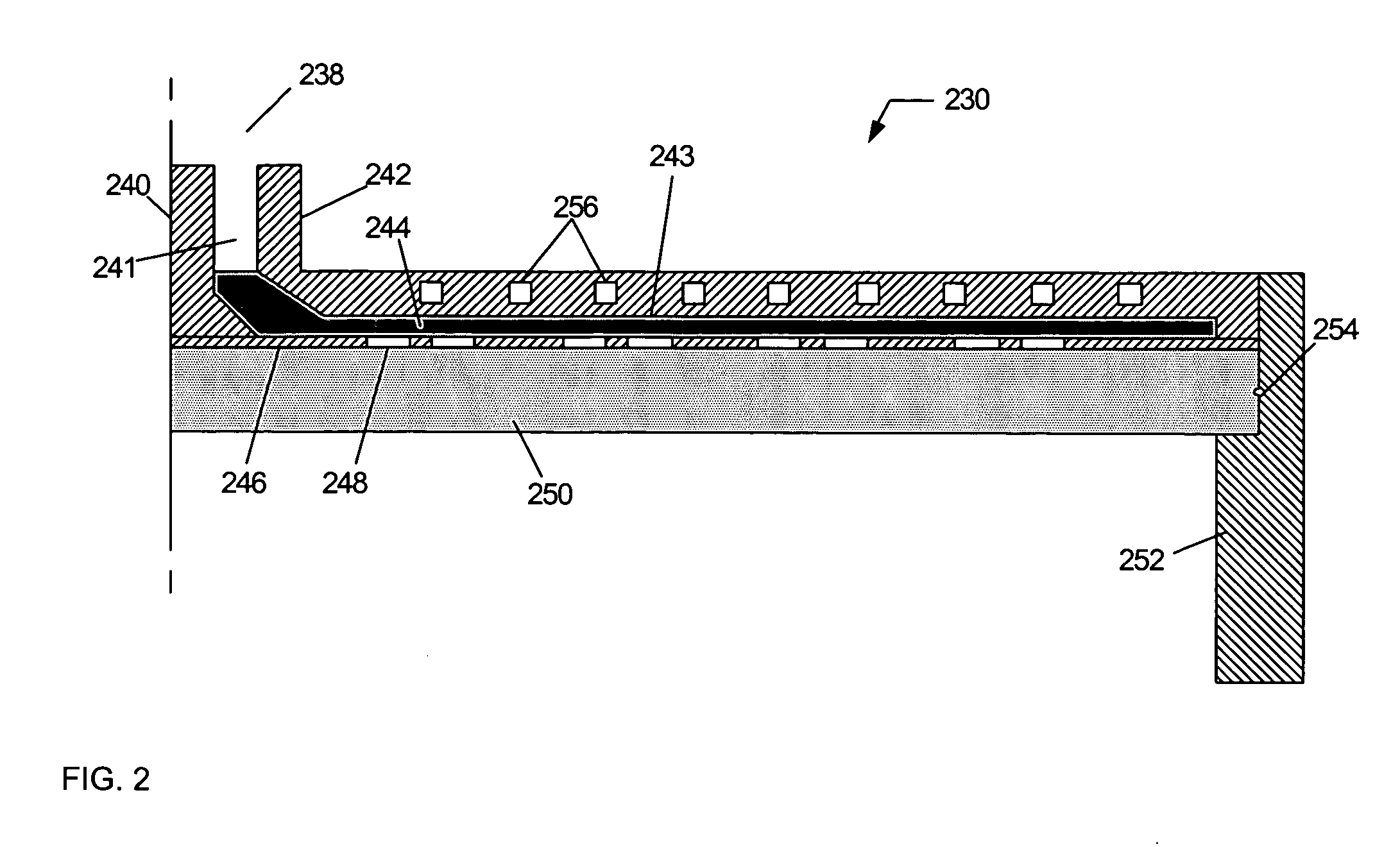

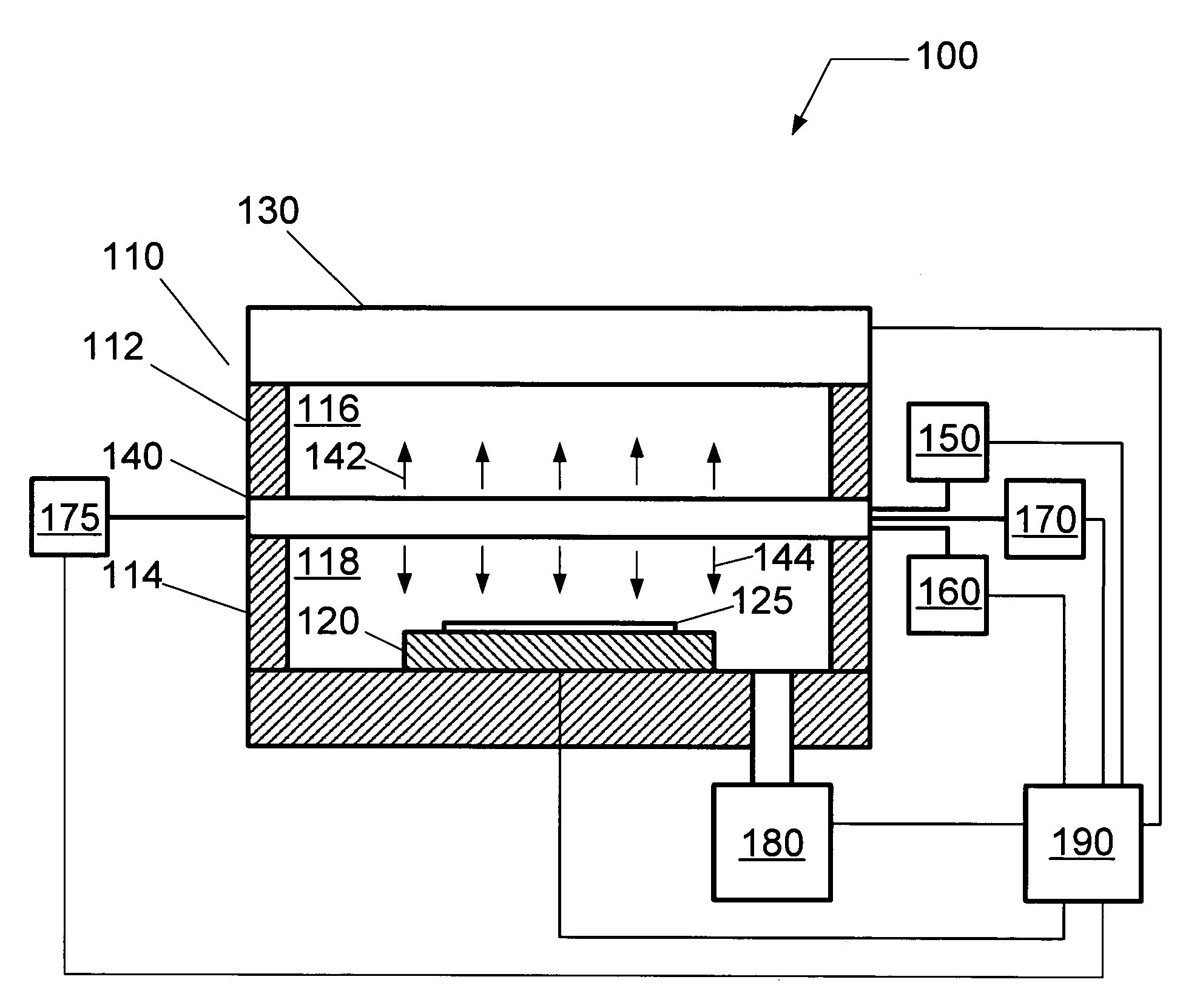

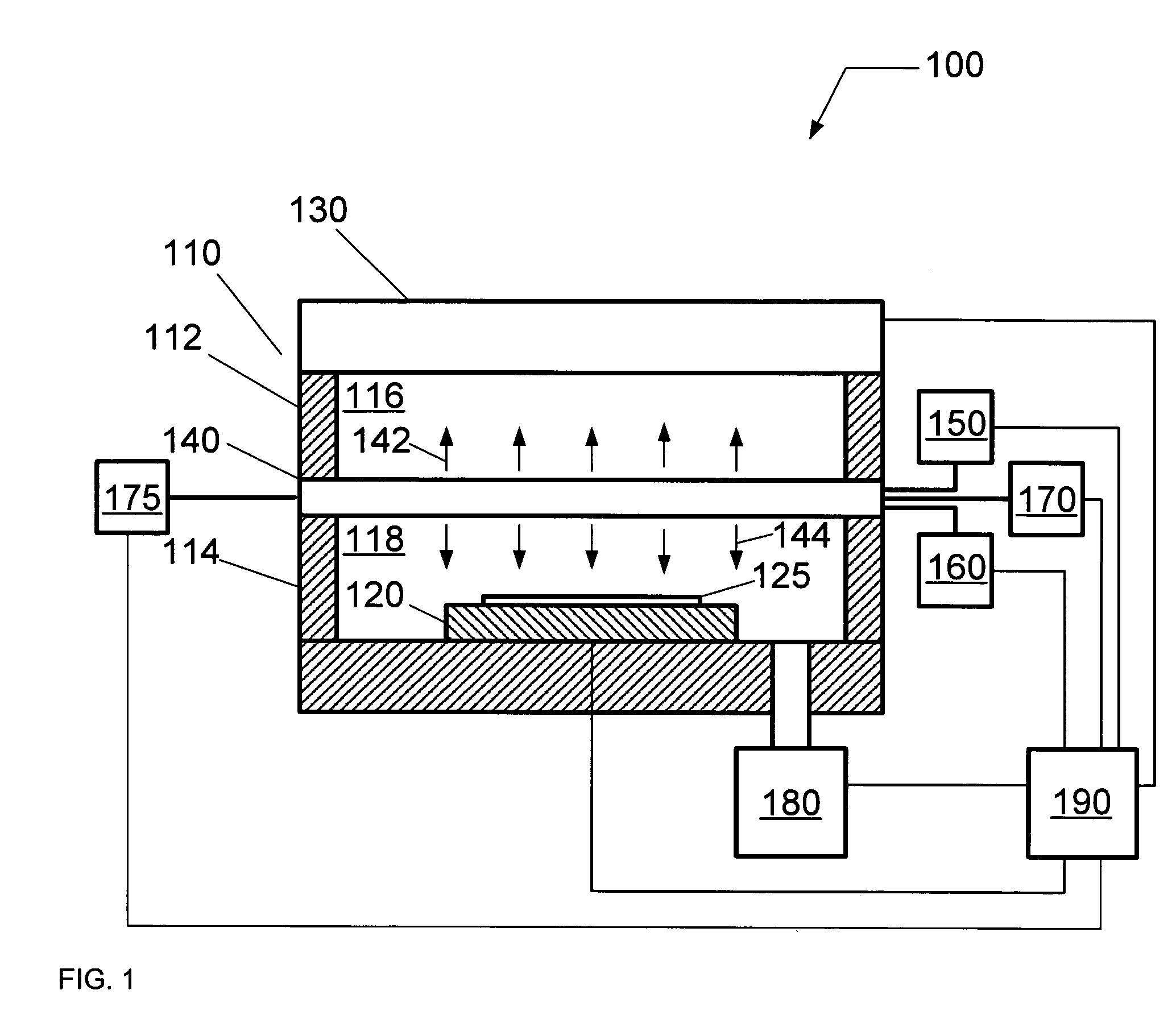

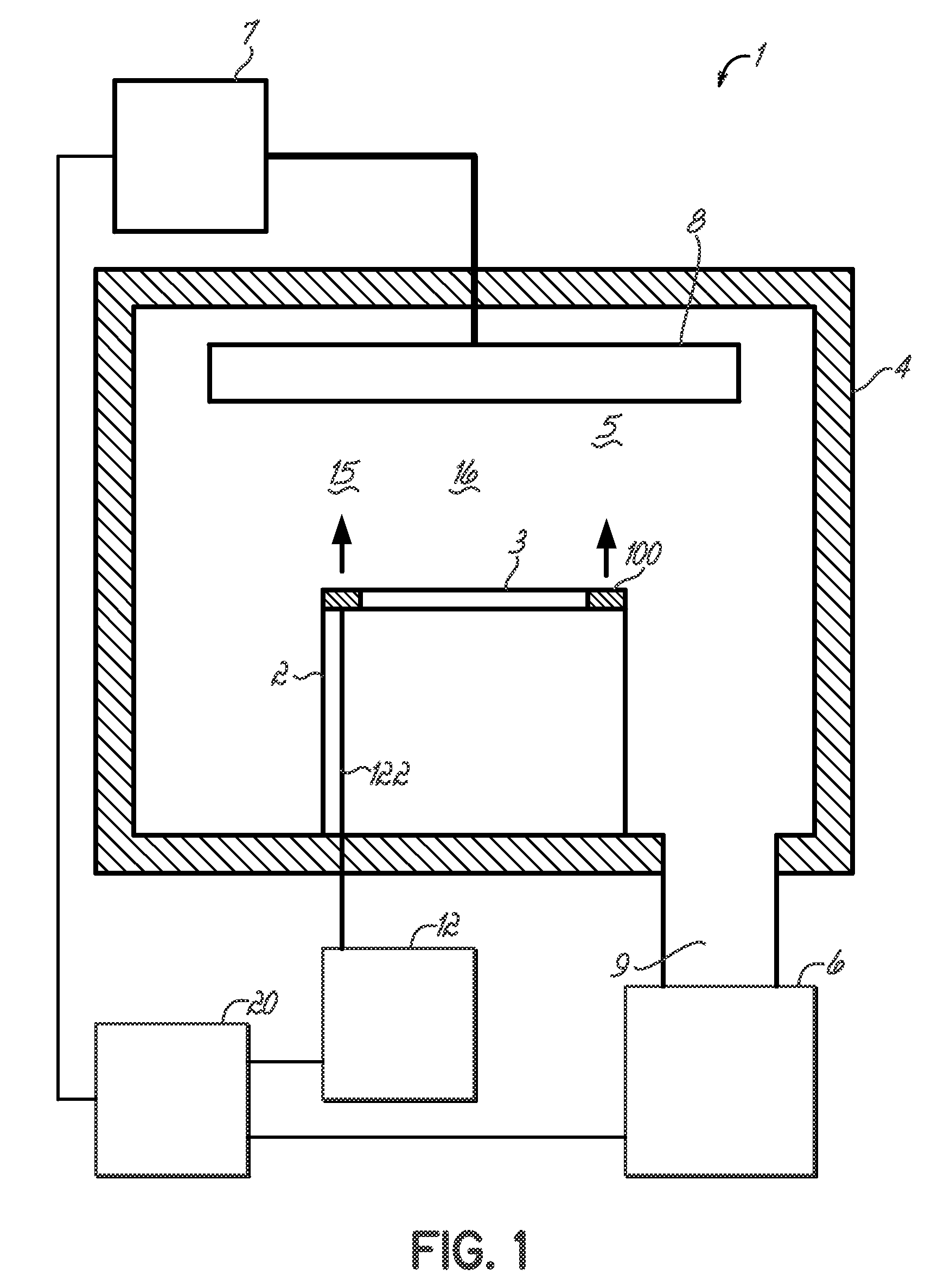

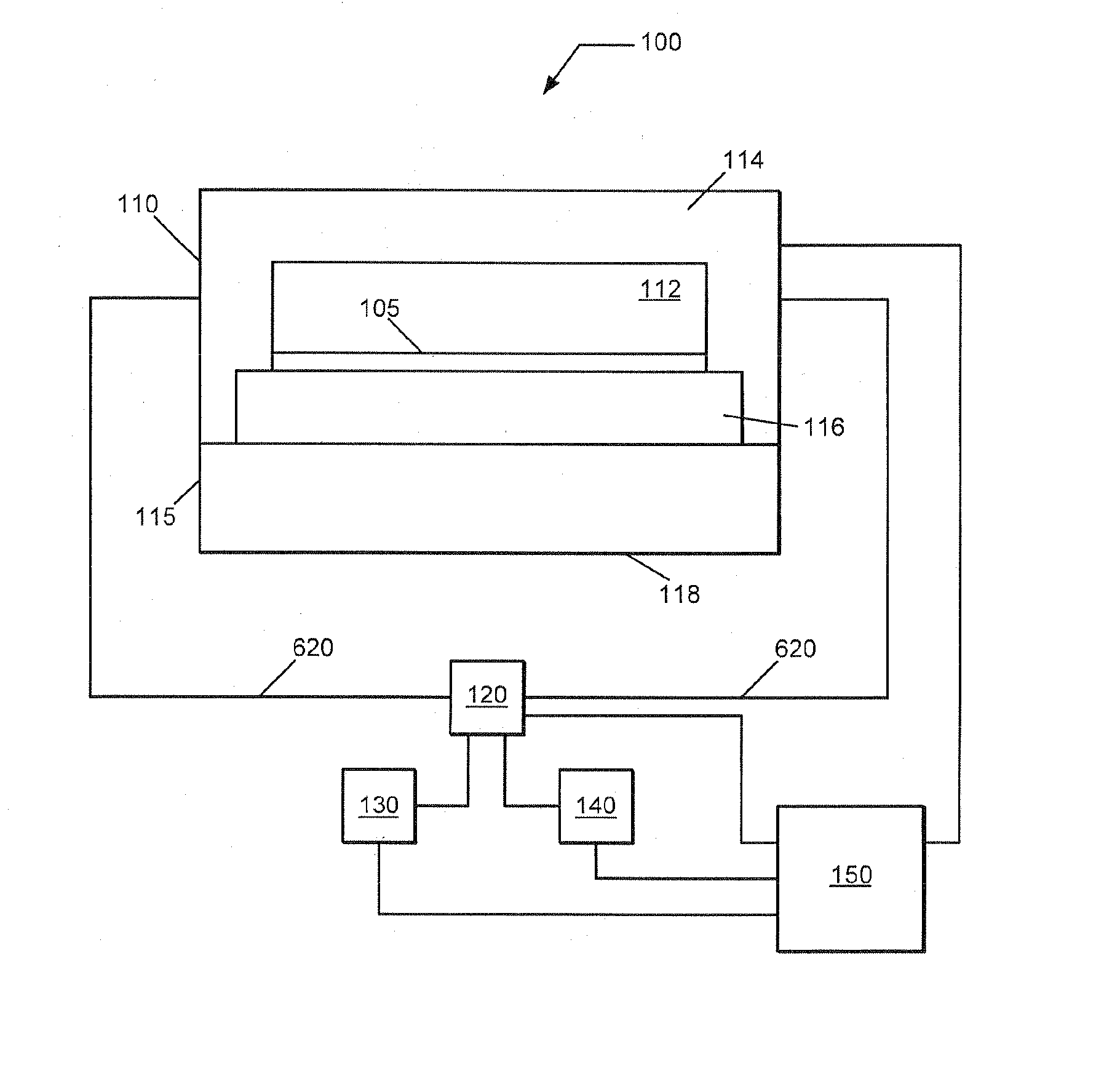

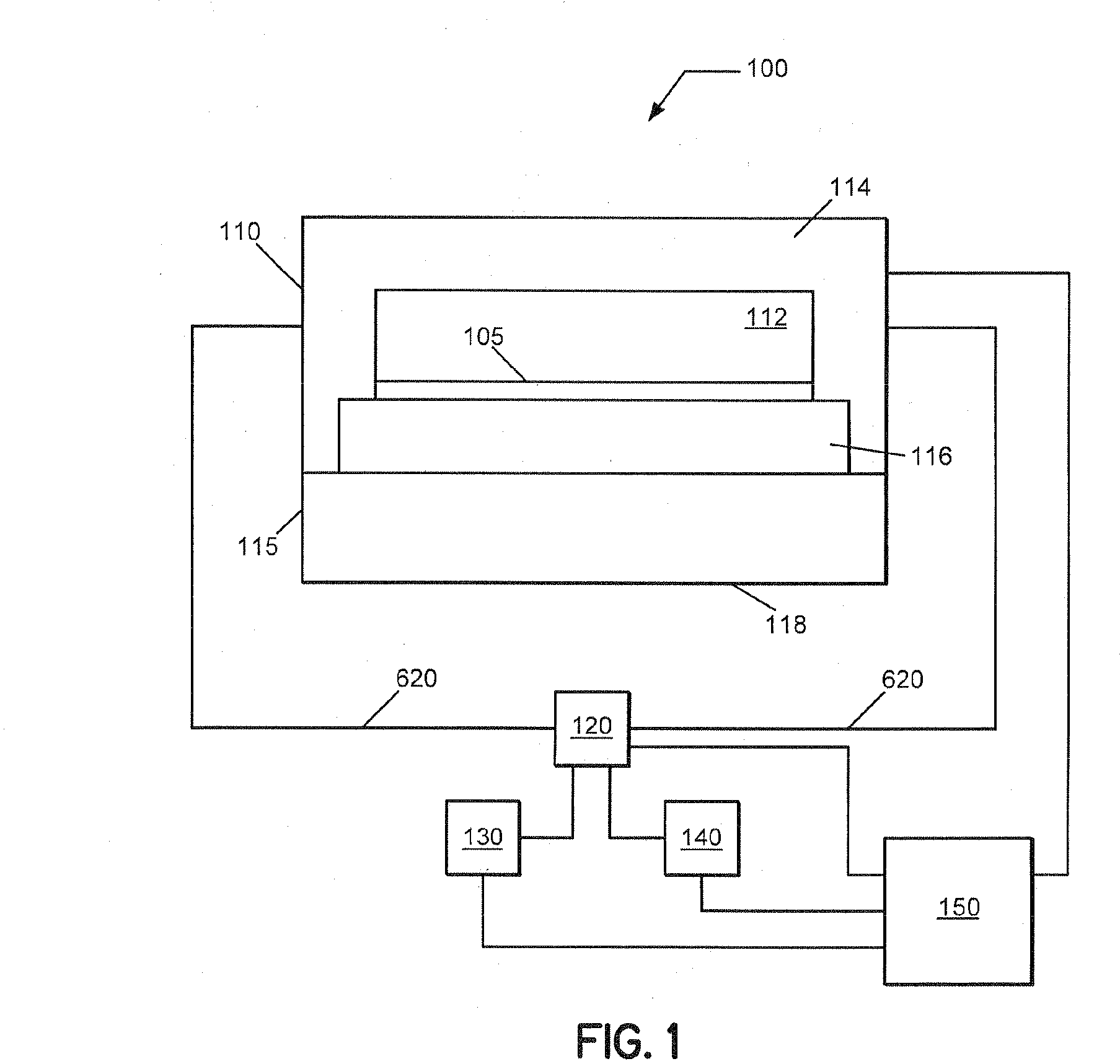

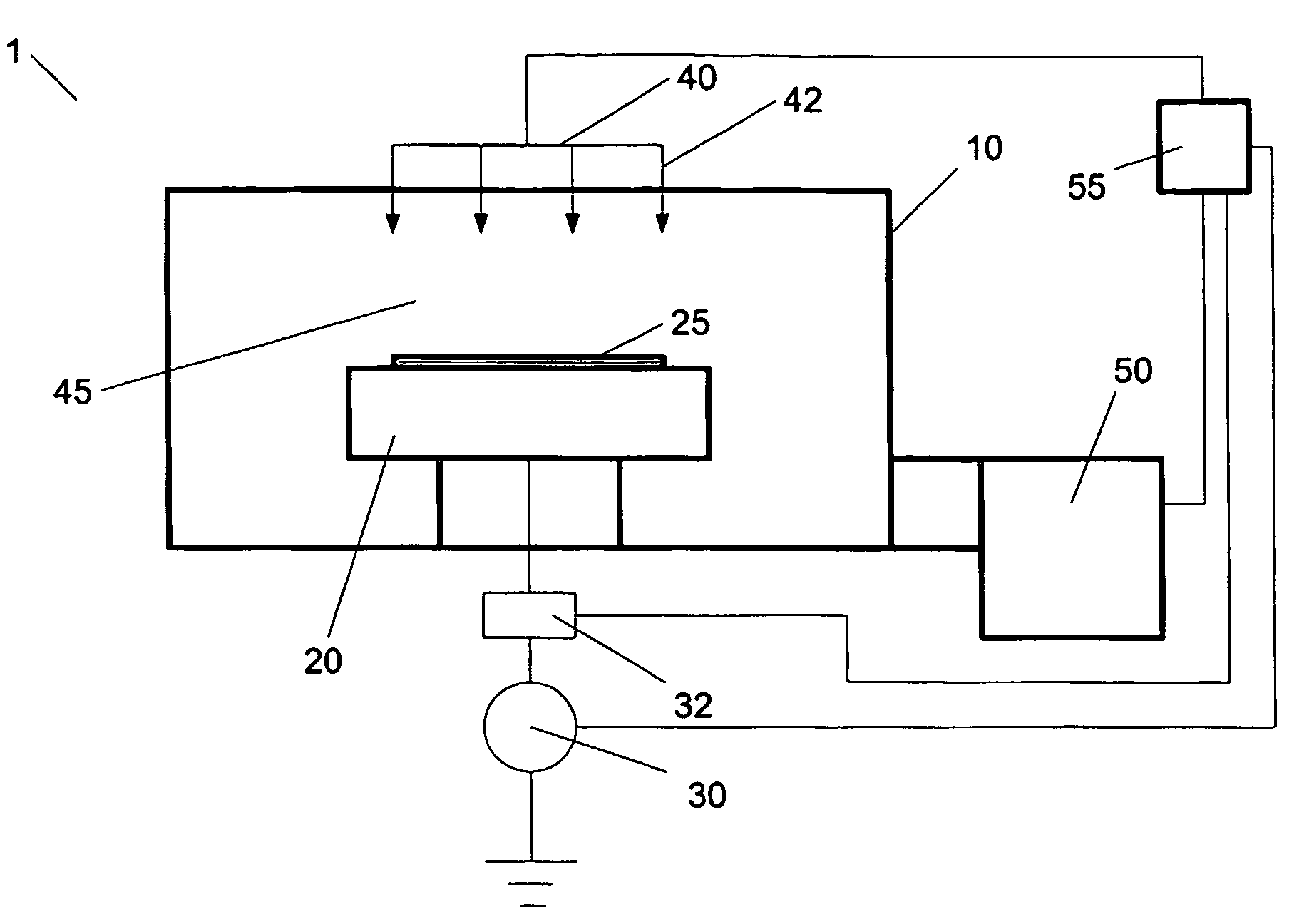

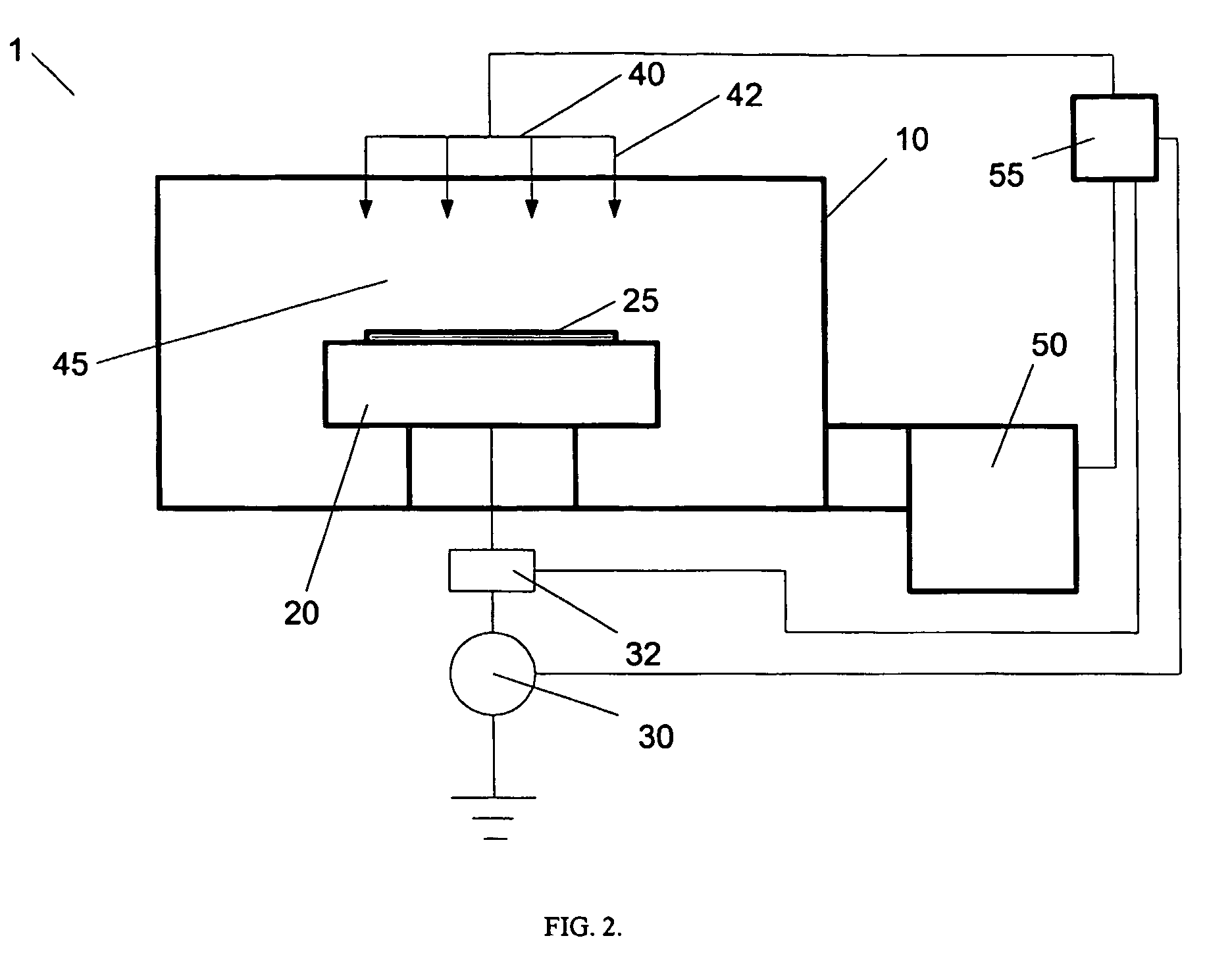

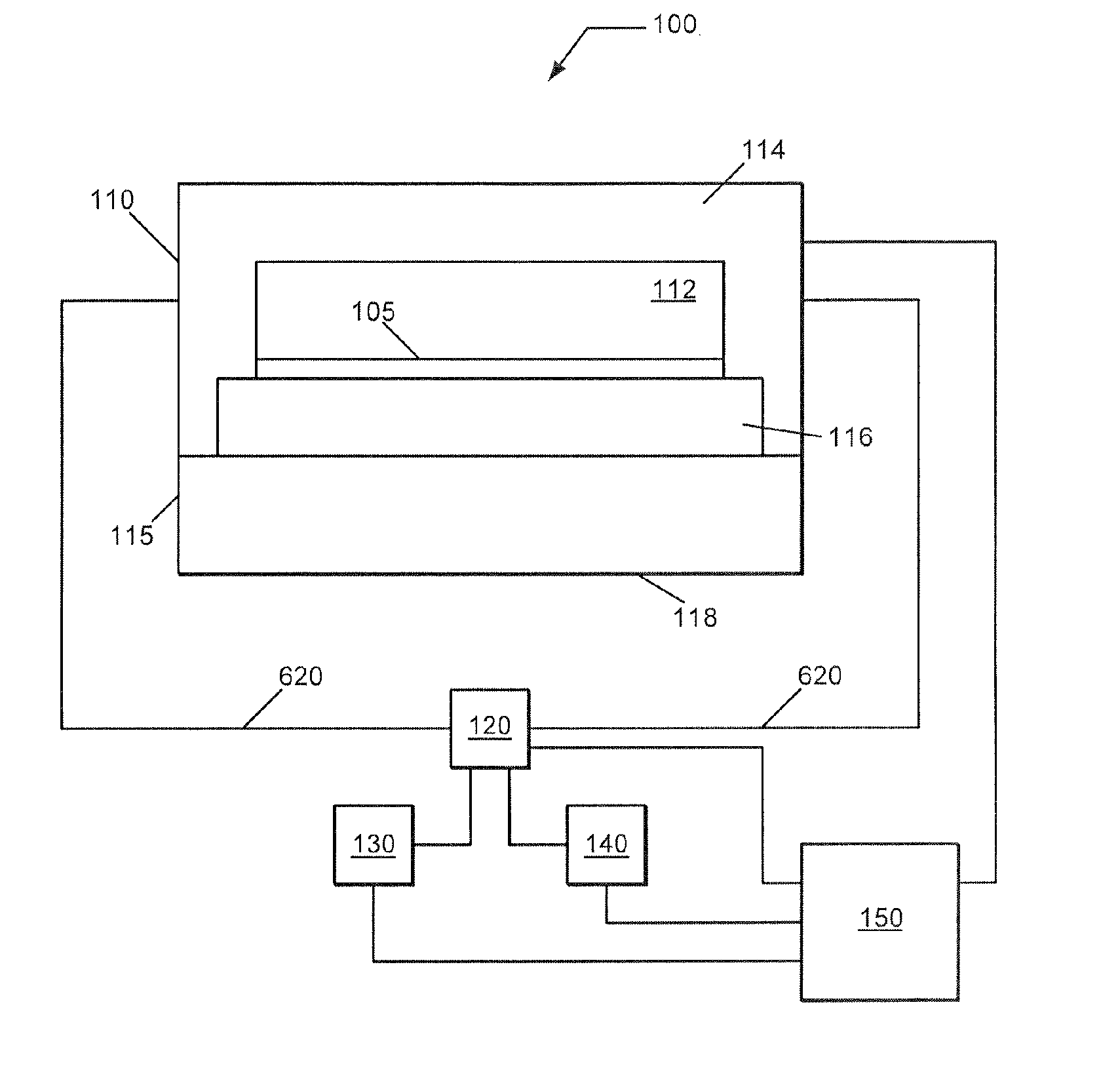

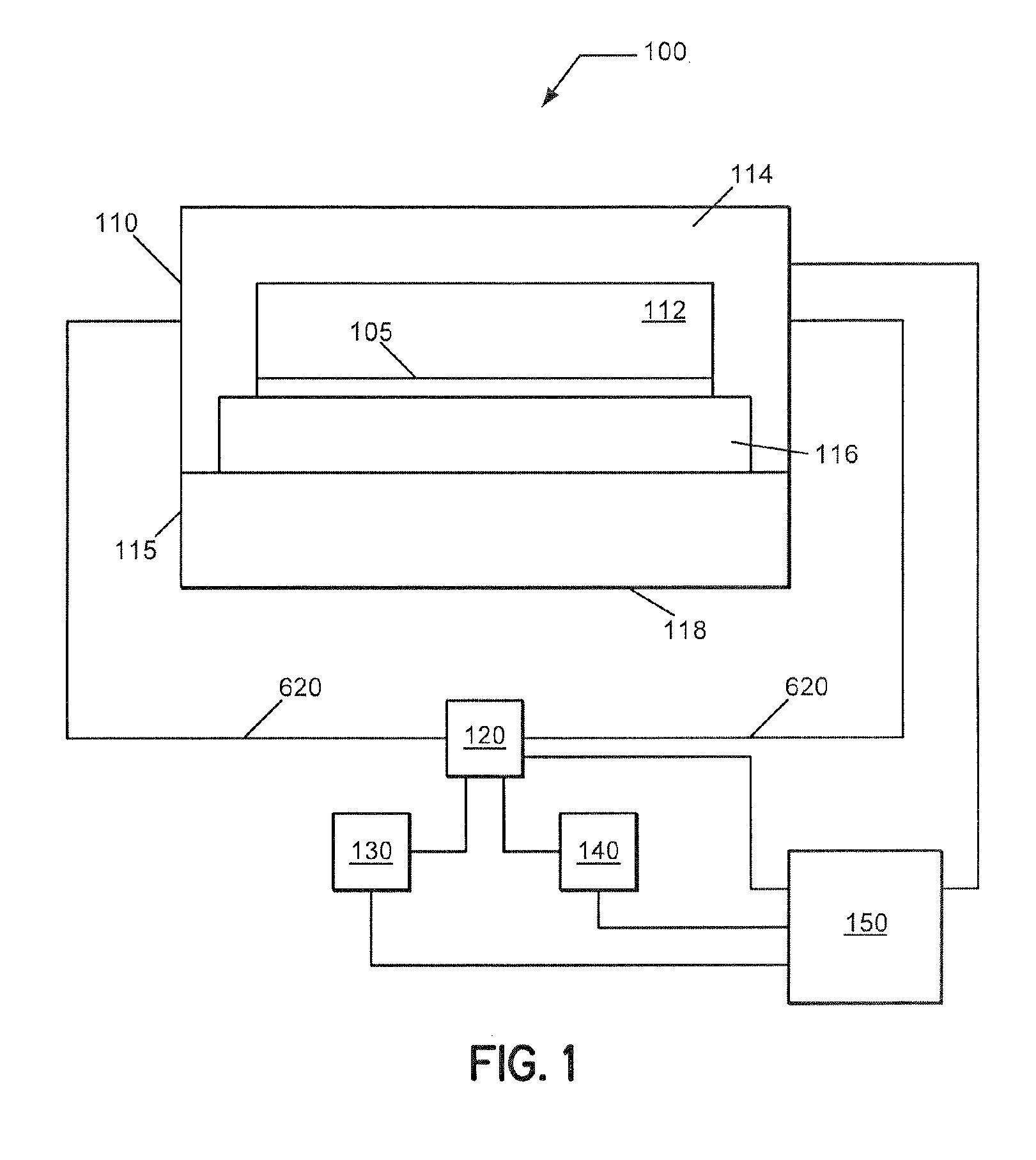

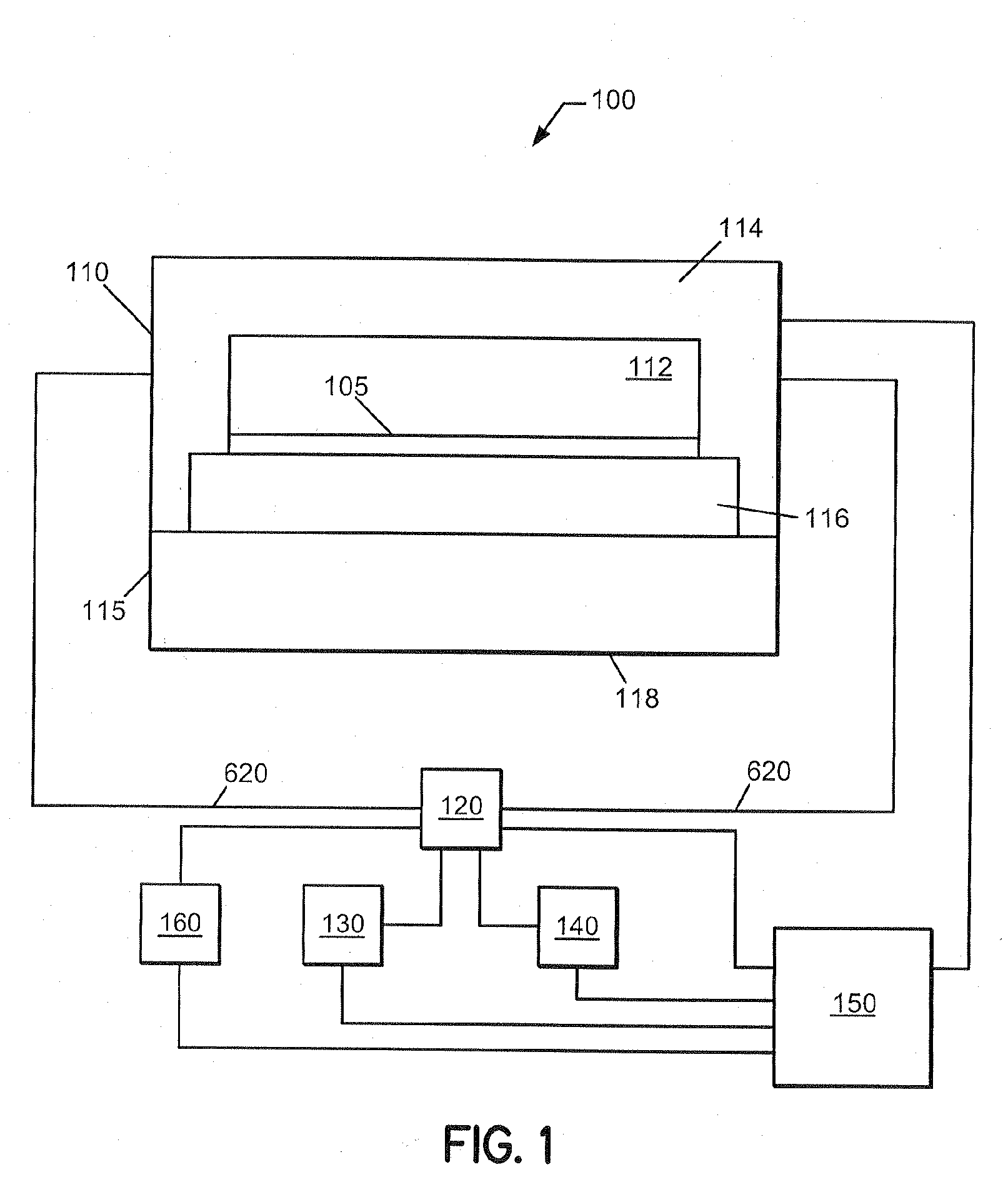

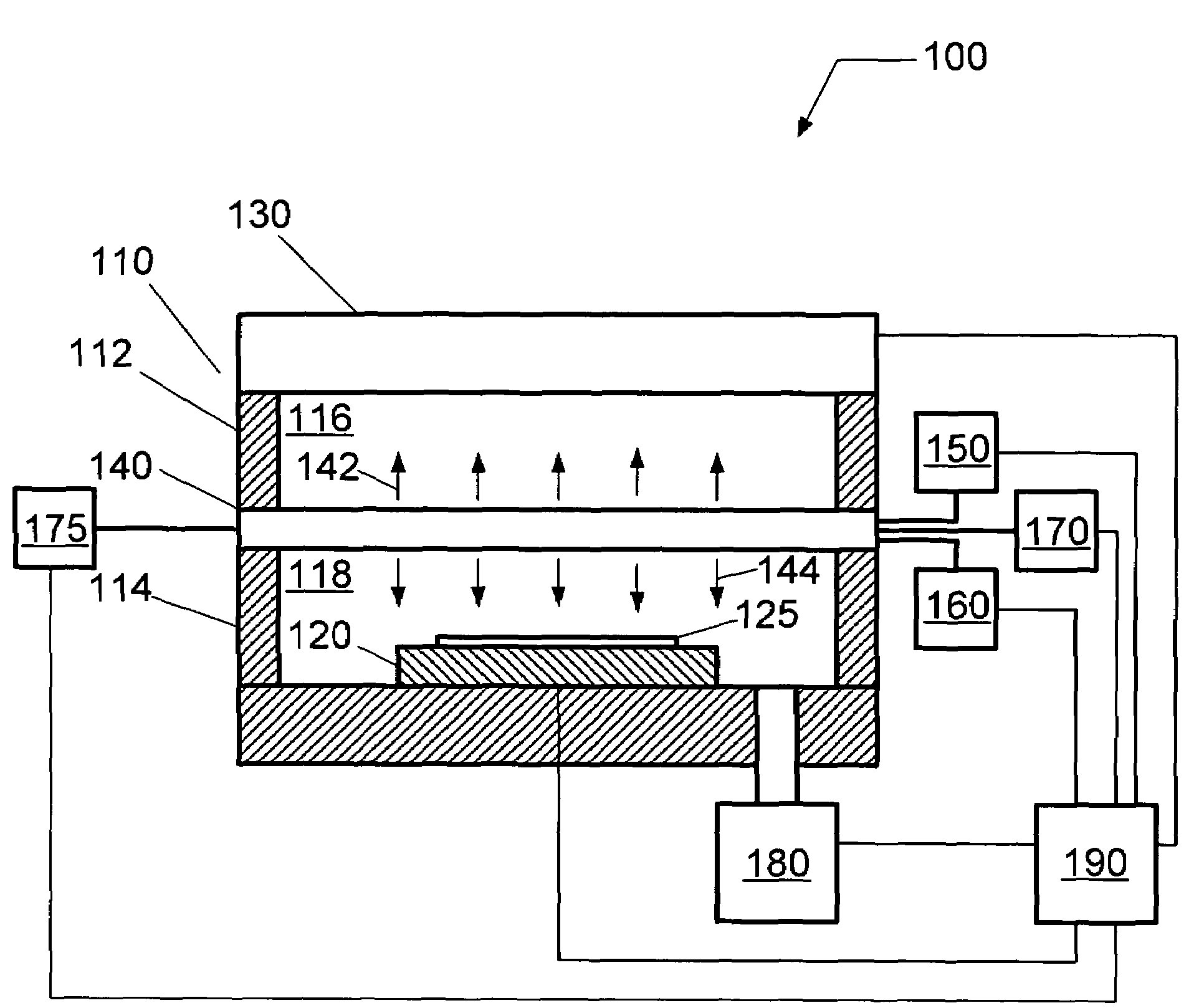

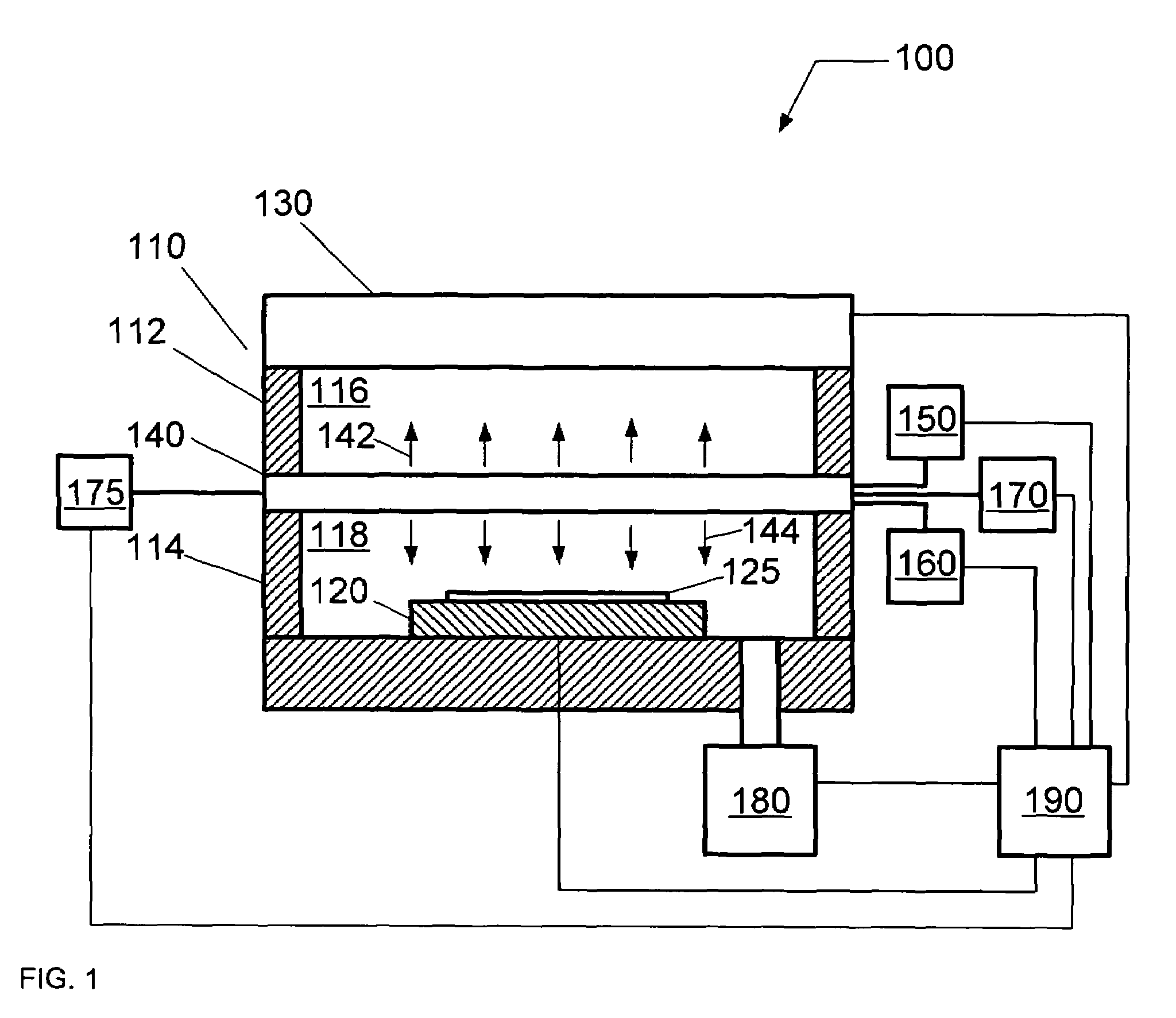

Plasma processing system for treating a substrate

ActiveUS7396431B2Reduce harmReduce the possibility of damageElectric discharge tubesSemiconductor/solid-state device manufacturingProcess chemistryEngineering

A plasma processing system for treating a substrate includes a processing chamber including a first chamber portion configured to receive a first gas for providing a plasma space, and a second chamber portion configured to receive a second gas for providing a process space having process chemistry to treat the substrate. A substrate holder is coupled to the second chamber portion of the processing chamber, and configured to support the substrate proximate the process space, and a plasma source is coupled to the first chamber portion of the processing chamber, and configured to form a plasma in the plasma space. A grid is located between the plasma space and the process space, and configured to permit the diffusion of the plasma between the plasma space and the process space in order to form the process chemistry from the process gas.

