Patents

Literature

36results about How to "Good desiliconization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation purification method for siliceous distillate

ActiveCN101343565AIncrease capacityFast inactivationTreatment with hydrotreatment processesPurification methodsHydrogen

The invention relates to a silicon-containing distillate oil hydrofining method, which adopts the method that the silicon-containing distillate oil raw material and hydrogen pass through at least two hydrofining catalyst beds under the hydrofining condition, the silicon-containing distillate oil raw material first passes through a hydrogenising catalyst bed with the silicon catching function, and then passes through a conventional hydrofining catalyst bed; wherein the hydrogenising catalyst with the silicon catching function has a greater pore volume and a specific surface area and a relatively lower metal content. Compared with the prior art, the method has the advantages that the process is simple, the good hydrodesulfurization and hydrodedenitrification performance is kept on the premise of enhancing the silicon-containing ability, and the running period of the device is effectively prolonged. The method can be applied to various silicon-containing distillate oil hydrofining processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

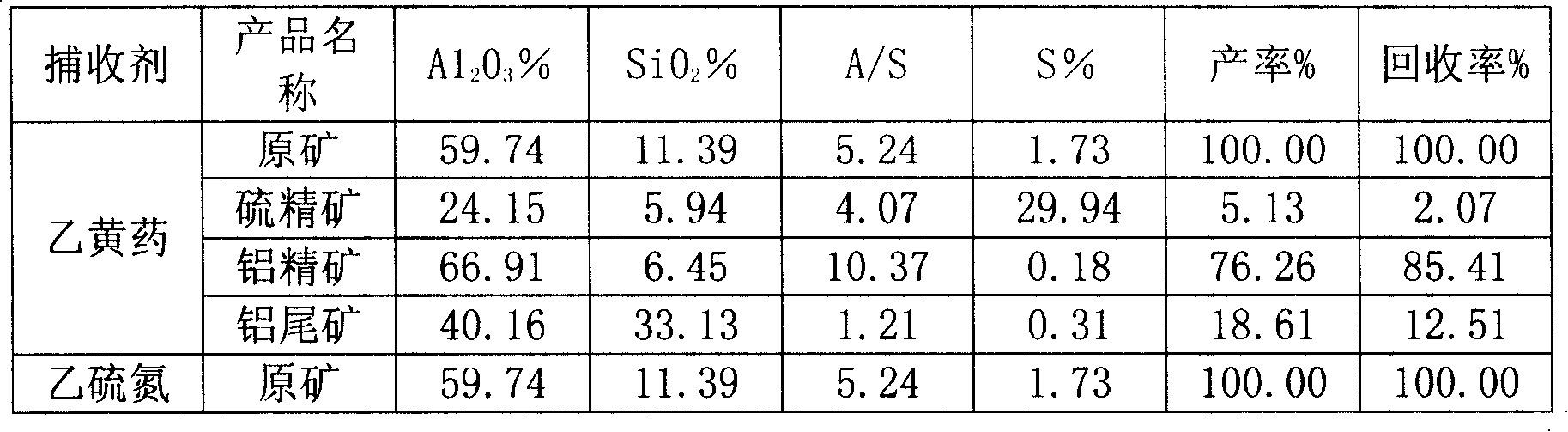

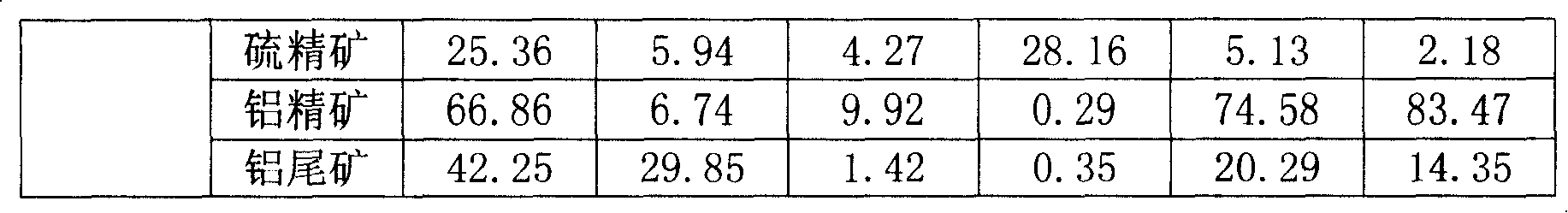

Method of flotation desulfur desilicon in bauxite

ActiveCN1868599AAdvanced technologyIncrease production capacityAluminates/aluminium-oxide/aluminium-hydroxide purificationFlotationResource utilizationFatty acid

A floatation process for bauxite to remove S and Si includes such steps as grinding the crude bauxite, adding the yellow catching agent B, reverse floatation for removing S, grinding, adding the match of saponified fatty acid and naphthenic acid, and forward floatation. The resultant bauxite concentrate can be used to prepare aluminum oxide by Bayer method.

