Patents

Literature

2049 results about "Sodium sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium sulfide is the chemical compound with the formula Na₂S, or more commonly its hydrate Na₂S·9H₂O. Both are colorless water-soluble salts that give strongly alkaline solutions. When exposed to moist air, Na₂S and its hydrates emit hydrogen sulfide, which smells like rotten eggs. Some commercial samples are specified as Na₂S·xH₂O, where a weight percentage of Na₂S is specified. Commonly available grades have around 60% Na₂S by weight, which means that x is around 3. Such technical grades of sodium sulfide have a yellow appearance owing to the presence of polysulfides. These grades of sodium sulfide are marketed as 'sodium sulfide flakes'. Although the solid is yellow, solutions of it are colorless.

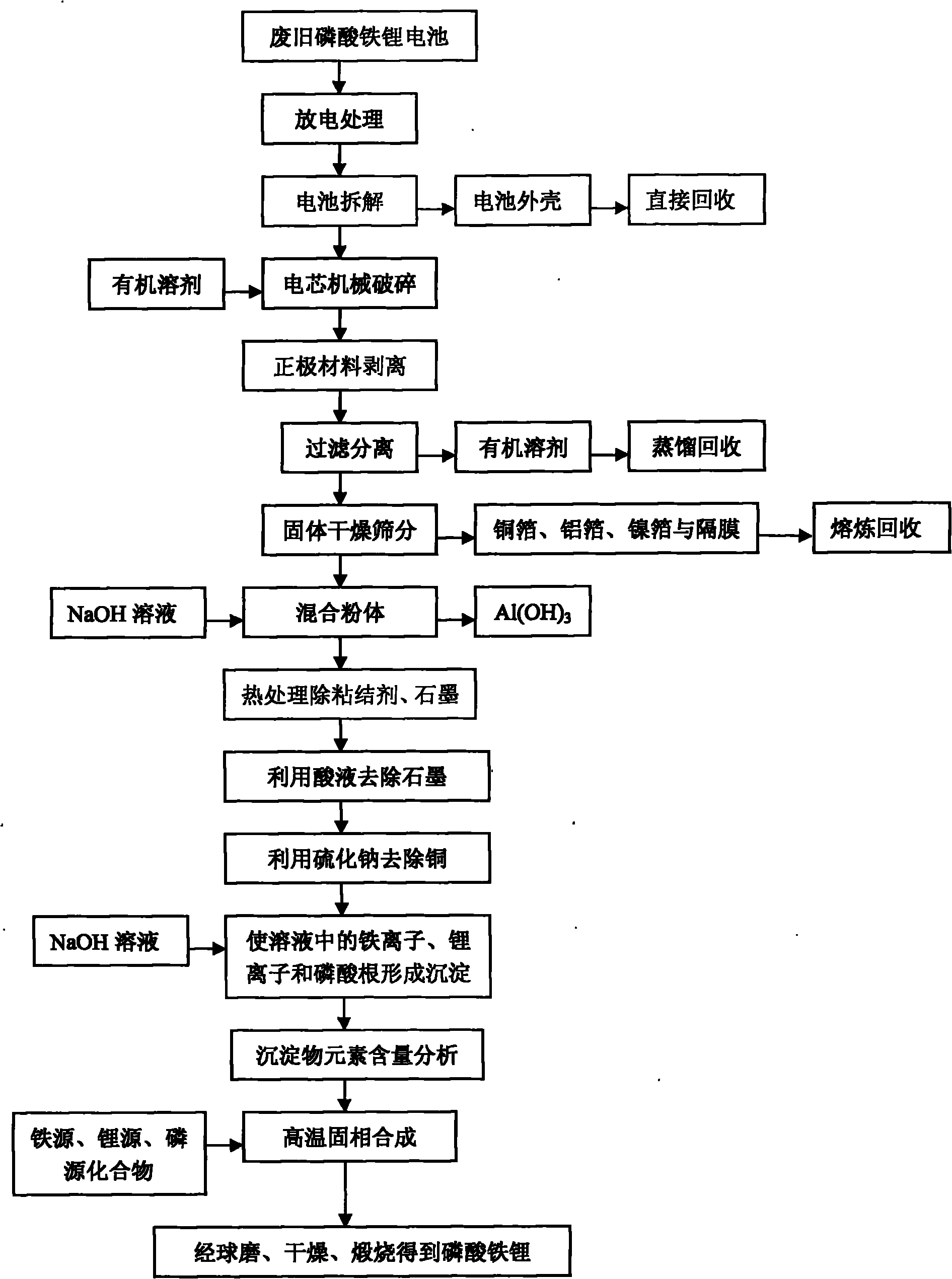

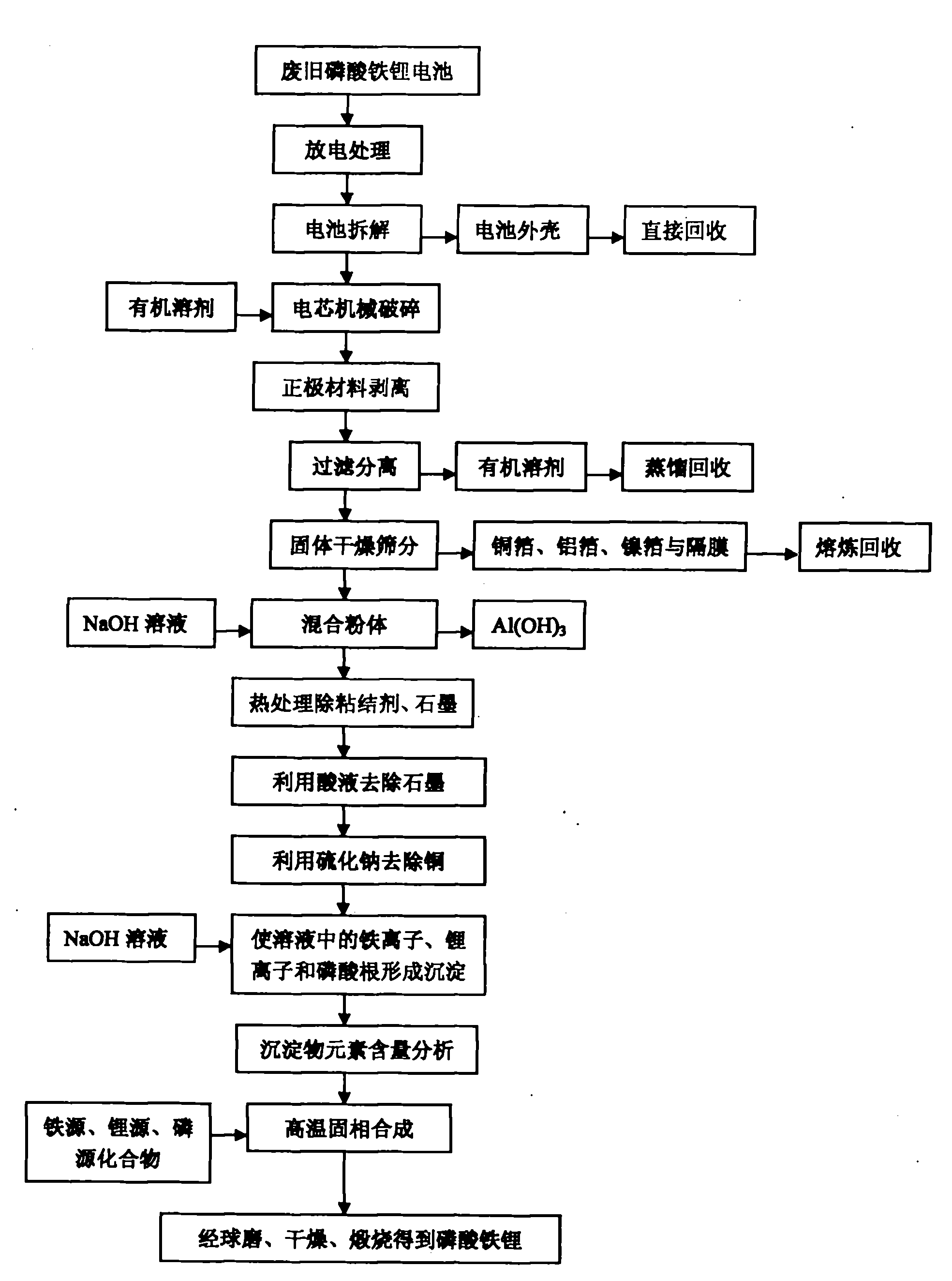

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

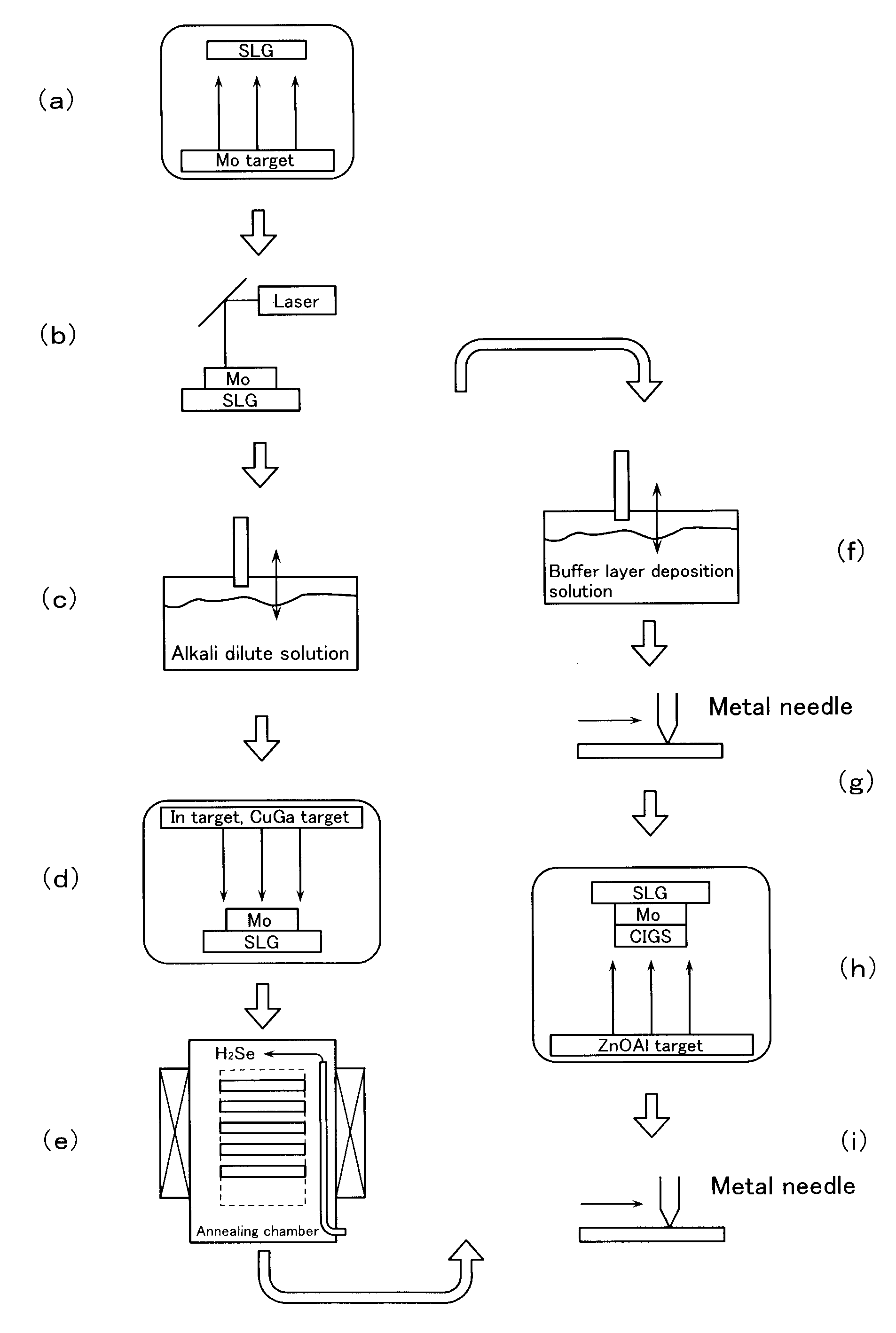

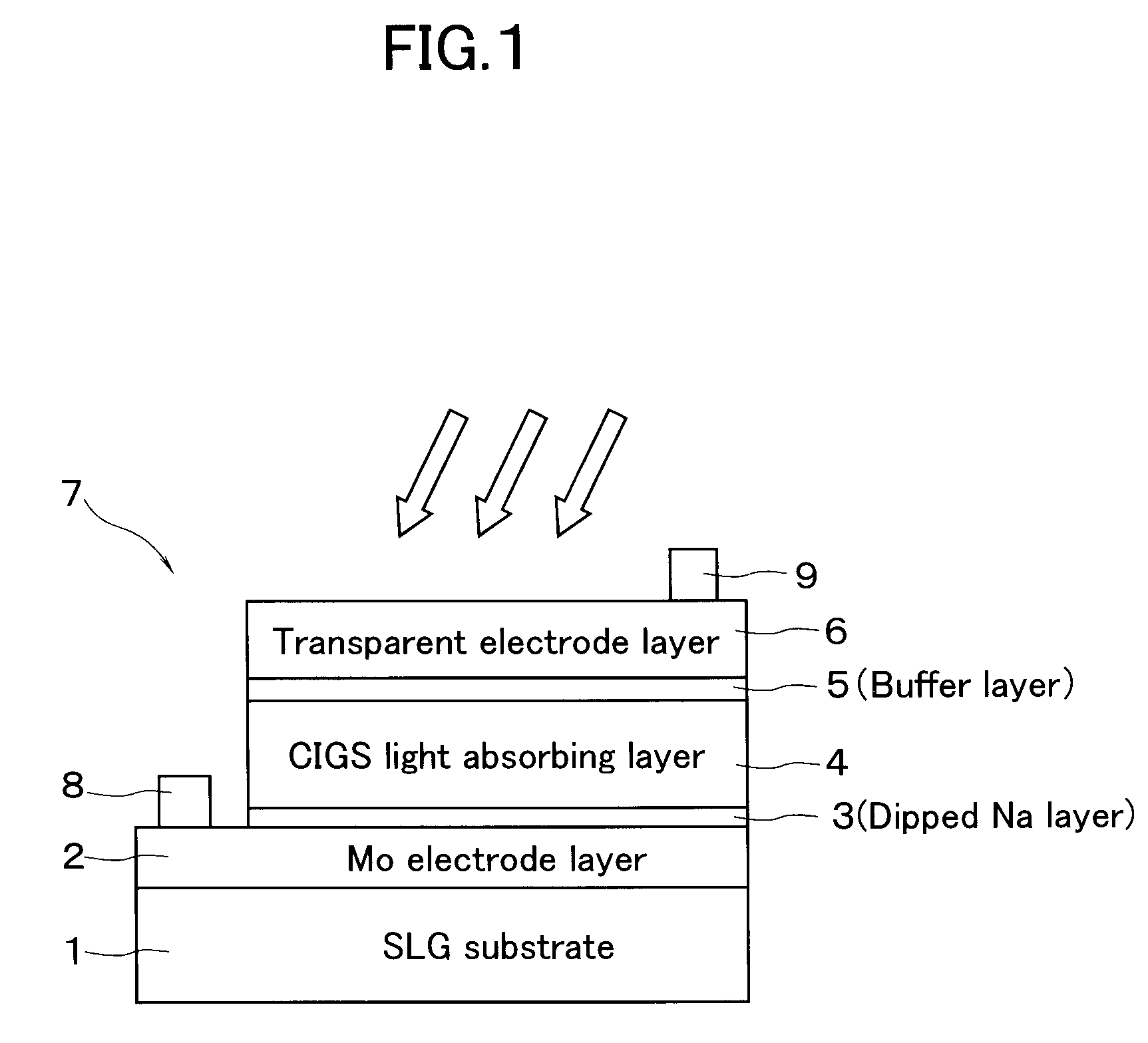

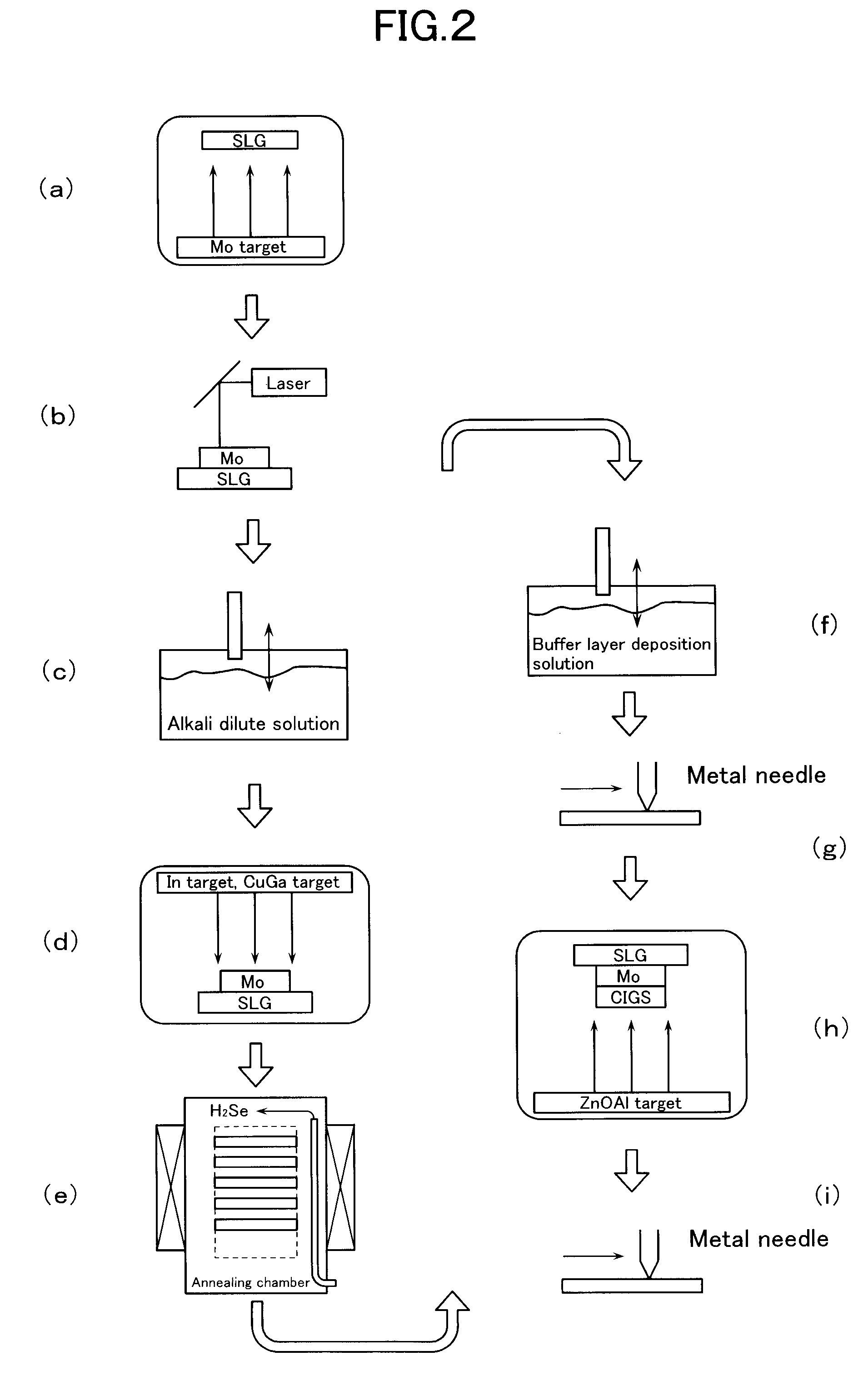

Method for Manufacturing Chalcopyrite Thin-Film Solar Cell

InactiveUS20080283389A1External appearance defectImprove photoelectric conversion efficiencyFinal product manufacturePV power plantsSputteringAlloy

A method for fabricating a chalcopyrite-type thin film solar cell includes a first step of forming onto a Mo electrode layer 2 a precursor including an In metal layer and a Cu—Ga alloy layer by sputtering, a second step of attaching an alkali-metal solution onto the precursor, a selenization step of subjecting the substrate 1 which has undergone both the first and the second steps to a selenization treatment, and a transparent electrode forming step of depositing an optically transparent conductive layer. As the alkali-metal solution, an aqueous solution of an alkali metal compound, such as sodium tetraborate, sodium sulfide, and sodium aluminum sulfate, can be used.