Owner:TOKYO ELECTRON LTD

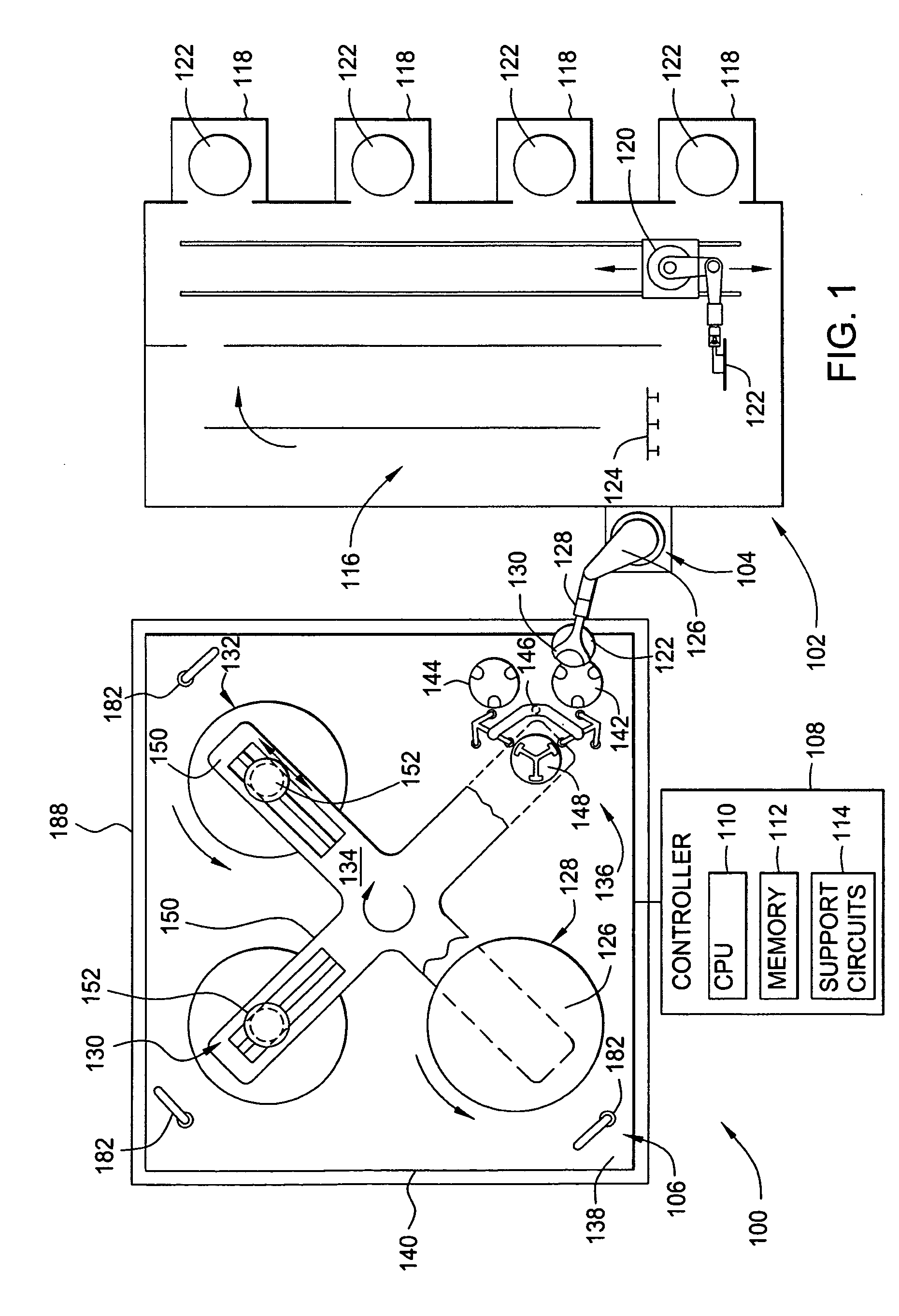

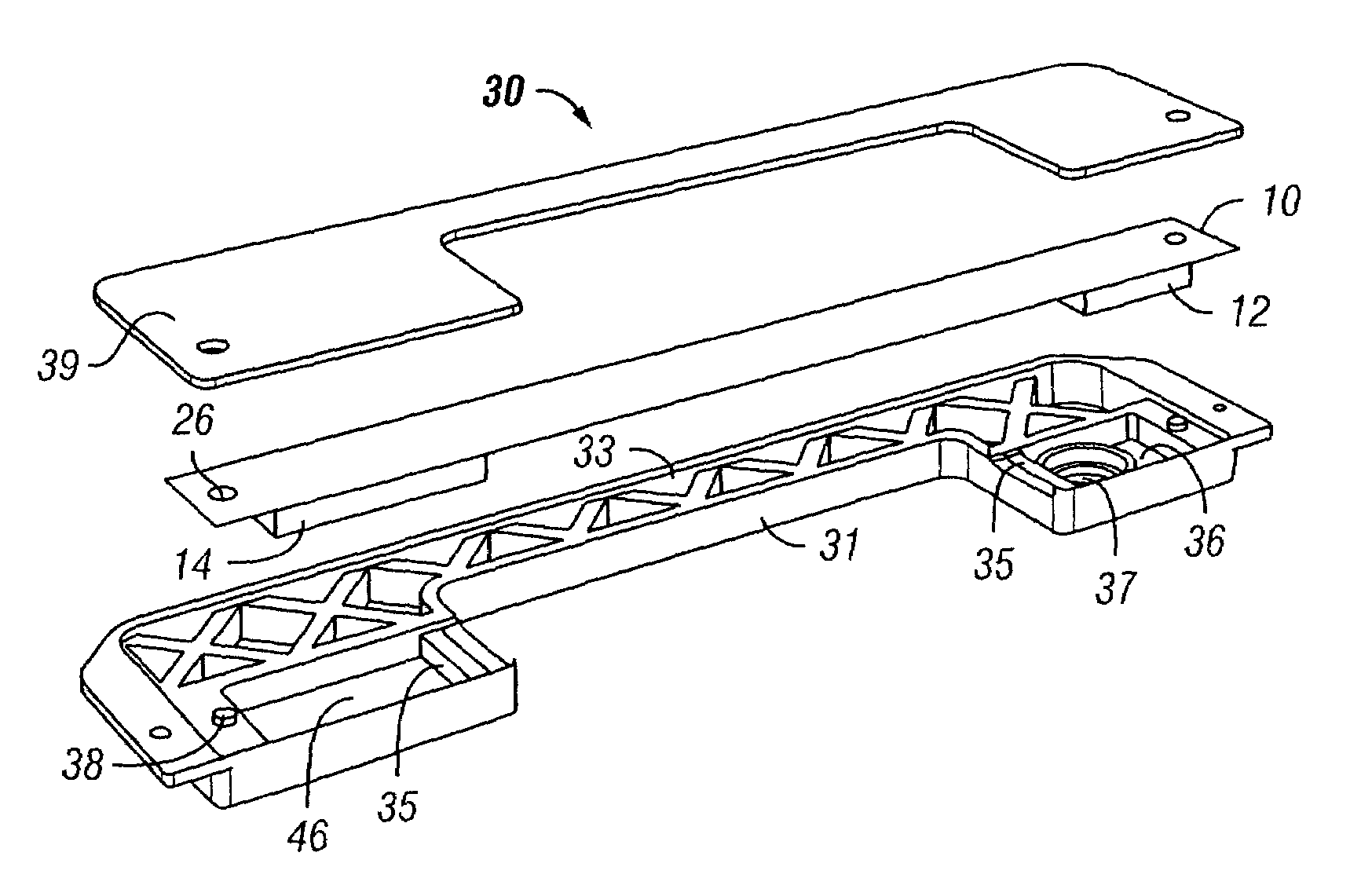

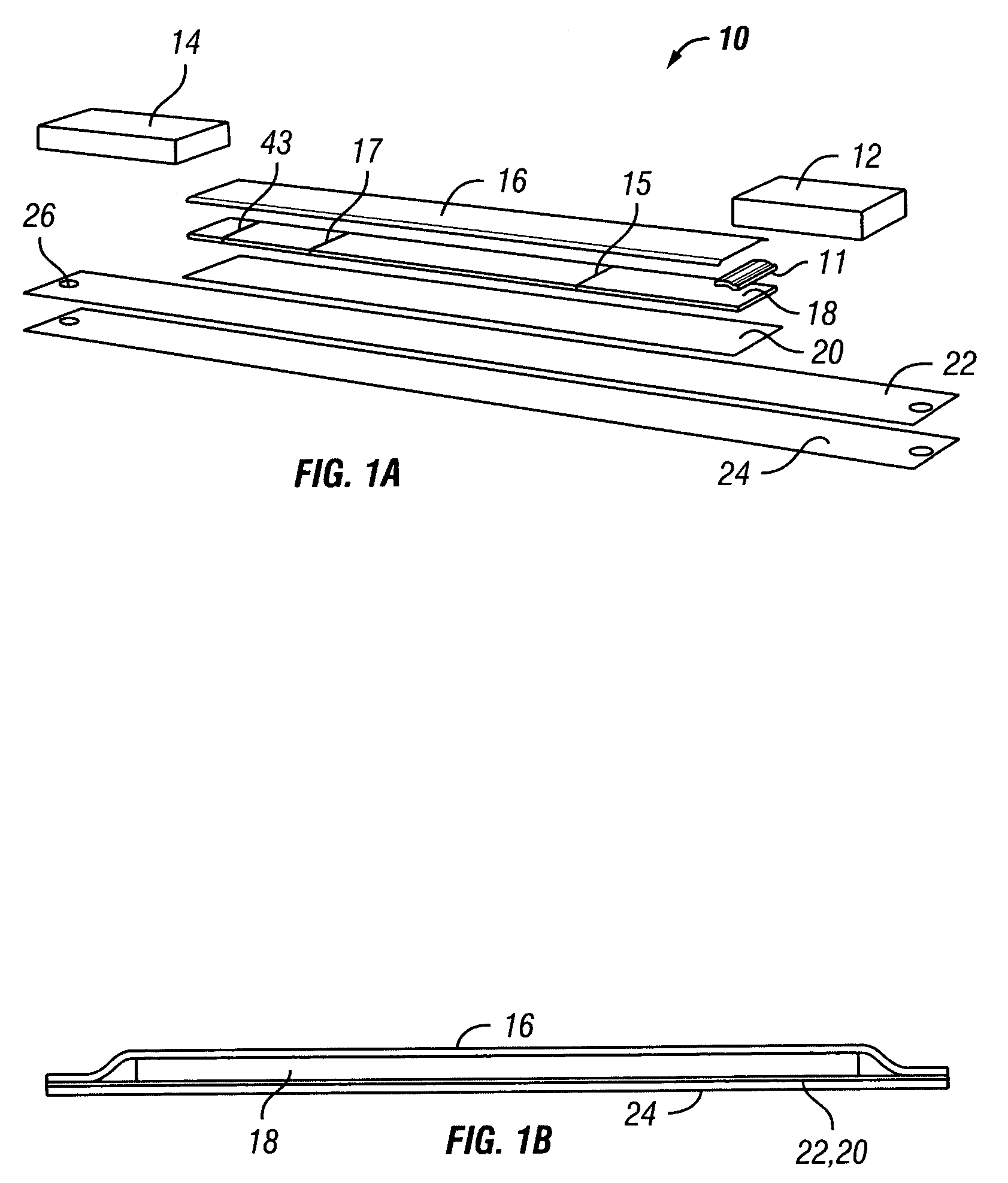

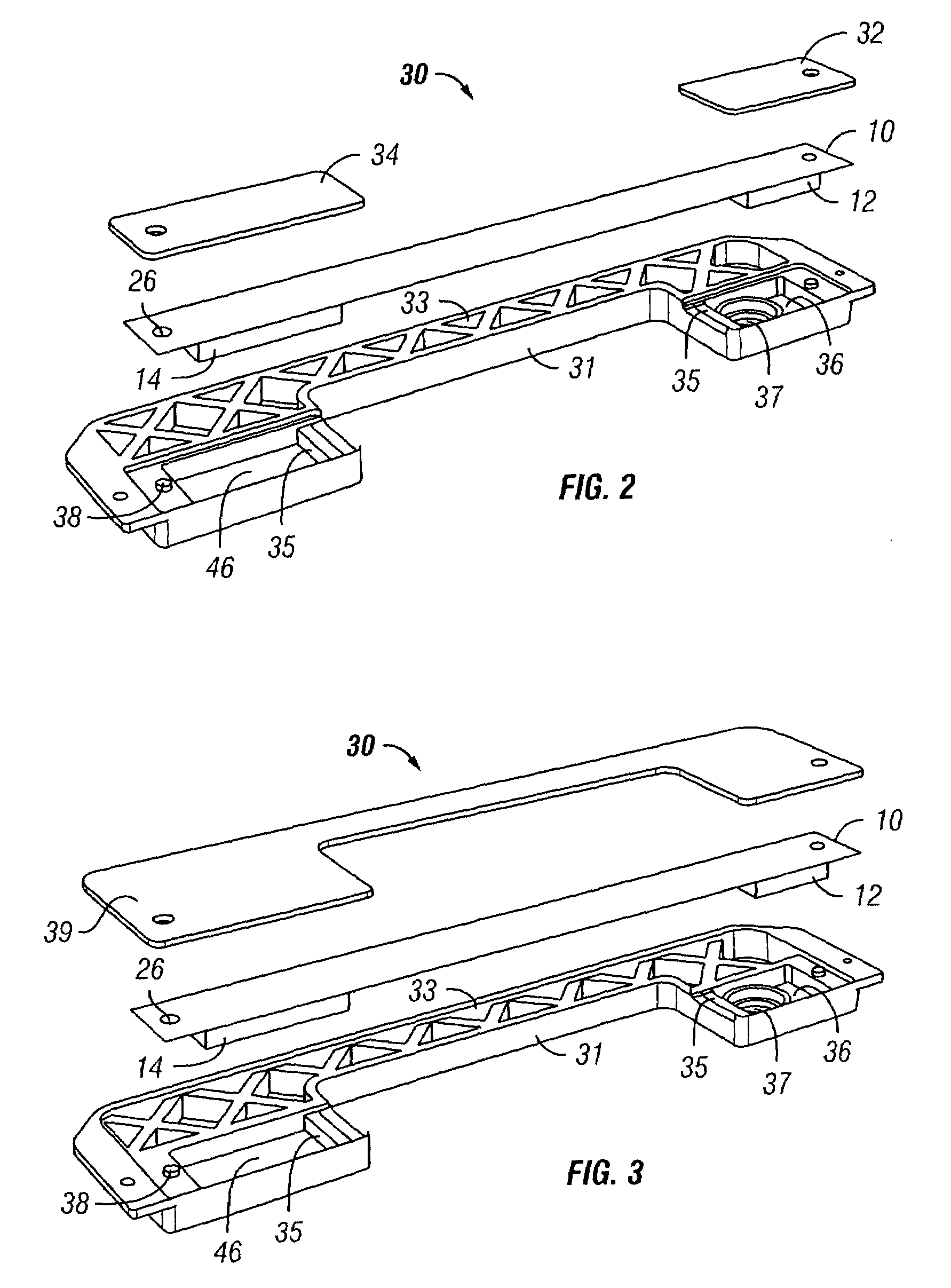

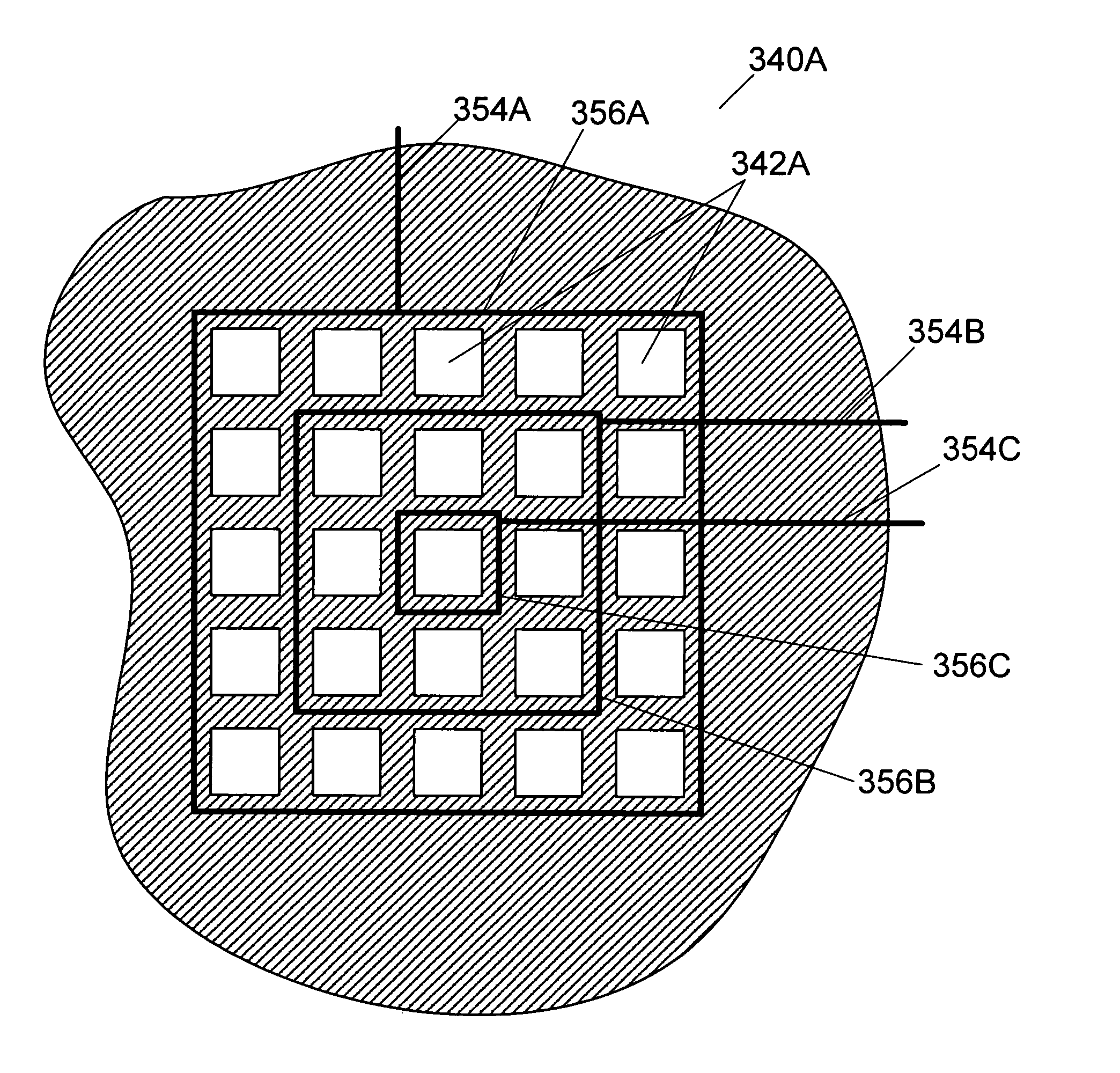

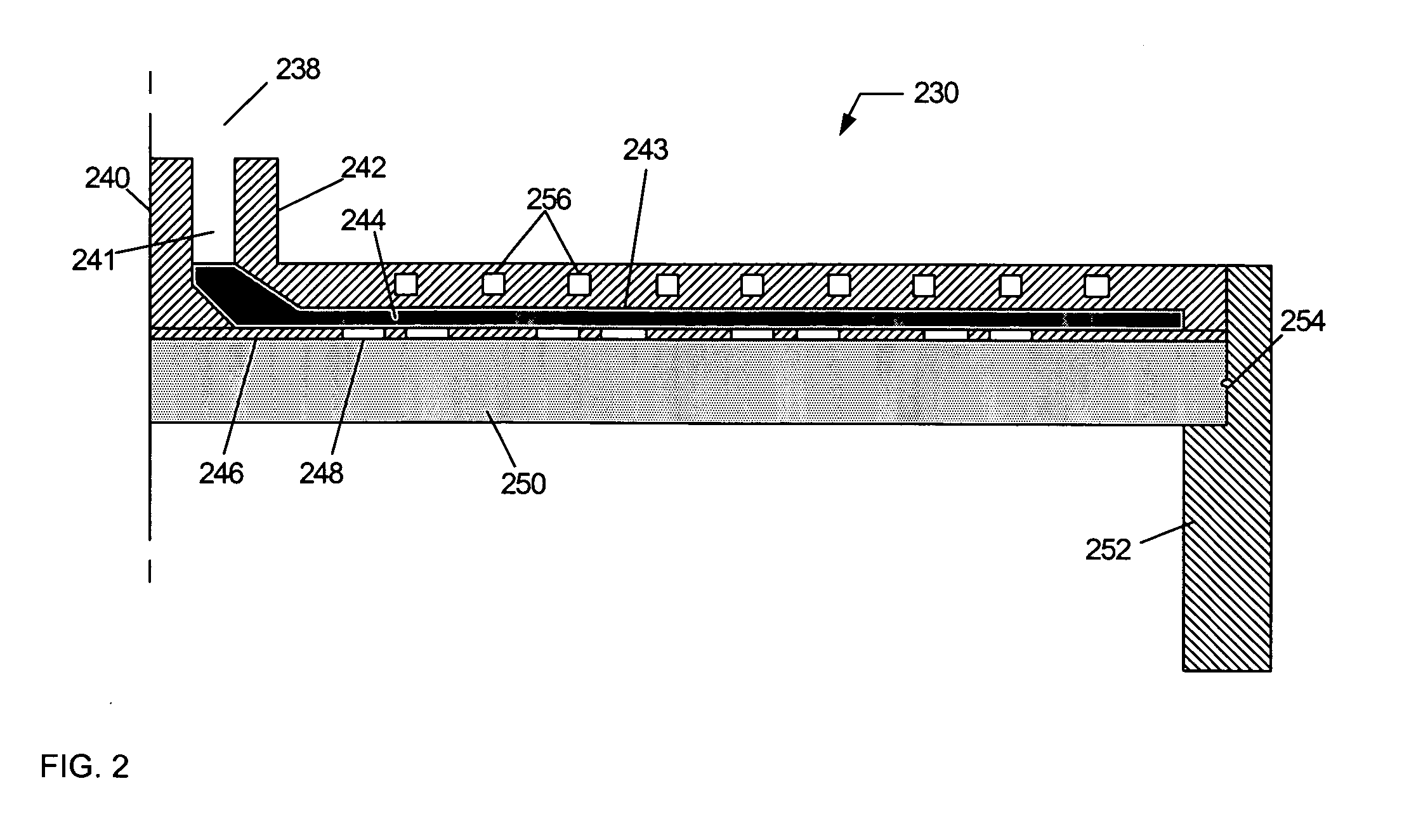

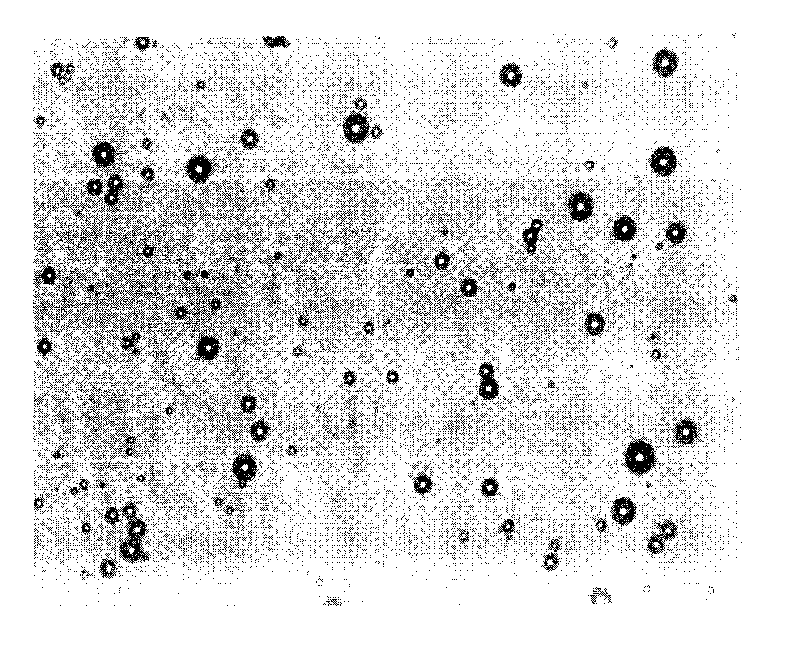

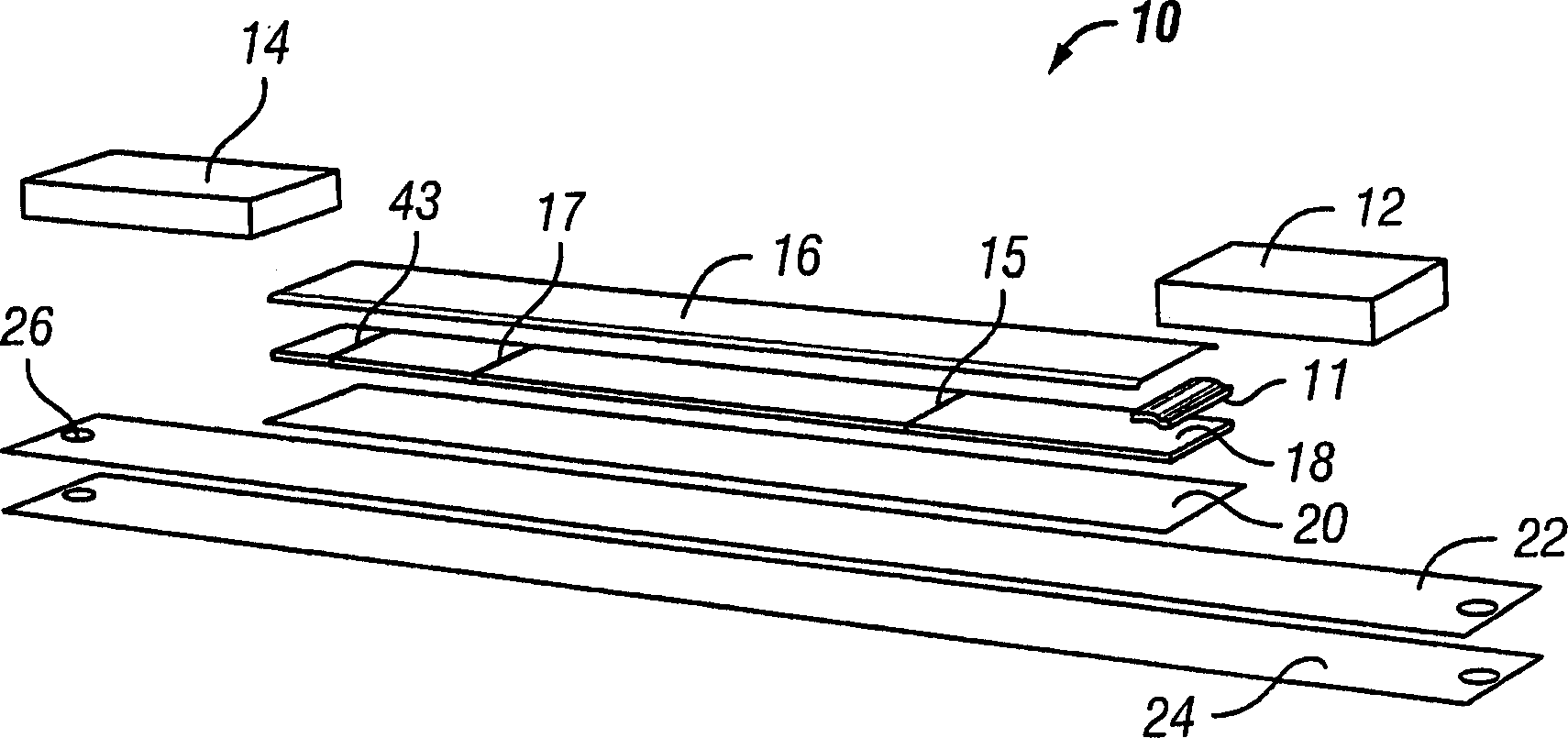

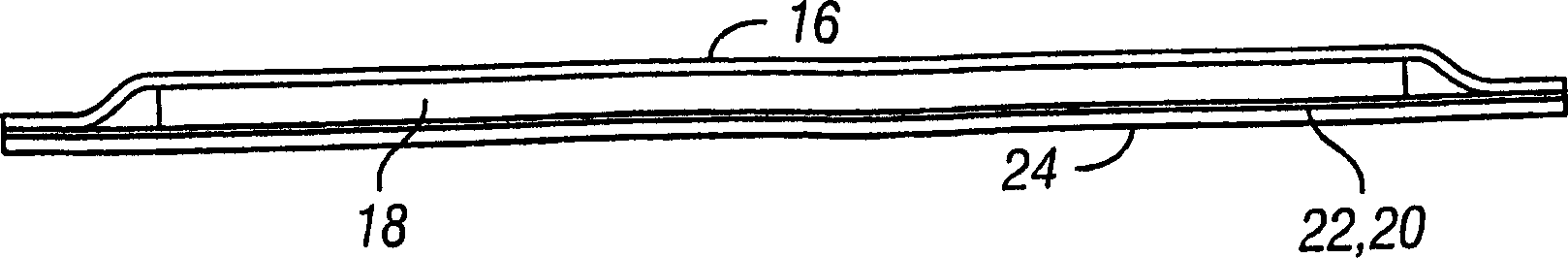

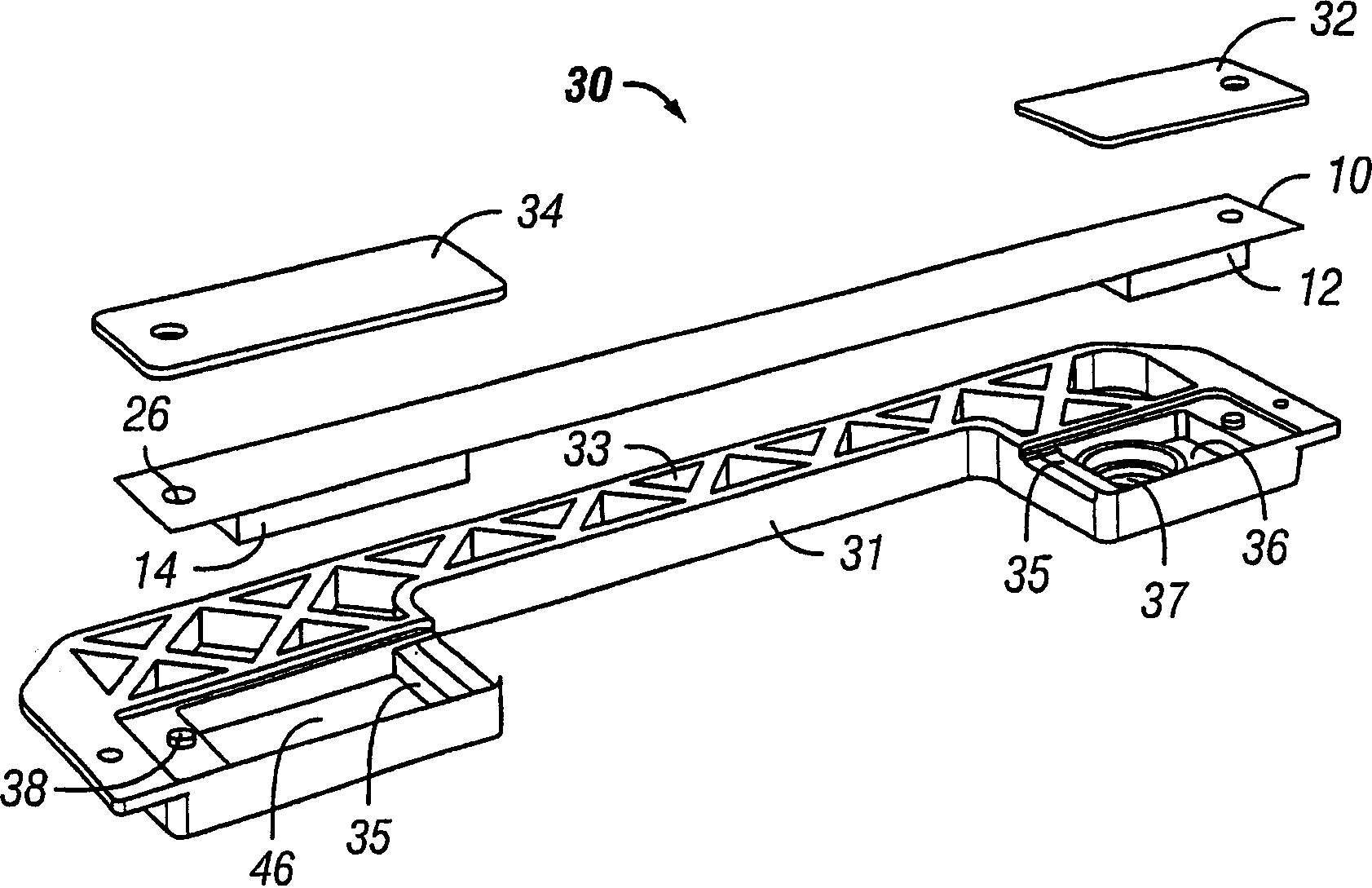

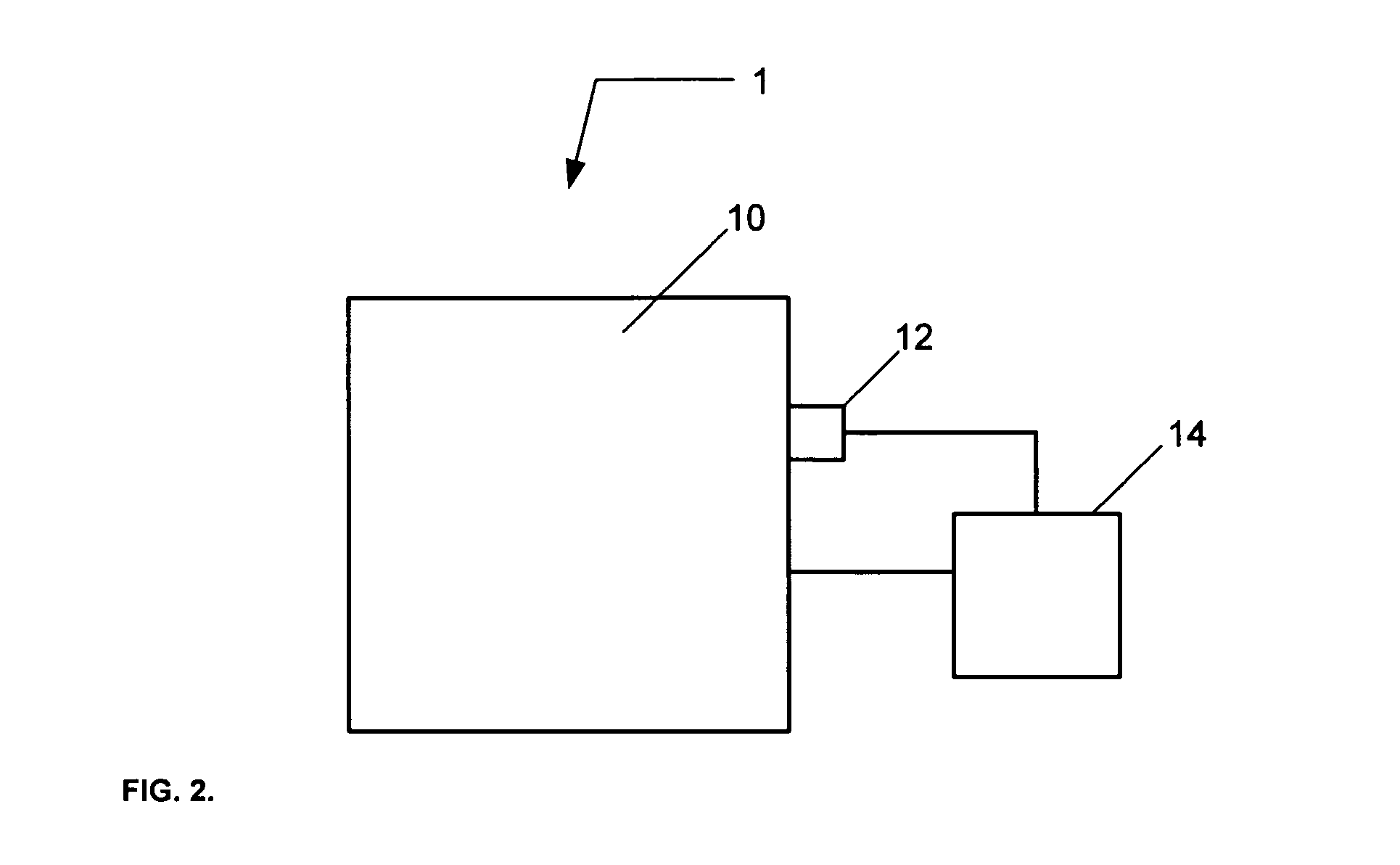

Accessible assay and method of use

ActiveUS7323139B2Gap minimizationHigh sensitivityAnalysis using chemical indicatorsMaterial thermal conductivityProcess chemistryEngineering

An assay test strip and cassette. The test strip is positioned in a housing shaped and configured to allow a detector to access the test strip from the side, rather than from the lengthwise axis of the test strip. The housing may contain one or more test strips which may also be disposed on one or more surfaces of the housing. Preferably, the housing is generally C-shaped with the test strip spanning the space between the two arms of the C-shape. The housing is sealed to protect both the operator and instrument from possible contamination. The test strip is preferably embedded with paramagnetic particles and process chemistry specific for a particular application. Quantitative analysis may be accomplished using a magnetic reader device. In additional embodiments, detection is accomplished by visual means.

Owner:QUANTUM DESIGN

Plasma processing system for treating a substrate

ActiveUS20060065367A1Reduce harmReduce the possibility of damageElectric discharge tubesSemiconductor/solid-state device manufacturingProcess chemistryEngineering

A plasma processing system for treating a substrate includes a processing chamber including a first chamber portion configured to receive a first gas for providing a plasma space, and a second chamber portion configured to receive a second gas for providing a process space having process chemistry to treat the substrate. A substrate holder is coupled to the second chamber portion of the processing chamber, and configured to support the substrate proximate the process space, and a plasma source is coupled to the first chamber portion of the processing chamber, and configured to form a plasma in the plasma space. A grid is located between the plasma space and the process space, and configured to permit the diffusion of the plasma between the plasma space and the process space in order to form the process chemistry from the process gas.

Owner:TOKYO ELECTRON LTD

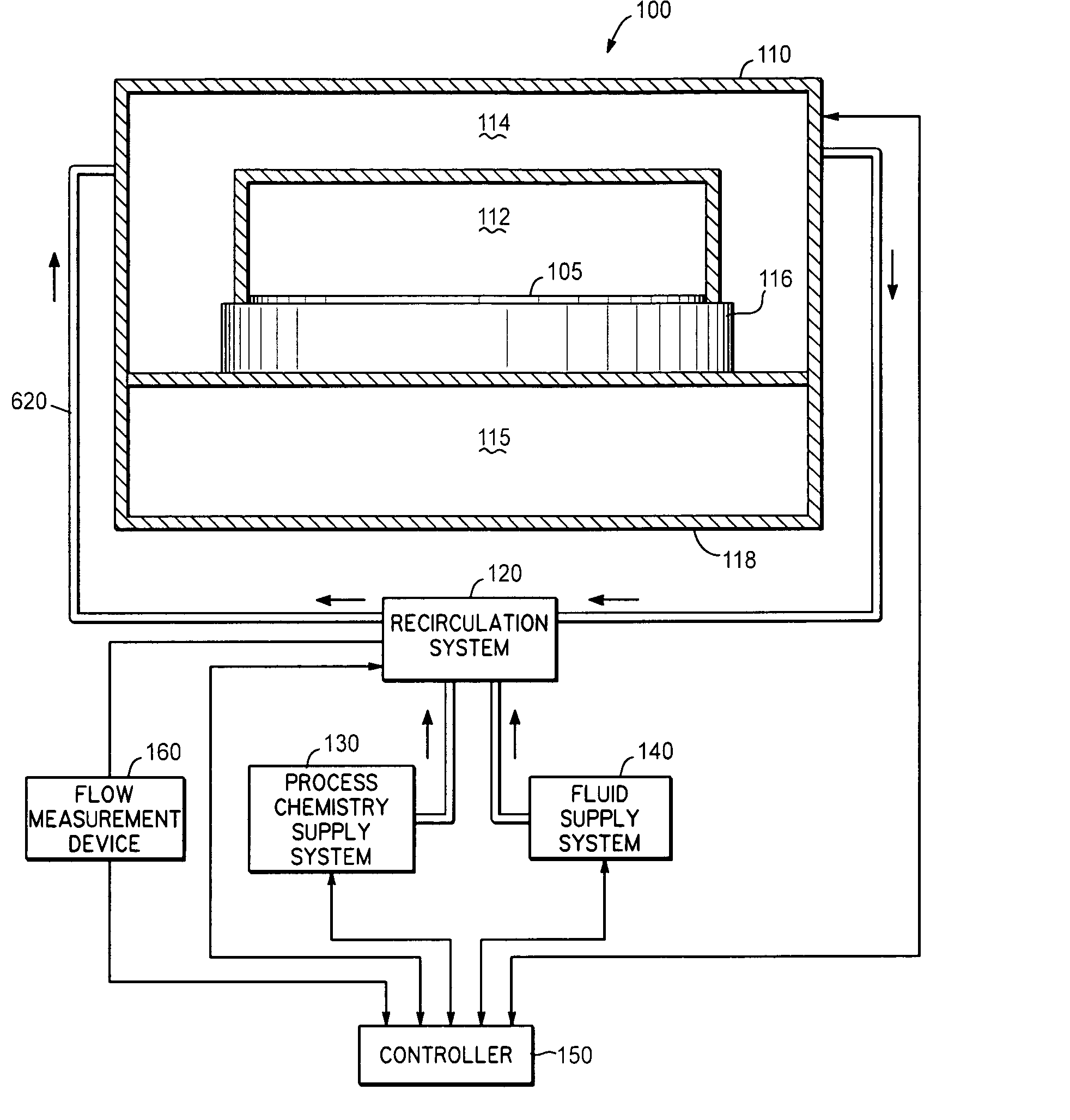

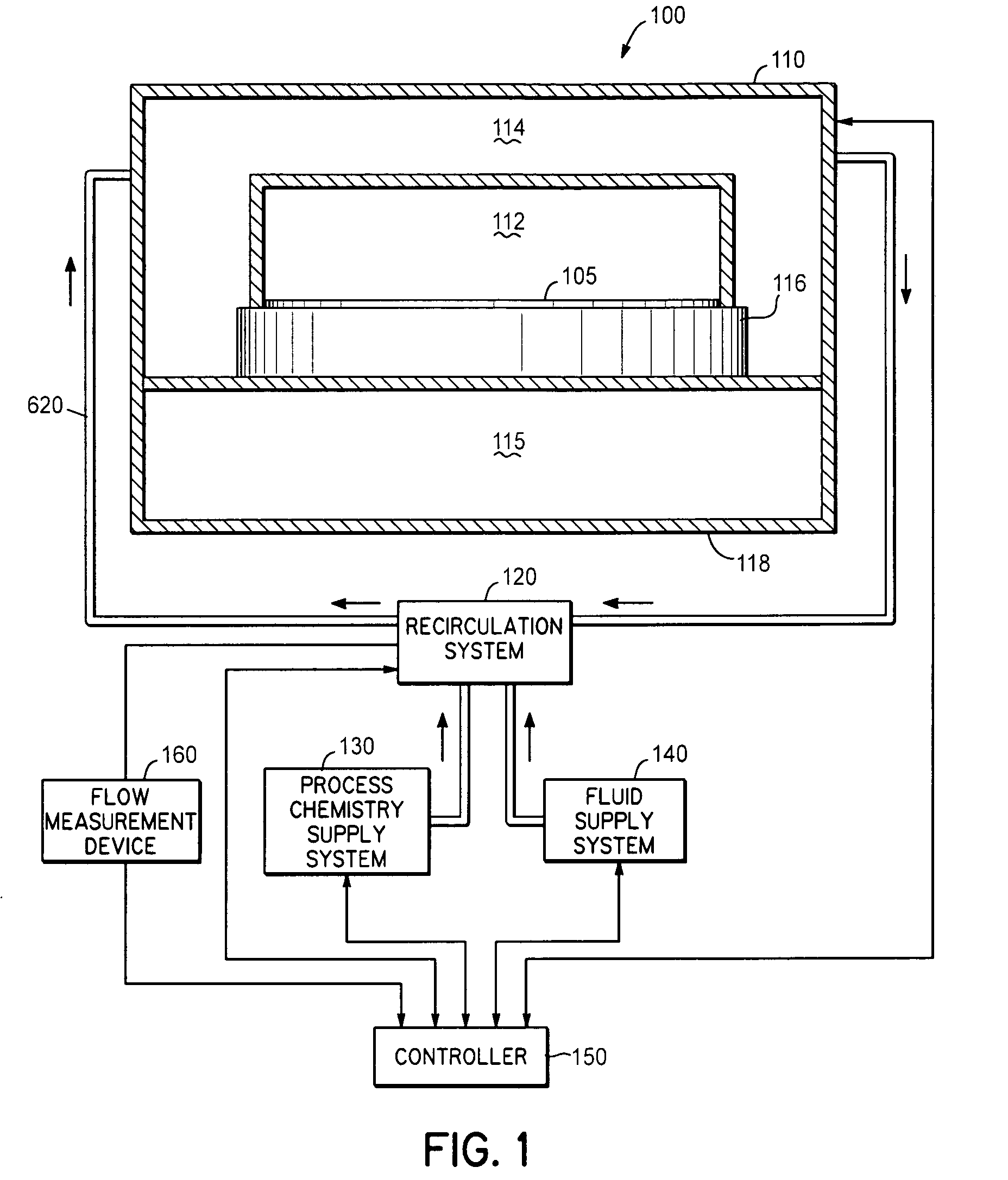

Method and system for determining flow conditions in a high pressure processing system

InactiveUS20060180175A1Vacuum evaporation coatingScattering properties measurementsProcess chemistryMeasurement device

In a high pressure processing system configured to treat a substrate, a flow measurement device is utilized to determine a flow condition in the high pressure processing system. The flow measurement device can, for example, comprise a turbidity meter. The flow parameter can, for example, include a volume flow rate or a time to achieve mixing of a process chemistry within a high pressure fluid used to treat the substrate.

