Method and device for oxidative conversion of sodium sulfide in alkali fusant

A conversion device and alkali-melt technology, applied in the field of pulp and paper making, can solve the problems of large evaporation of dilute black liquor and inability to recover lignin, reduce production costs, facilitate flow and discharge of furnace body, and improve oxidation reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

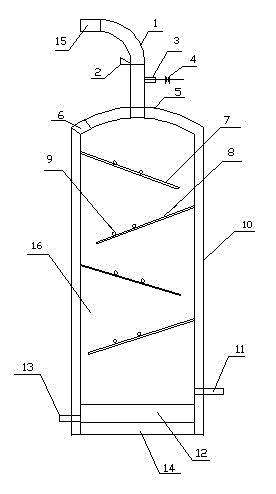

[0040] Such as figure 1 , a method for oxidative conversion of sodium sulfide in an alkali melt, comprising the following steps:

[0041] 1. Furnace body preheating: open the hot gas flow control valve 2, introduce the hot tail gas from the furnace of the alkali recovery furnace, and preheat the furnace cavity 16 through the heat insulating pipe 1, and the preheating temperature is 600°C;

[0042] 2. Importing alkali melt: the alkali melt from the alkali recovery furnace enters the furnace chamber 16 through the alkali melt inlet 6, and the flow rate of the alkali melt is 2000kg / h (the processing capacity of the alkali recovery furnace is 100 tons / day);

[0043] 3. Introduce air: open the air flow control valve 4, the air enters from the air inlet 3, and the air flow is 50000m 3 / h, and mixed with hot gas in the heat-insulating pipe 1 to obtain mixed hot gas at 350-600°C;

[0044] 4. Control of hot gas flow: adjust the hot gas flow control valve 2 to control hot tail gas ent...

Embodiment 2

[0049] Such as figure 1 , a method for oxidative conversion of sodium sulfide in an alkali melt, comprising the following steps:

[0050] 1. Furnace body preheating: open the hot gas flow control valve 2, introduce the hot exhaust gas from the furnace of the alkali recovery furnace, and preheat the furnace cavity 16 through the heat insulating pipe 1, and the preheating temperature is 750°C;

[0051] 2. Importing alkali melt: the alkali melt from the alkali recovery furnace enters the furnace chamber 16 through the alkali melt inlet 6, and the flow rate of the alkali melt is 6000kg / h (the processing capacity of the alkali recovery furnace is 300 tons / day);

[0052] 3. Introduce air: open the air flow control valve 4, the air enters from the air inlet 3, and the air flow is 150000m 3 / h, and mixed with hot gas in the heat-insulating pipe 1 to obtain mixed hot gas at 350-600°C;

[0053] 4. Control of hot gas flow: adjust the hot gas flow control valve 2 to control hot tail gas...

Embodiment 3

[0058] Such as figure 1 , a method for oxidative conversion of sodium sulfide in an alkali melt, comprising the following steps:

[0059] 1. Furnace body preheating: open the hot gas flow control valve 2, introduce the hot tail gas obtained by burning fuel oil or fuel, and preheat the furnace chamber 16 through the heat-insulating pipe 1, and the preheating temperature is 900°C;

[0060] 2. Importing alkali melt: the alkali melt from the alkali recovery furnace enters the furnace chamber 16 through the alkali melt inlet 6, and the flow rate of the alkali melt is 50000kg / h (the processing capacity of the alkali recovery furnace is 2500 tons / day);

[0061] 3. Introduce air: open the air flow control valve 4, the air enters from the air inlet 3, and the air flow is 2500000m 3 / h, and mixed with hot gas in the heat-insulating pipe 1 to obtain mixed hot gas at 350-600°C;

[0062] 4. Control of hot gas flow: adjust the hot gas flow control valve 2 to control hot tail gas entering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com