Owner:HONDA MOTOR CO LTD

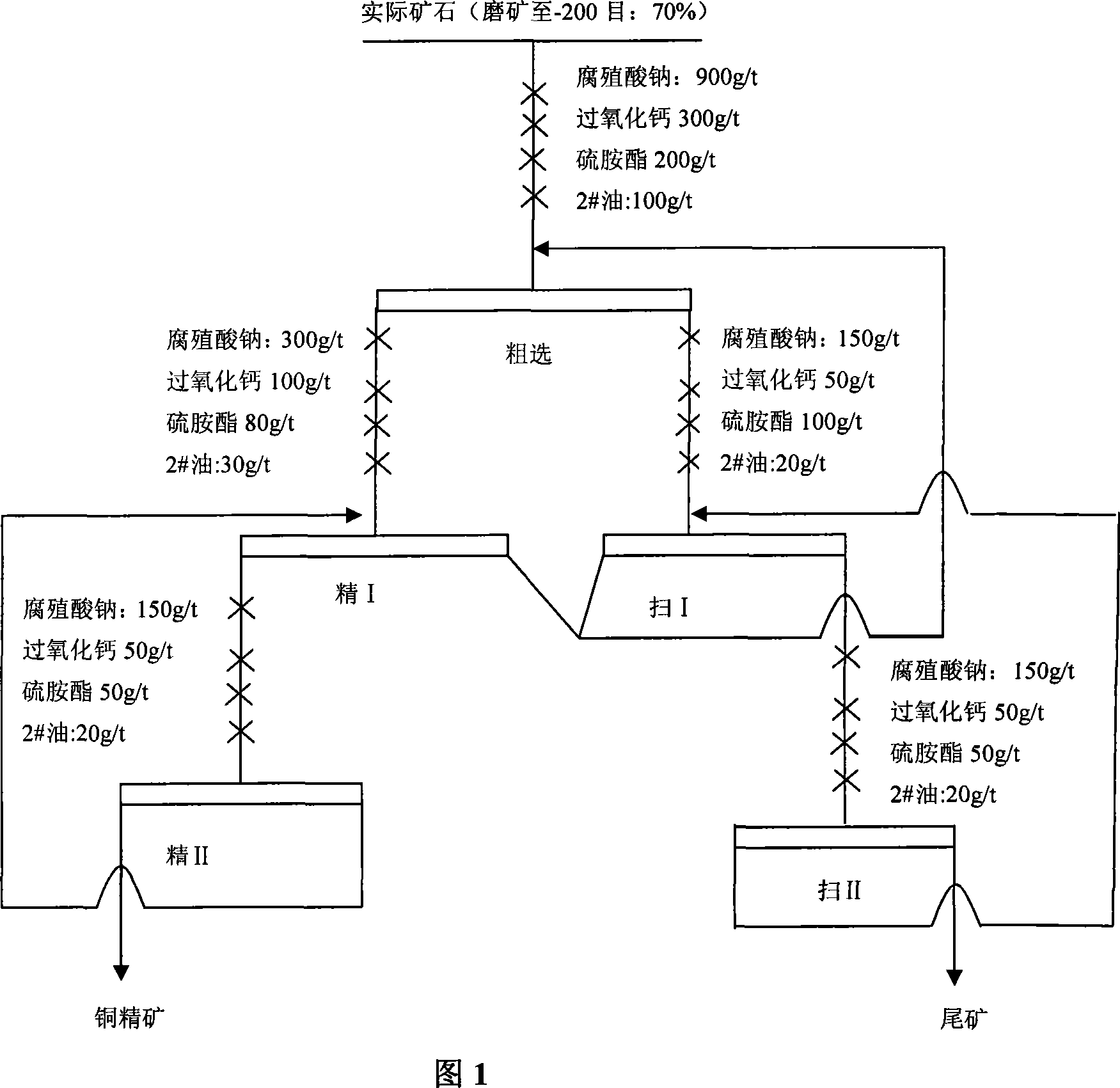

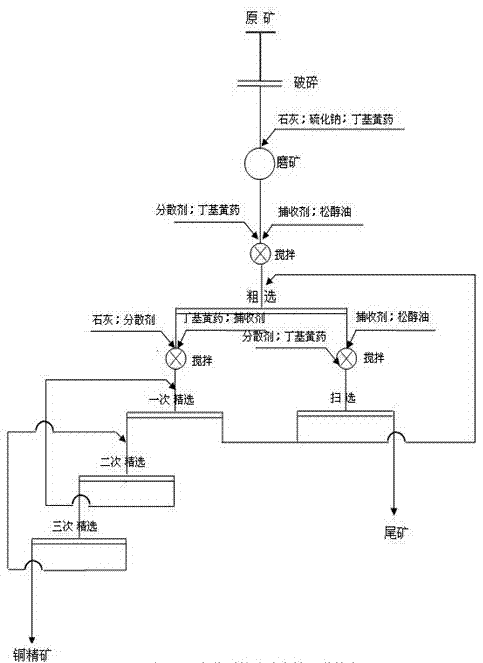

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

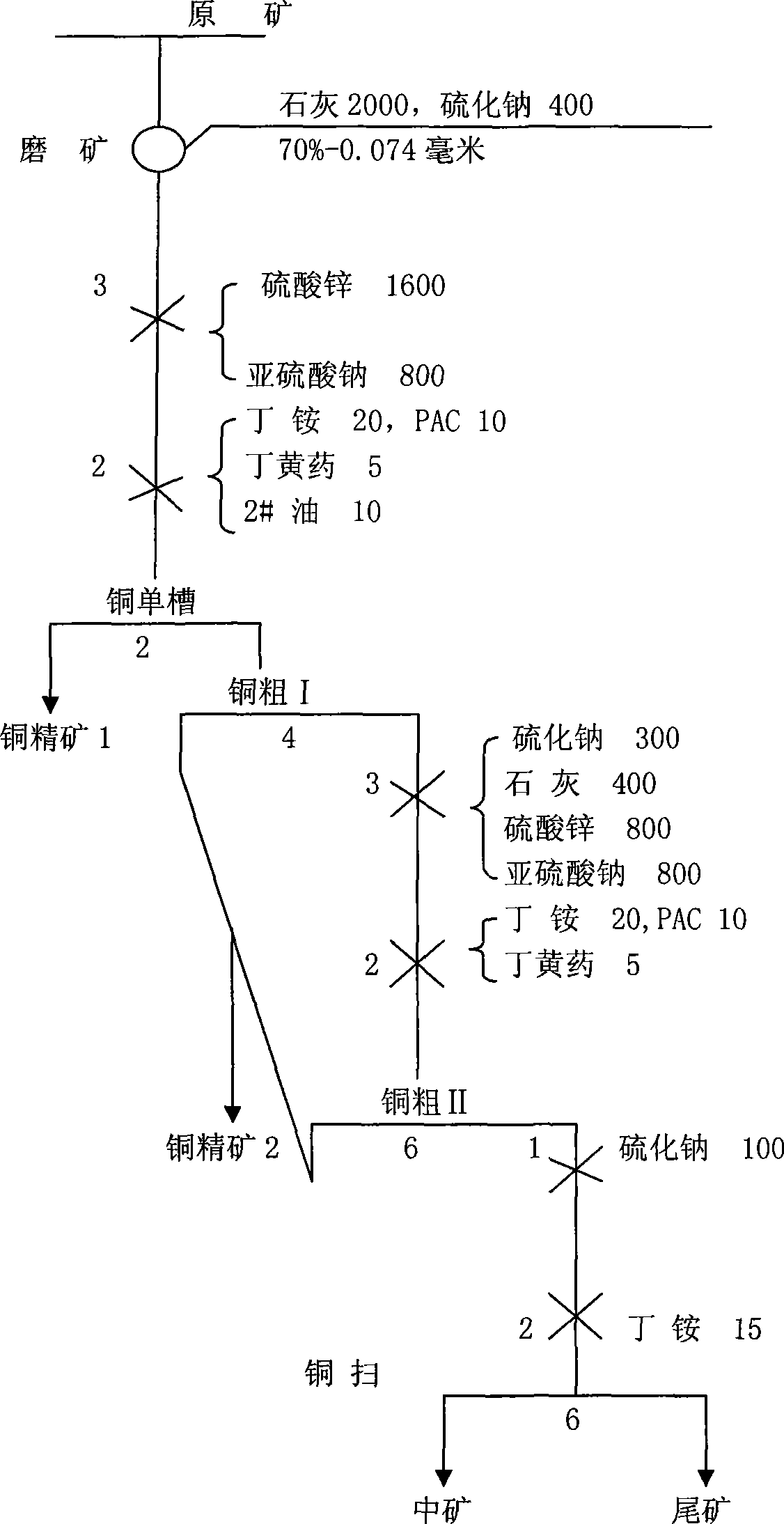

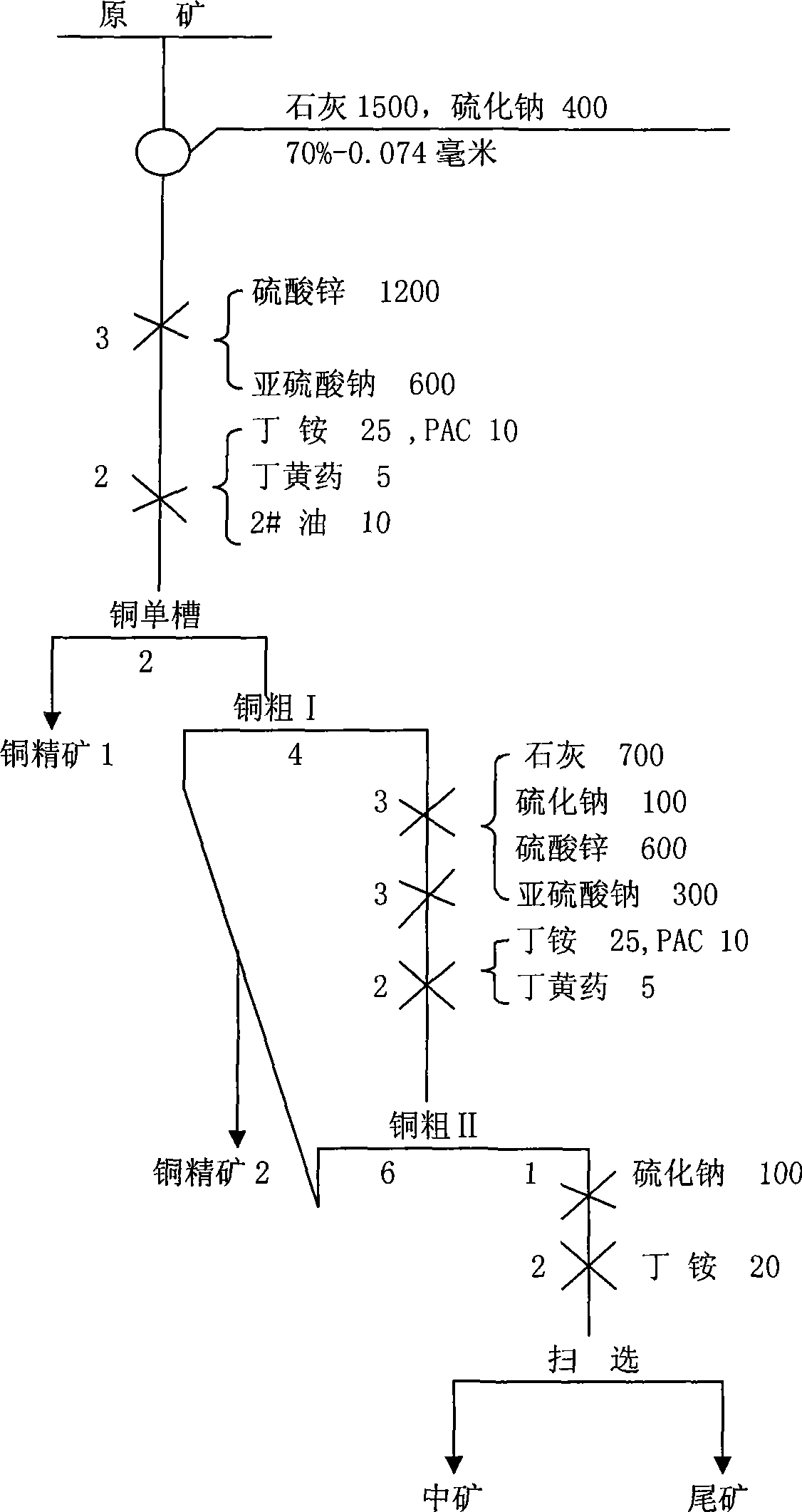

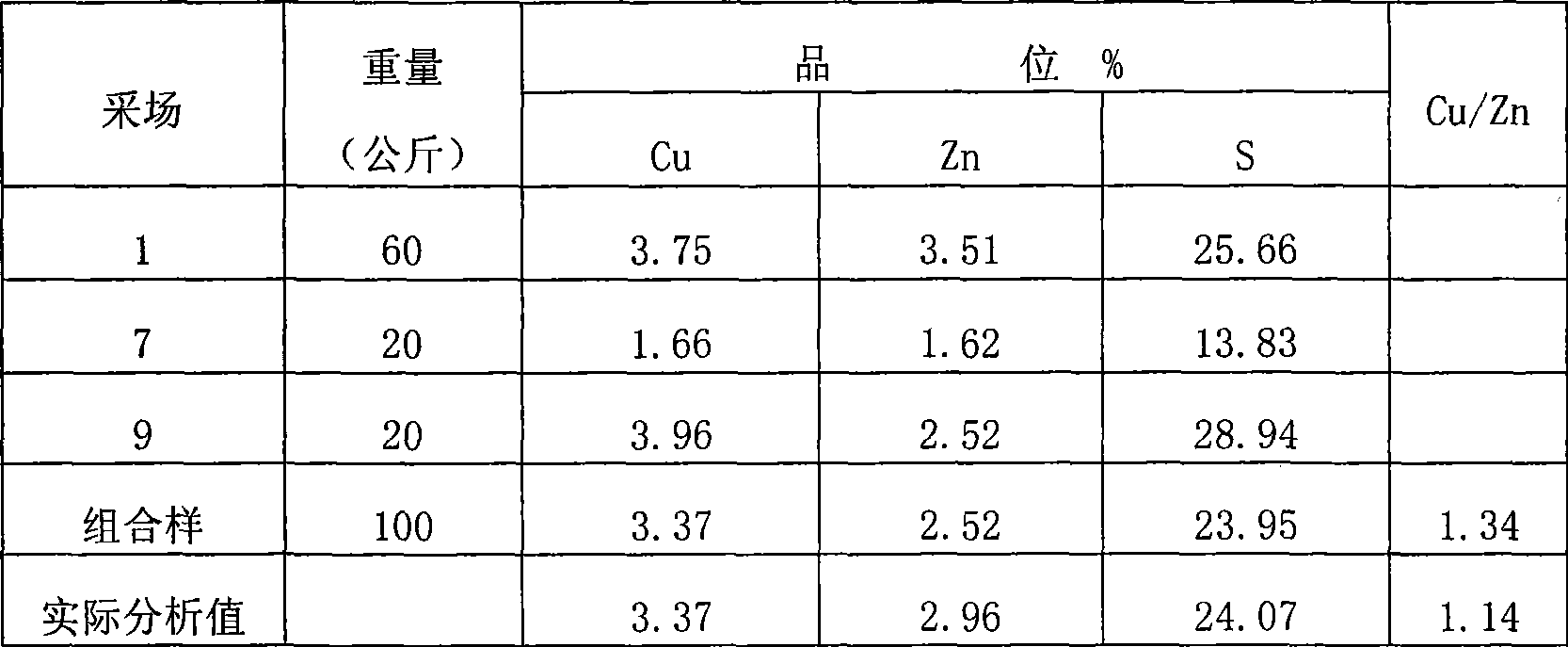

Copper-zinc separation beneficiation method

InactiveCN101428250ARaise the gradeRealize zinc suppression and floating copperFlotationSulfite saltSulfate

The invention relates to a copper-zinc separation beneficiation method which comprises the following steps: (1) primary grinding, that is, adopting a combined depressant comprising lime, sodium sulfide, zinc sulfate, and sodium sulfite under the condition that the size and the content of grinding particles are respectively -0.074 mm and 65 to 70 percent; (2) copper rough concentrates regrinding and concentration, that is, selecting out high-quality copper concentrates which contain high-grade copper and silver, but low zinc by adopting single groove speed flotation method and continually using the combined depressant constituted by lime, sodium sulfide, zinc sulfate, and sodium sulfite, so as to realize the zinc depressing and copper flotation; (3) zinc-sulfur separation, that is, using butyl xanthate as a collecting agent to float zinc, obtaining zinc-sulphur bulk concentrate, conducting pulp conditioning by adding lime so as to depress sulfur and float copper and obtain zinc concentrates and partial sulfur concentrates, conducting the iso-flotation on the tailings and further adding the butyl xanthate to conduct flotation and obtain partial sulfur concentrate. The invention has the advantages of adopting the processes of ore blending, primary grinding, copper rough concentrates regrinding and concentration, and zinc-sulphur iso-flotation technological process, thereby better solving the problem that the copper concentrates contain too much zinc or the copper content in the zinc concentrates is over standard.

Owner:杭州建铜集团有限公司

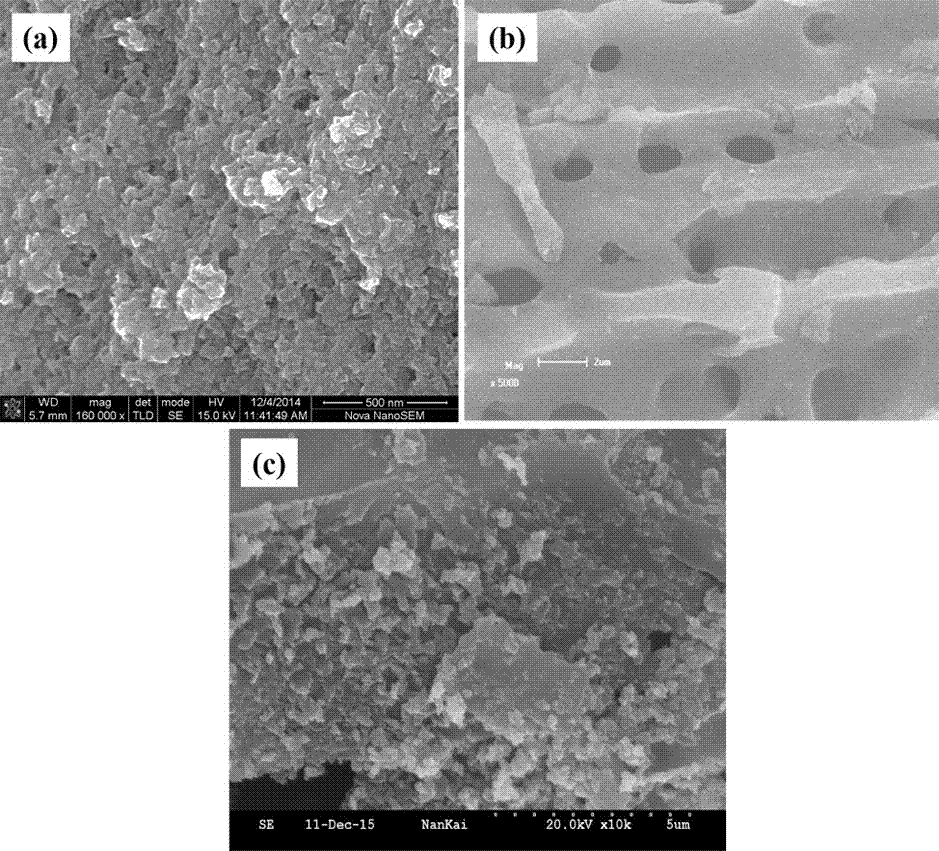

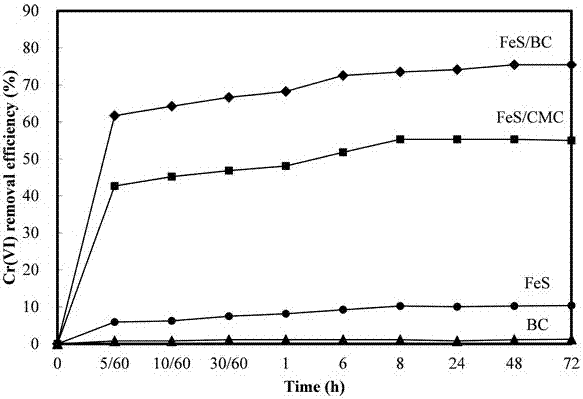

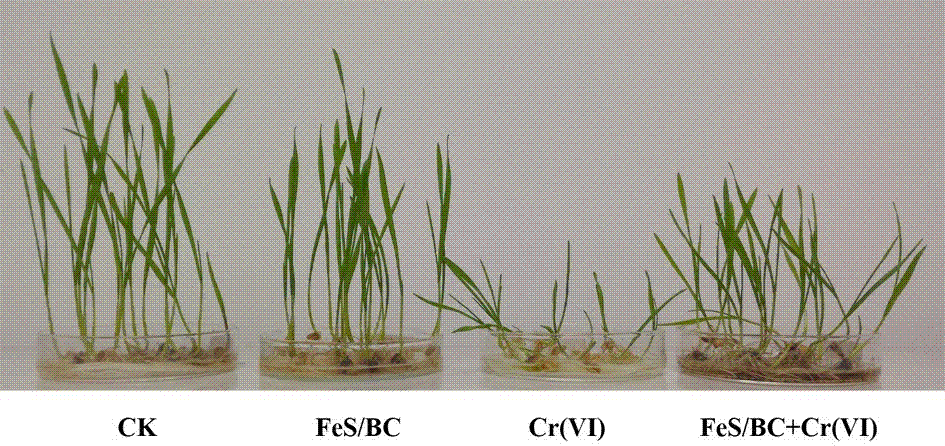

Preparation method and applications of ferrous sulfide/biological carbon composite material

ActiveCN106966456ALow biological toxicityEfficient removal abilityWater contaminantsWater/sewage treatment by sorptionCarboxymethyl celluloseSulfate

The present invention discloses an efficient ferrous sulfide / biological carbon composite material and a preparation method thereof, and applications of the ferrous sulfide / biological carbon composite material in repair of heavy metal pollution water bodies. According to the present invention, biological carbon is adopted as a carrier, a ferrous sulfate solution and the biological carbon are mixed, sodium carboxymethyl cellulose is added as a stabilizer and a dispersant, a sodium sulfide solution is added to the system in a dropwise manner under the nitrogen protection, and vigorous stirring is performed to make the generated ferrous sulfide nanoparticles uniformly grow on the surface of the biological carbon, such that the disadvantage that the ferrous sulfide nanoparticles are easily agglomerated is substantially improved so as to increase the effective contact area between the ferrous sulfide nanoparticles and the pollutant, and the adsorption ability and the oxidation reduction ability of the ferrous sulfide and the biological carbon are integrally combined so as to improve the pollutant removal ability; the preparation method has advantages of simple and rapid process, low production cost, environmental protection and no secondary pollution; and the efficient ferrous sulfide / biological carbon composite material can strongly repair the Cr(VI) polluted water body, can effectively reduce the biological toxicity of the Cr(VI) on wheat seeds, and has wide application prospects in the fields of repair of organic pollution and inorganic pollution in environments.

Owner:NANKAI UNIV

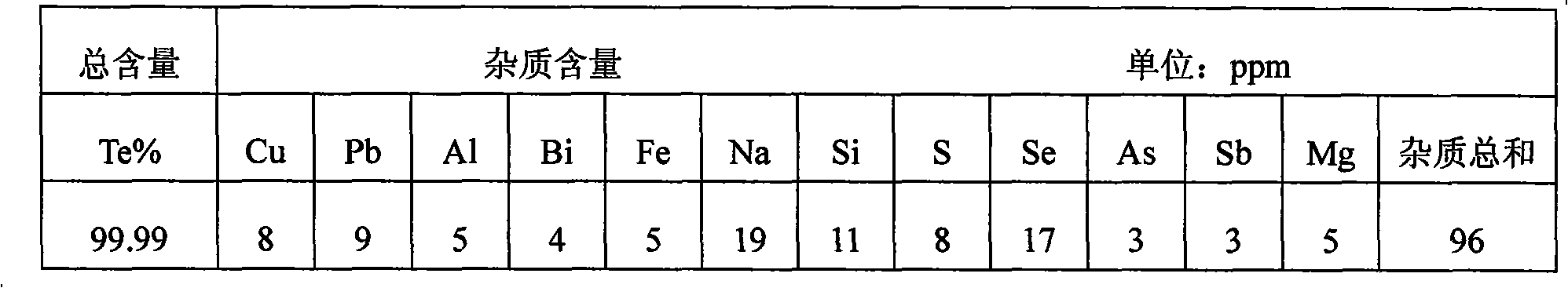

Method for extracting refined tellurium from tellurium-contained smelting slag

InactiveCN101565174AImprove leaching rateReduce invalid consumptionElemental selenium/telluriumSlagTe element

The invention relates to a method for extracting refined tellurium from tellurium-contained smelting slag, which is characterized in that the method comprises the following steps of: oxidizing and leaching inorganic acid, replacing noble metal with a copper plate, depositing the copper by sodium sulfide, counteracting and depositing tellurium, alkaline leaching coarse TeO2, removing impurities by Na2S, concentrating and electrowinning. The method has the advantages of high recovery rate for tellurium, comprehensive and effective recovery of other useful metals, and suitably treating the tellurium-contained waste slag with high water content and small granularity generated in the metallurgy process by a wet-method.

