Patents

Literature

155results about How to "Solve the burning problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

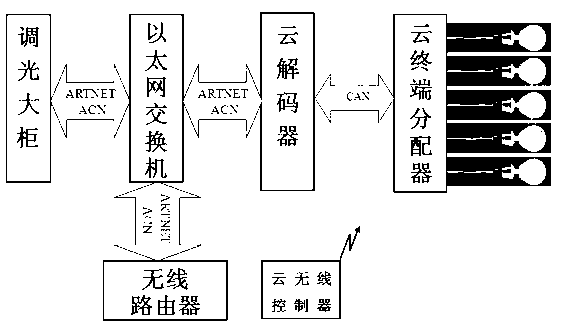

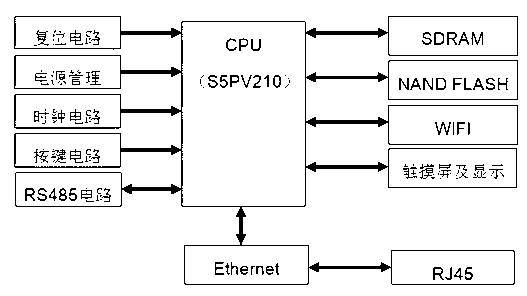

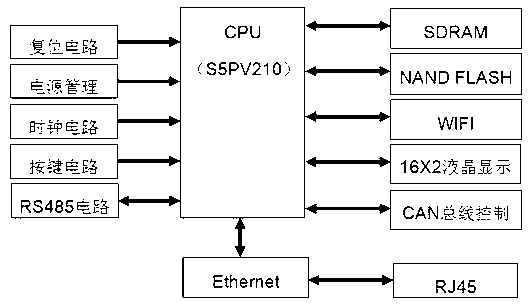

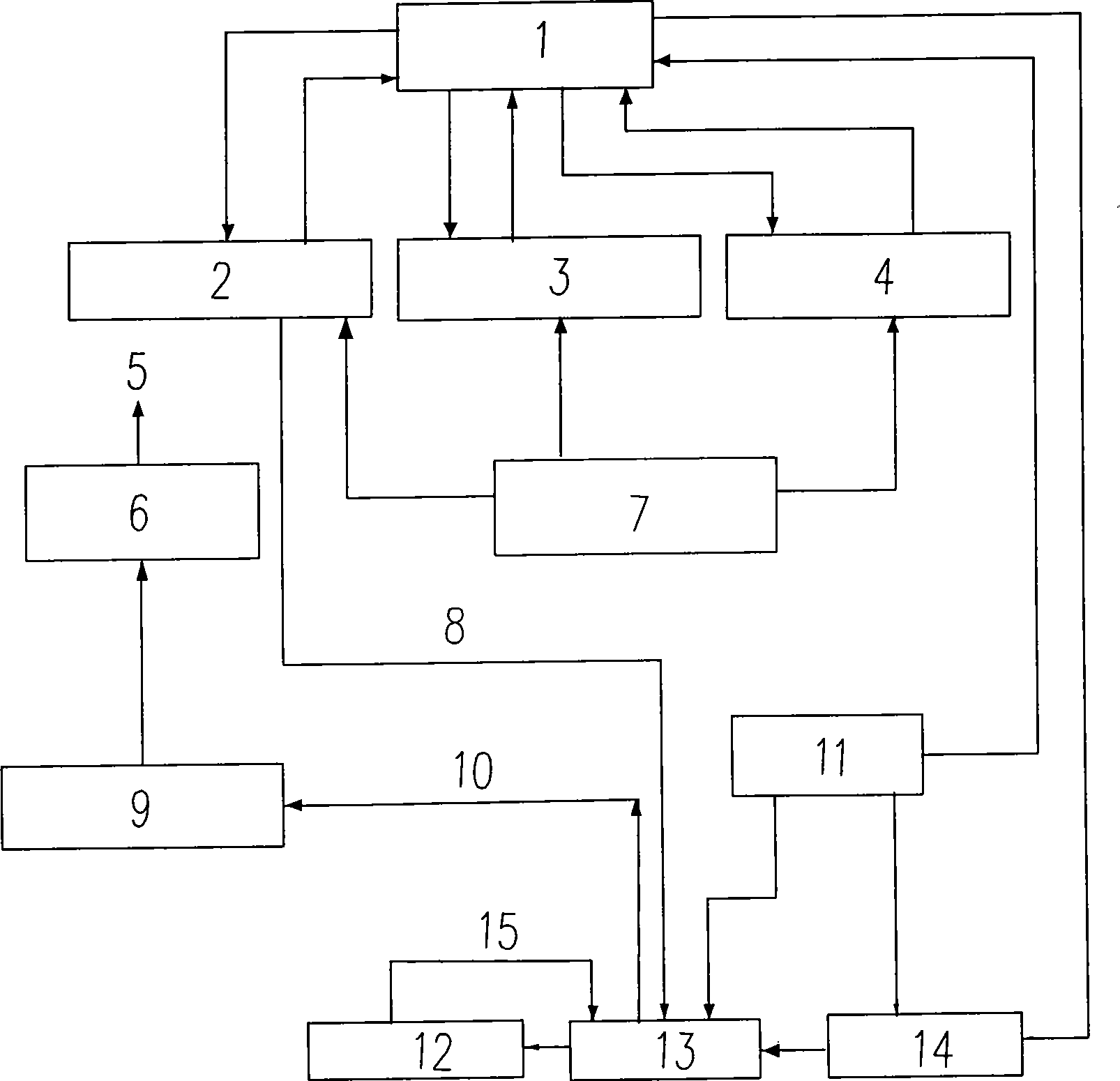

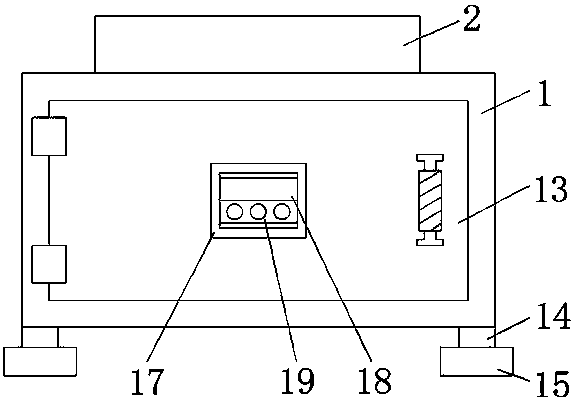

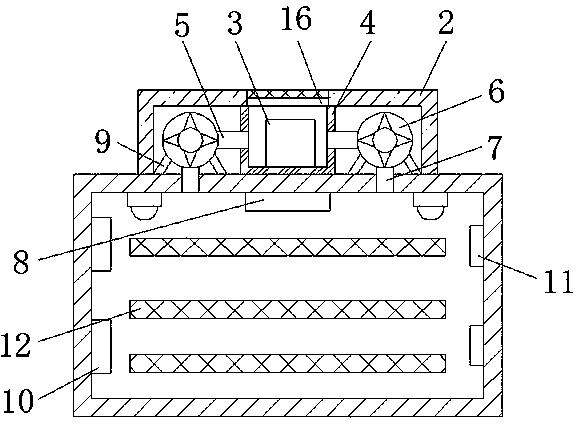

Intelligent stage lighting cloud terminal controlling system

ActiveCN103327689ASolve the burning problemAddressing Fire DefectsElectric light circuit arrangementEnergy saving control techniquesStage lightingControl system

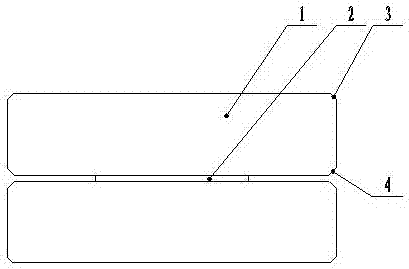

The invention relates to an intelligent stage lighting cloud terminal controlling system. The intelligent stage lighting cloud terminal controlling system comprises a large dimming cabinet, a network transmission device, a cloud decoder and a cloud terminal distributor. The large dimming cabinet receives parameter information of light, codes and packs the parameter information, and then sends the parameter information to the cloud decoder through the network transmission device, the cloud decoder unpacks and decodes the received information, and then transmits the received information to the cloud terminal distributor, the cloud terminal distributor is used for controlling each stage light, stage lights send working state information to the cloud decoder through the cloud terminal distributor, the cloud decoder codes and packs the working states, and then sends the working states of the stage lights to the large dimming cabinet through the network transmission device, and the large dimming cabinet conducts unpacking and decoding on the state information and then conducts changing, storing and displaying on the state information. The intelligent stage lighting cloud terminal controlling system can monitor working states of the stage lights in real time, circuit information can be set in a remote mode, and safety is improved.