Owner:TOKYO ELECTRON LTD

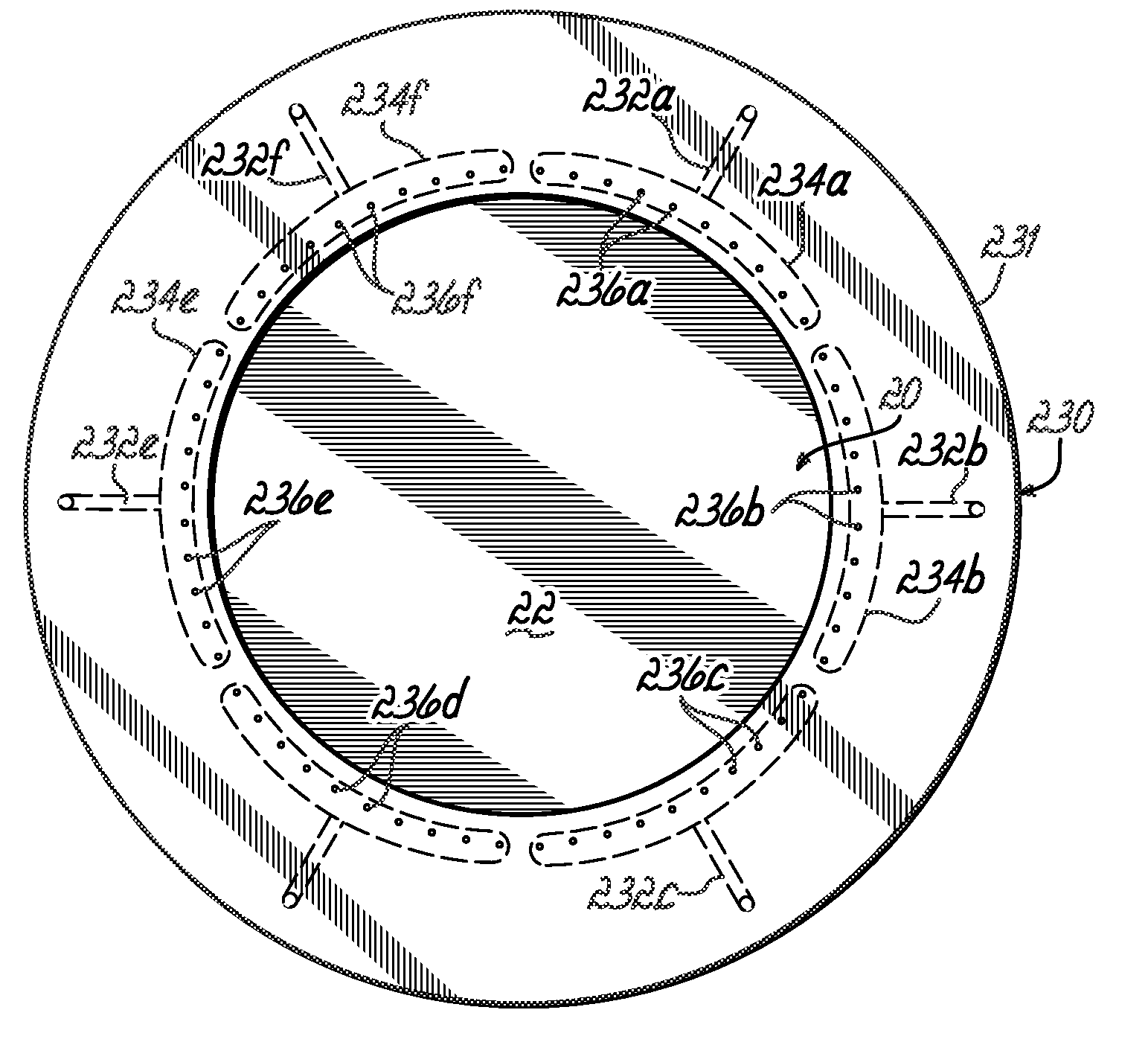

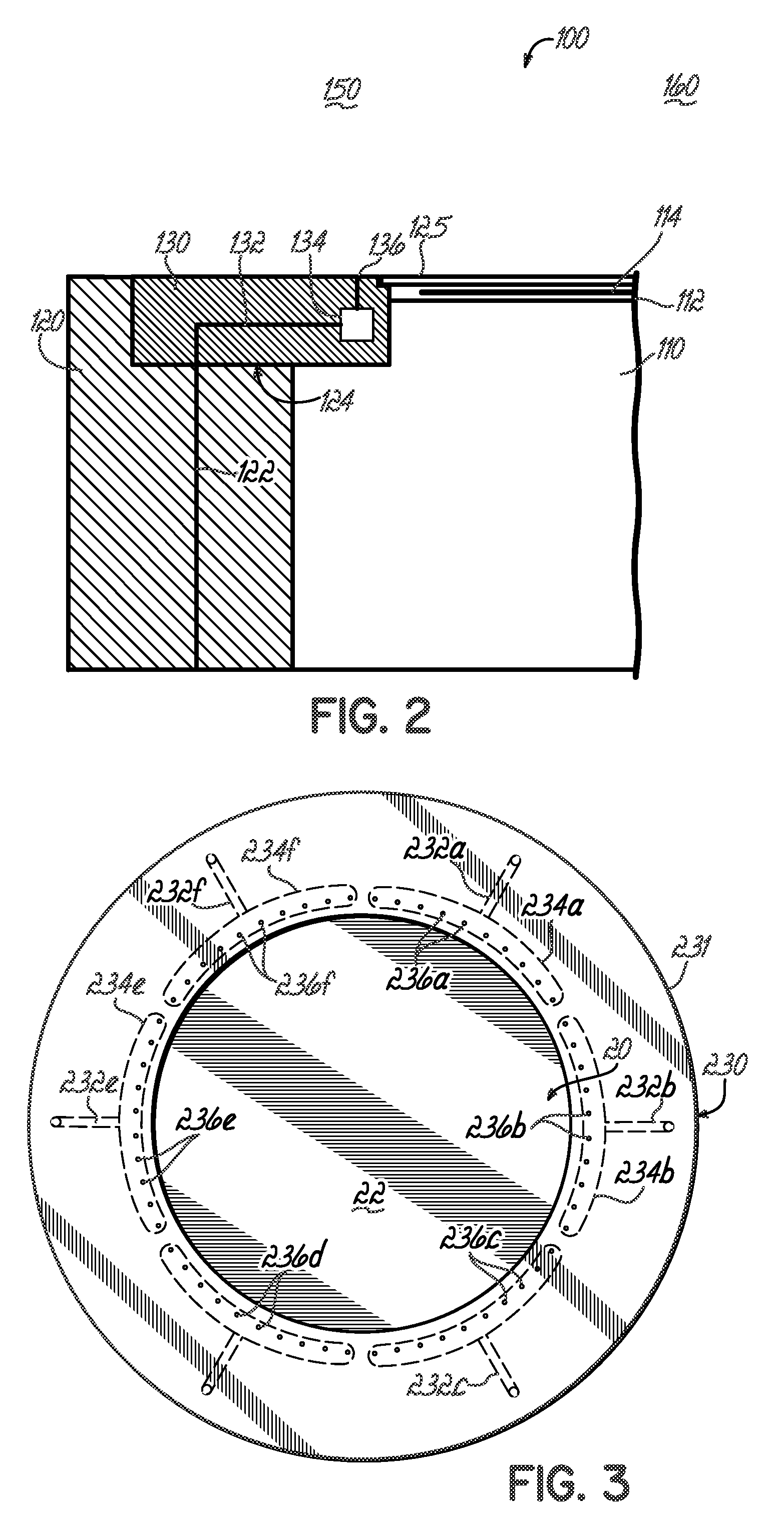

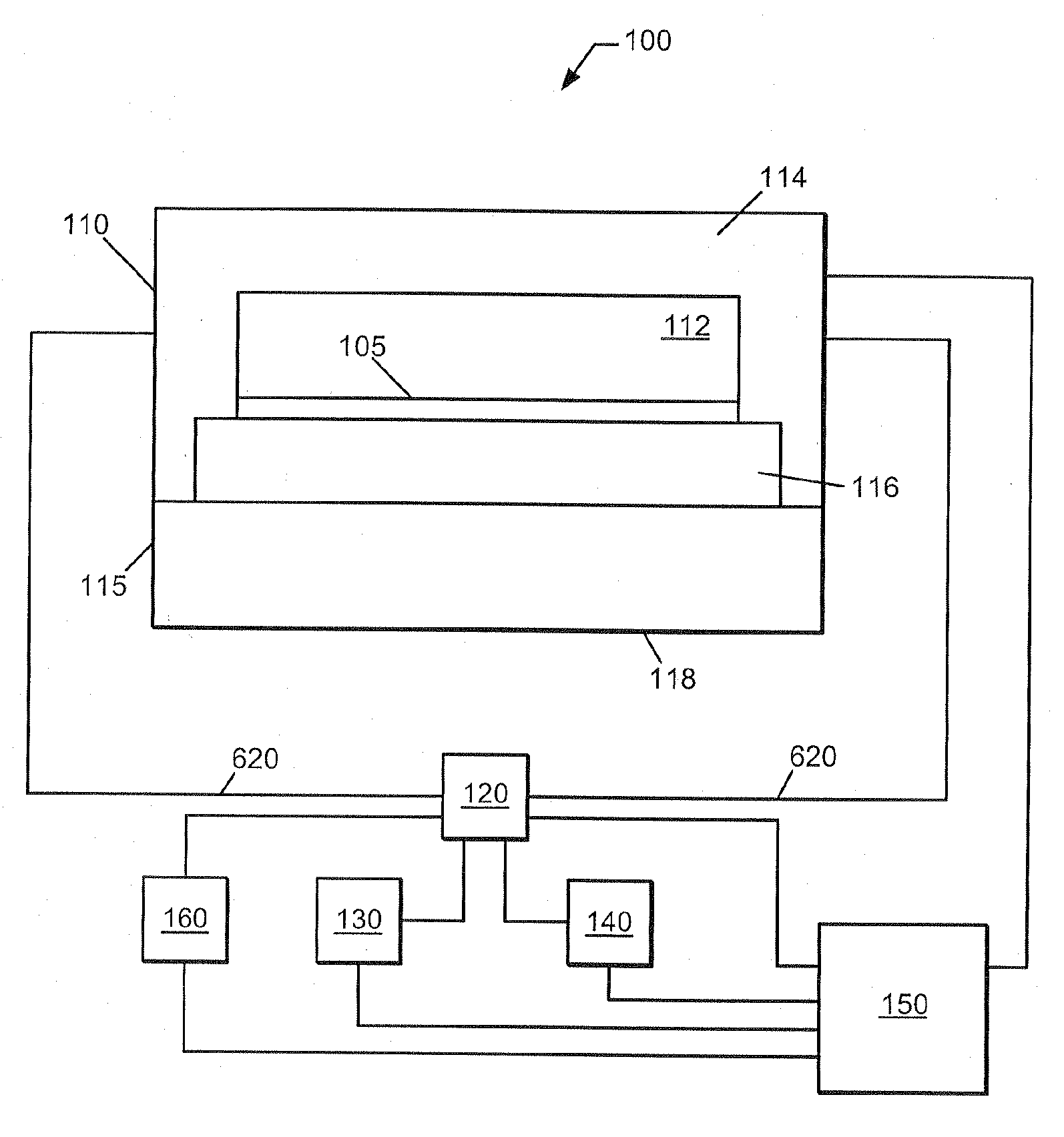

Dynamic control of process chemistry for improved within-substrate process uniformity

InactiveUS20080223873A1Improve uniformityPower operated devicesDecorative surface effectsProcess chemistryProcess engineering

A method and system for dynamically controlling a process chemistry above a substrate is described. The system for adjusting the process chemistry comprises a ring configured to surround a peripheral edge of a substrate in a vacuum processing system. The ring comprises one or more gas distribution passages formed within the ring and configured to supply an additive process gas through an upper surface of the ring to the peripheral region of the substrate, wherein the one or more gas distribution passages are configured to be coupled to one or more corresponding gas supply passages formed within the substrate holder upon which the ring rests.