Owner:中铝郑州有色金属研究院有限公司

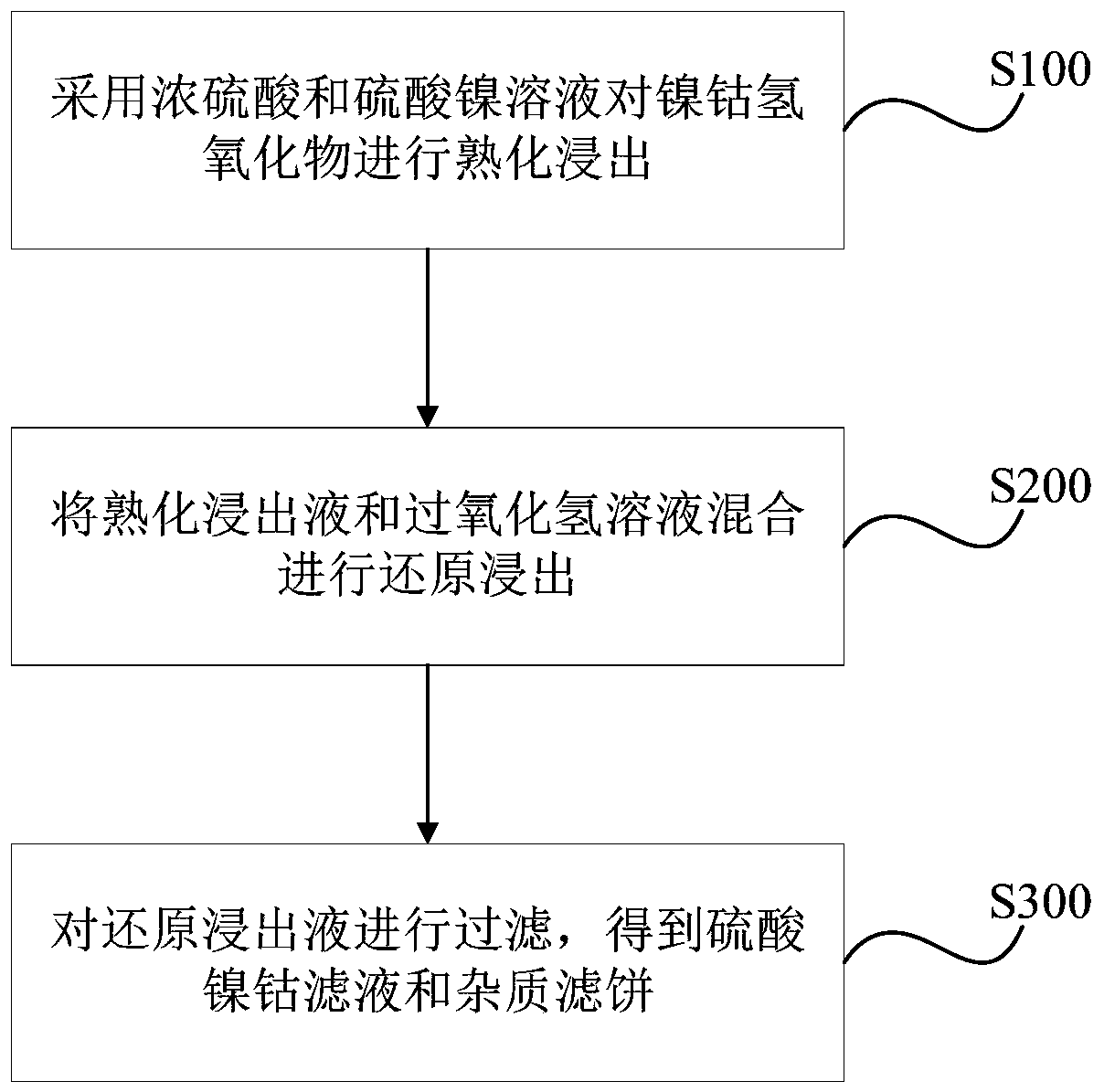

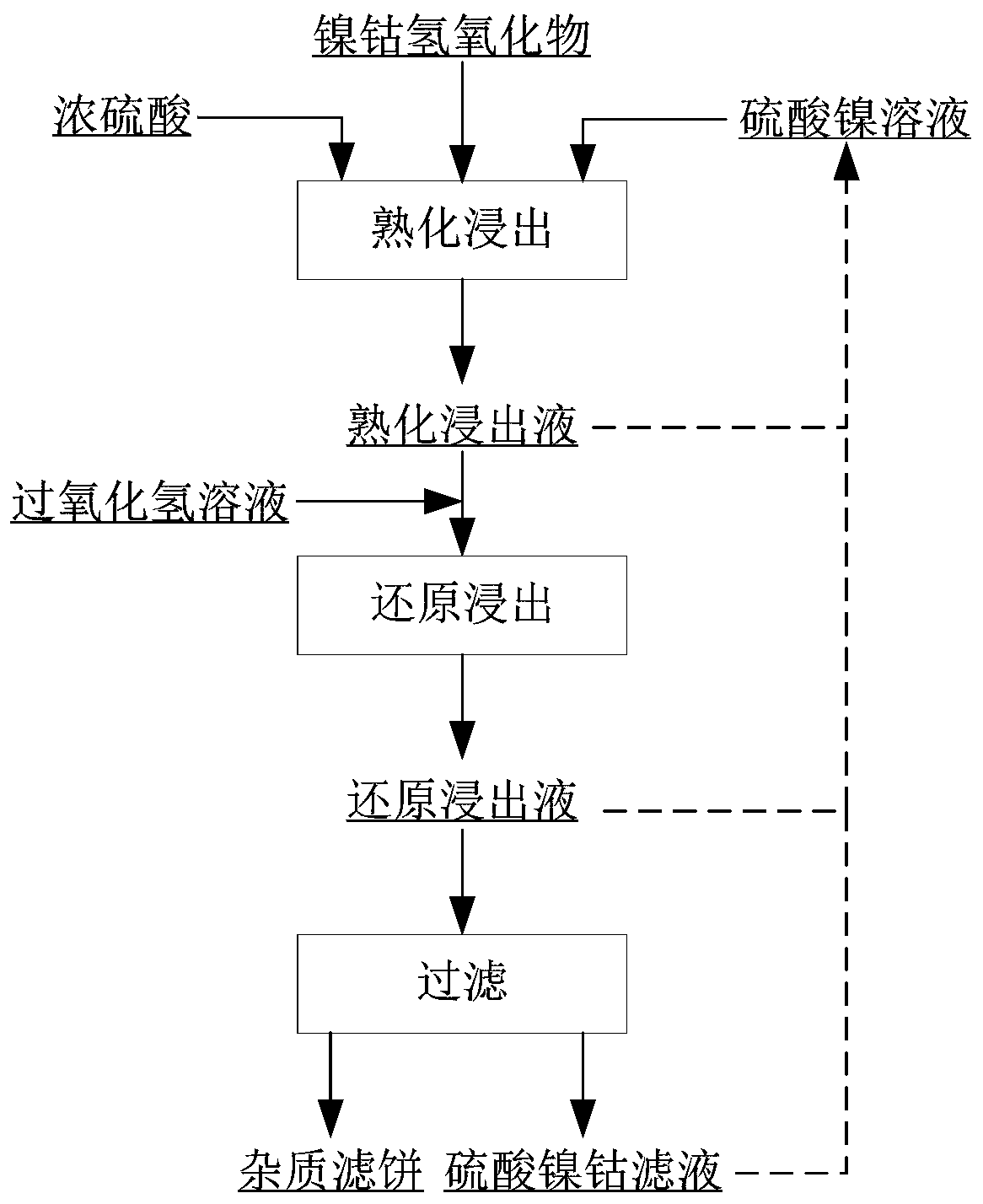

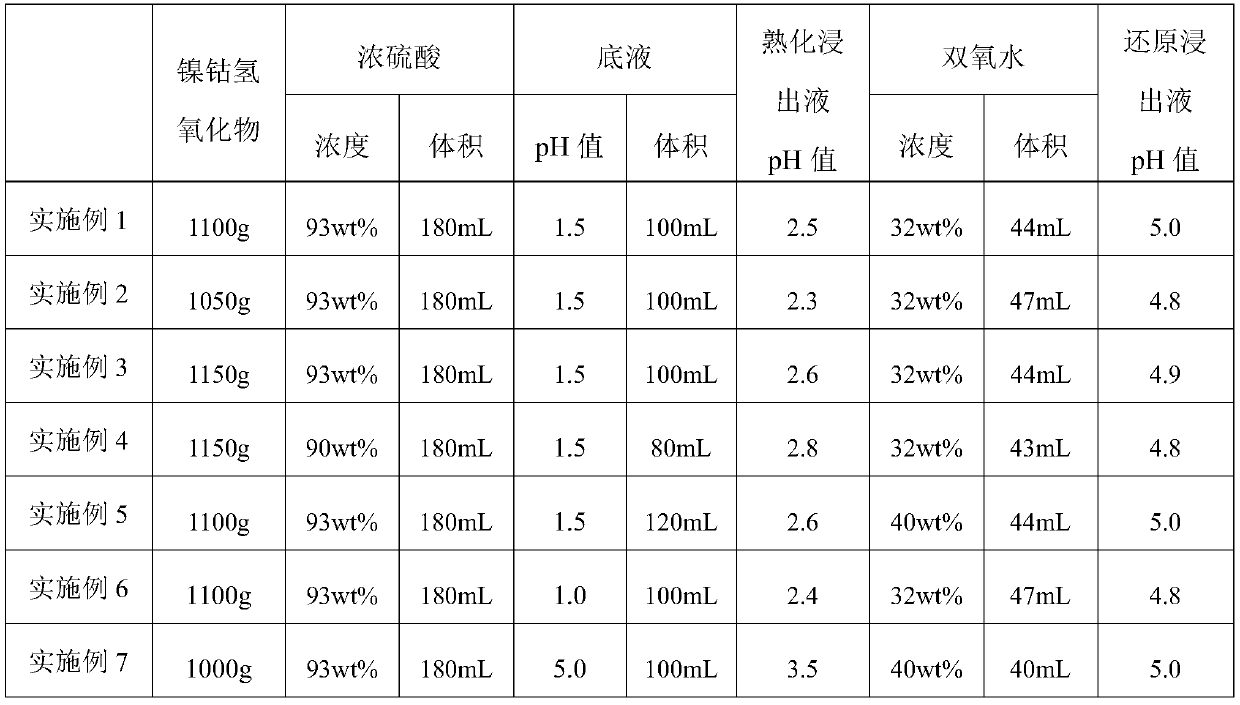

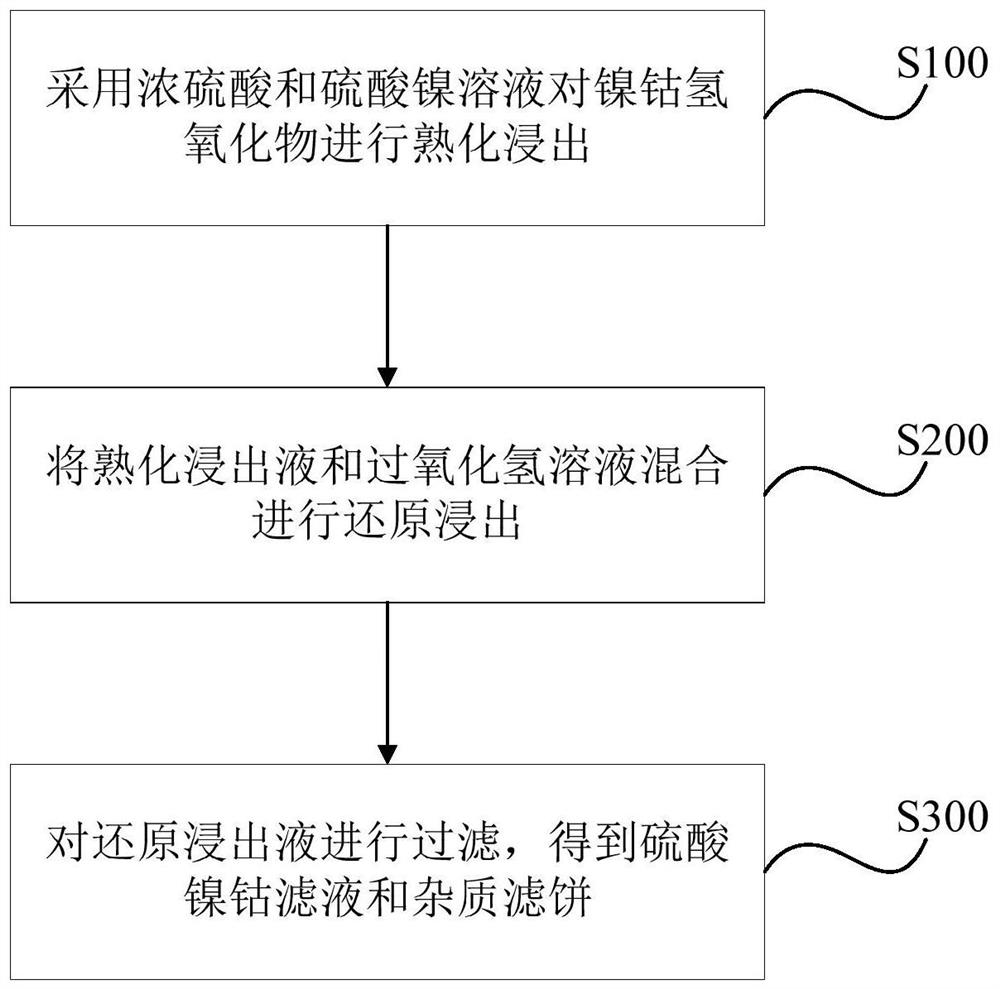

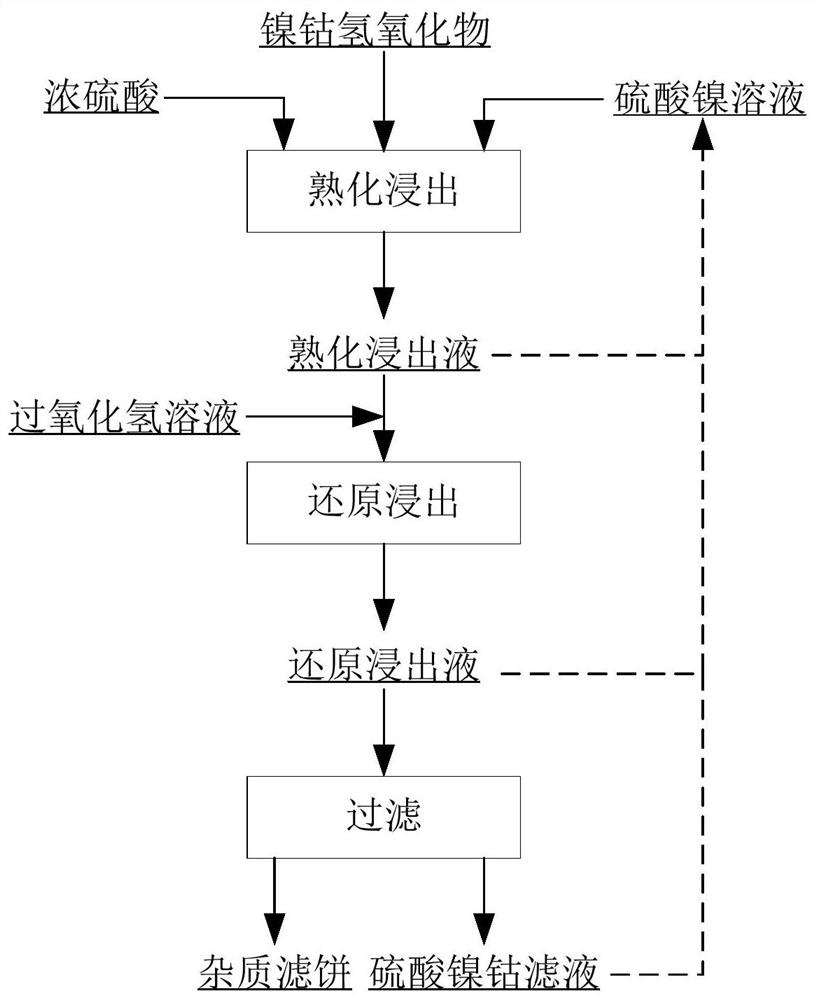

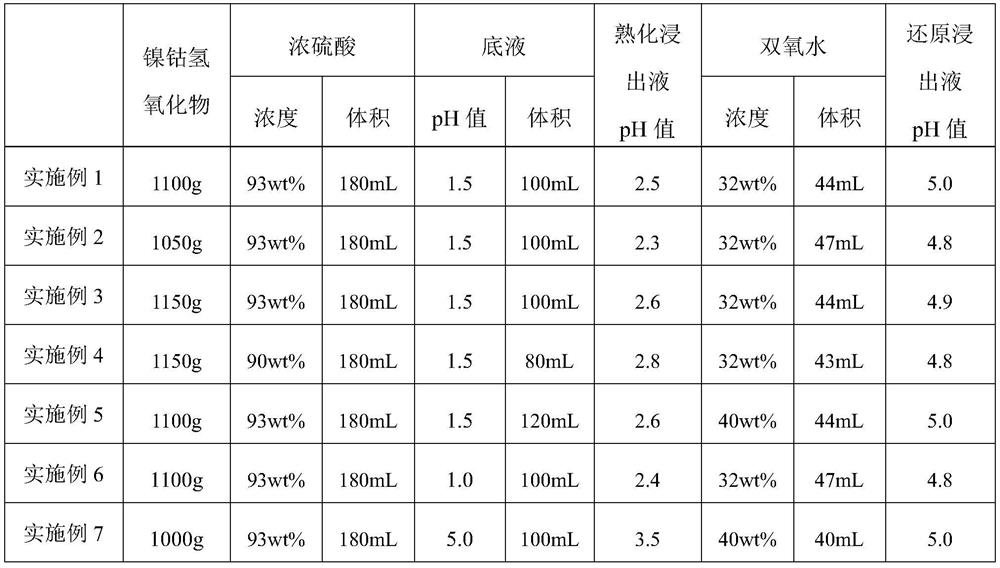

Method for treating nickel-cobalt hydroxide

The invention discloses a method for treating nickel-cobalt hydroxide. The method comprises the following steps that (1) curing leaching is carried out on the nickel-cobalt hydroxide by adopting concentrated sulfuric acid and a nickel sulfate solution so as to obtain a cured leaching solution; (2) the cured leaching solution is mixed with a hydrogen peroxide solution for carrying out reduction leaching so as to obtain a reduction leaching solution; and (3) the reduction leaching solution is filtered so as to obtain nickel-cobalt sulfate filtrate and an impurity filter cake, wherein the nickel-cobalt hydroxide is obtained by recovering nickel-cobalt from laterite-nickel ore, and the pH value of the reduction leaching solution is 3 - 5. According to the method for treating the nickel-cobalthydroxide, the consumption of auxiliary materials can be effectively reduce, the production cost is reduced, the recovery rate of nickel is remarkably improved, and a remarkable effect of removing silicon and removing flocculant is achieved; and the silicon content in the finally obtained nickel-cobalt sulfate filtrate is not higher than 40 mg / L, the sodium ion content is not higher than 1.0 g / L,the COD value is not higher than 100 mg / L, and the requirements of producing ternary precursor products can be effectively met.

Owner:中冶瑞木新能源科技有限公司

Desiliconization process in zinc hydrometallurgy

ActiveCN102828051AReduced soluble silicon contentGood desiliconization effectProcess efficiency improvementIron removalHydrometallurgy

The invention belongs to the technical field of zinc hydrometallurgy and relates to a desiliconization process in the zinc hydrometallurgy. The process mainly controls pulp in a soaking groove to alternately react in a pH value region between 1.5-2.0 and 3.5-4.0 on the basis of process steps of zinc hydrometallurgy such as neutral leaching, acid leaching, preneutralization, vitriol sediment and iron removal, avoids a pH value region between 2.0-2.5 when silica gel is easy to separate out, and easily guarantees finish pH value of leached central and upper clear liquid. The desiliconization process is simple in process requirement and obvious in desiliconization effect, obviously improves a pulp filtration rate, and improves adaptability of raw materials.