Owner:RGB LIGHTING EQUIP

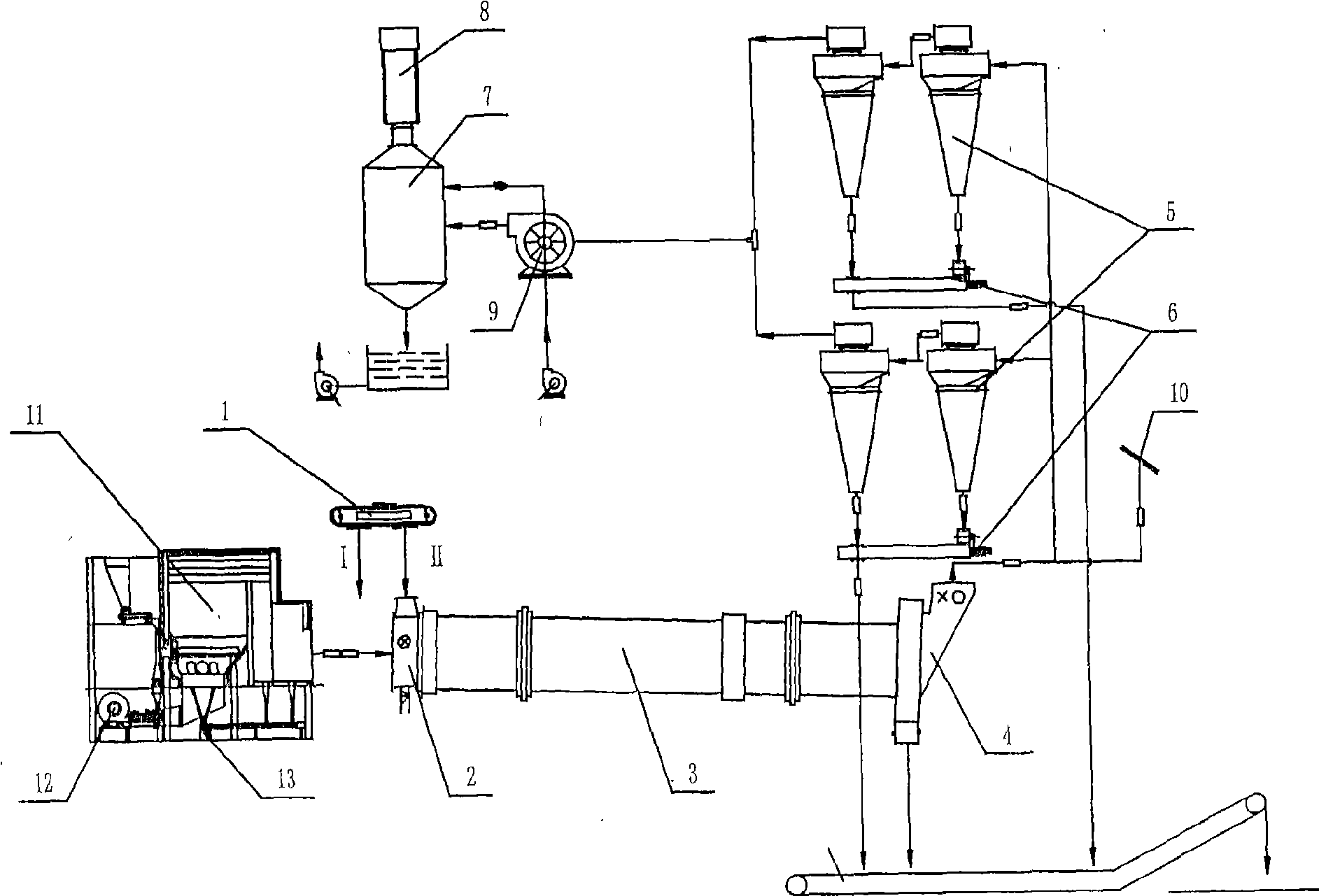

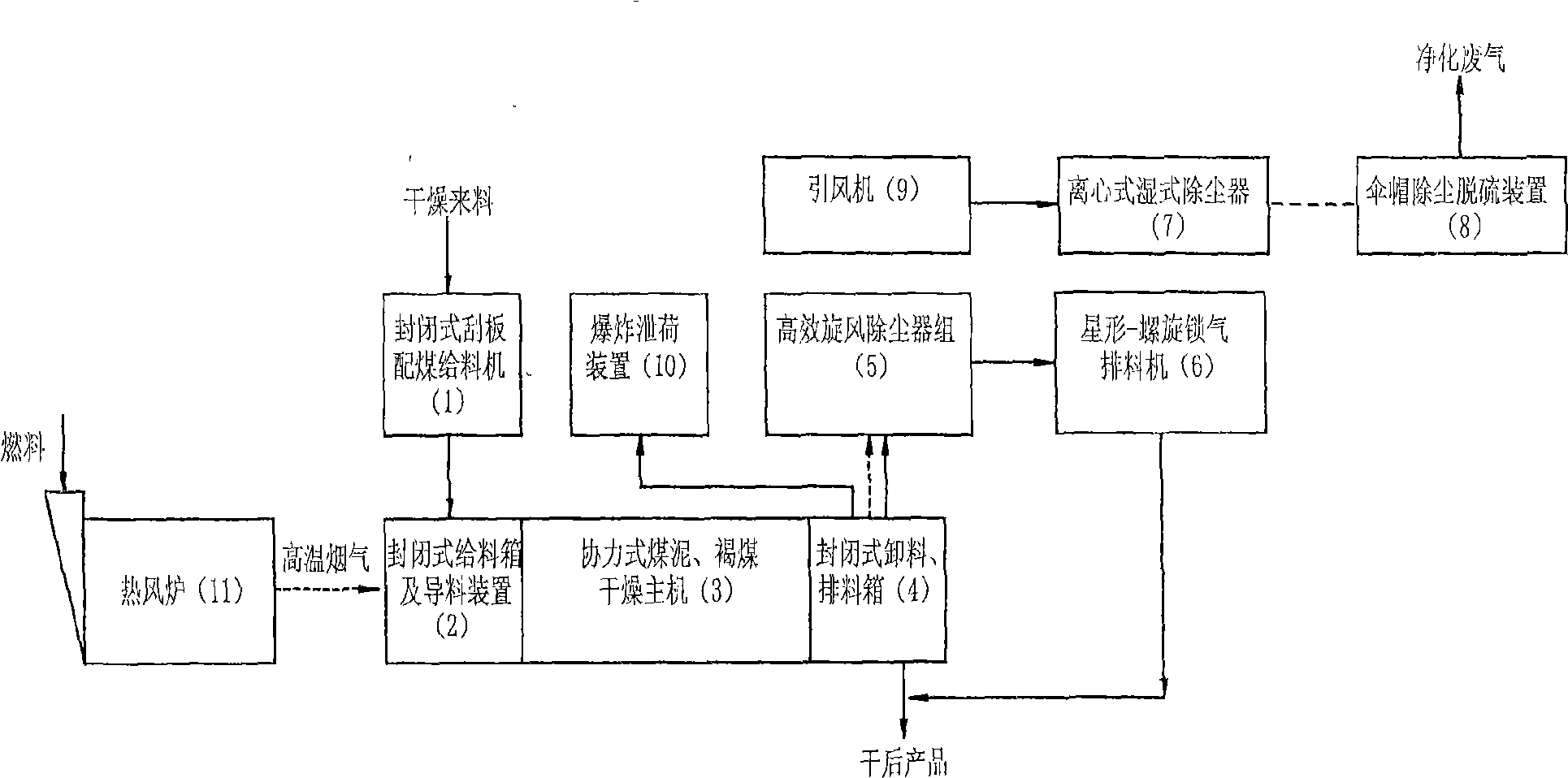

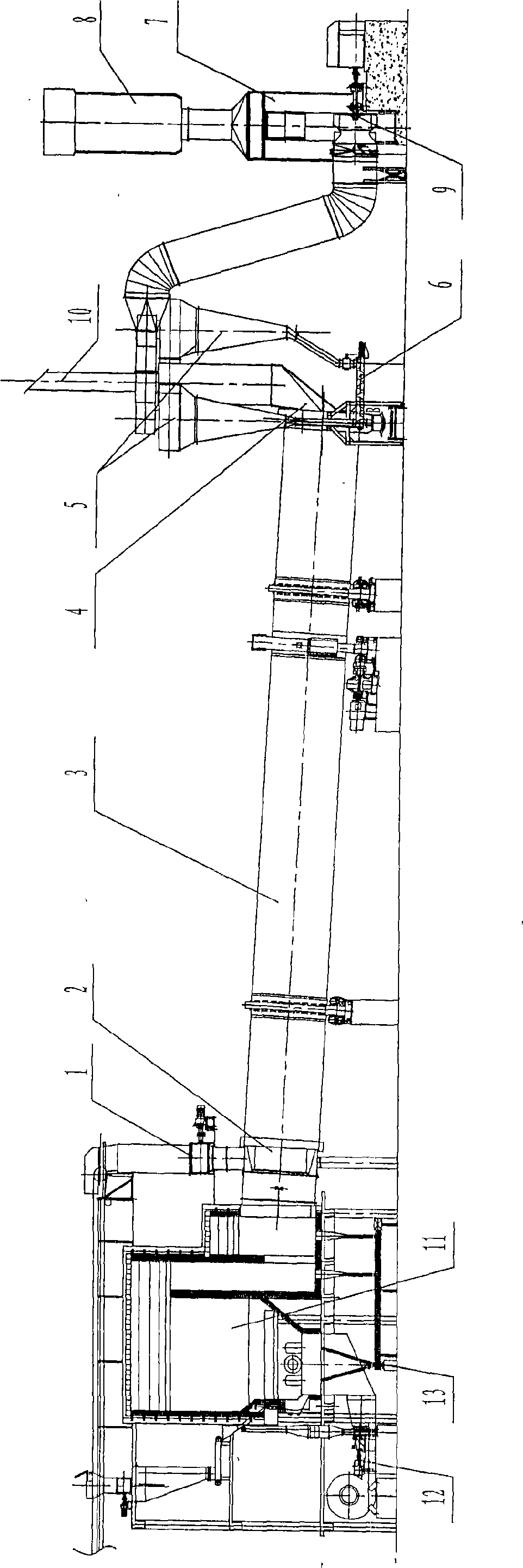

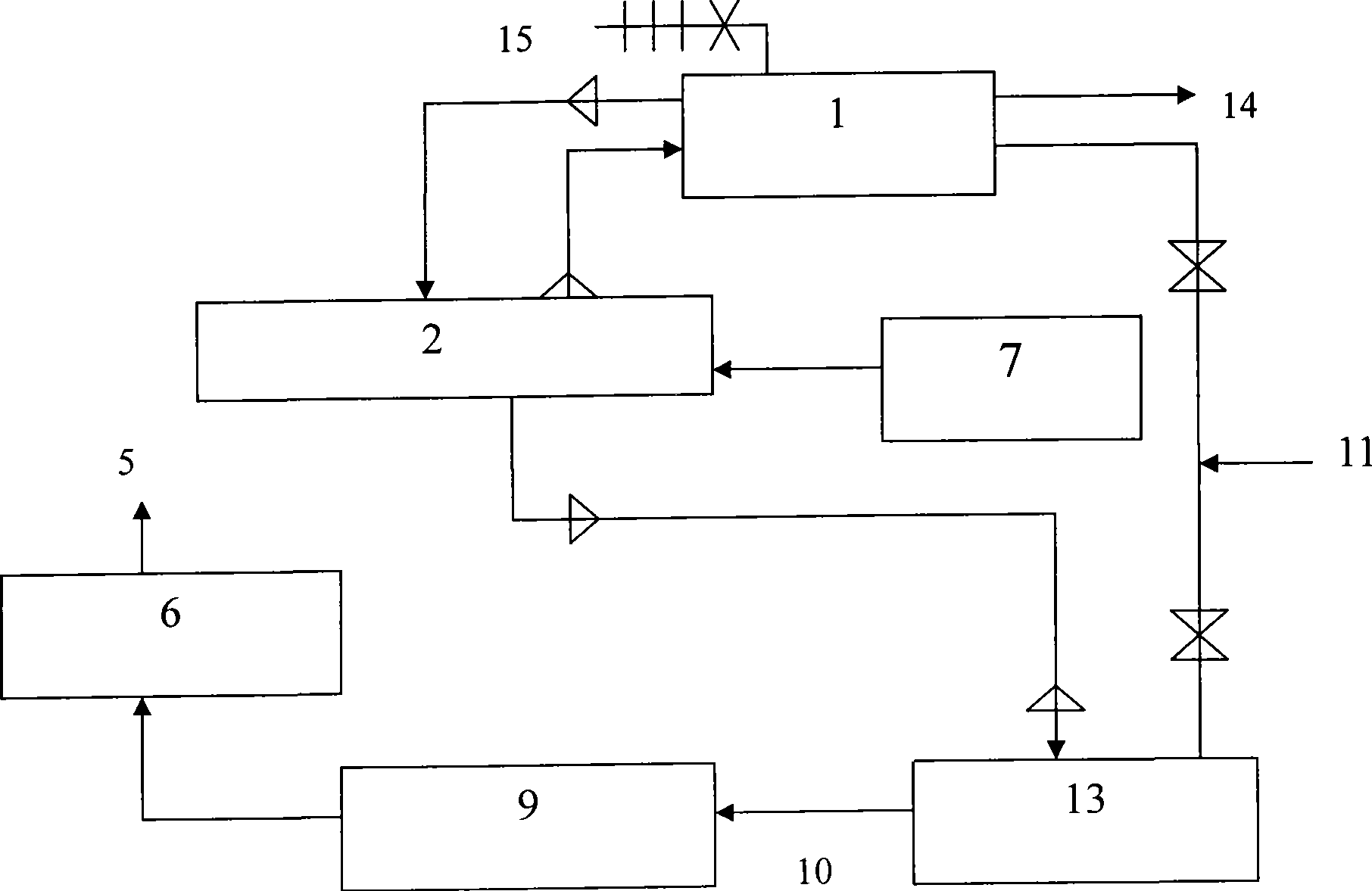

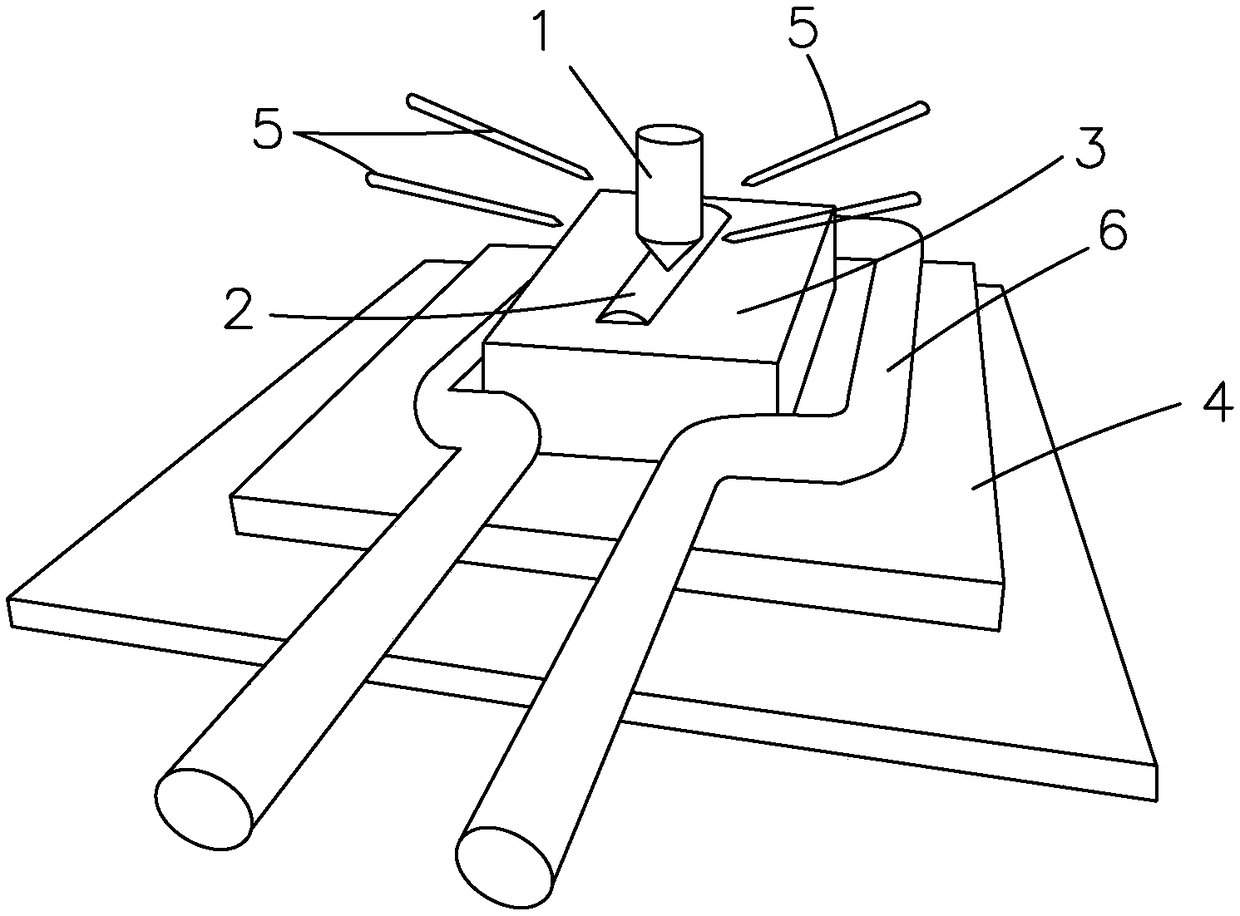

Process and equipment for improving the quality of coal slurry and lignite through drying same

InactiveCN101519617ASolve frequent blockagesSolve the burning problemSolid fuelsDrying peatEconomic benefitsProcess engineering

The invention relates to process and equipment for improving the quality of coal slurry and lignite through drying the same. The process comprises the following steps: (1) the coal slurry and the lignite are predried and then quantitatively fed to a drying system; (2) the coal slurry and the lignite are dried to be improved in quality by a material drying system; and (3) products are produced from the dried coal slurry and lignite of improved quality. The coal slurry and the lignite are dried and dewatered according to the physical and chemical properties of the same and the coal slurry and the lignite can not adhered to the wall of a cylinder of the equipment and can be cleaned automatically; the equipment is arranged integrally lineally on a plane so that the height of a factory building is lowered and the investment on the equipment is reduced by half compared with investment on the equipment arranged in a laminated mode; in addition, the equipment integrates feeing equipment, drying equipment and discharging equipment, has good sealing performance and high thermal efficiency which is increased to over 70 percent from the original 30-40 percent, saves energy to be consumed by one third, is environmentally friendly, can efficiently dewater the coal slurry and the lignite to improve the quality thereof and can be used safely and reliably so as to obtain obvious economic benefits.

Owner:张兆奇

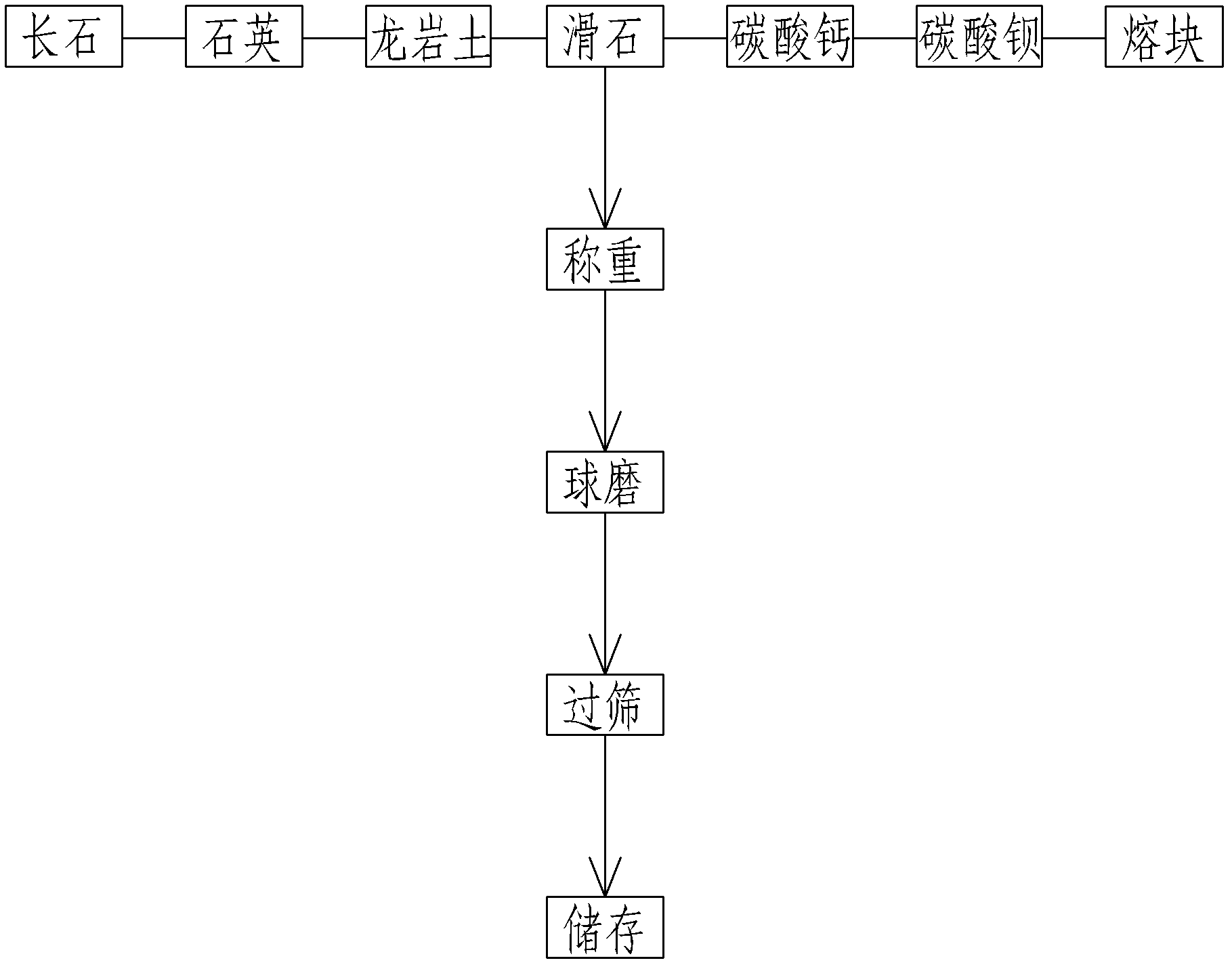

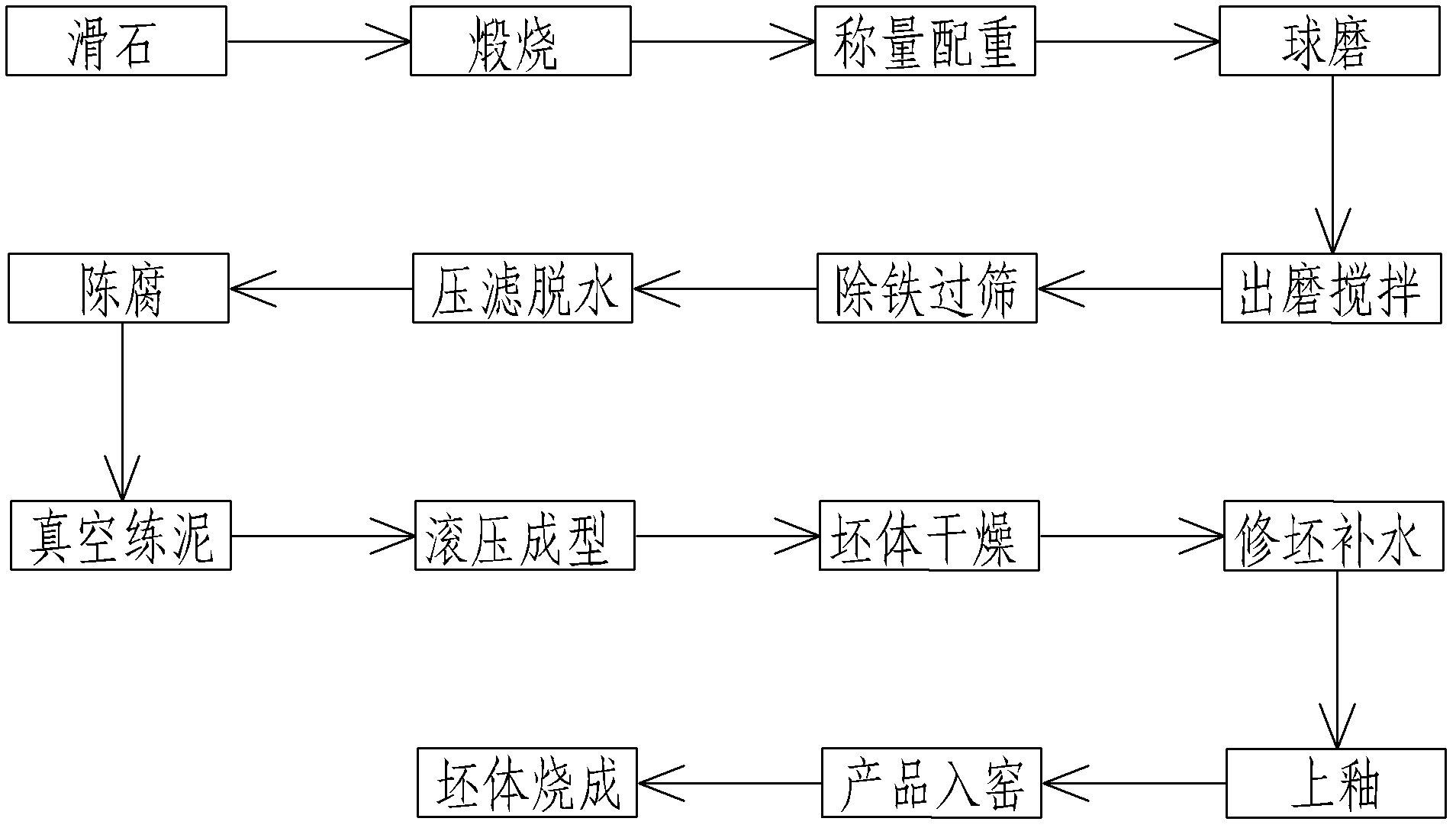

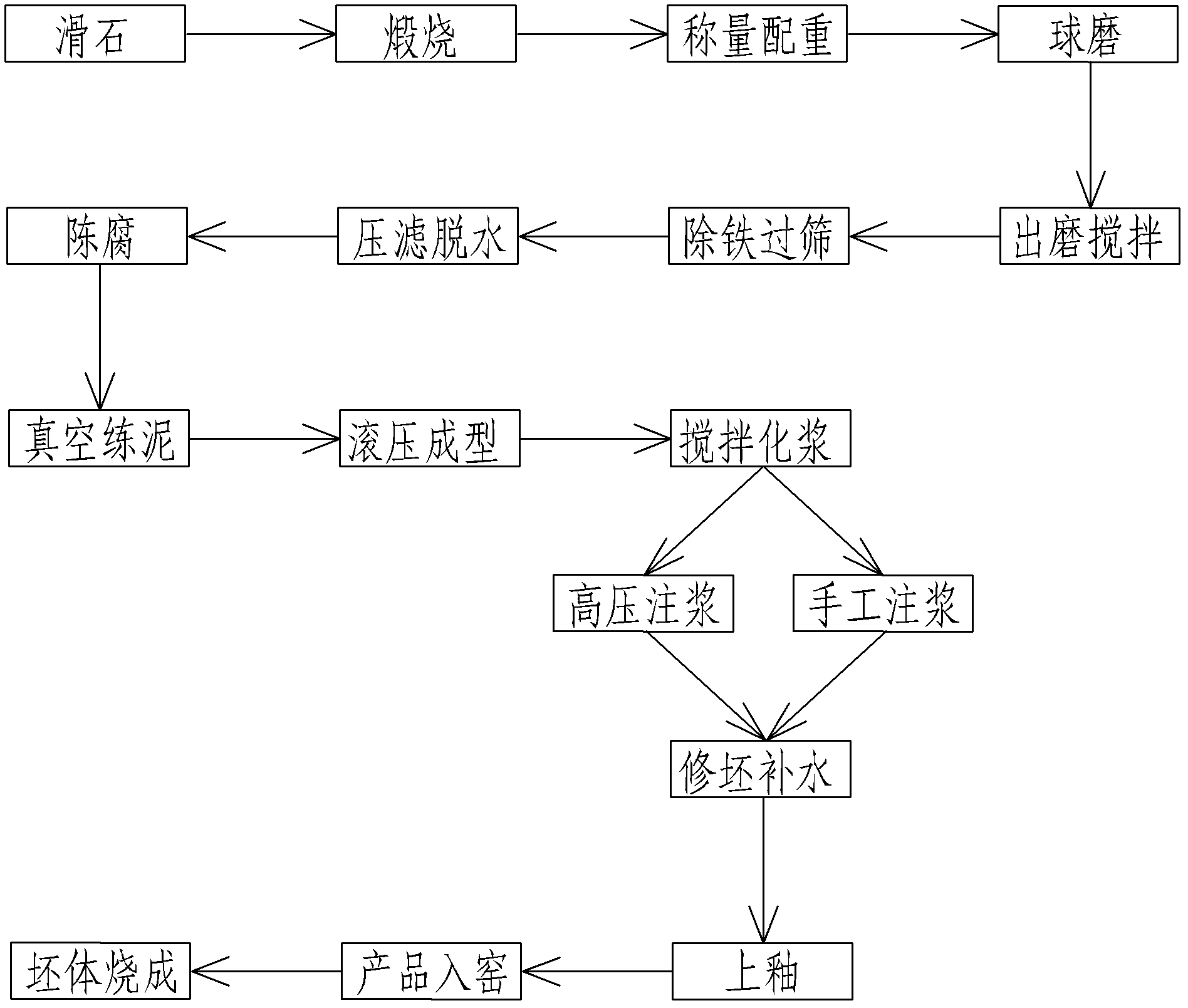

Magnesium jade porcelain formula and one-time calcining manufacture method

The invention relates to a magnesium jade porcelain formula and one-time calcining manufacture method, the raw materials are weighted according to the formula of a blank material and glaze, the method comprise the following steps: calcining a talcum raw material at the temperature of 1150-1250 DEG C; mixing 75-85% of calcined talcum, 5-15% of magnesian clay, 1-5% of feldspar, 1-5% of bentonite, 2-6% of kaolin, 0.1-0.3% of carboxymethylcellulose sodium for ball milling; stirring the clay after mixing and ball milling, deironing and sieving and controlling the particles in the clay less than 30 mum; carrying out press filtration, on the clay after deironing and sieving, dehydrating, aging, vacuum mixing and roll forming; preparing the clay after roll forming into biscuit, glazing, entering into a kiln and calcining a base substrate. One-time calcining of magnesium jade porcelain can be realized, and the problems of poor product regularity and thermal shock resistance performance generated by calcining temperature by using a lot of talcum material can be overcome and enhanced.

Owner:FUJIAN GUANFU IND CO LTD

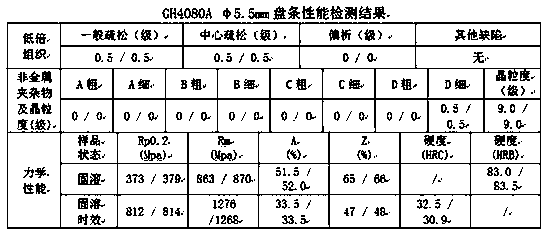

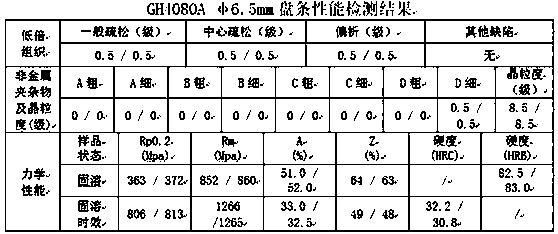

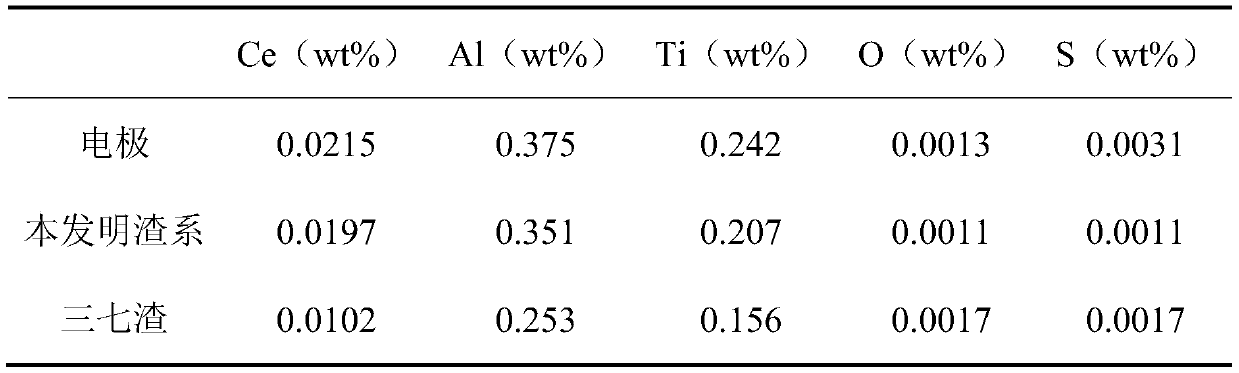

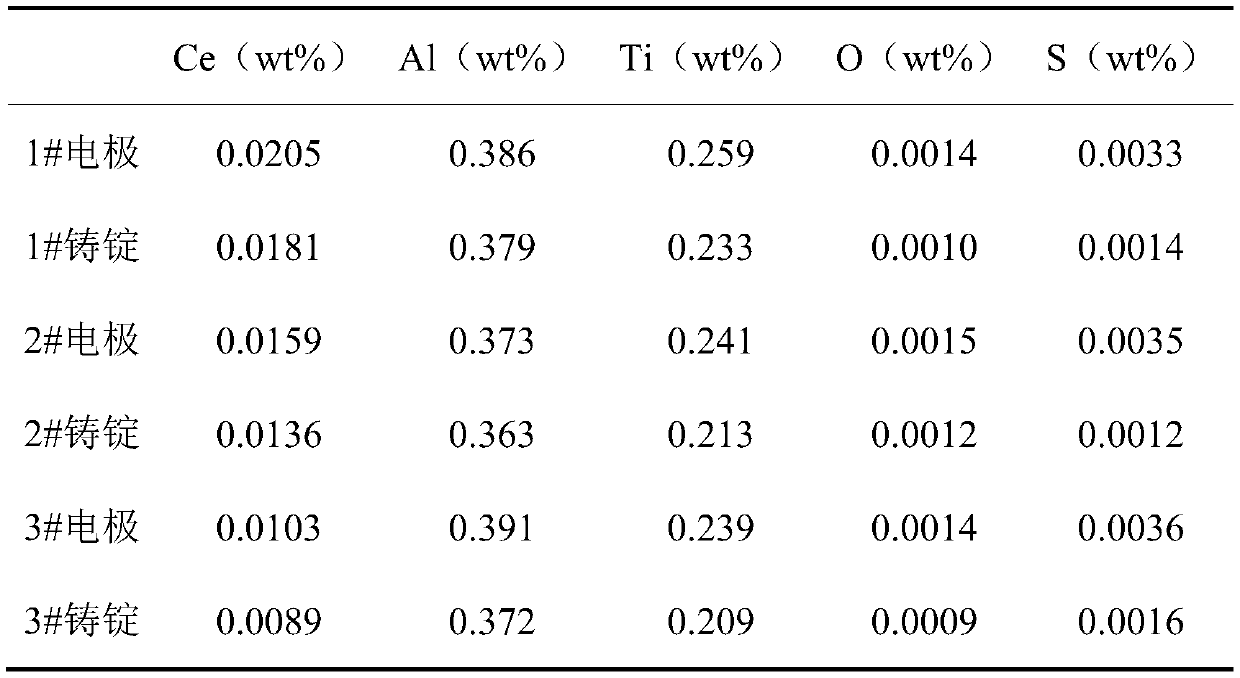

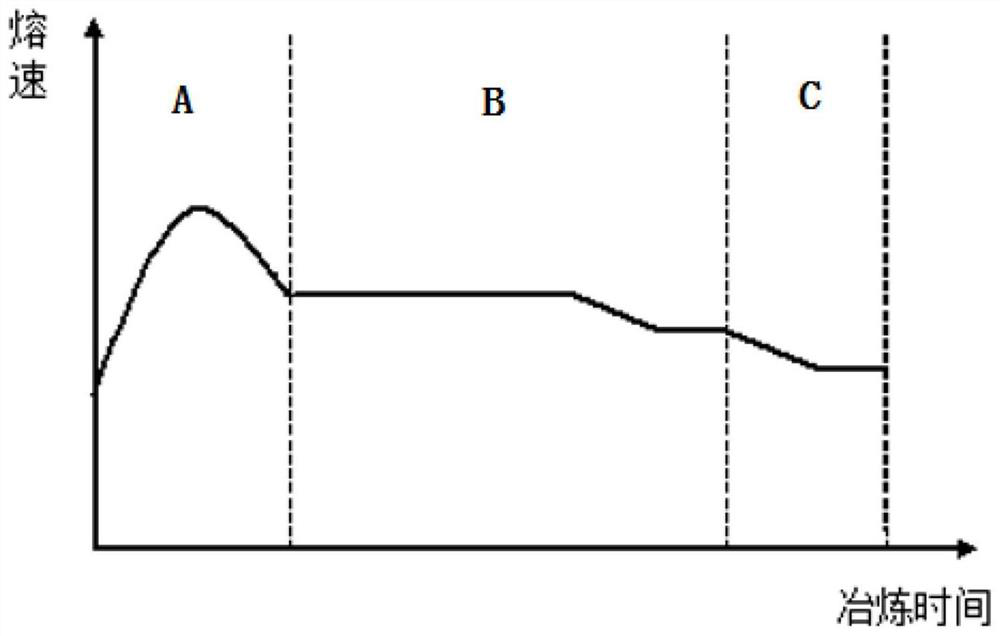

Production method of nickel-based GH4080A alloy wire rod

InactiveCN109985926AImprove purityImprove material performanceWork heating devicesMetal rolling arrangementsControllabilitySmelting

The invention belongs to the technical field of machining and manufacturing of special alloy materials, and particularly relates to a production method of a nickel-based GH4080A alloy wire rod. The production method comprises the following steps of material preparing, vacuum induction smelting, electroslag remelting, heat treatment, forging cogging, billet trimming and grinding, heat treatment, wire rolling, on-line solid solution and finishing. According to the production method of the nickel-based GH4080A alloy wire rod, a vacuum induction melting furnace and electroslag remelting furnace smelting technique is used for obtaining electroslag ingots, the electroslag remelting adopts an appropriate slag system proportion and a smelting argon protection method, which can effectively solve the burning loss problem of easy-to-oxidize elements of Al and Ti in the materials, and remarkably improve the purity of the materials; the Al and Ti retention rate of an induction electrode is increased to more than 96% from about 80% in the past; the material performance is improved; the qualified rate of finished products is high; the cost of raw materials is less; the production process is easyto control; the high-temperature performance is good; the surface forming is good; the yield is high; the grinding weight loss is less; and the controllability is good.