Owner:TOKYO ELECTRON LTD

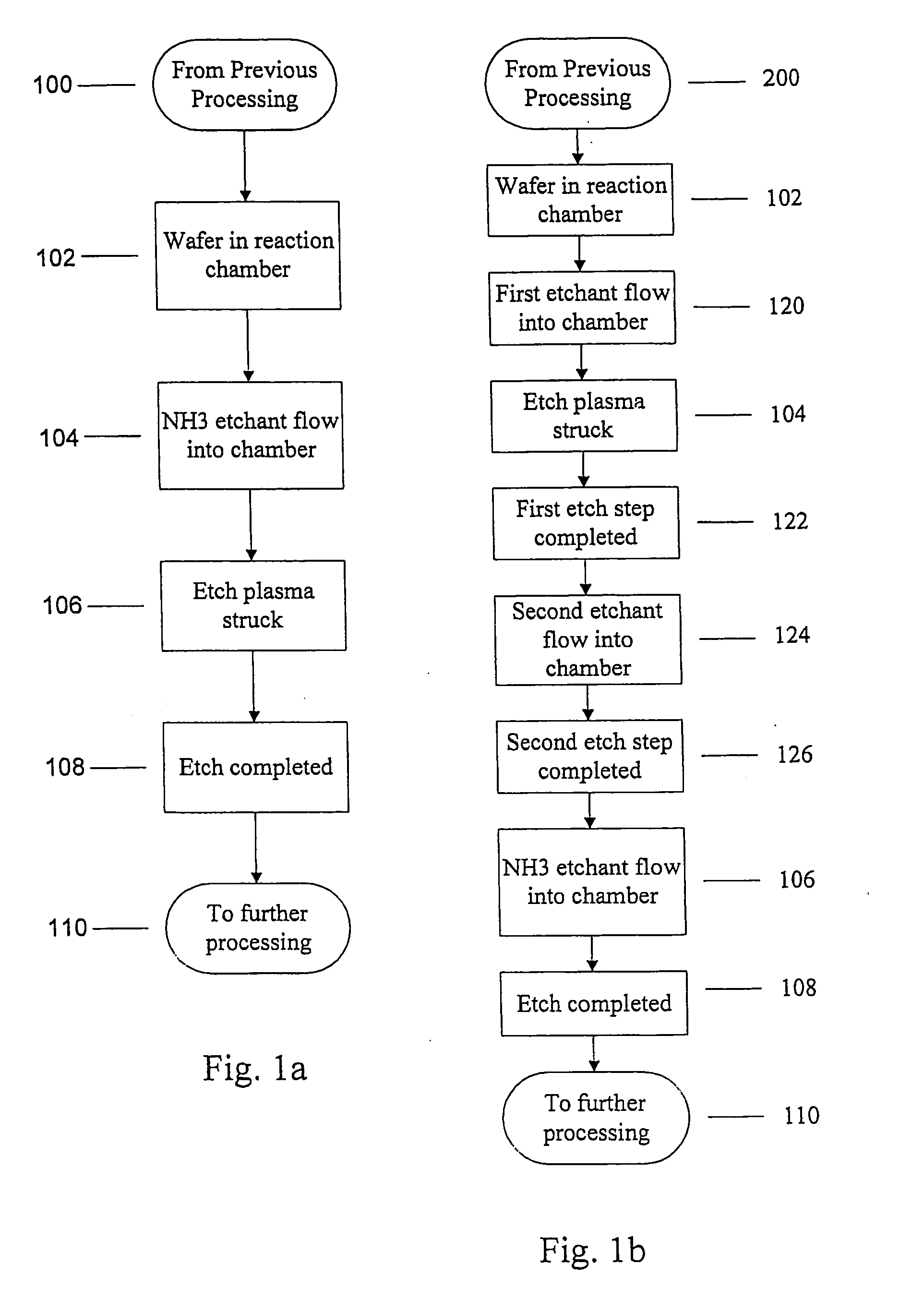

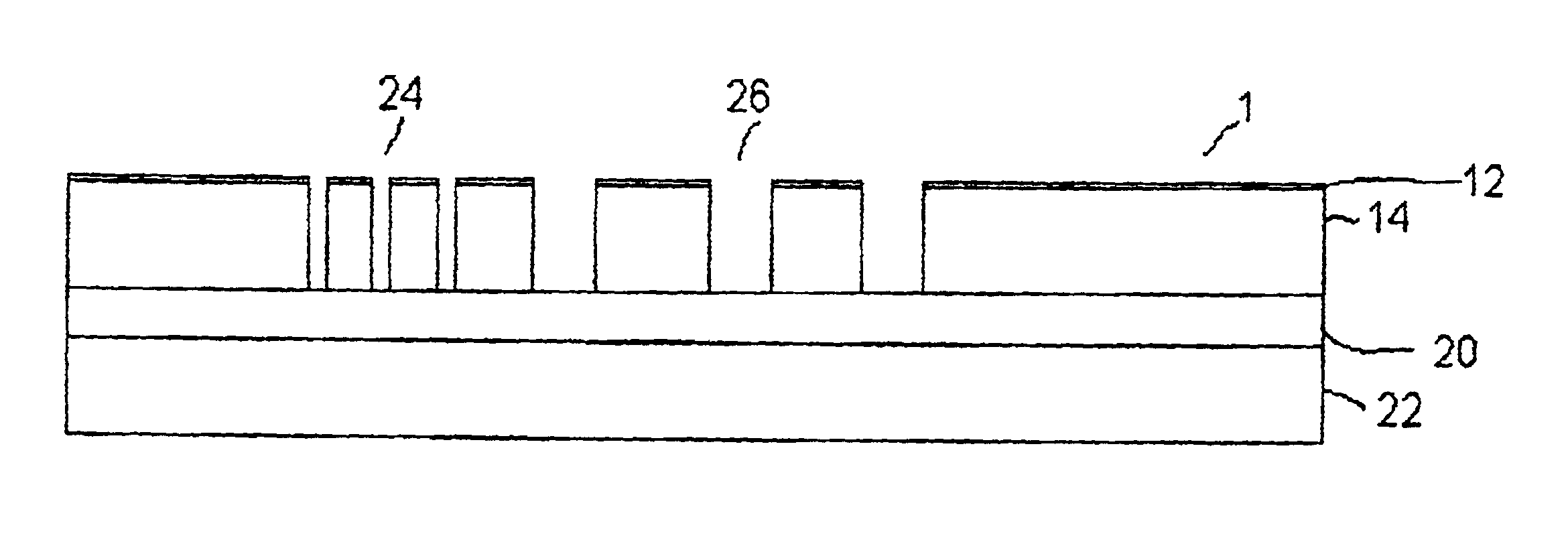

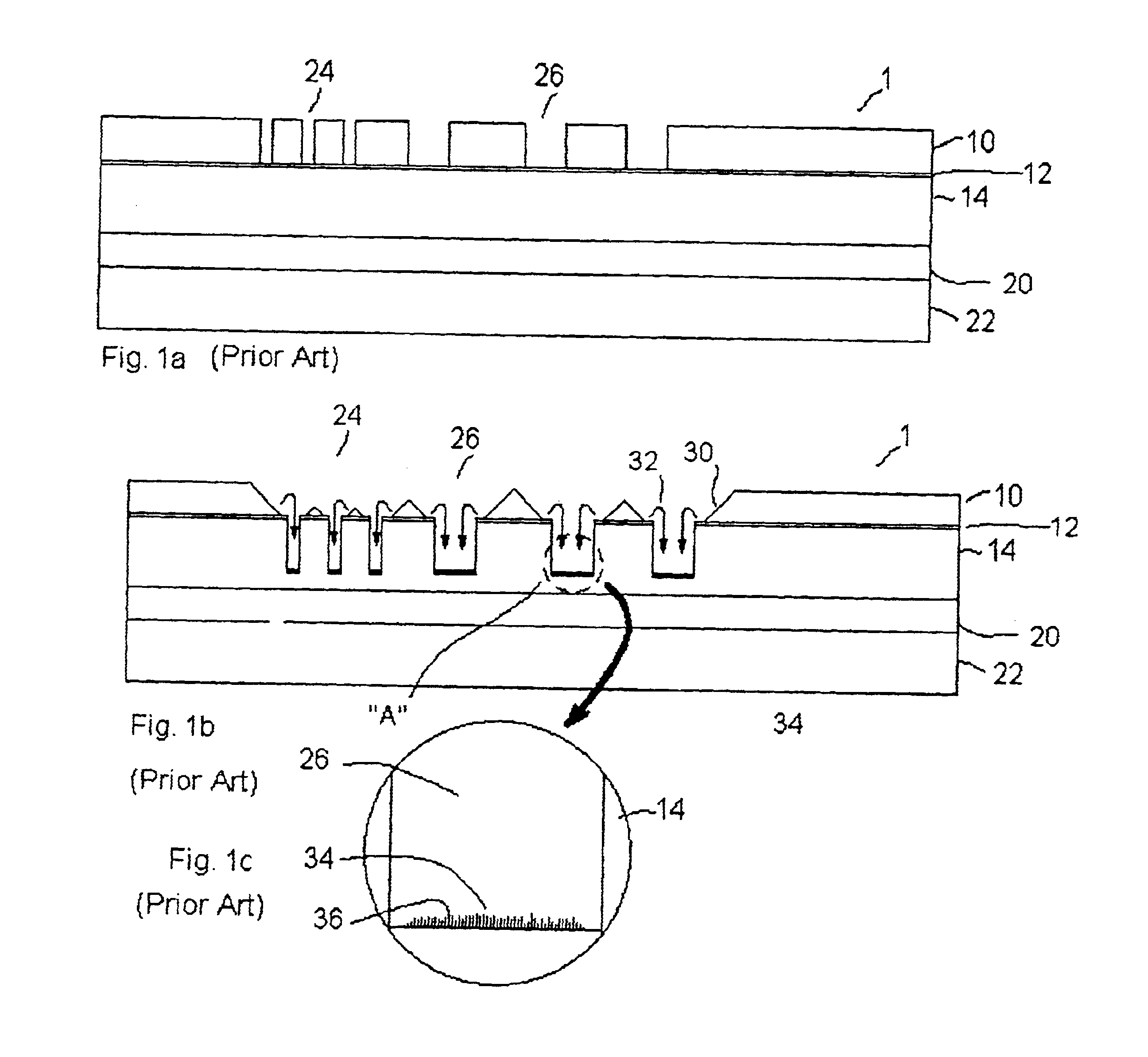

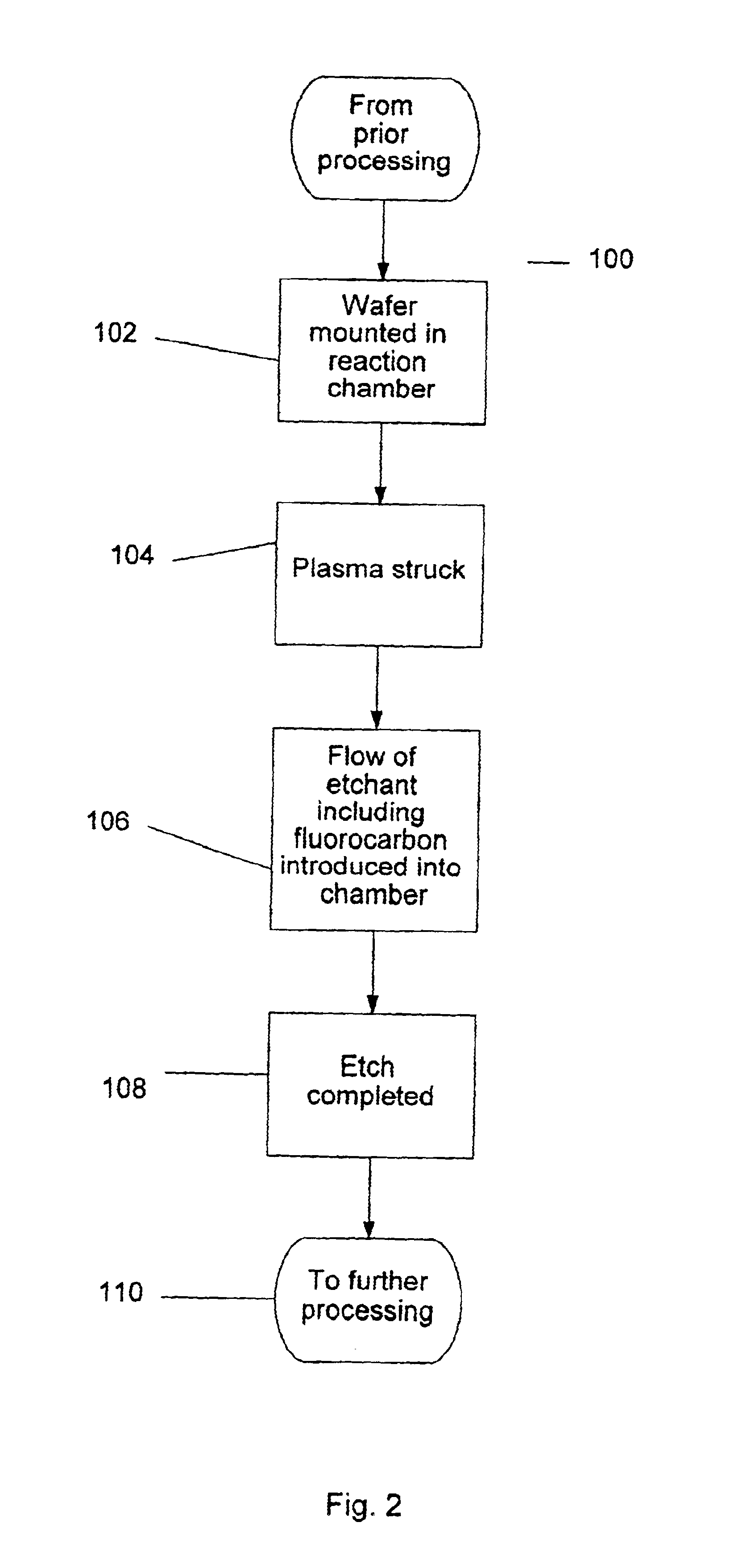

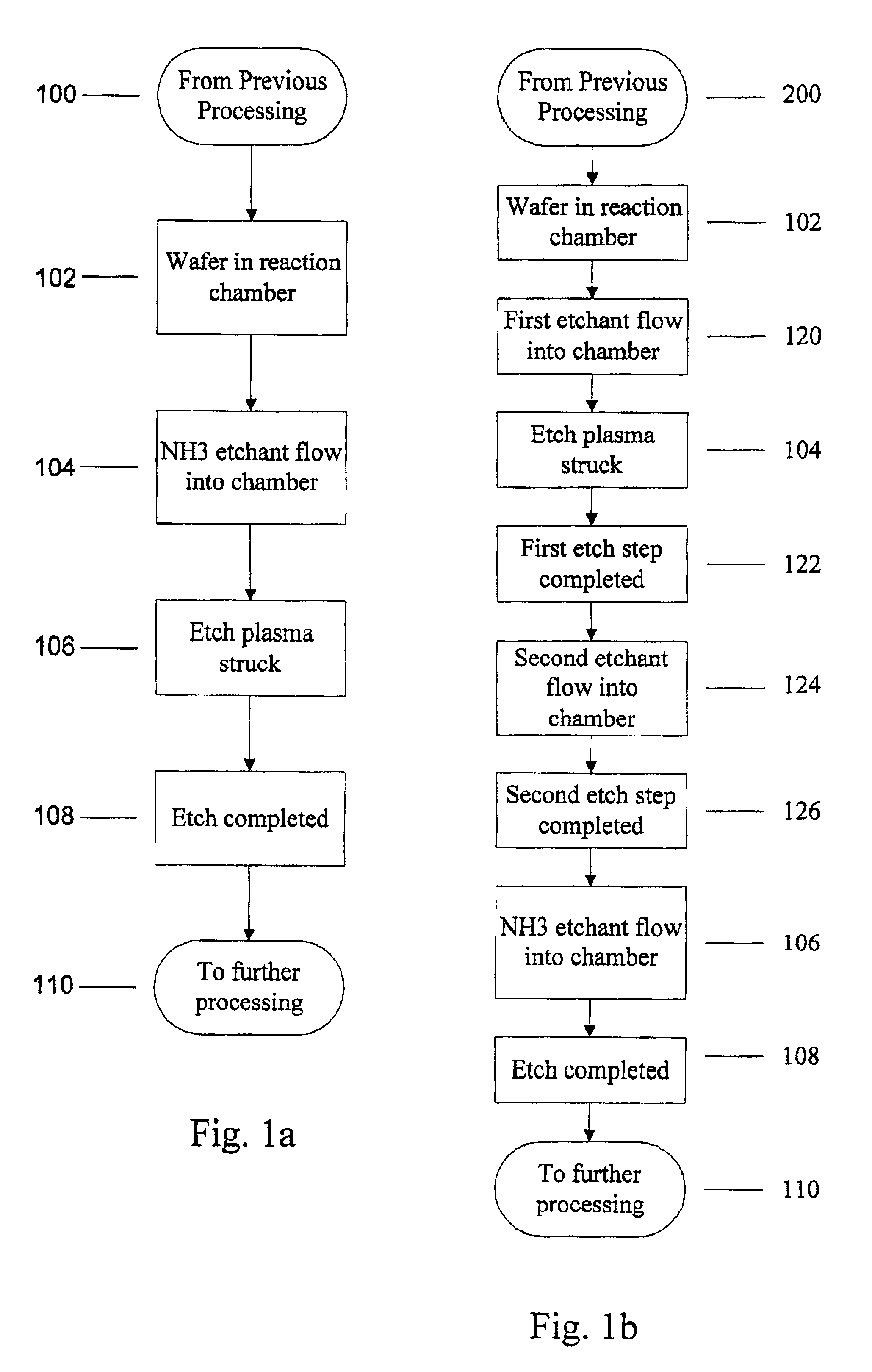

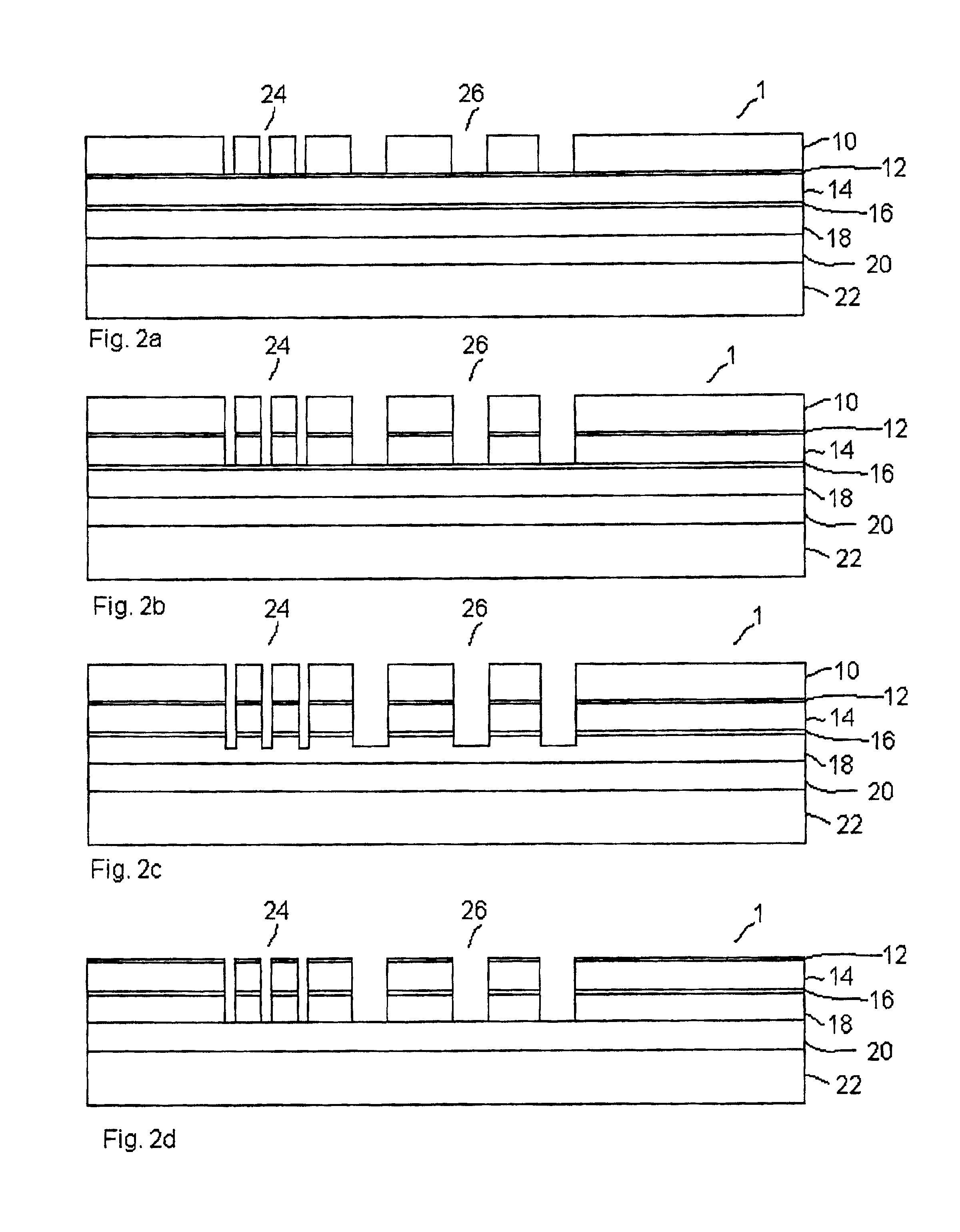

Unique process chemistry for etching organic low-k materials

InactiveUS6841483B2Reduce etch rateEliminate residue formationSemiconductor/solid-state device manufacturingSputteringProcess chemistry

Method for etching a feature in an integrated circuit wafer with minimized effect of micromasking. The method introduces a flow of etchant gas including a fluorocarbon gas to the wafer, and uses the etchant gas to form a plasma in proximity with at least a portion of the wafer. The plasma is used to etch at least a portion of the feature in the wafer. Disassociation of the fluorocarbon into fluorine and hydrocarbon species performs two functions. The fluorine species prevents or significantly reduces sputtered hardmask components from depositing on the floor of the etched feature during etching. The hydrocarbon species acts to form a passivation layer on the sidewalls of the feature.

Owner:LAM RES CORP

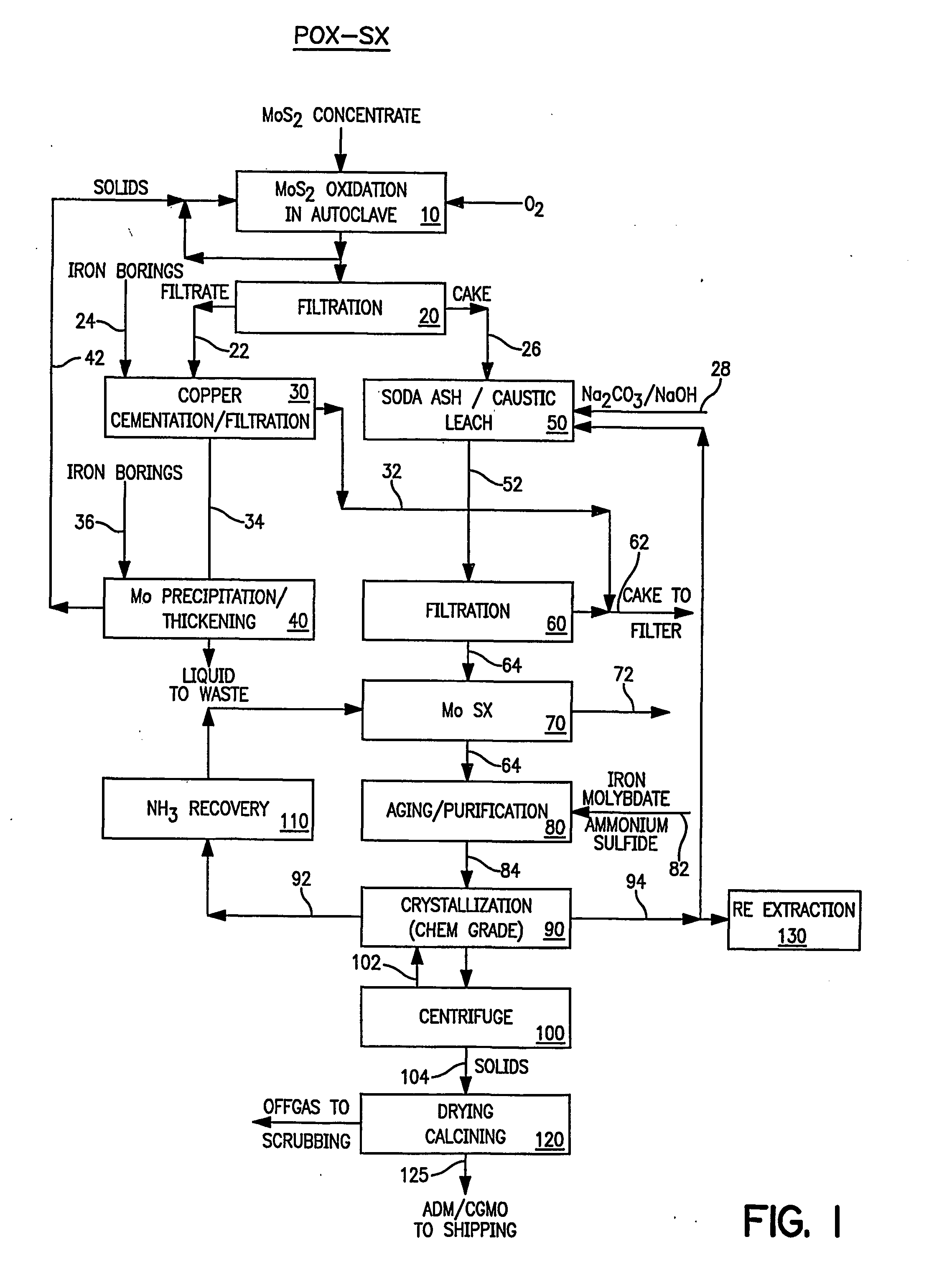

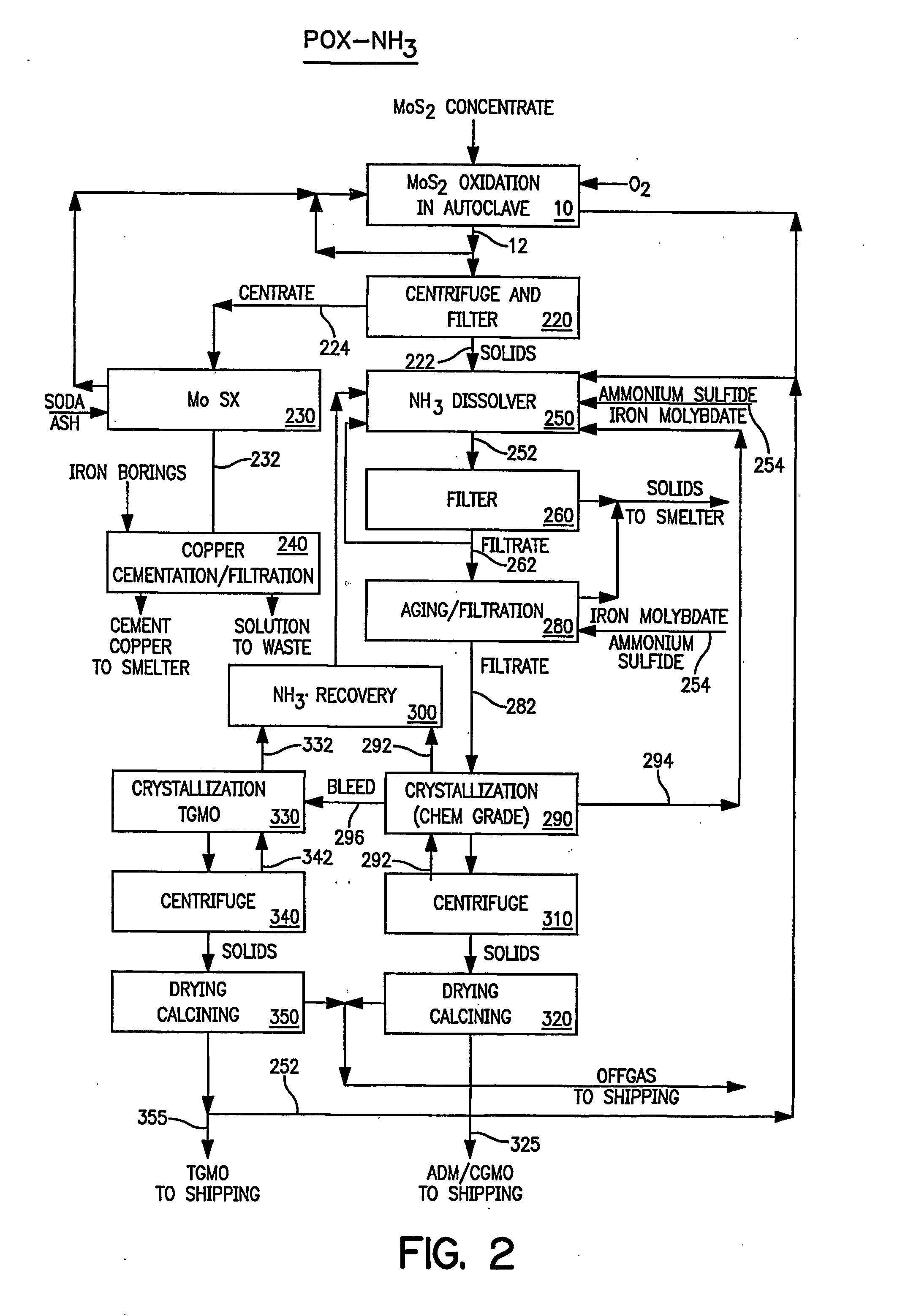

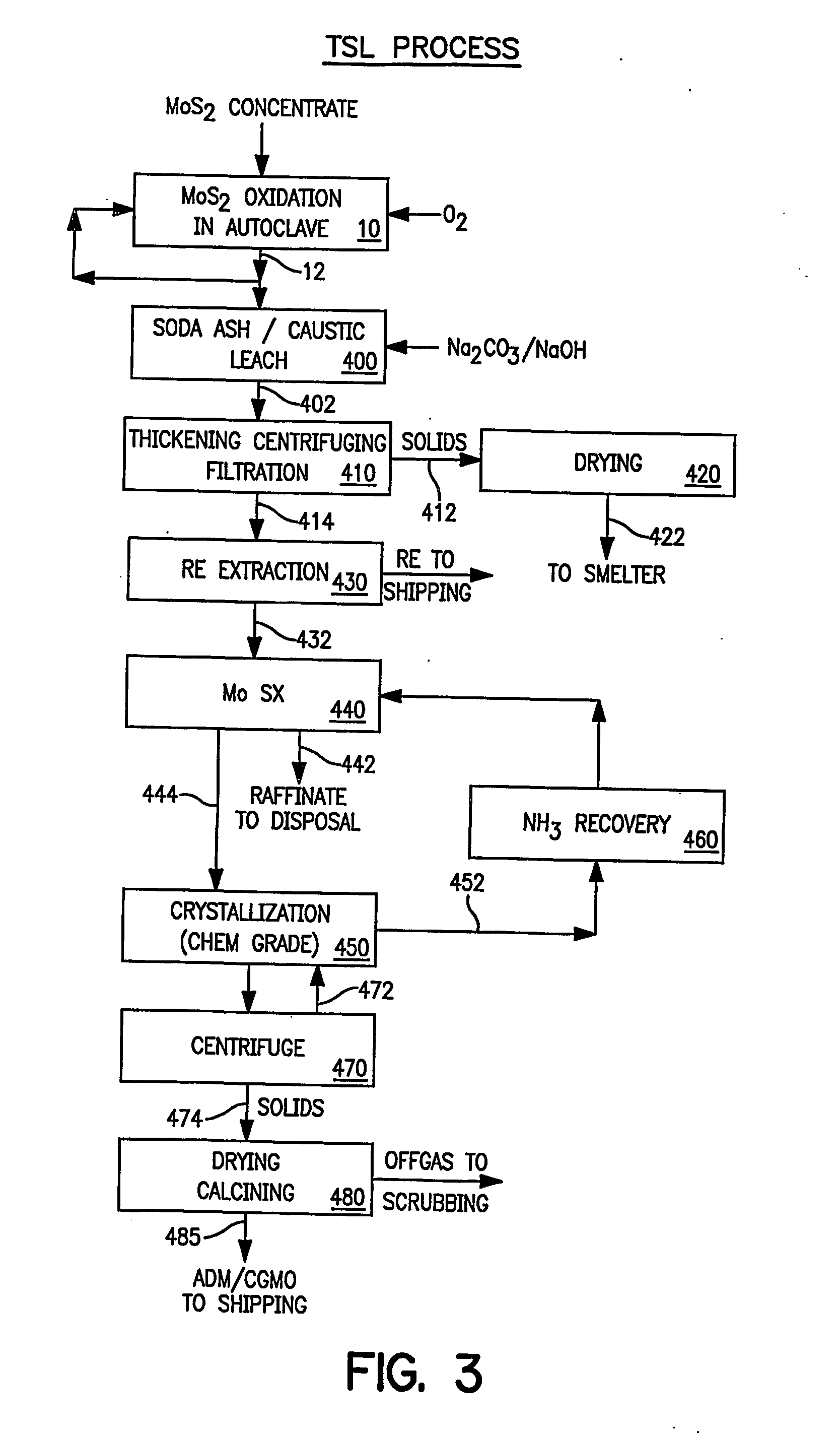

Production of pure molybdenum oxide from low grade molybdenite concentrates

InactiveUS20050019247A1High purityValue maximizationOxide/hydroxide preparationMolybdeum compounds preparationProcess chemistryFiltration

High purity ammonium dimolybdate or molybdenum oxide is produced by the pressure oxidation of low grade molybdenite concentrates or molybdenum intermediates. The process entails nearly complete oxidation of the sulfide minerals while optimizing the process chemistry and autoclave conditions to solubilize as little of the molybdenum values as possible. The autoclave discharge 12 is then subjected to a leaching step, either an alkaline leach 50, 400 or ammonium leach 250 process, before or after a liquid / solid separation step 20, 220, 410. The solution is then subjected to (a) filtration 60, 410, solvent extraction 70, 440, crystallization 90, 450, and calcination 120, 480 or (b) filtration 260, 280, crystallization 290, and calcination 320 to produce a product suitable for chemical-grade molybdenum oxide 125, 325, 485.

Owner:BALLIETT ROBERT W +6

Degumming process for kudzu vine

InactiveCN103835006AReduce usageReduce hard bar rateFibre treatment to obtain bast fibreProcess chemistryEngineering

The invention provides a degumming process for a kudzu vine. Directed at the problems of a great usage amount of chemicals, a high fiber strength damage rate, severe environmental pollution and the like in conventional chemical degumming process, the invention provides a degumming method for the kudzu vine through low temperature refrigeration and vacuum technology. The process comprises the following steps: changing the interior structure of a raw kudzu vine by using low temperature vacuum technology so as to form considerable micropores, thereby increasing the surface area of a fiber; and then fully injecting dilute alkali lye and a low-concentration hydrogen peroxide solution into the interior of the fiber by using vacuum negative pressure technology so as to allow alkali lye and hydrogen peroxide to exert maximum efficacy. The process provided by the invention substantially reduces the usage amount of chemicals, shortens degumming flow and has a high gum and lignin removal rate and a low fiber damage rate.

Owner:姜著川

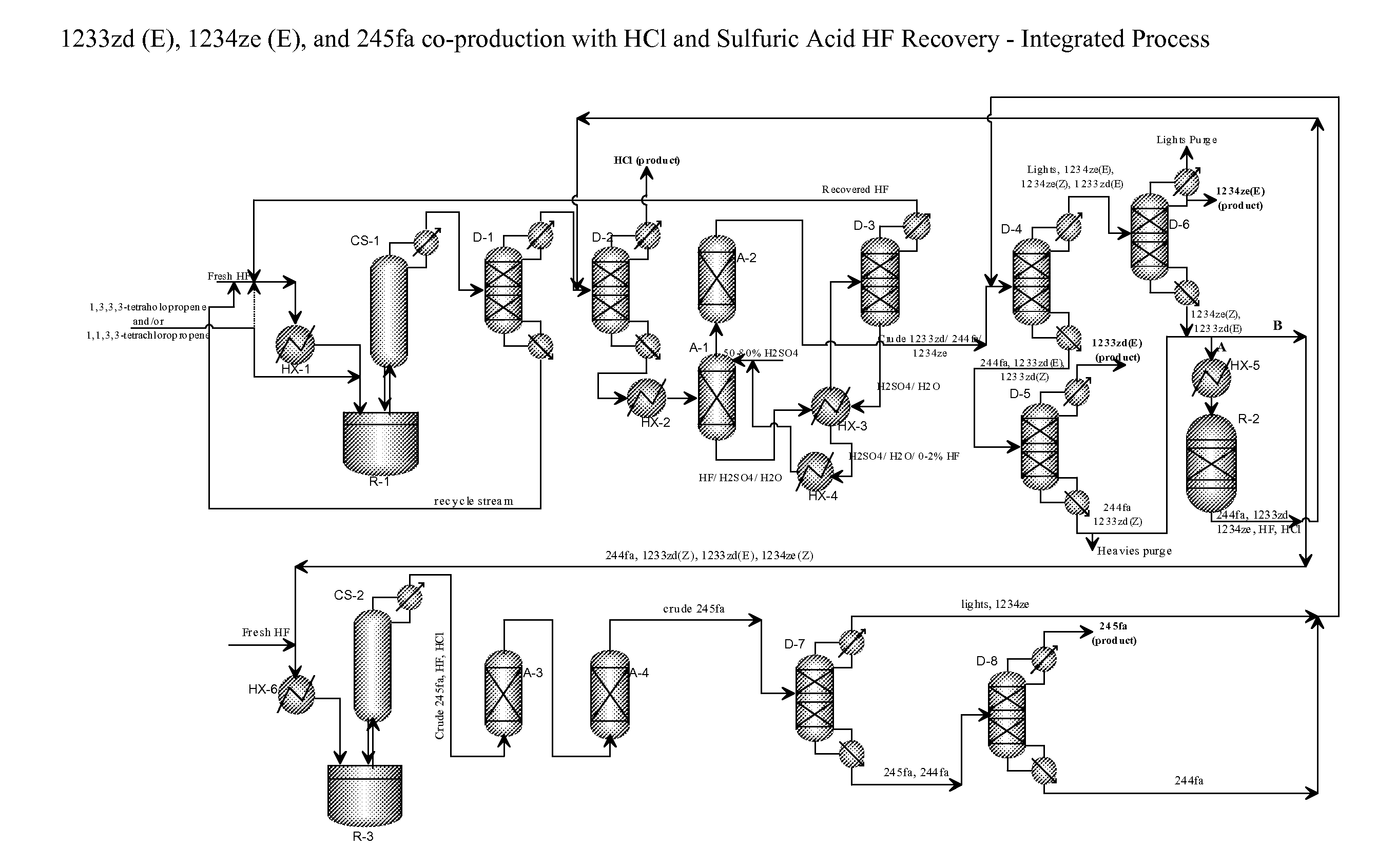

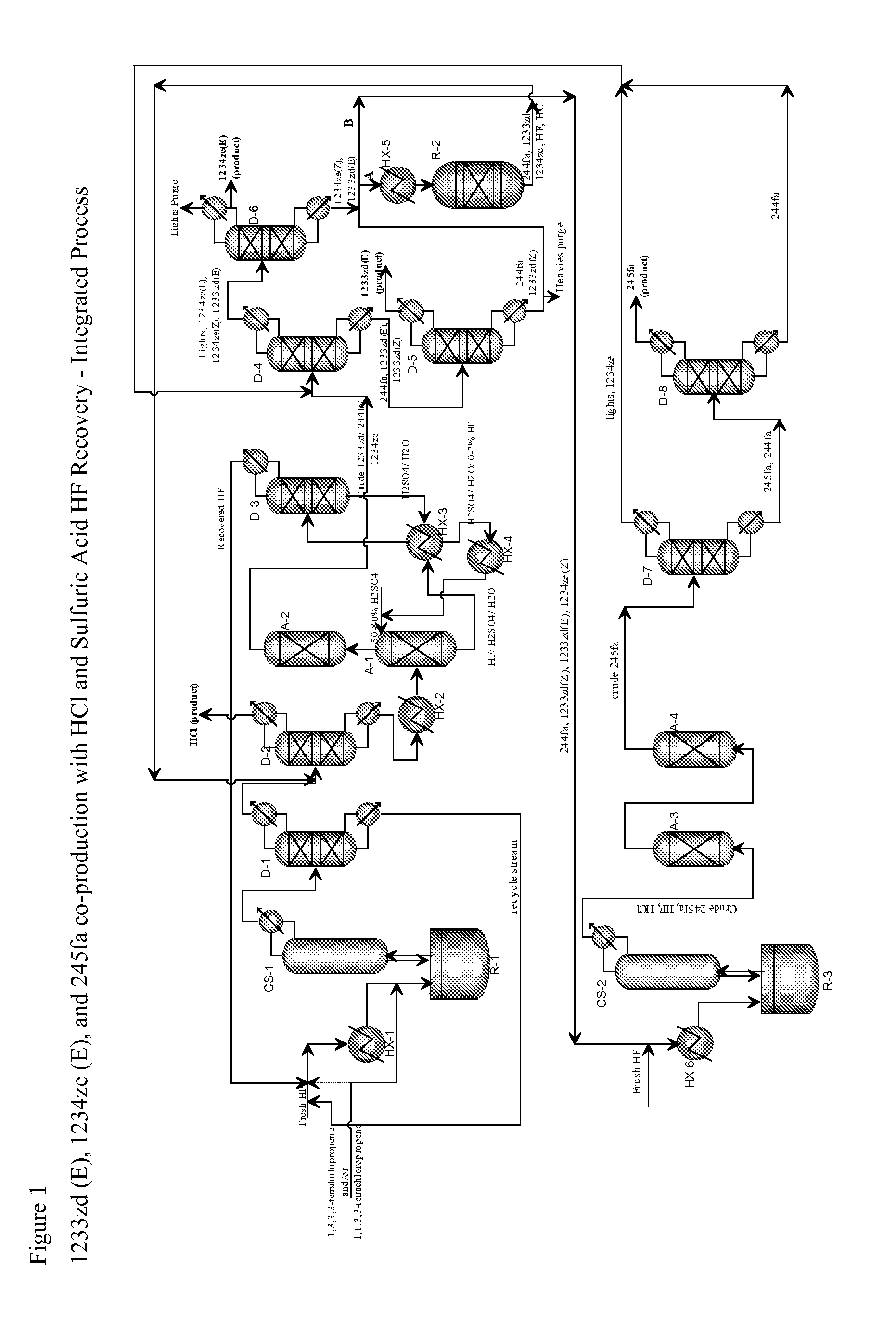

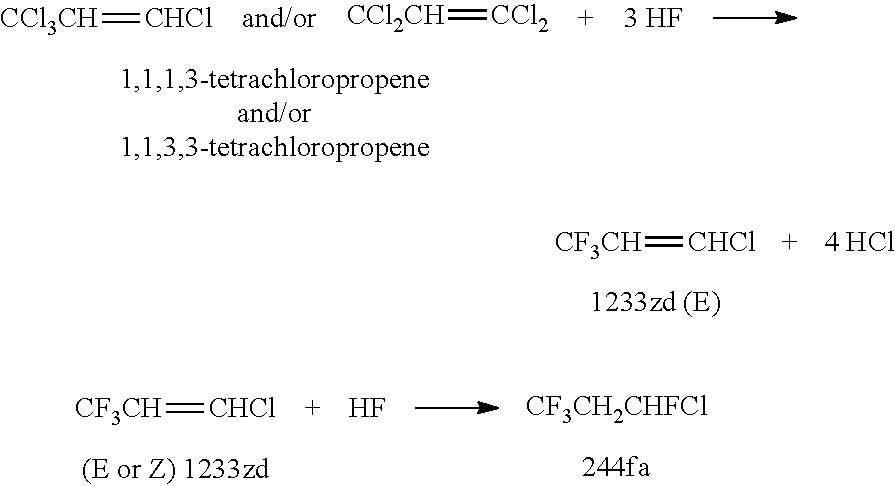

Integrated process for the co-production of trans-1-chloro-3,3,3-trifluoropropene, trans-1,3,3,3-tetrafluoropropene, and 1,1,1,3,3-pentafluoropropane

ActiveUS20130261354A1Good flexibilityMaximize raw material utilizationPreparation by hydrogen halide split-offHalogenated hydrocarbon separation/purificationHydrogen fluorideChemical reaction

Disclosed is an integrated process to co-produce trans-1-chloro-3,3,3-trifluoro-propene (1233zd (E)), trans-1,3,3,3-tetrafluoropropene (1234ze (E)), and 1,1,1,3,3-pentafluoropropane (245fa). Overall the co-production is a three-step process. The chemistry involves the steps of:(1) the reaction of 1,1,1,3-tetrachloropropene and / or 1,1,3,3-tetrachloropropene with anhydrous HF in excess in a liquid-phase catalyzed reactor in such a way as to co-produce primarily 1233zd (E) and 244fa (plus by-product HCl); an optionally(2) the 244fa stream can then be used to directly produce any (or all) of the following desired products;(a) the 244fa stream can be dehydrochlorinated to produce the desired second product 1234ze (E); and / or(b) the 244fa stream can be dehydrofluorinated to produce 1233zd (E) if more of that product is desired; and / or(c) the 244fa stream can be further fluorinated to form 245fa.