Owner:BAIYIN NONFERROUS GROUP

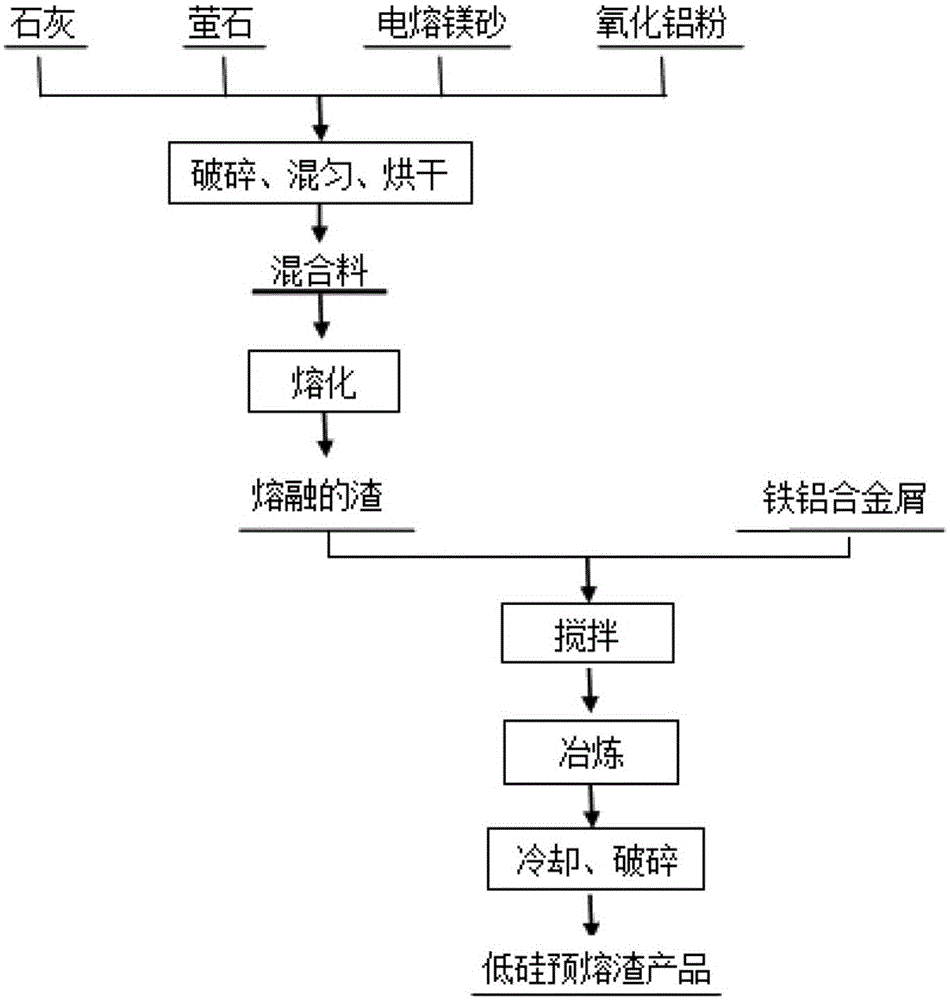

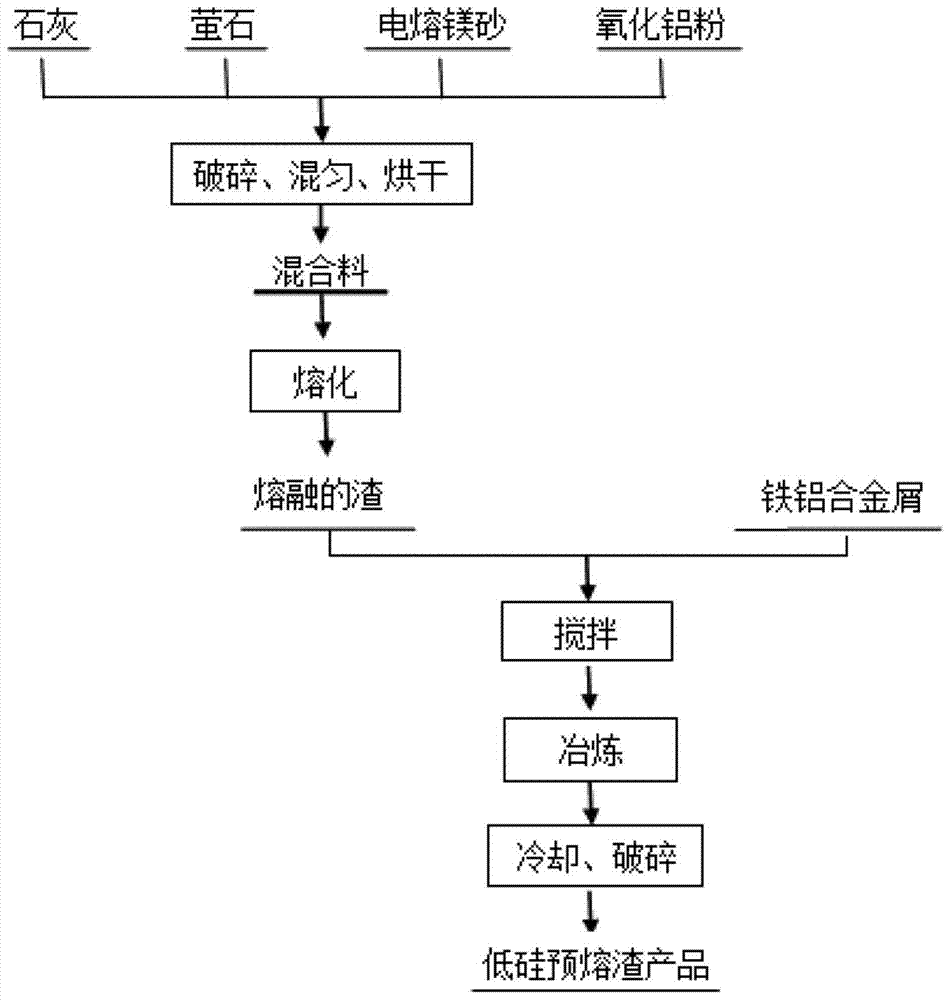

Preparing method of low-silicon pre-melted slag for electroslag remelting

The invention provides a preparing method of low-silicon pre-melted slag for electroslag remelting. The preparing method comprises the first step of even slag charge mixing, the second step of slag smelting and the third step of aluminum iron alloy adding and smelting. According to the preparing method of low-silicon pre-melted slag for electroslag remelting, the requirement for equipment is low, operation is easy, control is convenient, and cost is low. The problem that Al, Ti and elements prone to oxidation are burned down in the electroslag remelting process can be effectively solved.

Owner:NORTHEASTERN UNIV

Method for preparing porous conductive carbon with rice husks as raw materials

InactiveCN104528688ATo achieve the purpose of making holesMild conditionsSolid waste disposalHydrofluoric acidDecomposition

The invention belongs to the high-valued application field of agricultural solid residues, and particularly relates to a method for preparing porous conductive carbon on the basis of rice husks. The method uses the rice husks as raw materials, conductive carbon is prepared through the catalytic, hole forming and other characteristics of products generated after heating decomposition of zinc carbonate, and the prepared materials has the advantages of being porous, highly dispersed, good in electrical conductivity and the like. According to the technical scheme, the rice husks are smashed first, and desilicication rice husk powder is prepared after hydrofluoric acid desilicication is carried out; zinc carbonate is then added to the desilicication rice husk powder, and the porous conductive carbon is obtained through high-temperature calcination.