Owner:YONGXING SPECIAL STAINLESS STEEL

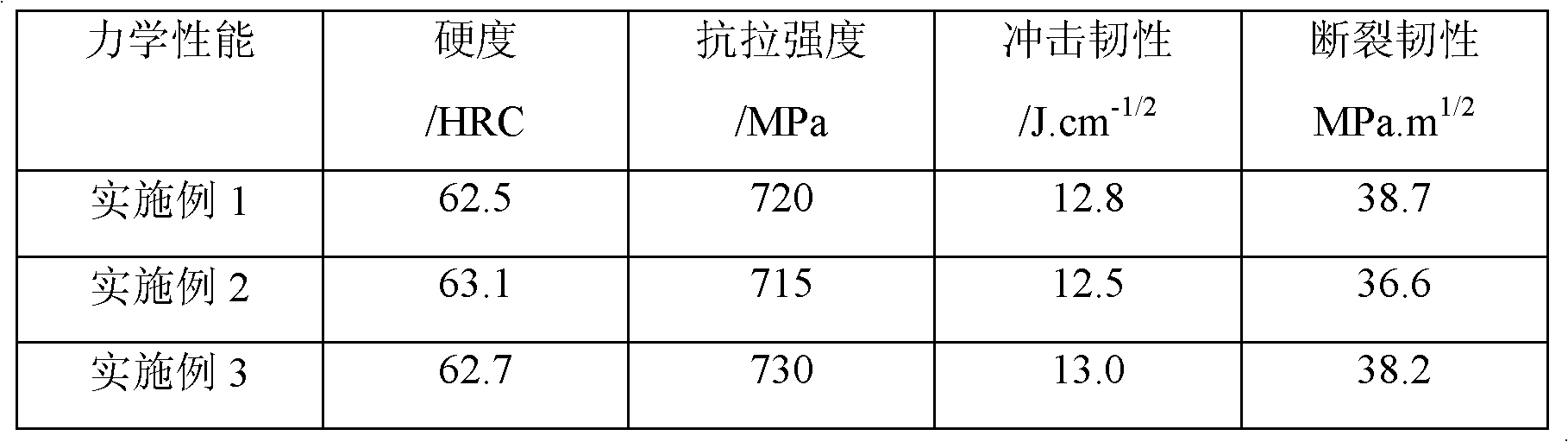

Compound processing method of boron-containing high-speed steel roller material

The invention discloses a compound processing method of a boron-containing high-speed steel roller material, belonging to the technical field of wear-resistant materials. The method comprises the following steps: smelting a high-speed steel roller material in an electric furnace, deoxidizing and desulfurizing the molten steel, raising the temperature to 1630-1650 DEG C, discharging, heating to 1000-1100 DEG C, crushing into boron iron particles of 2-6mm, and flushing the boron iron particles into a ladle along with the flow; previously adding a compound modifier, which contains rare earth, potassium, magnesium, strontium, calcium and various other microelements, into the bottom of the ladle; 3-5 minutes after the discharge of the molten steel, carrying out argon-blowing purifying treatment on the molten steel at the bottom of the ladle for 6-10 minutes; and after the temperature of the molten steel reaches 1460-1480 DEG C, casting the molten steel to obtain the roller. The roller has the characteristics of fewer inclusions, high mechanical properties, long service life and the like, and has high economic benefit for popularization and application.

Owner:BEIJING UNIV OF TECH

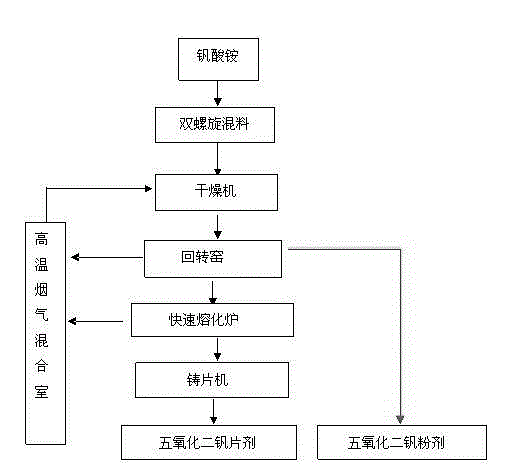

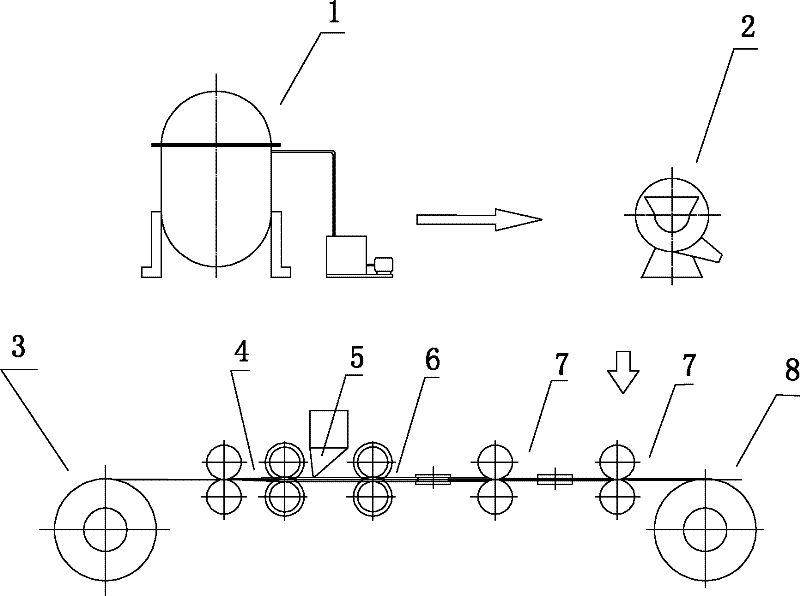

Production method and production system for vanadium pentoxide

The invention discloses a production method and a production system for vanadium pentoxide. The production method comprises the following steps of breaking industrial ammonium vanadate filter cakes and then continuously adding the industrial ammonium vanadate filter cakes into drying equipment and drying by using high-temperature gas; enabling the dried ammonium vanadate to enter calcinating equipment for deaminizing oxidation to obtain mixer of powder vanadium pentoxide or vanadium oxide; and enabling the mixer of the powder vanadium pentoxide or vanadium oxide to enter melting equipment for melting and casting pieces to obtain flaky vanadium pentoxide. According to the production method, drying for dehydration, calcinating for deaminizing and melting and piece casing processes of ammonium polyvanadate or ammonium metavanadate are respectively operated in three sets of equipment; the temperature, the furnace charge stay time and oxidation supply atmosphere (hot air) can be effectively controlled according to different function phases of drying, deaminizing and oxidizing and optimal conditions, and thus each function phase is operated under the optimal condition and further stability, high quality and high yield are achieved. The production method can be used for producing flaky and powder vanadium pentoxide and the yield of metal vanadium is respectively greater than 99 percent.

Owner:HEBEI IRON AND STEEL

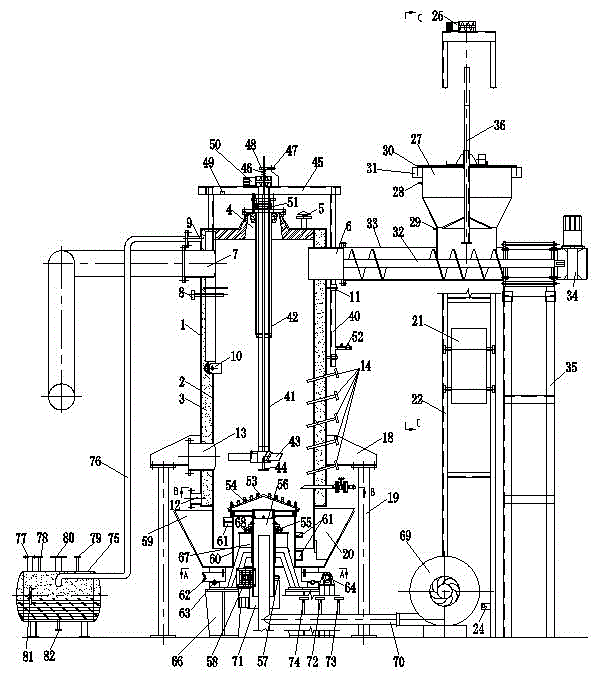

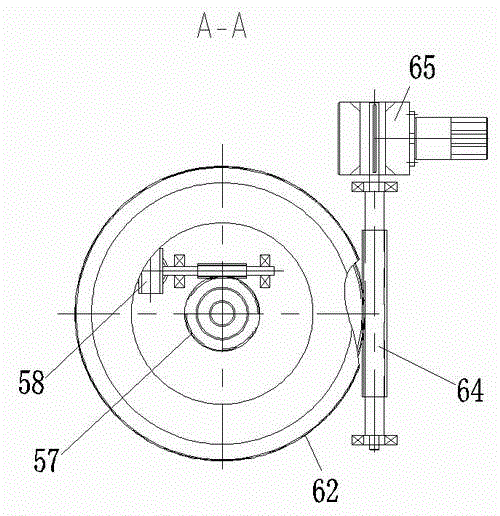

Intelligent control household garbage pyrolysis gasifier

ActiveCN104896479AConsistent thicknessEasy to controlIncinerator apparatusCombustionResource utilization

The invention discloses an intelligent control household garbage pyrolysis gasifier, and belongs to the technical field of household garbage resource utilization. The gasifier comprises an air supply system, a feeding device, a material distributing device, a rotary furnace grate and an ash disc drive mechanism. The feeding device comprises a spiral feeding bind and a lifting bucket, the periphery of a material bin cover is provided with a water seal structure, and the center position is provided with a material pressing rod connected with an electrician push rod. The material distributing device is disposed on a transverse support frame driven by two oil cylinders, and an electric speed reducer drives a shifting piece on a material distributing main shaft to rotate. The rotary furnace grate drives a worm gear gear ring through a worm by utilizing an electric worm and gear speed reducer. An ash disc adopts an electric worm and gear speed reducer to drive the ash disc to rotate. The air supply system is divided into a bottom air supply part and a side air supply part. The pyrolysis gasifier solves the air distribution non-uniform problem, and the rotary furnace grate can smoothly and effectively solve the deviant combustion problem of the gasifier. The rotary furnace grate separates air distribution from ash arrangement, the air distribution or the ash arrangement can be adjusted in the operation process as needed, and then operation of the gasifier is stable.

Owner:DALIAN HUICHUAN ENVIRONMENTAL PROTECTION TECH

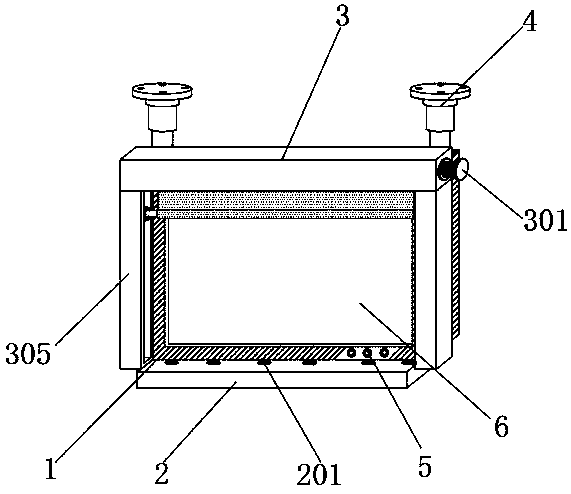

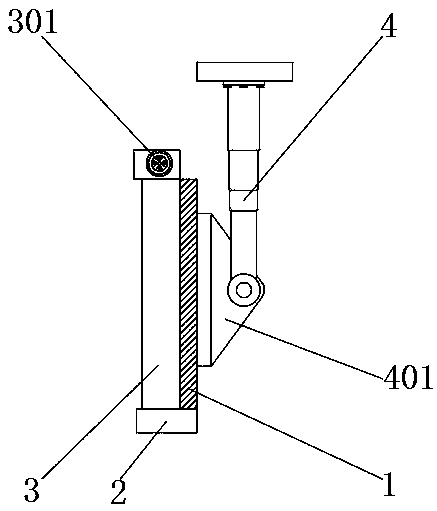

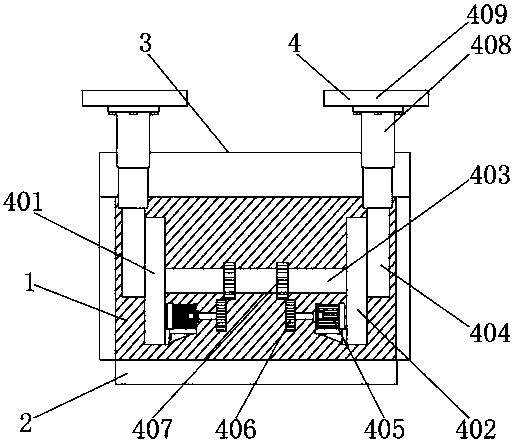

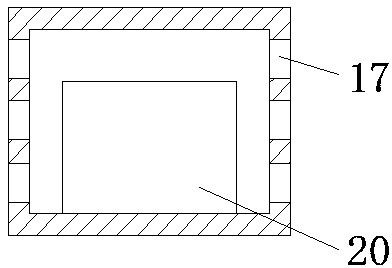

Electronic information exhibiting equipment

InactiveCN108269494AExpel fastSolve the burning problemFouling preventionCleaning using toolsEngineeringControl switch

Owner:邵庭轩

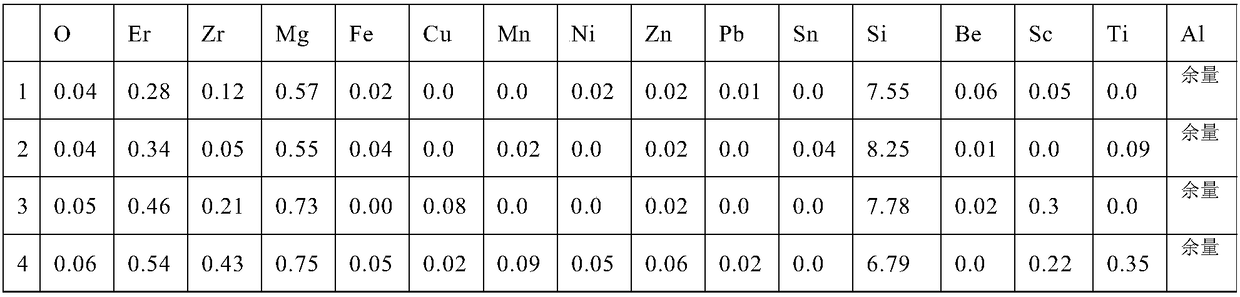

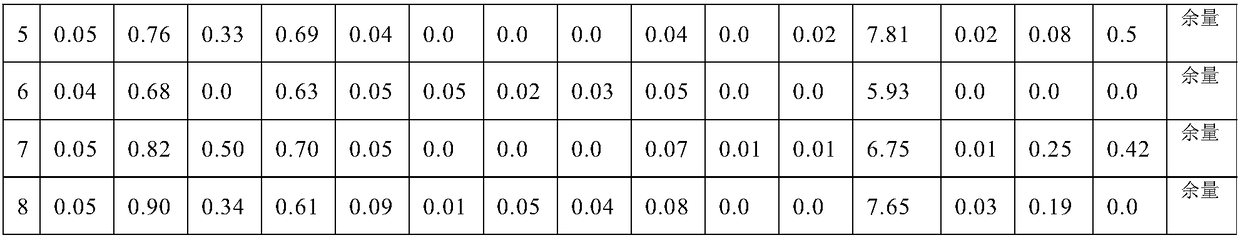

Rare earth erbium element reinforced AlSi7Mg aluminum alloy powder specially used for SLM, and application thereof

InactiveCN108486429AHigh strengthHigh specific strengthAdditive manufacturing apparatusTransportation and packagingSelective laser meltingManufacturing technology

The invention relates to the technical field of intelligent manufacturing, and discloses a rare earth erbium element reinforced AlSi7Mg aluminum alloy powder specially used for SLM (selective laser melting), and a preparation method and an application thereof. The rare earth erbium element reinforced AlSi7Mg aluminum alloy powder specially used for SLM comprises, by mass, 5.5-8.5% of Si, 0.55-0.75% of Mg, 0.2-0.9% of Er, 0.05-0.5% of Zr, below 0.1% of Zn, below 0.1% of Cu, below 0.1% of Mn, below 0.1% of Fe, below 0.05% of Ni, below 0.05% of Pb, below 0.05% of Sn, below 0.07% of Be, below 0.10% of O, and the balance of Al. AlSi7Mg aluminum alloy powder is reinforced with the rare earth erbium element, so the strength of an SLM molded part is improved, the weight reduction of an aviation part is realized, and the full performance of the SLM technology in the aerospace field is promoted.