Owner:HONEYWELL INT INC

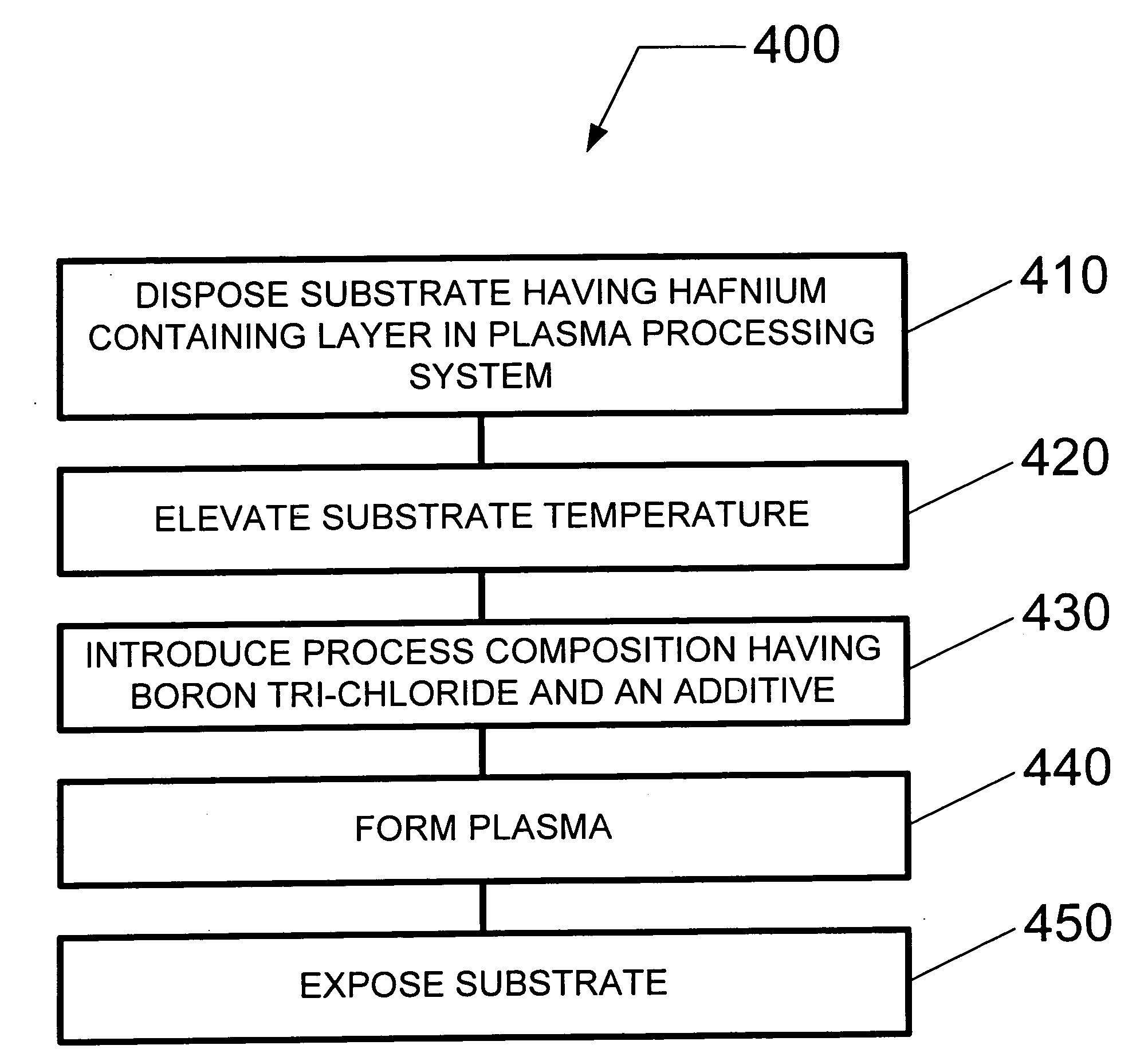

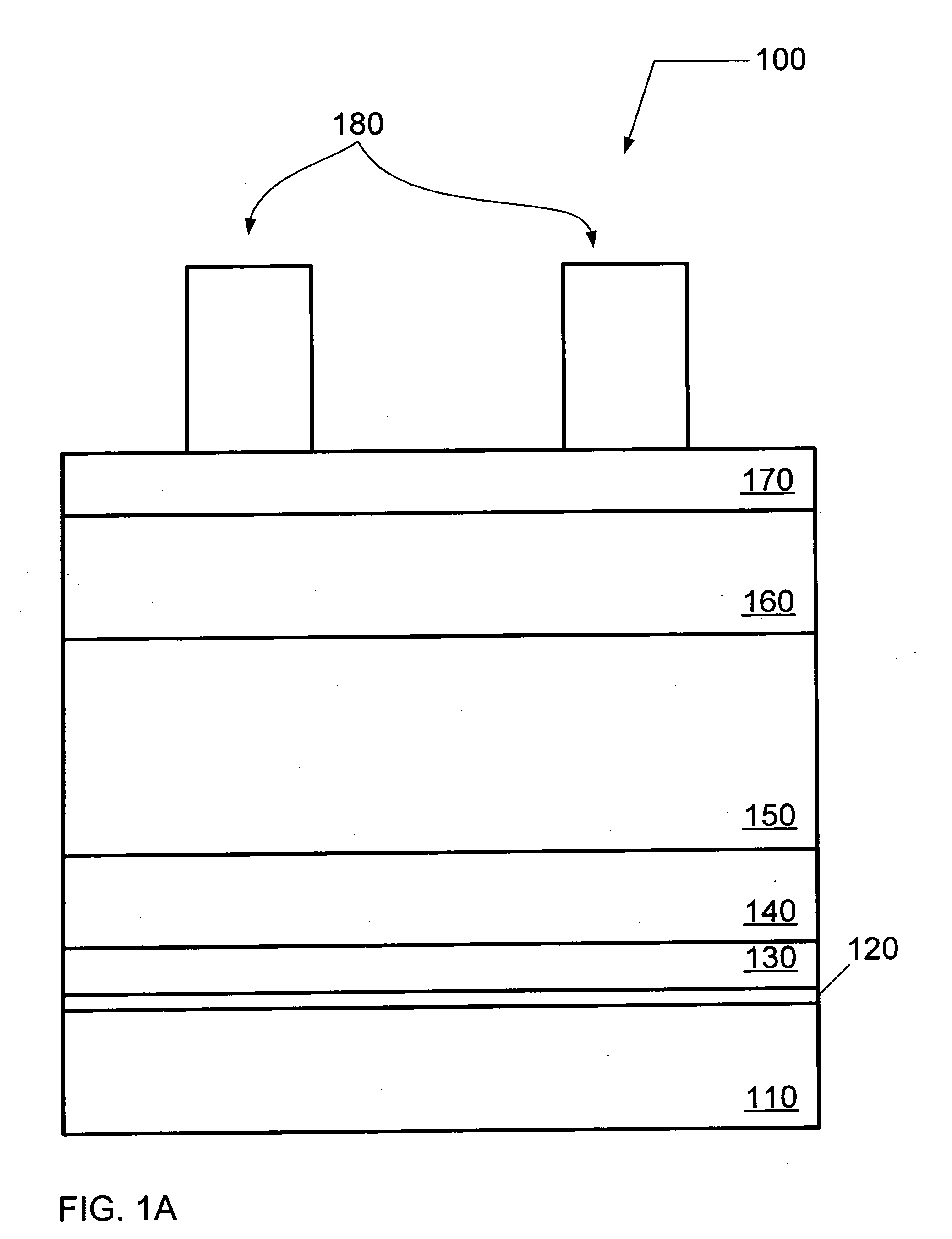

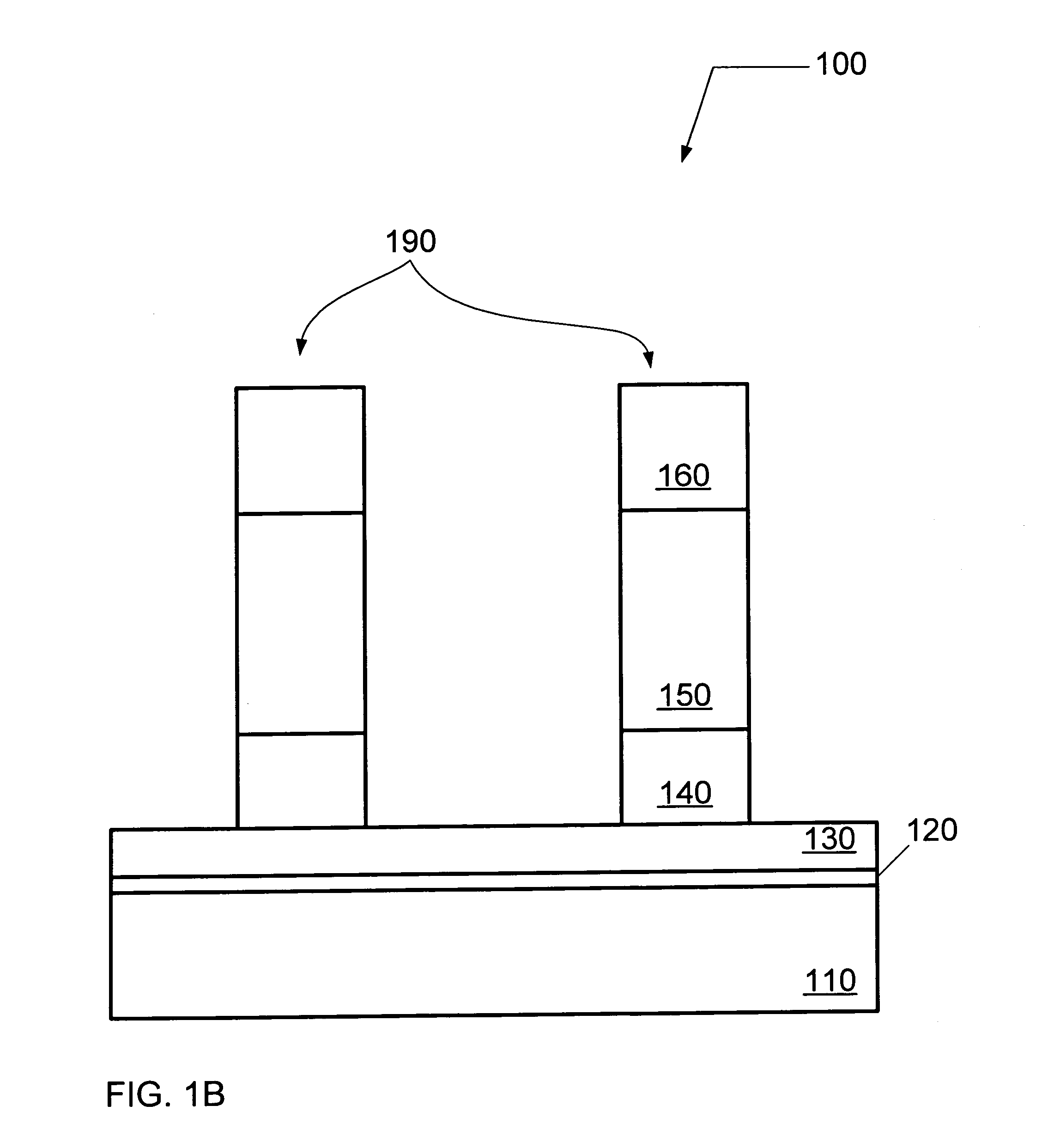

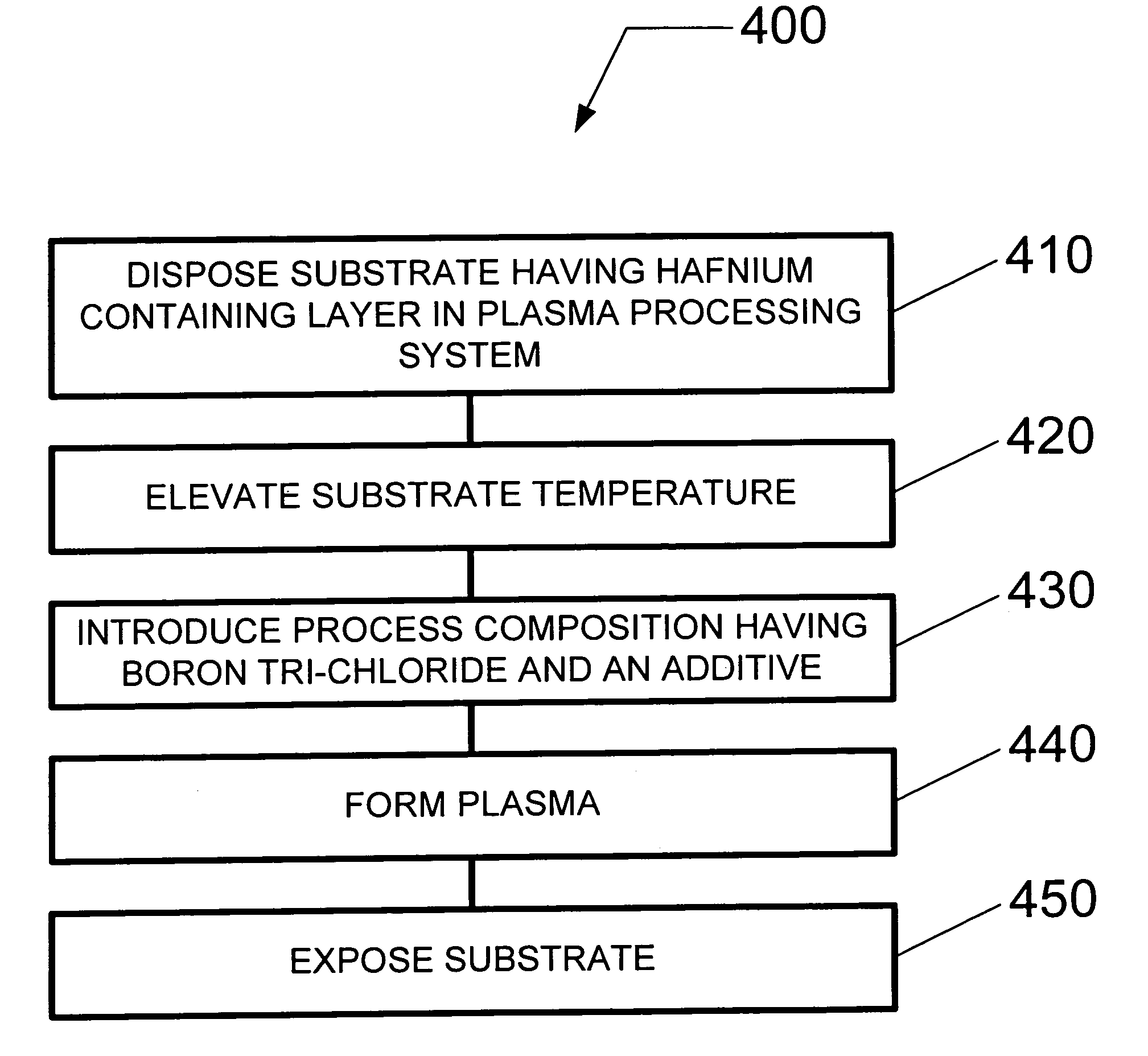

Method and system for dry etching a hafnium containing material

ActiveUS20080064220A1Electric discharge tubesDecorative surface effectsProcess chemistryBoron trichloride

A method and system for etching a hafnium containing material using a boron tri-chloride (BCl3) based process chemistry is described. A substrate having a hafnium containing layer, such as a layer of hafnium dioxide (HfO2) is subjected a dry etching process comprising BCl3 and an additive gas including: an oxygen-containing gas, such as O2; or a nitrogen-containing gas, such as N2; or a hydrocarbon gas (CxHy), such as CH4; or a combination of two or more thereof.

Owner:TOKYO ELECTRON LTD

Use of ammonia for etching organic low-k dielectrics

InactiveUS6893969B2High selectivityIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingProcess chemistryHigh plasma

Method for etching organic low-k dielectric using ammonia, NH3, as an active etchant. Processes using ammonia results in at least double the etch rate of organic low-k dielectric materials than processes using N2 / H2 chemistries, at similar process conditions. The difference is due to the much lower ionization potential of NH3 versus N2 in the process chemistry, which results in significantly higher plasma densities and etchant concentrations at similar process conditions.

Owner:LAM RES CORP

Method for preparing medicine-carrying microvesicle

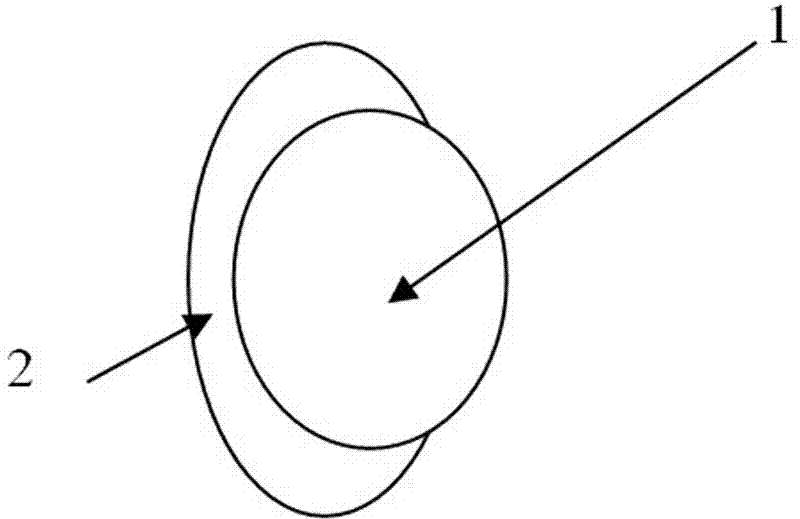

InactiveCN101711736APromote ruptureEfficient slow release and controlled releasePharmaceutical delivery mechanismPharmaceutical non-active ingredientsControlled releaseProcess chemistry

The invention relates to the field of medicines, in particular to a medicine-carrying microvesicle and a preparation method thereof. In the method, medicine-carrying high molecular polymer class nano particles are connected with a lipid microvesicle by an amido bond so as to prepare the medicine-carrying microvesicle. Under an ultrasonic action, the lipid microvesicle of the medicine-carrying microvesicle is broken, and the medicine-carrying high molecular polymer class nano particles which are connected with the lipid microvesicle of the medicine-carrying microvesicle are released and enter the clearances of tissues to exert an action. The method has mild reaction conditions and superior chemical selectivity of the reaction process; and the prepared medicine-carrying microvesicle can be used as an ultrasonic contrast agent, can also be used as a controlled release carrier for various medicines and has extensive application prospect.

Owner:CHONGQING MEDICAL UNIVERSITY

Removal of post etch residue for a substrate with open metal surfaces

InactiveUS20060180572A1Decorative surface effectsPhotomechanical apparatusProcess chemistryTrifluoroacetic acid

A method and system is described for treating a substrate having an open metal surface thereon using a high pressure fluid, such as carbon dioxide in a supercritical state. A process chemistry is introduced to the high pressure fluid for removing residues from the substrate surface. The process chemistry comprises trifluoroacetic acid (TFA).

Owner:TOKYO ELECTRON LTD

Method of etching high aspect ratio features

A plasma processing system for and method of utilizing an improved etch chemistry for effectively etching high aspect ratio silicon features. The process chemistry employs precursor gases suitable for producing a fluorine / chlorine etch chemistry as well as precursor gases suitable for forming chemical bonds of sufficient strength to create stable feature side-walls. The improved process chemistries include SO2 / SF4 / SiCl4, SO2 / SF4 / Cl2, SO2 / SiF4 / SiCl4, SO2SIF4 / Cl2, O2 / F2 / Cl2, N2 O / F2 / Cl2, and NO2 / F2 / Cl2-based chemistries.

Owner:TOKYO ELECTRON LTD

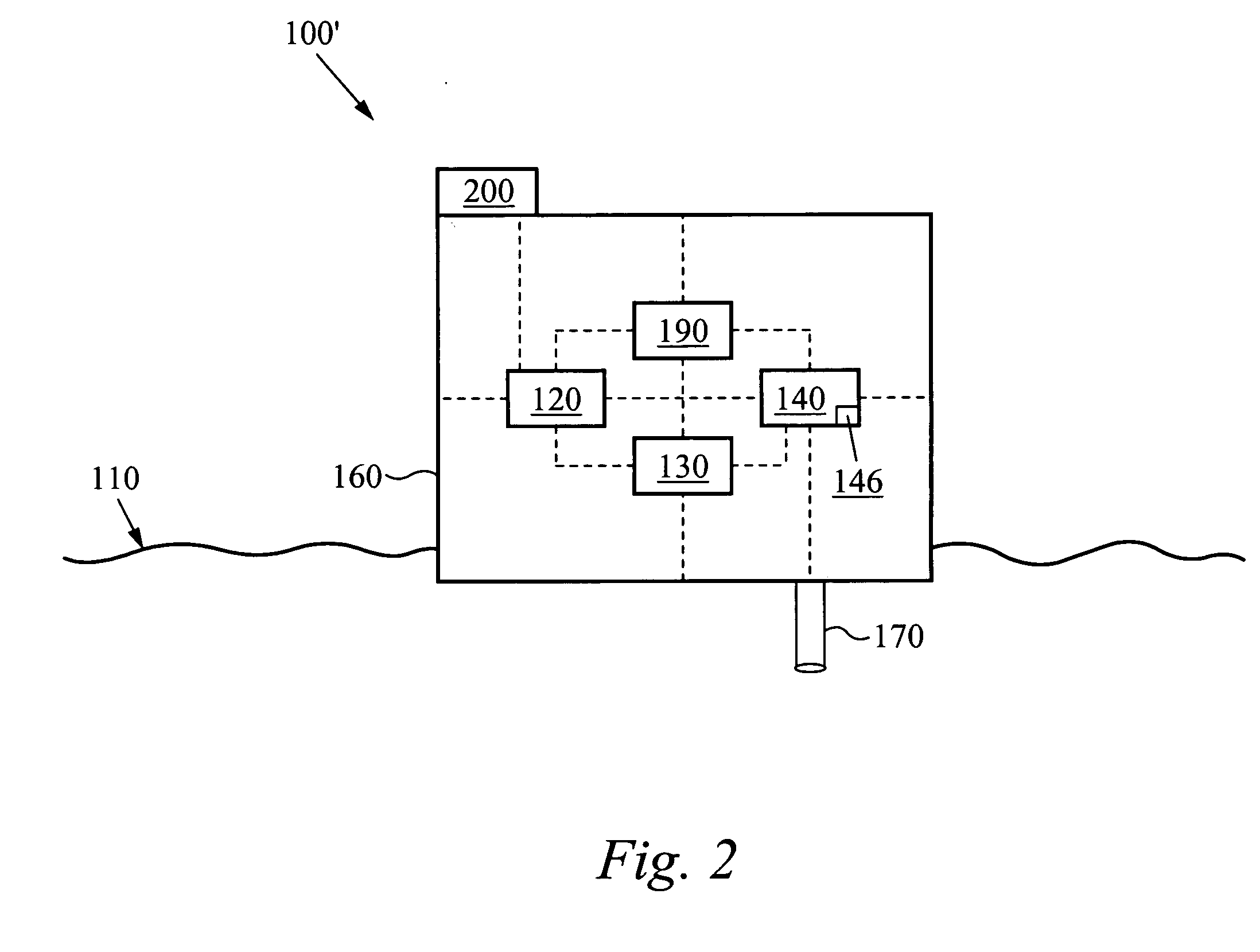

In-situ water analysis method and system

ActiveUS20060292043A1Improve securityImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesWaterborne vesselsProcess chemistryAnalysis method

An automatic system for monitoring chemistry information for a body of water comprises a sensor for determining chemistry information, a microprocessor for processing chemistry information, and a housing coupled to at least one of the sensor and the microprocessor. Preferably the housing is floatable or mountable. The method of providing chemistry information of a body of water comprising the steps of obtaining a sample of the body of water and determining chemistry information.