Owner:CHANGZHOU UNIV

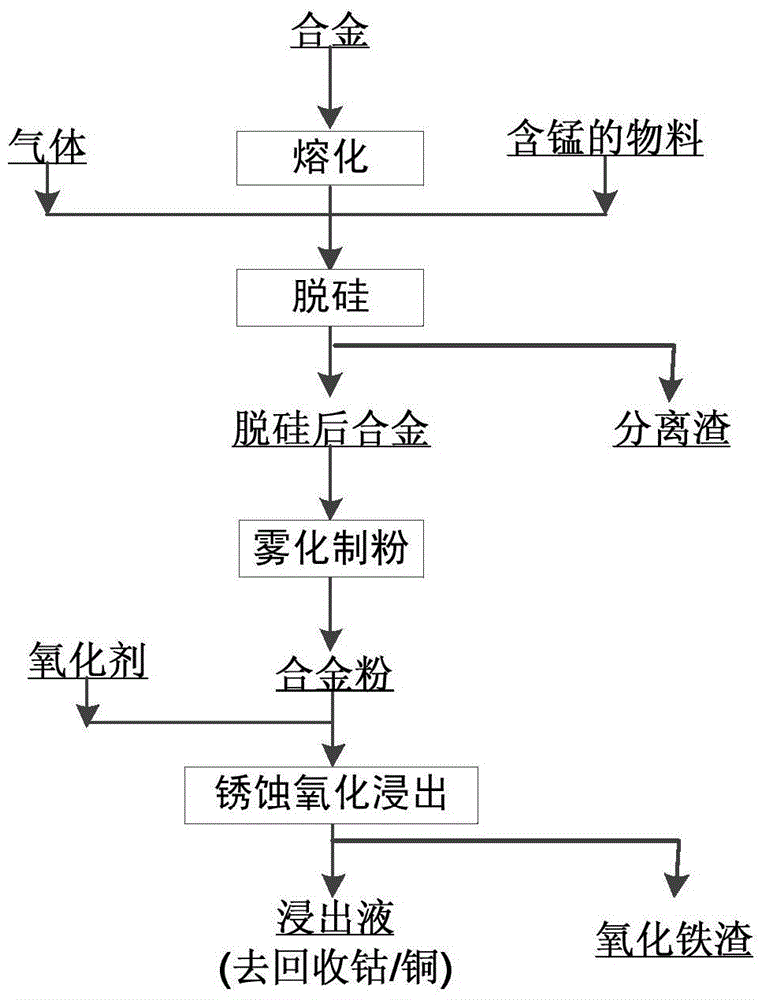

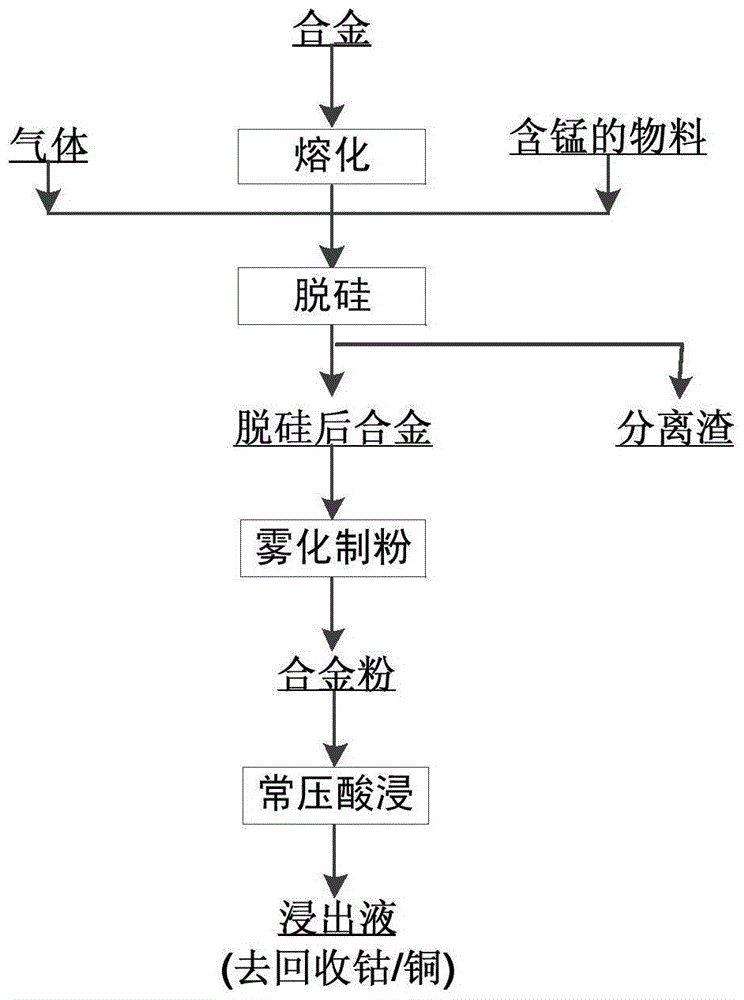

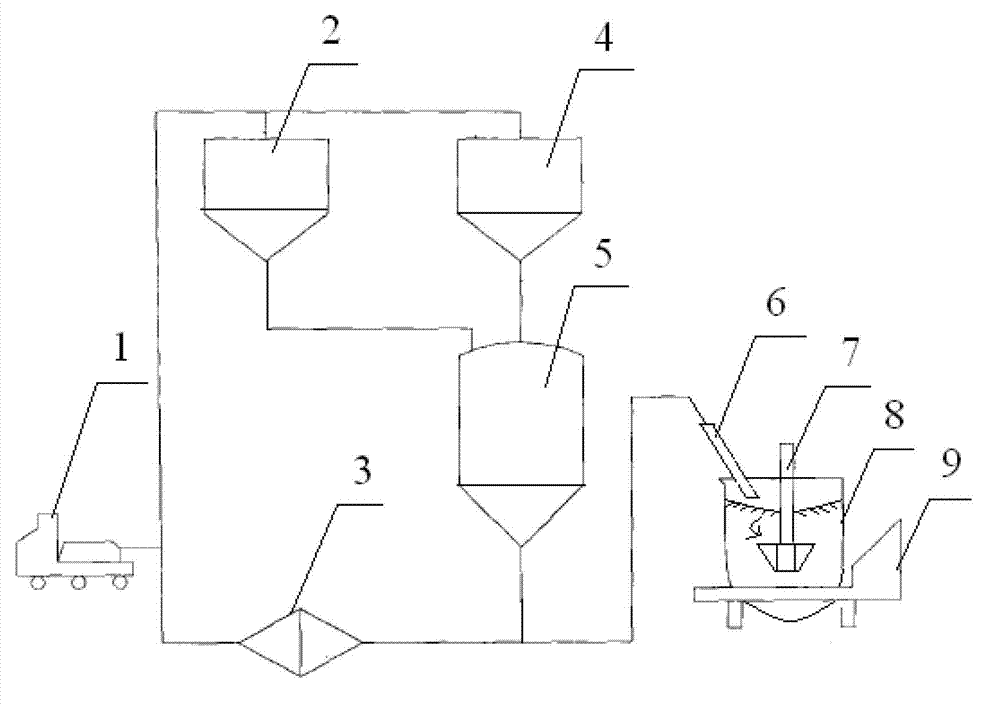

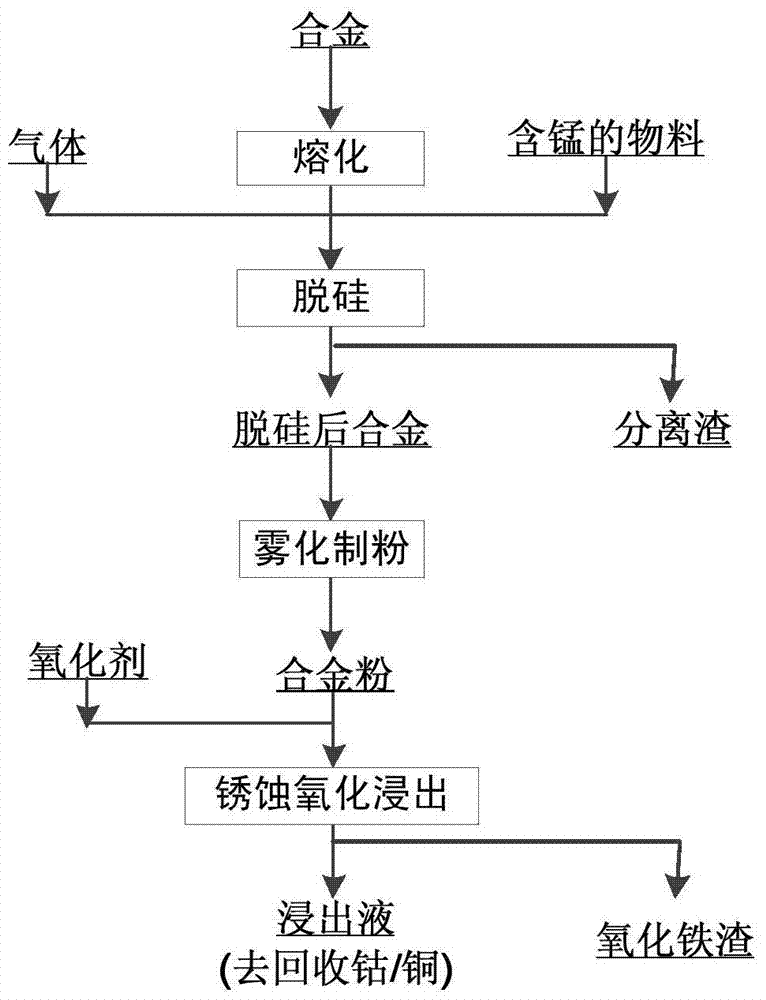

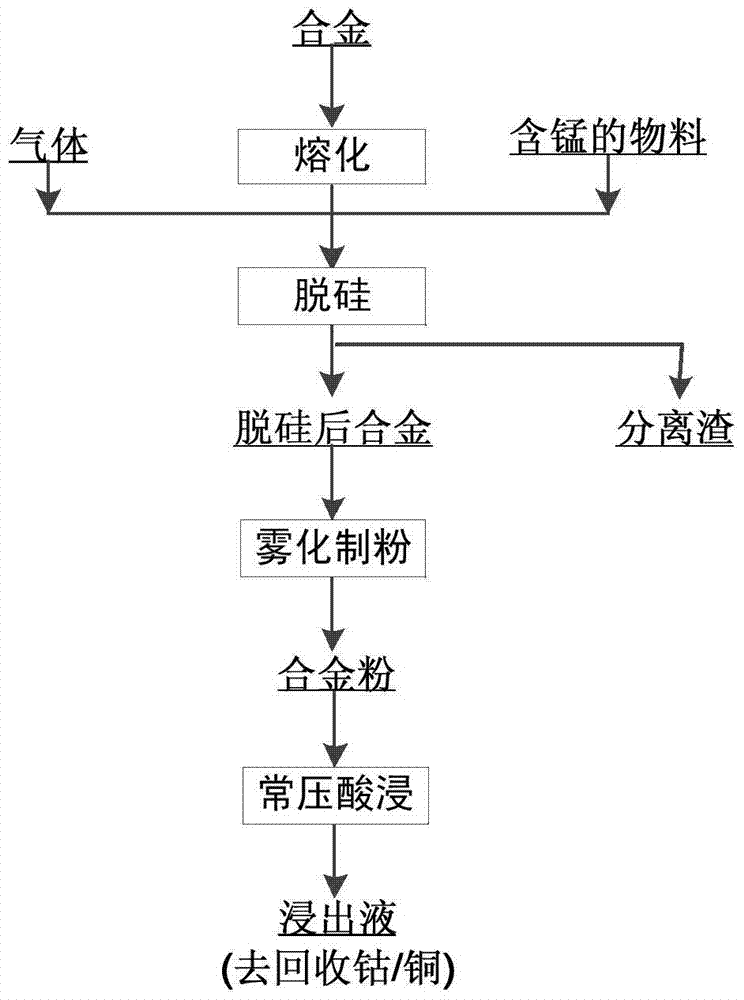

Method for leaching valuable metal from cobalt-copper white alloy

ActiveCN105063353AGuaranteed not to be oxidizedAchieve separationProcess efficiency improvementSlagManganese

The invention discloses a method for leaching valuable metal from cobalt-copper white alloy. The method includes the following steps that (1) the cobalt-copper white alloy is melted into an alloy melt, wherein the cobalt-copper white alloy contains silicon and almost contains no manganese; (2) a Mn-containing material is added into the alloy melt, and meanwhile gas is led in for blowing and slagging; (3) obtained slag is separated from the melt; (4) the melt with the slag separated out is atomized into alloy powder, wherein the mass friction of Mn in the alloy powder is 0.5%-20%; and (5) the alloy powder is subjected to acid leaching, and the valuable metal is recovered. Due to the fact that the Mn-containing material is added and reacts with the silicon in the cobalt-copper white alloy to generate the MnO-SiO2 slag, the silicon removal effect is achieved, and the method has the beneficial effects of being good in silicon removal effect and small in valuable metal loss. Besides, the melting temperature is much lower than the melting point of CaO-(MgO)-SiO2 binary system or ternary system slag in the prior art.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

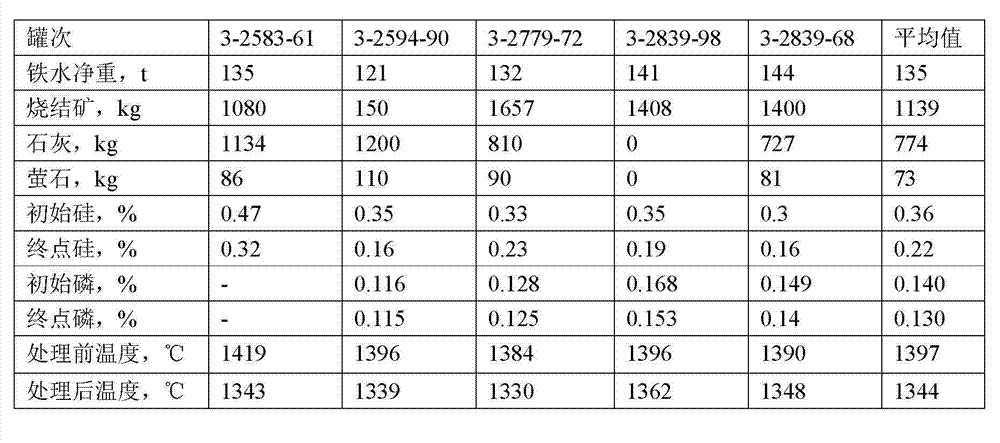

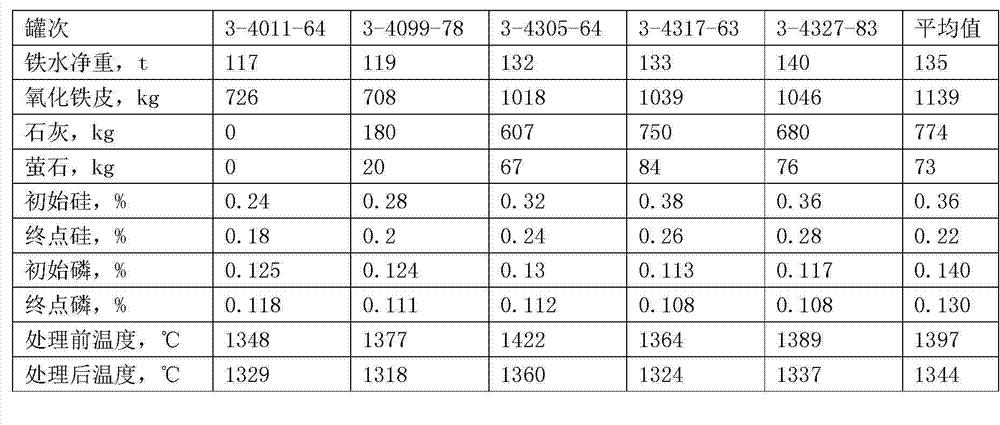

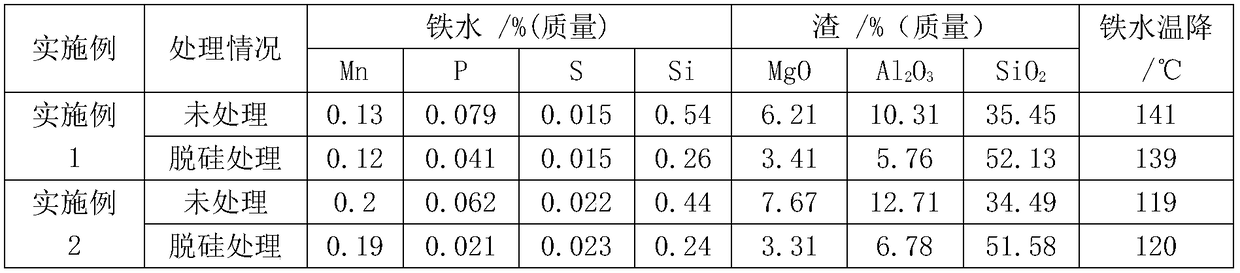

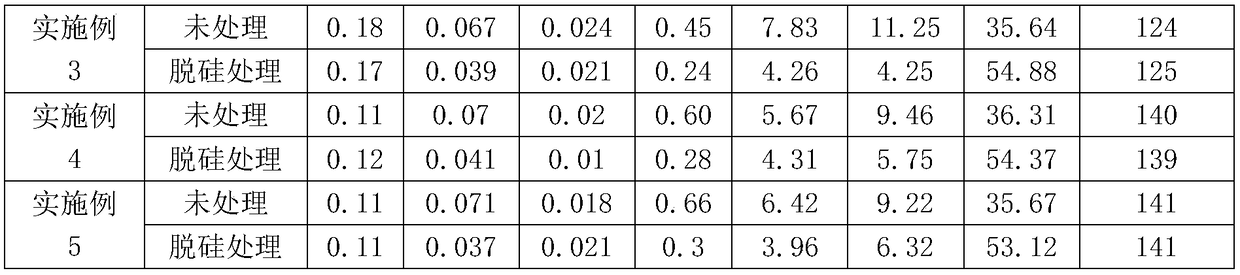

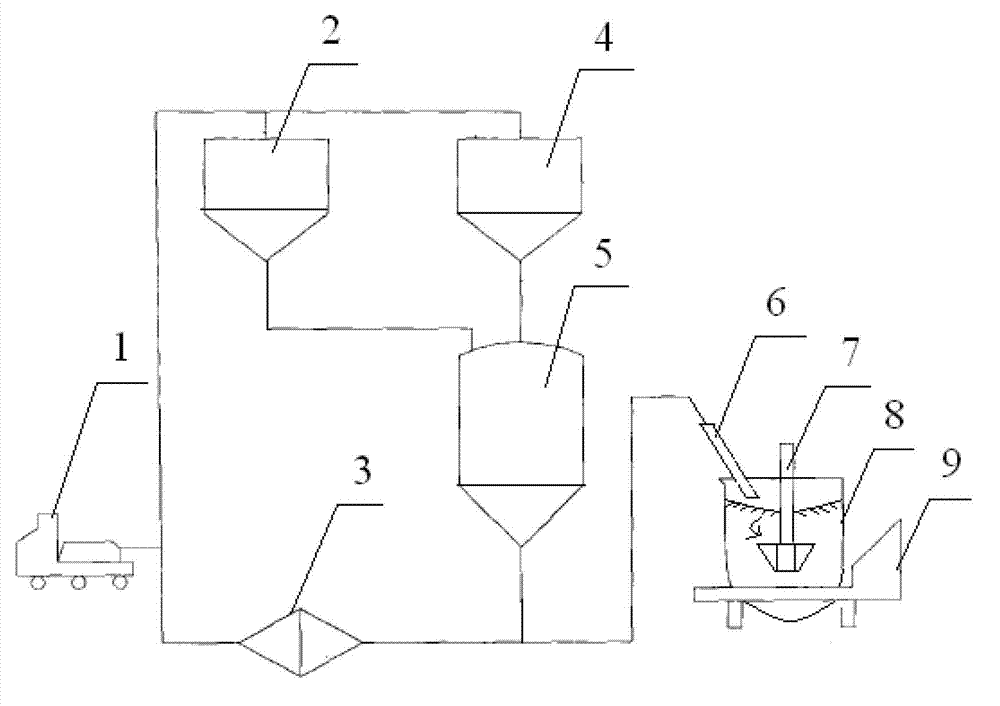

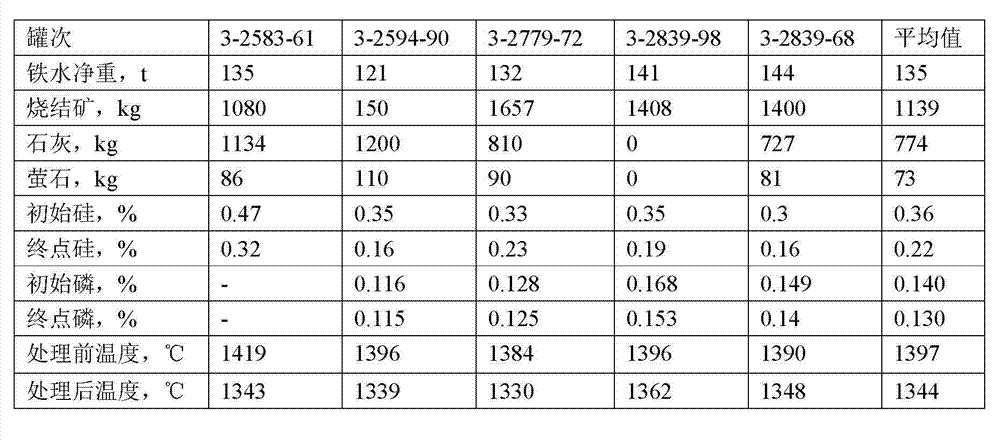

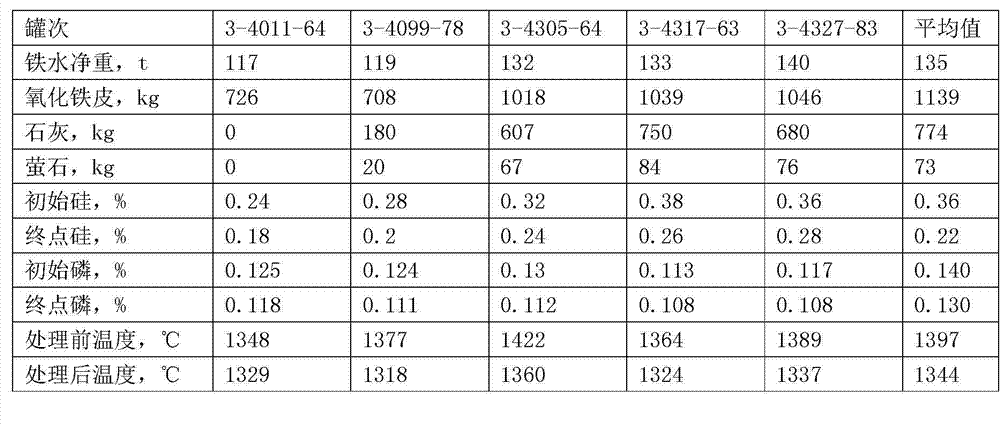

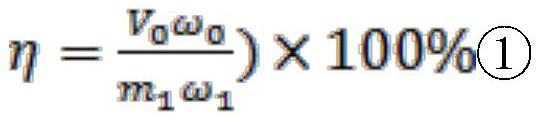

Method for desilicating molten iron by stirring

The invention relates to a method for desilicating molten iron by stirring, which belongs to the technical field of molten iron pretreatment. The method comprises four steps: allowing a stirring paddle to stir at a low speed; adding a desiliconization agent; allowing the stirring paddle to stir at a high speed for desilicication; and stopping the stirring paddle. The content of the desilicication agent is kept between 0.05 percent and 0.40 percent; the stirring paddle has a four-blade or three-blade steel structure coated with a fireproof material; the solid desiliconization agent is blown by a blowing device to the surface of the molten iron; the stirring may be realized by continuous or intermittent rotation or alternating clockwise and anticlockwise rotation; in any of the three stirring modes, the stirring paddle can rotate up and down a certain height; and when the method is used, the Si content in the molten iron may be reduced from about 0.50 percent to 0.20 percent, so the desilicication efficiency is over 50 percent. The method can also be used for desilicication during refining raw iron in casting field.