Owner:上海康速金属科技有限公司

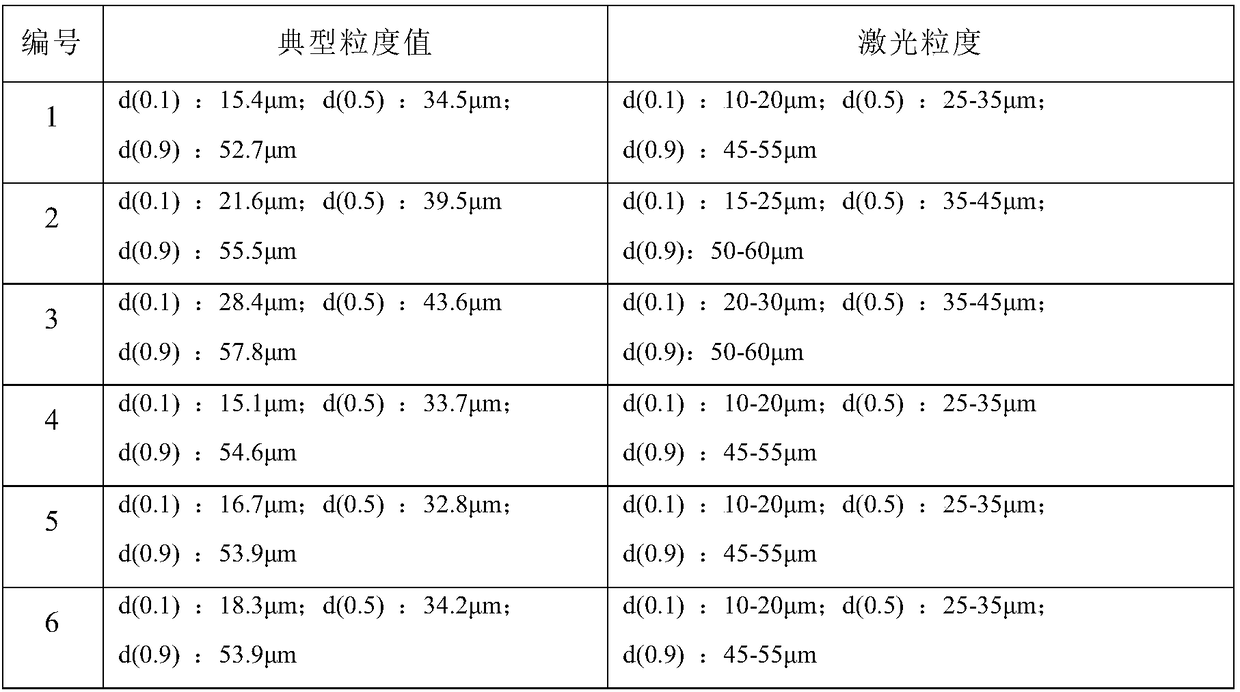

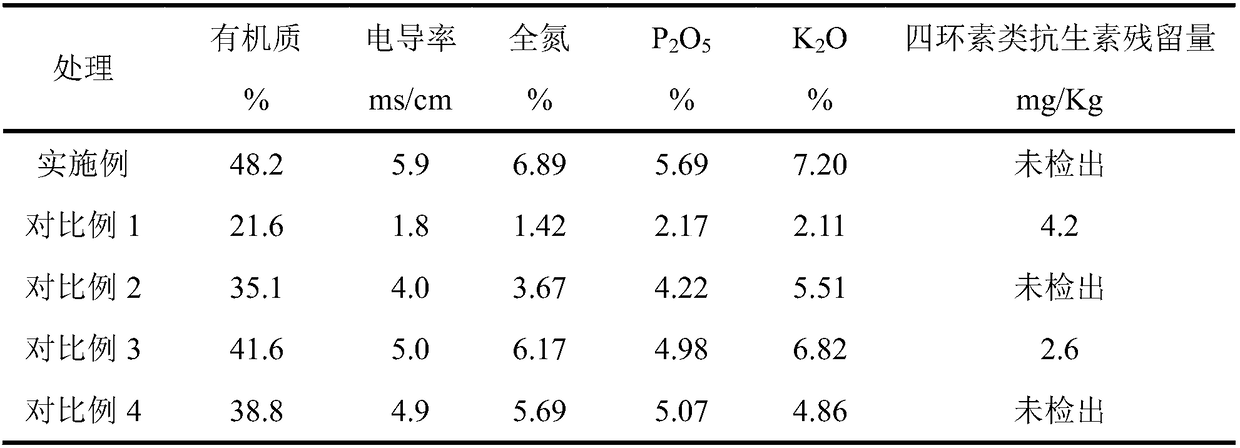

Ecological comprehensive utilization system for livestock breeding feces

ActiveCN108605863AAchieve sustainable developmentImplementing Handling DifficultiesWaste water treatment from animal husbandryLivestock managementOperational costsFeces

The invention relates to the technical field of agriculture ecology, in particular to an ecological comprehensive utilization system for livestock breeding feces. The system comprises a movable of detachable livestock breeding shed, a dry and wet separation device, an anaerobic fermentation device, a discharging and dewatering device, a biogas power generation device and a vegetable and fruit treeplanting area, the feces is separated into day feces and biogas slurry by the dry and wet separation device, the biogas slurry is used for anaerobic fermentation, the day feces is used for compost, and generated manure is transported to the vegetable and fruit tree planting area and utilized. The system is high in automation degree, operating investment and running cost are reduced, the resourceutilization efficiency of agricultural and pastoral waste is improved, a livestock breeding park with a closed energy structure can be built by the system, a circular agriculture industry chain is achieved, rural straw gasification clean energy is utilized, comprehensive utilization of village or enterprise livestock breeding waste is achieved, the system can be truly implemented and normally run,waste materials are truly changed into things of value, and due contribution is made to 'beautiful villages, wealthy framers and strong agriculture'.

Owner:河南邓农食品股份有限公司

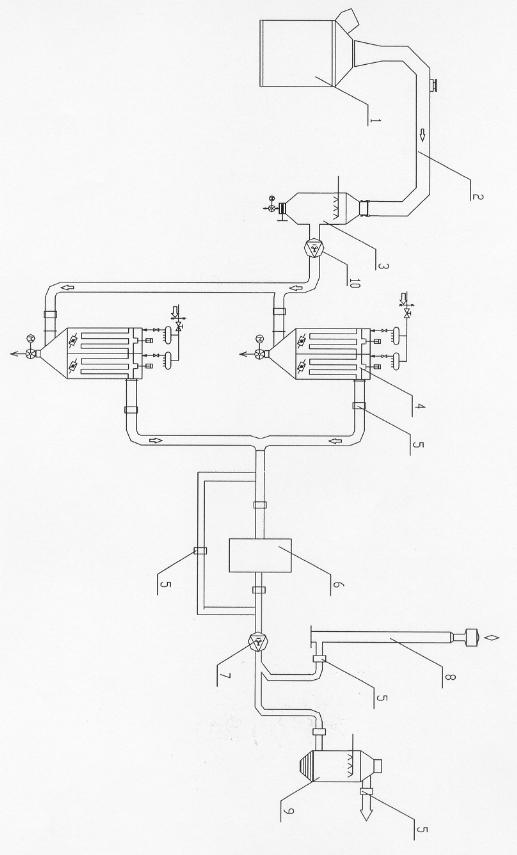

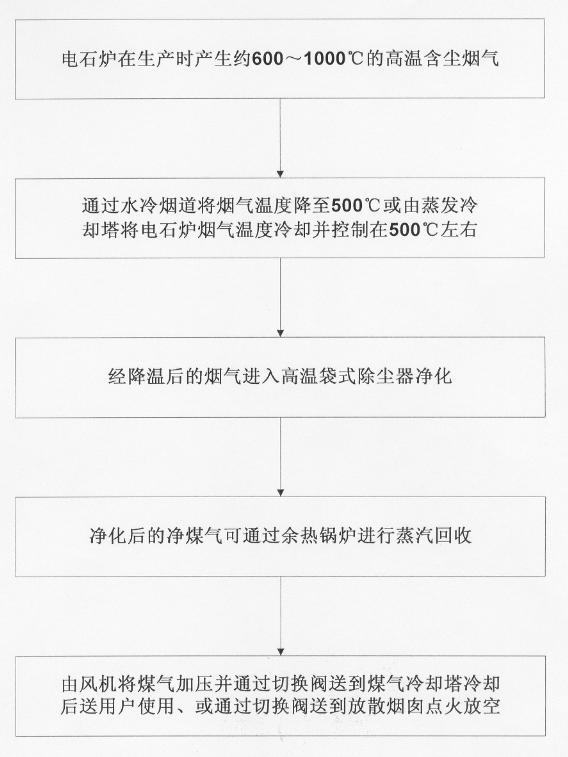

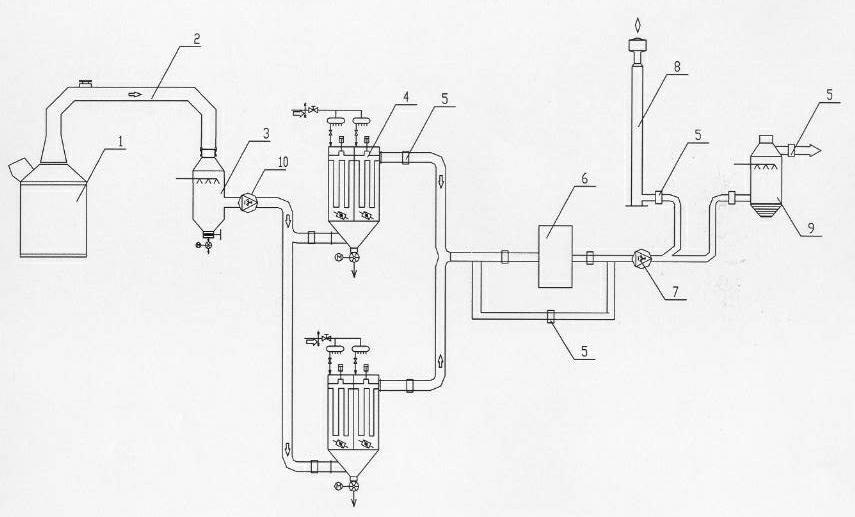

Smoke high-temperature dust removal and steam and coal gas recovery system and method for calcium carbide furnace

InactiveCN102183155ANo energy consumptionDoes not affect normal productionIncreasing energy efficiencyWaste heat treatmentRecovery methodCooling tower

The invention relates to a smoke high-temperature dust removal and steam and coal gas recovery system and a smoke high-temperature dust removal and steam and coal gas recovery method for a calcium carbide furnace. The calcium carbide furnace is connected with an evaporative cooling tower through a water-cooling flue and connected with the bottom of a high-temperature bag-type dust remover; the upper part of the calcium carbide furnace is connected with an afterheat boiler; and the afterheat boiler is connected with the bottom of a radiation chimney and the bottom of a coal gas cooling tower respectively. The method comprises the following steps of: reducing smoke temperature of the calcium carbide furnace to 500 DEG C through the water-cooling flue or cooling the smoke temperature of the calcium carbide furnace through the evaporative cooling tower and controlling the temperature at 500 DEG C or so; purifying the smoke with reduced temperature in the high-temperature bag-type dust remover; recovering steam of the purified coal gas through the afterheat boiler; and pressurizing the coal gas by a fan and sending the coal gas into the coal gas cooling tower through a switching valve, cooling the coal gas and sending the cooled coal gas to a user or sending the coal gas to the radiation chimney through the switching valve for ignition and emptying. In the invention, the high-temperature dust remover which can resist the temperature more than 400 DEG C is adopted and an air cooler is canceled, so that the problem that a filter bag of the bag-type dust remover is burned or pasted due to factors such as the smoke temperature, tar and the like can be solved, the dust removal efficiency is improved and a stable and clean coal gas source can be provided for a gas kiln.

Owner:BAOSTEEL ENG & TECH GRP

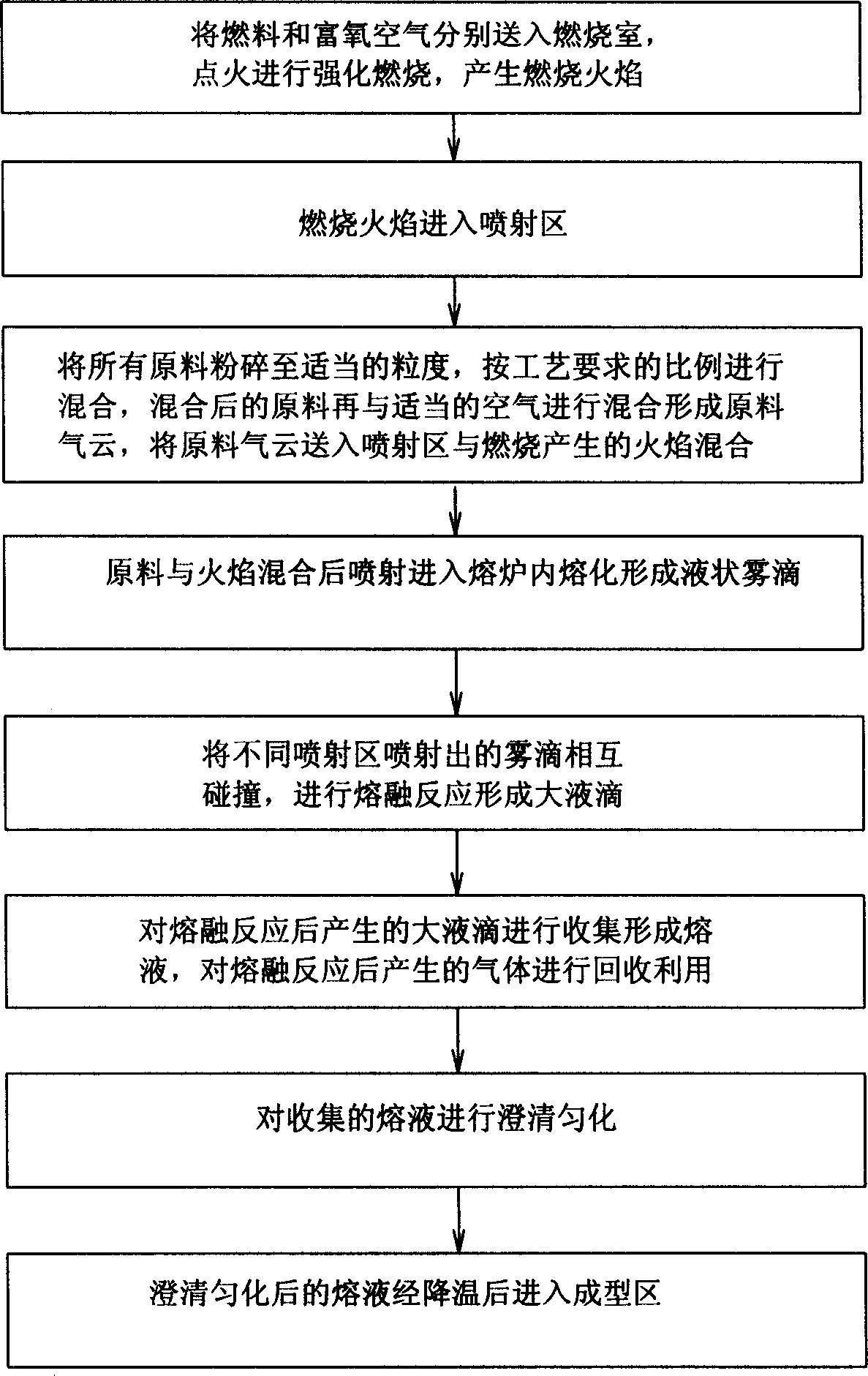

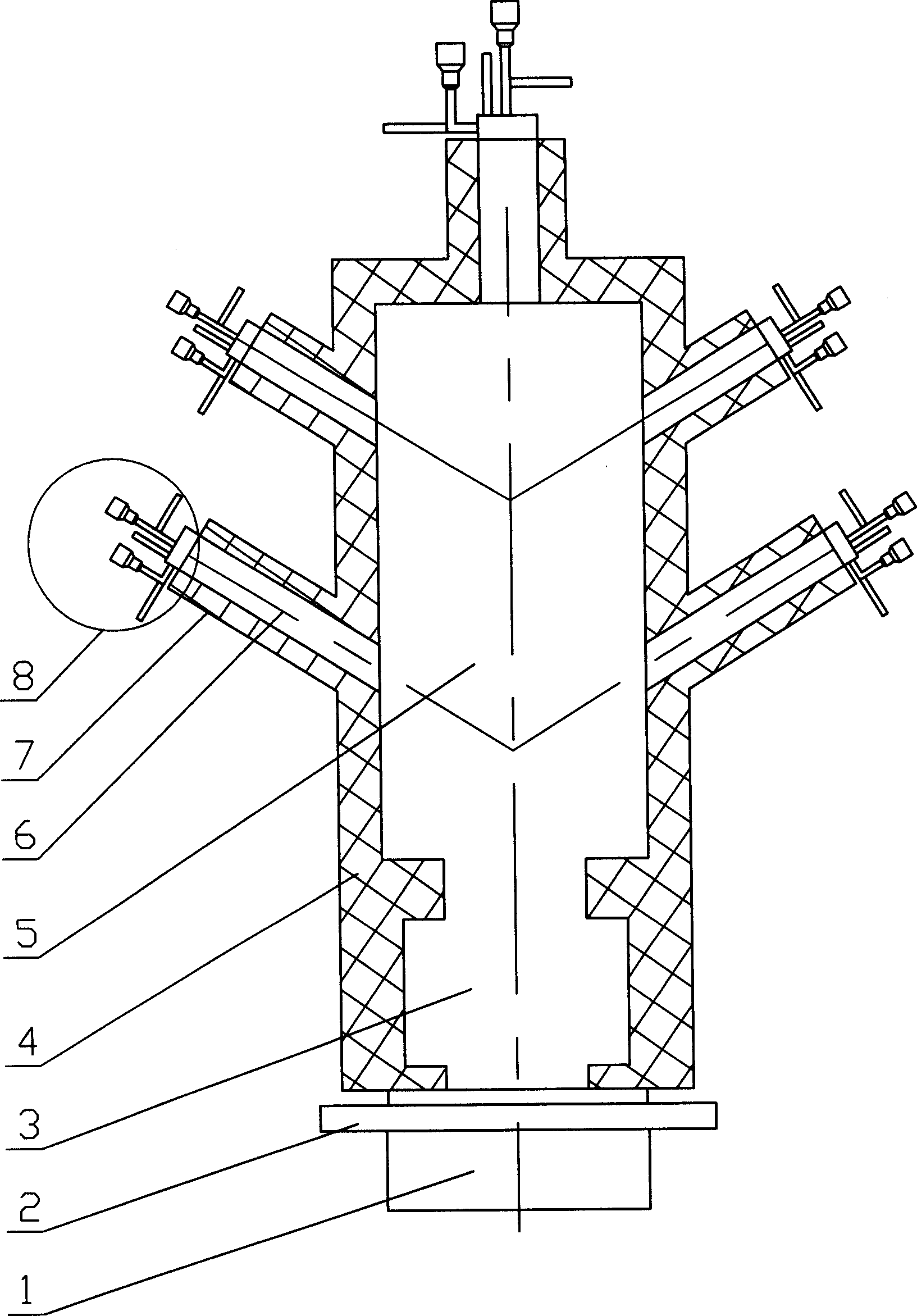

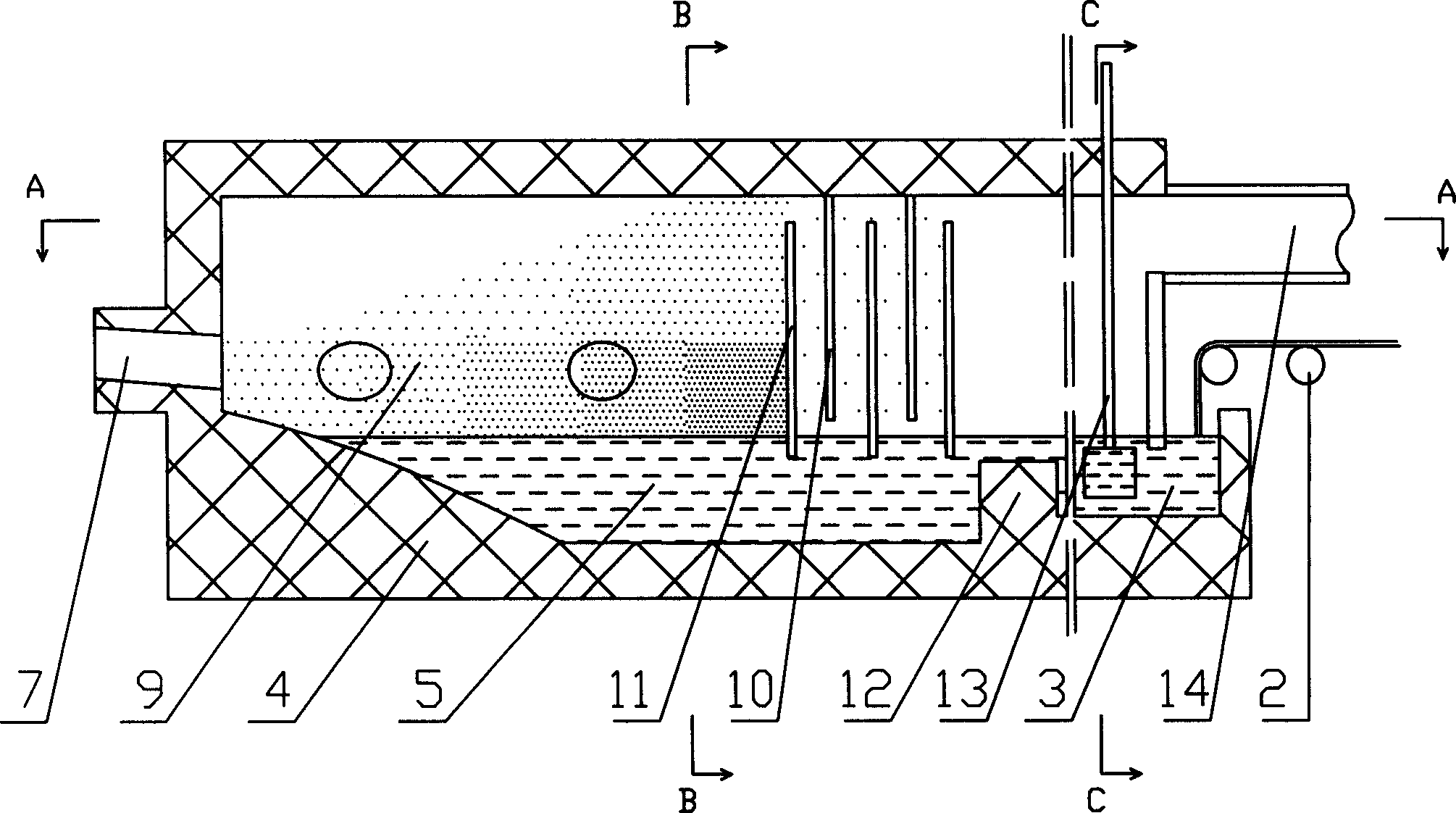

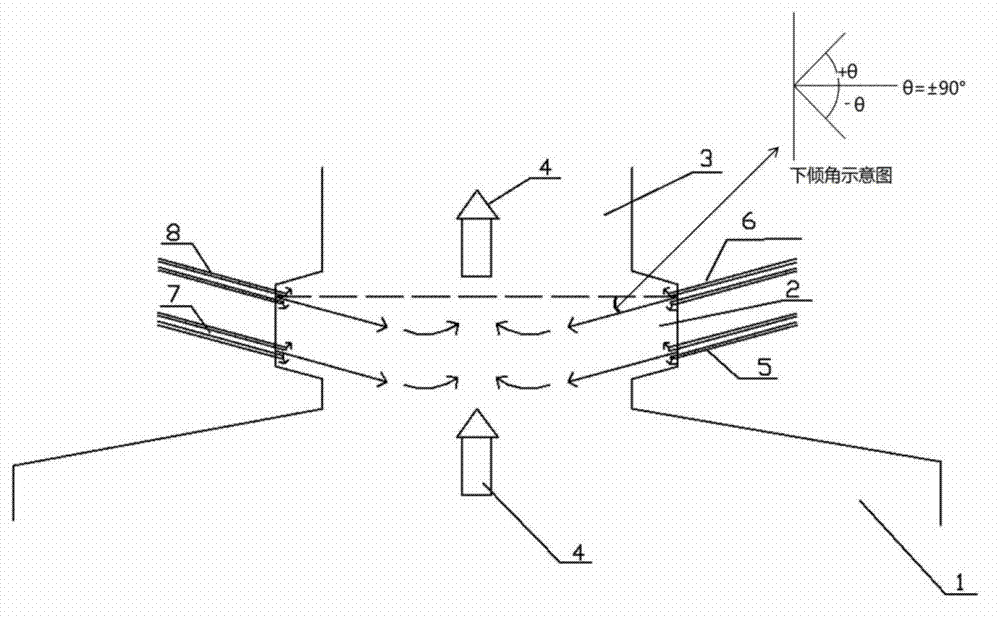

Full premixed combustion smelting method and smelting furnace for producing glass using the method

InactiveCN1594149AAvoid wastingSolve pollutionCharging furnaceGlass furnace apparatusCombustionHeat energy

The invention relates to a full premixed combustion smelting method and smelting furnace for producing glass using the method, wherein the method consists of disintegrating the raw materials, mixing and loading into flame for full contact with the flame, thus realizing completely premixed combustion and smelting, the droplets formed in smelting fall into the smelting pool through colliding each other and forming shaped liquid. The disclosed method can increase utilization factor of heat energy substantially.