Owner:YONGXING XINTAI SILVER IND

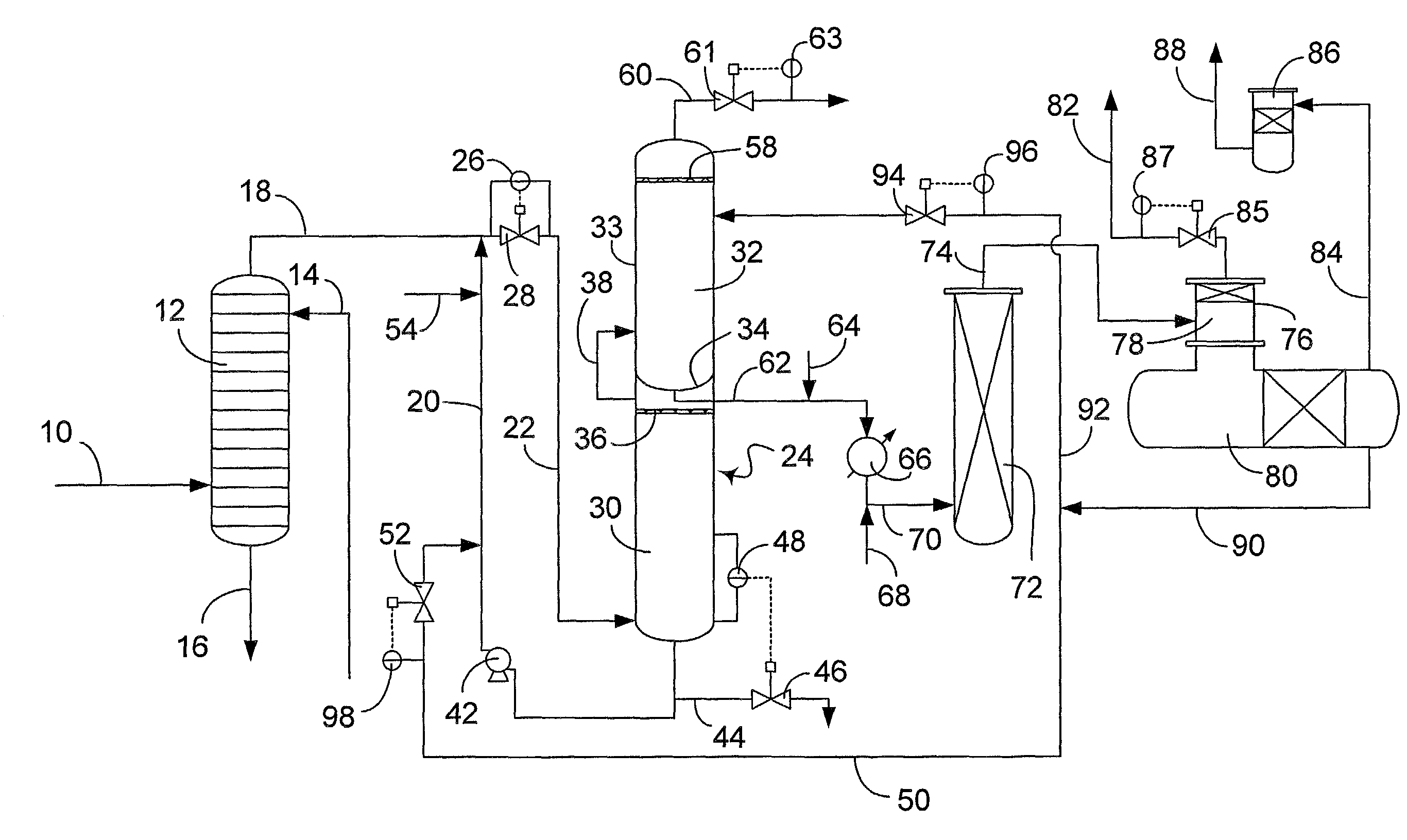

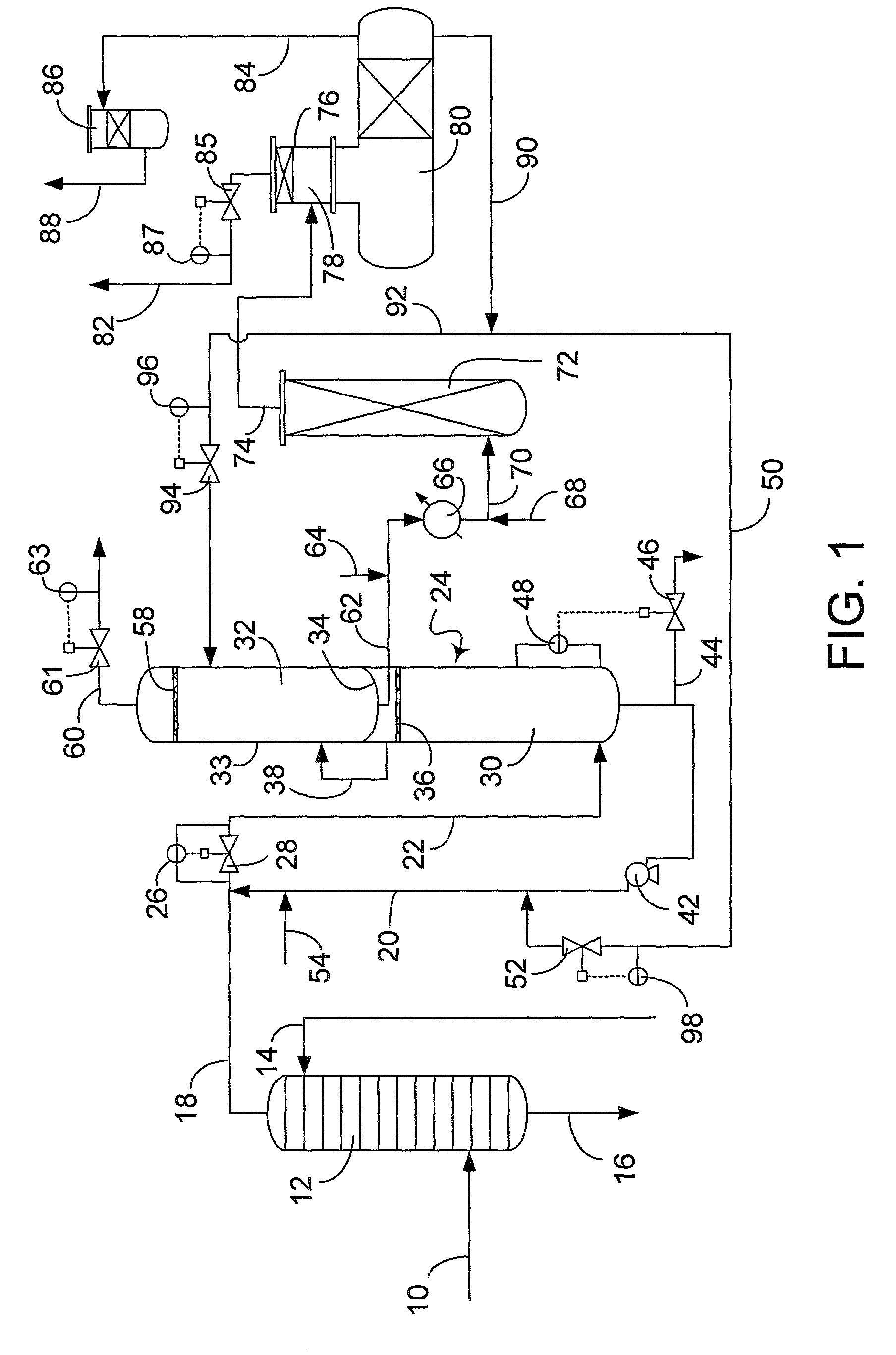

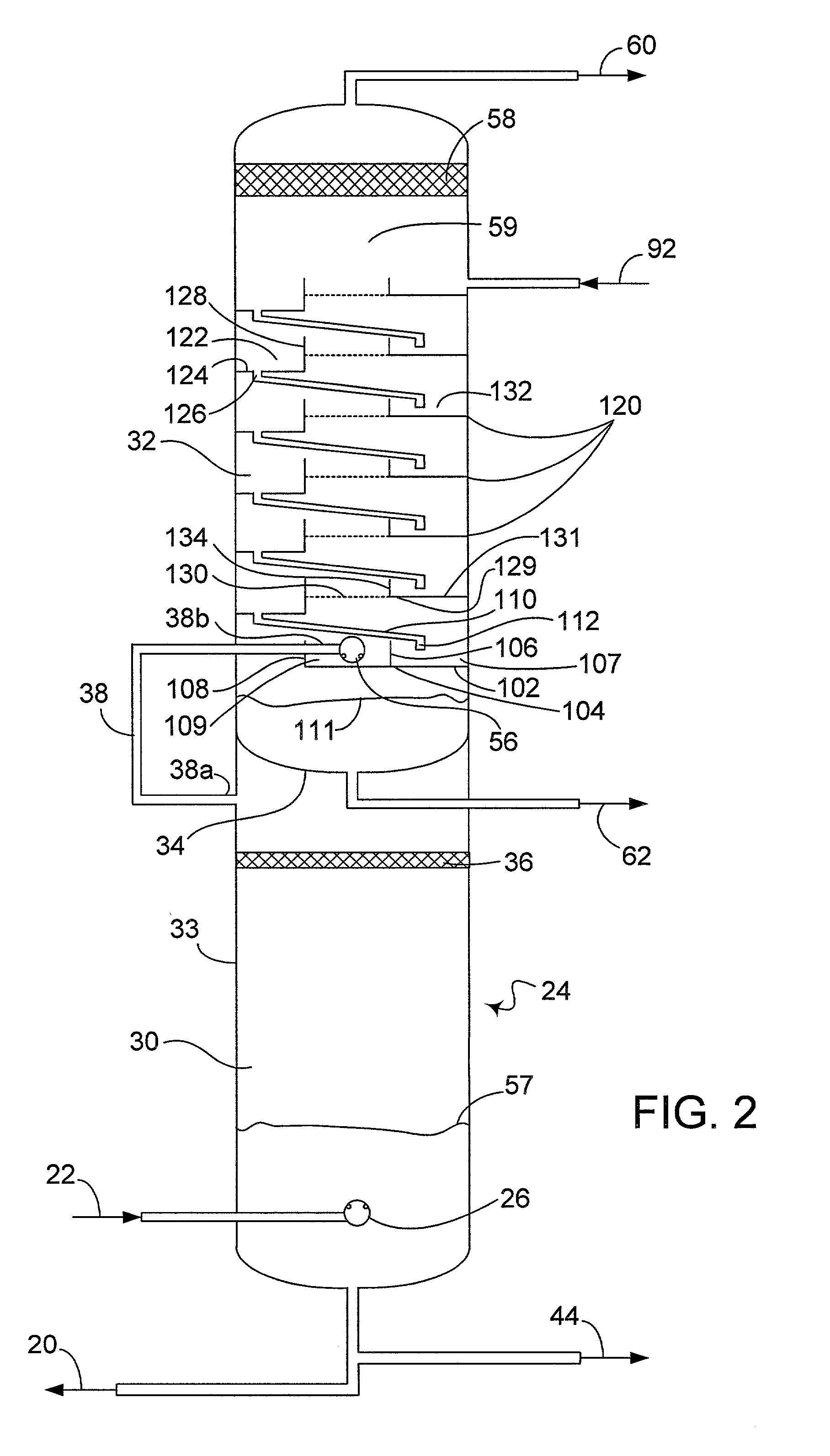

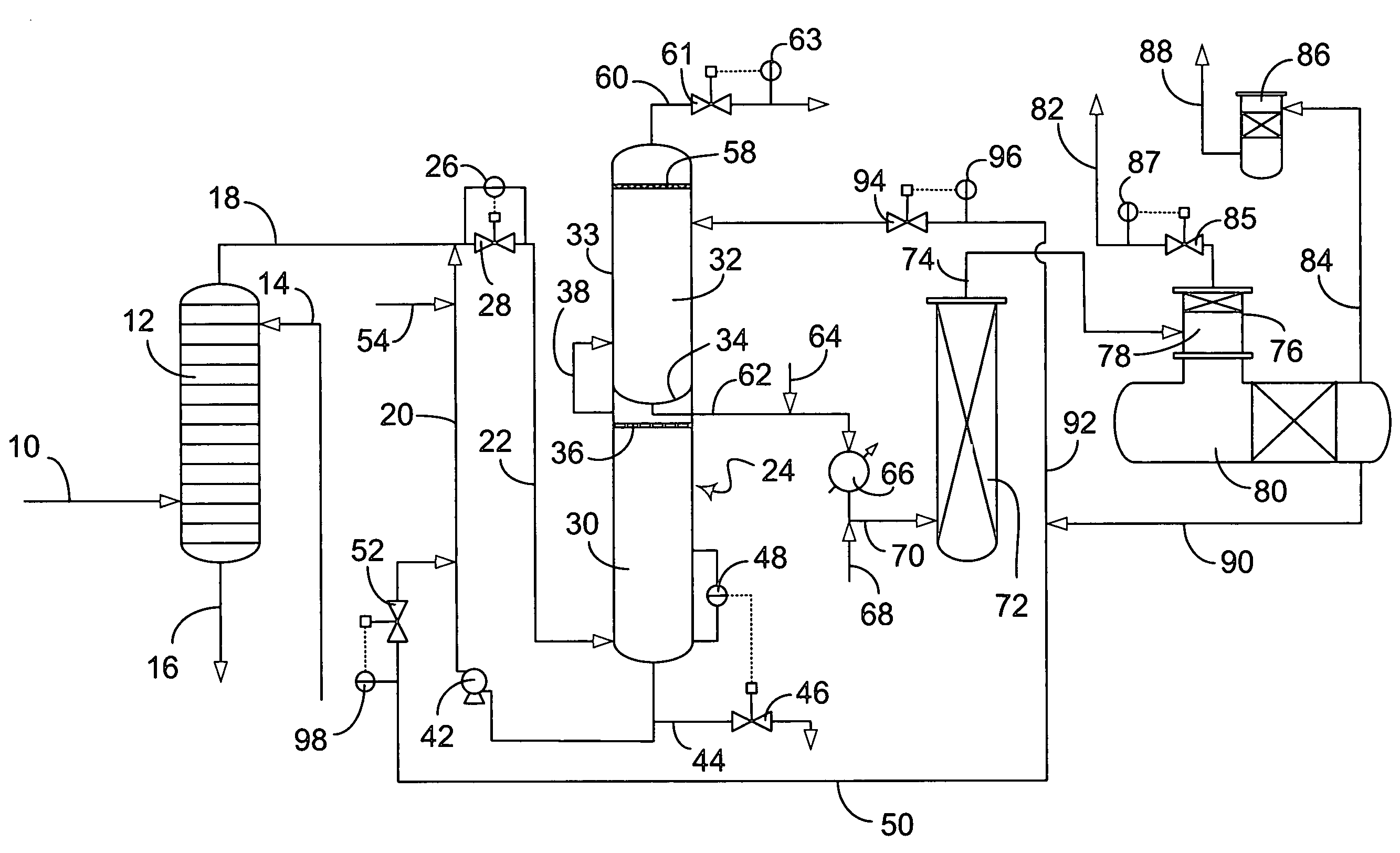

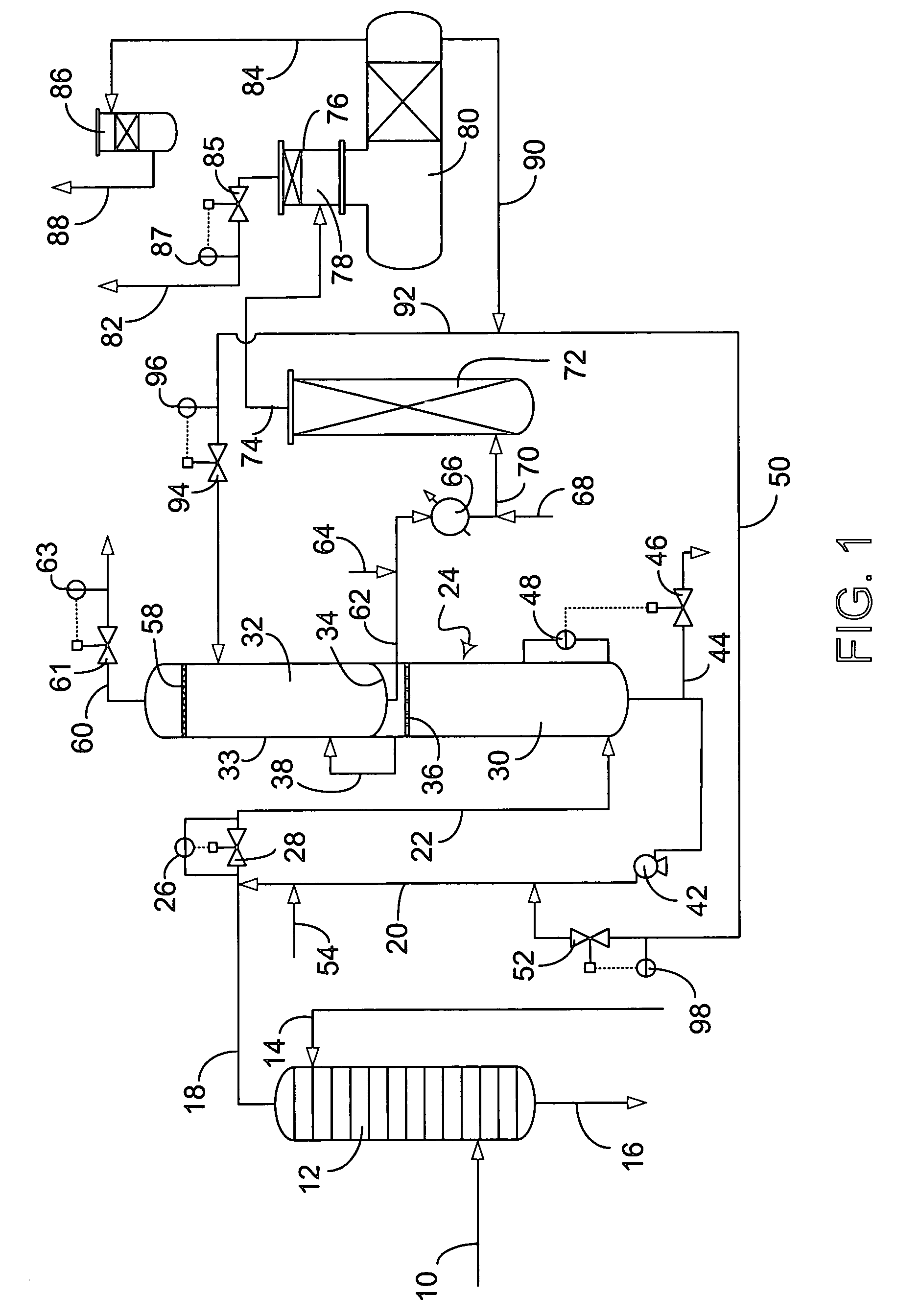

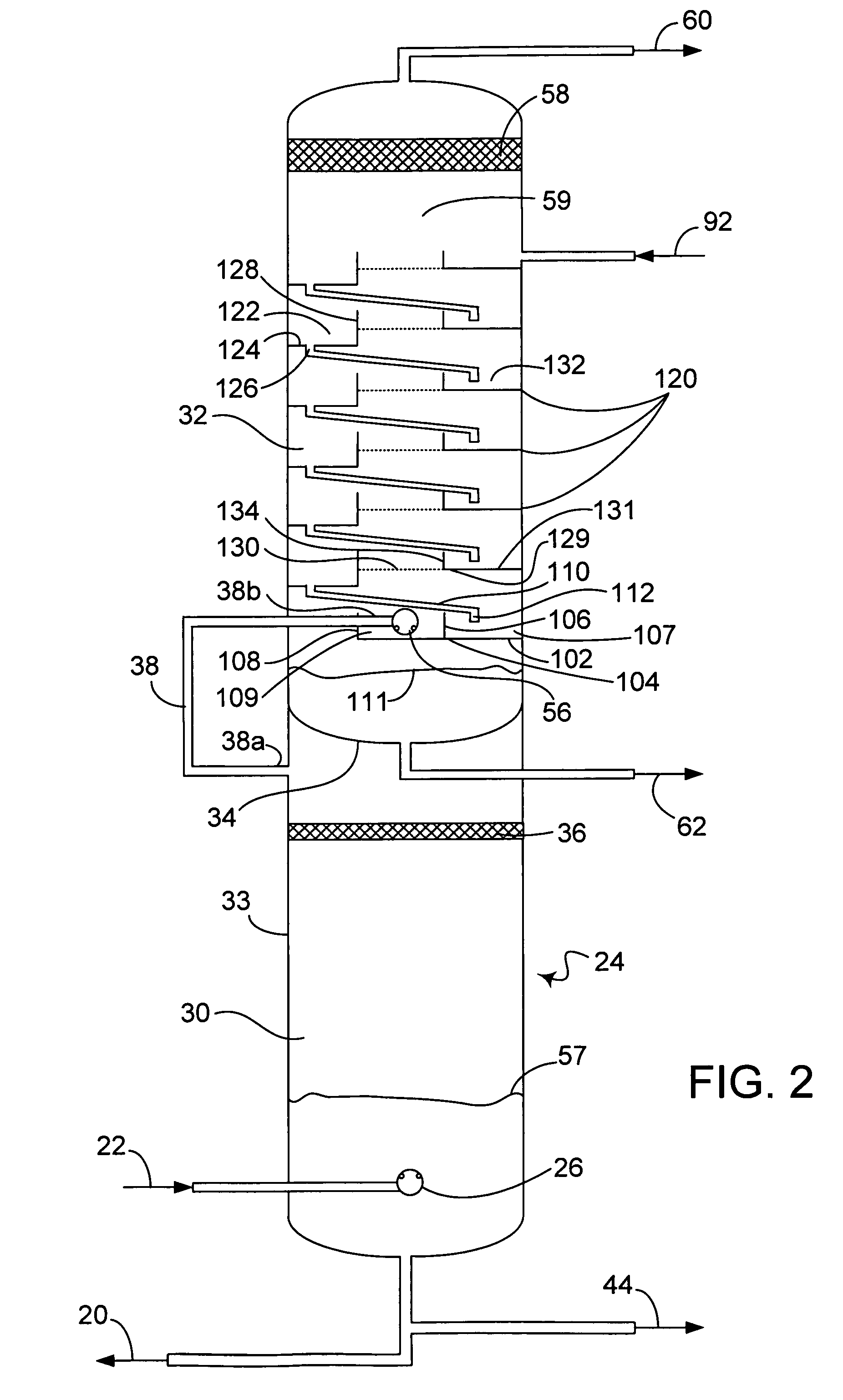

Apparatus and process for extracting sulfur compounds from a hydrocarbon stream

Described is an apparatus and process for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic communicates with an extractor section disposed directly above the prewash section for converting mercaptans to mercaptides by reaction with alkali. Hydrocarbon product exits the extractor section through a coalescer that prevents alkali from exiting with the hydrocarbon product stream.