Owner:CENT IRON & STEEL RES INST

Method of microorganism induction bauxite flotation desilicication

A method of microorganism induction bauxite flotation desilicication relates to the technical field of bauxite flotation, by adding microorganism into ore pulp of bauxite, the microorganism carries out surface modification to the mineral in the ore pulp, accordingly, the hydrophilia of the mineral per se is changed, and thus the mineral is more easily subjected to flotation separation. Compared with a conventional flotation technology in the prior art, the method has the advantages of high bauxite recovery rate, good desilicication effect, less energy consumption and reagent consumption, and the like, and furthermore, the method does not cause pollution to the environment; simultaneously, the microorganism treatment time is short, so that the method can be applied to industrialization flotation on a large scale.

Owner:平顶山市华兴浮选工程技术服务有限公司

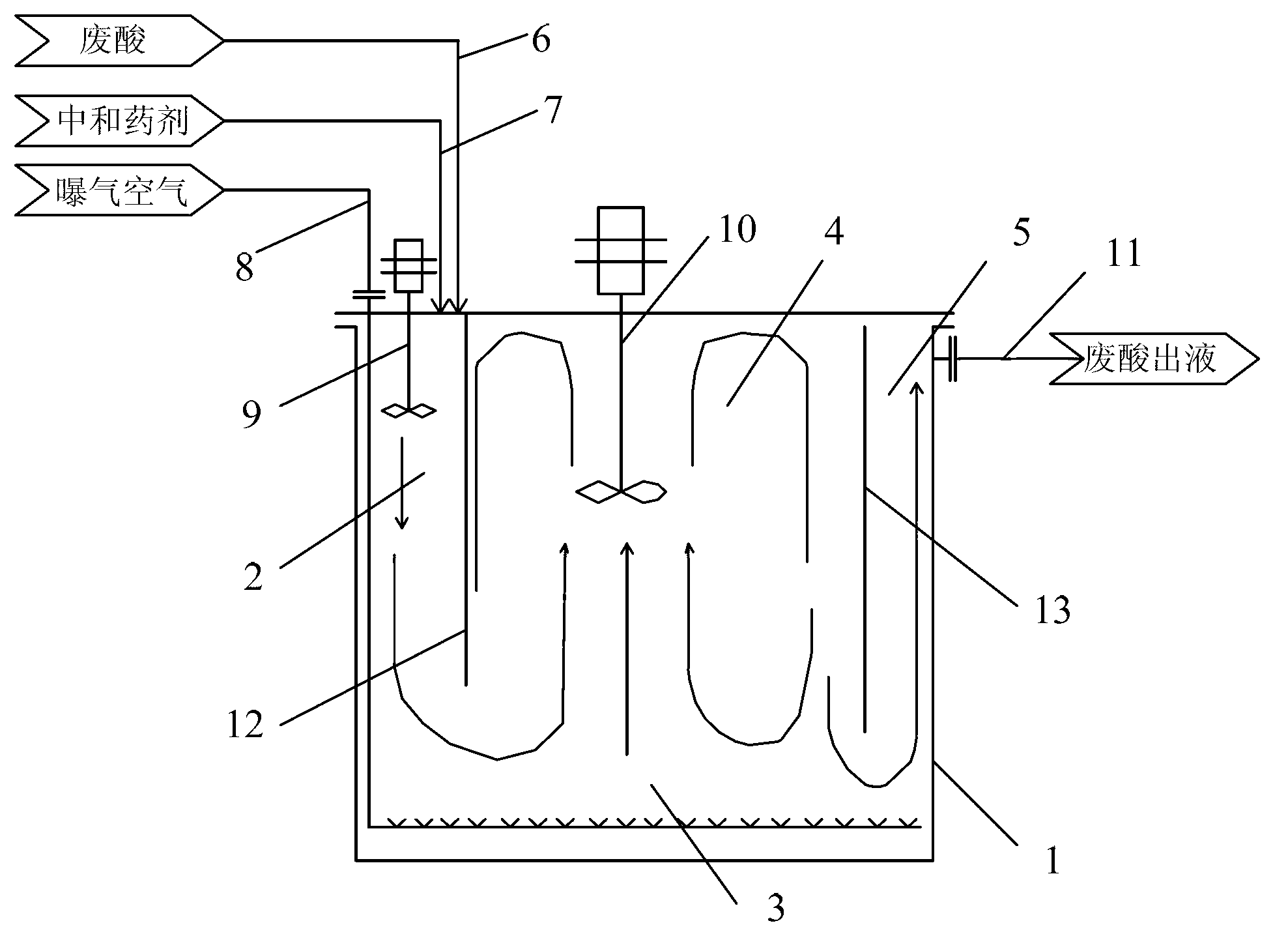

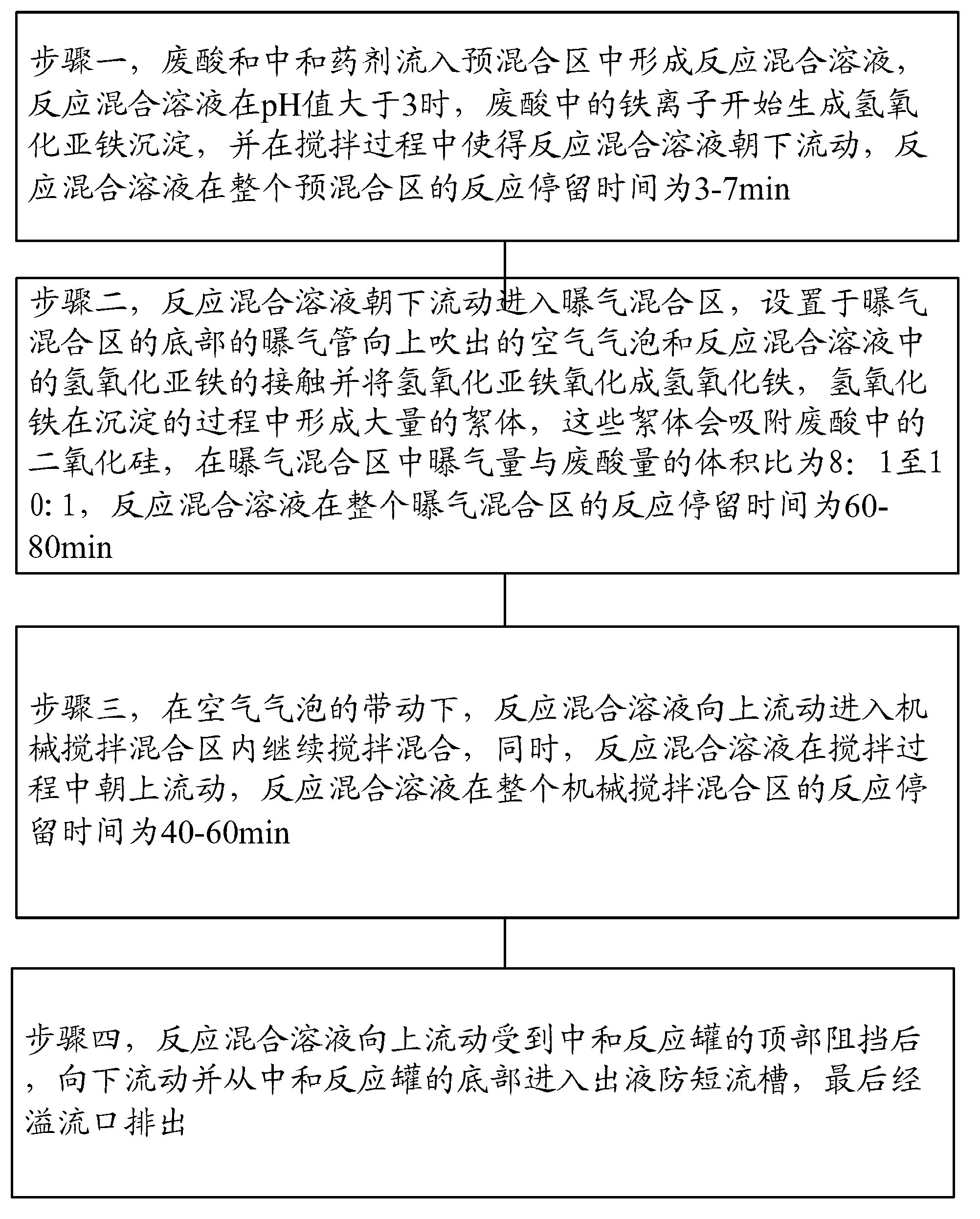

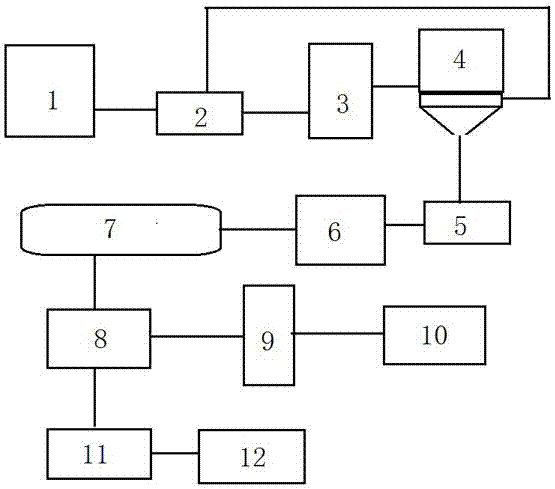

Neutralization device and method for hydrochloric acid regeneration and desiliconization

InactiveCN103011081AShorten the timeAvoid short flowChlorine/hydrogen-chloride purificationMultistage water/sewage treatmentSpent acidEngineering

The invention discloses a neutralization device and a neutralization method for hydrochloric acid regeneration and desiliconization. The device comprises a neutralization kettle; an inlet section of the neutralization kettle is connected with a waste acid supply pipe and a neutralizing chemical supply pipe respectively; a premixing zone, an aerating and mixing zone, a mechanical stirring and mixing zone and a short effluent stream resisting groove are contained inside the neutralization kettle; the premixing zone is formed by arranging a first clapboard in the inlet section of the neutralization kettle; the short effluent stream resisting groove is formed by arranging a second clapboard in an outlet section of the neutralization kettle; the mechanical stirring and mixing zone is located between the first clapboard and the second clapboard; and the aerating and mixing zone is below the premixing zone, the aerating and mixing zone and the short effluent stream resisting groove and connects the three with each other. According to the invention, the mixing efficiency and the reaction efficiency of the neutralization and oxidization of reactive mixed solution are increased, and the stability of ferric hydroxide is guaranteed, so that the desiliconization efficiency of the waste acid is guaranteed and the recycling of the waste acid is benefited.

Owner:BAOSTEEL ENG & TECH GRP

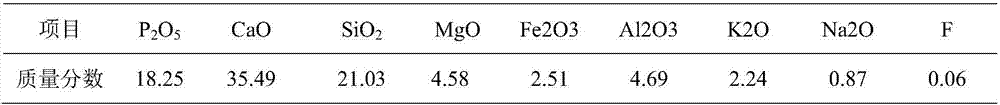

Technology and device for co-producing ofproducing industrial monoammonium phosphate and co-producing high-quality monoammonium phosphate by utilizing middle-grade and low-grade collophanite

PendingCN107381525AGood harvesting effectImprove resource utilizationPhosphatesPhosphoric acidReaction temperature

The invention discloses a technology and a device for co-producing ofproducing industrial monoammonium phosphate and co-producing high-quality monoammonium phosphate by utilizing middle-grade and low-grade collophanite. The technology comprises the following steps: carrying out ore dressing on the middle-grade and low-grade collophanite by utilizing a heavy medium-double-reverse flotation technology to prepare phosphorus concentrate pulp with the mass percent of 32 percent or more based on P2O5; extracting the phosphorus concentrate pulp by utilizing sulfuric acid to obtain phosphoric acid ore pulp; carrying out high-temperature and vacuum filtering on the phosphoric acid ore pulp under the conditions that the temperature is 83 DEG C to 85 DEG C and the pressure is -0.06MPa to -0.07MPa, so as to obtain a phosphoric acid solution; adding a sedimentation agent into the phosphoric acid solution and carrying out sedimentation and filtering to further remove impurities; finally, obtaining a phosphoric acid solution with the P2O5 beingmass percent of 27 percent to 30 percent based on the P2O5; adding the obtained phosphoric acid solution into an ammoniation reactor and carrying out neutralization on the phosphoric acid solution and ammonia; controlling the neutralization degree to be 1.1 to 1.15 and the reaction temperature to be 90 DEG C to 100 DEG C; after finishing neutralization reaction, cooling and crystallizing; then filtering, and concentrating and crystallizing filtrate to obtain the industrial monoammonium phosphate; concentrating and granulating filtering residues to obtain the high-quality monoammonium phosphate. By adopting the technology and the device, disclosed by the invention, the key problem that the phosphorous content of wet-process phosphoric acid produced by from middle-grade and low-grade phosphorous ore and down-stream products thereof is low is effectively solved.