Owner:谢西平

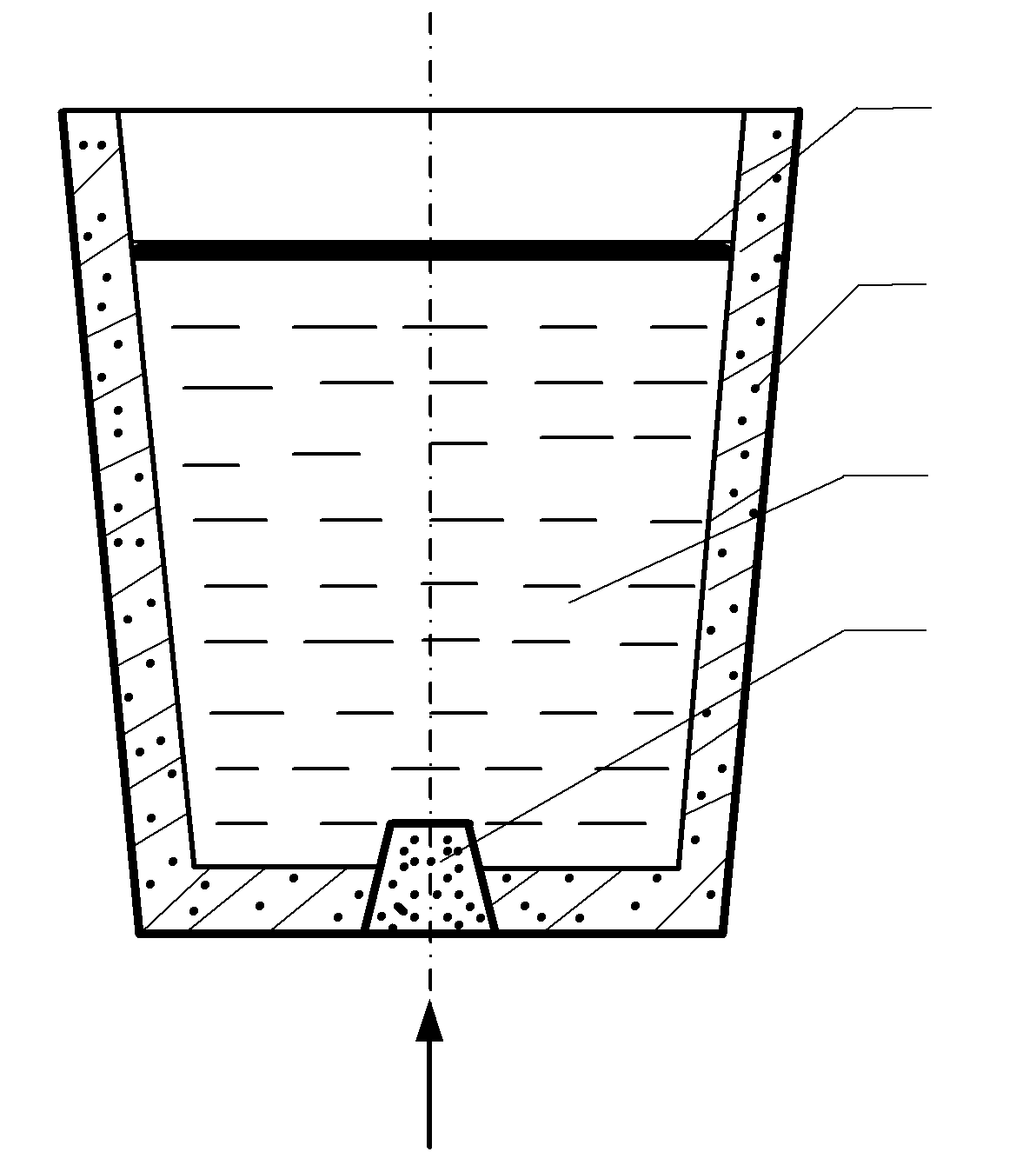

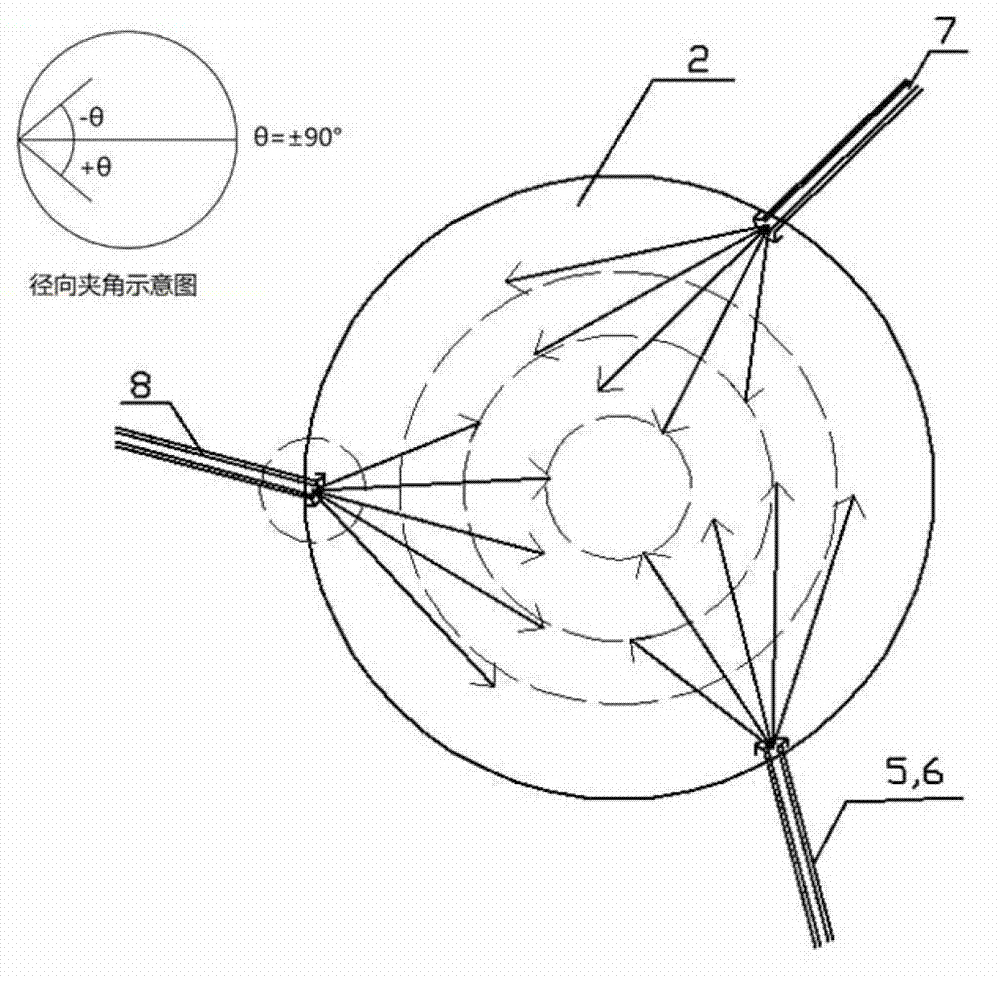

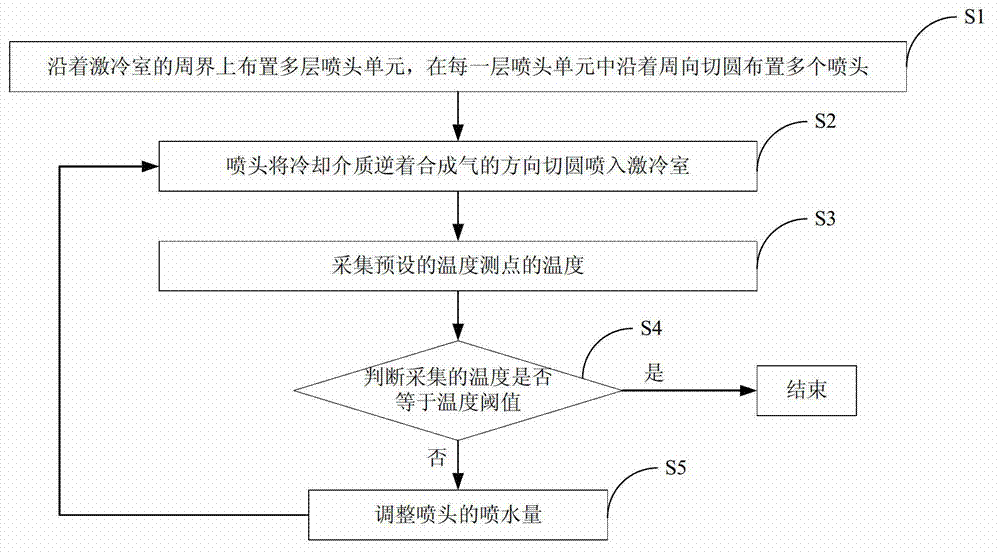

High-temperature synthetic gas chilling device and high-temperature synthetic gas chilling method for gasification furnace

ActiveCN102952588AIncrease mixing intensityReduce residual rotational momentumCombustible gas productionSyngasProcess engineering

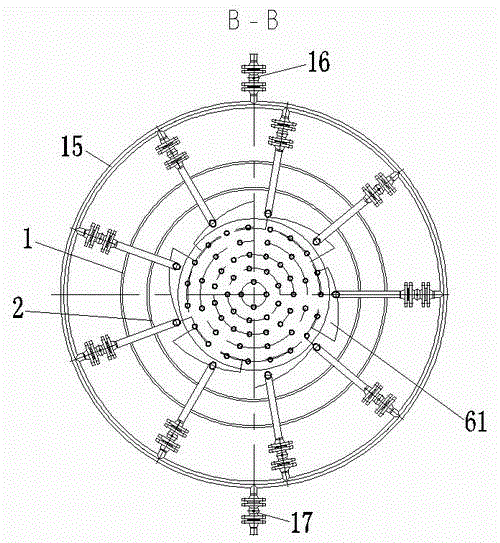

The invention discloses a high-temperature synthetic gas chilling device and a high-temperature synthetic gas chilling method for a gasification furnace. The chilling device comprises the coal gasification furnace, a chilling chamber and a synthetic gas guide pipe, wherein the chilling chamber is a space formed in a mode that a round, rectangular or polygonal section moves along the normal direction of the section; multiple layers of sprayer units are distributed on the periphery of the chilling chamber; and each sprayer unit comprises multiple sprayers distributed in a tangential circle shape along the circumferential direction; when the synthetic gas generated by the coal gasification furnace enters into the chilling chamber through the synthetic gas guide pipe so as to be chilled, the sprayers spray a cooling medium along a direction opposite to the synthetic gas movement direction, so that the cooling medium and the synthetic gas are uniformly mixed. According to the device and the method, multiple layers of multiple sprayers distributed in a tangential circle shape along the circumferential direction are adopted for spraying the cooling medium along the direction opposite to the synthetic gas movement direction, so that the influence of the chilling boundary on the temperature of the gasification furnace is reduced; and the cooling medium is sprayed along the direction opposite to the synthetic gas movement direction, so that the mixing intensity is improved, the residual rotation momenta of the synthetic gas are reduced, the length of the outlet guide pipe of the chilling chamber of the gasification furnace is greatly shortened, and the cost is lowered.

Owner:HUAZHONG UNIV OF SCI & TECH +1

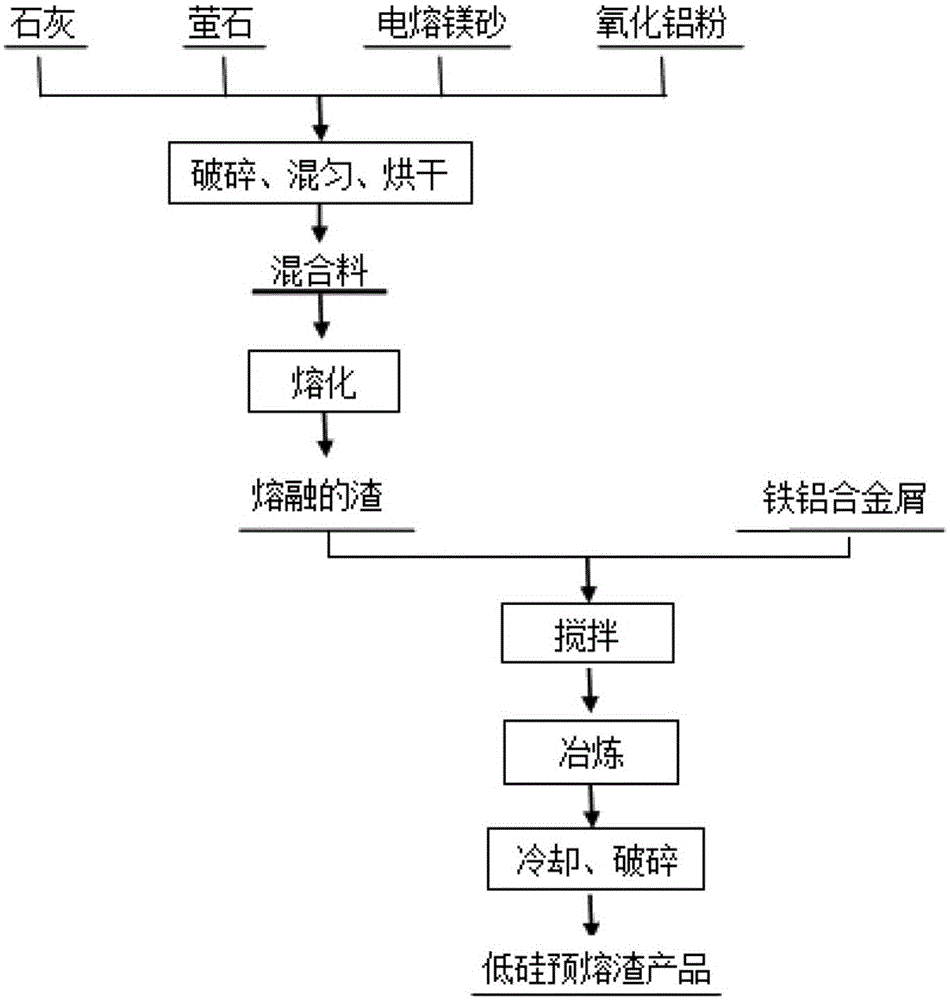

Preparing method of low-silicon pre-melted slag for electroslag remelting

The invention provides a preparing method of low-silicon pre-melted slag for electroslag remelting. The preparing method comprises the first step of even slag charge mixing, the second step of slag smelting and the third step of aluminum iron alloy adding and smelting. According to the preparing method of low-silicon pre-melted slag for electroslag remelting, the requirement for equipment is low, operation is easy, control is convenient, and cost is low. The problem that Al, Ti and elements prone to oxidation are burned down in the electroslag remelting process can be effectively solved.

Owner:NORTHEASTERN UNIV

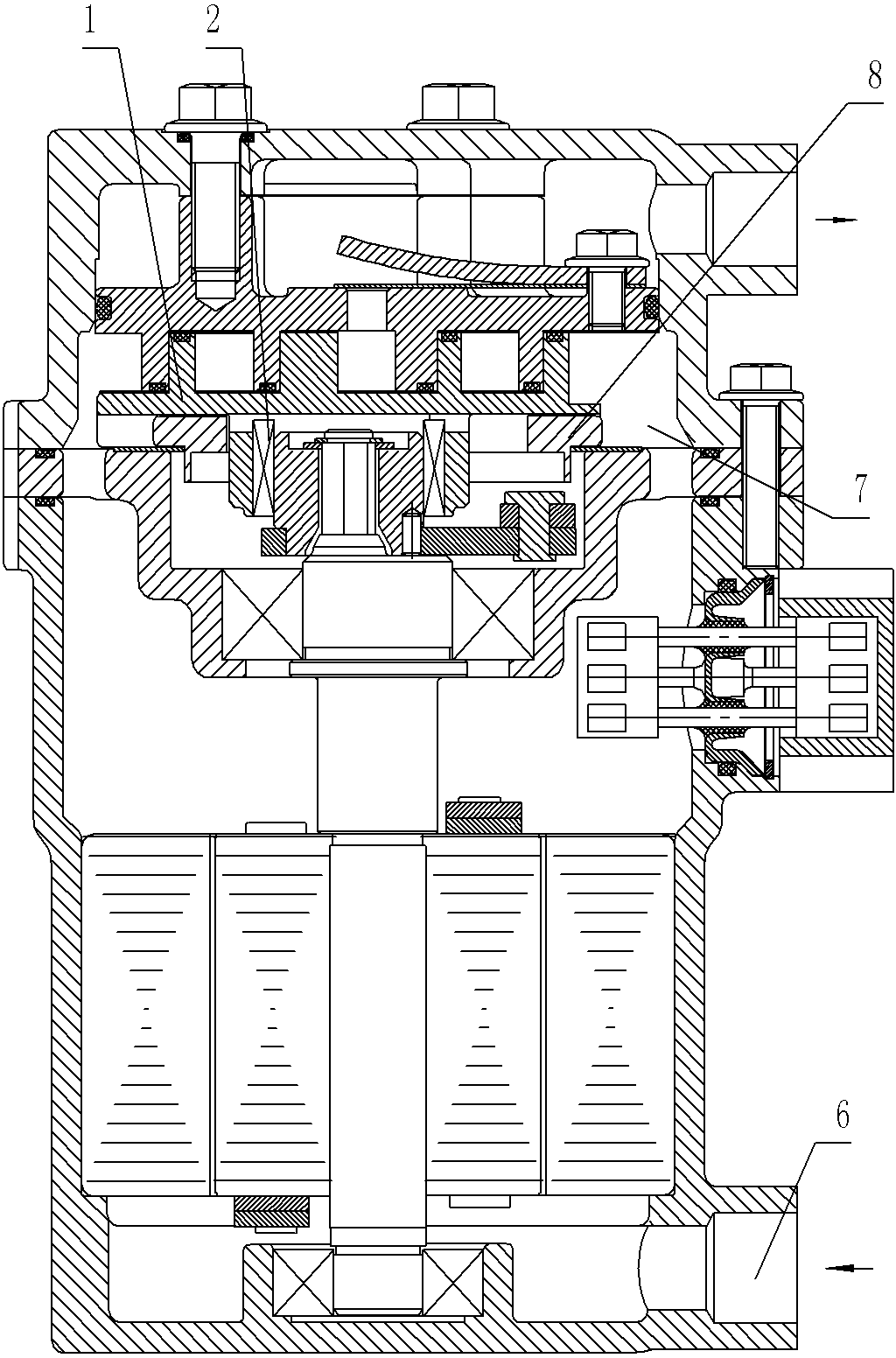

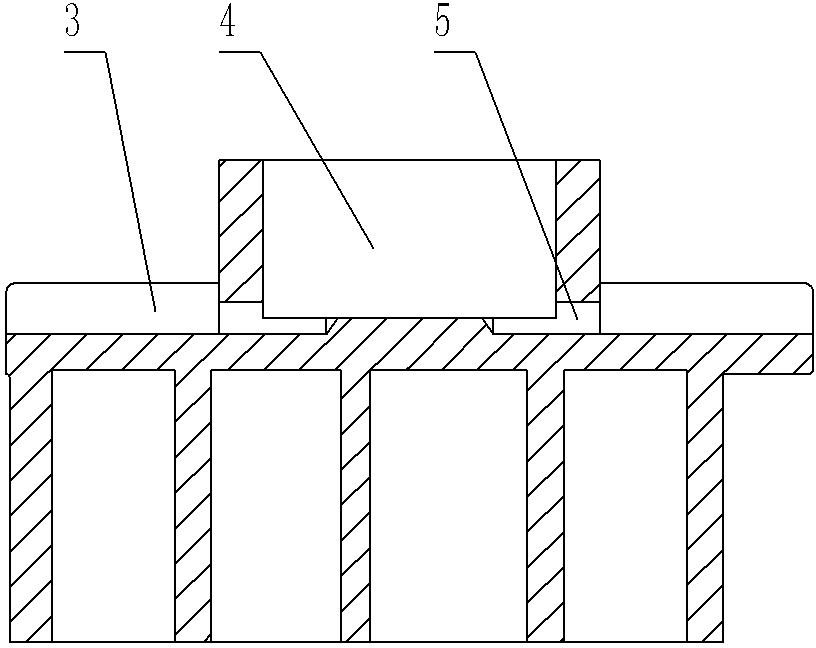

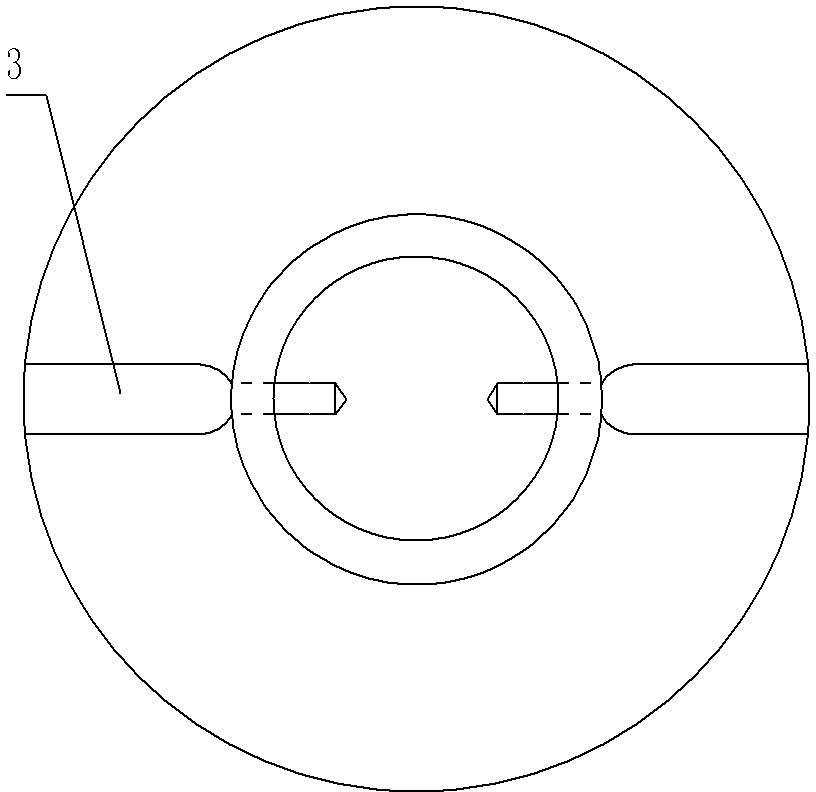

Scroll compressor

InactiveCN103089620AImprove lubricationSolve the burning problemRotary piston pumpsRotary piston liquid enginesEngineeringLubrication

The invention discloses a scroll compressor, relating to the technical field of manufacturing of fluid machinery. The scroll compressor comprises a movable scroll plate, a static scroll plate and bearings installed in a bearing carrier on the back surface of the movable scroll plate, wherein the static scroll and the movable scroll mesh with each other to form a variable-volume compression chamber. The invention is characterized in that at least two groups of through holes are drilled from the inner end of a slip ring groove at the back end surface of the movable scroll plate to the inner cavity of the bearing carrier, so that lubricating oil outside the movable scroll plate can smoothly enter the inner cavity of the bearing carrier of the movable scroll plate. Compared with the prior art, the invention can enable the lubricating oil outside the bearing carrier of the movable scroll plate to enter the inner cavity of the bearing carrier through the drilled channels, so that the bearings installed in the bearing carrier can be sufficiently cooled and lubricated, thereby greatly reducing the phenomenon of bearing burnout caused by bearing overheating due to defective lubrication or oil shortage of the bearings.