Owner:UOP LLC

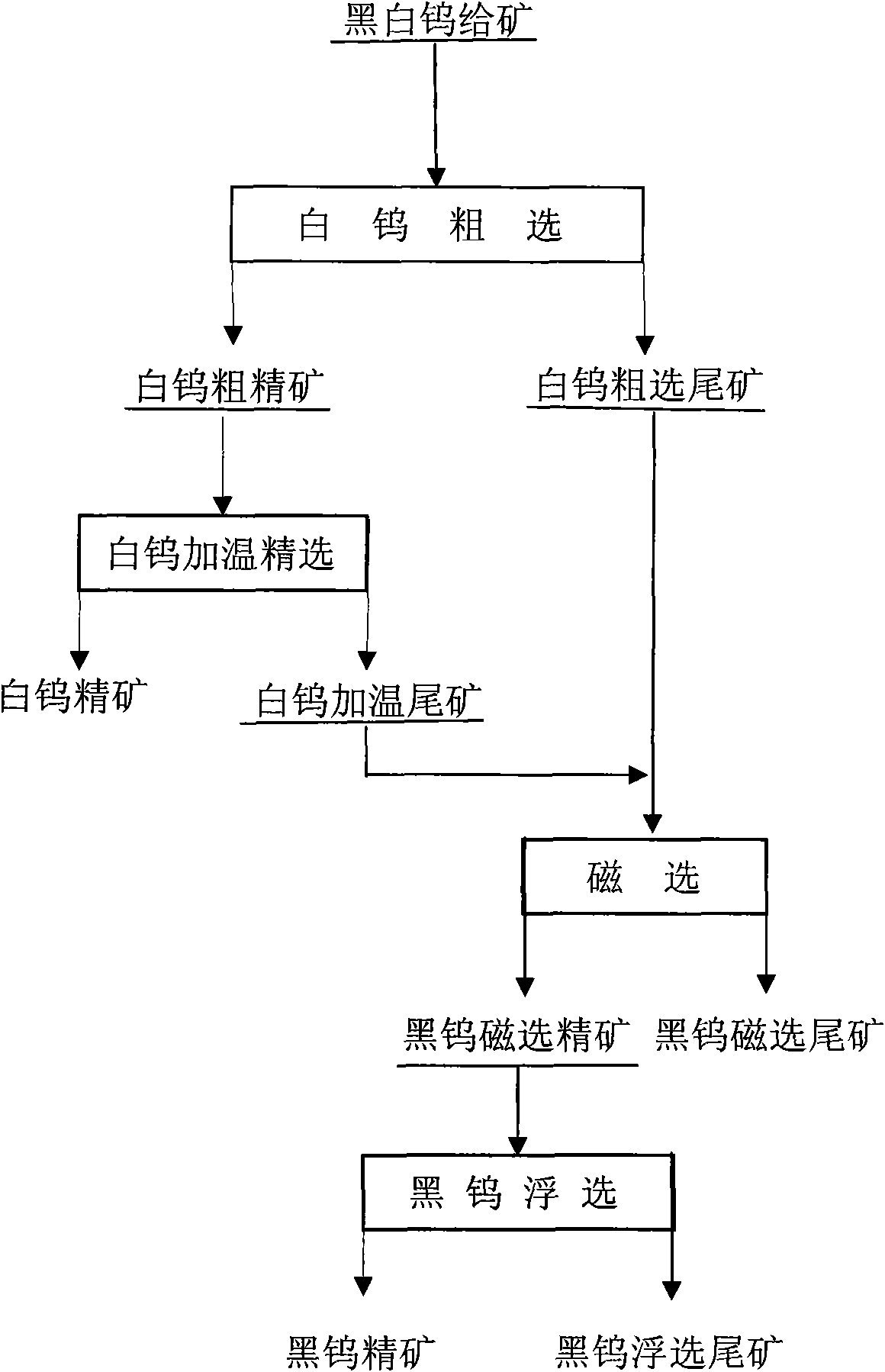

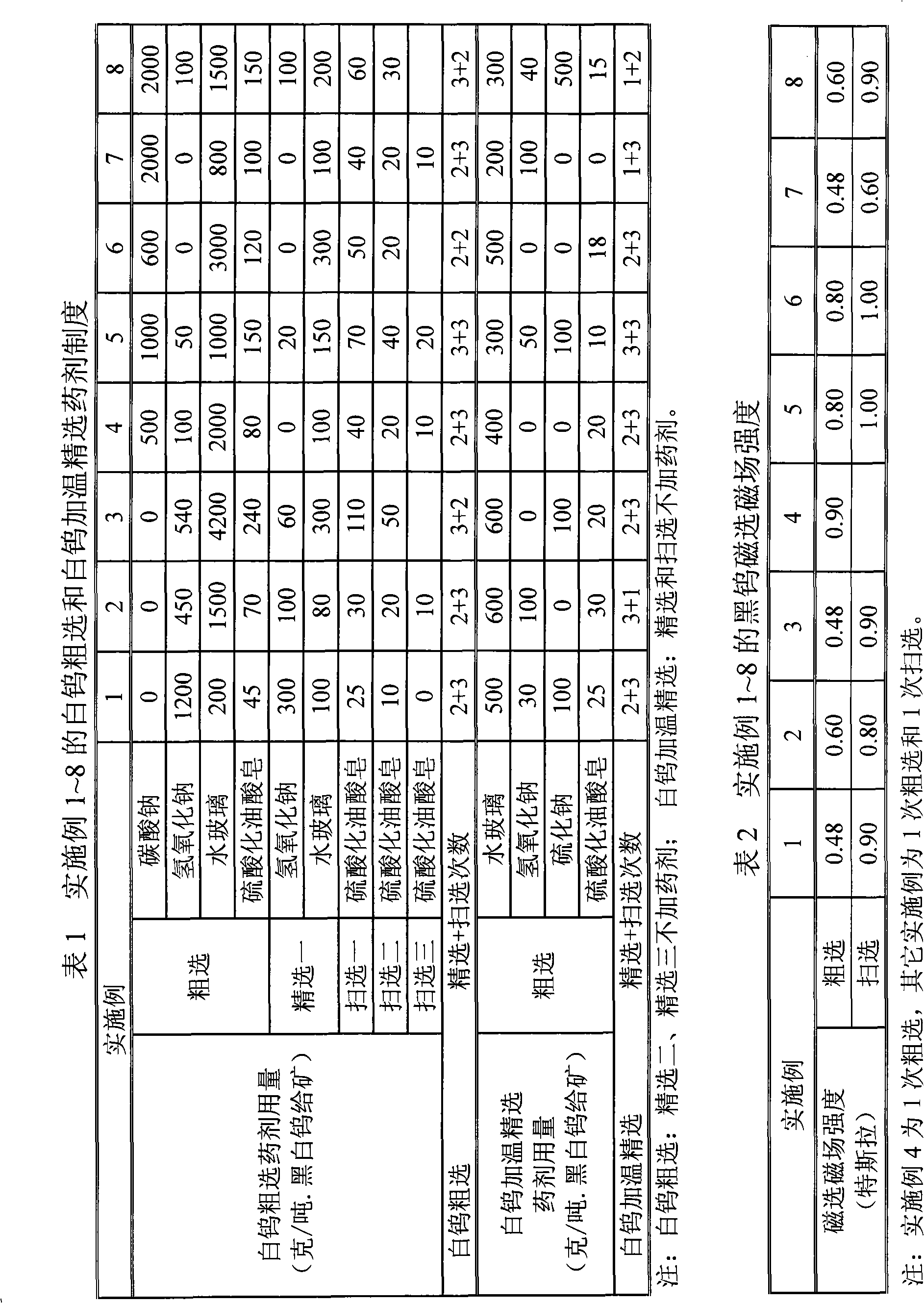

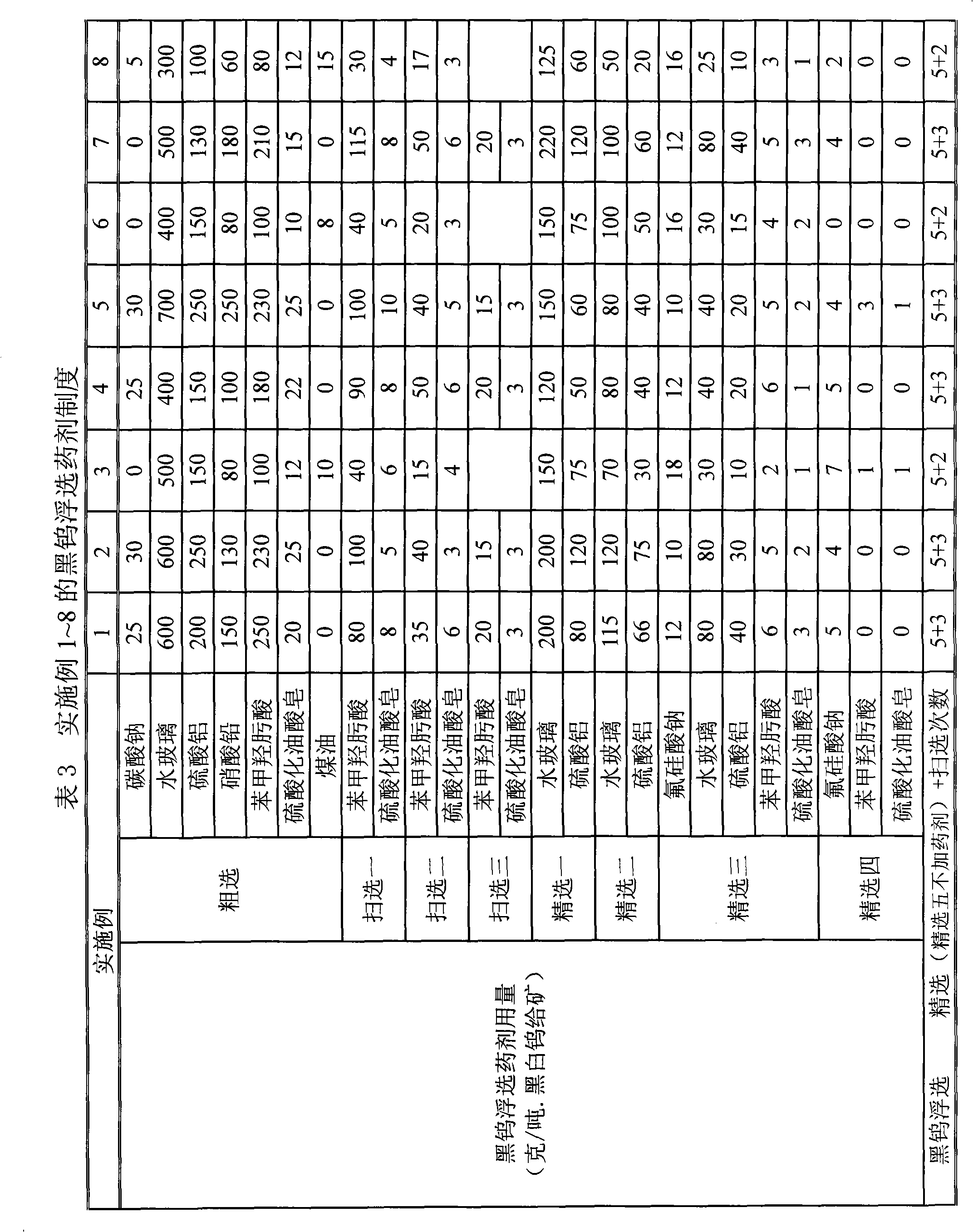

Beneficiation method of black and white tungsten mineral

The invention relates to a beneficiation method of black and white tungsten mineral.The method is characterized in that: black and white tungsten mineral through sulfide floatation and magnetic separation deferrization is added with sodium hydroxide, sodium carbonate, sodium silicate and sulphated nascent soap for white tungsten roughing, so as to obtain white tungsten rough concentrate and white tungsten rougher tailings; the white tungsten rough concentrate is added with sodium silicate, sodium hydroxide, sodium sulfide and sulphated nascent soap for white tungsten warming cleaning, so as to obtain white tungsten concentrate and white tungsten warming tailings; the white tungsten rougher tailings and the white tungsten warming tailings are mixed for magnetic separation, so as to obtain black tungsten magnetic separation concentrate and black tungsten magnetic separation tailings; the black tungsten magnetic separation concentrate is added with sodium carbonate, sodium silicate, aluminum sulfate, lead nitrate, sodium fluosilicate, benzohydroxamic acid, sulphated nascent soap and karaffin oil for black tungsten flotation, so as to obtain black tungsten concentrate and black tungsten flotation tailings. The method of the invention is simple in recovery technology, steady in process, high in tungsten recovery rate and low in reagent cost, the used beneficiation reagent does not pollute the environment, and tailings water can meet emission requirement. The invention is applicable to black and white tungsten mineral with WO3 content of .15-2.0% and black and white tungsten proportion of 1:9 to 9:1.

Owner:广东省资源综合利用研究所

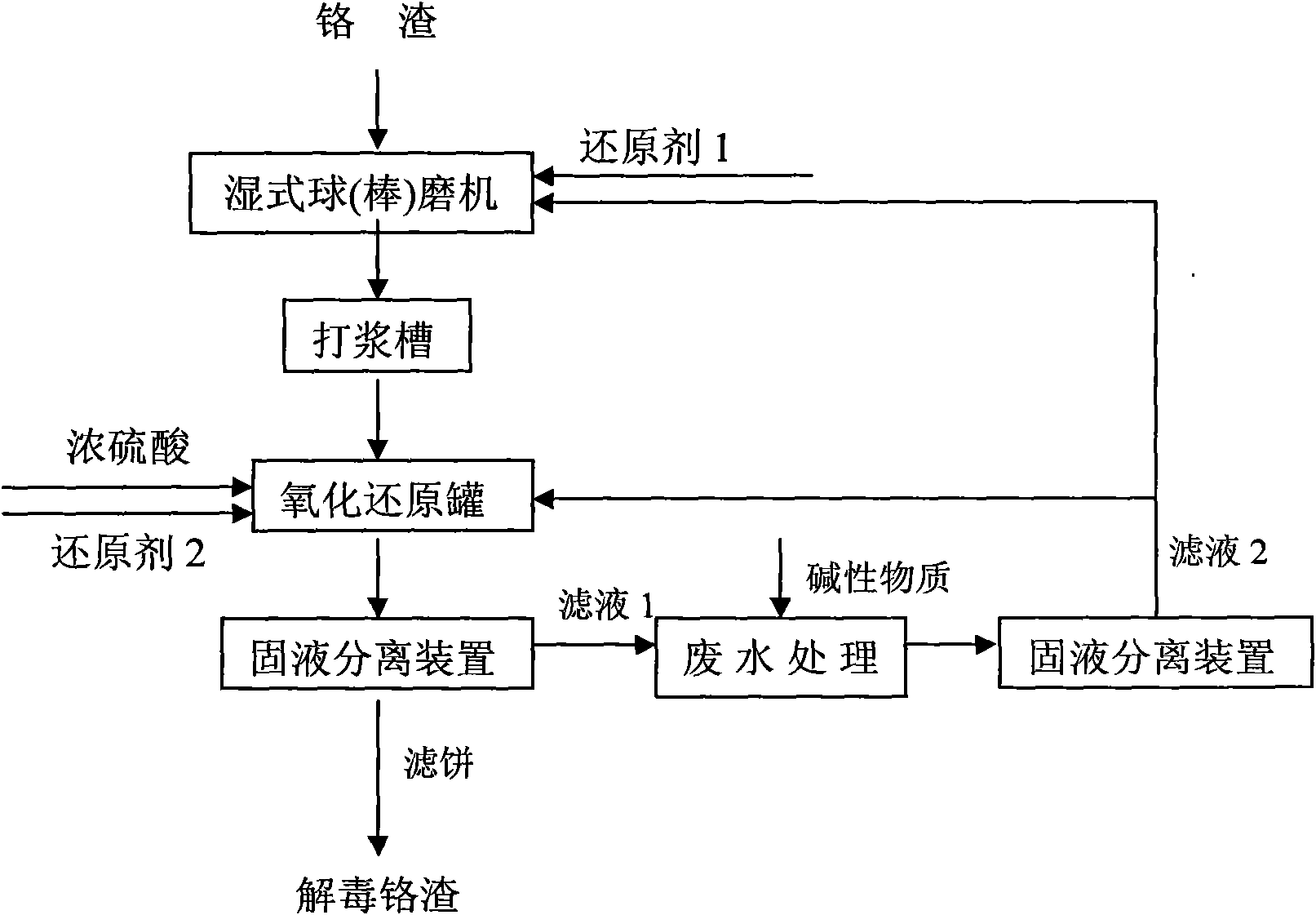

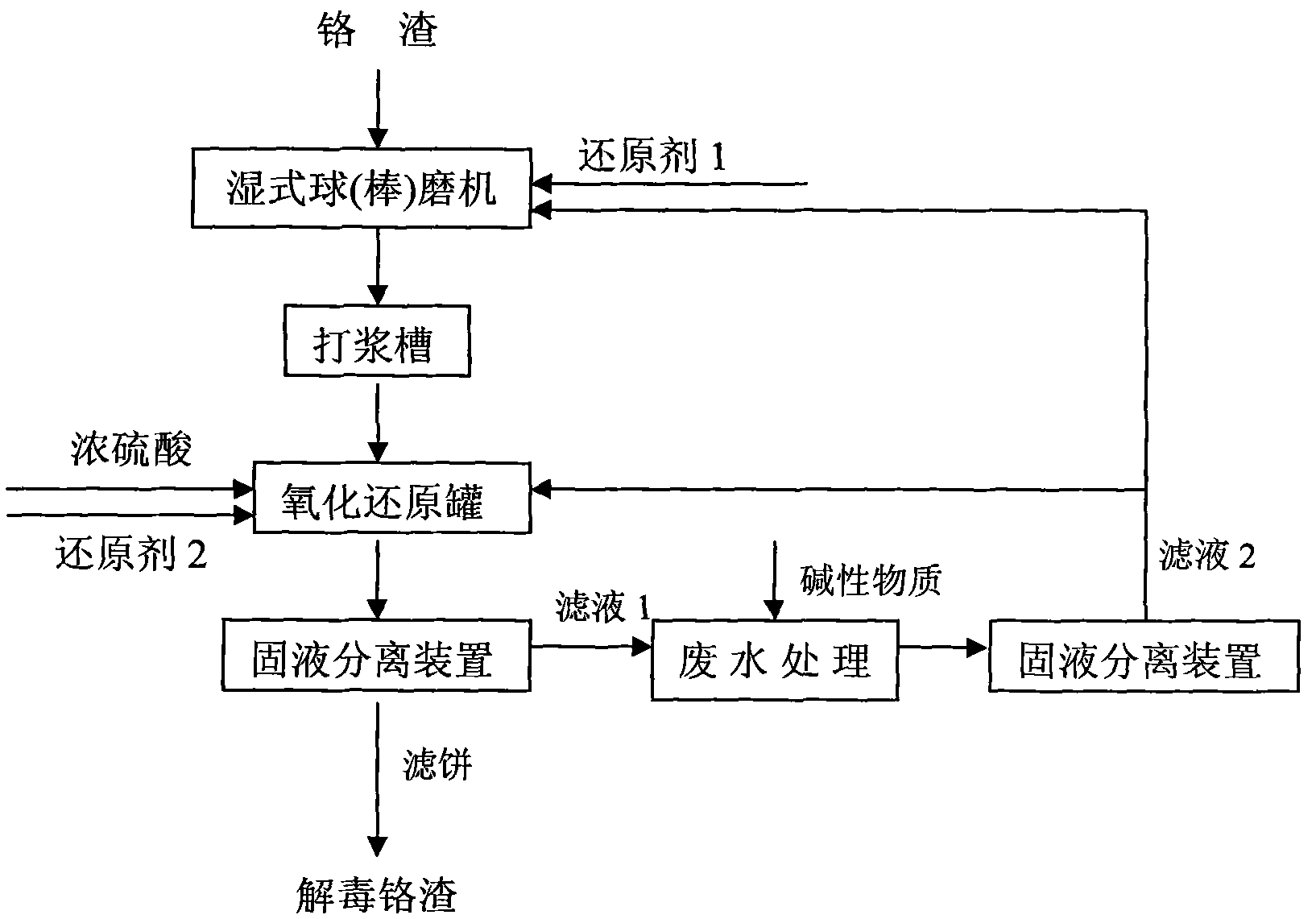

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

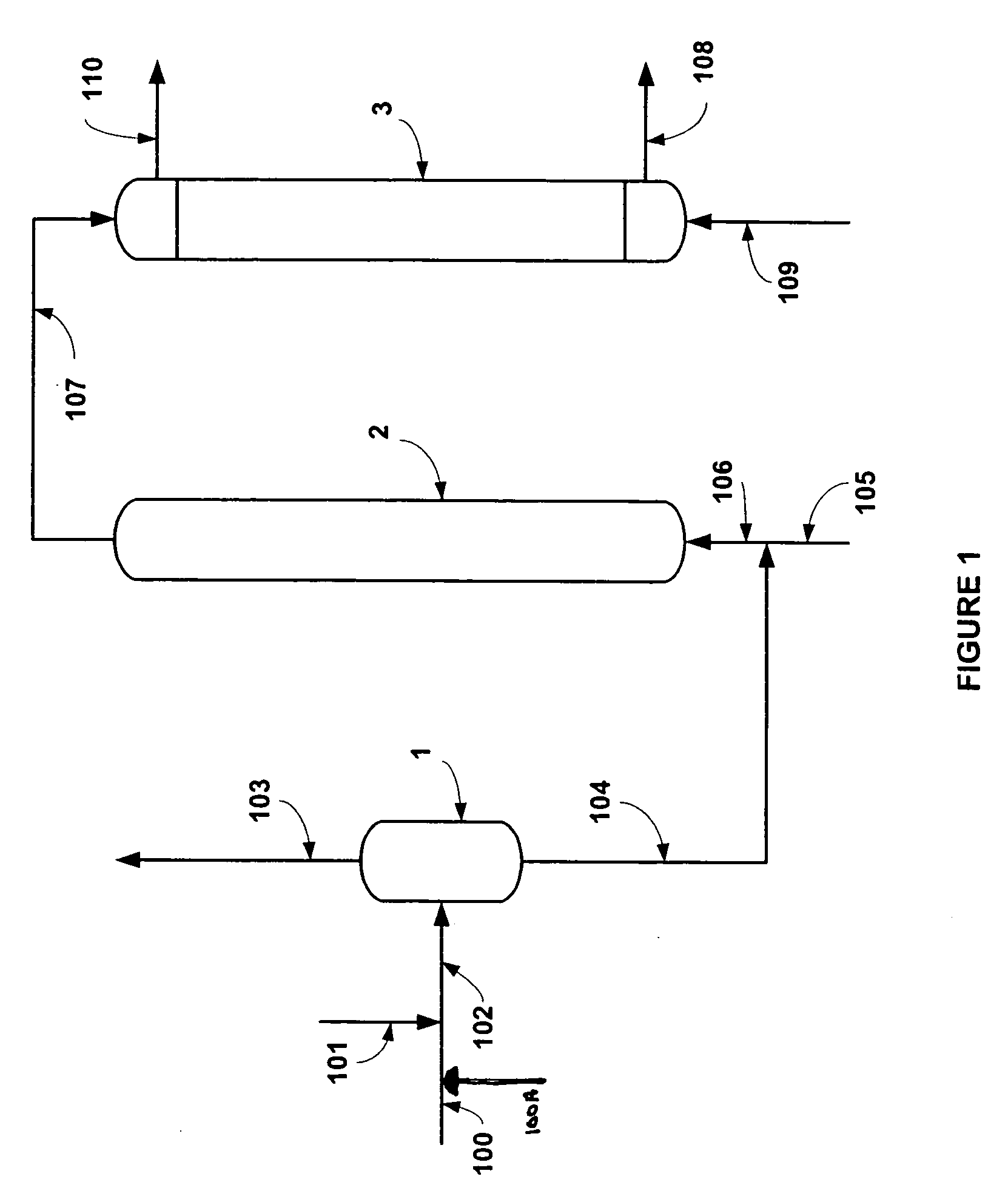

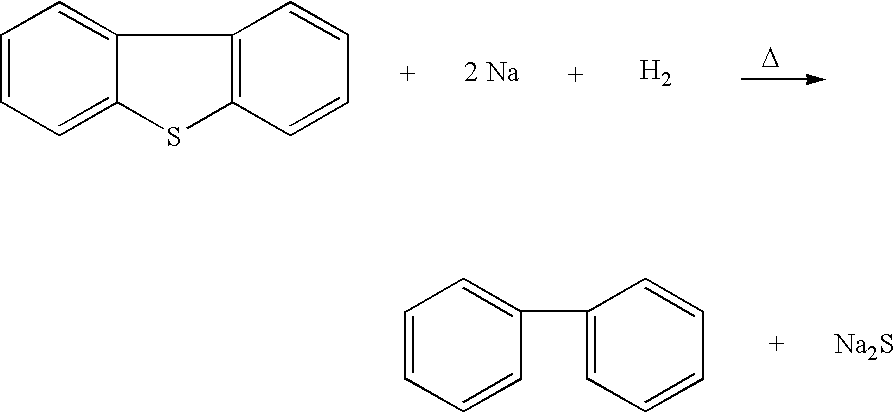

Desulfurization of petroleum streams using metallic sodium

The invention is a method of removing sulfur from a hydrocarbon feed using the steps of dissolving metallic sodium in a solvent and combining the sodium / solvent solution with a liquid hydrocarbon feed containing an organosulfur species. The pressure of combination is above the vapor pressure of the solvent. The combined hydrocarbon feed and solvent solution are placed in a low pressure environment to vaporize the solvent. The resulting stream is combined with hydrogen gas and this stream is heated and pressurized to form a liquid hydrocarbon product containing sodium sulfide. This product is then cooled, and the sodium sulfide is extracted.