Owner:HUBEI DAJIANG CHEM GRP

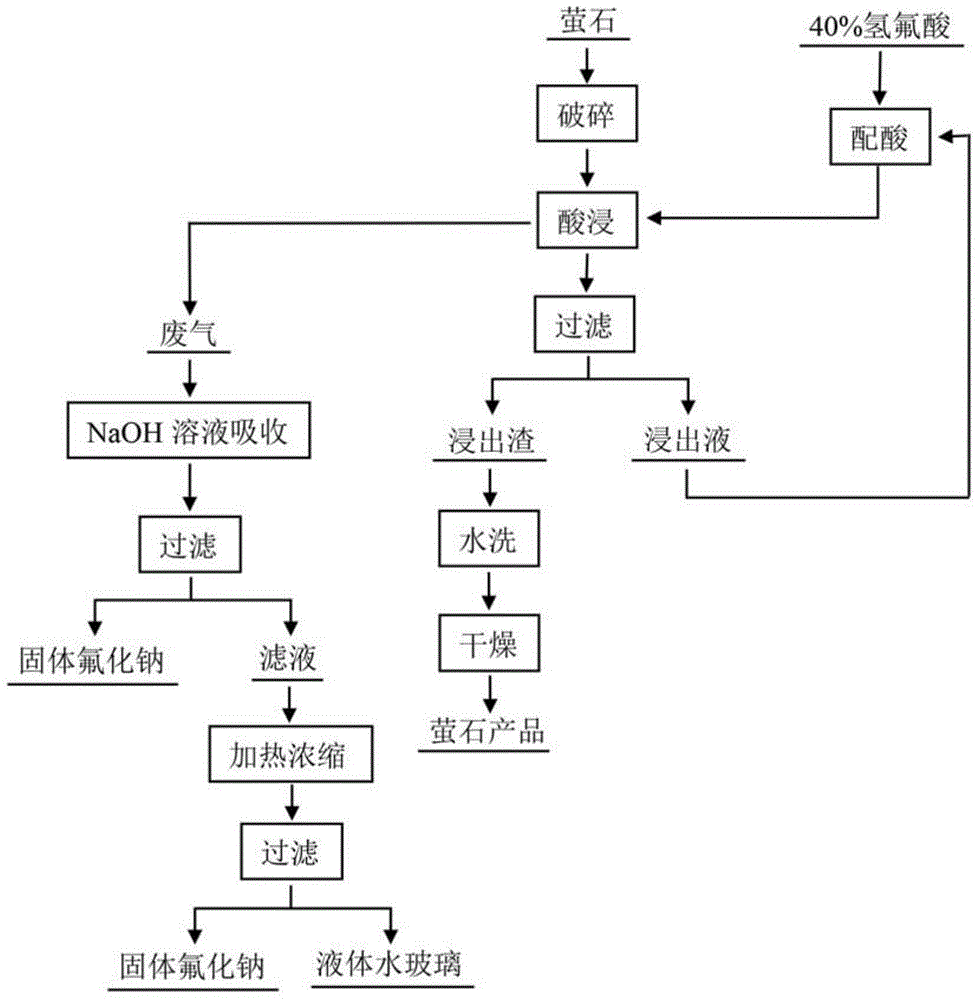

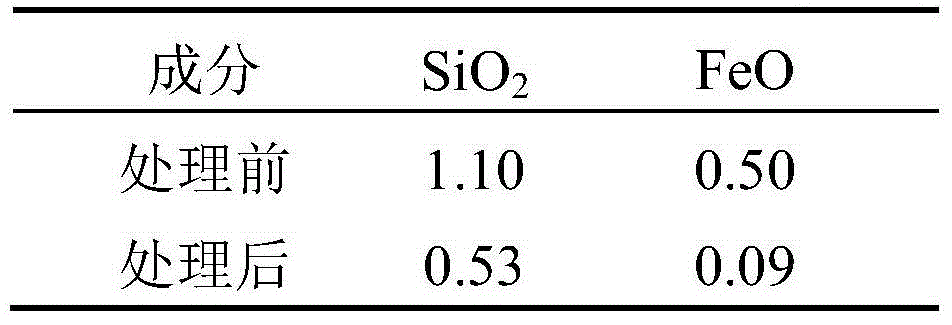

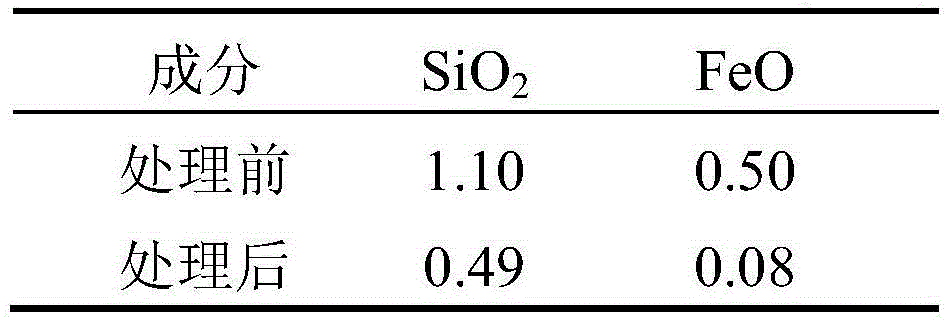

De-silicication purifying method for fluorite for pre-melted slag

InactiveCN104692440AReduce energy consumptionReduce pollutionCalcium/strontium/barium fluoridesWood impregnation detailsSlagTechnical grade

The invention discloses a de-silicication purifying method for fluorite for pre-melted slag, and belongs to the technical field of fluorite purification. The method comprises the following steps: mixing fluorite in which SiO2 is less than or equal to 1.2 percent with hydrofluoric acid to be leached for 8-13 hours to obtain a leaching liquid, leaching slag and waste gas; washing the leaching slag by using deionized water and drying to obtain a fluorite product; introducing the waste gas into a 4-8 mol / L sodium hydroxide solution for performing innocent treatment; adding industrial-level hydrofluoric acid solution containing 40 percent by weight of hydrogen fluoride into the leaching liquid to prepare a solution with the concentration required by the acid leaching process for cyclic use. The fluorite purification process is simple in procedures, low in energy consumption, and high in cyclic utilization rate; the mass percentages of the obtained fluorite products are that CaF2 is more than or equal to 97 percent, SiO2 is less than or equal to 0.6 percent, and FeO is less than or equal to 0.2 percent; and high-quality raw materials are provided for production of high-quality pre-melted slag, and the fluorite is suitable for being popularized.

Owner:NORTHEASTERN UNIV

Shaking ladle premelting process for producing medium and low carbon ferromanganese

The invention relates to a shaking ladle premelting process for producing medium and low carbon ferromanganese. Medium manganese pre-shaking slag with alkalinity of 1.2-1.3 and MnO content of 20-25% and liquid silicomanganese are mixed according to the weight ratio of 1.0:1-1.2:1, and the mixture is loaded into a shaking ladle. The capacity of the ladle is 15 m<3>, a desilication reaction is carried out in the shaking ladle, the revolution of the shaking ladle is 40-60 RPM, and the shaking smelting time is 15-20 min. The invention has the advantages that one shaking ladle is big enough to match a 5000 kVA electric refining furnace to produce because the capacity of the shaking ladle is enlarged, the production capability of the 5000 kVA electric refining furnace is fully exerted, the heat loss is small, and the desilication rate is high. By reasonably controlling the revolution of the shaking ladle and the shaking smelting time, an optimal desilication effect can be achieved, the consumption of secondary refining ore is reduced, the smelting time is shortened, manganese element in slag can be recovered to the maximum extent, and the production cost of medium manganese alloy is reduced.

Owner:CITIC JINZHOU METAL

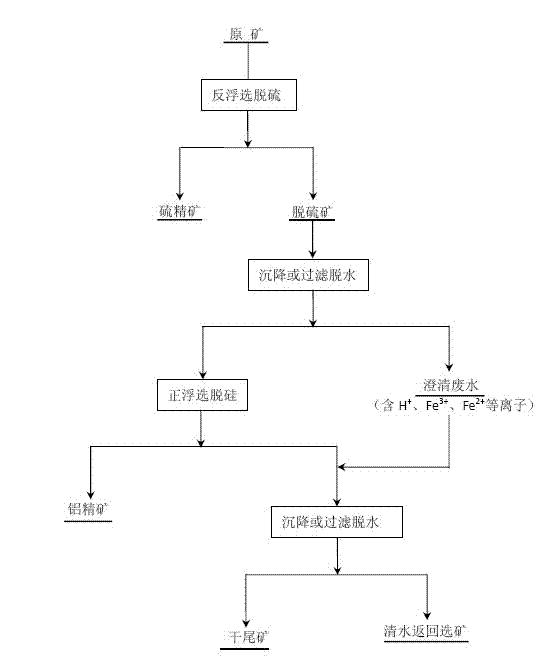

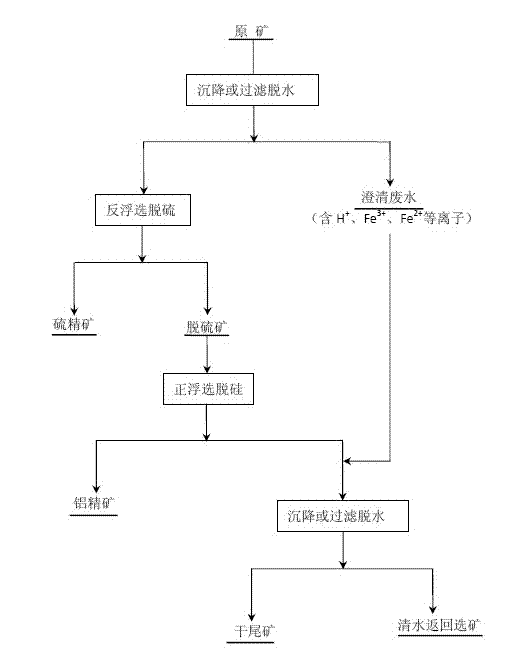

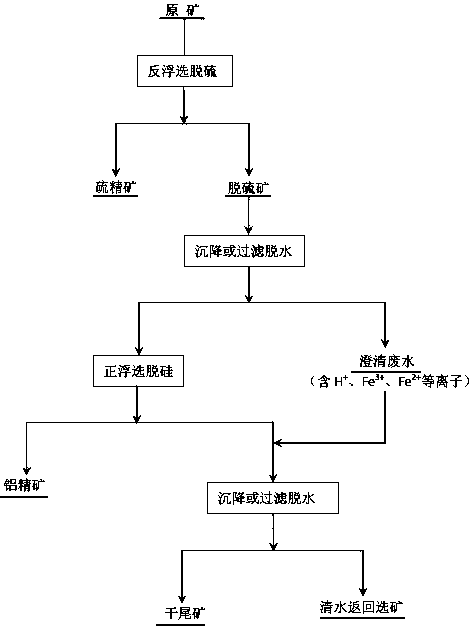

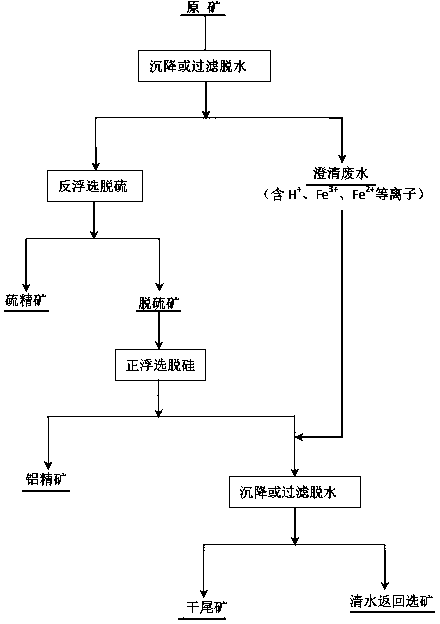

Method for treating sulfureous bauxite

InactiveCN102806137ASolve the problem of alkaline flocculationReduce dosageFlotationWet separationFlocculationRed mud

The invention discloses a method for treating sulfureous bauxite and relates to the technical field of sulfureous bauxite treatment process. The method includes the steps of grinding, desulfuration by reverse flotation and desilication by obverse flotation, and the step of removing H+, Fe3+ and Fe2+ in ore pulp is added before grinding, between grinding and desulfuration by reverse flotation, between desulfuration by reverse flotation and desilication by obverse flotation, or after desilication by obverse flotation. The ore pulp during flotation desilication can be dispersed sufficiently, index of flotation desilication is increased, and the problem of difficulty in alkaline flocculation of alkaline products of concentrates, tailings or red mud in bauxite beneficiation is solved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method of vanadium slag pretreatment desilication and medium circulation

InactiveCN108130425AReduce manufacturing costImprove efficiencyProcess efficiency improvementSlagSlurry

The invention belongs to the field of chemical engineering and metallurgy, and specifically relates to a method of vanadium slag pretreatment desilication and medium circulation. The method of the vanadium slag pretreatment desilication and the medium circulation aims at solving the problems of complicated process, high cost and low desilication efficiency in removing silicon from the vanadium slag. The method comprises the following steps that a, coarse vanadium slag is mixed with calcium material and alkaline medium to wet ball milling, and then the vanadium slag and iron particles are separated after the ball milling; b, a flotation desilicication treatment is carried out to the slurry containing vanadium slag separated from the step a, and the slurry after desilicication is obtained; and c, desilicated slurry after the step b is naturally settled and the alkaline medium and fine vanadium slag are obtained by separation. The silicon in the vanadium slag can be removed to less than 0.5%, the desiliconization effect is good, the technology is simple, the cost is low, and the method is suitable for popularization and application

Owner:PANZHIHUA UNIV

A method for leaching valuable metals from cobalt-copper white alloy

ActiveCN105063353BReduce lossesAchieve the effect of removing siliconProcess efficiency improvementMetal leachingSlag

The invention discloses a method for leaching valuable metal from cobalt-copper white alloy. The method includes the following steps that (1) the cobalt-copper white alloy is melted into an alloy melt, wherein the cobalt-copper white alloy contains silicon and almost contains no manganese; (2) a Mn-containing material is added into the alloy melt, and meanwhile gas is led in for blowing and slagging; (3) obtained slag is separated from the melt; (4) the melt with the slag separated out is atomized into alloy powder, wherein the mass friction of Mn in the alloy powder is 0.5%-20%; and (5) the alloy powder is subjected to acid leaching, and the valuable metal is recovered. Due to the fact that the Mn-containing material is added and reacts with the silicon in the cobalt-copper white alloy to generate the MnO-SiO2 slag, the silicon removal effect is achieved, and the method has the beneficial effects of being good in silicon removal effect and small in valuable metal loss. Besides, the melting temperature is much lower than the melting point of CaO-(MgO)-SiO2 binary system or ternary system slag in the prior art.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

