Activation method for flotation process of difficultly processed copper oxide ores

A technology of copper oxide ore and flotation process, which is applied in flotation, solid separation, etc., can solve problems such as difficult treatment of oxide copper ore, and achieve the effect of improving recovery rate and flotation index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

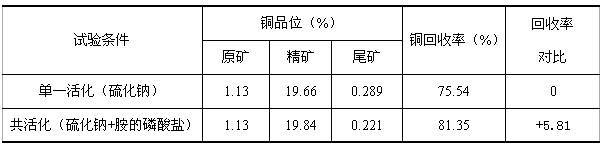

Embodiment 1

[0021] Refractory copper oxide ore raw ore sample properties (mass percentage): Cu: 1.13%, oxidation rate 61.39%, binding rate: 16.74%, CaO: 21.38%, MgO: 16.17%, Al 2 o 3 : 1.63%, SiO 2 : 21.04%, Fe 2 o 3 : 2.11%, Au: <0.2 g / t, Ag: 9.2 g / t.

[0022] (1) Wet-grind 1 ton of copper oxide ore to a mass percentage of 320 mesh qualified particle size accounting for 90% to obtain a slurry with a mass concentration of 75%;

[0023] (2) Add 120 grams of ethylenediamine phosphate to the slurry in step (1), then add 1450 grams of sodium sulfide for co-activation, and then add 320 grams of isobutyl xanthate and amyl xanthate, of which isobutyl The mass ratio of xanthate and pentyl xanthate is 1:1, 60 grams of terpineol oil is added, and multi-stage flotation is carried out. After roughing, sweeping and refining, copper concentrate and tailings are produced.

Embodiment 2

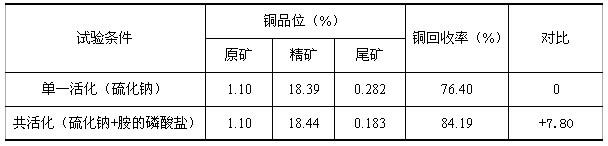

[0025] Refractory copper oxide ore raw ore sample properties (mass percentage): Cu: 1.10%, oxidation rate 60.23%, binding rate: 15.29%, CaO: 21.99%, MgO: 16.87%, Al 2 o 3 : 1.71%, SiO 2 : 20.55%, Fe 2 o 3 : 2.23%, Au: <0.2 g / t, Ag: 9.6 g / t.

[0026] (1) Wet-grind 1 ton of copper oxide ore to a mass percentage of 320 mesh qualified particle size accounting for 90% to obtain a slurry with a mass concentration of 75%;

[0027] (2) Add 100 grams of ethylenediamine phosphate to the slurry in step (1), then add 1450 grams of sodium sulfide for co-activation, and then add 300 grams of isobutyl xanthate and amyl xanthate, of which isobutyl The mass ratio of xanthate and pentyl xanthate is 1:1, 60 grams of terpineol oil is added, and multi-stage flotation is carried out. After roughing, sweeping and refining, copper concentrate and tailings are produced.

Embodiment 3

[0029] Refractory copper oxide ore raw ore sample properties (mass percentage): Cu: 1.13%, oxidation rate 61.39%, binding rate: 16.74%, CaO: 21.38%, MgO: 16.17%, Al 2 o 3 : 1.63%, SiO 2 : 21.04%, Fe 2 o 3 : 2.11%, Au: <0.2 g / t, Ag: 9.2 g / t.

[0030] (1) Wet-grind 1 ton of copper oxide ore to a mass percentage of 320 mesh qualified particle size accounting for 85% to obtain a slurry with a mass concentration of 60%;

[0031] (2) Add 80 grams of ethylenediamine phosphate and ammonium hydrogen phosphate to the slurry in step (1), then add 2000 grams of sodium sulfide for co-activation, then add 250 grams of isobutyl xanthate, and add 50 grams of pinitol Oil is subjected to multi-stage flotation, and after roughing, sweeping and beneficiation, copper concentrate and tailings are produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com