Owner:LIUZHOU YIZHOU AUTOMOBILE AIR CONDITIONER

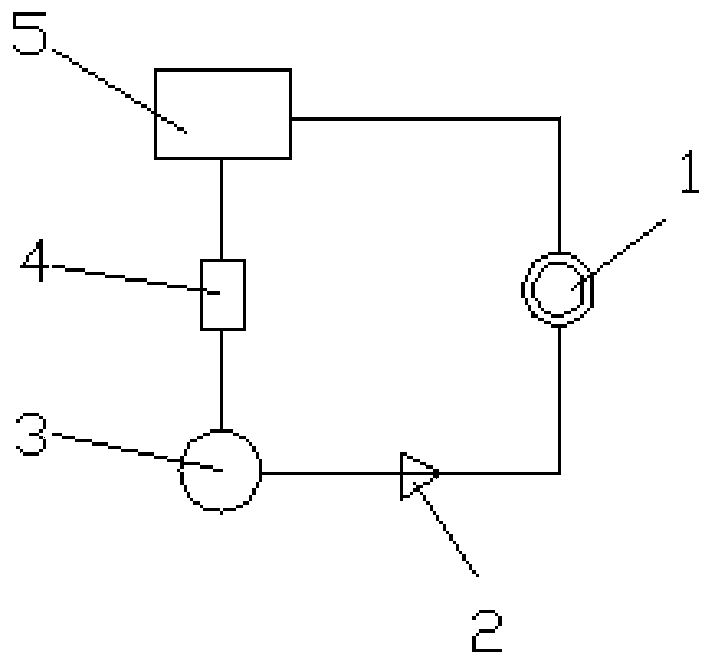

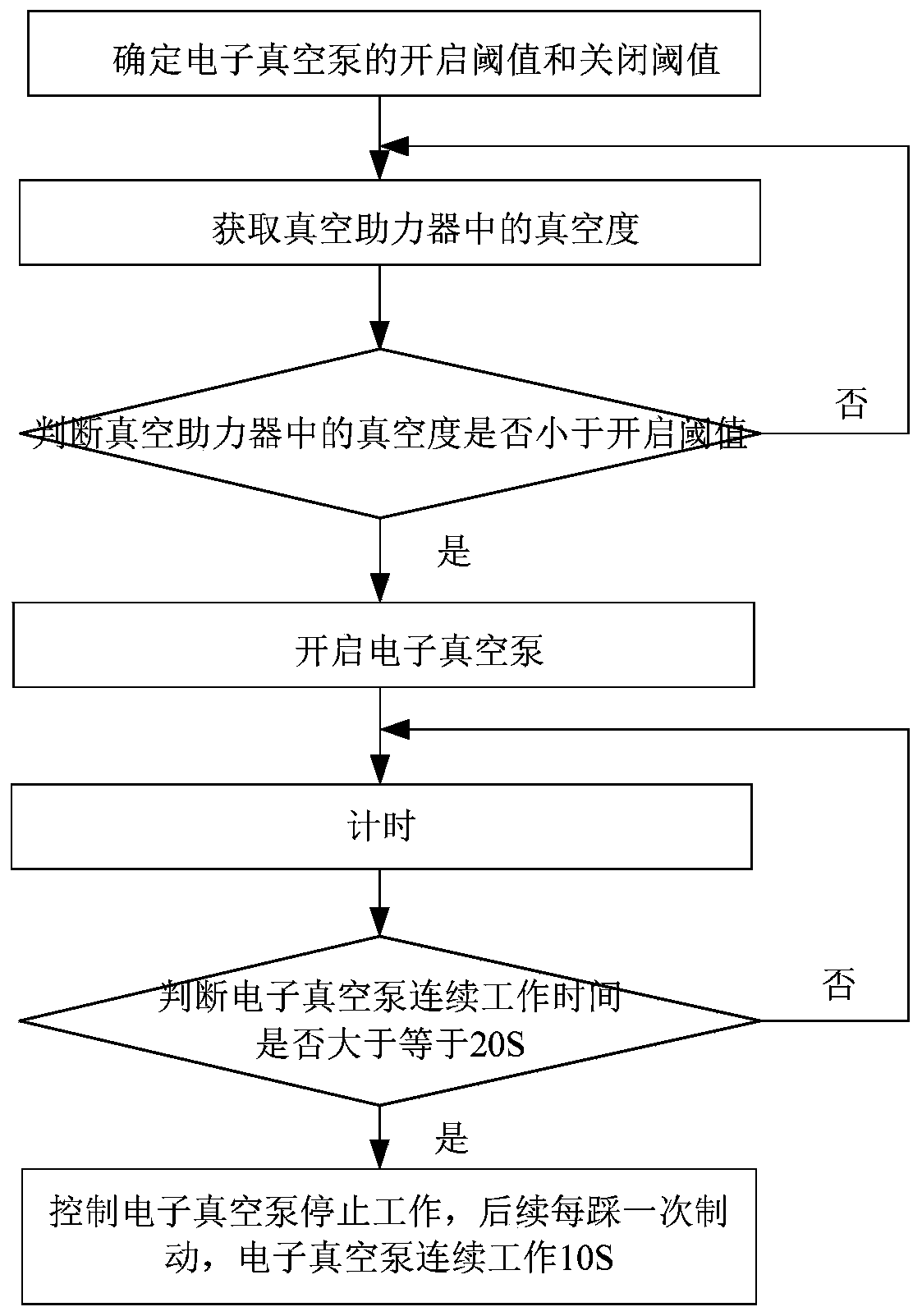

Control method for electronic vacuum pump and computer readable storage medium

InactiveCN109823328AMeet the needs of normal workMeet the needs of vacuumingBraking action transmissionEngineeringVacuum pump

The invention discloses a control method for an electronic vacuum pump and a computer readable storage medium. The control method comprises the following steps of determining an switch-on threshold and a switch-off threshold of the electronic vacuum pump; obtaining the vacuum degree in a vacuum booster; responding to the situation that the vacuum degree in the vacuum booster is lower than the switch-on threshold, switching on the electronic vacuum pump and starting timekeeping; responding the situation that it is detected that the continuous working time of the electronic vacuum pump is longerthan or equal to a first preset time and the vacuum degree in the vacuum booster is lower than the switch-off threshold, switching off the electronic vacuum pump, and each time when it is detected that a brake pedal is stepped down, controlling the electronic vacuum pump to continuously work for a second preset time, and then switching off the electronic vacuum pump, wherein the first preset timeis longer than the second preset time. According to the work time of the electronic vacuum pump, whether the electronic vacuum pump is in a high-altitude area is judged, and therefore, the problem that the electronic vacuum pump runs on and on in the high-altitude area to cause burnout is avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

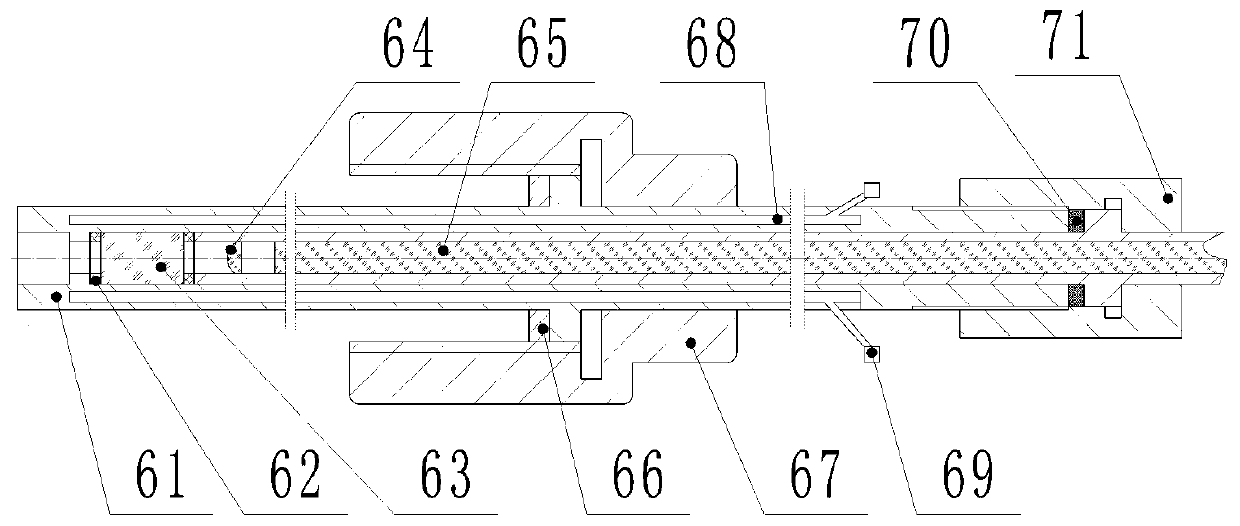

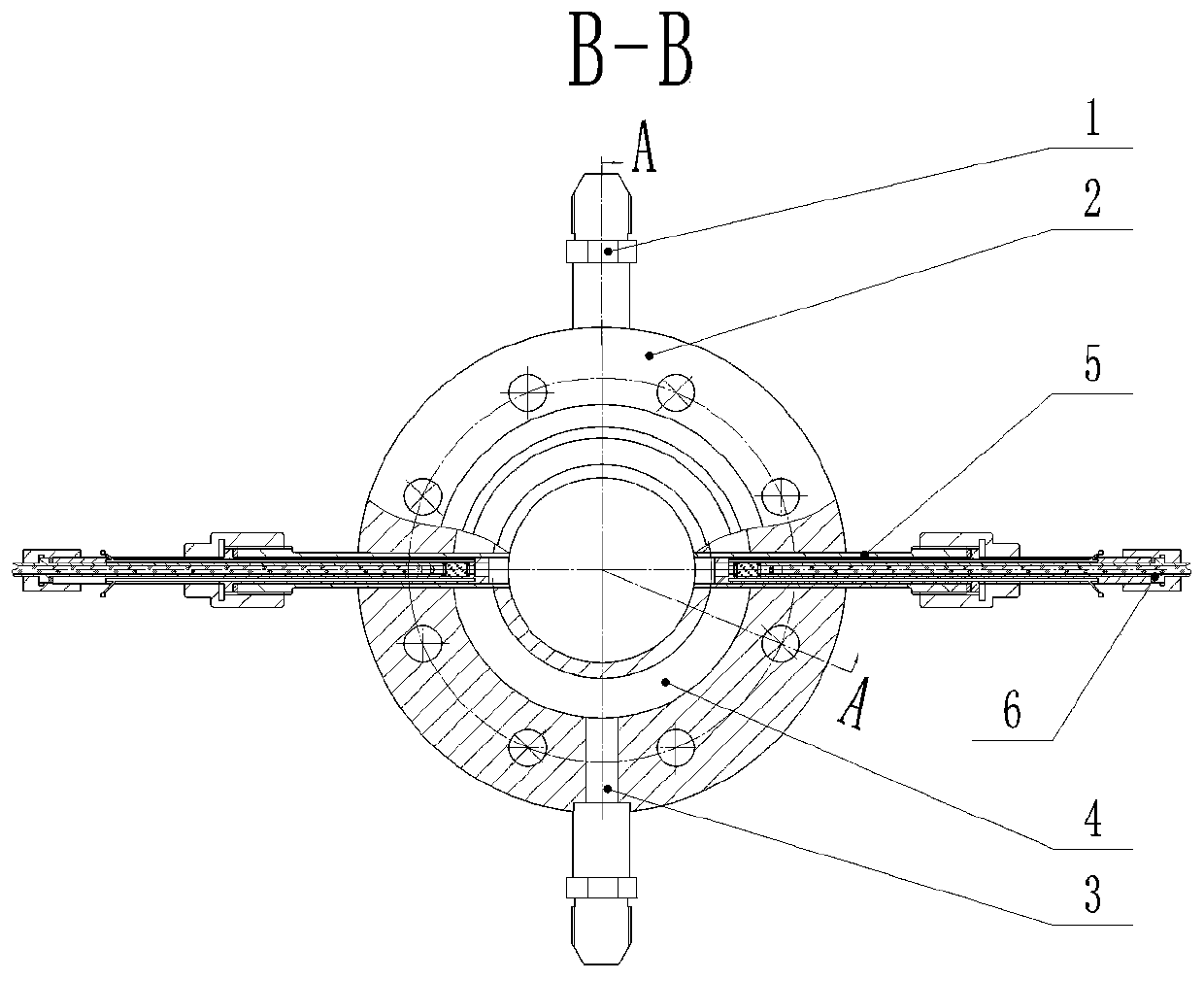

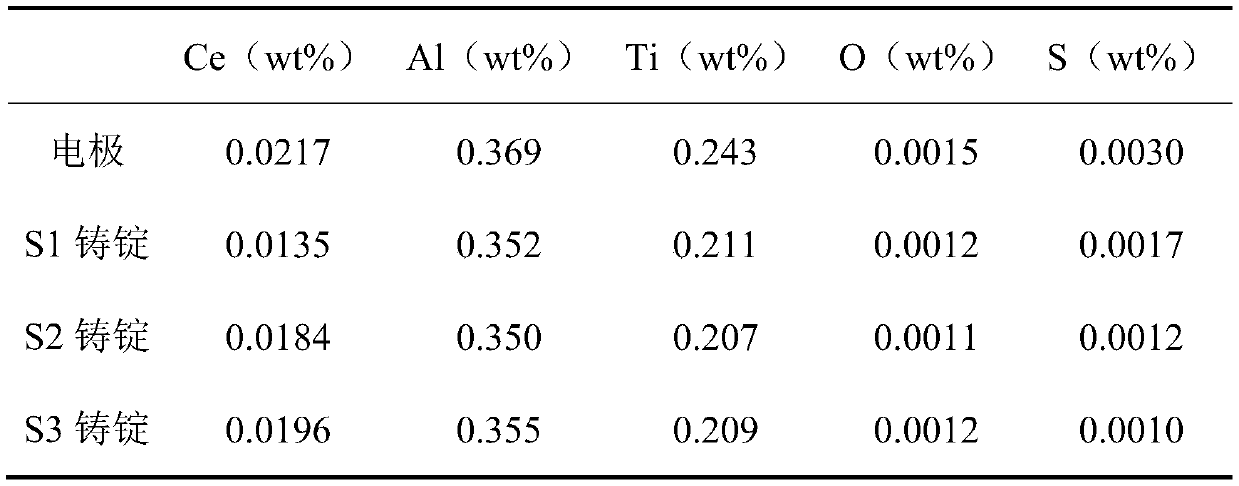

Nickel-based alloy electro slag remelting smelting method

The invention relates to a nickel-based alloy electro slag remelting smelting method. The method comprises the following steps that I, nickel-based alloy is selected to be made into a steel billet; II, the steel billet is cut into two nickel-based alloy steel billet bodies with the length being 2200-2250 mm and the width being 100-250 mm; III, a titanium plate is machined into a titanium plate body with the width being 40-105 mm and the length being 300+ / -50 mm, the titanium plate body is sandwiched between the two nickel-based alloy steel billet bodies, then explosion face welding is conducted, and the width of the titanium plate body is smaller than that of the nickel-based alloy steel billet bodies; and IV, electro slag remelting is conducted, specifically, tribasic slag of CaF2, CaO and Al2O3 is used as the basis for a premelting slag system, MgO is added, then TiO2 is added, a new premelting slag system is manufactured, and the adding amount of new premelting slag is 0.045-0.065 kg per kilogram of the nickel-based alloy steel billet bodies. According to the nickel-based alloy electro slag remelting smelting method, the burning loss of titanium elements in the electro slag remelting process is low, the Al element content in cast ingots is low, and the alloy components are even after remelting.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

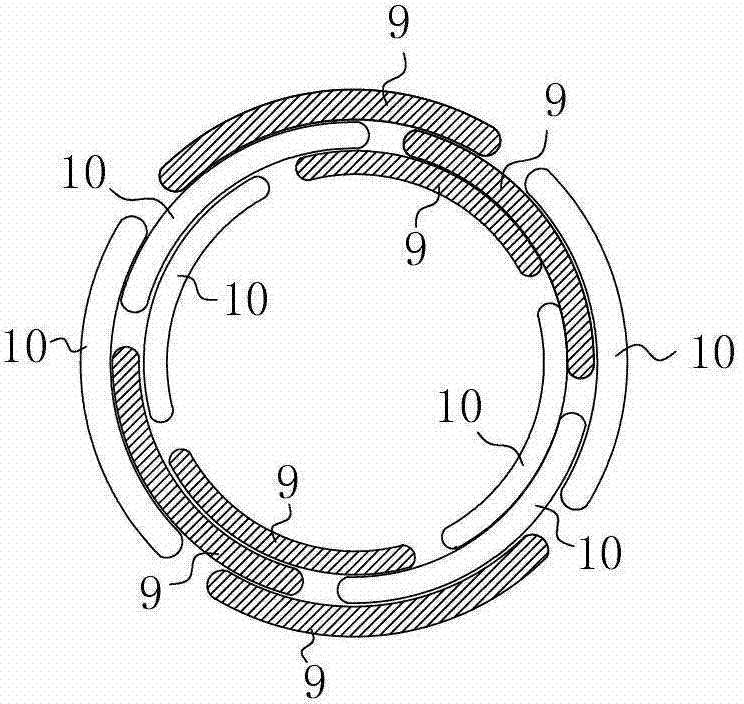

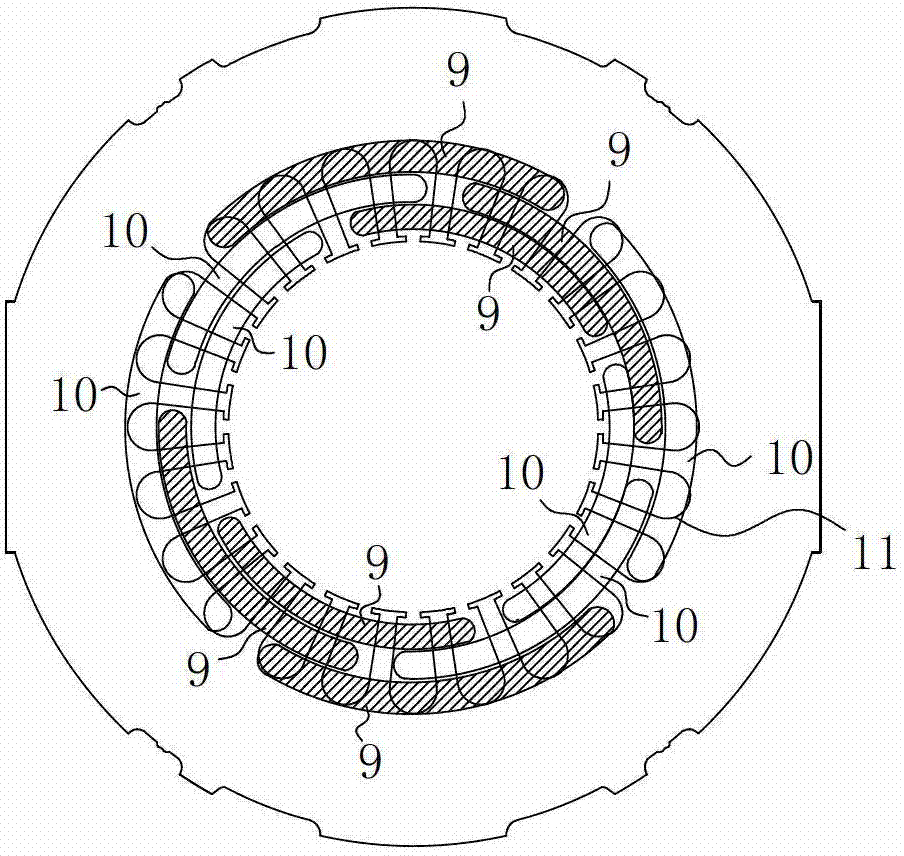

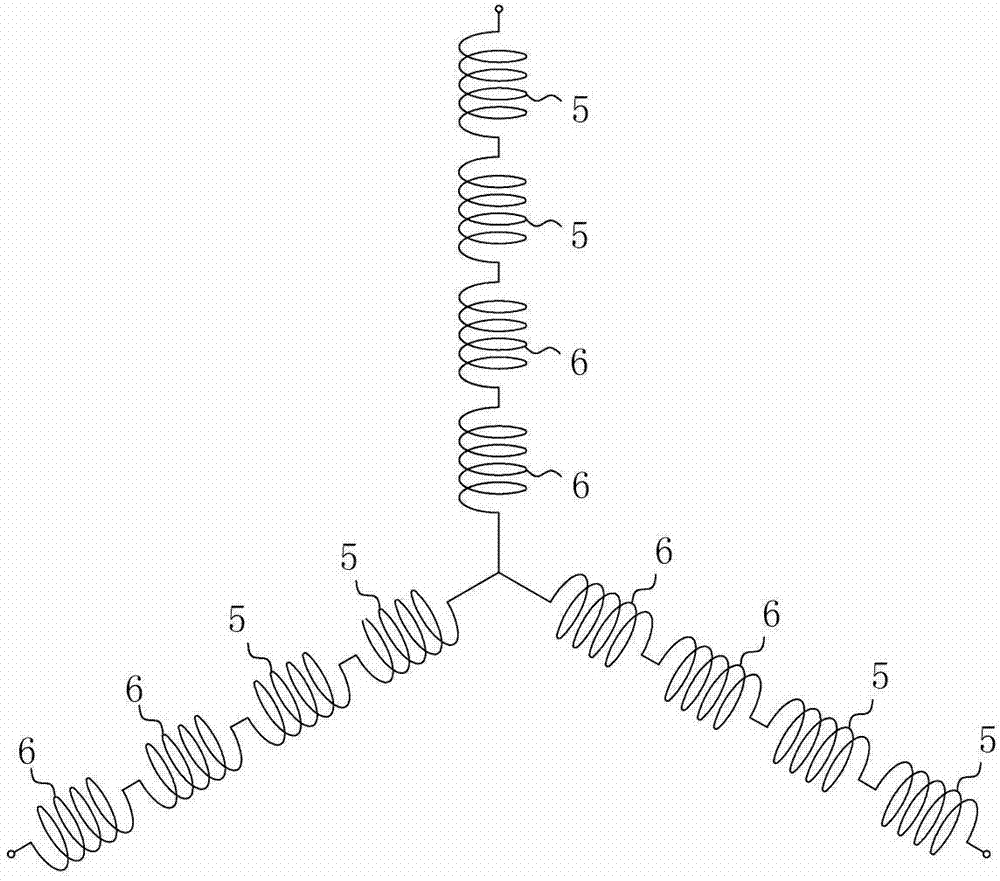

Stator winding configuration of three-phase electric motor

ActiveCN103208874AWeight increaseReduce weightWindings conductor materialWindings conductor shape/form/constructionCopper wireThree-phase

The invention discloses a stator winding configuration of a three-phase electric motor. The stator winding configuration comprises a three-phase coil and a plurality of coil slots, wherein the three-phase coil comprises a first phase coil body, a second phase coil body and a third phase coil body which are arranged inside the plurality of coil slots sequentially from outside to inside, the three-phase coil is composed of copper wires and aluminum wires, the copper wire and the aluminum wire in each phase coil body are in series connection, aluminum wires in two phase coil bodies are connected with the copper wire in the rest phase coil body, copper wires and aluminum wires in each phase coil body are provided with n units in coil slots respectively, n is a natural number lager than 1, copper wire units and aluminum wire units in each phase coil body are distributed inside the plurality of coil slots alternately, and only two phases of identical aluminum wires or copper wires are arranged in each of the coil slots for the three-phase coil. The stator winding configuration solves the problem that a winding of the electric motor is burnt due to the fact that heating is centralized at one position when the three-phase electric motor is connected with a large current.