Owner:TRANS IONICS CORP

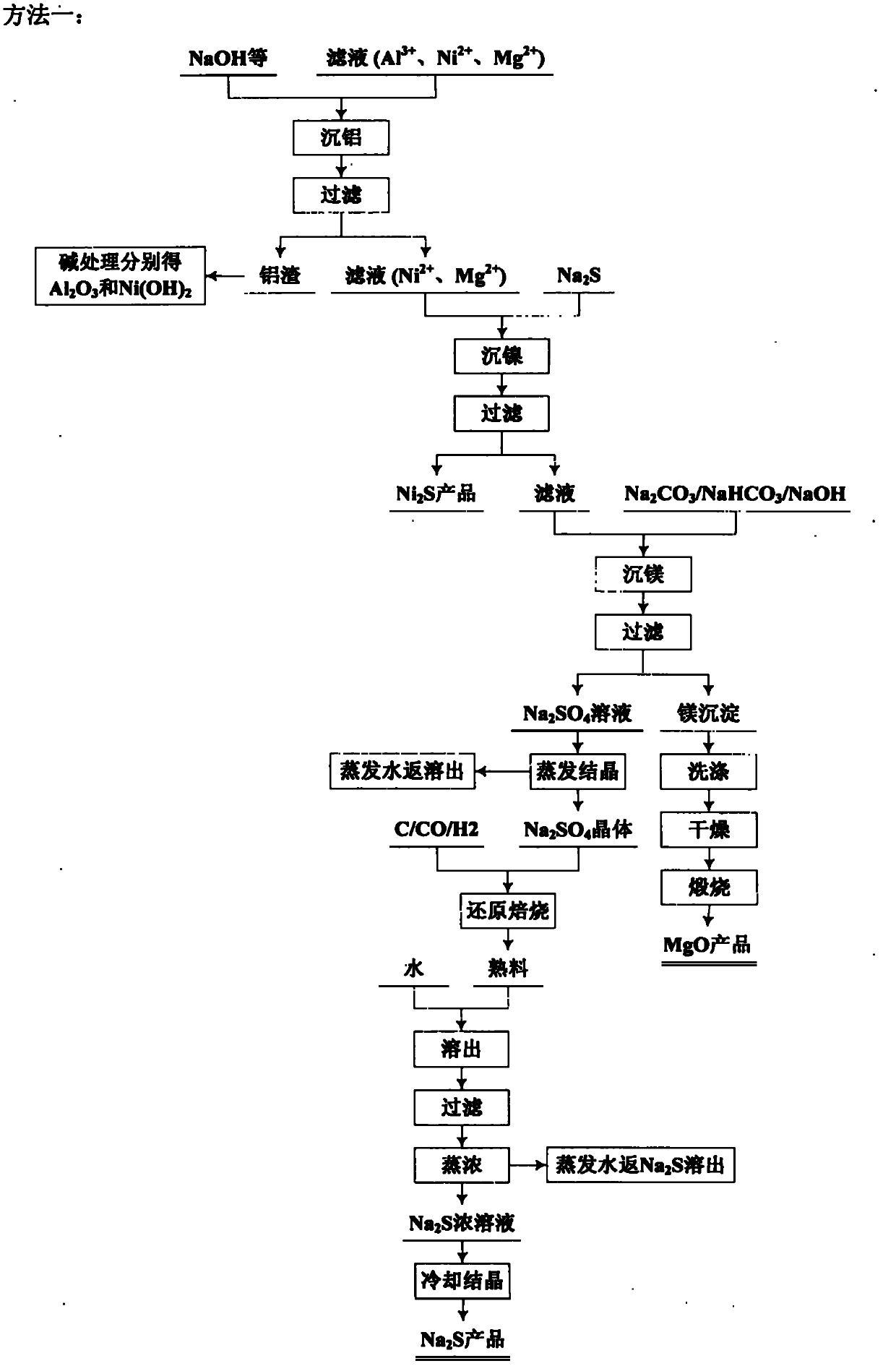

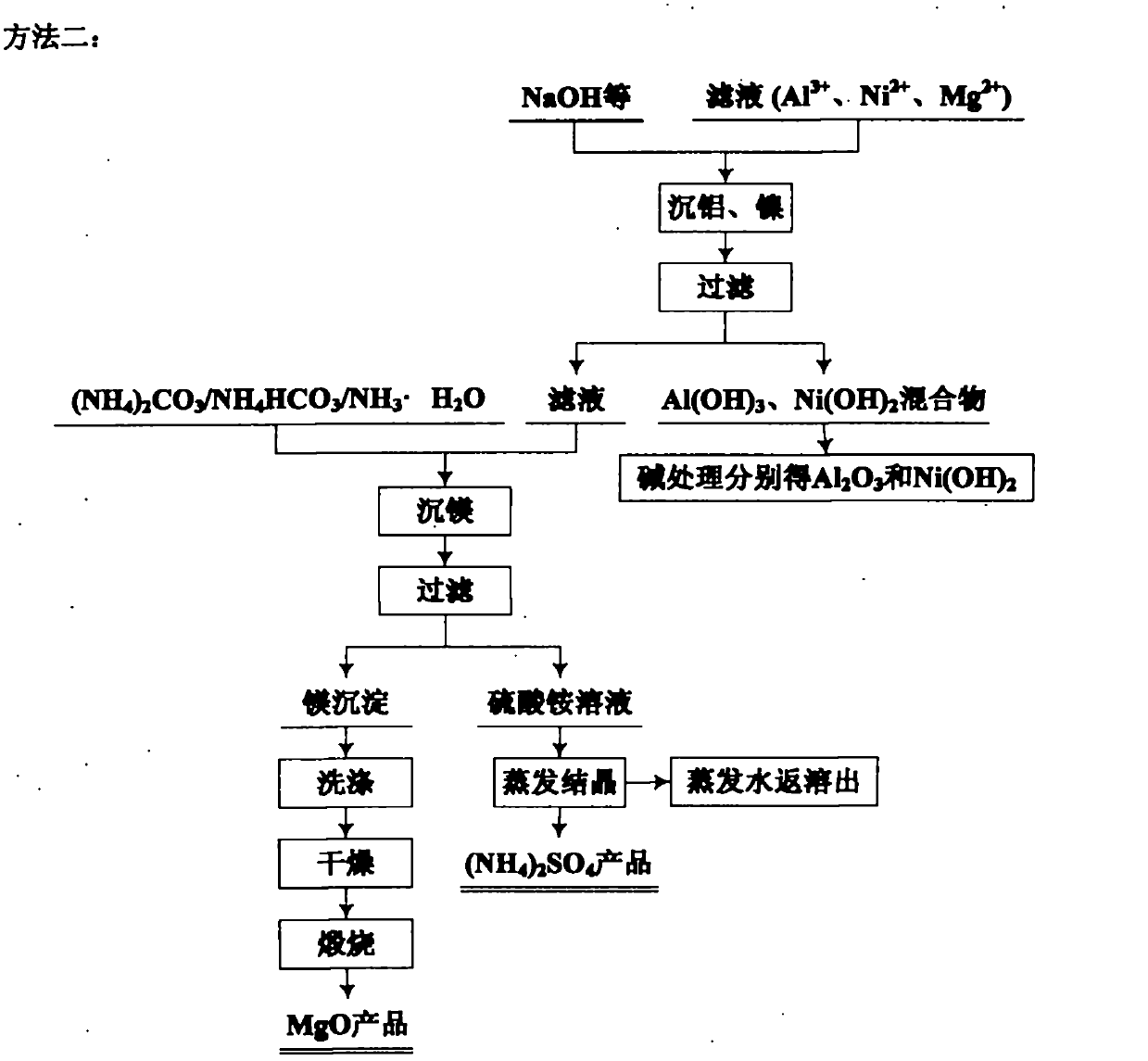

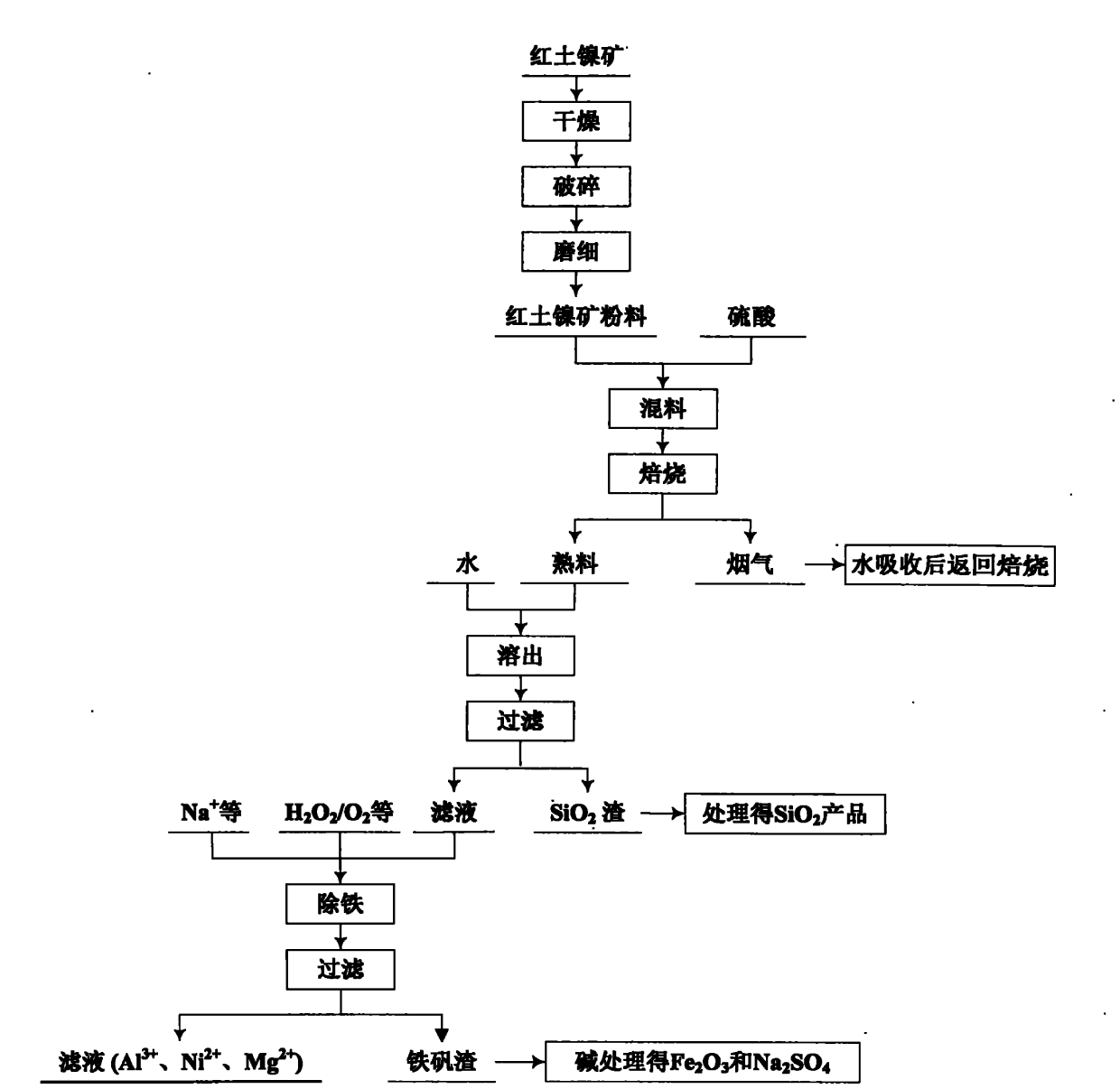

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

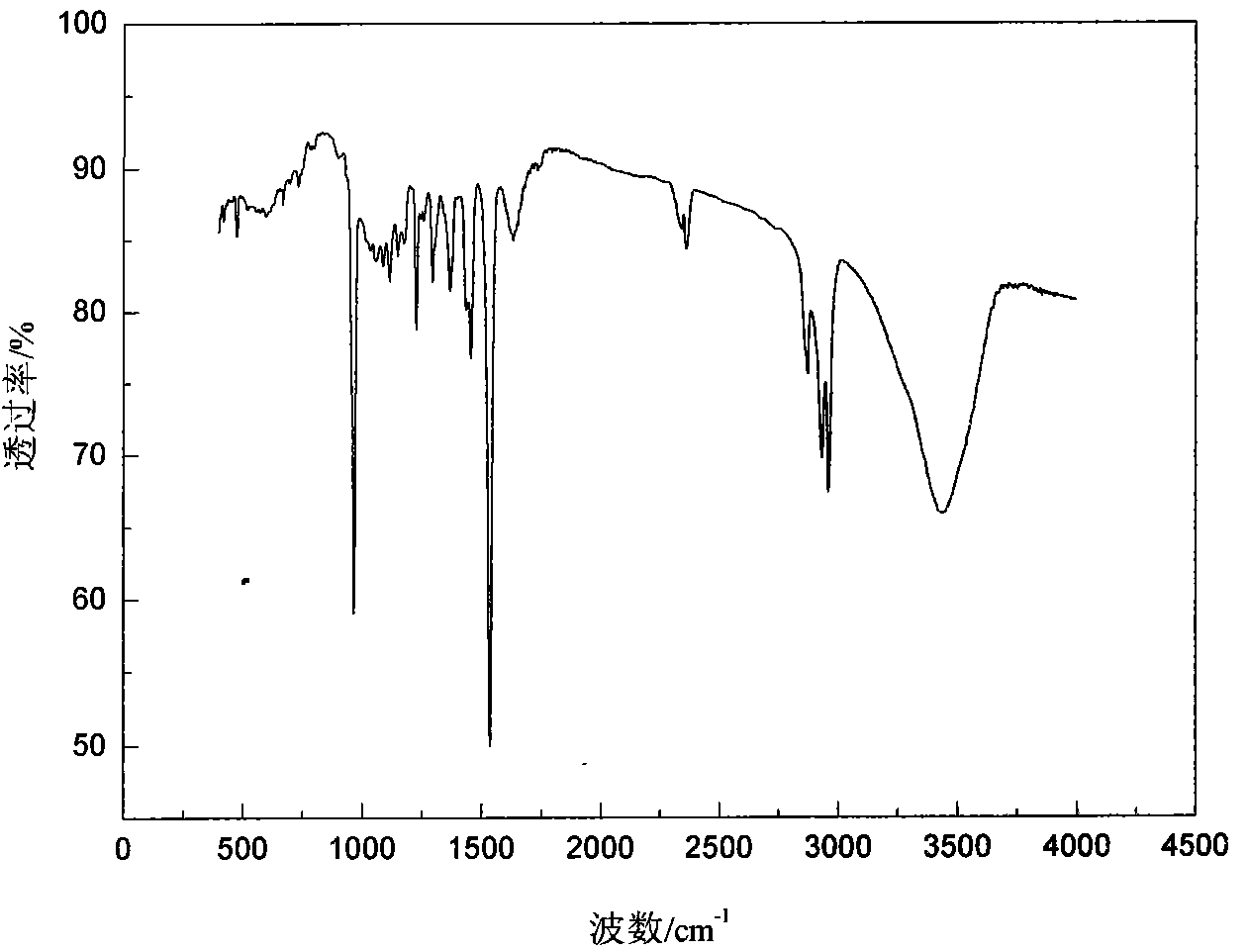

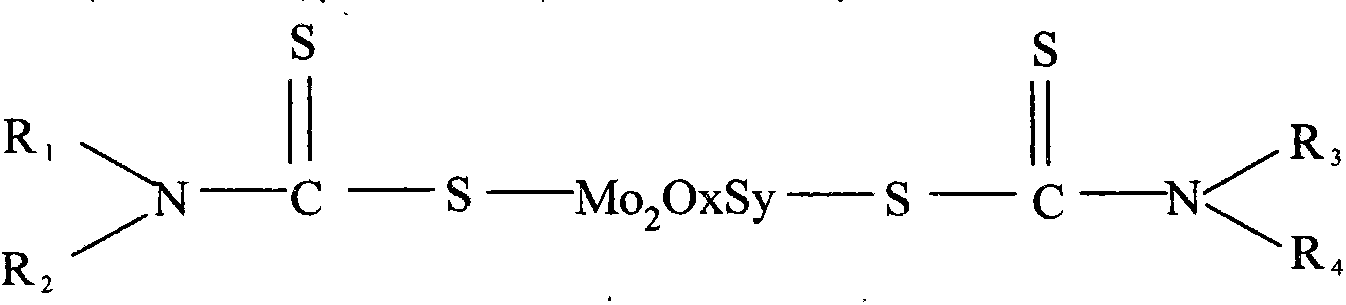

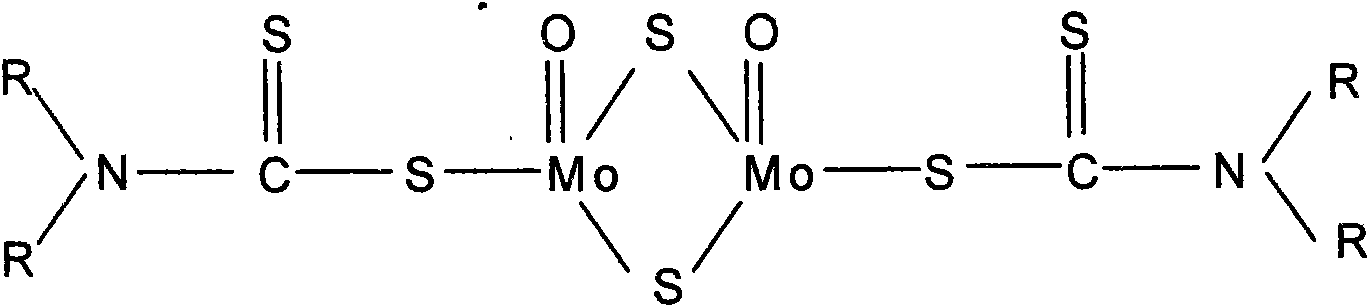

Oil-soluble self-vulcanizing molybdenum catalyst, and preparation method, use method and application of oil-soluble self-vulcanizing molybdenum catalyst

InactiveCN103349999AImprove catalytic performanceReduce yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingSlurry reactorFiltration

The invention provides an oil-soluble self-vulcanizing molybdenum catalyst, and a preparation method, a use method and an application of the oil-soluble self-vulcanizing molybdenum catalyst. The preparation method comprises the following steps of (1) sequentially putting a molybdenum source, water, sodium sulfide, a solvent and inorganic acid in a container under the protection of nitrogen, uniformly mixing and stirring, cooling to 5-50 DEG C for reaction for 10-150min, (2) adding alkylamine and carbon disulfide, uniformly stirring, heating to 60-200 DEG C for reaction for 3-10h, and (3) after reaction, sufficiently cooling a product, performing suction filtration, sufficiently washing with methanol, and drying to obtain the oil-soluble self-vulcanizing molybdenum catalyst. The oil-soluble self-vulcanizing molybdenum catalyst can be vulcanized and decomposed to form a molybdenum disulfide active component in situ, is used for a slurry reactor hydrocracking technology for poor heavy oil with a high metal content, a high carbon residue content and a high sulfur content, can reduce the coke yield, and keeps long-period operation of a device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Animal fur clean depilation and fur fiber loosing method for preparing leather and application thereof

ActiveCN101235421AEliminate pollution and other issuesFine grainPre-tanning chemical treatmentFiberEnzyme system

The invention provides a method for unhairing leather and loosening leather fiber without sodium sulfide and lime in a leather production process and the application of the method. The method is characterized in that a method for combining unhairing by non-sulfur (sodium sulfide) depilatory under the alkaline condition and enzyme fiber loosening under the under the non-lime (lime) alkaline swelling condition are adopted, the enzyme unhearing and the enzyme fiber loosening take protease, lipase, amylase and glucoamylase as a compound enzyme system. The method achieves the effects for unhairing and loosening the leather fiber through adopting the method for combining compound enzyme water immersion, compound enzyme unhairing, unhairing with sodium sulfide depilatory, expansion regulator-sodium hydroxide expansion and the enzyme unhairing under the alkaline condition and eliminates the pollution which is brought by the sodium sulfide and the lime in animal unhairing or leather fiber loosening procedures in the leather production process. The method of the invention is suitable for unhairing and leather fiber dispersed processing of various animal leather of leather with various usages.

Owner:SICHUAN UNIV +1

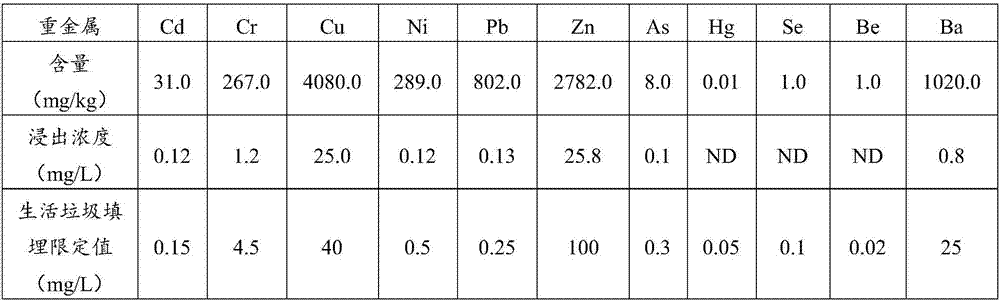

Heavy metal chelating agent for waste incineration fly ashes and preparation method for heavy metal chelating agent

InactiveCN106955451AImprove stabilityReduce dosageChemical protectionHeavy metal chelationSodium phosphates

The invention discloses a heavy metal chelating agent for waste incineration fly ashes. The heavy metal chelating agent for the waste incineration fly ashes comprises a compound chelating agent and a sodium hydroxide solution mixed with a weight ratio being 1:2-3, wherein the compound chelating agent comprises, by weight percentage, 60-90% of an organic chelating agent, and 10-40% of an inorganic chelating agent, the organic chelating agent is dithiocarbamates and is one or more selected from zinc diethyl dithiocarbamate, zinc dimethyl dithiocarbamate, sodium dibutyl dithiocarbamate or sodium dibenzyl dithiocarbamate, and the inorganic chelating agent is one or two selected from sodium sulfide and sodium phosphate. The heavy metal chelating agent for the waste incineration fly ashes is capable of reducing the leaching concentration of heavy metals and ensuring that a fly ash solidification sample block can meet the limit value of the leaching concentration. The invention further provides a preparation method for the heavy metal chelating agent for the waste incineration fly ashes.

Owner:湖南云平环保科技有限公司

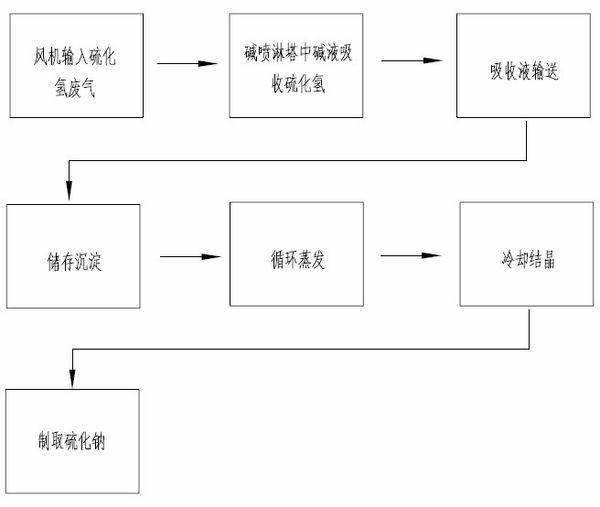

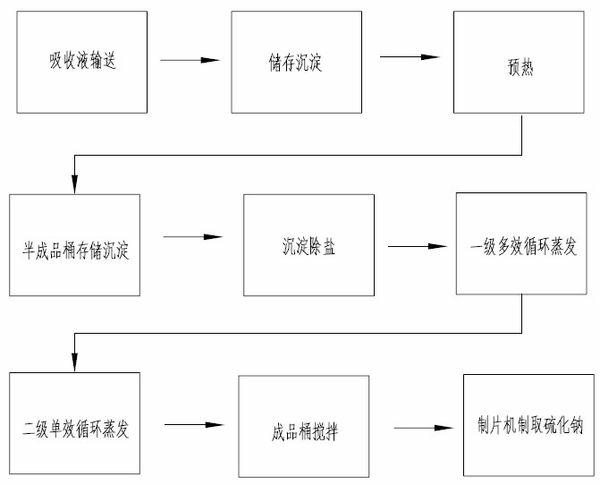

Method for preparing sodium sulfide from hydrogen sulfide waste gas produced in production of viscose fibre

InactiveCN102515112AAchieve optimized generationIncrease production costAlkali metal sulfides/polysulfidesImpurityWaste gas

The invention relates to the field of production of viscose fibre in the textile industry, in particular to a method for preparing sodium sulfide from hydrogen sulfide waste gas produced in the production of the viscose fibre. The method comprises the steps as follows: A, the waste gas is fed into an alkali spray tower; B, hydrogen sulfide is absorbed in an alkali liquor in the alkali spray tower; C, impurities are removed; D, a preheated absorption liquid is delivered into a primary multi-effect evaporator; E, a solution is subject to settlement and desalination; F, the desalinated solution is filled into a semi-finished product barrel, and caustic soda is added into the desalinated solution; G, the solution in the semi-finished product barrel is delivered into a secondary single-effect evaporator; H, after undergoing the secondary evaporation, the solution is filled into a finished product barrel, and then is stirred for crystallization; and I, crystal sodium sulfide is made into tablets. The method has the advantage of realizing the optimal generation of sodium sulfide through the setting of processing parameters such as the size of main equipment, the pore diameter of a delivery pipeline, wind volume, wind velocity, the concentration of the alkali liquor, absorption time, circulating evaporation time, evaporation temperature, evaporation vacuum degree, precipitation time, stirring velocity, the rotational speed of a tablet making machine, and the like.

