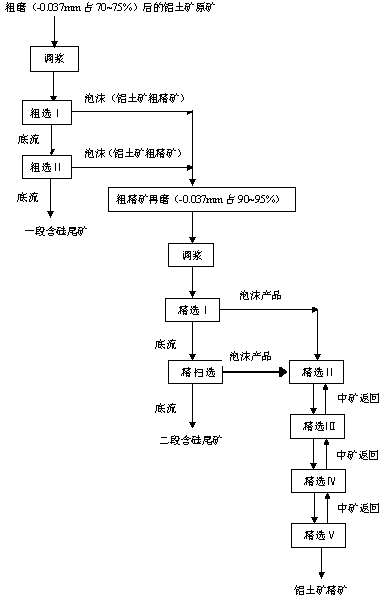

Flotation two-stage desiliconization method for high-silicon bauxite

A high-silicon bauxite and bauxite technology, applied in flotation, solid separation, etc., can solve the problems affecting the recovery rate of concentrate, fine particle size of embedding, easy grinding, etc., to improve flotation index and flotation rate, reduction of silica content, and the effect of high-efficiency enrichment and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) First, the Ludian bauxite in Zhaotong, Yunnan Province (the main component of bauxite is Al 2 o 3 60.50wt%, SiO 2 18.68wt%, TiO 2 2.06wt%, Fe 2 o 3 0.55wt%, CaO 0.55wt%, MgO 0.52wt%, K 2 O 3.17 wt%, Na 2 O 0.10%, aluminum-silicon ratio 3.24, aluminum-containing minerals are mainly diaspore, silicon-containing minerals are mainly kaolinite, illite, chlorite, pyrophyllite, quartz, muscovite, etc.) The raw ore is crushed and screened to - 2mm, then coarsely grind it until the particle size is -0.074mm, accounting for 75 wt%, add water to adjust the pulp concentration to 35 wt%, then add 5000g / t sodium carbonate to the pulp once, adjust the pH value to 8, and then add water in turn 500g / t of glass, 300g / t of sodium hexametaphosphate, 200g / t of lead acetate, 900g / t of sodium oleate, 20g / t of pine oil are used for pulping. The foam obtained by selecting I is bauxite coarse concentrate, and the underflow in the tank passes through roughing II in (2) as follows; ...

Embodiment 2

[0028] (1) Firstly, the bauxite of Zunyi Bauxite in Guizhou Province (the main component of bauxite is Al 2 o 3 56.70wt%, SiO 2 17.32wt%, TiO 2 2.31wt%, Fe 2 o 3 0.95wt%, CaO 0.45wt%, MgO 0.76wt%, K 2 O 2.18wt%, Na 2 O 0.32%, aluminum-silicon ratio 3.27, aluminum-containing minerals are mainly diaspore, silicon-containing minerals are mainly kaolinite, illite, chlorite, pyrophyllite, quartz, muscovite, etc.) The raw ore is crushed and screened to - 2mm, then roughly grind it until the particle size is -0.074mm, accounting for 70 wt%, add water to adjust the pulp concentration to 33 wt%, then add 5500g / t sodium carbonate to the pulp once, adjust the pH value to 8.7, and then add water in turn Glass 550g / t, sodium hexametaphosphate 330g / t, lead acetate 260g / t, sodium oleate 1000g / t, pine oil 15g / t for pulping, after pulping, carry out flotation for a stage of desiliconization roughing I, roughing The foam obtained by selecting I is bauxite coarse concentrate, and the ...

Embodiment 3

[0034] (1) First, bauxite from Tiandong Bauxite Mine in Guangxi (the main component of bauxite is Al 2 o 3 62.20wt%, SiO 2 18.30wt%, TiO 2 2.47wt%, Fe 2 o 3 1.43wt%, CaO 0.37wt%, MgO 0.68wt%, K 2 O1.20wt%, Na 2 O 0.22%, aluminum-silicon ratio 3.40, aluminum-containing minerals are mainly diaspore, silicon-containing minerals are mainly kaolinite, illite, chlorite, pyrophyllite, quartz, muscovite, etc.) The raw ore is crushed and screened to - 2mm, then roughly grind it until the particle size is -0.074mm, accounting for 72 wt%, add water to adjust the pulp concentration to 30 wt%, then add 6000g / t sodium carbonate to the pulp once, adjust the pH value to 9, and then add water in turn Glass 600g / t, sodium hexametaphosphate 500g / t, lead acetate 300g / t, sodium oleate 800g / t, pine oil 10g / t for pulping, and after pulping, carry out flotation for a stage of desiliconization. The foam obtained by selecting I is bauxite coarse concentrate, and the underflow in the tank pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com