Owner:SUZHOU AICHI TECH CO LTD

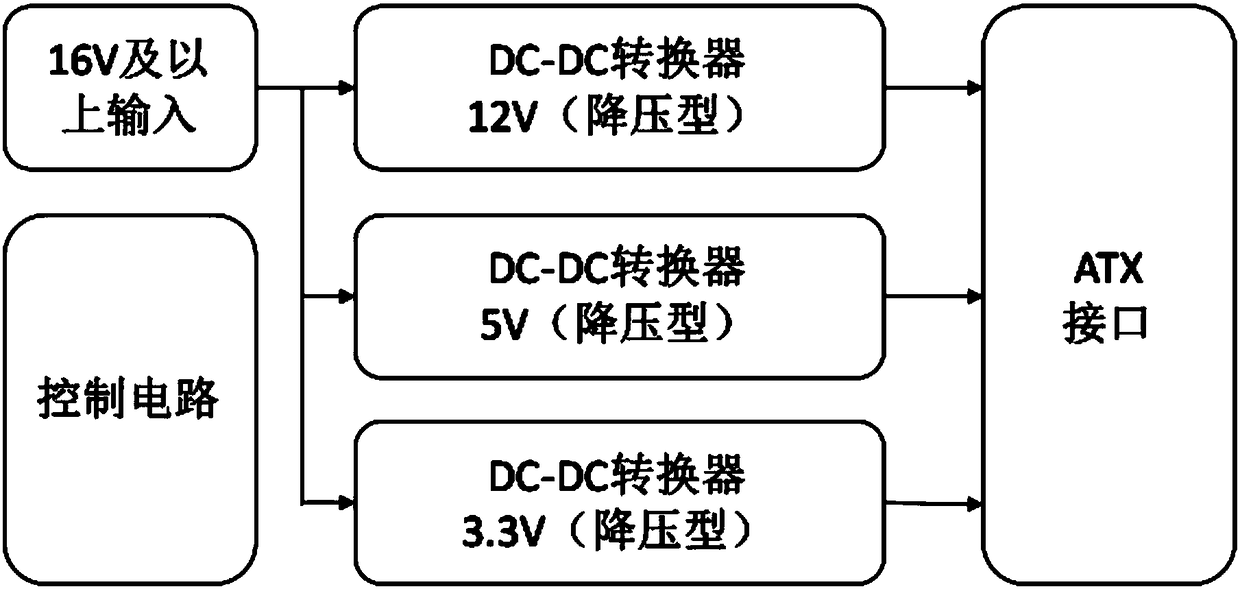

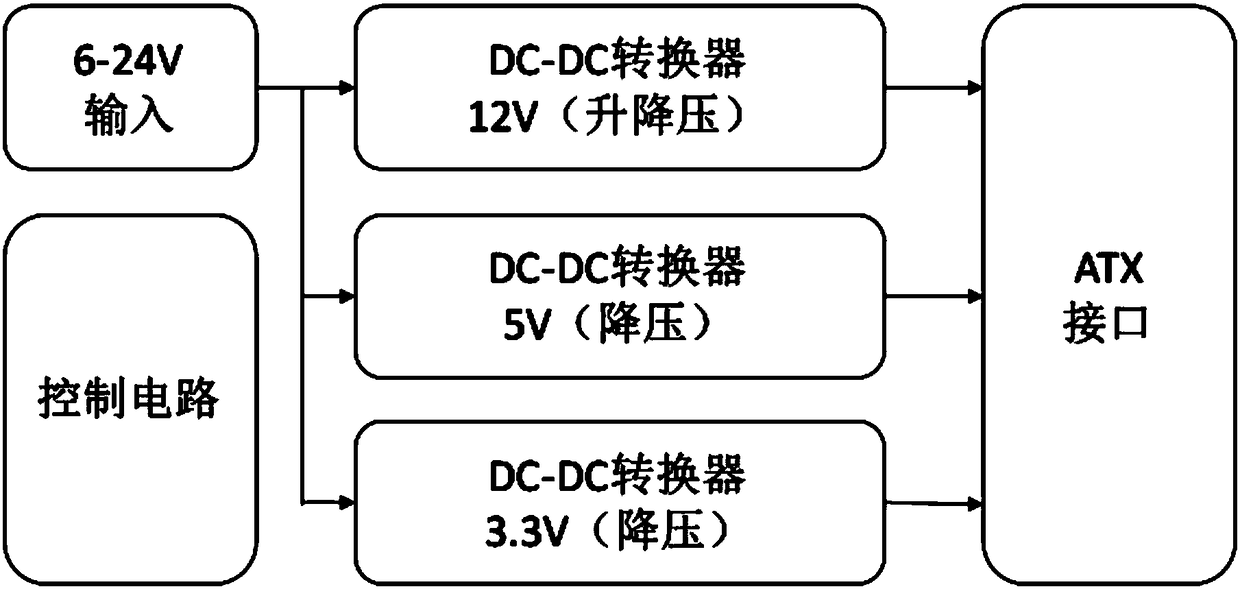

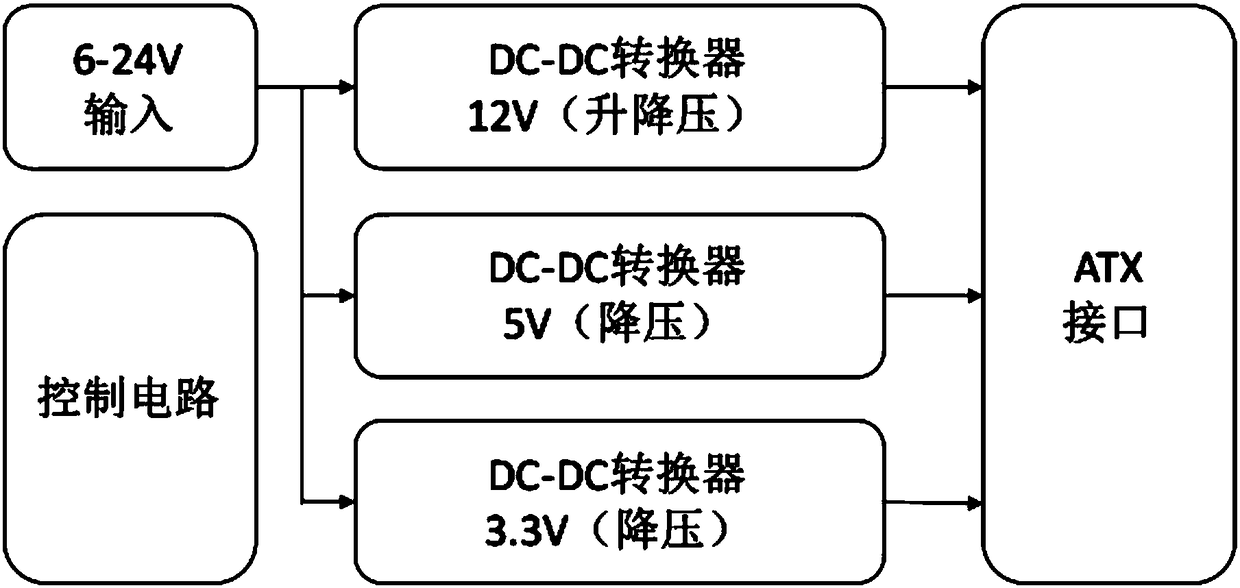

DC ATX power supply supporting a plurality of input voltages

PendingCN108566082AReduced input requirementsSolve the burning problemVolume/mass flow measurementDc-dc conversionComputer moduleEngineering

The invention provides a DC ATX power supply supporting a plurality of input voltages, comprising an external voltage supply terminal, a control module and a DC-DC conversion module. The control module is used for detecting an external input voltage; comparing the input voltage with preset voltage; when the input voltage is higher than the preset voltage, starting the DC-DC conversion module to control the DC-DC conversion module to decrease the input voltage to the working voltage required by the DC ATX power supply; and when the input voltage is equal to the preset voltage, turning off the DC-DC conversion module in order that the external input voltage is directly output to an ATX interface. Thus, the DC ATX power supply can be compatible with various voltage inputs so as to support voltage input over 12V, solves the problem that the DC ATX power supply causes a computer motherboard to burn out when using power over 16V by mistake, and reduces the requirement for 12V voltage input.

Owner:深圳市微电元科技有限公司

Waste heat recovery and utilization system for waste gas of revolving furnace

InactiveCN101482373ASolve the burning problemEnergy industryIncreasing energy efficiencySteelmakingSteam pressure

The invention relates to a converter exhaust gas heat recycling system, comprises a converter smoke helmet first exhaust-heat boiler, a steam-water separator, a coaming plate and ceiling, a smoke purifying system, a second dust smoke removing box, a smoke purifying system and a steam generator; the smoke outlet of the converter smoke helmet calandria exhaust-heat boiler is connected with a converter waste gas down going pipeline which is connected with a second exhaust-heat boiler system; the second exhaust-heat boiler system consists of a second exhaust-heat boiler, a steam outlet, a smoke outlet, a soft water pipeline, a flowmeter and pipeline valve gate, a steam pressure meter, a fluviograph and safety valve and a suction adjusting multi-leaf valve. The invention collects all the steam from the first dedusting, second dedusting, second recovery and upper coaming plate of the exhaust-heat boiler, recycles the converter waste gas heat as much as possible, reduces the water consumption of OG system, reduces the cement slurry treating capacity in the subsequent processes, achieves the aim of energy saving and emission reducing, and realizes the converter steelmaking with minus energy consumption.

Owner:徐文玉

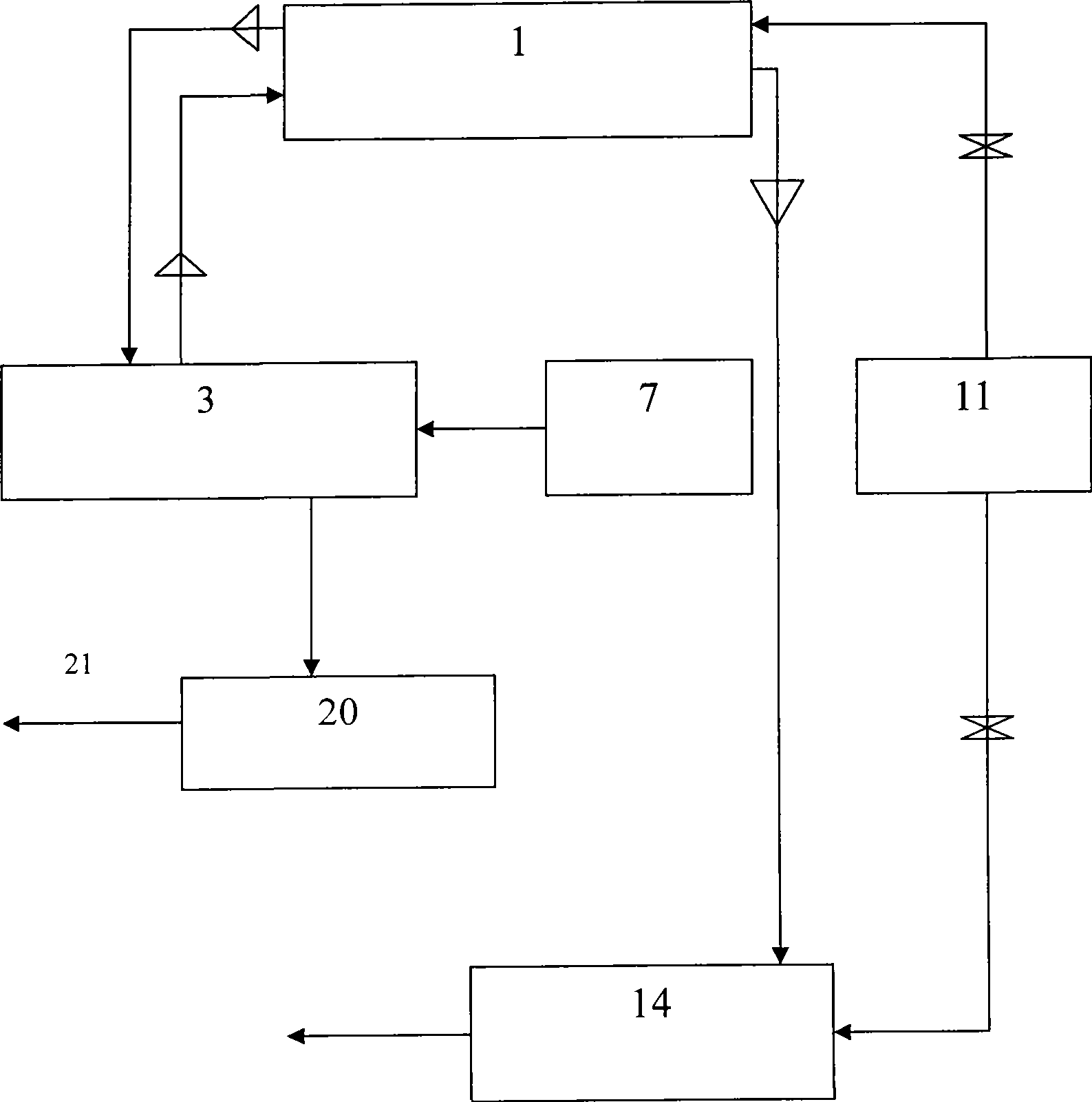

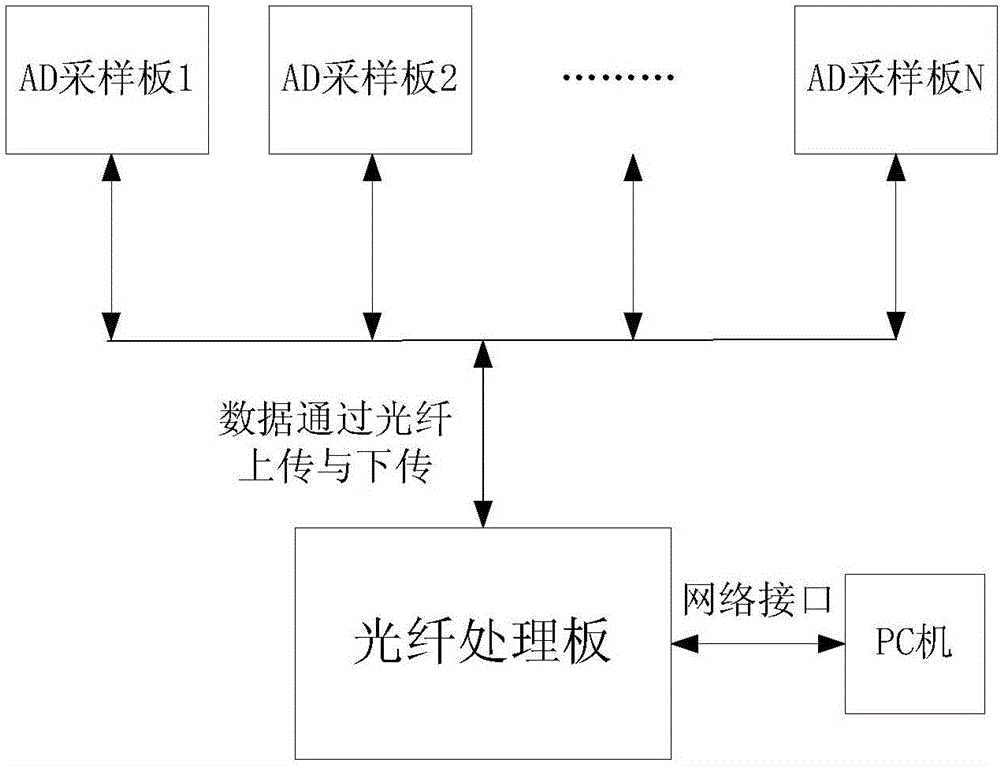

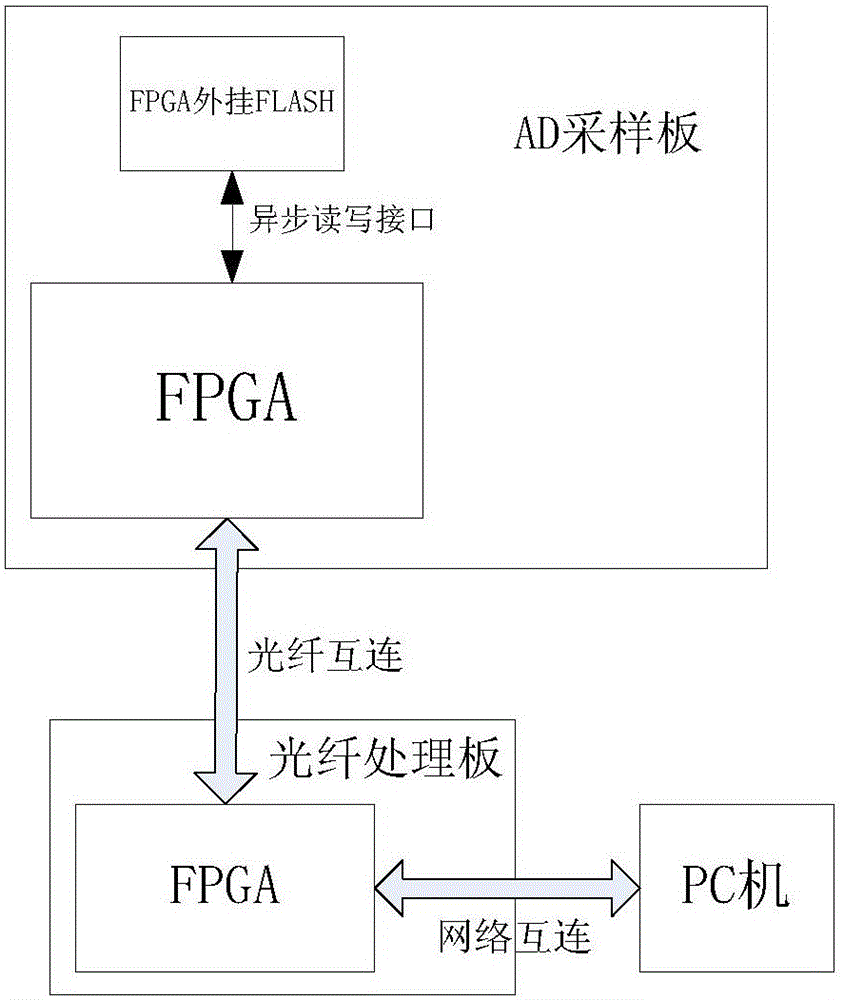

Multi-board FPGA program writing method realized based on network and optical fiber data transmission

InactiveCN106020864AMature and stable applicationStrong debuggabilityProgram loading/initiatingSoftware deploymentData transmissionNetwork interface

The present invention designs a multi-board FPGA program programming system and method based on network and optical fiber data transmission. Multiple digital receiving boards are connected to optical fiber processing boards through optical fibers, and the optical fiber processing boards communicate with PCs through network interfaces. The PC transmits the program to be updated to the optical fiber processing board through the network interface, and the optical fiber processing board uses the optical fiber to transmit the program to multiple digital receiving boards at the same time. Programming of FPGA programs for multiple boards.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