Owner:YIBIN HIEST FIBER +2

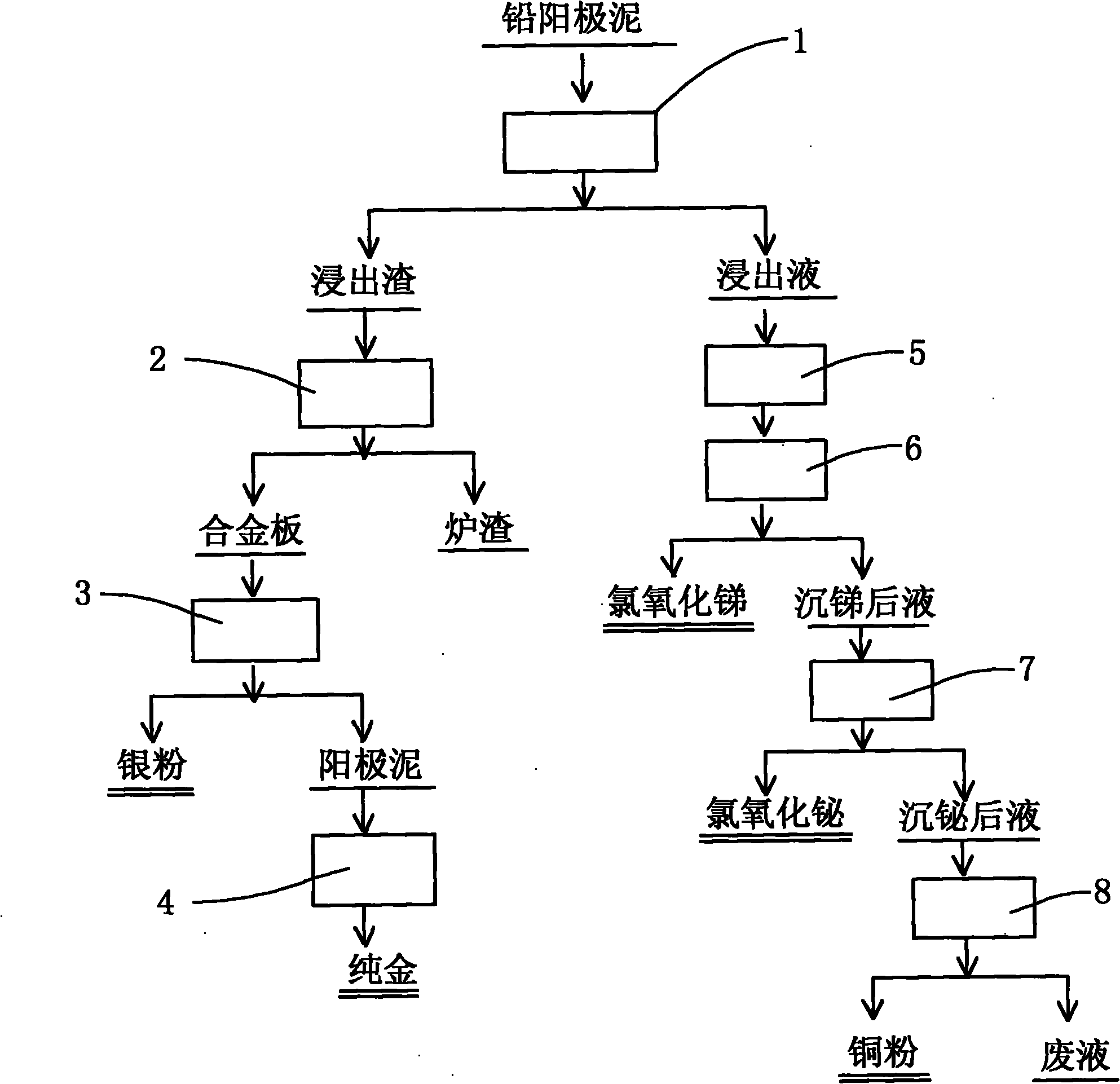

Method for recovering gold, silver, bismuth, stibium and copper from lead anode mud

InactiveCN101831551AAchieve recyclingContinuous processProcess efficiency improvementElectrolysisCopper

The invention relates to a method for recovering gold, silver, bismuth, stibium and copper from lead anode mud. The method is carried out through the following working procedures of: (1) leaching by using hydrochloric acid; (2) smelting leached residues; (3) electrolyzing silver; (4) chloridizing to extract gold; (5) precipitating the silver by using sodium sulfide; (6) hydrolyzing to precipitate the stibium; (7) neutralizing to precipitate the bismuth; and (8) displacing copper by using iron. In the invention, through the steps of pre-oxidizing before wet-process leaching of the lead anode mud, leaching by using hydrochloric acid at normal temperature, precipitating the silver by using the sodium sulfide, hydrolyzing to precipitate the stibium, neutralizing to precipitate the bismuth, displacing to precipitate the copper, smelting the leached residues, electrolyzing the silver and chloridizing to extract the gold, the purpose of comprehensively extracting the valuable metals of the gold, the silver, the bismuth, the stibium and the copper from the lead anode mud is achieved. The method has continuous process, low energy consumption, low pollution, easy operation and high extraction rate and is suitable for extracting the valuable metals from the lead anode mud in the field of metal smelting.

Owner:HULUDAO ZINC IND CO LTD

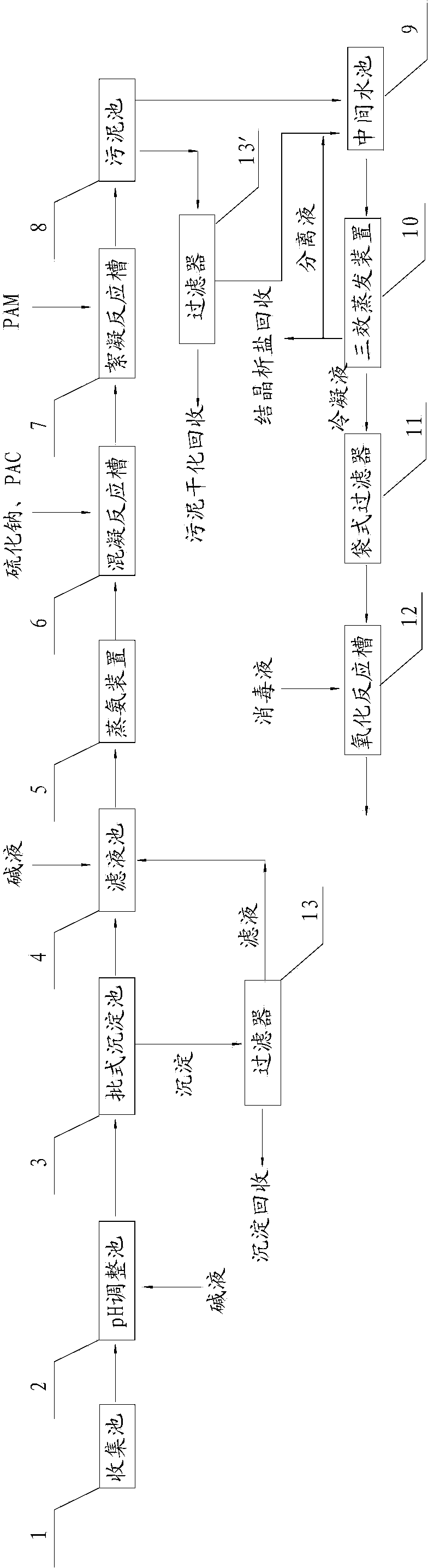

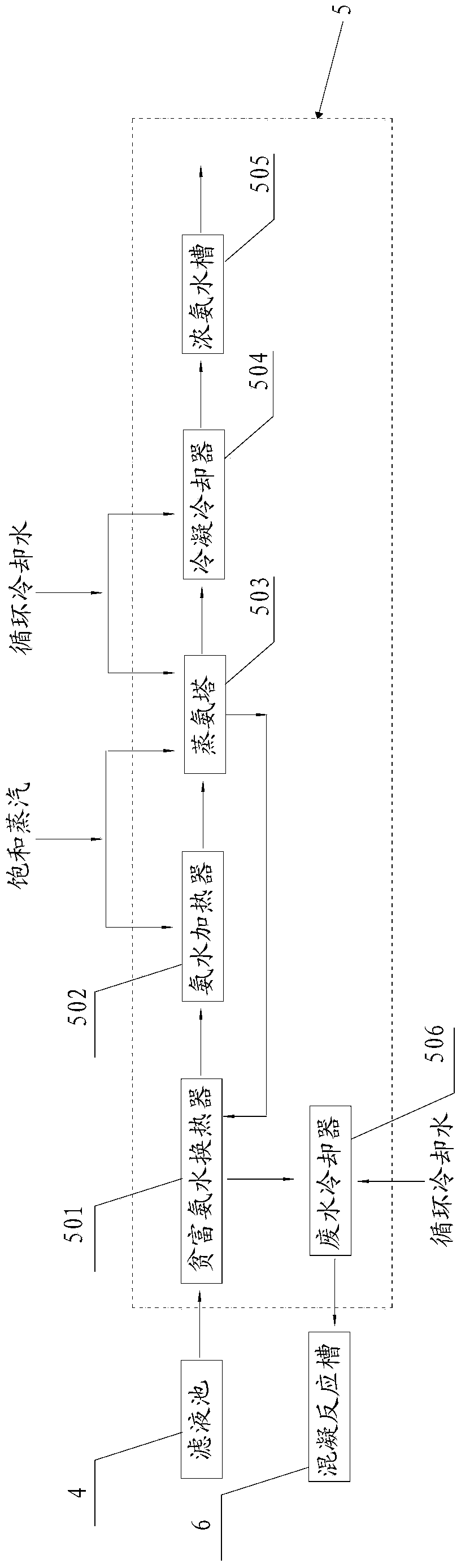

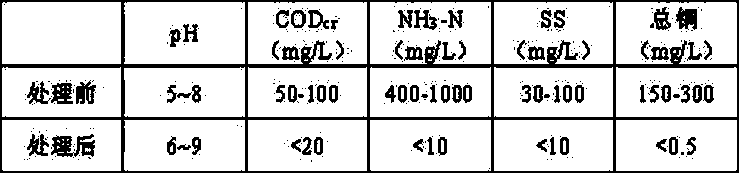

Material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and treatment system

InactiveCN103466870AHarm reductionMeet emission standardsMultistage water/sewage treatmentAmmonia preparation/separationRecovery methodHigh concentration

The invention relates to a material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and a wastewater treatment system. The material recovery method comprises the following steps: regulating the pH value, ammonia stilling, precipitating, evaporating and the like. The invention further relates to the corresponding treatment system. After the adoption of alkali liquor to precipitate metal ions, sodium sulfide is continuously added to further remove the metal ions left in the waste liquor to reach the emission standard; stronger ammonia water, solid precipitates and the like produced during the wastewater treatment process are recovered to reduce the environmental harm effectively and produce certain economic benefits.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

Method for preparing sodium sulfhydrate from hydrogen sulfide tail gas

InactiveCN101186280AImprove protectionReduce pollutionSulfur compoundsSodium hydrosulfideAbsorption rate

A purpose of the invention is to provide a sodium hydrosulfide preparation method utilizing hydrogen sulfide exhaust. The invention not only can resolve the treatment problems of the three wastes of barium carbonate and strontium carbonate enterprises, but also can reuse calcium sulfate, the byproduct from the preparation of sodium hydrosulfide, as raw materials for other chemical production, which realizes the recycling of raw materials and products. The production ability of the traditional alkali solution absorbing method, the absorbing adaptability of mixed hydrogen sulfide exhaust and the sodium hydrosulfide preparation rate are enhanced; while the production cost is reduced and the exhaust can be discharged according to standards after being absorbed by alkali solution. The invention resolves the problems of low absorption rate of hydrogen sulfide gas, low production efficiency of preparation of sodium hydrosulfide, large investment of technical devices and difficulty of solid phase recycling existing in a method of 'one step for preparation of sodium hydrosulfide' using hydrogen sulfide gas, calcium hydroxide and sodium sulfide as raw materials.

Owner:QINGDAO AOHAIKE TRADE

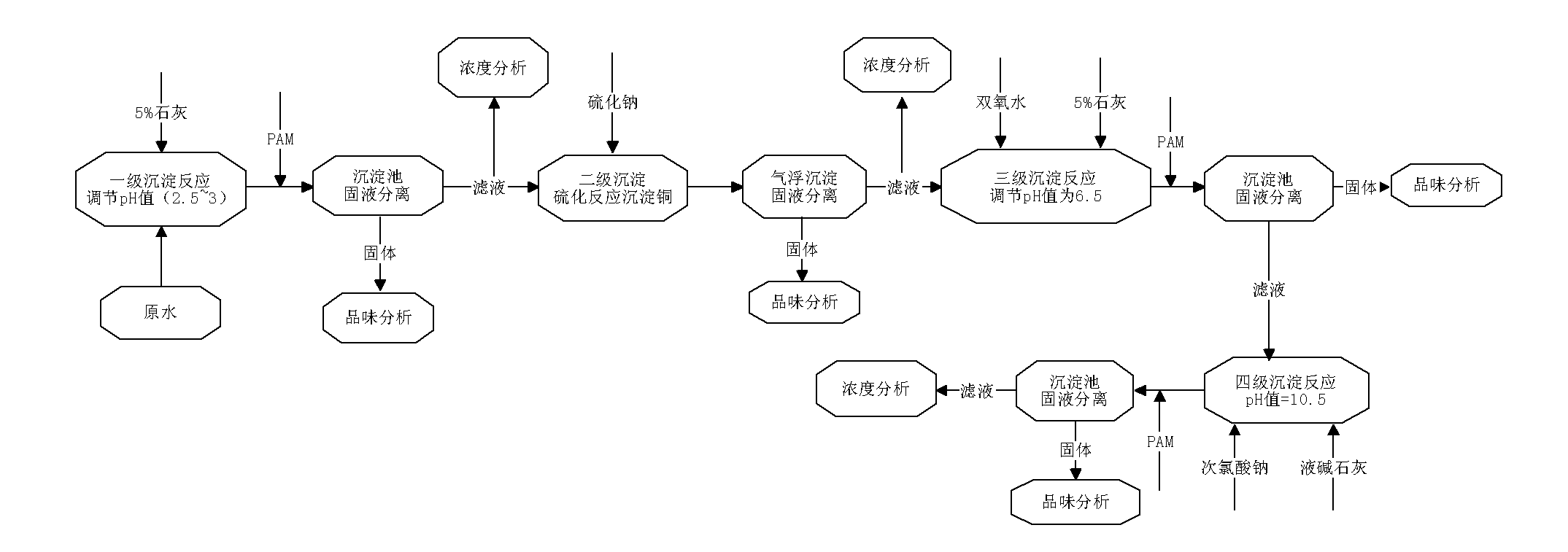

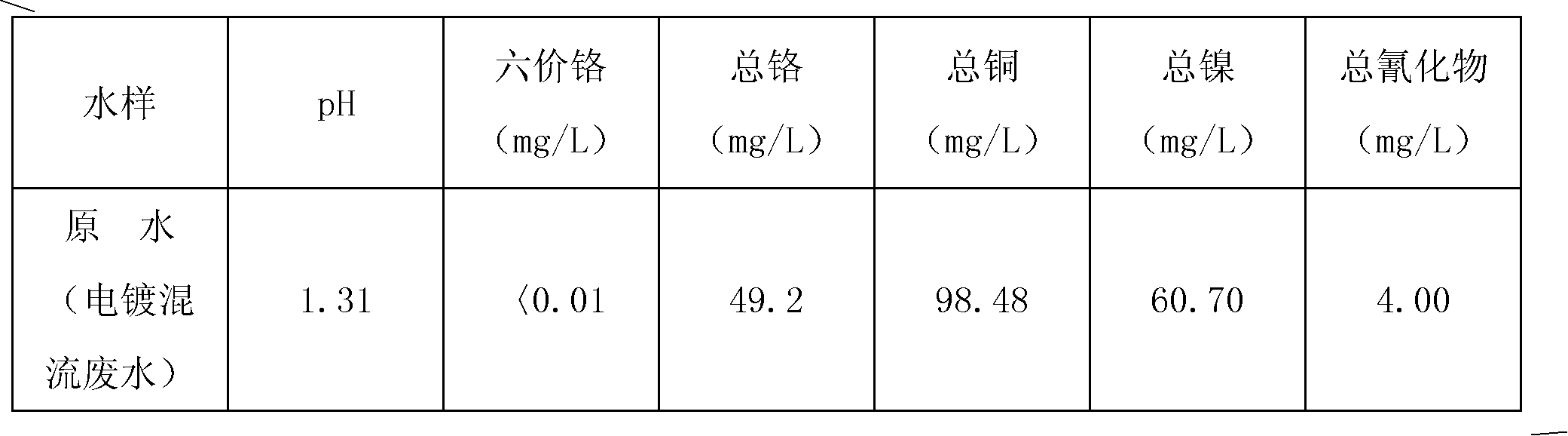

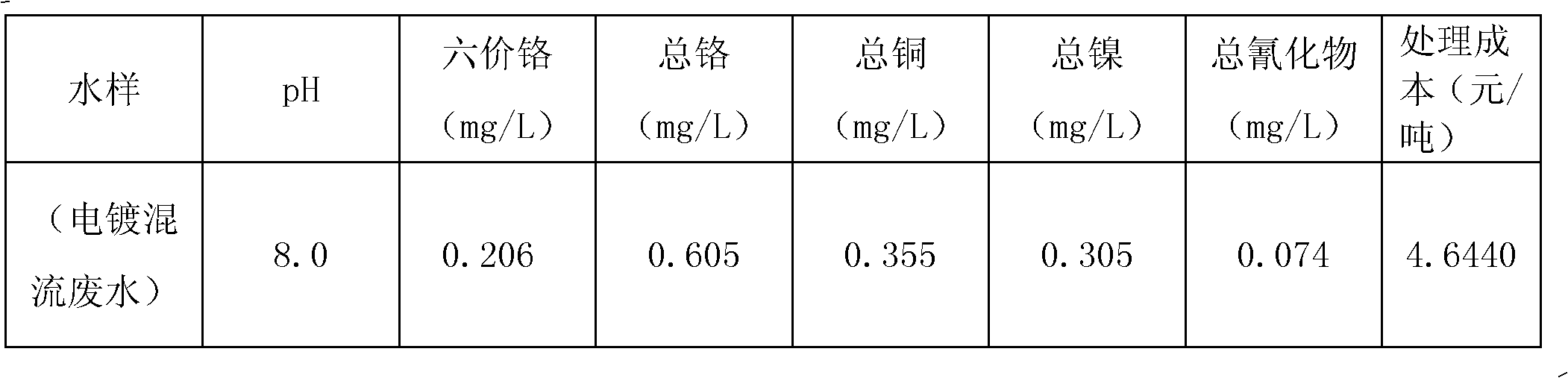

Recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water

ActiveCN102557299AReduce lossesReduce loss rateWaste water treatment from metallurgical processMultistage water/sewage treatmentRecovery methodCopper sulfide

The invention relates to a recovery method of copper-nickel heavy metals in electroplated mixed-flow waste water. The recovery method comprises the following steps of: using lime to adjusting the pH value to be 2.5-3 in the electroplated mixed-flow waste water containing copper and nickel, adding a flocculating agent PAM (polyacrylamide), generating precipitate, and carrying out solid-liquid separation; then adding sodium sulfide, generating copper sulfide precipitate, and carrying out solid-liquid separation; then adding hydrogen peroxide for preventing complexation, using the lime to adjusting the pH value to be 6.5, simultaneously precipitating copper and chromium ions, adding the flocculating agent PAM, and carrying out solid-liquid separation; then using the lime to adjusting the pH value to be 10.5, simultaneously adding sodium hypochlorite for preventing complexation, generating precipitate containing nickel hydroxide, adding the flocculating agent PAM, carrying out solid-liquid separation, and recovering nickel mud; and finally, adjusting the pH value of the discharged water to be 8 by adding sulfuric acid, and realizing standard discharging. The recovery method has the advantages that the process is simple and convenient, the operation is easy, the recovery cost is low and the recovery rate is higher.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