Owner:HITEK AQUA SYST

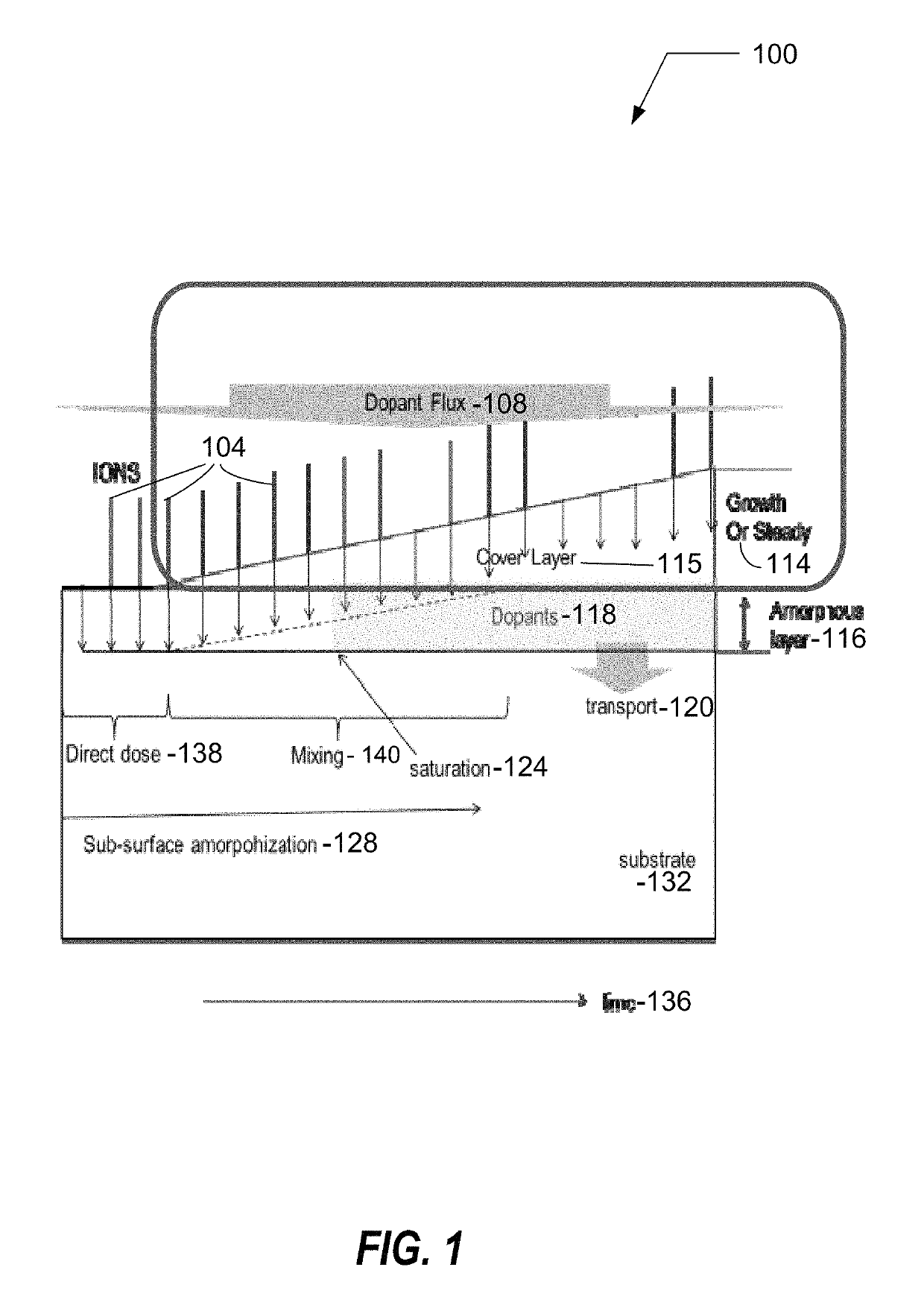

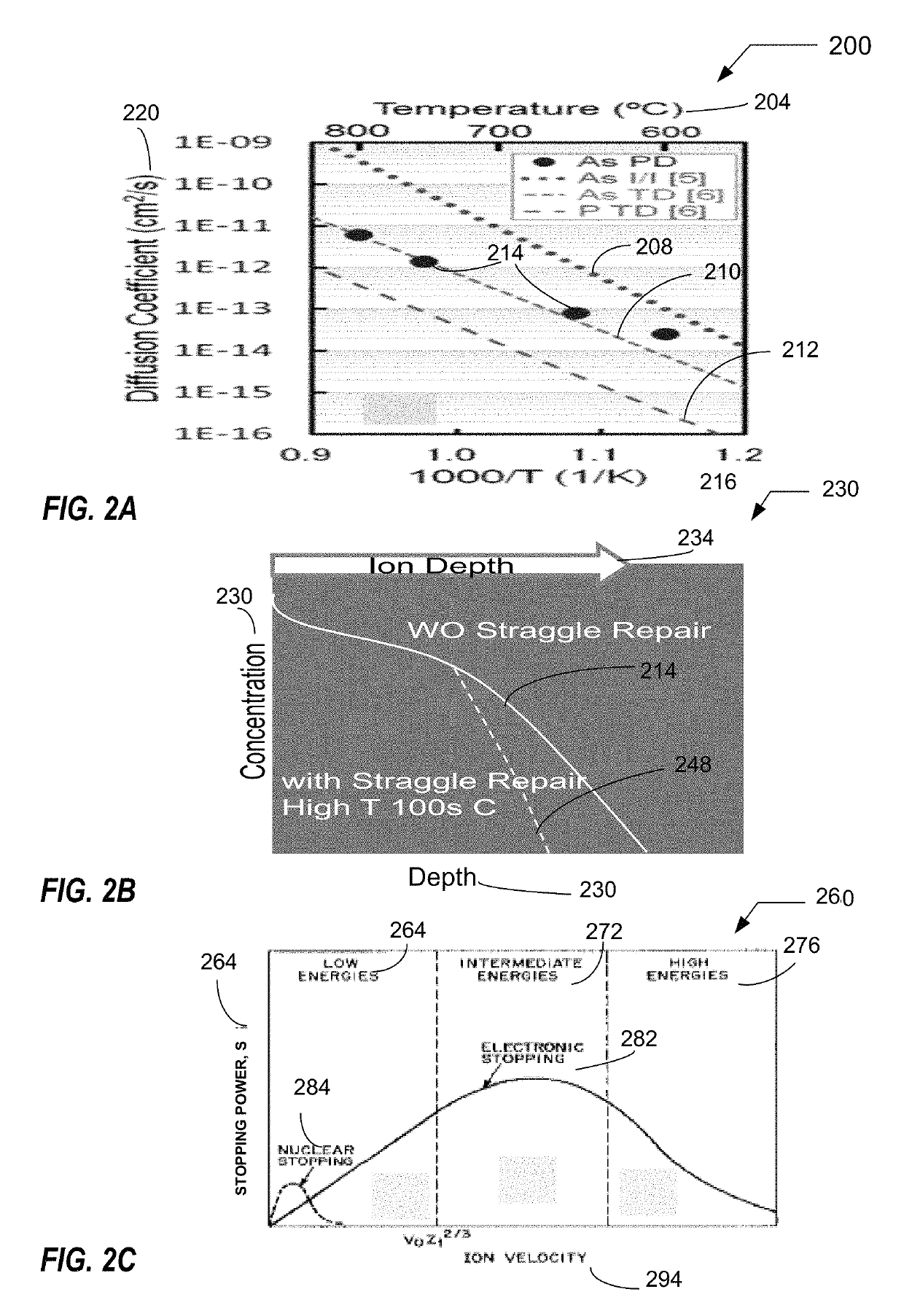

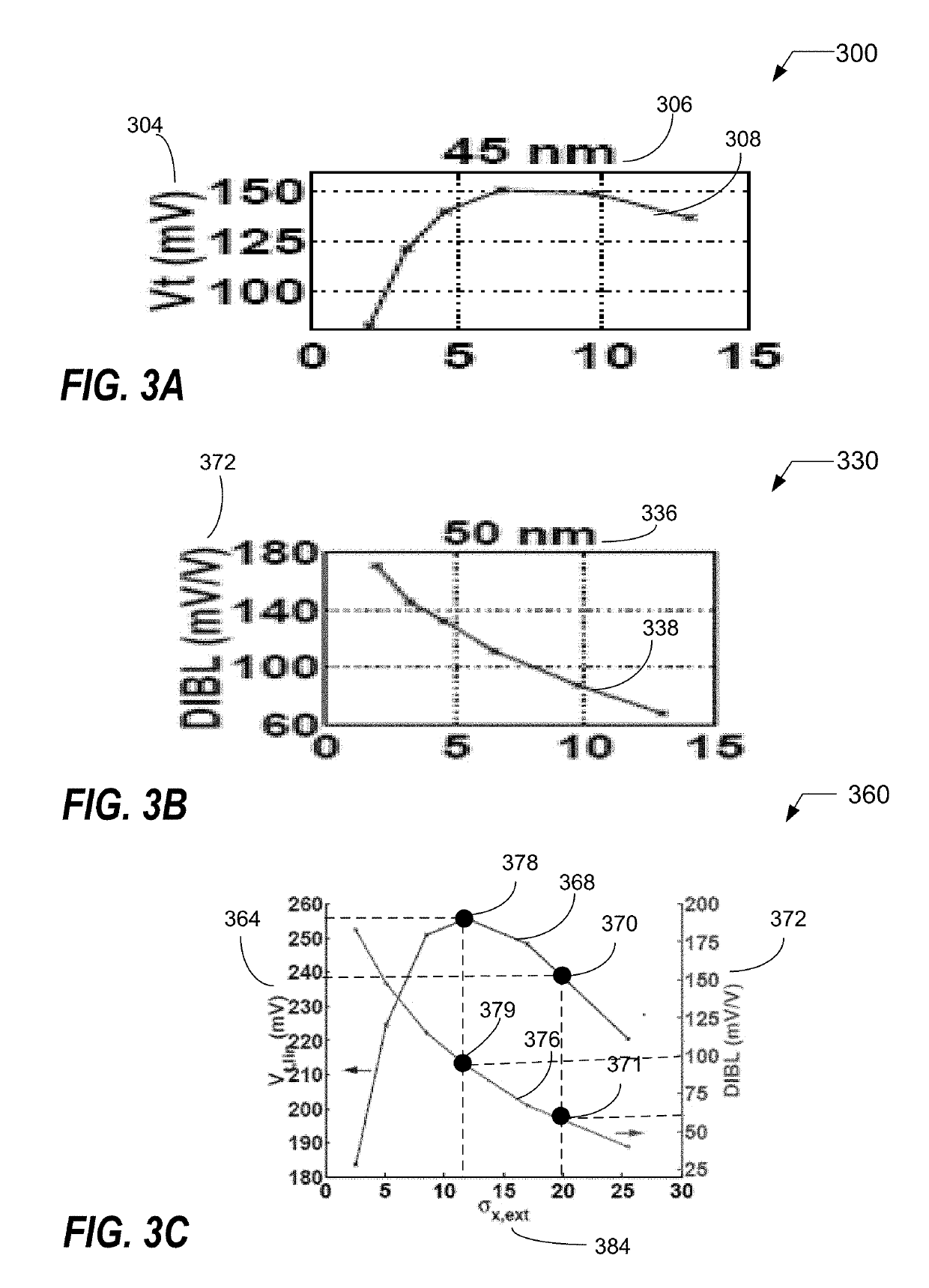

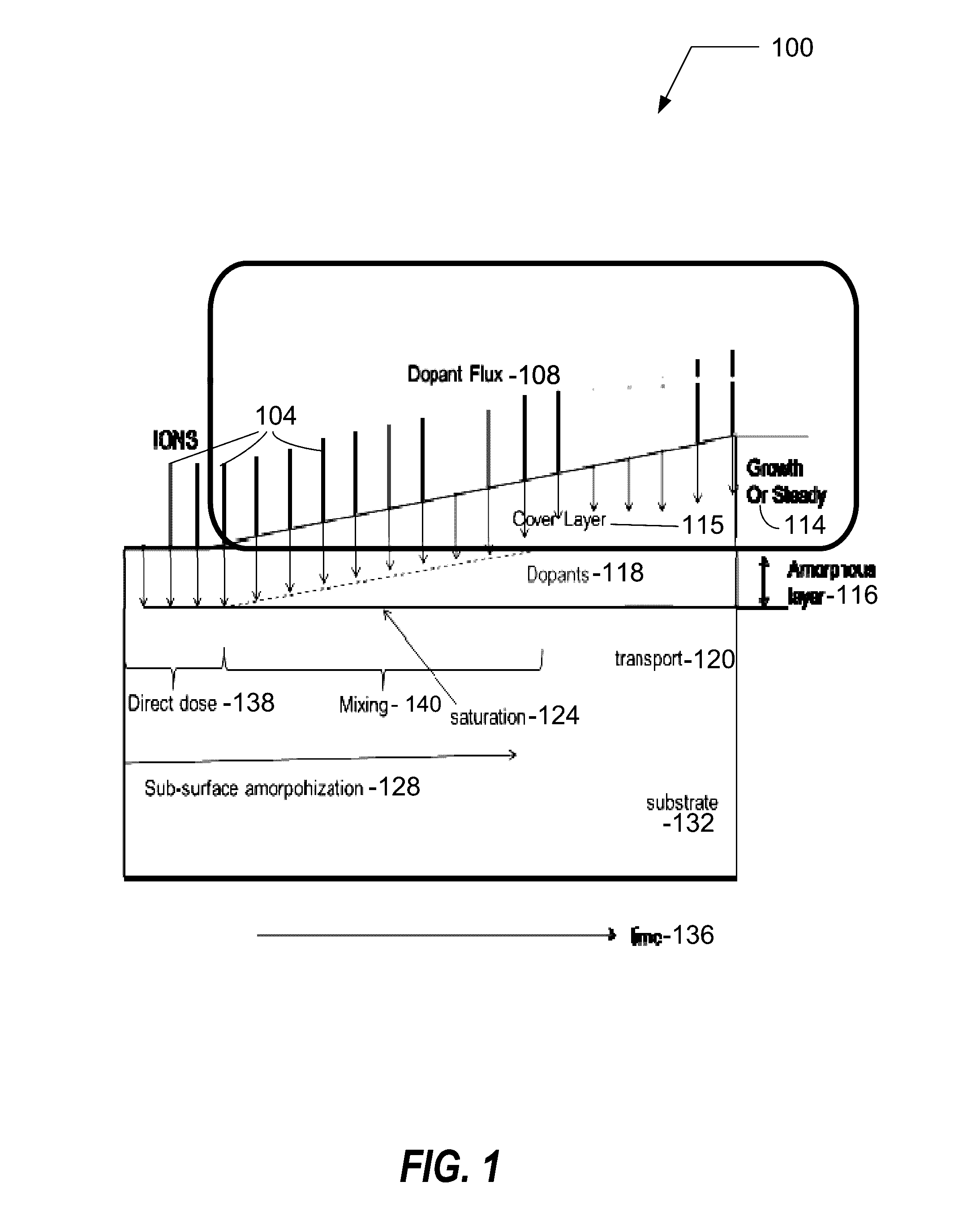

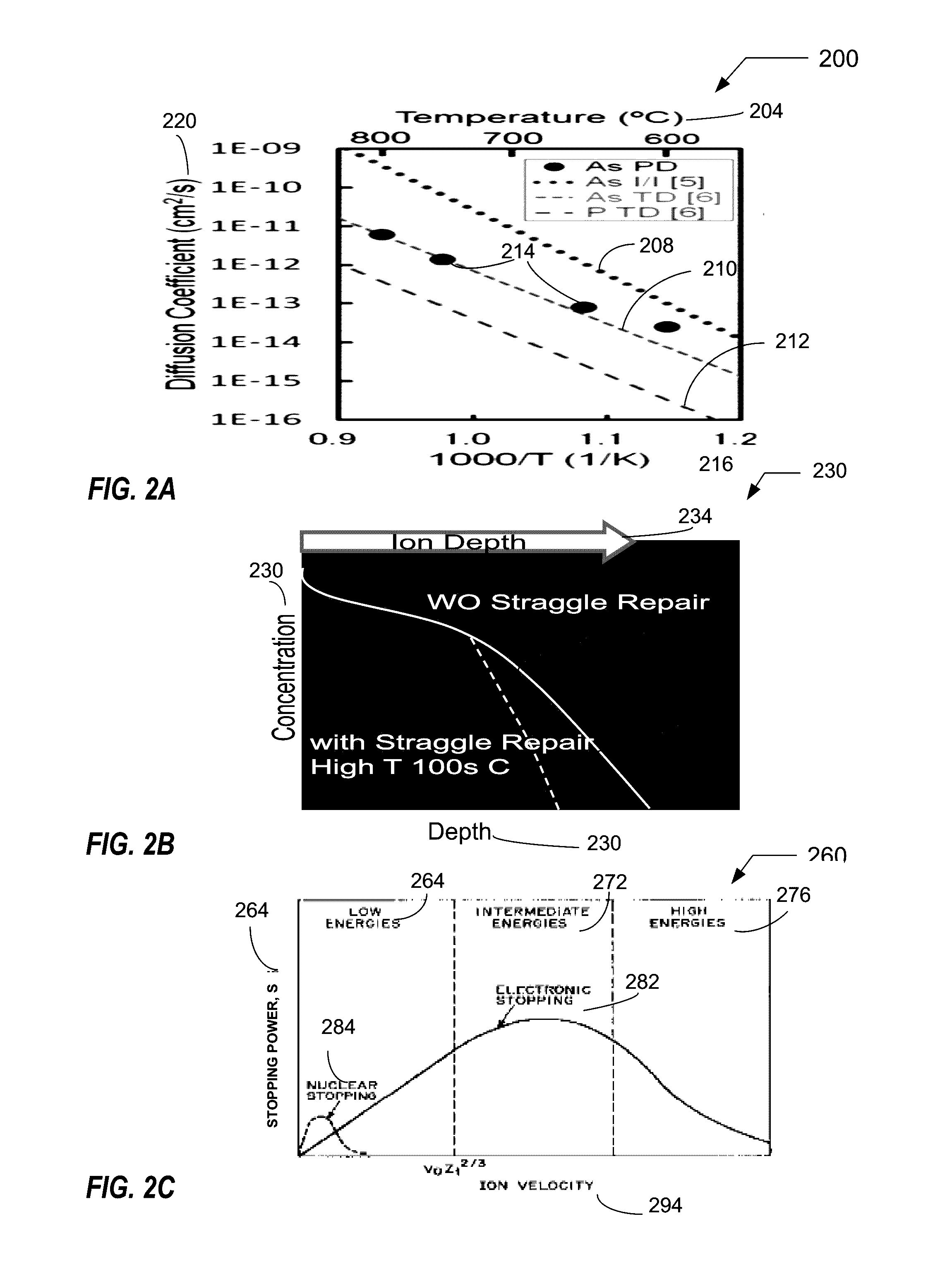

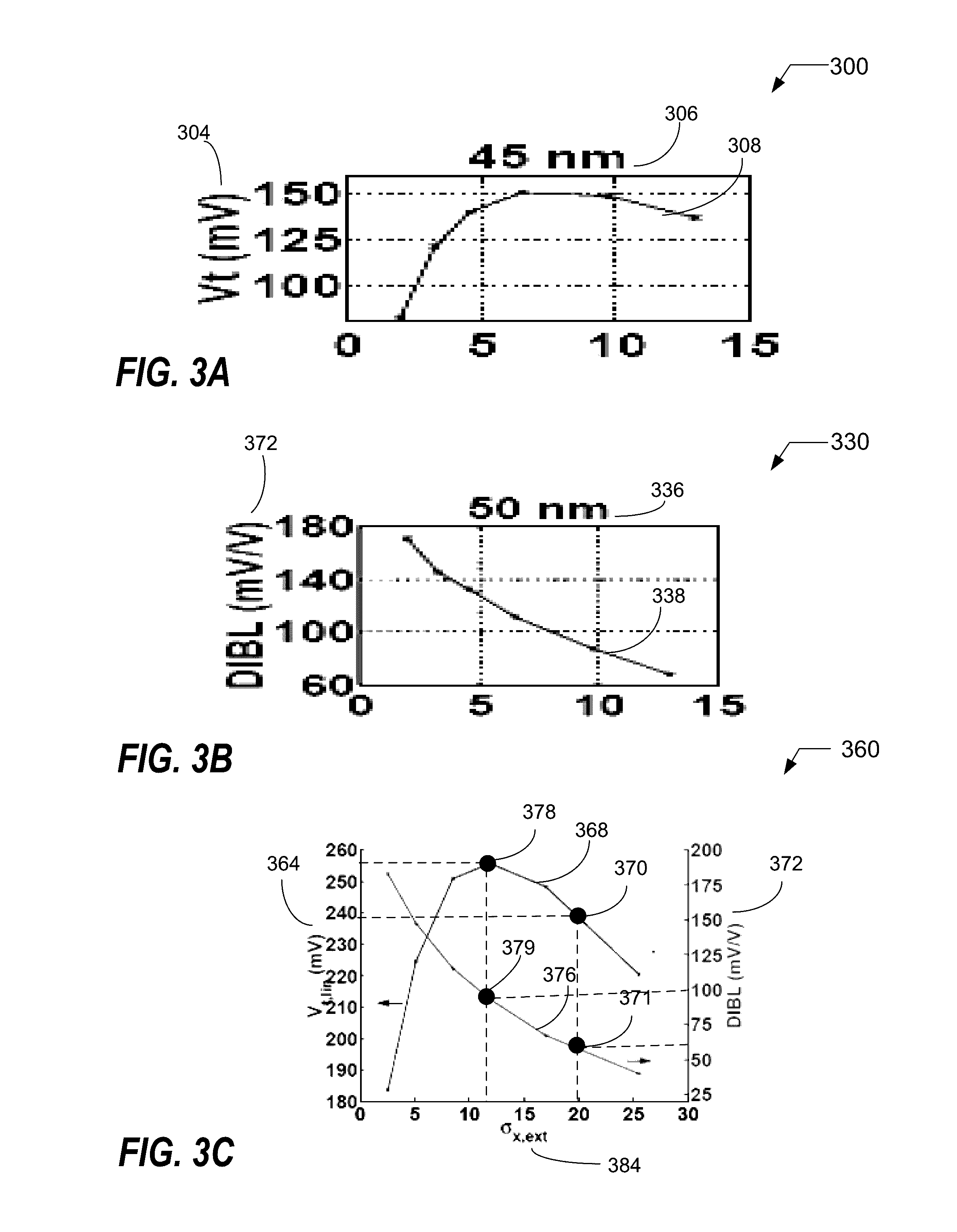

Method for using heated substrates for process chemistry control

ActiveUS10249498B2Facilitated DiffusionSemiconductor/solid-state device manufacturingProcess chemistryOperating variables

A method of controlling doping of a substrate, the method comprising: providing the substrate in a process chamber of a doping system; performing a doping process to impart a target dose on a surface of the substrate using a abruptness depth control technique; and controlling selected operating variables of plasma doping in order to meet doping objectives.

Owner:TOKYO ELECTRON LTD

Accessible assay device and method of use

An assay test strip(10) and cassette(30). The test strip is positioned in a housing shaped and configured to allow a detector to access the test strip from the side, rather than from the lengthwise axis of the test strip. The housing may contain one or more test strips which may also be disposed on one or more surfaces of the housing. Preferably, the housing is generally C-shaped with the test strip spanning the space between the two arms of the C-shape. The housing is sealed to protect both the operator and instrument from possible contamination. The test strip is preferably embedded with paramagnetic particles and process chemistry specific for a particular application. Quantitative analysis may be accomplished using a magnetic reader device. In additional embodiments, detection is accomplished by visual means.

Owner:QUANTUM DESIGN

Removal of particles from substrate surfaces using supercritical processing

InactiveUS20060255012A1Facilitate particle removalGood removal effectDecorative surface effectsSemiconductor/solid-state device manufacturingProcess chemistryHigh pressure

A method and system is described for treating a substrate to remove particles using a supercritical fluid, such as carbon dioxide in a supercritical state. A process chemistry is introduced to the high pressure fluid for removing particles from the substrate surface. The process chemistry comprises an etchant, a surfactant and, optionally, a co-solvent.

Owner:TOKYO ELECTRON LTD

Process and system for etching doped silicon using SF6-based chemistry

InactiveUS20070056926A1Sampled-variable control systemsDecorative surface effectsProcess chemistryFluorocarbon

A process and system for anisoptropically dry etching through a doped silicon layer is described. The process chemistry comprises SF6 and a fluorocarbon gas. For example, the fluorocarbon gas can include CxFy, where x and y are integers greater than or equal to unity, for example, C4F8.

Owner:TOKYO ELECTRON LTD

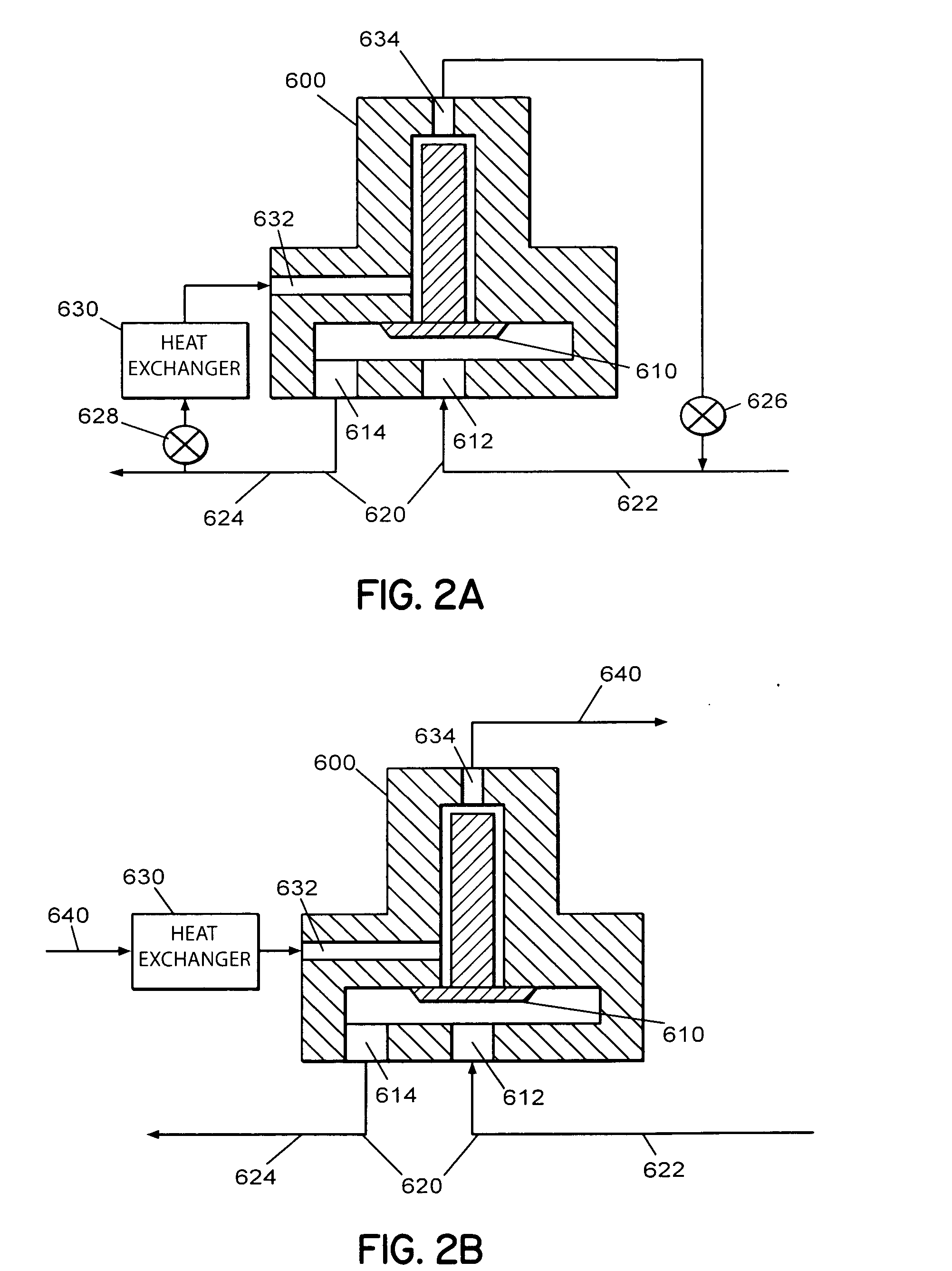

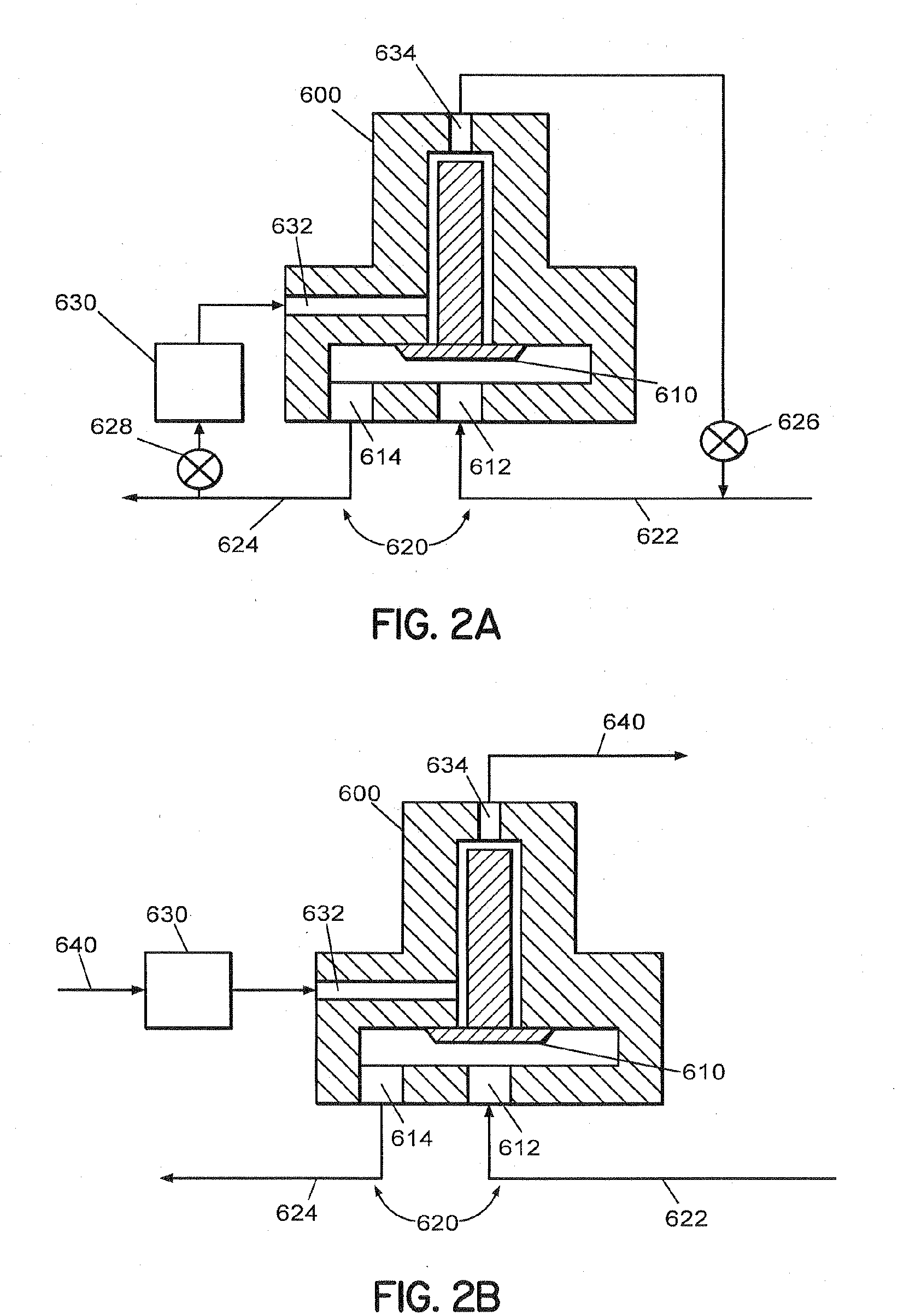

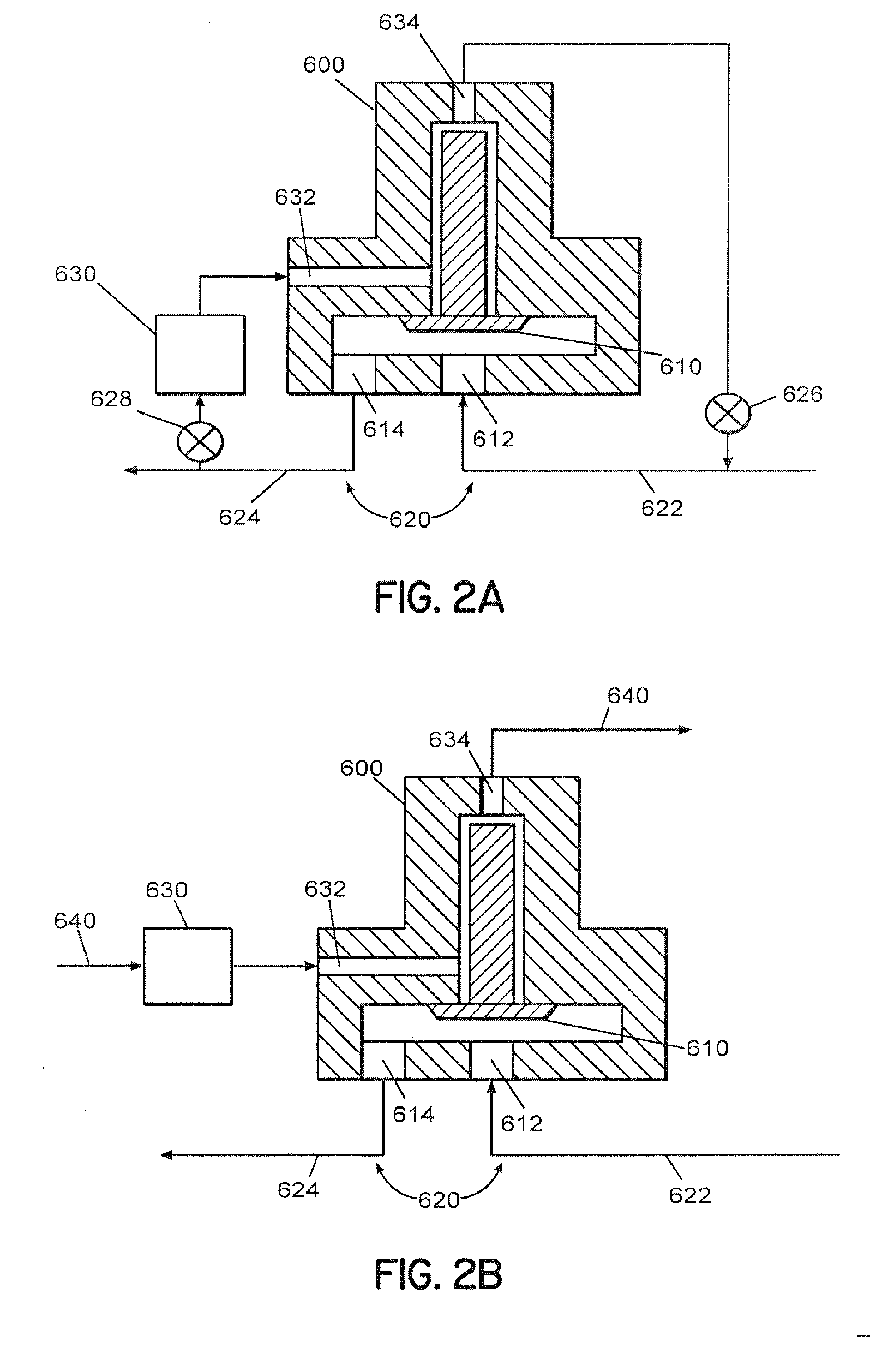

Method and system for homogenization of supercritical fluid in a high pressure processing system

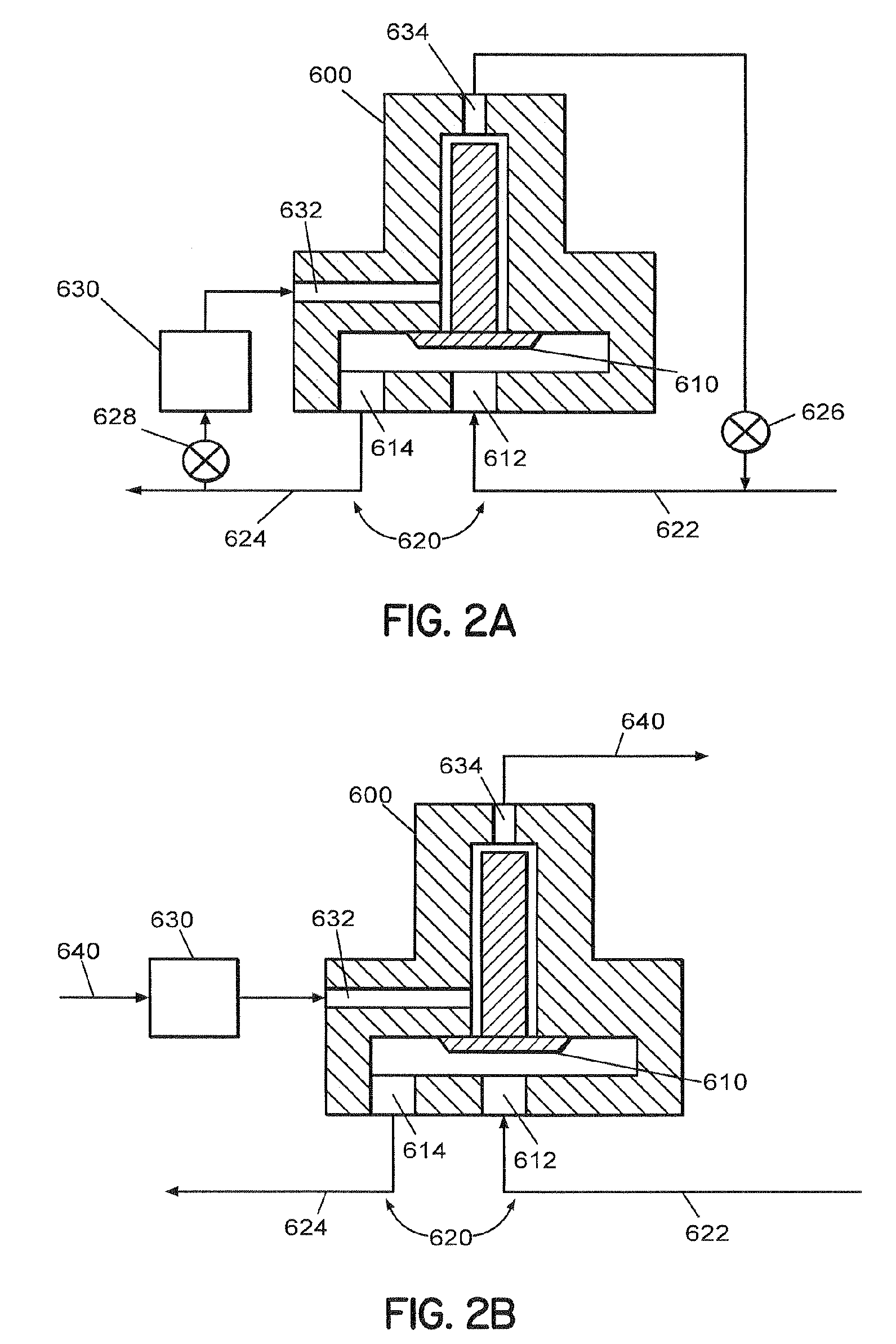

InactiveUS20060065189A1Liquid surface applicatorsVacuum evaporation coatingProcess chemistryHigh pressure

A method and system for providing a homogeneous processing environment in a high pressure processing system is described. A high pressure fluid and a process chemistry are mixed in a pre-mixing system prior to exposure with the fluid in a supercritical state of a substrate in the high pressure processing system. For example, the pre-mixing system can include a fluid circulation system configured to bypass the high pressure processing system until the high pressure fluid and the process chemistry are mixed. Alternatively, the pre-mixing system can include a mixing chamber, and optionally include means for agitating the high pressure fluid and process chemistry in the mixing chamber.

