Semiconductor photochemical catalyst with copper phosphate modified surface and preparation method thereof

A photocatalyst and surface modification technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy recombination, reduced photocatalytic efficiency, and large band gap of TiO2. Simplicity, increased photocatalytic rate, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Method 1 The preparation method 1 of the semiconductor photocatalyst with copper phosphate modified surface comprises the following steps:

[0044] 1) At room temperature, the precursor semiconductor photocatalyst is dispersed in an aqueous solution of copper ions as a precipitant, and the molar ratio of semiconductor photocatalyst to copper ions is 12500:2~12500:780;

[0045] 2) Under vigorous stirring, add phosphate aqueous solution, the molar ratio of semiconductor photocatalyst to phosphate anion is 12500:1~12500:520, and the molar ratio of copper ion to phosphate anion is 0.75:1~3:1;

[0046] 3) Make the pH of the reaction solution between 6 and 11 by adding a pH regulator;

[0047] 4) At room temperature, stir for 30 minutes and sonicate for 30 minutes;

[0048] 5) The precipitate is filtered, washed with water, dried at 70°C to 120°C, and ground into powder to obtain a semiconductor photocatalyst with a copper phosphate-modified surface.

[0049] The above proc...

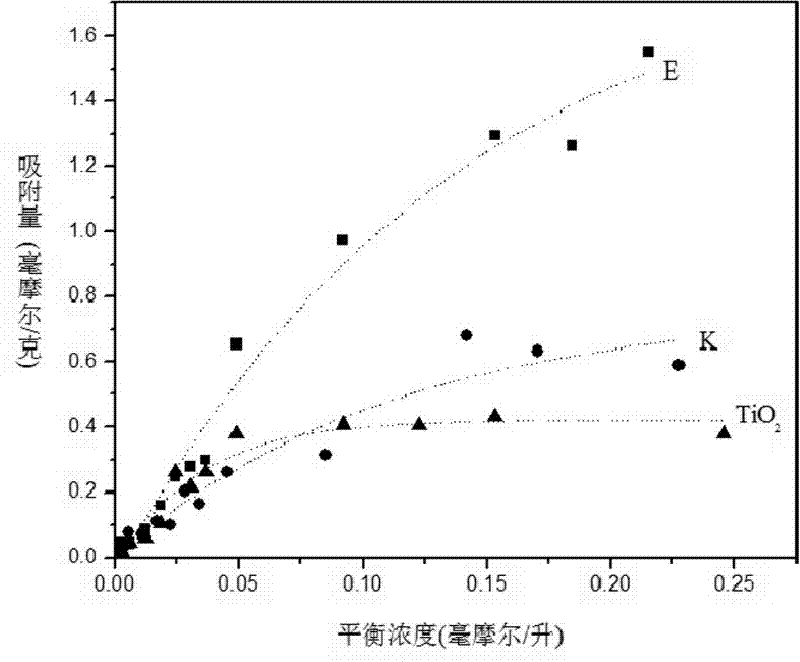

Embodiment 1

[0087] Get 2.6g commercial titanium dioxide, disperse in 40ml concentration and be 0.516mM Cu(NO 3 ) 2 In the aqueous solution (Solution S1), placed on a magnetic stirrer at room temperature to stir, slowly drop 40mL of Na with a concentration of 0.762mM 3 PO 4 aqueous solution (solution S2). By adding 20% dilute ammonia water, the pH value of the control system is about 10. After the dropwise addition is completed, continue stirring for 30 min and ultrasonication for 30 min. The resulting precipitate was filtered, washed, and dried at 90° C. to obtain a titanium dioxide catalyst A with a copper phosphate-modified surface. where TiO 2 With Cu element, PO 4 3- The feeding molar ratio of ions is 12500:7.77:11.96. Using the above photocatalytic activity evaluation method, after 2 hours of irradiation under ultraviolet light, the degradation rates of catalyst A and titanium dioxide to phenol were 42.61% and 20.33%, respectively. Obviously, under the same conditions, Cat...

Embodiment 2

[0090] Experimental condition, step are the same as embodiment one, wherein change the feed ratio of each material, get 0.9949g commercial titanium dioxide, be dispersed in 40ml concentration and be the Cu(NO 3 ) 2 In the aqueous solution, add dropwise 40ml of Na with a concentration of 2.027mM 3 PO 4 Aqueous solution, in which TiO 2 With Cu element, PO 4 3-The feeding molar ratio of ions is 12500:39.87:81.51. Using the above photocatalytic activity evaluation method, after irradiating with ultraviolet light for 2 hours, the degradation rates of catalyst B and titanium dioxide to phenol were 23.77% and 20.33%, respectively.

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com