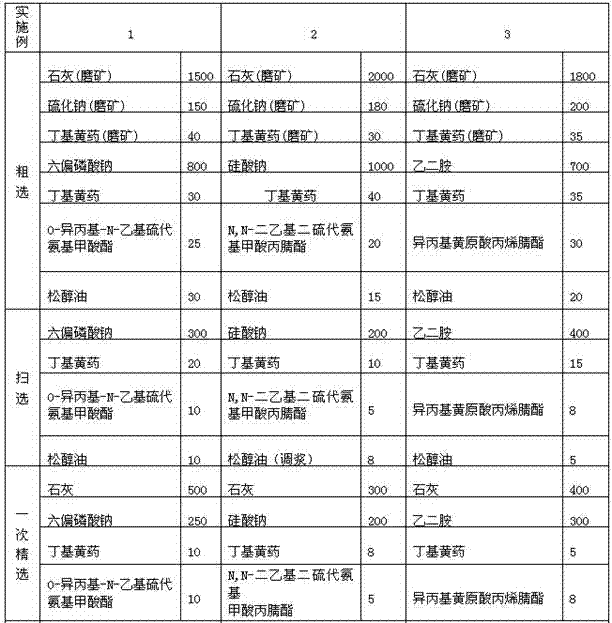

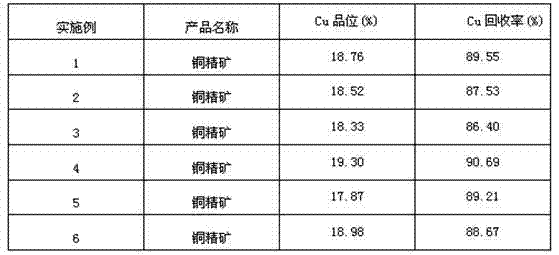

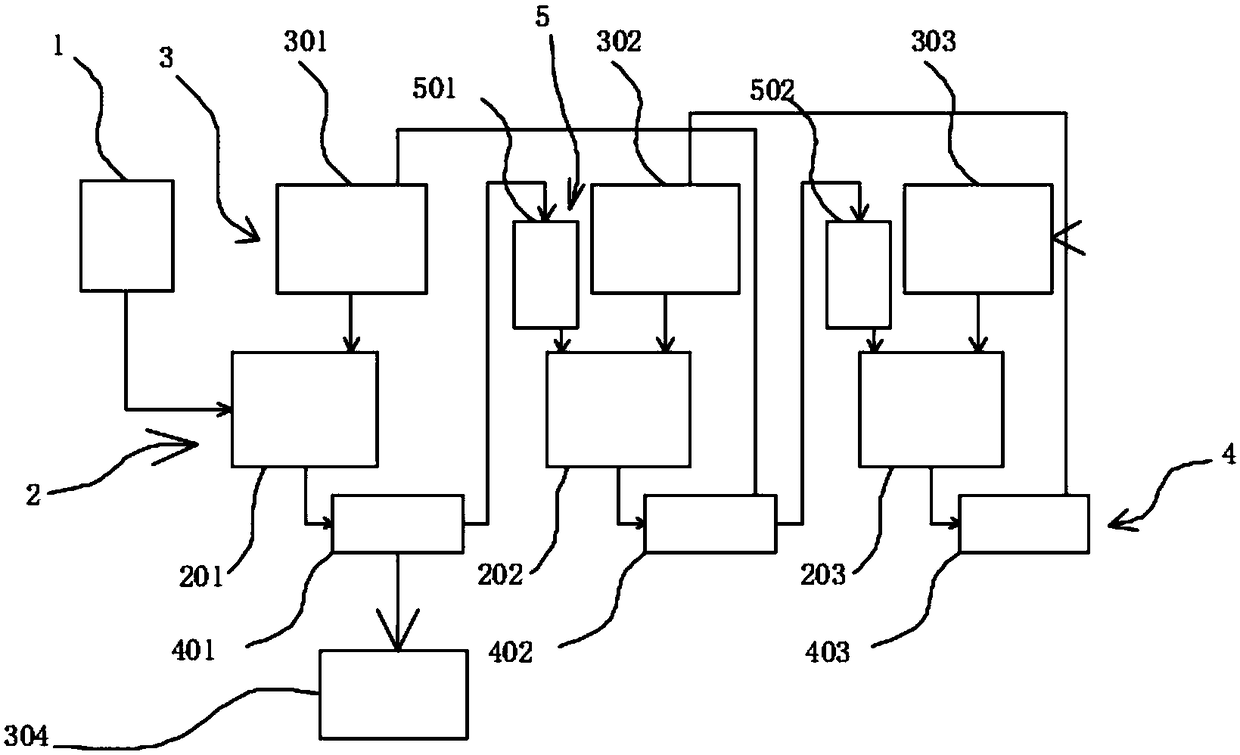

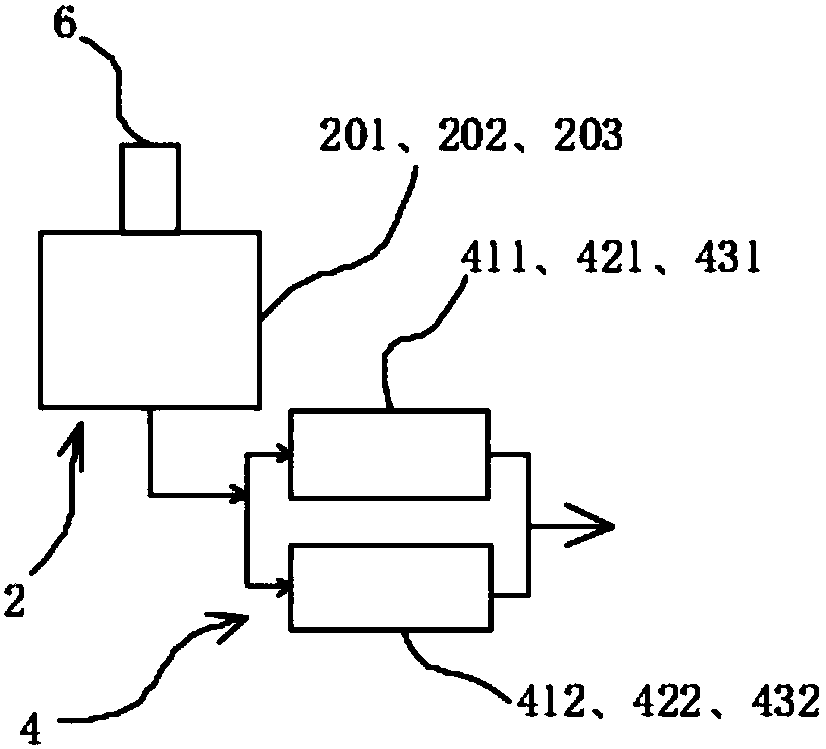

Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

The invention relates to a beneficiation method for copper sulfide ore containing easily-sliming gangue minerals. According to the method, lime is adopted as pH regulator and pyrite depressant of flotation pulp of the copper sulfide ore containing the easily-sliming gangue minerals; sodium sulfide serves as activator of a small number of copper oxide minerals in the ore; sodium hexametaphosphate, sodium silicate or ethylenediamine serves as gangue slurry dispersant; a combination of butyl xanthate and other collectors serves as a collector of copper sulfide minerals; terpernic oil serves as foaming agent. The ore is subjected to primary grinding, primary roughing, primary scavenging and three-time concentration; the ore pulp is subjected to strong stirring and pulp mixing before starting to be subjected to primary roughing, primary scavenging and primary concentration, so that copper contained in the ore is efficiently recovered. According to the method, through reasonable combination and addition of chemicals, the ore grinding and pulp mixing process is strengthened, the adverse influence of gangue slurry on copper sulfide mineral floatation is eliminated, the surface characteristics of copper sulfide minerals are improved, the preferential adsorption of the collector on the surfaces of the copper sulfide minerals is enhanced, and accordingly, compared with a conventional method, the copper grade and the copper recovery rate of copper concentrate are substantially increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method of comprehensively utilizing serpentine

InactiveCN101235440ATake advantage ofFull controlSilicon oxidesProcess efficiency improvementFerric hydroxideSoluble glass

The invention relates to a method for comprehensively utilizing serendipities, which comprises: magnetically separating the serpentinites in a strong magnetic field, obtaining amorphous silica powder which contains silicon dioxide more than 90% through filtering acid dipping solution, dissolving the amorphous silica powder through using caustic soda under high temperature, which is used for manufacturing soluble glass with medium high modulus or taken as raw materials for producing white carbon black, then, mixing sulphuric acid and hydrochloric acid or nitric acid or mixing the sulphuric acid, the hydrochloric acid and nitric acid, adding acid dipping additive to carry out compound alternative and circulating acid dipping for ore powder which is magnetically separated and processed, fractionally depositing, filtering, and removing impurity for magnesium sulfate solution which is filtered through the acid dipping and contains the impurity, through adjusting the pH value, obtaining inorganic industrial dyes which mainly contain iron oxide yellow, ferric hydroxide and aluminum hydroxide, enriching the nickel, which is convenient for abstracting the nickel from the serpentinites, finally obtaining high purity magnesium oxide through refining refined magnesium sulfate solution whose impurity is removed after ammonium hydrogen carbonate and ammonial solution or sodium sulfide is used to deposit, and also obtaining ammonium sulfate or sodium sulfate which contains magnesium and calcium after liquid which is filtered is evaporated.

Owner:刘湘霖 +1

Garbage fly ash recycling treatment process

InactiveCN109133472AIncrease profitRich downstream productsCalcium/strontium/barium carbonatesSolid waste disposalPotassiumSodium sulfate

The invention relates to the technical field of garbage fly ash treatment, in particular to a garbage fly ash recycling treatment process. The process comprises the following steps: (1) washing garbage fly ash with water to remove chloride; (2) removing heavy metals: removing the heavy metals from washing wastewater, specifically comprising: adding excessive sodium sulfide into the washing wastewater, then adding ferrous sulfide, and removing sediments; (3) detecting the content of calcium ions in the water, adding sodium sulfate into the wastewater according to the calcium ions, and removingthe sediments; (4) adding sodium carbonate into the wastewater, removing the sediments, and controlling the adding amount of the sodium carbonate; (5) adjusting the pH of upper supernate back to 6.5 to 7.5; (6) performing evaporative crystallization to obtain a sodium chloride product; (7) cooling and crystallizing mother liquor to obtain coarse potassium chloride, and refining the coarse potassium chloride to obtain a potassium chloride product. The process recycles the garbage fly ash to obtain desulphurization gypsum, calcium carbonate, sodium chloride and potassium chloride products.

Owner:丁仲军 +1

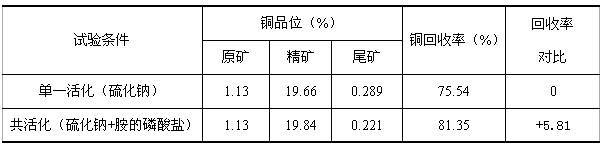

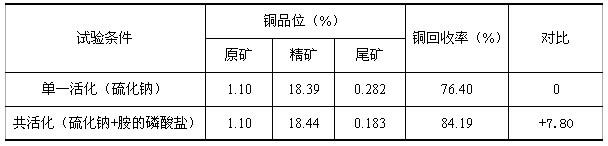

Activation method for flotation process of difficultly processed copper oxide ores

The invention provides an activation method for a flotation process of difficultly processed copper oxide ores. The method comprises the following steps: carrying out wet grinding on copper oxide ores until the mass percentage of the qualified grains with the granularity of 320 mesh is 85-95%, thus obtaining a pulp; adding an activating agent into the pulp, wherein each ton of copper oxide ores are added with 80-200g of the activating agent; and adding sodium sulphide, wherein each tone of the copper oxide ores are added with 1000-2000g of the sodium sulphide; performing activation together; adding 250-400g of conventional collector and 50-80g of foaming agent into one tone of the copper oxide ores, and performing multistage flotation; and producing copper concentrates and tailings via roughing, scavenging and concentrating. The activation effect achieved by the method provided by the invention is better than the effect of conventional activation, and the total use amount of sodium sulphide can be reduced by 10-30%. Compared with the conventional activation flotation, the copper quality of the copper concentrates is slightly increased, and the recovery ratio can be improved by 3-8% by using the activation method provided by the invention.

Owner:KUNMING UNIV OF SCI & TECH

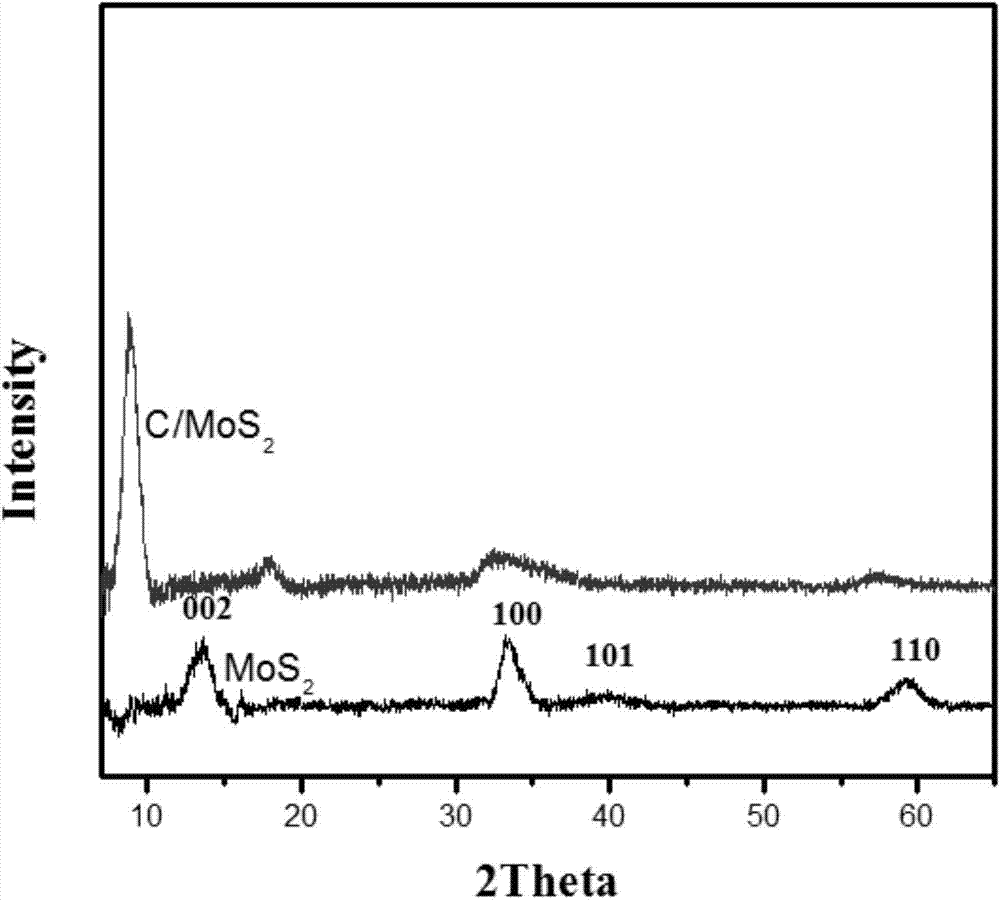

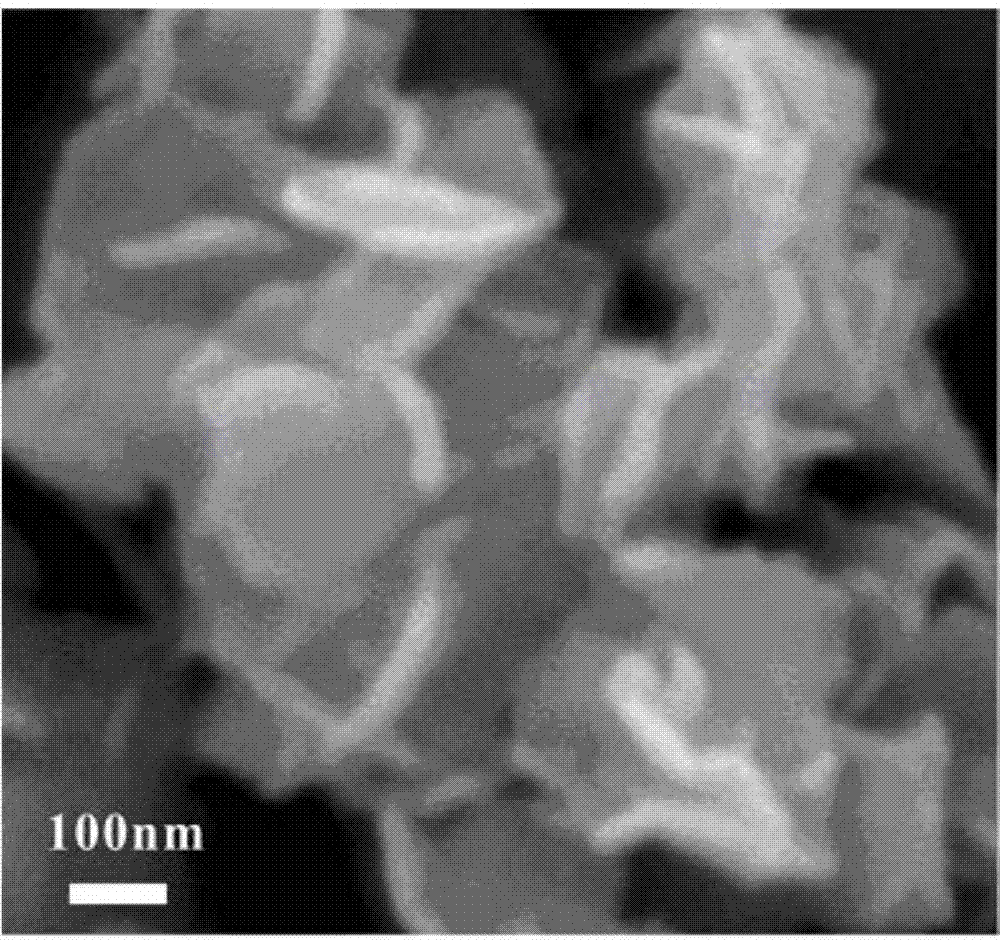

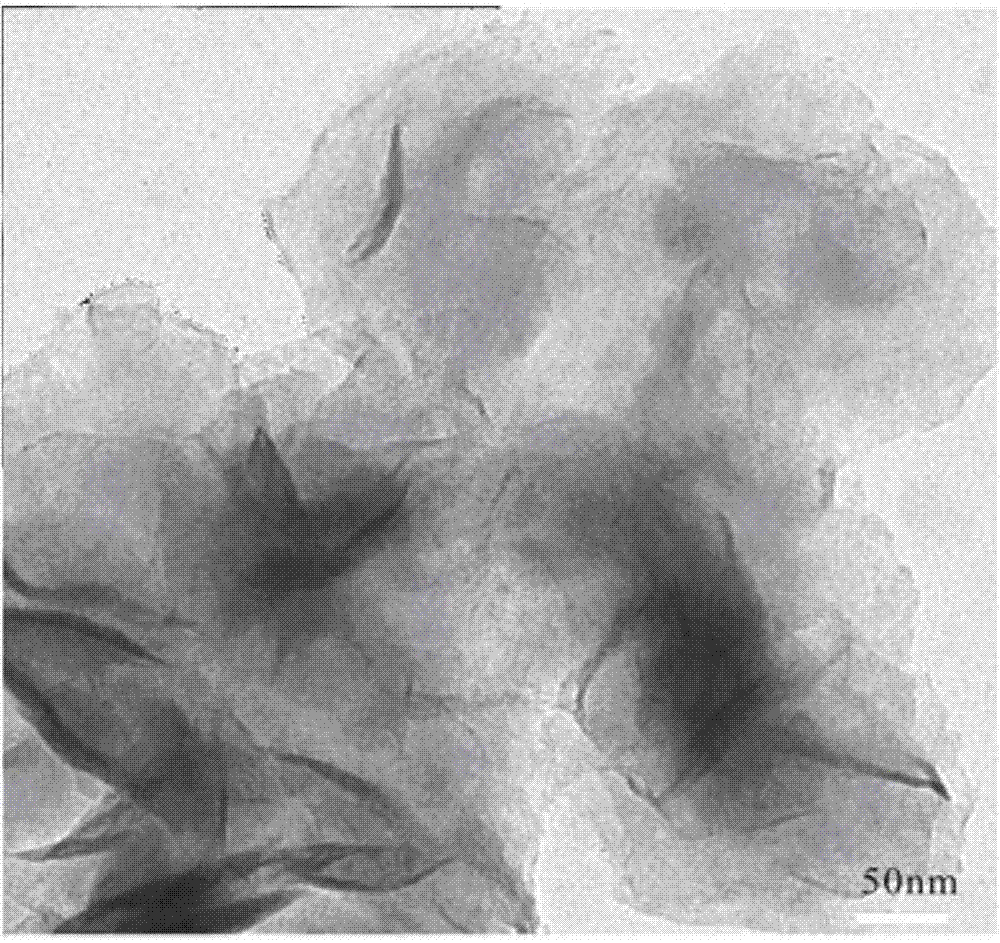

Preparation method of carbon-doped molybdenum disulfide nanometer material

InactiveCN104495937AImprove cycle stabilityLittle change before and afterMaterial nanotechnologyMolybdenum sulfidesSodium acetateDispersity

The invention provides a preparation method of a carbon-doped molybdenum disulfide nanometer material. The method comprises the following steps: weighing sodium molybdate, ammonium molybdate or molybdenum oxide and thiourea, sodium sulphide, potassium rhodanate or dithiocyano sodium acetate to be firstly dissolved into an ethylene glycol solution, then dissolved into ultrapure water, and fully stirring, so as to prepare a mixed solution; adjusting the pH value of a mixed solution with ammonia water and hydrochloric acid; transferring the mixed solution into a reaction kettle, and carrying out solvothermal reaction; taking out the mixed solution after reaction, and naturally cooling to room temperature; sequentially washing with ultrapure water and ethyl alcohol, and collecting a black substance; and drying the black substance in a vacuum drying oven, so as to prepare the carbon-doped molybdenum disulfide nanometer material. According to the carbon-doped MoS2 nanometer material prepared by the method, the sheet is uniform in size, good in dispersity, small in pollution in preparation process, and free of harmful air; and the molybdenum disulfide nanometer material with good dispersity can be greatly prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