Owner:TOKYO ELECTRON LTD

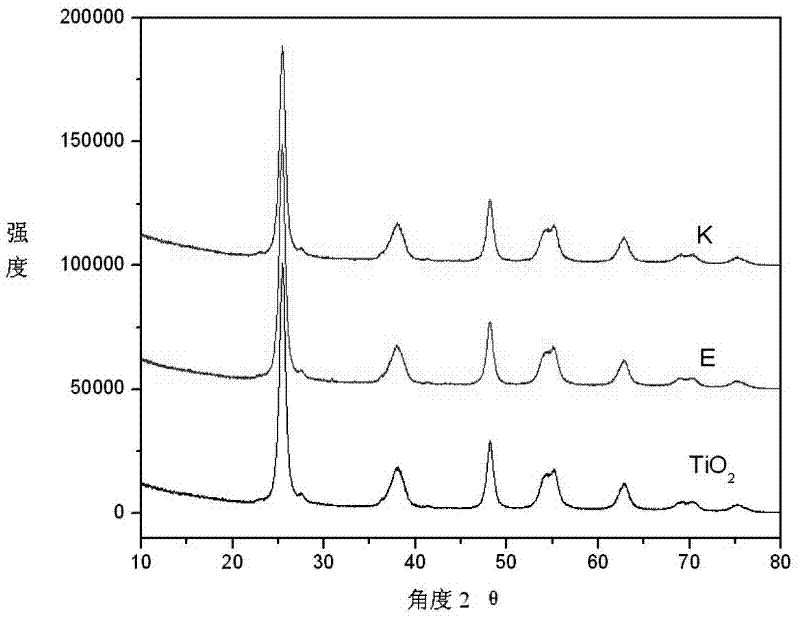

Semiconductor photochemical catalyst with copper phosphate modified surface and preparation method thereof

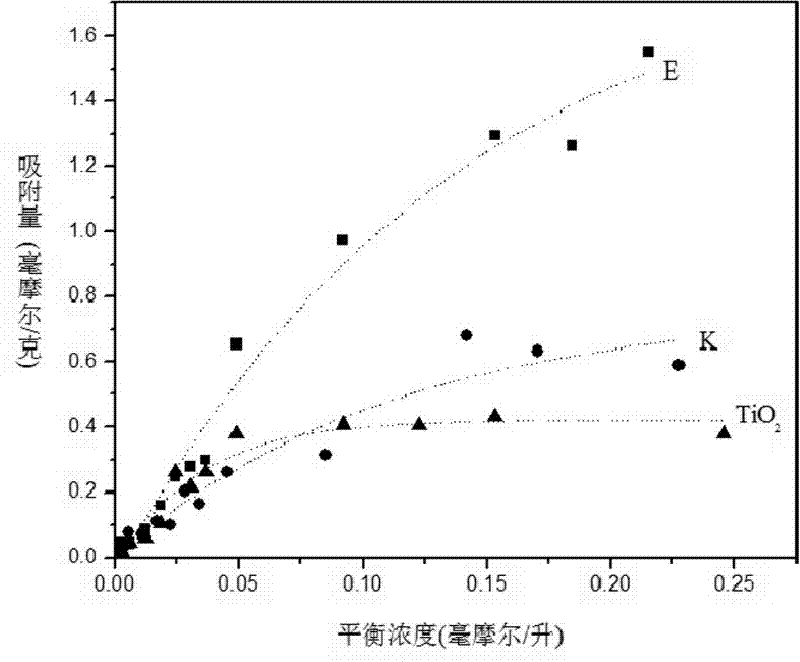

InactiveCN102527416AIncreased photocatalytic rateLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsProcess chemistryPhosphate

The invention provides a semiconductor photochemical catalyst with a copper phosphate modified surface, which comprises semiconductor powder particles with copper phosphate arranged outside. The copper phosphate is evenly dispersed on the surfaces of the semiconductor power particles in solid powder mode. Photochemical rate of the semiconductor photochemical catalyst is remarkably improved. The invention further provides a preparation method of the semiconductor photochemical catalyst. The preparation method uses the semiconductor photochemical catalyst as a precursor, uses copper phosphate as modification materials and deposits and disperses copper phosphate particles on the surfaces of the semiconductor power particles evenly in wet process chemistry method. The semiconductor photochemical catalyst with the copper phosphate modified surface is prepared without changing self crystal texture, crystal phase composition and even grain size of precursor semiconductor. The semiconductor photochemical catalyst with the copper phosphate modified surface is low in raw material cost and the preparation method is simple in device and easy to operate. Compared with pure semiconductor photochemical catalyst, ultraviolet visible light catalytic activity of the obtained photochemical catalyst is obviously improved, and adsorbability to organic pollution is improved.

Owner:ZHEJIANG UNIV

Method and system for treating a substrate with a high pressure fluid using fluorosilicic acid

InactiveUS7291565B2Decorative surface effectsDetergent mixture composition preparationProcess chemistryHigh pressure

A method and system is described for treating a substrate with a high pressure fluid, such as carbon dioxide in a supercritical state. A process chemistry is introduced to the high pressure fluid for treating the substrate surface. The process chemistry comprises fluorosilicic acid.

Owner:TOKYO ELECTRON LTD

Method for Using Heated Substrates for Process Chemistry Control

ActiveUS20160372327A1Facilitated DiffusionSemiconductor/solid-state device manufacturingProcess chemistryOperating variables

A method of controlling doping of a substrate, the method comprising: providing the substrate in a process chamber of a doping system; performing a doping process to impart a target dose on a surface of the substrate using a abruptness depth control technique; and controlling selected operating variables of plasma doping in order to meet doping objectives.

Owner:TOKYO ELECTRON LTD

Method and system for dry etching a hafnium containing material

ActiveUS8183161B2Electric discharge tubesDecorative surface effectsProcess chemistryBoron trichloride

A method and system for etching a hafnium containing material using a boron tri-chloride (BCl3) based process chemistry is described. A substrate having a hafnium containing layer, such as a layer of hafnium dioxide (HfO2) is subjected a dry etching process comprising BCl3 and an additive gas including: an oxygen-containing gas, such as O2; or a nitrogen-containing gas, such as N2; or a hydrocarbon gas (CxHy), such as CH4; or a combination of two or more thereof.

Owner:TOKYO ELECTRON LTD

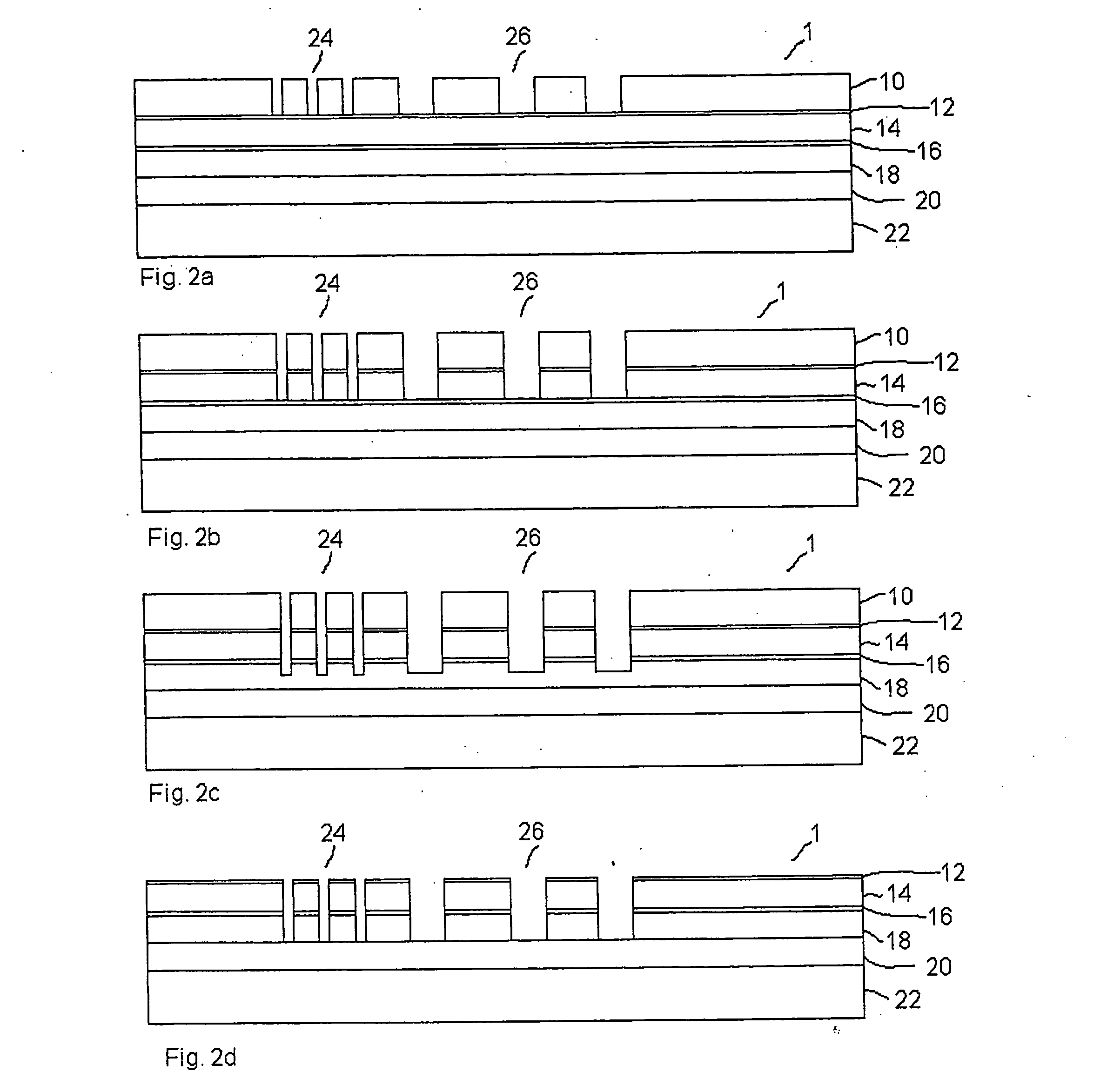

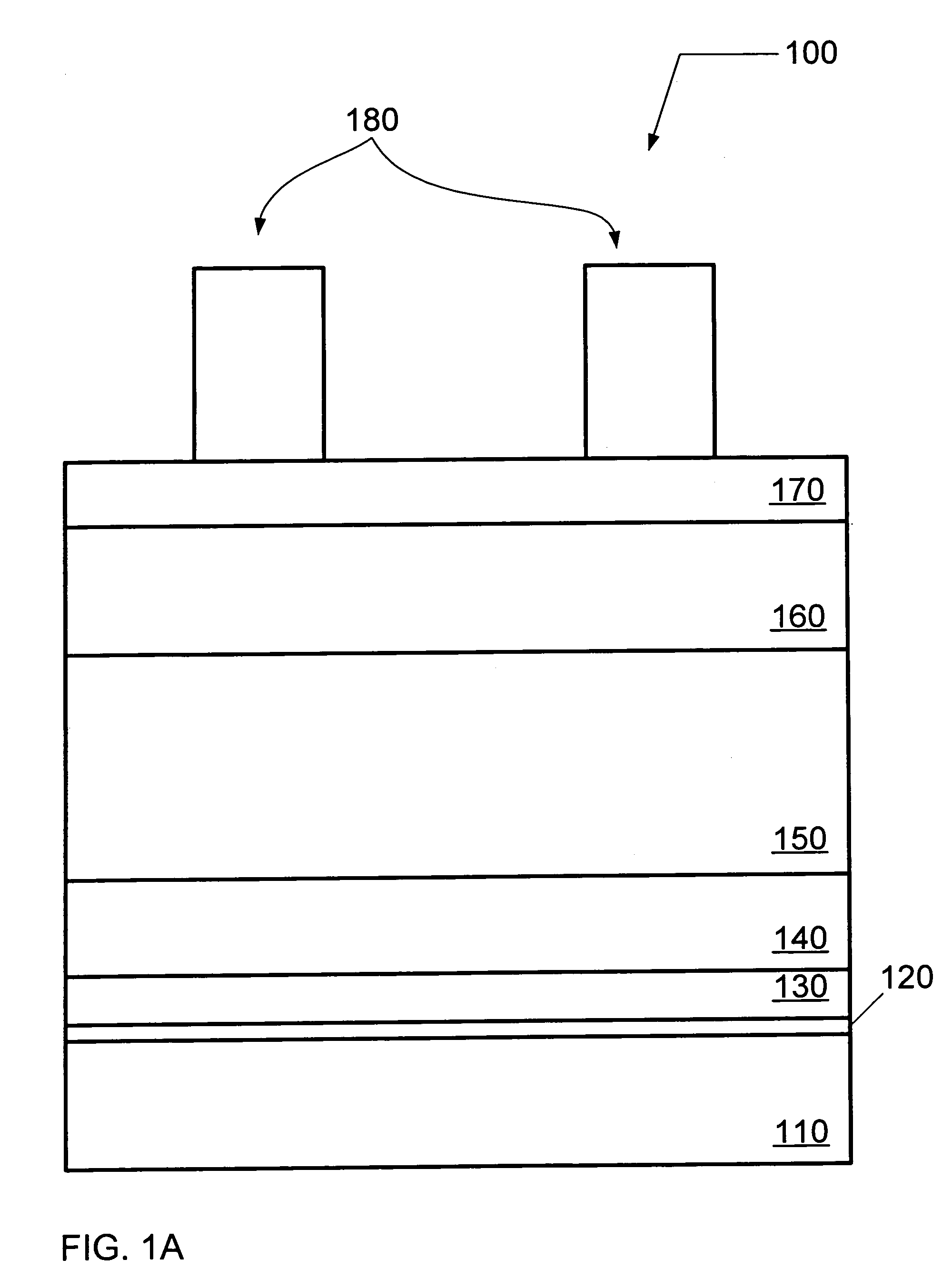

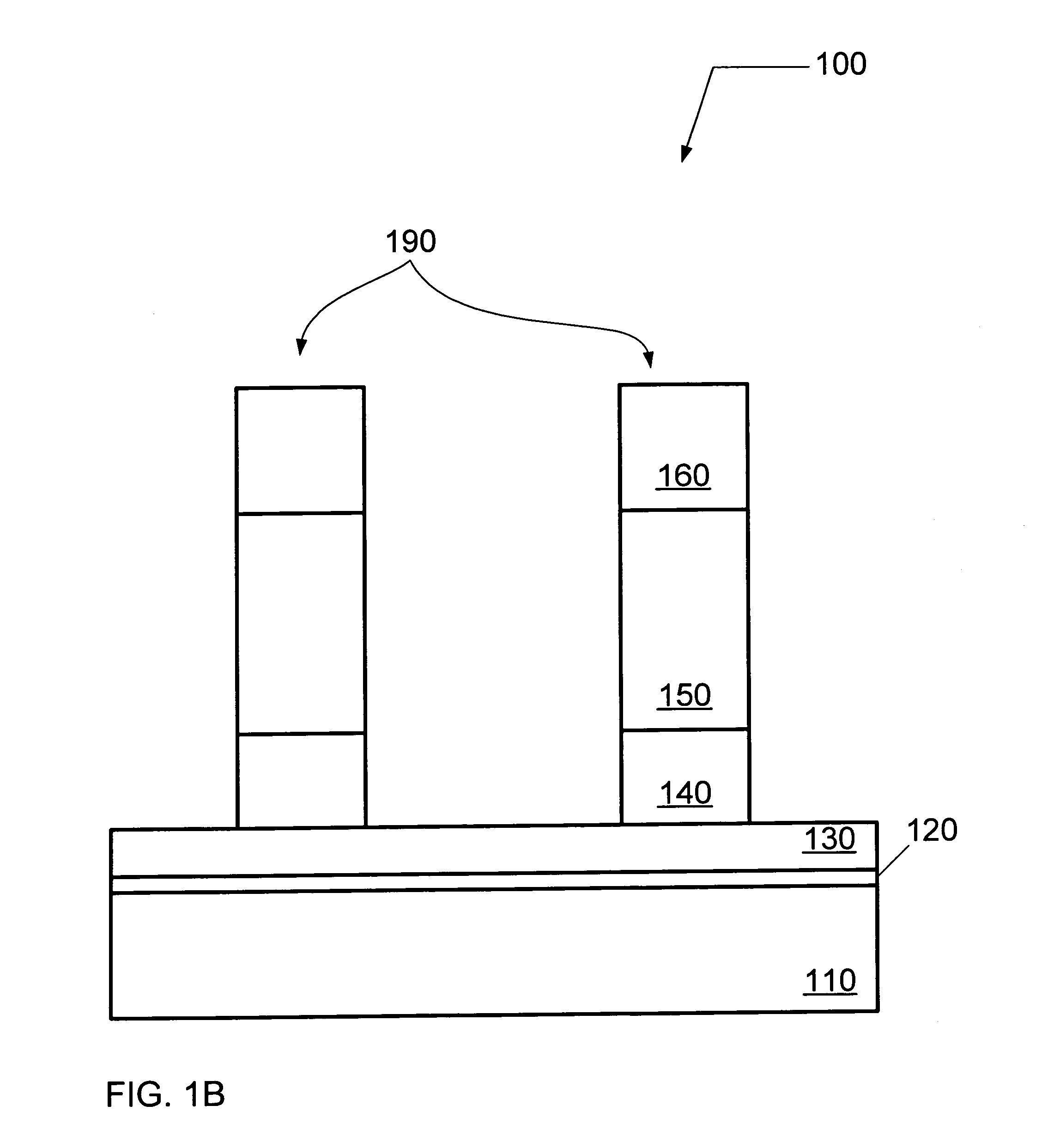

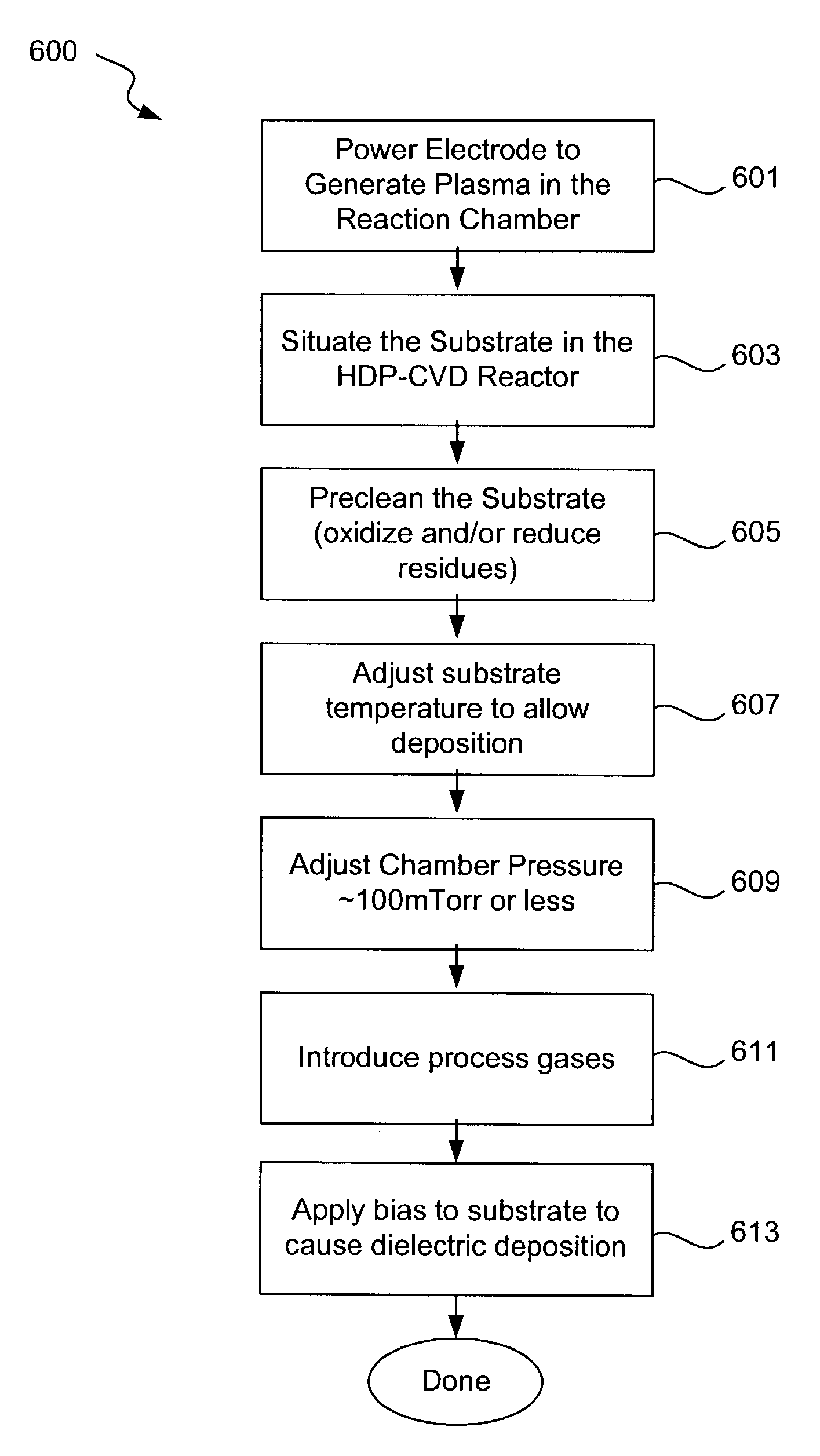

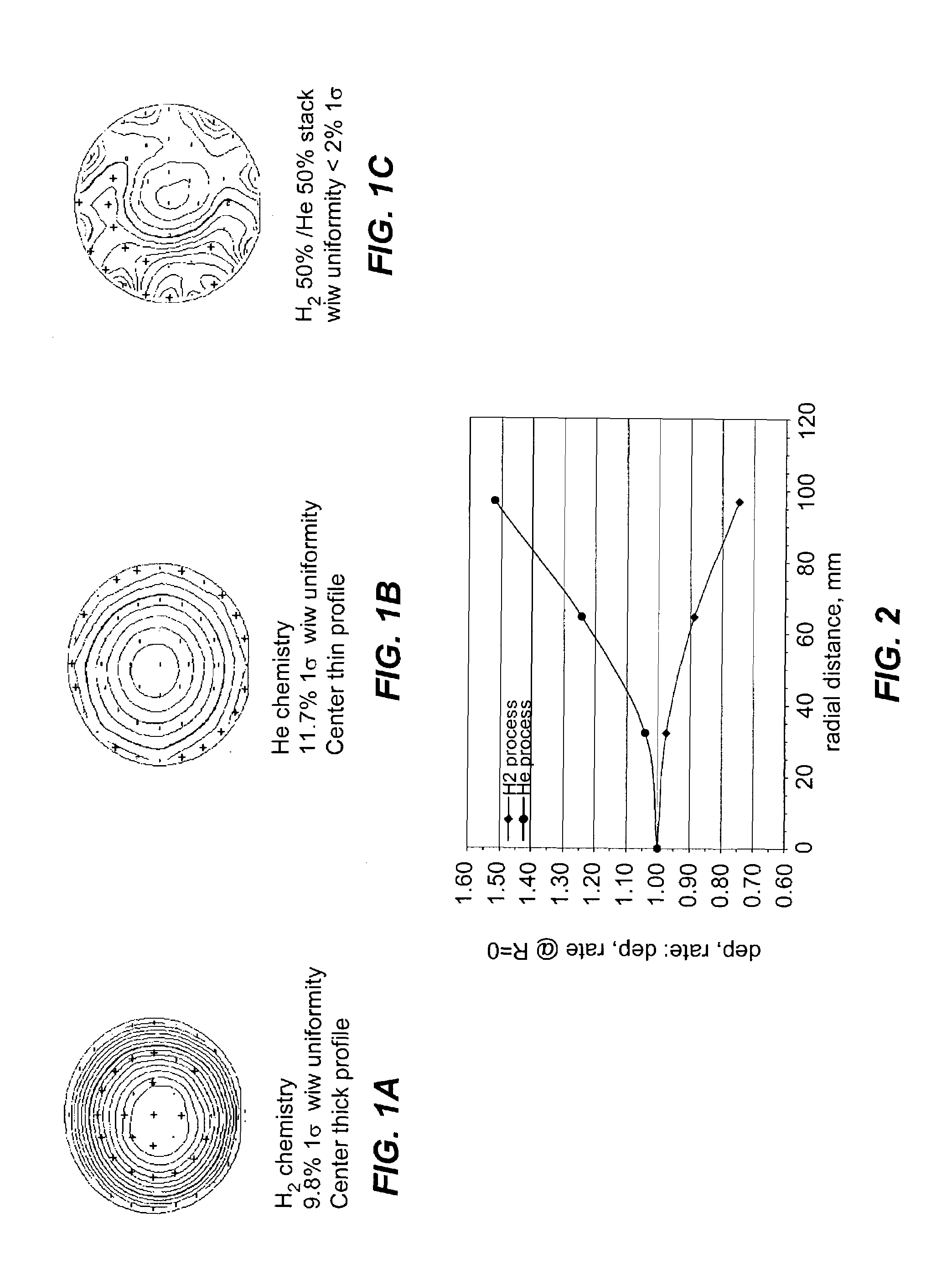

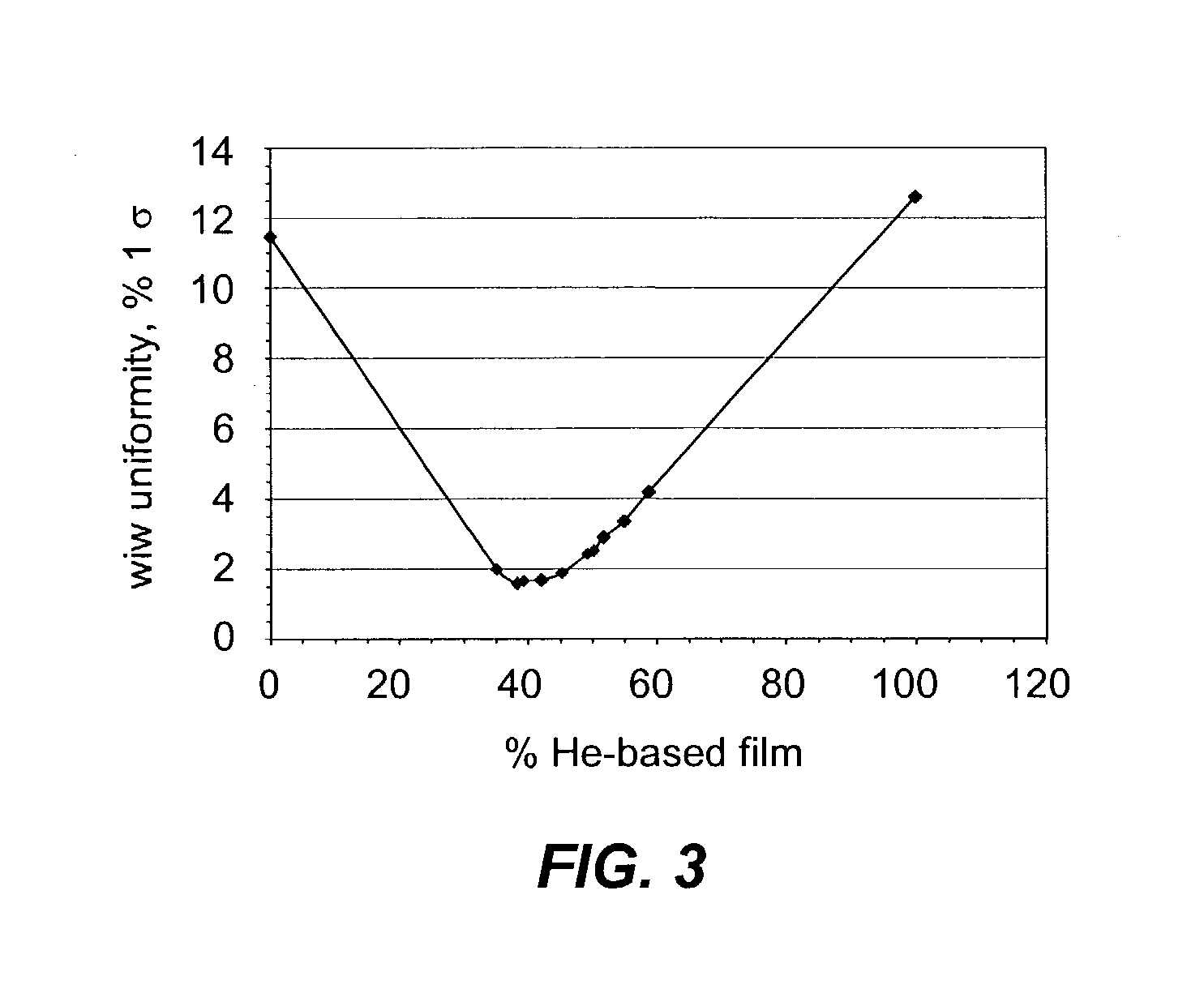

Deposition profile modification through process chemistry

InactiveUS7122485B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess chemistryPolymer science

Disclosed are methods for modifying the topography of HDP CVD films by modifying the composition of the reactive mixture. The methods allow for deposition profile control independent of film deposition rate. They rely on changes in the process chemistry of the HDP CVD system, rather than hardware modifications, to modify the local deposition rates on the wafer. The invention provides methods of modifying the film profile by altering the composition of the reactive gas mixture, in particular the hydrogen content. In this manner, deposition profile and wiw uniformity are decoupled from deposition rate, and can be controlled without hardware modifications.

Owner:NOVELLUS SYSTEMS

Method and system for treating a substrate with a high pressure fluid using a peroxide-based process chemistry in conjunction with an initiator

InactiveUS20060180174A1Promote formationPhotomechanical apparatusElectrostatic cleaningProcess chemistryCombined use

A method and system is described for treating a substrate with a high pressure fluid, such as carbon dioxide in a supercritical state. A process chemistry containing a process peroxide is introduced to the high pressure fluid for treating the substrate surface. The peroxide-based chemistry is used in conjunction with an initiator, wherein the initiator facilitates the formation of a radical of the process peroxide.

Owner:TOKYO ELECTRON LTD

Method for treating a substrate

InactiveUS7268084B2Reduce harmReduce the possibility of damageElectric discharge tubesDecorative surface effectsProcess chemistryEngineering

A method of treating a substrate includes disposing the substrate in a processing chamber having a first chamber portion configured to define a plasma space and a second chamber portion configured to define a process space, introducing a first gas to the plasma space and introducing a second gas to the process space. A plasma is formed in the plasma space from the first gas using a plasma source coupled to the upper chamber portion, and a process chemistry for treating the substrate is formed in the process space by providing a grid positioned between the first chamber portion and the second chamber portion such that the plasma can diffuse from the plasma space to the process space.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com