Preparing method of low-silicon pre-melted slag for electroslag remelting

A technology of electroslag remelting and pre-melting slag, which is applied in the field of preparation of low-silicon pre-melting slag for electroslag remelting, can solve the problems of unfavorable large-scale promotion, high cost, and increased production cost, and achieves a significant desiliconization effect , low equipment requirements, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

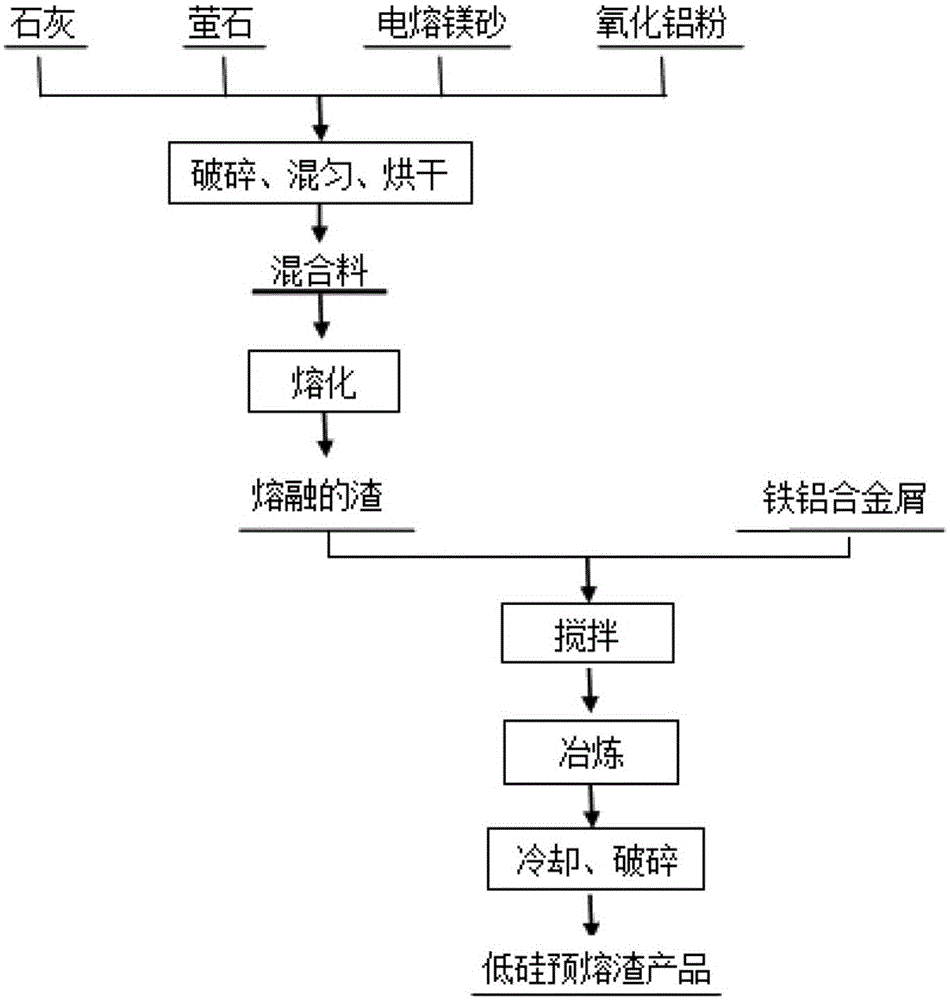

Method used

Image

Examples

Embodiment 1

[0038] Lime, fluorite and fused magnesia are crushed to 0mm-10mm, uniformly mixed with alumina powder to prepare slag, and dried, wherein the slag includes: CaO: 26 %, CaF 2 : 37%, Al 2 o 3 : 34.5%, MgO: 1.0%, SiO 2 : 0.95%, FeO: 0.15%, and the rest are impurities. Weigh 600kg of slag material and add it to a 1600kg three-phase slag melting furnace; turn on the power, start arcing at a voltage of 35kV, and after the current reaches a stable value (1.5kA), adjust the voltage and current to 49kV and 2.3kA respectively, and use 30kg Add 800kg of slag to it at a speed of 1 / min, and the smelting time is 85min; all the slag is melted, and the temperature of the molten slag is controlled to be 1590°C. The iron-aluminum alloy rod with an aluminum content of 15% by mass percentage is turned with a lathe to obtain iron-aluminum alloy chips with a size ≤ 50 mm, and 47.04 kg of iron-aluminum alloy chips are added to the molten slag to make it evenly distributed on the surface of the s...

Embodiment 2

[0040] Lime, fluorite and fused magnesia are crushed to 0mm-10mm, uniformly mixed with alumina powder to prepare slag, and dried, wherein the slag includes: CaO: 26 %, CaF 2 : 37%, Al 2 o 3 : 34.5%, MgO: 1.0%, SiO 2 : 0.95%, FeO: 0.15%, and the rest are impurities. Weigh 550kg of slag material and add it to a 1600kg three-phase slag melting furnace; turn on the power, start arcing at a voltage of 35kV, and after the current reaches a stable value (1.4kA), adjust the voltage and current to 49kV and 2.3kA respectively, and use 30kg Add 850kg of slag to it at a speed of 1 / min, the smelting time is 85min, all the slag is melted, and the temperature of the molten slag is controlled to be 1600°C. The iron-aluminum alloy rod with an aluminum content of 15% by mass percentage is turned with a lathe to obtain iron-aluminum alloy chips with a size ≤ 50 mm, and 49.28 kg of iron-aluminum alloy chips are added to the molten slag to make it evenly distributed on the surface of the slag ...

Embodiment 3

[0042] Lime, fluorite and fused magnesia are crushed to 0mm-10mm, uniformly mixed with alumina powder to prepare slag, and dried, wherein the slag includes: CaO: 27 %, CaF2: 42%, Al2O3: 28%, MgO: 1.4%, iO2: 1.1%, FeO: 0.18%, and the rest are impurities. Weigh 550kg of slag material and add it to a 1600kg three-phase slag melting furnace; turn on the power, start arcing at a voltage of 35kV, and after the current reaches a stable value (1.5kA), adjust the voltage and current to 48kV and 2kA respectively, and set the temperature at 20kg / min Add 800kg of slag at a high speed, and the smelting time is 85min; all the slag is melted, and the temperature of the molten slag is controlled to be 1570°C. The iron-aluminum alloy bar with an aluminum content of 15% by mass percentage is turned with a lathe to obtain iron-aluminum alloy chips with a size ≤ 50 mm, and 59.4 kg of iron-aluminum alloy chips are added to the molten slag to make it evenly distributed on the surface of the slag po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com