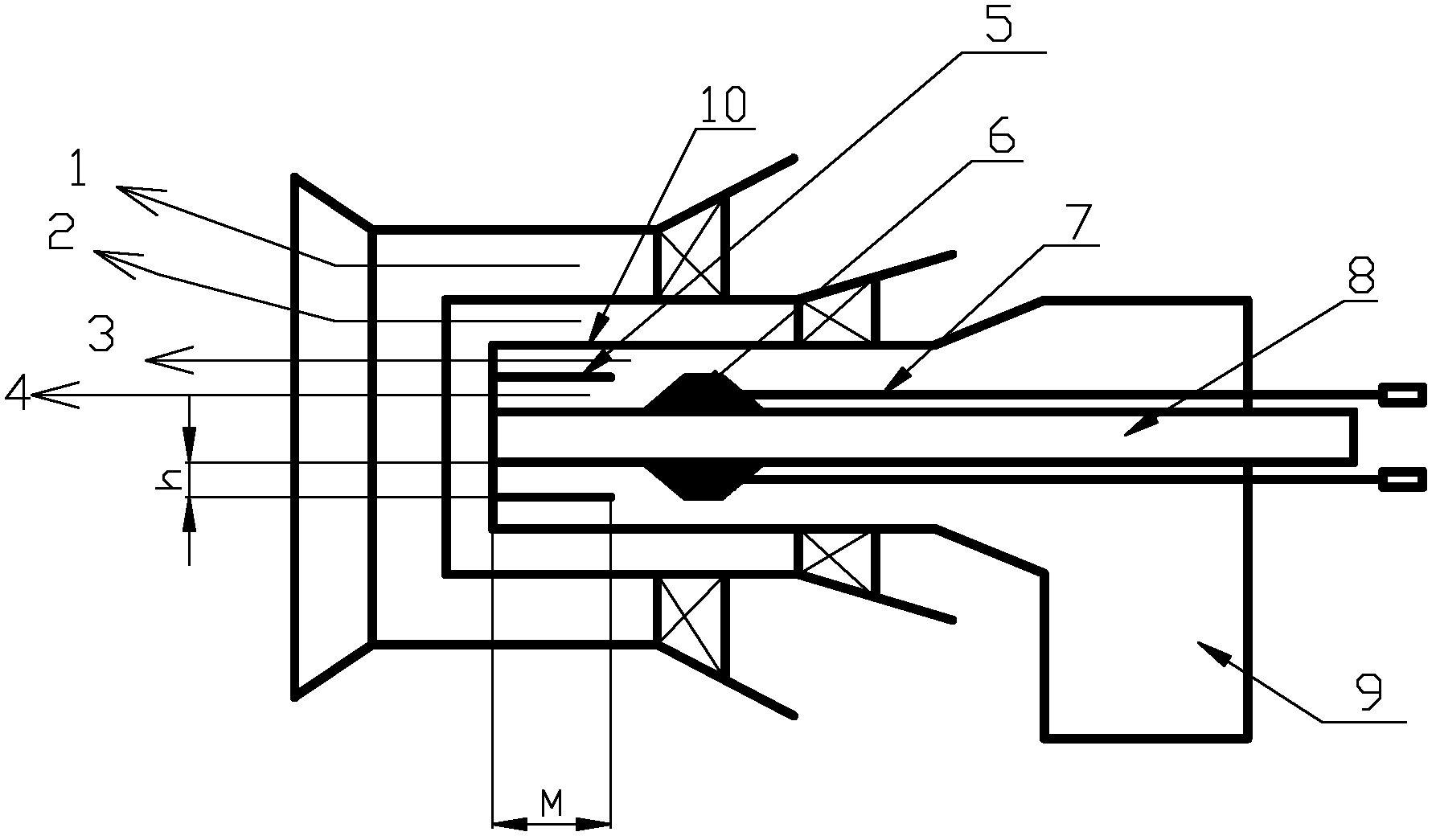

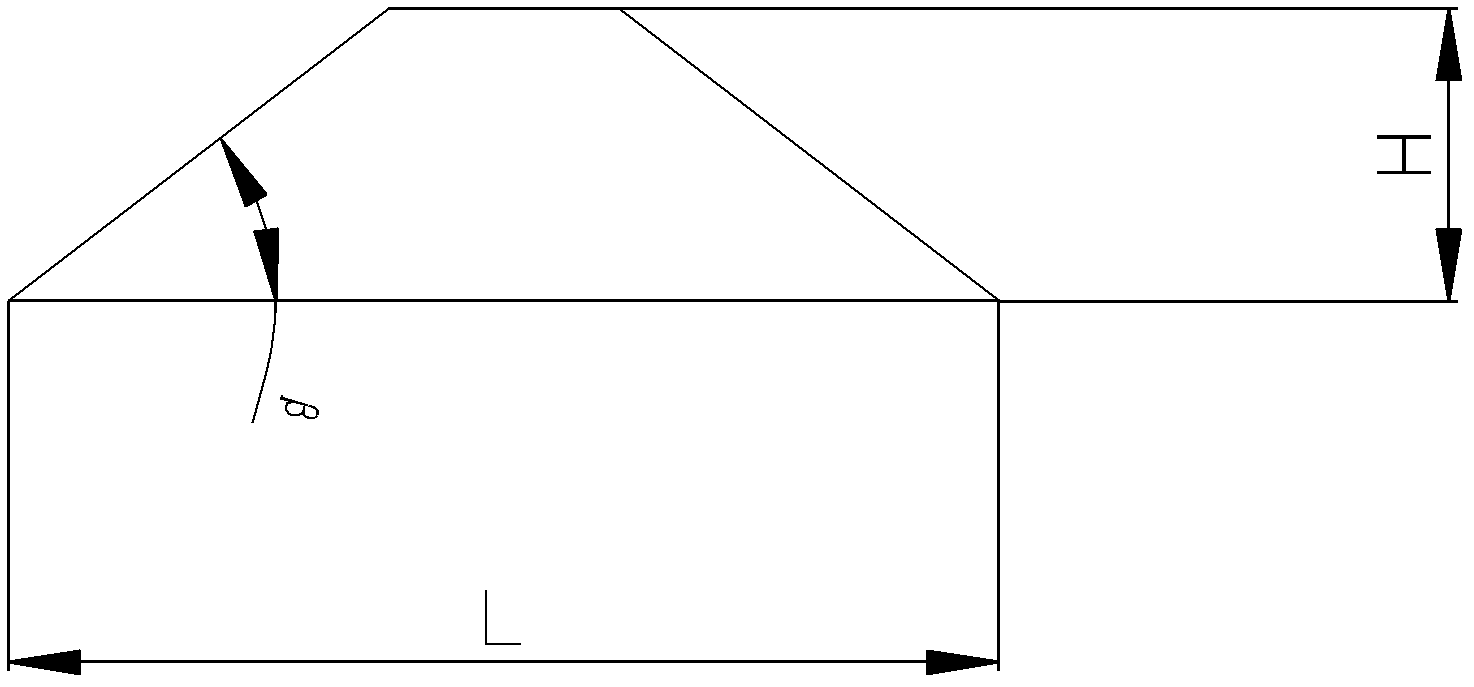

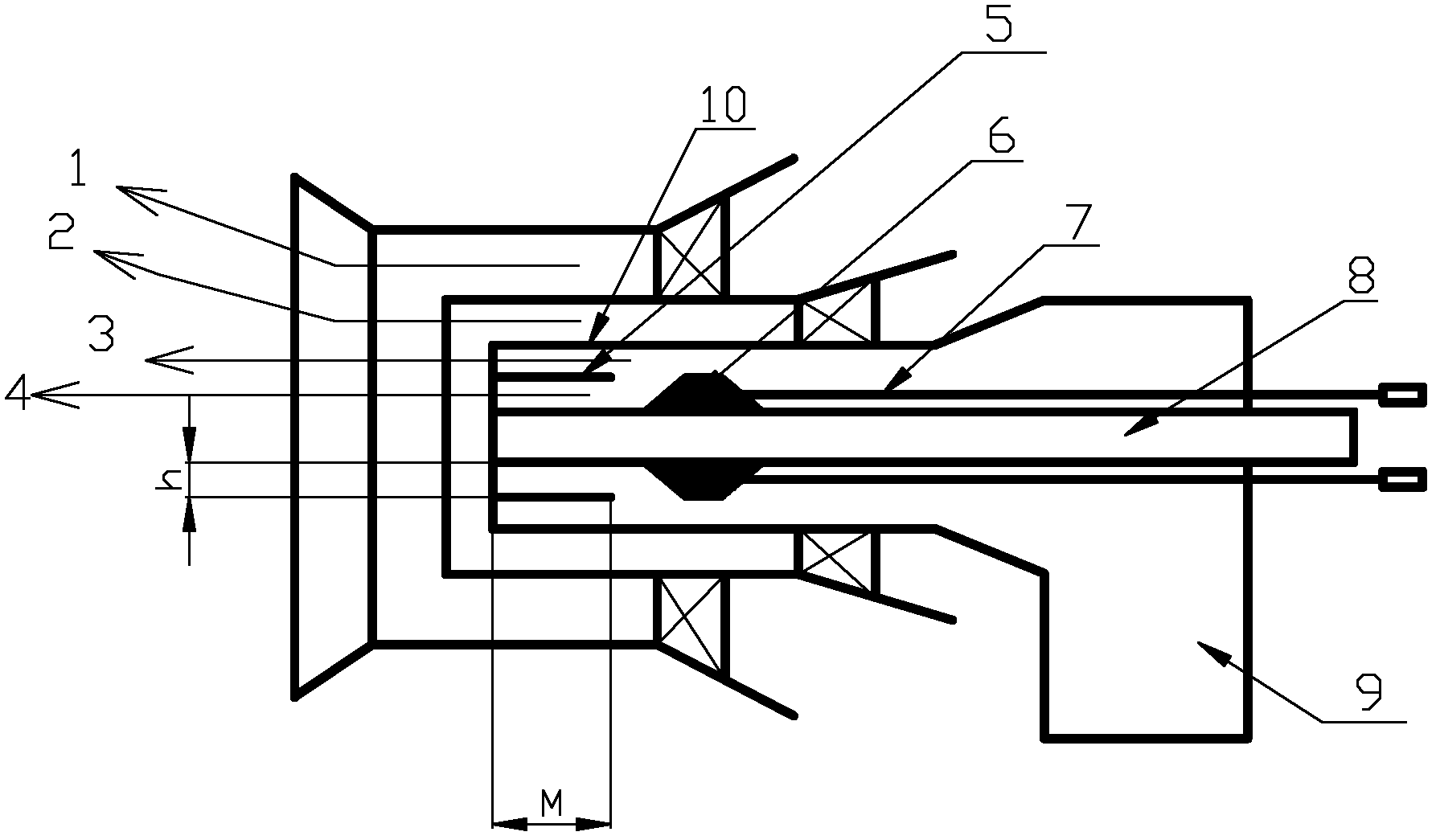

Variable-section cyclone burner

The invention discloses a variable-section cyclone burner, which comprises a central air duct. A primary air pipe is sleeved outside the central air duct, a partition sleeve is sleeved at an outlet of the primary air pipe and divides the primary air pipe into an inner space and an outer space, an annular sliding stopper is mounted on the central air duct, and the annular sliding stopper is connected with a pull rod arranged on the outside of the cyclone burner. As the primary air is divided into inner primary air and outer primary air by the partition sleeve additionally mounted at the outlet of the primary air pipe of the cyclone burner and the annular sliding stopper is mounted on the central air duct, when the annular sliding stopper is pulled backwards, the inner primary air and the outer primary air ventilate simultaneously, ventilation area is expanded, primary air speed is reduced, and the requirement for reducing air speed is met; and further, when the annular sliding stopper is pushed forwards, a passage of the inner primary air is blocked, only a passage of the outer primary air ventilates, ventilation area is reduced, and accordingly primary air speed is increased.

Owner:SHANDONG ZHONGSHI YITONG GRP

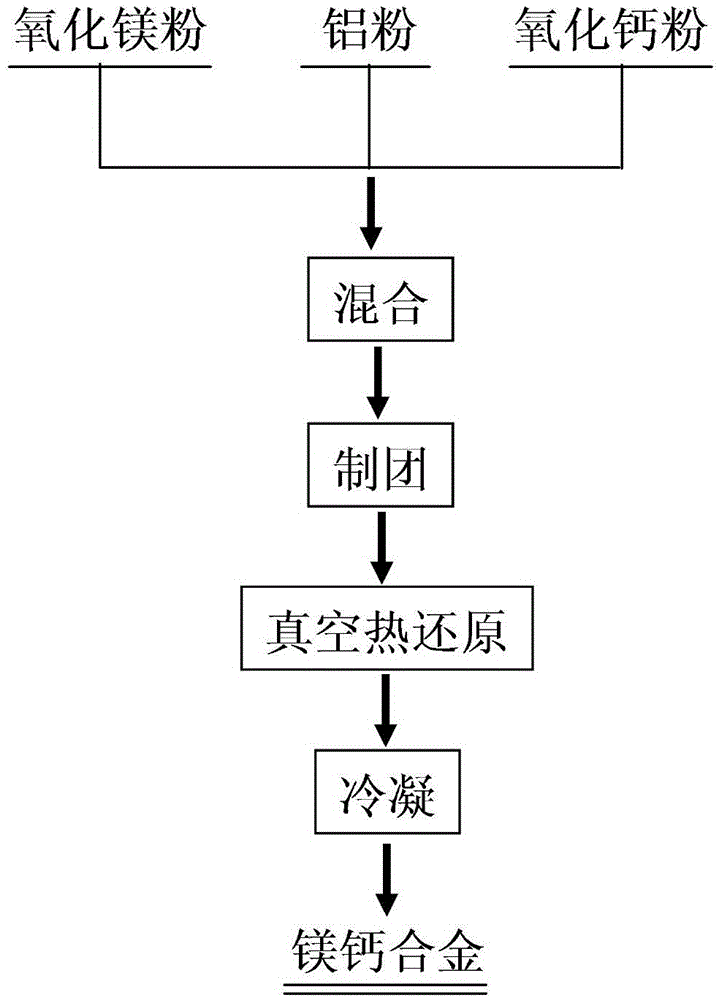

Method for preparing magnesium-calcium alloy through aluminothermic reduction

ActiveCN105525108ASolve the burning problemIncrease productivityProcess efficiency improvementAl powderAluminium hydroxide

The invention relates to a method for preparing a magnesium-calcium alloy through aluminothermic reduction. The method includes the following steps that (1) MgO powder, CaO powder and Al powder are evenly mixed; (2) a mixed material is pressed into chunks; (3) the chunks are placed into a reduction pot, the reduction pot is vacuumized, heat preservation is carried out on the reduction pot for 3 h to 6 h at the temperature ranging from 1150 DEG C to 1300 DEG C, and magnesium oxide and calcium oxide are restored into magnesium steam and calcium steam; and (4) after the magnesium steam and the calcium steam are congealed, and the magnesium-calcium alloy is generated in a crystallizer. According to the method for preparing the magnesium-calcium alloy through aluminothermic reduction, the magnesium oxide and the calcium oxide serve as raw materials, aluminite powder serves as a reduction agent, and the magnesium-calcium alloy is obtained through one step of vacuum heat reduction, so that the problem of burning losses formed by a doping method is solved, the production efficiency is high, the cost is low, the environment is good, the product purity is high, and produced waste residues can be fully used for producing high-strength cement or used for extracting aluminum hydroxide.

Owner:NORTHEASTERN UNIV

Water-cooled light-concentrating optical fiber probe used for stable section of hypersonic-speed low-density wind tunnel

PendingCN110715789ASolve the burning problemImprove light collection efficiencyAerodynamic testingPhysicsOptical measurements

The invention discloses a water-cooled light-concentrating optical fiber probe used for a stable section of a hypersonic-speed low-density wind tunnel. Optical glass, a convex lens and an optical fiber are sequentially installed on the axis of the optical fiber probe from front to back, and sealing rings I are installed on both sides of the optical glass; a protective sleeve is installed outside the convex lens and the optical fiber in a sleeving mode, the front end of the protective sleeve closely abuts against the sealing ring I behind the optical glass, and a boss is arranged at the rear end of the protective sleeve; a shell sleeves the optical glass and the protective sleeve and is internally provided with a cooling water channel. The cooling water channel is connected with an externally-arranged cooling water system through a cooling water connector installed on the shell. The rear end of the shell and the boss at the rear end of the protective sleeve are connected by a connectingnut, and the rear end of the shell and the boss at the rear end of the protective sleeve are sealed by a seal ring III; and a step is arranged on the middle part of the shell, and a nut is installedat the step in a sleeving mode. The optical fiber probe is simple in structure and high in reliability, and can lead light generated by high-temperature and high-pressure gas in the stable section ofthe hypersonic-speed low-density wind tunnel to an optical measuring instrument.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Slag system for smelting GH3625 nickel-base alloy containing rare earth Ce and electroslag remelting smelting method thereof

The invention relates to a slag system for smelting a GH3625 nickel-base alloy containing rare earth Ce and an electroslag remelting smelting method thereof. The slag system comprises, by weight, 20-25% of CaO, 17-21% of Al2O3, 5-7% of NaF, 3-5% of MgO, 1-2% of TiO2, 4-6% of CeO2, 1-2% of SiO2, and the balance CaF2. The slag system is suitable for electroslag remelting smelting of the GH3625 alloycontaining rare earth, and the problem of Ce, Al and Ti burning loss in the process of electroslag remelting smelting of the GH3625 alloy containing Ce can be well solved.

Owner:上海一郎合金材料有限公司

Storage box for agricultural by-products

InactiveCN109515984ASolve the problem of not having the function of storage and preservationWon't spoilShock-sensitive articlesExternal fittingsPlasma generatorAgricultural engineering

The invention discloses a storage box for agricultural by-products. The storage box comprises a storage box body, wherein the top of the storage box body is fixedly connected with a cooling box; the bottom of the inner cavity of the cooling box is fixedly connected with a housing; the bottom of the inner cavity of the housing is fixedly connected with a refrigerating device; and the two sides of the housing communicate with air suction tubes. According to the storage box disclosed by the invention, the storage box body, the cooling box, the refrigerating device, the housing, the air suction tubes, a fan, an air outlet tube, a temperature sensor, a mounting frame, a plasma generator, a sterilizing device, a placing plate, a box door, a base, an anti-sliding pad, a vent hole, a control box,a display panel, a control panel and a processor are matched with one another, so that the advantages of storing and retaining freshness are achieved, and therefore, the problem that an existing storage box for agricultural by-products does not have the functions of storing and retaining freshness is solved; and when the agricultural by-products are stored, the agricultural by-products do not go bad, so that eating or selling of people is not affected, and therefore, practicability of the storage box for agricultural by-products is improved.

Owner:许昌涉步餐饮管理有限公司

Ultrasonic and induction heating-assisted laser cladding method of composite nanometer coating

ActiveCN108588708ASolve the problem that it is easy to generate tensile stress and greatly increase the crack sensitivitySolve the problem of greatly increased crack susceptibilityMetallic material coating processesUltrasonic assistedOptoelectronics

The invention provides an ultrasonic and induction heating-assisted laser cladding method of a composite nanometer coating. A laser, a precoated layer, a base body, a working table, an ultrasonic vibrator and an induction heating coil are arranged. The ultrasonic and induction heating-assisted laser cladding method of the composite nanometer coating comprises the following concrete steps of (10) after preprocessing the base body, placing the precoated layer on the base body, placing the base body with the precoated layer onto the working table, and moving a laser head of the laser to a position to be cladded of the base body; (20) starting the induction heating coil, and using the induction heating coil for heating the base body and the precoated layer to 200 to 400 DEG C; (30) switching on the laser and the ultrasonic vibrator, wherein the laser is used for laser-cladding the base body through the laser head, and the ultrasonic vibrator is used for ultrasonic-assisting the laser cladding process; (40) after finishing laser cladding, switching off the ultrasonic vibrator and the laser; (50) switching off the induction heating coil; and (60) taking out the base body subjected to laser cladding.

Owner:FUJIAN UNIV OF TECH

Smelting method for controlling aluminum and titanium burning losses of iron and nickel-based high-temperature alloy electroslag ingot

The invention provides a smelting method for controlling aluminum and titanium burning losses of an iron and nickel-based high-temperature alloy electroslag ingot. By adopting a quaternary slag systemwhich comprises 55-65% of CaF2, 15-20% of Al2O3, 15-20% of CaO and 2-6% of TiO2 and optimizing electrical systems in an electroslag remelting starting stage, a smelting stage and a filling stage, thesmelting method is suitable for smelting the iron and nickel-based high-temperature alloy electroslag ingot, wherein the ingot comprises 41.5-53.0 parts of Ni, 16.0-18.0 parts of Cr, 0.3-0.5 part ofAl, 0.9-1.8 parts of Ti, 3.0-5.0 parts of Nb, 0.01-0.04 part of C and the balance Fe, and the diameter is 810-1100 mm. The smelting method for controlling aluminum and titanium burning losses of the iron and nickel-based high-temperature alloy electroslag ingot can solve the problem of burning losses of aluminum and titanium in a remelting process of a large dimension iron and nickel-based high-temperature alloy electroslag ingot, the diameter of which is 810-1100 mm, effectively.

Owner:BEIJING CISRI GAONA TECH +1

Preparation process of intermediate alloy containing volatile element

The invention discloses a preparation process of intermediate alloy containing a volatile element and relates to the technical field of alloy. The process comprises the following steps: 1), burdening intermediate alloy components and parent metal according to a design proportion, smelting and pouring to form cast blank in a furnace; 2) smashing the cast blank and grinding to obtain smashed particles; and 3) uncoiling a metal strip coil, rolling the middle of the width of the metal strip coil along the unfolding direction of the metal strip coil to form a U shape, putting a powder material in a U-shaped groove, carrying out roll forming and pressing on the strip edge of the alloy to form a tube shape so as to obtain wire coil. According to the practical demand, the wire coil is uncoiled and alloy line is continuously added or the required alloy line is cut to be added into a smelting process so that the problem that the intermediate alloy containing less element, especially volatile burning loss element can not be continuously added in the smelting process, or the quantitative addition of the intermediate alloy is not correct is solved, thereby well producing the blank with uniform components for a manufactured lumber.

Owner:苏州新金相金属材料有限公司 +1

Method for calcining limestone by using relaxed discharged gas of synthetic ammonia as fuel

InactiveCN101003421ASolve the burning problemSolve the phenomenon of overheatingGaseous fuelsLime productionHydrogenAmmonia

This invention discloses a method for calcining limestone by using the discharge gas from ammonia synthesis. The method utilizes the flammability of methane and hydrogen in the discharge gas to calcine limestone in limekiln and produce quick lime product. The method adequately utilizes the fuel resource of the discharge gas from ammonia synthesis, and has such advantages as reasonable process, and saved energy.

Owner:HUBEI YIHUA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com