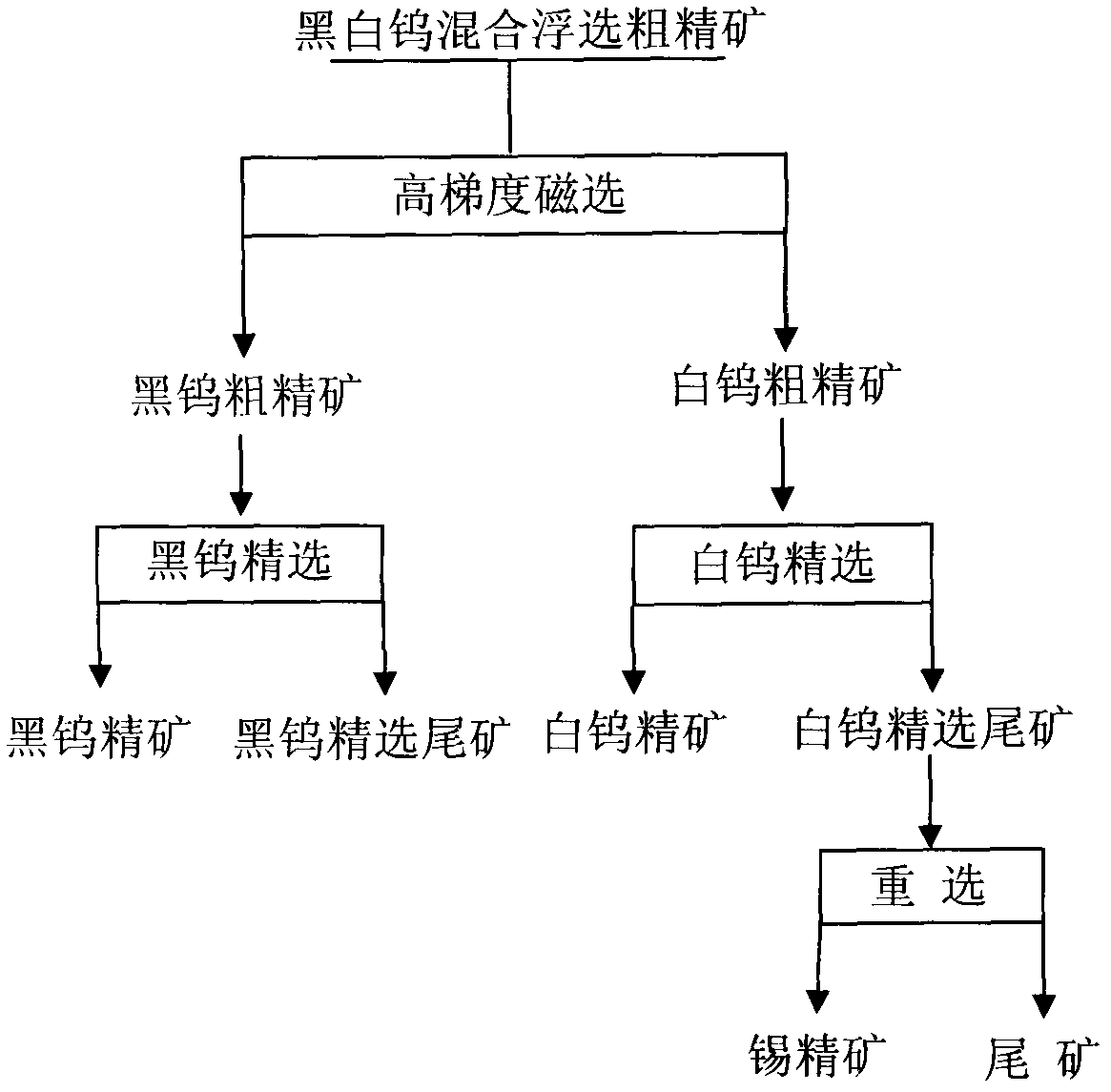

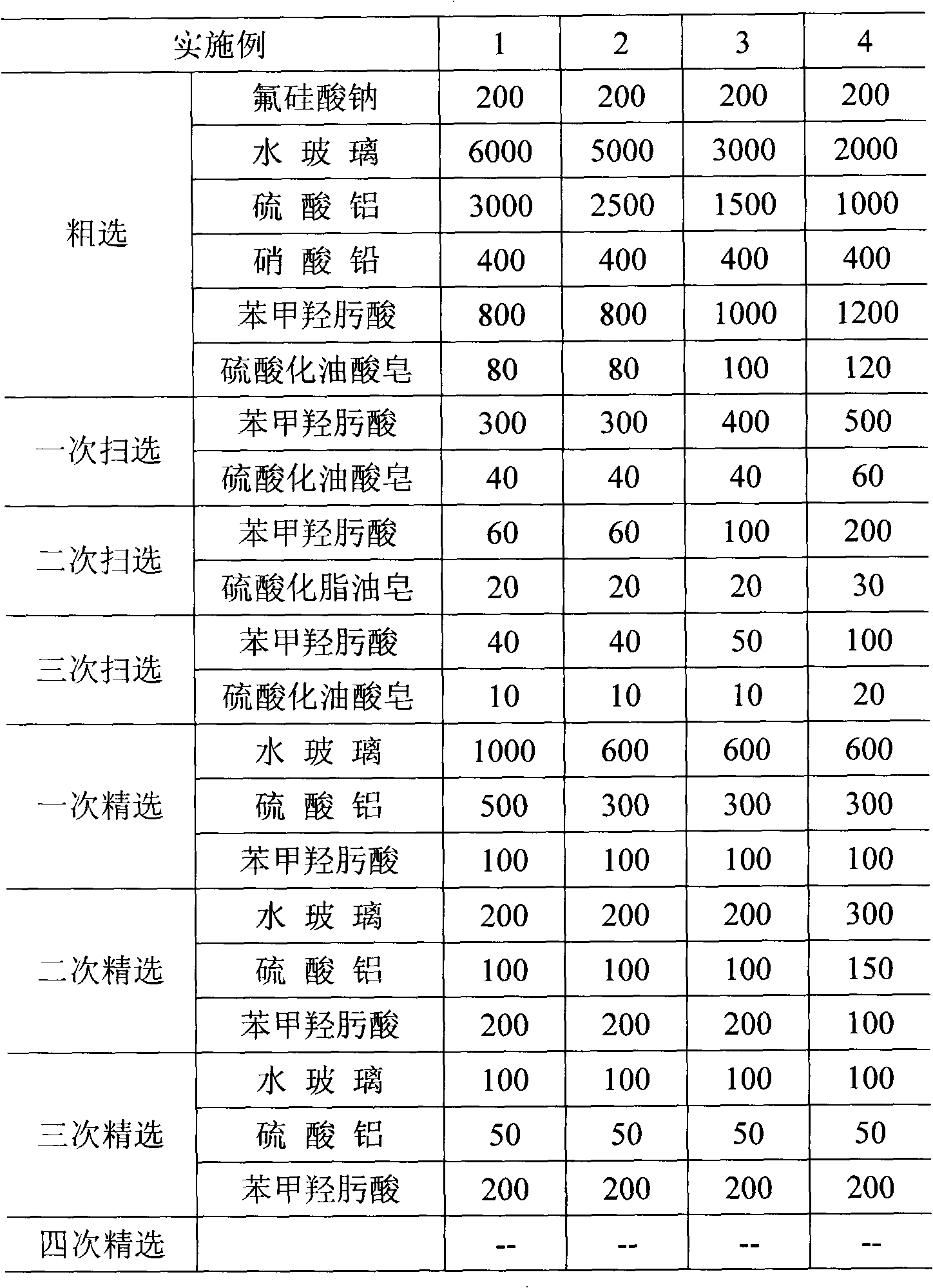

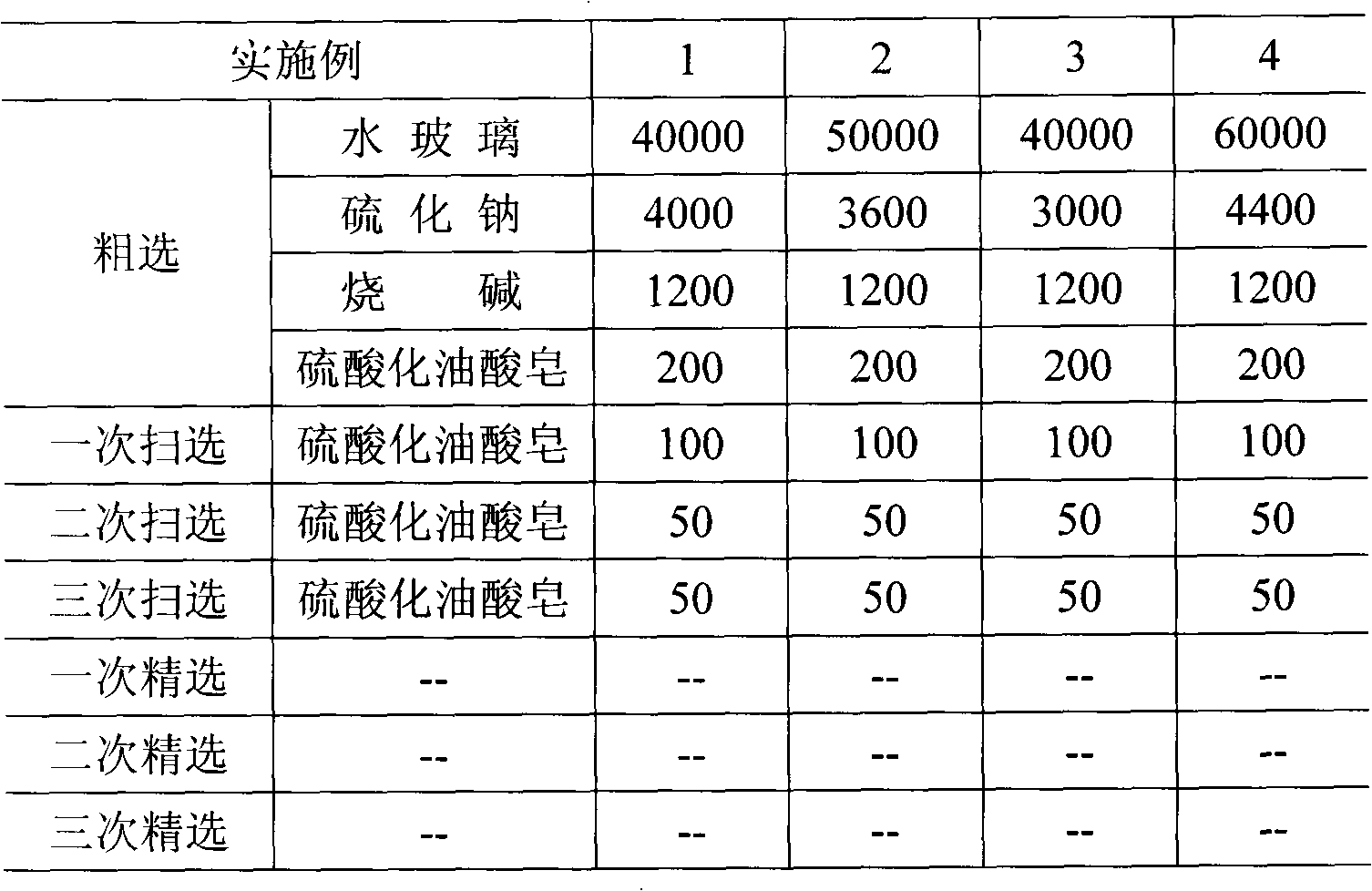

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

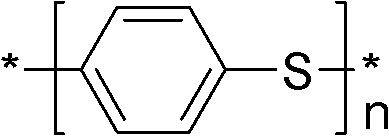

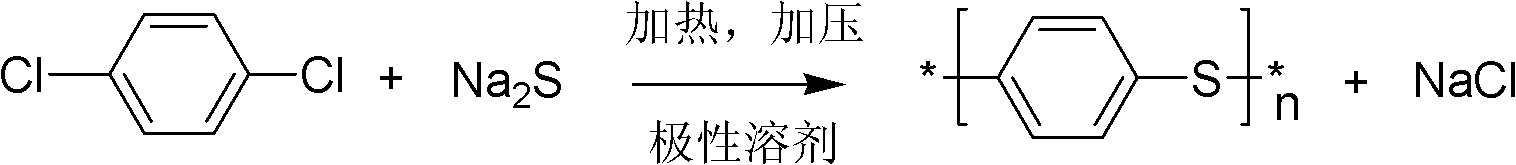

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

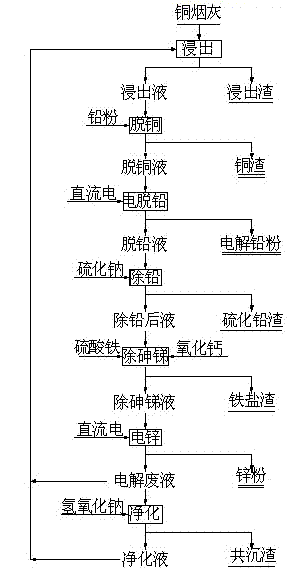

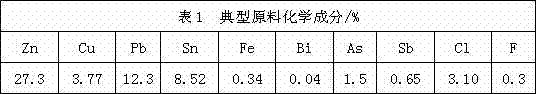

Technology for recovering production of electrolytic zinc powder and lead powder from smelting ash through alkali leaching method

ActiveCN102851707AWide adaptabilityEasy to operateProcess efficiency improvementElectrolysisWaste material

The invention discloses a technology for the recovering production of electrolytic zinc powder and lead powder from smelting ash through an alkali leaching method. The technology comprises a step of copper removal of lead powder, a step of ingot casting for lead removal through electrodeposition, a step of lead removal through using sodium sulfide, a step of arsenic and antimony removal and a step of zinc powder electrodeposition. The technology is characterized in that chemical components in the smelting ash are analyzed, and the smelting ash is leached through a sodium hydroxide leaching agent; the electrolytic lead powder is added to the resultant leachate to remove copper; the electrolytic lead powder is produced through electrodeposition of the resultant copper removed solution; residual lead in the resultant lead removed liquid is separated and deposited through adopting the sodium sulfide as a lead removal agent; arsenic and antimony in the lead removed liquid are removed; and the arsenic and antimony removed purified liquid undergoes electrodeposition to produce zinc powder, and an electrolytic waste liquid returns to the leaching operation as an alkaline leaching agent, or enters the purification operation for removing impurity ions from the waste liquid and then returns to the leaching operation as the alkaline leaching agent for recycle. The technology which can process different types of zinc-containing dust waste materials has the advantages of simple operation, less equipment investment, high zinc and lead recovery rate, and loop cycle, no wastewater discharge and environmental protection in the whole technological process.

Owner:江西自立环保科技有限公司

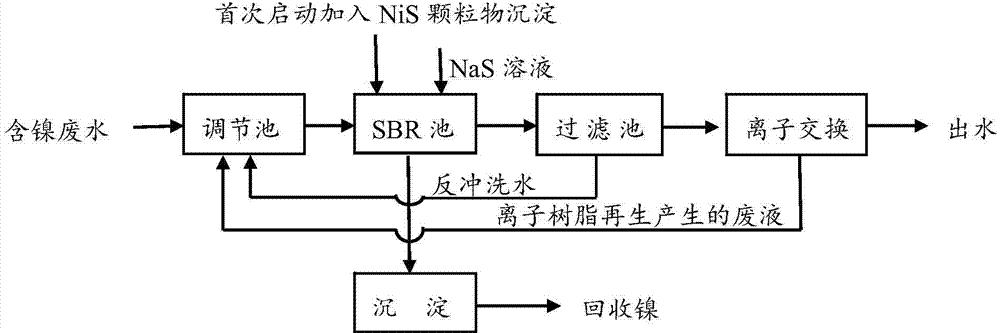

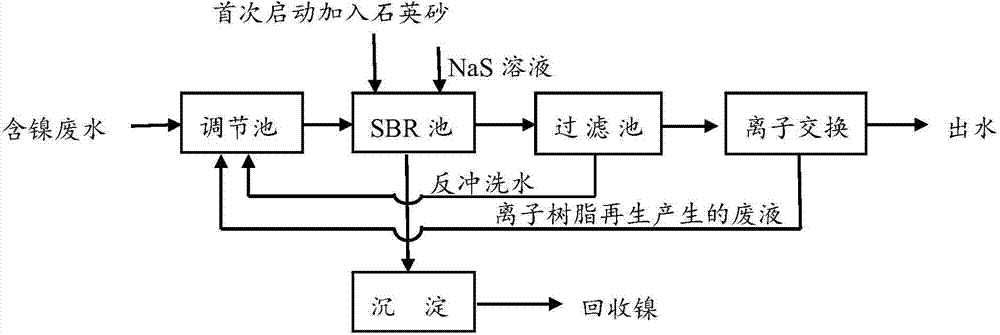

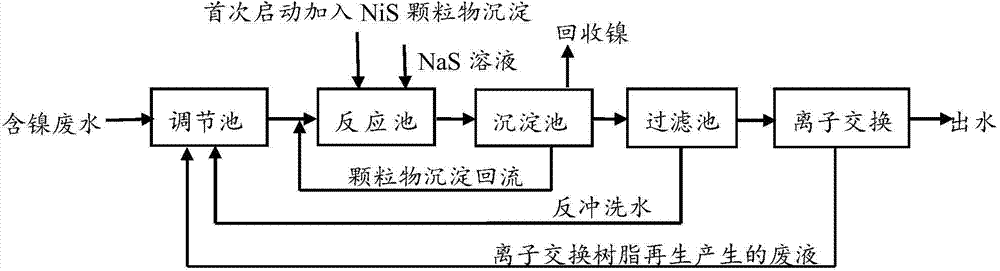

Treatment method of heavy metal wastewater

InactiveCN104261526ATo achieve the purpose of purifying wastewaterLarge particle sizeWater treatment compoundsWater contaminantsParticulatesFiltration

The invention provides a treatment method of heavy metal wastewater, and particularly relates to a method for treating heavy metal wastewater by virtue of a precipitation method. The method comprises the following steps: adding sodium sulfide in a heavy metal wastewater treatment process, reacting sulfur ions with heavy metal ions in the wastewater to generate particulate matters, further adding sulfide precipitates of heavy metal, stirring, standing, and accelerating the sedimentation of micro particulate matters and other substances by using generated particulate matter precipitates; further preferably adding quartz sand, and accelerating the rapid sedimentation of the particulate matters and other substances under the wrapping action of quartz sand; further performing subsequent process treatment including sand filtration and ion exchange on a supernatant liquor obtained after sedimentation to reach the emission standard; and periodically discharging and collecting part of the precipitates, and recycling heavy metals in the precipitates. Because the method provided by the invention is simple in working procedure, low in cost and high in efficiency, the method can be widely applied to the treatment of industrial wastewater particularly the heavy metal wastewater.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

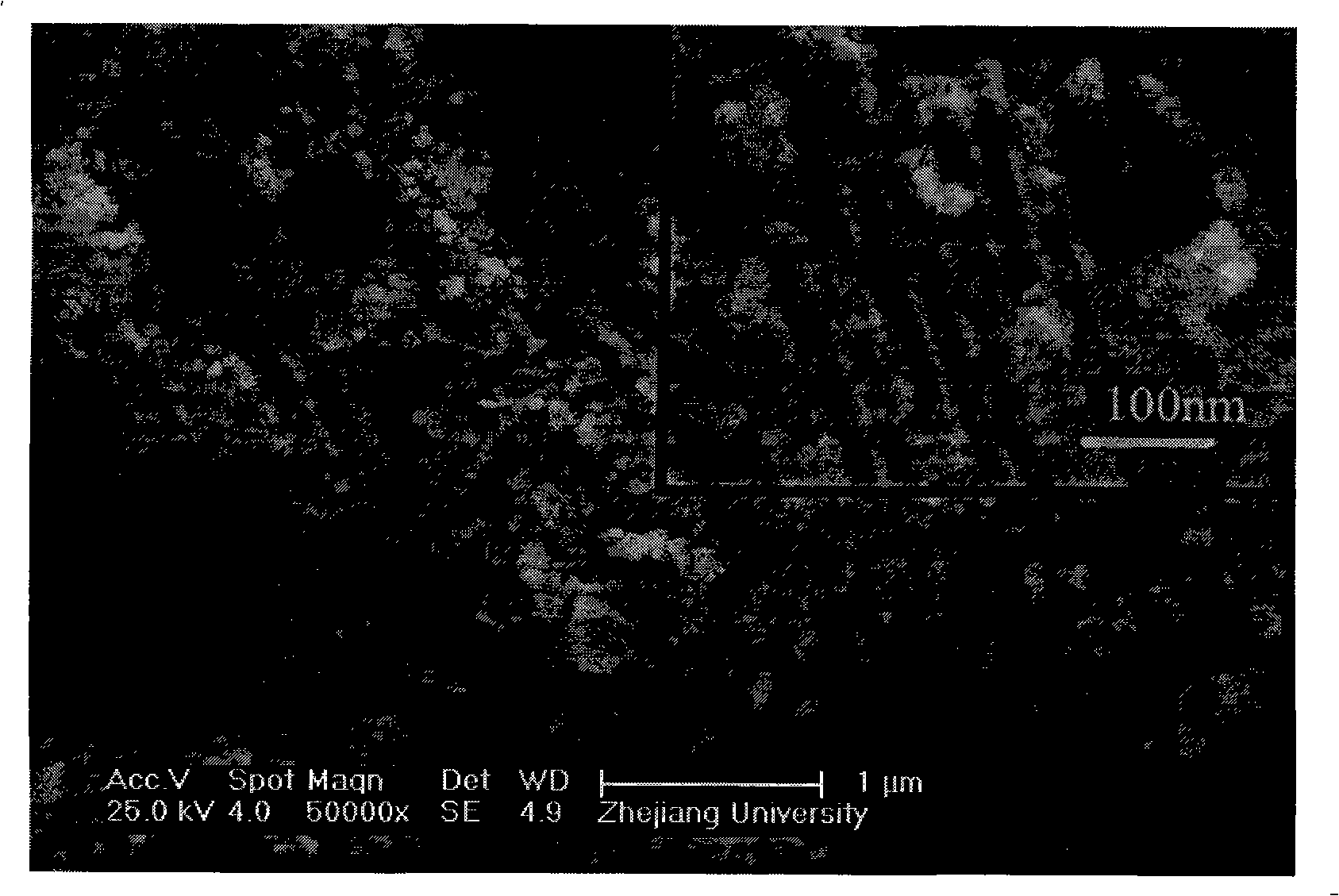

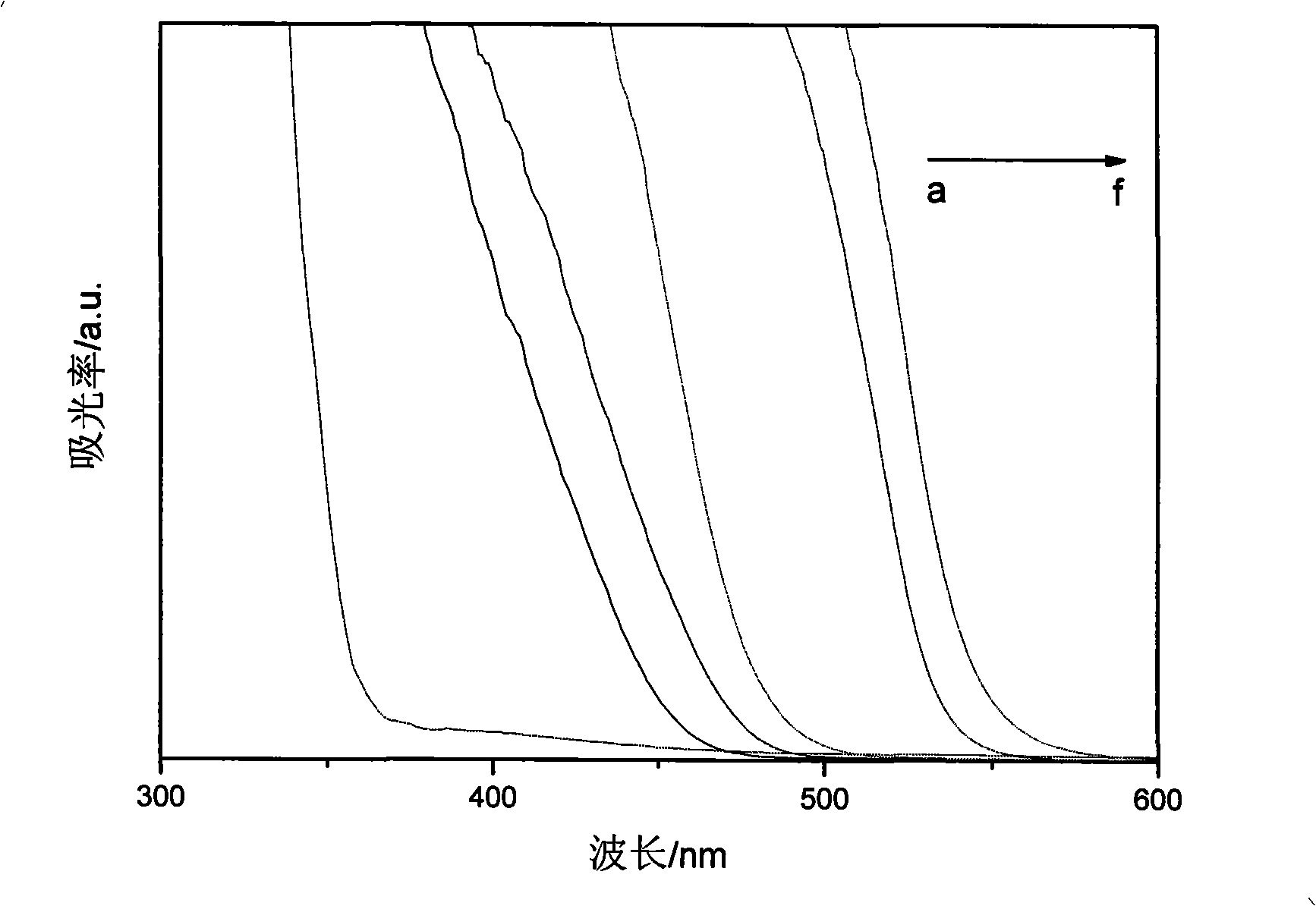

Precipitating-hydrothermal preparation with high visible light catalytic activity nano CdxZn1-xS photocatalyst

InactiveCN101254467AControl ingredient ratioControl grain sizeCatalyst activation/preparationZinc nitrateVisible light photocatalytic

The invention discloses a deposition-hydrothermal method for preparing a nano-sized CdxZn<1-x>S photocatalyst with high visible-light photocatalytic activity. The method includes the following steps: 1) adding dropwise a mixed solution of cadmium nitrate and zinc nitrate into a sodium sulfide solution, stirring at a medium rate for 0.5-3 hours, maintaining the temperature at 10-40 DEG C to obtain a nano-sized powdery precursor precipitate; 2) placing the nano-sized powdery precursor precipitate in a reaction vessel, raising the temperate at a rate of 1-5 DEG C / min up to 150-240 DEG C, maintaining the temperature, allowing hydrothermal reactions for 12-24 hours, stopping the hydrothermal reactions, naturally cooling down to room temperature, taking out the reaction products, washing with the deionized water and the anhydrous alcohol for 3-4 times, drying at 50-80 DEG C in a vacuum drying oven to obtain a solid solution of nano-sized CdxZn<1-x>S photocatalyst. The production method is carried out in water phase with easy operation and low cost. The product has uniform distribution of particle size, the forbidden band width and optical properties thereof are controlled by changing components, and the product has high visible-light photocatalytic activity and good prospects in industrial application.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com