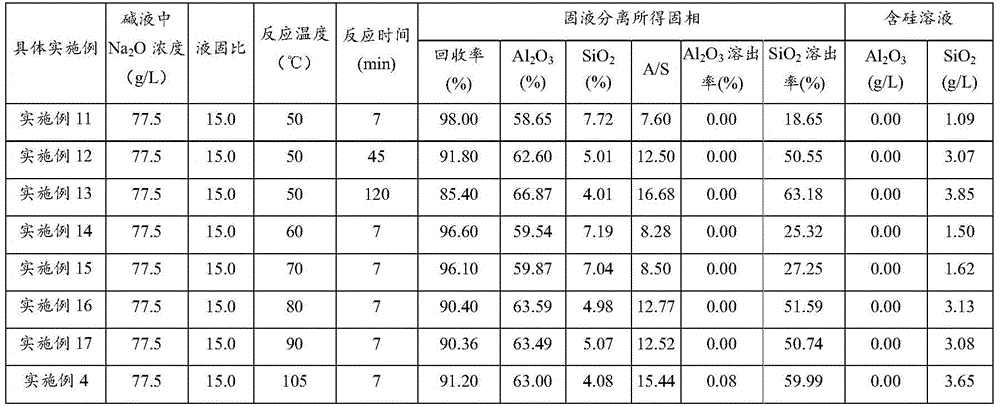

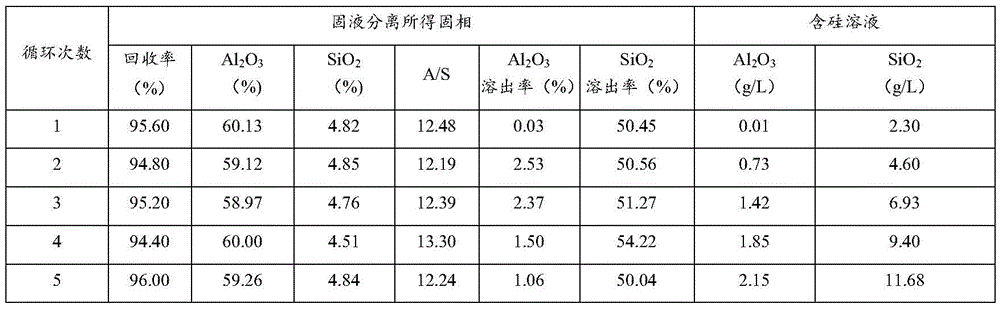

Method for efficient and fast desilication of bauxite

ActiveCN105585039ATo achieve the purpose of desiliconizationEfficient use ofAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMicrowaveRed mud

The invention belongs to the technical field of bauxite desilication and particularly discloses a method for efficient and fast desilication of bauxite. The method for efficient and fast desilication of bauxite includes the steps that bauxite and alkali liquor are mixed and prepared into reaction slurry, the liquid-to-solid ratio of the reaction slurry is 2-50, the reaction slurry reacts in a microwave reactor so that silicon can be dissolved out, reaction temperature is 10-130 DEG C, reaction time is 2-220 min, reaction liquid is subjected to solid and liquid separation after the reaction ends, an obtained liquid phase is a silicon-containing solution, and the SiO2 content in the silicon-containing solution is 0.3-50 g / L. According to the method for efficient and fast desilication of bauxite, reaction is performed in the microwave reactor for desilication, and the purpose of efficiently dissolving out silicon in bauxite is achieved in a short time by determining the liquid-to-solid ratio of the reaction slurry, the reaction temperature and the reaction time. Silicon minerals in bauxite are purified and recycled, no red mud enters the silicon minerals, and therefore the production amount of red mud in alumina production is greatly reduced.

Owner:国家电投集团山西铝业有限公司

Blast furnace external molten iron pretreatment desiliconization agent, and preparation method and use method thereof

ActiveCN108929931ANo additional processing time requiredThe temperature drop does not change significantlyPre treatmentFly ash

The invention relates to a blast furnace external molten iron pretreatment desiliconization agent, and a preparation method and a use method thereof. The desiliconization agent is a composite agglomerate composed of an inner mixture layer and an outer mixture layer, wherein the inner mixture layer comprises, by mass, 0-40% of blast furnace fly ash, 0-25% of coking fly ash, 10-30% of fluorite powder, 0-5% of a binder, and the balance of one or more of sintered fly ash, converter fly ash and steel rolling iron sheet; and the outer mixture layer comprises, by mass, 50-85% of iron concentrate, 10-45% of quicklime and 0.5-10% of the binder. The problems of sever temperature decrease of molten iron, caused by low desiliconization efficiency and long time in the prior art, are solved, the self solid waste resources of steel enterprises are fully utilized, a special device or a blowing device does not need to be additionally mounted, and extra purchasing of a special desiliconization agent material is not needed, so cheap, simple and effective desiliconization of molten iron is achieved.

Owner:ANGANG STEEL CO LTD

Synthesis of sodium aluminate solution desilicifying additive and its use method

InactiveCN1775690AIncreased molecular ratioIncrease in molecular ratio and decrease in cycle efficiency of production processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateSilicon

The invention relates to a method for synthesizing and using sodium aluminate solution desiliconizing additive, relating to a method for synthesizing and using sodium aluminate solution desiliconizing agent in the courses of producing alumina by sintering and by mixed connection, characterized in adding lime into the sorting mother solution in a theoretical quantity that alumina completely becomes 3CaO.Al2O3.nH2O, reacting 10-80 minutes at 40 deg.C-105 deg.C, filtering and the solid phase products are the desiliconizing additive. According to the CaO content of the synthetic additive, the synthetic additive is converted into the lime, and on the condition of the addition quantity the same as that of the lime, and the desiliconizing effect of the synthetic additive is somewhat better than that of the lime. Therefore, the synthetic additive can completely replace the lime and be used in the desiliconizing process of sodium aluminate solution in the producing course, so as to avoid the increase of confluent pulp alpha k caused by directly adding lime and the reduction of circulating efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for desilicating molten iron by stirring

The invention relates to a method for desilicating molten iron by stirring, which belongs to the technical field of molten iron pretreatment. The method comprises four steps: allowing a stirring paddle to stir at a low speed; adding a desiliconization agent; allowing the stirring paddle to stir at a high speed for desilicication; and stopping the stirring paddle. The content of the desilicication agent is kept between 0.05 percent and 0.40 percent; the stirring paddle has a four-blade or three-blade steel structure coated with a fireproof material; the solid desiliconization agent is blown by a blowing device to the surface of the molten iron; the stirring may be realized by continuous or intermittent rotation or alternating clockwise and anticlockwise rotation; in any of the three stirring modes, the stirring paddle can rotate up and down a certain height; and when the method is used, the Si content in the molten iron may be reduced from about 0.50 percent to 0.20 percent, so the desilicication efficiency is over 50 percent. The method can also be used for desilicication during refining raw iron in casting field.

Owner:CENT IRON & STEEL RES INST

Method for enhancing desilicication of low-grade bauxite by utilizing brown fused alumina fly ash

PendingCN112939041AEasy to operatePromote desilicationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFly ashBauxite

The invention discloses a method for enhancing desilicication of low-grade bauxite by utilizing brown fused alumina fly ash. The method comprises the following steps: adding the brown fused alumina fly ash into pre-roasted low-grade bauxite, and then carrying out desilicication. The method has the characteristics that operation is simple, the bauxite desilicication effect is better, the brown aluminum oxide fly ash is turned into wealth, and the technological process is environment-friendly.

Owner:GUIZHOU UNIV

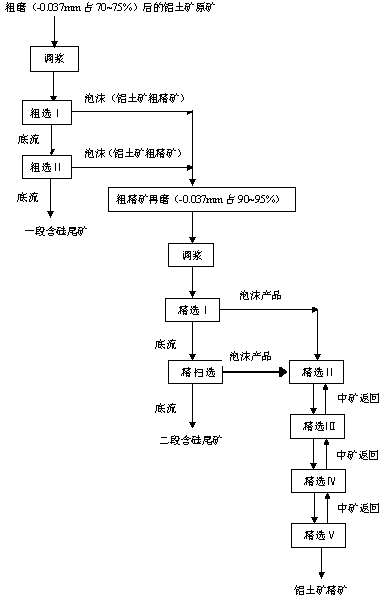

Flotation two-stage desiliconization method for high-silicon bauxite

ActiveCN102489411BGood desiliconization effectAvoid the effects of the desiliconization processFlotationSodium phosphatesEngineering

The invention relates to a flotation two-stage desiliconization method for high-silicon bauxite, which is a flotation desiliconization technology for bauxite and belongs to the technical field of mineral processing engineering. The method comprises the following steps of: coarsely grinding the bauxite into particles with certain fine granularity; under the condition of a certain ore pulp concentration, performing flotation first-stage desiliconization by using sodium carbonate as a pH regulator and a dispersing agent of the ore pulp, water glass and sodium hexametaphosphate as a combined inhibitor of gangue mineral, lead acetate as an activating agent of the bauxite, sodium oleate as a collector of the bauxite and pine oil as a foaming agent, wherein the base flow in a flotation groove is a section of silicon-containing tailings; allowing foam products to enter a grinding machine and grinding the foam products into particles with fine granularity; adding the medicaments sequentially and mixing pulp; performing flotation second-stage desiliconization, wherein the base flow in the flotation groove is a section of silicon-containing tailings; and selecting the foaming products for multiple times to form bauxite concentrate. The sectional desiliconization method for 'flotation first-stage desiliconization after coarse grinding and flotation second-stage desiliconization after regrinding rough concentrate' is utilized, so the influence of ore argillization phenomenon on desiliconization is greatly reduced, the flotation desiliconization effect on the high-silicon bauxite is obvious, the silicon dioxide content of the bauxite concentrate can be reduced greatly, the ratio of aluminum to silicon of the bauxite concentrate is increased, and the recovery rate is high.

Owner:山西道尔铝业有限公司

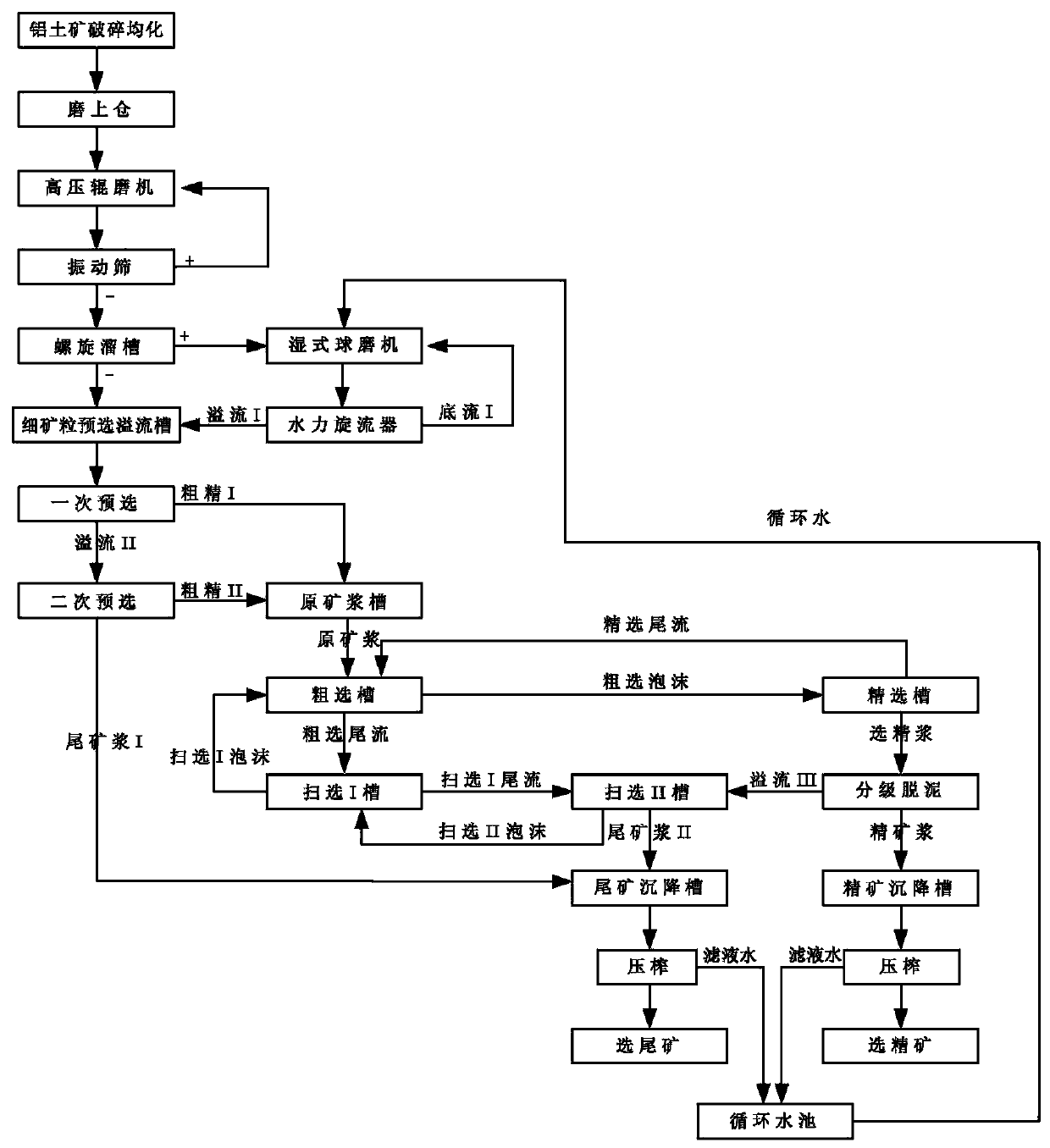

Desiliconization method for bauxite separated concentrate producing by using ultralow-grade raw ores

The invention relates to a desiliconization method for bauxite separated concentrate producing by using ultralow-grade raw ores. The desiliconization method comprises the following steps of (1) homogenizing and crushing; (2) carrying out mineral monomer dissociation; (3) pre-separating fine ore particles; (4) carrying out micro-bubble floatation; (5) desliming separated fine ore pulp; (6) carryingout secondary dehydrating on the fine ore pulp; and (7) carrying out secondary dehydrating on tail ore pulp. The desiliconization method is novel and unique, scientific and reasonable, easy to operate, high in working efficiency and good in desiliconization effect, the silicon-aluminum ratio can be effectively improved, the productivity can be improved, the consumption of flotation reagents can be reduced, the concentrate quality can be improved, the pressure on a setting tank of tailings is relieved, the production process can be normally and continuously operated, the production cost is low, and the environmental pollution is reduced; and the method is a creative option on ore separation, and has huge economic and social benefits.

