Bauxite low temperature continuous dissolving out technology

A bauxite, low-temperature technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of high energy consumption and large equipment investment, and achieve the simplification of employee operation, reduction of operation intensity and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

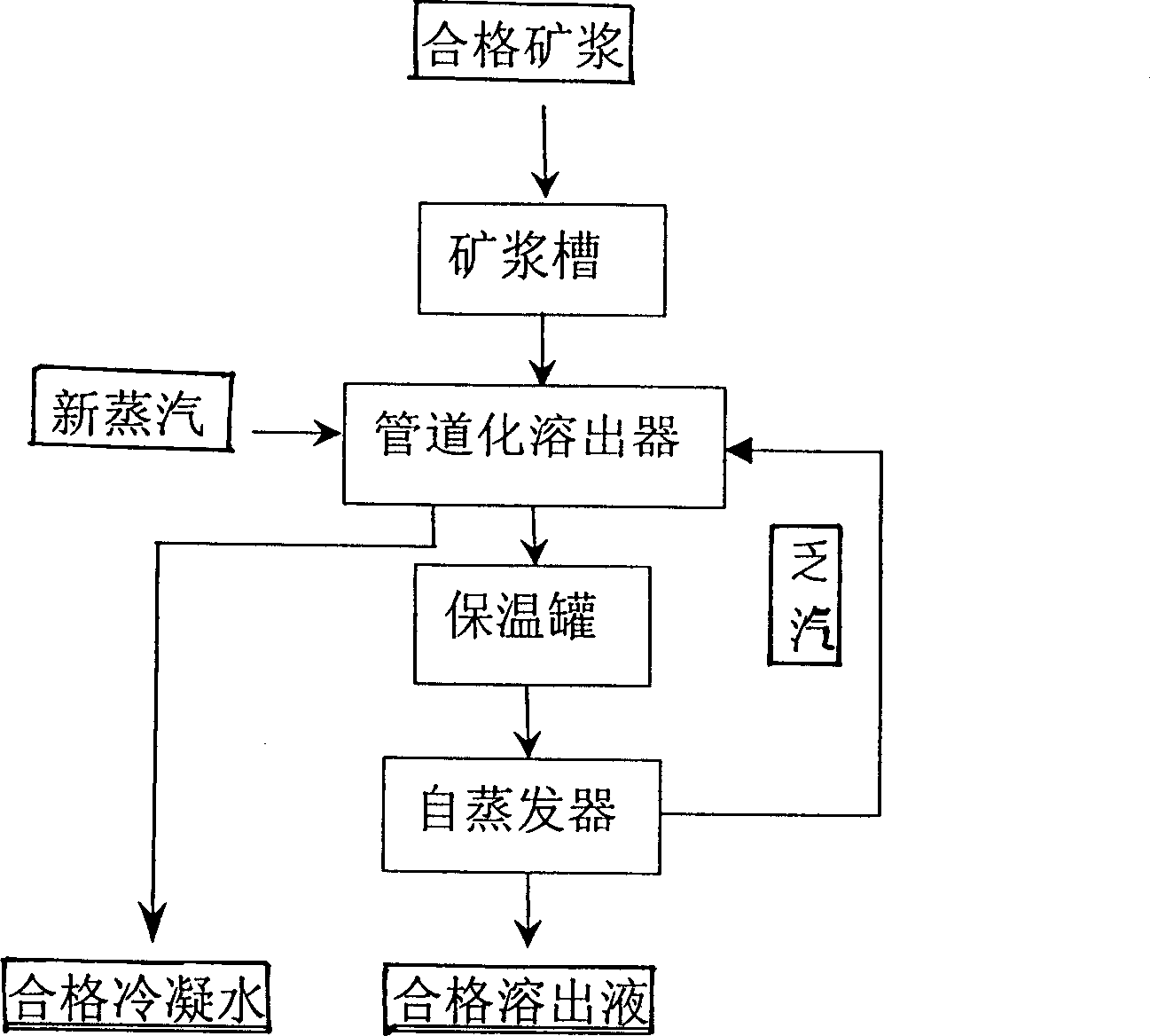

Method used

Image

Examples

Embodiment 1

[0020] The main components of bauxite are: aluminum oxide 52%, iron oxide 8.2%, silicon oxide 5.8%, aluminum silicon ratio 8.96, the treatment process of low temperature continuous dissolution process is as follows:

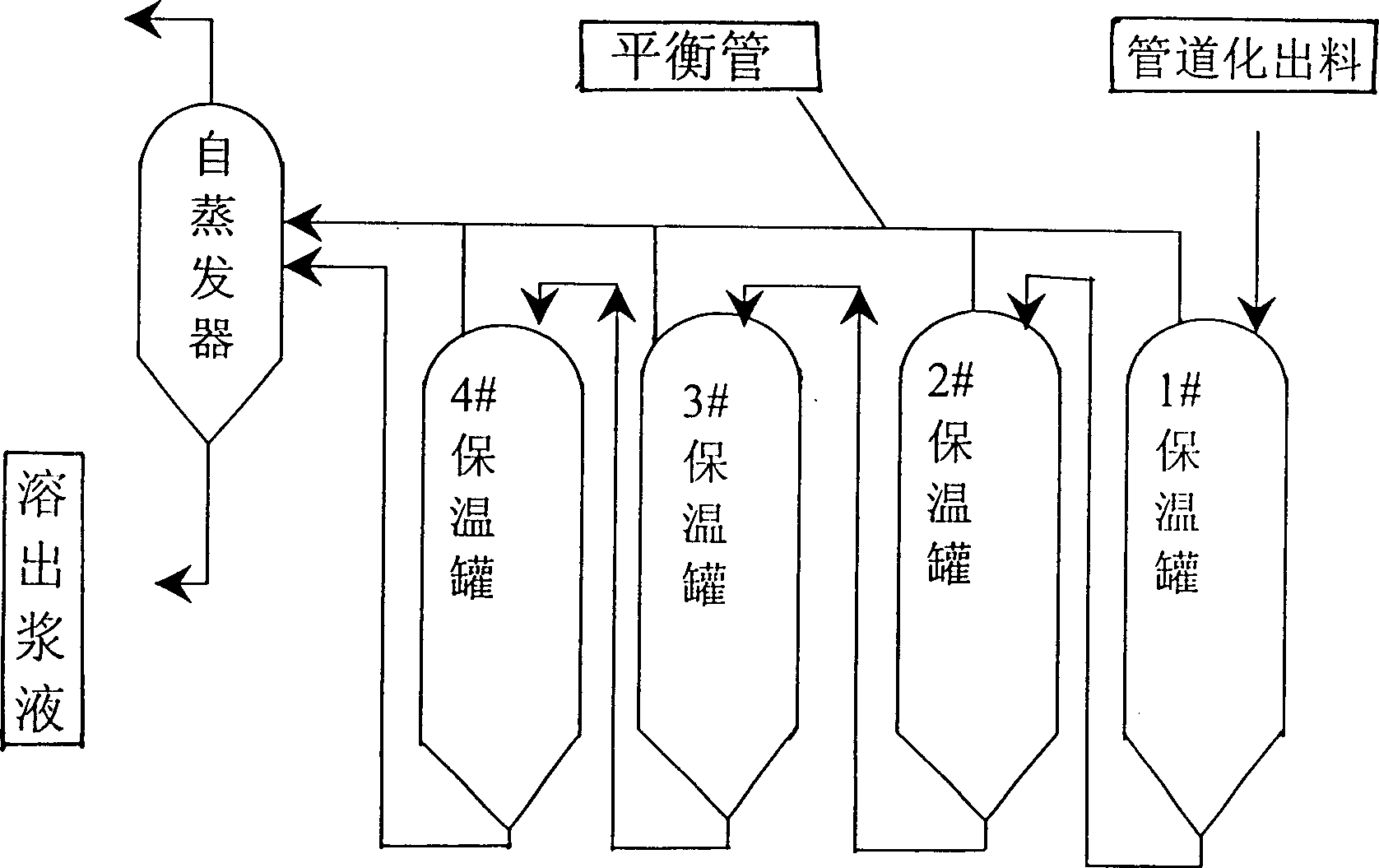

[0021] Firstly, it is ground to a solid content of 300g / l and a fineness of +100 # 45% qualified pulp, the pulp temperature is 65°C, and then at 150m 3 The feed rate of / h enters the pipeline dissolution device. There is a heated steam chamber outside the dissolution pipeline. The dissolution tube is spirally coiled from bottom to top. The first layer of the feed is heated by steam condensed water, and the second and third layers are from bottom to top. It is heated with secondary exhaust steam, the fourth and fifth layers are heated with primary exhaust steam, and the top four layers are heated with new steam with a steam pressure of 0.65MPa. The temperature is 142°C, the alumina concentration is 200g / l, the A / S value is 183, and the caustic ratio of the soluti...

Embodiment 2

[0024] The main components of bauxite are: 55% aluminum oxide, 8.8% iron oxide, 5.6% silicon oxide, and the treatment process of the low-temperature continuous dissolution process is as follows:

[0025] First grind it to a solid content of 250g / l, fineness +100 # 40% qualified pulp, the temperature of the pulp is 63°C, and then at 150m 3 The feed rate of / h enters the pipeline dissolution device, the new steam vapor pressure is 0.60MPa, after passing through the tubular dissolution with a flow rate of 1.6m / s, the discharge temperature is 135°C, the alumina concentration is 210g / l, A / S The value is 189, and the solution caustic ratio is 1.41. Then the slurry enters 42m in turn 3 The large and small 0.35MPa pressure insulation tanks are subjected to continuous four-stage heat preservation for 50 minutes. At this time, the desiliconization index is 210, and then enters two stages of self-evaporation cooling.

[0026] Others are basically the same as in Example 1.

Embodiment 3

[0028] The main components of bauxite are: 58% aluminum oxide, 10.4% iron oxide, 6.7% silicon oxide, and the treatment process of the low-temperature continuous dissolution process is as follows:

[0029] First grind it to a solid content of 340g / l, fineness +100 # 38% qualified pulp, the temperature of the pulp is 65°C, and then at 148m 3 The feed rate of / h enters the pipeline dissolution device, the new steam vapor pressure is 0.72MPa, after passing through the tubular dissolution with a flow rate of 1.8m / s, the discharge temperature is 145°C, the alumina concentration is 190g / l, A / S The value is 185, and the solution caustic ratio is 1.38. Then the slurry enters 42m in turn 3 The 0.46MPa pressure insulation tank with large and small sizes is subjected to continuous four-stage heat preservation for 55 minutes. At this time, the desiliconization index is 196, and then enters two-stage self-evaporation cooling.

[0030] Others are basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com