Owner:HENAN DONGDA TECH CO LTD

A method for processing nickel-cobalt hydroxide

ActiveCN110551905BGood removal effectTo avoidCobalt sulfatesNickel sulfatesPregnant leach solutionPhysical chemistry

The invention discloses a method for treating nickel-cobalt hydroxide. The method comprises: (1) using concentrated sulfuric acid and nickel sulfate solution to mature and leach nickel-cobalt hydroxide so as to obtain a mature leachate; (2) mixing the mature leachate and hydrogen peroxide solution for reduction leaching to obtain a reduced Leaching solution; (3) filtering the reducing leaching solution to obtain nickel-cobalt sulfate filtrate and impurity filter cake, wherein the nickel-cobalt hydroxide is obtained by reclaiming nickel-cobalt from laterite nickel ore, and the reducing leaching solution The pH value is 3-5. This method can not only effectively reduce the consumption of auxiliary materials, reduce production costs, and significantly increase the recovery rate of nickel, but also has a remarkable effect of desiliconization and removal of flocculants, and the silicon content in the finally obtained nickel-cobalt sulfate filtrate is not higher than 40mg / L, and the sodium The ion content is not higher than 1.0g / L, and the COD value is not higher than 100mg / L, which can effectively meet the requirements for the production of ternary precursor products.

Owner:中冶瑞木新能源科技有限公司

Preparation method of low-silicon pre-melted slag for electroslag remelting

The invention provides a method for preparing low-silicon pre-melted slag for electroslag remelting. The preparation method comprises the following steps: (1) mixing the slag; (2) melting the slag; (3) adding aluminum Ferroalloying and smelting. According to the preparation method of low-silicon pre-melting slag for electroslag remelting of the present invention, the requirements for equipment are relatively low, the operation is simple, easy to control, and the cost is low; it can effectively solve the problem of easily oxidized elements such as Al and Ti in the electroslag remelting process. The problem of burnout.

Owner:NORTHEASTERN UNIV LIAONING

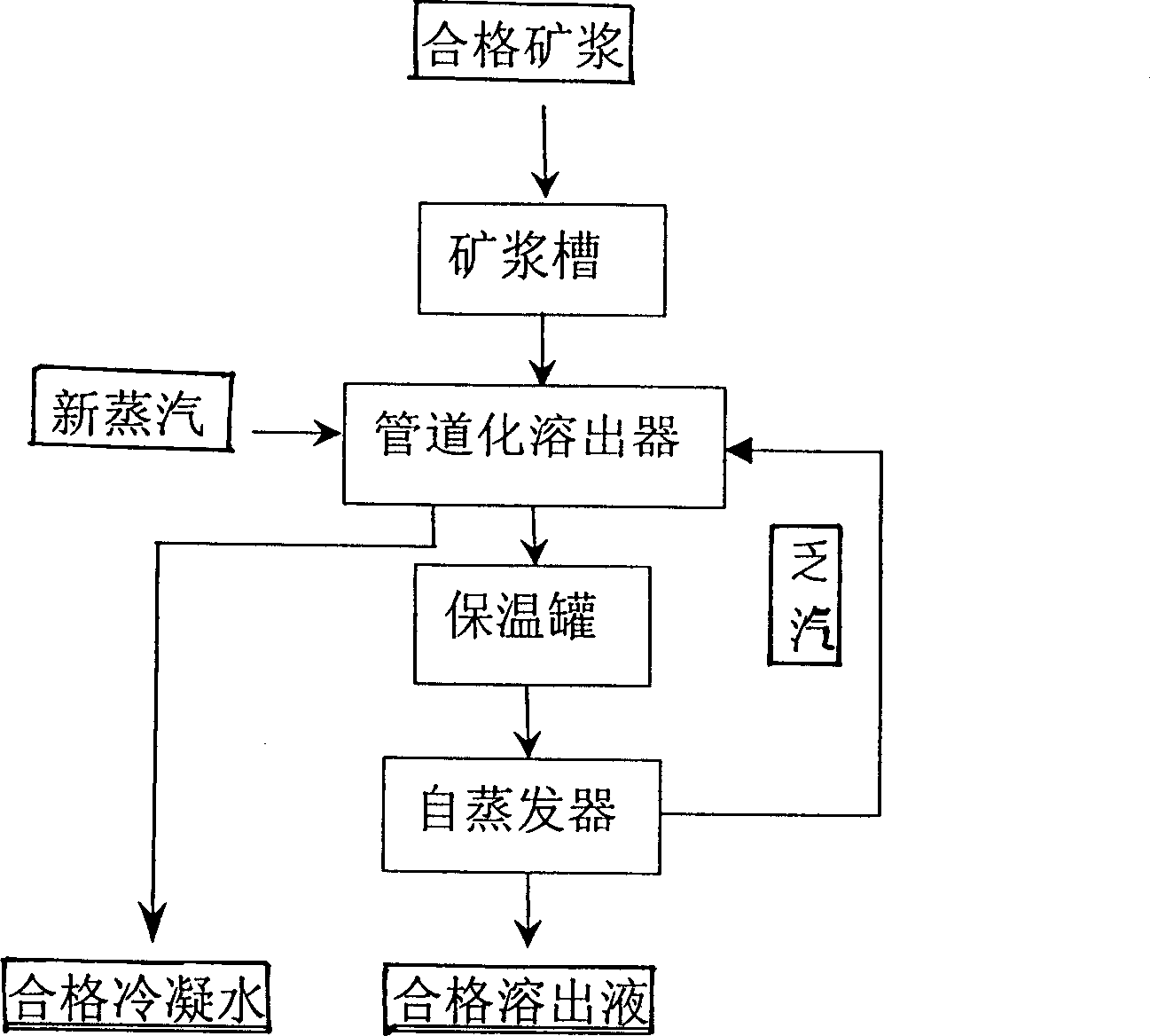

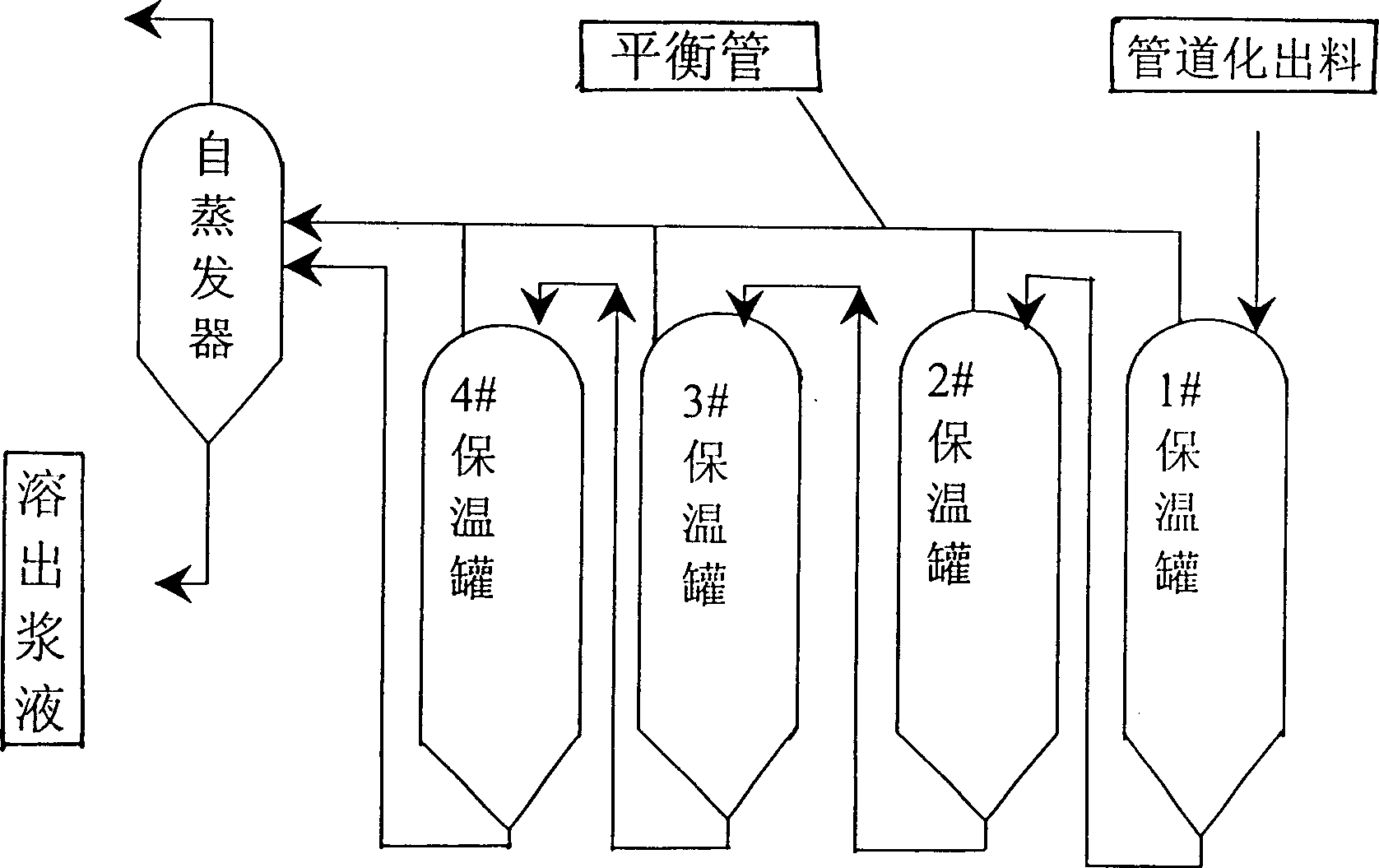

Bauxite low temperature continuous dissolving out technology

ActiveCN1260128CEasy to manufactureEasy to useAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationEvaporationEngineering

The invention belongs to the technical field of alumina production, and specifically relates to a low-temperature continuous dissolution process for bauxite, which includes pipeline dissolution, heat preservation and desilication under pressure, and self-evaporation cooling. The cooled exhaust steam is used for dissolution preheating; the pipeline dissolution is indirect steam heating and dissolution, and there is a heating steam chamber outside the dissolution pipeline, and the spirally coiled dissolution tube from bottom to top corresponds to the feed layer. First-level exhaust steam heating, first-level exhaust steam heating and fresh steam heating. The indirect heating of the bauxite low-temperature dissolution process of the present invention avoids the situation of directly heating the condensed water in the slurry, realizes continuous production, and makes effective use of steam condensed water and exhaust steam waste heat from evaporation and cooling, reducing The amount of steam is reduced, the energy consumption of production is reduced, the operation is simple, it is beneficial to the actual industrial production, and the economic and social benefits are considerable.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for controlling compressed air under non-production mode by virtue of acid regeneration desilication system

The invention discloses a method for controlling compressed air under a non-production mode by virtue of an acid regeneration desilication system, and the method comprises the following step of: intermittently introducing the compressed air when the acid regeneration desilication system is under the non-production mode. By adopting the method for controlling the compressed air under the non-production mode by virtue of the acid regeneration desilication system, the problem that a compressed air tube is blocked under the desilication non-production mode for a long time is solved by accurately controlling the opening time sequence and flow of the compressed air under the desilication non-production mode, and the pH value of acid liquor in a reaction tank is not influenced, so that a desilication system can achieve a good desilication effect in short time after production is resumed.

Owner:SHOUGANG CORPORATION

A method for preparing porous conductive carbon using rice husk as raw material

InactiveCN104528688BTo achieve the purpose of making holesMild conditionsSolid waste disposalCarbon preparation/purificationHydrofluoric acidDecomposition

The invention belongs to the high-valued application field of agricultural solid residues, and particularly relates to a method for preparing porous conductive carbon on the basis of rice husks. The method uses the rice husks as raw materials, conductive carbon is prepared through the catalytic, hole forming and other characteristics of products generated after heating decomposition of zinc carbonate, and the prepared materials has the advantages of being porous, highly dispersed, good in electrical conductivity and the like. According to the technical scheme, the rice husks are smashed first, and desilicication rice husk powder is prepared after hydrofluoric acid desilicication is carried out; zinc carbonate is then added to the desilicication rice husk powder, and the porous conductive carbon is obtained through high-temperature calcination.

Owner:CHANGZHOU UNIV

Method for treating sulfureous bauxite

InactiveCN102806137BSolve the problem of flotation desilicationEliminate scattered effectsFlotationWet separationFlocculationRed mud

The invention discloses a method for treating sulfureous bauxite and relates to the technical field of sulfureous bauxite treatment process. The method includes the steps of grinding, desulfuration by reverse flotation and desilication by obverse flotation, and the step of removing H+, Fe3+ and Fe2+ in ore pulp is added before grinding, between grinding and desulfuration by reverse flotation, between desulfuration by reverse flotation and desilication by obverse flotation, or after desilication by obverse flotation. The ore pulp during flotation desilication can be dispersed sufficiently, index of flotation desilication is increased, and the problem of difficulty in alkaline flocculation of alkaline products of concentrates, tailings or red mud in bauxite beneficiation is solved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method of flotation desulfur desilicon in bauxite

ActiveCN100398216CAdvanced technologyIncrease production capacityAluminates/aluminium-oxide/aluminium-hydroxide purificationFlotationResource utilizationFatty acid

A floatation process for bauxite to remove S and Si includes such steps as grinding the crude bauxite, adding the yellow catching agent B, reverse floatation for removing S, grinding, adding the match of saponified fatty acid and naphthenic acid, and forward floatation. The resultant bauxite concentrate can be used to prepare aluminum oxide by Bayer method.

Owner:中铝郑州有色金属研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com